Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Stable for long-term use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

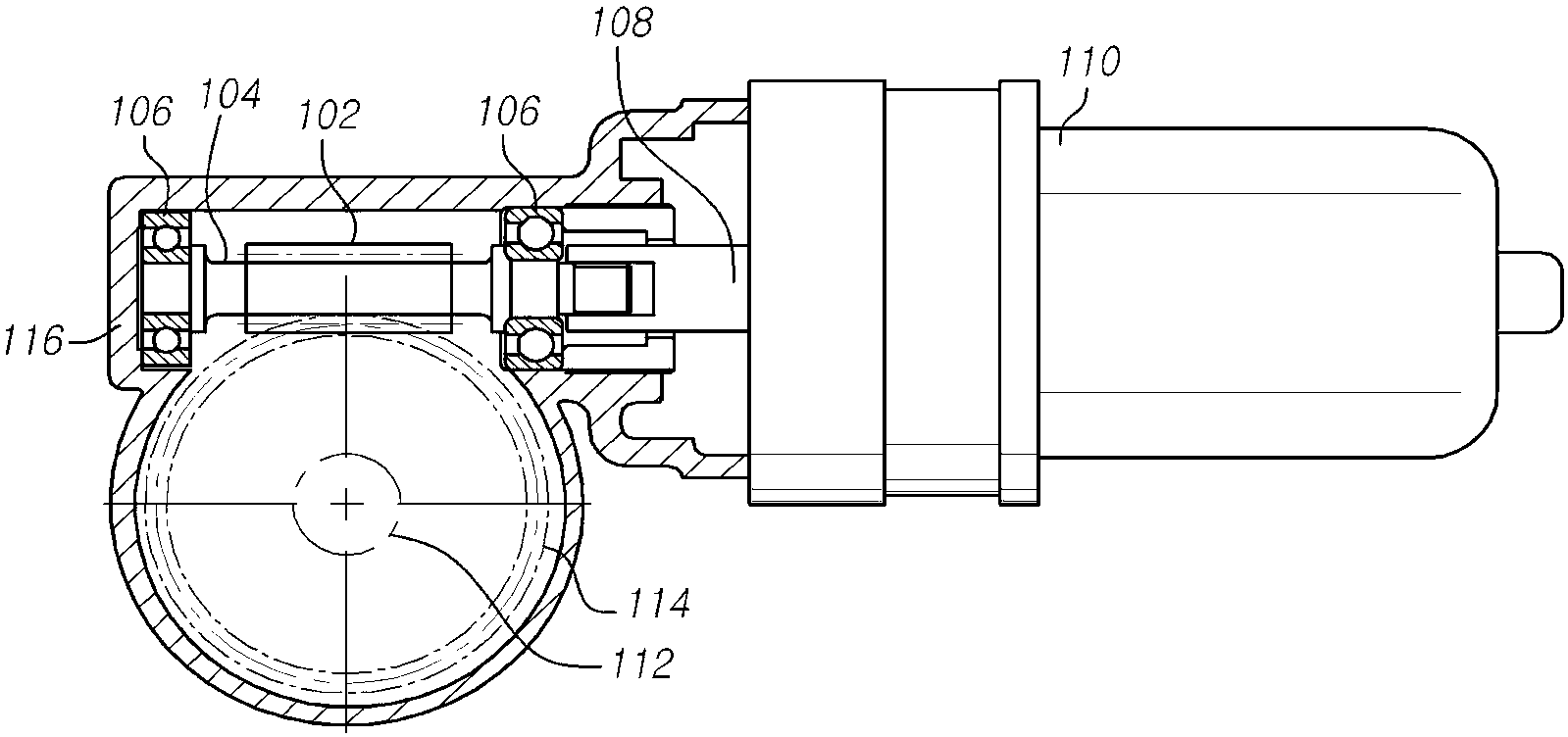

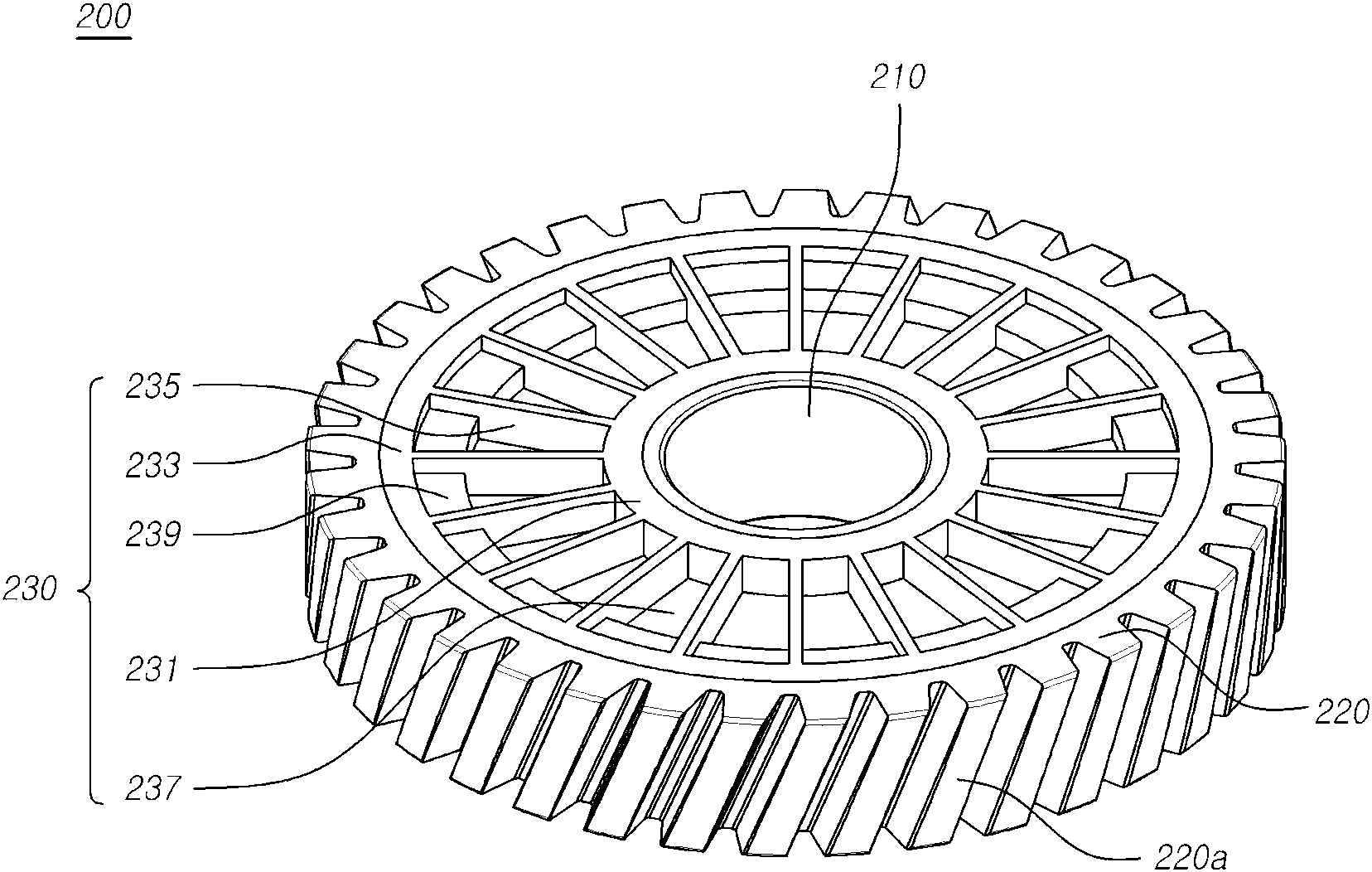

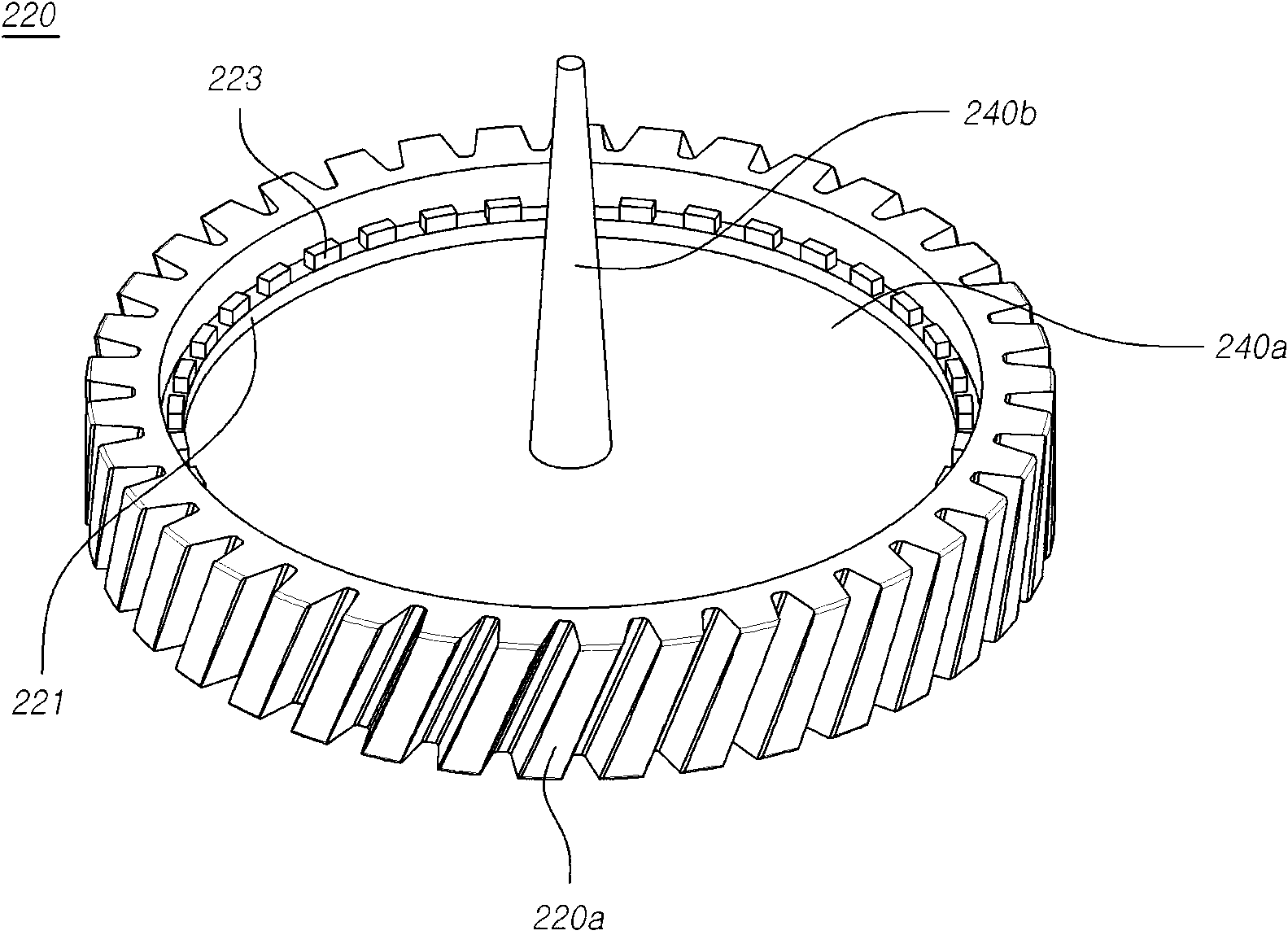

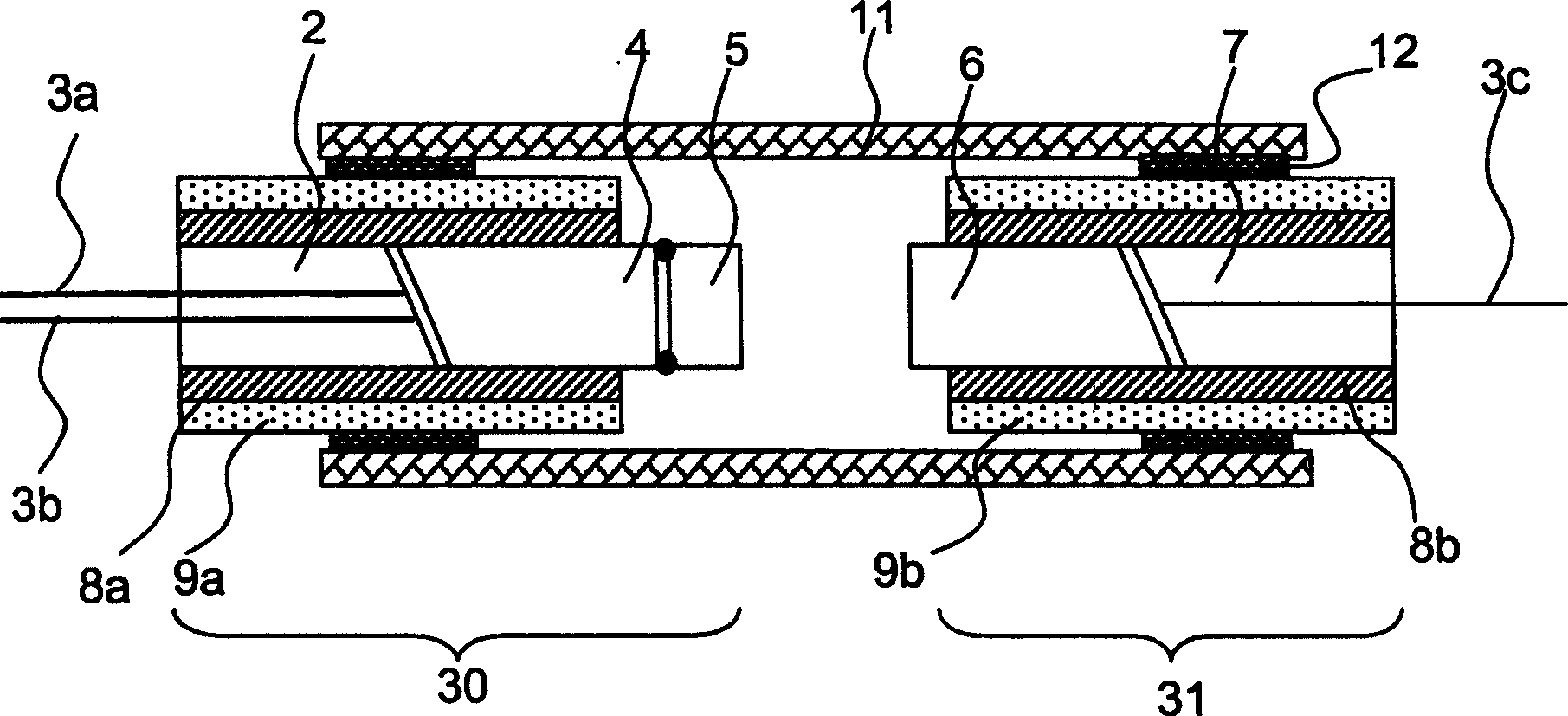

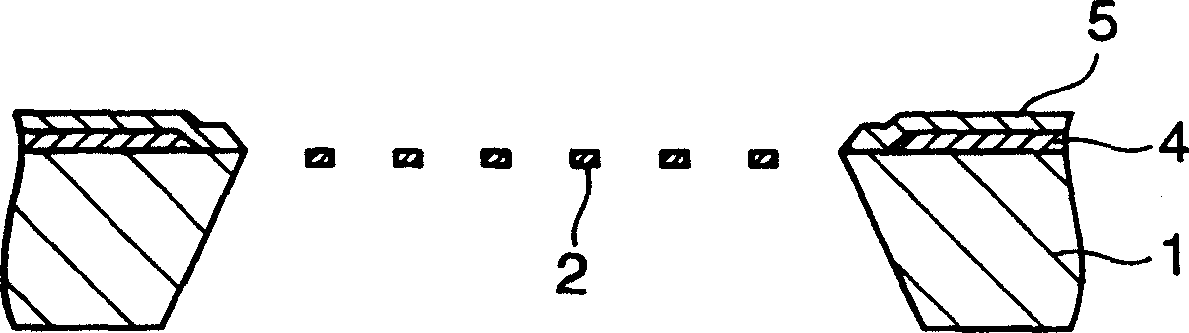

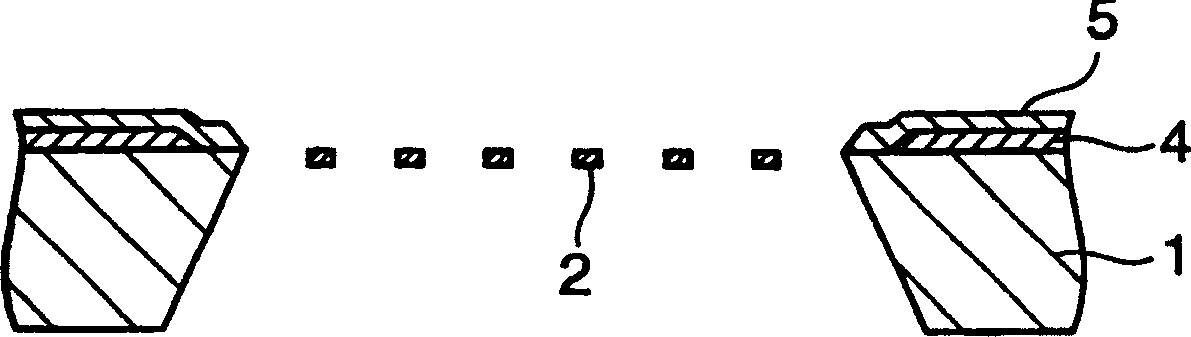

Worm wheel for electric power steering apparatus and method for manufacturing the same

InactiveCN103287481AStable for long-term useGood molding effectMechanical steering gearsGear wheelsElectric power steeringReduction drive

Disclosed is a worm wheel of a reducer of an electric power steering apparatus which is manufactured by integrally injection-molding a hub, a boss, and a gear forming part, thereby making it possible to increase a forming performance of the worm wheel and reduce an amount of material, and increasing a mechanical durability and frictional characteristics of the worm wheel to allow the reducer to be stably used for a long time, and a method for manufacturing the same.

