Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Smooth temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

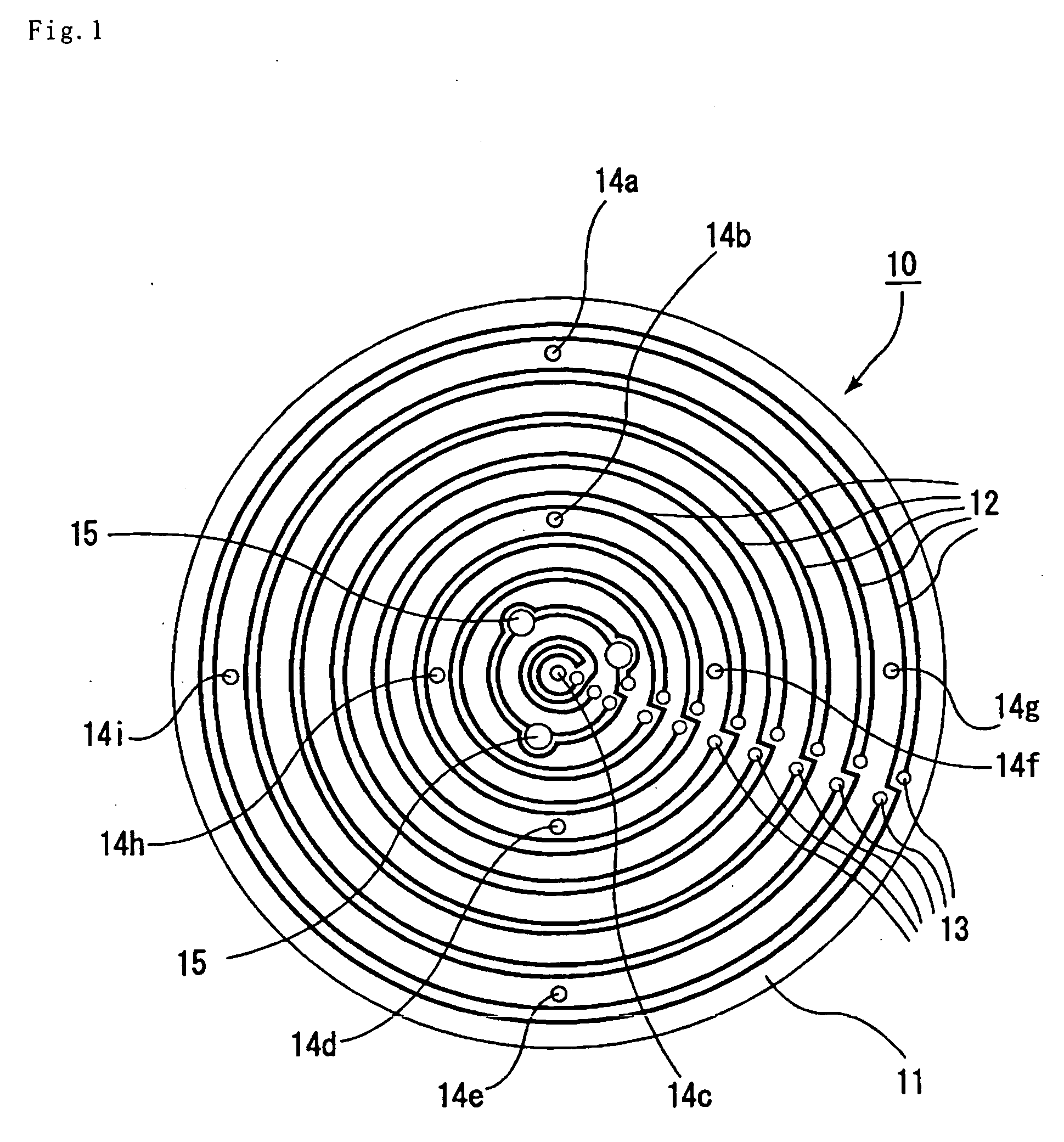

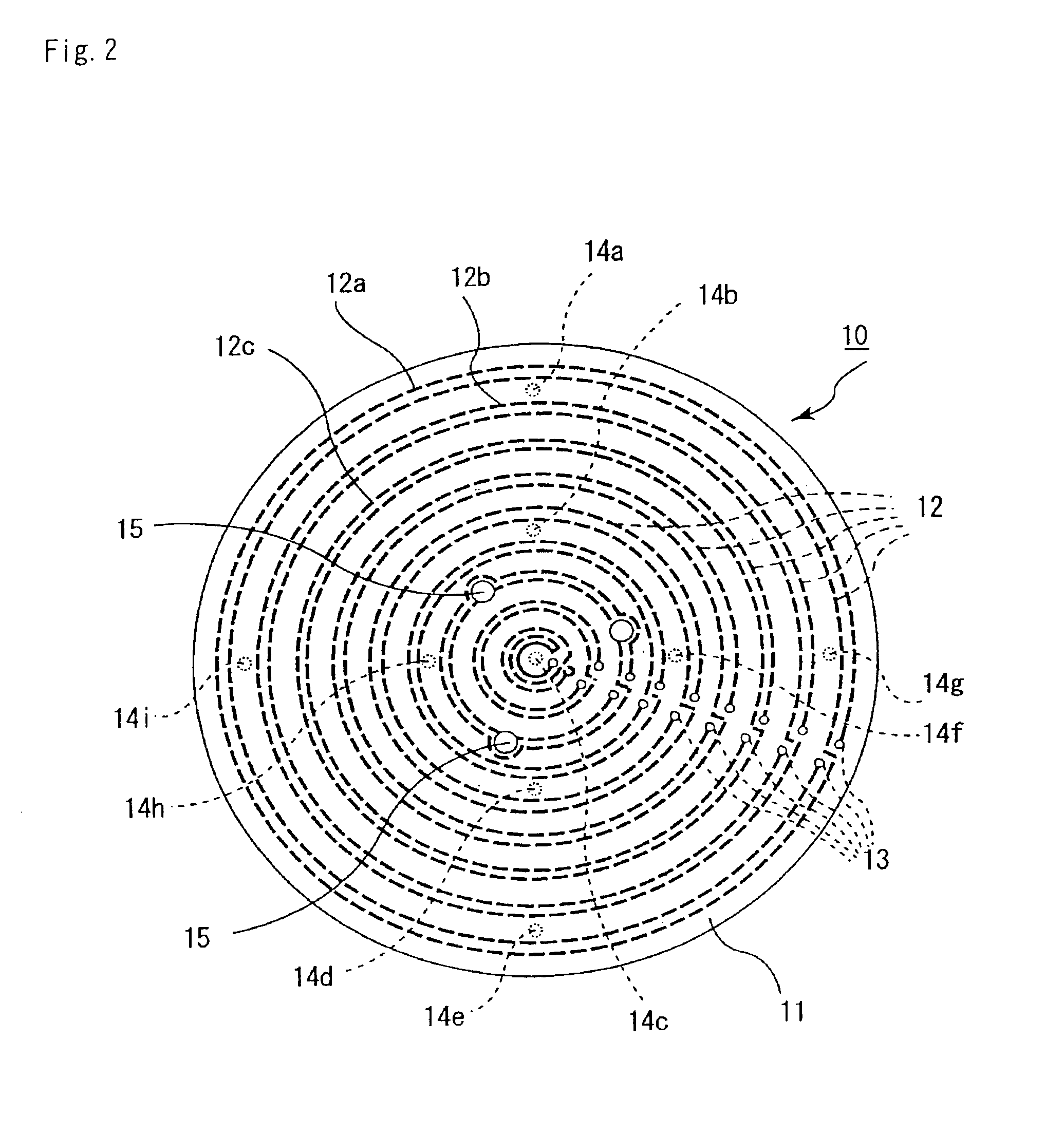

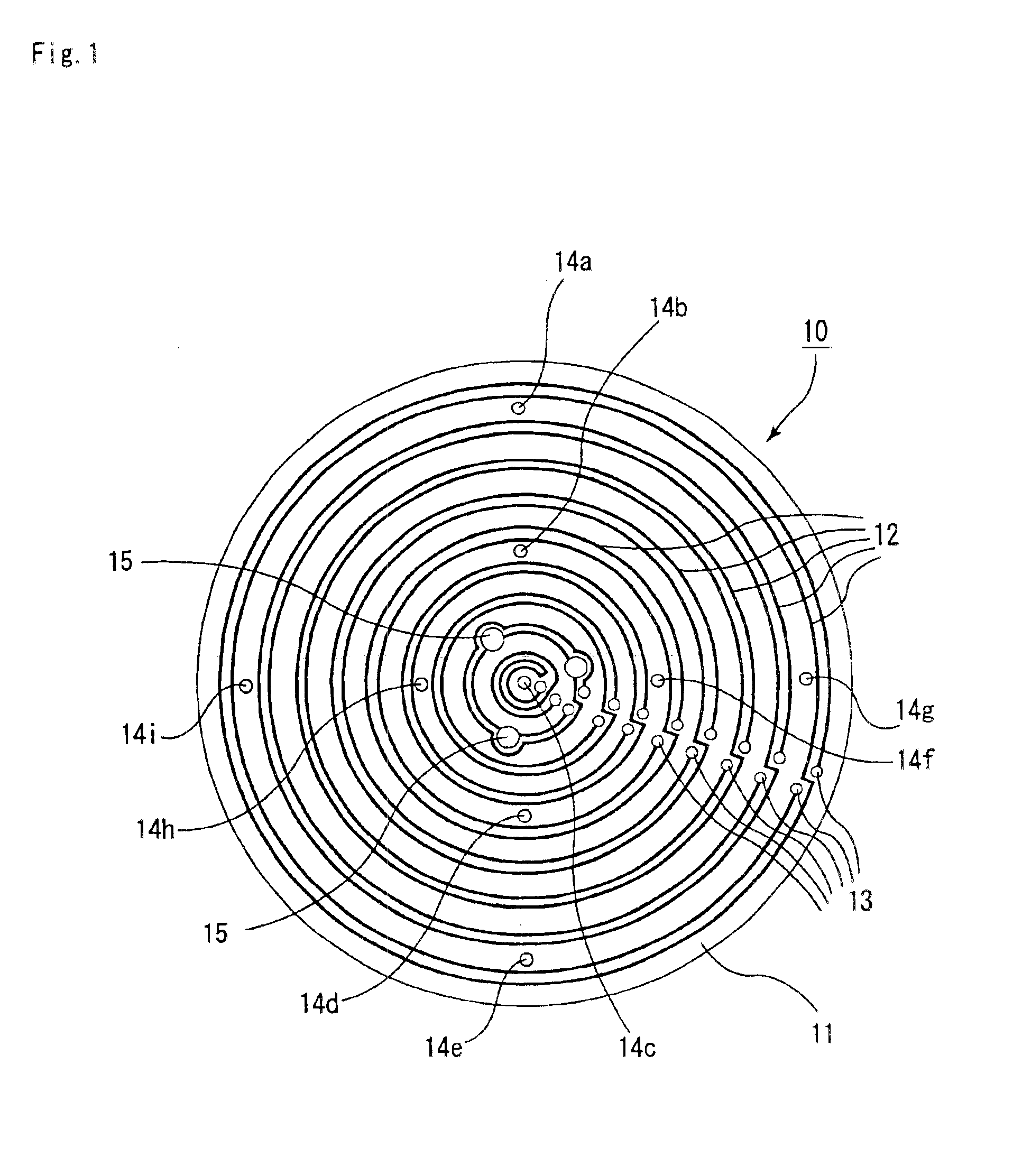

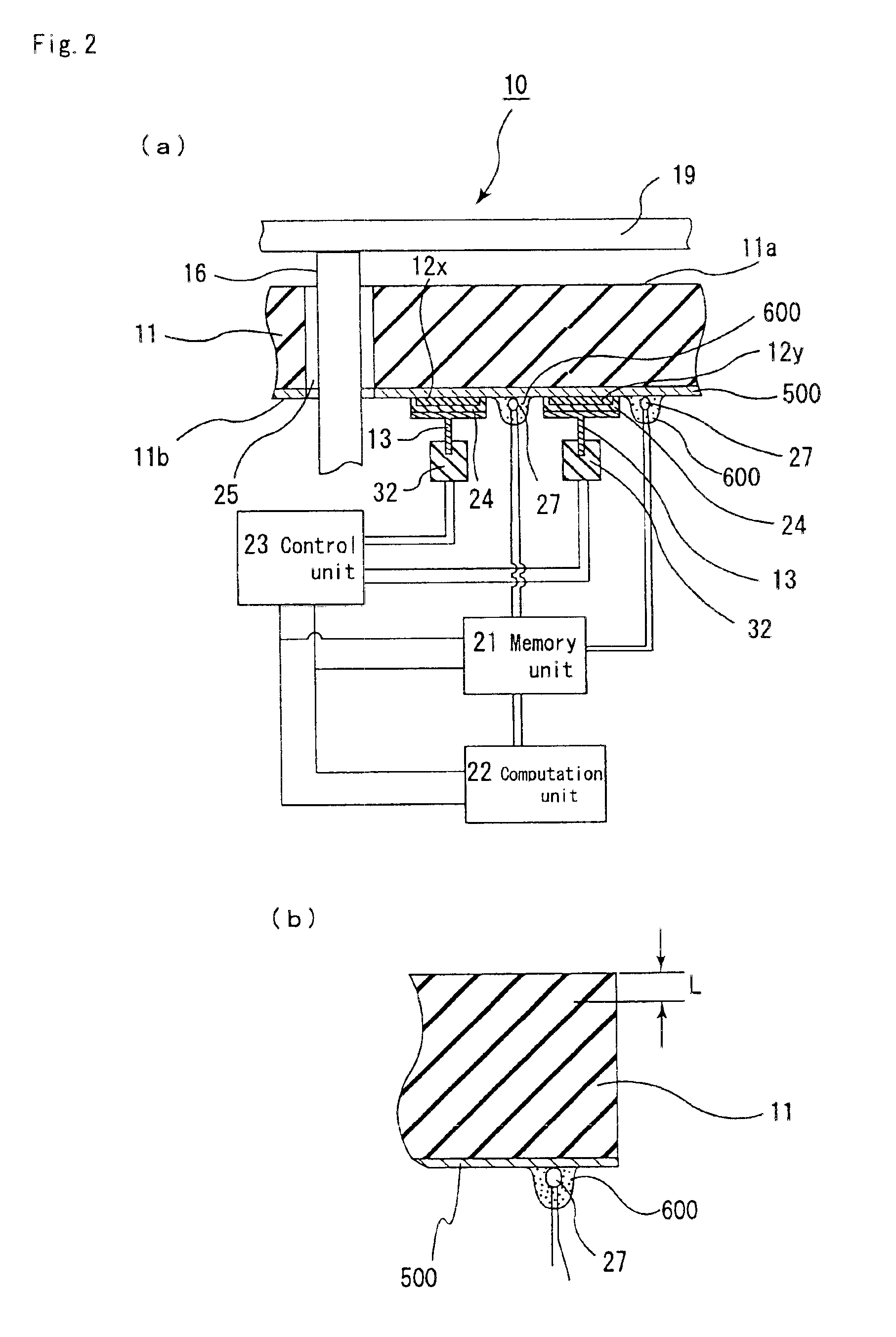

Ceramic heater for semiconductor manufacturing and inspecting equipment

InactiveUS20050092733A1Improve responseCausing temperature distributionMuffle furnacesSemiconductor/solid-state device manufacturingMetallurgySemiconductor

A ceramic heater for a semiconductor producing / examining device including a ceramic substrate having a heating surface for receiving a semiconductor wafer, a heating device for generating heat sufficient for producing / examining the semiconductor wafer and formed on the heating surface or inside the ceramic substrate, and a temperature measuring device for measuring a temperature of the heating surface and pressed against the ceramic substrate.

Owner:IBIDEN CO LTD

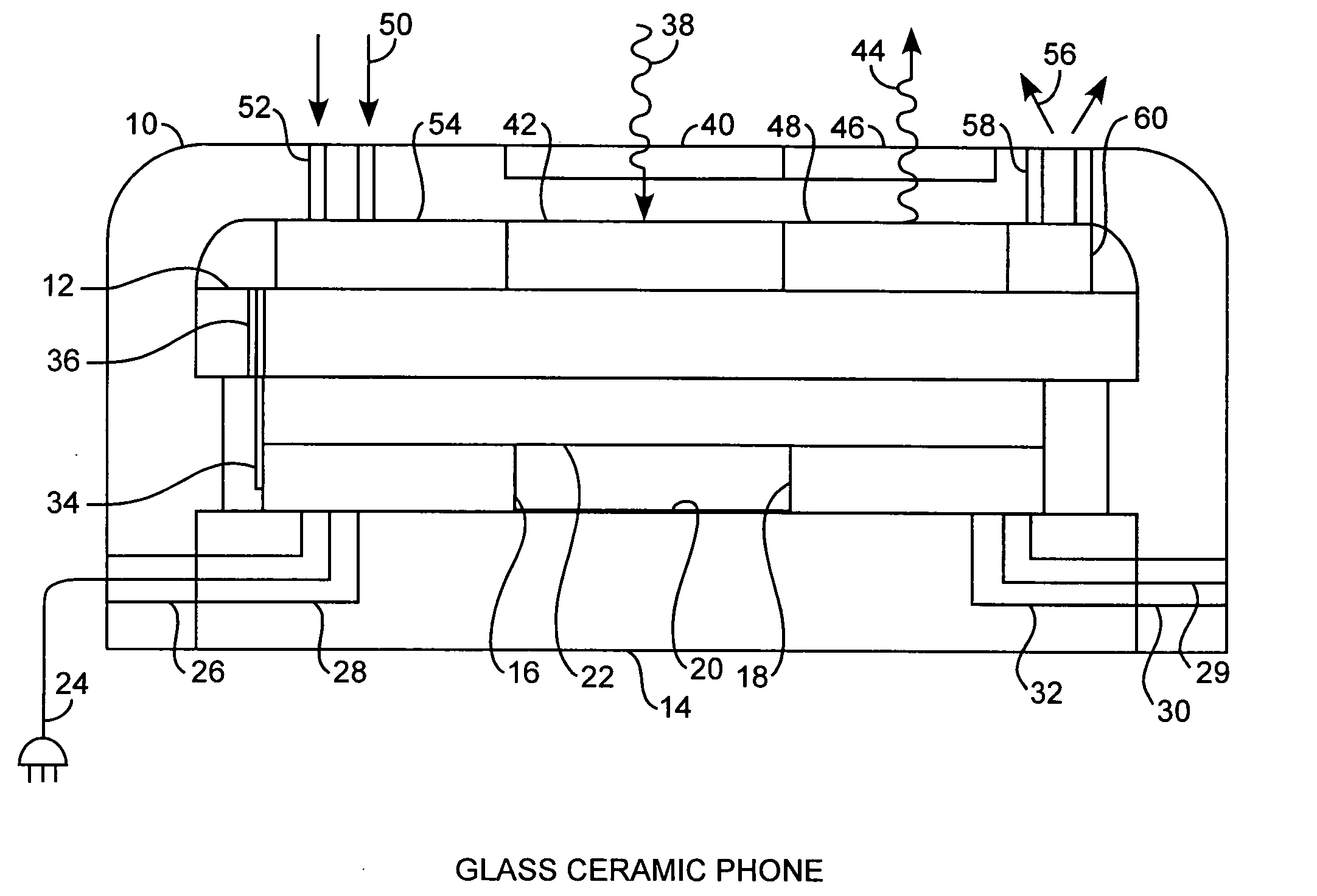

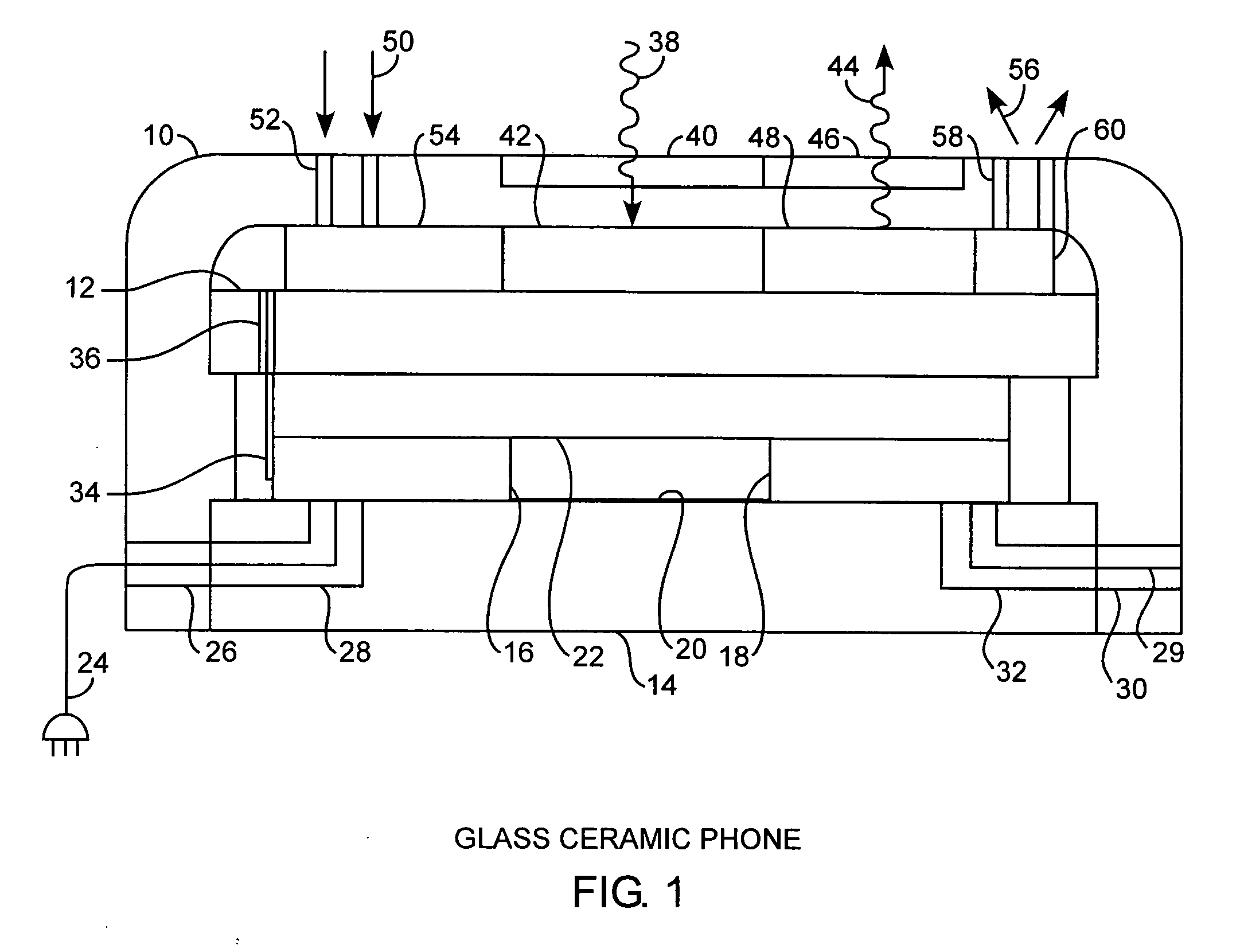

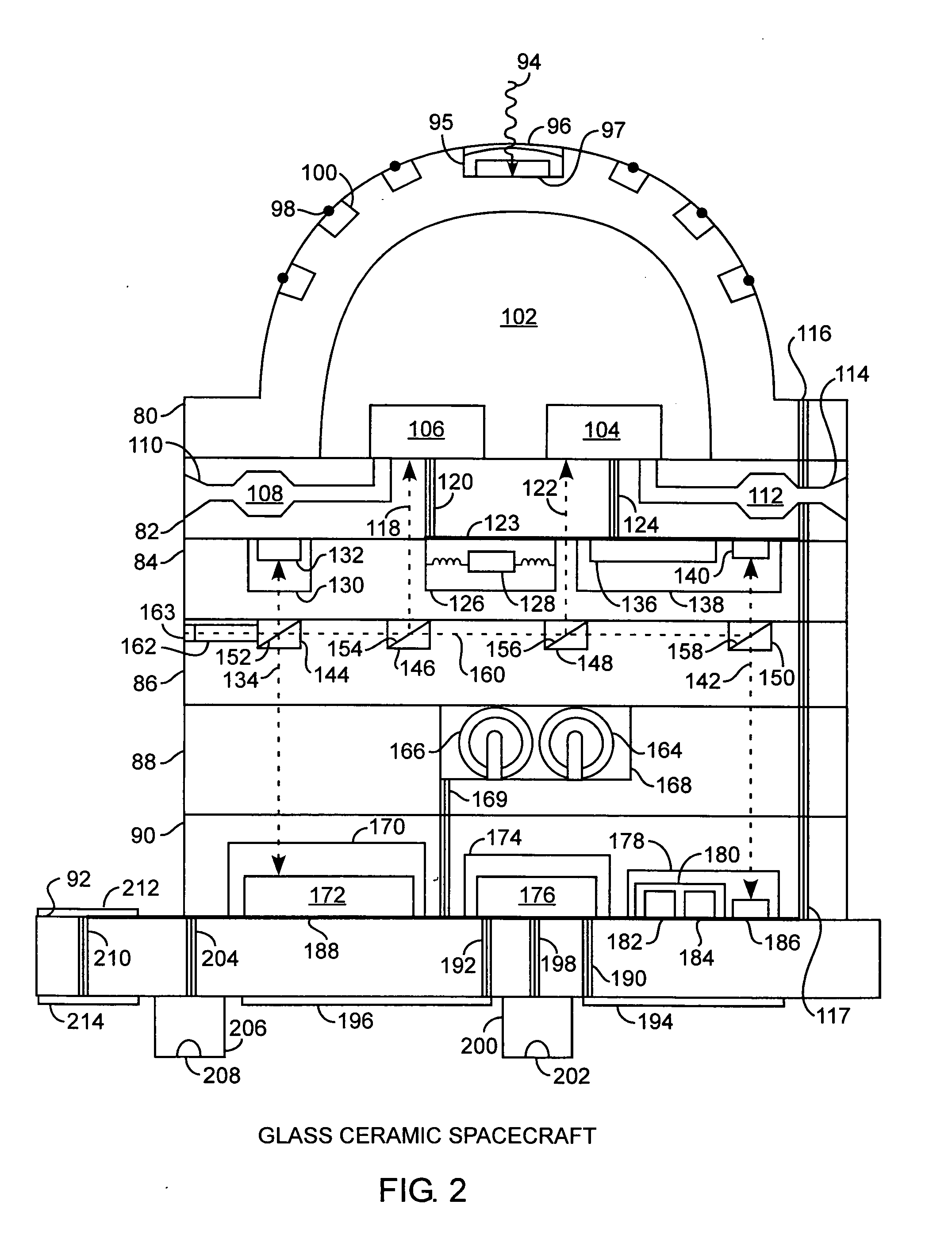

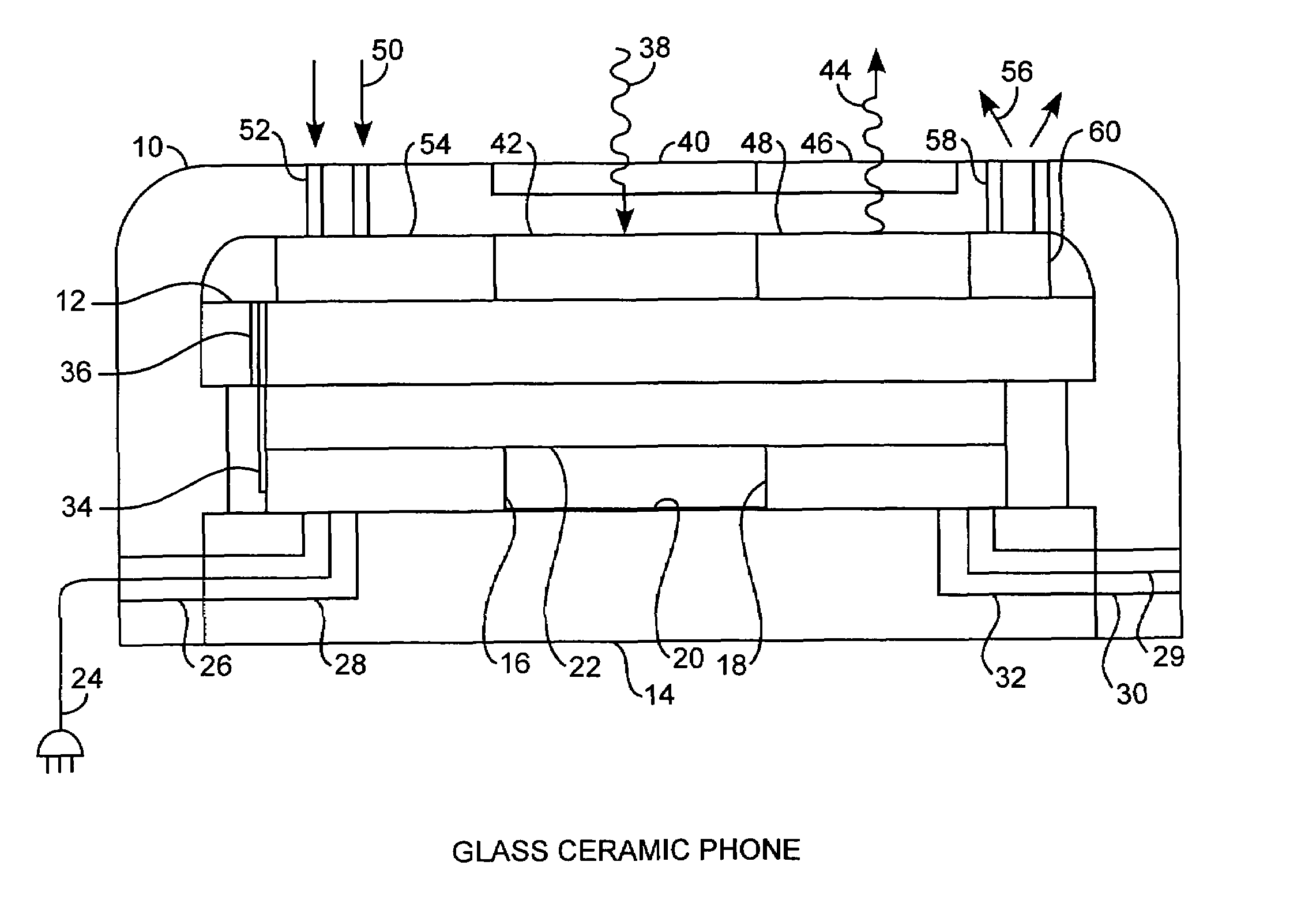

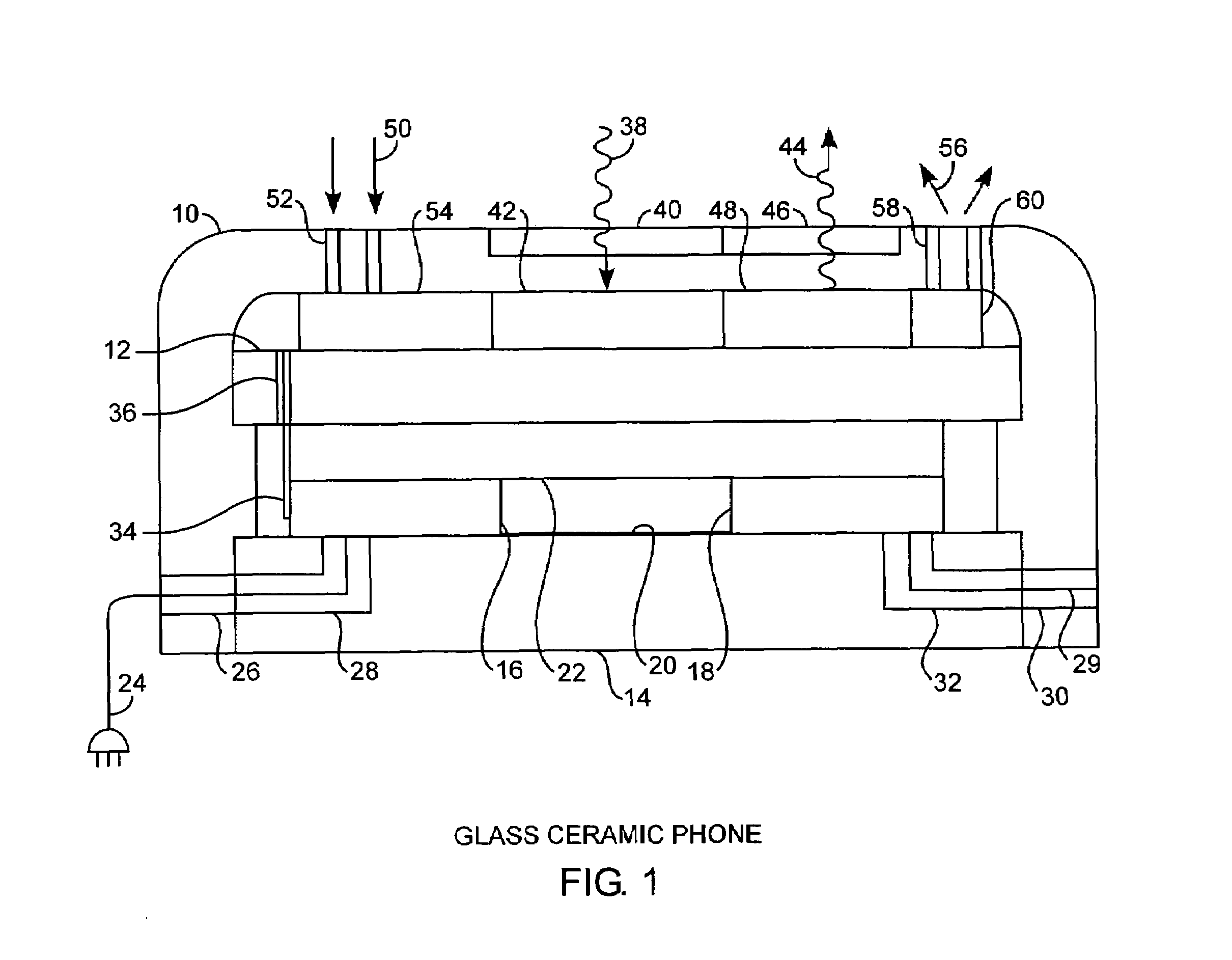

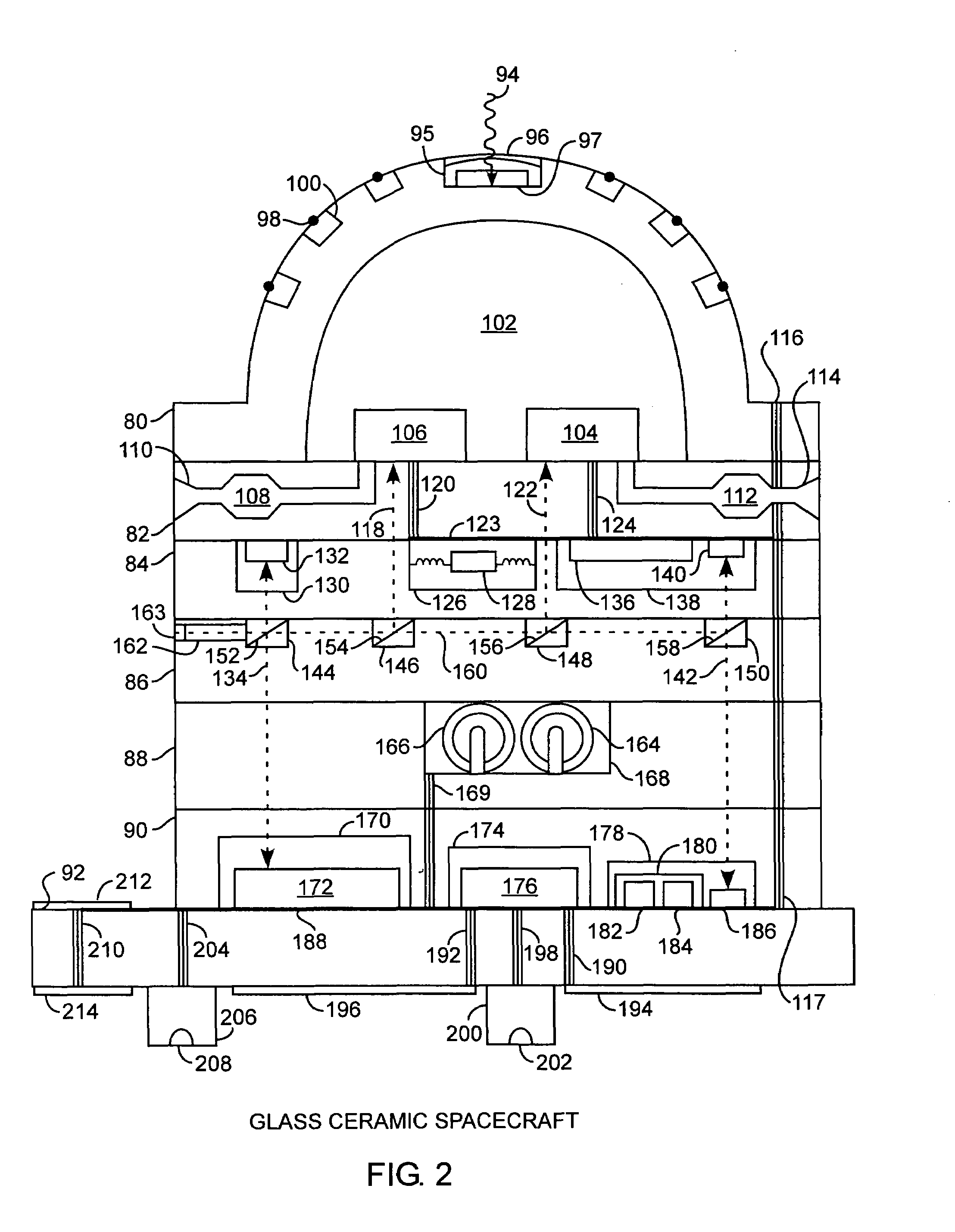

Integrated glass ceramic systems

ActiveUS20050135724A1Enhance dielectric propertyAdditional strengthCosmonautic propulsion system apparatusCosmonautic power supply systemsOpto electronicElectricity

Integrated glass ceramic spacecraft include a plurality of glass ceramic components including molded, tempered, annealed, and patterned glass ceramic components coupled together for forming a support structure or frame or housing through which is communicated optical signals through an optical communications grid and electrical signals through an electrical communications grid, with the optical communications grid and electrical communication grid forming a composite electrooptical communications grid for spacecraft wide intercommunications. The support structure multifunctions as a frame, a housing, a support, a thermal control system, and as part of an electrooptical communications grid while encapsulating a plurality of optical, electronic, electrical, and MEMS devices between which is communicated the electrical and optical signals over the electrooptical communication grid.

