Fluidized bed wet-process molecular sieve device integrated with flue gas desulfurization, denitrification and dust removal functions

A desulfurization, denitrification, and fluidized bed technology, applied in the field of flue gas purification, can solve the problems of fine particle pollution, damage to air quality, large capital investment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

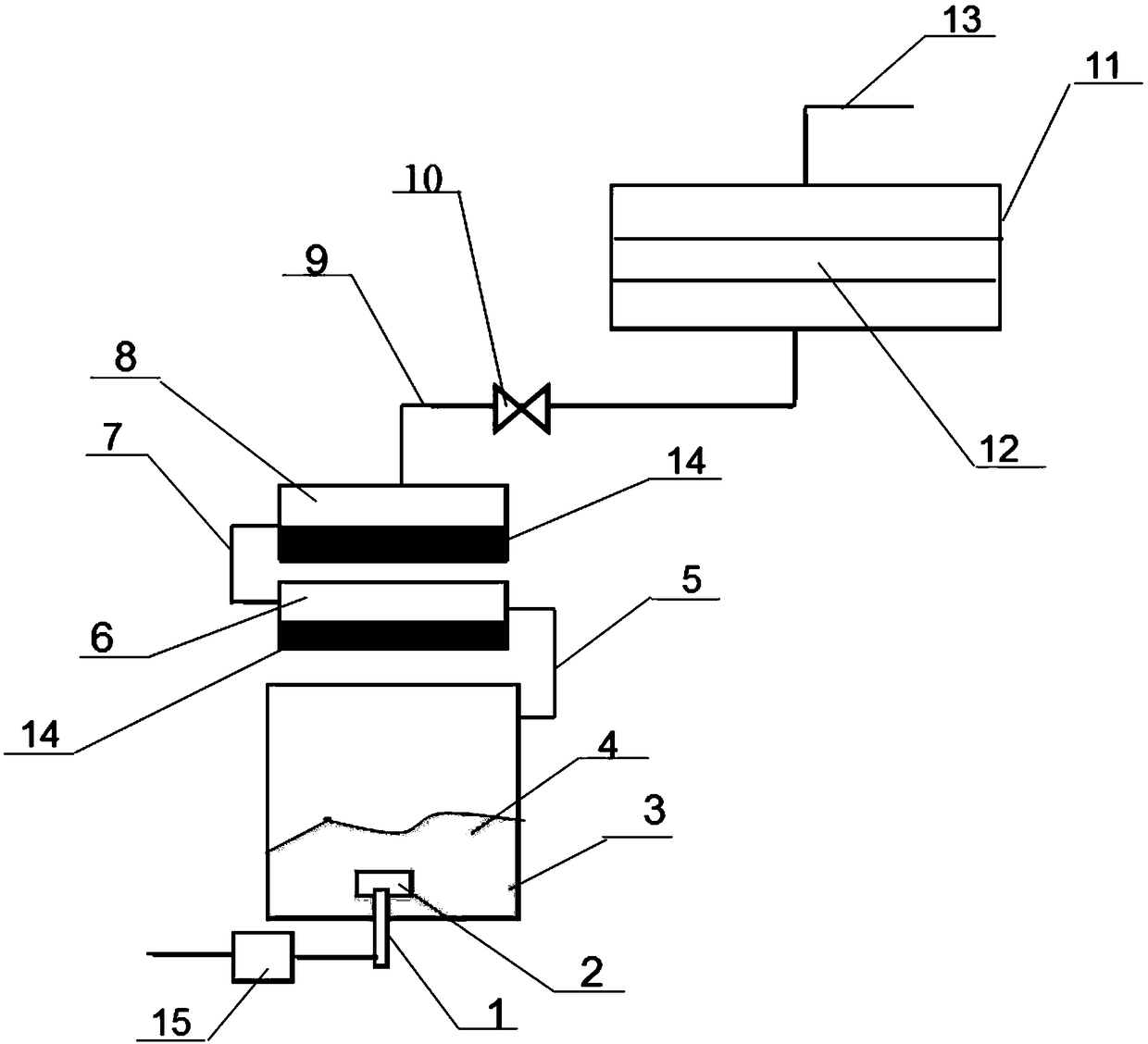

[0029] see figure 1 , is a fluidized bed wet molecular sieve device for collecting flue gas desulfurization, denitrification and dust removal of the present invention, the fluidized bed 3 is connected with a flue gas pipe 1, and the desulfurizing agent 4 in the fluidized bed 3 preferably uses lime slurry powder, and in the flue gas The pipe is provided with a heater 15, a flow rate meter and a control valve; the fluidized bed 3 is preferably made of heat-resistant cast steel hood 2 as an air distribution device, and the fluidized bed 3 is also connected with an air-introduction pipe 5 made of an acid-resistant alloy. 5 is connected with the denitration system, and the denitration system is filled with denitration liquid 14, and the proportion of nitrite in the denitration liquid is about 12%.

[0030] The denitrification system preferably adopts a multi-stage denitrification system: including a first-stage denitrification pipe 6, a second-stage denitrification pipe 8, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com