Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Slow down the temperature drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot-forming and forging method for large-sized high-temperature alloy turbine disc

ActiveCN1654140ARealize localizationReduce minimum loadWheelsHeating/cooling devicesIngotHot working

The hot forging process of high temperature large alloy turbine disc includes the following steps: 1) conventional upsetting and drawing to form cylindrical alloy blank of 730 mm diameter with electroslag ingot of 900 mm diameter; 2) low temperature heating the blank at 900 deg.c, coating the sides with diathermic cotton, further heating to stipulated temperature and maintaining for prolonged 5 hr; 3) upsetting the blank to intermediate blank of 1700 mm diameter through the first traditional process to machining limit of the press and then local deforming with rectangular upper anvil of width below 400 mm; 4) coating the lower surface of the circular cake blank and heating in furnace for 2 hr; and 5) final rotary forging for local deformation with upper anvil of width of 200 mm and rotating angle of 15 deg to forge the intermediate blank of 1700 mm diameter into finished product of 2000 mm diameter in the reducing amount of 25 mm and deformation amount of 35 %.

Owner:宝武特种冶金有限公司

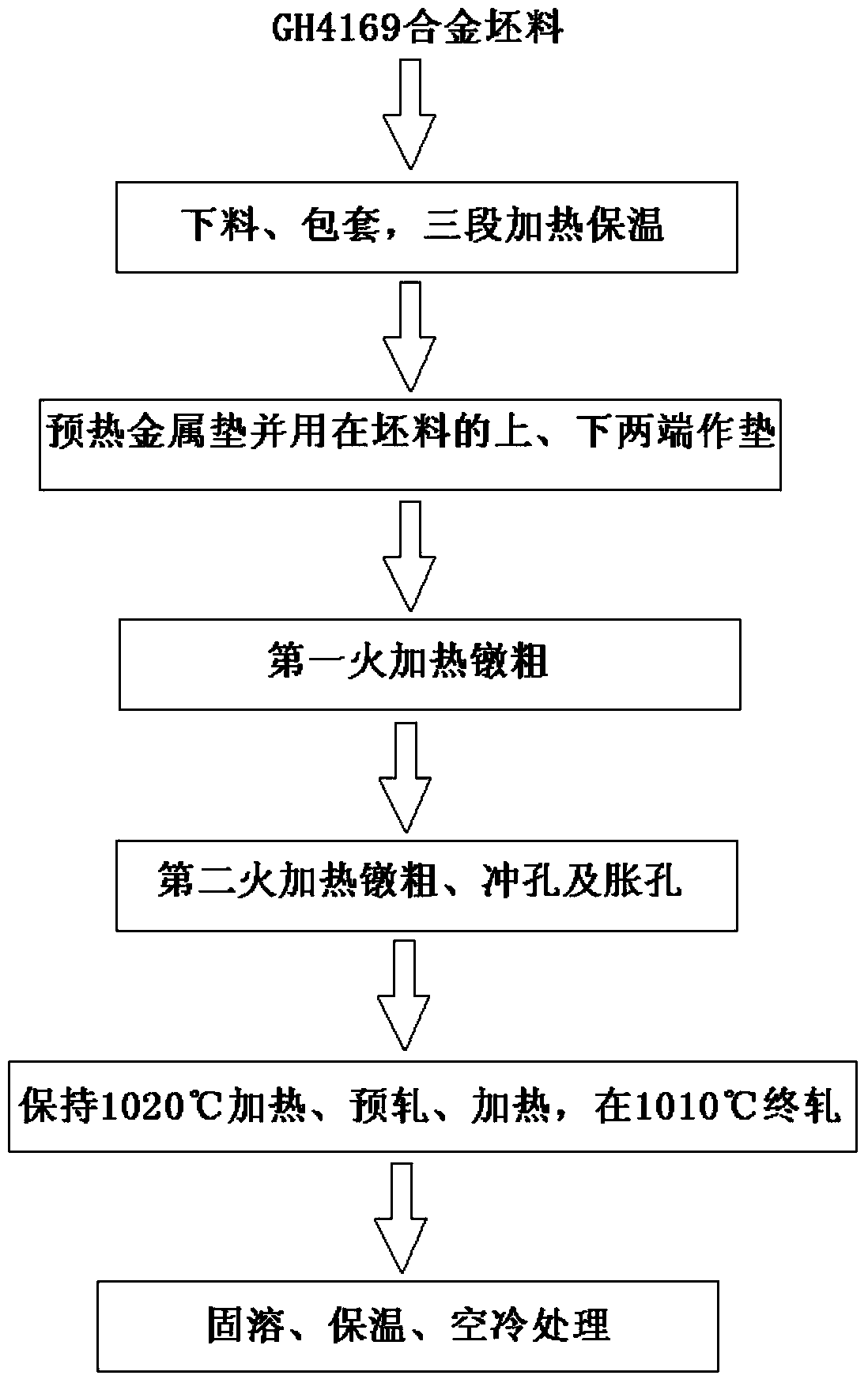

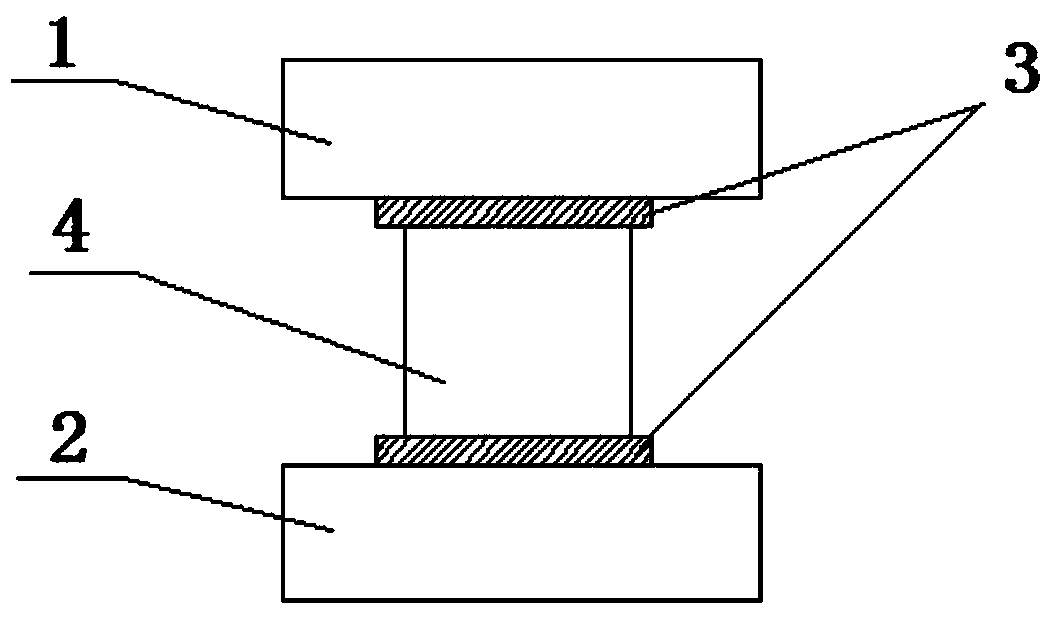

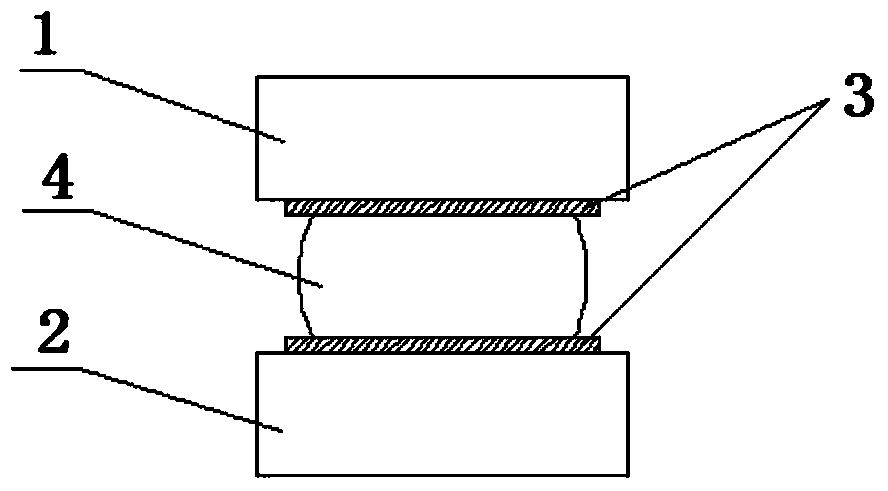

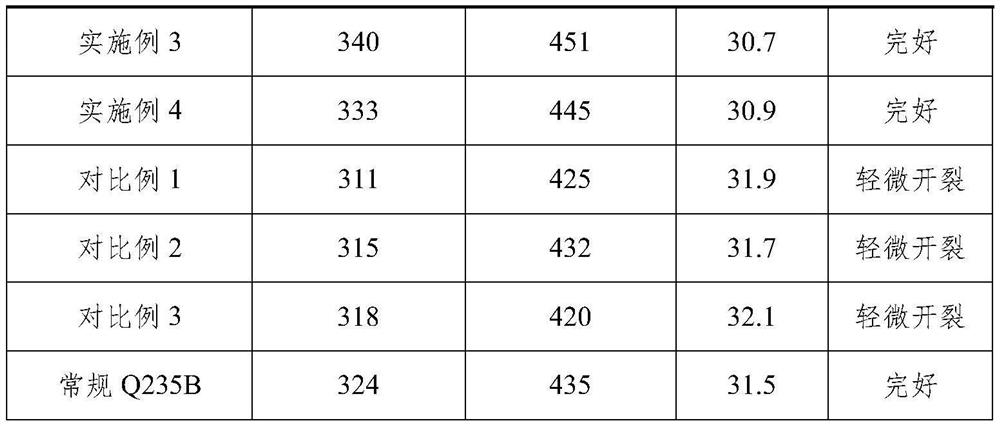

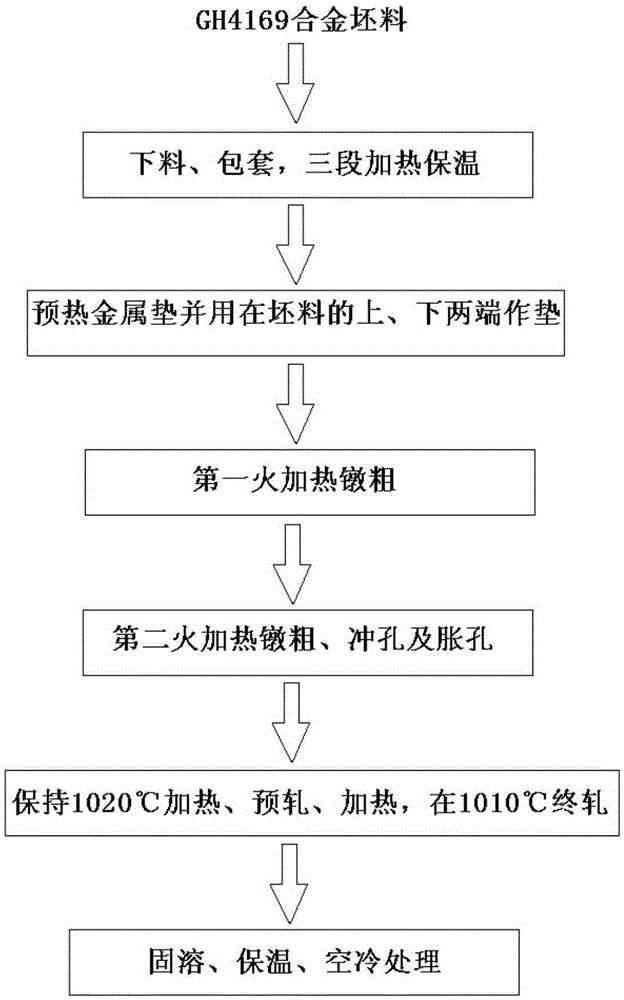

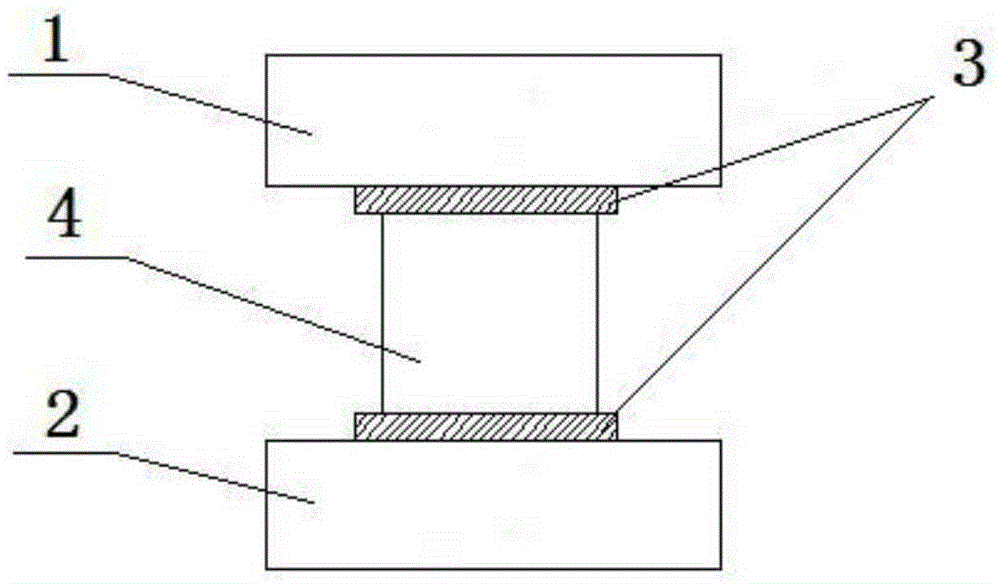

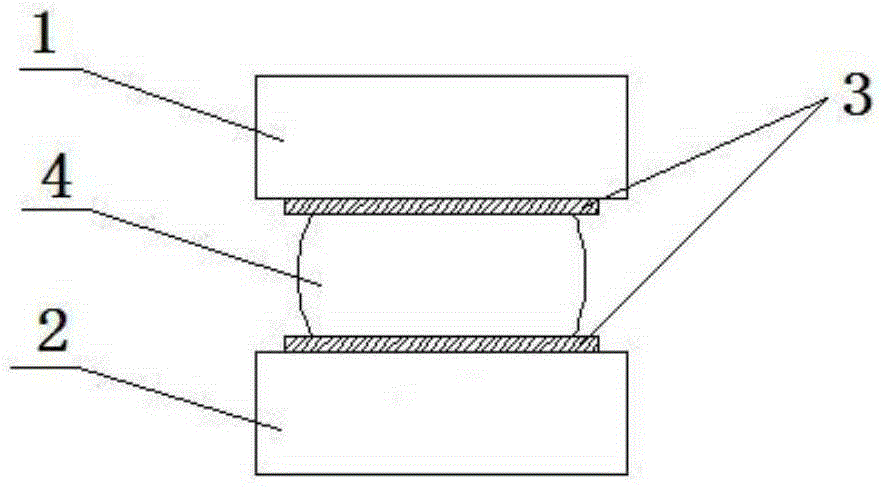

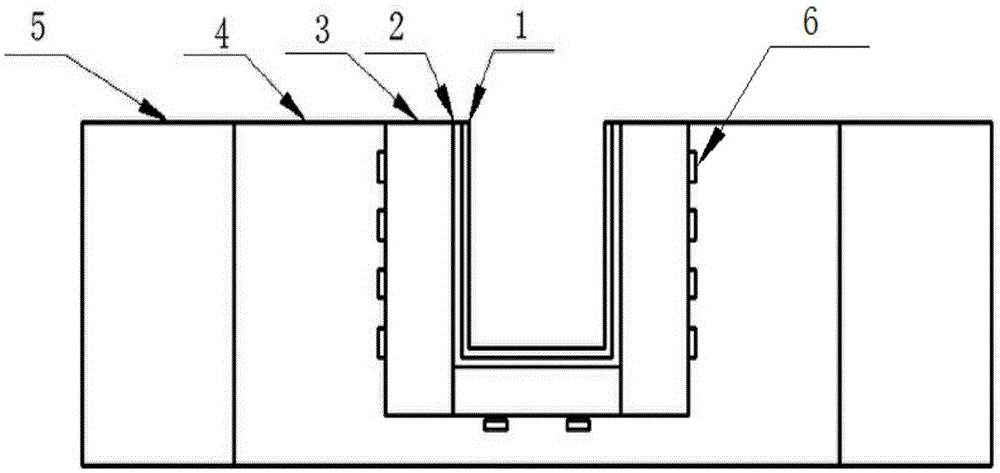

Method for manufacturing GH4169 alloy aplitic plate blank

ActiveCN103465027ASlow down the temperature dropGuaranteed uniformityForging/hammering/pressing machinesOther manufacturing equipments/toolsPunchingGrain structure

The invention discloses a method for manufacturing a GH4169 alloy aplitic plate blank. A GH4169 primary blank is prepared into the GH4169 alloy aplitic plate blank by blank heating, primary heating and upsetting, secondary heating and upsetting, punching and rolling. The method is characterized by adopting an asbestine sheath, using a three-section heating way to process the blank, preheating metal pads and heating and upsetting the blank after the metal pads are placed at the two ends of the blank, upsetting, punching and expanding the blank at 1020 DEG C, and rolling at 1010 DEG C. According to the method, the temperature reduction speed of a workpiece can be slowed down to obtain more operable time, so that the deflection of the upper and lower end planes of the blank can be brought into correspondence with the deflection of the middle section of the blank so as to guarantee the uniformity of the sturctures on the parts of the workpiece, so that coarse grains caused by the critical strain is prevented, the final grain size is prior to level 8, the fineness of grain structures can be guaranteed, the grain refining of the GH4169 alloy aplitic plate blank can be realized, and the anti-fatigue performance of the GH4169 alloy can be greatly improved.