Owner:THE AEROSPACE CORPORATION

Integrated glass ceramic systems

ActiveUS6952530B2Improve structural strengthLow thermal conductivityCosmonautic propulsion system apparatusCosmonautic power supply systemsElectricityOptical communication

Integrated glass ceramic spacecraft include a plurality of glass ceramic components including molded, tempered, annealed, and patterned glass ceramic components coupled together for forming a support structure or frame or housing through which is communicated optical signals through an optical communications grid and electrical signals through an electrical communications grid, with the optical communications grid and electrical communication grid forming a composite electrooptical communications grid for spacecraft wide intercommunications. The support structure multifunctions as a frame, a housing, a support, a thermal control system, and as part of an electrooptical communications grid while encapsulating a plurality of optical, electronic, electrical, and MEMS devices between which is communicated the electrical and optical signals over the electrooptical communication grid.

Owner:THE AEROSPACE CORPORATION

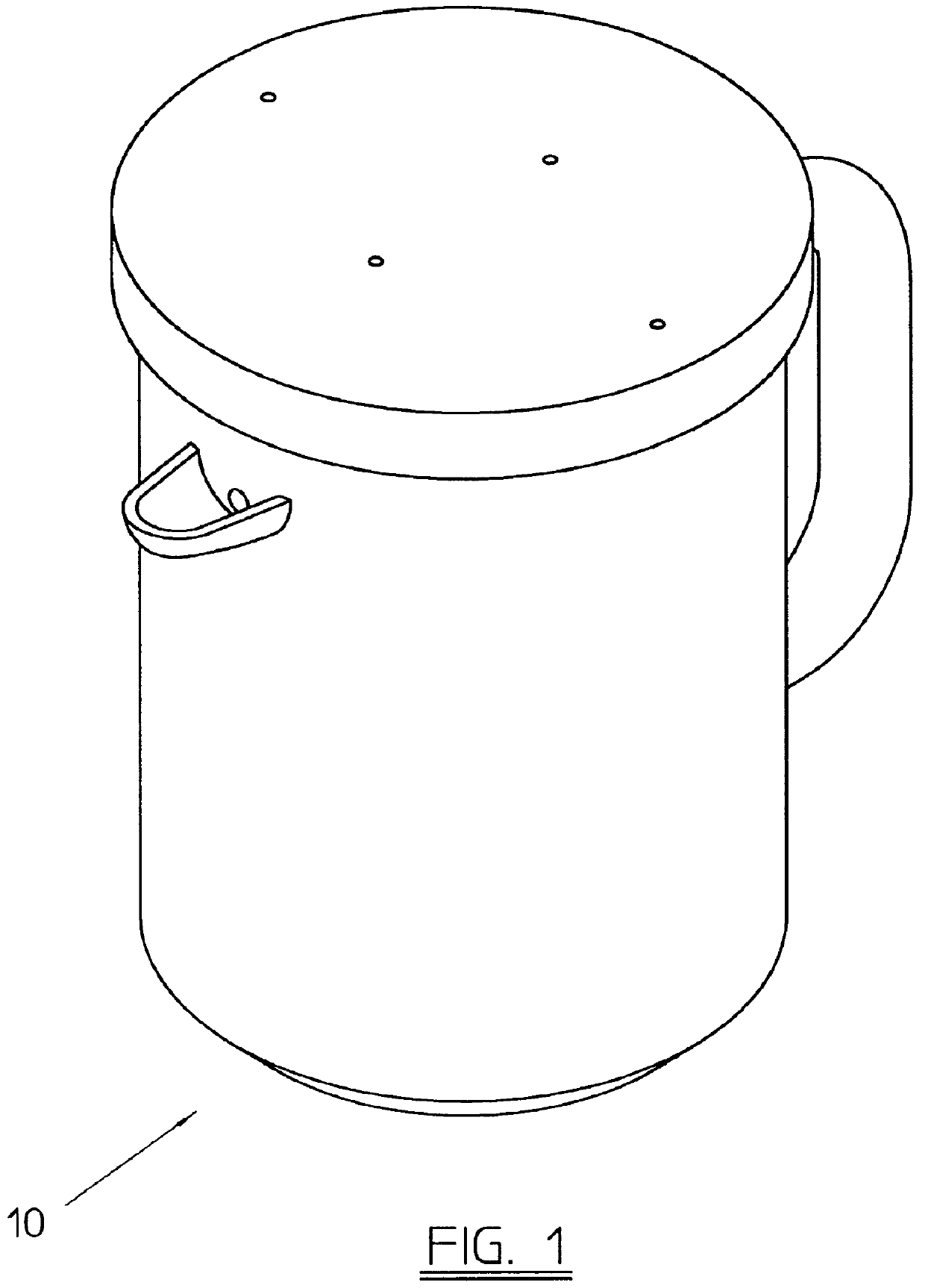

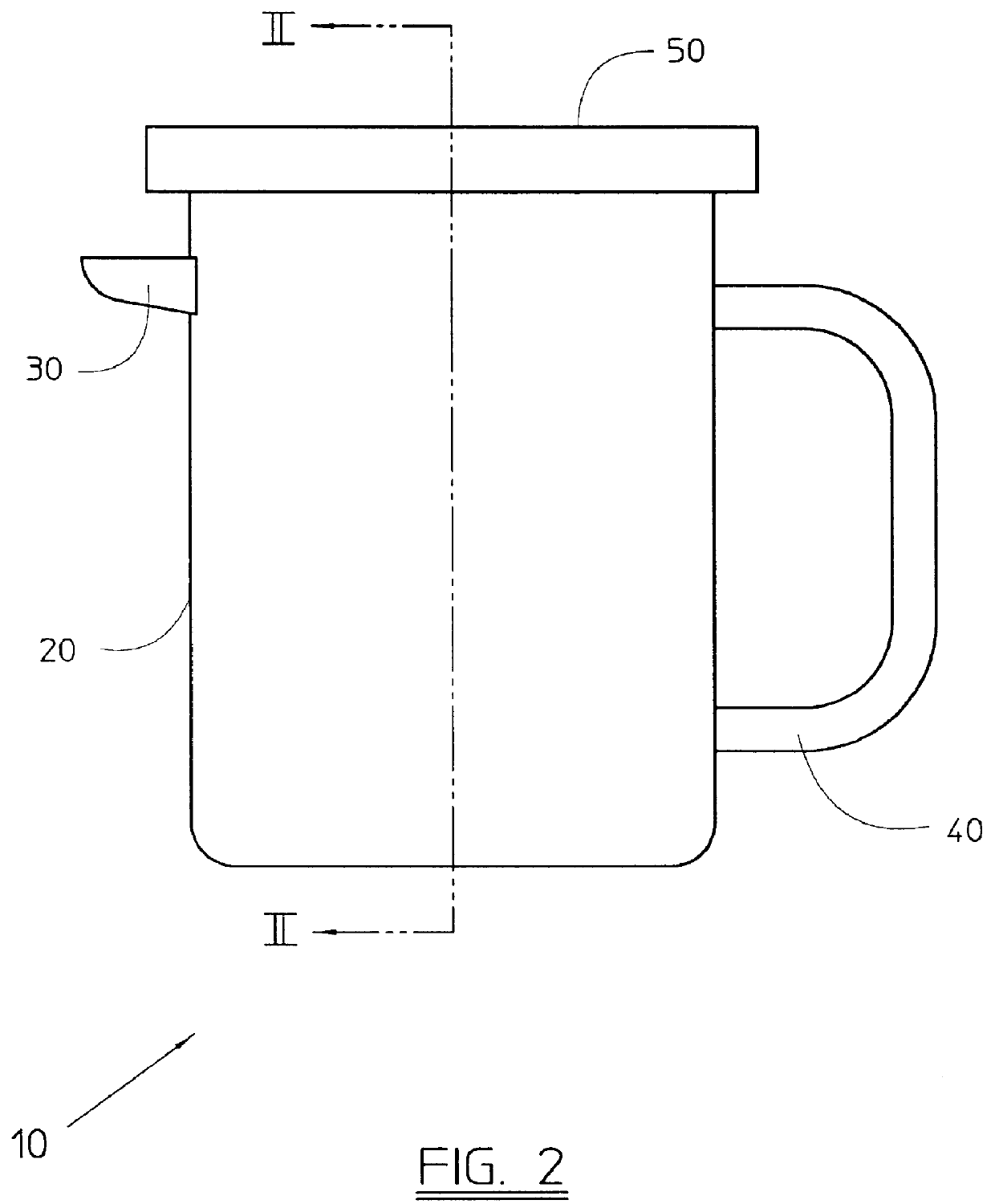

Constant temperature beverage cup

InactiveUS6161720AKeep warmSmooth temperatureDomestic cooling apparatusLighting and heating apparatusRespiratorEngineering

The invention is a drinking vessel that keeps coffee or other hot beverages hot, yet readily drinkable. The basic design of the invention is an inner beverage vessel and an outer beverage chamber with an insulator chamber of air between them. There is a small hole in the bottom of the inner beverage vessel which allows the contents to flow into the outer beverage chamber. When the drinker tips the cup to drink, beverage flows from the inner beverage vessel to the outer beverage surrounding the cup and pours out of a mouthpiece. The amount of liquid that fills the outer beverage chamber quickly cools enough to drink, but still remains warm. The insulator chamber keeps the beverage in the inner beverage vessel hot for a longer period of time. The lid for the cup is sealed to keep the contents warm but has a small pinhole to eliminate the build-up of a vacuum.

Owner:CASTLE BENEDICT P

Gas-phase oxidization process and process for the preparation of phthalic anhydride

InactiveUS6369240B1Change activityHigh activityOrganic oxidationOrganic compound preparationMaleic anhydrideChemistry

This invention relates to the vapor-phase oxidation of hydrocarbons by passing a gaseous mixture comprising of a molecular oxygen-containing gas and hydrocarbons which may contain substituents to a fixed bed of catalyst and provides a process for vapor-phase oxidation to be effected by passing a gaseous mixture of raw materials to a fixed bed of catalyst in which the void ratio of the catalyst layers increases by stages in one step or more from upstream downward in the flow of the gaseous mixture of raw materials. For example, the process can oxidize in vapor phase such hydrocarbons as naphthalene, xylene, benzene, toluene, durene, butene, acenaphthene, anthracene, indene and their derivatives in high yields with high productivity. Moreover, the process can prepare phthalic anhydride in high yields with high productivity by the vapor-phase oxidation of naphthalene or ortho-xylene.

Owner:NIPPON MICROMETAL

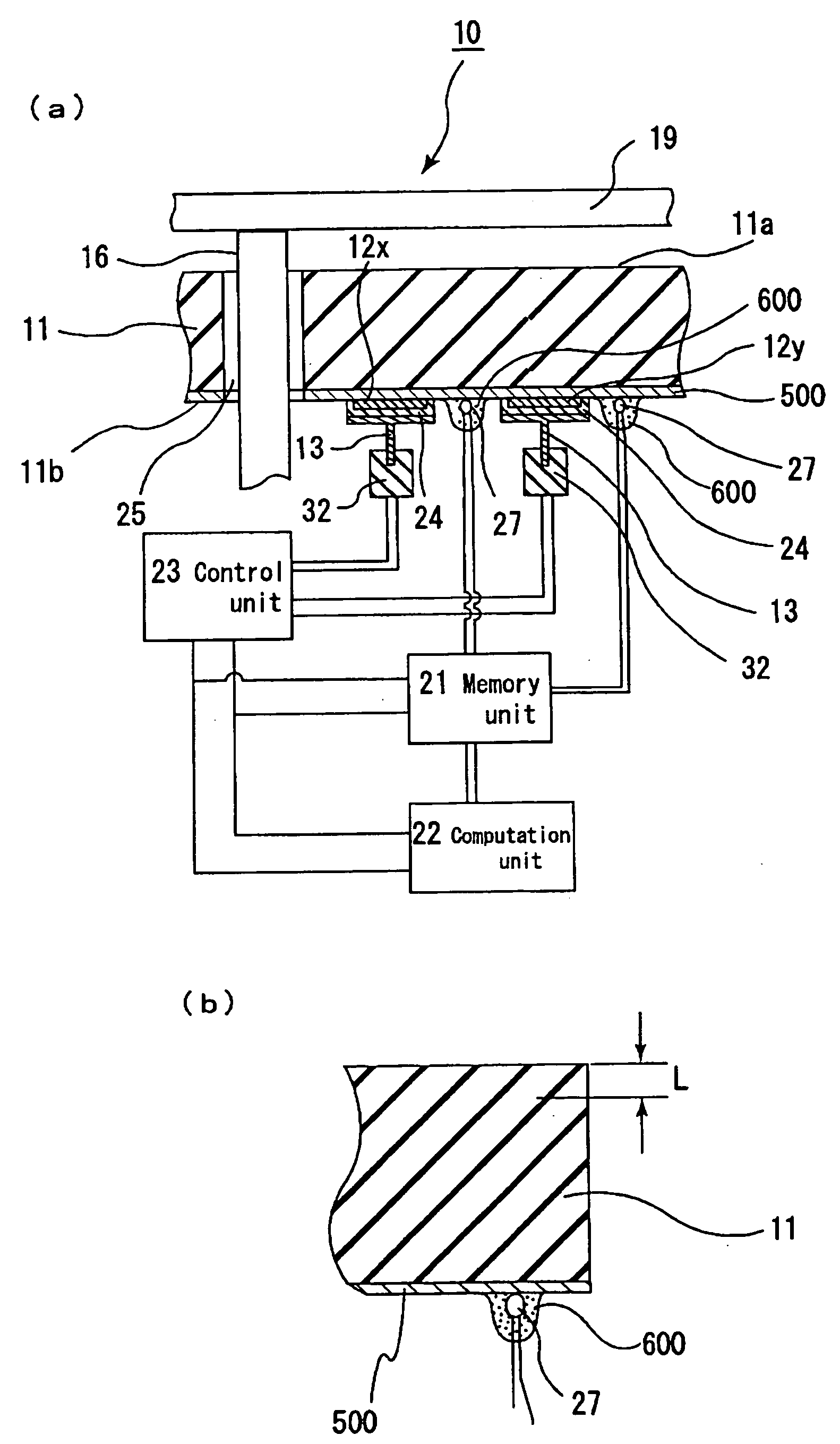

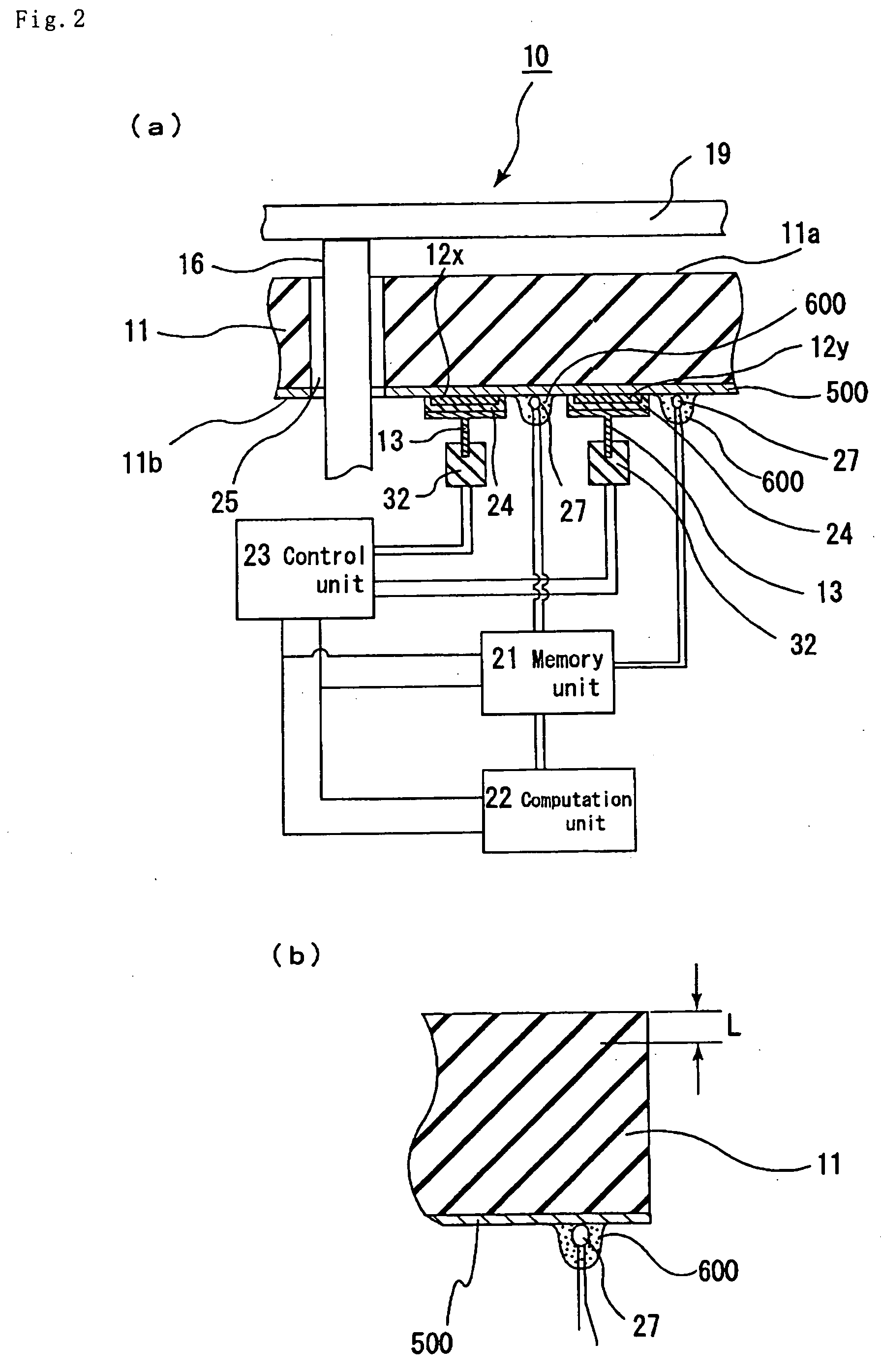

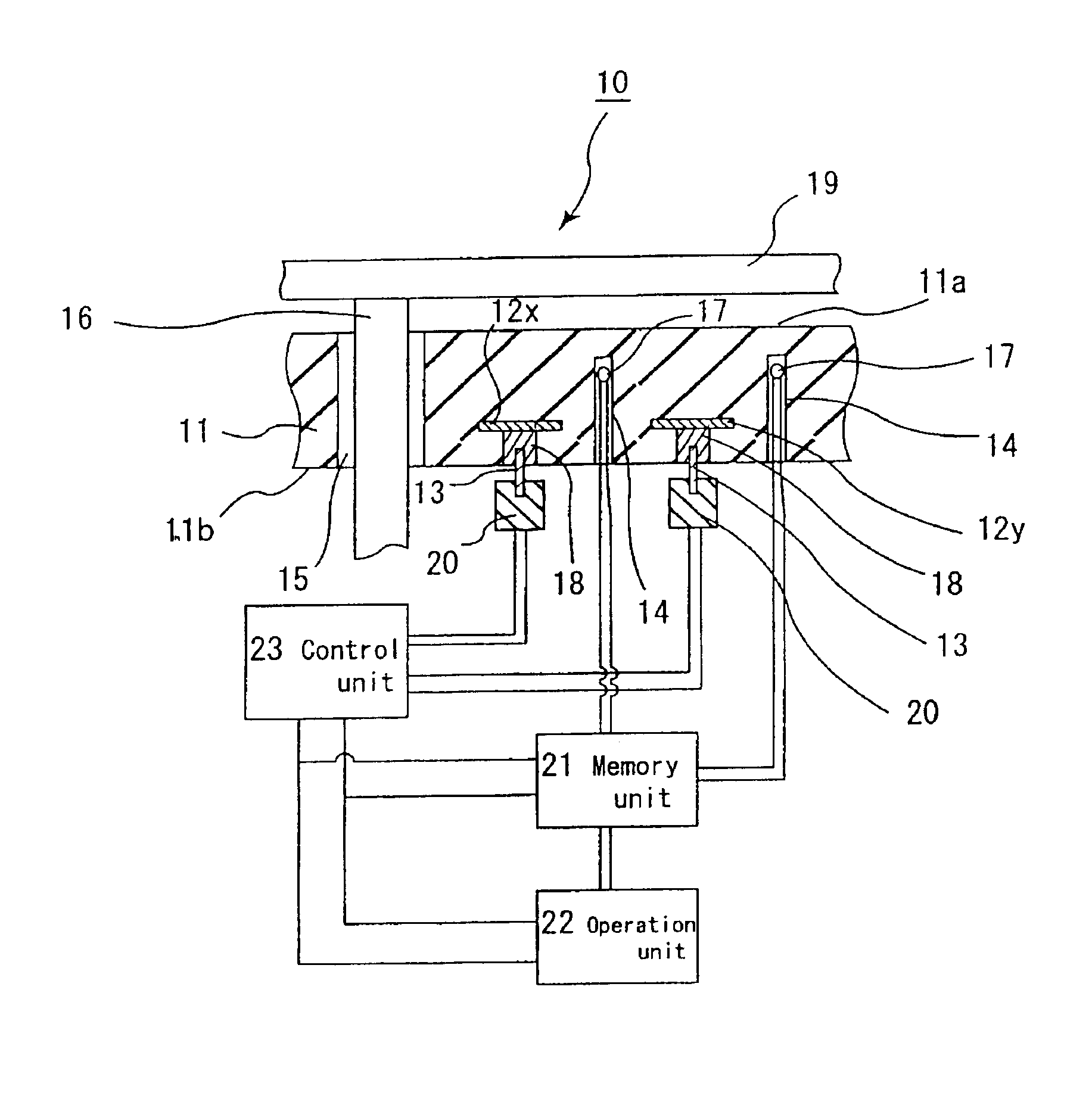

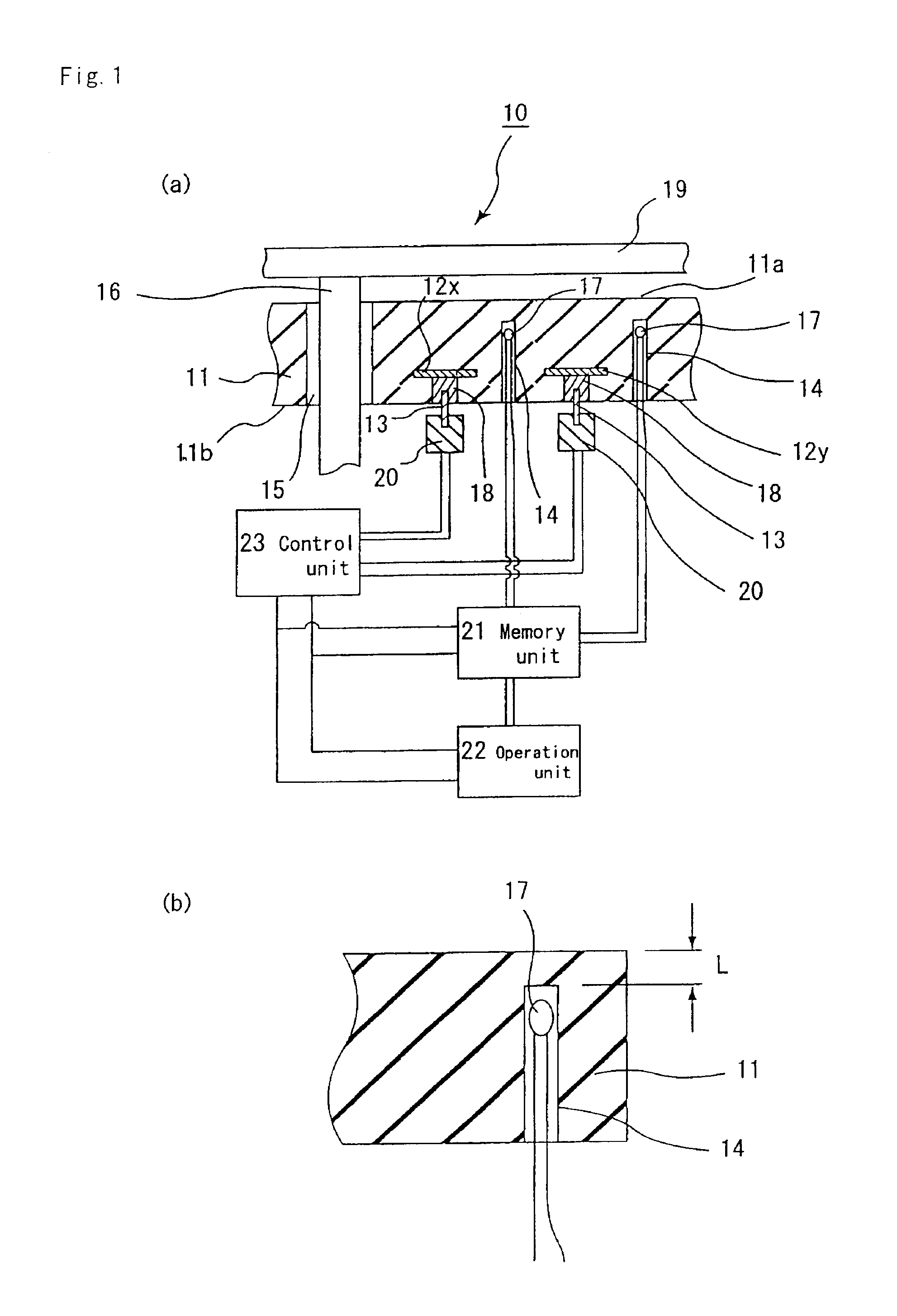

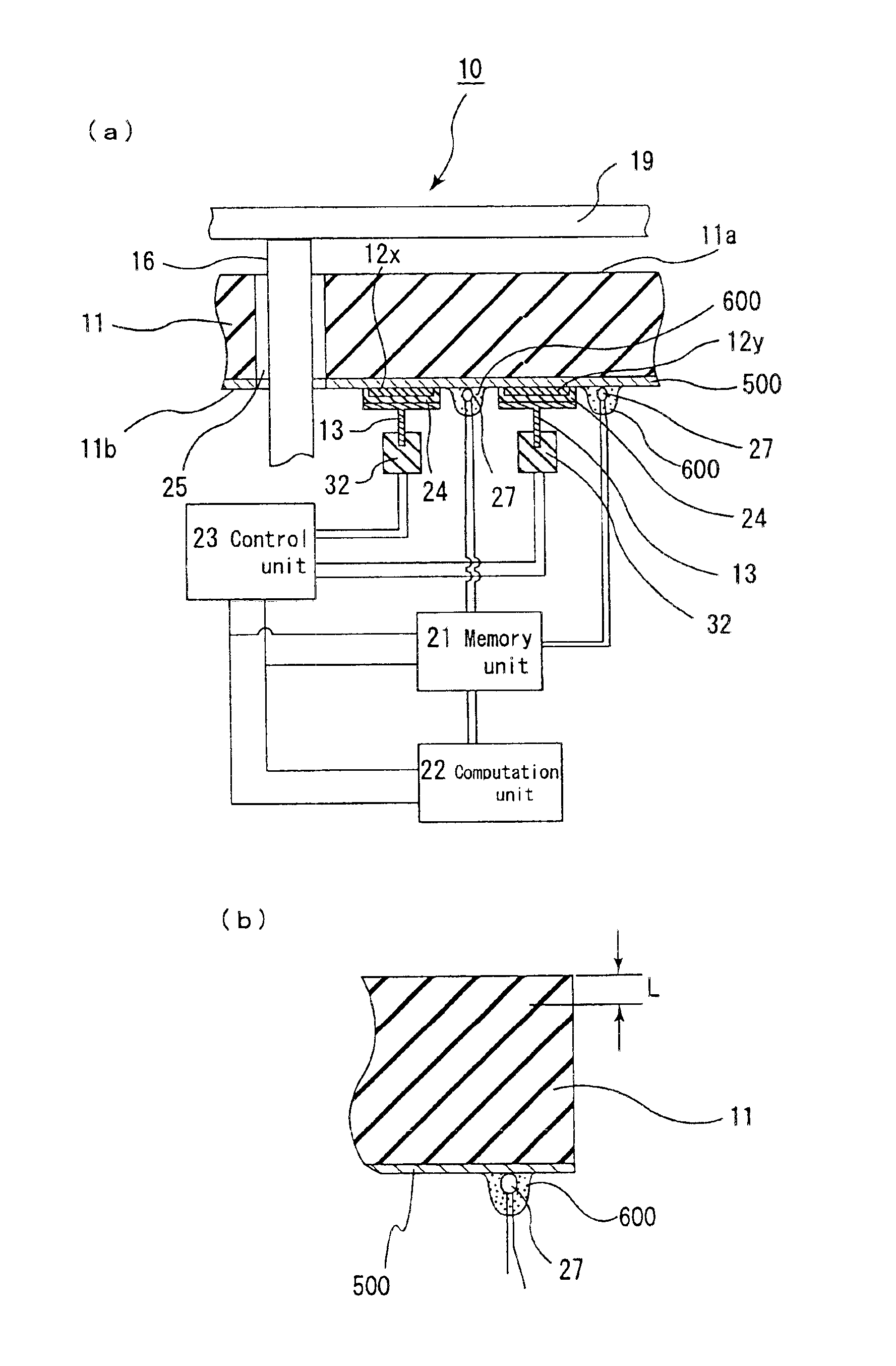

Ceramic heater

InactiveUS6956186B1Avoid damageSmooth temperatureTemperature control using digital meansMuffle furnacesElectrical resistance and conductanceElectric power system

An objective of the present invention is to provide a ceramic heater making it possible to heat an object to be heated, such as a silicon wafer, evenly. The ceramic heater of the present invention is a ceramic heater having and a resistance heating element formed on the surface of the ceramic substrate or inside the ceramic substrate, wherein: said ceramic heater is equipped with: a temperature-measuring means measuring the temperature of said ceramic substrate and an object to be heated; a control unit supplying electric power to said heating element; a memory unit memorizing the temperature data measured by said temperature-measuring means; and an operation unit calculating electric power required for said heating element from said temperature, said ceramic heater being constituted such that said heating element is divided into at least 2 or more circuits and different electric power is supplied to each of the circuits of said resistance heating element.

Owner:IBIDEN CO LTD

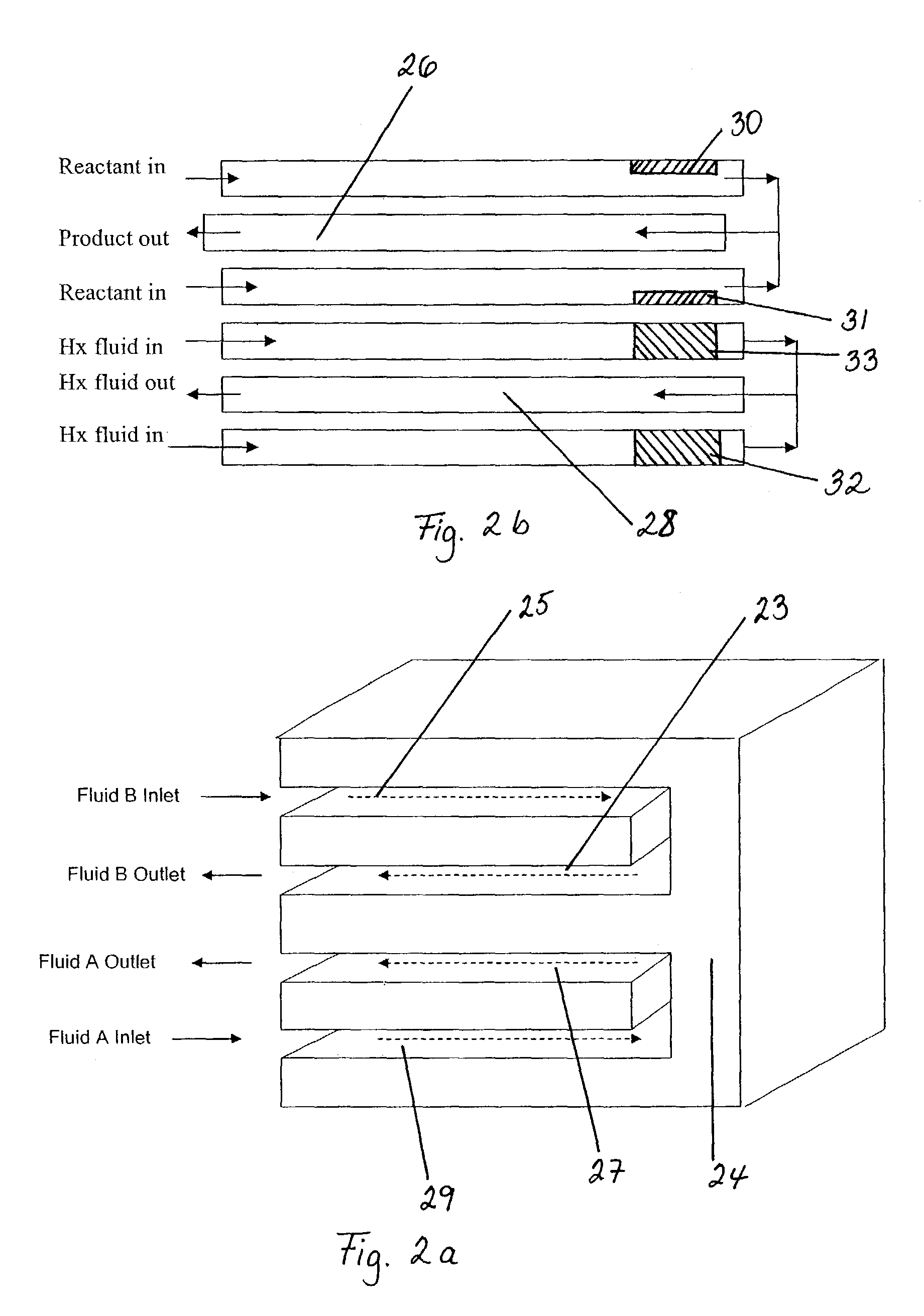

Dehydrogenation reactions in narrow reaction chambers and integrated reactors

Methods of dehydrogenating hydrocarbons to yield unsaturated compounds are described. Reactor configurations useful for dehydrogenation are also described. Hydrocarbons can dehydrogenationed, for relatively long periods of time-on-stream, in a reaction chamber having a dimension of 2 mm or less to produce H2 and an olefin. Techniques have been developed that reduce coke and allow stable, relatively long-term operation in small reactors.

