Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Stable fluidization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

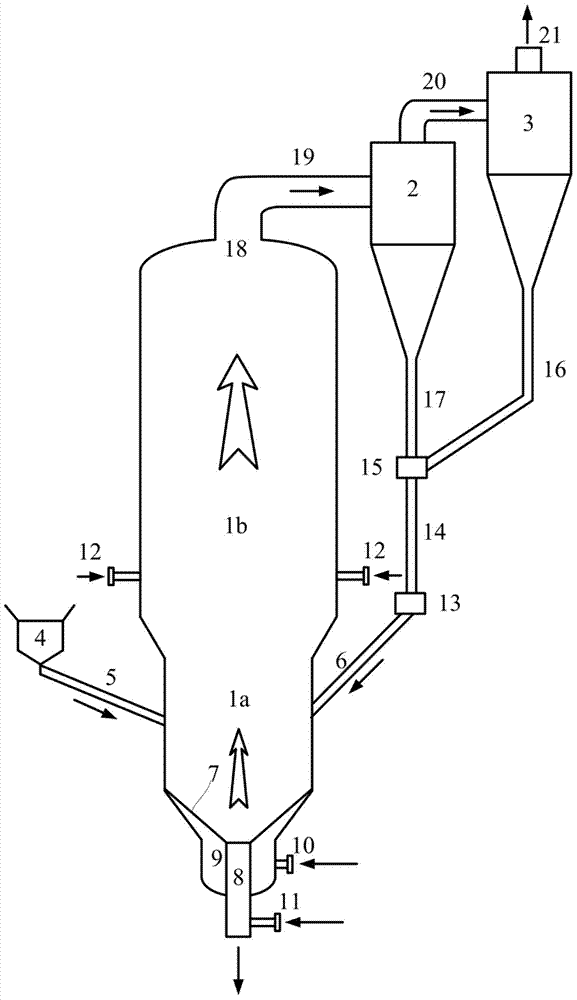

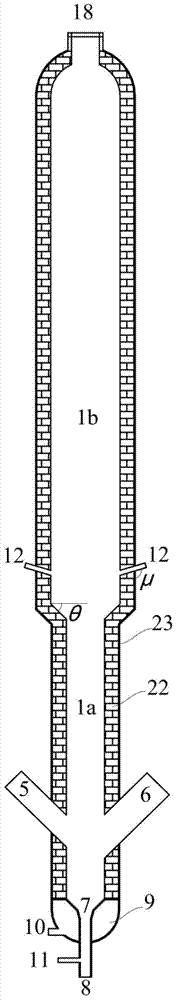

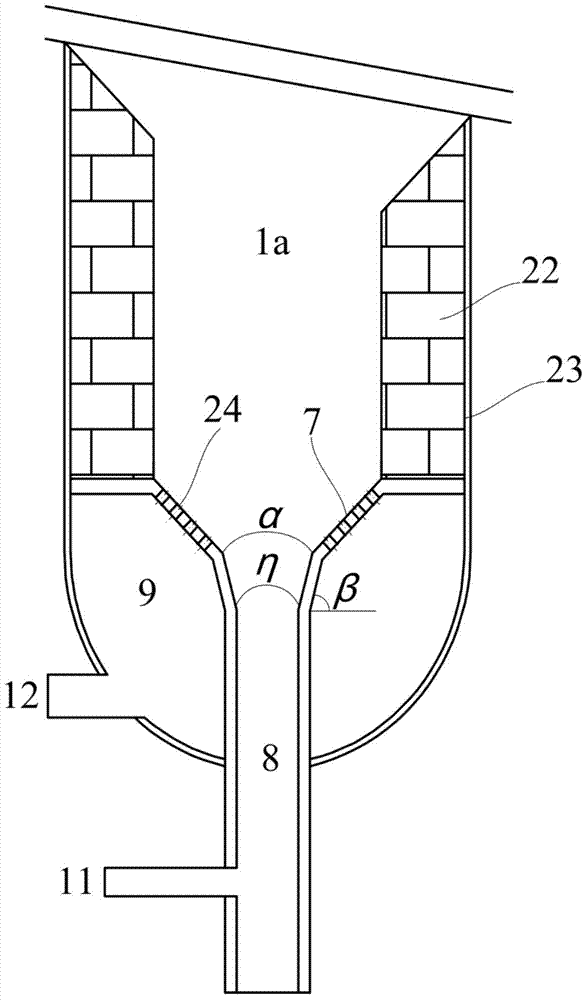

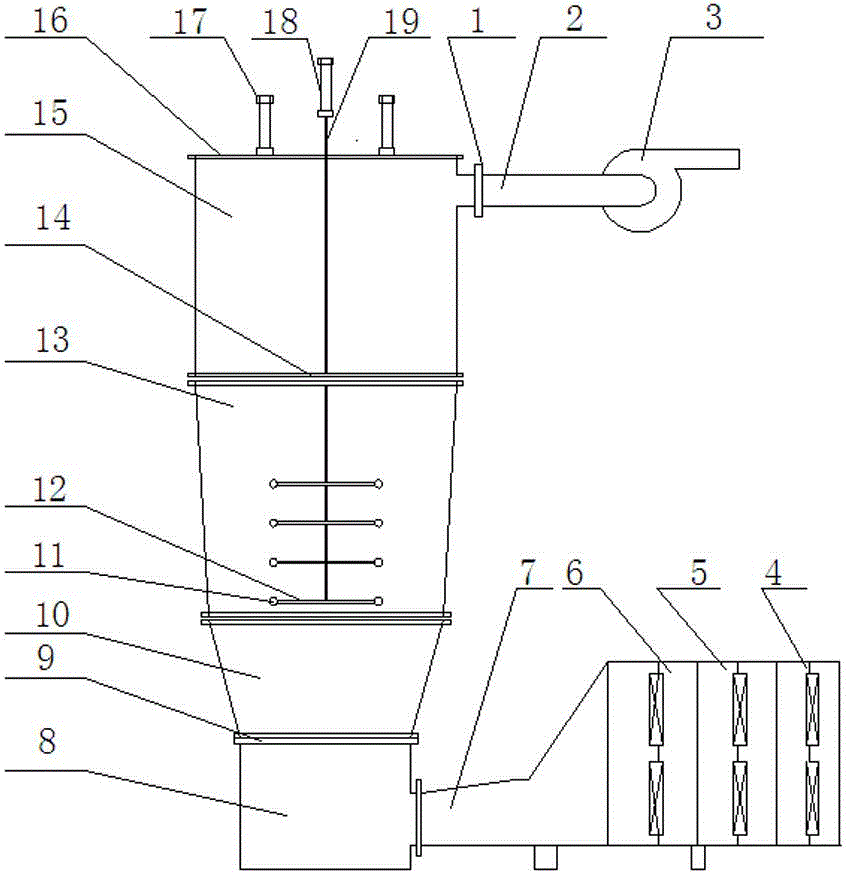

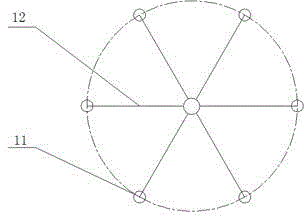

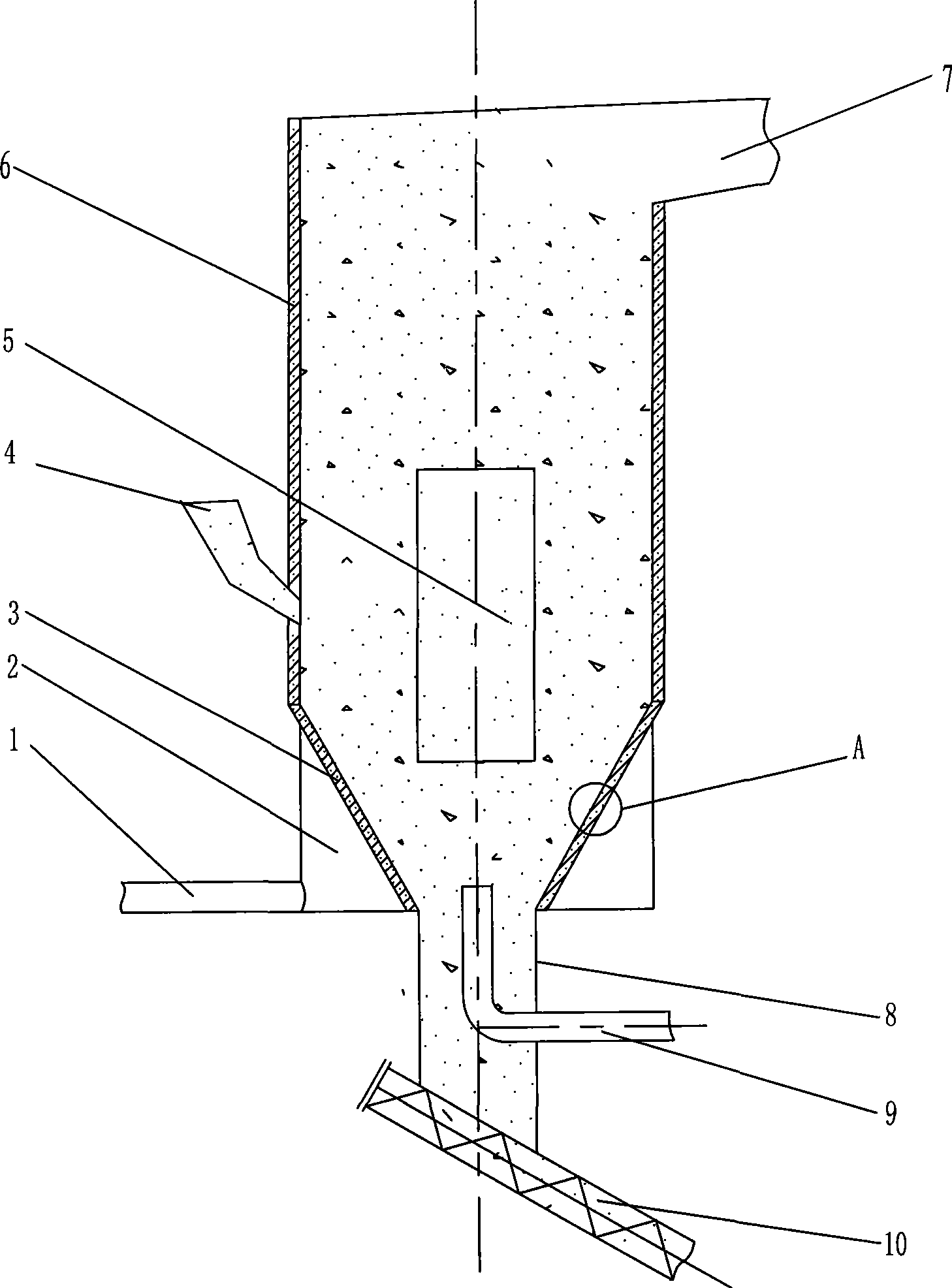

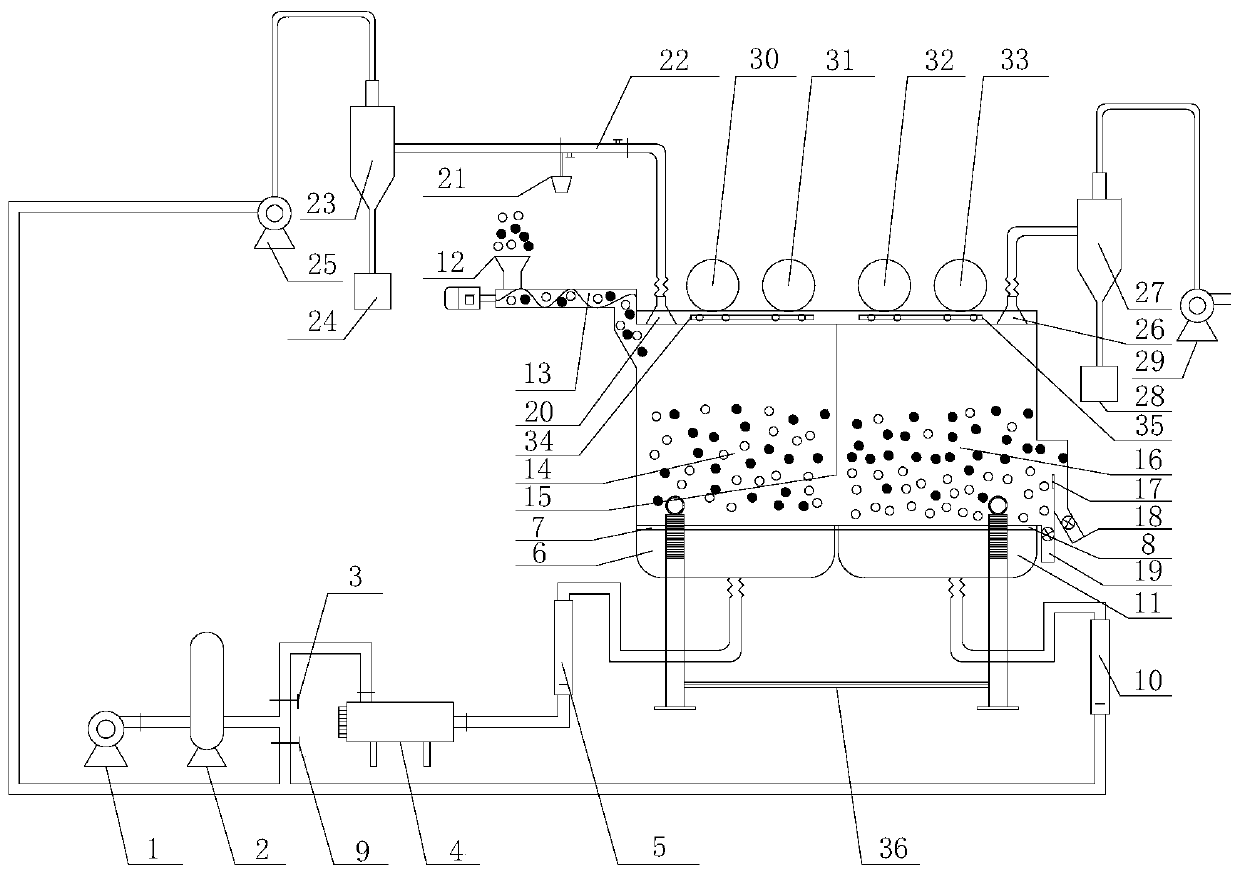

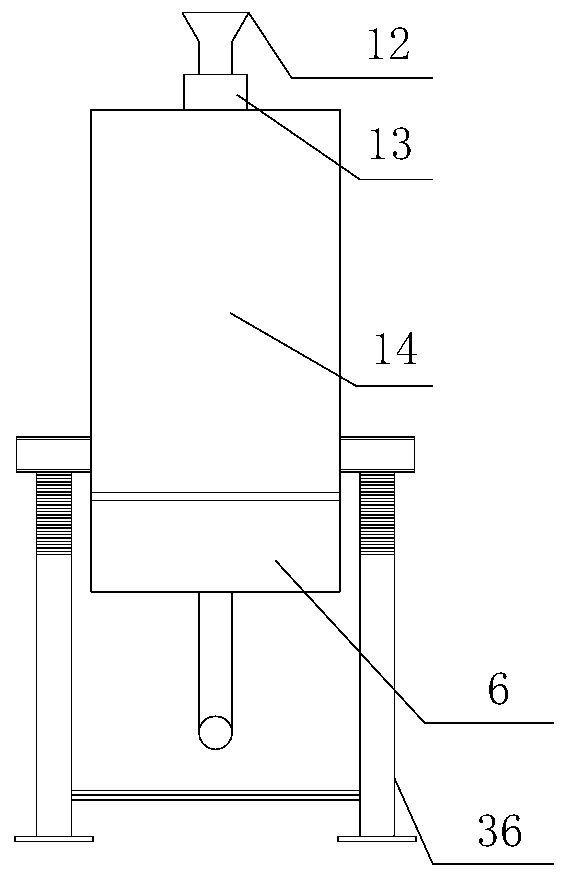

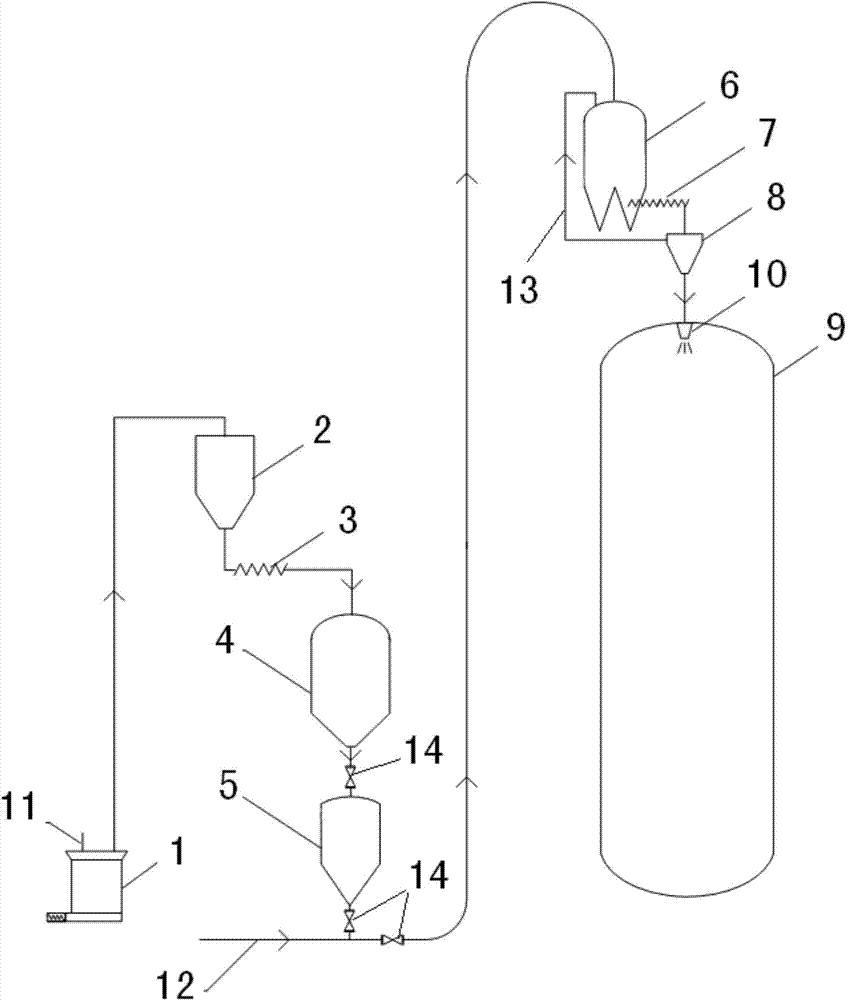

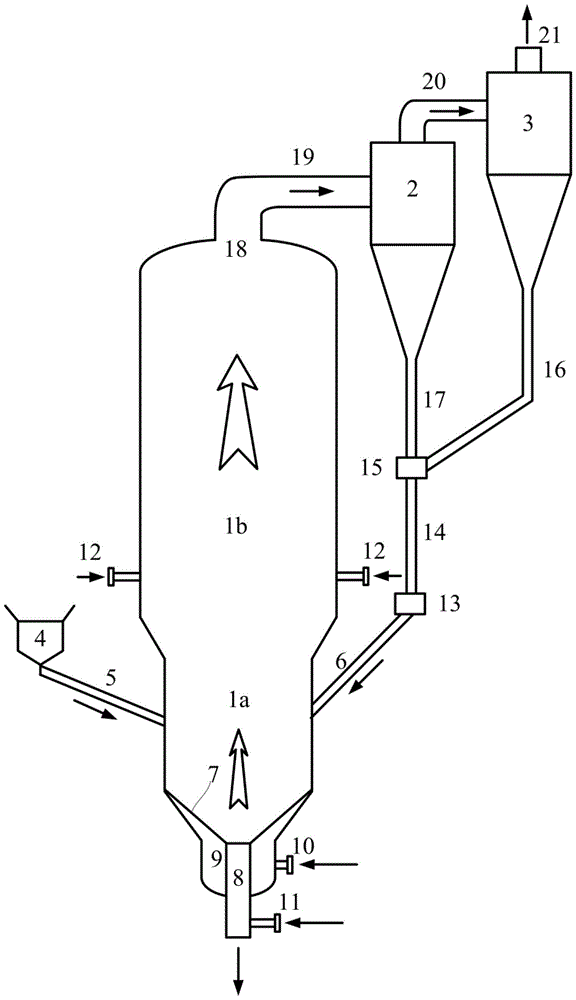

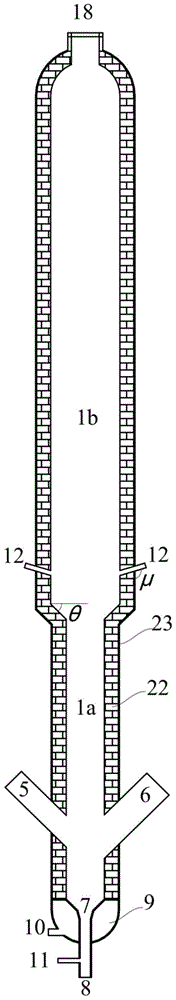

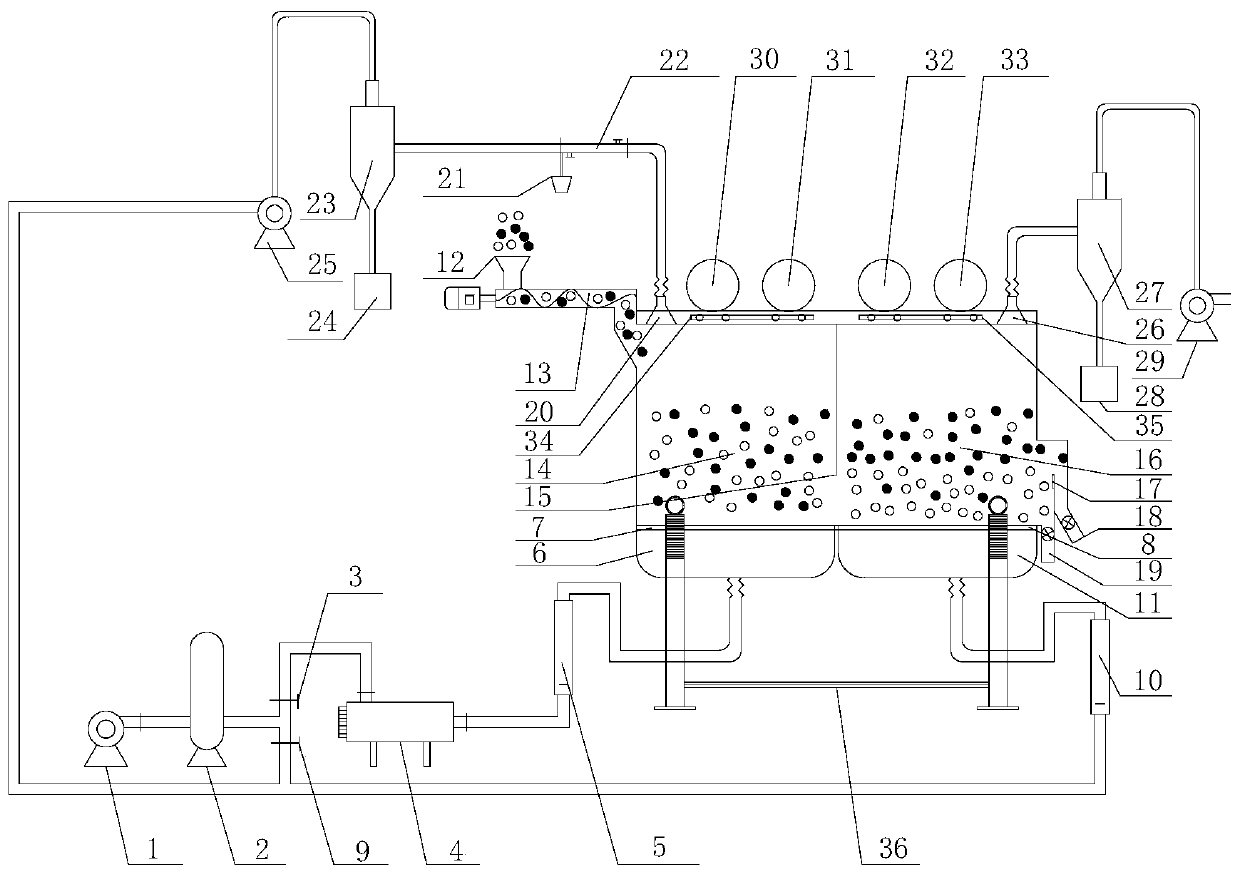

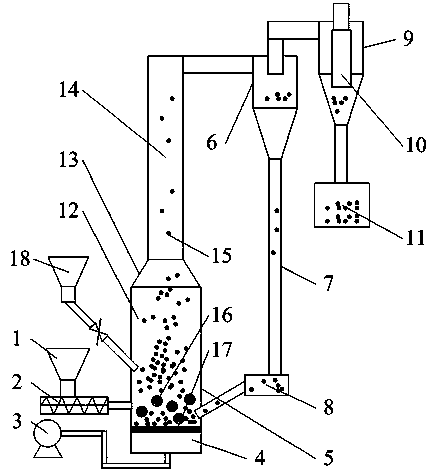

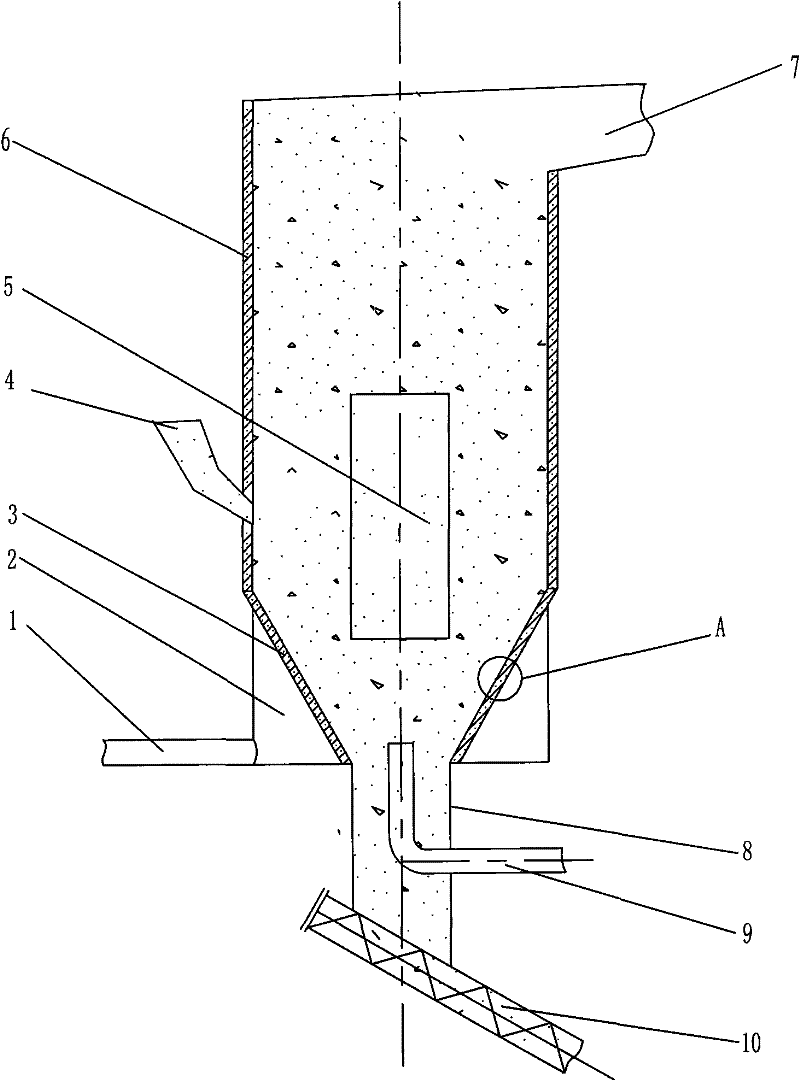

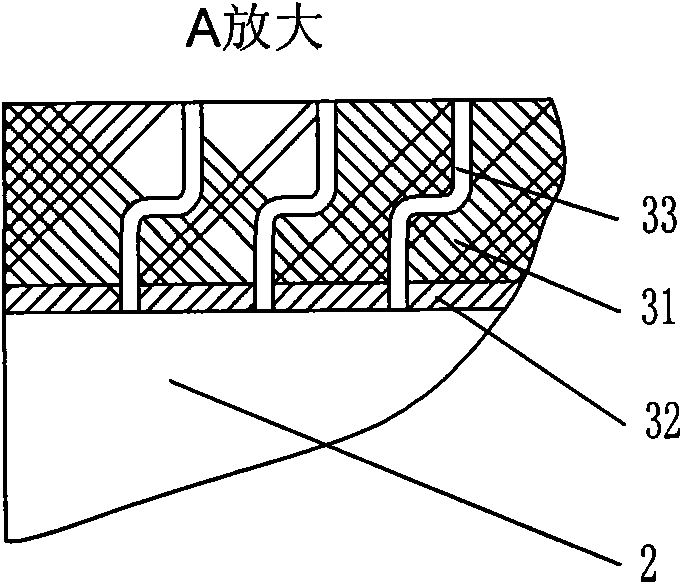

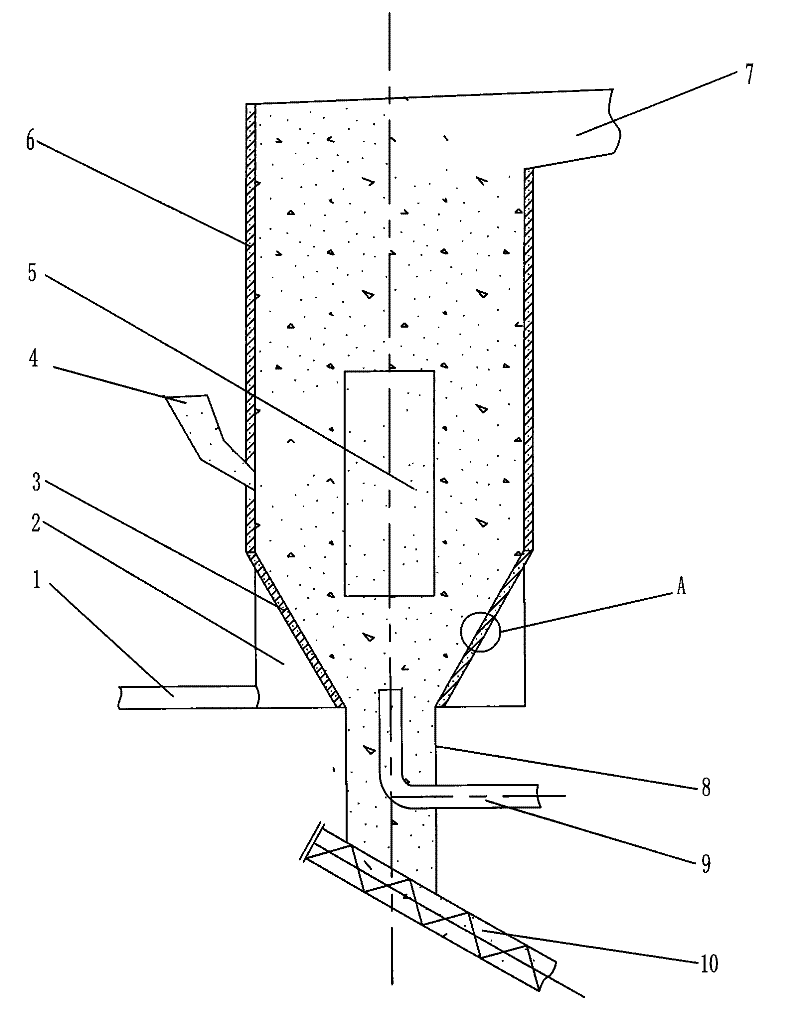

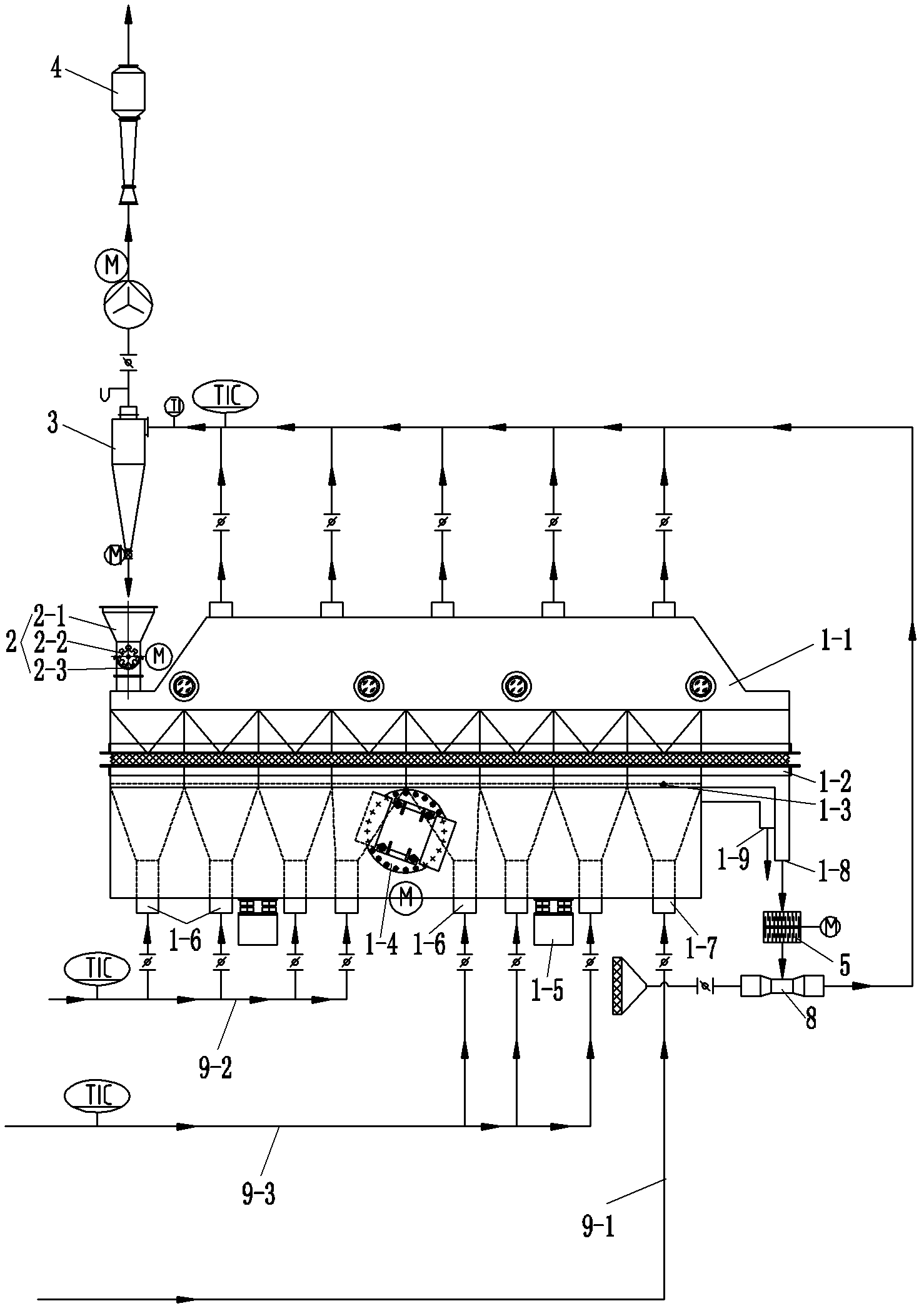

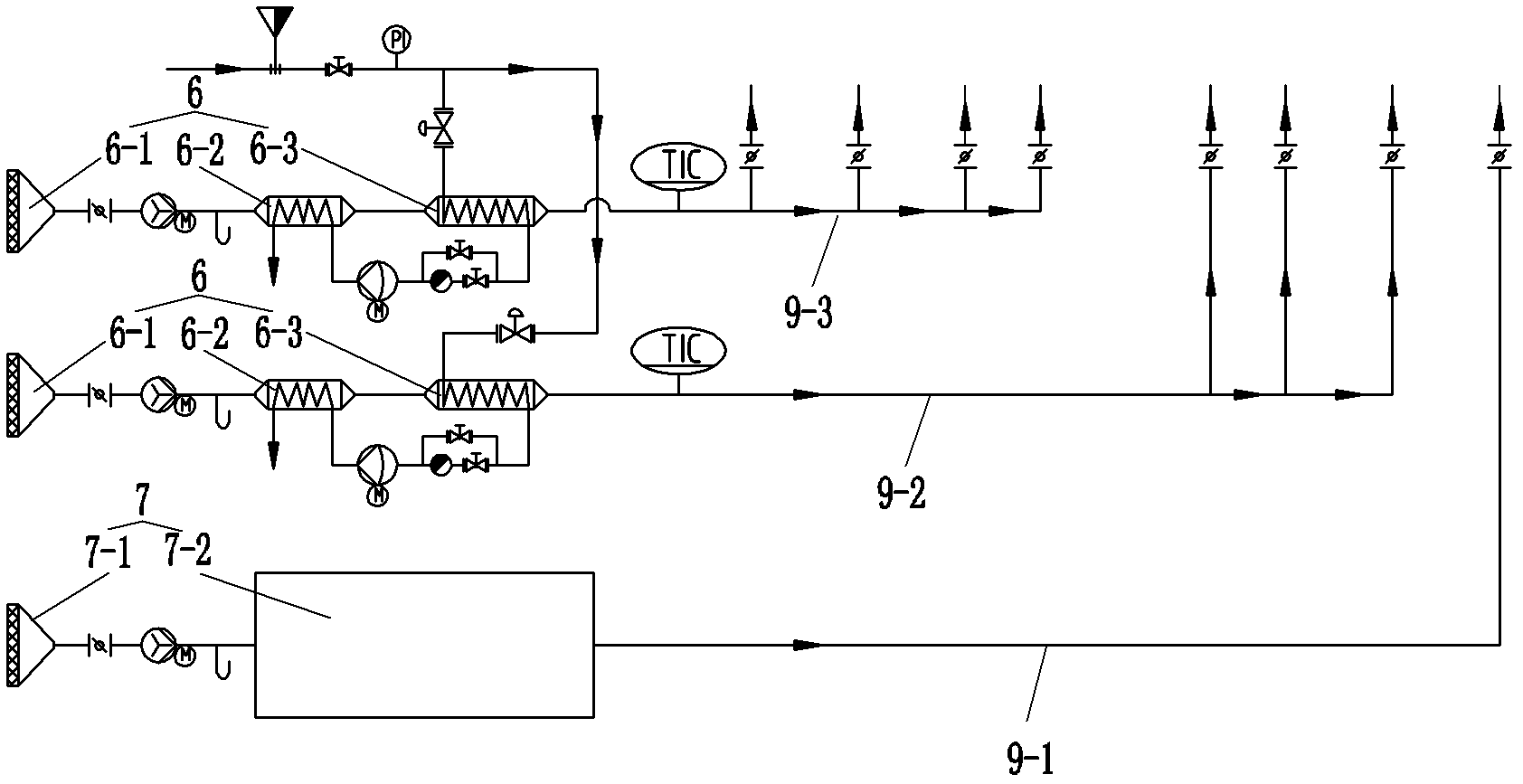

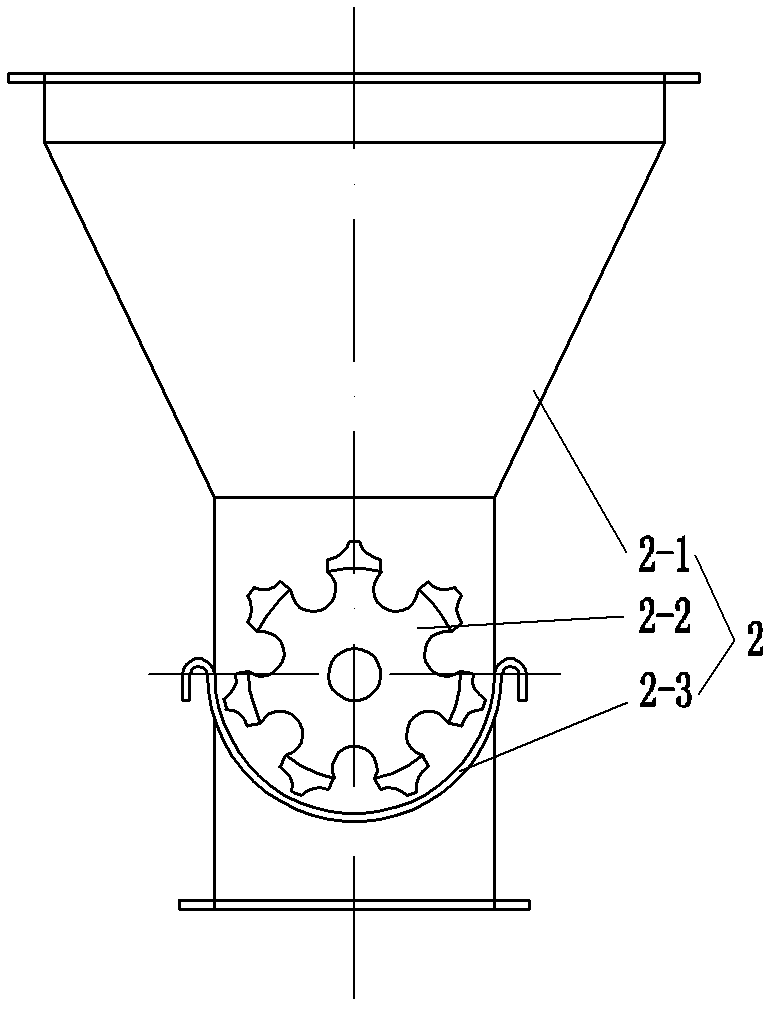

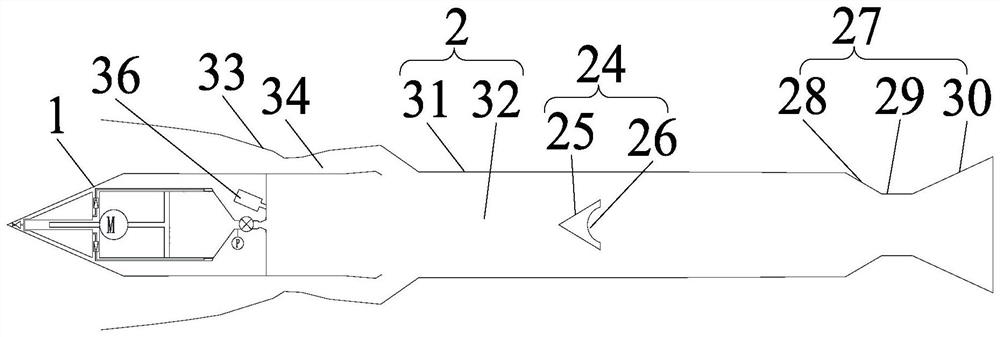

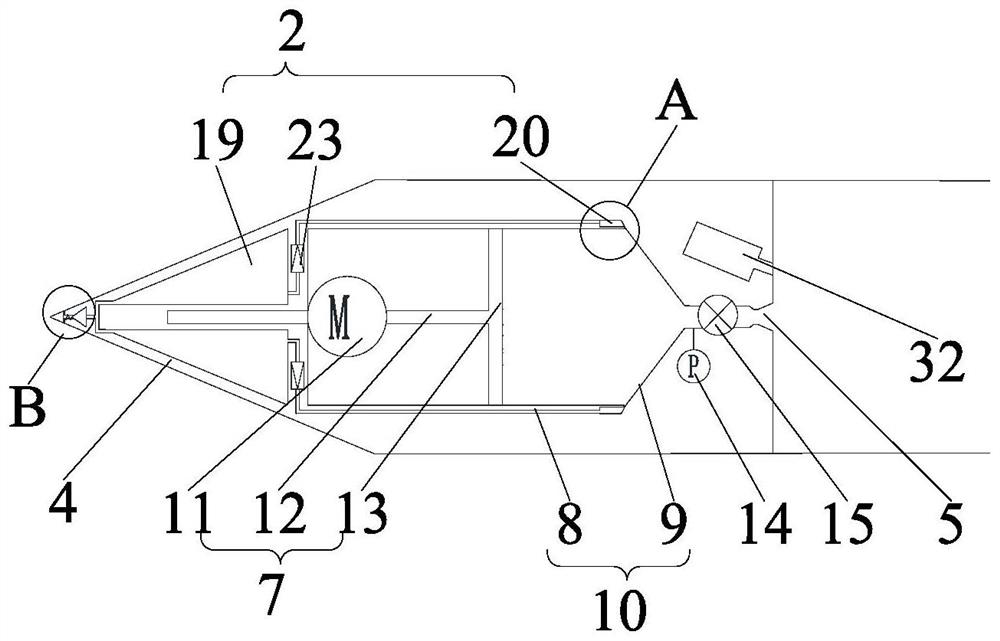

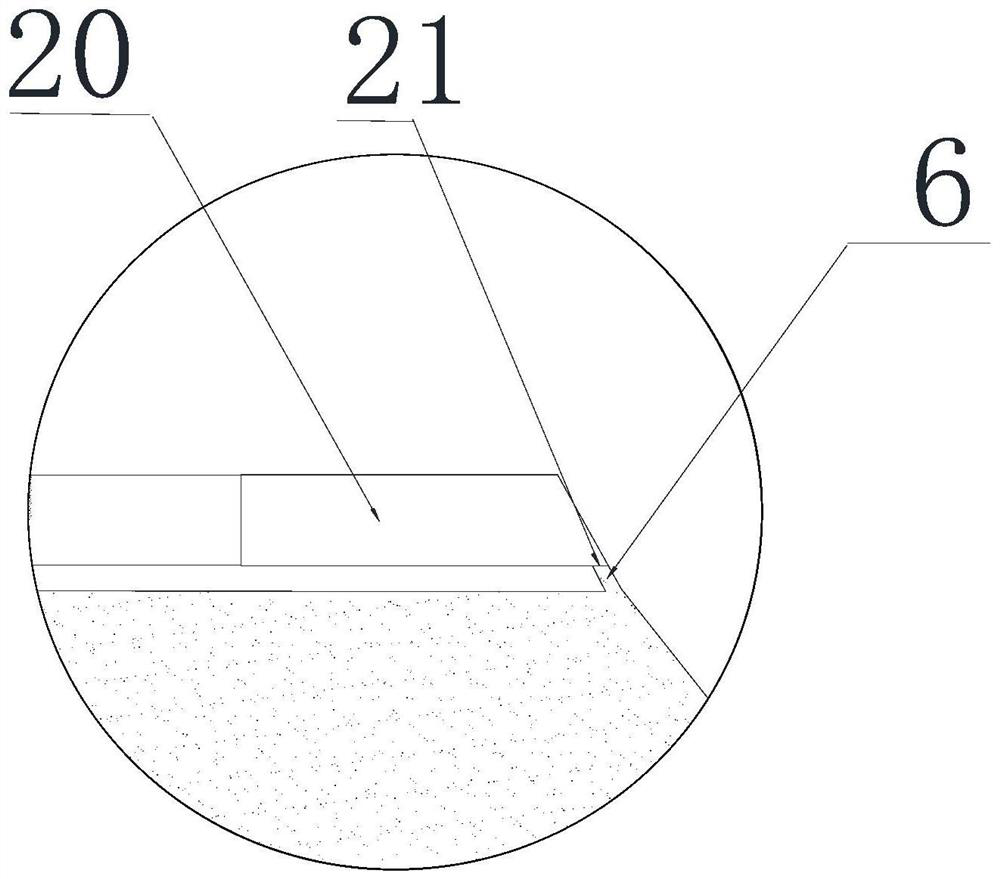

Dry-process deslagging fluidized bed gasification reaction device