Owner:GUIZHOU AVIATION TECHN DEV

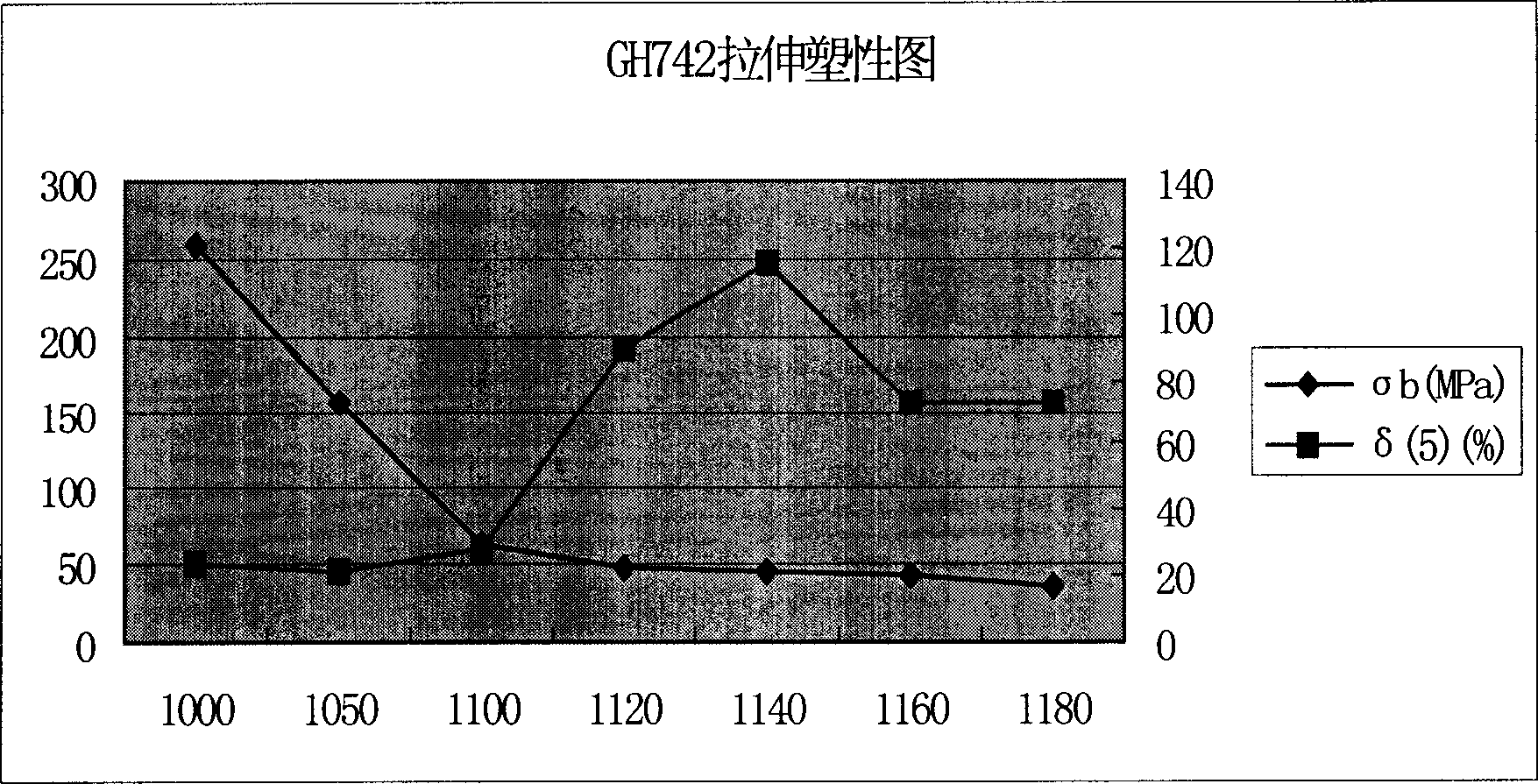

Heat keeping and forging and blank cogging method for GH742 alloy large steel ingot

ActiveCN1683097ATo achieve the purpose of heat preservation forgingReduce lossesMetal-working apparatusFiberAdhesive

The heat insulating, forging and blank cogging method of large GH742 alloy steel ingot features the high temperature adhesive of marketable glass powder with softening temperature over 800 deg.c and the heat insulating material of marketable asbestos blanket with aluminum silicate fiber; the steel ingot heat insulating process including spreading glass powder onto the asbestos blanket and coating the steel ingot after heating at 900 deg.c; the heat insulating period of 5-6 hr; the blank cogging of heating at high temperature with forging time not less than 5 min, reducing amount of 30 mm and deformation amount not less than 50 %; and the performance test of the formed alloy blank. The present invention solves the difficult problem of hot blank cogging and forming large GH742 alloy steel ingot.

Owner:宝武特种冶金有限公司

Wheat stub no-tillage rape cultivation method

InactiveCN102204472AReduce wind erosionExtend plant cover timeClimate change adaptationHorticultureFertilizerNutrient

The invention relates to a sowing technique, in particular to a stub no-tillage mechanical sowing cultivation method. The wheat stub no-tillage rape cultivation method comprises the steps of mechanically harvesting wheat, mixing selected rape seeds, chemical fertilizers and sheep dung, sowing rape seeds, performing rape field management, harvesting and the like. The method has the advantages of increasing soil moisture, reducing wind erosion and water and soil loss, regulating ground temperature, increasing nutrients in soil, improving activity of soil enzymes, preventing lodging, increasing forage grass and the like.

Owner:GANSU AGRI UNIV

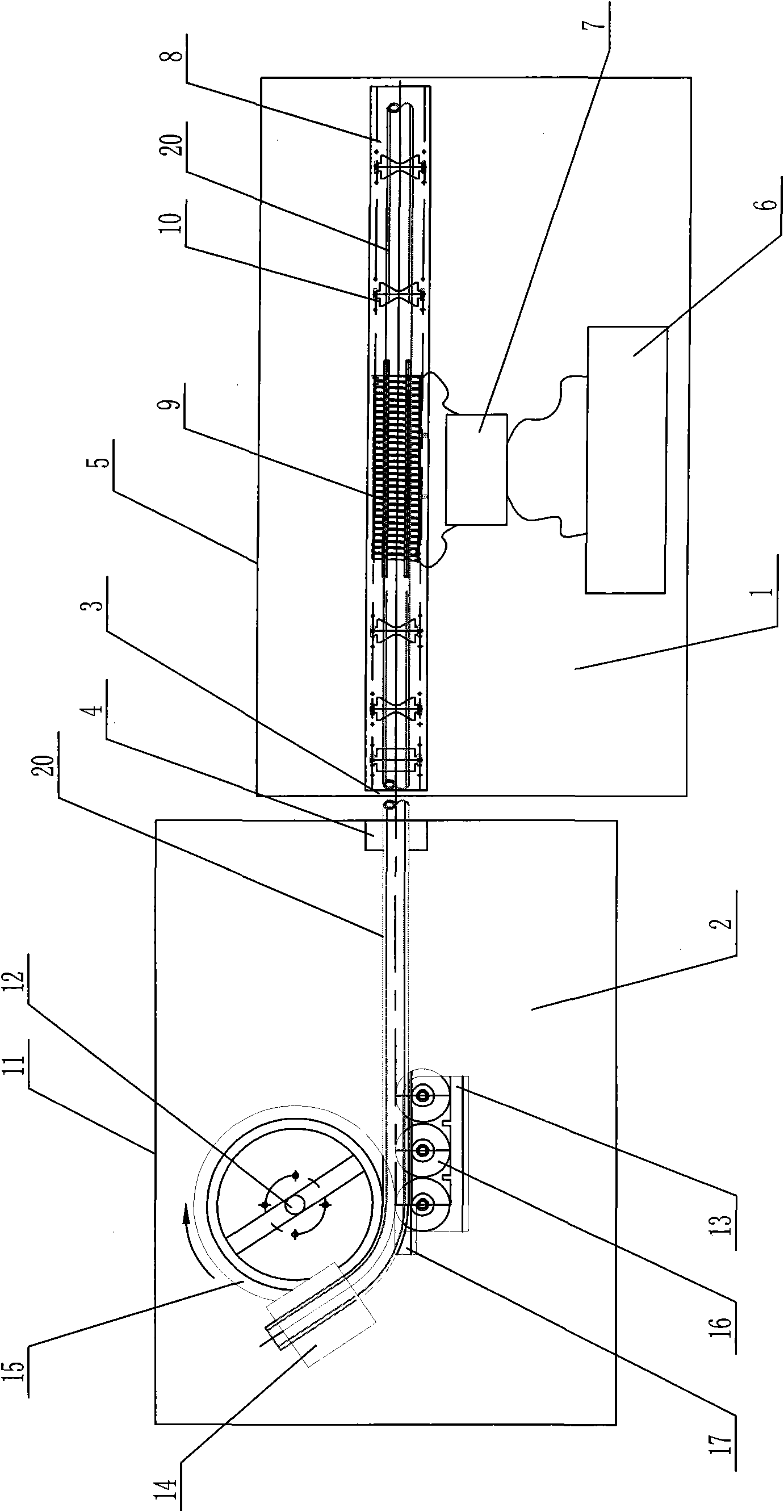

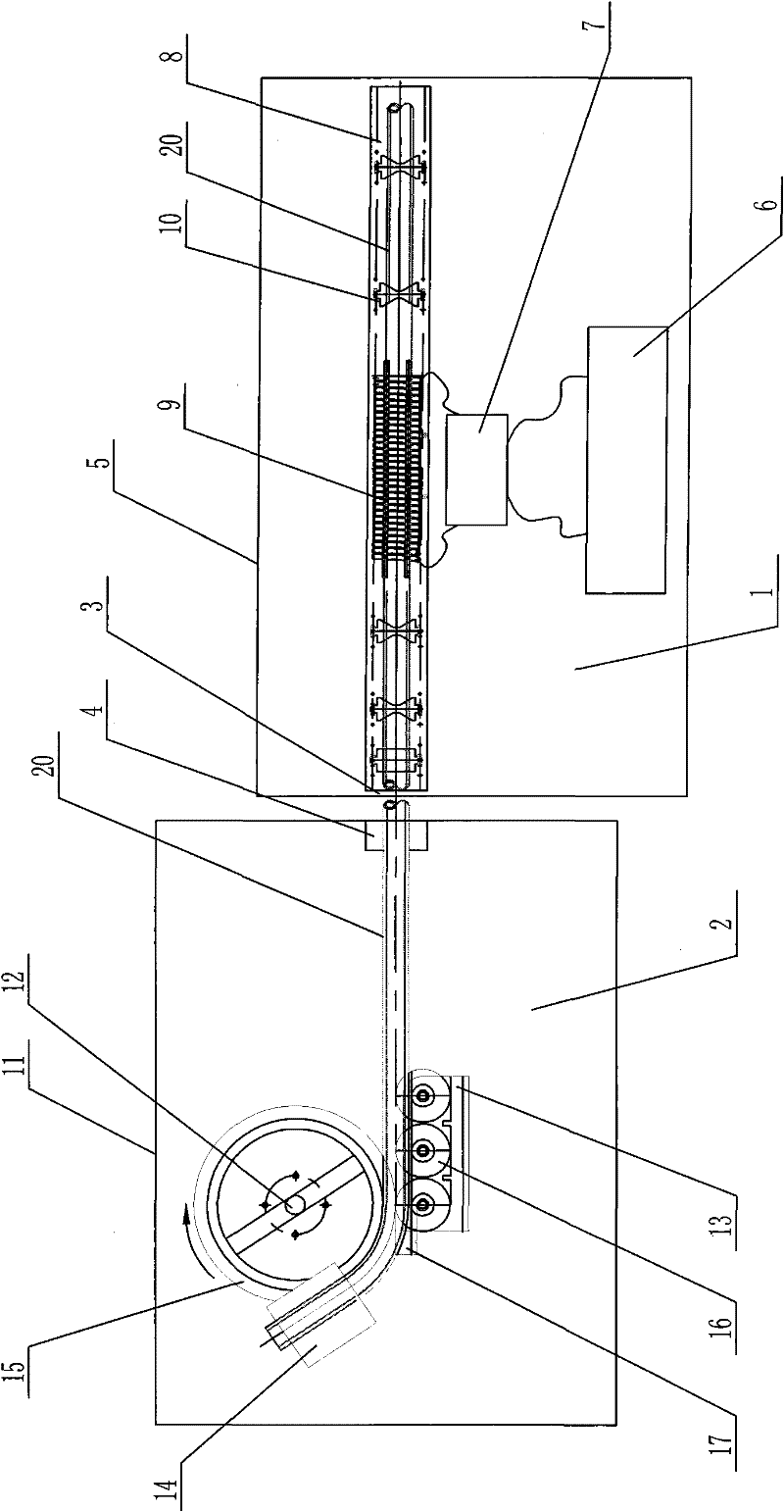

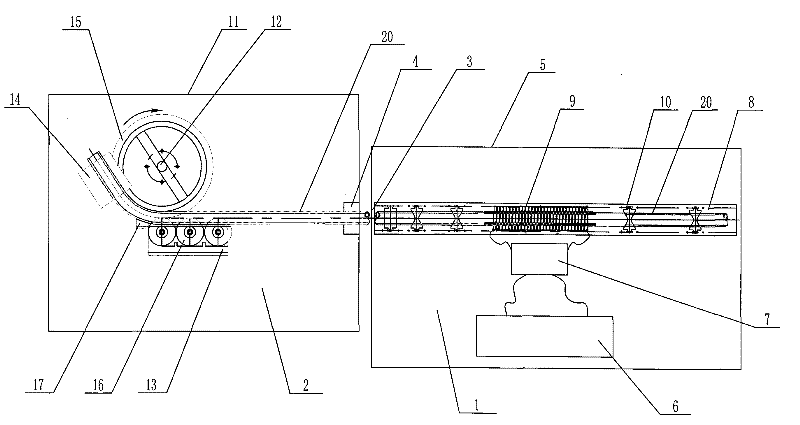

Processing method for cold bending pipes by medium frequency heating

ActiveCN101623724AHeating evenlyHeating environmental protectionCoil arrangementsMetal-working feeding devicesMedium frequencyEngineering

The invention discloses a processing method for cold bending pipes by medium frequency heating, comprising the following steps: firstly, heating the part, which is required to be bent, of a pipeline to certain temperature by adopting the medium frequency heating mode, and then bending the pipeline. The method has the advantages that the design is reasonable, the heating effect is good, the work efficiency is high, the pipeline bending quality is good and the labor intensity of workers is reduced, and the method can provide good productivity benefits for the enterprises.