Owner:VELOCYS CORPORATION

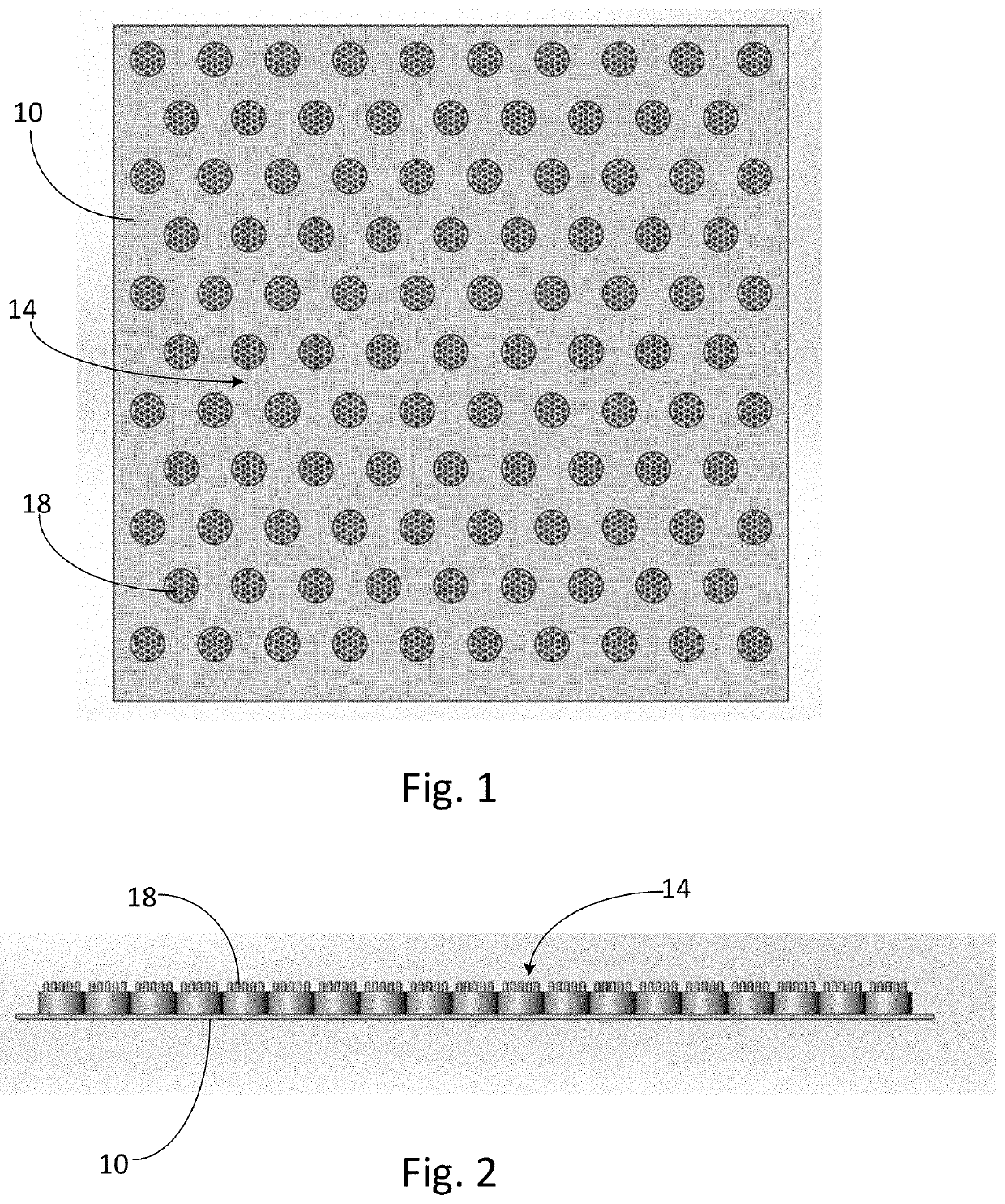

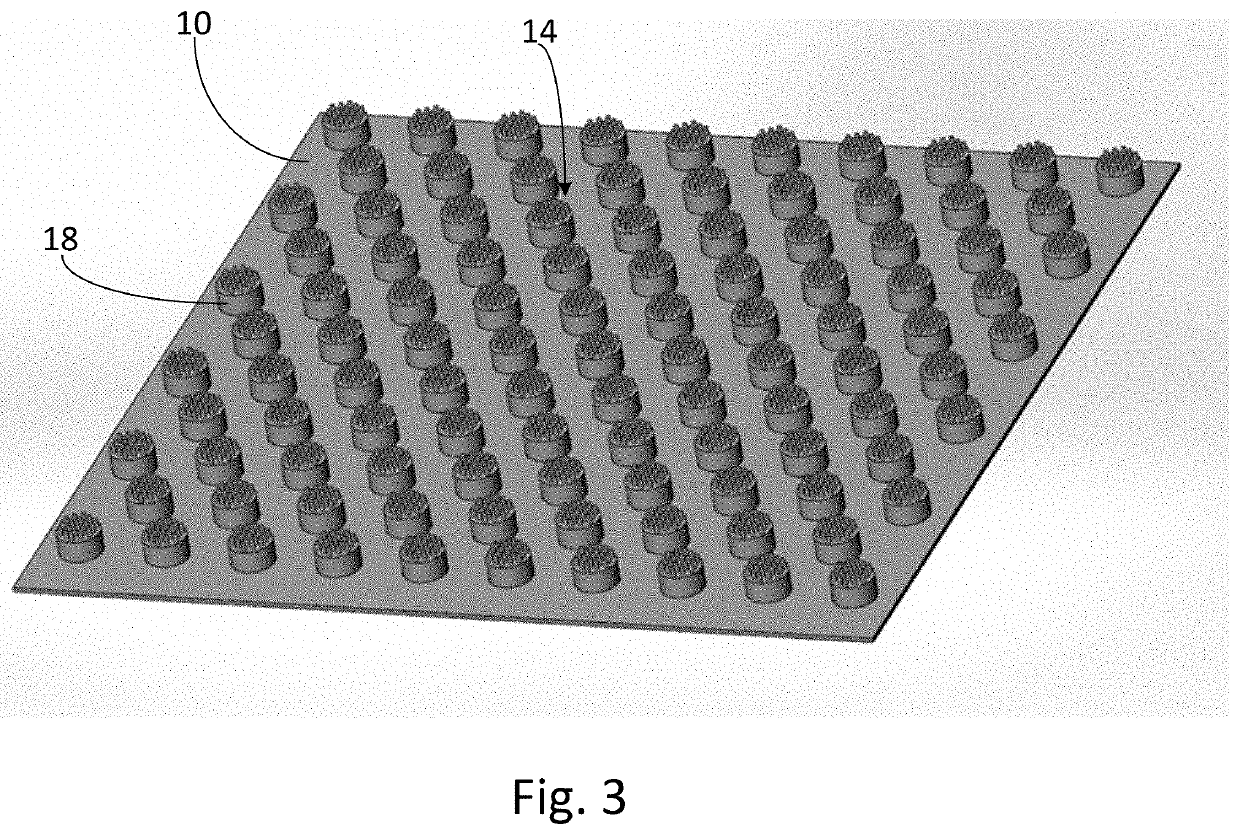

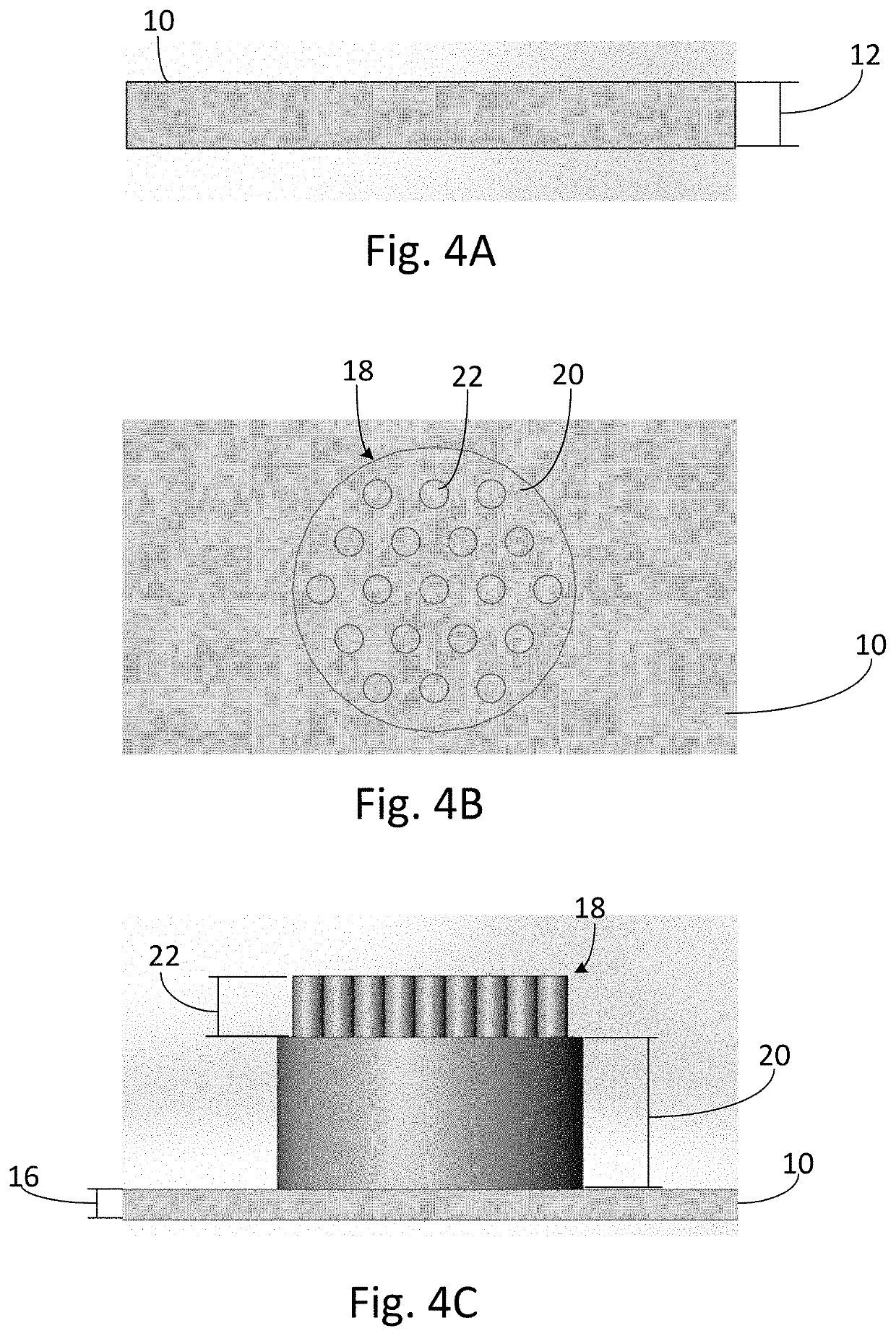

Thin film with high grip microfeatures

InactiveUS20200338808A1Reduce coefficient of frictionConvenient introductionFlat articlesPolymer scienceThin membrane

A polymer film having an initial thickness of 20 to 200 microns. A two-level micro pattern formed on at least one side of the film so that the polymer film has a base thickness less than the initial thickness of the film following the addition of the two-level micro pattern. A plurality of microfeatures defining the micro pattern wherein a height of the microfeatures on the film is in a range from about 0.3 to about 4 times the initial film thickness while maintaining the structural stability of the microfeatures to resist bending and provide increased grip against biological tissue and simultaneously providing reduced friction against dry hard plastic and metal surfaces.

Owner:HOOWAKI

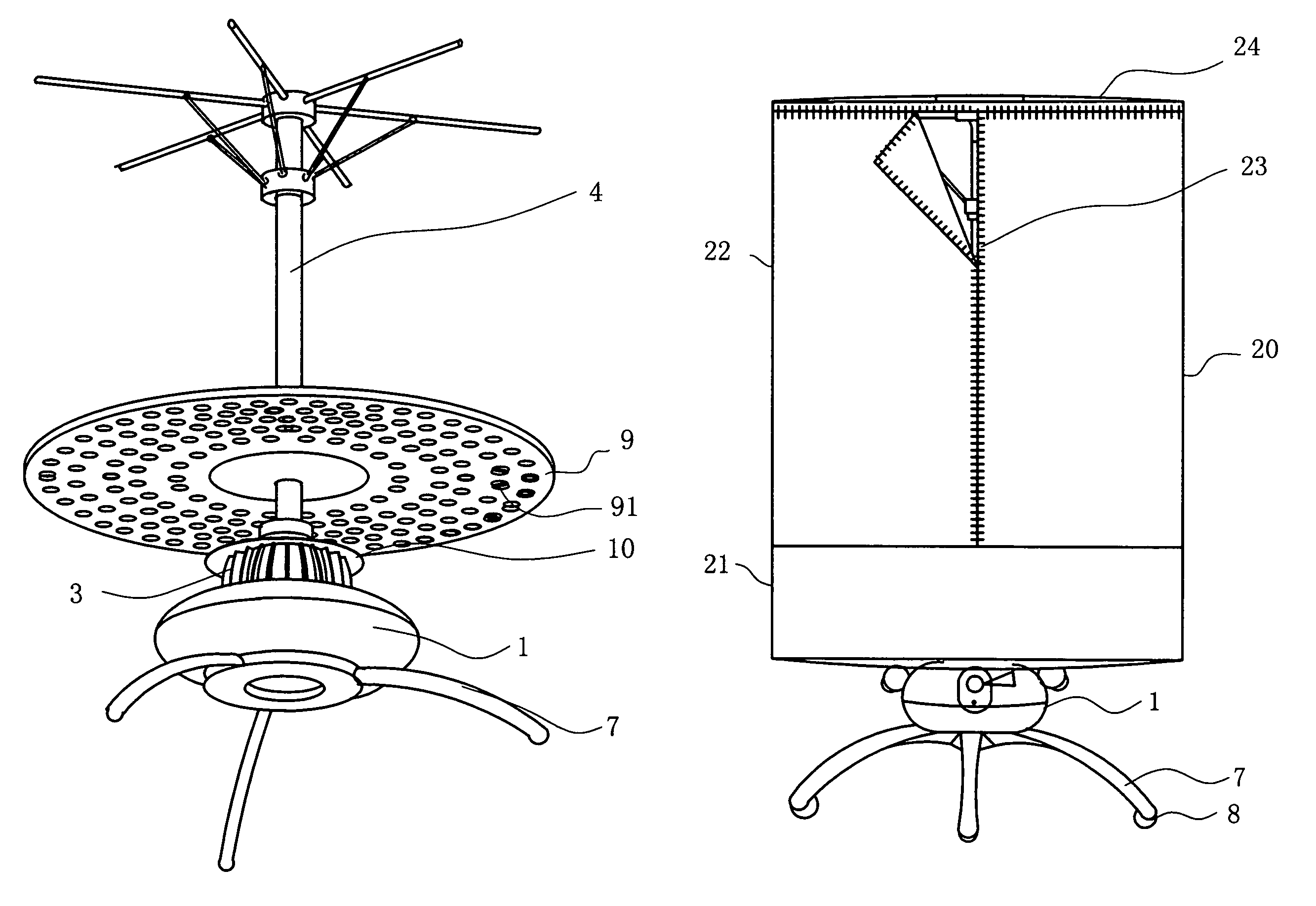

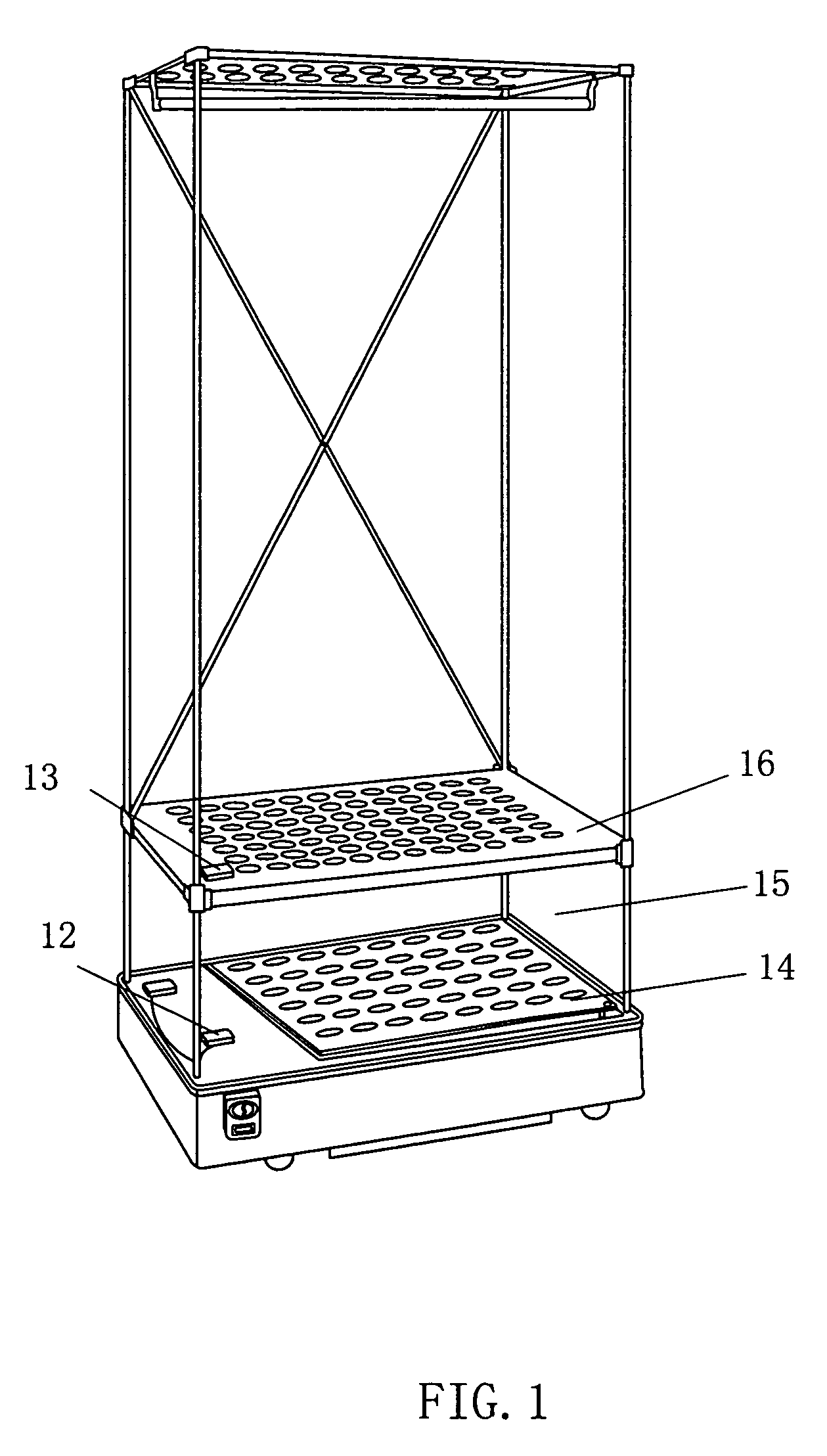

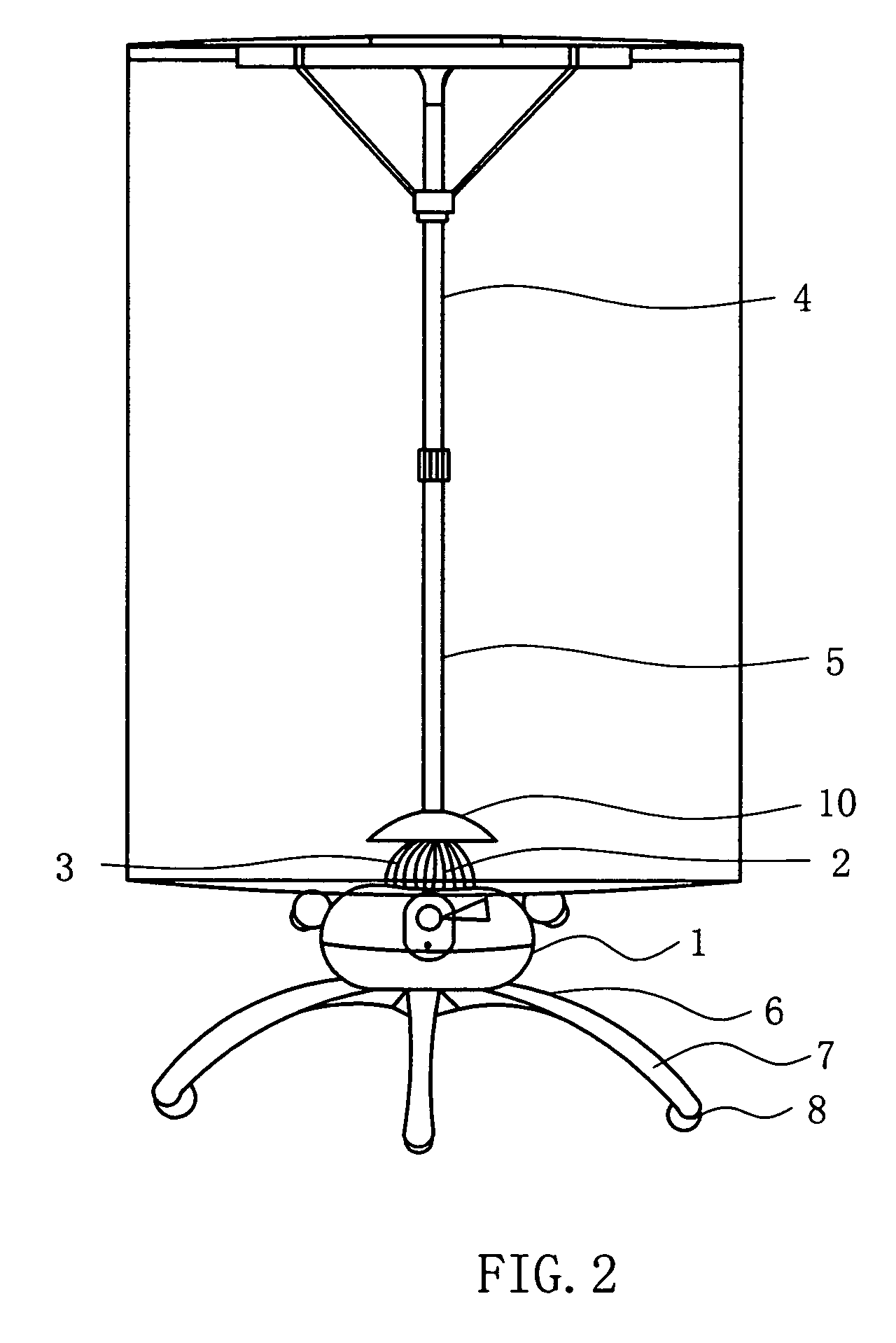

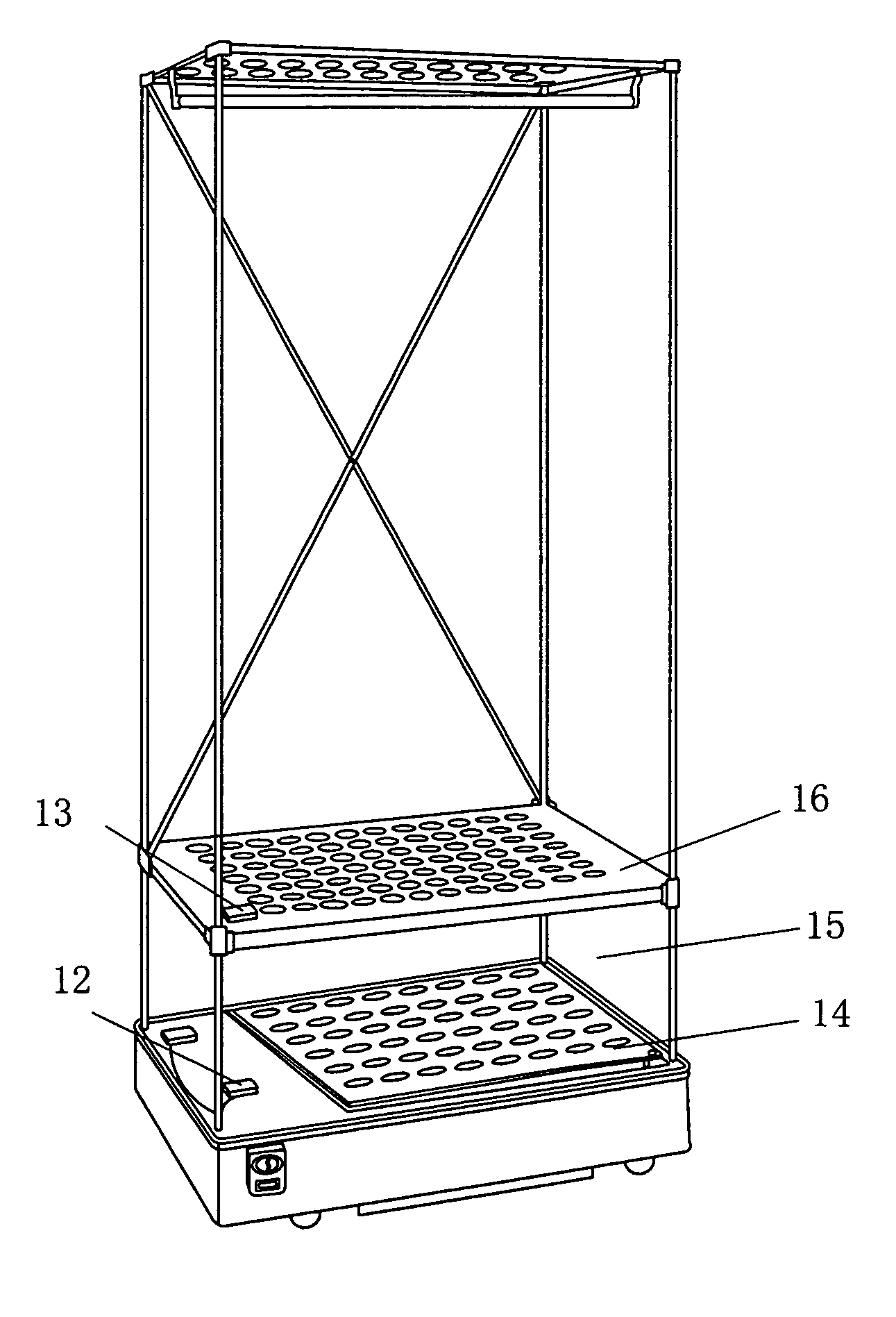

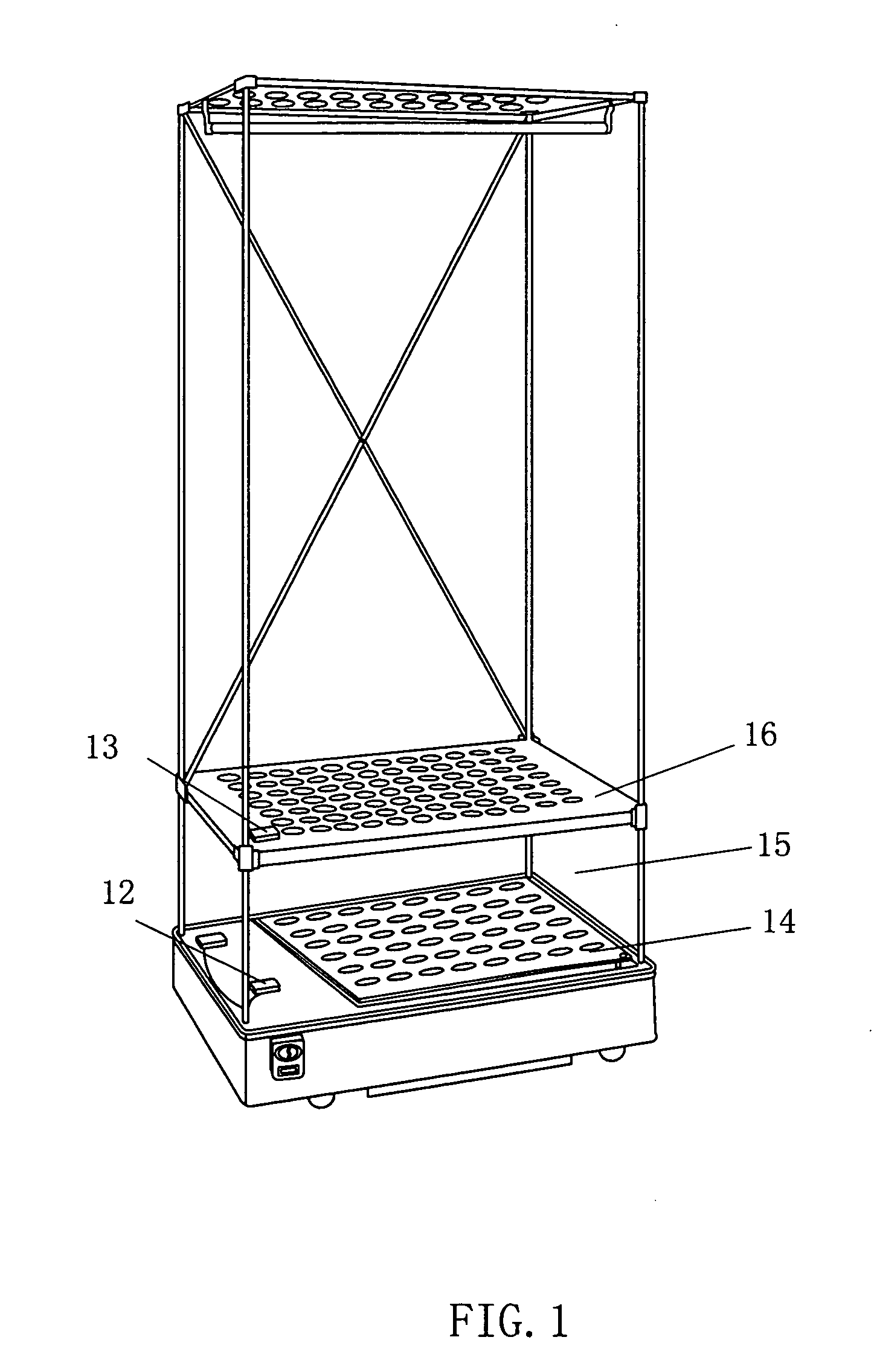

Shed type clothes dryer with safety plate

InactiveUS8327558B2Improve securityAchieve securityOther washing machinesDrying chambers/containersElectrical and Electronics engineeringAirflow