Owner:HL MANDO CORP

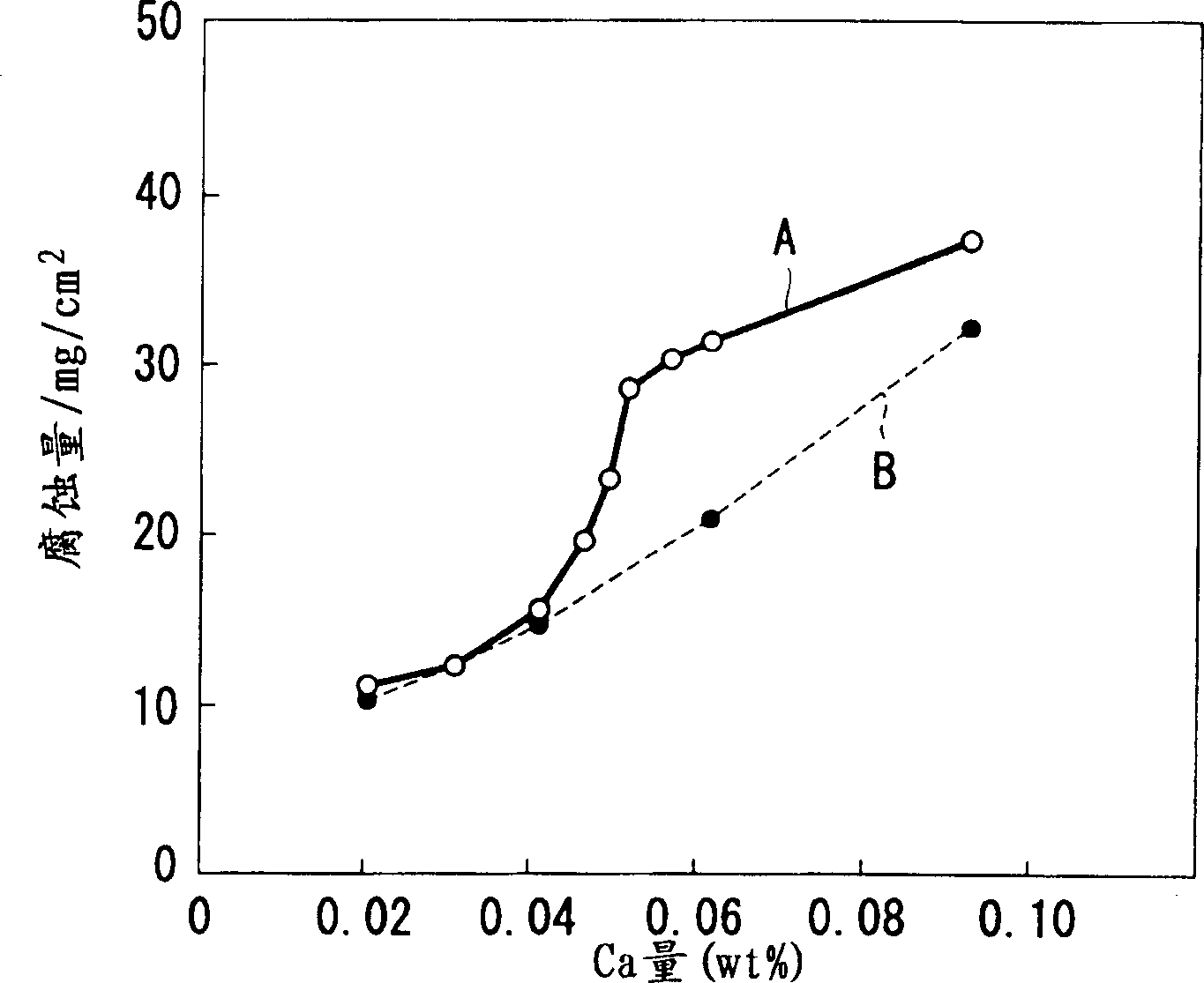

Lead-based alloy for lead acid battery substrate for lead acid battery and lead-acid battery

InactiveCN1533617AImprove corrosion resistanceHigh mechanical strengthElectrode carriers/collectorsAlloyImpurity

Provided is a lead-based alloy for a lead-acid battery, comprising not less than 0.02% and less than 0.05% by weight of calcium, not less than 0.4% and not more than 2.5% by weight of tin, not less than 0.005% and not more than 0.04% by weight of aluminum, not less than 0.002% and not more than 0.014% by weight of barium, and the balance of lead and unavoidable impurities.

Owner:THE FURUKAWA BATTERY CO LTD +1

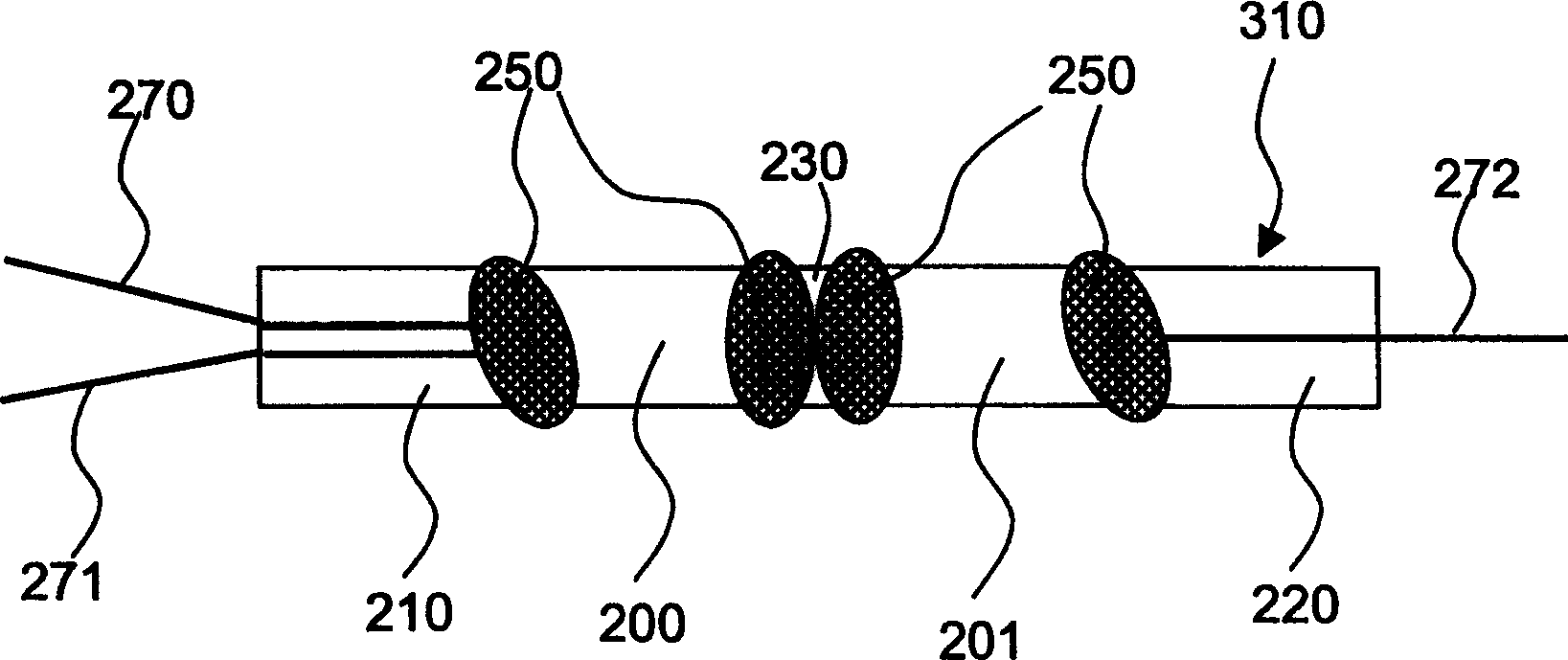

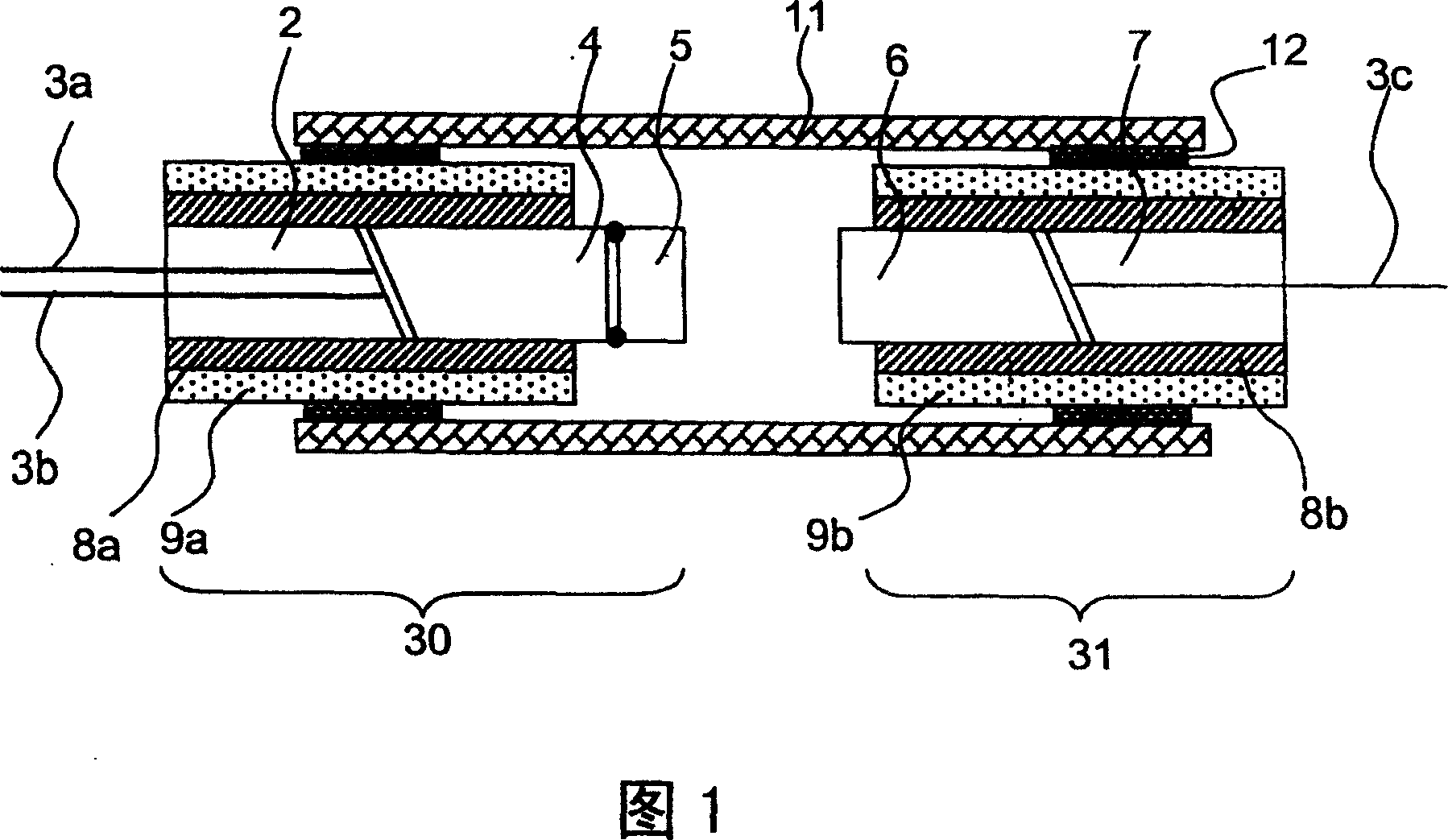

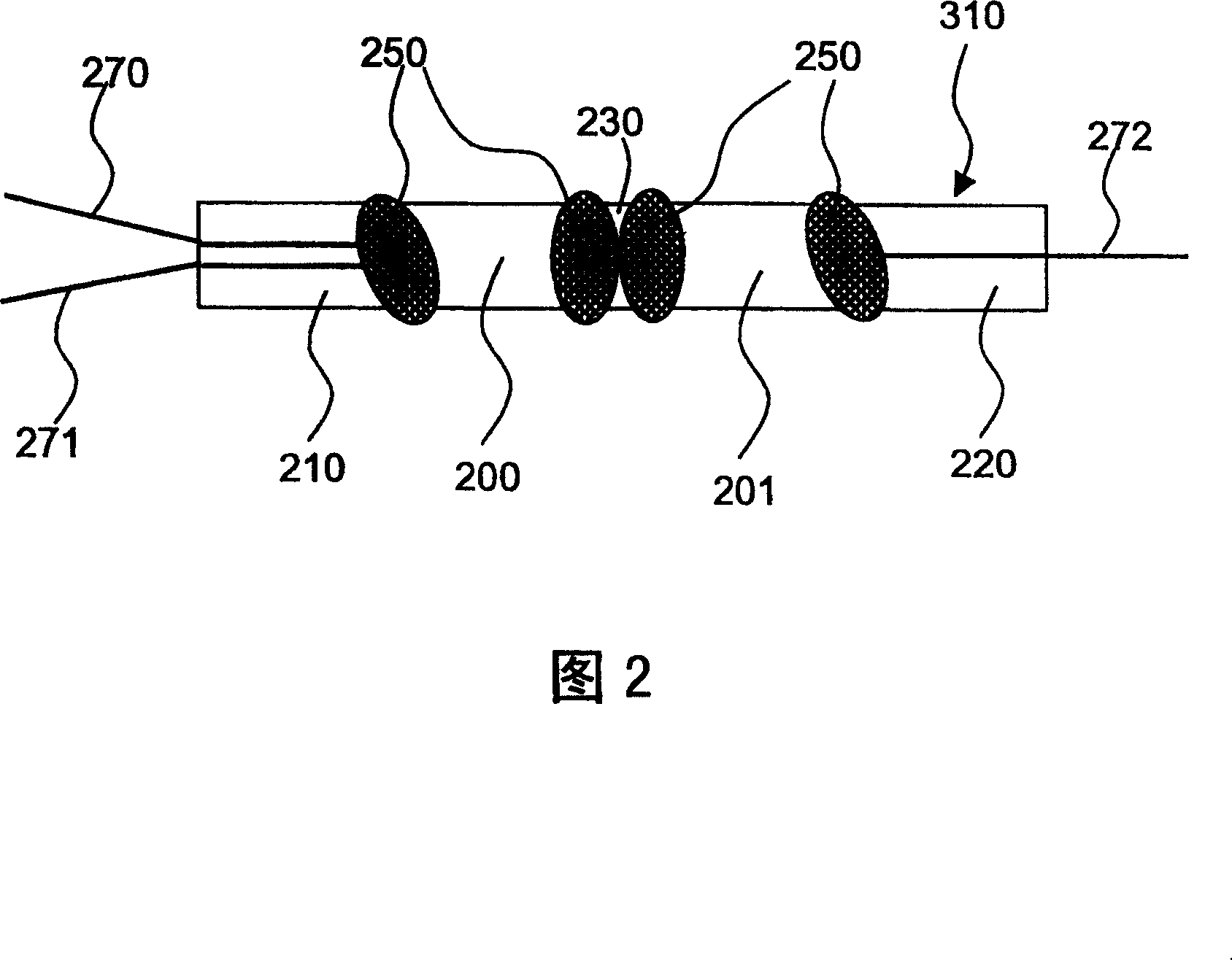

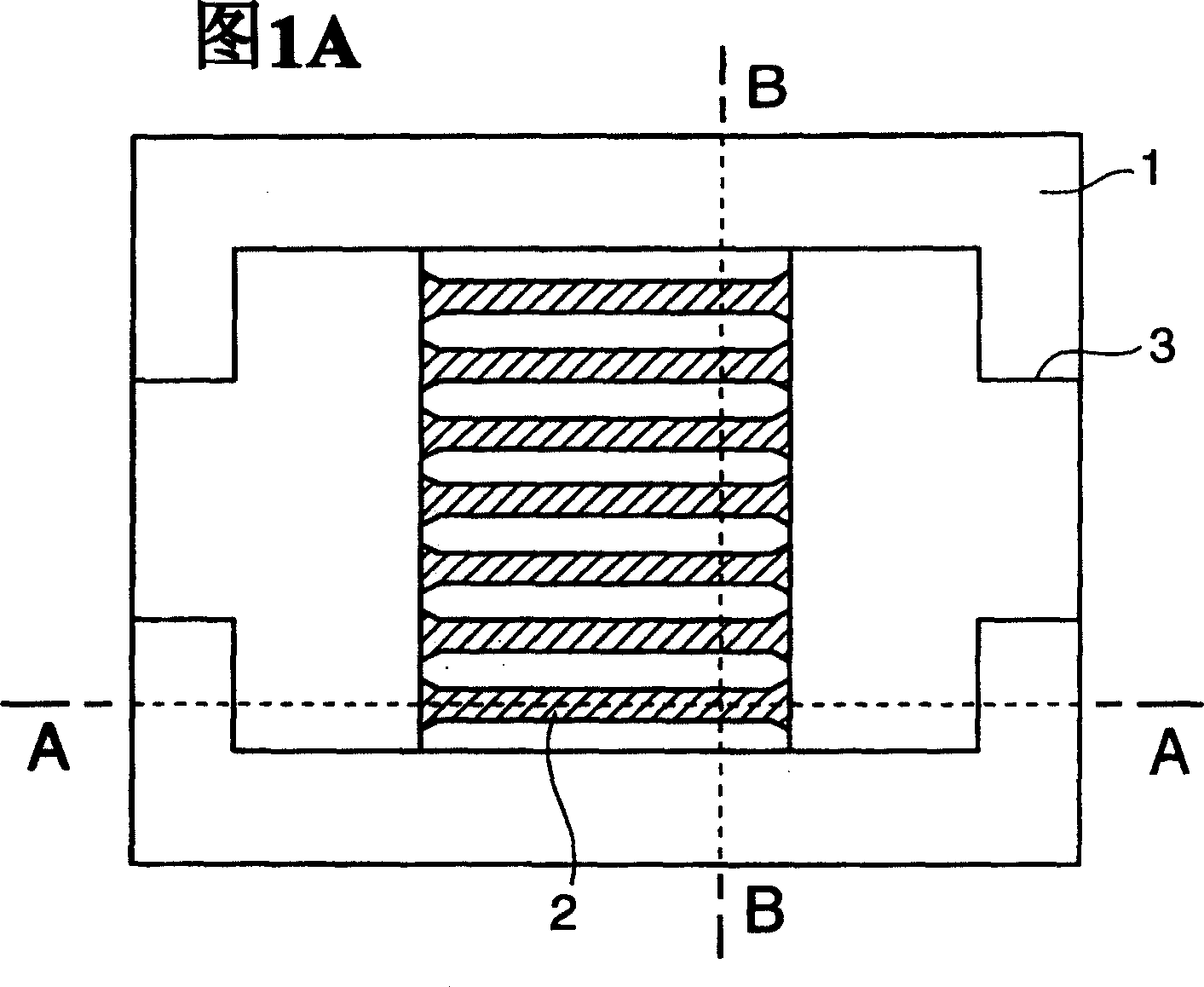

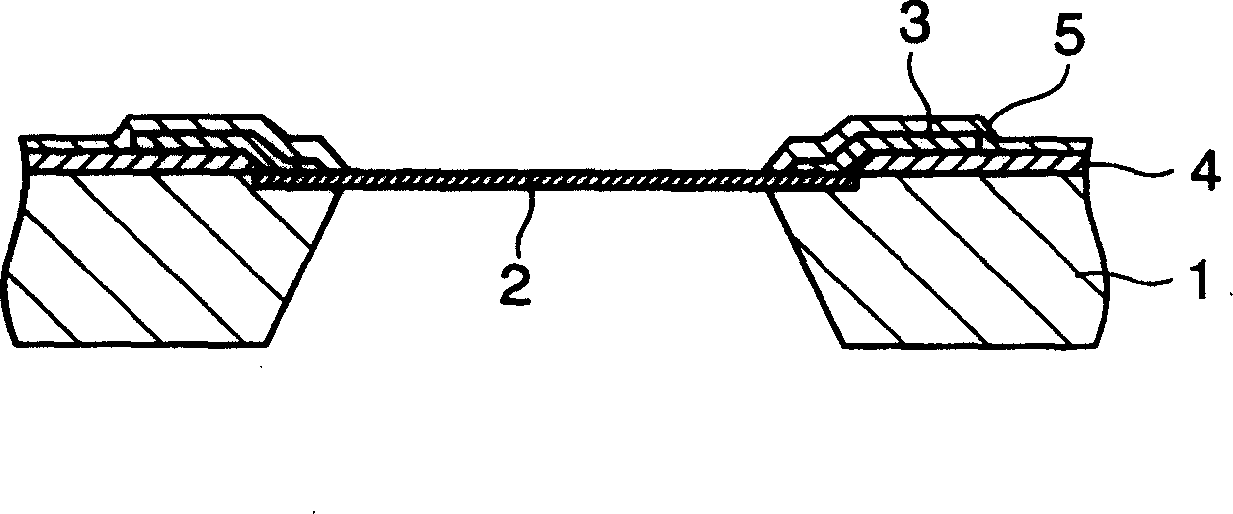

Packing method and structure of optical fiber optical element

InactiveCN1601311AGood optical performanceStable for long-term useCoupling light guidesEngineeringSoldering

The invention includes a subcombination of optical fibre optical device with extended optical fibre, a ring cap, a sleeve and an external package pipe, a binding agent can be infiltrated into miniature gap between subcombination of said optical fibre optical device and all the components by utilizing capillary action so as to attain the goal of compact combination and sealed package. This combination mode is different from and superior to that of general optical component by using tin soldering paste.