Owner:HENAN HUADIAN JINYUAN PIPING

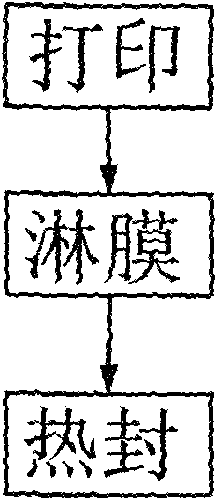

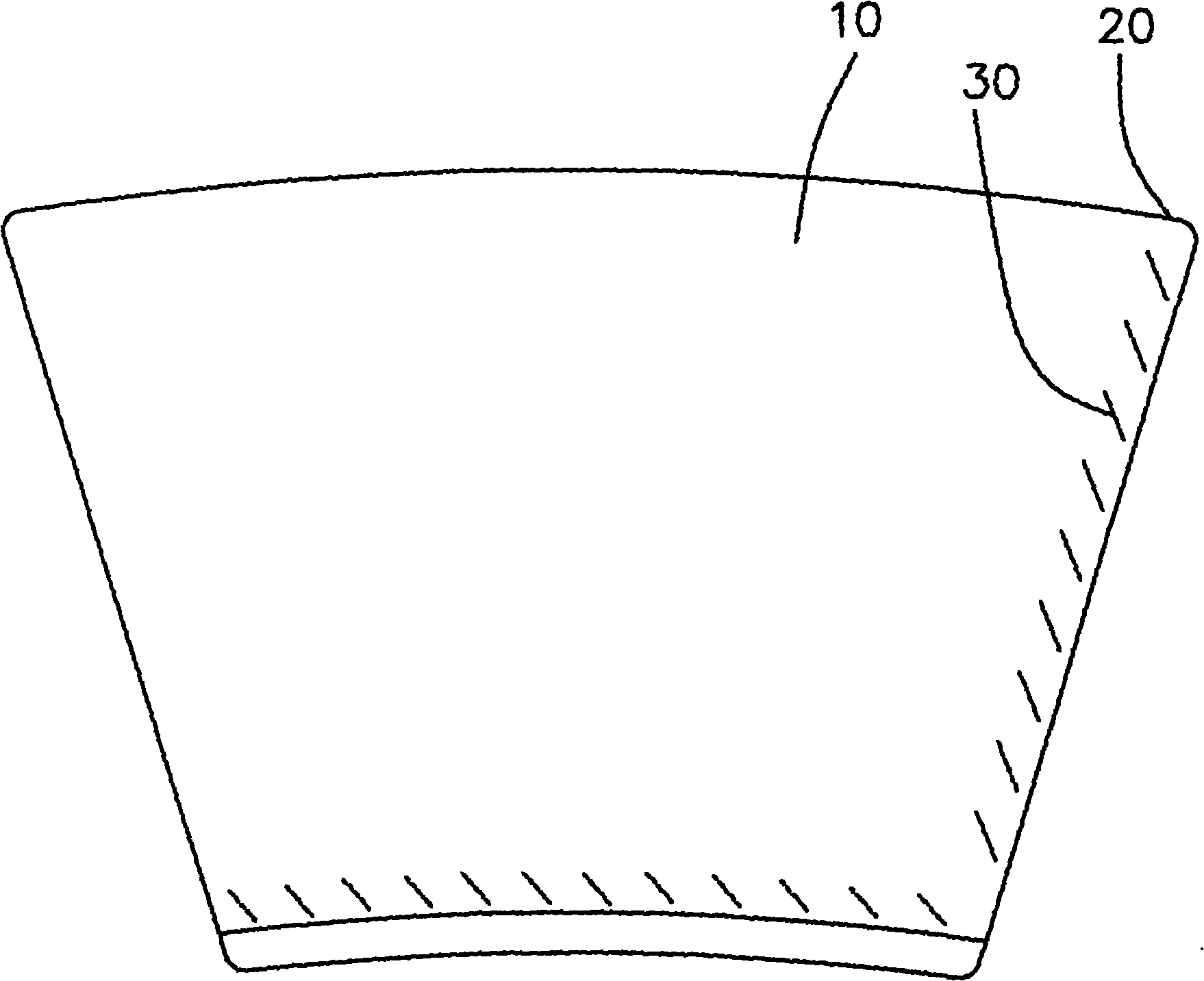

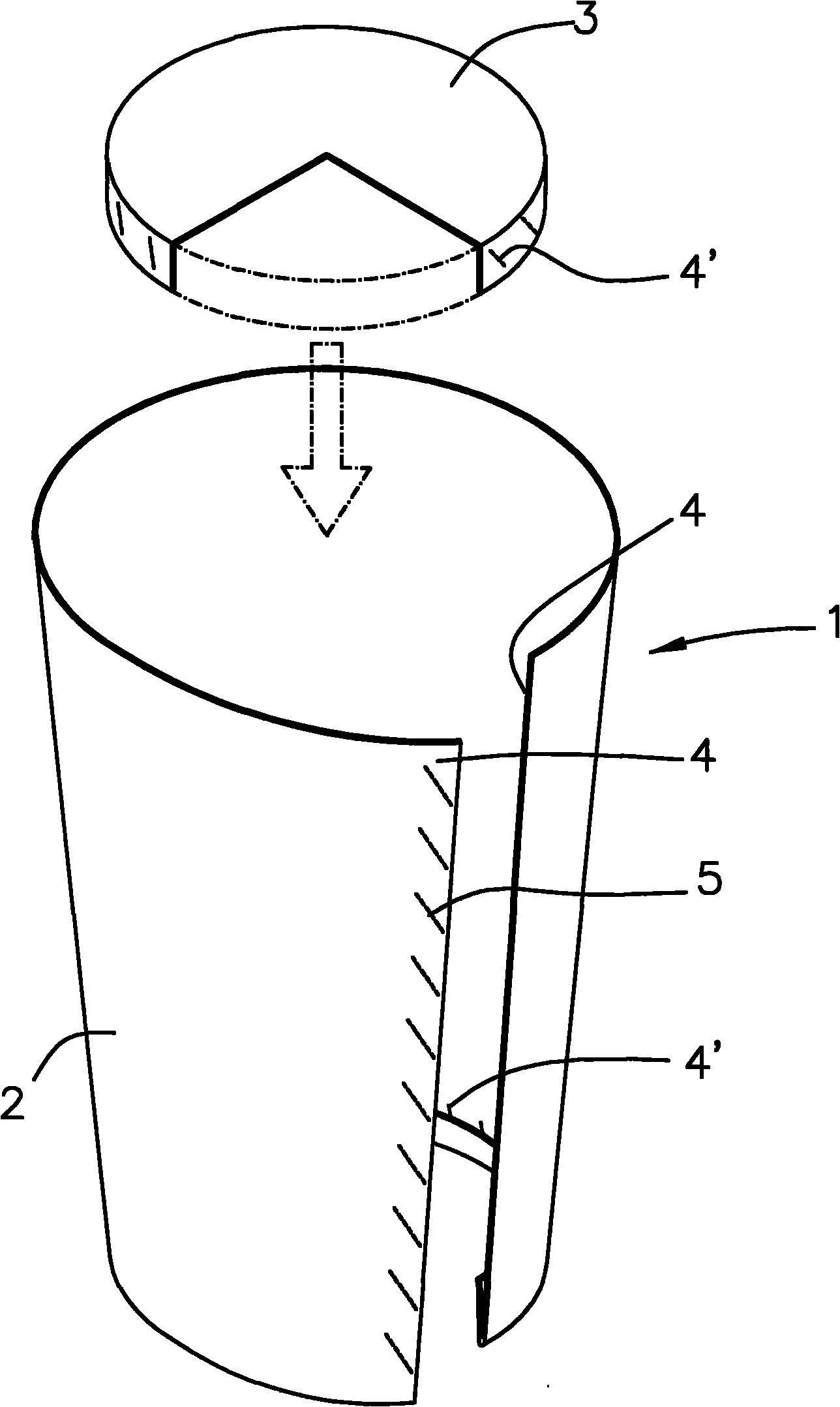

Method for manufacturing paper container and paper container

InactiveCN101875248AStrong binding strengthFast productionBio-packagingBox making operationsPulp and paper industryViscosity

The invention discloses a method for manufacturing a paper container and the paper container. The manufacturing method comprises the steps of printing, laminating and heat sealing, and comprises the following specific steps of: printing a paper substrate, wherein the paper substrate comprises at least one pair of jointing edges, and at least one of the pair of the jointing edges is provided with one or more grooves; in the paper substrate, paving and laminating a waterproof thermally-bonded film on at least one side with the groove; and under the heating condition, making the waterproof thermally-bonded film generate viscosity, and bonding the jointing edge with the groove and the corresponding jointing edge under increased pressure subsequently. The paper container comprises a body part and a bottom plate positioned at the bottom end of the body part. The manufacturing method can slow down the degree of temperature reduction of the waterproof thermally-bonded film during the heat sealing, additionally provides an unsmooth surface required by increasing bond strength, achieves the prospective bond strength, and reduces overall time required by the heat sealing step; and the paper container has the advantages of high manufacturing speed and high bond strength.

Owner:RICH CUP BIO CHEM TECH

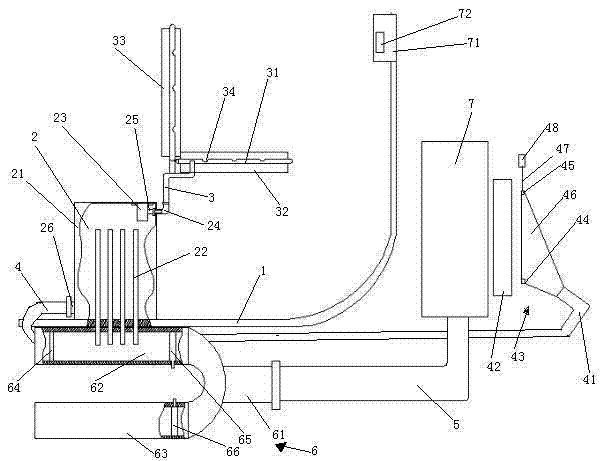

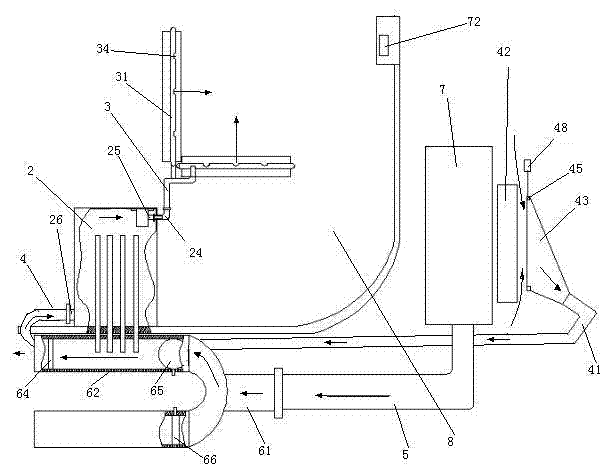

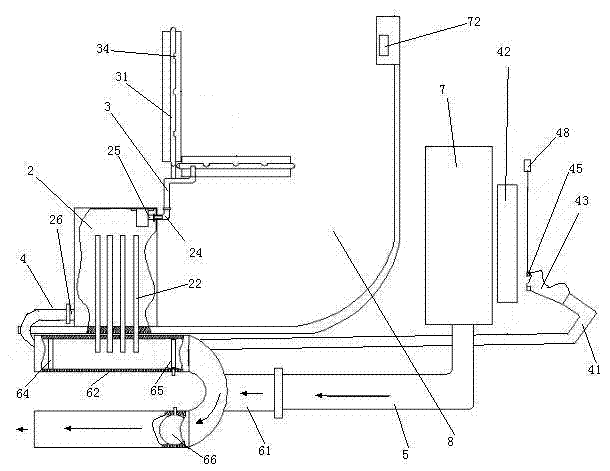

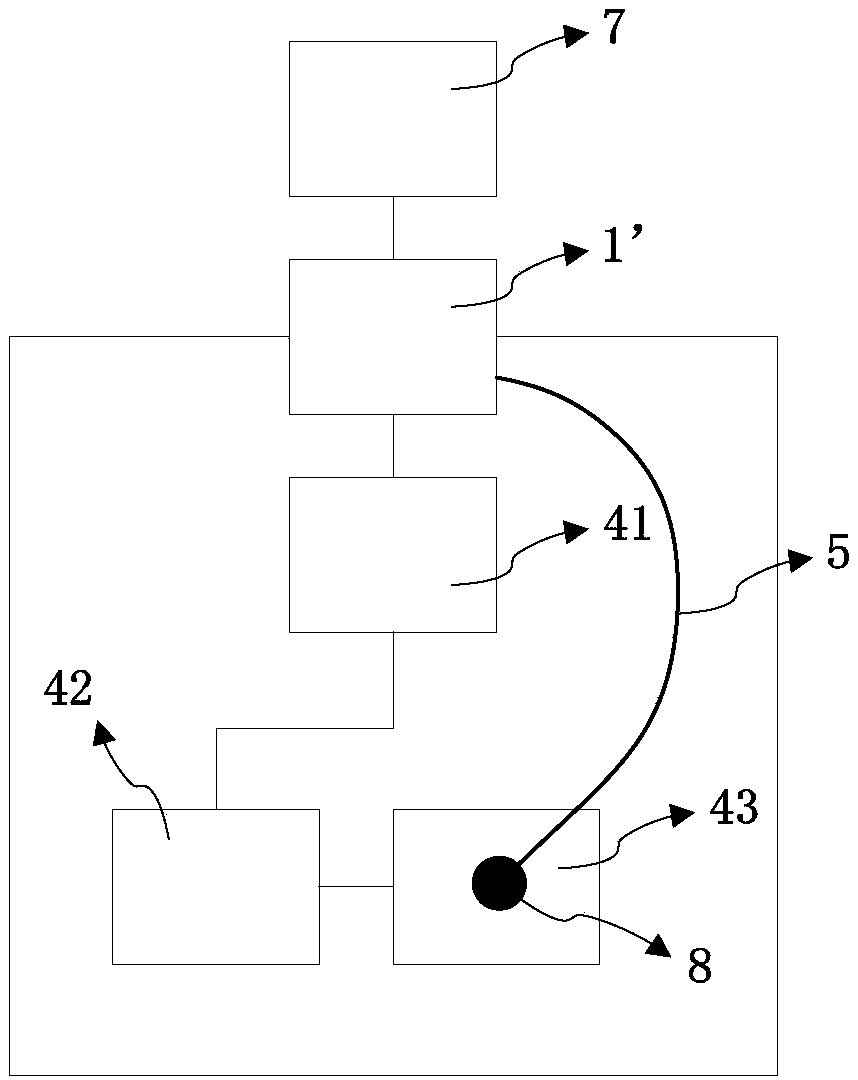

car heating device

ActiveCN102259572ASolve poor heating effectSolution volumeAir-treating devicesVehicle heating/cooling devicesEvaporationEngineering

The invention relates to an automobile heating system. The automobile heating system comprises a heat exchange tube used for transferring heat by utilizing change of three states of matter as well as a heat exchange chamber and a three-way pipe, wherein the heat exchange tube is arranged in the heat exchanger chamber, the heat exchange chamber is provided with a blast blower, an air inlet and an air outlet, the three-way pipe comprises an air inlet pipe, a first air outlet pipe and a second air outlet pipe, the air inlet pipe is connected with an automobile exhaust pipe, the second air outletpipe is provided with a second valve, the air inlet end of the first air outlet pipe is provided with a first valve, the air outlet end of the first air outlet pipe is provided with a suction blower,the evaporation end of the heat exchange tube penetrates the heat exchange chamber and then is connected with the first air outlet pipe, the evaporation end of the heat exchange tube is arranged between the suction blower and the first valve. The invention provides the automobile heating system with good heating effect and protective action to an engine and solves the problems that the traditional automobile heating system has poor heating effect and large volume and is inconvenient to mount.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