Owner:HU JIEBO

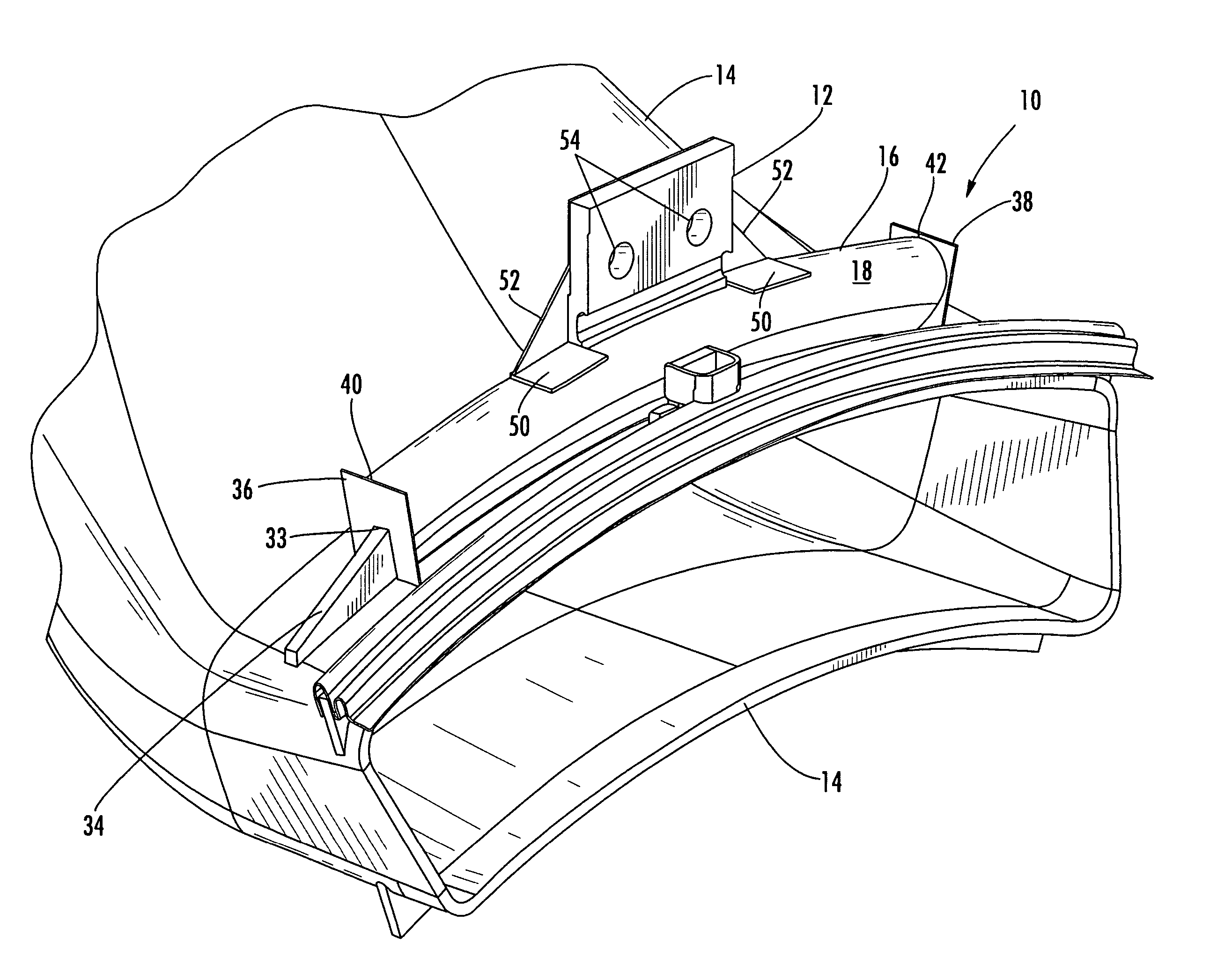

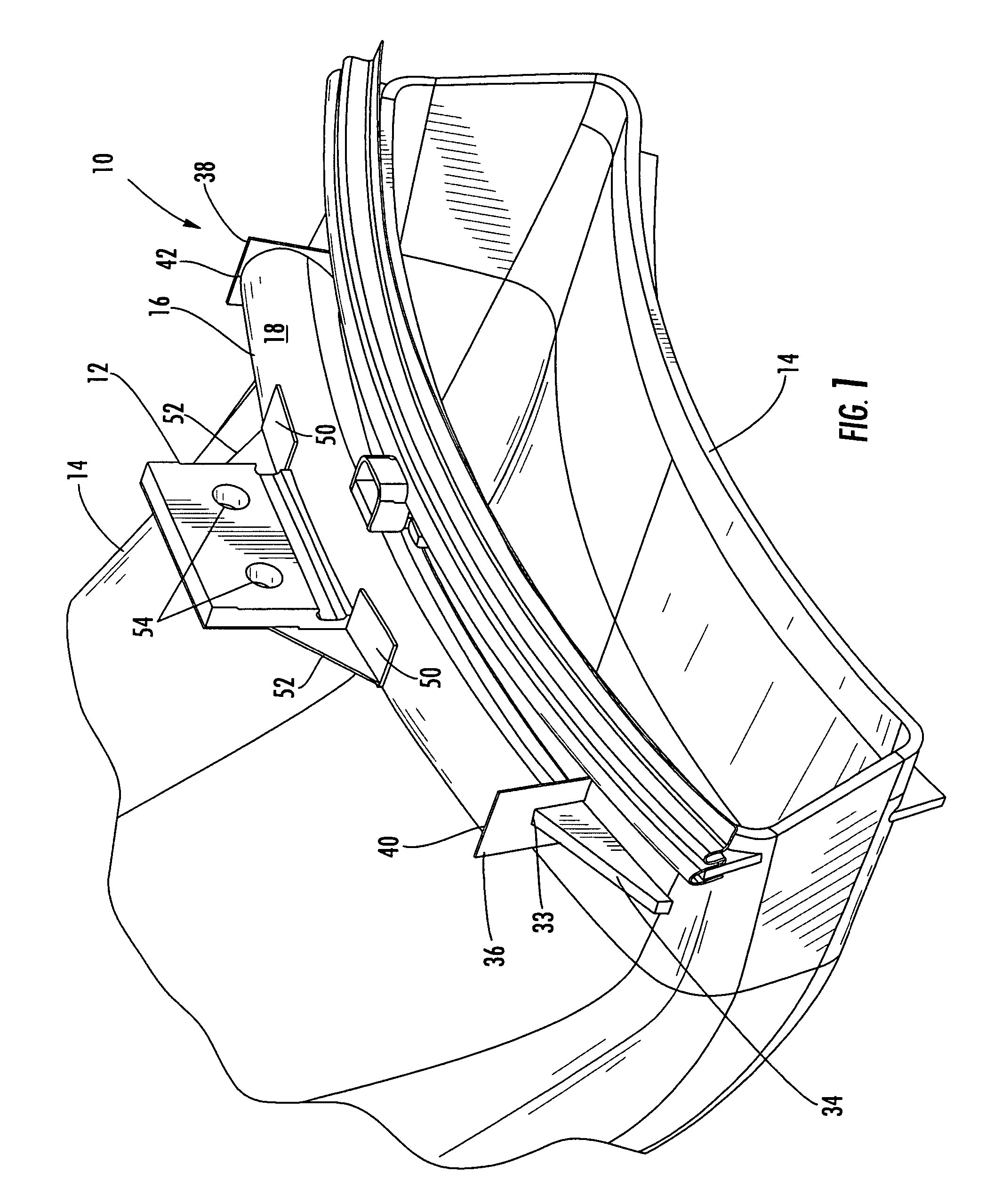

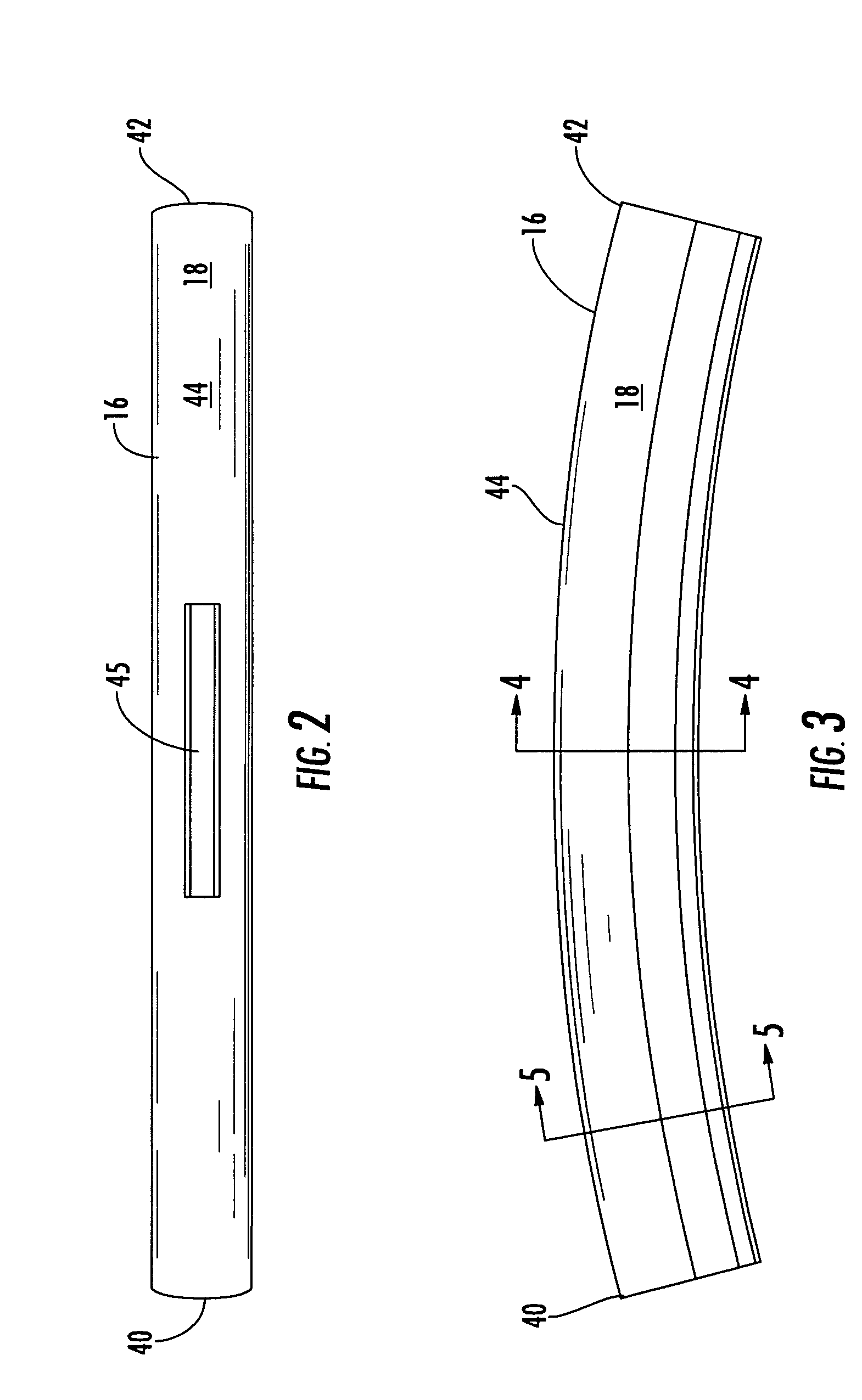

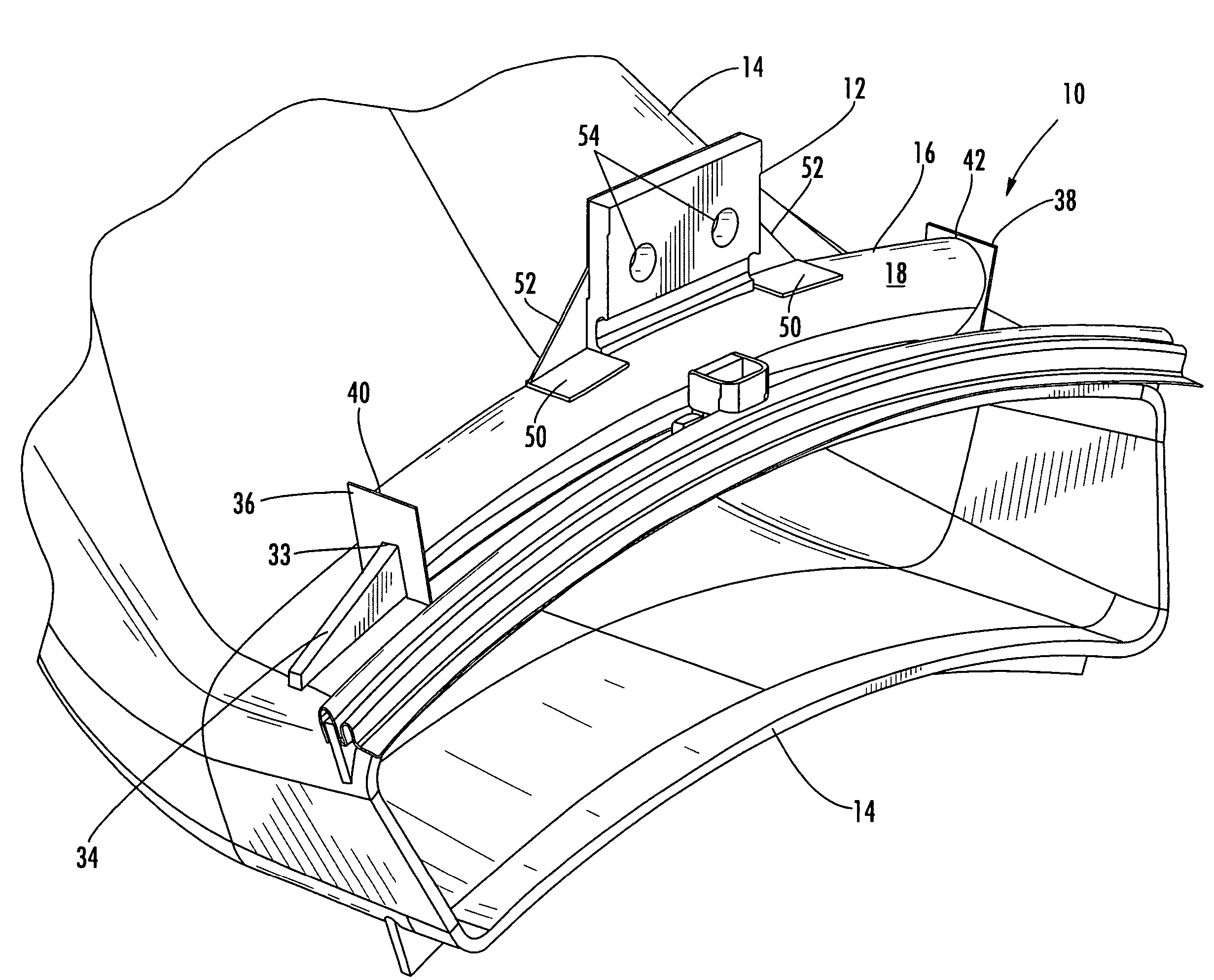

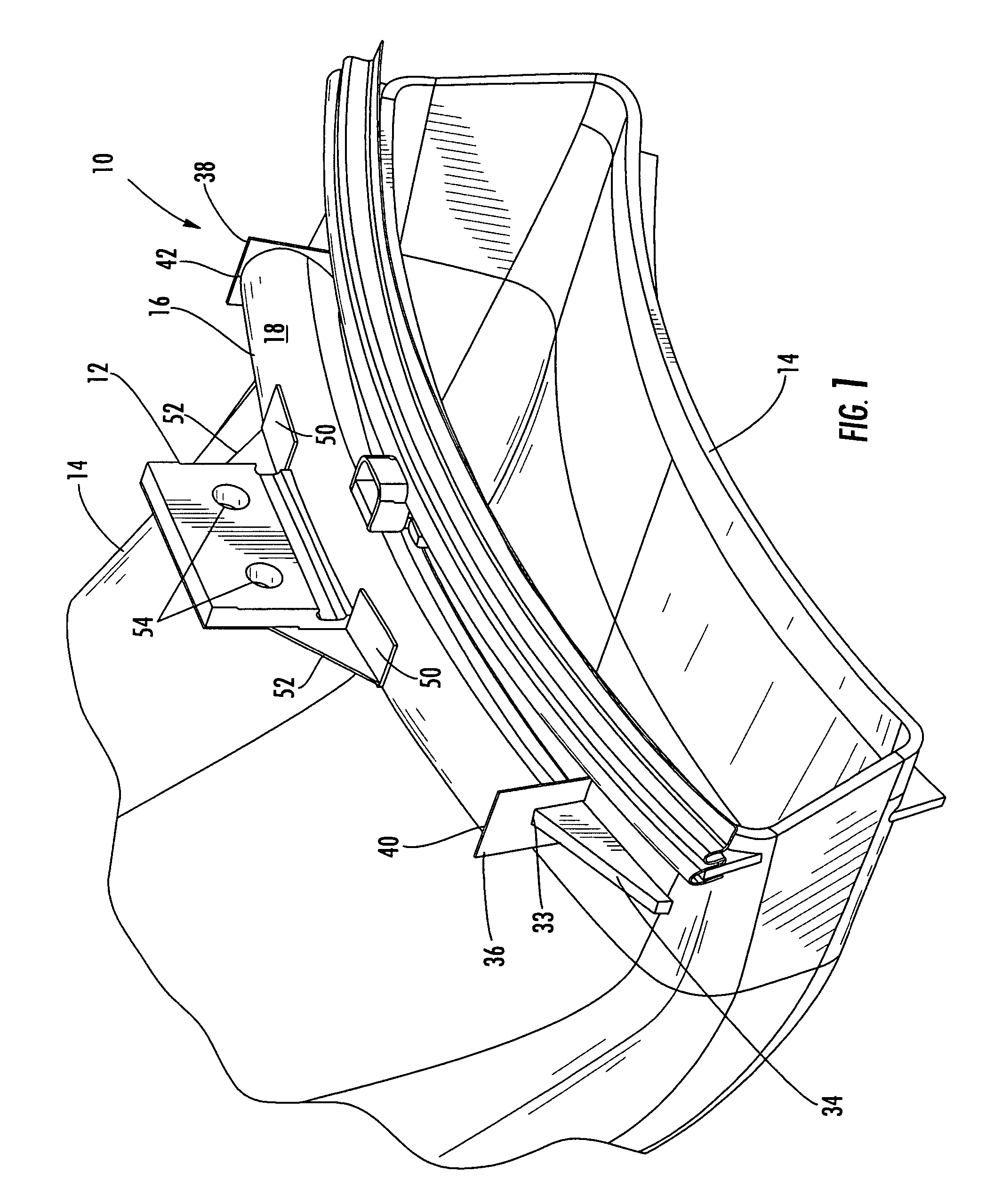

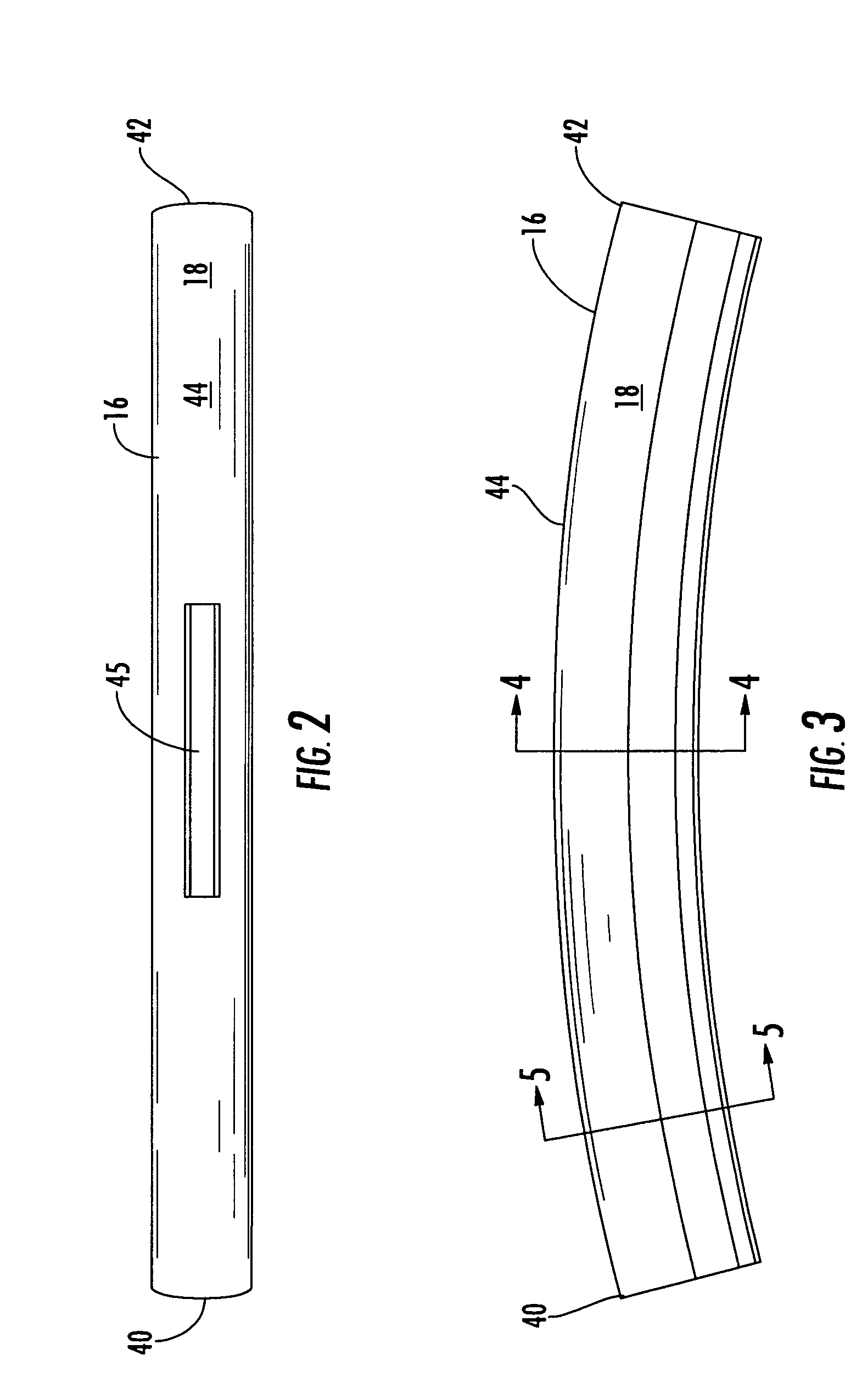

Cooling system for a transition bracket of a transition in a turbine engine

ActiveUS20060162314A1Reduce temperature differenceLikelihood of failureContinuous combustion chamberEngine fuctionsExhaust gasTurbine blade

A heat shield for a transition of a turbine engine for coupling a transition component of a turbine engine to a turbine vane assembly to direct combustor exhaust gases from the transition into the turbine vane assembly. The heat shield may be capable of reducing the temperature differential across a transition bracket extending from a transition component, thereby reducing the likelihood of premature failure of the bracket or the transition, or both. The heat shield may reduce the temperature differential by insulating the transition bracket and transition bracket rib from cooling gases. The heat shield may be formed from a tubular elongated body having first and second end attachments configured to attach the elongated heat shield body to the transition.

Owner:SIEMENS ENERGY INC

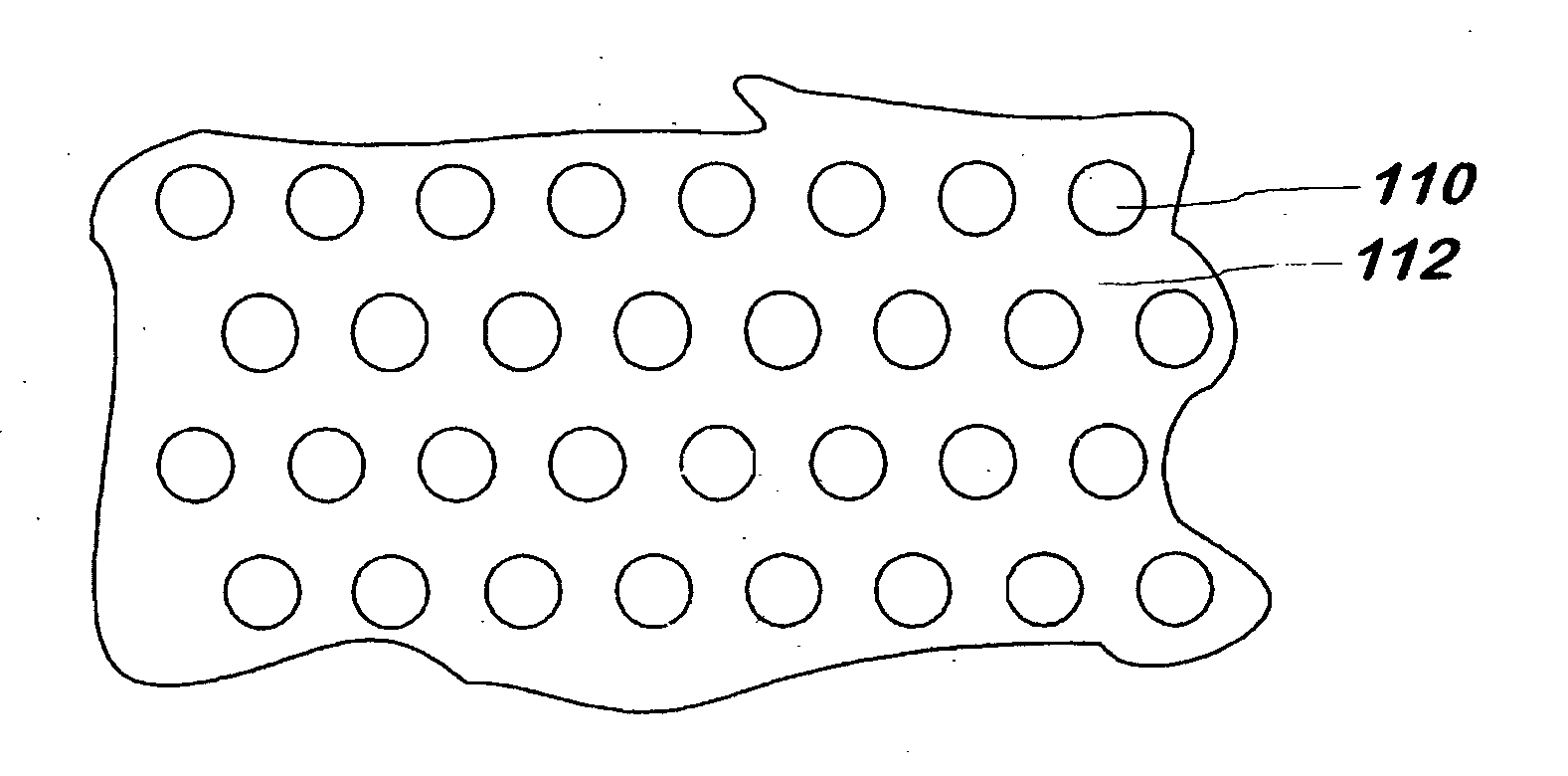

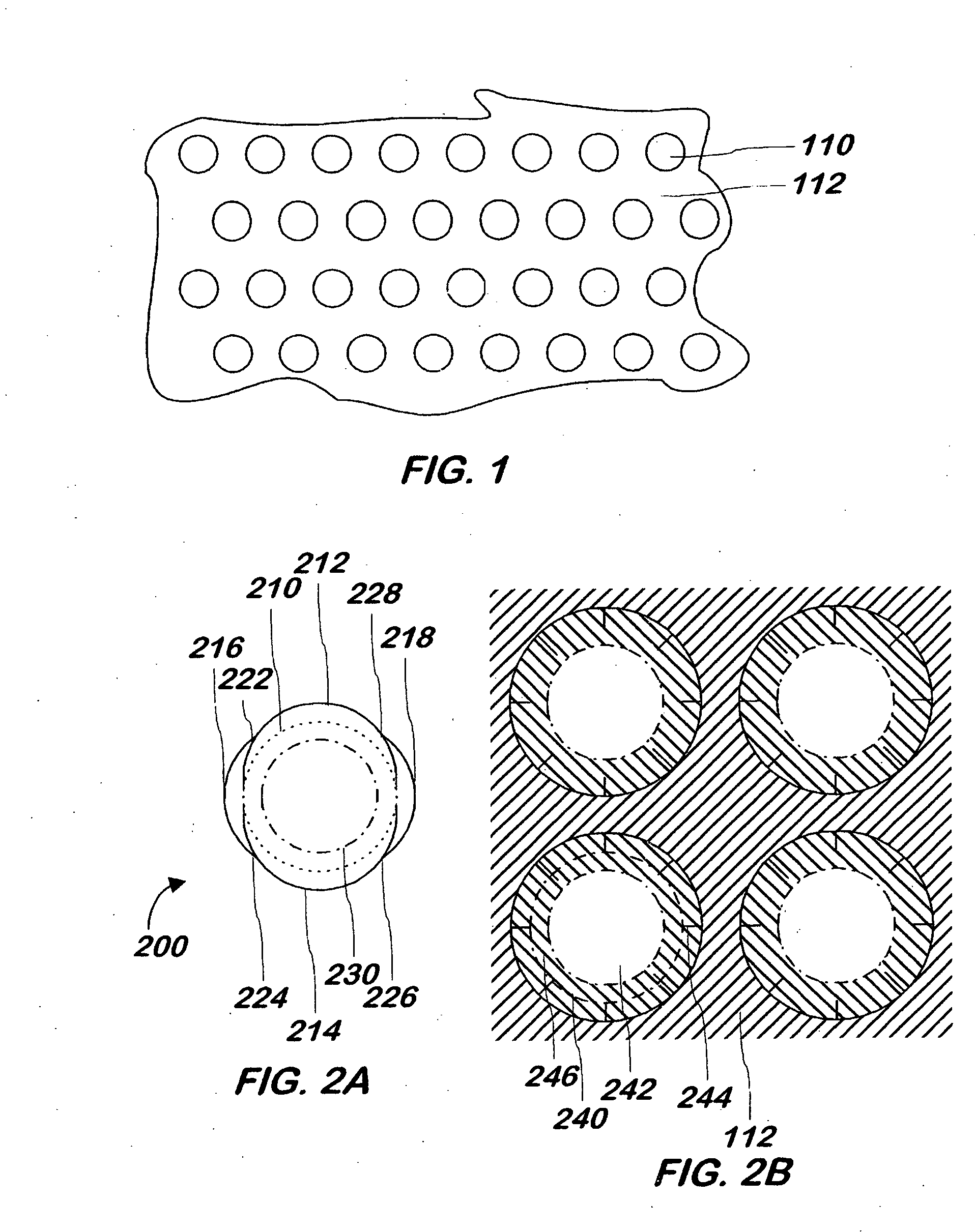

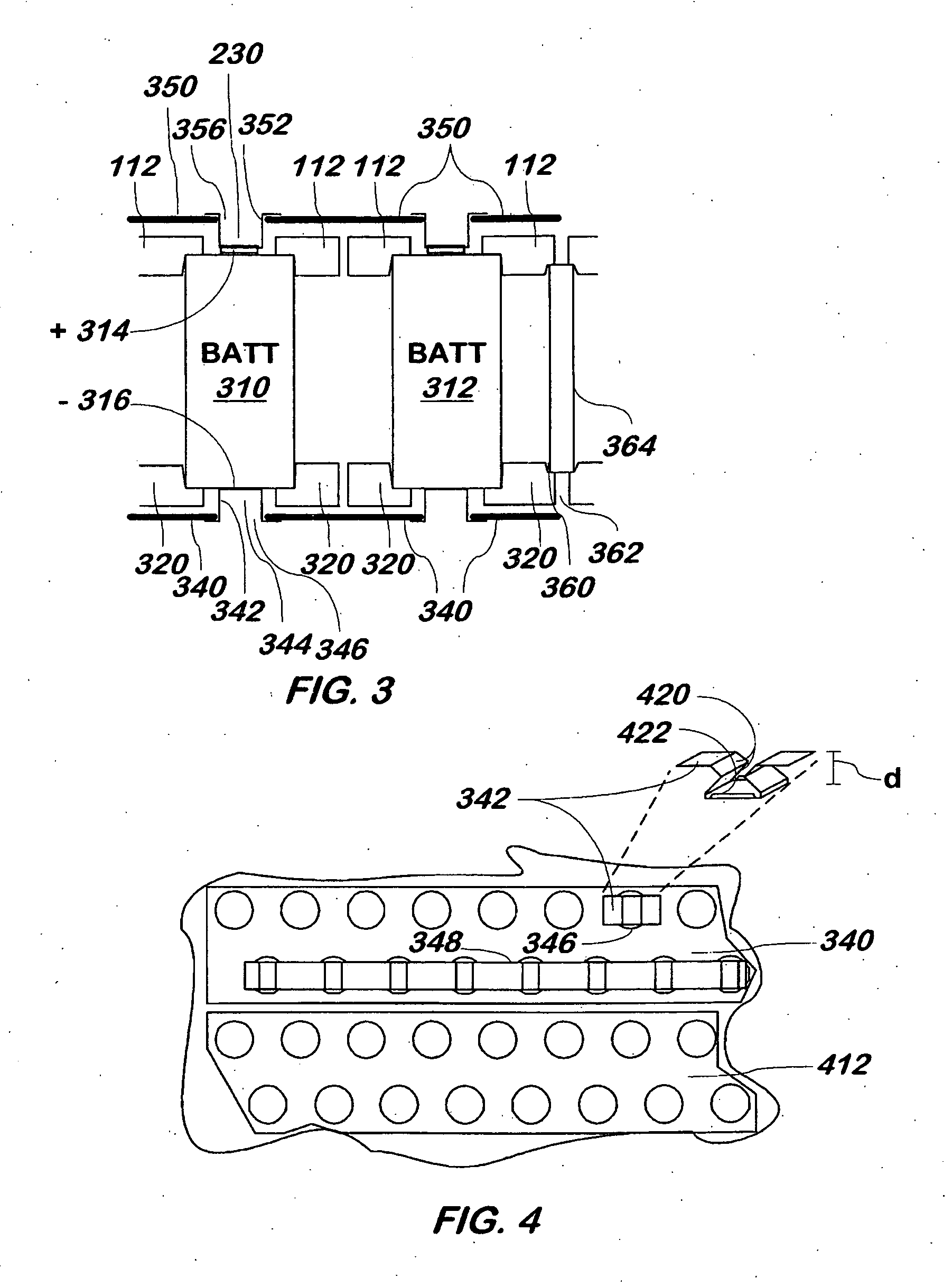

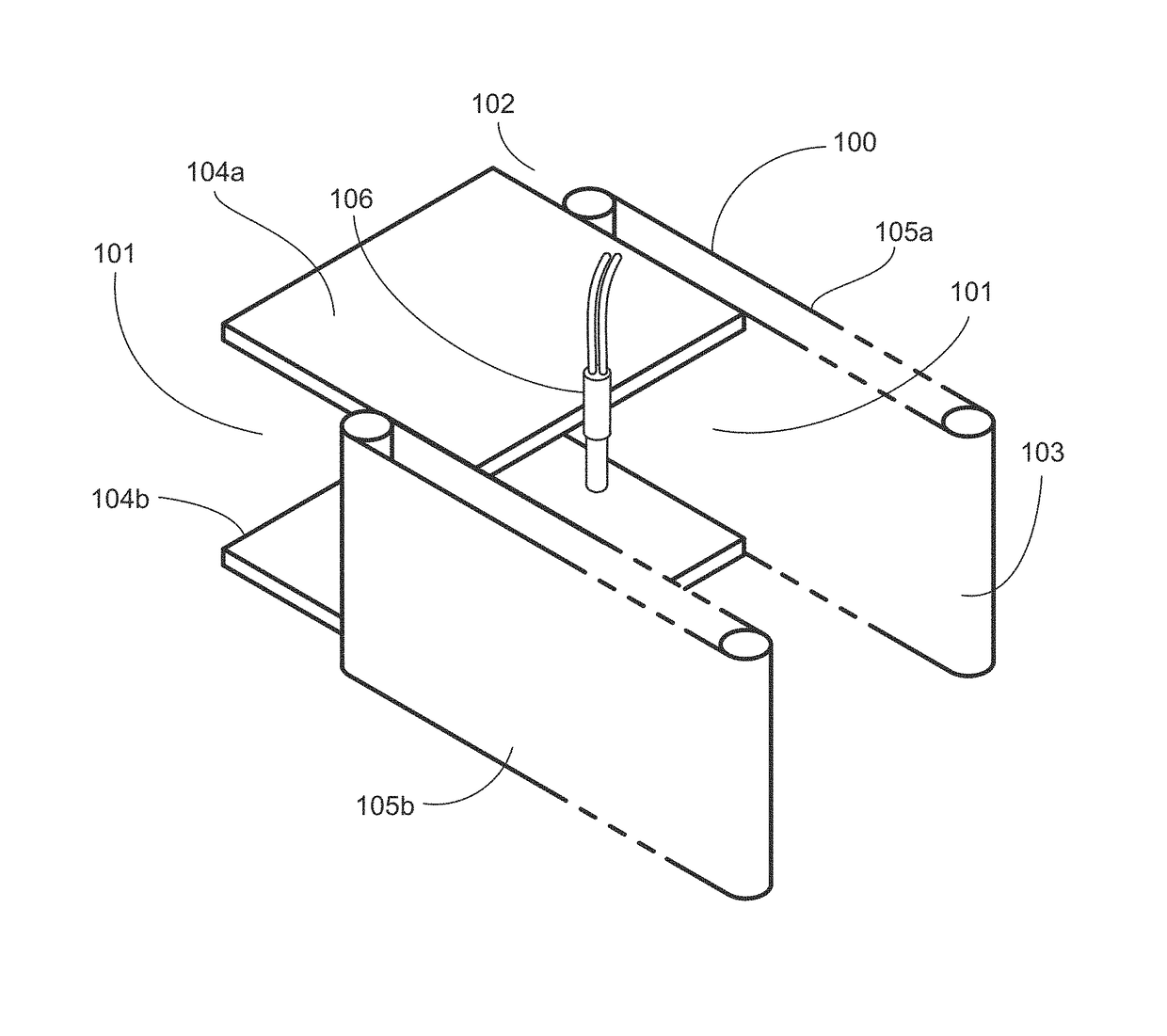

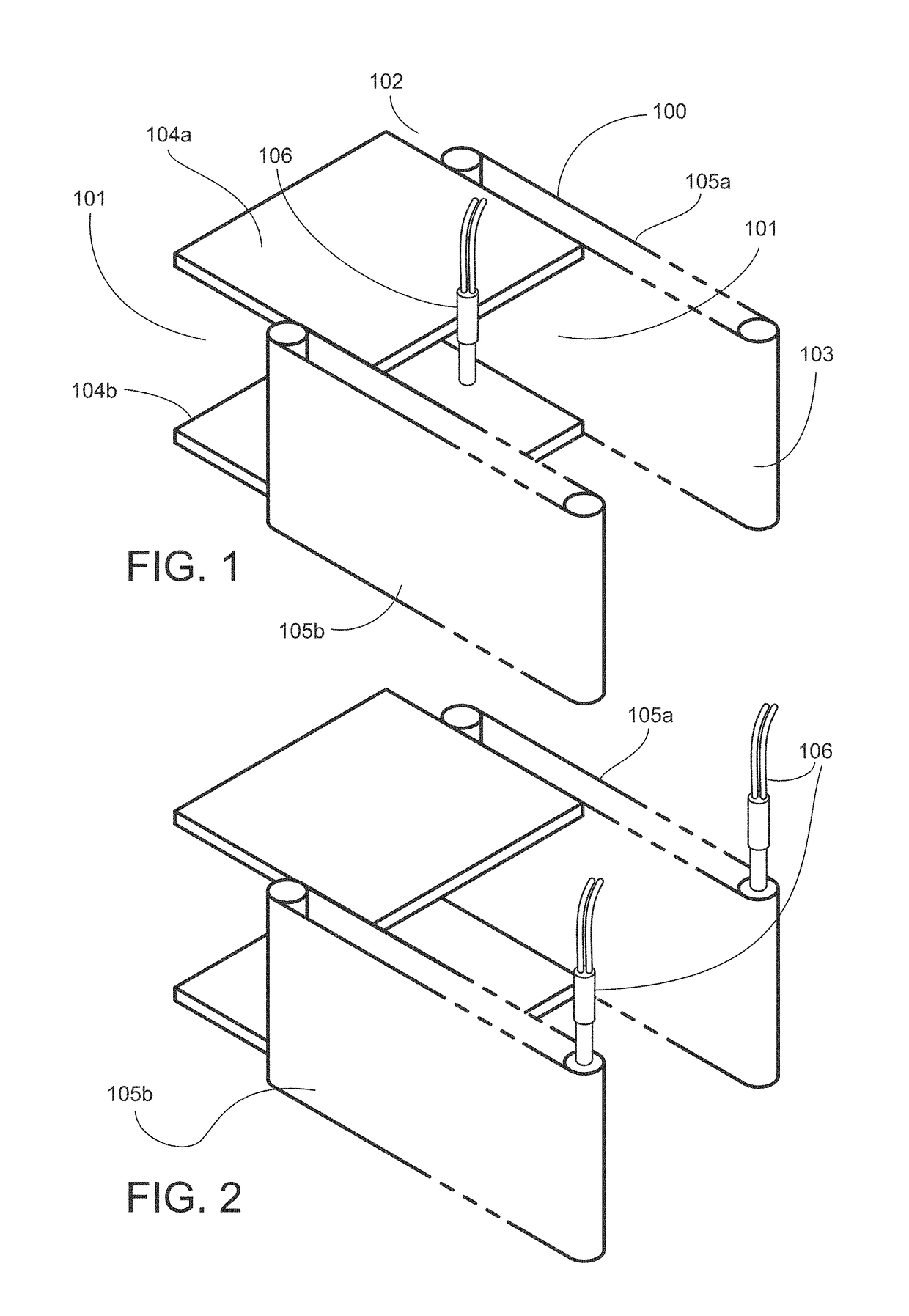

Battery mounting and cooling system

InactiveUS20110020678A1Less likely can be crushedMaximize usePrimary cell to battery groupingSecondary cellsEngineeringBattery system

A battery system is provided in which the batteries are mounted between a pair of substrates, the system further including at least one cooling tube mounted next to the batteries, the cooling tube used to withdraw heat from the batteries via a circulating liquid coolant.