ActiveCN104277881AGuaranteed uptimeEasy to scale upGasifier mechanical detailsGranular/pulverulent flues gasificationFluidized bedCyclonic separation

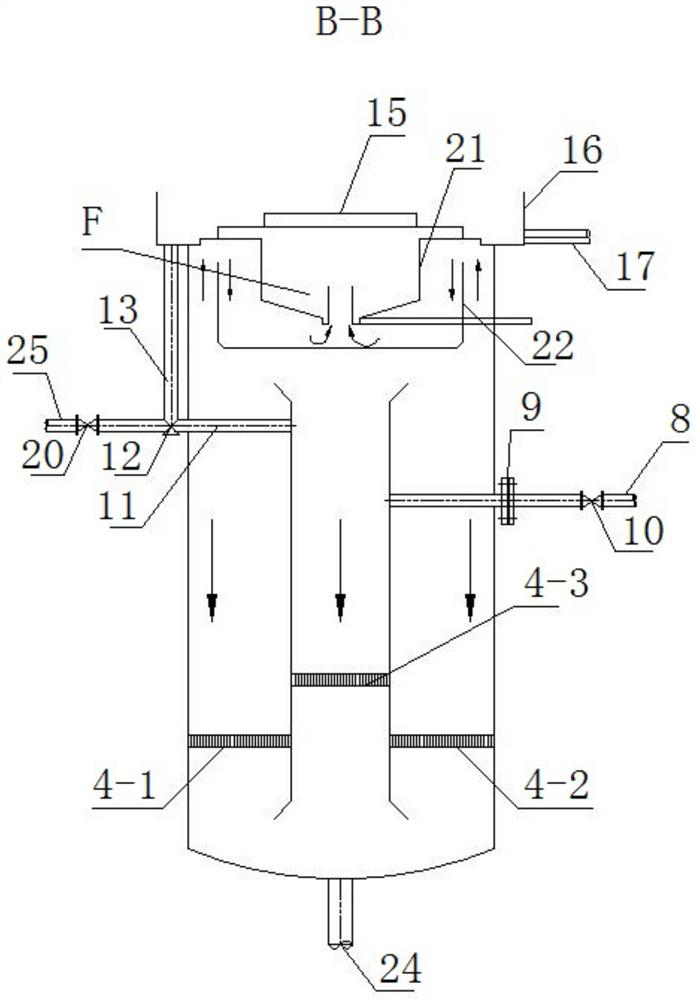

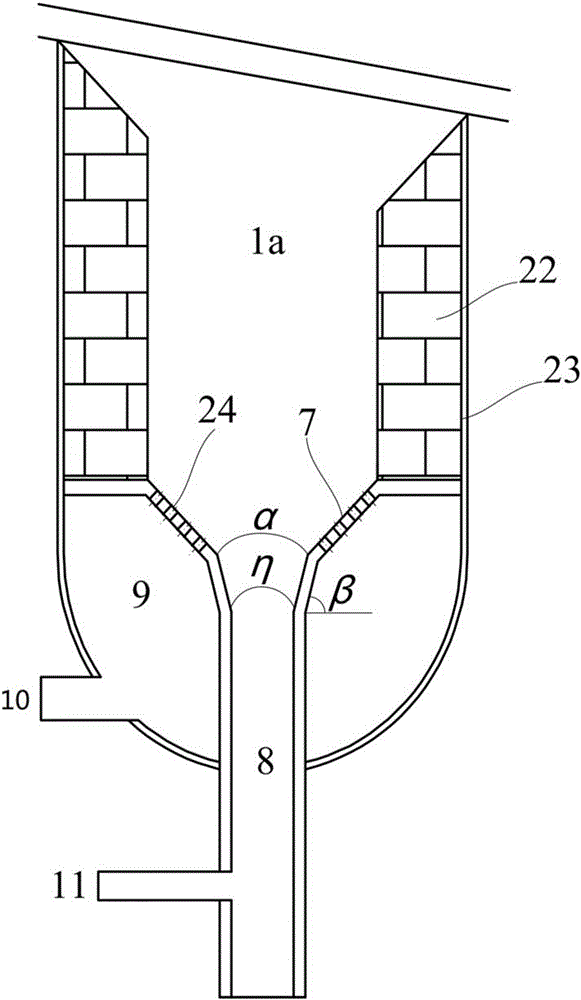

The invention discloses a dry-process deslagging fluidized bed gasification reaction device which comprises a reactor body, a multi-stage cyclone separating device, an air distribution device, a feed system and a return system. The dry-process deslagging fluidized bed gasification reaction device disclosed by the invention adopts a circulating fluidized bed reactor as a gasification reaction body, realizes the dry-process deslagging by adopting medium-high temperature gasification, achieves the purpose of improving carbon transformation rate and cooled coal gas efficiency by adopting two-stage type graded gasification, enhances the operation and running stability by combining a simplified deslagging device and an air distribution plate design, is suitable for the gasification transformation of various carbon-containing solid fuels and has large-scale popularization and application prospect.

