Granulating, fluidizing and drying system

A technology of fluidized drying and granulation, which is applied in the directions of drying solid materials, heating to dry solid materials, and granulating raw materials. It can solve problems such as complex structures and achieve high efficiency, environmental protection, and no dead ends. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

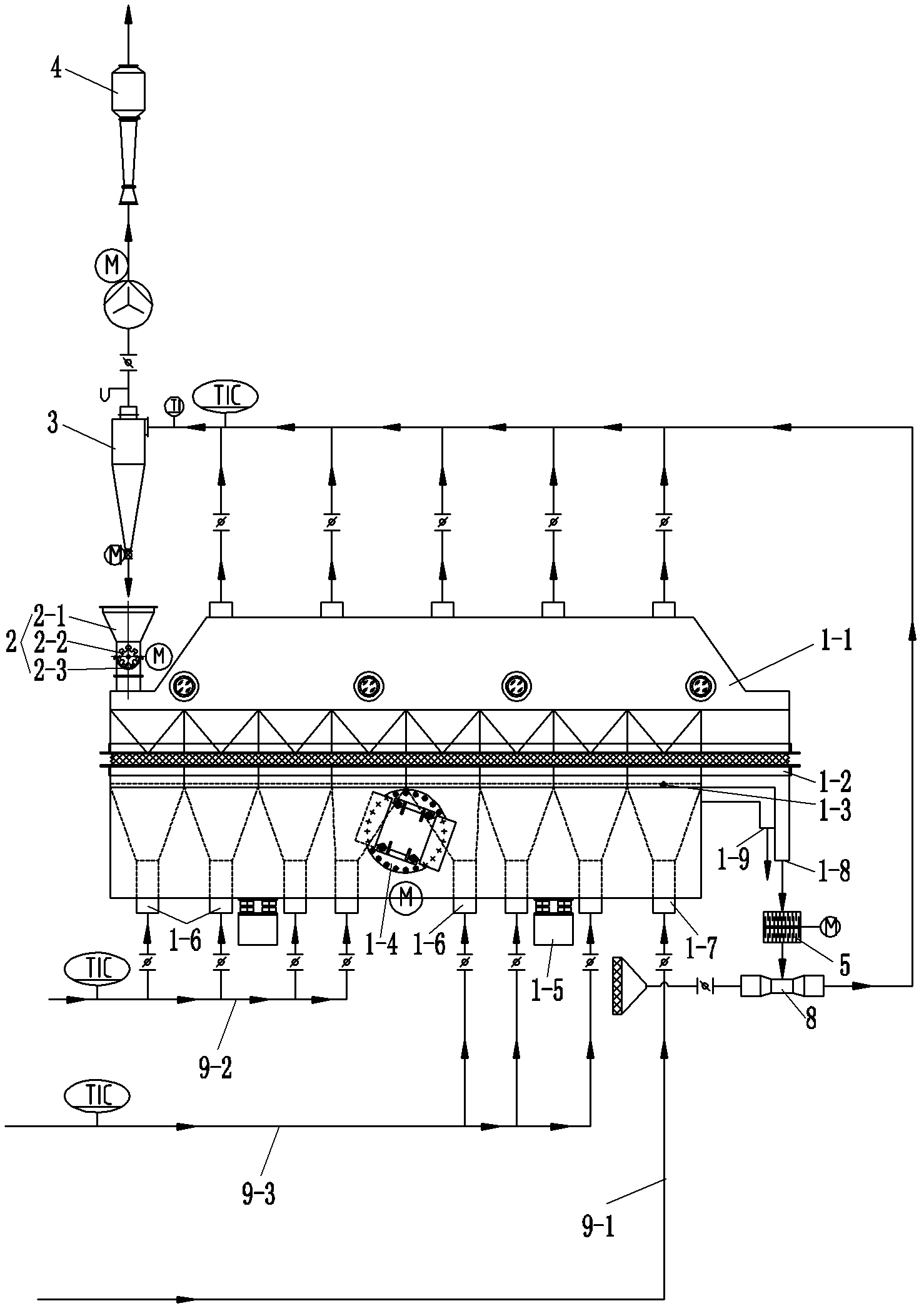

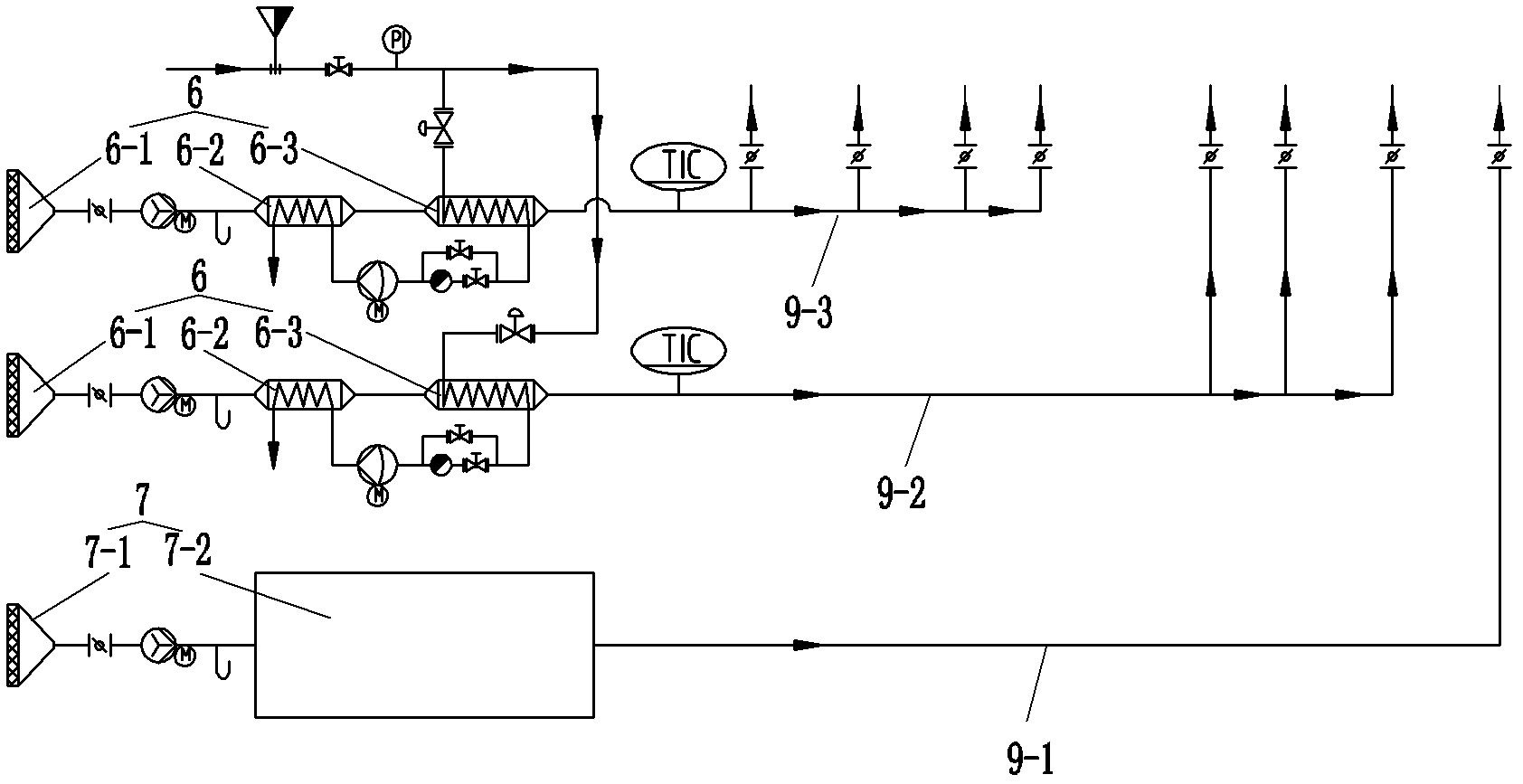

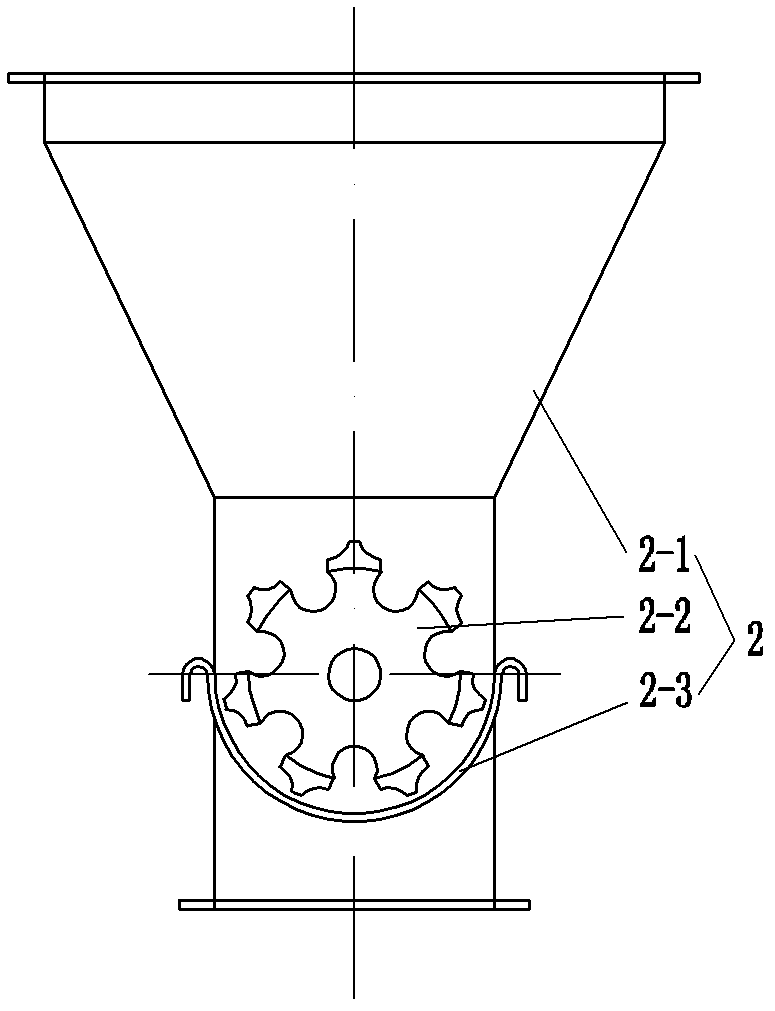

[0017] See Figure 1 to Figure 4 , This embodiment has a vibrating fluidizer 1, a granulator 2, a cyclone separator 3, a water film dust collector 4, a crusher 5, a heating device 6 and a cooling device 7.

[0018] The vibrating fluidizer 1 includes an upper cover 1-1, a casing 1-2, a bed board 1-3 and a vibrating motor 1-4 connected to the casing 1-2. The upper cover 1-1 is fixed by a bracket, and the casing 1 -2 is supported by the shock absorber 1-5, the upper cover 1-1 is softly connected with the box body 1-2, and the bottom of the bed board 1-3 is an air chamber. The end of described bed board 1-3 has sifter 1-3b (see Figure 4 ), the flange part 1-3c is surrounded by the bed board 1-3. A coarse particle outlet 1-8 and a finished product outlet 1-9 are respectively provided on the box body 1-2 below the sifter 1-3b. When the vibration motor starts, the upper cover 1-1 does not participate in the vibration.

[0019] The ventilation area on the bed board 1-3 of the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com