Owner:BROWAVE CORP

Manufacturing method of steel rotational moulding pipeline with polyolefin lining layer

The invention relates to a manufacturing method of a steel rotational moulding pipeline with a polyolefin lining layer, comprising the following steps: welding, sandblasting, heating and preserving the temperature, rotationally moulding, lowering the temperature, carrying out a pressure test under negative pressure, carrying out a pressure test under a positive pressure, detecting the lining and the like. The pipeline obtained by utilizing the method in the invention not only has the strength of steel, but also has corrosion resistance property of plastics, and is resistant to acid, alkali and salt of various concentrations and some organic solutions in the range from minus 60 DEG C to 100 DEG C. The pipeline in the invention is an ideal material to substitute rubber, fibre reinforced plastic, stainless steel, titanium timber and brick lining, is stable for long-term use in strong corrosive mediums such as various organic acid, inorganic acid, alkali salt and the like, and is characterized by acid-base mixing, shock cooling or heating or alternation of cold and hot.

Owner:南通楠瑞碳素制品有限公司

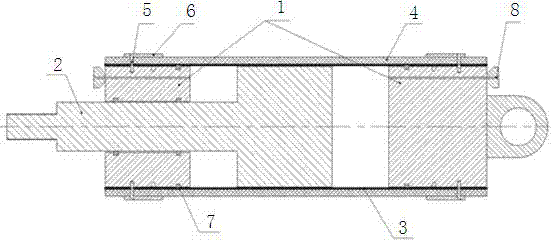

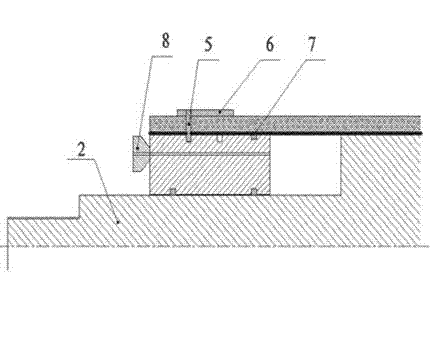

Lightweight high-strength carbon fiber composite hydrocylinder

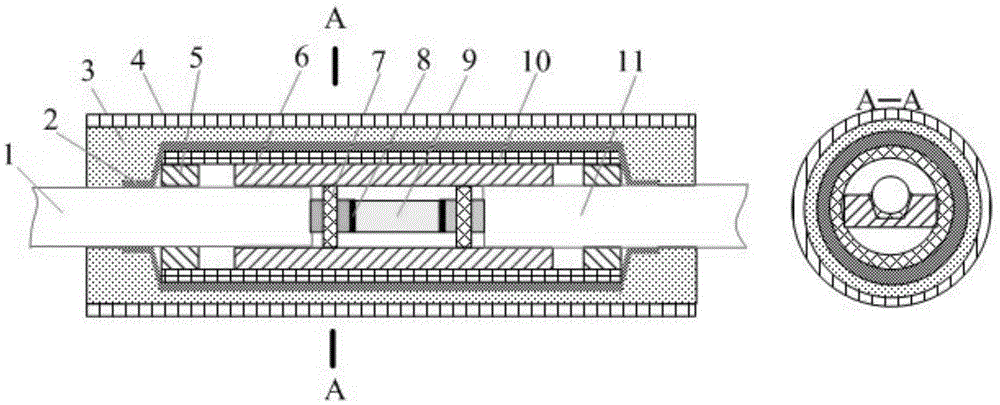

InactiveCN103591078AIncrease productivityAvoid eccentricityFluid-pressure actuatorsResin matrixHigh intensity

The invention provides a lightweight high-strength carbon fiber composite hydrocylinder. The hydrocylinder comprises metal heads, a hydrocylinder piston, a metal liner formed by a hydrocylinder barrel, fixing parts, metal lantern rings and sealing rings, the metal liner is externally and integrally coated with a reinforcing layer formed by a carbon fiber composite, the metal lantern rings are sleeved outside the reinforcing layer which is formed by taking thermosetting resin as a matrix and carbon fiber as a reinforcement, and the thermosetting resin matrix accounts for 23-40% of the reinforcing layer by weight. Compared with all-metal hydrocylinders in the prior art, the lightweight high-strength carbon fiber composite hydrocylinder has the advantages that strength, rigidity and fatigue resistance of the hydrocylinder are all obviously improved under various working conditions, so that safety of the hydrocylinder is improved effectively, weight is reduced by 30-65%, and the objectives of mechanical pump truck weight reduction and complete truck cost reduction are achieved.

Owner:HENGSHEN

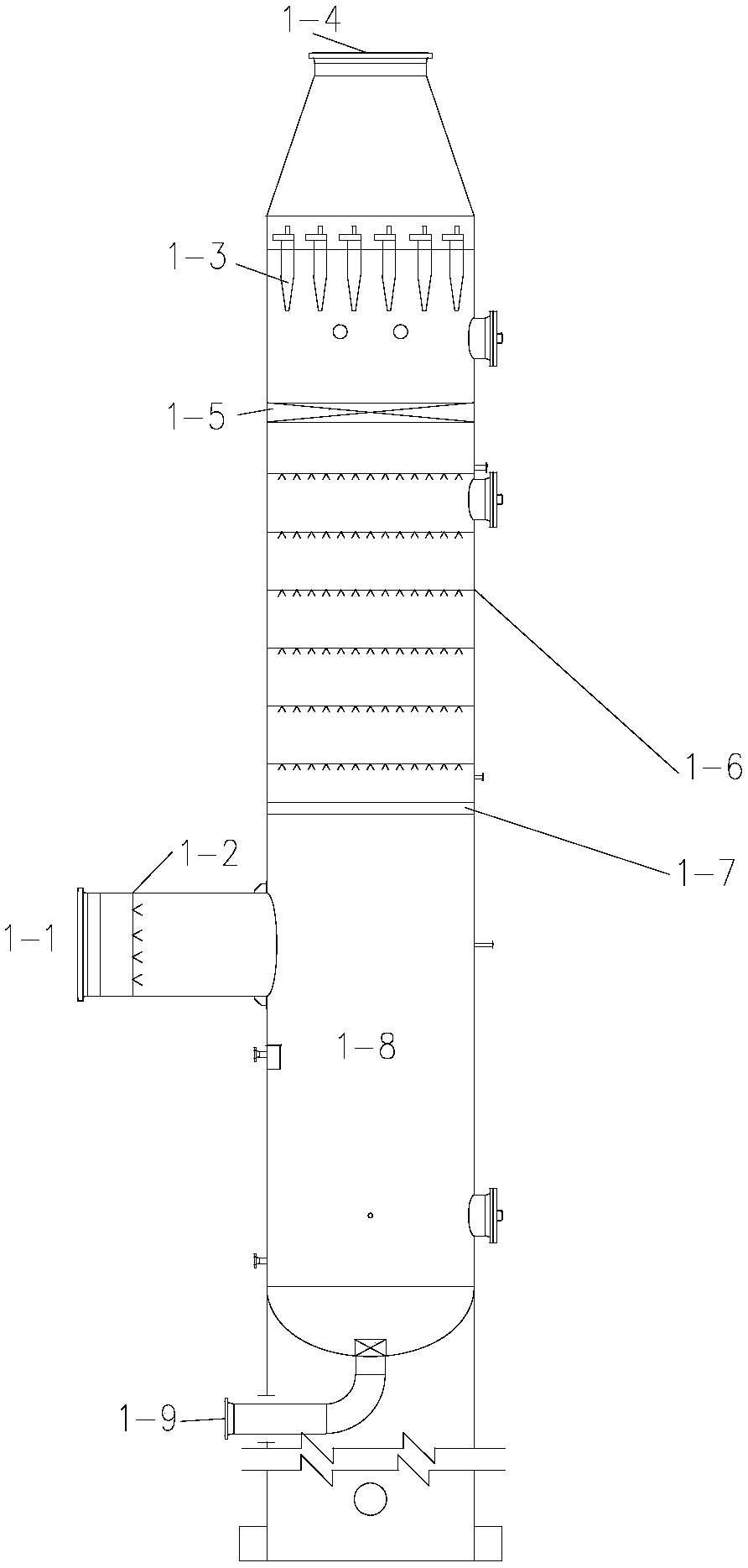

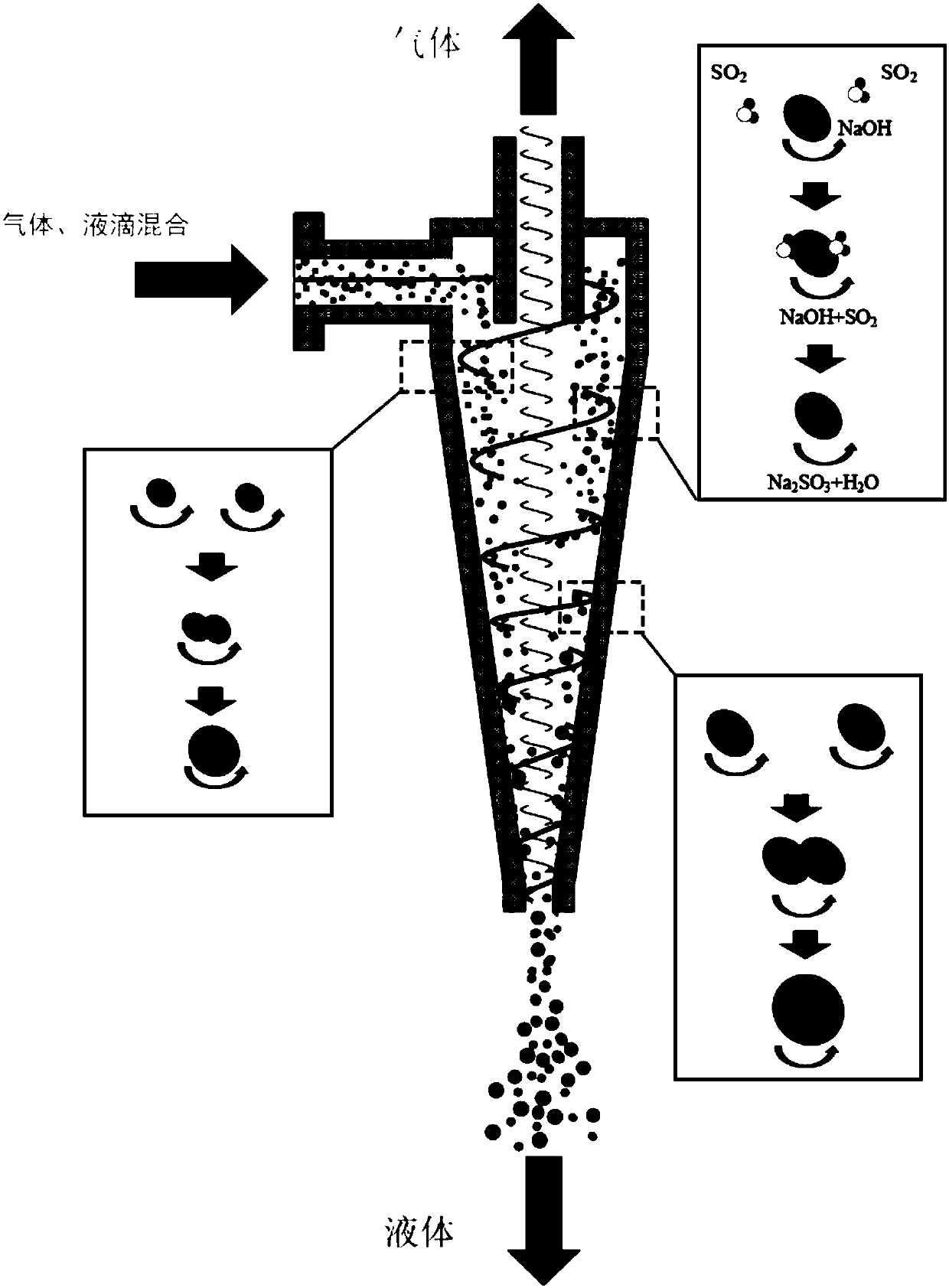

Method and device for deep desulfurization and alkali control of sulfur incineration tail gas by sodium process

PendingCN109966879AImprove desulfurization efficiencyImprove desulfurization effectCombination devicesGas treatmentAtmospheric airQuenching

Relating to methods and devices for deep desulfurization and alkali control of sulfur incineration tail gas by sodium process, the invention provides a method for deep desulfurization and alkali control of sulfur incineration tail gas by sodium process. The method includes the steps of: (A) subjecting the sulfur incineration tail gas to air cooling, then letting the cooled tail gas enter a desulfurization tower quenching section, and then introducing the tail gas into a desulfurization tower body; (B) ) in the desulfurization tower body, enabling the tail gas to enter the spray zone of the desulfurization tower from the lower part, and performing multilayer spraying of a circulating absorbent to ascending gas for reaction to absorb most of the sulfur in the tail gas; (C) letting the tail gas carrying atomized droplets ascend to the swirling flow zone of the desulfurization tower and enter swirling flow tubes for further contact absorption of alkaline droplets and non-fully reacted sulfur dioxide to strengthen the desulfurization effect, and letting the alkaline droplets gather and drip from the lower openings of the swirling flow tubes to flow back into the desulfurization tower body; and (D) mixing the purified gas obtained in step (C) with the heated air in step (A), and then discharging the mixed gas into the atmosphere together. The invention also provides a device for deepdesulfurization and alkali control of sulfur incineration tail gas by sodium process.

Owner:ZHENHAI PETROCHEMICAL ENG CO LTD

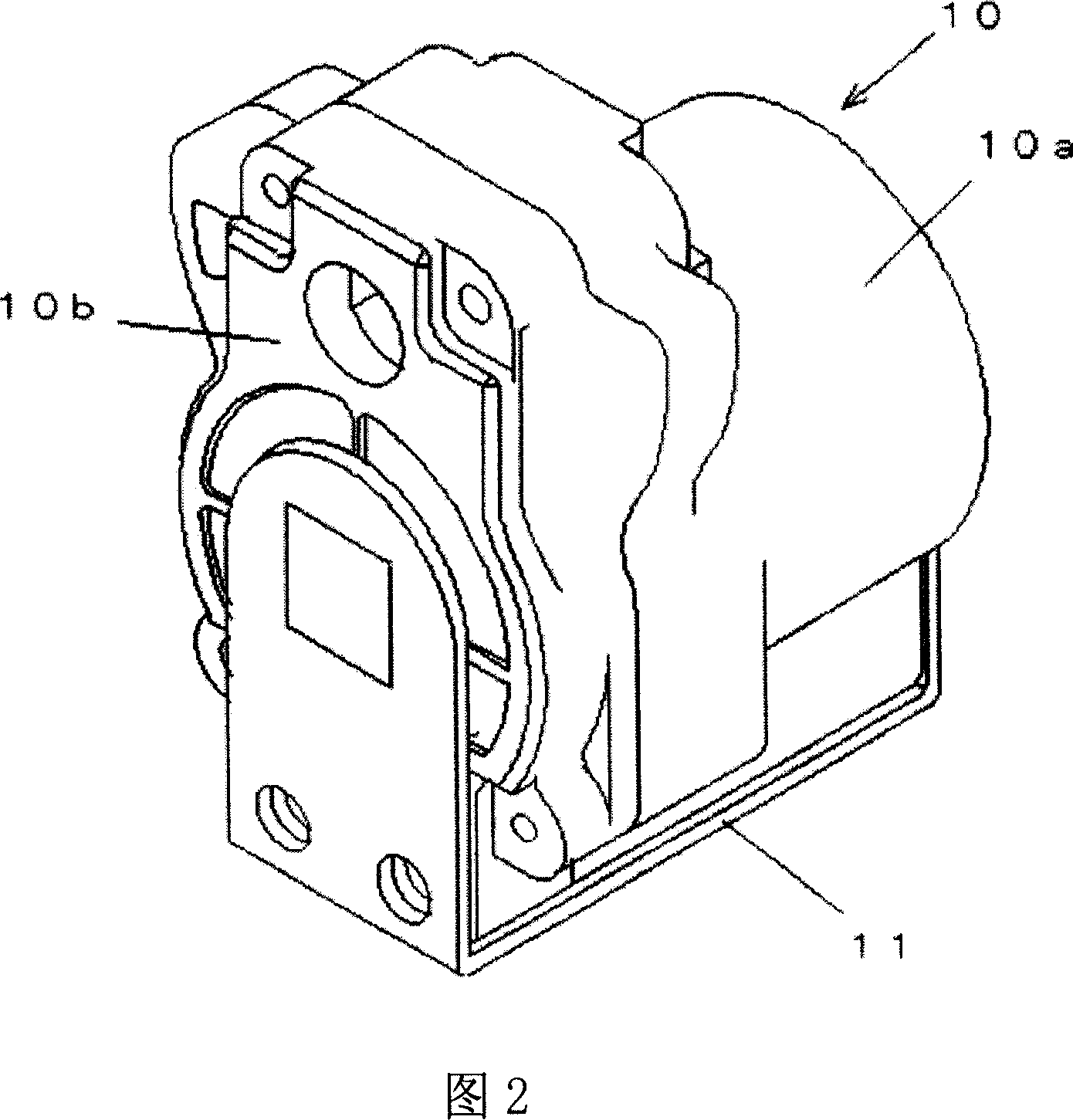

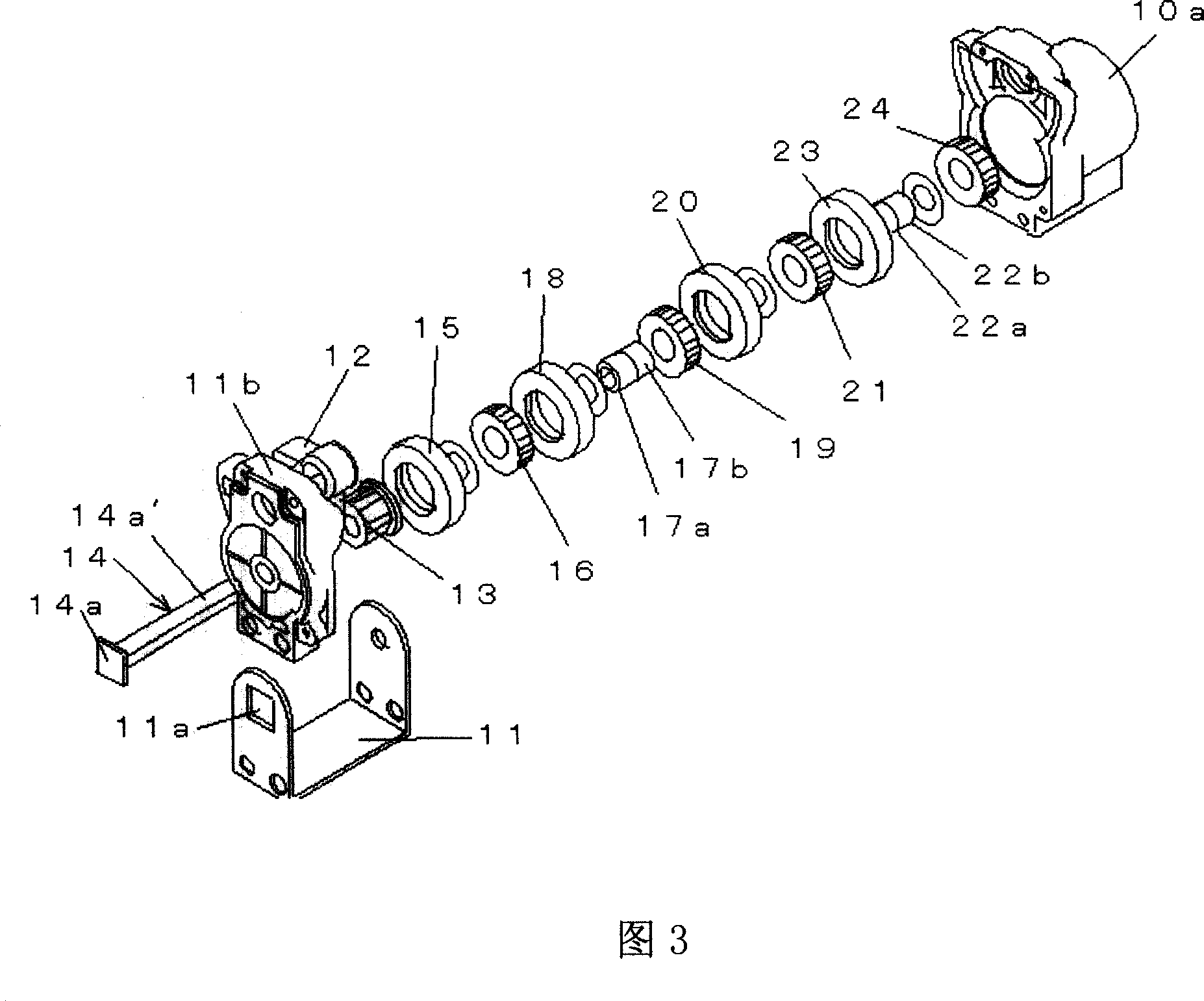

Hinge buffer for open-close device

InactiveCN101016818AImprove energy absorptionStable for long-term useBuilding braking devicesWing accessoriesEnergy absorptionGear wheel

The invention provides a hinge buffer of switch device having excellent energy absorption capacity with simple structure of buffer function. The device is composed of: rotation axis driving by the rotation of the rotation parts and rotationally fixed on frame; gear rotationally fixed on the rotation axis and forming internal tooth; transportation device transporting the rotation of the switch device to the gear; planetary gear having tooth meshing to the internal tooth of the gear; rotation regulating device regulating the rotation of the planetary gear to move it in circle trajectory whose centre is near the rotation centre; and absorption device absorbing rotational energy of the gear.