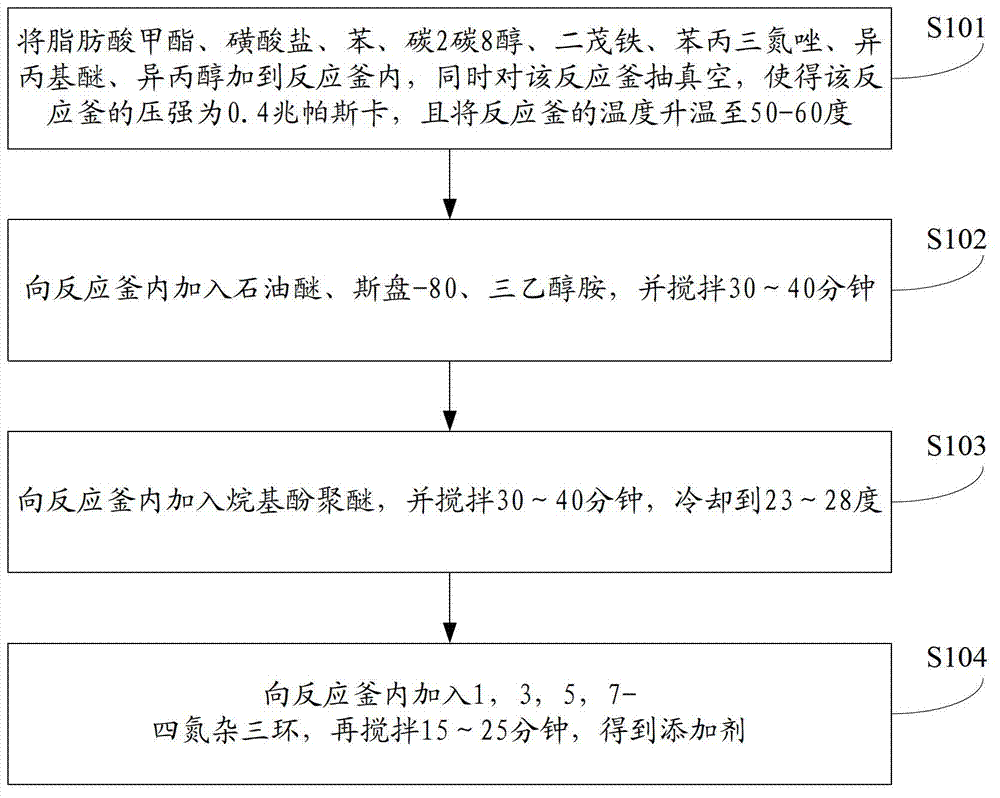

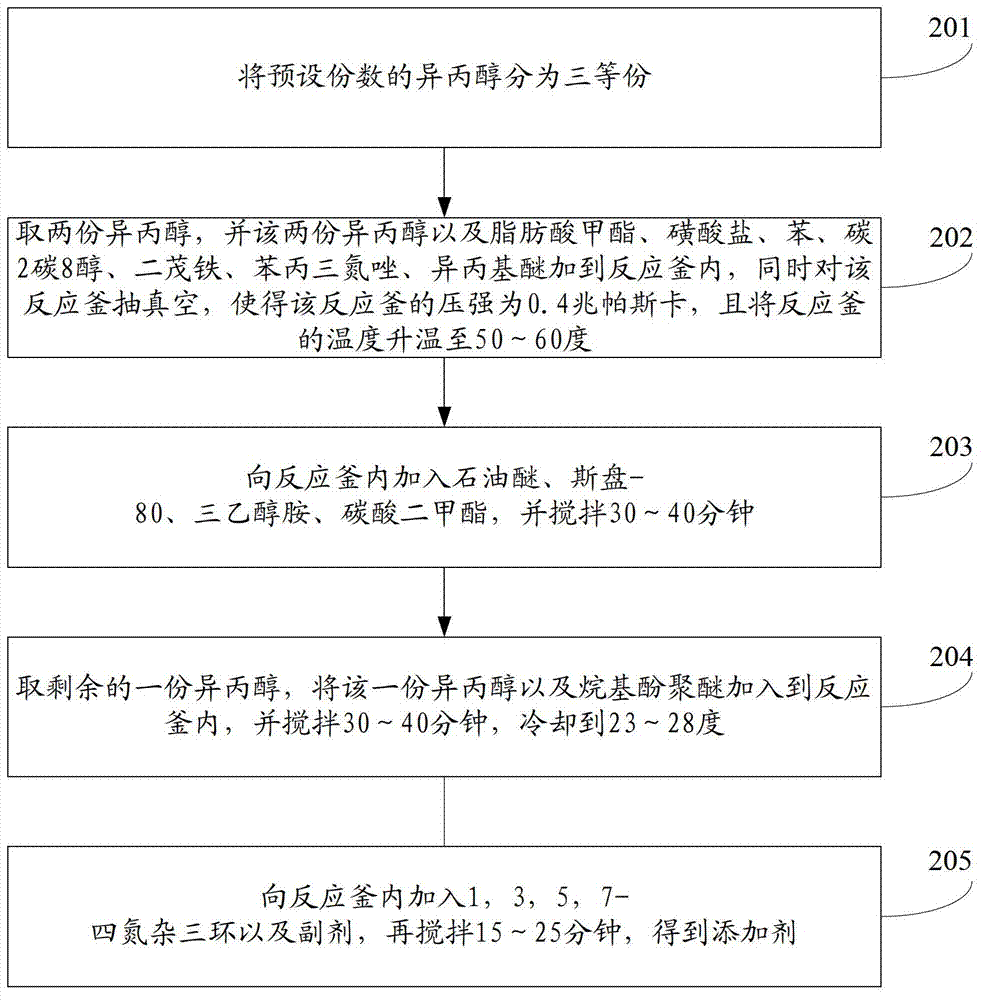

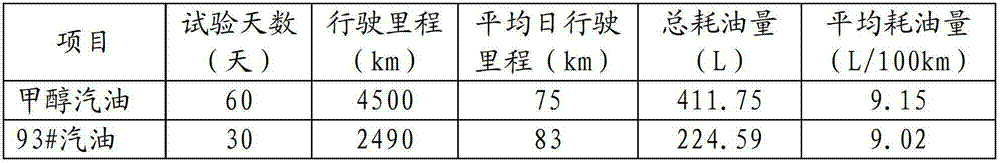

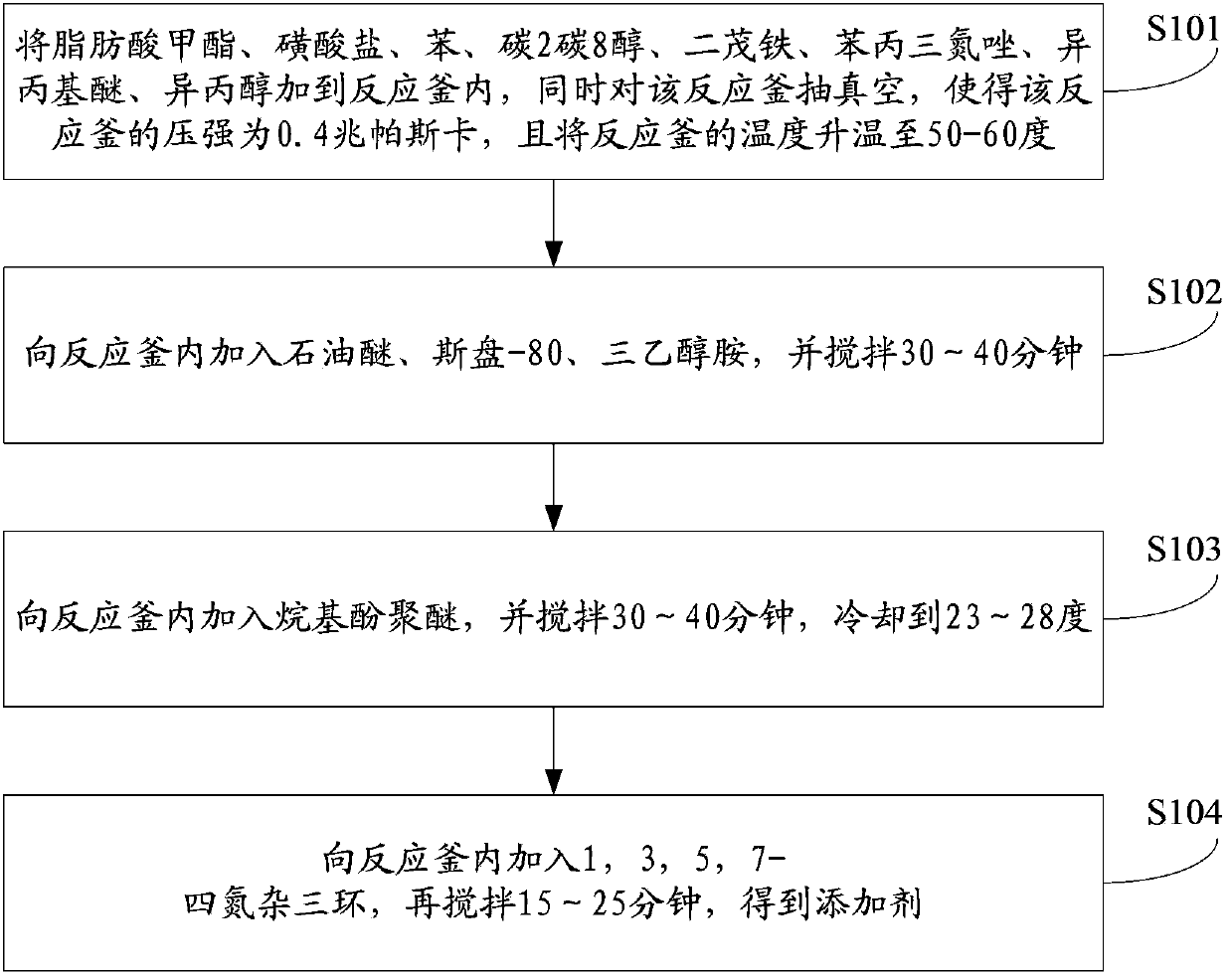

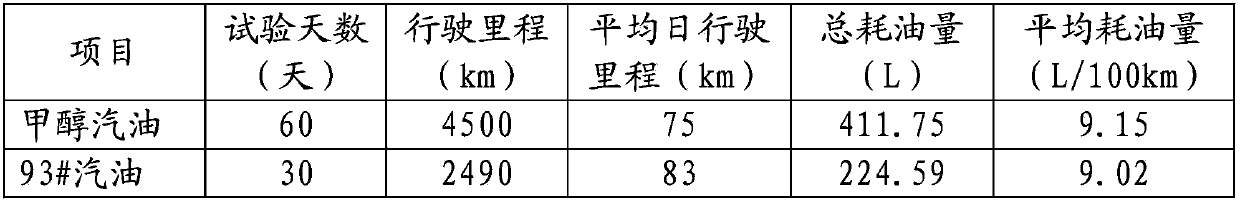

Methanol gasoline additive and preparation method

InactiveCN102732339AImprove stabilityReduce consumptionLiquid carbonaceous fuelsFuel additivesOil additiveAlkylphenol

The invention belongs to the field of an automobile, and particularly relates to a methanol gasoline additive and a preparation method, and the additive can effectively reduce the swelling corrosion on the automobile. The additive comprises isopropyl ether, phenylpropyl triazole, petroleum ether, ferrocene, fatty acid methyl ester, C2C8 alcohol, benzene, Span-80, triethanolamine, 1,3,5,7-tetraazatricycle, isopropanol, alkylphenol polyether and sulfonate; and the additive is composed of the following components in parts by weight: 0.15-0.67 part of the isopropyl ether, 0.03-0.1 part of the phenylpropyl triazole, 0.01-0.08 part of the petroleum ether, 0.02-0.08 part of the ferrocene, 0.03-0.09 part of the fatty acid methyl ester, 0.2-0.8 part of the C2C8 alcohol, 0.4-0.9 part of the benzene, 0.03-0.09 part of the Span-80, 0.03-0.08 part of the triethanolamine, 0.2-0.7 part of the 1,3,5,7-tetraazatricycle, 0.3-0.8 part of the isopropanol, 0.08-0.16 part of the alkylphenol polyether and 0.02-0.08 part of the sulfonate.

Owner:王自恒

Ultrahigh-strength reinforcing bar and production method thereof

The invention discloses an ultrahigh-strength reinforcing bar and a production method thereof. The ultrahigh-strength reinforcing bar is prepared from the chemical compositions in percentage content by mass: 0.21-0.31% of C, 0.50-0.80% of Si, 1.40-1.60% of Mn, 0.06-0.27% of V, 0.01-0.20% of Nb, 0.010-0.017% of N, 0.02-0.10% of Als and the balance of Fe and unavoidable impurities. The production method comprises the procedures of steel slab heating, steel slab rolling and heat preservation after rolling. According to the ultrahigh-strength reinforcing bar and the production method thereof, thecomponent design of the ultrahigh-strength reinforcing bar adopts low content of precious alloy elements, the reinforcing bar after rolling is additionally covered with a heat preservation cover during cooling, the temperature dropping speed is decelerated, sufficient precipitation of V(C / N) is facilitated, and the obtained ultrahigh-strength reinforcing bar has the advantages that the mechanicalproperties are good, the content of the precious alloy elements is low.

Owner:HEBEI IRON AND STEEL

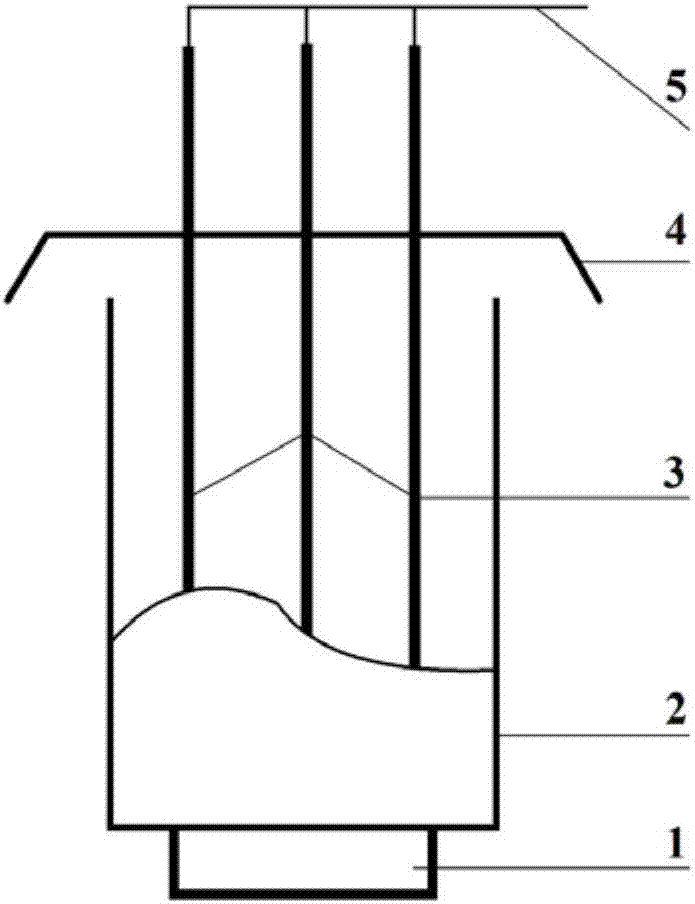

Method for smelting vanadium-based alloy

The invention relates to a method for smelting a vanadium-based alloy. The method comprises the steps that a vanadium source, a reduction agent and a slag former are mixed and are placed in a reaction tank, and ignition for the reduction reaction is carried out; after the reaction is finished, the bottom of the reaction tank is subject to primary ultrasonic refining treatment, and the reaction tank is fixed and subject to sedimentation treatment; after sedimentation is finished, secondary ultrasonic refining treatment is carried out, and sedimentation treatment is continuously carried out; third-time ultrasonic refining treatment is carried out, and sedimentation treatment is continuously carried out; ultrasonic refining treatment and reaction tank static sedimentation treatment are alternatively carried out until molten alloy is solidified, and the vanadium-based alloy is obtained. The alloy raw material performance is improved while the production period is not prolonged, the alloy A-grade product rate is increased, the use amount of the reduction agent is reduced, and the comprehensive economic benefit is improved. The method can be applied to other metal heat reduction processes, a high-purity uniform middle alloy raw material can be produced, and can be widely applied to the high-technology industry of aerospace, nuclear energy and the like, and the good application prospect is achieved.

