Advanced oxidation reactors as well as toxic and refractory wastewater treatment devices and methods

A technology for advanced oxidation and wastewater treatment, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve problems such as improvement, increased operating costs, unfavorable wastewater treatment efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

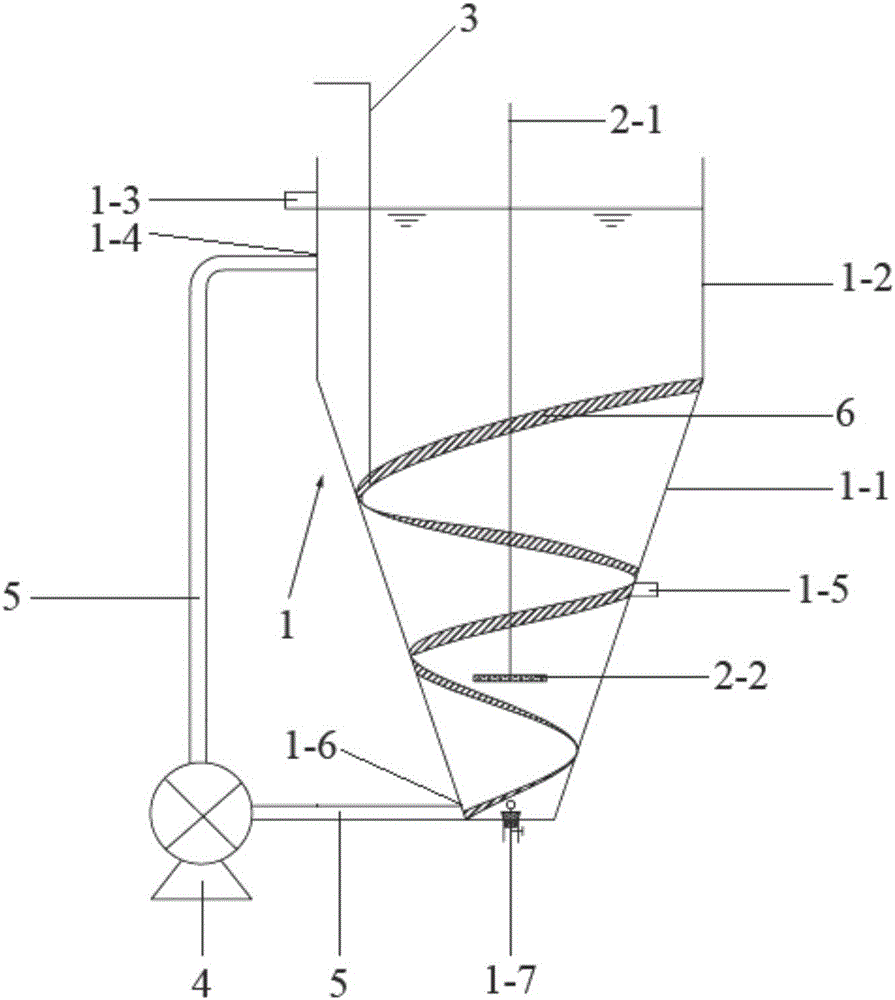

[0063] Embodiment 1: the advanced oxidation reactor of the first structural form

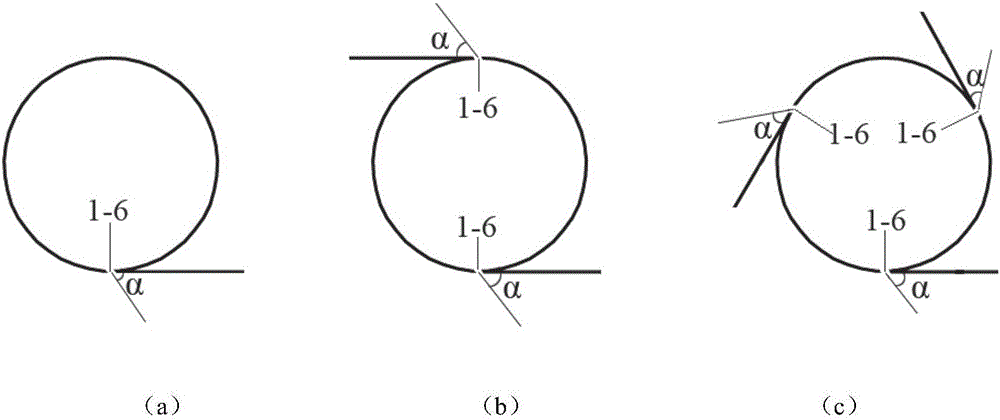

[0064] In this example, the structural schematic diagram of the advanced oxidation reactor is as follows figure 1 As shown, the reactor includes a reaction tank 1, a return pump 4, a return pipe 5, an aeration element installed in the reaction tank, a first dosing pipe 3, and a deflector 6, and the aeration element is formed by an air guide pipe 2 -1 and aeration head 2-2,

[0065] Described reaction tank 1 is made up of truncated conical body 1-1 and cylindrical body 1-2 that small end is closed, big end is open, and the internal diameter of large end of truncated conical body is equal to the internal diameter of cylindrical body, and truncated conical body 1 The large end of -1 is connected with the lower end of the cylindrical body 1-1, the ratio of the inner diameter of the large end to the small end of the frusto-conical cylindrical body 1-1 of the reaction tank is 3:1, and the height of t...

Embodiment 2

[0068] Embodiment 2: the advanced oxidation reactor of the first structural form

[0069] In this example, the structural schematic diagram of the advanced oxidation reactor is as follows figure 1 As shown, the reactor includes a reaction tank 1, a return pump 4, a return pipe 5, an aeration element installed in the reaction tank, a first dosing pipe 3, and a deflector 6, and the aeration element is formed by an air guide pipe 2 -1 and aeration head 2-2,

[0070] Described reaction tank 1 is made up of truncated conical body 1-1 and cylindrical body 1-2 that small end is closed, big end is open, and the internal diameter of large end of truncated conical body is equal to the internal diameter of cylindrical body, and truncated conical body 1 The large end of -1 is connected with the lower end of the cylindrical body 1-1, the ratio of the inner diameter of the large end to the small end of the frusto-conical cylindrical body 1-1 of the reaction tank is 4:1, and the height of t...

Embodiment 3

[0073] Embodiment 3: the advanced oxidation reactor of the second structural form

[0074] In this example, the structural schematic diagram of the advanced oxidation reactor is as follows figure 2 As shown, the reactor includes a reaction tank 1, a return pump 4, a return pipe 5, an aeration element installed in the reaction tank and a first dosing pipe 3, a deflector 6, an outlet weir 7 and an annular baffle 8, The aeration element is composed of an air duct 2-1 and an aeration head 2-2,

[0075] Described reaction tank 1 is made up of truncated conical body 1-1 and cylindrical body 1-2 that small end is closed, big end is open, and the internal diameter of large end of truncated conical body is equal to the internal diameter of cylindrical body, and truncated conical body 1 The large end of -1 is connected with the lower end of the cylindrical body 1-1, the ratio of the inner diameter of the large end to the small end of the frusto-conical cylindrical body 1-1 of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com