Inner unit for dehumidification machine

A technology for dehumidifiers and indoor units, applied in mechanical equipment, household heating, space heating and ventilation details, etc., can solve the problems of poor filtering effect, limited dehumidification power, poor mute effect, etc., to increase connection strength and dehumidification. The effect of uniform temperature control and good dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

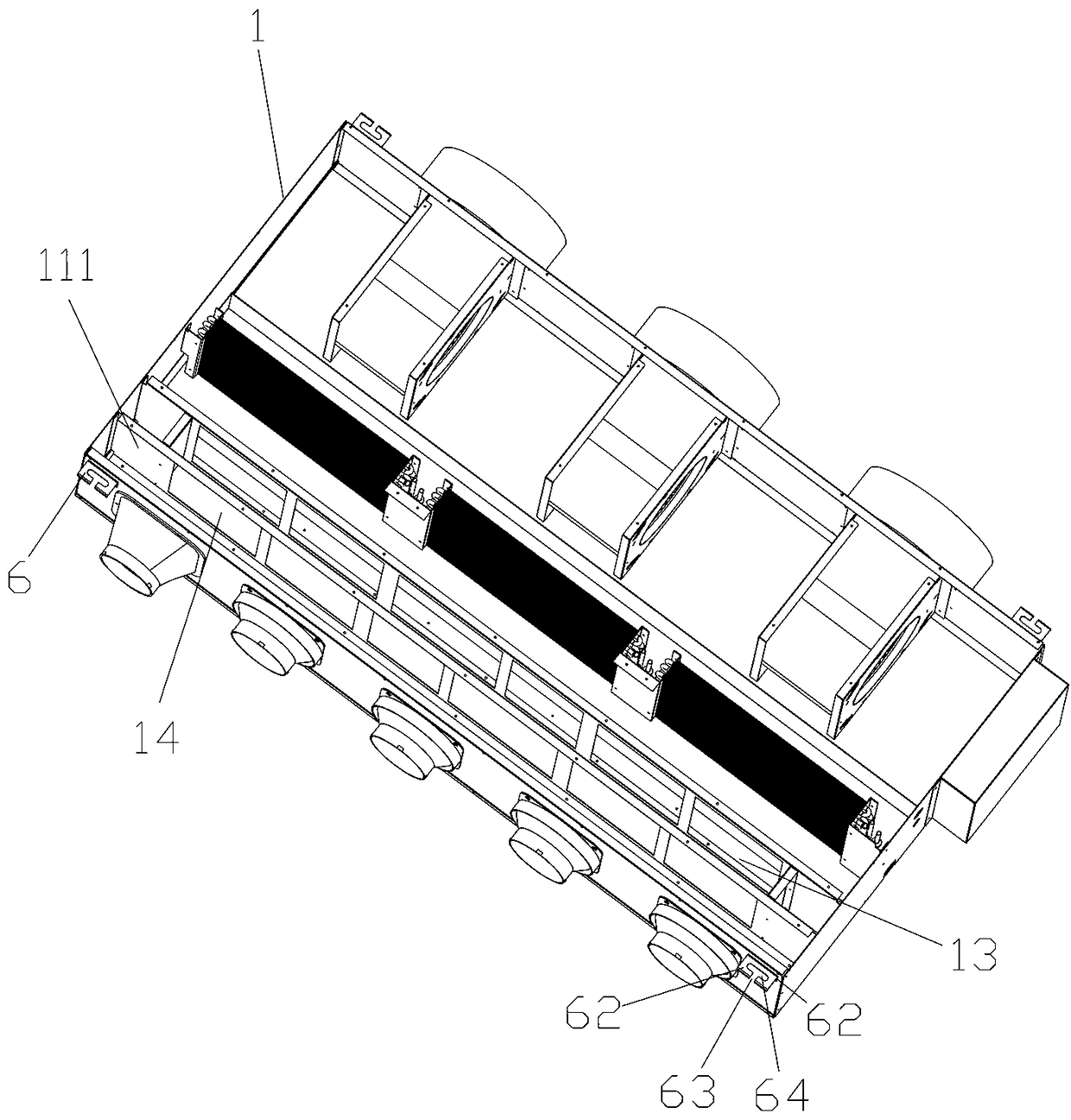

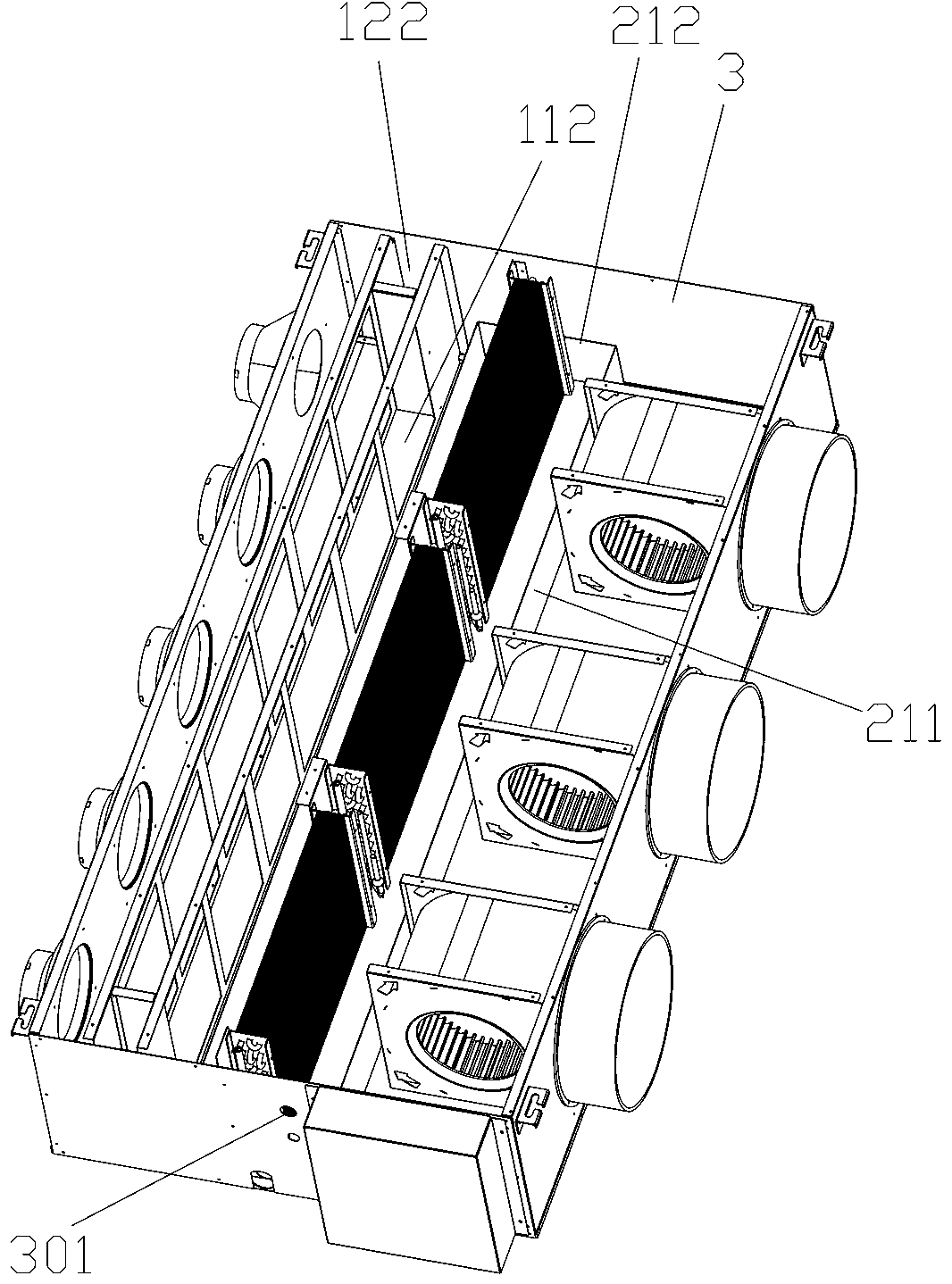

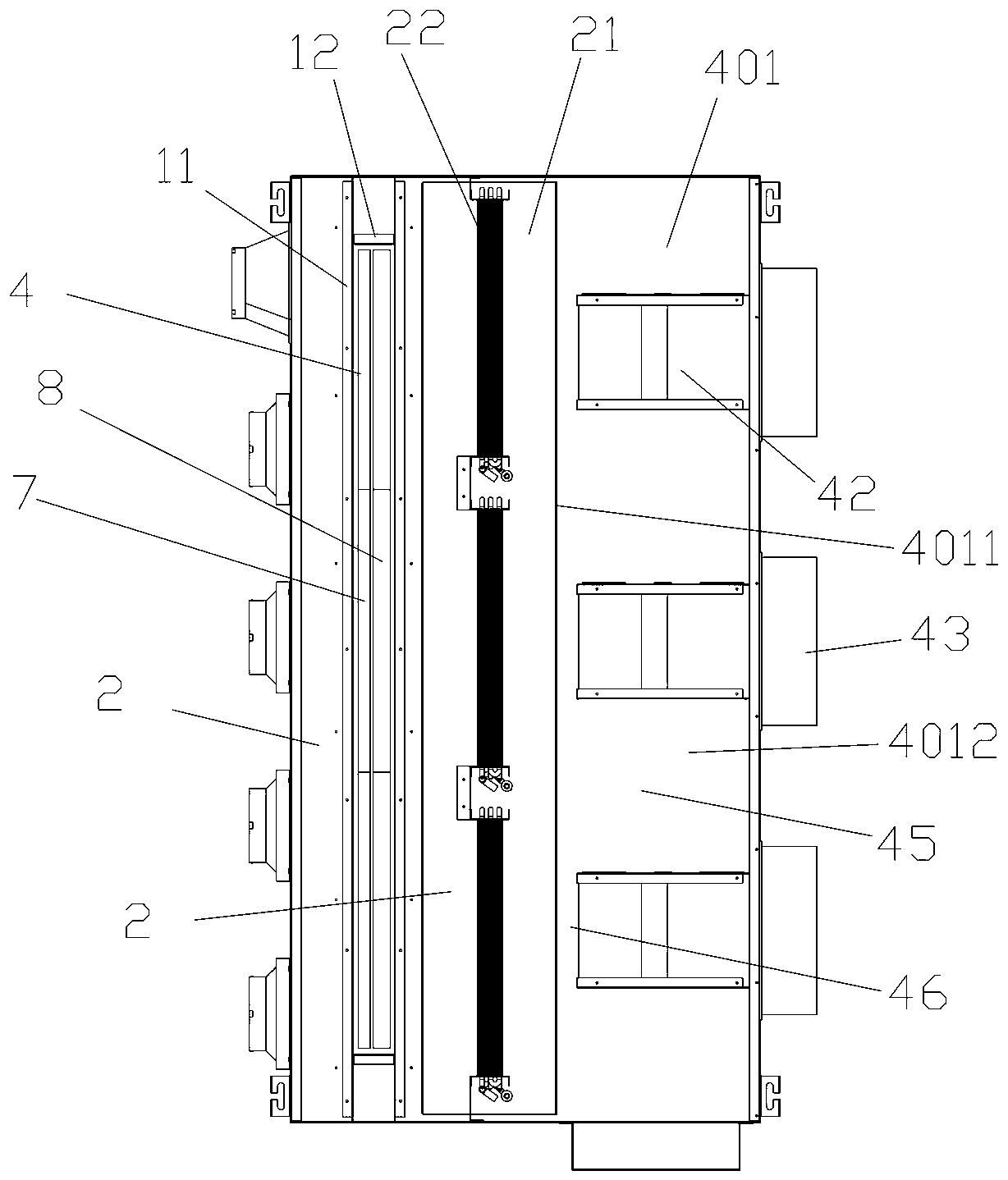

[0061]An inner unit of a dehumidifier, comprising a body shell 1 and a filter structure, a dehumidification structure, and an air blowing structure arranged in the body shell along the air flow direction from the air inlet to the air outlet; The body plate is connected to the body end plates 3 at both ends between the side body plates, the base plate at the bottom, and the top plate at the top; The air outlet body plate; the filter structure includes a filter core frame and a filter core 4 arranged in the filter frame, and the dehumidification structure includes a collection and drainage groove 21 and one or more edges arranged