Owner:TESLA INC

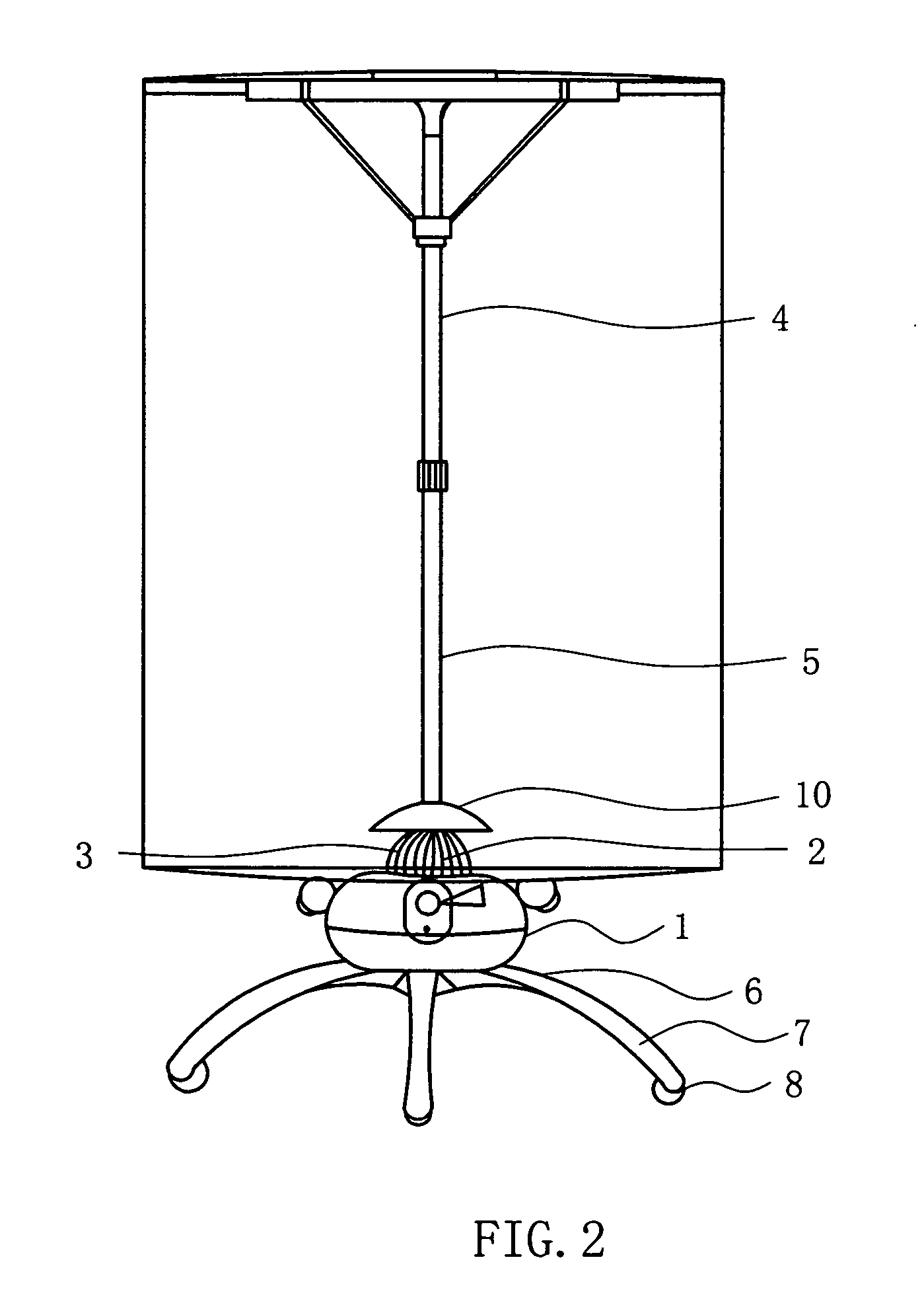

Shed type clothes dryer with safety plate

InactiveUS20090307923A1Improve securityAchieve securityDrying chambers/containersDrying solid materialsAirflowElectrical and Electronics engineering

A shed type clothes dryer, especially a shed type clothes dryer with safety ventilating member is disclosed. The shed type clothes dryer with safety ventilating member includes a heat blower, air outlet shed with plural air outlets which are set on the heat blower, umbrella shape support frame with center supporting stand which is set on the air outlet shed, clothes drying chamber formed from outer cover around the support frame. The safety ventilating member is set on the air outlet shed. A hot air relaxation chamber is formed between said safety ventilating member and the air outlet shed. The shed type clothes dryer with safety ventilating member has the following advantages: 1. mounted safety ventilating member preventing the clothes from falling on hot air port to make consumer securely use it, 2. automatically stopping after the clothes been dried by humiture probe controlling the humiture to ensure the clothes not over drying and energy saving, 3. the temperature of the hot air current let in the clothes drying chamber being uniform at each position, and the air current being mild, thus obtaining excellent clothes drying effect.

Owner:HU JIEBO

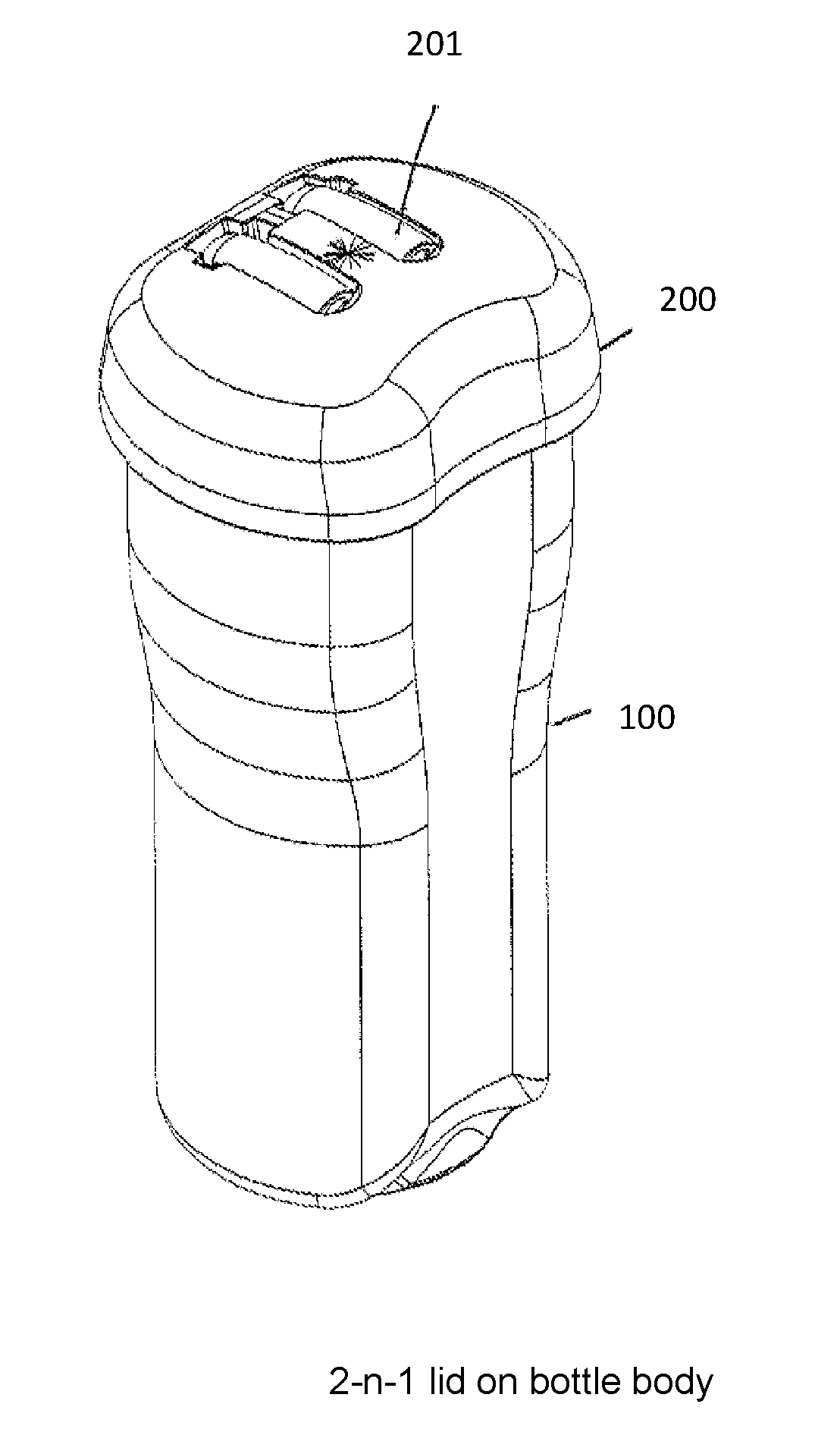

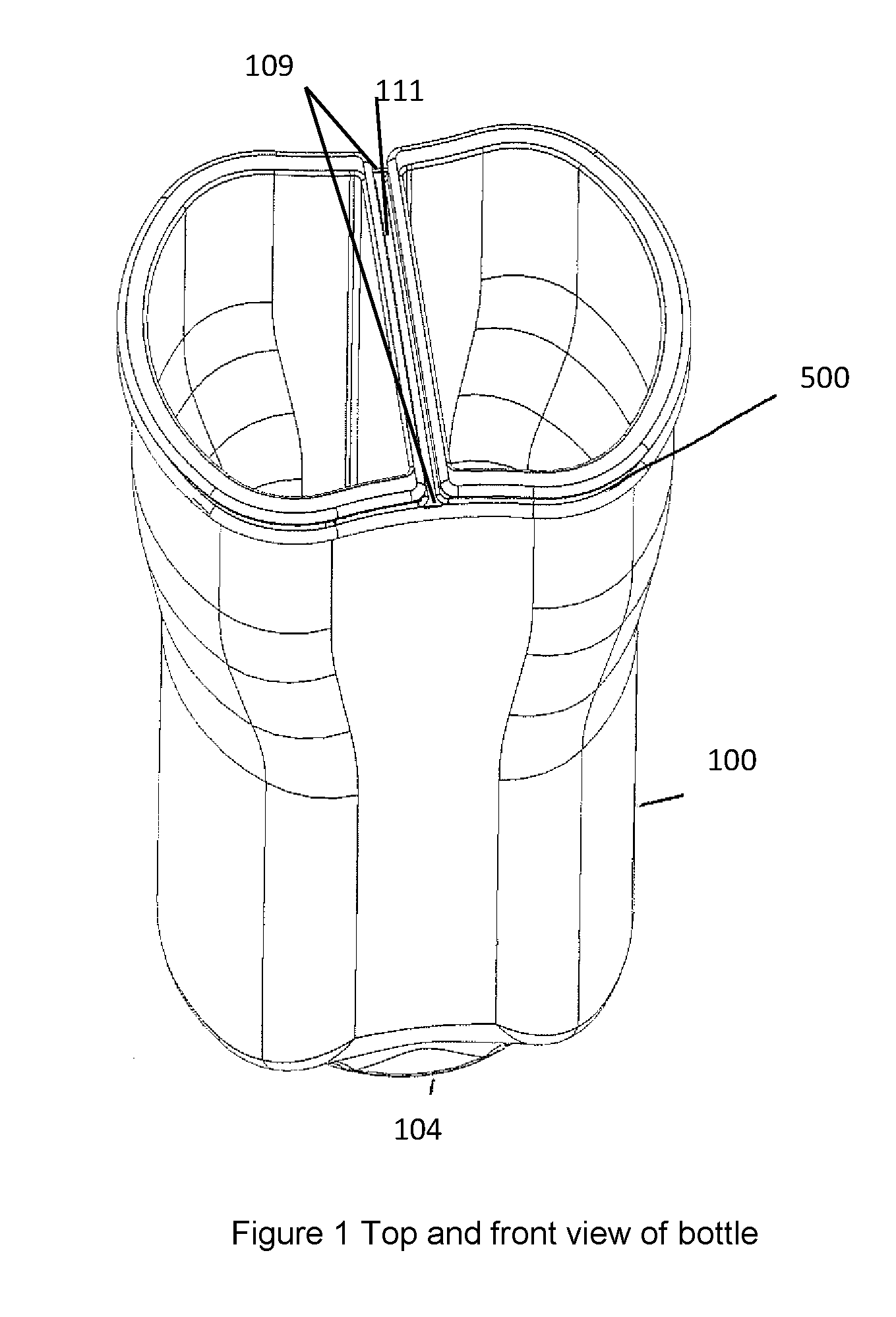

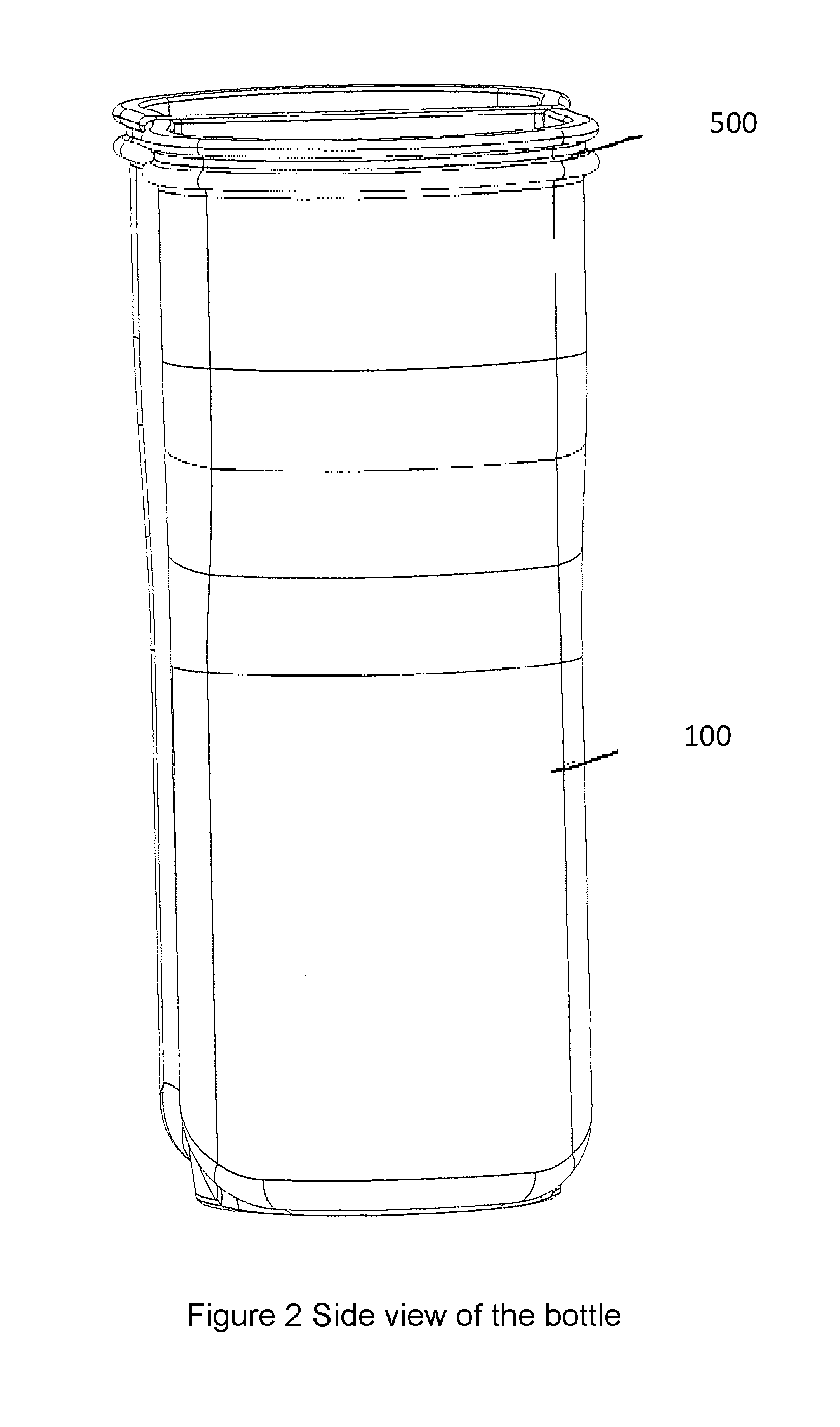

Dual chambered container with three interchangeable lids and ability to keep contents at separate temperatures

InactiveUS20160200474A1Tightly sealedPrevent heat transferClosuresBottlesEngineeringElectrical and Electronics engineering

Dual chambered container with partition space between the walls of the two chambers to prevent contents from reaching a uniform temperature; three interchangeable lids with flip up spouts: to pour or sip contents separately when spout is lifted up, to pour or sip contents mixed together when spout is lifted up, pour or sip from one chamber when flip up spout is lifted up and pick out snacks, chips etc from the other chamber; gasket between lid and bottle body to seal bottle and prevent leakage; stainless steel insert between the two content chambers so contents will reach uniform temperature or stainless steel clip sleeve to allow direct thermal contact between content of each chamber.

Owner:BURDEN GWENDOLYN D

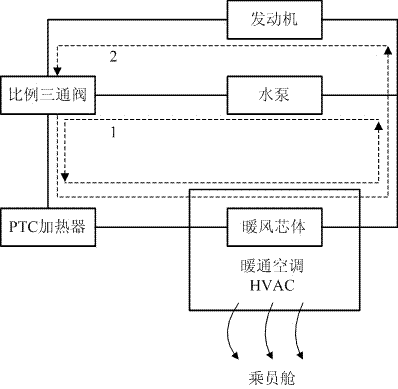

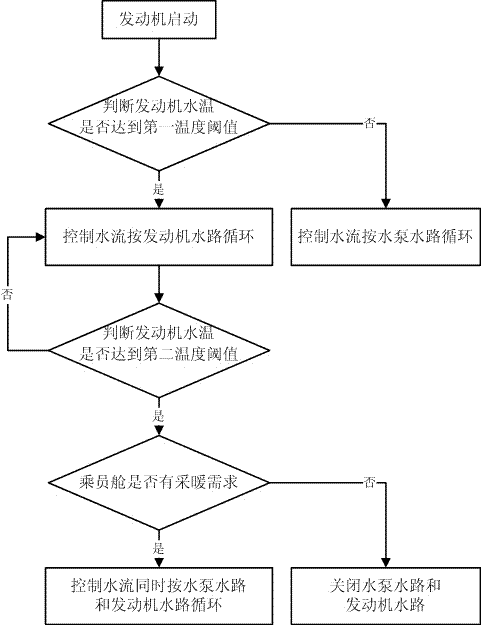

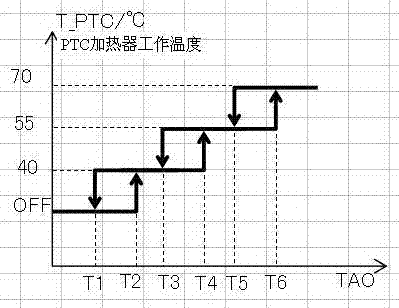

Control method for new energy vehicle heating

ActiveCN107150570AMeet heating needsSmooth temperatureAir-treating devicesVehicle heating/cooling devicesElectricityNew energy

The invention provides a control method for new energy vehicle heating. The method includes the steps that after an engine is started, whether or not water temperature of the engine reaches a first temperature threshold is judged, and if the water temperature of the engine does not reach the first temperature threshold, the water flow is controlled to circulate as the waterway of a water pump; if the water temperature of the engine reaches the first temperature threshold, the water flow is controlled to circulate as the waterway of the engine, then whether or not the water temperature of the engine reaches a second temperature threshold is further judged, if the water temperature of the engine reaches the second temperature threshold, the waterway of the water pump and the waterway of the engine are shut when a passenger compartment does not need heating, and the water flow is controlled to circulate as the waterway of the water pump and the waterway of the engine at the same time when the passenger compartment needs heating. According to the control method for new energy vehicle heating, not only is the heating requirement of the passenger compartment satisfied, but it is ensured that an air outlet of the passenger compartment is stable in temperature; in some working conditions, the working time and power of a PTC heater are reduced, electricity is saved, and the mileage is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

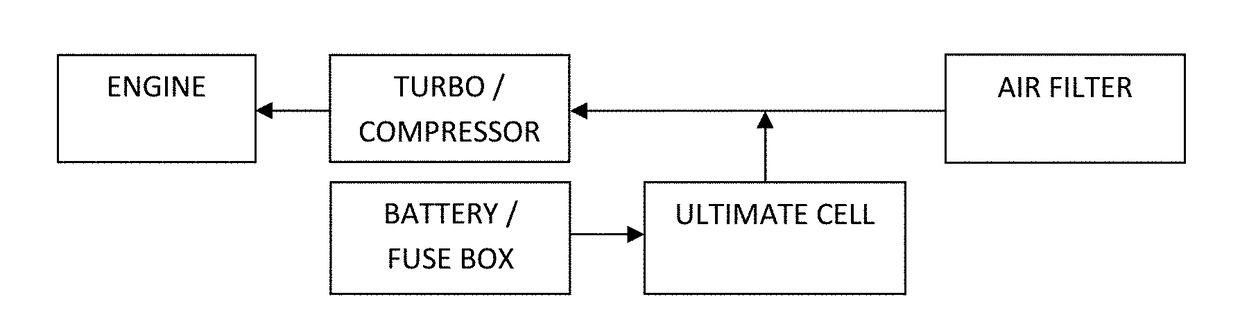

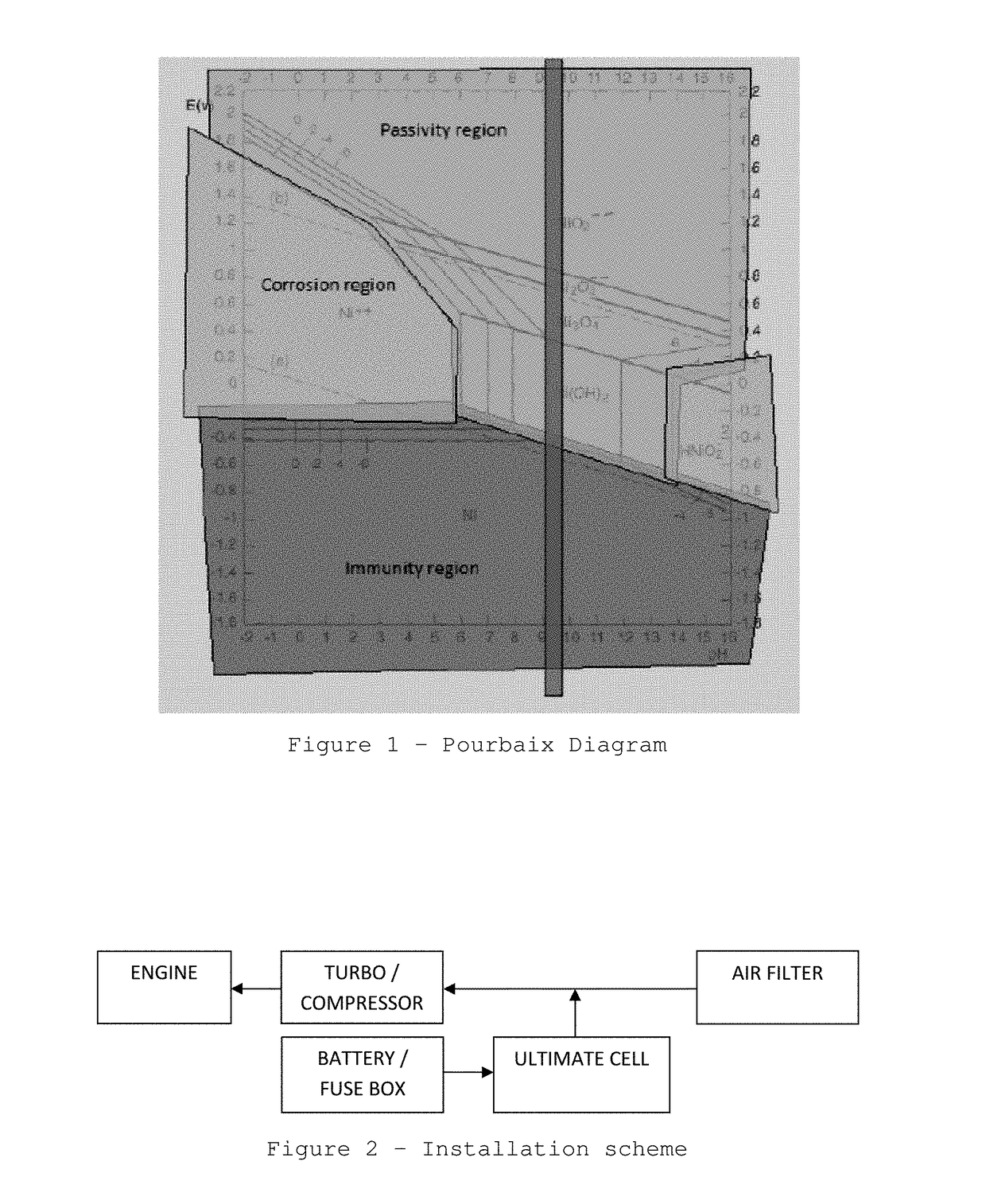

Method to increase the efficiency of combustion engines

ActiveUS20180058387A1Faster and complete combustionSmooth temperatureNon-fuel substance addition to fuelInternal combustion piston enginesCombustionElectrolysis

The present invention is related to an optimization method to internal combustion engines that reduces the fuel consumption and the exhaust emissions and particulated material. The operation principle is based in the introduction of small quantities of hydrogen in the air intake duct of the engine with the objective of optimizing the combustion of the traditional fuels, improving the parameters of the combustion reaction. This optimized combustion will increase the efficiency of the engine and reduce its environmental impact. The hydrogen is produced by an electrolysis reaction inside an electrochemical closed cell with non-circulating electrolyte.

Owner:UTIS ULTIMATE TECH TO IND SAVINGS LDA

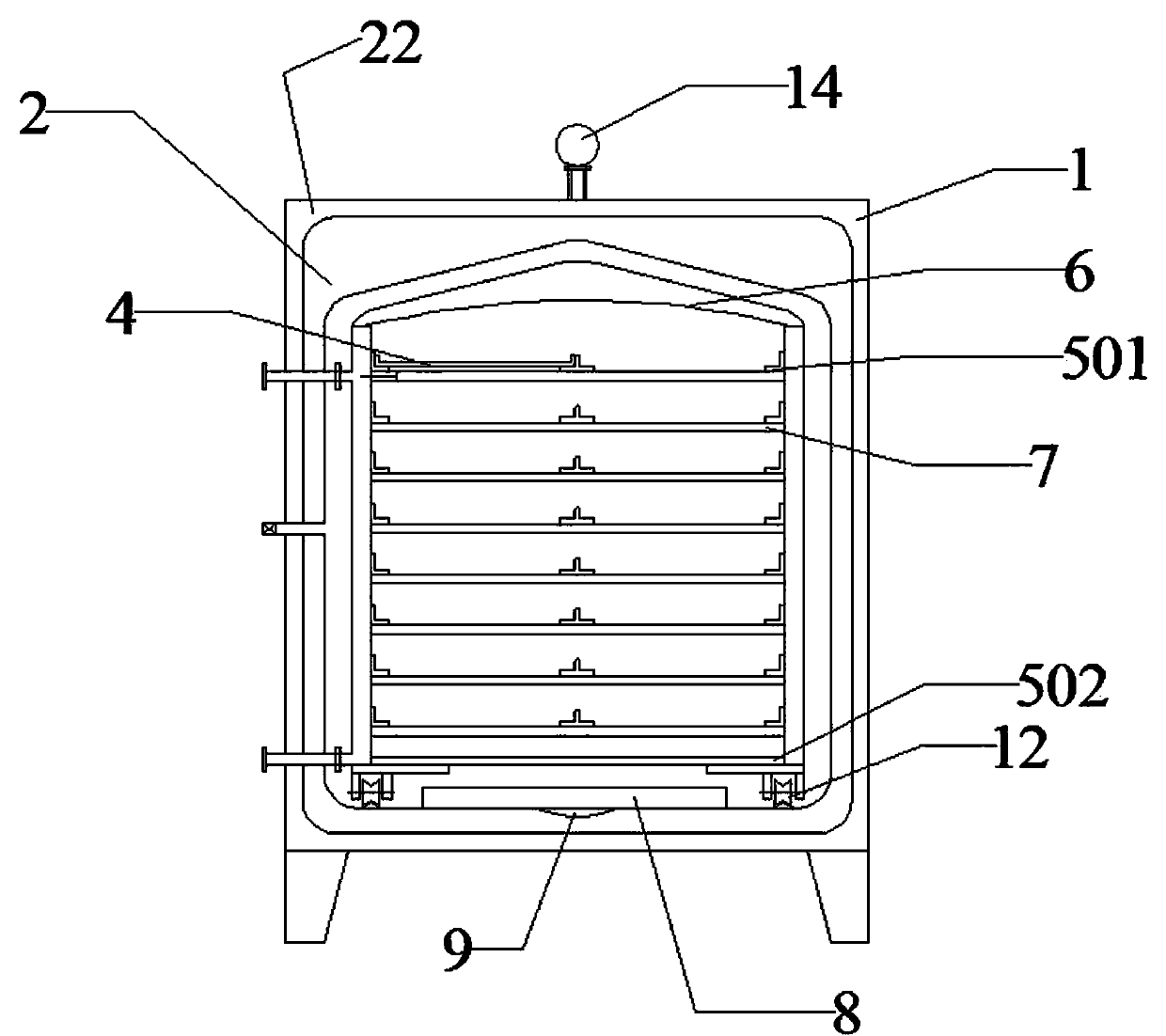

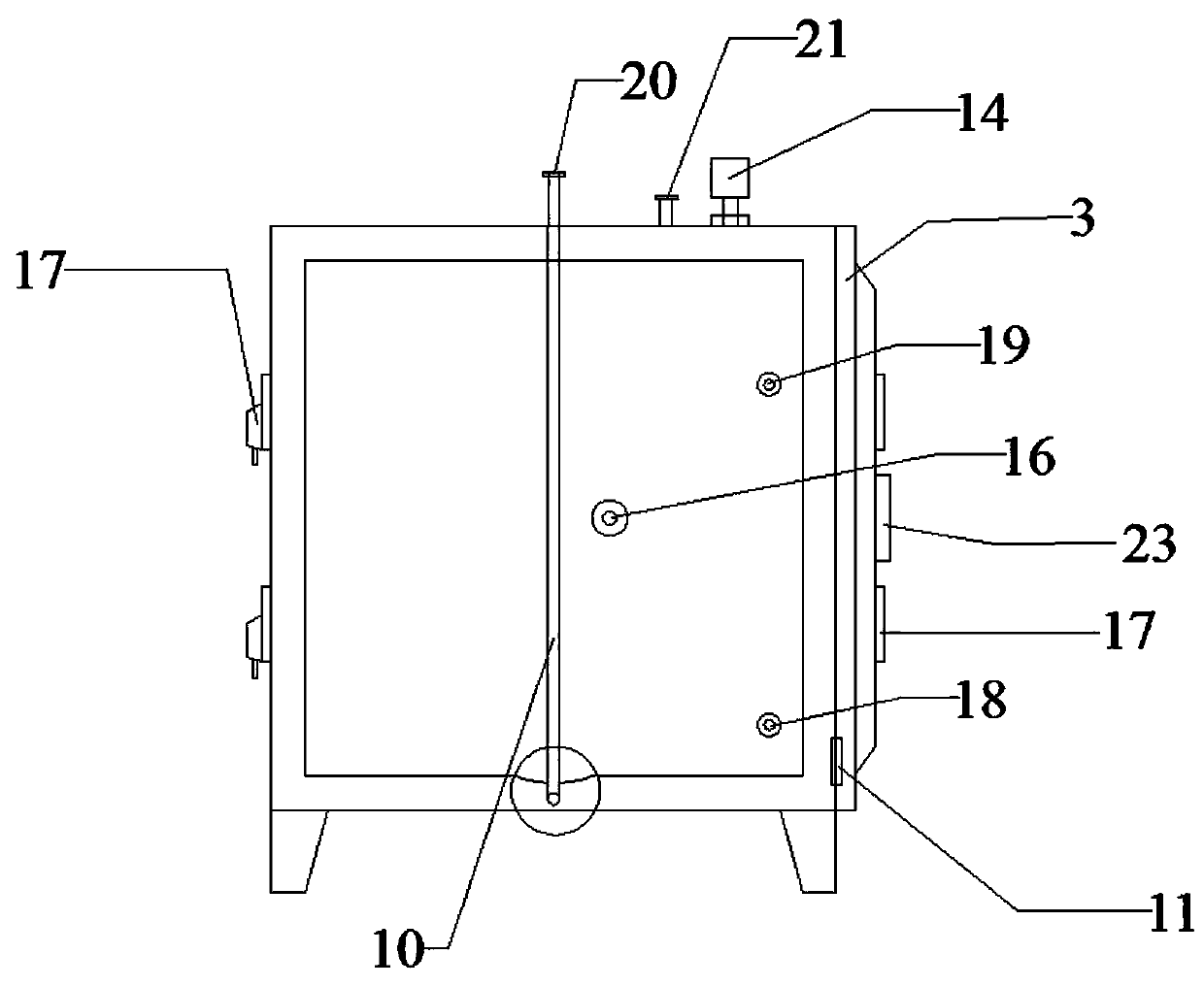

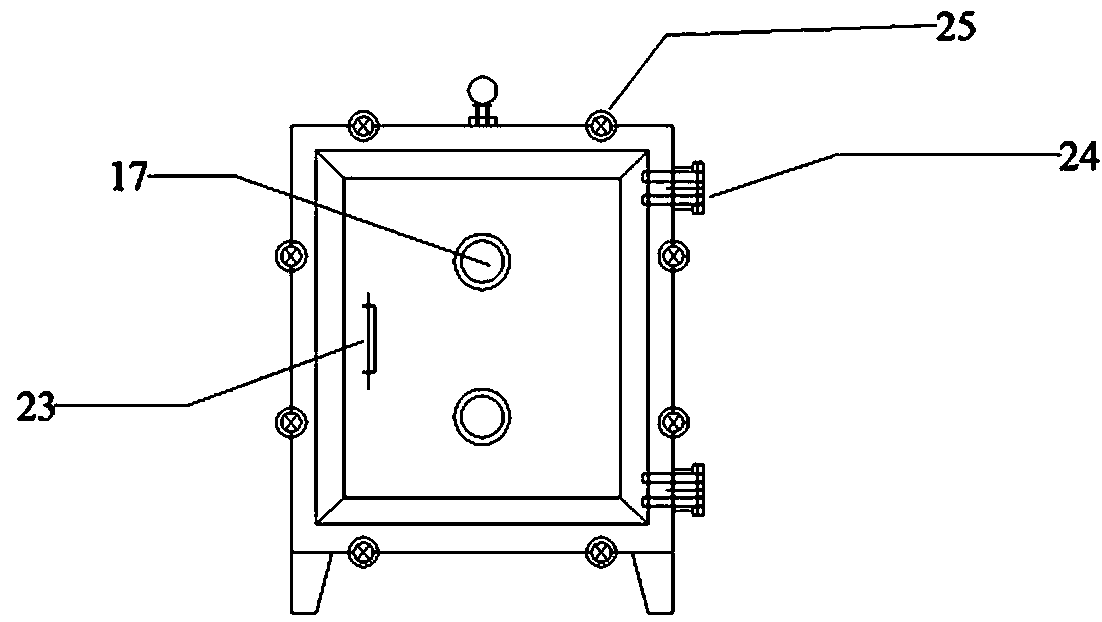

Low-temperature vacuum drying box

ActiveCN103471353ASmooth temperatureUniform temperatureDrying chambers/containersDrying solid materialsEngineeringDry box

The invention discloses a low-temperature vacuum drying box which comprises a box body, a working chamber disposed inside the box body and a box door disposed outside the box body. The low-temperature vacuum drying box is characterized in that the working chamber comprises a drying plate, a first-kind drying frame for placing the drying plate, a retaining plate disposed below the top of the working chamber, a radiating coil disposed below the first-kind drying frame, a water retaining strip disposed at the bottom, close to the box door, of the working chamber, and a second-kind drying frame located below the first-kind drying frame. The low-temperature vacuum drying box has the advantages that the inner top of the working chamber is semi-elliptical, the structure with four arc corners allows temperature in the box body to be smooth and even during heating, in the meantime, steam drops generated by drying can flow from two sides into the central bottom of the box body and be pumped out by a vacuum pump via a bottom draining hole and a vacuum connecting pipe, and dryness in the box is kept all the time.