Owner:SHIMONISHI GIKEN KOGYO KK

Manufacturing method for steel rotational moulding storage tank with modified polypropylene inside liner

ActiveCN101863355AGood compactnessImprove mechanical propertiesPackaging corrosive chemicalsLinings/internal coatingsTemperature resistancePolypropylene

The invention relates to a manufacturing method for a steel rotational moulding storage tank with a modified polypropylene inside liner. The method comprises the following steps: welding, tapping, polishing, welding a wire mesh, arranging a rolling ring, adding modified polypropylene powder, heating and autorotating, rocking and autorotating, cooling, offloading, removing the rolling ring, trimming and the like. In the invention, the storage tank obtained by the method exactly overcomes the shortcomings of the prior art, the steel rotational moulding storage tank with the modified polypropylene inside liner has not only the strength of steel but also the corrosion resistance of polypropylene plastic, and the inside liner of the steel rotational moulding storage tank has obvious characteristics of good compactness, high mechanical property, high integrity, no joint, no welding line, uniform thickness, high temperature and low temperature resistance, negative pressure resistance, strong adhesion, corrosion resistance, impact resistance, no toxicity, easy maintenance and the like.

Owner:江苏兆辉防腐科技有限公司

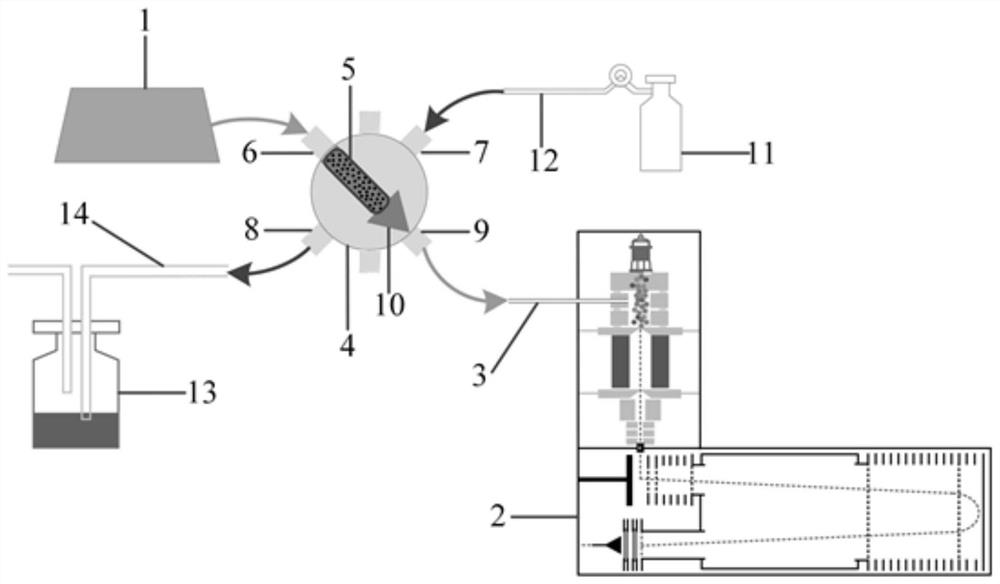

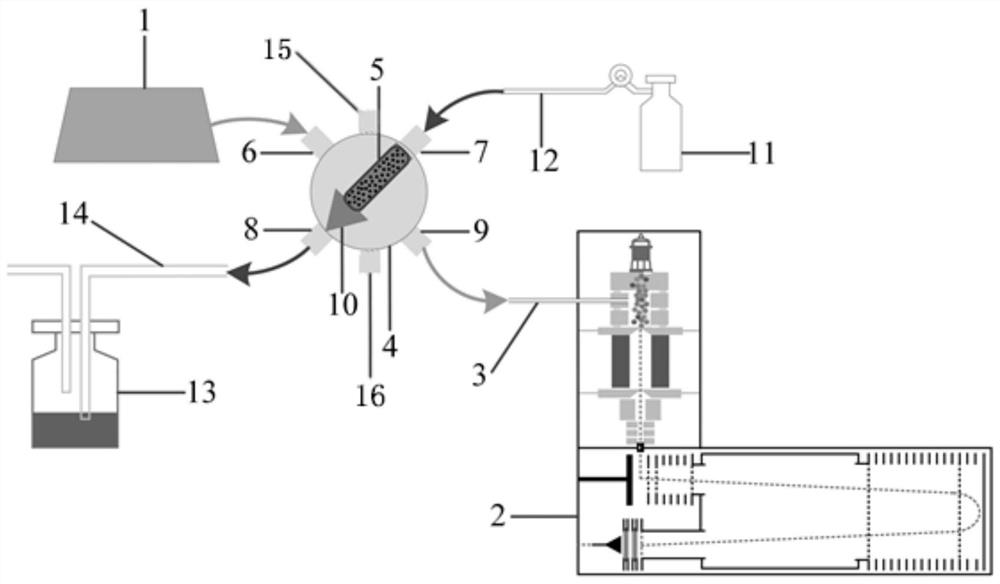

Device for relieving sample introduction capillary pollution through mass spectrometry

InactiveCN112710726AExtend the life cycleExtended service lifeDispersed particle filtrationSamples introduction/extractionMass spectrometry detectorCapillary Tubing

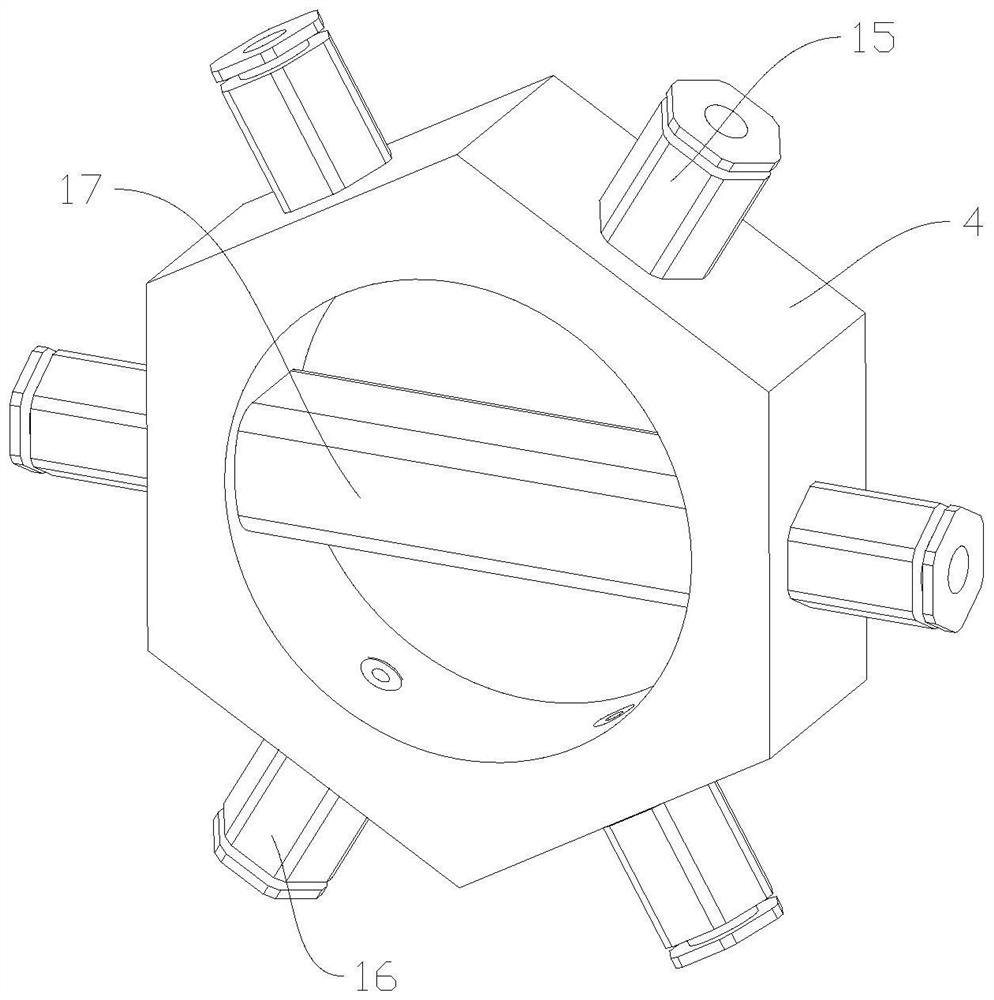

The invention discloses a device for relieving sample introduction capillary pollution through mass spectrometry. The device comprises a sample storage device, a mass spectrometry detector, a four-way control valve, a filter sand core, a purge gas source and a tail gas treatment device; the four-way control valve is at least provided with four connectors; every two connectors form a group; the filter sand core is rotatably mounted in the four-way control valve; the filter sand core is rotatably communicated with any group of connectors; the sample storage device and the mass spectrometry detector are connected to the connectors; the filter sand core purifies a sample entering from the sample storage device; the purge gas source is connected with the connector; and the tail gas treatment device is connected with the connector, and the tail gas treatment device is used for treating waste materials discharged from the filter sand core. A sample to be detected is conveniently filtered and then is detected, a filtering part is conveniently cleaned subsequently, the service life of the filtering part is prolonged; and meanwhile, the device is stable in structure and simple in operation.

Owner:SHENZHEN BREATHA BIOTECHNOLOGY CO LTD

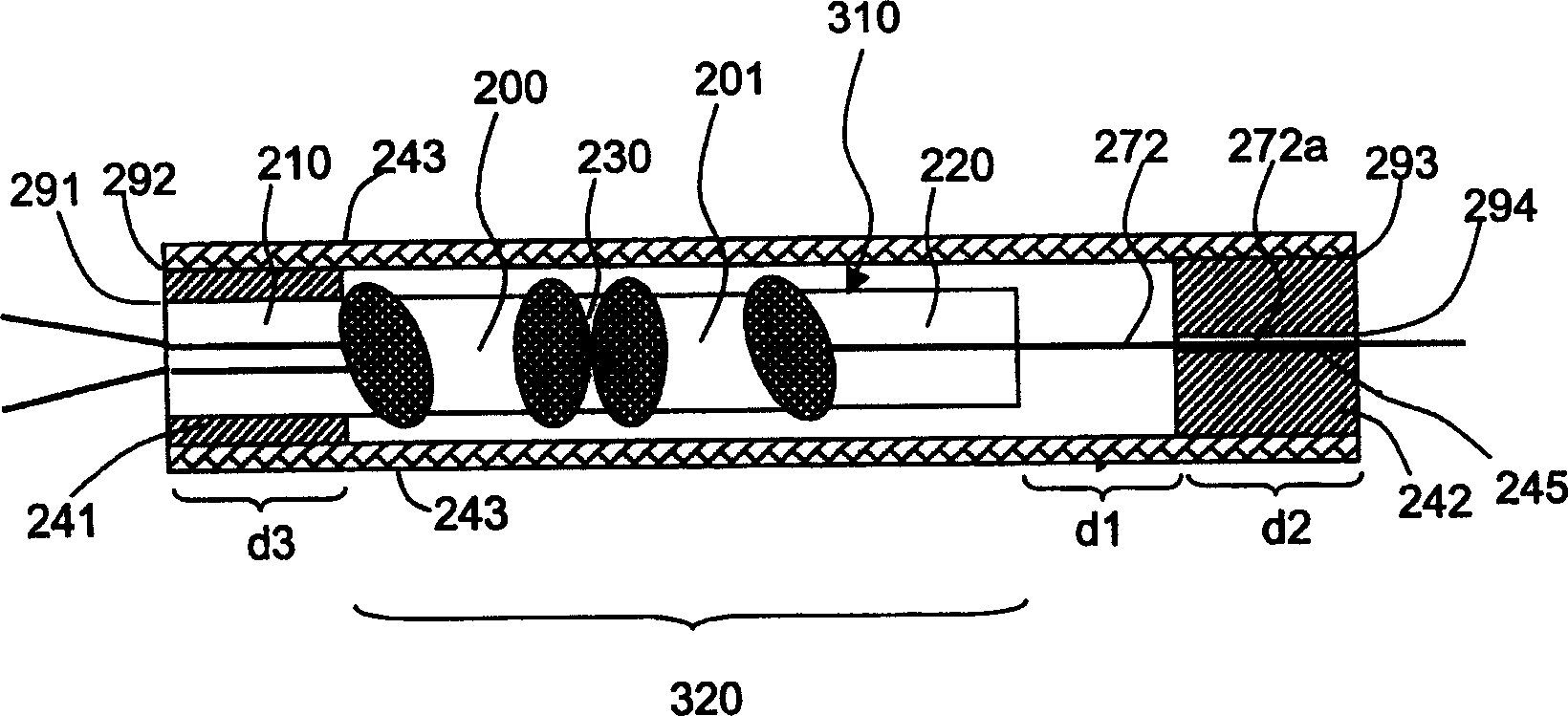

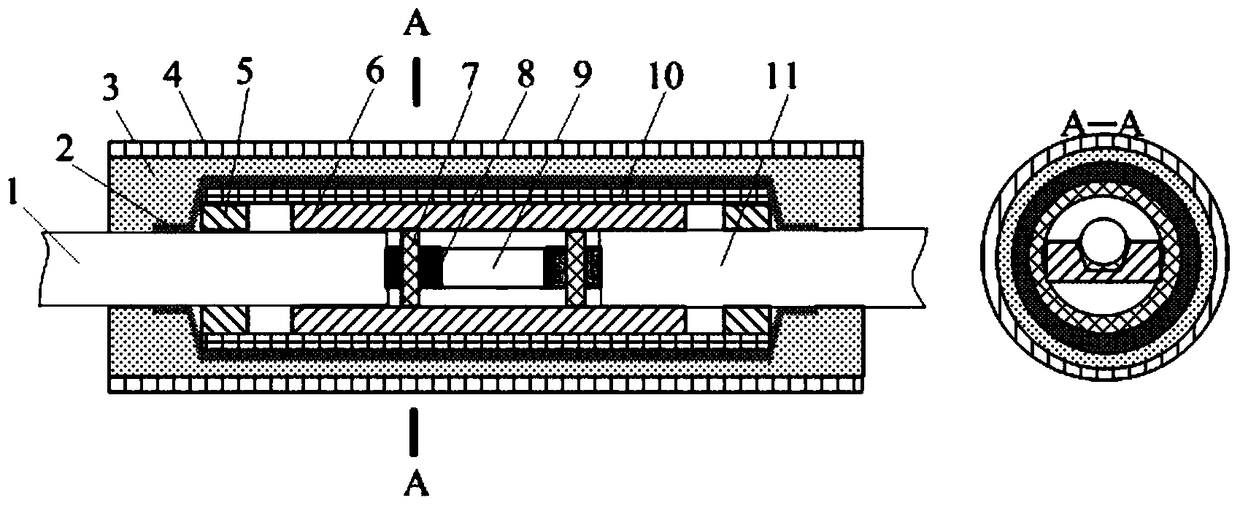

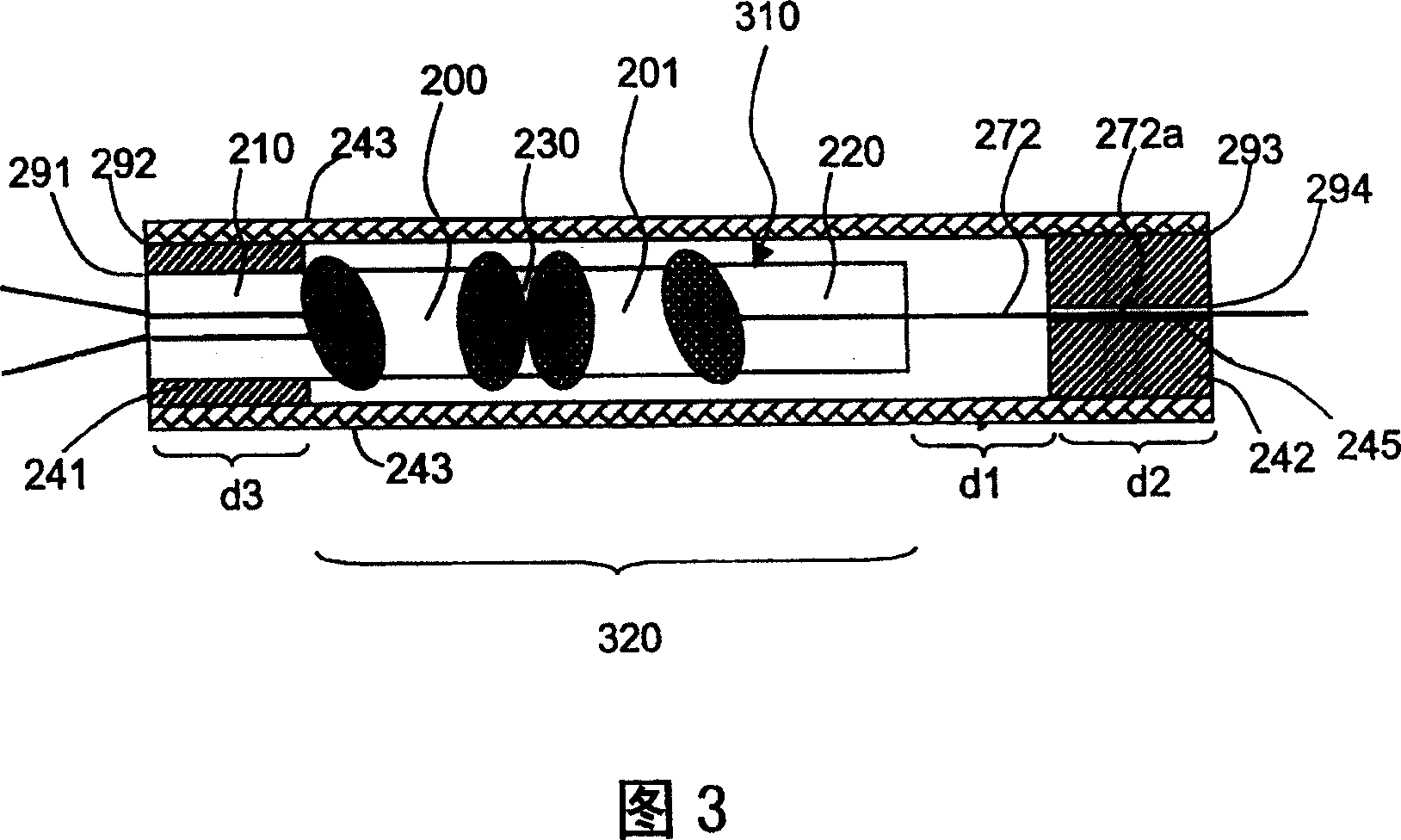

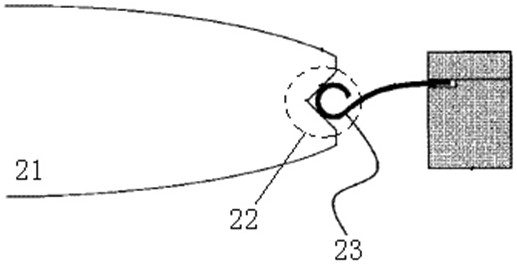

Optical fiber end surface reflecting mirror packaging method

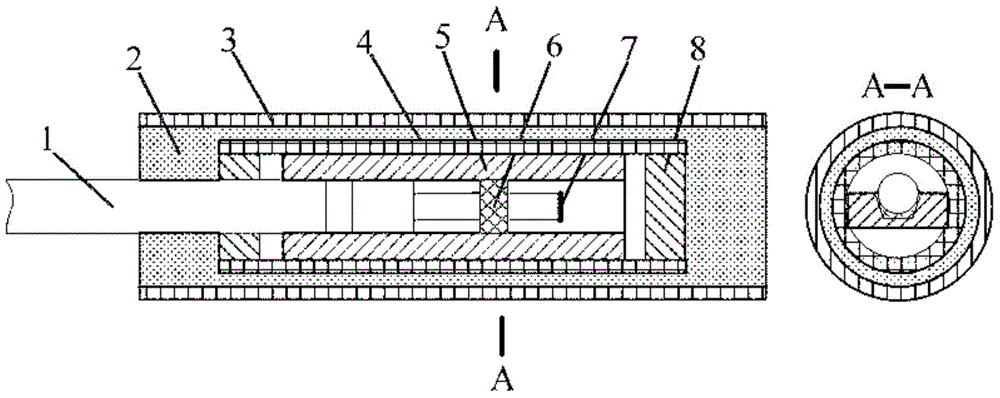

ActiveCN104950395ASimple structureImprove reliabilityCoupling light guidesToughened glassOptical fiber cable

