Convex airflow distribution plate and reactor thereof

A gas distribution plate and gas distribution technology, applied in chemical instruments and methods, refining to remove heteroatoms, chemical/physical processes, etc., can solve the imbalance of circumferential flow state and axial flow state, and cannot form a three-dimensional bed overall circulation, The force of the circular plate is worse than that of the shell, so that there is no dead zone, the space layout is safe and scientific, and the effect of protecting the shell wall is safe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

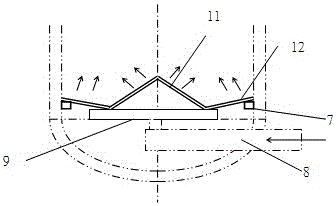

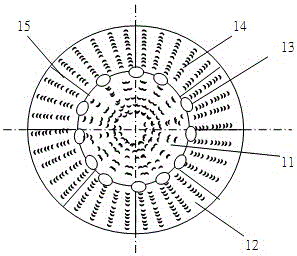

[0039] One of the specific implementations of a convex air distribution plate of the present application, refer to figure 1 and figure 2 As shown, it is formed by the improvement of a flat airflow distribution plate. The innovation of the present application is that the convex airflow distribution plate 10 includes a convex structure 11 protruding upward along the central axis of the convex airflow distribution plate 10 , and a bent structure 12 formed by bending the peripheral side of the convex air distribution plate 10 upward.

[0040] Specifically, the protruding structure 11 is a conical structure. The convex air flow distribution plate 10 is composed of a convex mechanism in the middle and a bending structure 12 on the peripheral side to form a similar convex air flow distribution plate. Studies have shown that the similar convex structure has radial elasticity and can adapt to the deformation of the reactor. Displacement without being distorted and deformed, so its p...

Embodiment 2

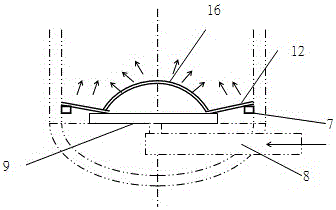

[0051] The second specific embodiment of a convex airflow distribution plate of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment adopt the explanation in embodiment 1, here No further details will be given. refer to image 3 As shown, the difference between this embodiment and Embodiment 1 is that, wherein, the protruding structure 11 is a spherical structure 16 . It can make the process gas flow upwards evenly in the reactor, and at the same time make the generated material particle products collect and discharge from the bottom through the convex air distribution plate, and can also resist vibration fatigue caused by large material flow and fast air velocity. An anti-sediment distribution plate that satisfies pressure drop stability and good fluidization quality.

Embodiment 3

[0053] The third embodiment of a convex airflow distribution plate of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment adopt the explanation in embodiment 1, here No further details will be given. refer to Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that, wherein, the protruding structure 11 is a protruding structure 17 composed of symmetrically arranged concave hyperboloids. It can make the process gas flow upwards evenly in the reactor, and at the same time make the generated material particle products collect and discharge from the bottom through the convex air distribution plate, and can also resist vibration fatigue caused by large material flow and fast air velocity. An anti-sediment distribution plate that satisfies pressure drop stability and good fluidization quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com