Refrigerating and heating vacuum pipeline structure

A vacuum pipeline, refrigeration and heating technology, applied in heating methods, pipeline layout, household heating, etc., can solve the problems of large indoor air flow, poor environmental protection, inconvenient maintenance, etc., to improve heat dissipation efficiency, not easily twisted or damaged, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

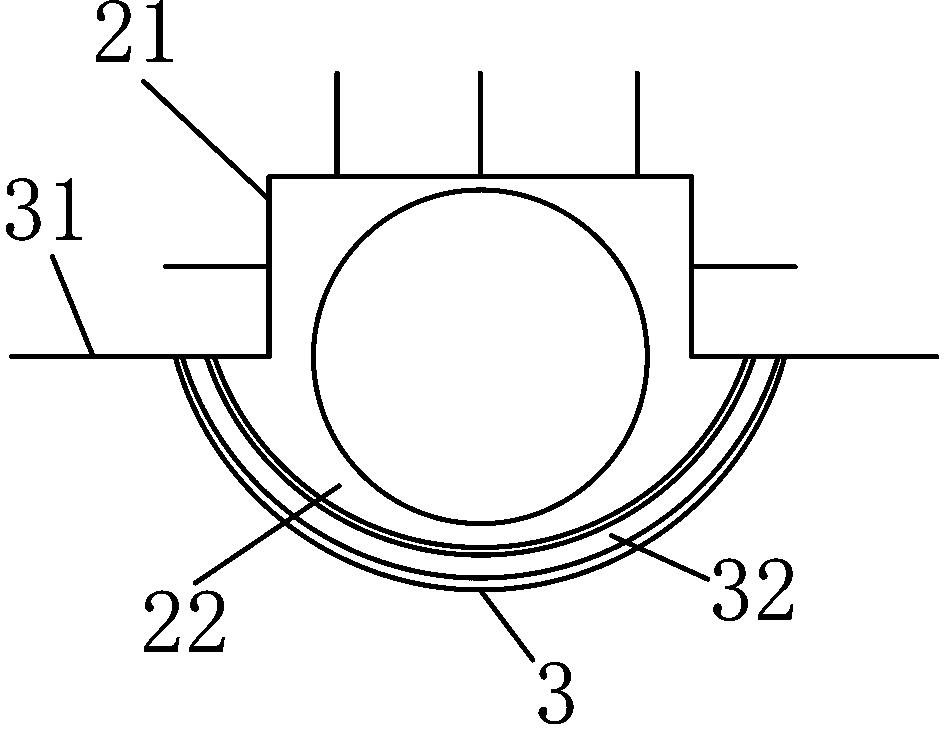

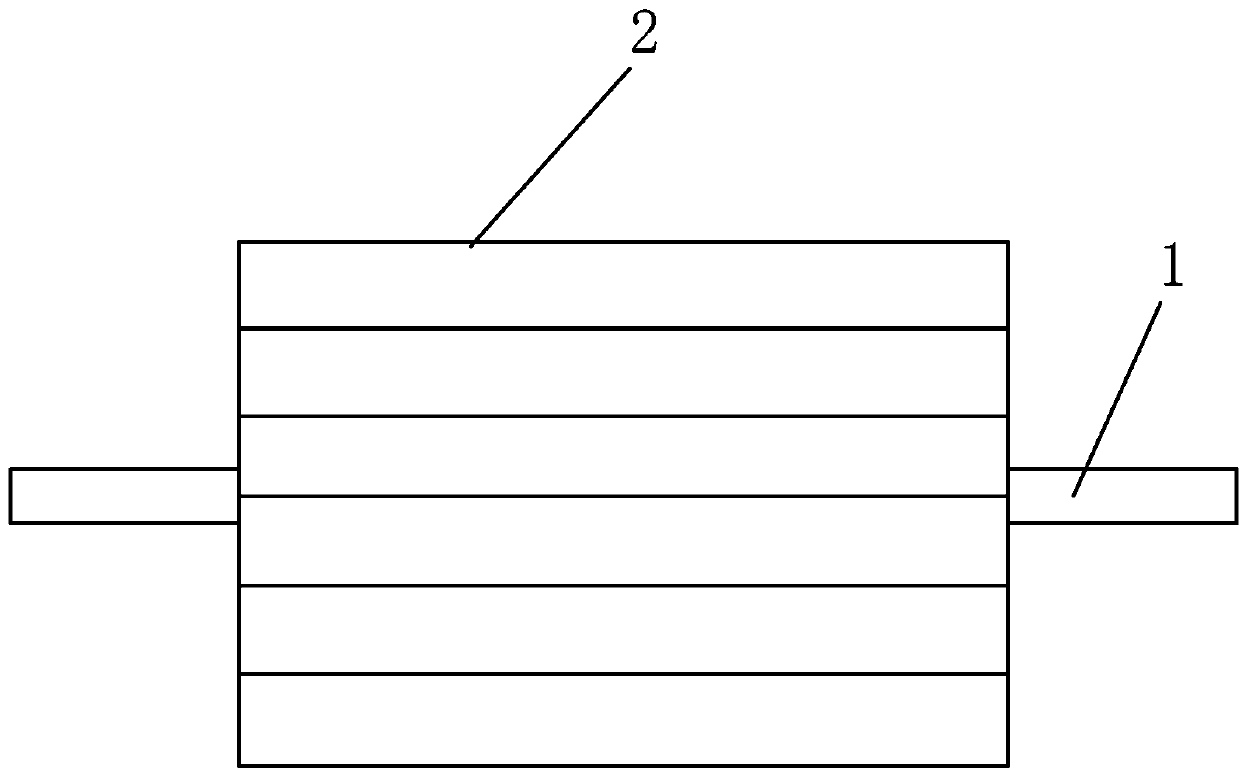

Embodiment 1

[0029] A vacuum pipeline structure for refrigeration and heating, including a pipe network system laid in the wallboard, floor or cement filling layer, and a main pipe 1 for supplying or returning air connecting the pipe network systems in each room. The pipe network system includes a plurality of vacuum network pipes 2 with circular pipes inside that are respectively connected to the main pipe at both ends. The lower part or the arc-shaped deflection part 22 that is convenient to adjust the network pipe connected to the lower part, the center line of the deflection part and the axis line of the circular pipe are all located on the symmetrical center plane of the stable