The invention particularly relates to an optical fiber end surface reflecting mirror packaging method used for a reflecting type optical fiber current transformer. The method comprises the following steps of (1.1)arrangement: an optical fiber end surface reflecting mirror is horizontally arranged in a quartz plate groove; (1.2) fixing: a first type of optical fiber fixing glue is coated at the specific positions of the left of a reflection-increasing film and right of the left port of a quartz plate and then heated and cured and stands; (1.3) sleeving and sealing: the quartz plate is sleeved in a quartz capillary tube, and a second type of optical fiber fixing glue is coated at the two ports and then heated and cured and stands; (1.4) drying: the quartz capillary tube is arranged in a high-temperature drying box to be dried and then stands; (1.5) protection and external packaging: packaging glue is evenly coated on the surface of the capillary tube and then is externally sleeved by a toughened glass tube; (1.6) temperature cycling; and (1.7) use after standing. The structure obtained by the optical fiber end surface reflecting mirror packaging method has outstanding advantages that the structure is simple, the size is small, sealing performance is great, reliability is high and long-term use is stable.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

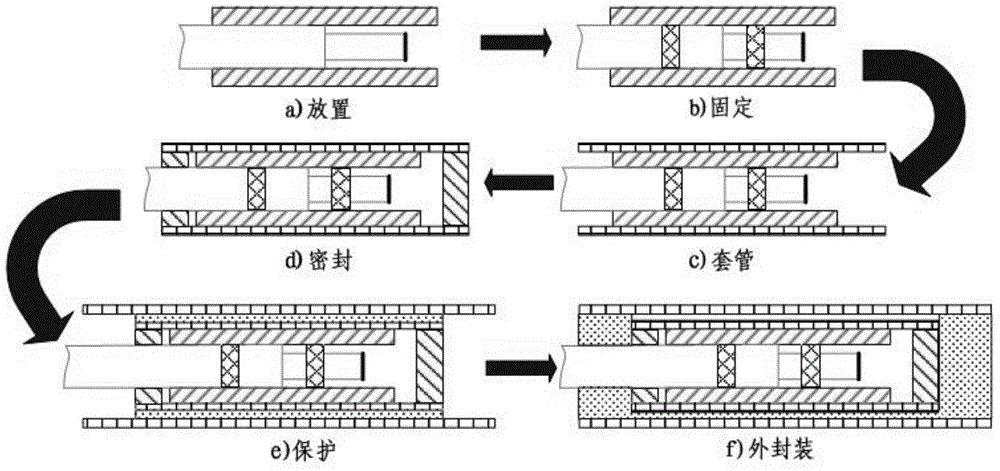

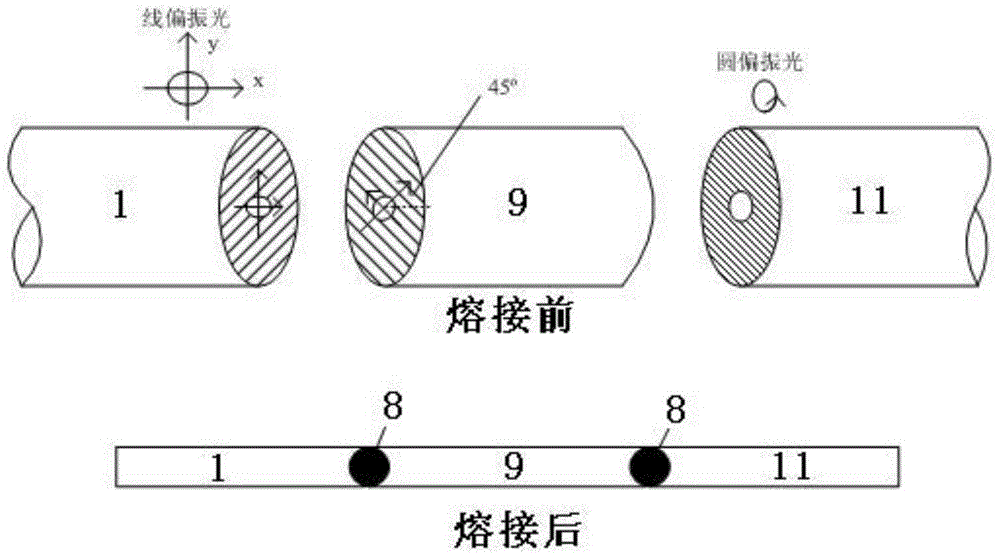

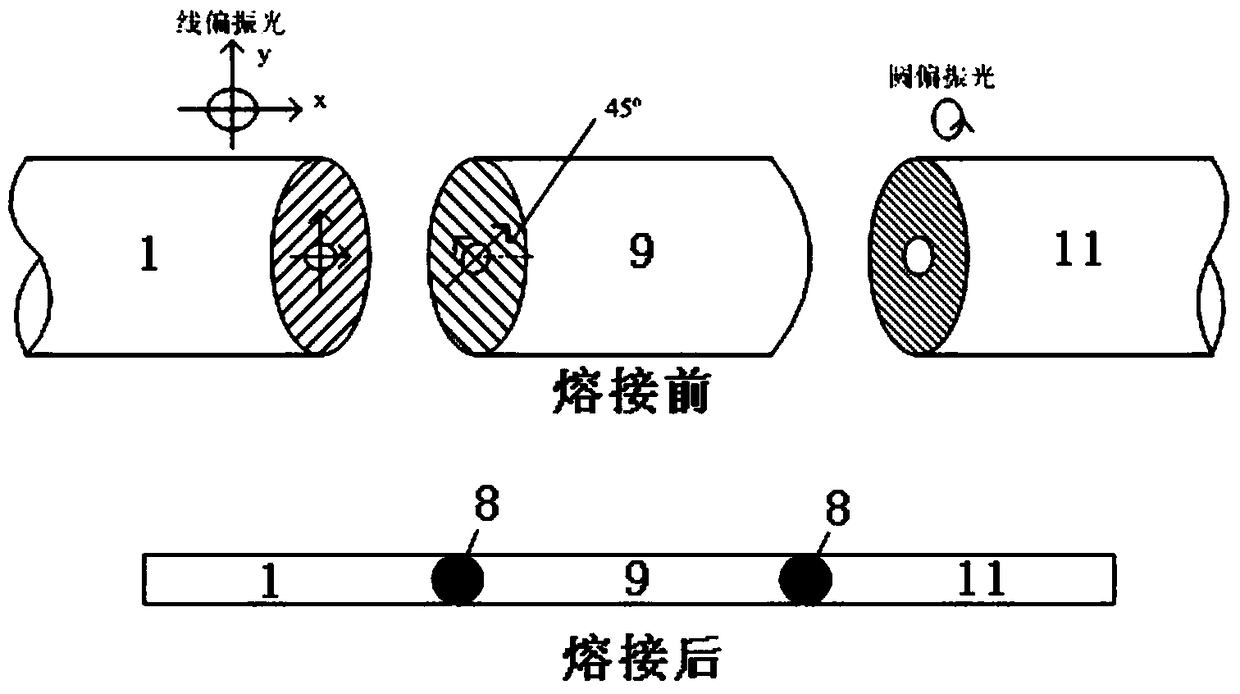

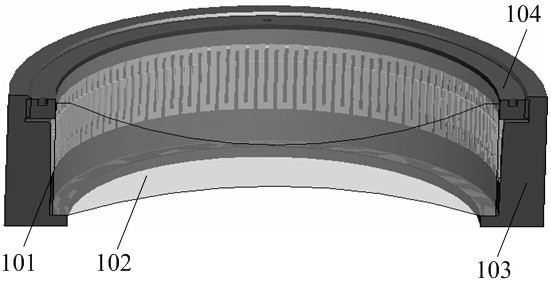

All-fiber quarter wave plate packaging method

The invention belongs to the technical field of a fiber current transformer and specifically relates to an all-fiber quarter wave plate packaging method. The method provides a manufacturing process flow to meet use requirement of the fiber current transformer through a reasonable three-layer packaging process and based on the practical application situation of the fiber current transformer. The all-fiber quarter wave plate packaging method has the obvious advantages of simple structure, small size, good seal performance, high reliability and stable long-term use, so that an all-fiber quarter wave plate can fully replace a crystal quarter wave plate in the application of the fiber current transformer, and becomes a high-precision, high-stability and high-reliability fiber current transformer core part.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

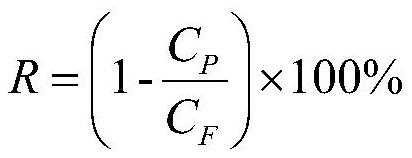

Polyethylene microporous membrane, polyvinyl nanofiltration membrane and preparation method thereof

PendingCN112473401AImprove performanceUniform and stable physical parametersSemi-permeable membranesPolymer scienceTap water

The invention relates to the technical field of nanofiltration membranes, and particularly discloses a polyethylene microporous membrane capable of being used for preparing a nanofiltration membrane,a polyvinyl nanofiltration membrane and a preparation method thereof. Compared with a nanofiltration membrane prepared from a commercialized polyethylene membrane on the market, the nanofiltration membrane prepared from the polyethylene microporous membrane with a limited range of the physical parameters is high in flux, high in bivalent salt retention rate, high in monovalent salt retention rate,high in tap water retention rate and more excellent in overall filtering performance, and can be applied to various scenes with different solvents, the flux is kept stable, no dead point or damage occurs on the membrane surface, the tolerance limit is reached only after 70DEG C, the tolerance performance is excellent, the service life is long, the market competitiveness is extremely high, and theapplication prospect is very considerable.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