Owner:SHANGHAI BOILER WORKS

Fluidized-bed reactor for oxidizing carbon black through ozone

InactiveCN1958145AEliminate channelingElimination of Broken AgglomeratesPigmenting treatmentChemical/physical processesFluidized bedProduct gas

A fluidized-bed reactor for oxidizing carbon black by ozone with stable fluidizing and no coagulation of carbon black particles has a main body with lower carbon black discharging outlet, gas inlet on its bottom, upper carbon black inlet, gas outlet on its top, internal barrier plate with slits, and gas distributing plate under the carbon black discharging outlet.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

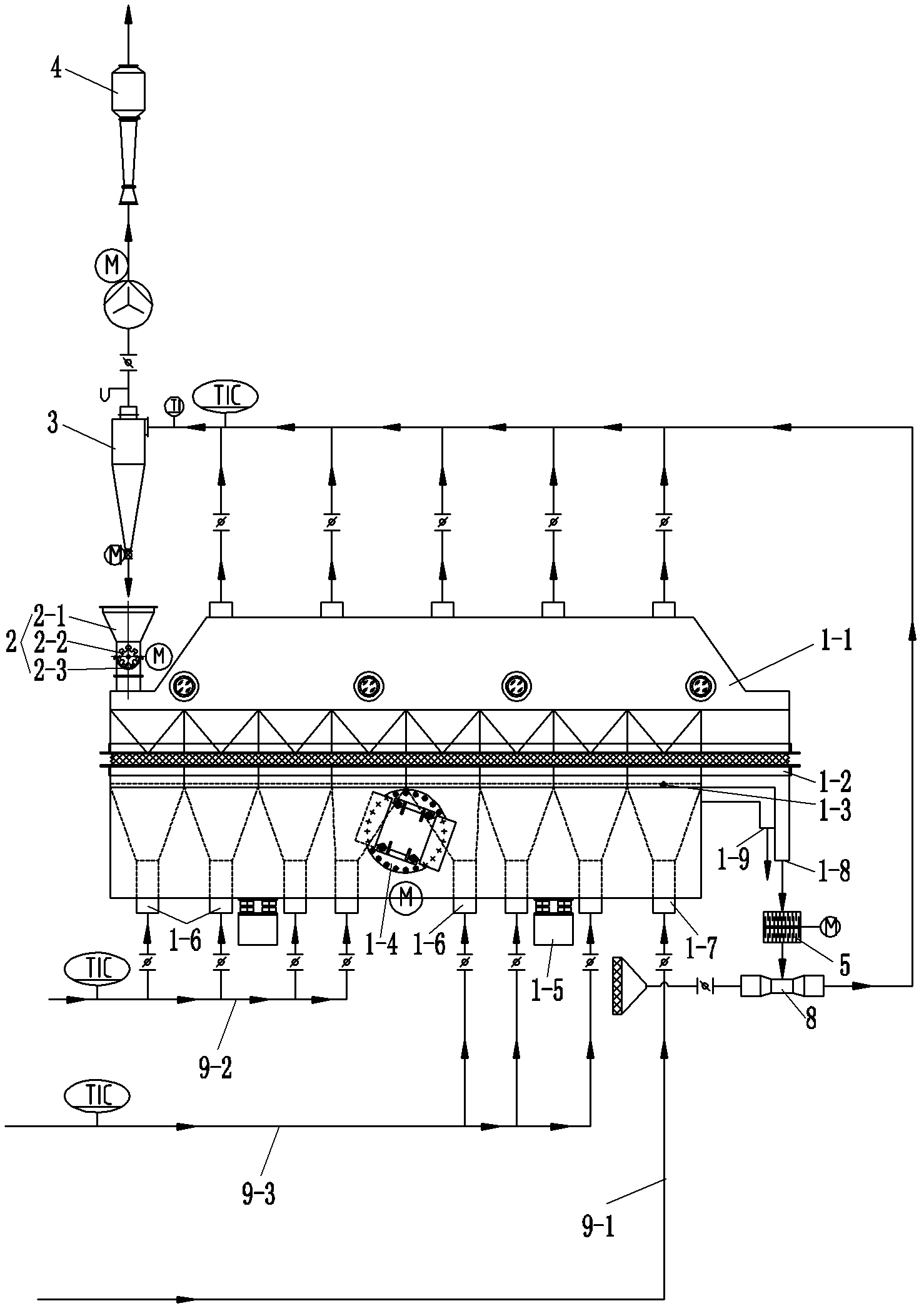

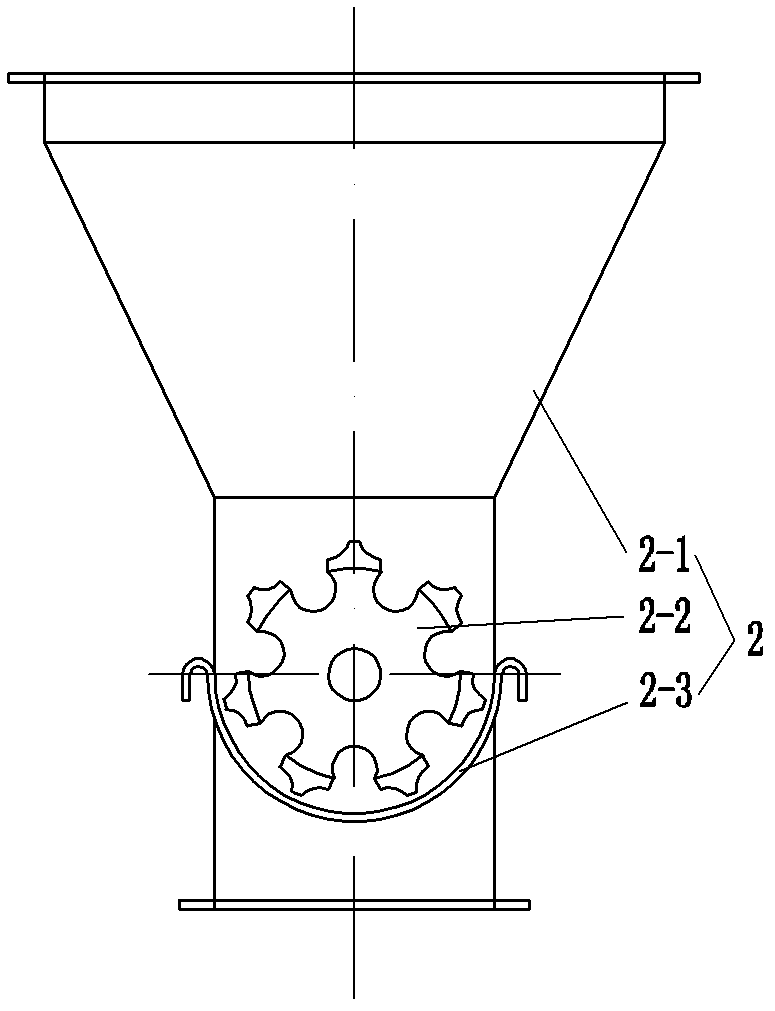

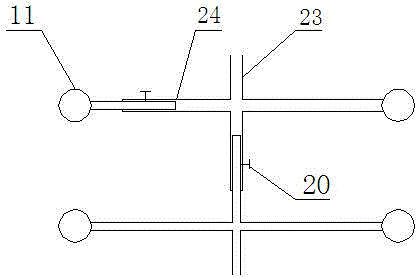

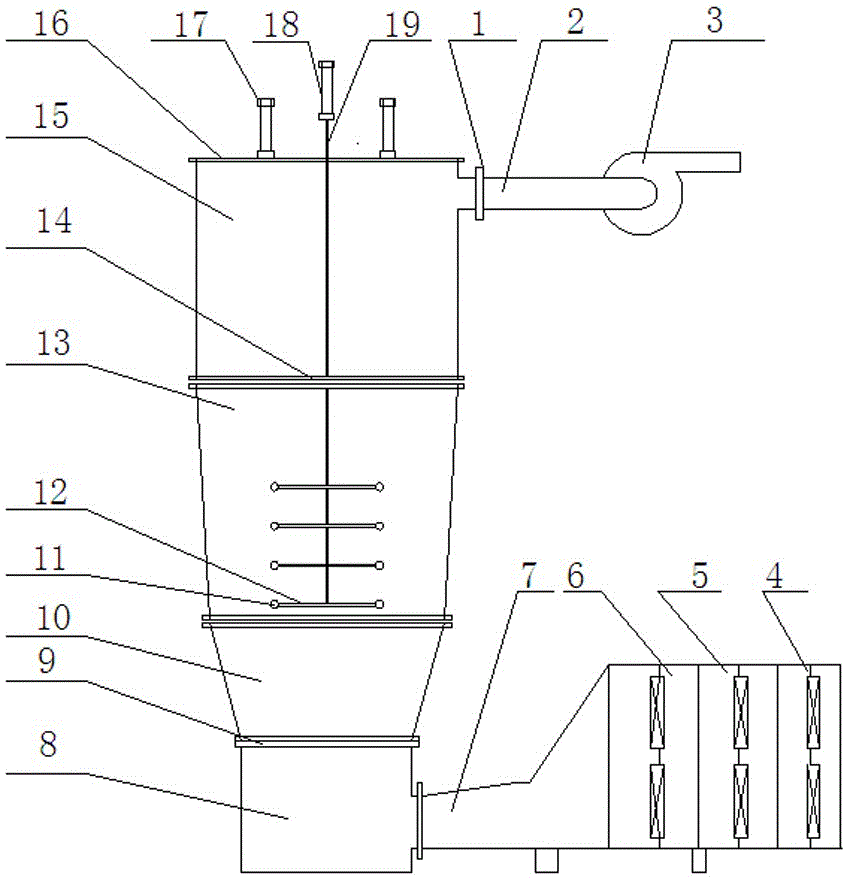

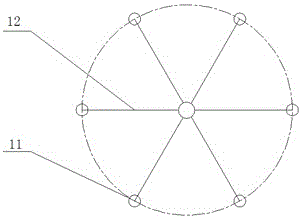

Granulating, fluidizing and drying system

InactiveCN102645088AImprove protectionStable fluidizationDrying solid materials with heatMaterial granulationEngineeringCrusher