Owner:HEBEI IRON AND STEEL

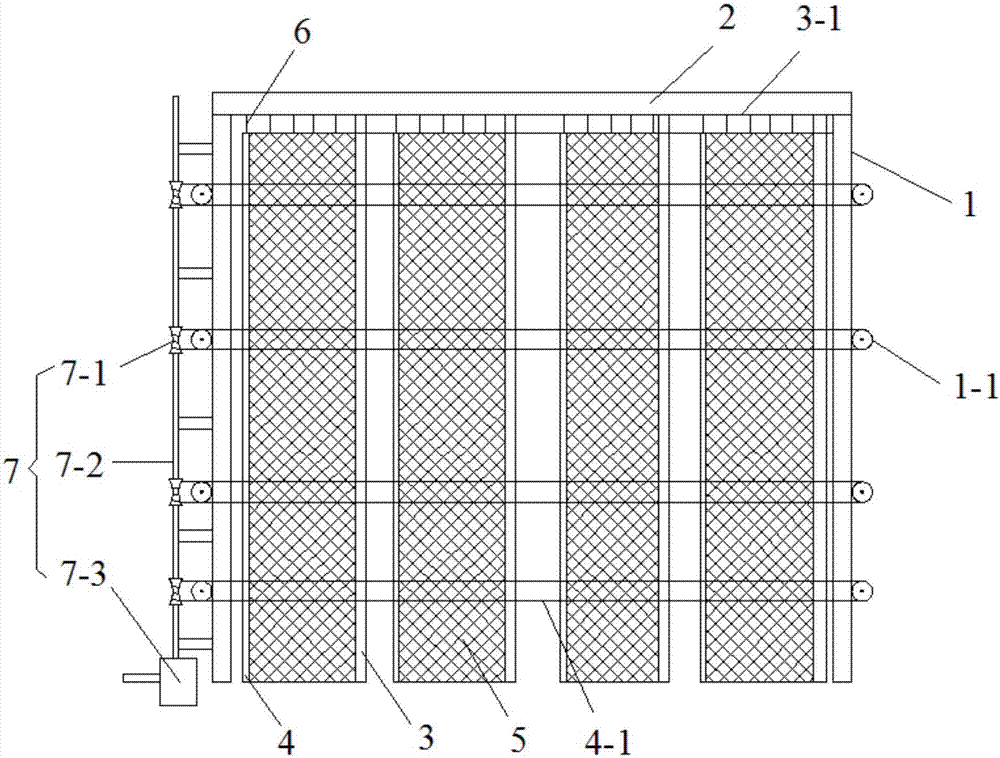

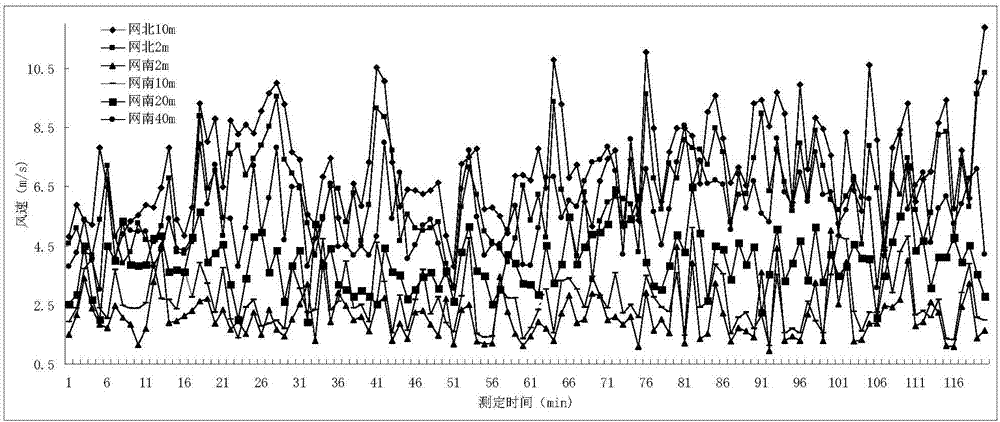

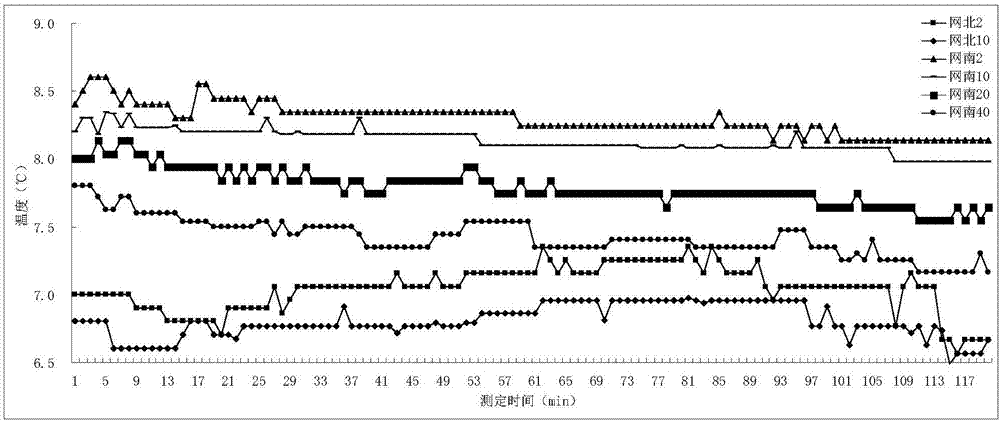

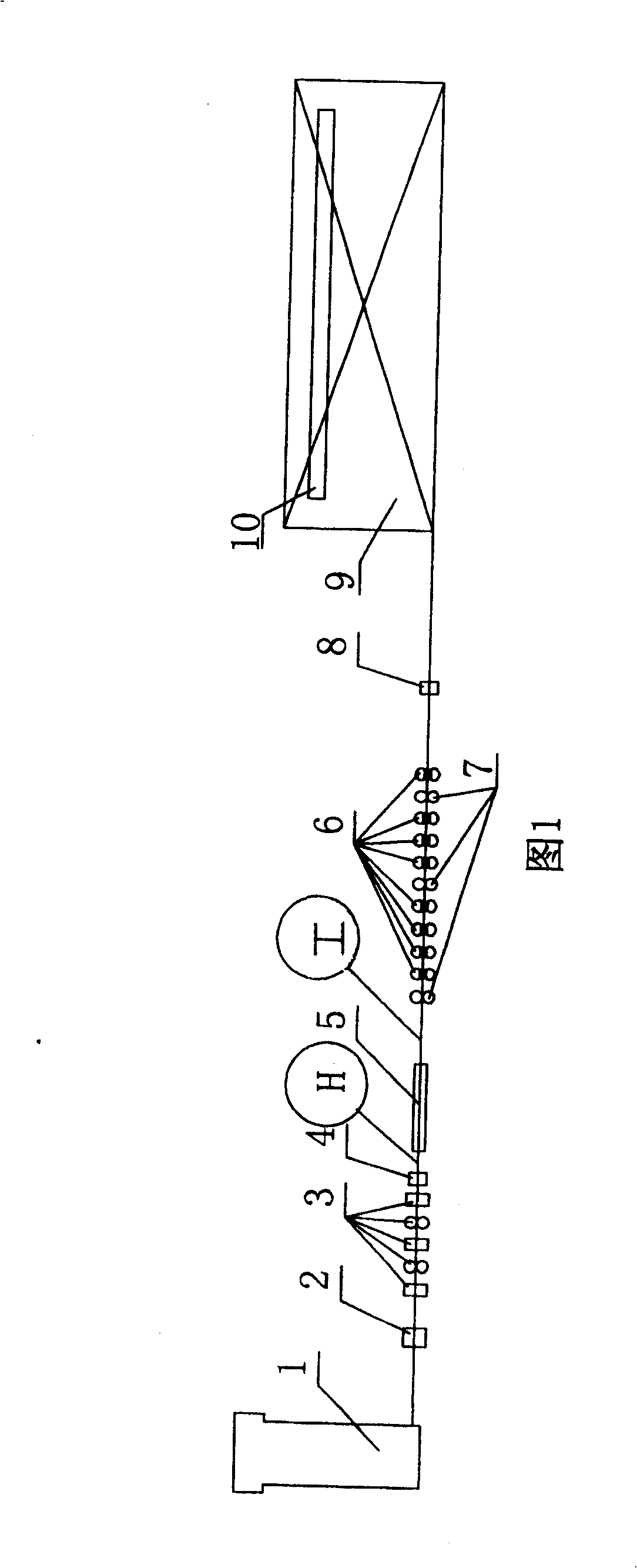

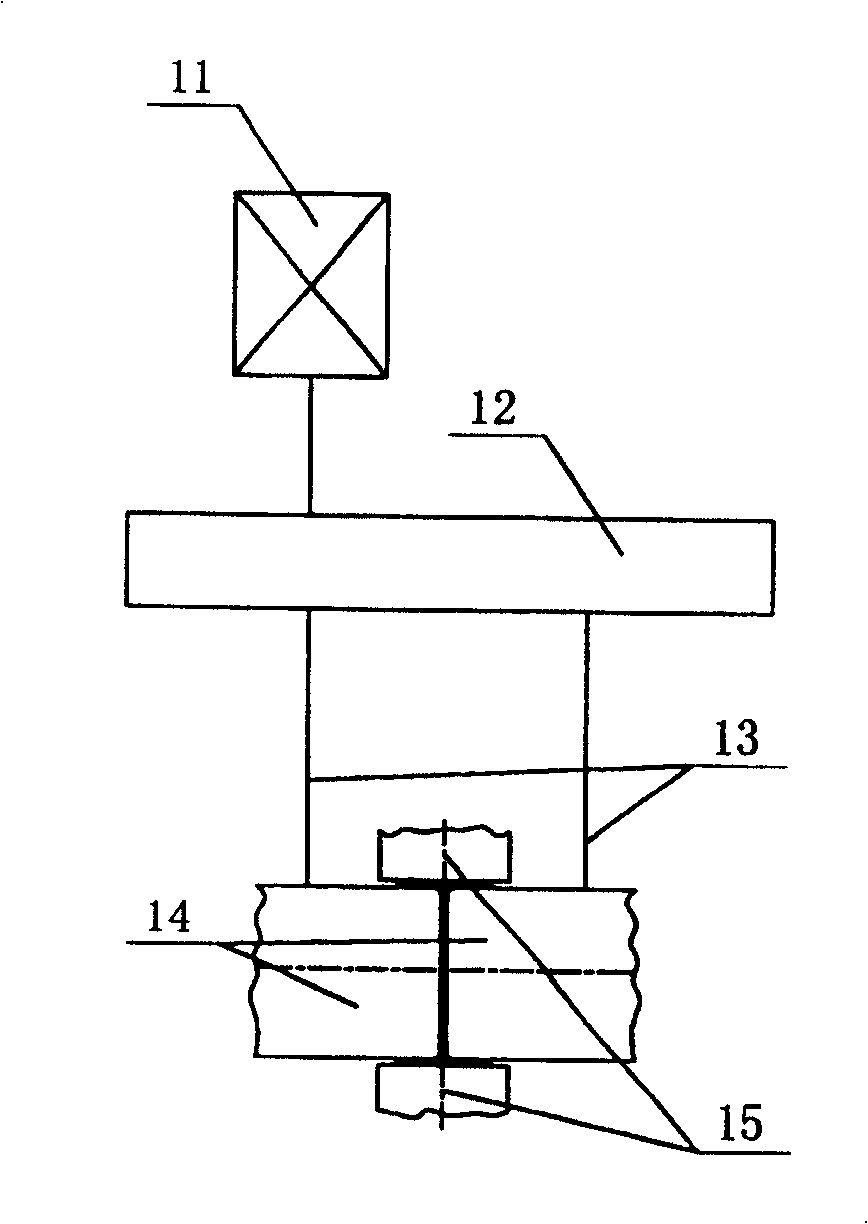

Adjustable windproof net for orchard

The invention discloses an adjustable windproof net for an orchard and belongs to the technical field of windproof nets. The windproof net comprises two first fixed upright posts, a cross beam, a plurality of second fixed upright posts and movable upright posts, wherein the top ends of the first upright posts are connected by the cross beam; the upper ends of the second fixed upright posts are connected with the cross beam; the lower ends of the second fixed upright posts are arranged on the ground; a protecting net is arranged between each movable upright post and the corresponding second fixed upright post; a fixing rope is arranged at the upper ends of the second fixed upright posts; the protecting nets and the upper ends of the movable upright posts are suspended on the fixing rope; a plurality of through holes are formed in the second fixed upright posts and the movable upright posts; pulling ropes are arranged in a mode of penetrating through the through holes; a plurality of fixed pulleys are arranged on the first fixed upright posts; the heights of the fixed pulleys arranged on the two first fixed upright posts are identical; a traction device is arranged on the outer side of one first fixed upright post; and the pulling rope bypasses the two fixed pulleys and the traction device. The adjustable windproof net disclosed by the invention can be folded and unfolded at any time and has the advantages of obvious windproof effect, high stability and easiness in construction.

Owner:SHENYANG AGRI UNIV

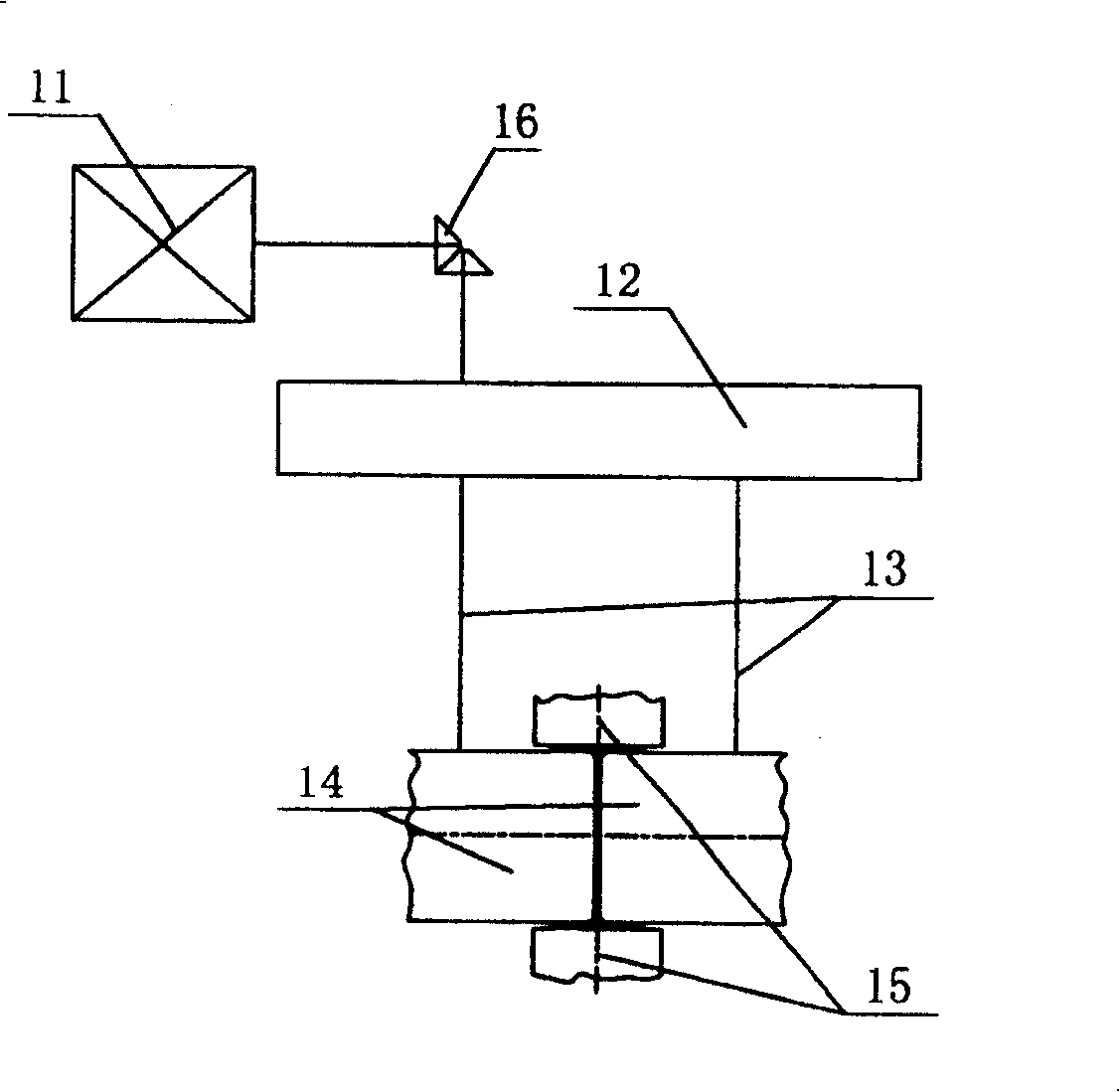

H-type shape steel vertical rolling method and apparatus

ActiveCN100448557CSlow down the temperature dropThin wallWork manipulationRolling mill drivesEngineeringMetal

The present invention relates to a vertical rolling method of wide flange steel and its equipment, belonging to the field of metal rolling technology. Said method includes the following steps: billet heating, des caling, blooming, cropping and rolling so as to obtain the rolled material with web plate and flange. Said invention also provides the concrete operation steps of said rolling process.

Owner:MAANSHAN IRON & STEEL CO LTD

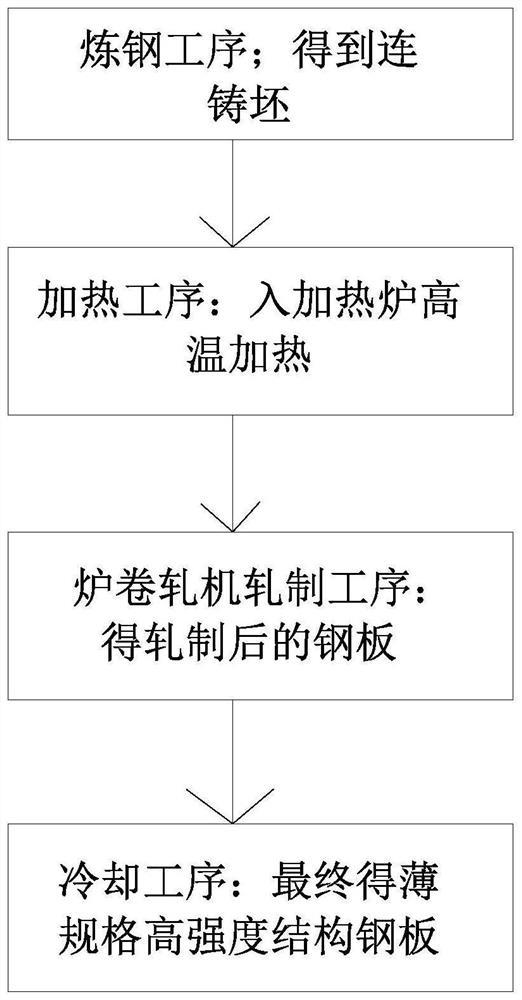

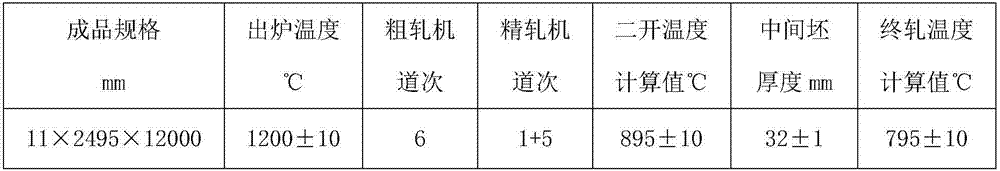

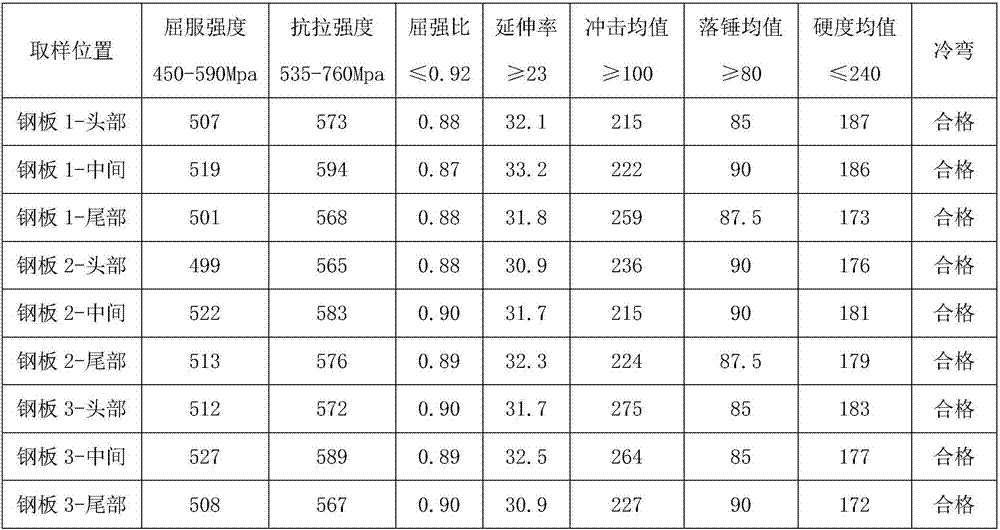

Method for producing thin-gauge high-strength structural steel plate by steckel mill

PendingCN114411060ASlow down the temperature dropSimple production processTemperature control deviceMetal rolling arrangementsSteelmakingTempering

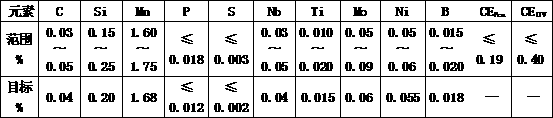

The invention discloses a method for producing a thin-specification high-strength structural steel plate by a steekle mill. Belongs to the metallurgy field. The method comprises the following specific steps: 1, steelmaking; a continuous casting blank is obtained; 2, heating: heating at high temperature in a heating furnace; 3, rolling by a steekle mill to obtain a rolled steel plate; and 4, cooling: finally obtaining the thin-gauge high-strength structural steel plate. The component design that the carbon content is 0.16-0.18% is adopted, microalloy elements of Nb, V and Ti are properly added, the advantage that a steekle mill can conduct heat preservation on a steel plate coil in a furnace in the rolling process of the thin steel plate with the thickness of 6-10 mm is utilized, the temperature reduction speed of the steel plate in the rolling process is reduced, the thin high-strength structural steel plate with the tensile strength of 570 MPa is obtained, and the steel plate is excellent in-5 DEG C impact performance, good in heat preservation performance and good in heat preservation performance. And the plate shape quality is good, the flatness does not exceed 6 mm / m, an additional heat treatment procedure of normalizing or quenching and tempering is not needed, the process is simple, and the cost is low.

