Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about How to "Simplify assembly work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

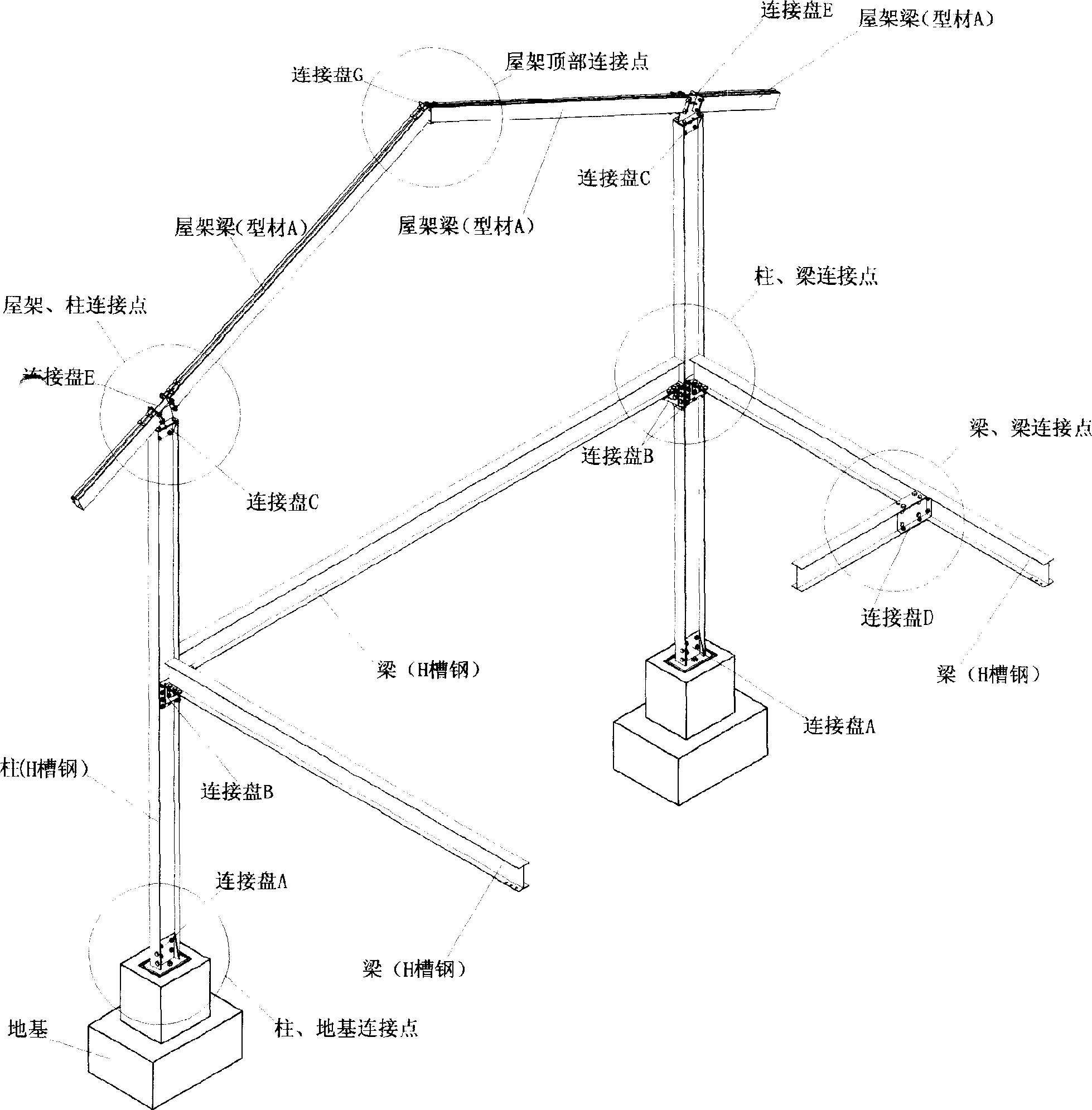

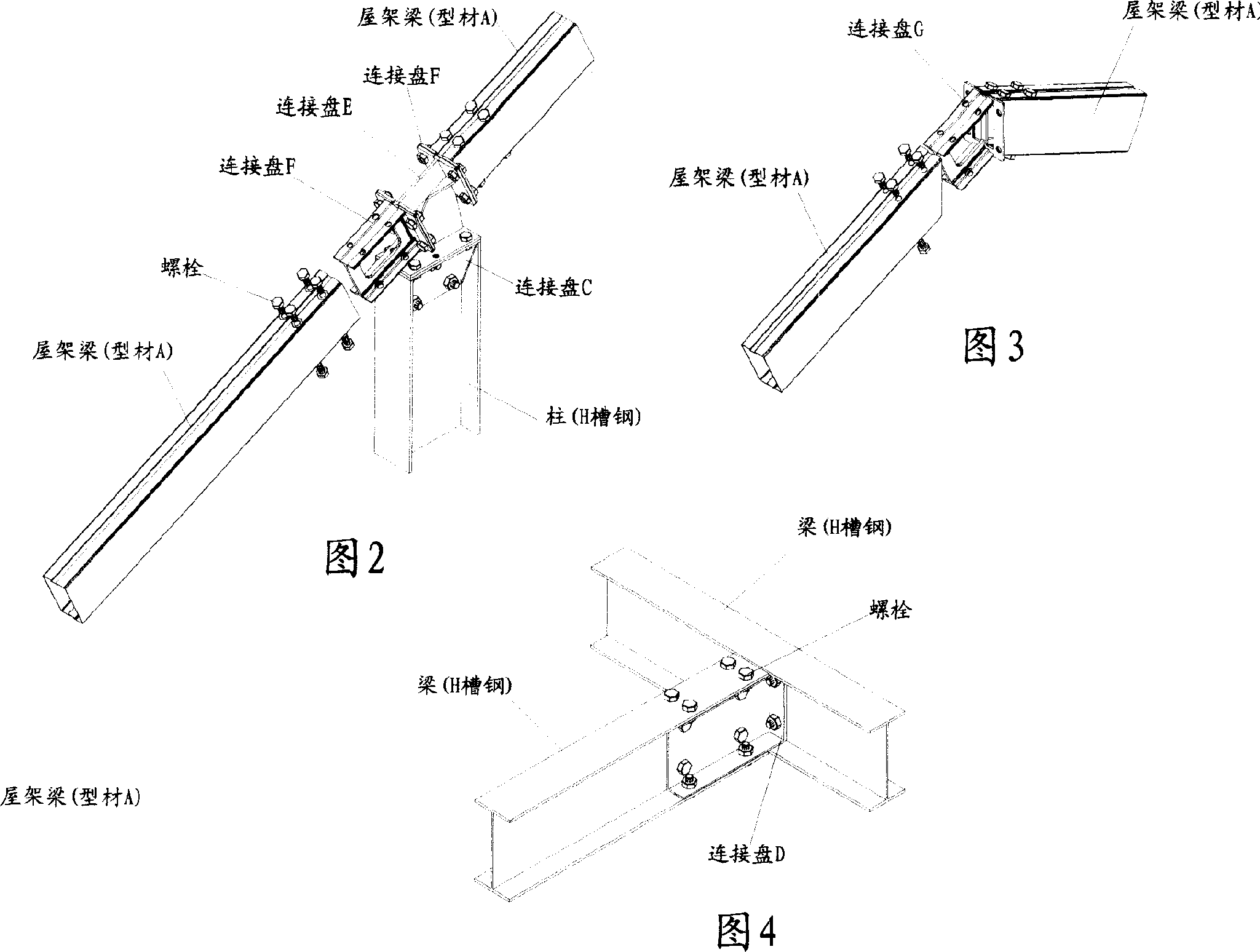

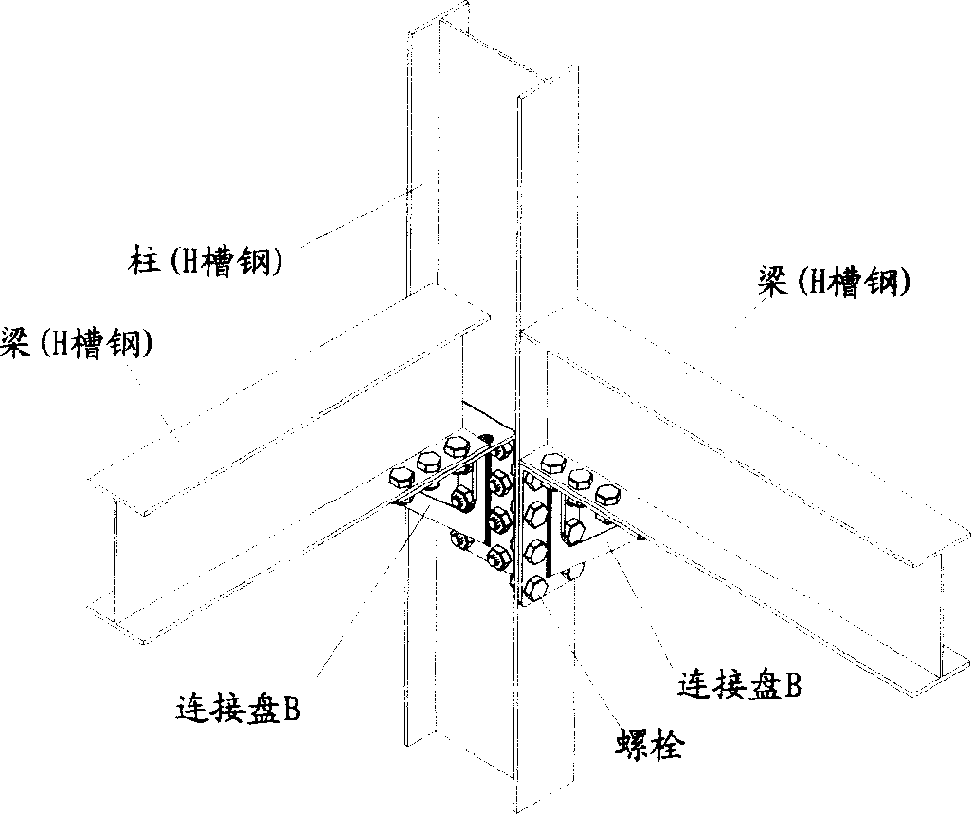

Method for assembling building

The present invention is characterized by using pre-fabricated H-type channel steel, member bar made up by using aluminium alloy section material with special section, specially-made connecting disk, connecting component, metal outer wall plate, reinforced concrete slab and conventional heat-insulating sound-insulating material, wood plate, gypsum board and screw bolt, etc. to assemble the column beam frame, roof truss, roffing, wall and floor of building, and adopting assembling method to implement building work.