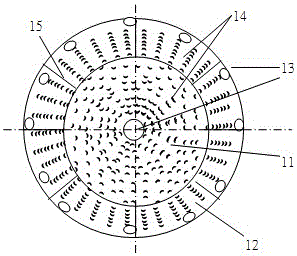

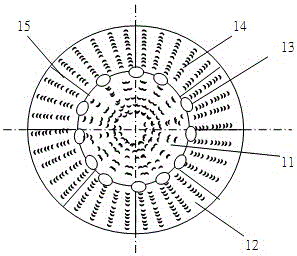

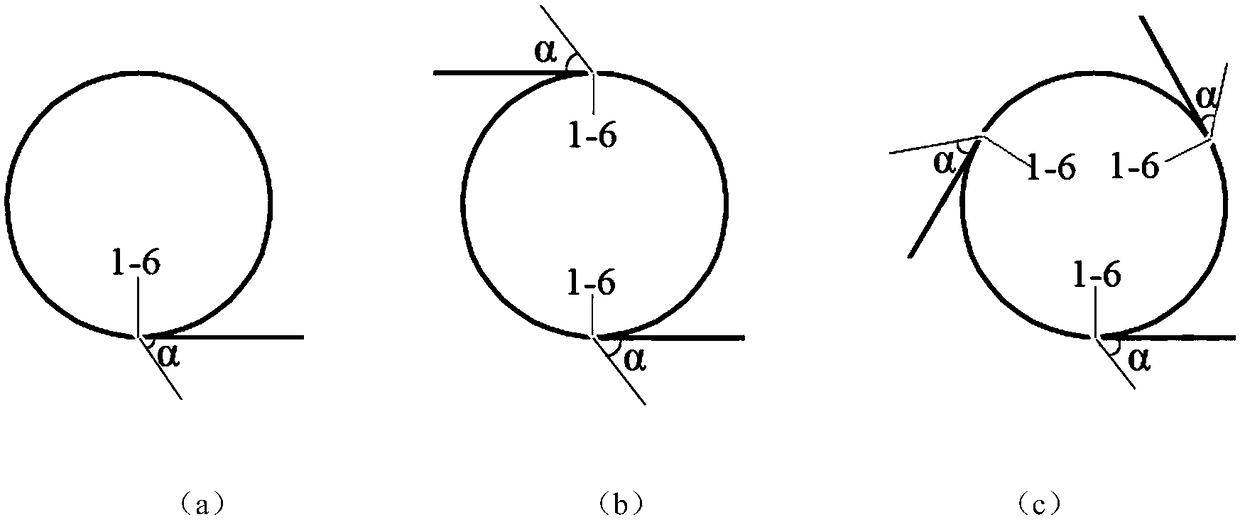

A granulating, fluidizing and drying system is provided with a vibration fluidizing machine, a granulating machine, a cyclone separator, a water film dust remover, a crusher, a heating device and a cooling device. A ventilation area on a bed plate of the vibration fluidizing machine is formed by connecting round unit ventilation areas which are arranged in a line. A screening device is arranged at the tail end of the bed plate, air holes at the middle square positions of the unit ventilation areas on the bed plate are straight holes, and air holes on four bow-shaped parts of the unit ventilation areas on the bed plate are scale holes. The air outlet direction of the scale holes on two bow-shaped parts on the front part in each unit ventilation area is towards a box wall, and the air outlet direction of the scale holes on two bow-shaped parts on the rear part in each unit ventilation area is towards the connection position of two unit ventilation areas. Air inlet tubes corresponding to the unit ventilation areas one by one are arranged in an air chamber. The granulating, fluidizing and drying system can integrally achieve granulation, drying, cooling and screening, has high efficiency, treats exhausted tail gas, and is favorable for environment protection. By means of a special shape of the bed plate and the distribution of the air holes, fluidization of the vibration fluidizing machine is stable and free of dead corners.

Owner:CHANGZHOU LEMAR DRYING ENG

Fluidizing and spray-drying granulator

InactiveCN104549044AExpand the atomization rangeImprove production efficiency and product qualityGranulation by powder suspensionEngineeringEnergy consumption

The invention discloses a fluidizing and spray-drying granulator. The granulator comprises a trapping chamber, a spraying chamber, a fluidizing chamber and an air inlet chamber which are sequentially arranged from top to bottom, wherein an air inducing pipe is arranged on the side wall of the upper part of the trapping chamber and connected with an induced draft fan, a bag filter is arranged in a position where the bottom of the trapping chamber and the top of the spraying chamber are connected, a position-adjustable spraying device is arranged in the spraying chamber, a perforated fluidizing plate is arranged in a position where the bottom of the fluidizing chamber and the top of the air inlet chamber are connected, an air inlet pipe is arranged on the side wall of the lower part of the air inlet chamber, and a filter, a dehumidifier and a heater are arranged on the air inlet pipe. The spraying device and the perforated fluidizing plate are movably connected, relative positions of all spraying guns, the spraying amount, the auxiliary material amount and the aperture ratio of the perforated fluidizing plate can be adjusted according to granulation requirements, and enlargement of the liquid atomization range and stable fluidization of seed powder are realized, so that the production efficiency and the product quality are improved, and the drying energy consumption is reduced.

Owner:XIANGTAN UNIV

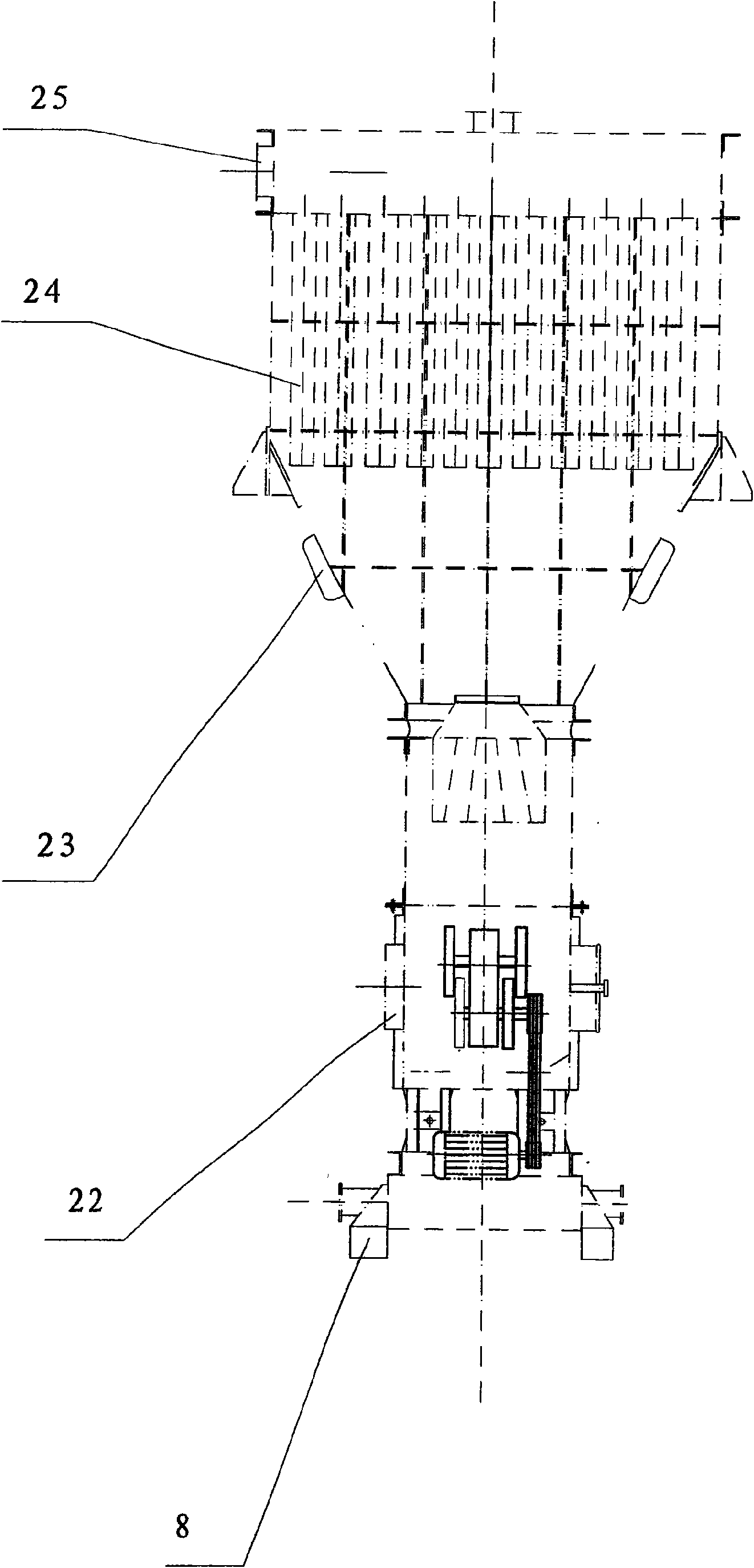

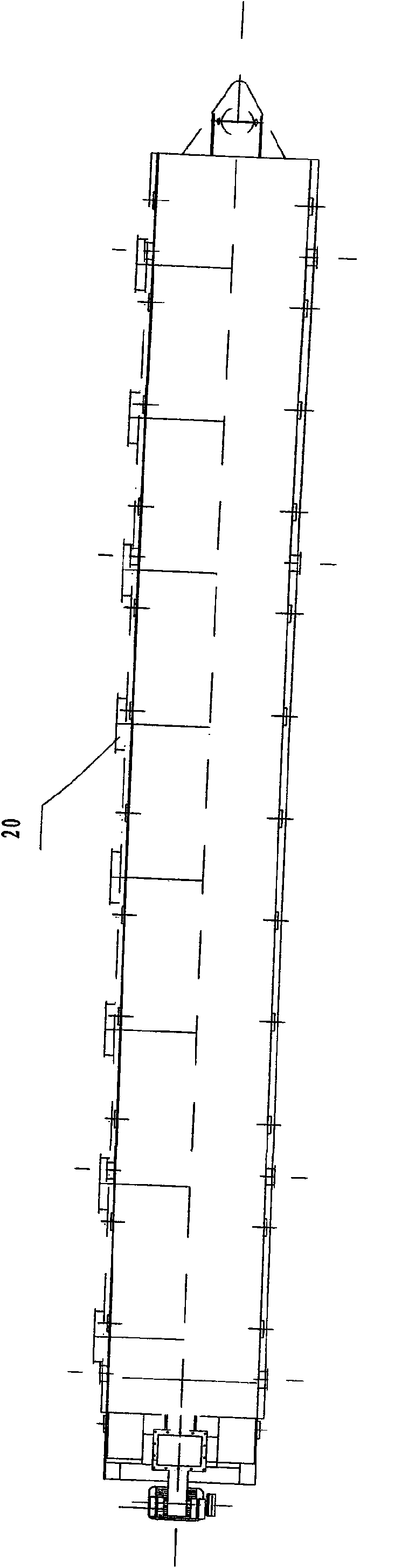

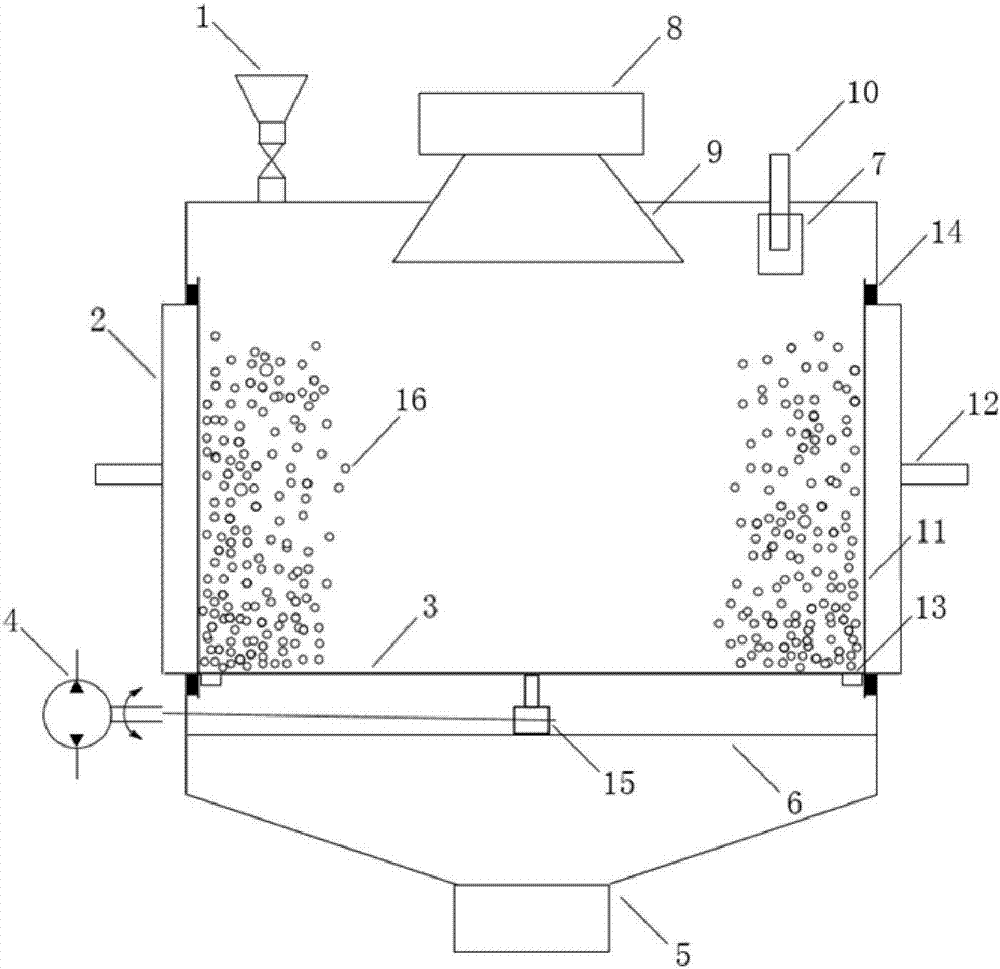

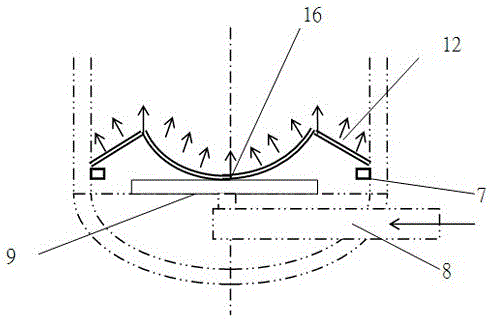

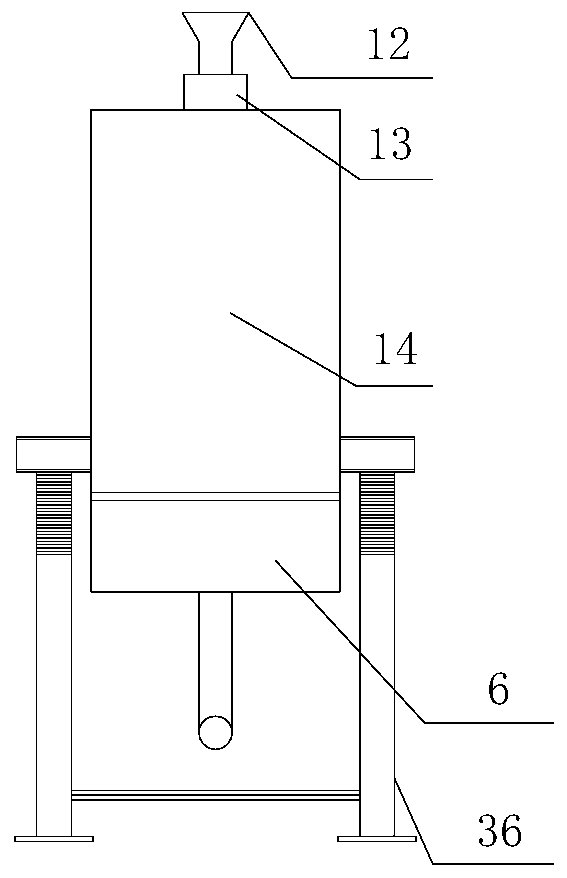

Three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer

InactiveCN101598484ASmooth vibrationConstant amplitudeDrying solid materials with heatHearth type furnacesVibratory fluidized bedEnvironmentally friendly

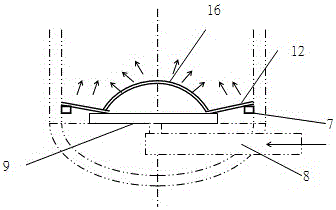

The invention relates to a three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer which is suitable for drying powder material of regular shape such as Laroflex MP with granularity ranging from 50mu m to 5000mu m. The drier comprises a foundation (9), a lower housing (13), a fluidized bed body (6), an upper housing (18) and a bag type dust collector (24); wherein the lower housing (13) is supported on the foundation (9) by a slantly arranged plate spring (12), a case type vibration exciter (14) is arranged at the front end of the lower housing (13), the fluidized bed body (6) is arranged above the lower housing (13) and internally provided with a hood-shaped fluidized bed plate (7), the upper housing (18) is arranged above the fluidized bed body (6) and internally provided with a plurality of groups of bag type dust collectors (24). An air-reserve tank (24.6) is arranged outside the upper housing (18), a plurality of air branch pipes (24.3) are internally arranged in the air-reserve tank (24.6), wherein each air branch pipe (24.3) is provided with a pulse solenoid valve (24.5), the bottom part thereof is provided with an air source hole (24.7). The drier of the invention features low energy consumption, high production efficiency, good operation stability and good uniformity of products.

