A manufacturing process of a heating plate for hot bending of 3D glass

A manufacturing process and heating plate technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of 3D glass flatness and easy deformation, so as to improve flatness, long-term use stability, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

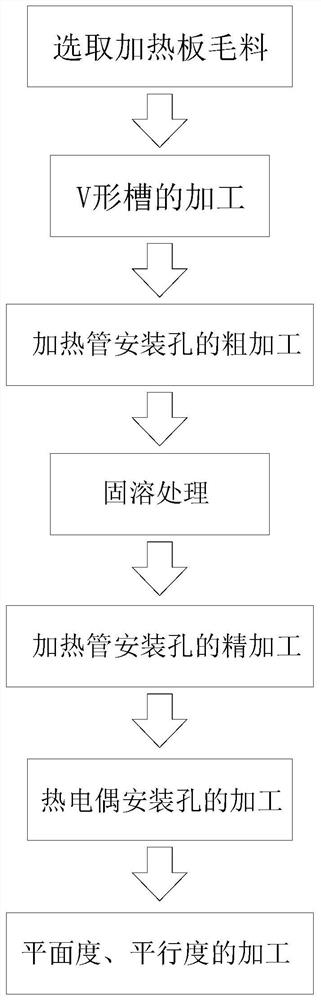

[0025] refer to Figure 1 to Figure 3 As shown, the present invention discloses a manufacturing process of a heating plate for hot bending 3D glass. Specifically, in this embodiment, the manufacturing process includes the following steps:

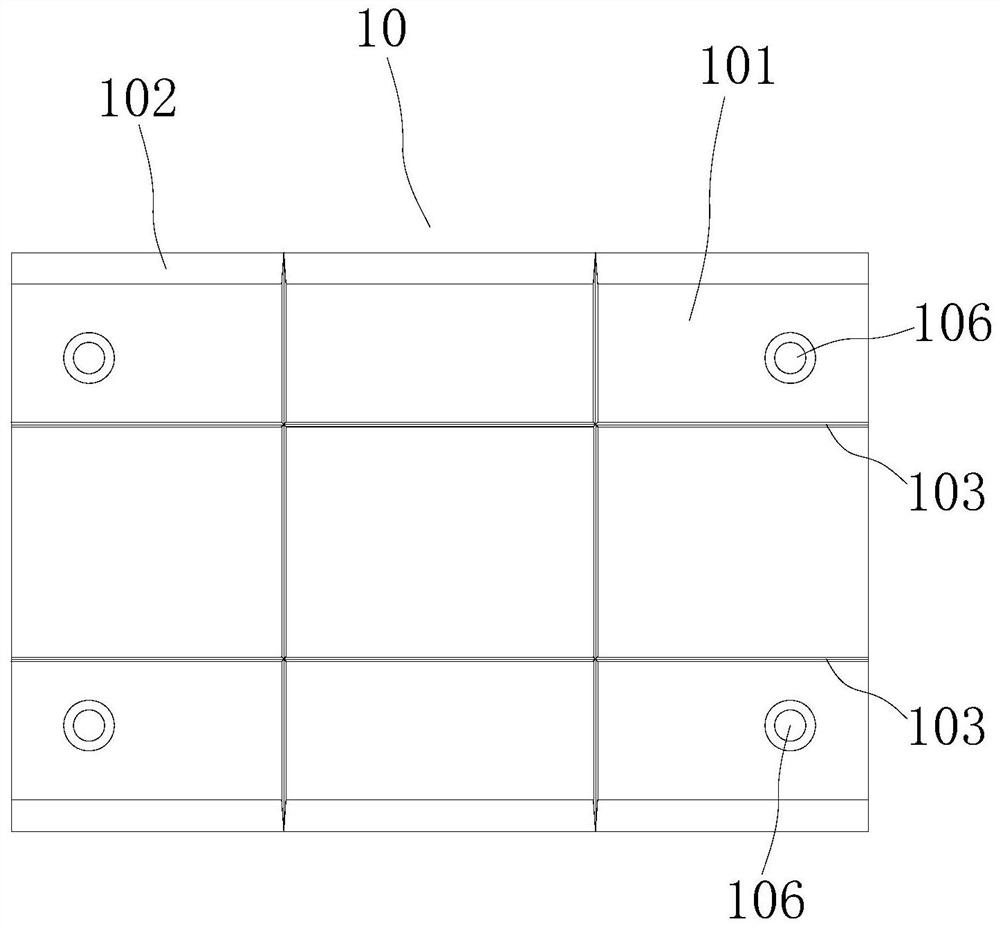

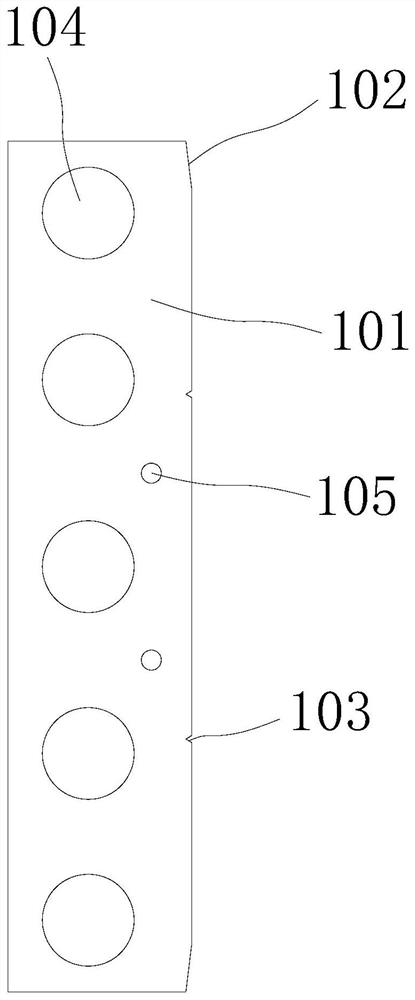

[0026] A. Select the heating plate wool 10, the heating plate wool 10 is in the shape of a cuboid, its upper surface is a heating surface 101, and the opposite ends of the heating surface 101 have an inclined surface 102 with a smooth transition;

[0027] B, the processing of V-shaped grooves, process a plurality of V-shaped grooves 103 with a V-shaped cross section on the heating surface 101 of the heating plate wool 10, and the plurality of V-shaped grooves 103 divide the heating surface 101 into a plurality of square heating area; in this example, such as figure 1 As shown, the heating surface 101 is provided with two V-shaped grooves 103 horizontally and vertically, and four V-shaped grooves 103 divide the heating surface 101 into nine...

Embodiment 2

[0034] refer to Figure 1 to Figure 3 As shown, the present invention discloses a manufacturing process of a heating plate for hot bending 3D glass. Specifically, in this embodiment, the manufacturing process includes the following steps:

[0035] A. Select the heating plate wool 10, the heating plate wool 10 is in the shape of a cuboid, its upper surface is a heating surface 101, and the opposite ends of the heating surface 101 have an inclined surface 102 with a smooth transition;

[0036] B, the processing of V-shaped groove 103, on the heating surface 101 of heating plate wool 10, process a plurality of V-shaped grooves 103 that are V-shaped in cross section, and a plurality of V-shaped grooves 103 divide the heating surface 101 into a plurality of square ones. heating zone; in this example, as figure 1 As shown, the heating surface 101 is provided with two V-shaped grooves 103 horizontally and vertically, and four V-shaped grooves 103 divide the heating surface 101 into ...

Embodiment 3

[0043] refer to Figure 1 to Figure 3 As shown, the present invention discloses a manufacturing process of a heating plate for hot bending 3D glass. Specifically, in this embodiment, the manufacturing process includes the following steps:

[0044] A. Select the heating plate wool 10, the heating plate wool 10 is in the shape of a cuboid, its upper surface is a heating surface 101, and the opposite ends of the heating surface 101 have an inclined surface 102 with a smooth transition;

[0045] B, the processing of V-shaped groove 103, on the heating surface 101 of heating plate wool 10, process a plurality of V-shaped grooves 103 that are V-shaped in cross section, and a plurality of V-shaped grooves 103 divide the heating surface 101 into a plurality of square ones. heating zone; in this example, as figure 1 As shown, the heating surface 101 is provided with two V-shaped grooves 103 horizontally and vertically, and four V-shaped grooves 103 divide the heating surface 101 into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com