Owner:万平华 +2

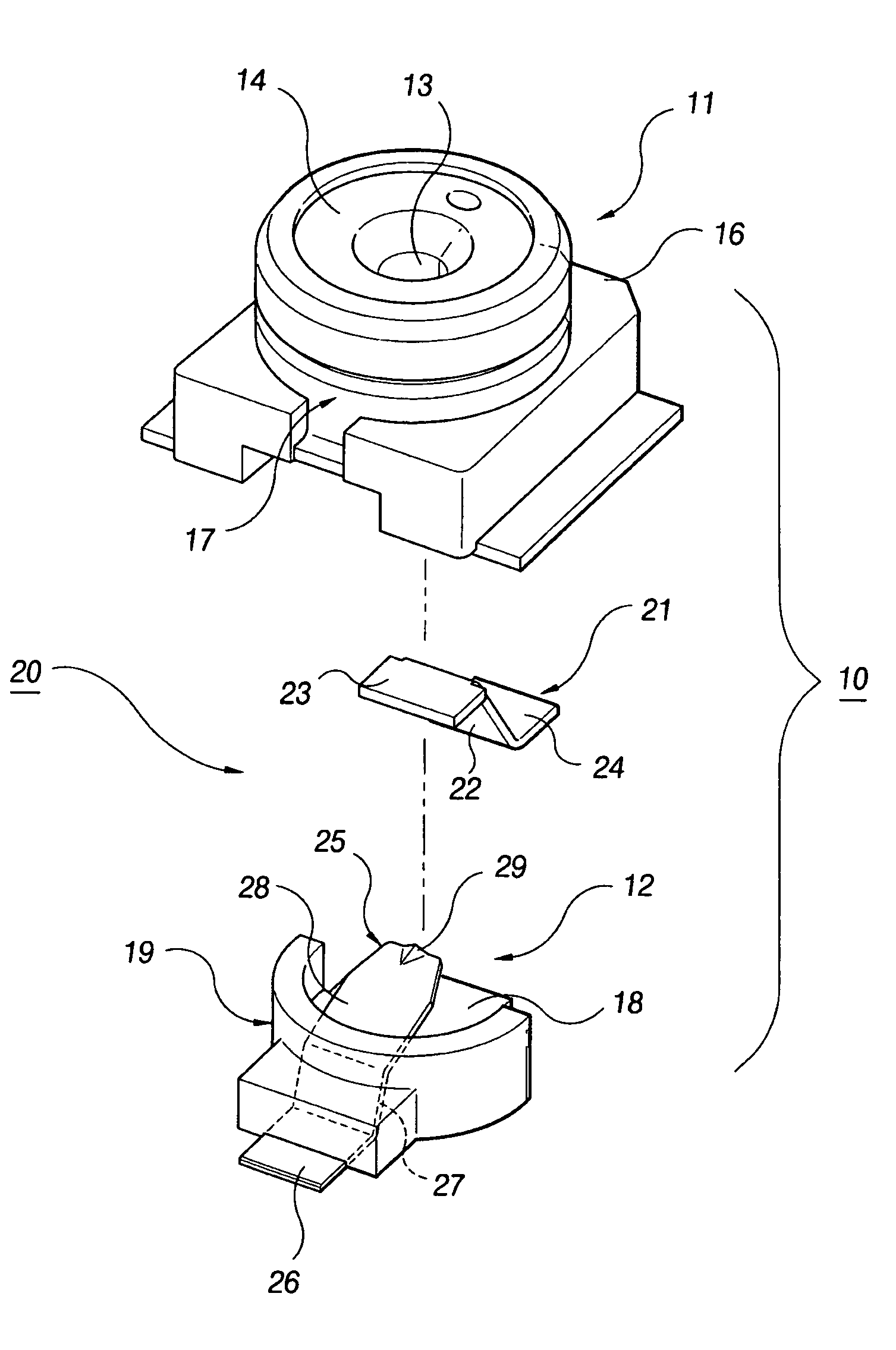

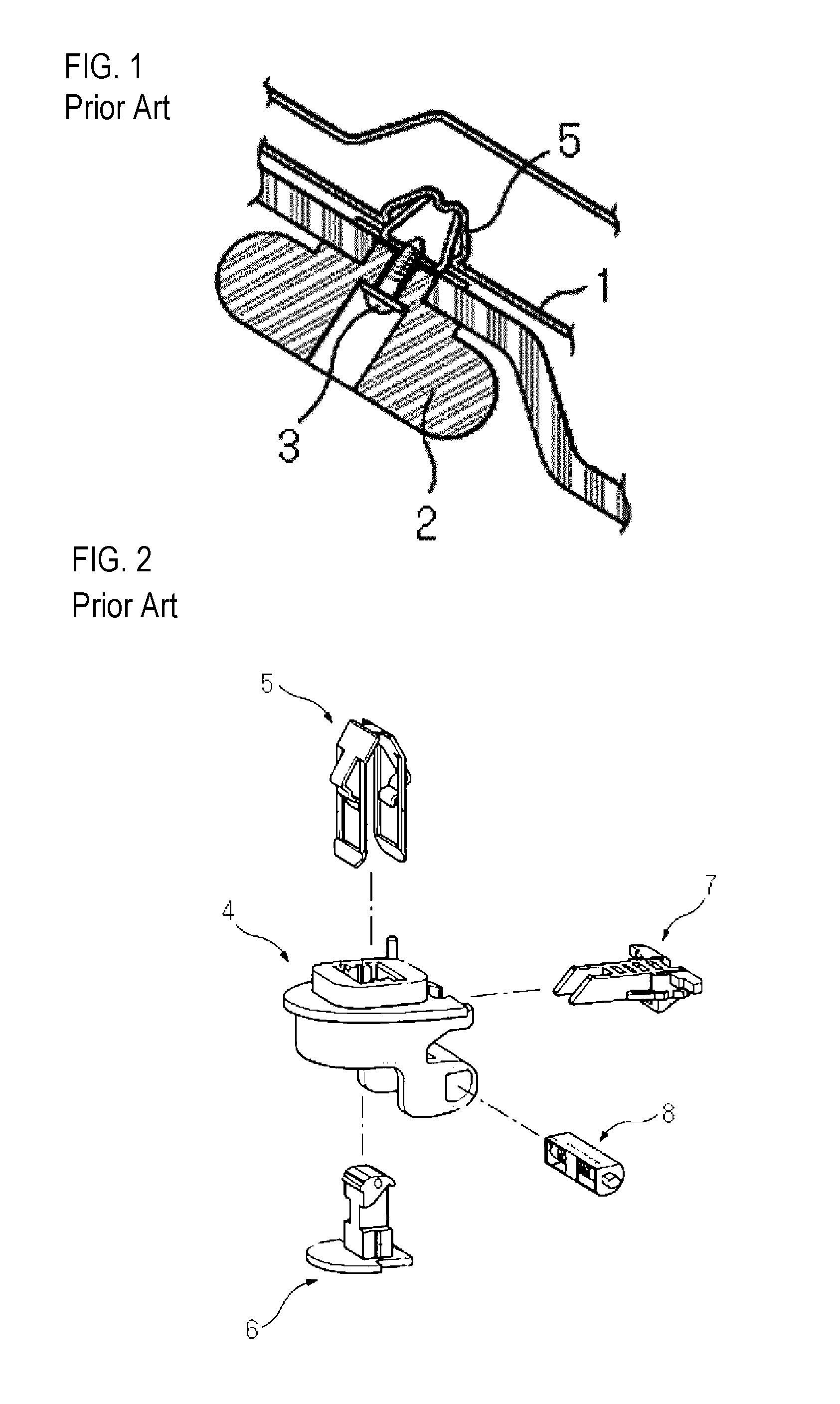

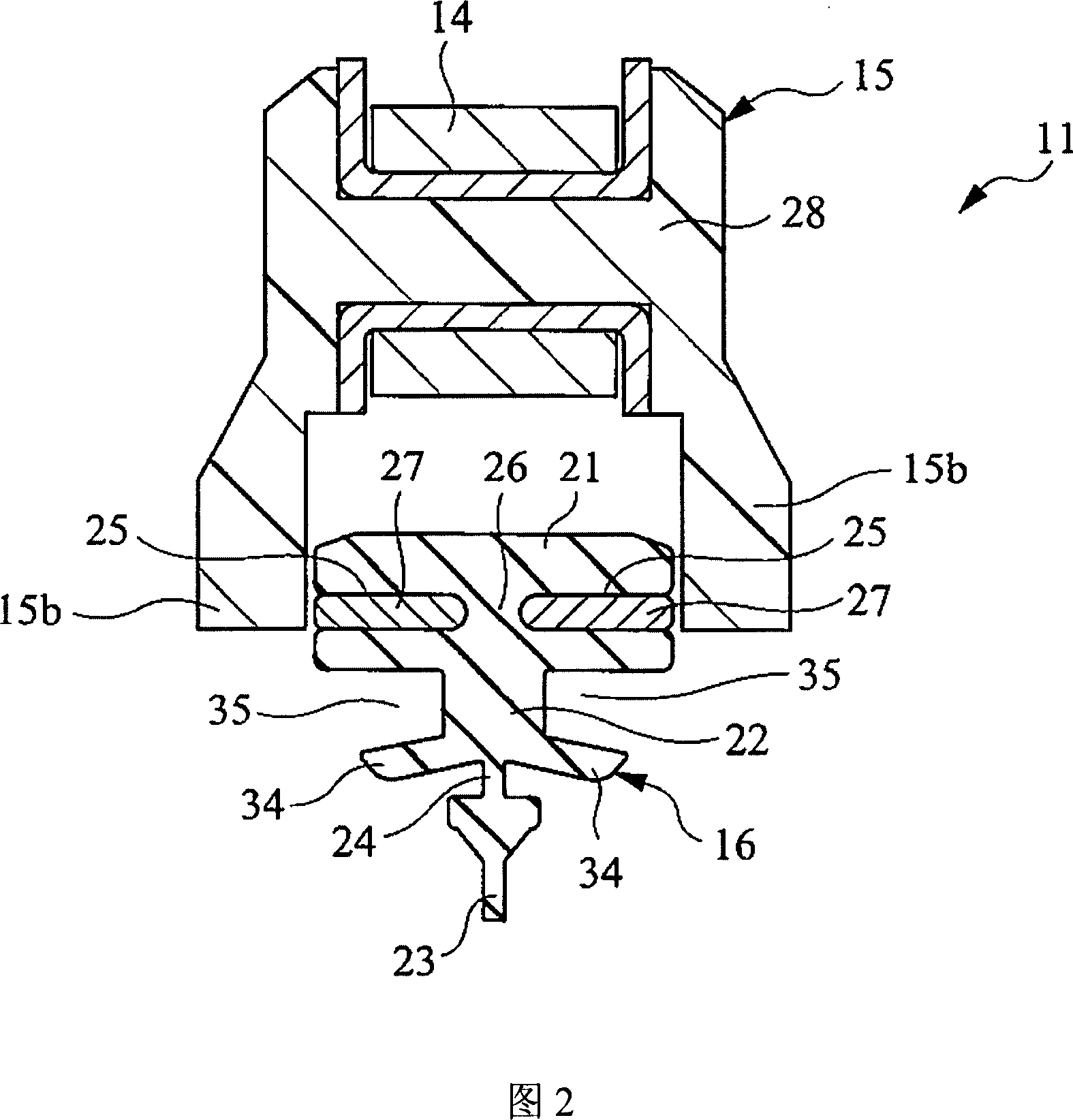

Coaxial connector with RF switch

InactiveUS6932615B1Poor contact with preventedAvoid high pressureTwo pole connectionsCoupling device detailsElectrical conductorHemt circuits

The present invention relates to coaxial connector with an RF switch. In particular, a housing 10 covered with an external conductor 17 is composed of upper and lower housings 11 and 12. A fixed terminal 21 connected to an RF circuit is insert molded in the upper housing 11, and a movable terminal 25 that is selectively brought into contact with the fixed terminal 21 is insert molded in the lower housing 12. The movable terminal 25 comprises a fixed portion 26 fixed to the lower housing 12; a waist portion 27 extending upwardly from the fixed portion 26 at a first angle α1 and molded to the lower housing 12; and an elastic piece 28 bent from the tip end of the waist portion 27 at a second angle α2, extending into a space 15 of the housing, and being contact with the fixed terminal 21.

Owner:HECTO

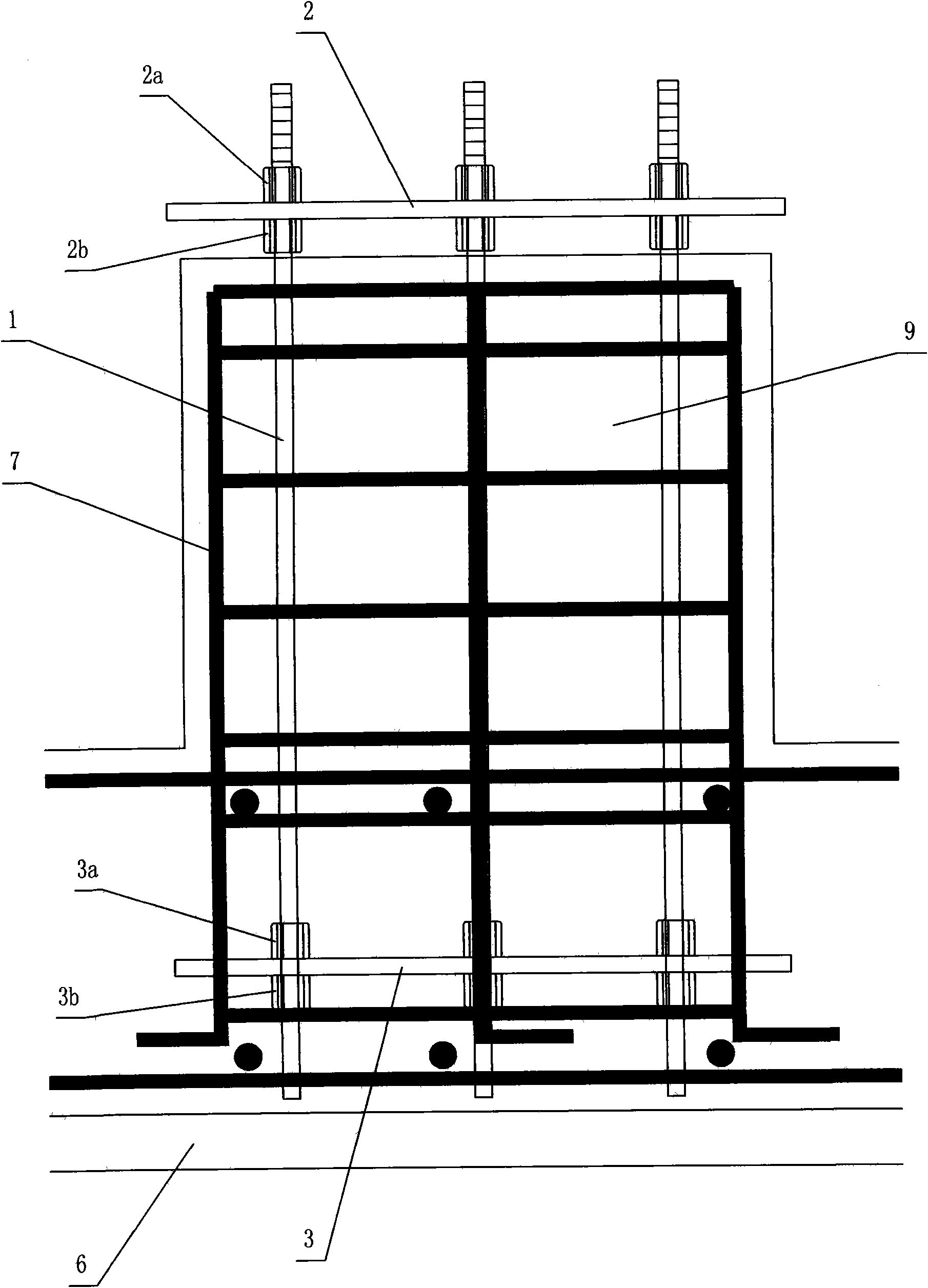

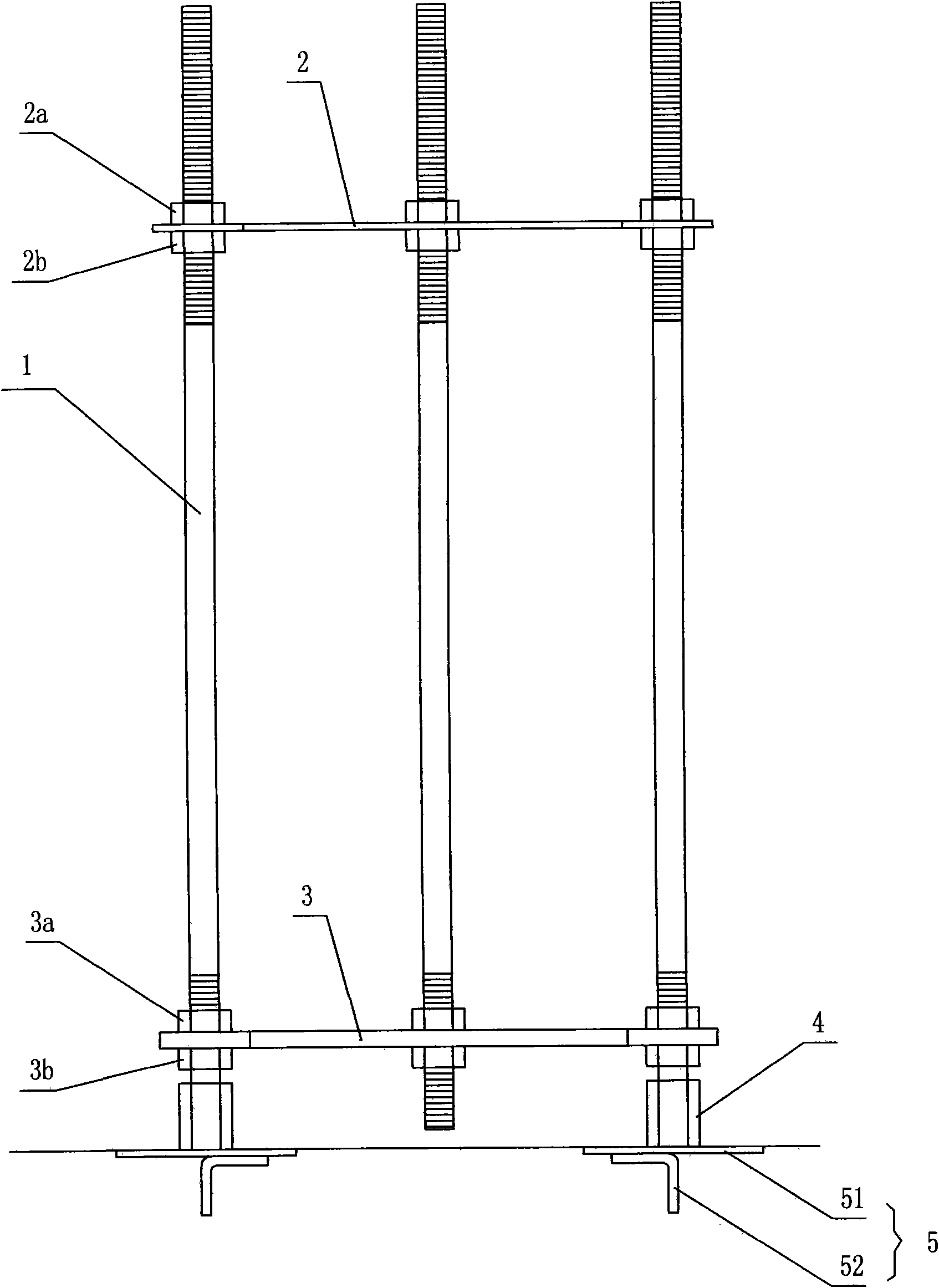

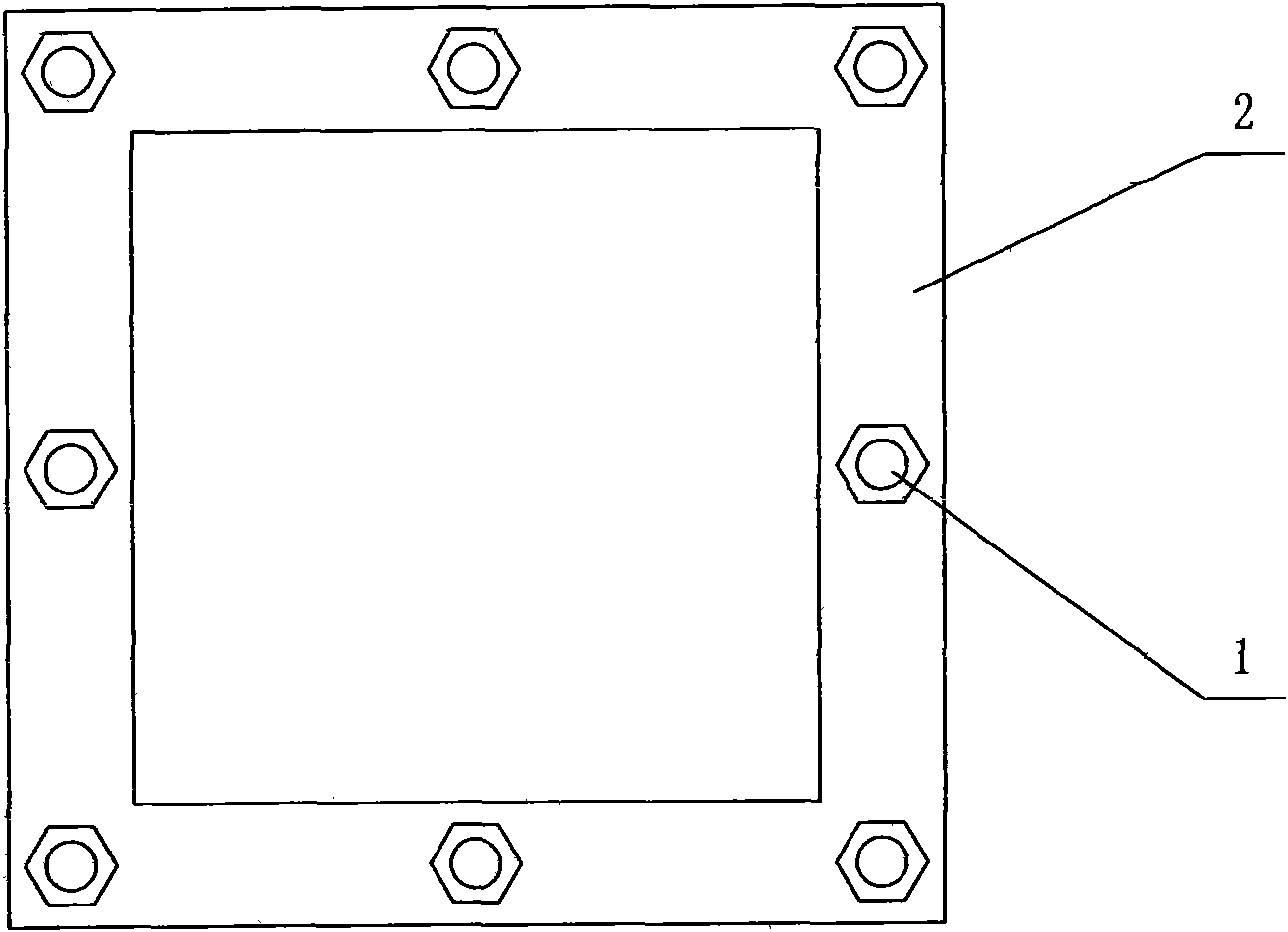

Steel structure assembled embedded part and construction method thereof

ActiveCN102061746AImprove quality and efficiencyImprove installation efficiencyBuilding material handlingArchitectural engineeringBuilding construction

The invention relates to a steel structure assembled embedded part and a construction method thereof, belonging to the technical field of building installation. The steel structure assembled embedded part comprises a plurality of embedded screws, the upper threaded parts of the embedded screws are jointly provided with a top template; the embedded screws are fixedly connected with the top template through clamping nuts 1 respectively positioned above the top template and packing nuts 1 positioned below the top template; the lower threaded parts of the embedded screws are jointly provided with a bottom template; the embedded screws are fixedly connected with the bottom template through clamping nuts 2 respectively positioned above the bottom template and packing nuts 2 positioned below the bottom template; the tail ends of the lower threaded parts of the embedded screws are provided with regulating bases, and the bottoms of the regulating bases are respectively fixed with embedded irons. The invention can decrease the work types of foundation construction, lower the technical requirements for construction, shorten the construction period and enable the foundation construction to have stable quality.