part; the bottom surface of the network pipe Covered with a plastic insulation board 3, the two sides of the insulation board extend upwards to the bottom of the stable part, and the sides of the insulation board continue to extend outwards to form insulation wings 31, and a sponge is also arranged between the i...

Embodiment 2

[0031] The difference from the above embodiment is that the upper and lower circles of the outer contour of the network pipe respectively form a stabilizing part and a deflecting part, and the two ends of the top of the deflecting part exceed the two side edges of the stabilizing part.

Embodiment 3

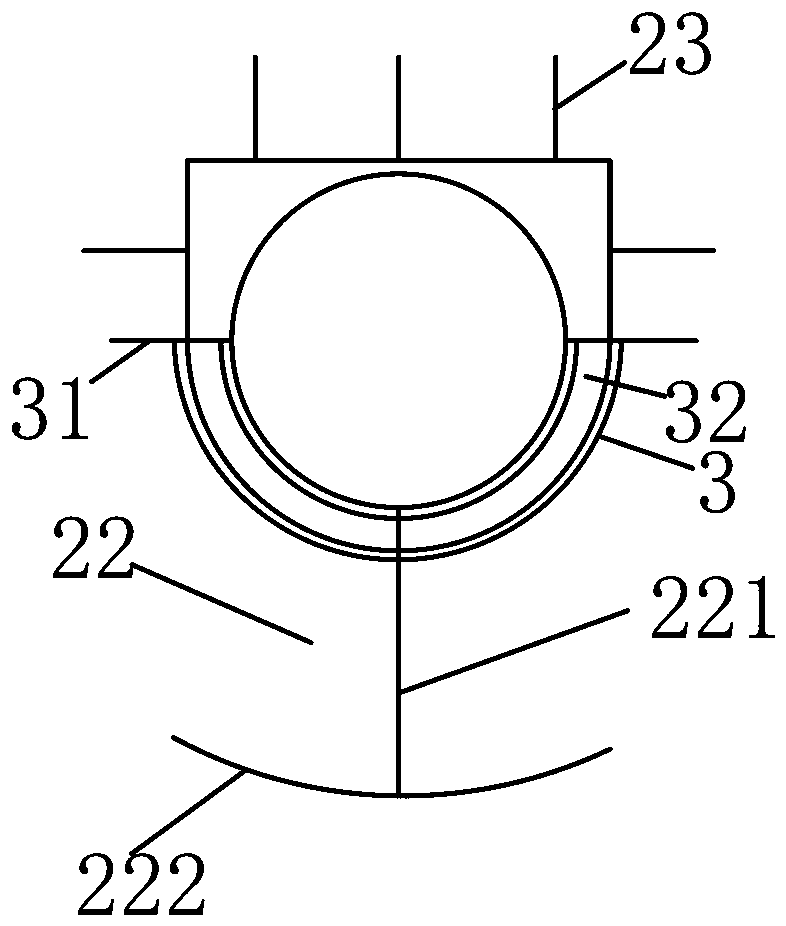

[0033] The difference from the above embodiment is that the bottom of the network pipe is connected with a deflection part; the deflection part includes a top connected to the network pipe, a bottom extending downwards to form a vertical beam frame 221 arranged radially along the circular pipe, and a center of symmetry connected to the The arc slats 222 at the bottom of the vertical beam frame, the two sides of the arc slats are raised upward in an arc shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com