Polyethylene microporous membrane, polyvinyl nanofiltration membrane and preparation method thereof

A polyethylene-based nano and microporous membrane technology, applied in the field of nanofiltration membranes, can solve the problems of poor membrane strength and low service life, and achieve the effects of long service life, high porosity and concentrated pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The specific embodiment of the present invention also provides a kind of preparation method of polyvinyl nanofiltration membrane, and this method comprises the steps:

[0047] Submerging the polyethylene microporous membrane that can be used to prepare nanofiltration membranes described in any of the above schemes in the polyamine aqueous phase solution;

[0048] The submerged membrane is taken out from the water phase, the excess water phase solution is removed, and then immersed in the oil phase solution containing polyacyl chloride monomers;

[0049] After the interfacial polymerization reaction, take it out, and then remove the excess oil phase solution to obtain a polyethylene-based nascent nanofiltration membrane with a functional nano-separation layer;

[0050] The primary nanofiltration membrane obtained in the above steps is subjected to heat treatment, and the polyethylene-based nanofiltration membrane is obtained after cleaning.

[0051] Further, the composi...

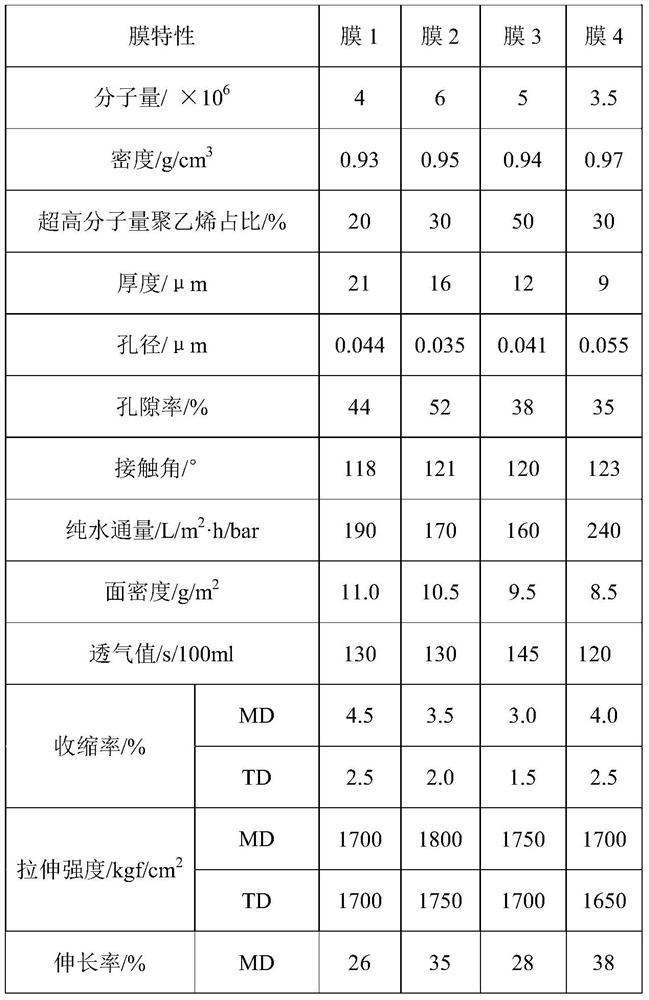

Embodiment 1

[0080] Use 32% polyethylene as raw material (high molecular weight polyethylene accounts for 40% of the blended polyethylene raw material), add 67% paraffin oil as diluent, 1% dibutyl hydroxytoluene as antioxidant, 200 ° C Mix and melt at low temperature, then extrude through twin-screw, and cast at 100°C until cooling and mixing. The films were stretched 8.2 times in the transverse direction and 6.8 times in the longitudinal direction. The membrane was extracted in dichloromethane, then heat-set at 80° C., and wound to obtain a polyethylene microporous membrane 1 . The polyethylene microporous membrane is immersed in the polyamine aqueous phase solution, which contains piperazine (mass concentration 2%), and the acid acceptor is triethylamine (mass concentration 0.75%) and sodium lauryl sulfate (mass concentration 0.1%) Take out afterward, remove superfluous liquid on the surface, immerse in polyacyl chloride oil phase solution, wherein polyacyl chloride monomer is trimesoyl...

Embodiment 2

[0082] The total mass fraction of 28% polyethylene is used as raw material (high molecular weight polyethylene accounts for 20% of the blended polyethylene raw material), the total mass of 2% phosphite is antioxidant, and the rest of the diluent is paraffin oil, mixed and melted at 240 ° C , and then extruded through twin-screws, casting at 80°C until cooling and mixing. The films were stretched 8.8 times in the transverse direction and 7.4 times in the longitudinal direction. The membrane was extracted in dichloromethane, then heat-set at 80° C., and wound to obtain a polyethylene microporous membrane 2 .

[0083] According to the method for preparing the polyethylene-based nanofiltration membrane in Example 1, the polyethylene-based nanofiltration membrane B2 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com