Owner:宝业集团浙江建设产业研究院有限公司

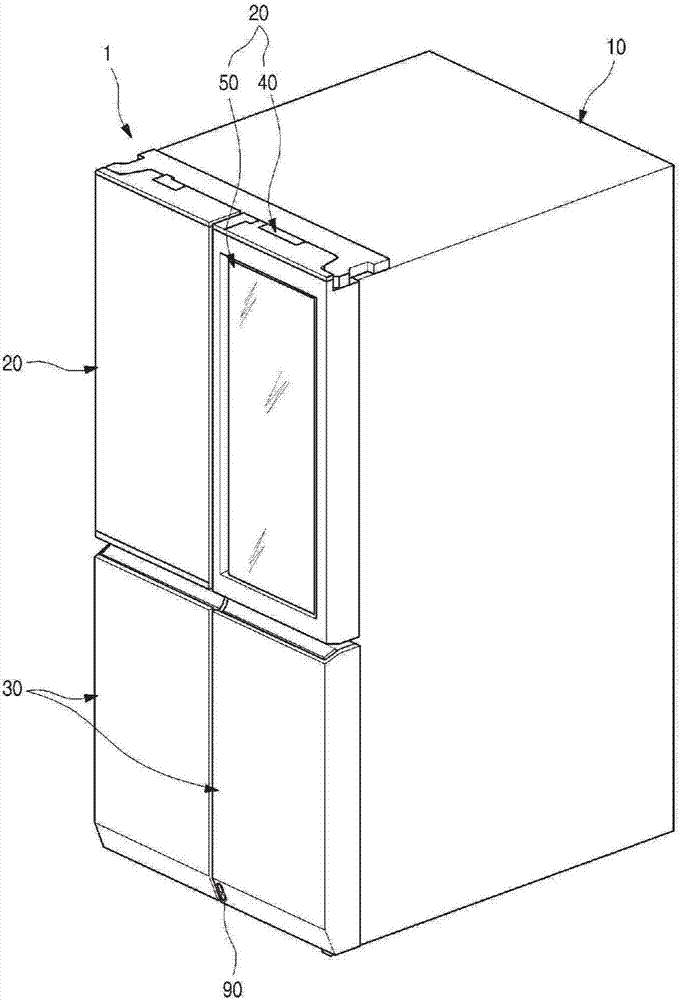

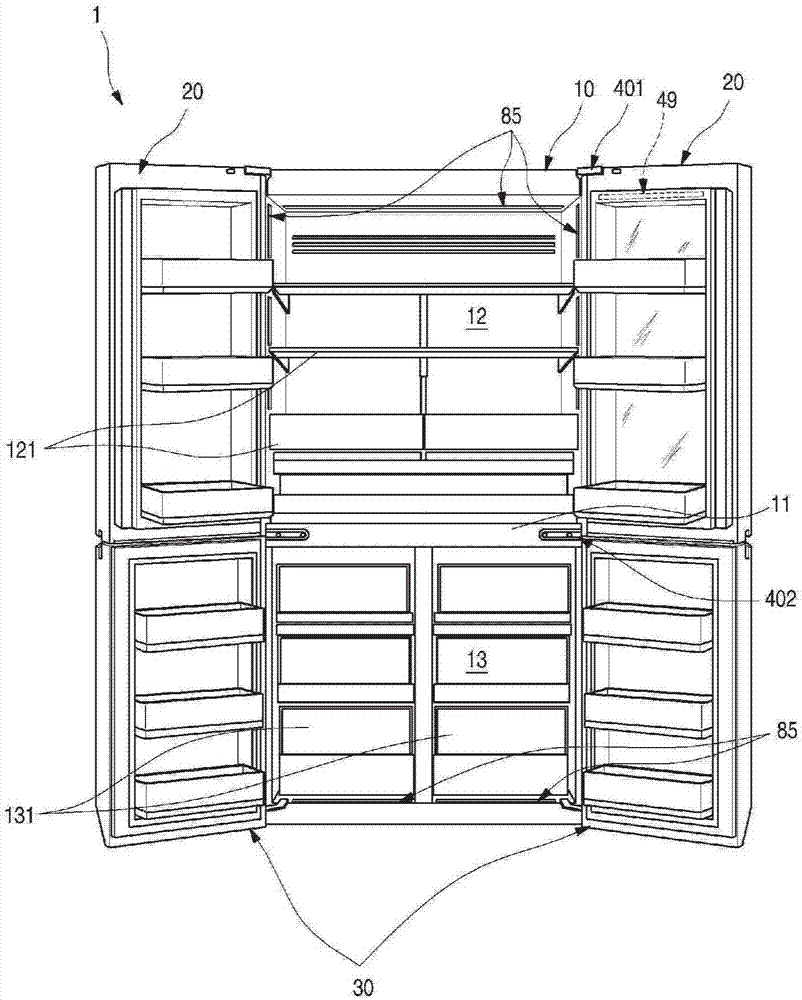

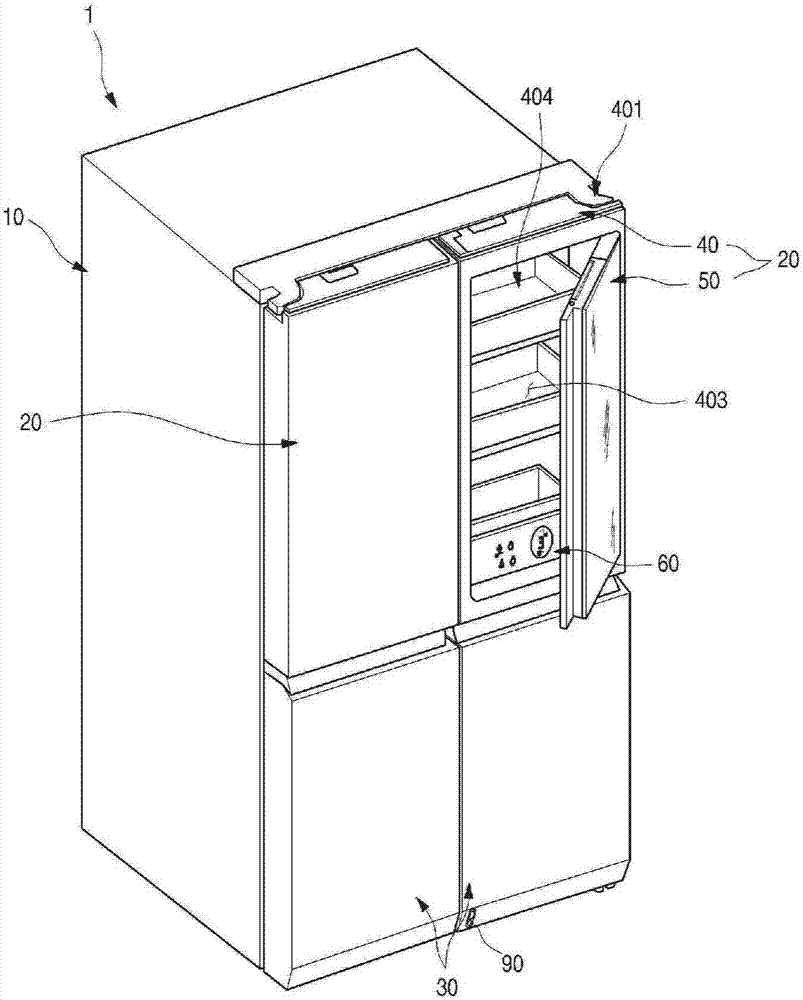

Refrigerator and method for opening a refrigerator door

ActiveCN107076509AImprove convenienceEasy door operationMechanical apparatusElectric circuit arrangementsRefrigerator carEngineering