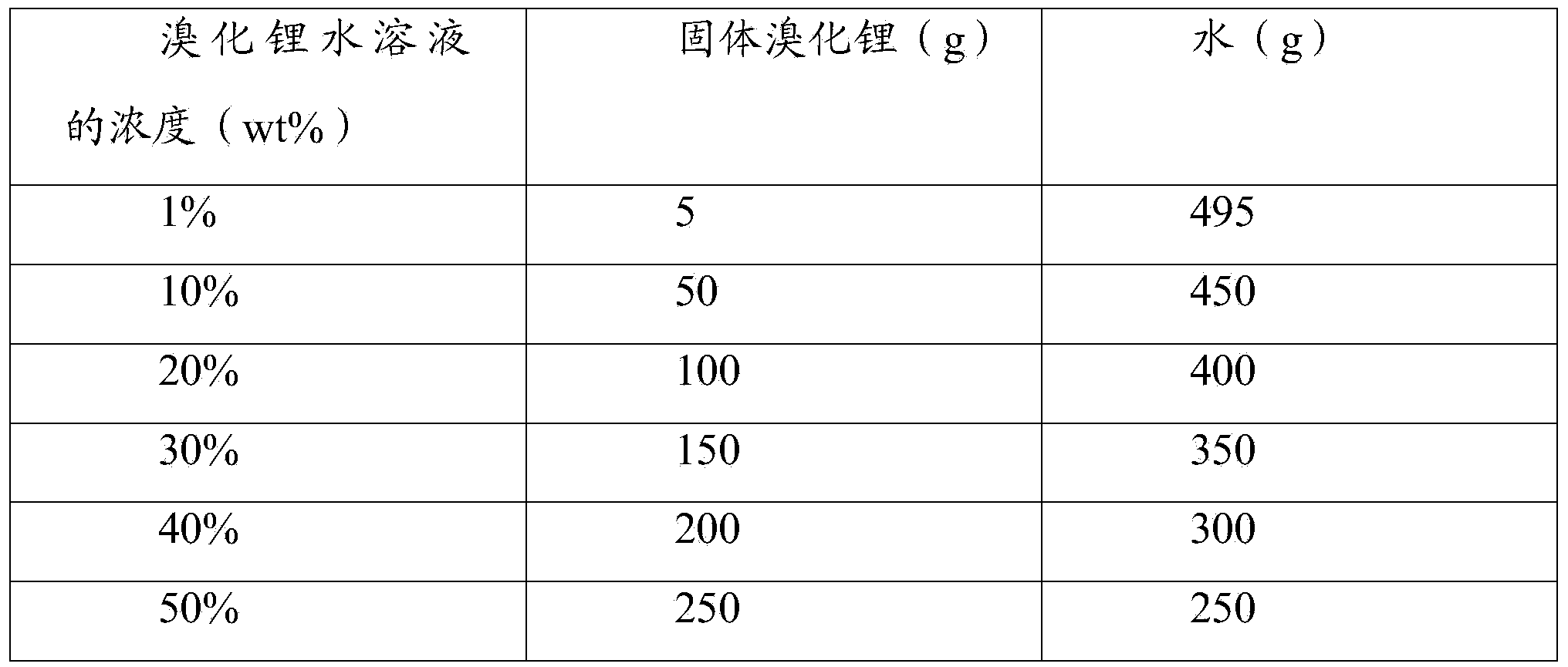

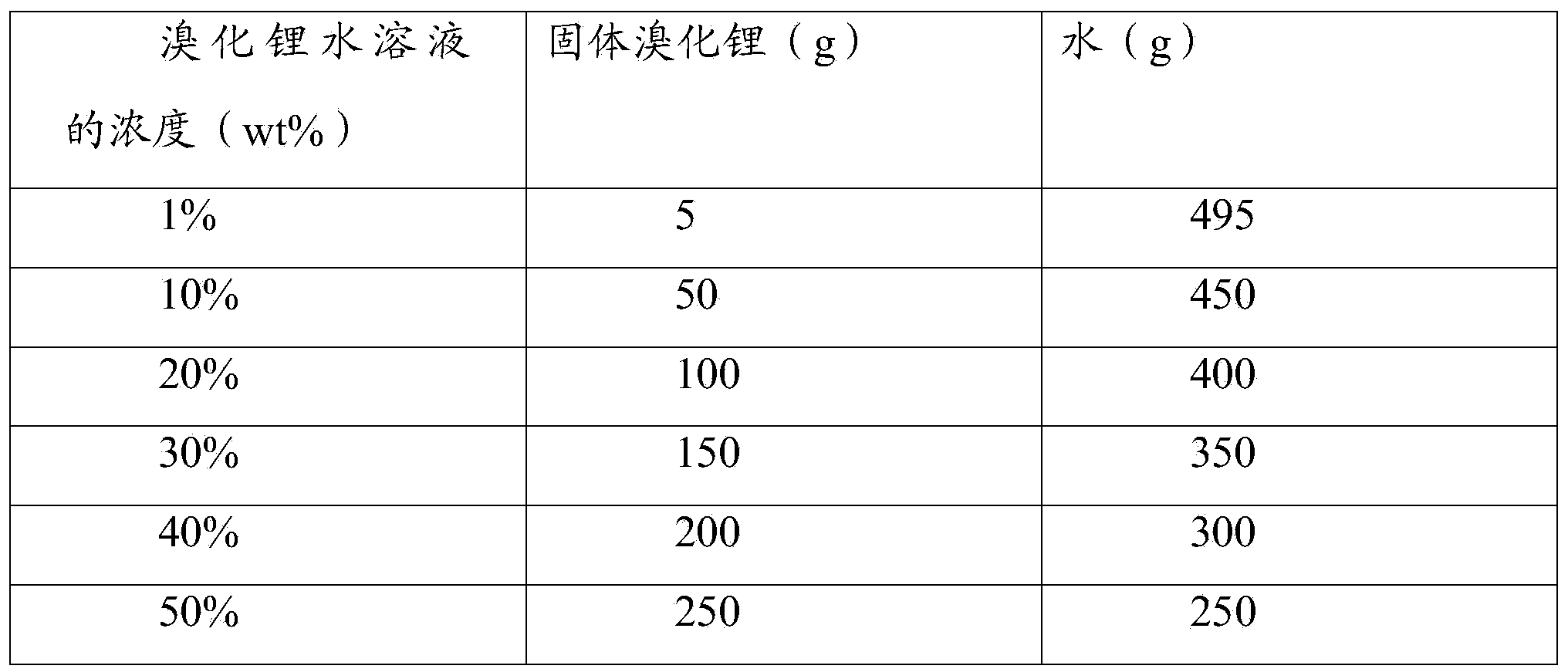

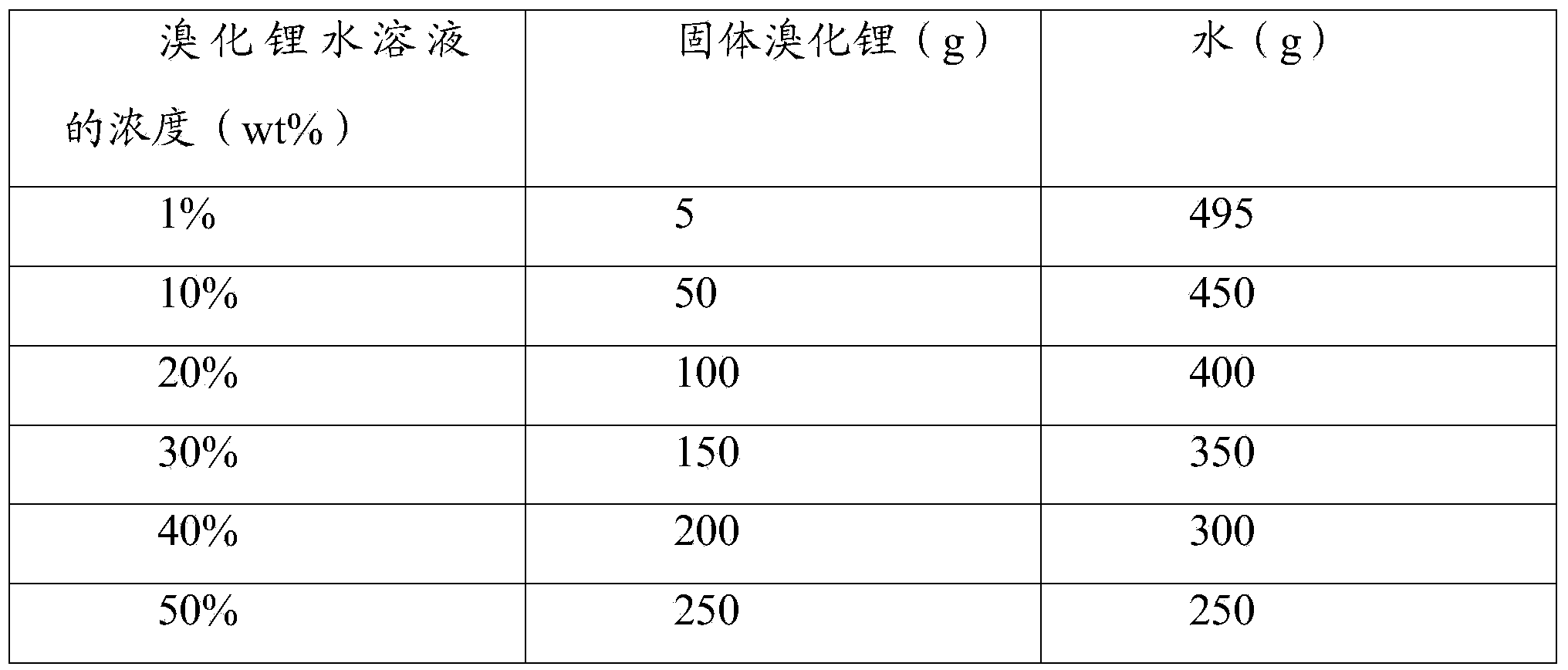

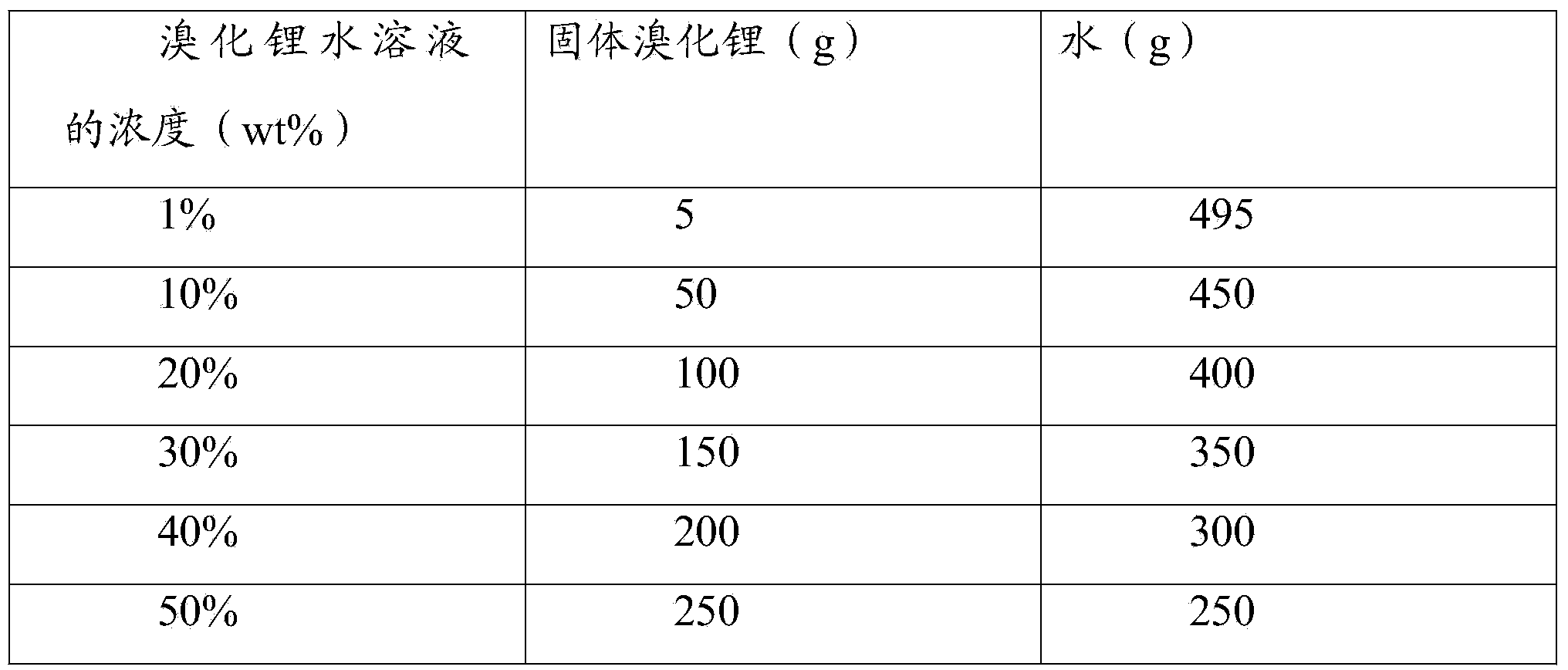

Lithium bromide absorption liquid with carbon nano tube disperse system and preparation method thereof

InactiveCN103509523AFacilitate conductionImprove dispersion stabilityHeat-exchange elementsDispersion stabilityCarbon nanotube

The invention discloses a lithium bromide absorption liquid with a carbon nano tube disperse system. The lithium bromide absorption liquid with the carbon nano tube disperse system is lithium bromide aqueous solution with the mass concentration of 1 to 50 percent; the lithium bromide aqueous solution comprises carbon nano tube particles accounting for 0.001 to 0.01 percent of the total weight of the lithium bromide aqueous solution, a surfactant accounting for 0.01 to 0.1 percent of the total weight of the lithium bromide aqueous solution, and a dispersion stabilizer accounting for 0.01 to 0.1 percent of the total weight of the lithium bromide aqueous solution. The lithium bromide absorption liquid has excellent dispersion stability and substance conductivity.

Owner:昆山市周市溴化锂溶液厂

Manufacturing method for steel rotational moulding storage tank with modified polypropylene inside liner

ActiveCN101863355BImprove compactnessImprove integrityPackaging corrosive chemicalsLinings/internal coatingsState of artHigh integrity

The invention relates to a manufacturing method for a steel rotational moulding storage tank with a modified polypropylene inside liner. The method comprises the following steps: welding, tapping, polishing, welding a wire mesh, arranging a rolling ring, adding modified polypropylene powder, heating and autorotating, rocking and autorotating, cooling, offloading, removing the rolling ring, trimming and the like. In the invention, the storage tank obtained by the method exactly overcomes the shortcomings of the prior art, the steel rotational moulding storage tank with the modified polypropylene inside liner has not only the strength of steel but also the corrosion resistance of polypropylene plastic, and the inside liner of the steel rotational moulding storage tank has obvious characteristics of good compactness, high mechanical property, high integrity, no joint, no welding line, uniform thickness, high temperature and low temperature resistance, negative pressure resistance, strong adhesion, corrosion resistance, impact resistance, no toxicity, easy maintenance and the like.

Owner:江苏兆辉防腐科技有限公司

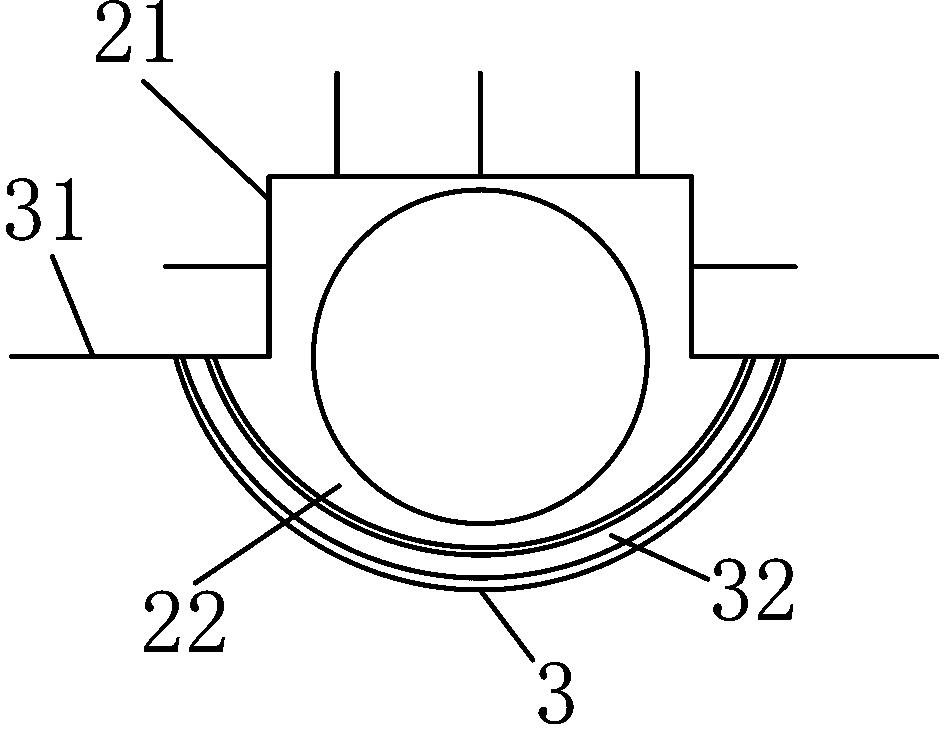

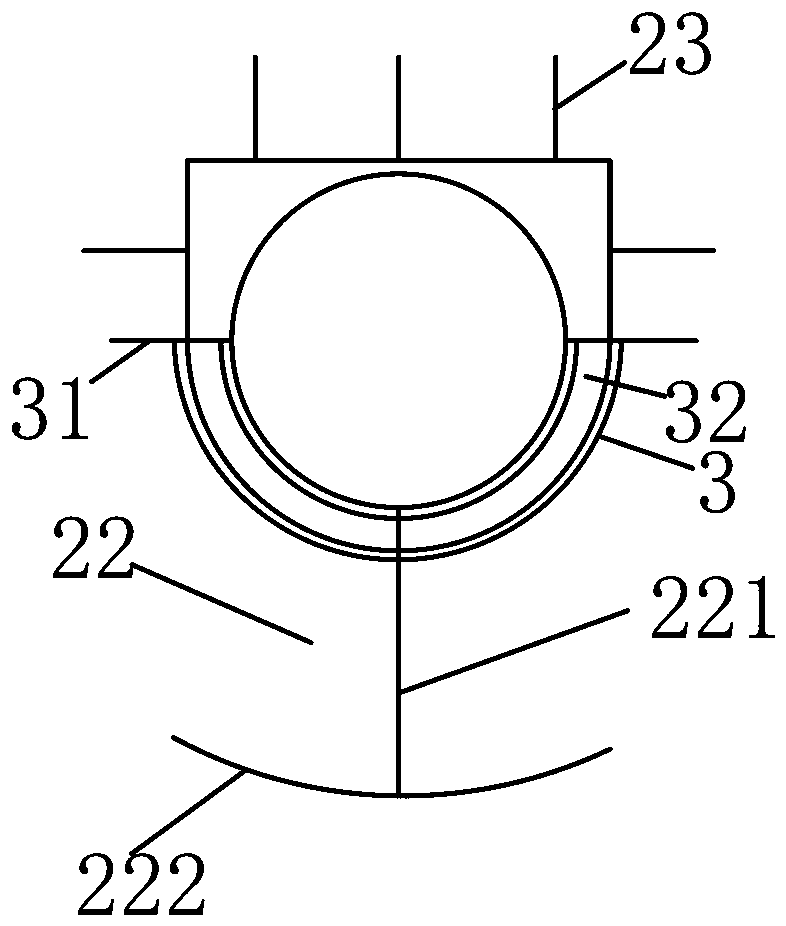

Refrigerating and heating vacuum pipeline structure

PendingCN107676898ATo achieve the effect of cooling and heatingImprove cooling effectDucting arrangementsLighting and heating apparatusEngineeringRefrigeration

The invention belongs to the field of heating and refrigeration, and particularly relates to a refrigerating and heating vacuum pipeline structure. The refrigerating and heating vacuum pipeline structure comprises a pipe network system laid in a wallboard, in the floor or in a cement filling layer, and a main pipe which is connected with the pipe network system of each indoor and is used for supplying air or returning air; and the pipe network system comprises a plurality of vacuum net pipes with two ends connected with the main pipe and internally provided with circular pipelines, wherein thenet pipes each comprise a stable part and an arc-shaped deflection part, the stable part is at least located at the upper part and is formed with a square outer contour and is used for stabilizing, the arc-shaped deflection part is arranged on the lower part or is connected to the lower part and is used for conveniently adjusting the net pipes, and circle centers of the net pipes are used as center positions of the deflection parts. According to the refrigerating and heating vacuum pipeline structure, the specific stable parts and the deflection parts are cooperated so that the steel net pipes can be stabilized, convenient and accurate in installation and capable of being stably and efficiently used for a long time and is prevented from being damaged easily.

Owner:ZHEJIANG XINGGUANGDIANKE SMART HOME TECH CO LTD

A packaging method for an all-fiber quarter-wave plate

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Packing method and structure of optical fiber optical element

InactiveCN1313852CGood optical performanceStable for long-term useCoupling light guidesEngineeringCapillary action

The invention includes a subcombination of optical fibre optical device with extended optical fibre, a ring cap, a sleeve and an external package pipe, a binding agent can be infiltrated into miniature gap between subcombination of said optical fibre optical device and all the components by utilizing capillary action so as to attain the goal of compact combination and sealed package. This combination mode is different from and superior to that of general optical component by using tin soldering paste.

Owner:BROWAVE CORP

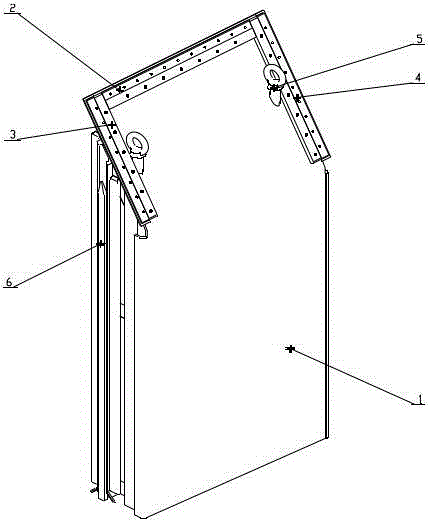

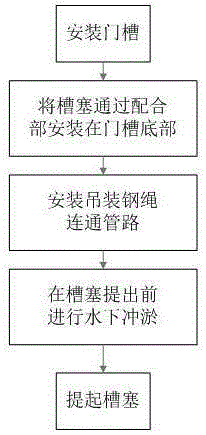

A door slot plug and its installation and removal method

ActiveCN103966983BEasy to installSmooth liftBarrages/weirsMechanical engineeringElectrical and Electronics engineering

The invention discloses a door slot plug and a dismounting method thereof. The slot plug includes a main body; a matching part, located at the side of the main body, which cooperates with the inner side of the door slot; and a guide part, which guides the discharge of materials on the top of the main body. The door slot plug of the present invention can be conveniently installed at the bottom of the door slot, and the sundries falling into the door slot can fall to the top of the slot plug and be led out by the guide parts without accumulating at the bottom of the door slot; , simply lift up or remove the slot plug from the side.

Owner:CHENGDU ALANGTECH

Manufacturing method of steel rotational moulding pipeline with polyolefin lining layer

Owner:南通楠瑞碳素制品有限公司

Manufacturing method of steel rotational moulding pipeline with modified polypropylene inner liner

ActiveCN101852315BImprove compactnessImprove mechanical propertiesCoatingsRigid pipesOrganic acidPositive pressure

The invention relates to a manufacturing method of a steel rotational moulding pipeline with modified polypropylene inner liner, which comprises the steps of: welding, sandblasting, heating and heat preservation, rotational moulding, cooling, negative pressure test, positive pressure test, detection of an inner liner and the like; the modified polypropylene inner liner inside the pipeline manufactured according to the invention has the prominent characteristics of good compactness, high mechanical properties, strong integrity, no joint and welding seam, even thickness, high / low temperature and negative pressure resistance, strong adhesive force, corrosive resistance, impact resistance, no toxicity, convenient maintenance, etc. The steel rotational moulding pipeline, as an ideal material for taking the place of rubber, glass steel and stainless steel, is quite stable for a long time in various strongly corrosive media such as organic acid, inorganic acid, base salt, etc., and is prominently characterized by acid-base mixing, quick heating and cooling or cold / hot alternation.

Owner:江苏兆辉防腐科技有限公司

Lithium bromide absorption liquid with nano-silver disperse system and preparation method thereof

InactiveCN103509522AFacilitate conductionImprove dispersion stabilityHeat-exchange elementsDispersion stabilityLithium bromide

The invention discloses a lithium bromide absorption liquid with a nano-silver disperse system. The lithium bromide absorption liquid with the nano-silver disperse system is lithium bromide aqueous solution with the mass concentration of 1 to 50 percent; the lithium bromide aqueous solution contains nano-silver particles accounting for 0.001 to 0.01 percent of the total weight of the lithium bromide aqueous solution, a surfactant accounting for 0.01 to 0.1 percent of the total weight of the lithium bromide aqueous solution, and a dispersion stabilizer accounting for0.01 to 0.1 percent of the total weight of the lithium bromide aqueous solution. The lithium bromide absorption liquid has excellent dispersion stability and substance conductivity.