Owner:江阴丰力生化工程装备有限公司

Combined fluidized bed slag cooling apparatus

ActiveCN101476721AImprove mobilityWell mixedFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention relates to a combined fluidized bed slag cooler, which comprises a body, a wind box, an air distributing device, a slag inlet pipe, a slag outlet pipe, an air inlet pipe and an air outlet pipe. The body is provided with the slag inlet pipe, and the bottom of the body is connected with the slag outlet pipe. The lower part of the body is provided with the air distributing device and connected with the wind box of the air inlet pipe, and the top of the body is connected with the air outlet pipe. The slag outlet pipe is provided with a spraying pipe for air intake inside to make the three working areas with different flowing states formed from the lower part to the upper part in the body, the lower part is a spraying area, the middle part is an annular fluidizing area, and the upper part is a suspending and settling area. The upper side of the spraying pipe is provided with a guide pipe. The outlet of the slag outlet pipe is provided with a mechanical slag outlet valve or a conveyor. The transverse and longitudinal mixing of gas-solid two-phase in the bed is obviously strengthened under the coaction of spraying air and fluidizing air. The problems of poor transverse mixing, easy accumulation of local bed materials, delamination, aggregation and the like of the fluidized bed slag cooler are solved. The furnace slag granules can be sufficiently and effectively cooled. The combined fluidized bed slag cooler is used for cooling bottom slag of a CFB boiler or other high-temperature solid granular materials.

Owner:EASTERN BOILER CONTROL CO LTD

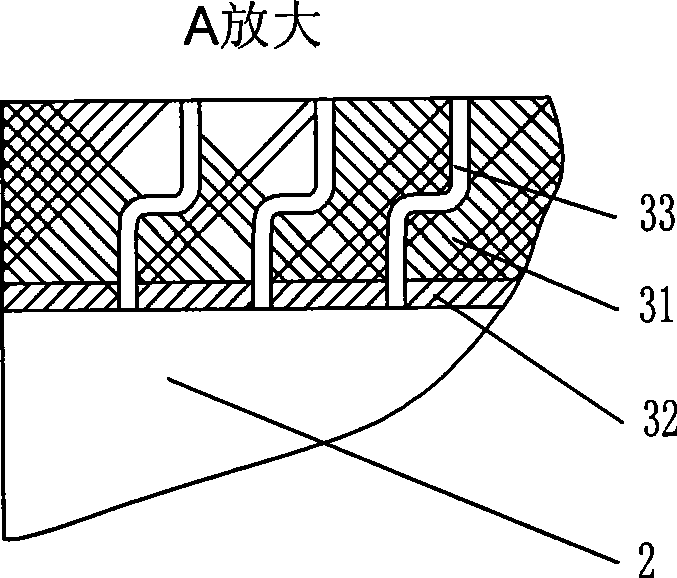

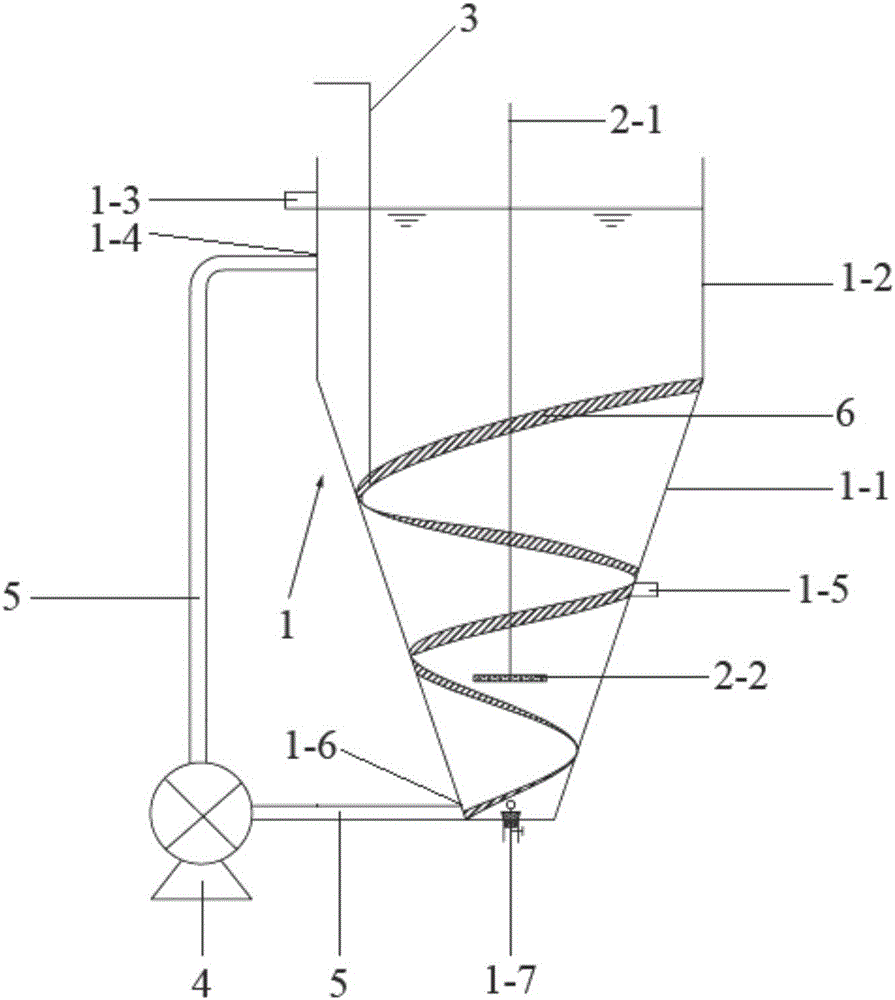

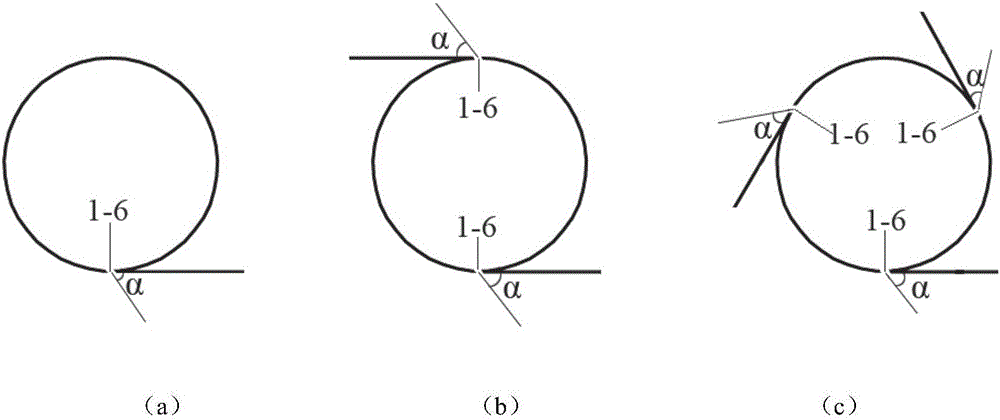

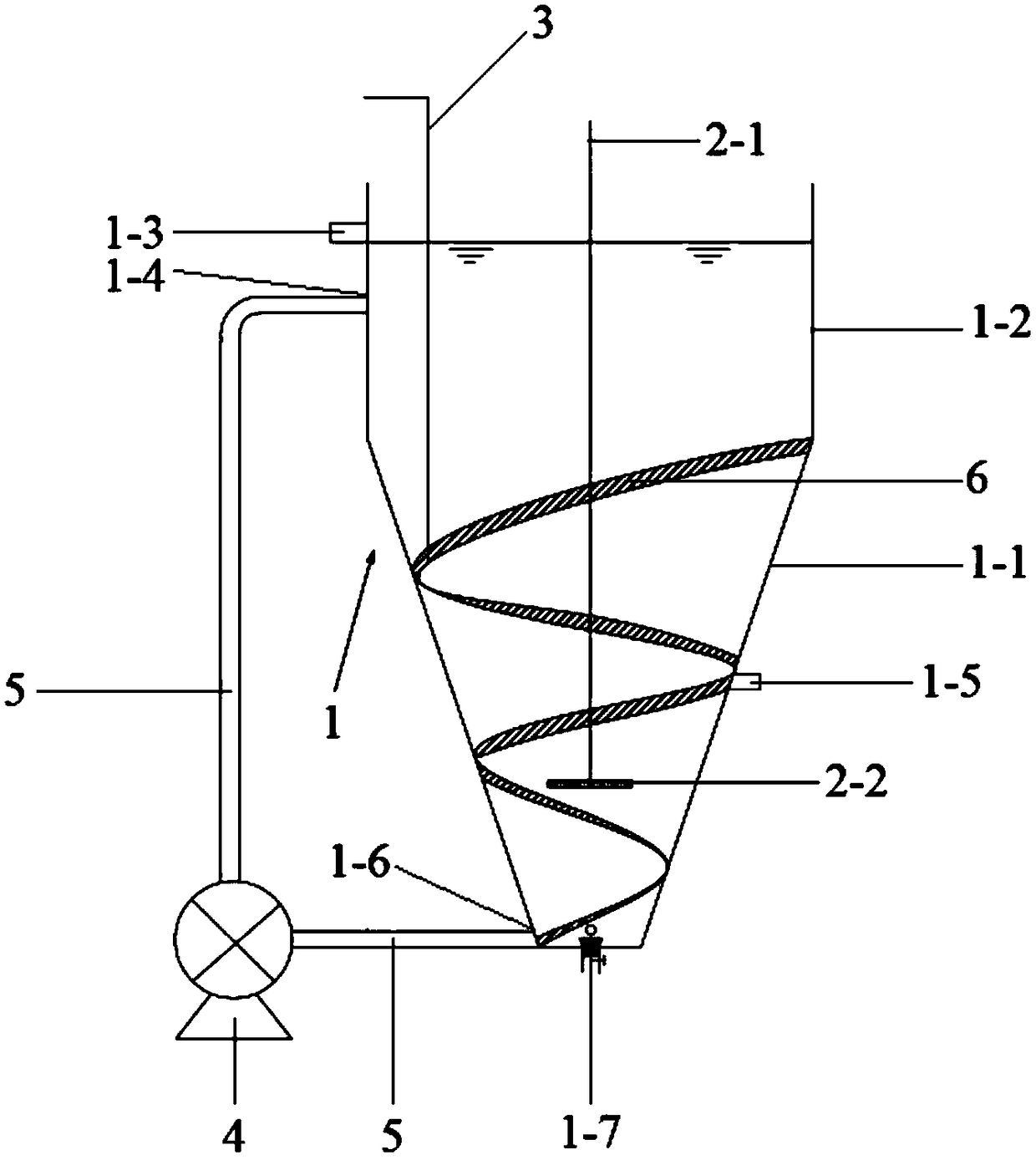

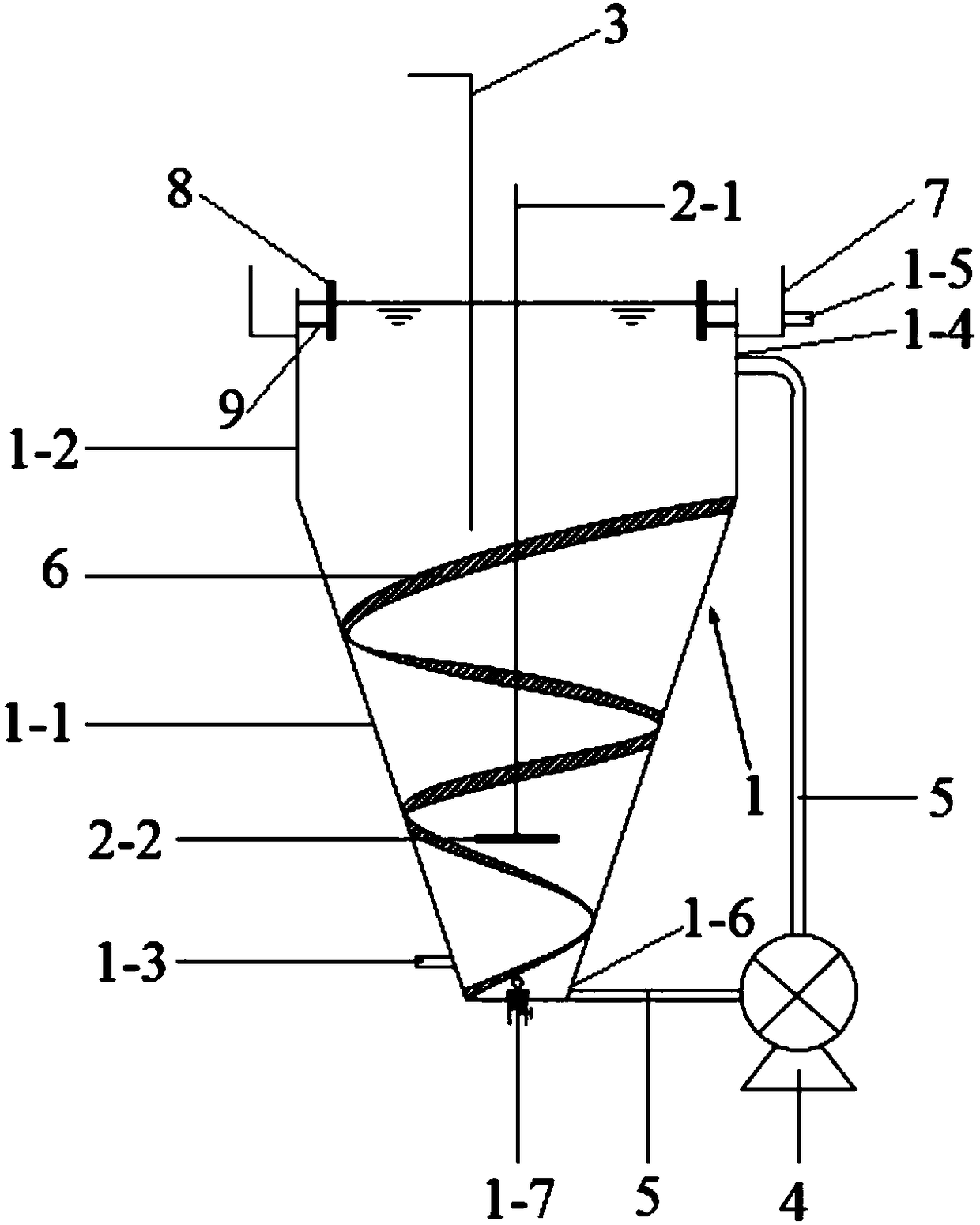

Device for cooperatively enhancing fluidization of nanoparticles by centrifugal field and sound field

InactiveCN106994322AOvercoming AdhesionGood fluidization behaviorEnergy based chemical/physical/physico-chemical processesBaghouseNanoparticle

The invention provides a device for cooperatively enhancing the fluidization of nanoparticles by a centrifugal field and a sound field. The device comprises a feeding hopper (1), an annular air inlet chamber (2), a centrifugal fluidized bed body (3), a stepping motor (4), a discharging hopper (5), a bed body supporting frame (6), a cloth bag dust collector (7), a sounder (8), a loudspeaker (9), an air outlet (10), an annular air distribution plate (11), an air inlet (12), an inner discharging hole (13), a sealing gasket (14) and a right-angle transmission gear box (15). According to the device provided by the invention, the fluidization of the nanoparticles is enhanced through the centrifugal field and the sound field, and abnormal fluidization phenomena including channeling, slugging even normal fluidization and the like of the nanoparticles in a fluidized bed can be effectively eliminated; an agglomeration-crushing process of particle agglomeration is enhanced and mixing between the particles is enhanced; the heat and mass transportation capability between the particles and a main body is improved; process application and amplification are easy to realize; the device has strong operation controllability and is stable to operate.

Owner:SOUTHEAST UNIV

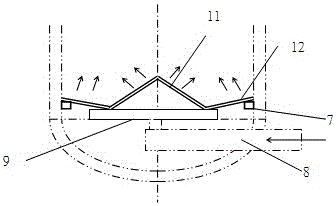

Concave flow distribution plate and reactor with same

ActiveCN106040107AStrong anti-deposition abilityFully fluidized materialChemical/physical processesPneumatic pressureAirflow

The application relates to a concave flow distribution plate and a reactor with the same. The concave flow distribution plate is formed by modifying a flat flow distribution plate and comprises a concave structure that is concave down along its axis and a bent structure bent down from the periphery of the concave flow distribution plate; the concave structure is conical structure, spherical structure or composed of symmetrical concave double-curved surface; the flow distribution plate helps process gas from the bottom of the reactor to flow out of flow holes so that material from the upper portion of the reactor and process gas rising from below can be balanced and fully contacted, thus keeping a relative pressure, the distribution plate has flow balancing performance, particulate mobility and internal structure fatigue resistance and is simple in combination structure and convenient to mount and maintain, a support of the distribution plate is more reasonably stressed, high stability is provided, spatial layout is safer and more scientific, the reactor is better in operation flexibility, reaction heat can be removed more flexibility, safety of a shell wall is protected, and the service life of the reactor is prolonged.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

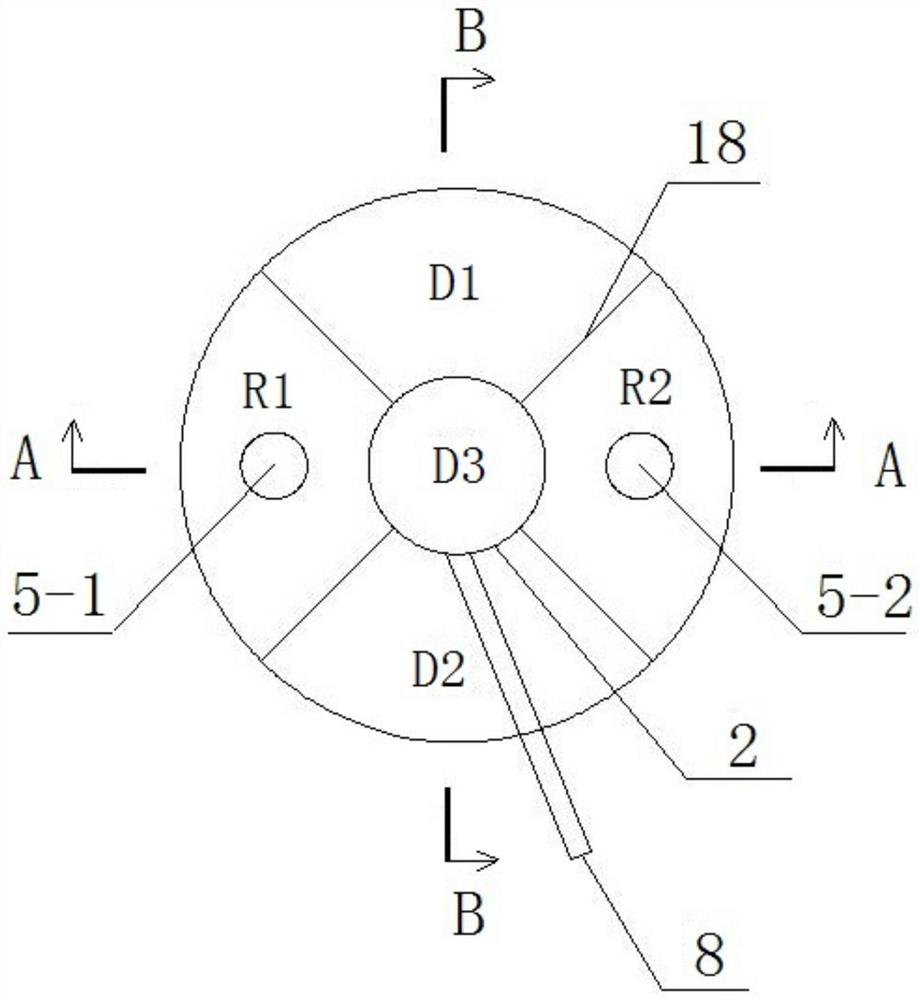

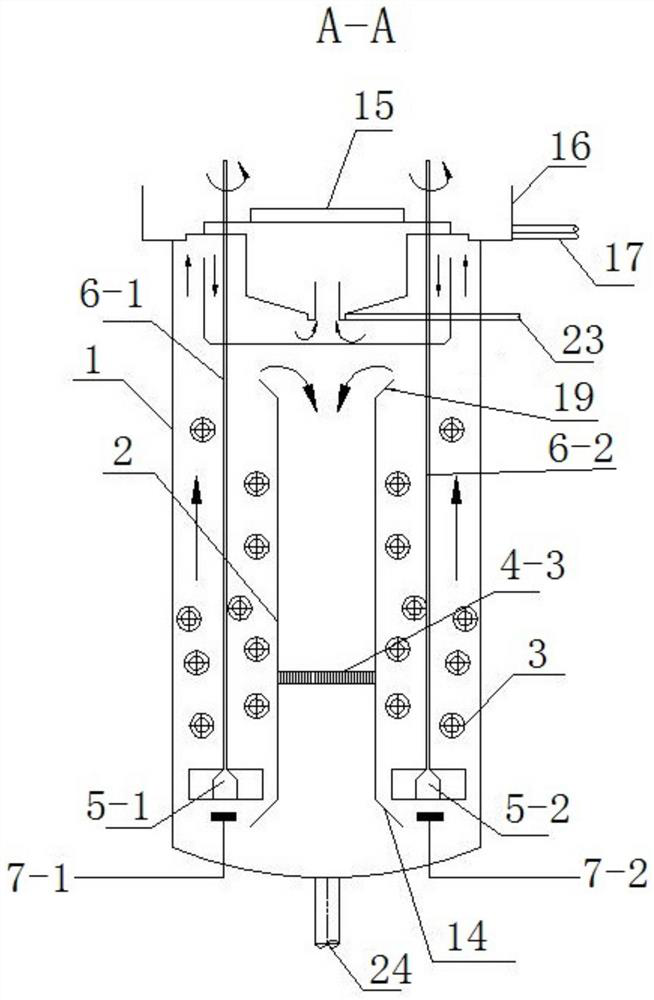

Three-phase biological fluidized bed for treating refinery wastewater

PendingCN112479490AImprove degreasing effectIncrease the surface area per unit volumeWater contaminantsTreatment involving filtrationFluidized bedRefinery wastewater

A three-phase biological fluidized bed for treating refinery wastewater is of an inner and outer cylinder structure and is mainly composed of an anaerobic facultative down-flow area, an aerobic up-flow area and a three-phase separation area, wherein the three-phase separation area is located at the top of the inner and outer cylinder structure; the anaerobic facultative down-flow area comprises adown-flow area D1, a down-flow area D2 and a down-flow area D3, the down-flow area D3 is an inner cylinder, and the down-flow area D1 and the down-flow area D2 are formed by a gap between the outer cylinder and the inner cylinder and are oppositely arranged; a water inlet pipe is arranged on the inner cylinder, and a filter screen is arranged in the down-flow area below the water inlet pipe; the aerobic up-flow area comprises an up-flow area R1 and an up-flow area R2, the up-flow area R1 and the up-flow area R2 are formed by a gap between the outer cylinder and the inner cylinder and are oppositely arranged, an air inlet pipe and an impeller are arranged at the bottom of the up-flow area, and a carrier is placed in the up-flow area; and the three-phase separation area comprises a separation area F and is mainly composed of a three-phase separator. The three-phase biological fluidized bed for treating refinery wastewater can effectively eliminate oil components in wastewater, and has the advantages of strong impact load resistance, good mass transfer effect and blockage prevention.