Owner:LG ELECTRONICS INC

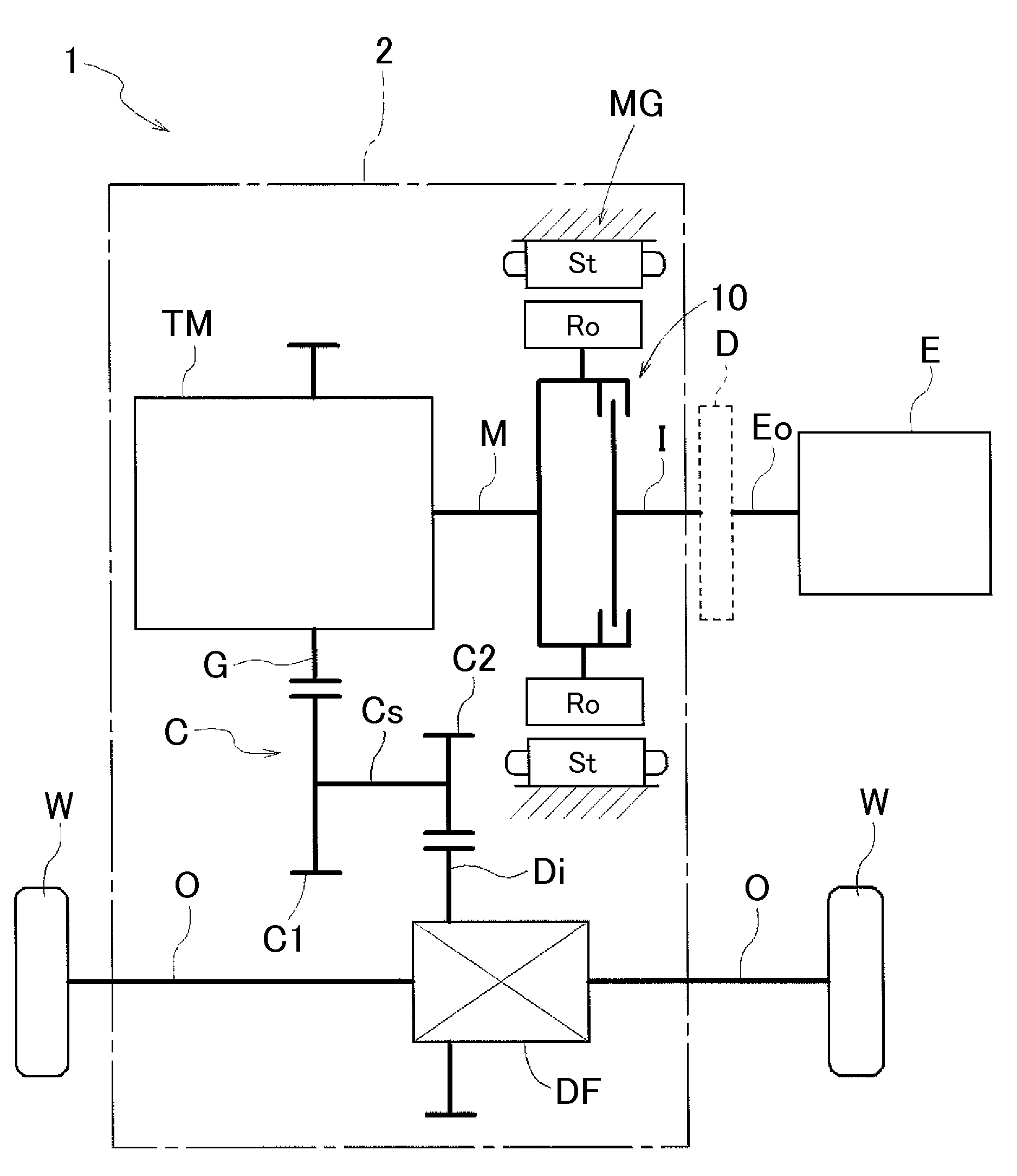

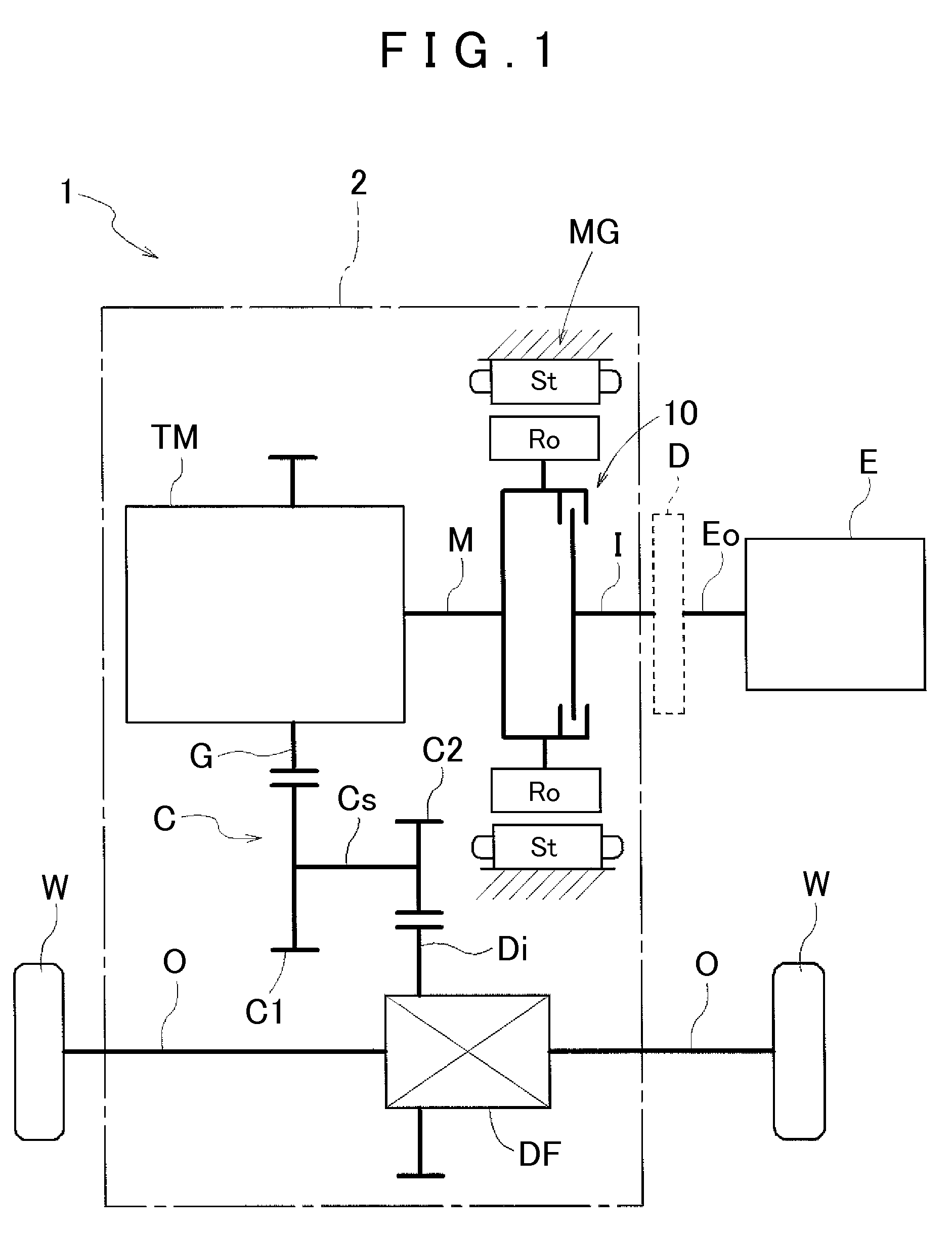

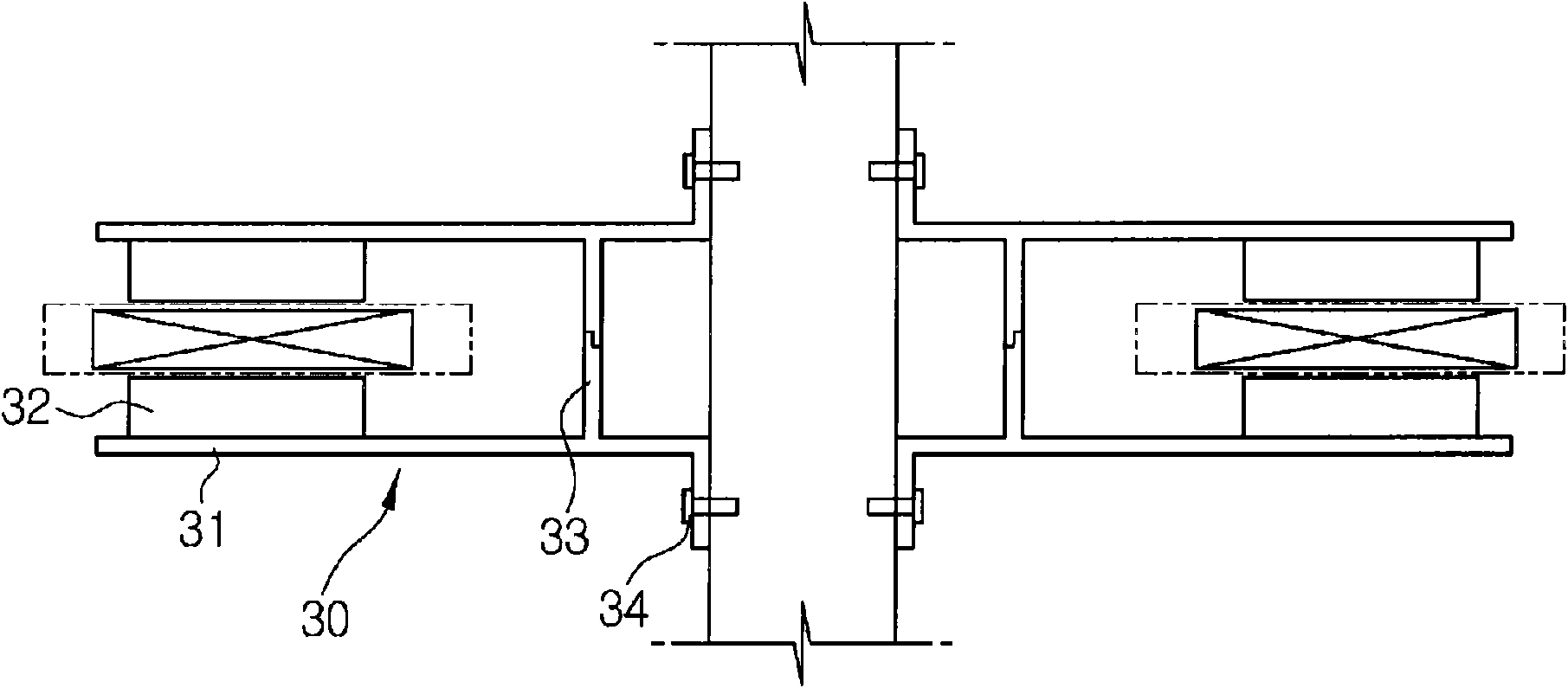

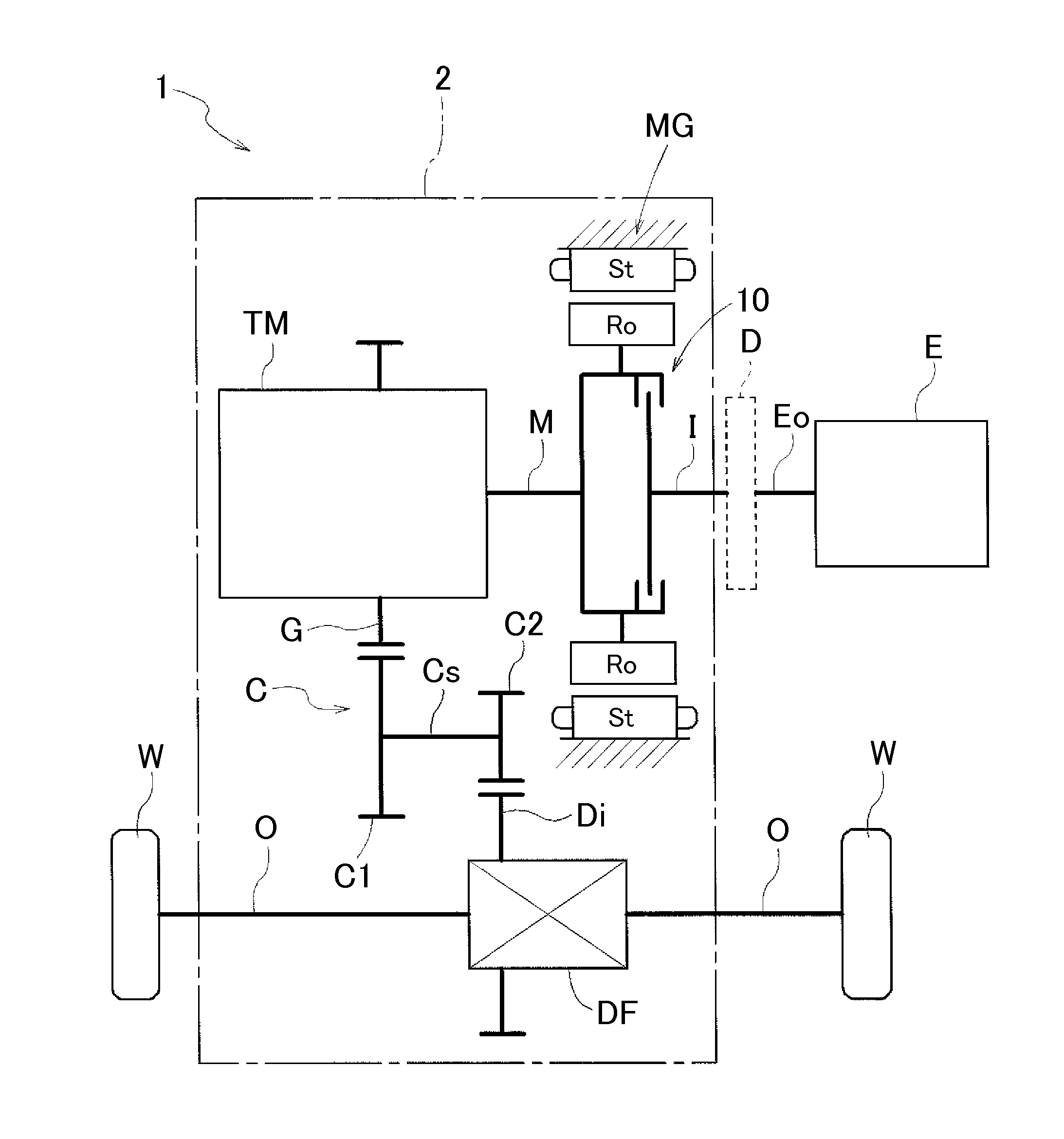

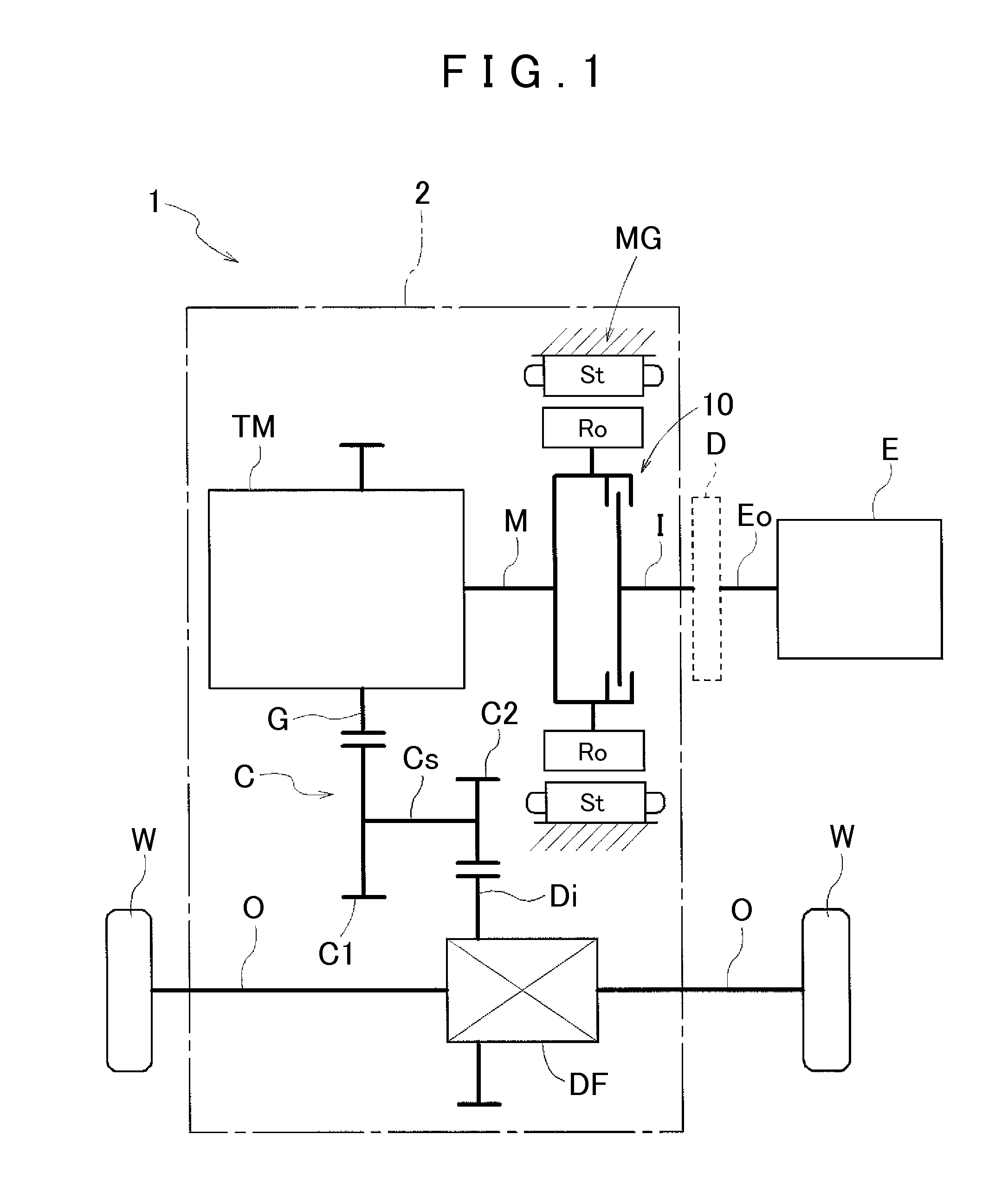

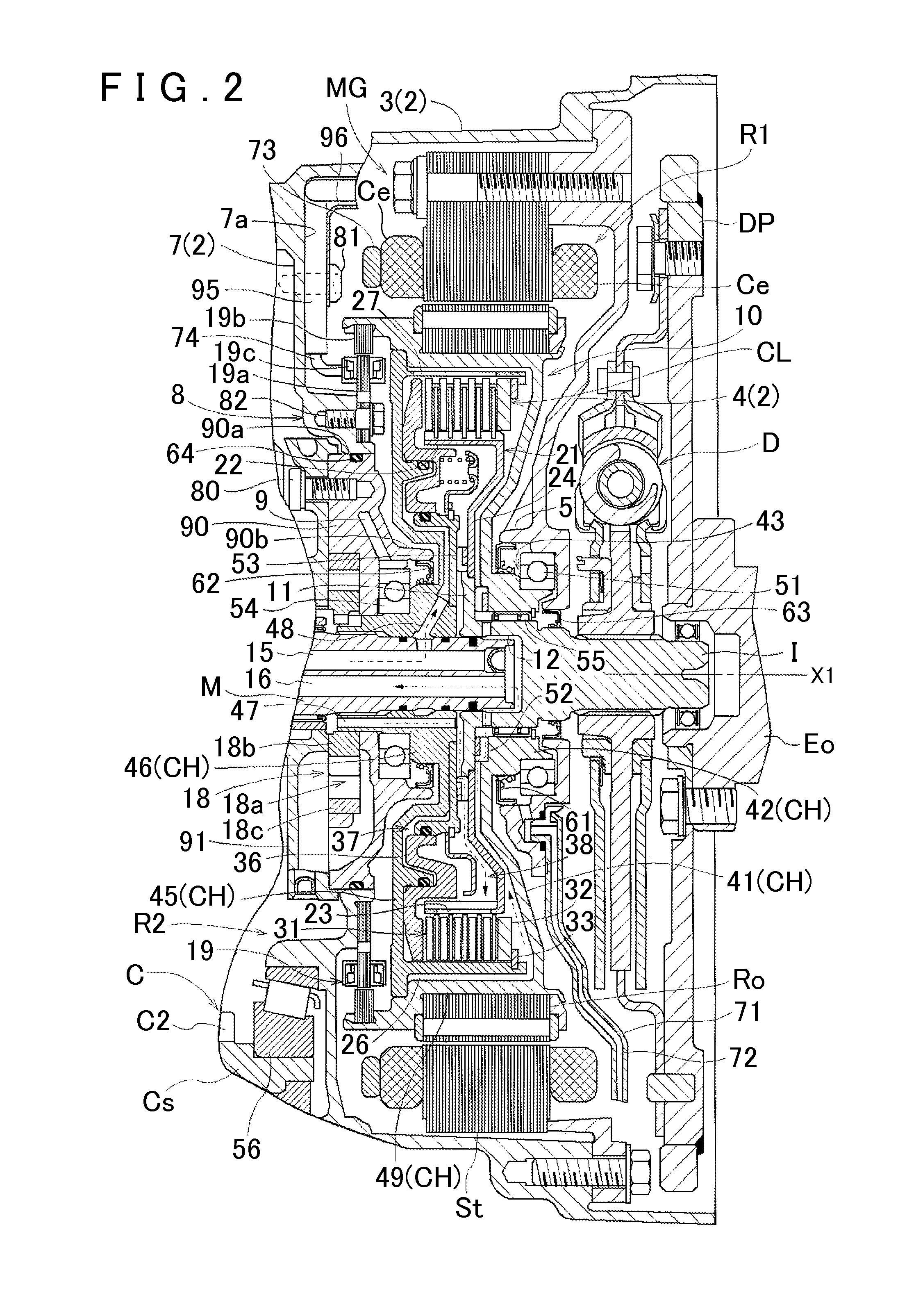

Hybrid drive speed change device

InactiveUS8448541B2Reduce axial sizeSimplify assembly workGearingFluid actuated clutchesElectric machineEngineering

To provide a hybrid drive speed change device in which a rotation sensor can be disposed appropriately from the viewpoint of reducing the axial dimension of the device. A rotary electric machine MG is disposed coaxially with an input shaft M, and includes a stator St and a rotor Ro provided radially inwardly of the stator St. An oil pump 18 includes a pump case 90, 91 in which a pump chamber 18a is formed, and a pump rotor 18b rotatably housed in the pump chamber 18a. The pump rotor 18b is disposed coaxially with the input shaft M. A rotation sensor 19 is disposed radially outwardly of the pump chamber 18a and radially inwardly of the stator St of the rotary electric machine MG, and disposed to overlap the oil pump 18 as seen from the radial direction of the input shaft M.

Owner:AISIN AW CO LTD

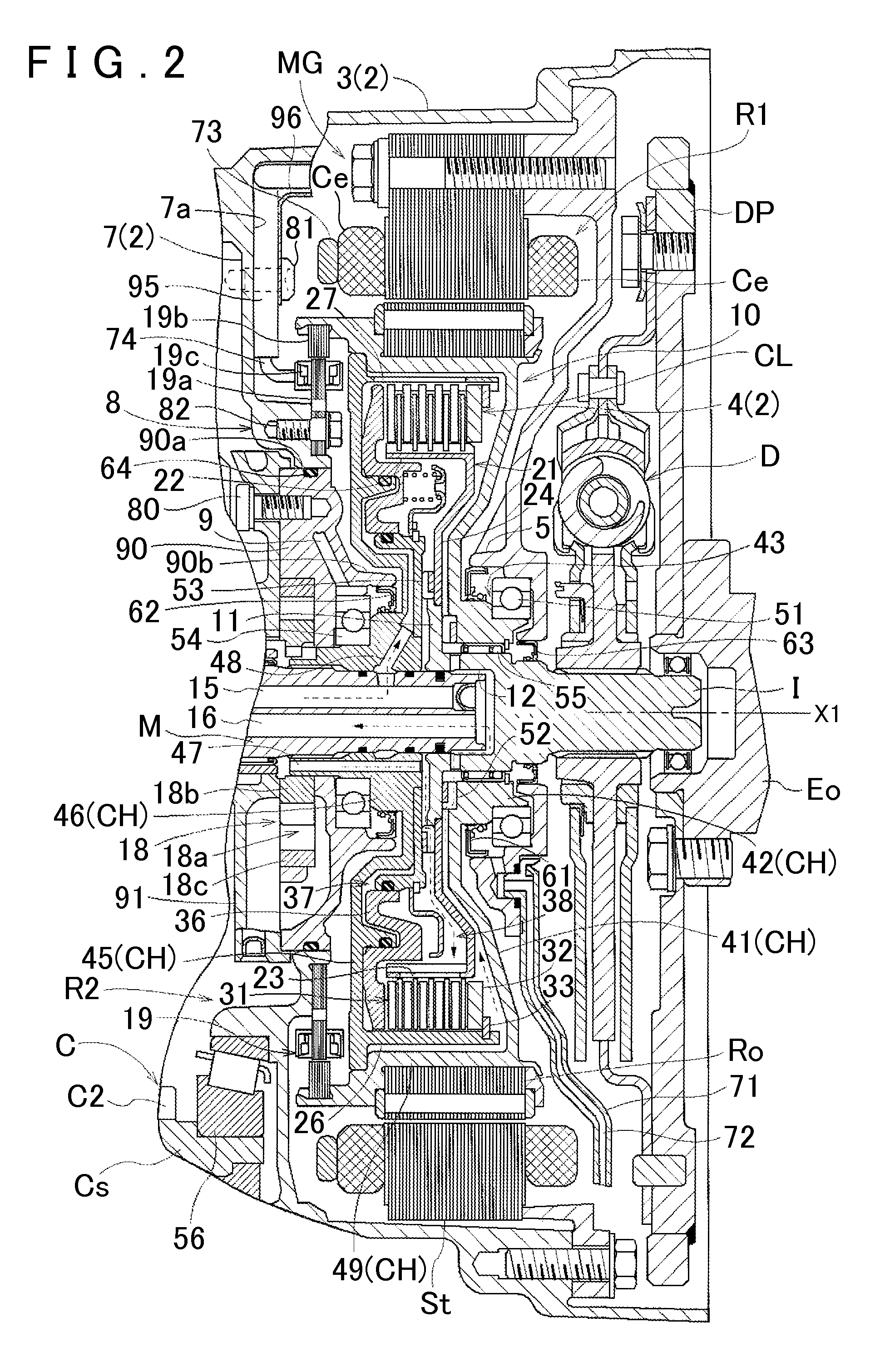

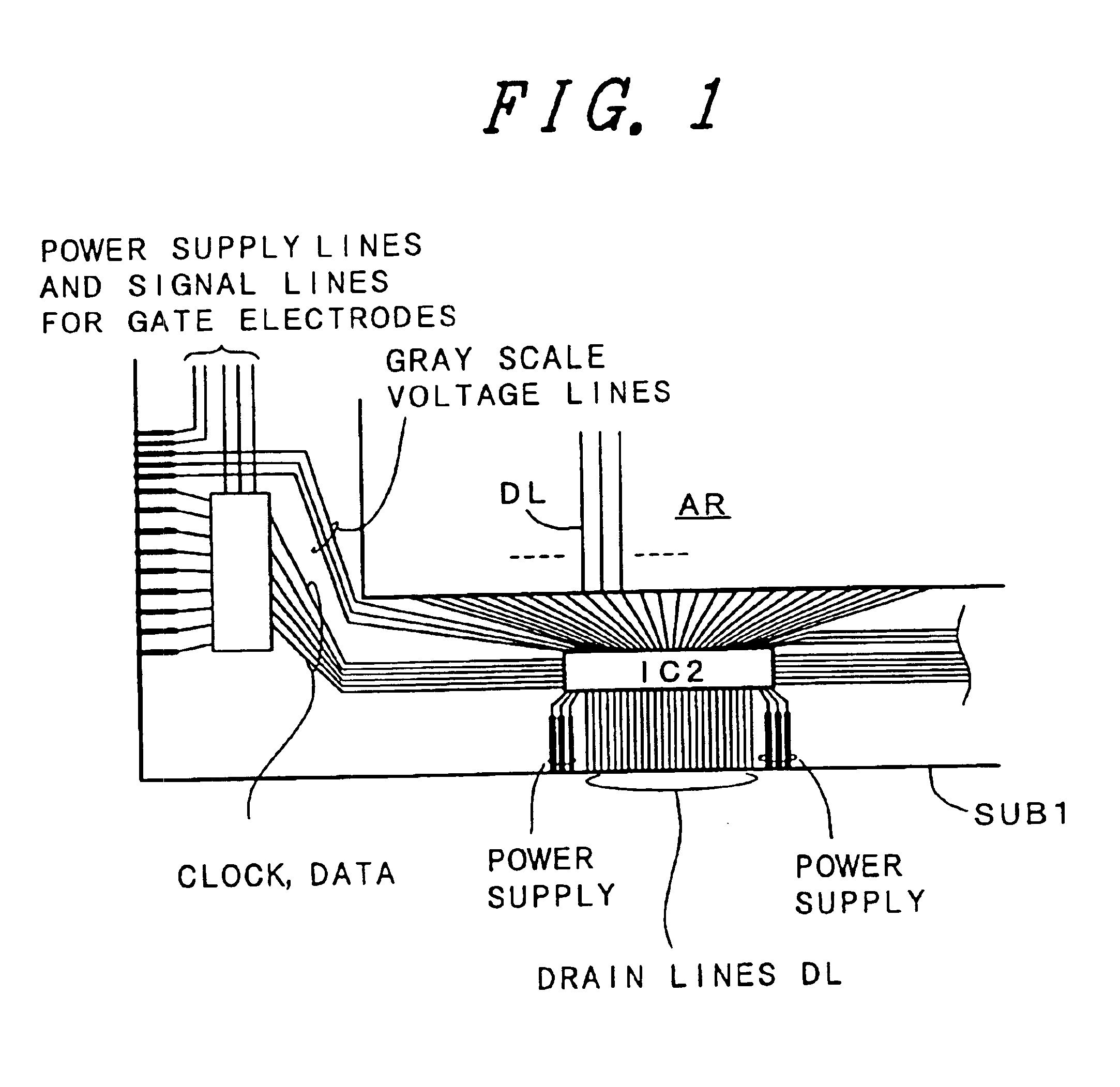

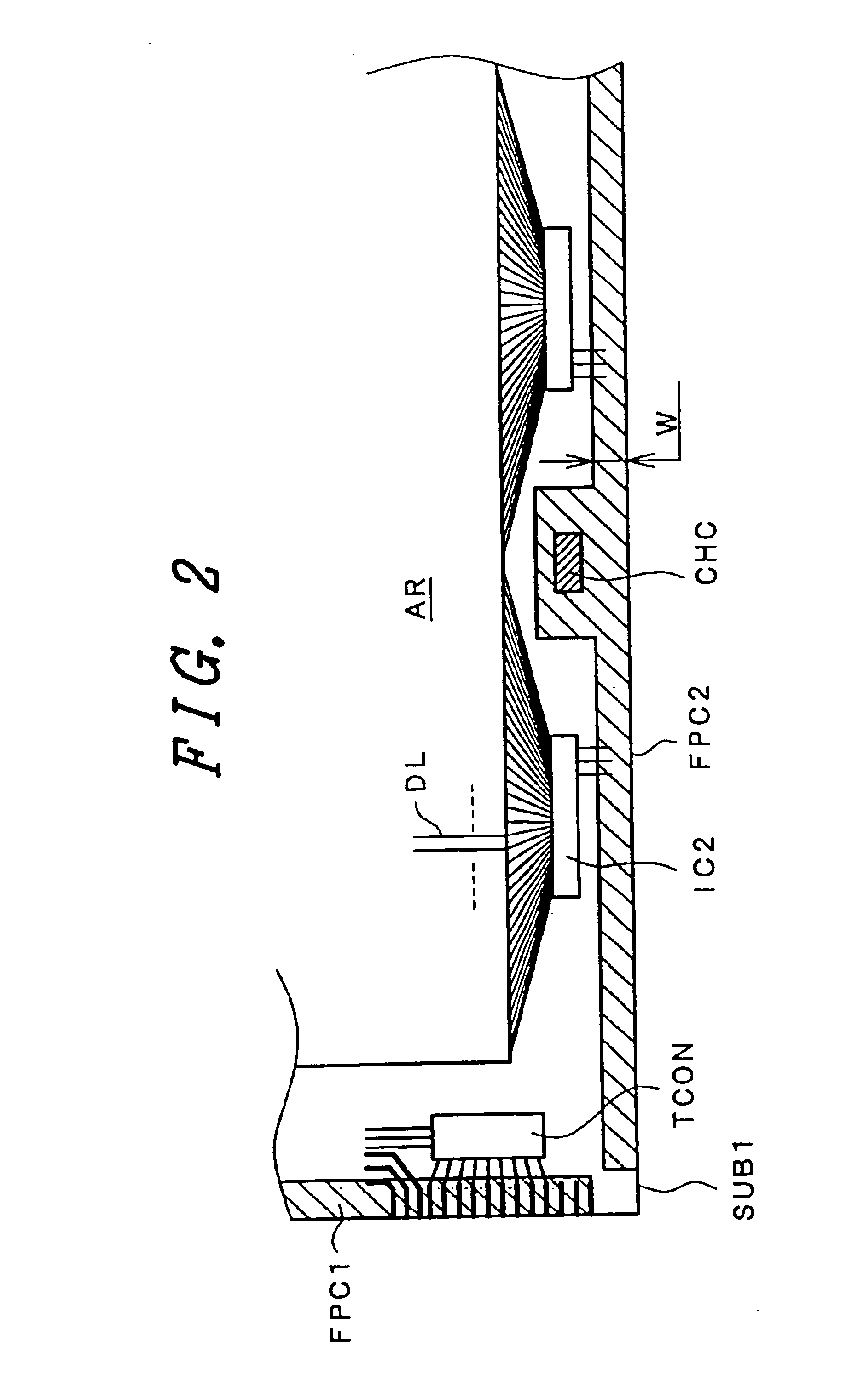

Display device

InactiveUS6842164B2Low production costEasy constructionCross-talk/noise/interference reductionCathode-ray tube indicatorsLiquid-crystal displayElectromagnetic interference