Owner:昆山市周市溴化锂溶液厂

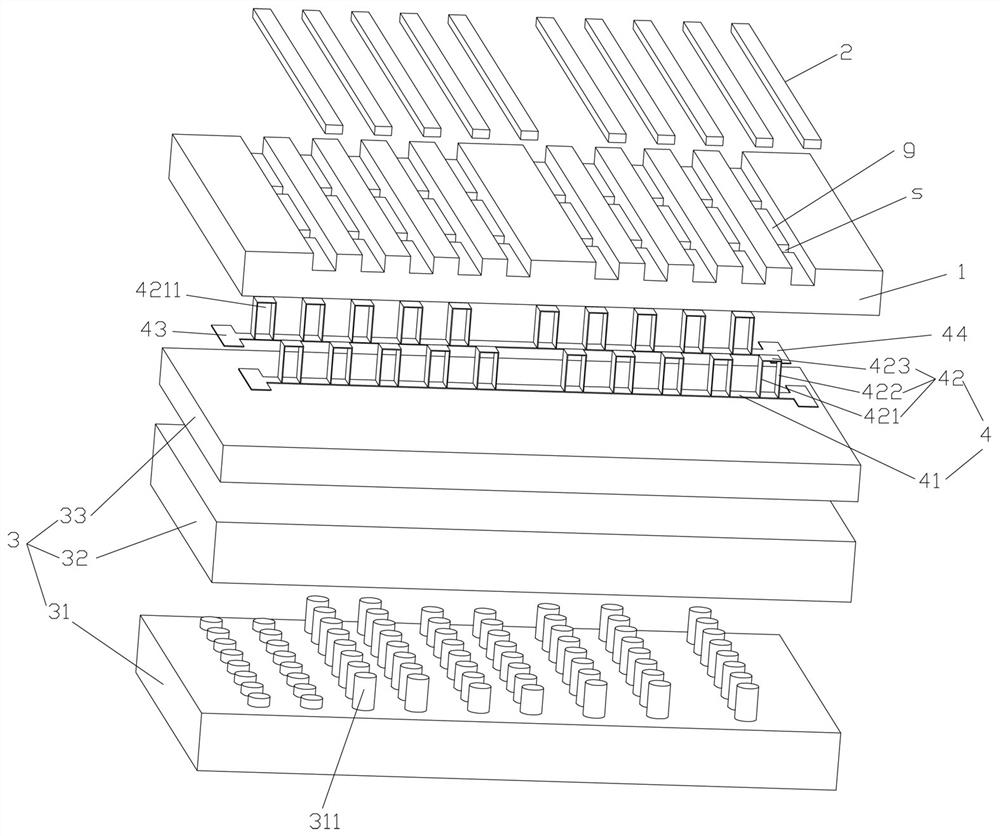

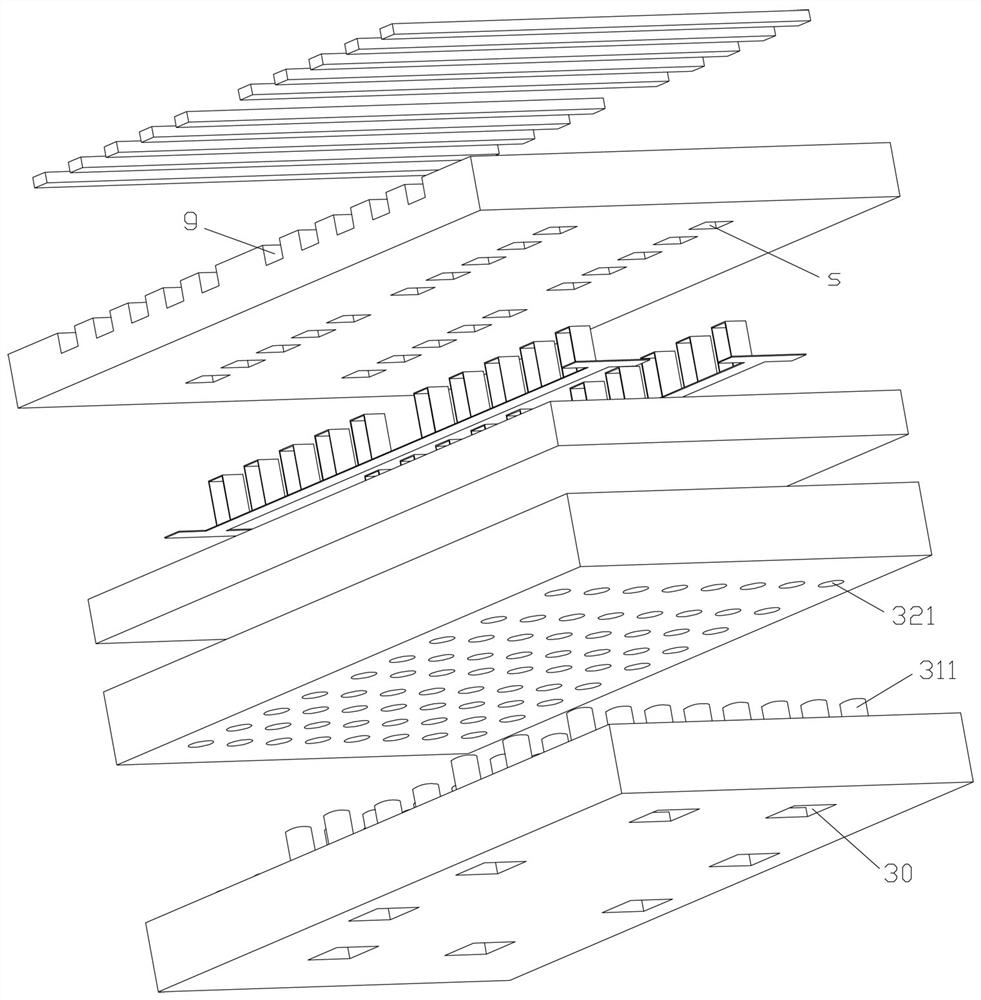

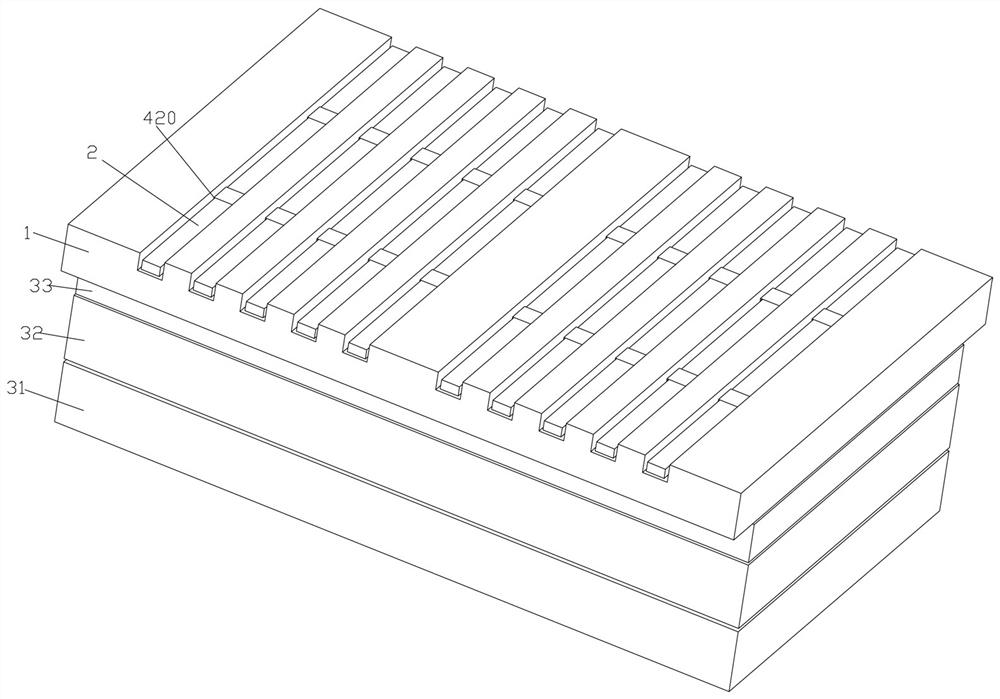

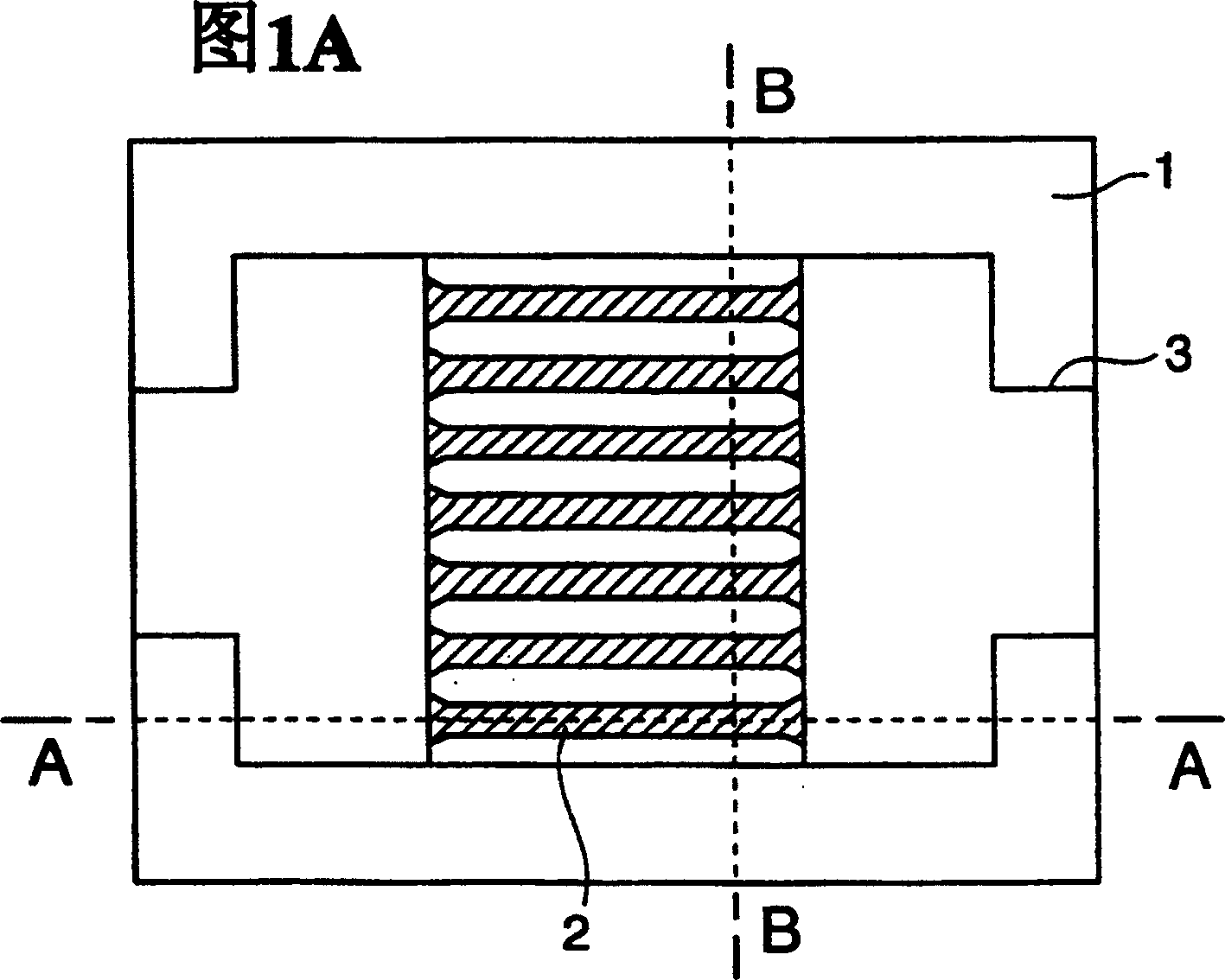

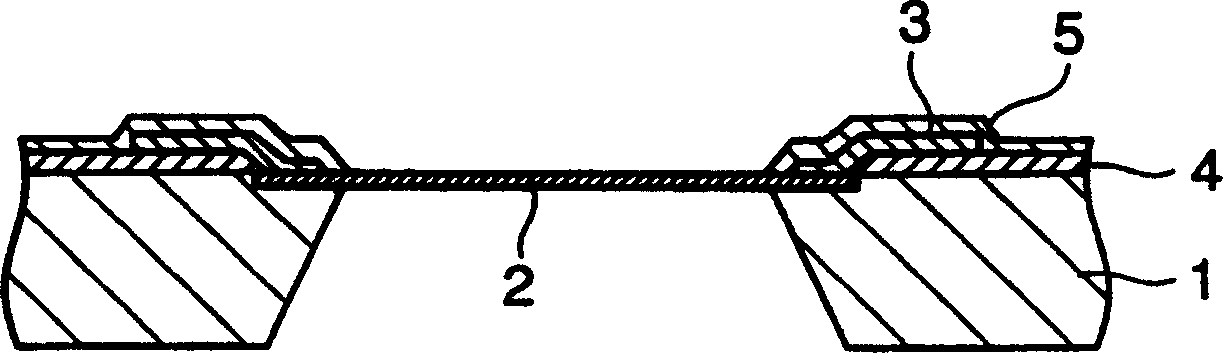

Heating element, heating base plate, method for making heating base plate, microswitch and fluid sensor

InactiveCN1567502AImprove stabilityIncreased durabilityElectrothermal relaysElectric switchesSiliconImpurity

The invention provides a good-stability and -durability heating component and a substrate as well as its high-efficiency and -accuracy making method and the device using them. It uses at least one part electroconductive silicon substrate diffused with impurities like B and so on as the material for etching processing, integrally makes a heating part, where the heating part is provided with one or many narrow slits without angle parts or with circular ones. At the same time, for controlling the heating state of the heating part and it forms a concave part arranged in the bottom part.

Owner:SEIKO EPSON CORP

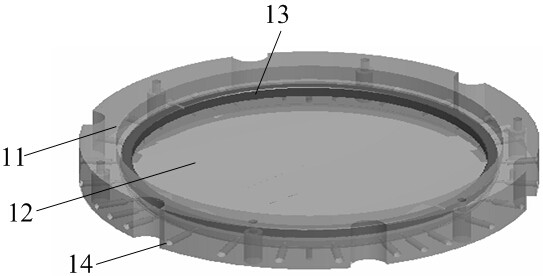

A lens fixing structure

The present invention proposes a lens fixing structure, which fixes the lens in the lens holder, and the fixing structure includes an elastic component, and a through hole for accommodating the lens is arranged in the elastic component, and the elastic component can move along the The radial elasticity of the through hole changes, and the elastic component is clamped between the lens and the lens seat to limit the movement of the lens. Compared with the prior art, the lens fixing structure proposed by the present invention can ensure that there is no gap in the lateral direction of the lens, and at the same time can well control the fixing pressure of the lens, can offset the influence of the thermal deformation of the lens on the pressure, and can completely replace the existing The glue used to fix the lens in technology. At the same time, because the contact area between the structure of the present invention and the lens is relatively large, the long-term use is relatively stable, and it is more reliable than fixing the lens with glue, and because the integration is relatively simple, assembly time can be saved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

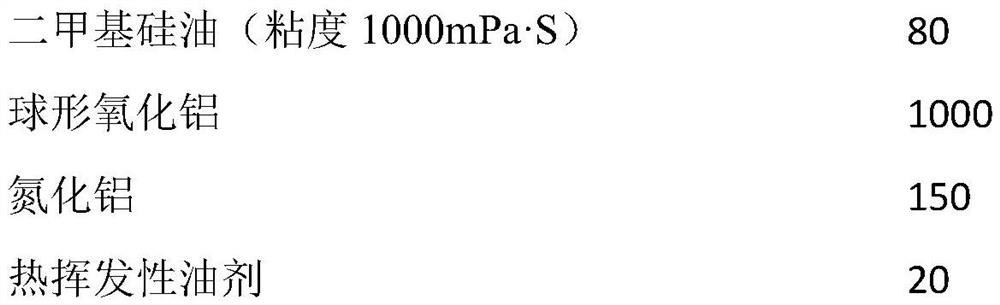

Heat-conducting silicone grease with gradually-increased heat conductivity coefficient and preparation method of heat-conducting silicone grease

PendingCN113717529AIncrease filling volumeEasy to useHeat-exchange elementsSilicone greaseSilicone oil

The invention discloses heat-conducting silicone grease with a gradually-increased heat conductivity coefficient. The heat-conducting silicone grease is prepared from the following raw materials in parts by weight: 80-100 parts of silicone oil, 1000-1200 parts of spherical aluminum oxide, 100-200 parts of aluminum nitride and 10-20 parts of a hot volatile oil agent. In addition, the invention further discloses a preparation method of the heat-conducting silicone grease with the gradually-increased heat conductivity coefficient. Through formula design, a certain proportion of hot volatile oil agent is used for replacing an oil agent with good thermal stability, after construction, the hot volatile oil agent is removed through self heating of a component but is not dried and solidified, and the product can still be kept stable in long-term use; and the effect of increasing the heat conductivity by increasing the filling amount of the heat-conducting powder is achieved in a disguised manner.

Owner:GUANGZHOU HUINA NEW MATERIAL TECH

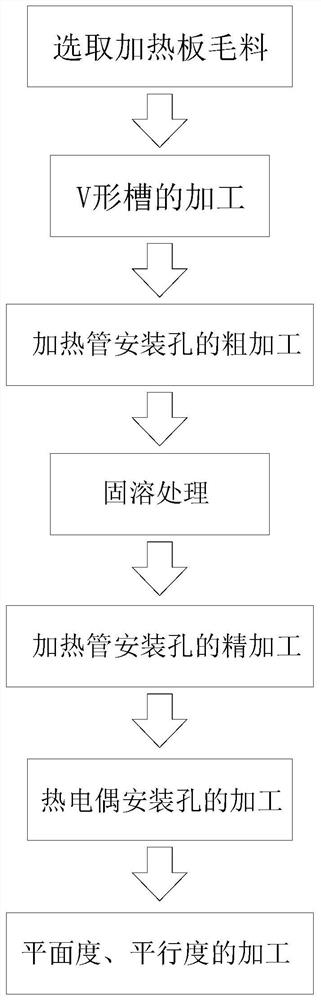

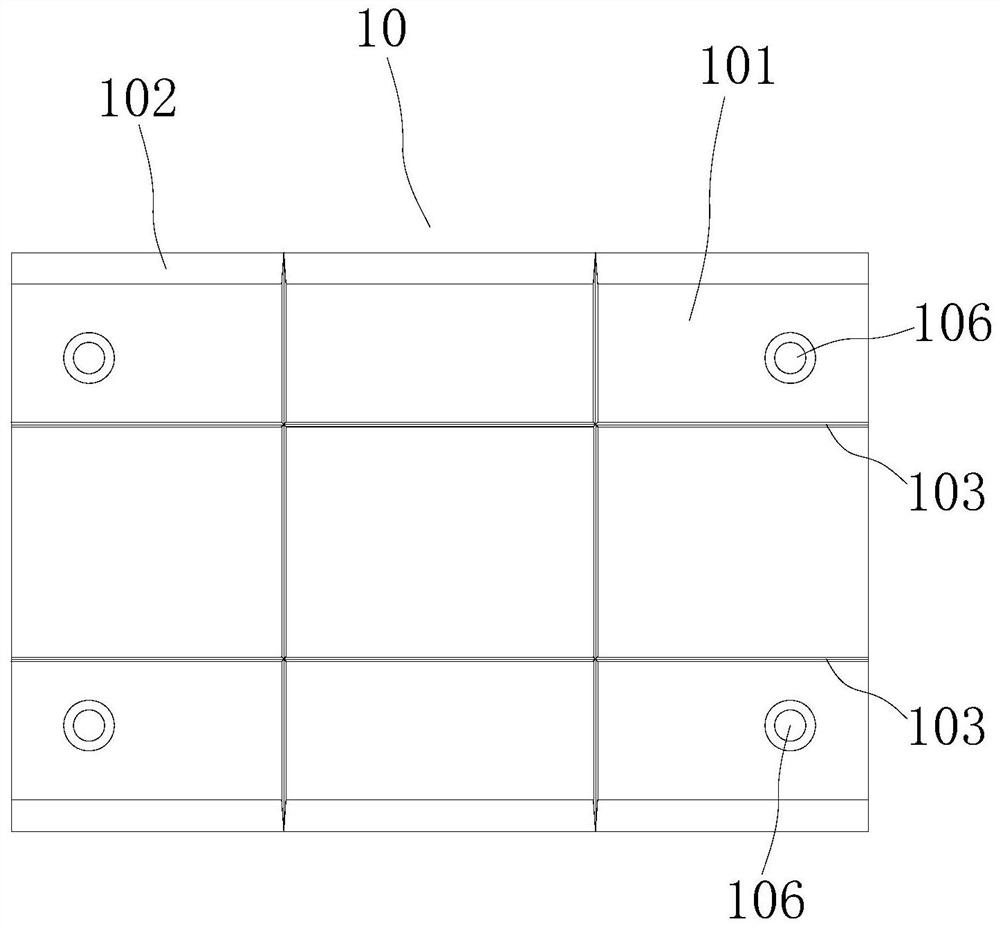

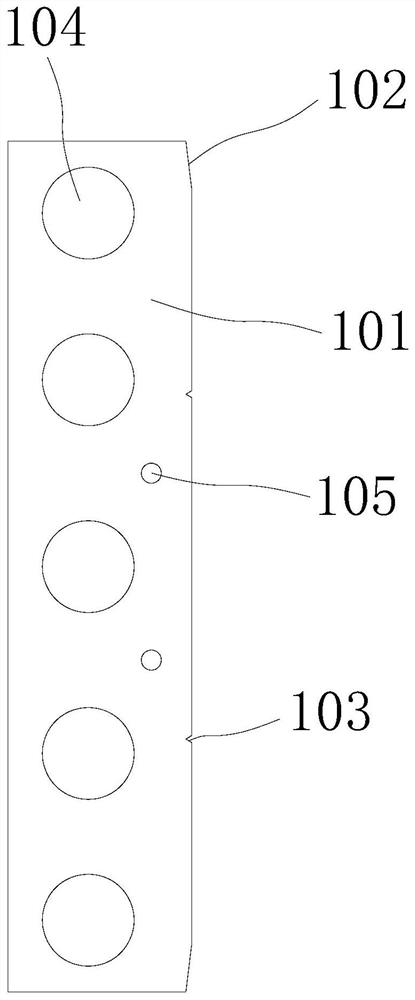

A manufacturing process of a heating plate for hot bending of 3D glass

ActiveCN108046577BImprove flatnessChange plasticityGlass reforming apparatusSolution treatmentEngineering

The invention discloses a manufacturing process of a heating plate for hot bending of 3D glass and relates to the technical field of hot bending of 3D glass. The manufacturing process comprises the following steps: A, selection of heating plate wool; B, processing of V-shaped grooves; C, rough processing of a heating pipe mounting hole; D, solution treatment; E, fine processing of the heating pipemounting hole; F, processing of a thermocouple mounting hole; G, planeness and parallelism processing. The manufacturing process disclosed by the invention has the beneficial effects that as the V-shaped grooves are formed in the heating surface, the heating surface is divided into a plurality of heating areas, so that the stress on the heating surface is released to a maximum extent, and the deformation cannot appear when the 3D glass is heated; the molecular peristalsis is accelerated through solution treatment, so that the plasticity and the toughness of the plate are changed; therefore, the manufacturing process is good in reliability and stable in long-term use, and the planeness of the 3D glass is improved, so that the processed heating plate meets the demands.

