Dry slag discharge fluidized bed gasification reaction device

A fluidized bed gasification and reaction device technology, which is applied in the mechanical details of gasification devices, granular/powdered fuel gasification, and combustible gas production. , high repair and maintenance costs, etc., to achieve stable dry slag discharge effect, easy to scale up, and stable fluidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

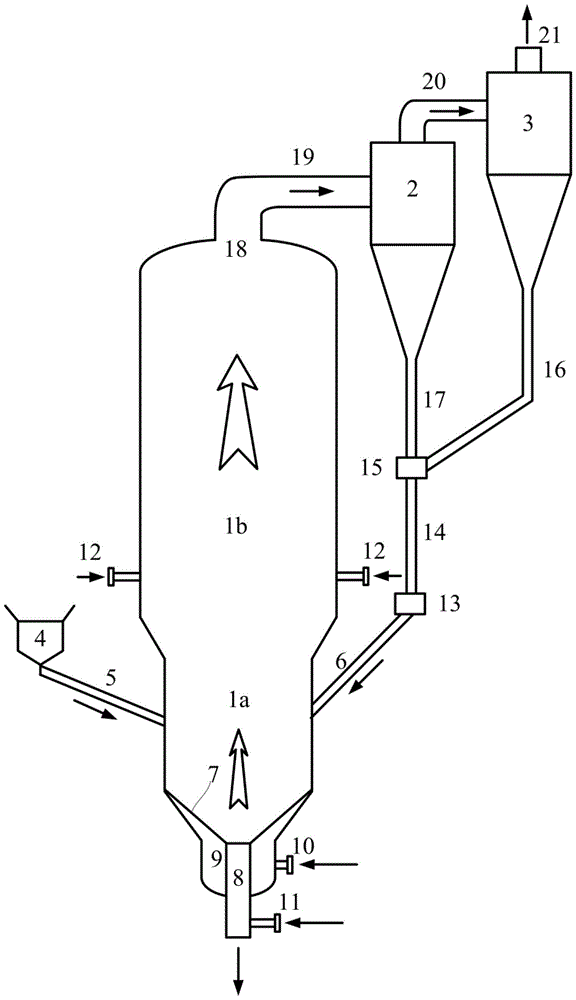

[0050] Take a fluidized bed gasification reactor with a daily processing capacity of 720 tons of lignite as an example. The coal quality data of fuel coal are shown in Table 1. The design parameters of the gasification reaction device are as follows:

[0051] Operating pressure: 0.5MPaG;

[0052] Operating temperature: 1000°C;

[0053] Gasification agent: pure oxygen and water vapor;

[0054] Fuel particle size: 0~10mm, average particle size 6mm;

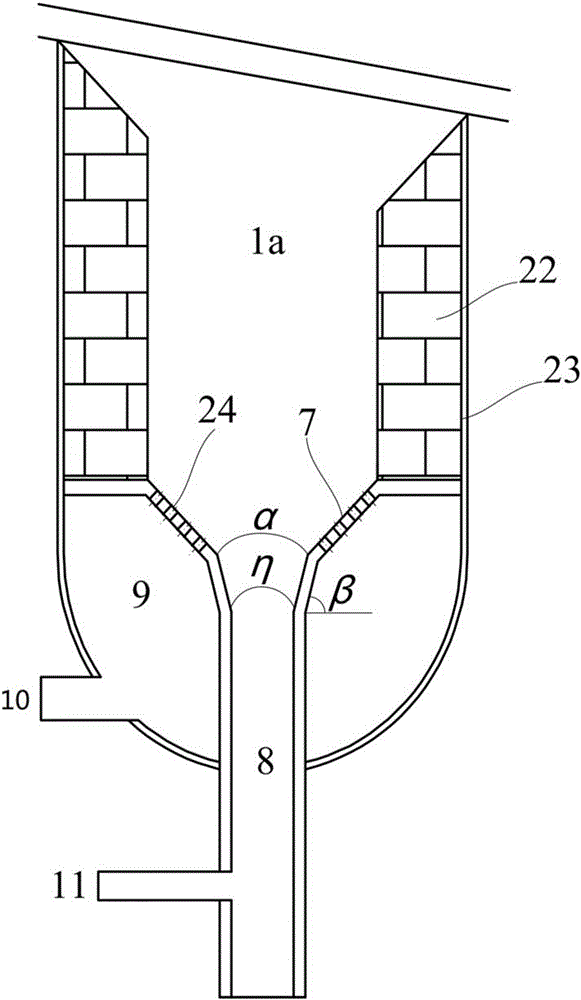

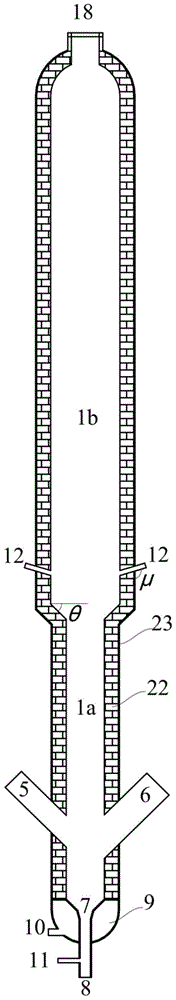

[0055] Reactor structure: the diameter of the gasification chamber in the lower section is 1.1m, and the height is 8m; the diameter of the gasification chamber in the upper section is 2.1m, and the height is 15m;

[0056] Cycle ratio: 30;

[0057] Gasification agent distribution: 65% of the central slag discharge pipe, 25% of the air distribution plate, and 10% of the second-stage burner chamber;

[0058] Slagging temperature: 900°C;

[0059] Superficial velocity of cross-section inside the reactor: 3.2m / s.

[0060] Table 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com