In a liquid crystal display comprising a plurality of pixels each of which has an switching element, a plurality of drain drivers and gate drivers for operating the switching elements and the pixels, and a plurality of drain lines and gate lines supplying signals from the drain drivers and the gate drivers to the switching elements being formed on one of a pair of substrates sandwiching a liquid crystal layer, the present invention provides wiring lines formed on the one of a pair of substrates for transferring display data signals and a clock signal between each pair of the plurality of drain drivers adjacent to one another, and provides at least one gate circuit for at least one of the plurality of drain drivers which is controlled by the clock signal and switches the display data signals and the clock signal either (1) to be acquired by the at least one of the plurality of drain drivers or (2) to be transferred to another of the plurality of drain drivers arranged adjacent to the at least one of the plurality of drain drivers. This liquid crystal display device has an advantage, for instance, or of suppressing electromagnetic interference (EMI) to another equipment surrounding the liquid crystal display device, of preventing the display data signals or the clock signal from being distorted in the wiring lines.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

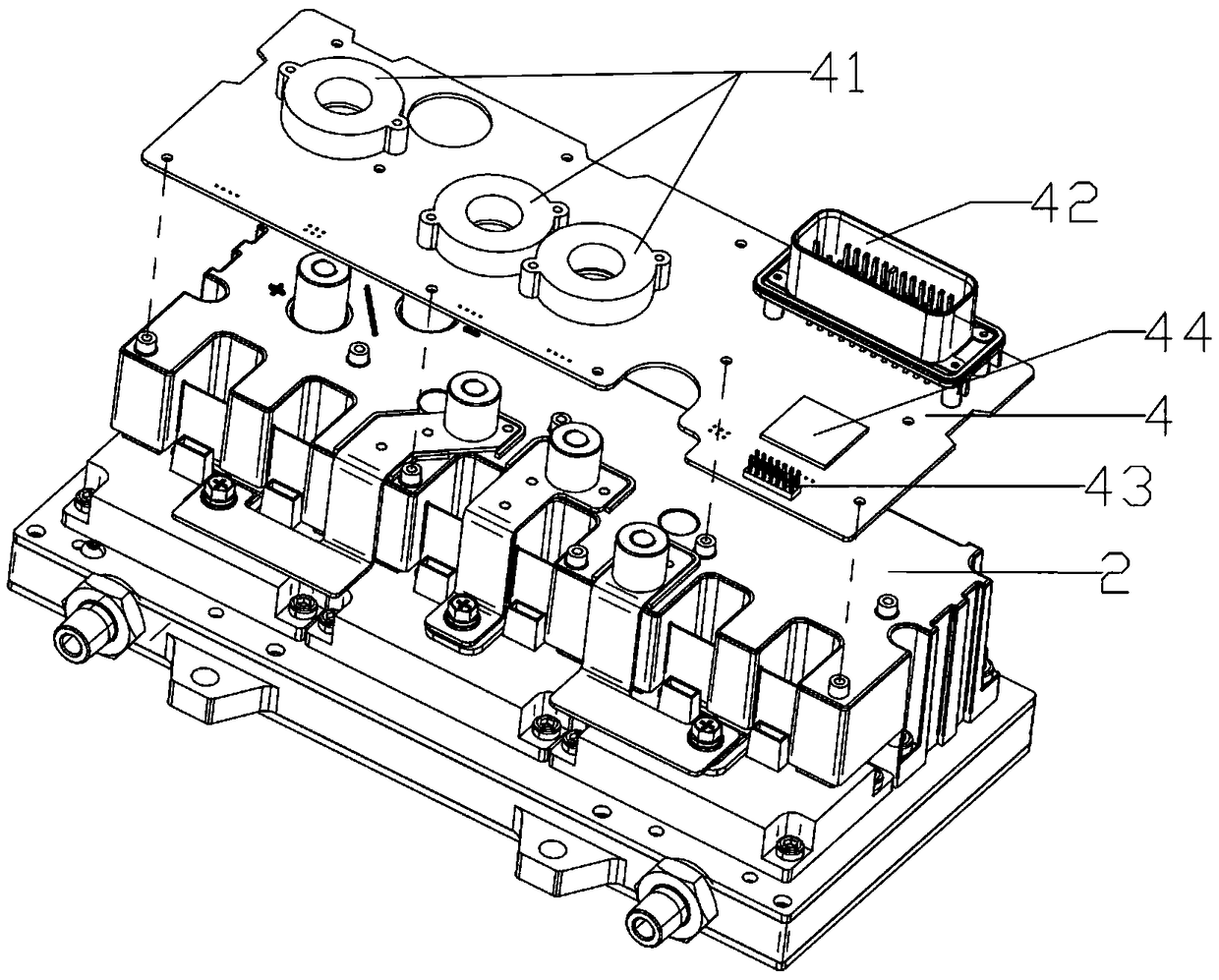

Motor controller

InactiveCN108880283AShorten the lengthReduce areaConversion constructional detailsCooling/ventilation/heating modificationsThree-phaseMotor controller

The invention relates to a motor controller for leading out power terminals upward. The motor controller comprises a heat sink bottom board, a capacitor module, a power module, a drive main control PCB board, and an insulating inner cover. The capacitor module and the power module are mounted on the heat sink bottom board in parallel. The driving main control PCB board and the insulating inner cover are overlaid on the capacitor module. A positive electrode, negative electrode input and a three-phase AC output copper column are distributed in the space above the capacitor module and the powermodule. The power module AC output terminal and the three-phase output copper column are electrically connected through a copper bus. The positive electrode, negative electrode input and the three-phase AC output copper column pass through the through hole of the driving main PCB board and the insulating inner cover, so that the positive electrode, negative electrode input and the three-phase AC output terminal are led out to the upper chamber of the housing and connected with the wiring terminal of the transfer copper bus or motor. The transfer copper bus of the positive electrode and negative electrode input copper column penetrate through the electromagnetic compatibility EMC magnetic ring. According to the motor controller, the controller is small in size and integrated, and the hardware cost is reduced.