Owner:惠州沃尔夫自动化设备有限公司

Lithium bromide absorption liquid with nanogold dispersion system and preparation method thereof

InactiveCN103555277AFacilitate conductionImprove dispersion stabilityHeat-exchange elementsLithium bromideDispersion stability

The invention discloses a lithium bromide absorption liquid with a nanogold dispersion system. The lithium bromide absorption liquid with a nanogold dispersion system is a lithium bromide aqueous solution with a mass concentration of 1-50%, and the lithium bromide aqueous solution contains nanogold particles accounting for 0.001-0.01% of the total weight of the lithium bromide aqueous solution, a surfactant accounting for 0.01-0.1% of the total weight of the lithium bromide aqueous solution and a dispersion stabilizer accounting for 0.01-0.1% of the total weight of the lithium bromide aqueous solution. The medium shows excellent dispersion stability and material conductivity.

Owner:昆山市周市溴化锂溶液厂

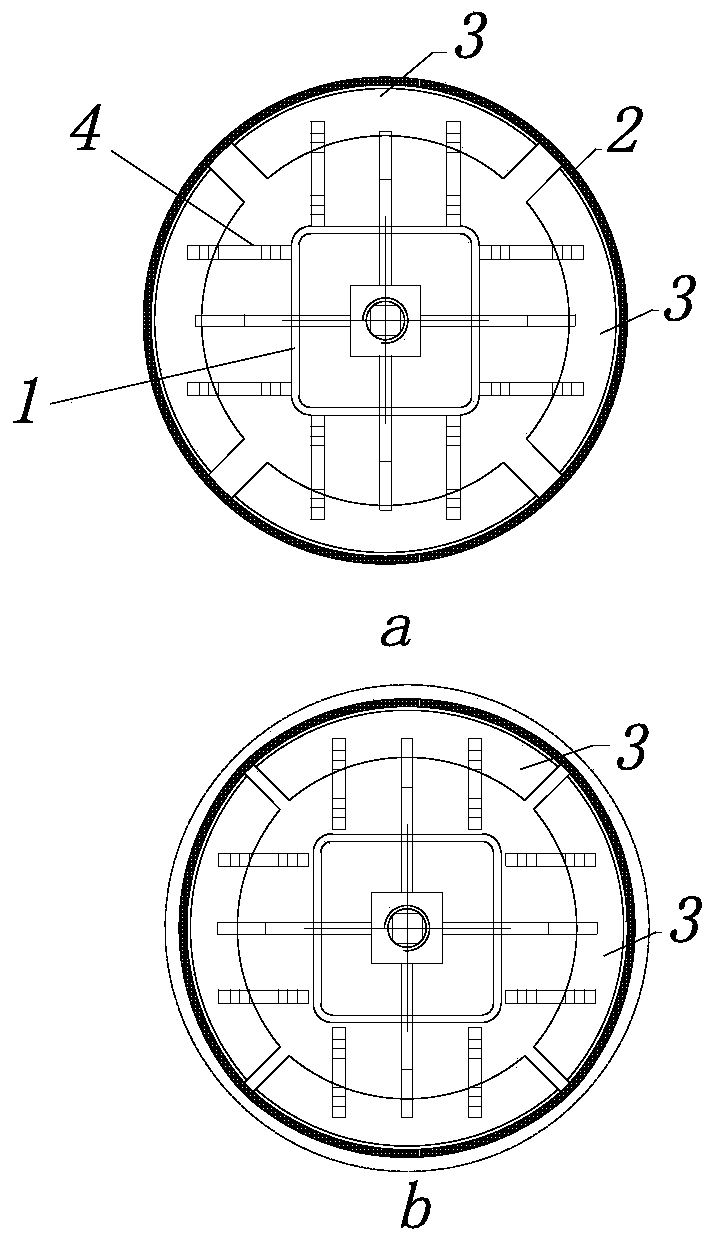

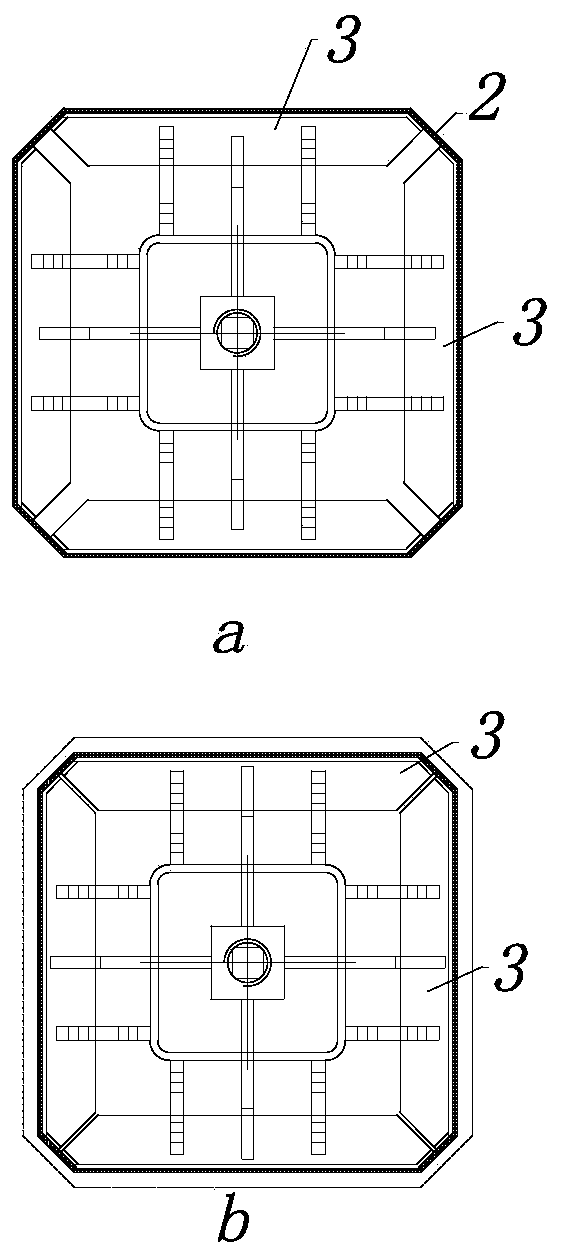

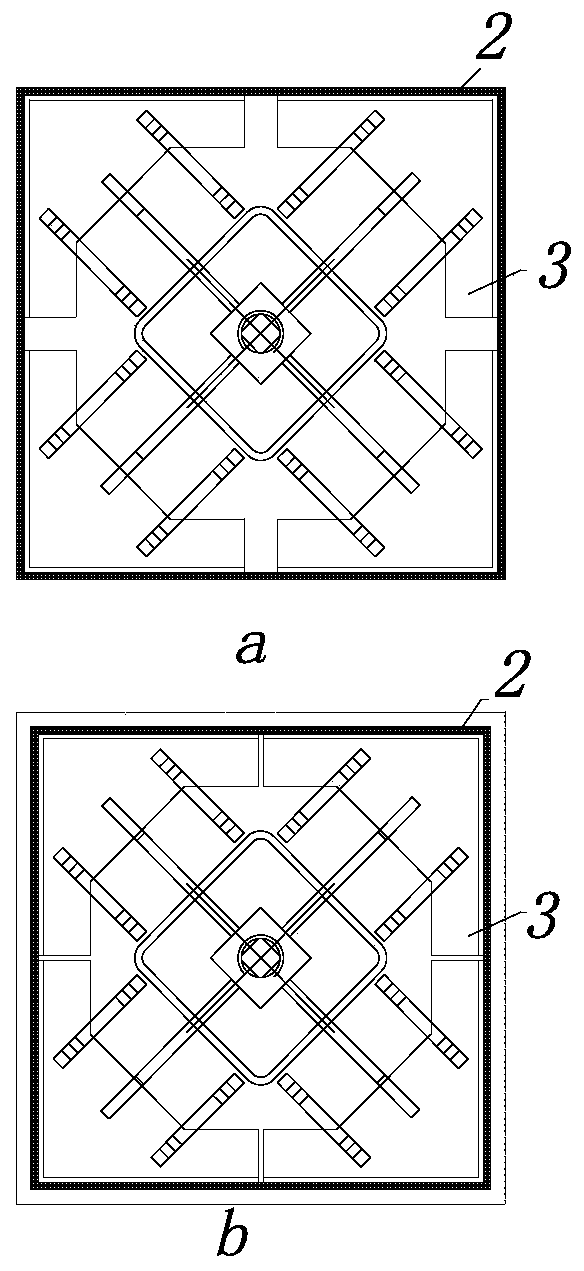

Concrete cavity forming mold and use method thereof

PendingCN111391079AProtective structureAvoid enteringDischarging arrangementMould separation apparatusMold fillingStructural engineering

The invention discloses a concrete cavity forming mold. The mold comprises a telescopic skeleton, an elastic wrapping layer and multiple supporting plates, the supporting plates are arranged around the outer side of the telescopic skeleton, the telescopic skeleton is connected with the supporting plates, the elastic wrapping layer is mounted on the outer sides of the supporting plates, and a use method of the mold comprises the steps of S1, mold filling, wherein the telescopic framework drives the supporting plates to shrink, the elastic wrapping layer is mounted on the outer sides of the supporting plates, the telescopic skeleton drives the supporting plates to extend until the size of the outer contour of the wrapping layer is consistent with a concrete cavity required to be formed, andfinally, the mold is filled in the position of a cavity; S2, concrete pouring; and S3, mold stripping, wherein during mold stripping, the telescopic framework drives the supporting plates to shrink, the elastic wrapping layer shrinks to be separated from the concrete cavity, and the mold is taken out. The mold has the advantages that the cavity structure does not need to be changed, the mold is suitable for concrete cavities in multiple section shapes, long-term use is stable, and reliability is achieved.

Owner:HUNAN WUXIN MACHINERY

Magnetic massage mattress

PendingCN113729444APrecise positioningStable for long-term useStuffed mattressesSpring mattressesEngineeringMechanical engineering

The invention relates to the technical field of household articles, in particular to a magnetic massage mattress, which comprises a composite supporting module, an upper sound insulation pad laid on the upper side of the composite supporting module and a plurality of magnetic strips arranged on the upper sound insulation pad, wherein the magnetic strips are mounted and positioned on the upper surface part of the upper sound insulation pad through more than two magnetic strip positioners which are arranged at intervals in the length direction of the magnetic strip, the magnetic strip positioner comprises a balance clamping sheet clamped between the upper sound insulation pad and the composite supporting module and a plurality of positioning piles which are connected to the balance clamping sheet, penetrate through the upper sound insulation pad upwards and are provided with parts exposed out of the upper surface of the upper sound insulation pad, a positioning frame allowing the magnetic strip to transversely penetrate through is formed on the portion, exposed out of the upper surface of the upper sound insulation pad, of the positioning pile, a positioning door opening transversely penetrating through the positioning frame and exposed out of the upper surface of the upper sound insulation pad is formed in the positioning frame, the magnetic strip penetrates through the positioning door opening, and the lower side of the magnetic strip abuts against the upper sound insulation pad. According to the invention, the positioning effect is better.

Owner:HEYE HEALTH TECH CO LTD

Heating element, heating base plate, method for making heating base plate, microswitch and fluid sensor

InactiveCN1292448CBroaden your optionsEasy to installElectrothermal relaysElectric switchesSiliconMaterials science

Owner:SEIKO EPSON CORP

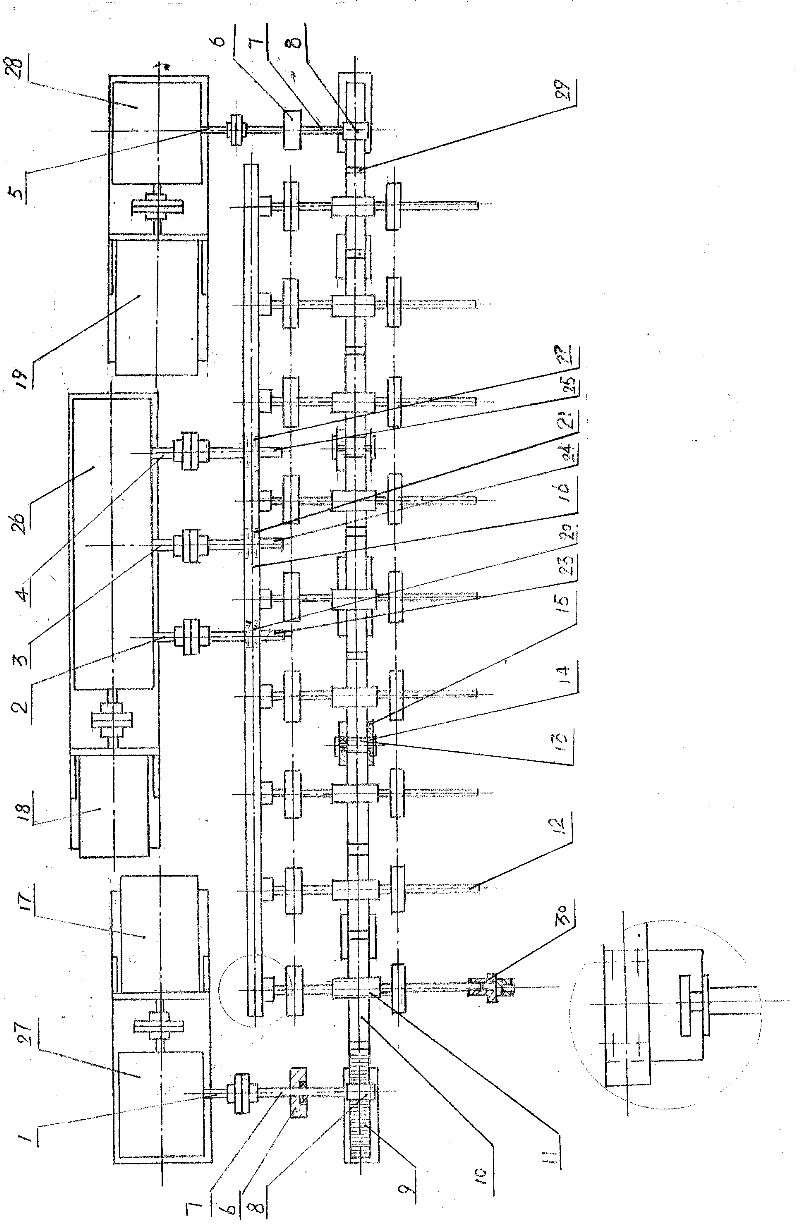

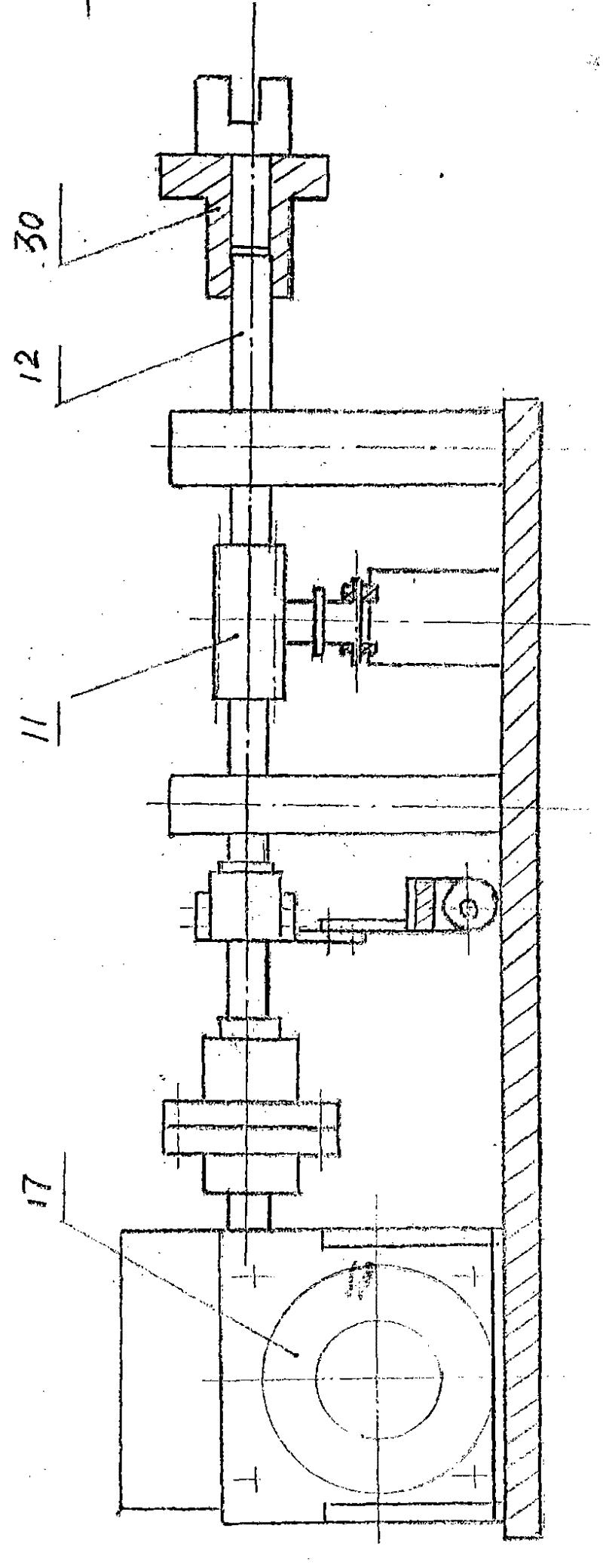

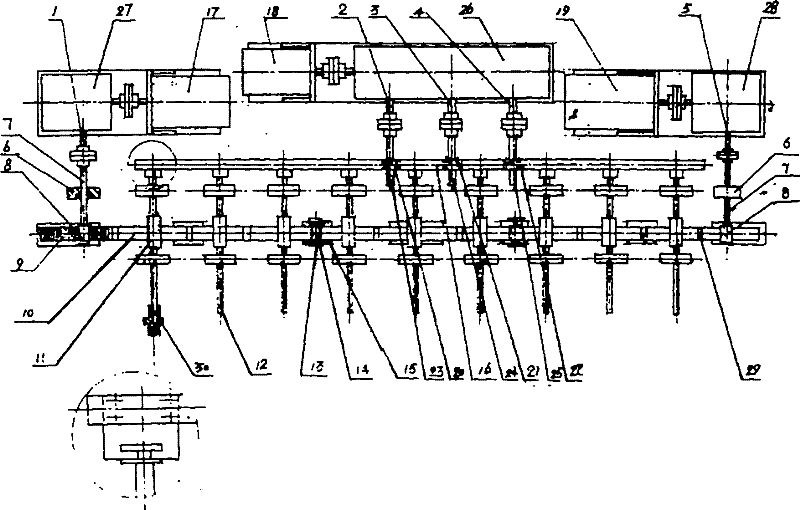

Transmission mechanism of multifunctional testing equipment for ignition lock

InactiveCN102011846BStable for long-term useMeet the technical requirements of the testFriction gearingsTesting equipmentDrive shaft

The invention relates to a transmission mechanism of multifunctional testing equipment for an ignition lock. The transmission mechanism comprises a reduction box (27) of a first stepper motor (17), a reduction box (28) of a third stepper motor and a three-output shaft reduction box (26) of a second stepper motor (18), wherein output shafts of the three-output shaft reduction box (26) are connected with three threaded screw rods (23) (24) and (25); the three threaded screw rods (23) (24) and (25) are in threaded connection with three nuts (20) (21) and (22) on a longitudinal reciprocating lever (29); the longitudinal reciprocating lever (29) is connected with 9 to 12 testing transmission shafts (12); each testing transmission shaft (12) is connected with a gear (11); the gear (11) is meshed with a rack (10) on a transverse reciprocating lever (16); and a gear (8) on a gear shaft (17) is also meshed with the rack (10) on the transverse reciprocating lever (16). The 9 to 12 testing transmission shafts can be rotated at the same time in a reciprocating way and moved longitudinally. The head of each testing transmission shaft (12) is provided with an automatic protective device (30) ofa tested part. The transmission mechanism is suitable for testing equipment of various ignition lock electrical appliances of different models.

Owner:苏州拓思达自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com