Owner:NANJING SHENPENG MACHINERY EQUIP

Ceramic heater for semiconductor manufacturing and inspecting equipment

InactiveUS6878906B2Accurate temperature measurementImprove responseSemiconductor/solid-state device manufacturingHot plates heating arrangementsWhole bodySurface roughness

An object of the present invention is to provide a ceramic heater for a semiconductor producing / examining device which is capable of accurately measuring the temperature of an object to be heated and evenly heating the whole body of a silicon wafer by adjusting the heating state of a heating element based on the temperature measurement result, and the ceramic heater for a semiconductor producing / examining device of the present invention is a ceramic heater including a ceramic substrate and a heating element formed on the surface or the inside of the ceramic substrate, wherein a temperature measurement element is formed while being brought into contact with the ceramic substrate and the surface roughness of the ceramic substrate brought into contact with the temperature measurement element is Ra≦5 μm.

Owner:IBIDEN CO LTD

Cooling system for a transition bracket of a transition in a turbine engine

ActiveUS7278254B2Reduce temperature differenceLikelihood of failureContinuous combustion chamberEngine fuctionsCombustorTurbine blade

A heat shield for a transition of a turbine engine for coupling a transition component of a turbine engine to a turbine vane assembly to direct combustor exhaust gases from the transition into the turbine vane assembly. The heat shield may be capable of reducing the temperature differential across a transition bracket extending from a transition component, thereby reducing the likelihood of premature failure of the bracket or the transition, or both. The heat shield may reduce the temperature differential by insulating the transition bracket and transition bracket rib from cooling gases. The heat shield may be formed from a tubular elongated body having first and second end attachments configured to attach the elongated heat shield body to the transition.

Owner:SIEMENS ENERGY INC

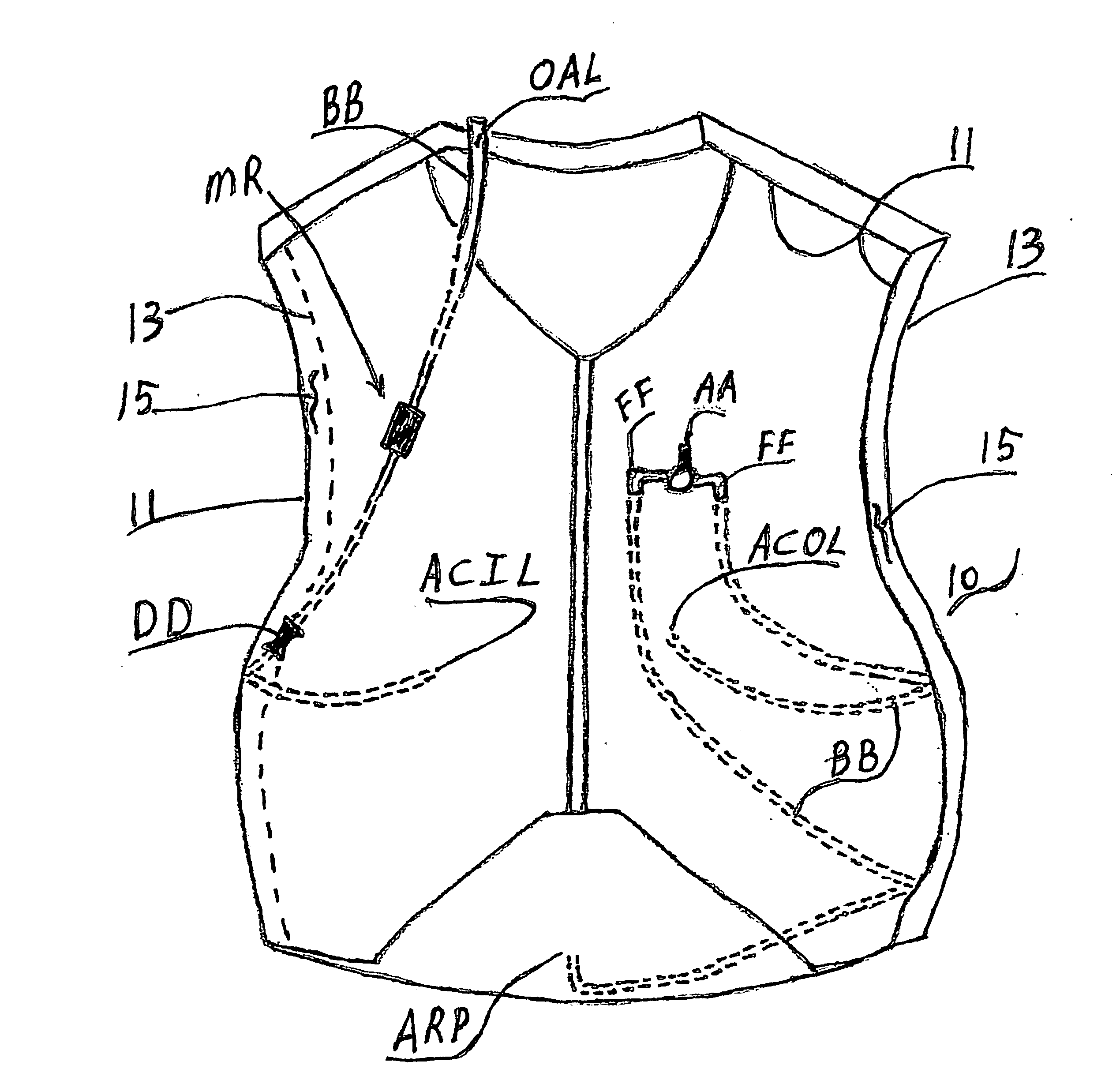

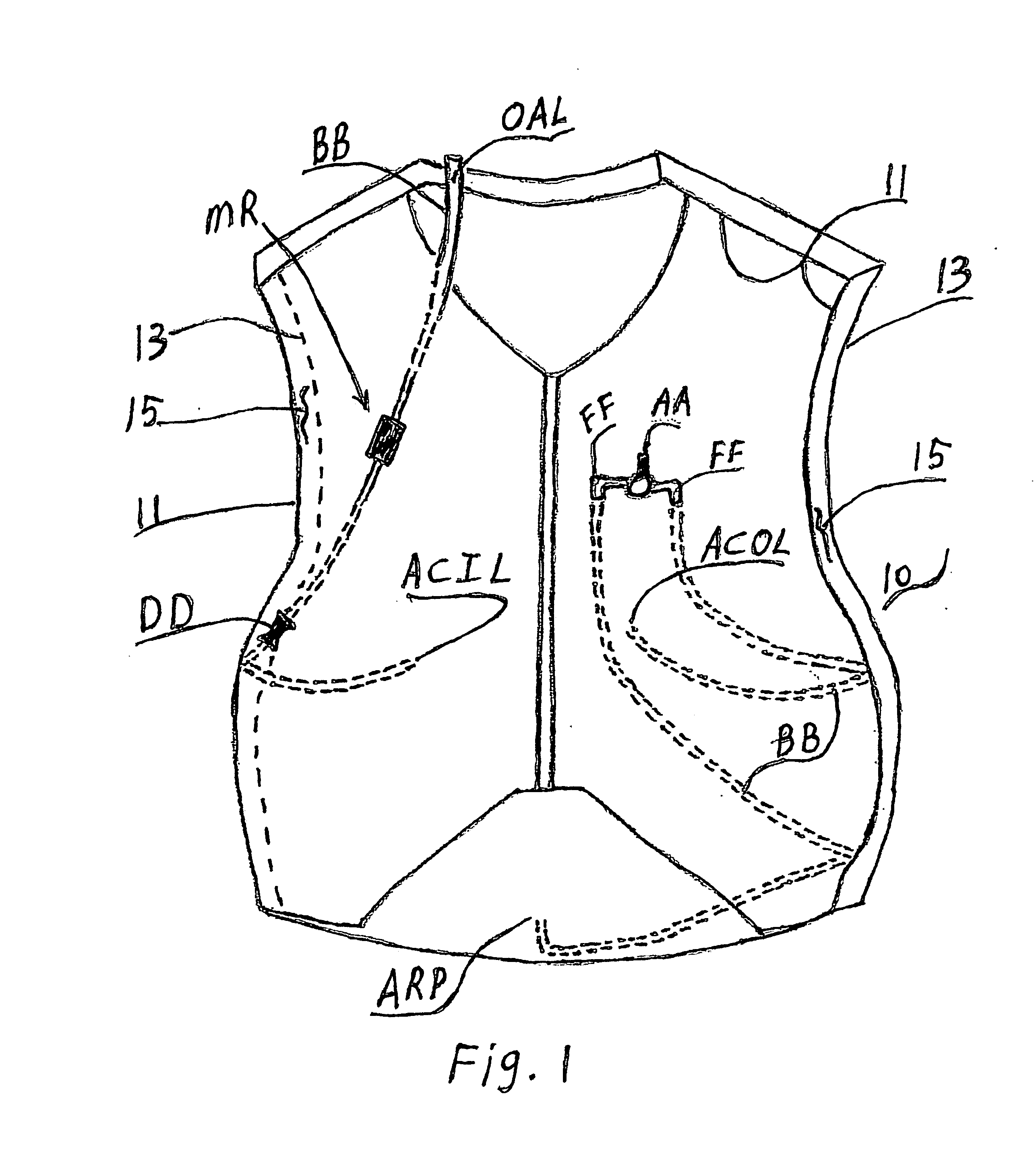

Blo-warm vest

InactiveUS20150327602A1Simple to manufactureEasily obtainLighting and heating apparatusAir conditioning systemsMoistureDesiccant

A garment including a one-way inlet line including a desiccant to remove moisture from the user's breath, the inlet line being connected to a chamber formed by at least a portion of the front and back of the garment. The line extends through a portion of the garment to a designated location where warm air from the user's breath is distributed in the chamber. There is a second valve that the user operates to release the contained air, such as when one goes inside or when one wants to replenish the warm air after a period of time has passed.

Owner:NELSON ROBERT ALBIN

Home cooling cycle

InactiveUS20050183435A1Lower heating costsSmooth interior temperatureDomestic refrigeratorsAir heatersAir cycleOne pass

The heart of the “New Home Cooling Cycle” is a concrete heat exchanger located under the home. The heat exchanger is constructed of concrete and PVC piping. There are two flow passes. Each is ninety degrees from the other. On a hot sunny day, heat absorbed by air inside the home is routed through one pass of the heat exchanger where the heat is removed by absorption into the concrete, thus removing heat from the home. Air is circulated using a small electric blower. Air leaving the heat exchanger is cool and is returned to the home ready to absorb heat again. The recycled air absorbs additional heat and the cycle is repeated through the heat exchanger. Regeneration of the heat exchanger is accomplished at night. Cool night air is blown, using a small electric blower, through the heat exchanger second pass, ninety degrees to the absorbing pass. This cooling air absorbs heat from the heat exchanger and exhausts it back to the night air. The two heat exchanger passes are totally isolated to prevent moisture from entering the house circuit. This same cycle is used during winter. On a sunny winter day, solar heat and heat from a wood burning fireplace is absorbed by air inside the home and is routed through the heat exchanger as in the summer cooling cycle. Heat is removed and stored in the heat exchanger and cooled air is returned to the home where the cycle repeats. At night, heat stored in the heat exchanger is routed into the home. During winter, there is no regeneration required for the heat exchanger. Usage of refrigerated air conditioning is radically reduced. In some United States climates, it may be possible to eliminate refrigerated air conditioning.

Owner:AUBIN DOUGLAS EDWARD

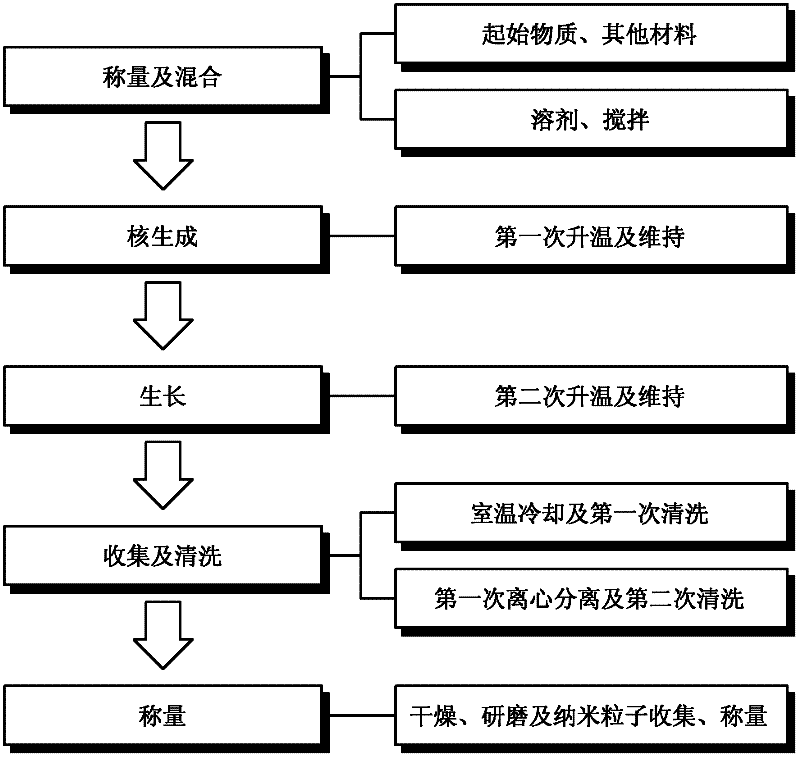

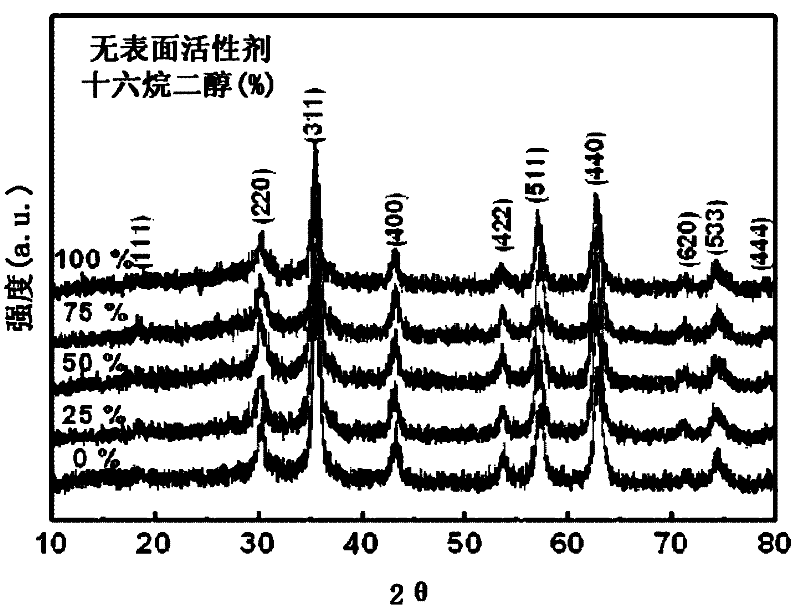

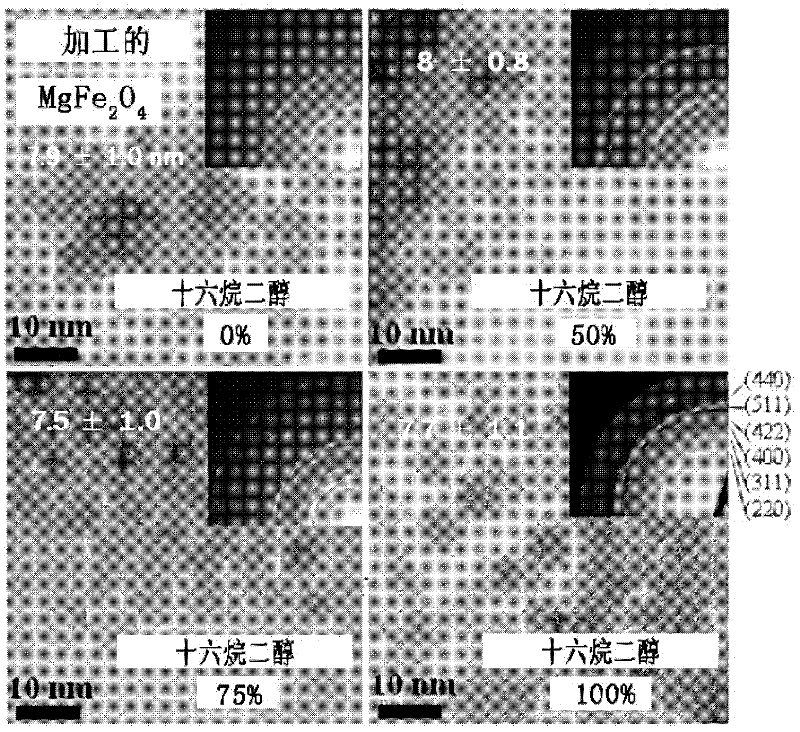

Manufacturing method of superparamagnetic magnesium-doped ferrite nanoparticles and the nanoparticles

InactiveCN102264632AGood biocompatibilitySmooth temperatureMaterial nanotechnologySenses disorderFerrite nanoparticlesCancer cell