Owner:深圳市容信科技有限公司

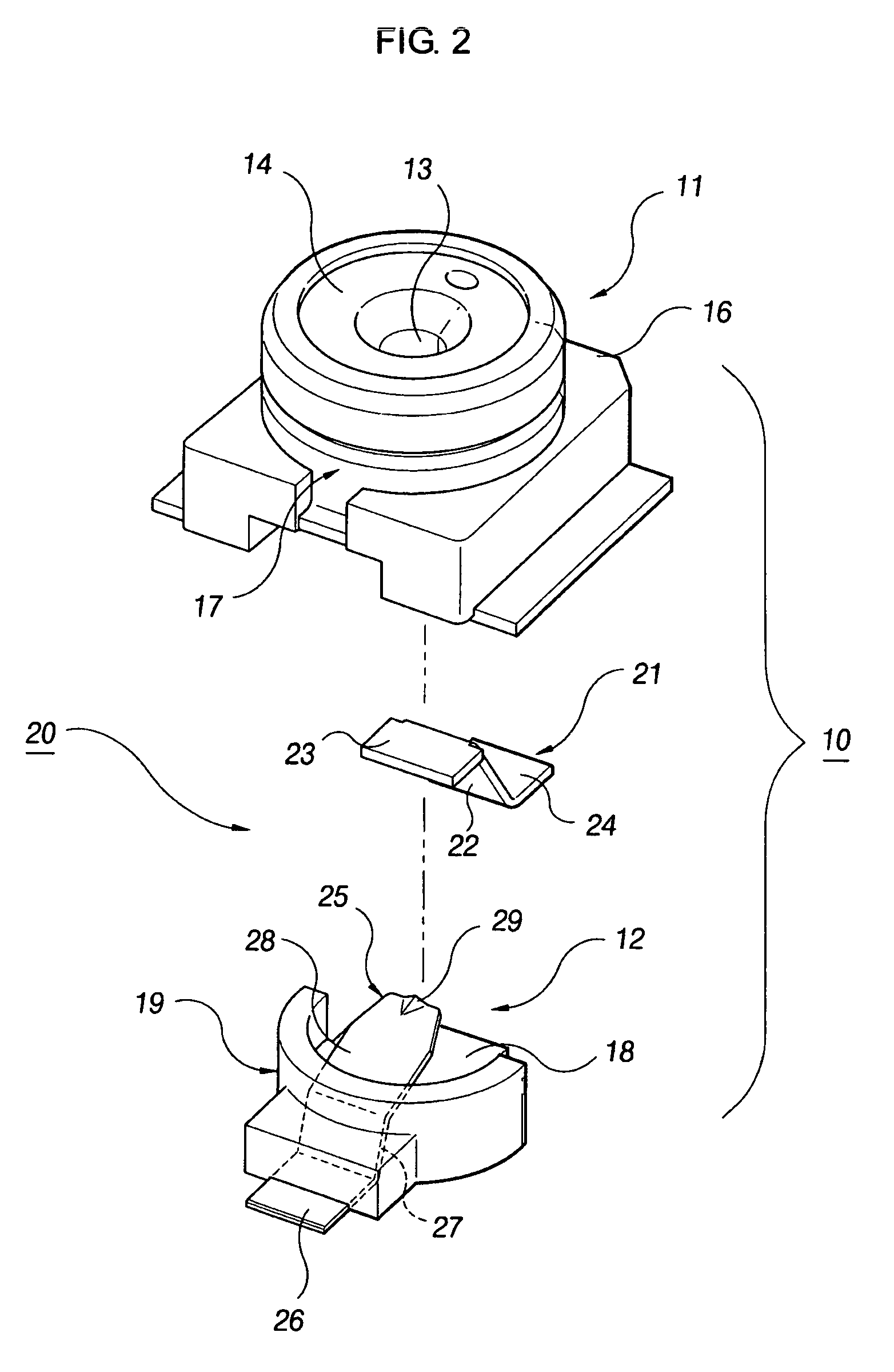

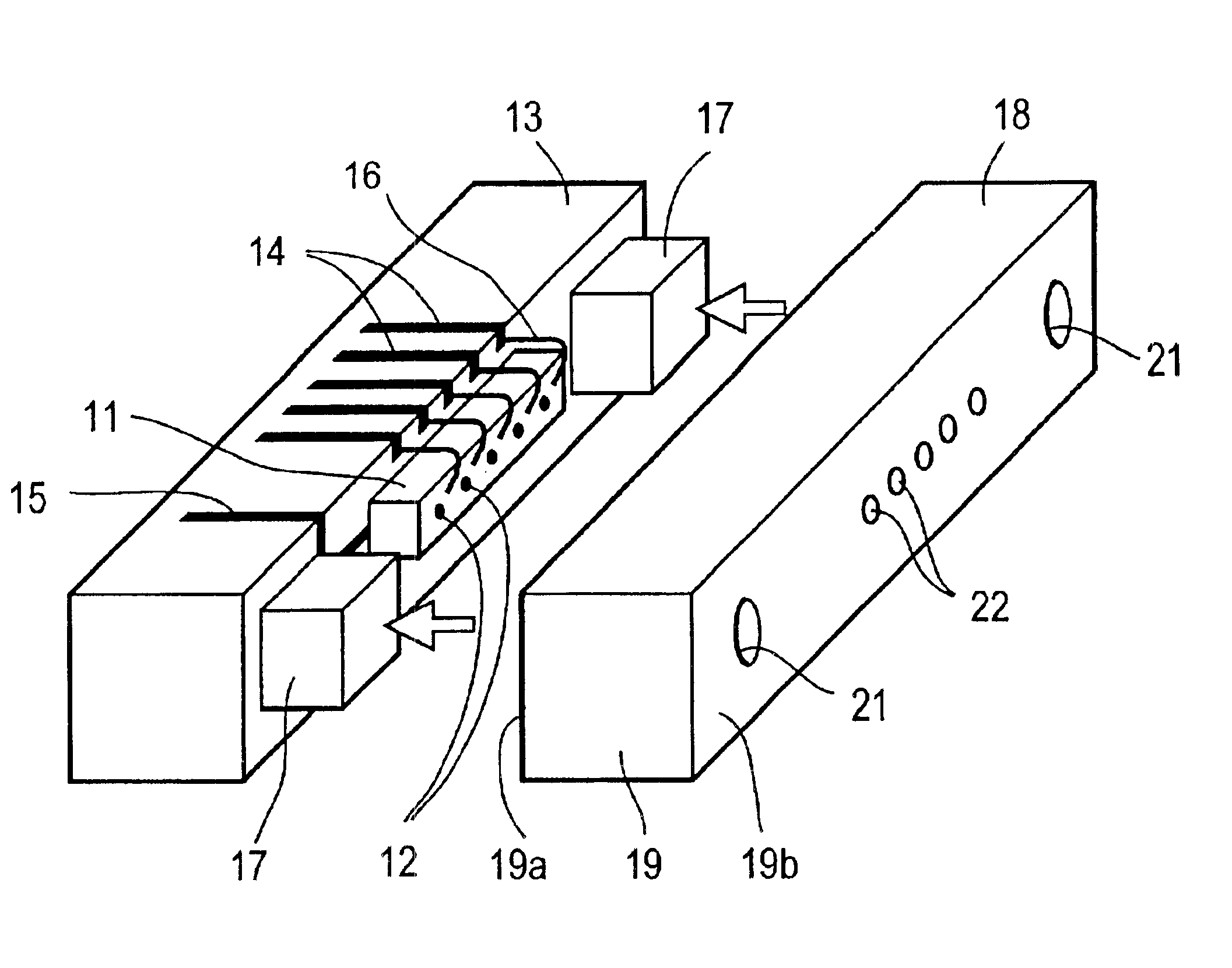

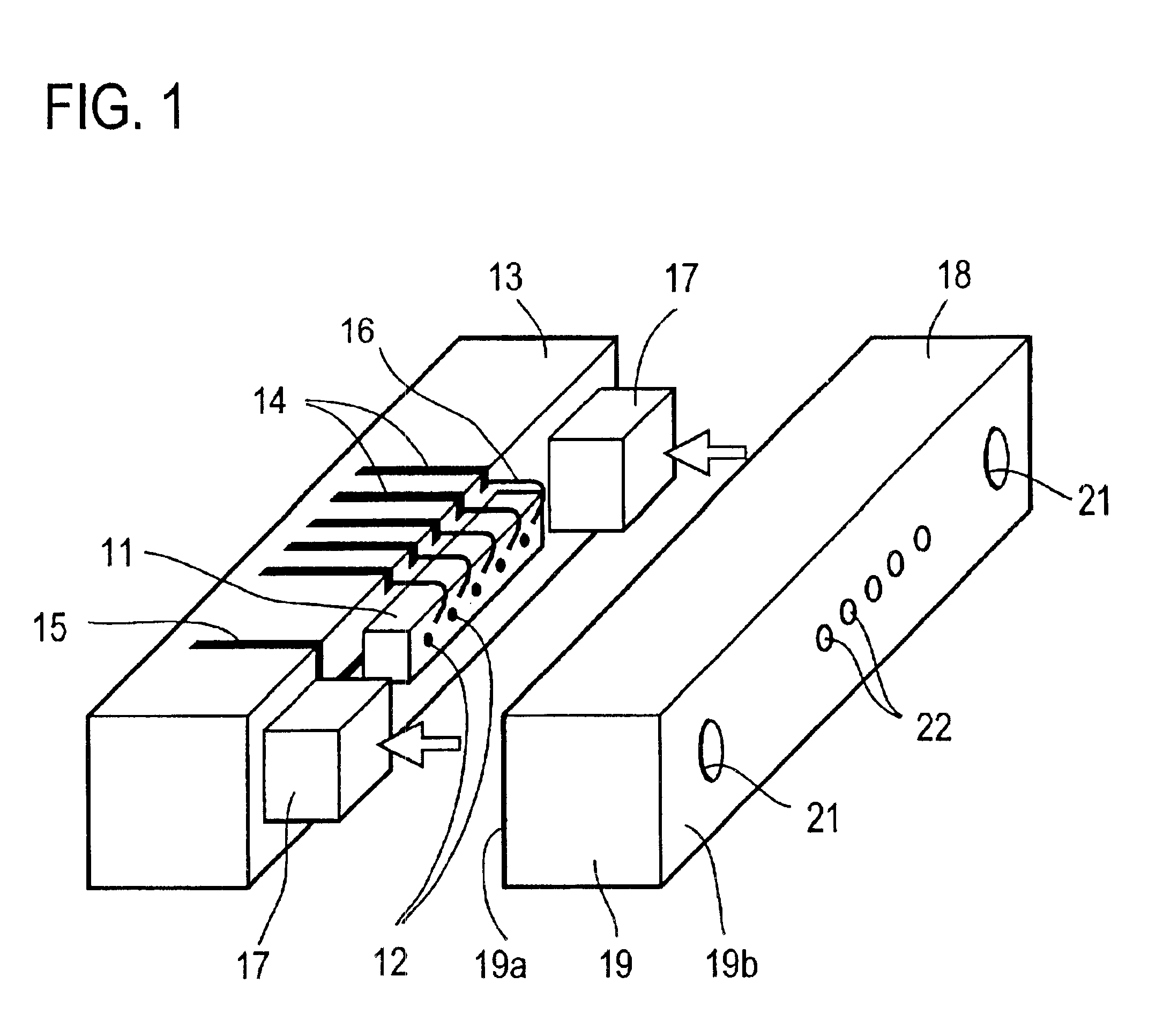

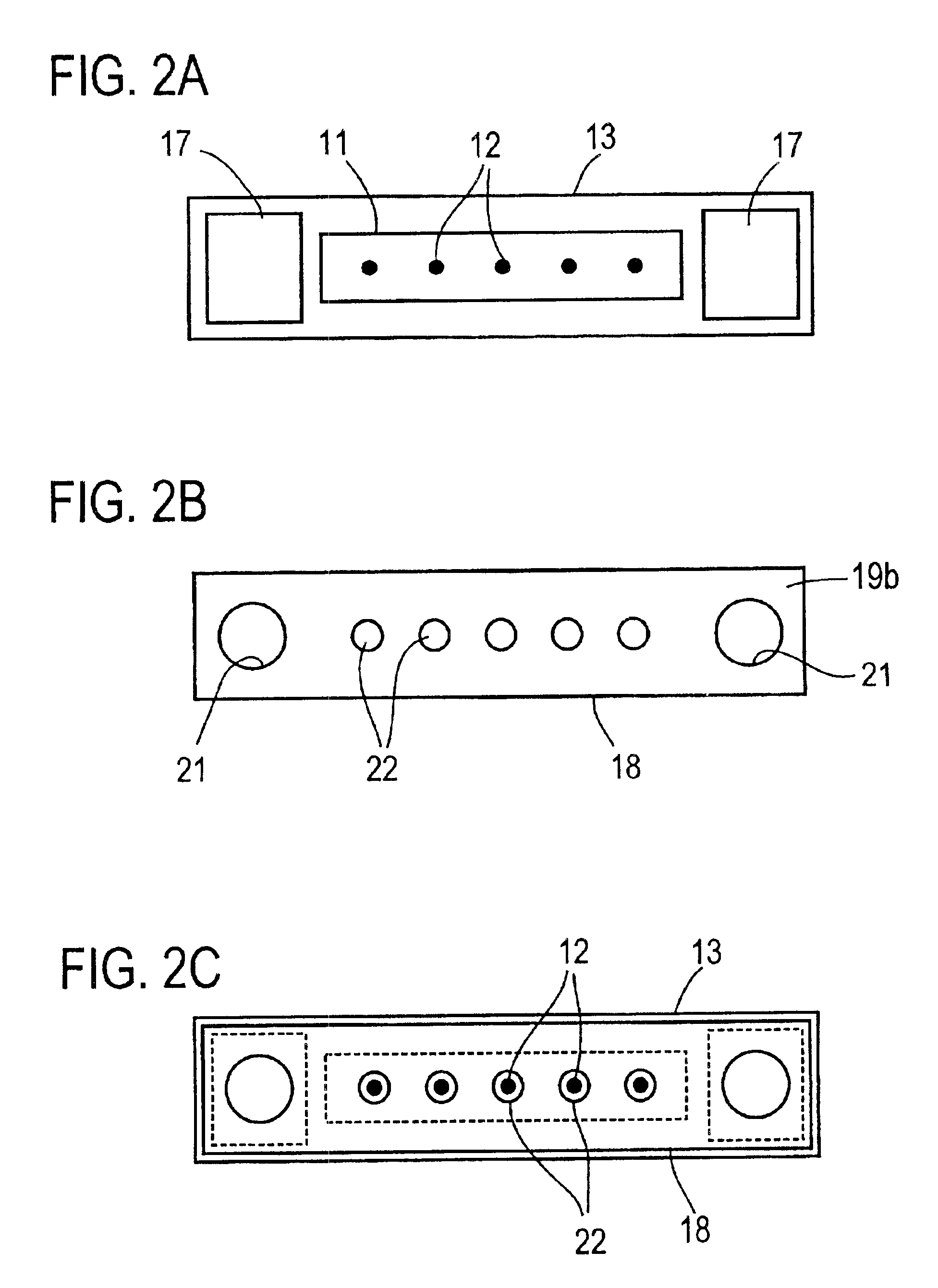

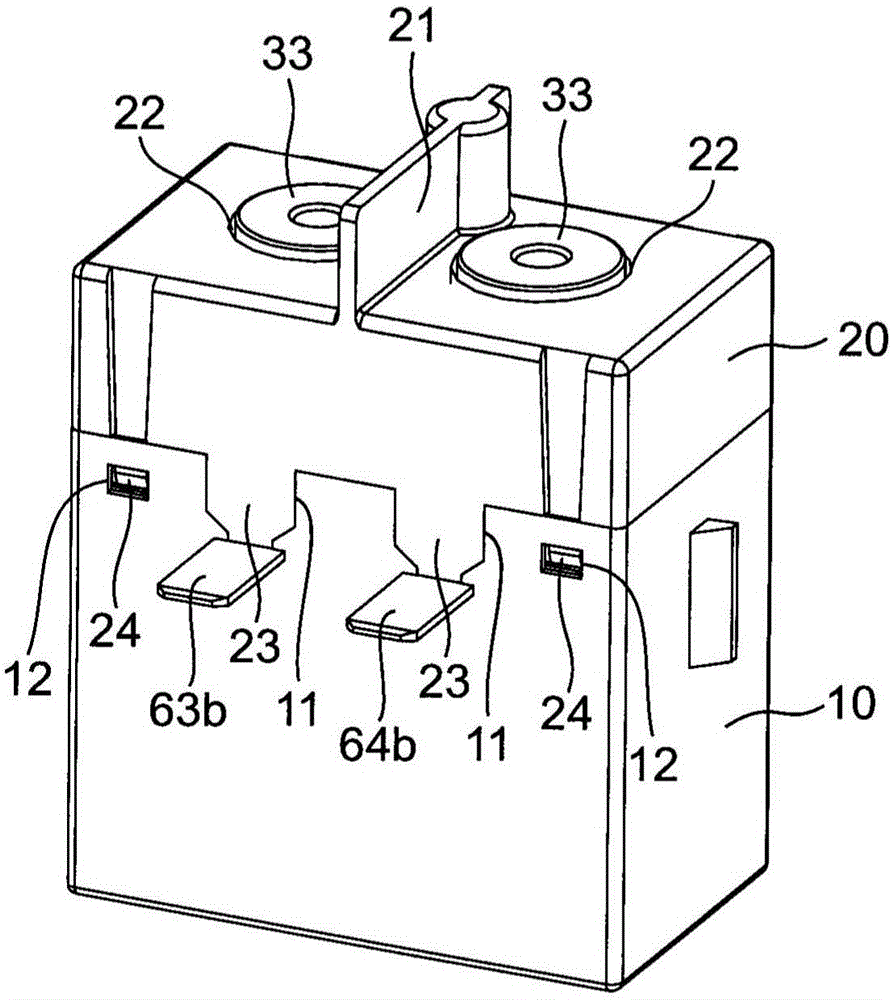

Optical module and method of assembling the optical module

InactiveUS6874952B2Simplify the assembly processReduce manufacturing costLaser detailsCoupling light guidesOptical ModuleFiber array

There are provided an optical module in which an assembling process of its optical coupling part can be simplified, and a method of assembling the optical module. After a surface light receiving type or a surface light emitting type optical element has been mounted on a substrate, in case of mounting an optical fiber array to the substrate with a spacer or spacers interposed between the substrate and the optical fiber array, the optical fiber array is mounted and fixed to the substrate with the spacer or spacers interposed therebetween while alignment between a plurality of light receiving elements or light emitting elements of the optical element and the end surfaces of a plurality of optical fibers of the optical fiber array is being carried out by image recognition thereof.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