Owner:ANHUI RESOURCE SAVING & ENVIRONMENTAL TECH CO LTD

Coal slime treatment method

InactiveCN109000221AImprove thermal efficiencyStable oxidation temperatureFluidized bed combustionApparatus for fluidised bed combustionResource utilizationFlue gas

The invention discloses a coal slime treatment method. The treatment method comprises the following steps: enabling coal slime to enter a reactor and be in contact with temperature-regulating medium particles in the reactor, carrying out a reaction under the effect of fluidizing air, performing separating treatment on the reacted flue gas, separating the large-size temperature-regulating medium particles taken out by the flue gas, returning to the reactor, and performing subsequent treatment on ground fine powder of small-particle coal slime and temperature-regulating medium particles in a flyash form along with the flue gas. According to the coal slime treatment method disclosed by the invention, due to use of the temperature-regulating medium particles in the reactor, a stable coal slime temperature is provided, coal slime reduction, innocent treatment and high-efficiency resource utilization can be realized, oxidation burning can be performed by taking pure coal slime as the raw material for recovering the heat, and the coal slime oxidation efficiency and thermal efficiency of the device are high.

Owner:DALIAN EAST REFRIGERATION EQUIP +1

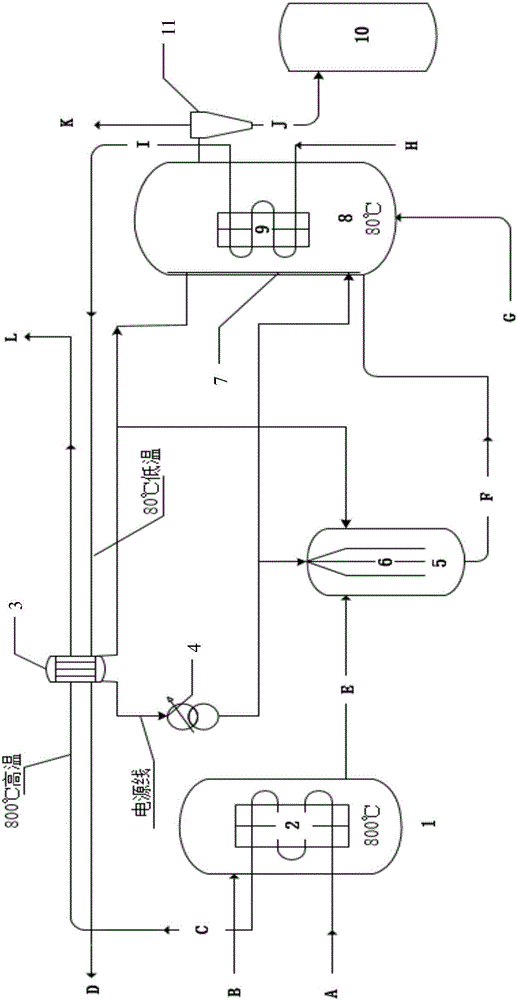

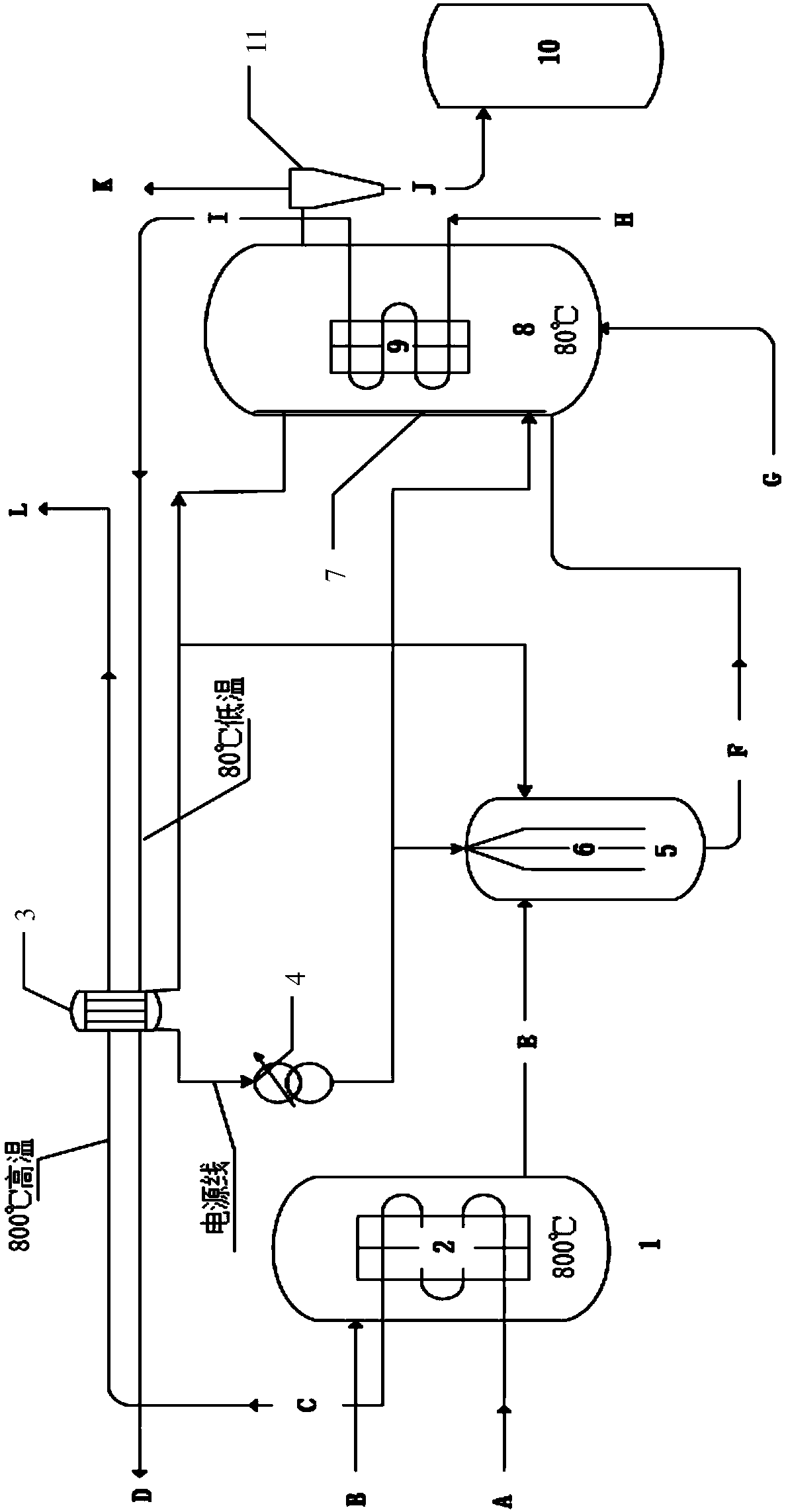

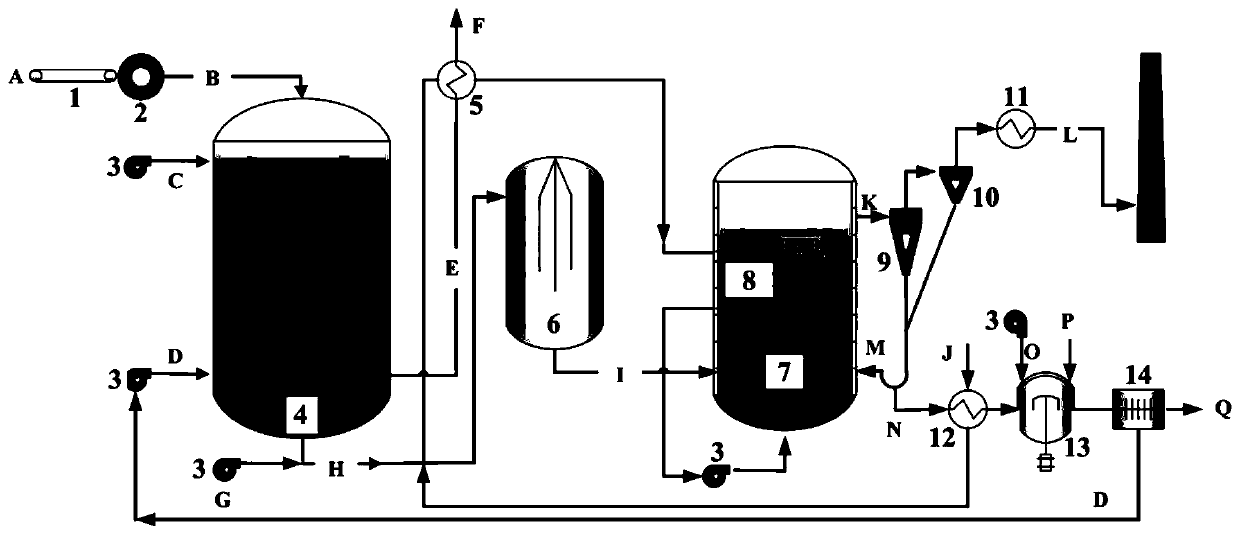

Device and method for removing CO2 from flue gas in power plant by using fly ash

ActiveCN106474912ARealize resource utilizationLow costGas treatmentDispersed particle separationCold airFluidized bed

The invention discloses a device for removing CO2 from flue gas in a power plant by using fly ash. The device comprises an activation reactor, a charging device, a fluidized bed, a cyclone separator and a waste material bin, wherein the output end of the activation reactor is connected with the charging device; the output end of the charging device is connected with the fluidized bed; the output end of the fluidized bed is connected with the cyclone separator; and the output end of the cyclone separator is connected with the waste material bin. The invention also discloses a method for removing the CO2 from the flue gas in the power plant by using the fly ash. The method comprises the following steps: conveying the fly ash into the activation reactor and carrying out activation treatment, then carrying out conveying into the charging device and carrying out charging treatment, then carrying out conveying into the fluidized bed so as to remove the CO2 in the flue gas, and finally carrying out conveying into the waste material bin. According to the invention, the device organically combines with a coal-fired power generating system; the flue gas and cold air in the coal-fired power plant can be utilized to provide a heat source and a cold source for the device; meanwhile, needed electric energy is provided for the device through a thermoelectric power generation technology; thus, an optimization scheme capable of reducing cost and energy consumption is realized.

Owner:NANJING NORMAL UNIVERSITY

Advanced oxidation reactors as well as toxic and refractory wastewater treatment devices and methods

ActiveCN106082422AImprove processing efficiencyStable fluidizationWater treatment parameter controlWater treatment compoundsFenton reactionTreatment effect

The invention belongs to the field of toxic and refractory wastewater treatment and provides advanced oxidation reactors with two structural forms and toxic and refractory wastewater treatment devices with two structural forms. Each toxic and refractory wastewater treatment device integrates three stages of reactors through coupling. The invention further provides toxic and refractory wastewater treatment methods. According to the methods, persulfate and a micro-grade microelectrolysis material are added to first-stage reactors of the wastewater treatment devices, hydrogen peroxide and persulfate are added to second-stage reactors, the micro-grade microelectrolysis material is added to second-stage reactors, and then a Fenton-like reaction, a Fenton reaction and an activated persulfate oxidization reaction are effectively coupled in the three stages of reactors; with the adoption of the methods, the wastewater treatment effect can be enhanced and improved, and the wastewater treatment cost can be reduced.