in the collection and drainage groove The heat exchanger 22 arranged in the longitudinal direction of the collection and drainage grooves, the air suction structure includes one or more air suction units 42 arranged side by side in sequence and connected to the outer surface of the air outlet body plate and together with the air suction unit. A correspo...

Embodiment 2

[0075] The difference from the above-mentioned embodiments is that the ventilation part includes at least two horizontal connecting rods 1121 arranged in parallel up and down and several vertical clamping rods 1122 connected between the frame connecting rods. The enclosure forms a transom window.

[0076] The vertical clamping bar is an arc-shaped clamping bar bar that is gradually concaved toward the inner part of the clamping groove cavity from the upper and lower ends to the middle. The curved design of the vertical clamping rod can improve the clamping degree of the filter element, the structure is more stable, and the noise is lower during use.

[0077] The outer upper, lower and both ends of the clamp frame are provided with a clamp frame solid edge 15 formed by turning outwards against the clamp groove cavity, and a number of holes for passing bolts are opened on the clamp frame solid edge. hole. The fixed edge of the clip frame can not only be used for the connection...

Embodiment 3

[0084] The difference from the above-mentioned embodiment is that the collection and drainage tank includes long tank walls 211 located on both sides and end tank walls 212 connected between the two long tank walls located at both ends, wherein the bottom of the end tank wall at one end has a hole The water outlet, the drain pipe structure is connected to the water outlet, the heat exchanger is connected to the water collection and drainage groove through the wind-proof connecting plates at both ends, and the two long groove walls are located at the outlet of the heat exchanger. The long groove wall on one side extends upward to form a speed-increasing baffle part 2111 for speeding up the wind, and the height of the speed-raising baffle part is higher than the long wall of the groove on the other side. The drain pipe adopts an anti-overflow drain pipe, and a section of water seal pipe that bends downwards can be set on the drain pipe, so that the water from the water outlet wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com