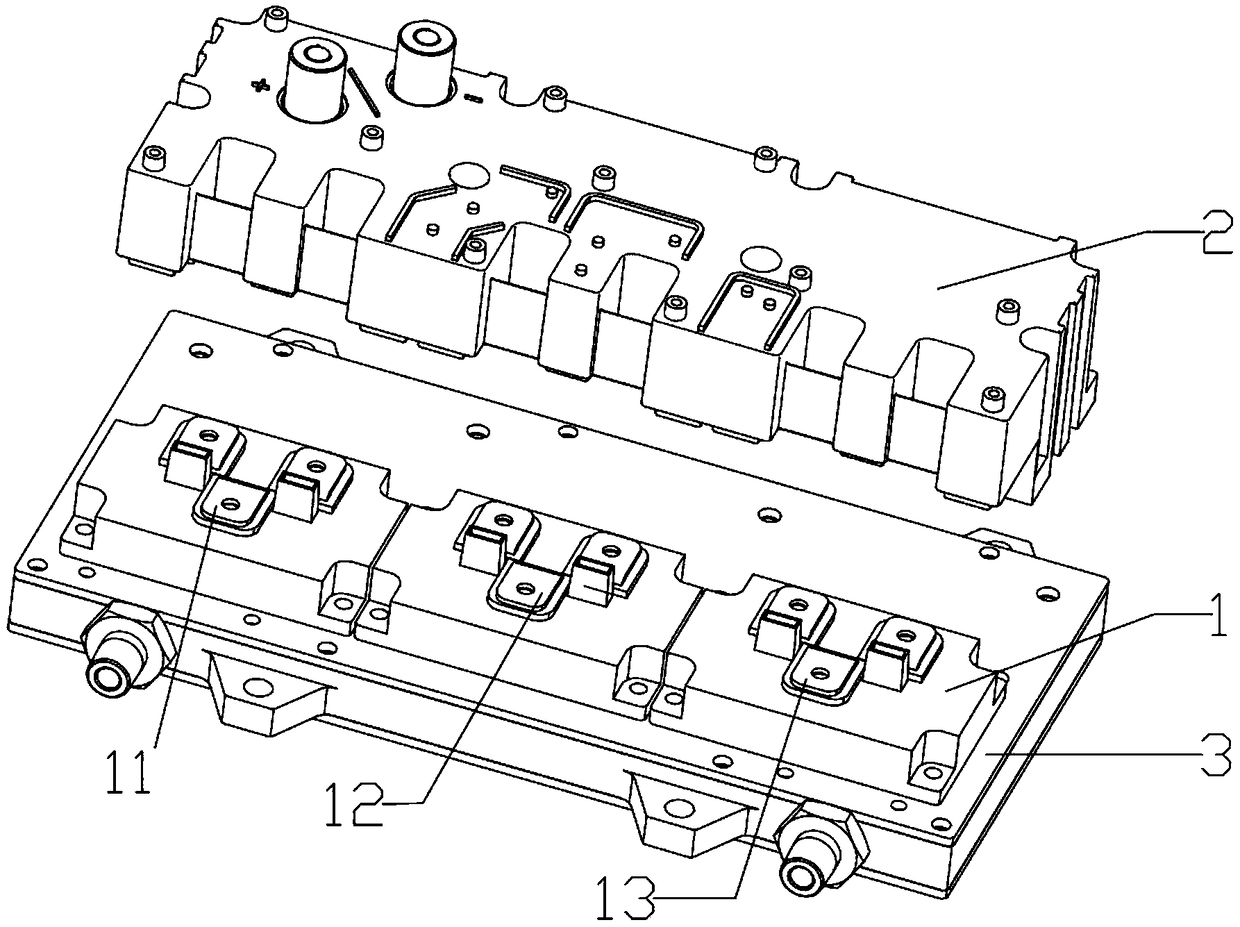

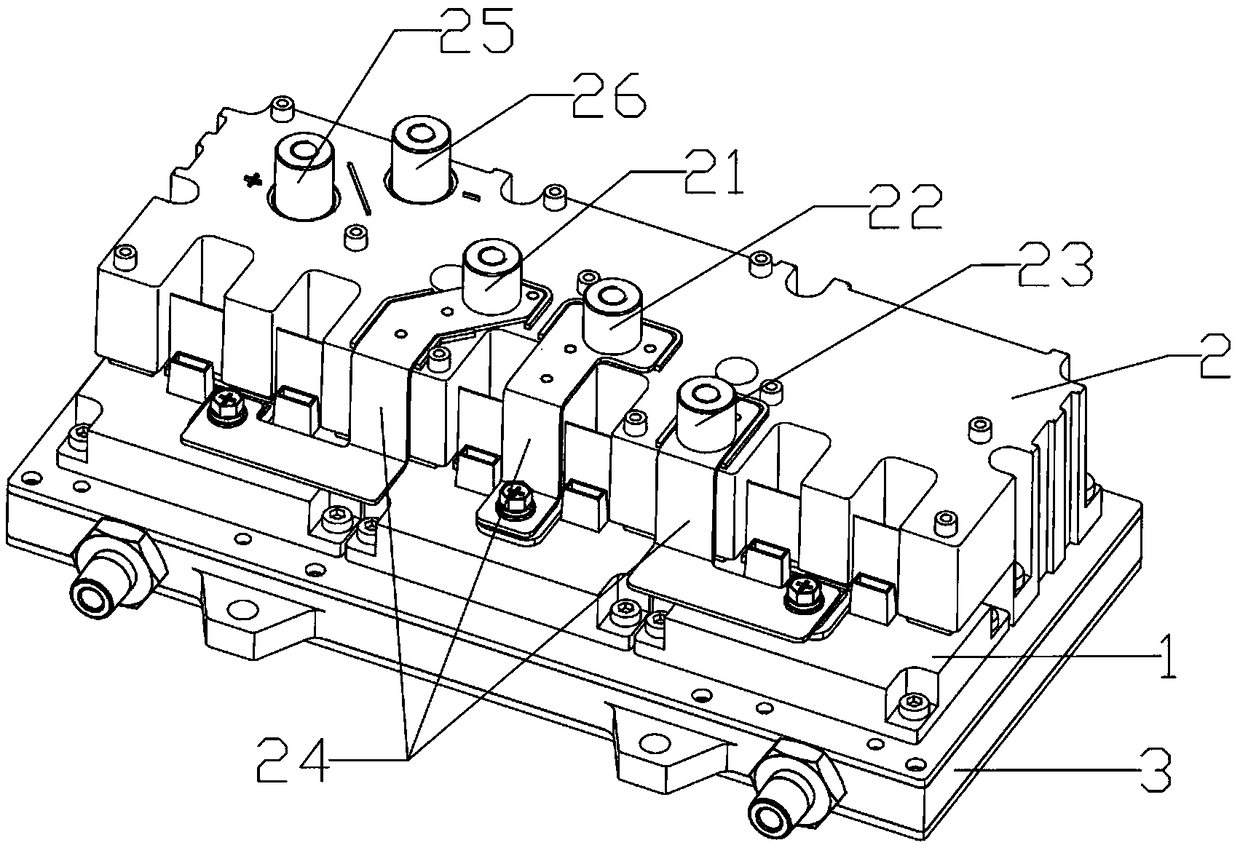

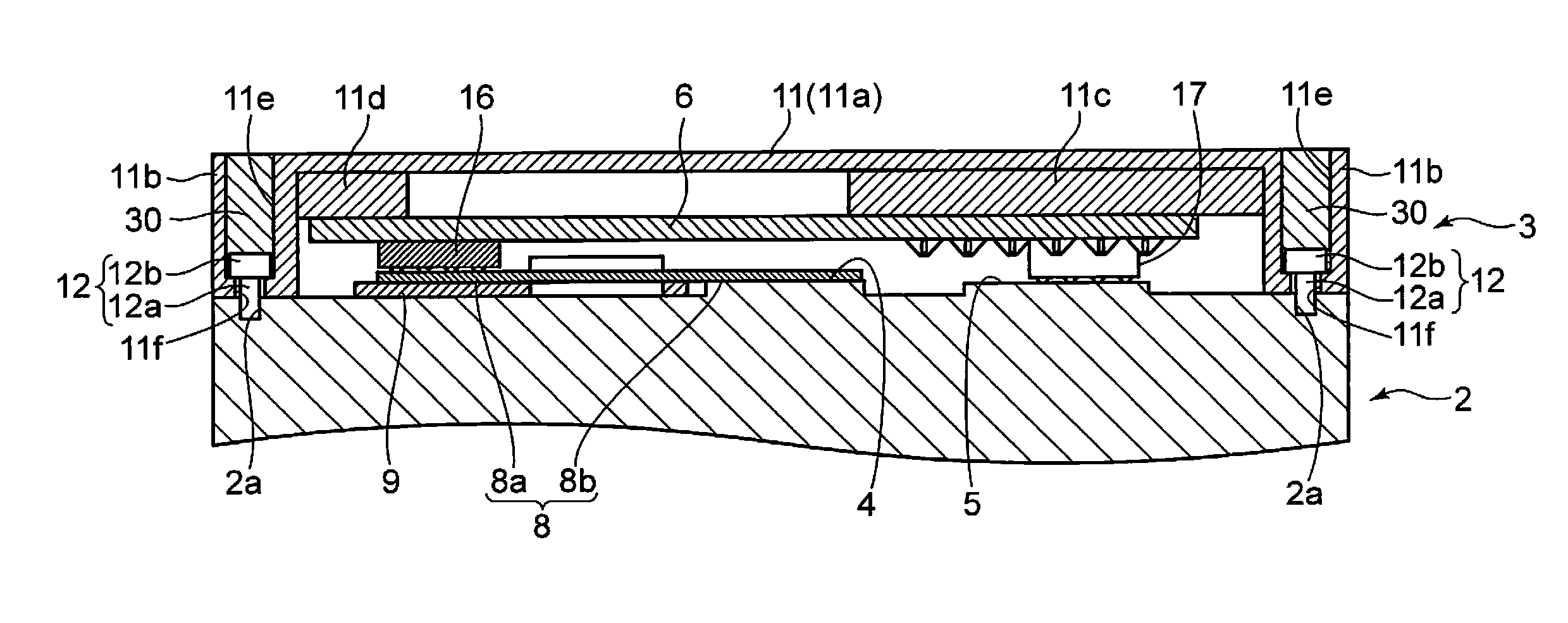

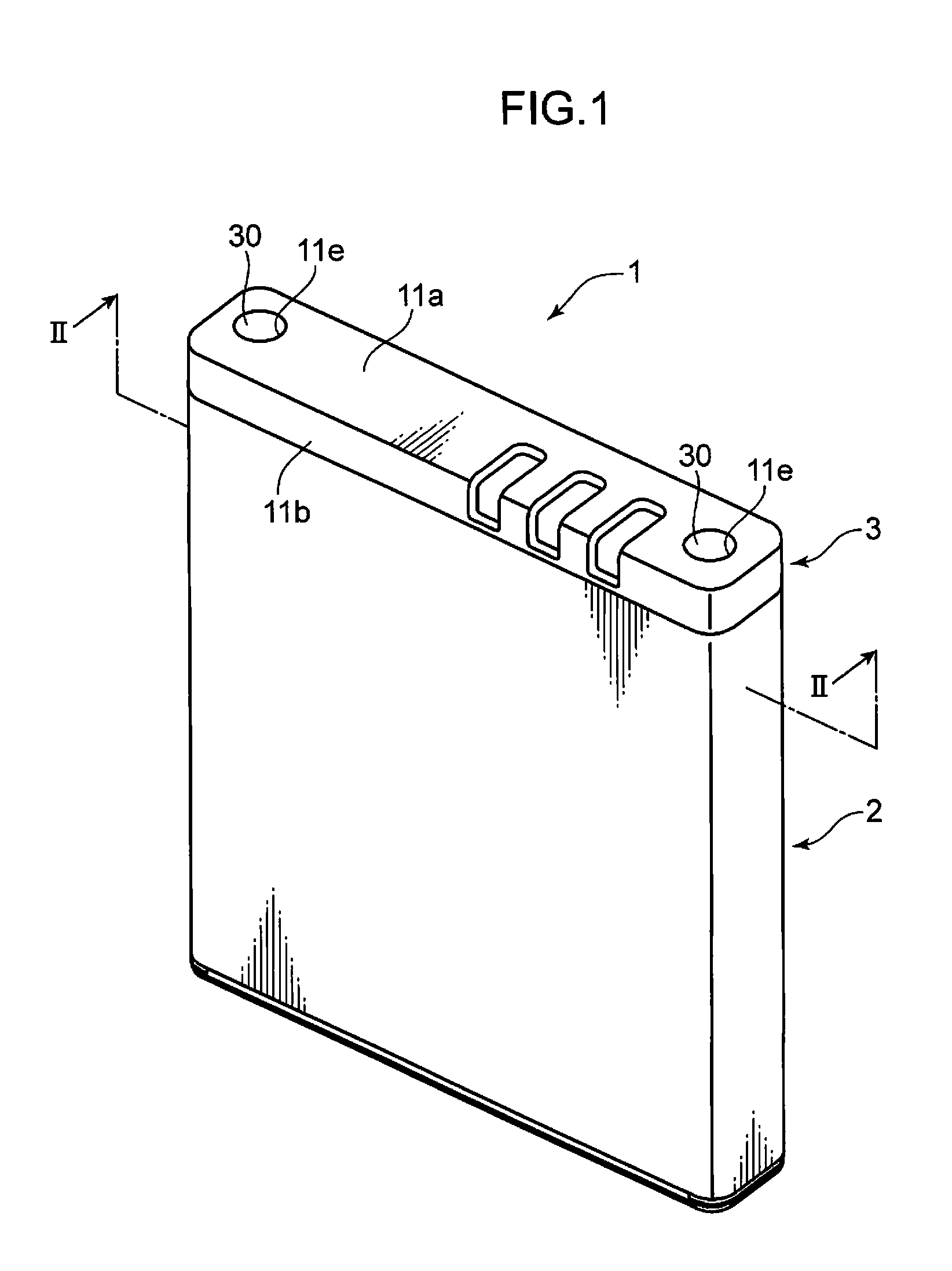

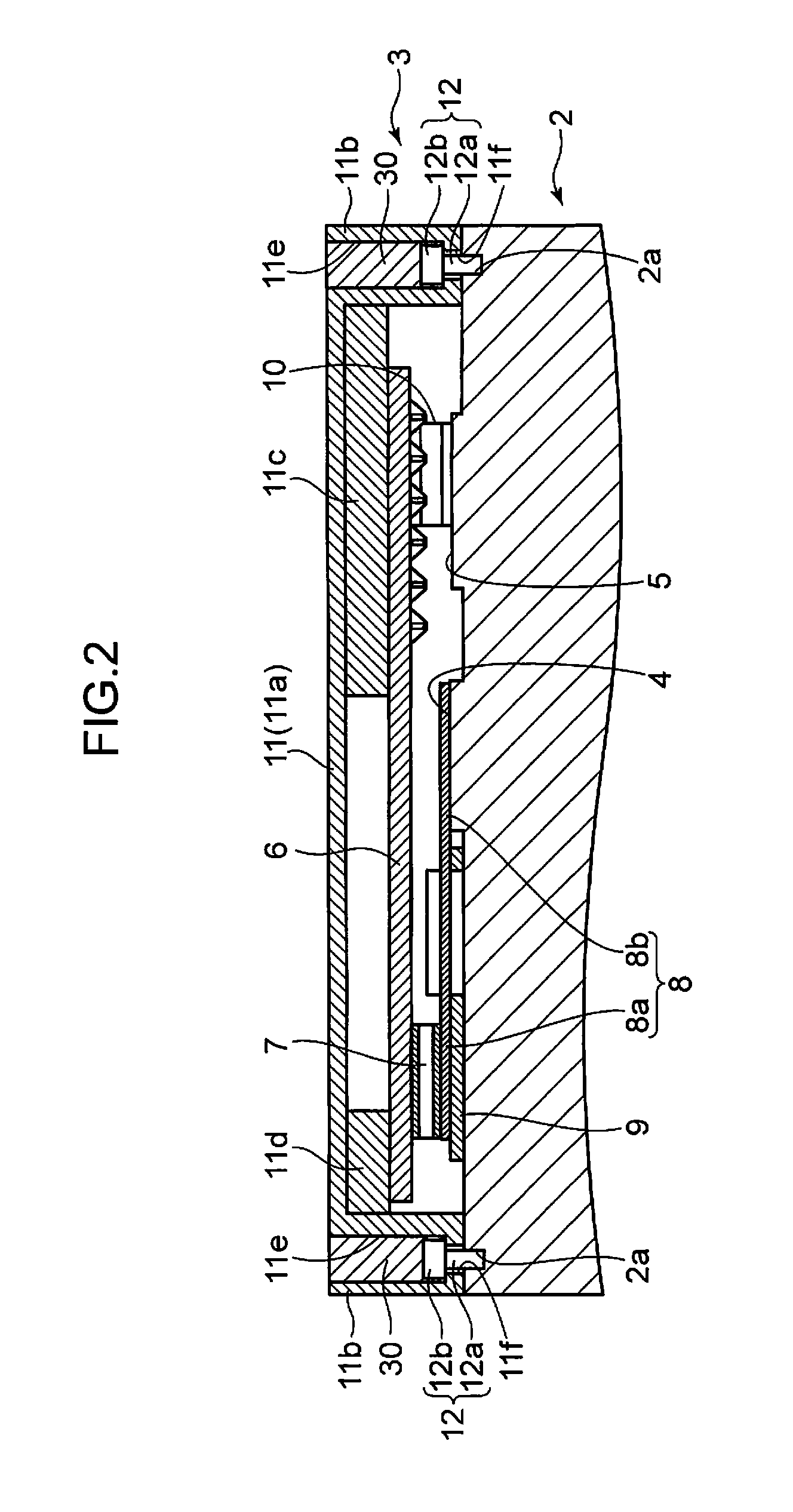

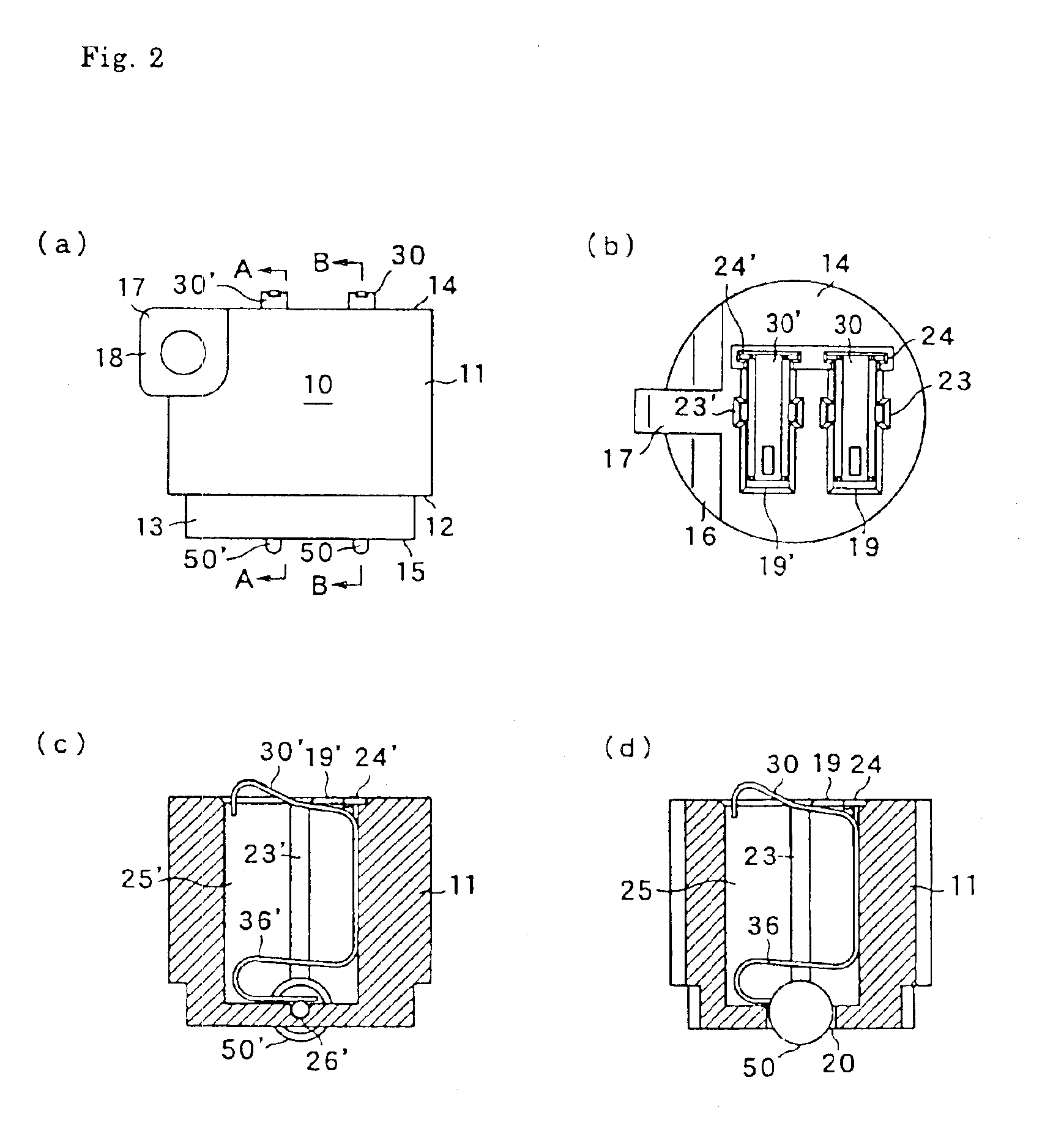

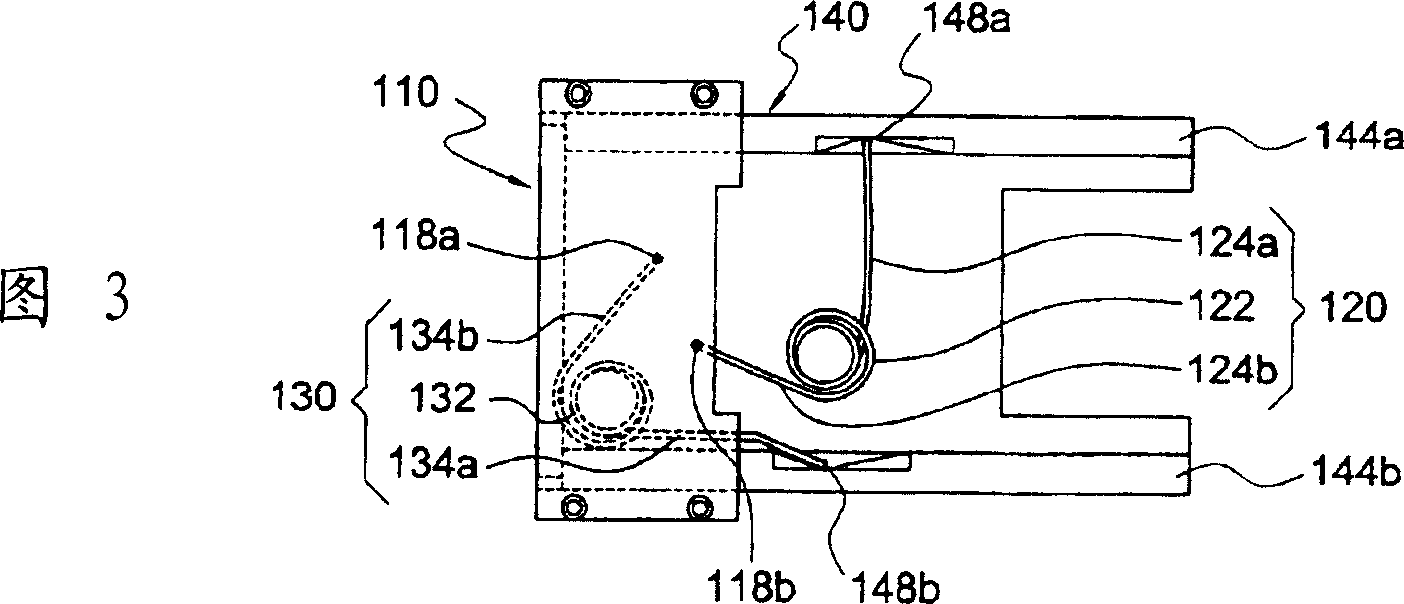

Battery pack and manufacturing method thereof

InactiveUS20120129017A1Streamline assembly workSimplify assembly workBatteries circuit arrangementsFinal product manufactureLead platePrinted circuit board

A battery pack and a manufacturing method thereof enabling the streamlining of assembly work are provided. This battery pack comprises a printed circuit board 6 including wiring, lead plates 7, 10 that are fixed to the printed circuit board 6 and that electrically connect the wiring of the printed circuit board 6 and both electrodes 4, 5 of a battery 2, and a screw 12 that presses the lead plates 7, 10 so as to maintain a state of electrically connecting of the lead plates 7, 10 to both electrodes 4, 5 of the battery 2 by being screwed into the battery 2.