Owner:成都柏溪环境科技有限公司

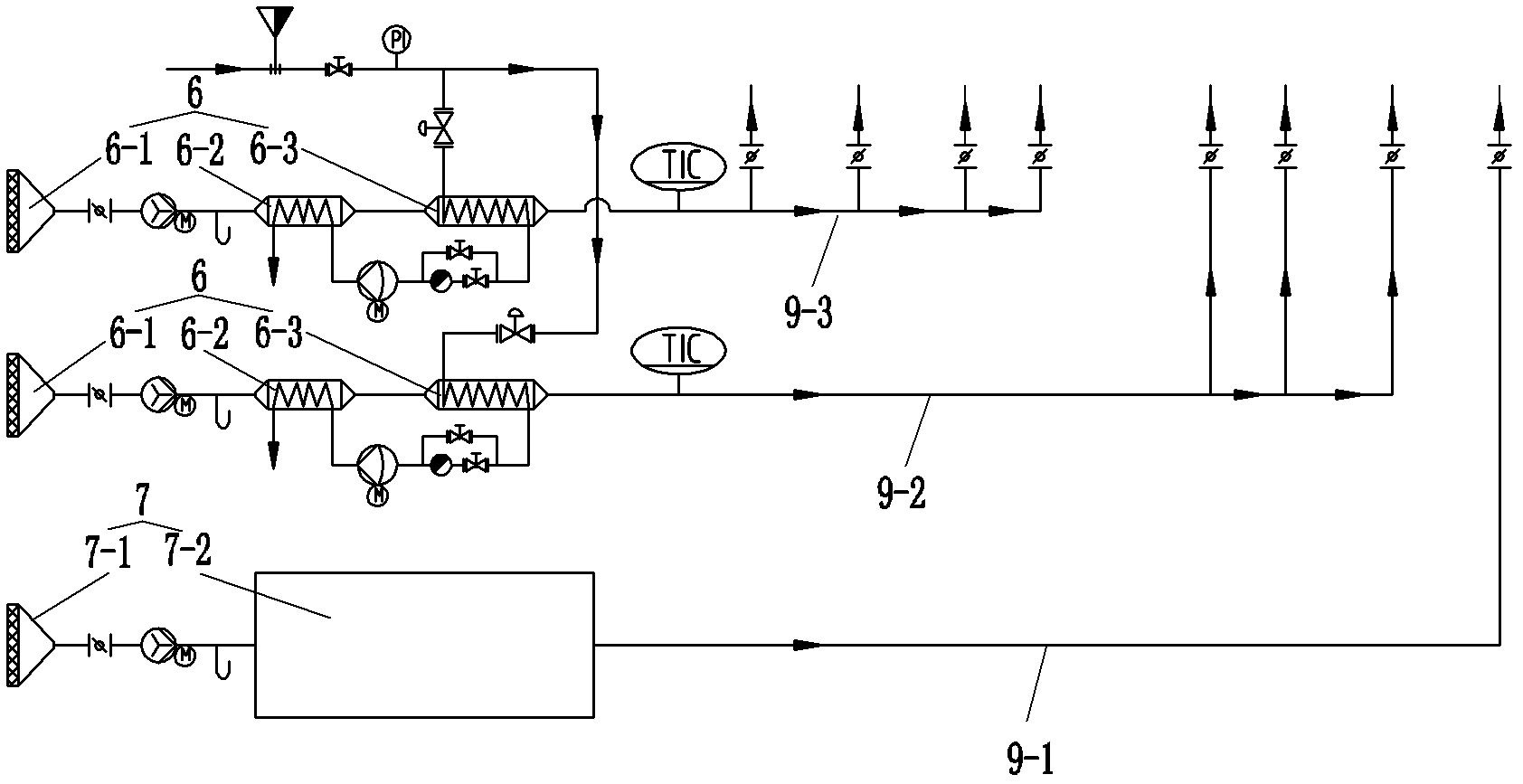

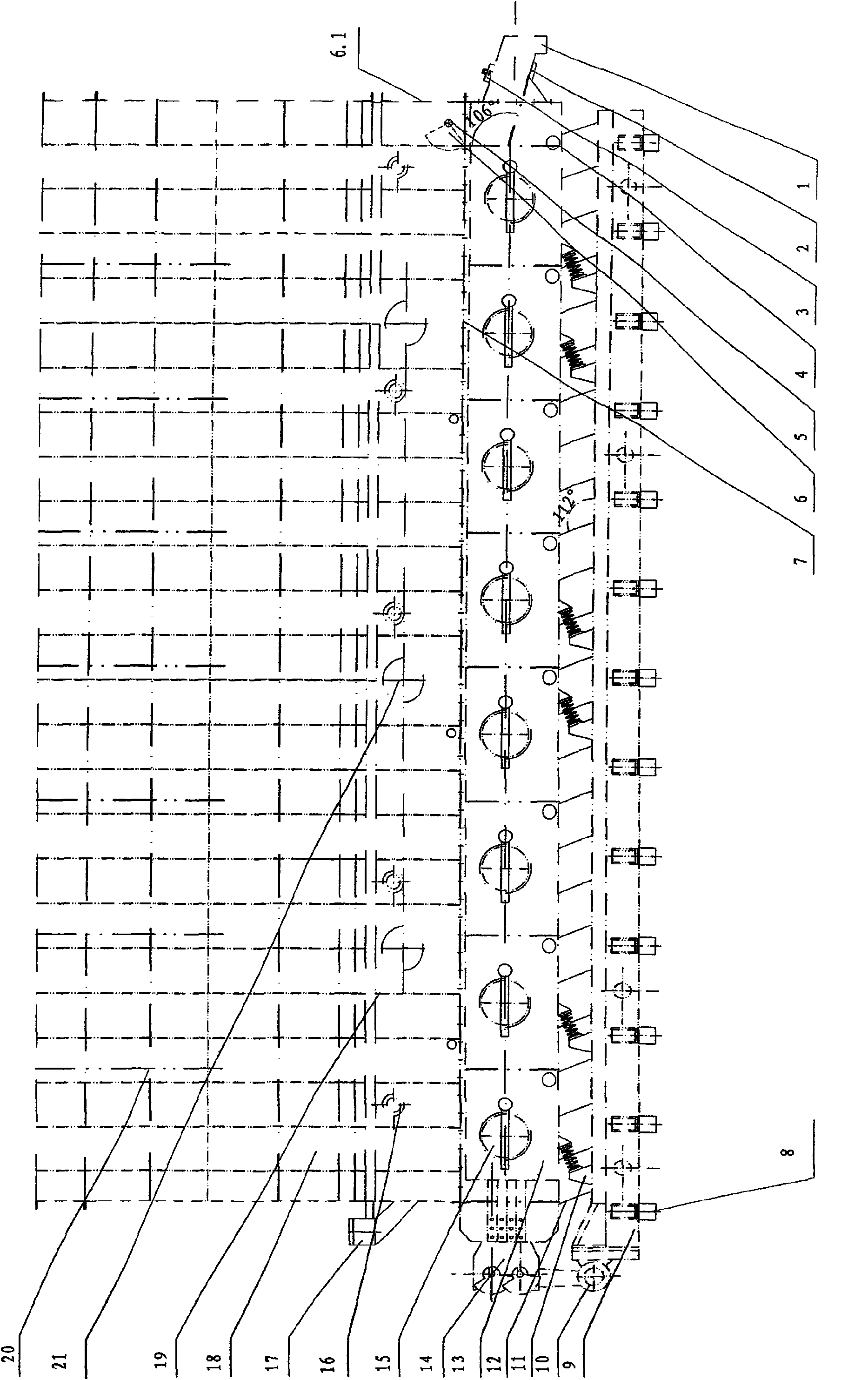

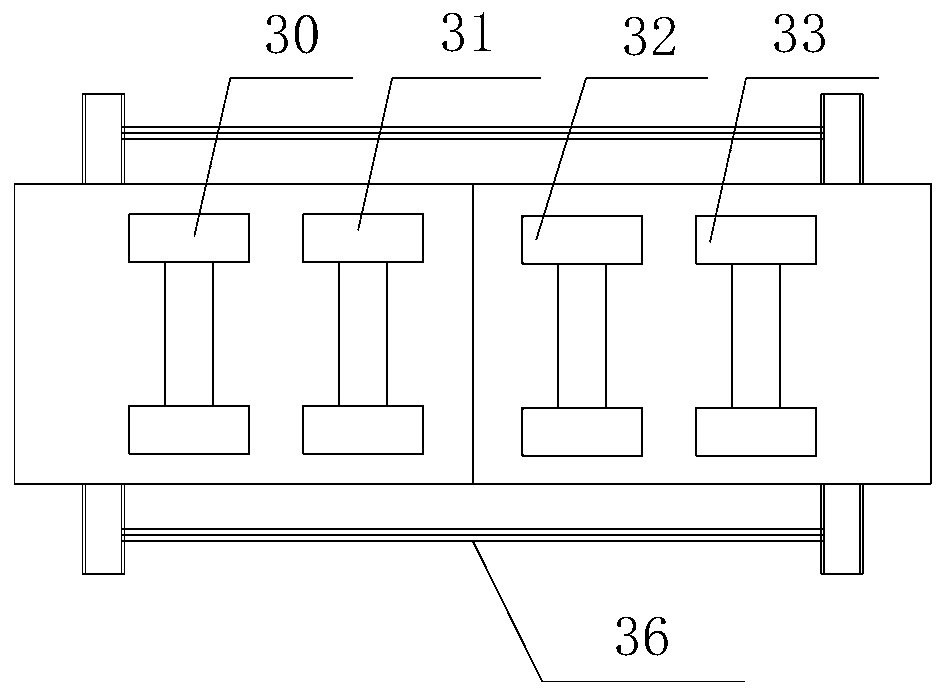

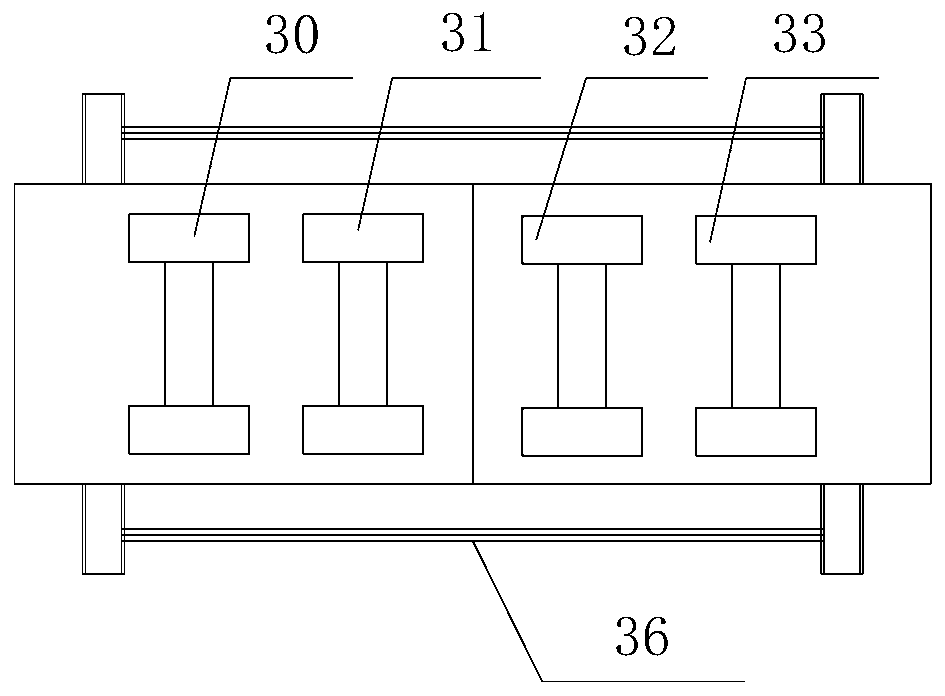

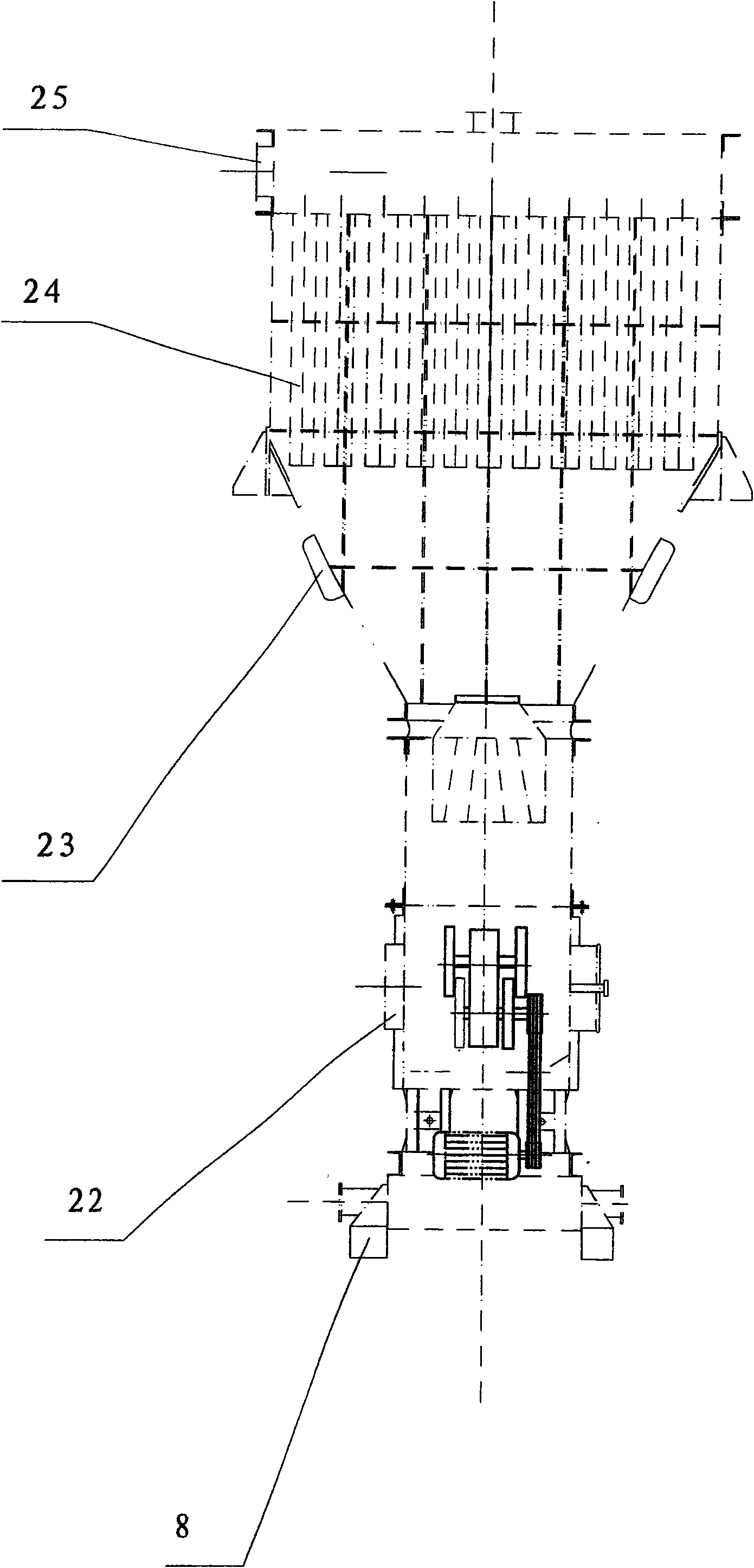

Coal variable-amplitude vibration fluidized bed drying and sorting system and sorting method

ActiveCN109731667AConvey evenlyStable deliveryDrying solid materials with heatPneumatic tablesVibration amplitudeFluidized bed drying

The invention relates to a coal variable-amplitude vibration fluidized bed drying and sorting system and a sorting method and belongs to the technical field of coal drying and sorting devices. The coal variable-amplitude vibration fluidized bed drying and sorting system is used for solving the technical problem that an existing coal drying device is poor in drying effect, and the sorting efficiency is difficult to improve. The drying and sorting system comprises a drying and sorting unit, an air supply unit, a feeding unit, a discharging unit, an induced draft dust-removing unit and a supporting unit. The air supply unit and the induced draft dust-removing unit are connected with the bottom and the top of the drying and sorting unit correspondingly. The supporting unit is used for supporting the drying and sorting unit. The drying and sorting unit is internally provided with a dividing plate and is divided into a drying section bed body and a sorting section bed body, wherein the top of the drying section bed body and the top of the sorting section bed body are provided with a drying section vibration exciting device and a sorting section vibration exciting device correspondingly,and the vibration amplitude of the drying section vibration exciting device is larger than that of the sorting section vibration exciting device. The coal variable-amplitude vibration fluidized bed drying and sorting system achieves integration of drying and sorting and has the characteristics of a good drying effect, high sorting efficiency, low cost, wide application range, convenient operationand the like.

Owner:CHINA UNIV OF MINING & TECH

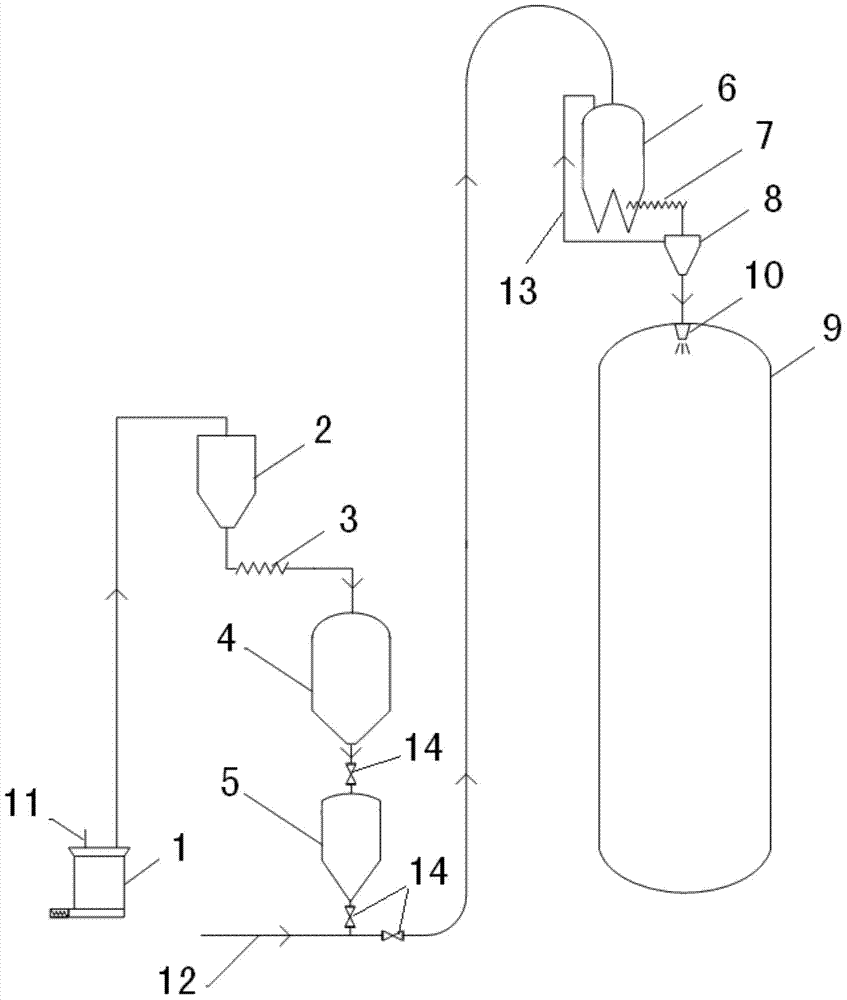

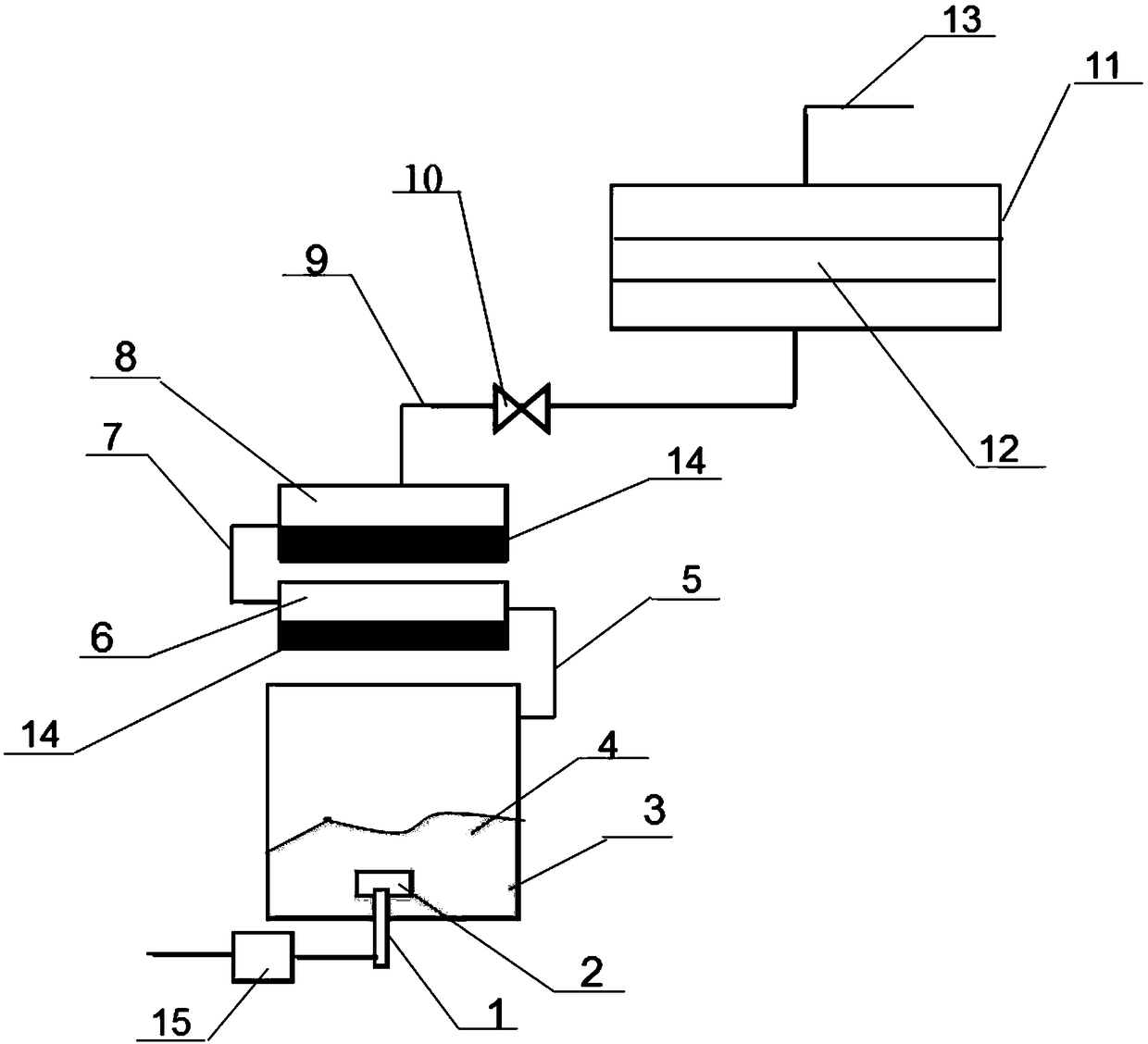

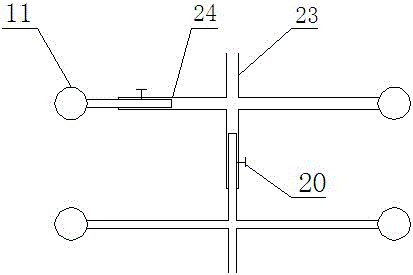

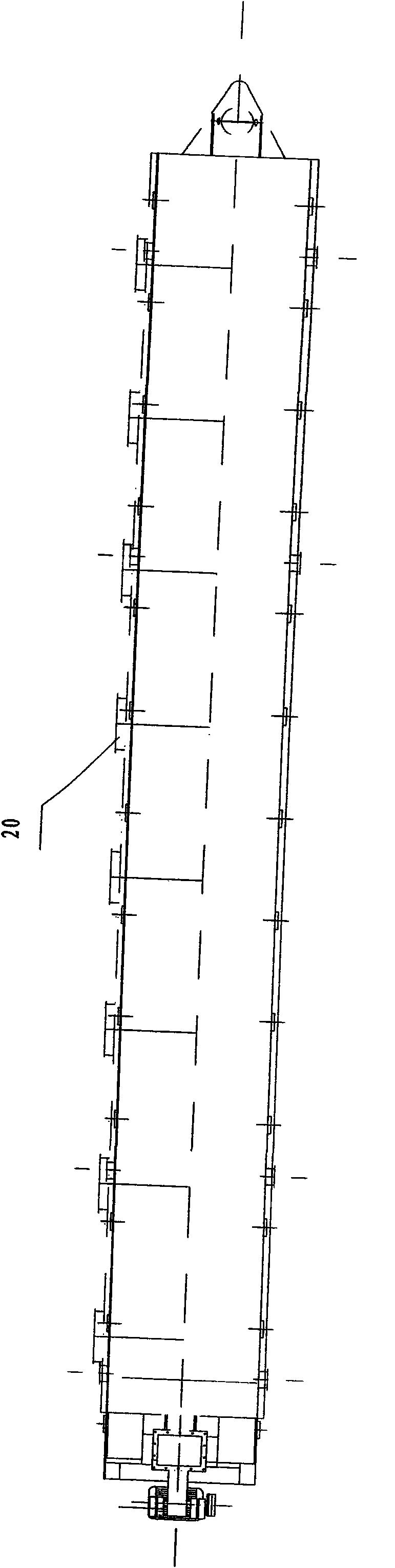

Coal powder conveying device

ActiveCN103789044BStable fluidizationFully fluidizedCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringCoal

The invention relates to a coal powder conveying device which comprises a coal grinder, wherein a raw coal inlet is formed in the coal grinder; an outlet of the coal grinder is connected with an inlet of a coal powder filter; an outlet positioned in the lower side of the coal powder filter is connected with a spiral feeder, a normal pressure cabin and a lock bucket through pipelines in sequence from top to bottom; an outlet pipeline of the lock bucket is communicated with a carrier gas pipeline and is connected with an inlet of a feeding cabin above the coal powder filter through the carrier gas pipeline; an outlet in the bottom of the feeding cabin is connected with a mechanical feeding device below the feeding cabin; an outlet positioned in the lower side of the mechanical feeding device is connected with a gas coning part and a burning nozzle of a gasification furnace through pipelines in sequence from top to bottom, and coal powder is sprayed into the gasification furnace through the burning nozzle; the burning nozzle of the gasification furnace is lower than the feeding cabin, and the lock bucket is arranged below the burning nozzle of the gasification furnace. The coal powder conveying device has the characteristics of stability in coal powder conveying, accuracy in metering, energy conservation, consumption reduction and the like, and is capable of reducing carrier gas entering the furnace.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Coal powder conveying device

ActiveCN103789044AStable fluidizationFully fluidizedCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringEngineering

The invention relates to a coal powder conveying device which comprises a coal grinder, wherein a raw coal inlet is formed in the coal grinder; an outlet of the coal grinder is connected with an inlet of a coal powder filter; an outlet positioned in the lower side of the coal powder filter is connected with a spiral feeder, a normal pressure cabin and a lock bucket through pipelines in sequence from top to bottom; an outlet pipeline of the lock bucket is communicated with a carrier gas pipeline and is connected with an inlet of a feeding cabin above the coal powder filter through the carrier gas pipeline; an outlet in the bottom of the feeding cabin is connected with a mechanical feeding device below the feeding cabin; an outlet positioned in the lower side of the mechanical feeding device is connected with a gas coning part and a burning nozzle of a gasification furnace through pipelines in sequence from top to bottom, and coal powder is sprayed into the gasification furnace through the burning nozzle; the burning nozzle of the gasification furnace is lower than the feeding cabin, and the lock bucket is arranged below the burning nozzle of the gasification furnace. The coal powder conveying device has the characteristics of stability in coal powder conveying, accuracy in metering, energy conservation, consumption reduction and the like, and is capable of reducing carrier gas entering the furnace.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Pulse fluidized bed electrode device

PendingCN109534458AFacilitates periodic dispersionAvoid stickingWater contaminantsWater/sewage treatment apparatusElectrolysisEngineering

The invention discloses a pulse fluidized bed electrode device. The structure of the pulse fluidized bed electrode device comprises a liquid supply system, a fluidized bed and an electrode system, wherein the liquid supply system is composed of a liquid storage trough, a magnetic pump, a piston pump and a rotor flow meter, the fluidized bed comprises a rectangular bed body and a pre-distributor, and a fluidized liquid outlet is formed in the side wall of the upper part of the bed body; and a material outlet is formed in the sidewall of the lower part of the bed body, and the electrode system is composed of a DC stabilizing power source, an anode plate, a cathode plate and an anode membrane. The device is suitable for electrolysis of heavy metal ion-containing wastewater, dead zones, channeling, particle bonding and other bad phenomena during fluidization are reduced or eliminated, the current efficiency and space-time efficiency of the fluidized bed electrode are improved, and the treatment cost of the heavy metal ion-containing wastewater is reduced.