Owner:NURI VISTA

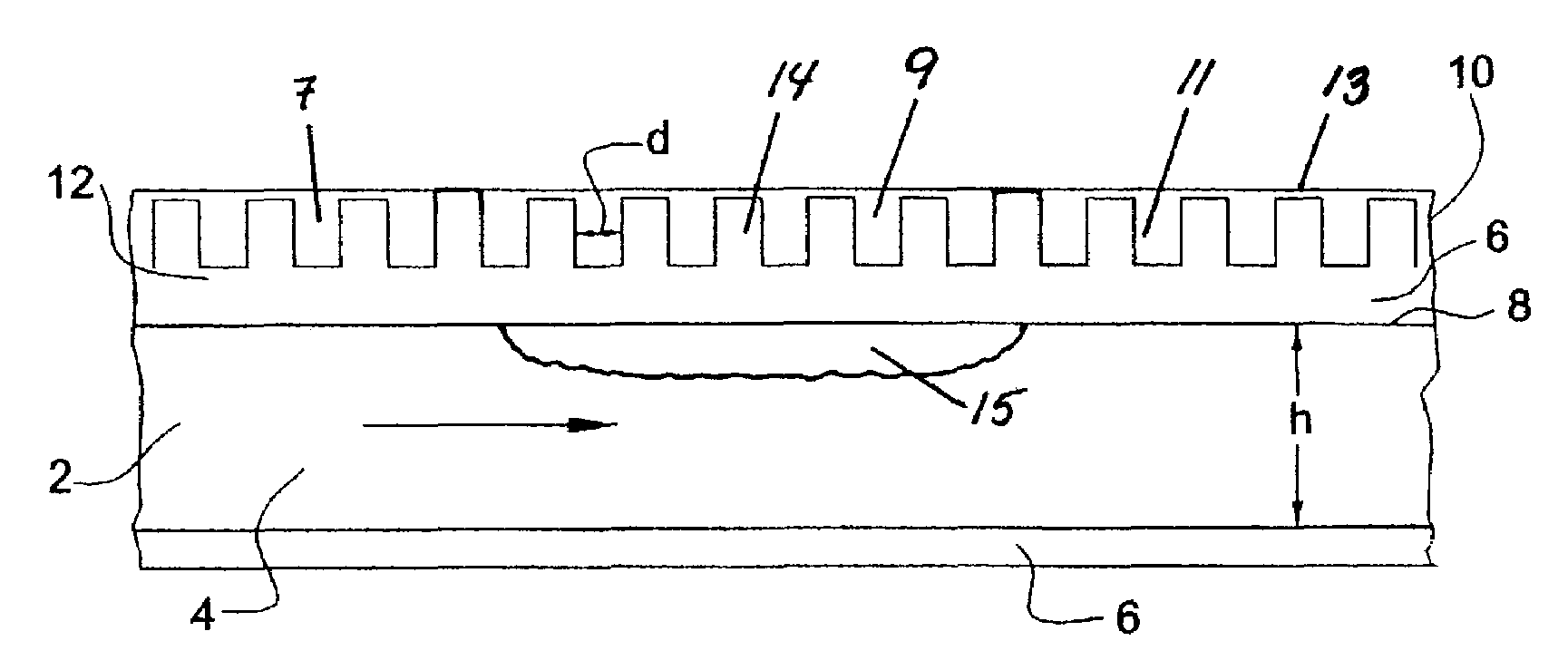

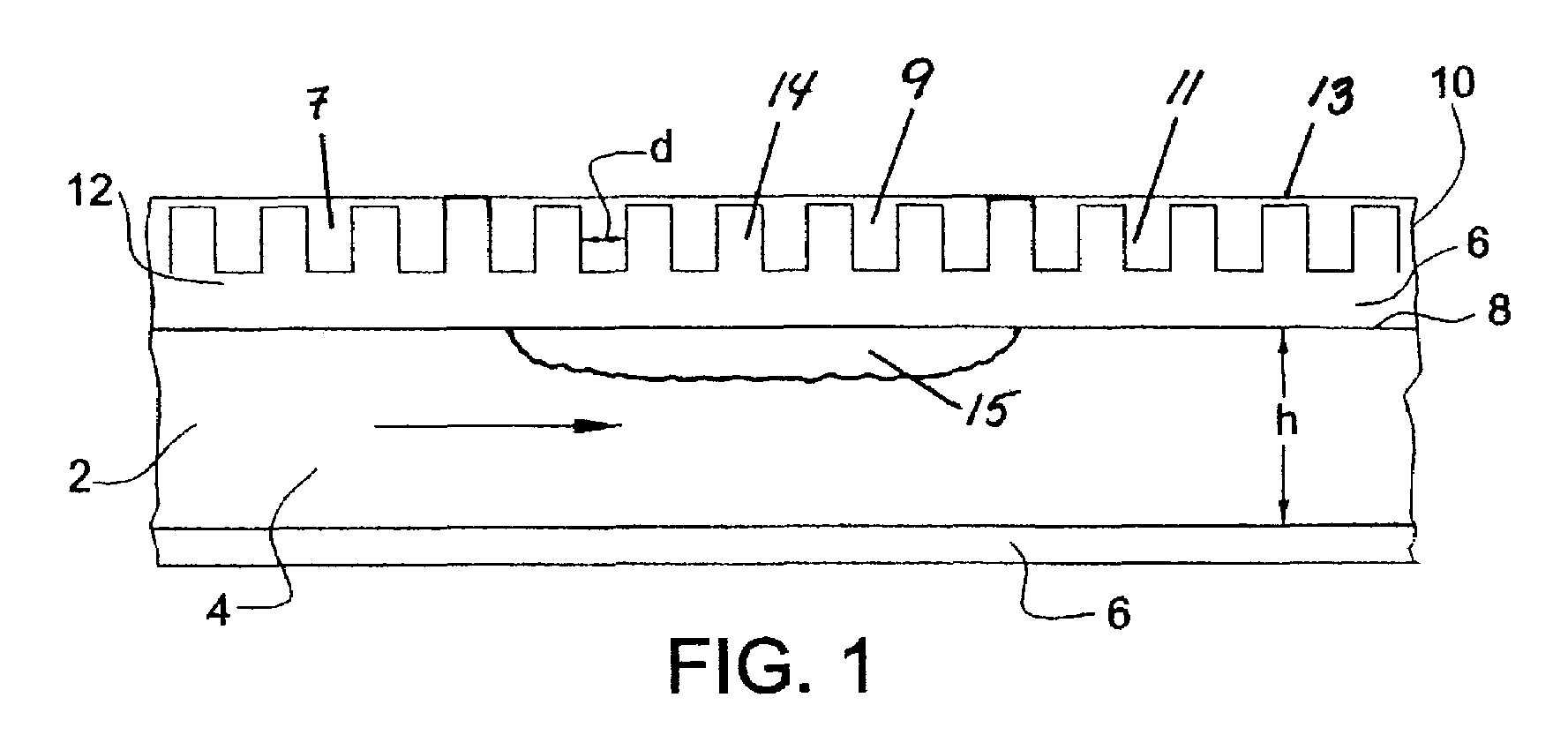

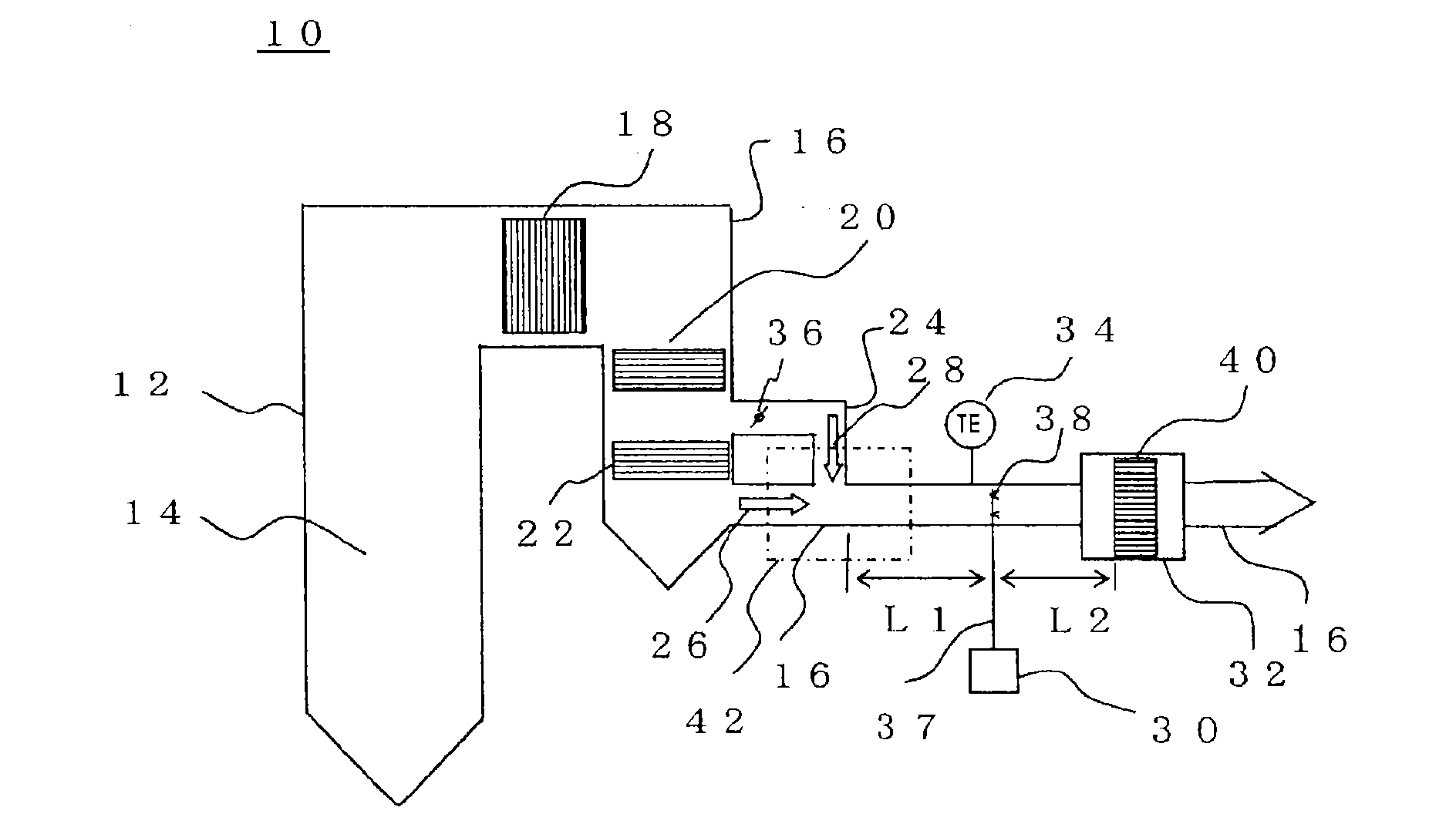

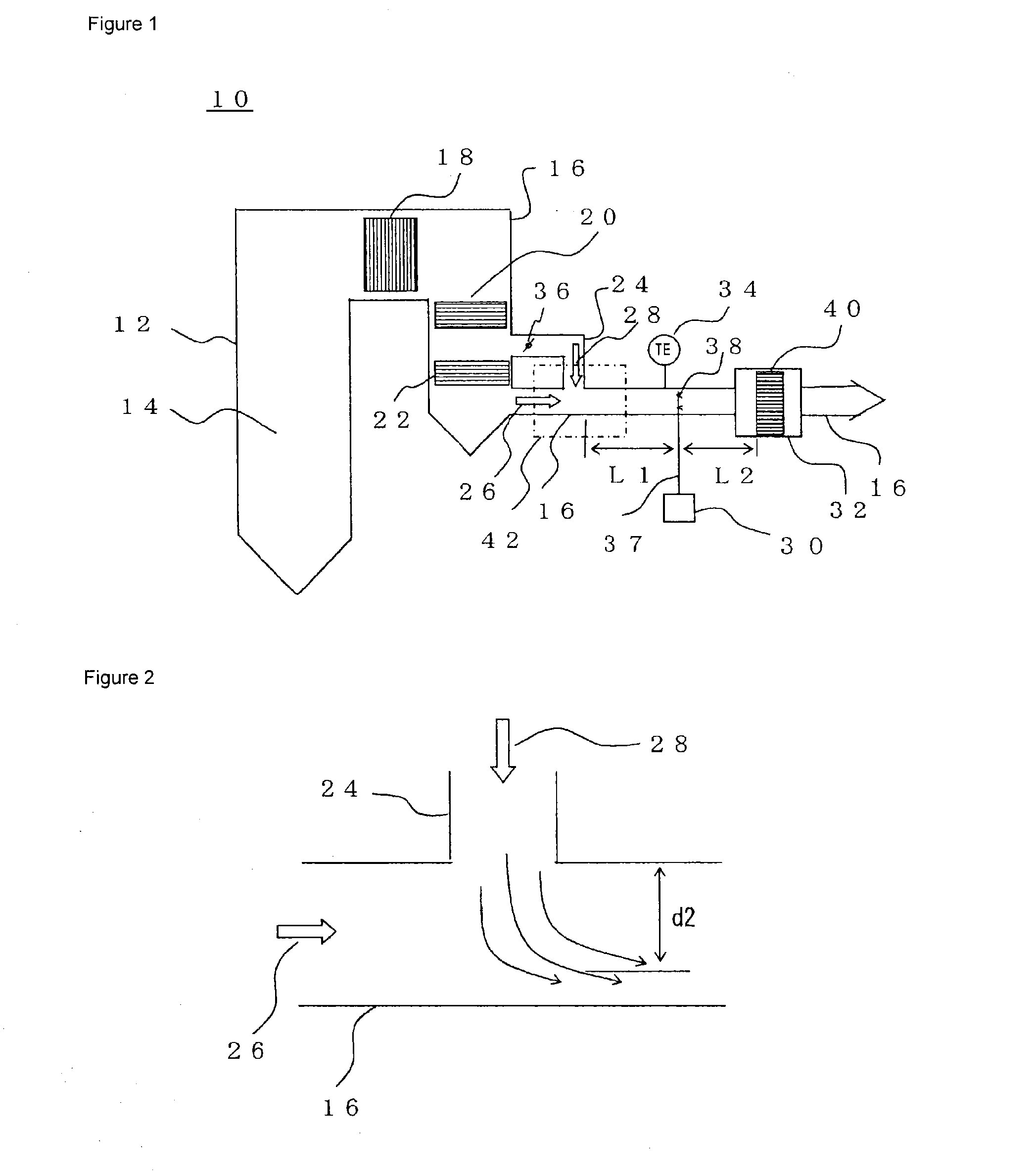

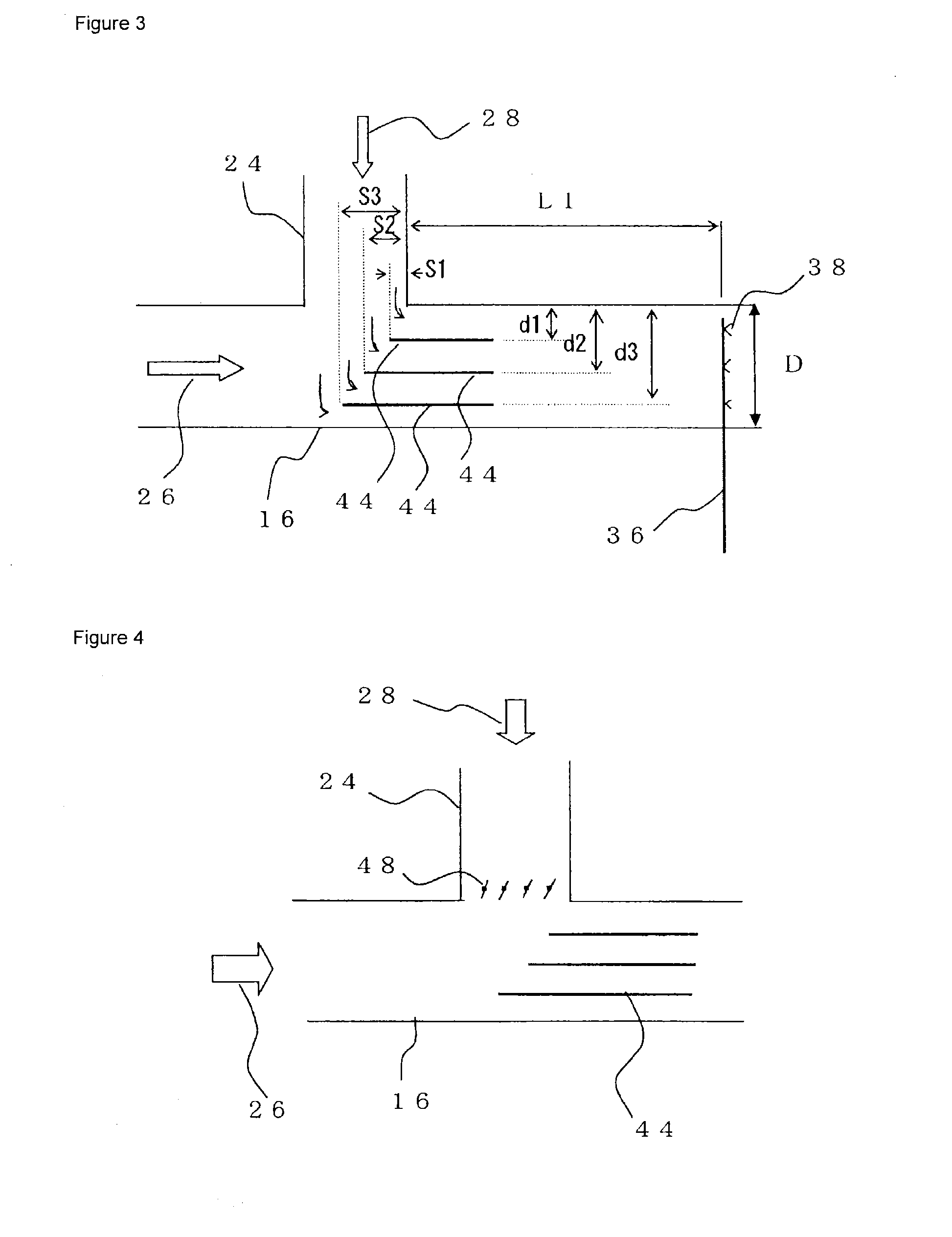

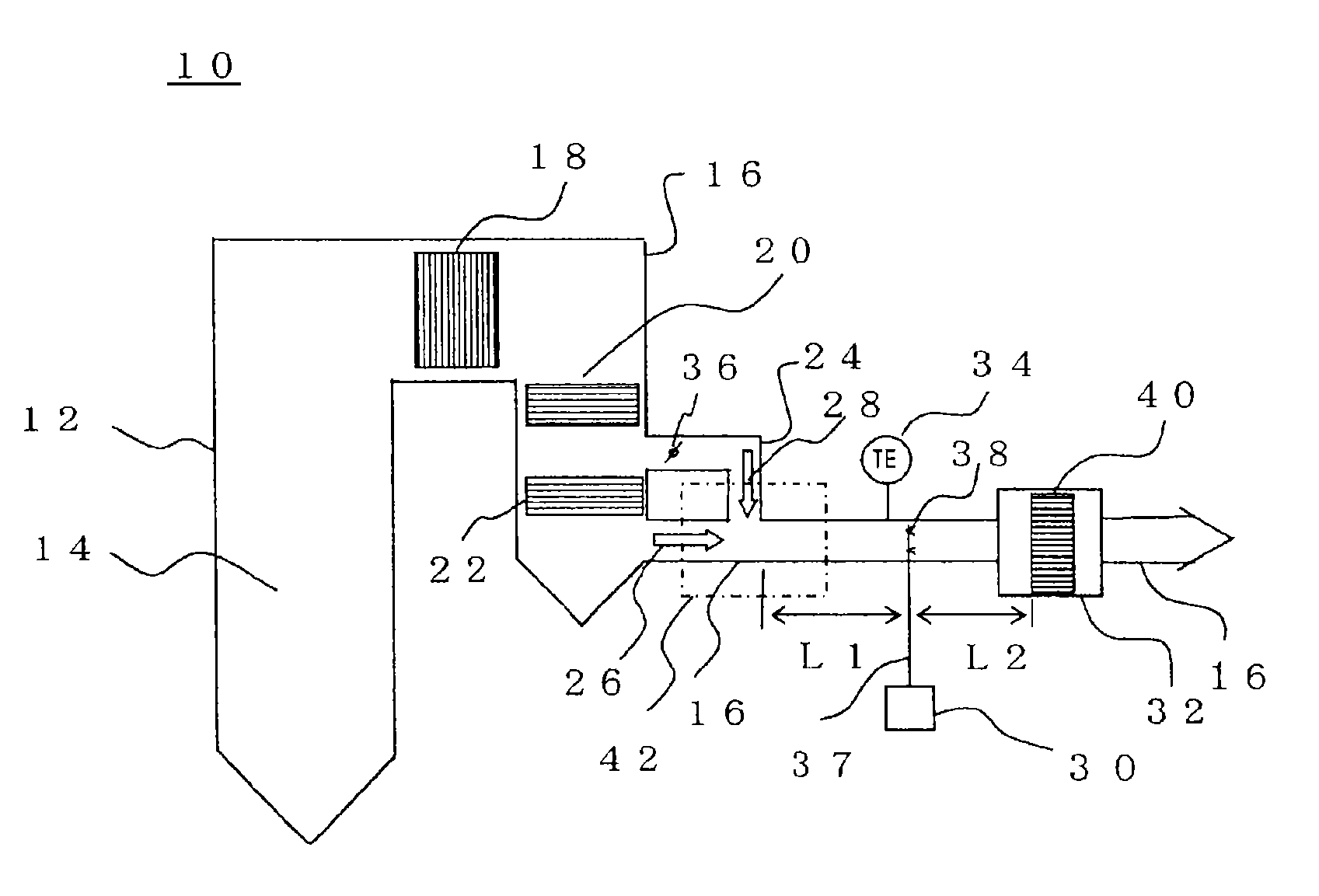

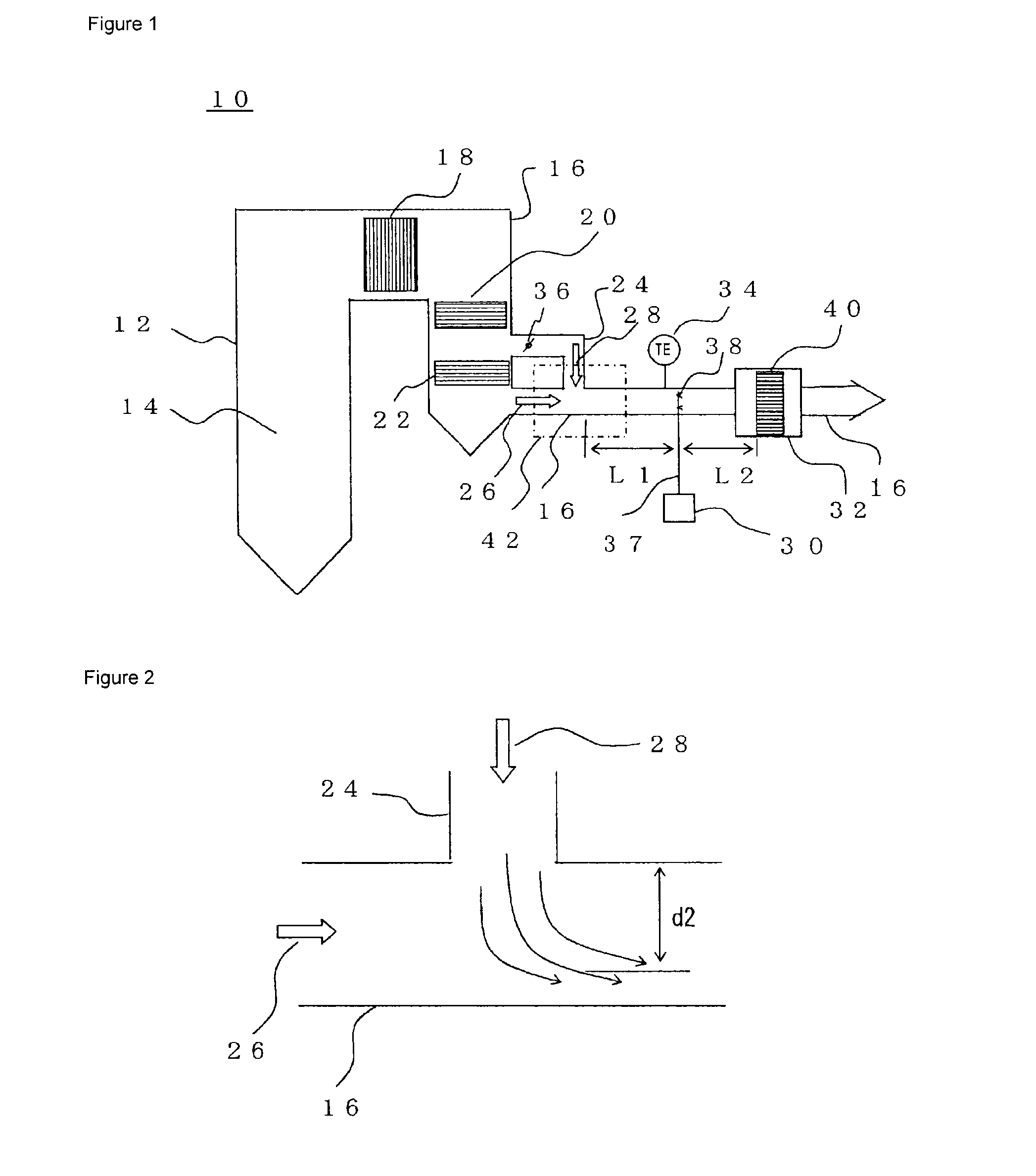

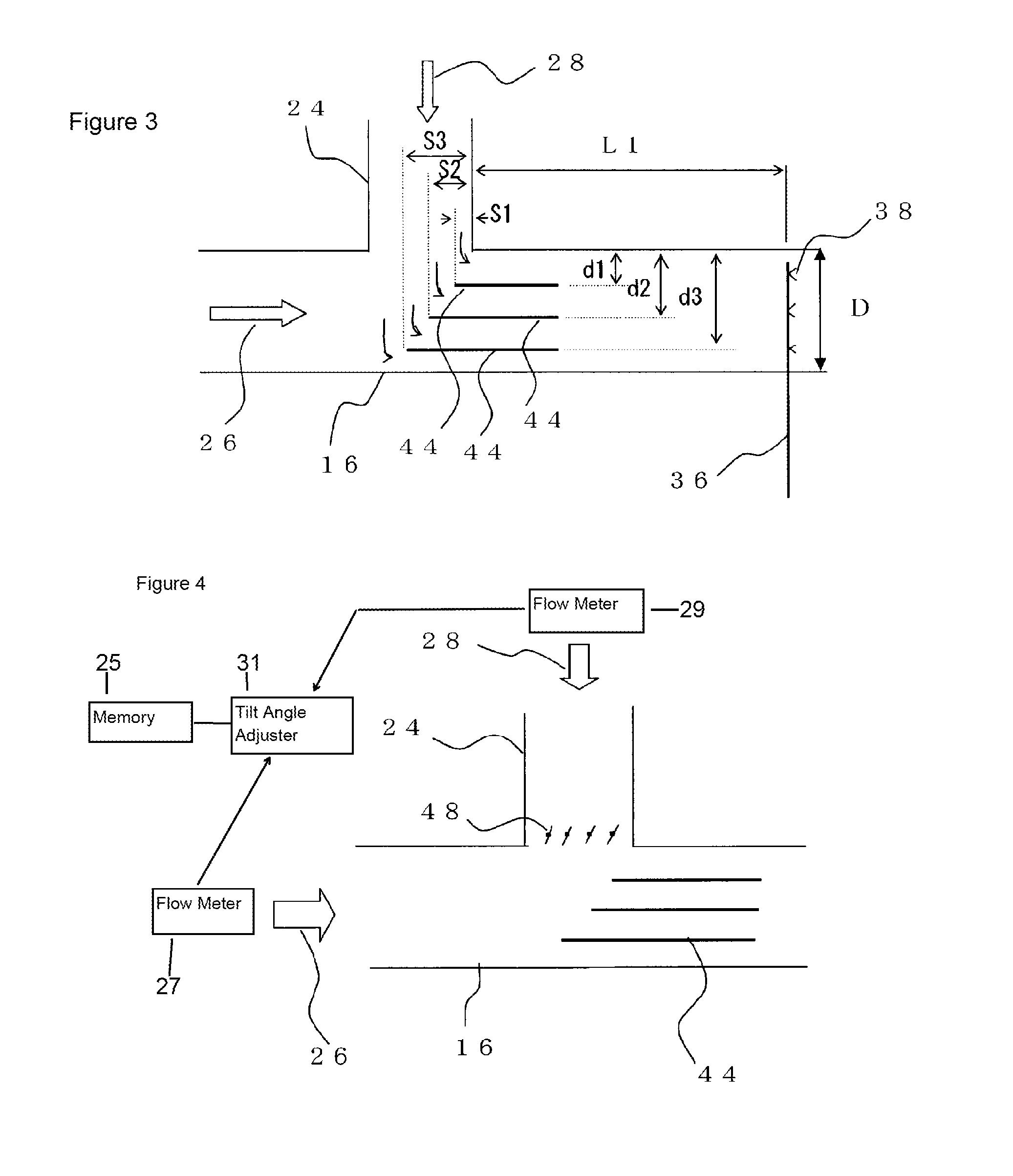

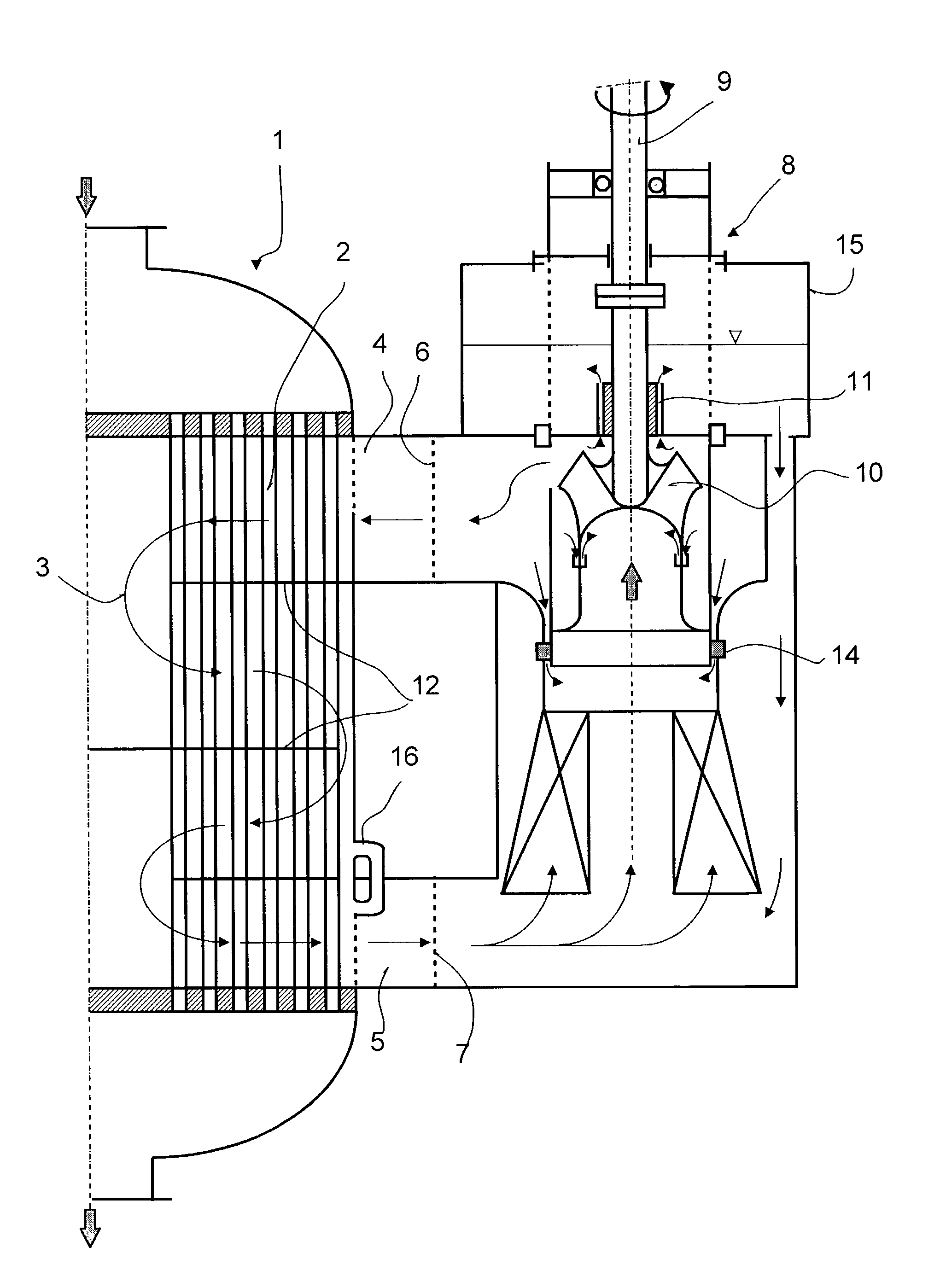

Exhaust gas denitrizer

ActiveUS20110150716A1Curbing increase in duct pressure lossSmooth temperatureGas treatmentExhaust apparatusProcess engineeringNitrogen oxide

An exhaust gas denitrizer removes nitrogen oxides from rejoined exhaust gas using a denitrification reactor after supplying ammonia gas to the rejoined exhaust gas made up of main exhaust gas cooled by a fuel economizer by flowing through a main duct and bypass exhaust gas maintained at high temperature by flowing through a bypass duct adapted to bypass the fuel economizer. At a meeting place between the main exhaust gas and bypass exhaust gas in the main duct, three partition plates are installed with plate surfaces turned to an inflow direction of the bypass exhaust gas, partitioning a main exhaust gas channel into a plurality of subchannels. Upstream-side ends of the partition plates face the incoming bypass exhaust gas by being shifted from one another toward an upstream side of the main exhaust gas starting from an inflow side of the bypass exhaust gas.

Owner:BABCOCK HITACHI KK

Exhaust gas denitrizer

ActiveUS8784740B2Curbing increaseSmooth temperatureGas treatmentFlow mixersNitrogen oxidesProcess engineering

An exhaust gas denitrizer removes nitrogen oxides from rejoined exhaust gas using a denitrification reactor after supplying ammonia gas to the rejoined exhaust gas made up of main exhaust gas cooled by a fuel economizer by flowing through a main duct and bypass exhaust gas maintained at high temperature by flowing through a bypass duct adapted to bypass the fuel economizer. At a meeting place between the main exhaust gas and bypass exhaust gas in the main duct, three partition plates are installed with plate surfaces turned to an inflow direction of the bypass exhaust gas, partitioning a main exhaust gas channel into a plurality of sub-channels. Upstream-side ends of the partition plates face the incoming bypass exhaust gas by being shifted from one another toward an upstream side of the main exhaust gas starting from an inflow side of the bypass exhaust gas.

Owner:BABCOCK HITACHI KK

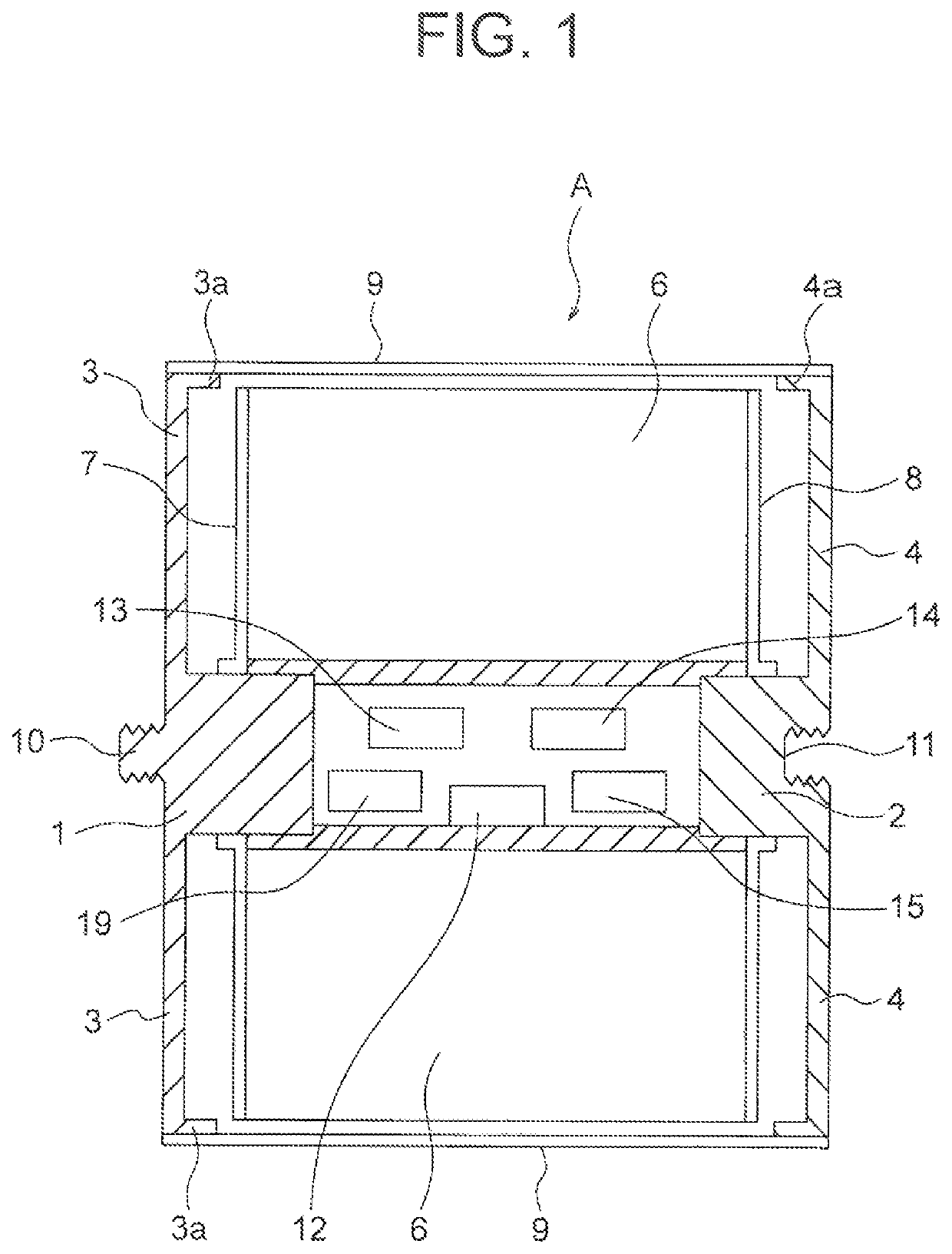

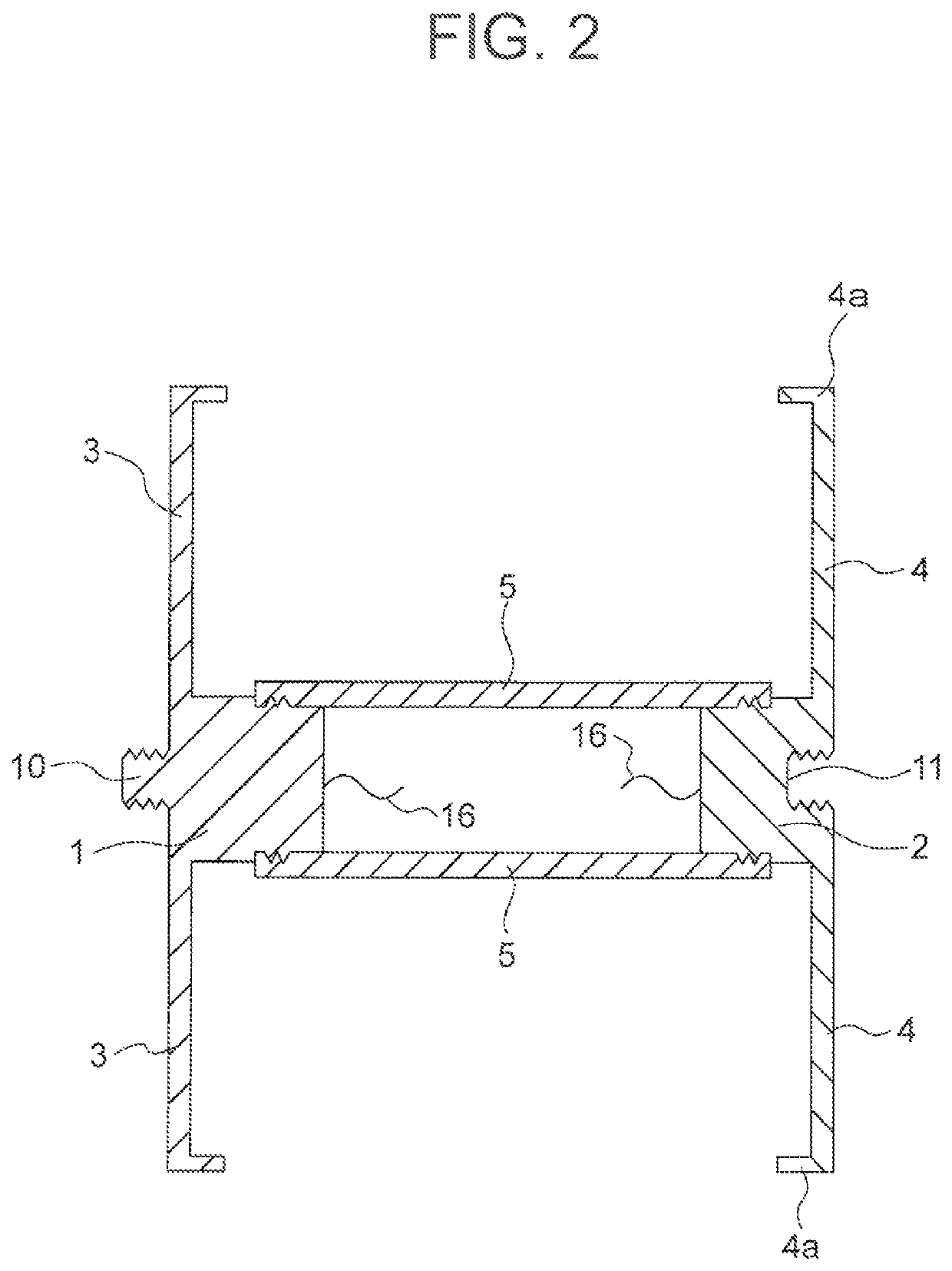

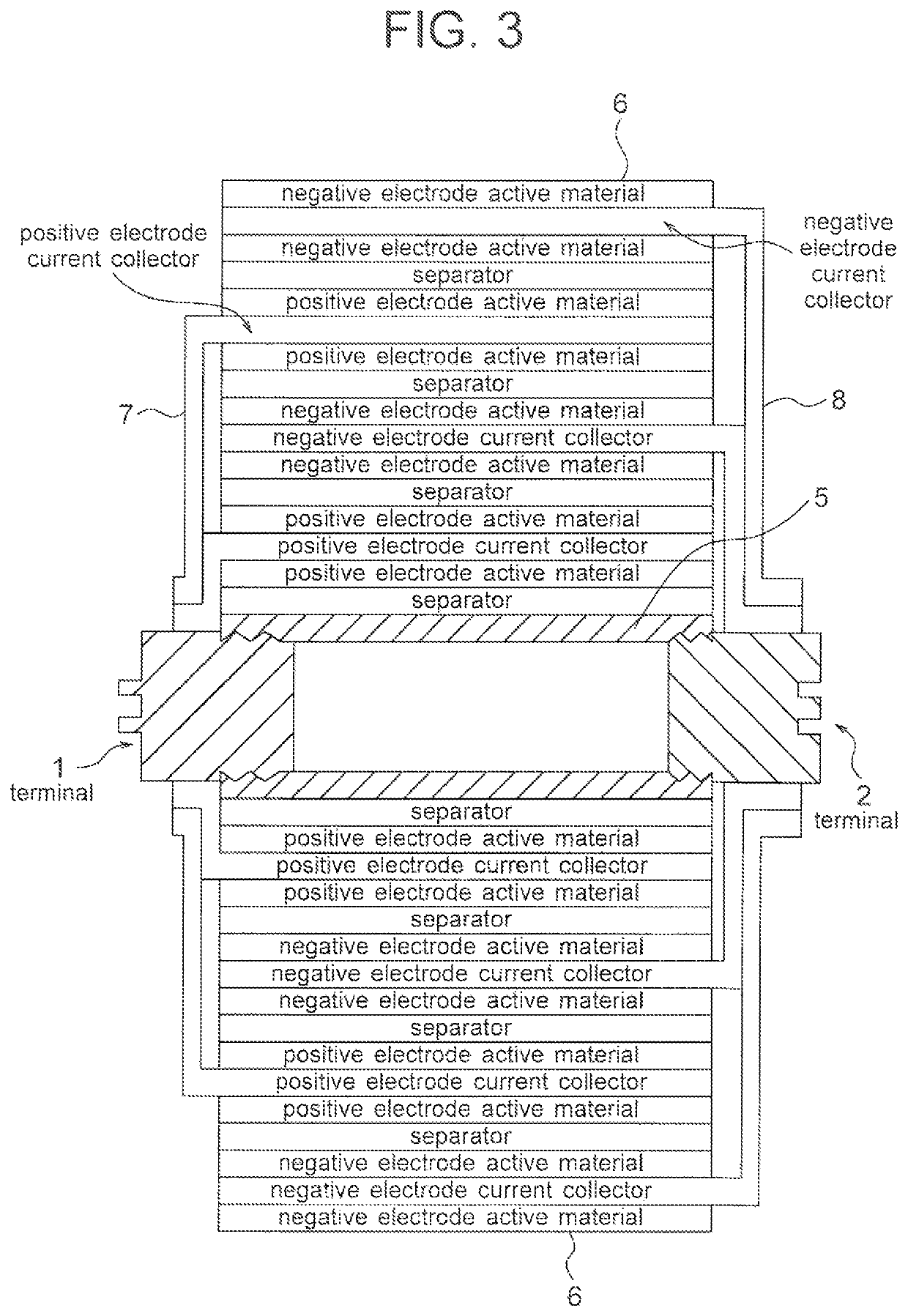

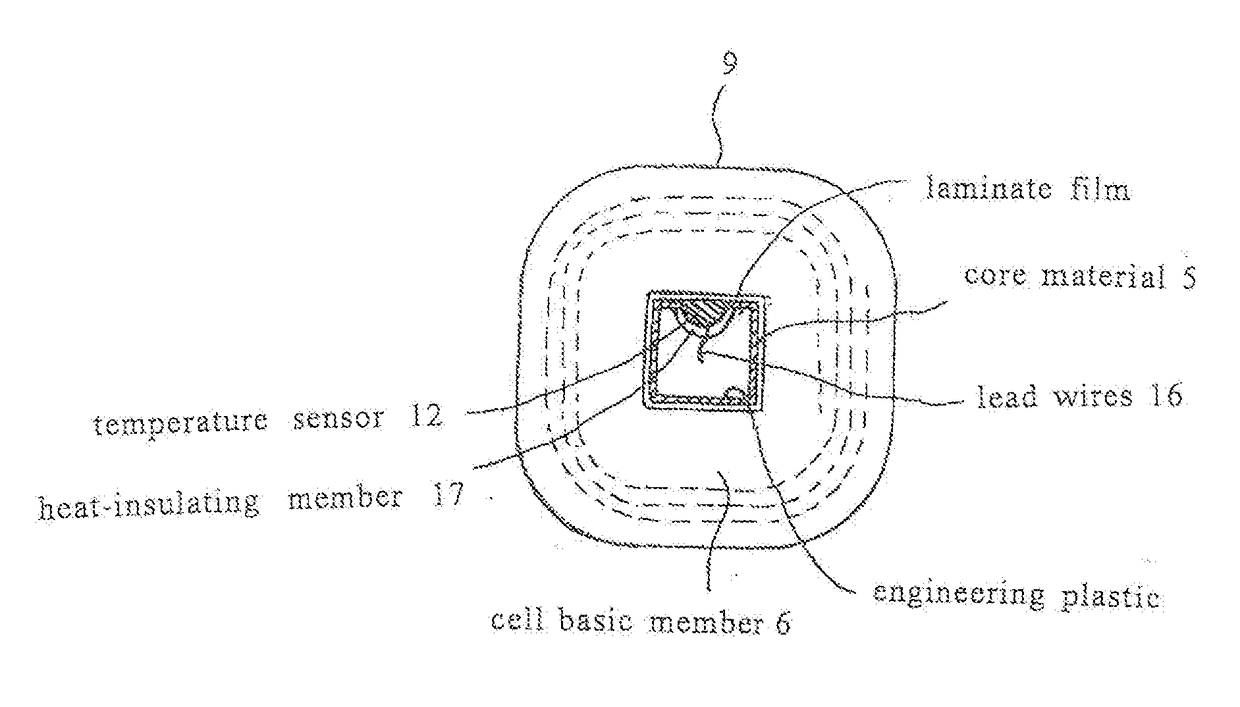

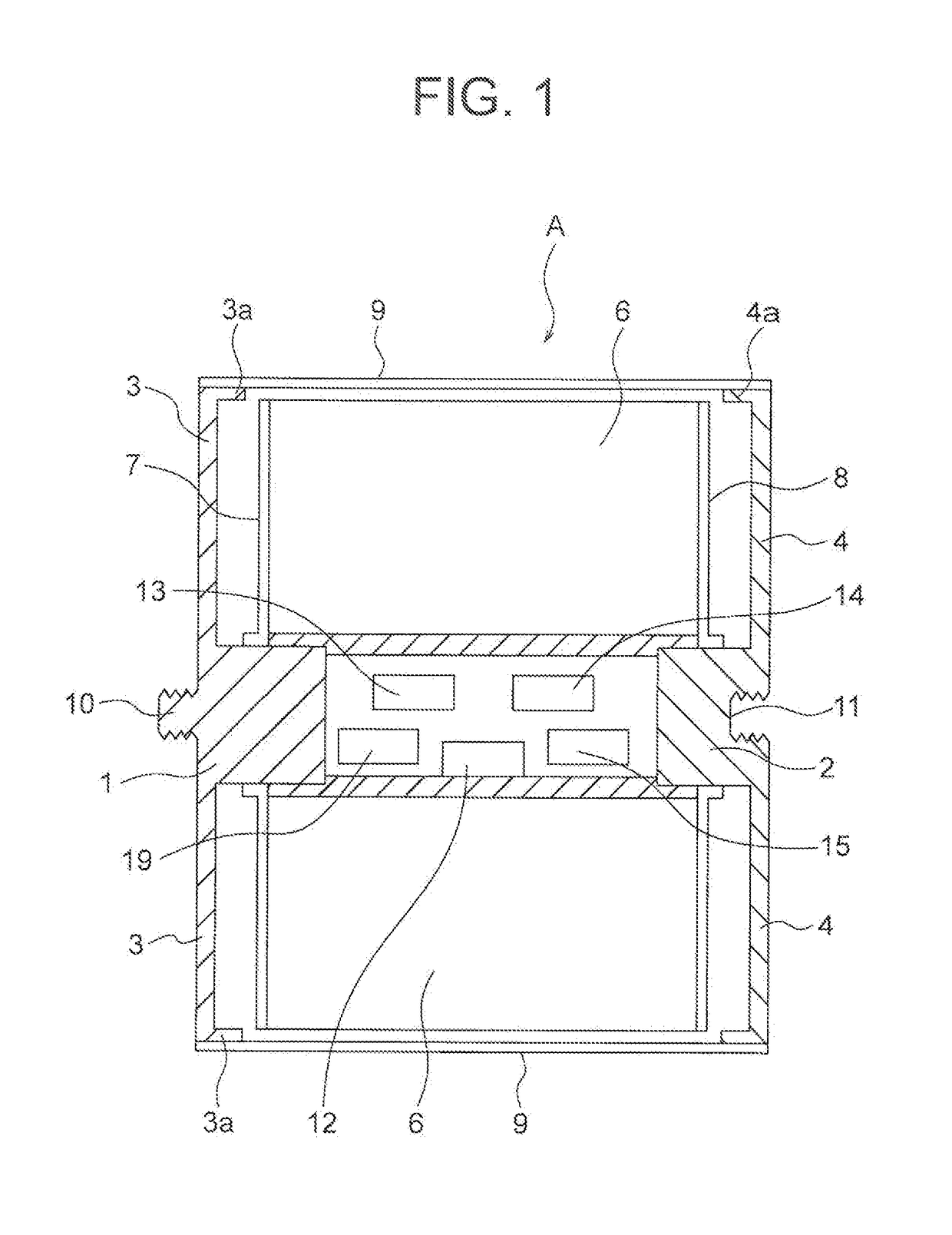

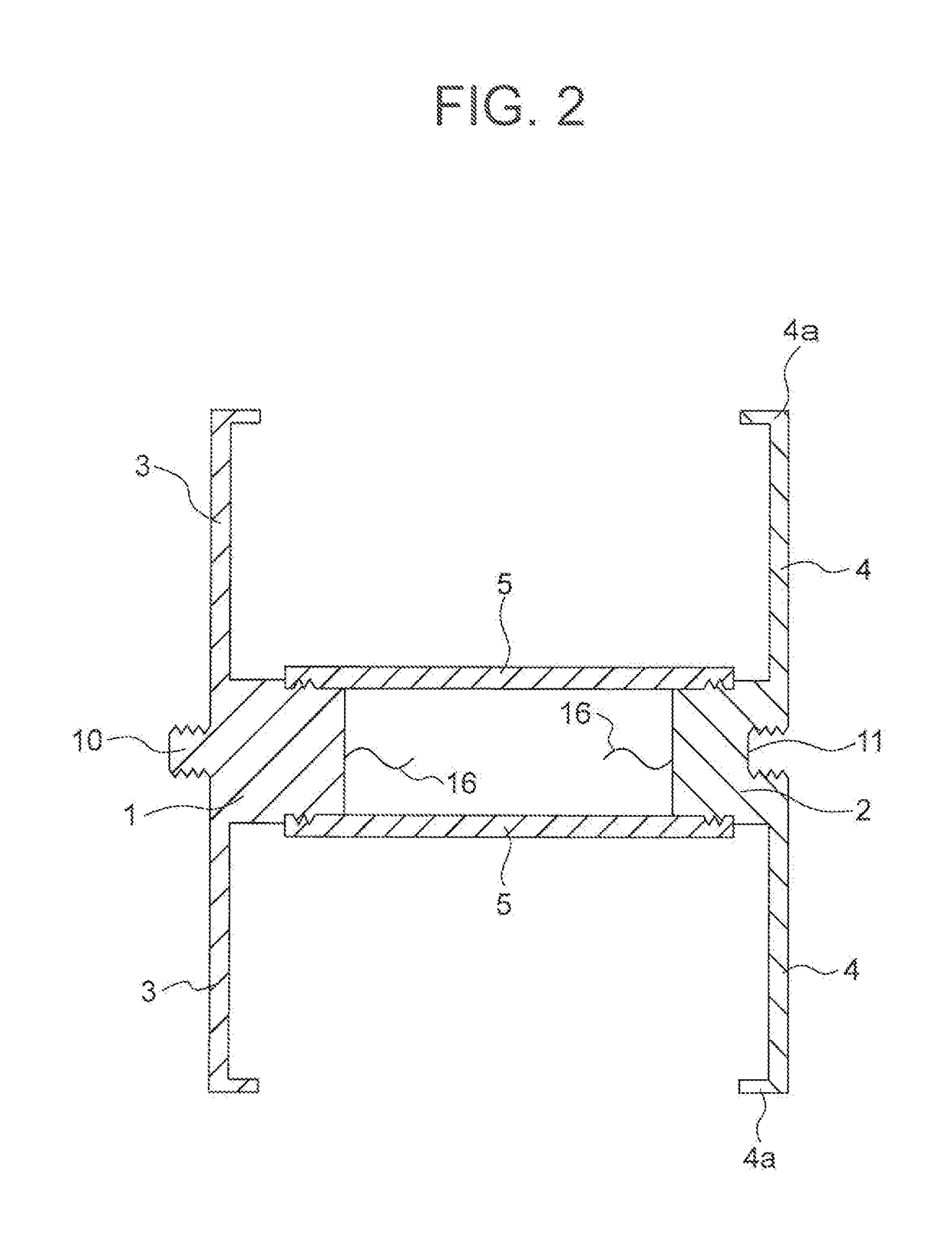

Non-aqueous electrolyte secondary battery cell and assembled battery using same

ActiveUS10707542B2Smooth temperatureAccurate temperatureBatteries circuit arrangementsFinal product manufactureElectrical batteryAqueous electrolyte

Non-aqueous electrolyte secondary battery cell having safety and increased energy density, and battery using same. The cell is shaped as a rounded square tube. A core material for preventing electrolyte permeation is at the cell center, the core member being a hollow cylindrical insulator of square cross-section. A cell monitoring system such as a temperature sensor is provided in the hollow part of the core material. A cell base member including positive electrode member, separator, and negative electrode member of a non-aqueous electrolyte secondary battery is wound around the core material. Terminals made of electroconductive metal electrically connected to the collector of the positive electrode member or the collector of the negative electrode member are exposed to the cell exterior. The temperature sensor is attached to the center part of the hollow part of the core material in close contact with the core material.