Owner:NANJING IRON & STEEL CO LTD

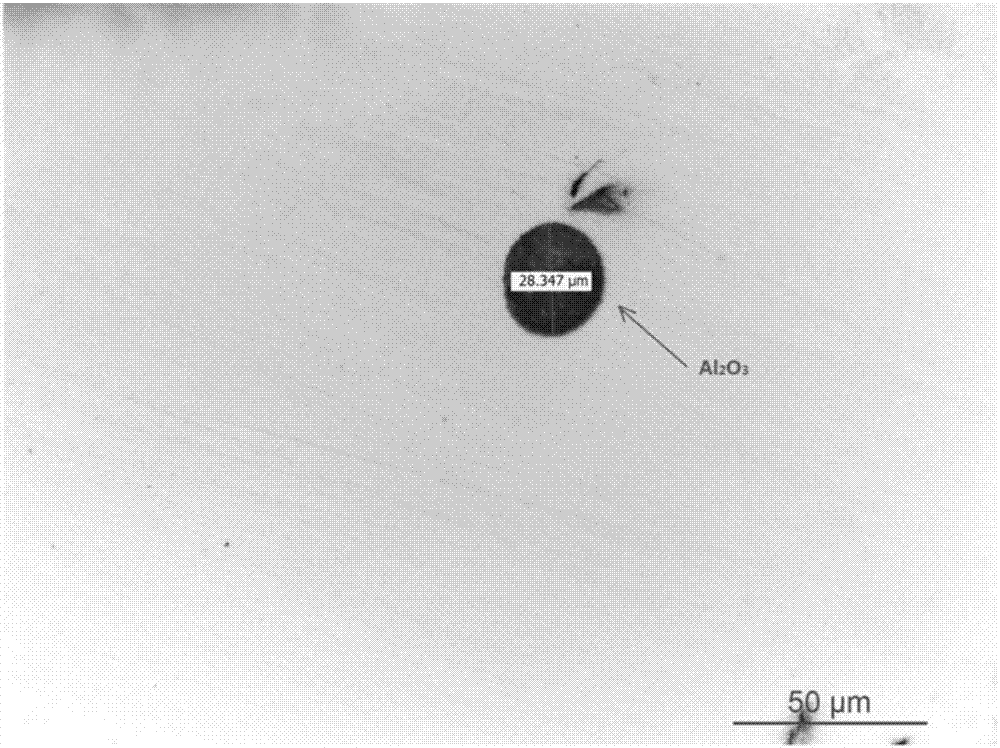

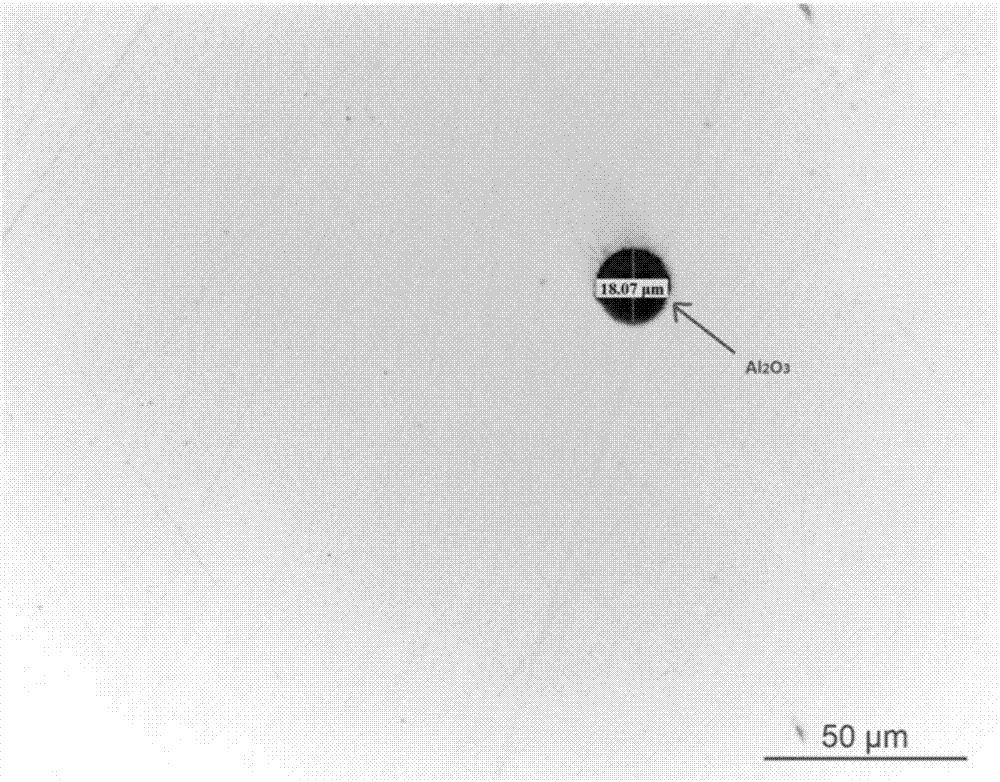

Production process of high-efficiency Q235B micro-titanized steel grade

ActiveCN114015930AReduced crack susceptibilityImprove internal qualityProcess efficiency improvementTitaniumCalcium handling

The invention relates to the technical field of steelmaking processes, and in particular relates to a high-efficiency Q235B micro-titanized steel grade. The steel grade is composed of, by weight, 0.04% to 0.07% of C, smaller than or equal to 0.10% of Si, 0.35% to 0.55% of Mn, smaller than or equal to 0.040% of P, smaller than or equal to 0.035% of S, 0.010% to 0.050% of Als, 0.030% to 0.050% of Ti and the balance Fe. The invention provides a production process of the high-efficiency Q235B micro-titanized steel grade. Desulfurization and calcium treatment process are carried out by adding titanium to reduce carbon and "slag washing" after converter furnace, low-superheat-degree casting is adopted in the continuous casting process, the influence of sulfide in steel and a finished product banded structure on the product and performance is reduced, and the cold bending process requirements of customers are met.

Owner:武安市裕华钢铁有限公司

Novel direct continuous casting slag washing mixed material and preparation process thereof

The invention relates to a novel direct continuous casting slag washing mixed material and a preparation process thereof, and belongs to the field of special-performance alloy and powder metallurgy novel material in metal materials of the novel materials. The novel heating slag washing mixed material comprises the following components in parts by weight: 30-65 parts of aluminum oxide powder, 30-50 parts of quick lime, 1-6 parts of magnesium oxide powder, 0-6 parts of fluorite and 5-6 parts of silicon dioxide powder. The preparation process of the novel heating slag washing mixed material comprises the following steps of: ball-milling the materials in a ball mill to obtain particle powder; press-moulding the ball-milled particle powder by a ball press, smelting in an electric-arc furnace; and adding 5-40 parts of aluminum powder to the molten liquid during a turning down process, and crushing the cooled material into particles. The novel direct continuous casting slag washing mixed material disclosed by the invention can be used for filtering deoxidized desulfurized molten steel very well, so that produced deoxidation products can be caught effectively and modification of impurities in the steel is promoted, so that the purpose of evolving the molten steel is reached.

Owner:涟源市飞达冶金炉料厂

A kind of manufacturing method of gh4169 alloy fine-grain disk billet

ActiveCN103465027BSlow down the temperature dropGuaranteed uniformityForging/hammering/pressing machinesOther manufacturing equipments/toolsPunchingGrain structure

Owner:GUIZHOU AVIATION TECHN DEV

Medium frequency heating cold bending pipe processing method

ActiveCN101623724BHeating evenlyHeating environmental protectionCoil arrangementsMetal-working feeding devicesIntermediate frequencyEngineering

The invention discloses a processing method for intermediate frequency heating cold-bending pipes. Firstly, intermediate frequency heating is used to heat the parts of the pipes to be bent to a certain temperature, and then the pipes are bent. The invention has the advantages of reasonable design, good heating effect, high work efficiency and good pipe bending quality, which reduces the labor intensity of workers and can create good production benefits for enterprises.

Owner:HENAN HUADIAN JINYUAN PIPING

Novel direct continuous casting slag washing mixed material and preparation process thereof

The invention relates to a novel direct continuous casting slag washing mixed material and a preparation process thereof, and belongs to the field of special-performance alloy and powder metallurgy novel material in metal materials of the novel materials. The novel heating slag washing mixed material comprises the following components in parts by weight: 30-65 parts of aluminum oxide powder, 30-50 parts of quick lime, 1-6 parts of magnesium oxide powder, 0-6 parts of fluorite and 5-6 parts of silicon dioxide powder. The preparation process of the novel heating slag washing mixed material comprises the following steps of: ball-milling the materials in a ball mill to obtain particle powder; press-moulding the ball-milled particle powder by a ball press, smelting in an electric-arc furnace; and adding 5-40 parts of aluminum powder to the molten liquid during a turning down process, and crushing the cooled material into particles. The novel direct continuous casting slag washing mixed material disclosed by the invention can be used for filtering deoxidized desulfurized molten steel very well, so that produced deoxidation products can be caught effectively and modification of impurities in the steel is promoted, so that the purpose of evolving the molten steel is reached.

Owner:涟源市飞达冶金炉料厂

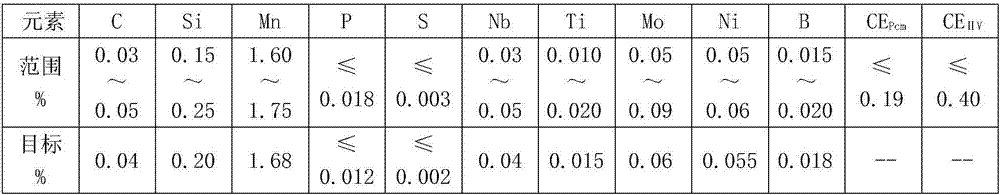

A thin-gauge pipeline steel rolling method

ActiveCN107363094BReduce carbon contentIncrease the content of alloying elementsRoll mill control devicesMetal rolling arrangementsOne passSheet steel

The invention relates to a thin gauge pipeline steel rolling method. In the steel, the content of C is within 0.05 percent; the content of Ni is 0.05 to 0.06 percent; the content of Ti is 0.01 to 0.02 percent; the content of B is 0.015 to 0.002 percent; the soaking temperature during rolling is 1,180 to 1,220 DEG C; the soaking time is 45 to 100 minutes; the torque of a roughing mill is 3,500 to 3,600 kN.m; the compression ratio is controlled to be 5 to 20; the width spread ratio is controlled to be 1.25 to 2.0; rough rolling is performed within 50 seconds after steel is discharged from a furnace; in rough rolling, the pressing down ratio of at least one pass is ensured not to be less than 21 percent when transverse rolling is performed, and the single pass pressing down ratio of at least two passes is ensured not to be less than 25 percent when longitudinal rolling is performed; and the temperature reducing speed is within 60 DEG C. According to the method, a controlled cooling link after the steel is rolled is cancelled by regulating chemical components of pipeline steel and heating; the type of a steel plate is improved; the production efficiency is greatly improved; and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

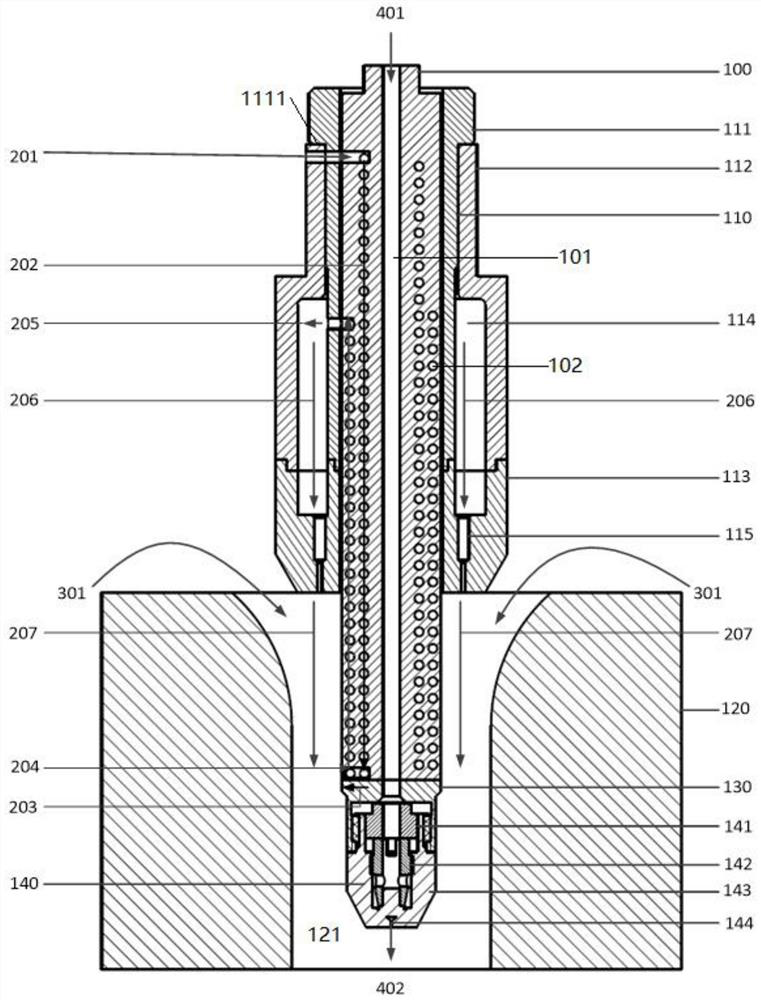

An anti-carbon fuel injection device

ActiveCN110005558BAvoid damageGuaranteed performanceMachines/enginesSpecial fuel injection apparatusCombustion chamberInjector nozzle