Owner:SICHUAN UNIV

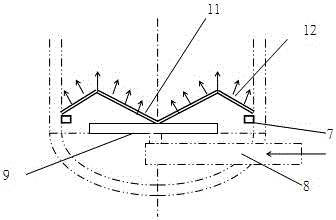

Convex airflow distribution plate and reactor thereof

ActiveCN106040105AGreat operating flexibilityStable fluidizationChemical/physical processesRefining to eliminate hetero atomsHyperboloidEngineering

The invention discloses a convex airflow distribution plate and a reactor thereof. The convex airflow distribution plate is formed by improving a flat-plate airflow distribution plate and comprises a protruding structure upwards protruding along the central axis and a bent structure formed by upwards bending the circumferential side of the convex airflow distribution plate. The protruding structure is a conical structure, a spherical structure or a protruding structure formed by inwards-concave two hyperboloids which are in symmetric arrangement. The convex airflow distribution plate is conducive to process gas entering from the bottom of the reactor to flow out through airflow holes, materials going down from the upper portion of the reactor and the process gas going up from the lower portion are enabled to contact uniformly and fully, and relatively stable air pressure is maintained; the airflow plate combines airflow balance, granular product fluidity and internal structure fatigue resistance and is simple in combined structure and convenient to mount and maintain, and a supporting member of the airflow plate is more reasonable in stress, high in stability and more safe and scientific in space layout, so that the reactor has high operation flexibility and can withdraw from reaction heat more swiftly, shell wall safety is protected, and service life is prolonged.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Fluidized bed wet-process molecular sieve device integrated with flue gas desulfurization, denitrification and dust removal functions

PendingCN108714358ACompact structureInnovative designGas treatmentDispersed particle filtrationParticulatesMolecular sieve

The invention discloses a fluidized bed wet-process molecular sieve device integrated with flue gas desulfurization, denitrification and dust removal functions, belonging to the technical field of flue gas purification. The fluidized bed wet-process molecular sieve device comprises a fluidized bed filled with a desulfurization agent, a denitrification system and a drying and dust removal chamber,wherein a smoke pipe is connected to the fluidized bed, and a heater is arranged on the smoke pipe; and a gas introduction pipe is further connected to the fluidized bed and is connected with the denitrification system, the denitrification system is connected with the drying and dust removal chamber through an air guiding pipe, a molecular sieve is arranged in the drying and dust removal chamber,and a smoke discharging pipe is further connected to the drying and dust removal chamber. The smoke enters the fluidized bed through the smoke pipe, adequately reacts with the fluidized desulfurization agent, enters the denitrification system through the air guiding pipe, adequately reacts with denitrification liquid in the denitrification system and enters the drying and dust removal chamber through the air guiding pipe, particulate matters and water in the smoke are removed through the molecular sieve in the drying and dust removal chamber, and the clean smoke is discharged out through the smoke discharging pipe. The fluidized bed wet-process molecular sieve device is compact in structure, novel in design, low in cost and environmentally friendly and has an energy-saving effect.

Owner:张俊霞

Dry slag discharge fluidized bed gasification reaction device

ActiveCN104277881BSolve the blockageImprove availabilityGasifier mechanical detailsGranular/pulverulent flues gasificationCycloneFluidized bed

The invention discloses a dry-process deslagging fluidized bed gasification reaction device which comprises a reactor body, a multi-stage cyclone separating device, an air distribution device, a feed system and a return system. The dry-process deslagging fluidized bed gasification reaction device disclosed by the invention adopts a circulating fluidized bed reactor as a gasification reaction body, realizes the dry-process deslagging by adopting medium-high temperature gasification, achieves the purpose of improving carbon transformation rate and cooled coal gas efficiency by adopting two-stage type graded gasification, enhances the operation and running stability by combining a simplified deslagging device and an air distribution plate design, is suitable for the gasification transformation of various carbon-containing solid fuels and has large-scale popularization and application prospect.

Owner:SHANGHAI BOILER WORKS

A fluidized spray drying granulator

InactiveCN104549044BExpand the atomization rangeStable fluidizationGranulation by powder suspensionTrappingMechanical engineering

The invention discloses a fluidizing and spray-drying granulator. The granulator comprises a trapping chamber, a spraying chamber, a fluidizing chamber and an air inlet chamber which are sequentially arranged from top to bottom, wherein an air inducing pipe is arranged on the side wall of the upper part of the trapping chamber and connected with an induced draft fan, a bag filter is arranged in a position where the bottom of the trapping chamber and the top of the spraying chamber are connected, a position-adjustable spraying device is arranged in the spraying chamber, a perforated fluidizing plate is arranged in a position where the bottom of the fluidizing chamber and the top of the air inlet chamber are connected, an air inlet pipe is arranged on the side wall of the lower part of the air inlet chamber, and a filter, a dehumidifier and a heater are arranged on the air inlet pipe. The spraying device and the perforated fluidizing plate are movably connected, relative positions of all spraying guns, the spraying amount, the auxiliary material amount and the aperture ratio of the perforated fluidizing plate can be adjusted according to granulation requirements, and enlargement of the liquid atomization range and stable fluidization of seed powder are realized, so that the production efficiency and the product quality are improved, and the drying energy consumption is reduced.

Owner:XIANGTAN UNIV

A Coal Variable Amplitude Vibration Fluidized Bed Drying and Separating System and Sorting Method

ActiveCN109731667BConvey evenlyStable deliveryDrying solid materials with heatPneumatic tablesFluidized bed dryingDust control

The invention relates to a coal variable-amplitude vibration fluidized bed drying and sorting system and a sorting method and belongs to the technical field of coal drying and sorting devices. The coal variable-amplitude vibration fluidized bed drying and sorting system is used for solving the technical problem that an existing coal drying device is poor in drying effect, and the sorting efficiency is difficult to improve. The drying and sorting system comprises a drying and sorting unit, an air supply unit, a feeding unit, a discharging unit, an induced draft dust-removing unit and a supporting unit. The air supply unit and the induced draft dust-removing unit are connected with the bottom and the top of the drying and sorting unit correspondingly. The supporting unit is used for supporting the drying and sorting unit. The drying and sorting unit is internally provided with a dividing plate and is divided into a drying section bed body and a sorting section bed body, wherein the top of the drying section bed body and the top of the sorting section bed body are provided with a drying section vibration exciting device and a sorting section vibration exciting device correspondingly,and the vibration amplitude of the drying section vibration exciting device is larger than that of the sorting section vibration exciting device. The coal variable-amplitude vibration fluidized bed drying and sorting system achieves integration of drying and sorting and has the characteristics of a good drying effect, high sorting efficiency, low cost, wide application range, convenient operationand the like.

Owner:CHINA UNIV OF MINING & TECH

Ultrafine particle mixing device

InactiveCN102614801BWell mixedEfficient mixingTransportation and packagingMixing methodsFluidized bedFine particulate

The invention discloses an ultrafine particle mixing device. An ultrafine particle mixing device system comprises a hopper, a spiral feeder, a Roots blower, an air chamber, a circulating fluidized bed, a cyclone dust collector, a vertical pipe, a material returning device, a bag-type dust collector and a material collector, wherein the circulating fluidized bed comprises a low speed bed, a transitional section and a high speed bed; a porous plate is arranged at the upper part of the air chamber as an air distribution plate; and the bag-type dust collector is connected with the cyclone dust collector. Ultrafine particles and auxiliary fluidized particles are available in the low speed bed. The auxiliary fluidized particles are added to the low speed bed through an auxiliary fluidized particle storage bin. The number of the types of the ultrafine particles is not less than two. The particle sizes of the ultrafine particles are less than 100 microns. The Roots blower supplies inert fluidizing gas which does not react with the ultrafine particles. The particle sizes of the auxiliary fluidized particles are more than 100 microns and less than 100 mm. A feeding device is the spiral feeder.

Owner:SOUTHEAST UNIV

Combined fluidized bed slag cooling apparatus

ActiveCN101476721BImprove mobilityWell mixedFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

Owner:EASTERN BOILER CONTROL CO LTD

Granulating, fluidizing and drying system

InactiveCN102645088BImprove protectionStable fluidizationDrying solid materials with heatMaterial granulationEngineeringCrusher

A granulating, fluidizing and drying system is provided with a vibration fluidizing machine, a granulating machine, a cyclone separator, a water film dust remover, a crusher, a heating device and a cooling device. A ventilation area on a bed plate of the vibration fluidizing machine is formed by connecting round unit ventilation areas which are arranged in a line. A screening device is arranged at the tail end of the bed plate, air holes at the middle square positions of the unit ventilation areas on the bed plate are straight holes, and air holes on four bow-shaped parts of the unit ventilation areas on the bed plate are scale holes. The air outlet direction of the scale holes on two bow-shaped parts on the front part in each unit ventilation area is towards a box wall, and the air outlet direction of the scale holes on two bow-shaped parts on the rear part in each unit ventilation area is towards the connection position of two unit ventilation areas. Air inlet tubes corresponding to the unit ventilation areas one by one are arranged in an air chamber. The granulating, fluidizing and drying system can integrally achieve granulation, drying, cooling and screening, has high efficiency, treats exhausted tail gas, and is favorable for environment protection. By means of a special shape of the bed plate and the distribution of the air holes, fluidization of the vibration fluidizing machine is stable and free of dead corners.

Owner:CHANGZHOU LEMAR DRYING ENG

Device and method for removing CO2 from power plant flue gas with fly ash

ActiveCN106474912BRealize resource utilizationLow costGas treatmentDispersed particle separationCold airFluidized bed

The invention discloses a device for removing CO2 from flue gas in a power plant by using fly ash. The device comprises an activation reactor, a charging device, a fluidized bed, a cyclone separator and a waste material bin, wherein the output end of the activation reactor is connected with the charging device; the output end of the charging device is connected with the fluidized bed; the output end of the fluidized bed is connected with the cyclone separator; and the output end of the cyclone separator is connected with the waste material bin. The invention also discloses a method for removing the CO2 from the flue gas in the power plant by using the fly ash. The method comprises the following steps: conveying the fly ash into the activation reactor and carrying out activation treatment, then carrying out conveying into the charging device and carrying out charging treatment, then carrying out conveying into the fluidized bed so as to remove the CO2 in the flue gas, and finally carrying out conveying into the waste material bin. According to the invention, the device organically combines with a coal-fired power generating system; the flue gas and cold air in the coal-fired power plant can be utilized to provide a heat source and a cold source for the device; meanwhile, needed electric energy is provided for the device through a thermoelectric power generation technology; thus, an optimization scheme capable of reducing cost and energy consumption is realized.

Owner:NANJING NORMAL UNIVERSITY

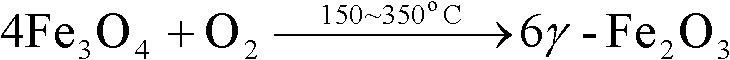

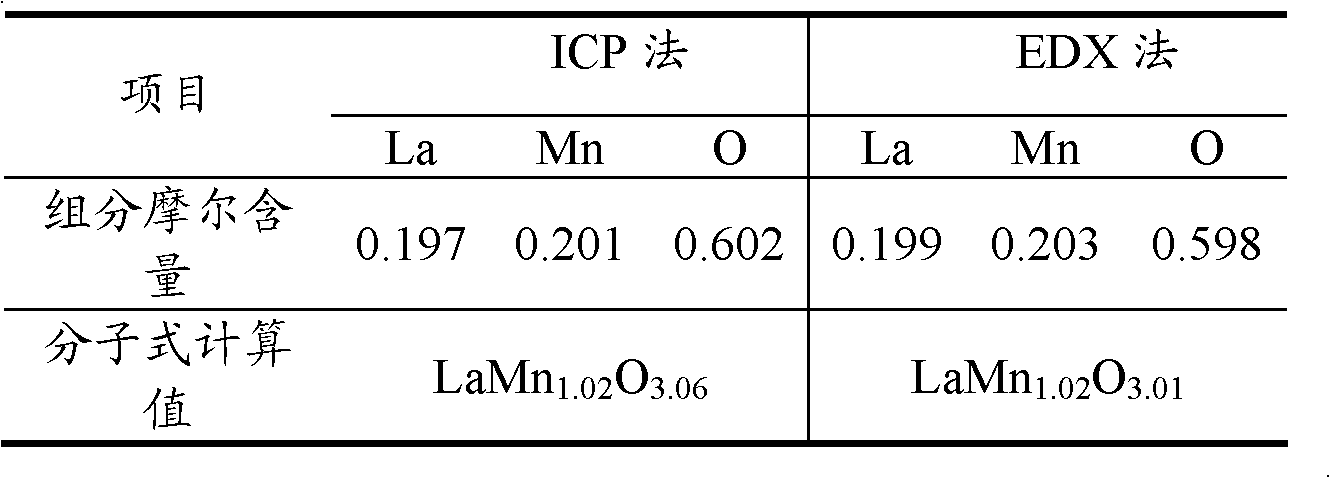

Magnetic catalyst for denitration of NH3-SCR smoke and application thereof

ActiveCN102019188BStable fluidizationHigh surface energyNitrous oxide captureDispersed particle separationActive componentReaction temperature

The invention discloses a magnetic catalyst for denitration of NH3-SCR smoke. The NH3-SCR active component of the catalyst is magnetic iron oxide; and a carrier is perovskite type lanthanum-manganese metal oxide composite or lanthanum of which lanthanum and manganese are partially replaced by alkali metal and transition metal. The invention also discloses application of the catalyst in denitration of NH3-SCR smoke. A magnetic fluid bed reactor with coupling magnetic induction of 0.01-0.1 T is adopted to add the magnetic catalyst at an air speed of 4,000-6,000 h-1; and high NH3-SCR reaction activity is always shown under the conditions that the NH3 / NO molar ratio is 1.0-1.3, the O2 content is 2-12% and a relatively wide range of reaction temperature is from 200 DEG C to 400 DEG C, and the denitration is over 80%. Due to relatively wide range of reaction temperature, various dedusting ways are available for the catalyst, and the method is NH3-SCR technology suitable for low and medium temperature.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Advanced oxidation reactor and toxic refractory wastewater treatment device and treatment method

ActiveCN106082422BImprove processing efficiencyStable fluidizationWater treatment parameter controlWater treatment compoundsFenton reactionThree stage

The invention belongs to the field of toxic and refractory wastewater treatment and provides advanced oxidation reactors with two structural forms and toxic and refractory wastewater treatment devices with two structural forms. Each toxic and refractory wastewater treatment device integrates three stages of reactors through coupling. The invention further provides toxic and refractory wastewater treatment methods. According to the methods, persulfate and a micro-grade microelectrolysis material are added to first-stage reactors of the wastewater treatment devices, hydrogen peroxide and persulfate are added to second-stage reactors, the micro-grade microelectrolysis material is added to second-stage reactors, and then a Fenton-like reaction, a Fenton reaction and an activated persulfate oxidization reaction are effectively coupled in the three stages of reactors; with the adoption of the methods, the wastewater treatment effect can be enhanced and improved, and the wastewater treatment cost can be reduced.

Owner:成都柏溪环境科技有限公司

Three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer

InactiveCN101598484BStable fluidizationStable deliveryDrying solid materials with heatHearth type furnacesSolenoid valveGranularity

The invention relates to a three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer which is suitable for drying powder material of regular shape such as Laroflex MP with granularity ranging from 50mu m to 5000mu m. The drier comprises a foundation (9), a lower housing (13), a fluidized bed body (6), an upper housing (18) and a bag type dust collector (24); wherein the lower housing (13) is supported on the foundation (9) by a slantly arranged plate spring (12), a case type vibration exciter (14) is arranged at the front end of the lower housing (13), the fluidized bed body (6) is arranged above the lower housing (13) and internally provided with a hood-shaped fluidized bed plate (7), the upper housing (18) is arranged above the fluidized bed body (6) and internally provided with a plurality of groups of bag type dust collectors (24). An air-reserve tank (24.6) is arranged outside the upper housing (18), a plurality of air branch pipes (24.3) are internally arranged in the air-reserve tank (24.6), wherein each air branch pipe (24.3) is provided with a pulse solenoid valve (24.5), the bottom part thereof is provided with an air source hole (24.7). The drier of the invention features low energy consumption, high production efficiency, good operation stability and good uniformity of products.

Owner:江阴丰力生化工程装备有限公司

A system and method for rice husk gasification coupled with sodium silicate to capture carbon dioxide from power plant flue gas

ActiveCN107983111BEfficient use ofSavings on decarbonization costsProductsGas treatmentPhysicsCoal fired power stations

Owner:NANJING NORMAL UNIVERSITY

Ramjet system

ActiveCN114033574AImprove clippingControl flowTurbine/propulsion fuel supply systemsRam jet enginesSonic nozzleRamjet

The invention relates to the technical field of aerospace, in particular to a ramjet system. The ramjet system comprises a fuel supply mechanism, a combustion mechanism and an ejection mechanism which are sequentially communicated, wherein the fuel supply mechanism comprises a first shell, and the first shell is internally provided with a gas supply unit with a gas supply part, a solid supply unit with a solid supply part and an injector communicated with the solid supply unit; a conduction gap is formed between the gas supply part and the solid supply part; and the conduction gap is used for guiding gas in the gas supply part into the solid supply part. According to the invention, carbon dioxide fluidizing gas accelerates at the conduction gap to the maximum speed and enters the solid supply part, the conduction gap at the moment is equivalent to a sonic nozzle, on the one hand, the flow of the carbon dioxide fluidizing gas can be controlled, on the other hand, the speed of the carbon dioxide fluidizing gas is increased, the shearing capacity of the carbon dioxide fluidizing gas is improved, stable supply of the carbon dioxide fluidizing gas and magnesium powder is guaranteed, and the fluidizing effect is better.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com