Owner:E GLE CO LTD

Non-aqueous electrolyte secondary battery cell and assembled battery using same

ActiveUS20180331399A1Suppression of sameAccurate measurementBatteries circuit arrangementsFinal product manufactureSquare cross sectionMonitoring system

Non-aqueous electrolyte secondary battery cell having safety and increased energy density, and battery using same. The cell is shaped as a rounded square tube. A core material for preventing electrolyte permeation is at the cell center, the core member being a hollow cylindrical insulator of square cross-section. A cell monitoring system such as a temperature sensor is provided in the hollow part of the core material. A cell base member including positive electrode member, separator, and negative electrode member of a non-aqueous electrolyte secondary battery is wound around the core material. Terminals made of electroconductive metal electrically connected to the collector of the positive electrode member or the collector of the negative electrode member are exposed to the cell exterior. The temperature sensor is attached to the center part of the hollow part of the core material in close contact with the core material.

Owner:E GLE CO LTD

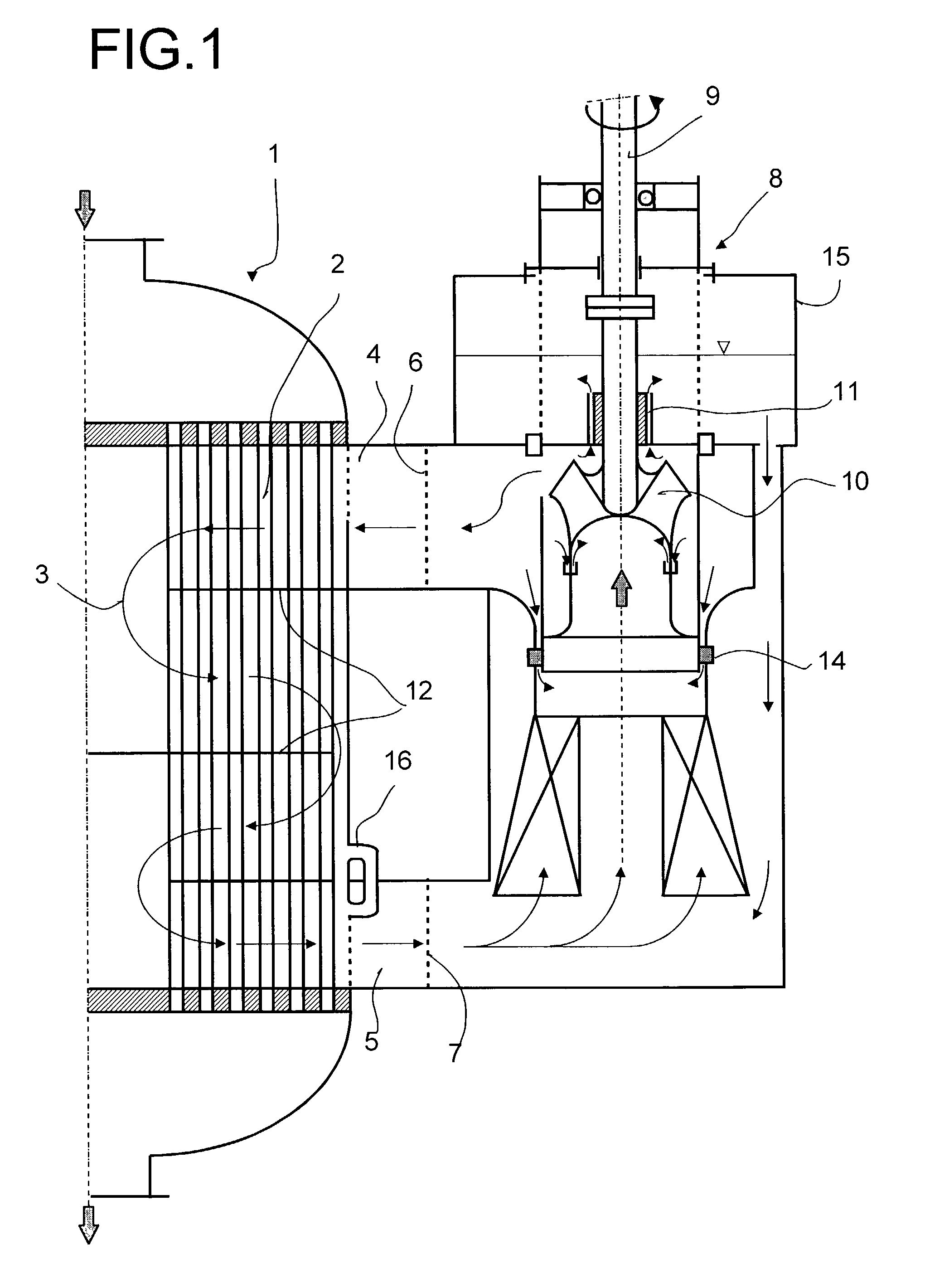

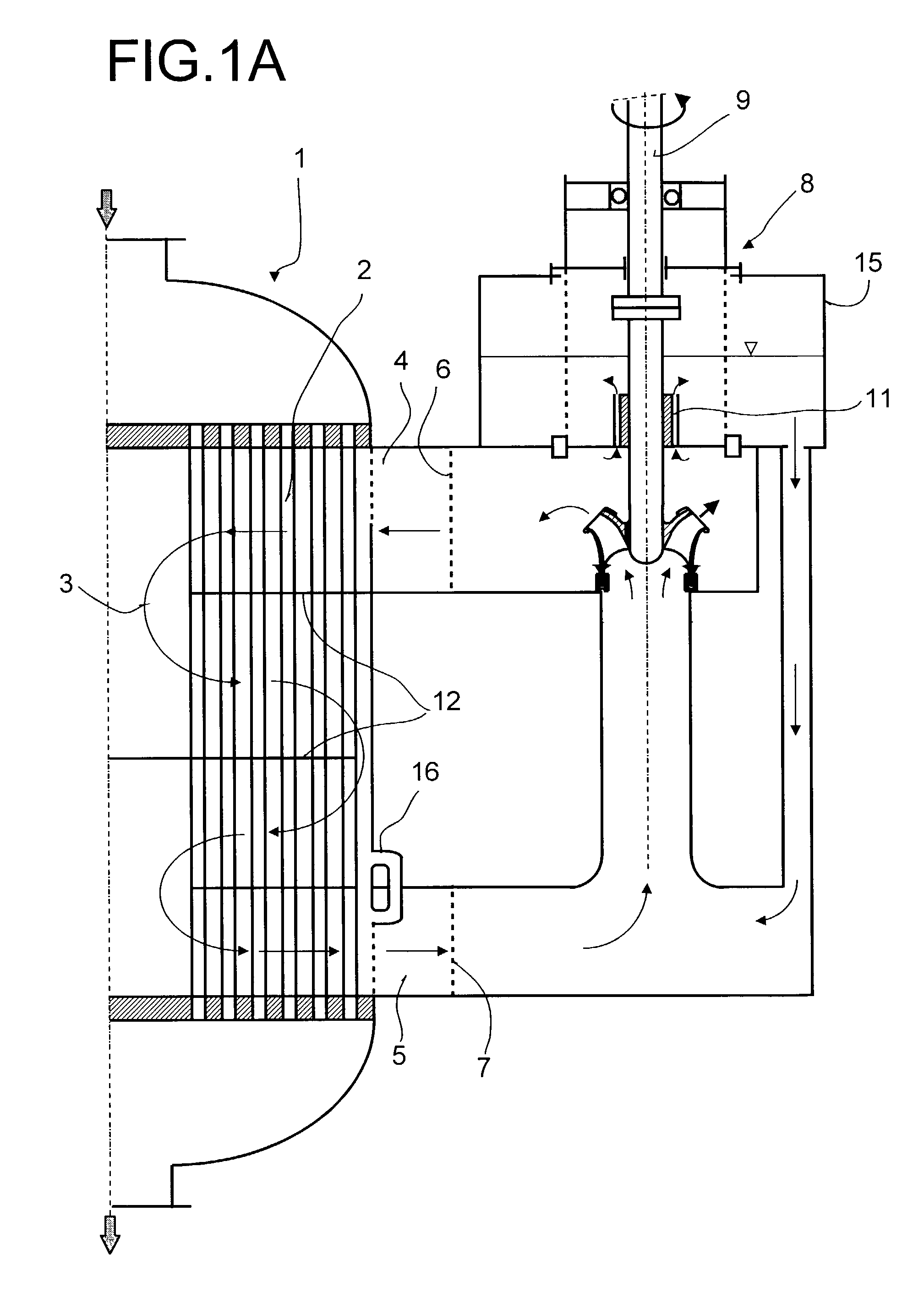

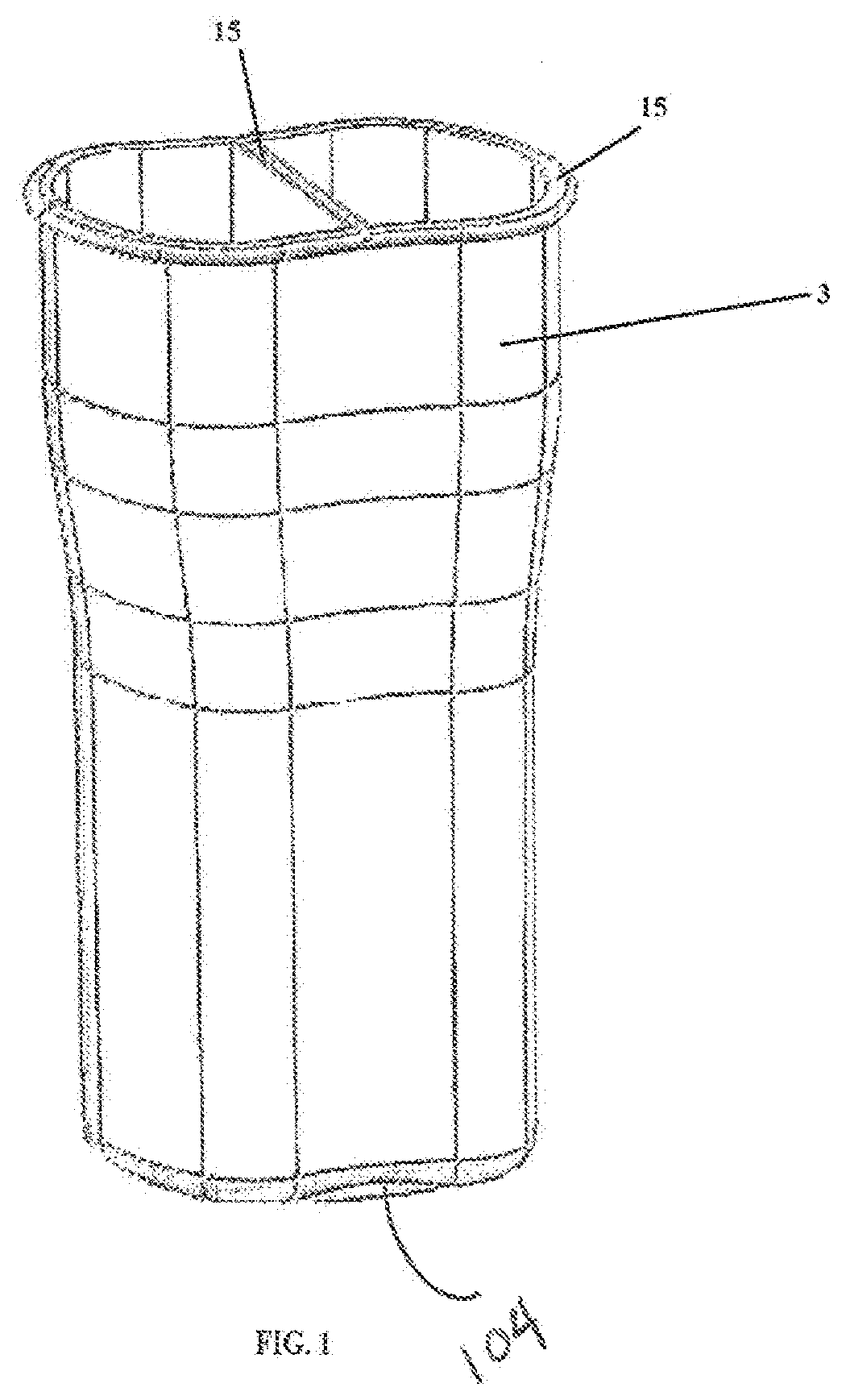

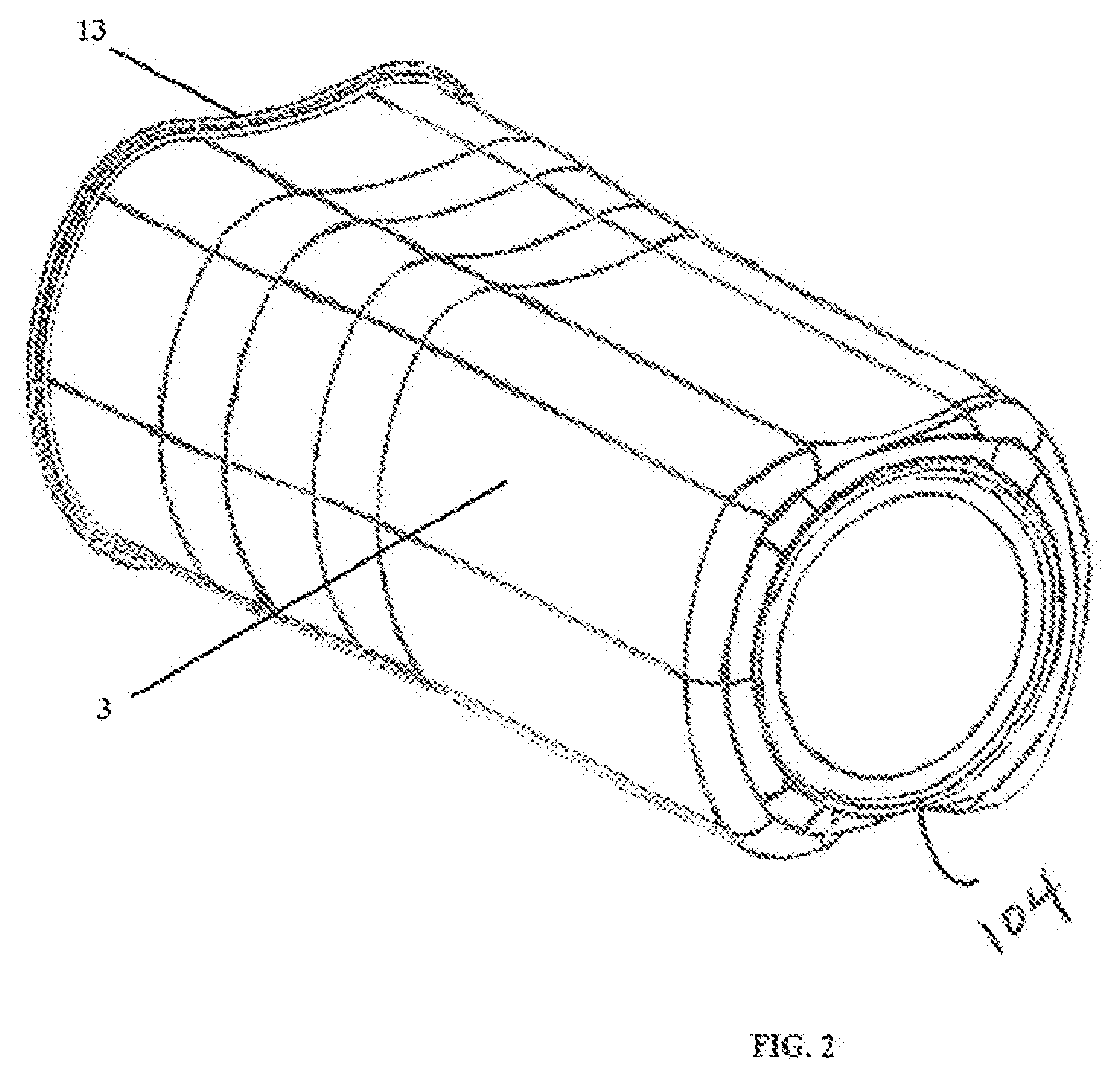

Reactor having a heat exchange medium circulation

ActiveUS7273593B2Simple designEasy to moveSpecific fluid pumpsPump componentsEngineeringMechanical engineering

A reactor including a bundle of catalyst tubes through which a reaction mixture is passed, and wherein a heat exchange medium is passed through a space surrounding the catalyst tubes and including ring lines at both reactor ends with jacket orifices for feeding in and removing the heat exchange medium by at least one pump. The heat exchange medium is fed to the upper ring line and is sucked in via the lower ring line by the at least one pump having at least one vertical pump shaft mounted and operated at its upper end. The at least one pump includes a diagonal rotor and a restrictor gap in the longitudinal direction of the at least one pump shaft, within the heat exchange medium, on the pressure side of the at least one pump for sealing and mounting the at least one pump shaft and reducing axial shear of the diagonal rotor.

Owner:BASF AG

Dual Chambered Canteen with Interchangeable Lids

PendingUS20210030176A1Improve sealingPrevent heat transferDomestic cooling apparatusClosuresEngineeringMechanical engineering

The dual-chambered liquid container canteen of the present invention includes a dual-chambered container with a vertical partition separating each chamber, the dual-chambered liquid container of the present invention includes a dual-chambered container with a vertical partition separating each chamber, three interchangeable lids with two separate non-removable inner wall compartments that fits inside each chamber of the container and securely separate the liquids while ensuring proper positioning of the lid over each compartment. A gasket molded into the rim of the container and vertical partition of the container to ensure a liquid airtight seal between each chamber and the lid, a gasket molded into the rim of the container and vertical partition of the container to ensure a liquid tight seal between each chamber and the lid, each lid has release holes for venting the container chambers to atmosphere as liquids are dispersed from the container.

Owner:BURDEN GWENDOLYN

Blend of PPC, PBAT, PCL and PBS and preparation method thereof

InactiveCN101724248BTough and strongImprove mechanical propertiesBLENDER/MIXERPrecipitated calcium carbonate

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

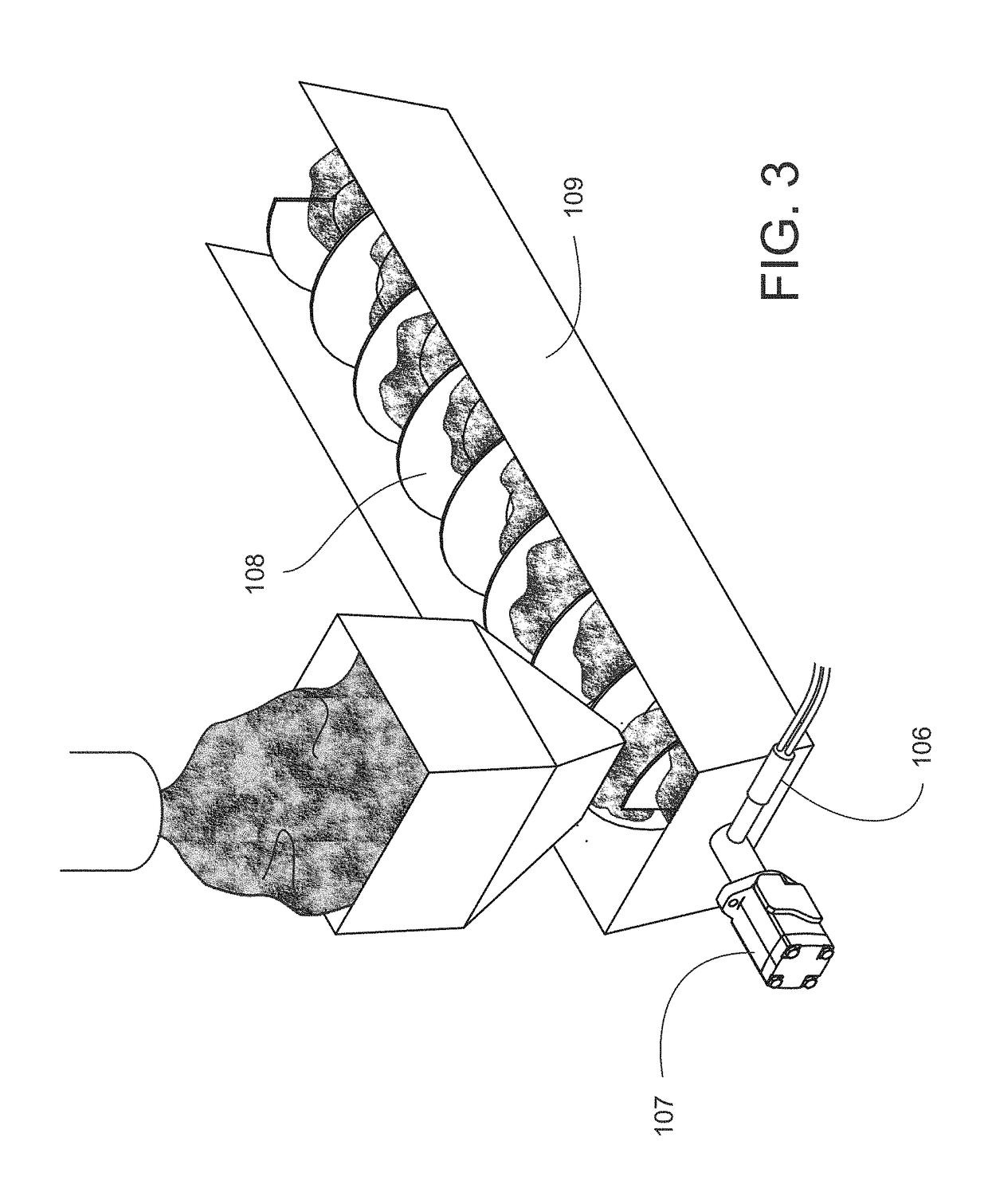

Method and device for preparing cheese by ohmic heat treatment

ActiveUS9924729B2Eliminate useEliminate dependenciesMilk treatmentCheese manufactureFiberElectricity

An invention directed to a process and device for electrically heating and preparing pasta filata type cheeses. The ohmic heating process of this invention is introduced after separation of initial curd from whey, as heated stretching is initiated to create nascent pasta filata cheese fibers. An apparatus is devised to receive the newly formed curd mass and to provide contact of the mass with an electric coupler that channels electric current through the conductive cheese mass as it is concurrently stretched. The features of this device include an electrically charged element, a grounding element and a texturizing tool.

Owner:LINDGREN DANIEL

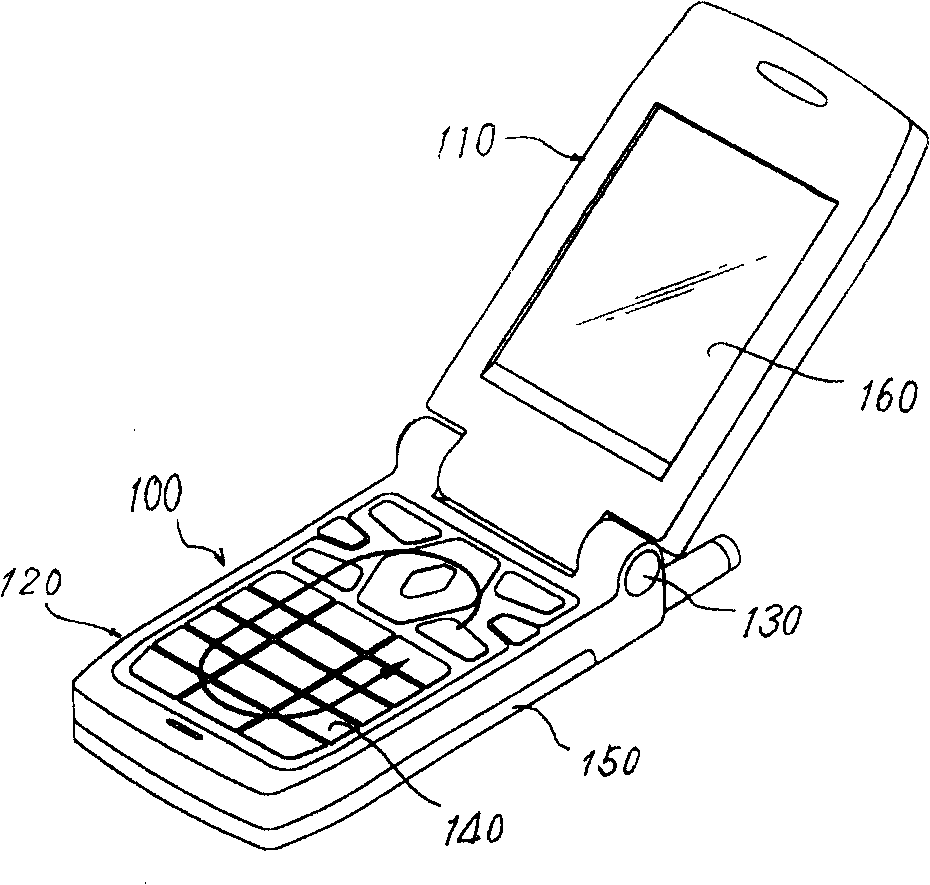

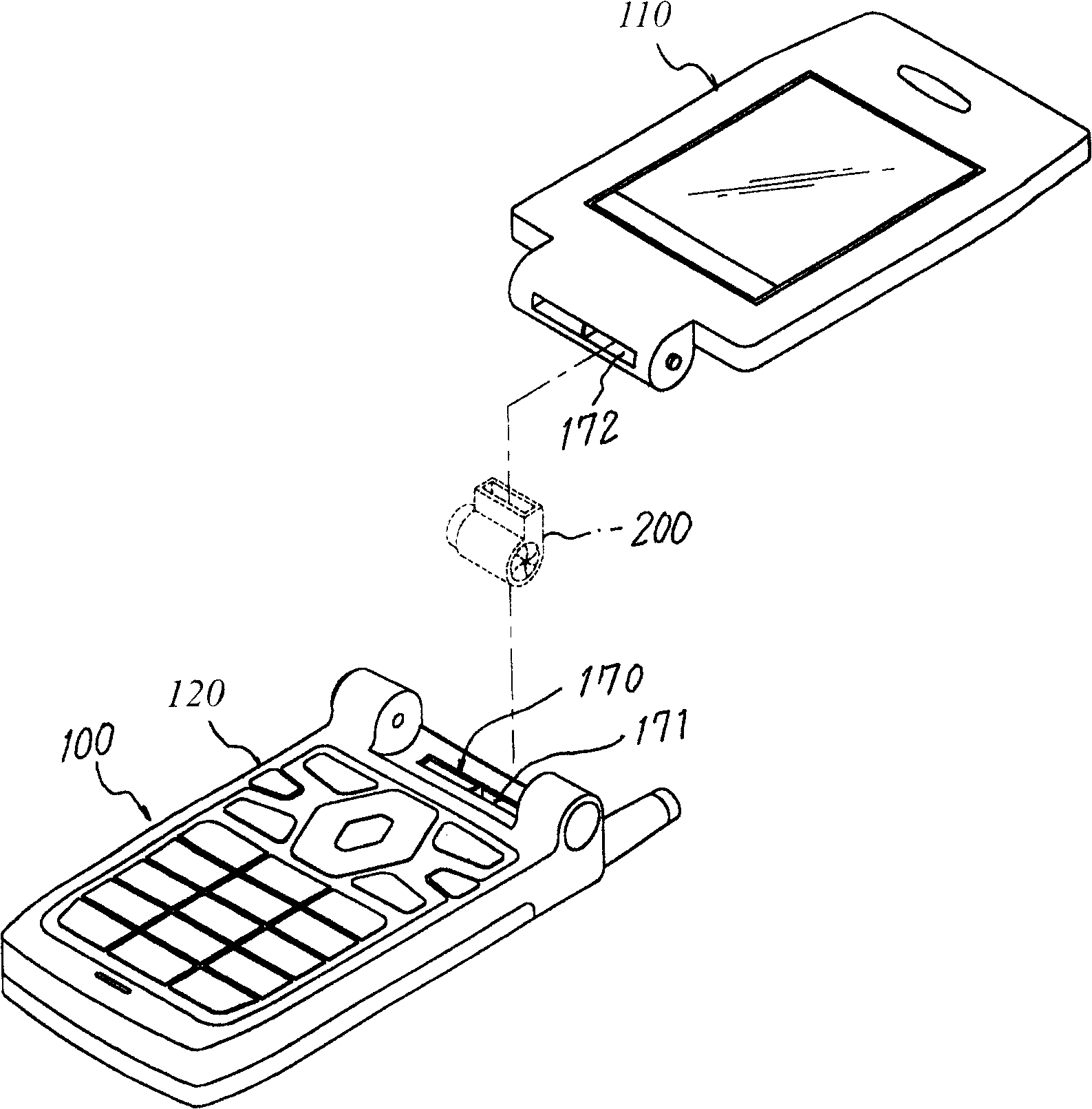

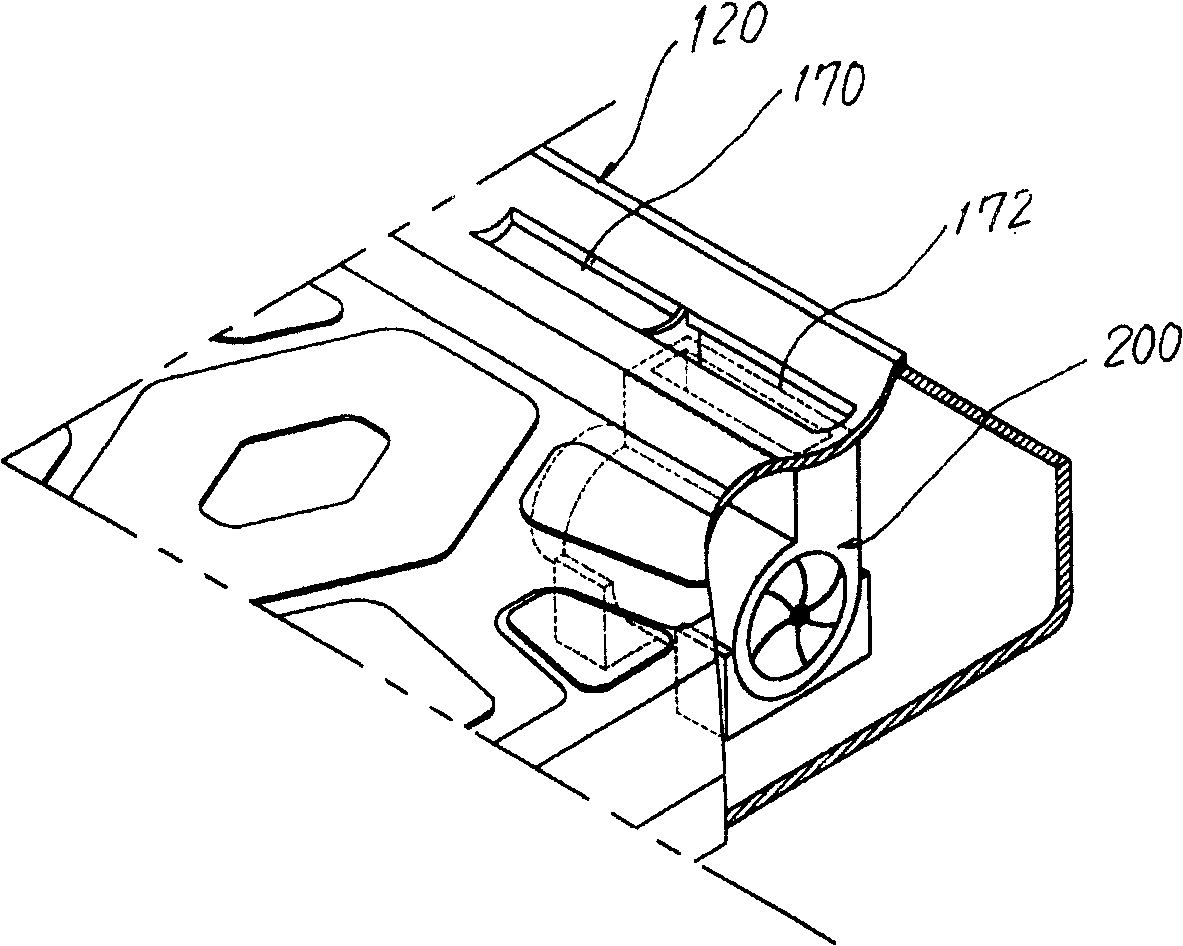

Cooler of mobile communication terminal

InactiveCN100423624CReduce the temperatureSmooth temperatureDevices with sensorInstrumental cooling apparatusEngineeringComputer terminal

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com