Owner:SHANGHAI MICROPOWERS

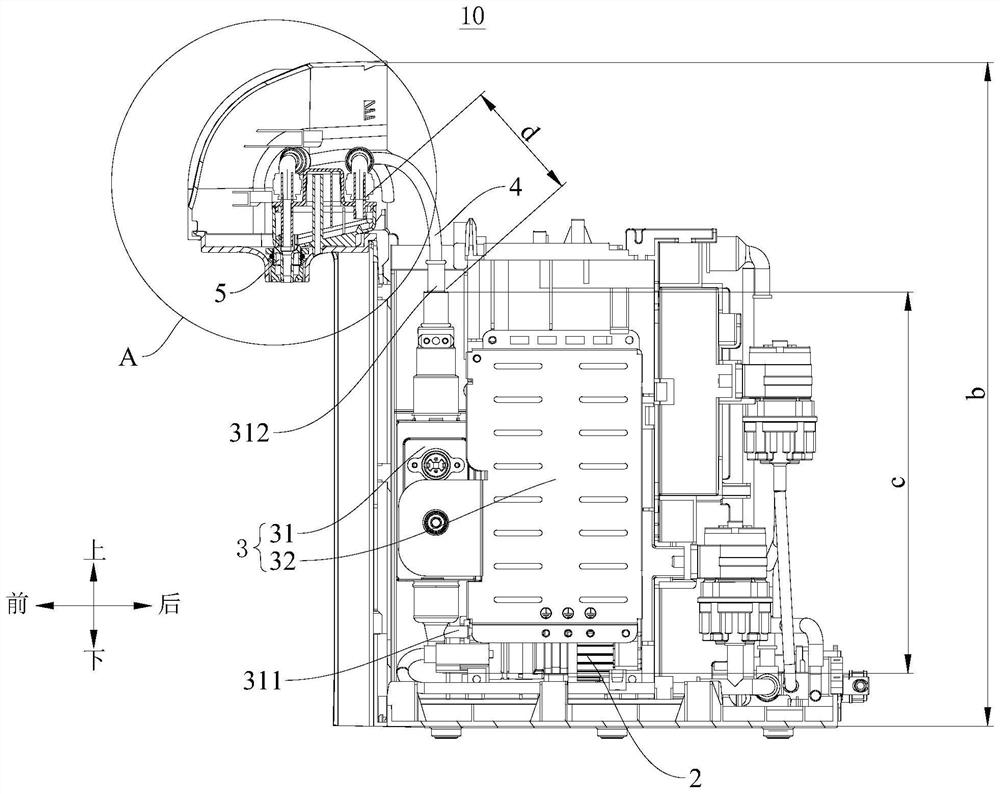

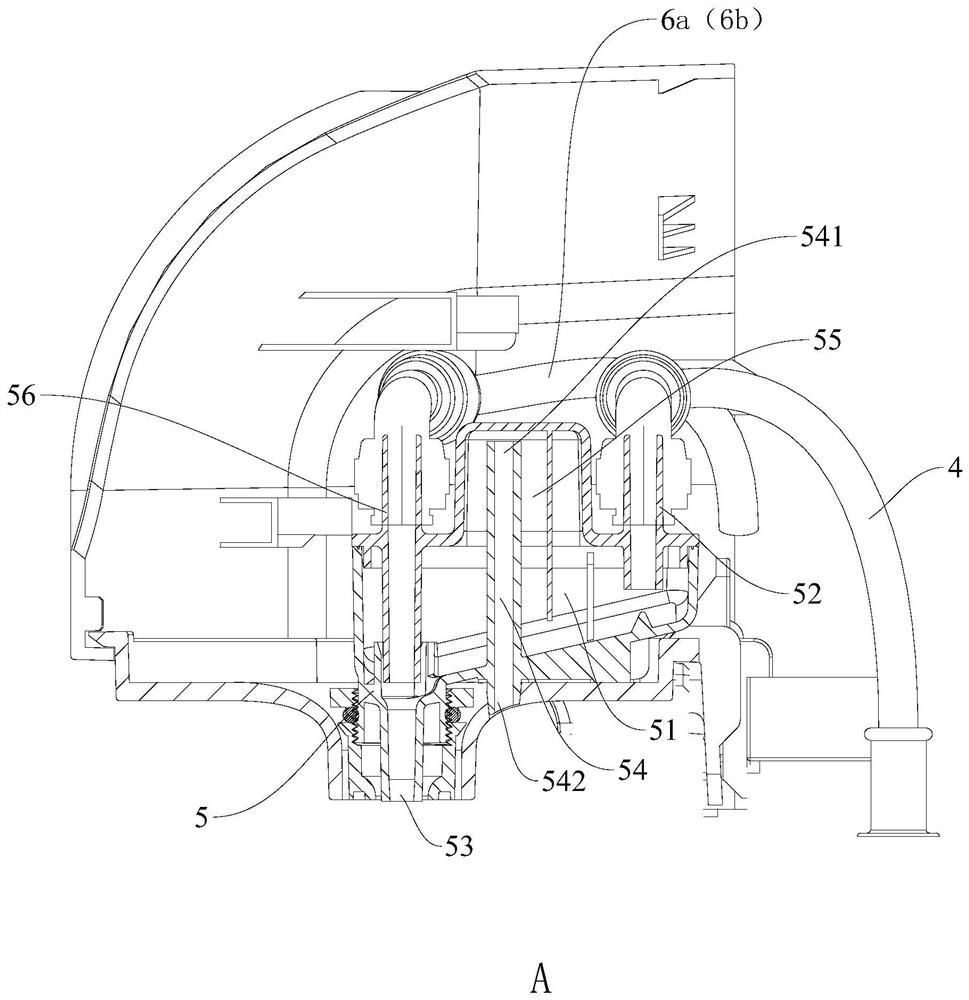

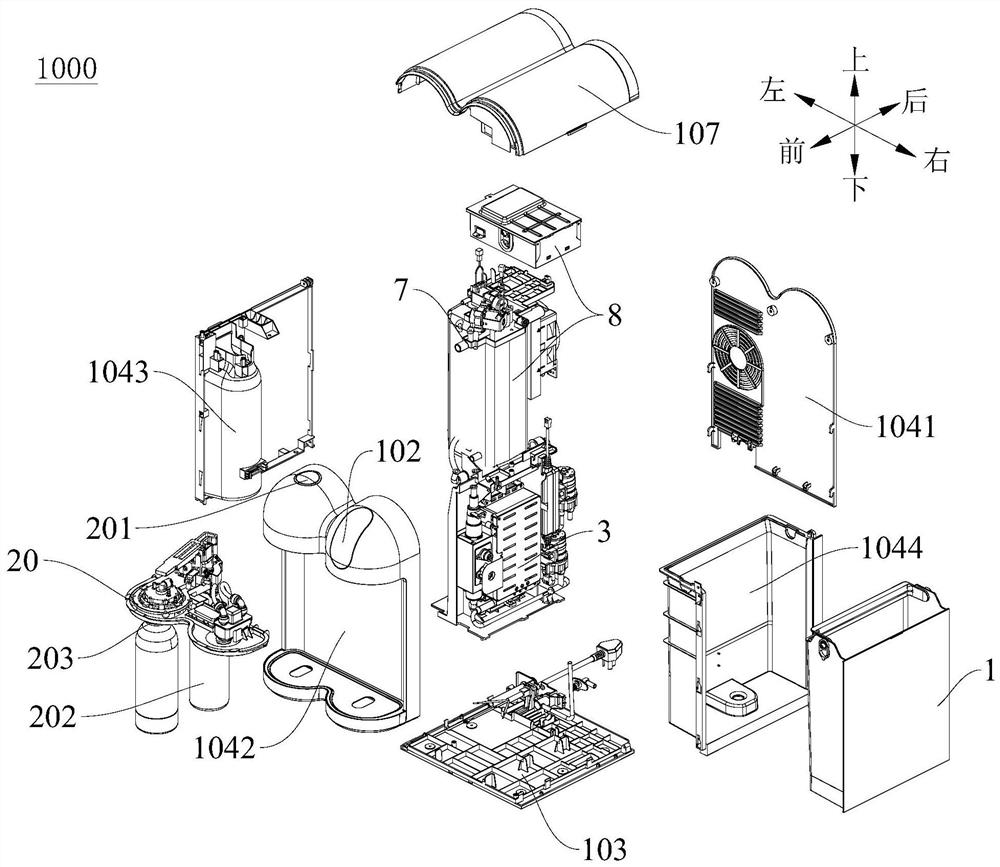

Waterway system and multifunctional water dispenser with same

PendingCN114158943AShorten the lengthReduce residual waterBeverage vesselsWater flowProcess engineering

The invention discloses a waterway system and a multifunctional water dispenser with the same. The waterway system comprises a water tank, a water pump, an instant heating assembly, a hot water pipeline and a water outlet assembly, the water pump is used for conveying water in the water tank to the instant heating assembly, the hot water pipeline is used for conveying water in the instant heating assembly to the water outlet assembly, and a water temperature sensor is arranged in the instant heating assembly. The water outlet assembly and the instant heating assembly are in a normally-communicated state through the hot water pipeline, and therefore water flowing out of the instant heating assembly can flow to the water outlet assembly without being blocked. According to the waterway system, the instant heating assembly and the water outlet assembly are in a normally-communicated state through the hot water pipeline, so that the length of the hot water pipeline is shortened, the residual water amount in the hot water pipeline is reduced, the temperature drop of a first cup of water when the multifunctional water dispenser prepares hot water is reduced, and the user requirements are met; and user experience is improved.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

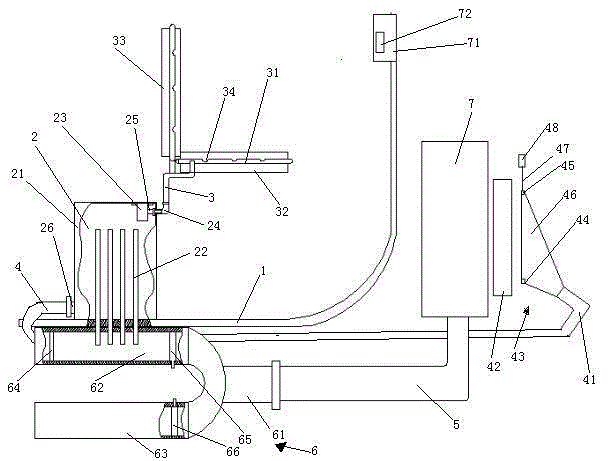

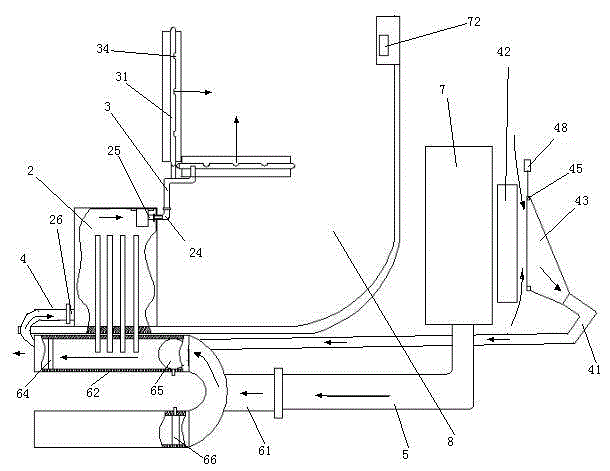

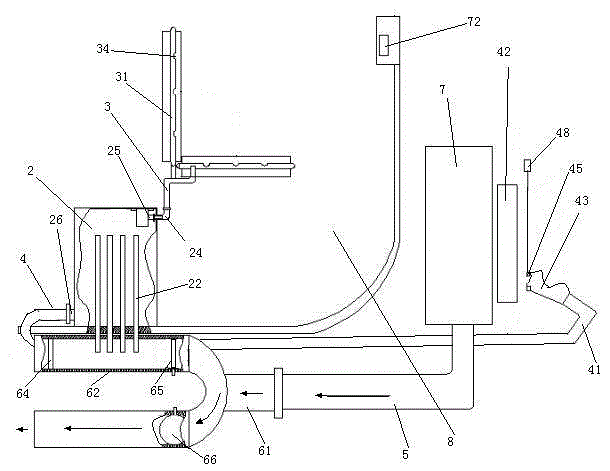

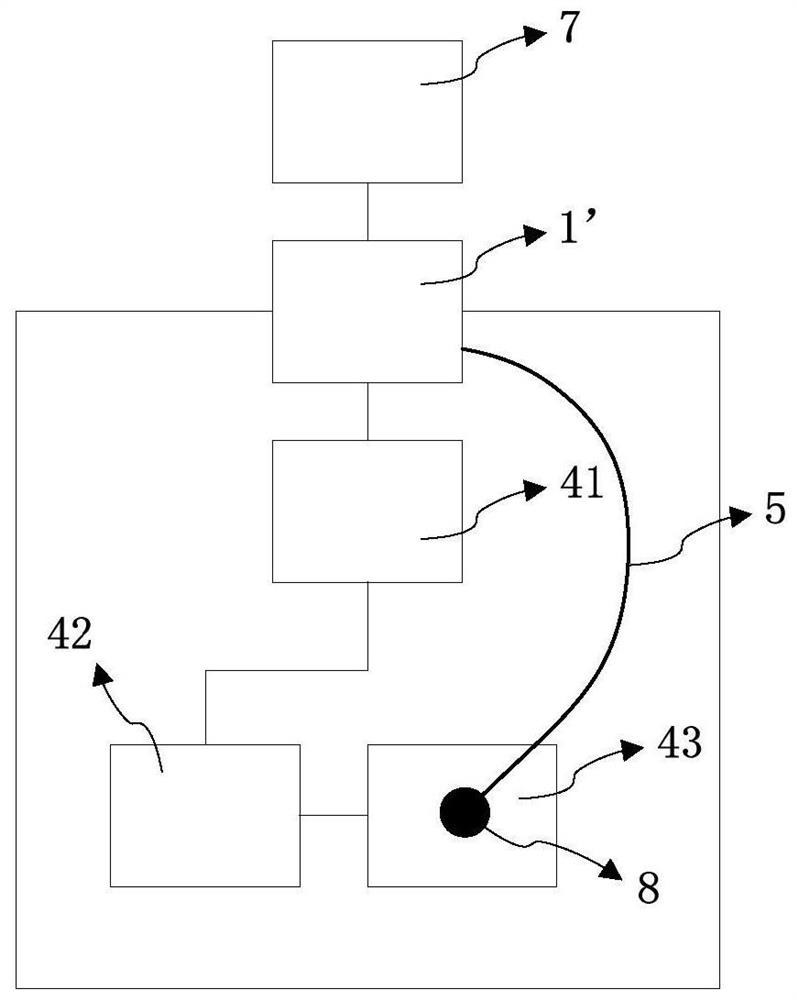

Automobile heating system

ActiveCN102259572BImprove comfortSlow down the temperature dropAir-treating devicesVehicle heating/cooling devicesEvaporationHeating effect

The invention relates to an automobile heating system. The automobile heating system comprises a heat exchange tube used for transferring heat by utilizing change of three states of matter as well as a heat exchange chamber and a three-way pipe, wherein the heat exchange tube is arranged in the heat exchanger chamber, the heat exchange chamber is provided with a blast blower, an air inlet and an air outlet, the three-way pipe comprises an air inlet pipe, a first air outlet pipe and a second air outlet pipe, the air inlet pipe is connected with an automobile exhaust pipe, the second air outletpipe is provided with a second valve, the air inlet end of the first air outlet pipe is provided with a first valve, the air outlet end of the first air outlet pipe is provided with a suction blower,the evaporation end of the heat exchange tube penetrates the heat exchange chamber and then is connected with the first air outlet pipe, the evaporation end of the heat exchange tube is arranged between the suction blower and the first valve. The invention provides the automobile heating system with good heating effect and protective action to an engine and solves the problems that the traditional automobile heating system has poor heating effect and large volume and is inconvenient to mount.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Cryogenic Sample Holder

ActiveCN110961171BSlow down the temperature dropReduce the temperatureHeating or cooling apparatusSupporting apparatusEngineeringElectric drive

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A kind of ultra-high-strength corrosion-resistant steel bar and its production method

ActiveCN109295390BImprove corrosion resistance at room temperatureExcellent high temperature and oxidation resistanceHeat conservationRebar

The invention discloses an ultrahigh-strength corrosion-resistant rebar and a producing method thereof. The ultrahigh-strength corrosion-resistant rebar is prepared from, by mass percent, 0.21% to 0.27% of C, 0.50% to 0.80% of Si, 1.10% to 1.30% of Mn, 0.06% to 0.20% of V, 0.01% to 0.02% of Nb, 0.010% to 0.017% of N, 0.02% to 0.10% of Als, 0.01% to 0.07% of Ce, 0.20% to 0.43% of Cr, 0.20% to 0.45%of Cu, and / or 0.10% to 0.70% of Mo and the balance Fe and inevitable impurities. The producing method comprises the procedures of casting blank heating, casting blank rolling and after-rolling heat preservation. According to the ingredient design of the ultrahigh-strength corrosion-resistant rebar, low-content valuable alloy elements are adopted, the rolled rebar is covered with a heat preservation cover during cooling, and the obtained product has the beneficial effects of being good in mechanical property and corrosion resisting property and low in valuable alloy element content.

Owner:HEBEI IRON AND STEEL

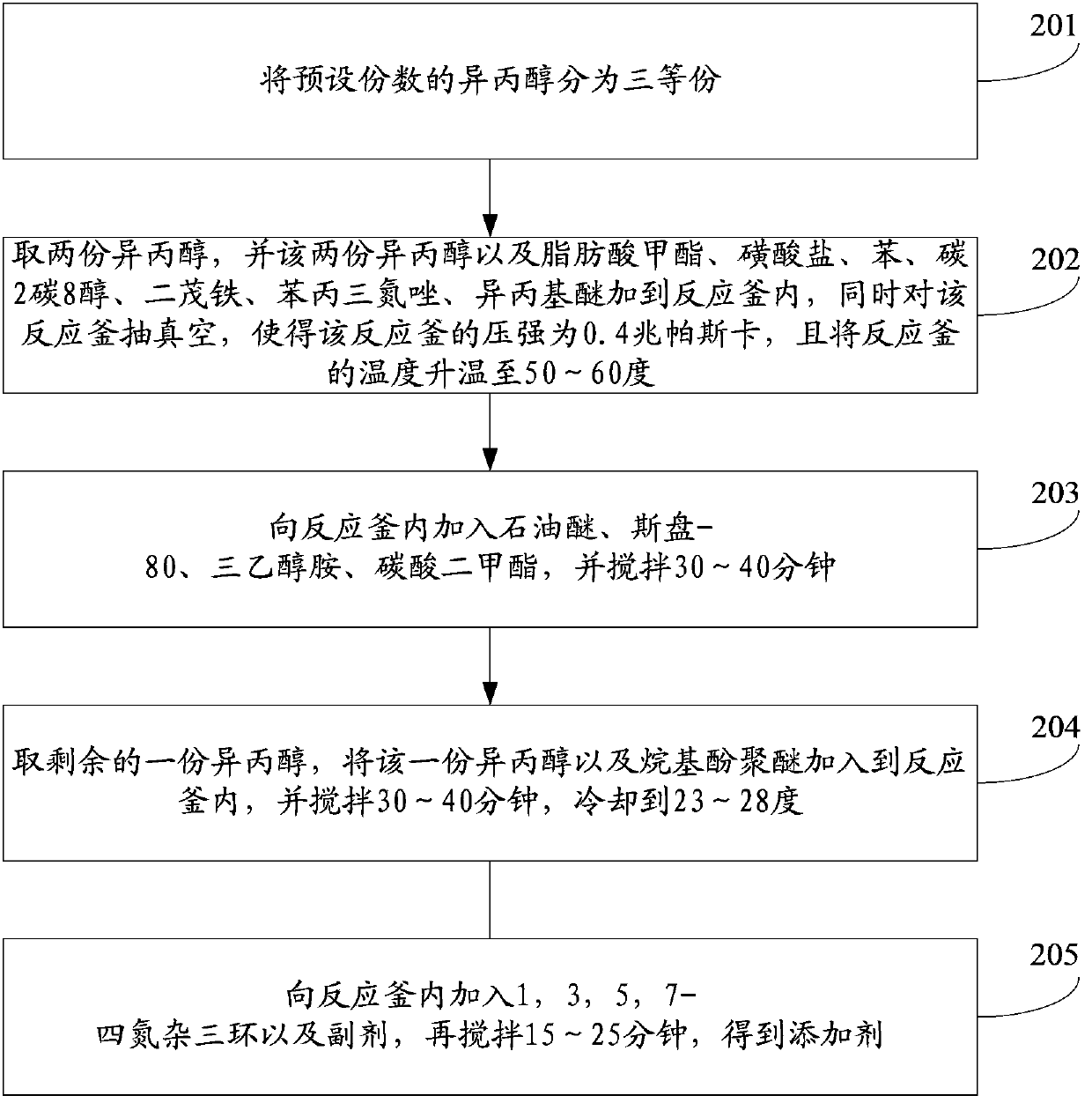

Methanol gasoline additive and preparation method

InactiveCN102732339BImprove stabilityReduce consumptionLiquid carbonaceous fuelsFuel additivesAlkylphenolFatty acid methyl ester

The invention belongs to the field of an automobile, and particularly relates to a methanol gasoline additive and a preparation method, and the additive can effectively reduce the swelling corrosion on the automobile. The additive comprises isopropyl ether, phenylpropyl triazole, petroleum ether, ferrocene, fatty acid methyl ester, C2C8 alcohol, benzene, Span-80, triethanolamine, 1,3,5,7-tetraazatricycle, isopropanol, alkylphenol polyether and sulfonate; and the additive is composed of the following components in parts by weight: 0.15-0.67 part of the isopropyl ether, 0.03-0.1 part of the phenylpropyl triazole, 0.01-0.08 part of the petroleum ether, 0.02-0.08 part of the ferrocene, 0.03-0.09 part of the fatty acid methyl ester, 0.2-0.8 part of the C2C8 alcohol, 0.4-0.9 part of the benzene, 0.03-0.09 part of the Span-80, 0.03-0.08 part of the triethanolamine, 0.2-0.7 part of the 1,3,5,7-tetraazatricycle, 0.3-0.8 part of the isopropanol, 0.08-0.16 part of the alkylphenol polyether and 0.02-0.08 part of the sulfonate.

Owner:王自恒

Thin gauge pipeline steel rolling method

ActiveCN107363094AImprovement of steel plate shapeIncrease productivityRoll mill control devicesMetal rolling arrangementsSteel platesSheet steel

The invention relates to a thin gauge pipeline steel rolling method. In the steel, the content of C is within 0.05 percent; the content of Ni is 0.05 to 0.06 percent; the content of Ti is 0.01 to 0.02 percent; the content of B is 0.015 to 0.002 percent; the soaking temperature during rolling is 1,180 to 1,220 DEG C; the soaking time is 45 to 100 minutes; the torque of a roughing mill is 3,500 to 3,600 kN.m; the compression ratio is controlled to be 5 to 20; the width spread ratio is controlled to be 1.25 to 2.0; rough rolling is performed within 50 seconds after steel is discharged from a furnace; in rough rolling, the pressing down ratio of at least one pass is ensured not to be less than 21 percent when transverse rolling is performed, and the single pass pressing down ratio of at least two passes is ensured not to be less than 25 percent when longitudinal rolling is performed; and the temperature reducing speed is within 60 DEG C. According to the method, a controlled cooling link after the steel is rolled is cancelled by regulating chemical components of pipeline steel and heating; the type of a steel plate is improved; the production efficiency is greatly improved; and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

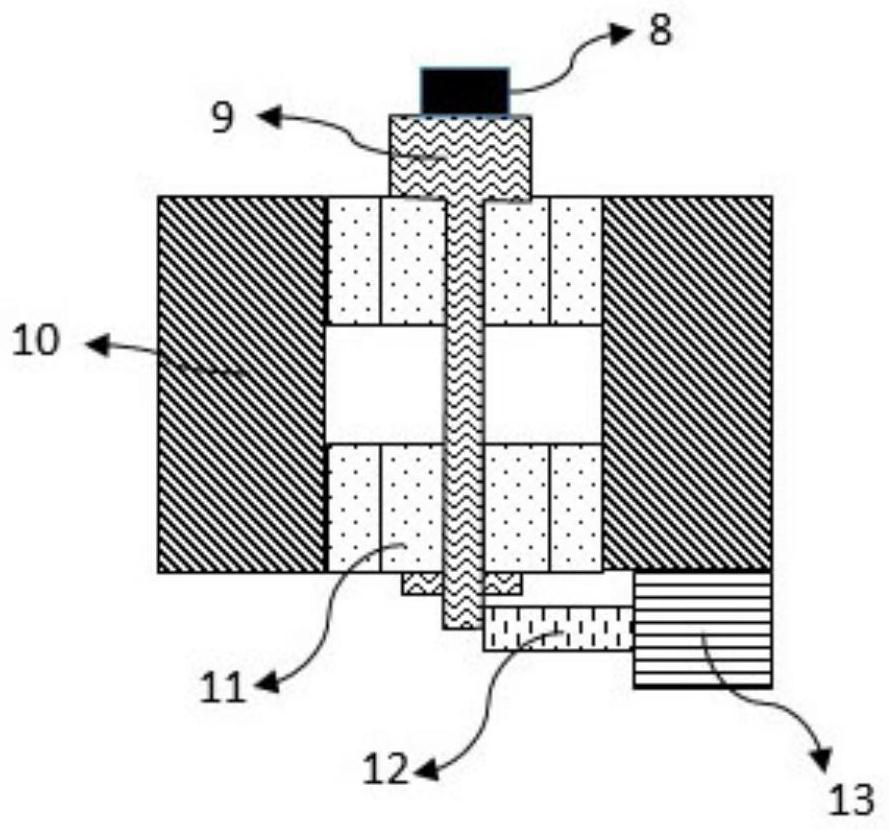

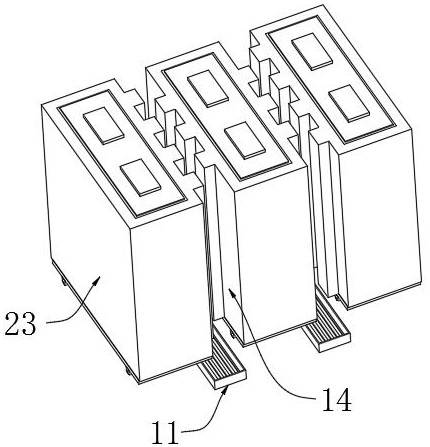

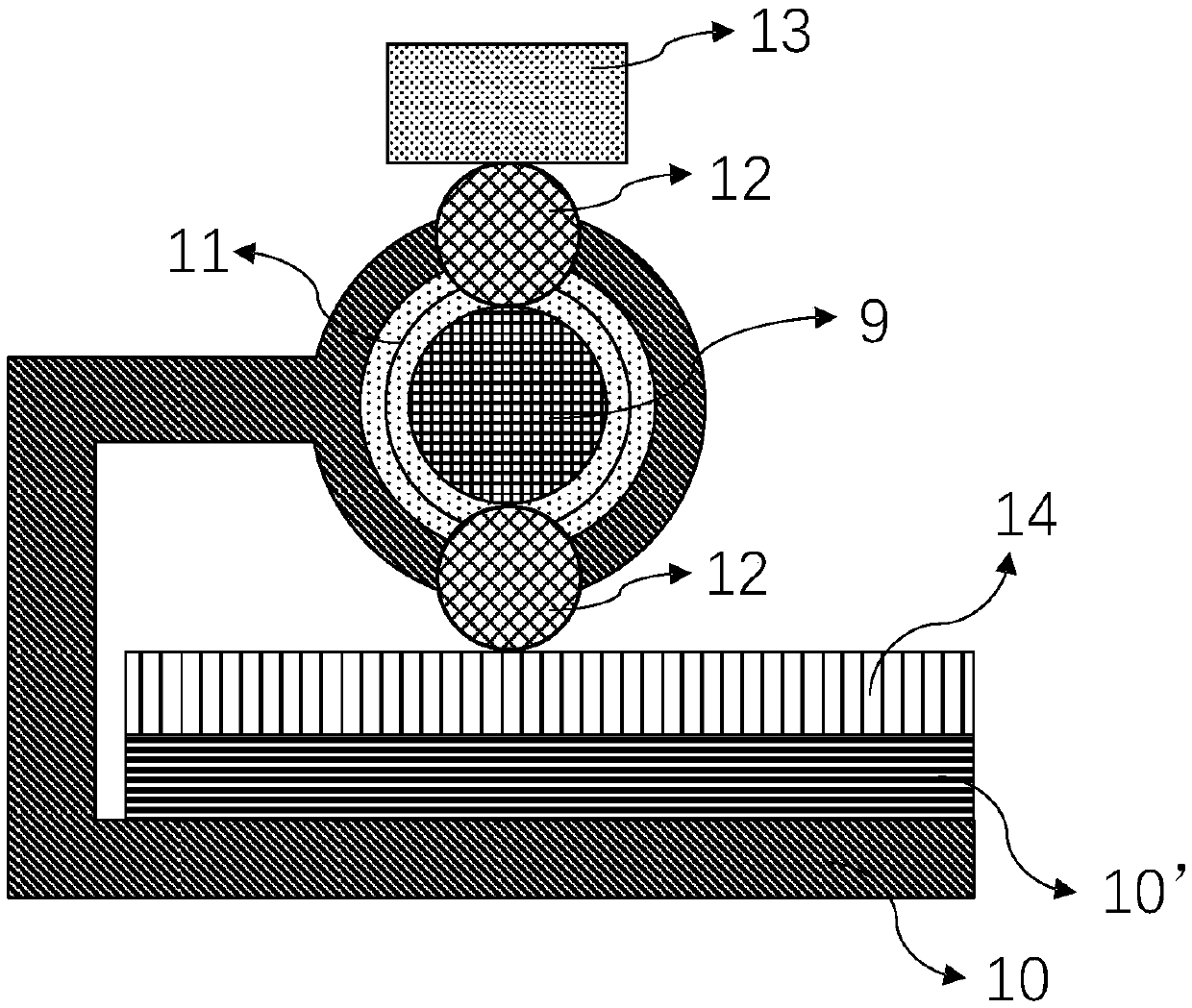

Lithium ion battery thermal management system and method based on phase change material and mutually embedded fins

ActiveCN114256535AImprove cooling effectSlow down the temperature dropCell temperature controlCell component detailsThermal management systemMechanical engineering

The invention belongs to the technical field of battery thermal management, and aims to provide a lithium ion battery thermal management system and method based on a phase change material and mutually embedded fins. The thermal management system comprises a battery box, and a lithium ion battery pack and a temperature detection unit are arranged in the battery box; the lithium ion battery pack at least comprises two battery monomers, the peripheries of the battery monomers are coated with a battery inner shell and a battery outer shell, and a phase change material is filled between the battery inner shell and the battery outer shell; a plurality of fins are arranged on the battery outer shell on the opposite sides of the two adjacent battery monomers, the plurality of fins are arranged at intervals, the fins on the opposite sides of the two adjacent battery monomers are arranged in a crossed manner, and a heat-conducting fin is connected between each fin and the battery inner shell; and the driving device is used for driving two adjacent single batteries to move in opposite directions so as to enable the fins on the surfaces of the single batteries to be mutually embedded to realize low-temperature thermal protection, or driving the two adjacent single batteries to move in opposite directions so as to enable the fins on the surfaces of the single batteries to be mutually disembedded to realize high-temperature heat dissipation.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

A kind of ultra-high-strength steel bar and its production method

Owner:HEBEI IRON AND STEEL

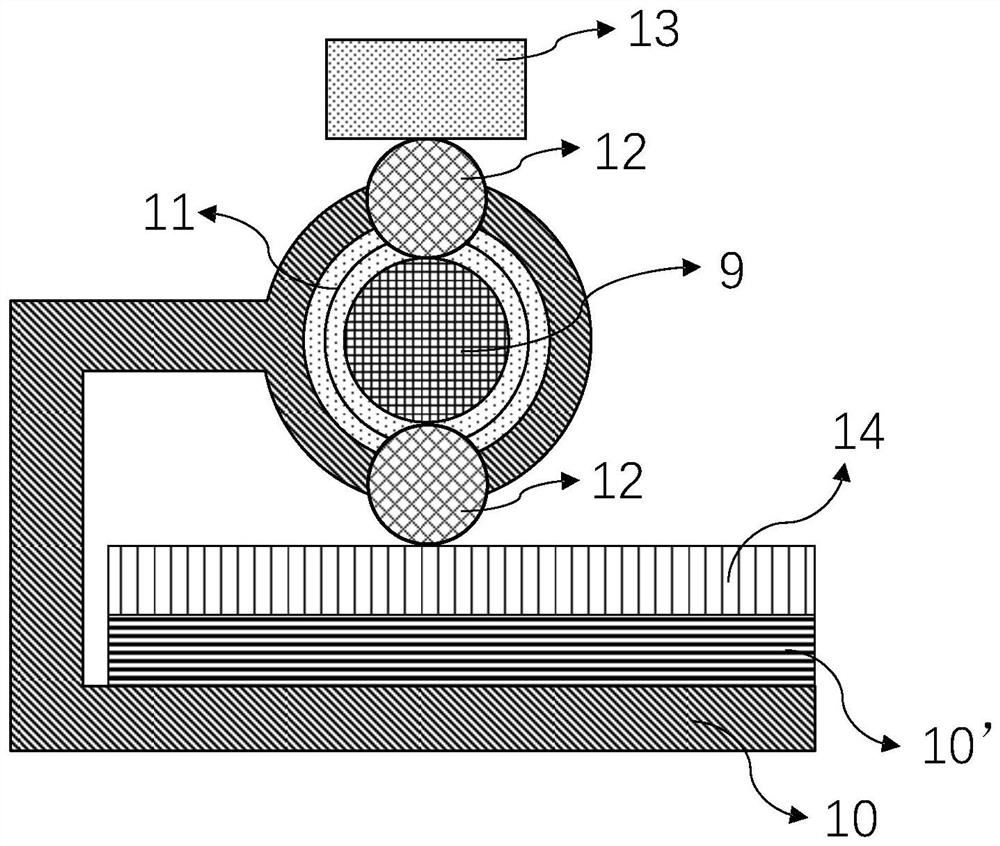

Low-temperature sample support

ActiveCN110961171ASlow down the temperature dropReduce the temperatureHeating or cooling apparatusSupporting apparatusEngineeringElectrical drive

The invention provides a low-temperature sample support. The low-temperature sample support is positioned in a vacuum cavity and at least comprises an electric movement mechanism, a refrigerating device and a three-dimensional moving device, wherein the electric movement mechanism is used for enabling a sample to move relative to the refrigerating device under the driving of electricity; the refrigerating device is used for achieving a low temperature of the sample; and the three-dimensional moving device is used for achieving three-dimensional movement of the refrigerating device and the electric movement mechanism relative to the vacuum cavity. According to the low-temperature sample support in the invention, the sample is electrically driven to move relative to the vacuum cavity, the low temperature of the sample is realized, and heat conduction between the electric movement mechanism and an external room temperature environment is achieved only by a heat conduction channel formed by an alloy wire, so the heat conductivity of the heat conduction channel between a low-temperature part and the external room temperature environment is effectively reduced; and therefore, lower sample temperature, lower vacuum leakage risks and more compact and smaller structure can be realized.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A kind of ferrous metal liquid die forging die and preparation method

The invention relates to a ferrous metal liquid die forging mould and a manufacturing method of the metal liquid die forging mould. A zirconium oxide or aluminum oxide coating is arranged on the inner surface of a mould cavity, diatomite thermal insulation coatings are arranged on the surface of the coating, the mould is sleeved with a copper sleeve, the copper sleeve is provided with a spiral cooling water channel which is arranged on the two sides and the bottom of the mould, and the copper sleeve is further sleeved with a supporting sleeve. The method comprises the following steps that (1), the mould is designed and manufactured according to a liquid die forge piece to be formed; (2), the zirconium oxide or aluminum oxide coating is sprayed on the inner surface of the mould cavity; (3), the mould is sleeved with the copper sleeve, the spiral cooling water channel is arranged on the copper sleeve, and the spiral cooling water channel is arranged on the two sides and the bottom of the mould; (4), the copper sleeve is sleeved with the supporting sleeve; (5), before each liquid die forge piece is forged, the diatomite thermal insulation coatings need to be sprayed on the surface of the coating of the mould. According to the ferrous metal liquid die forging mould and the manufacturing method of the metal liquid die forging mould, the temperature of the mould is decreased, and the service life of the ferrous metal liquid die forging mould is prolonged.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com