Owner:PANASONIC CORP

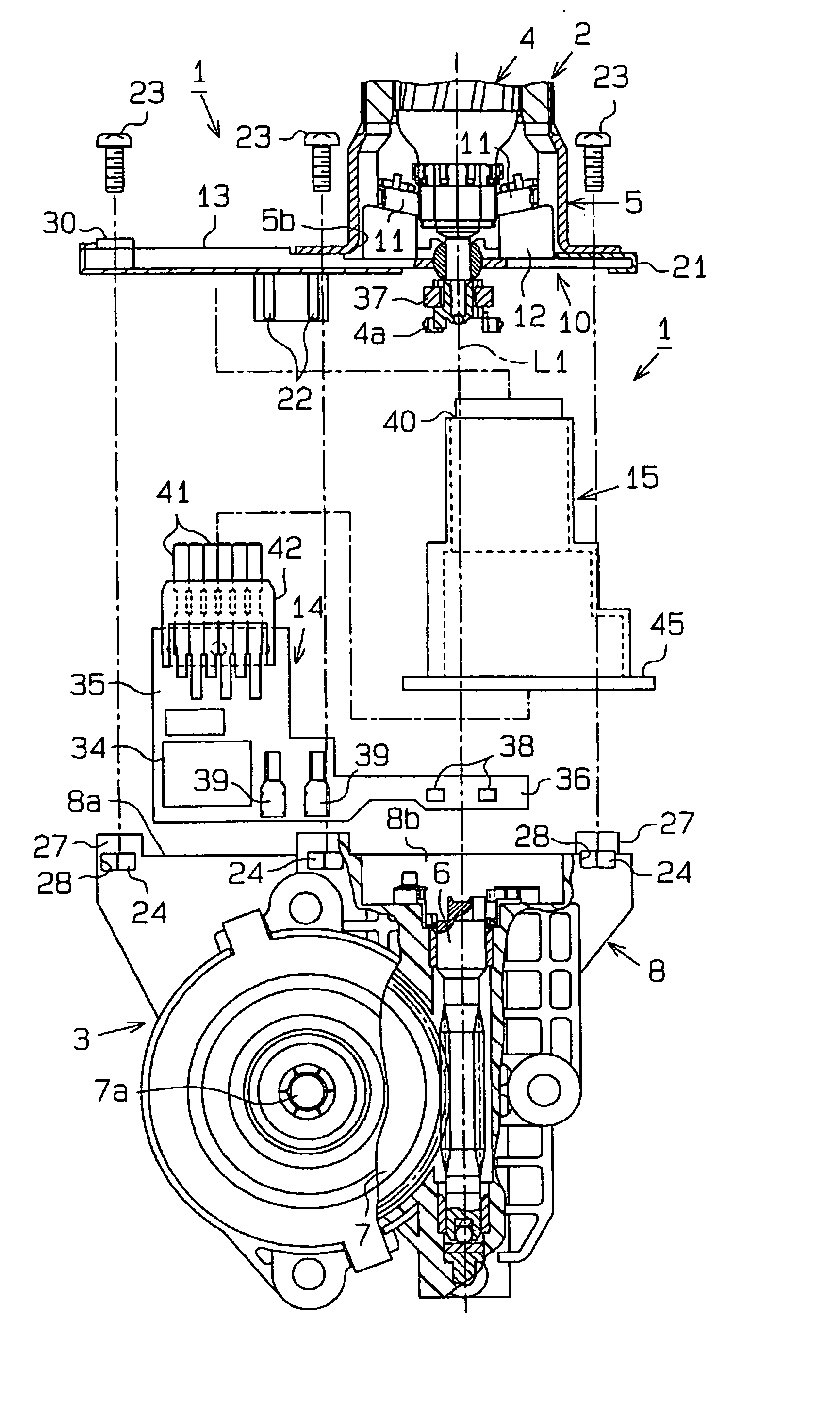

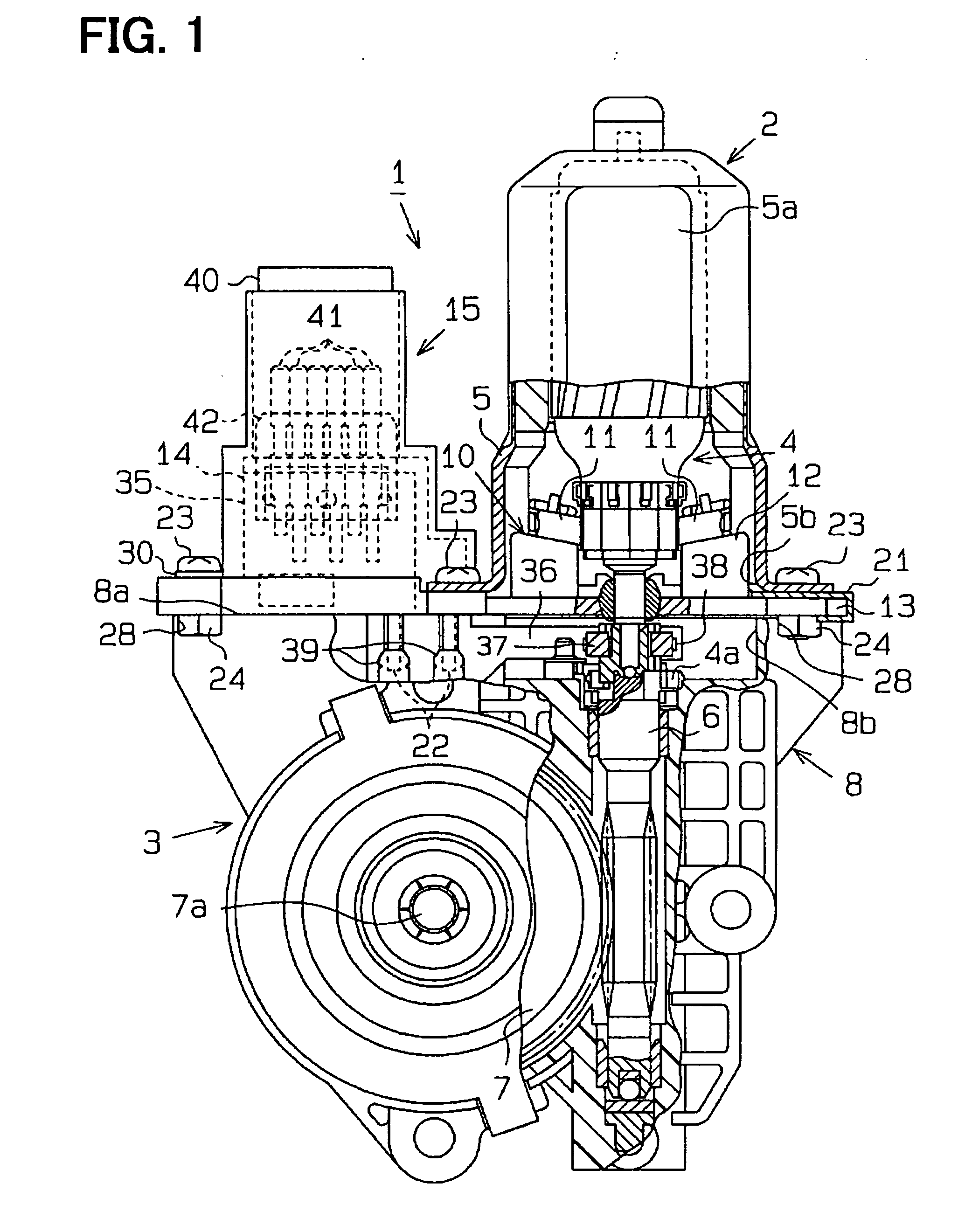

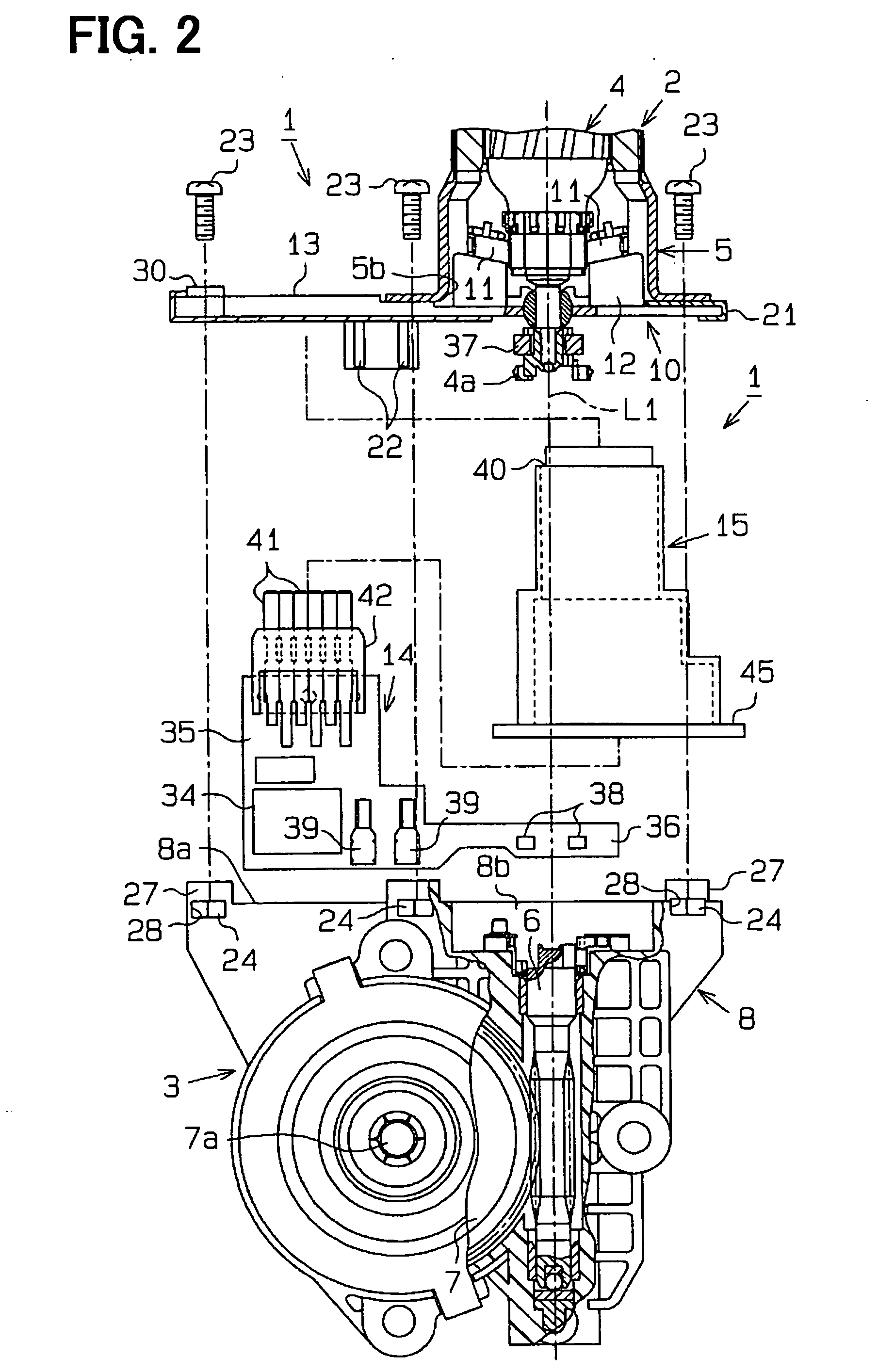

Motor

InactiveUS20050082925A1Easy to assembleSmall sizeAssociation with control/drive circuitsMechanical energy handlingEngineeringControl circuit

An end surface portion 8a of a gear housing 8, which is located on a motor unit 2 side of the gear housing 8, is opposed to the motor unit 2 and laterally extends. A brush holder 10 includes a plate portion 13 that is opposed to the end surface portion 8a. A case 15, which receives the control circuit board 14, is formed separately from the plate portion 13. A receiving through hole, through which the circuit board receiver 15 is receivable, is formed in the plate portion 13. The case 15 is constructed to be positionable next to the yoke 5 in a state where the case 15 is received through the receiving through hole. The yoke 5, the gear housing 8, the brush holder 10, the control circuit board 14 and the case 15 are assembleable in a direction parallel to an axial direction of the motor unit 2. The control circuit board 14 projects from the gear housing 8 on the motor unit 2 side, and a projected part of the control circuit board 14, which projects from the gear housing 8 on the motor unit 2 side, is received in the case 15. In this way, in the motor that integrally includes the motor unit, the speed reducing unit and the control circuit board, the gear housing of the speed reducing unit can be made compact, and the assembly work can be simplified.

Owner:ASMO CO LTD

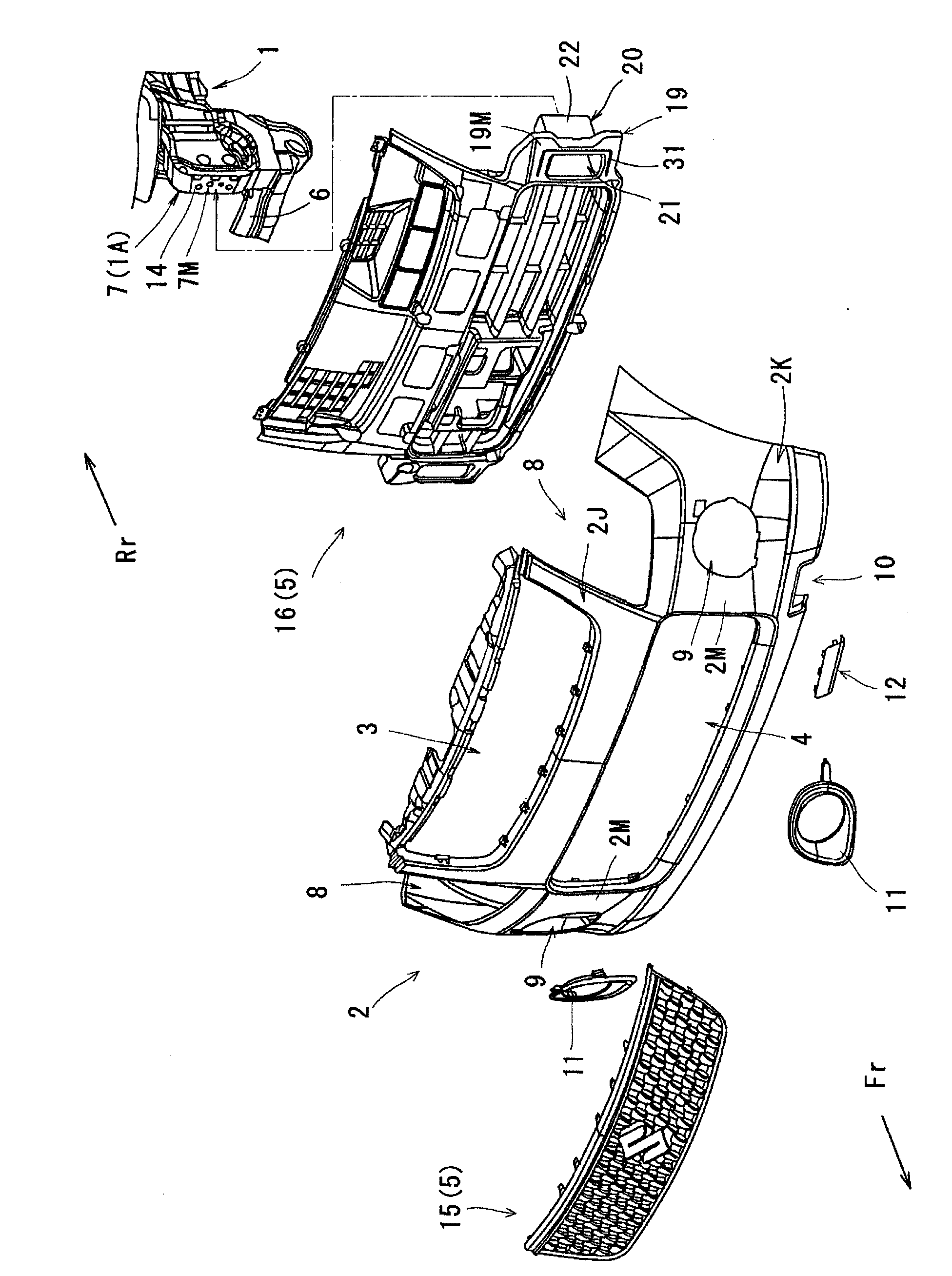

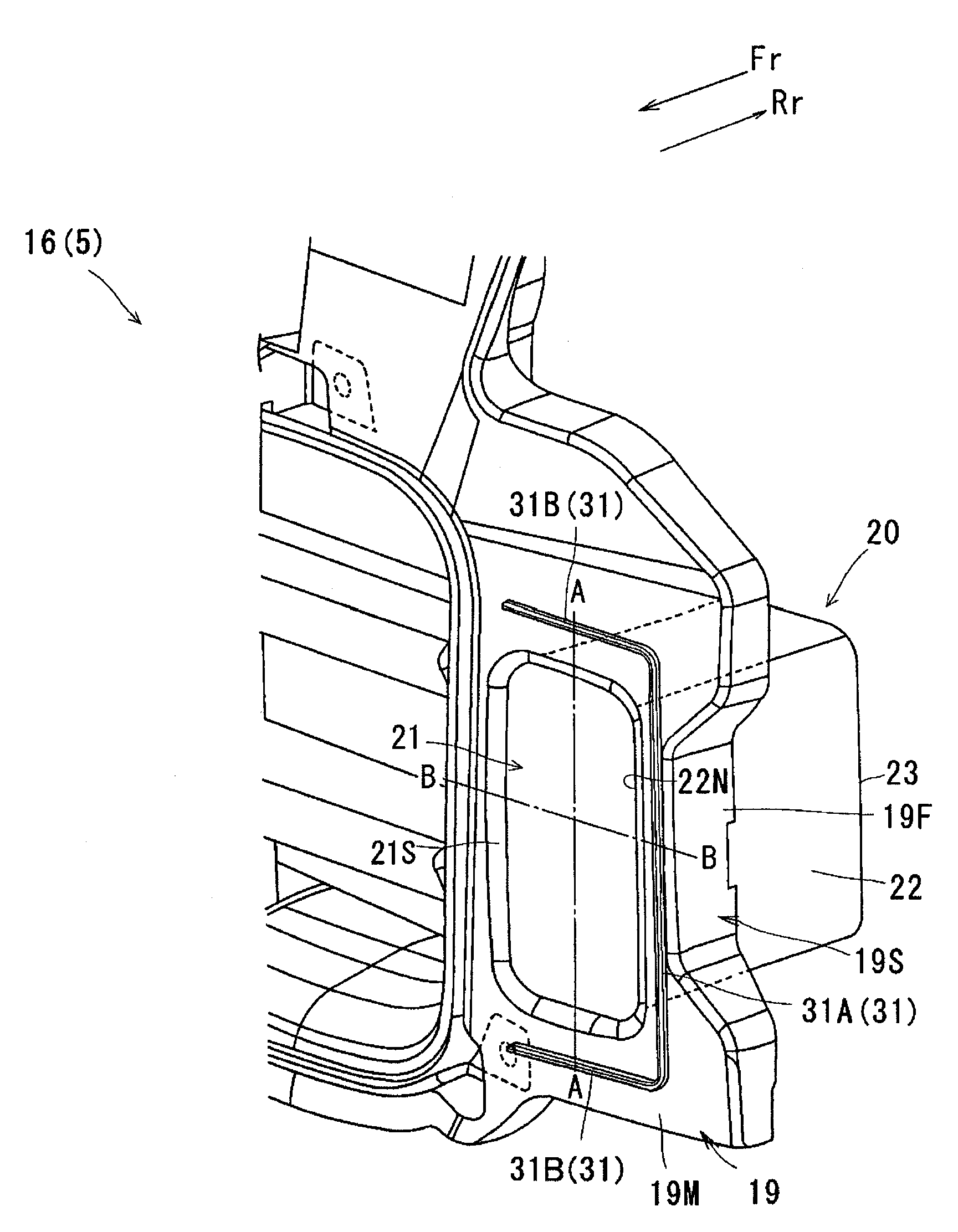

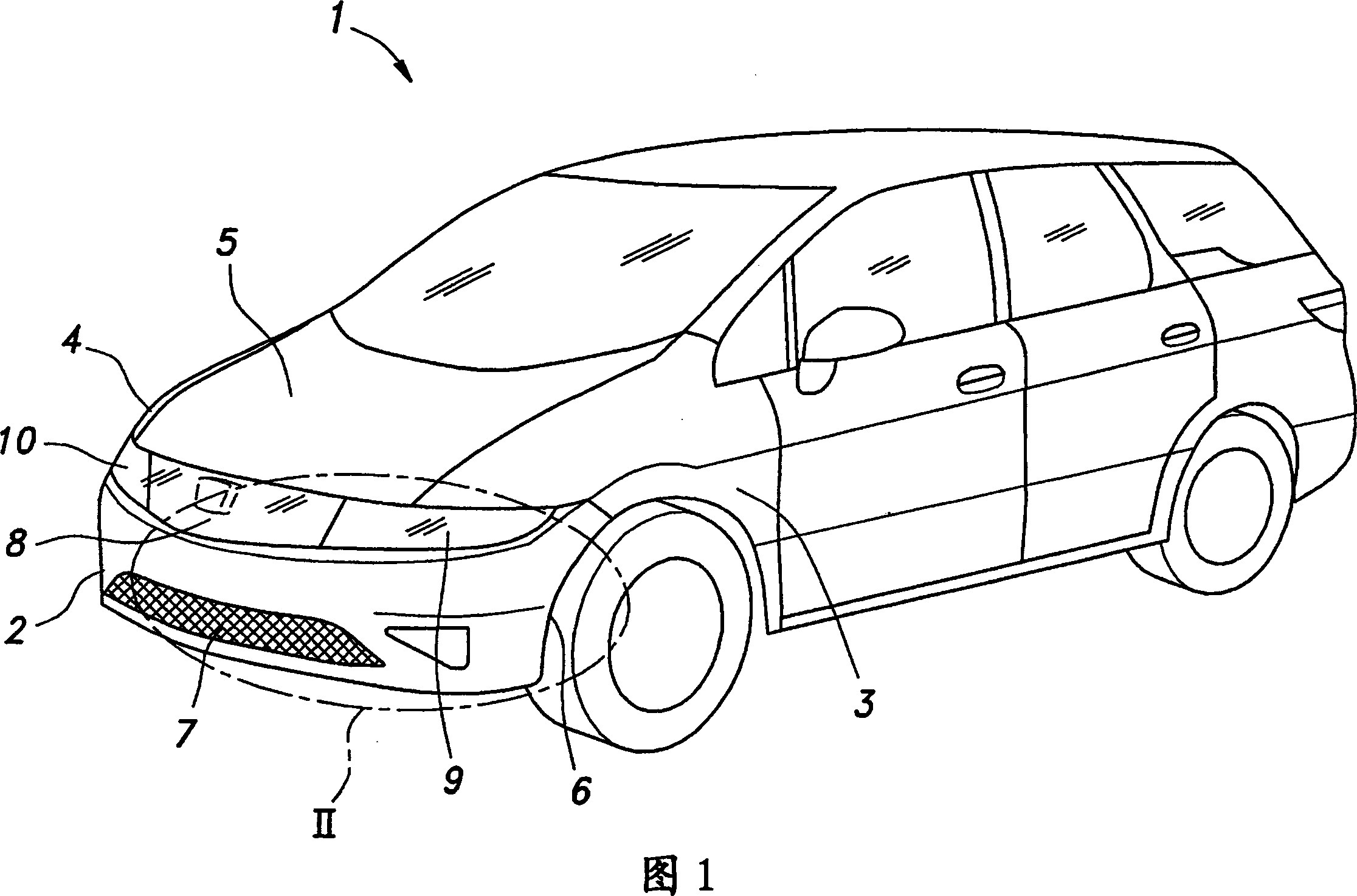

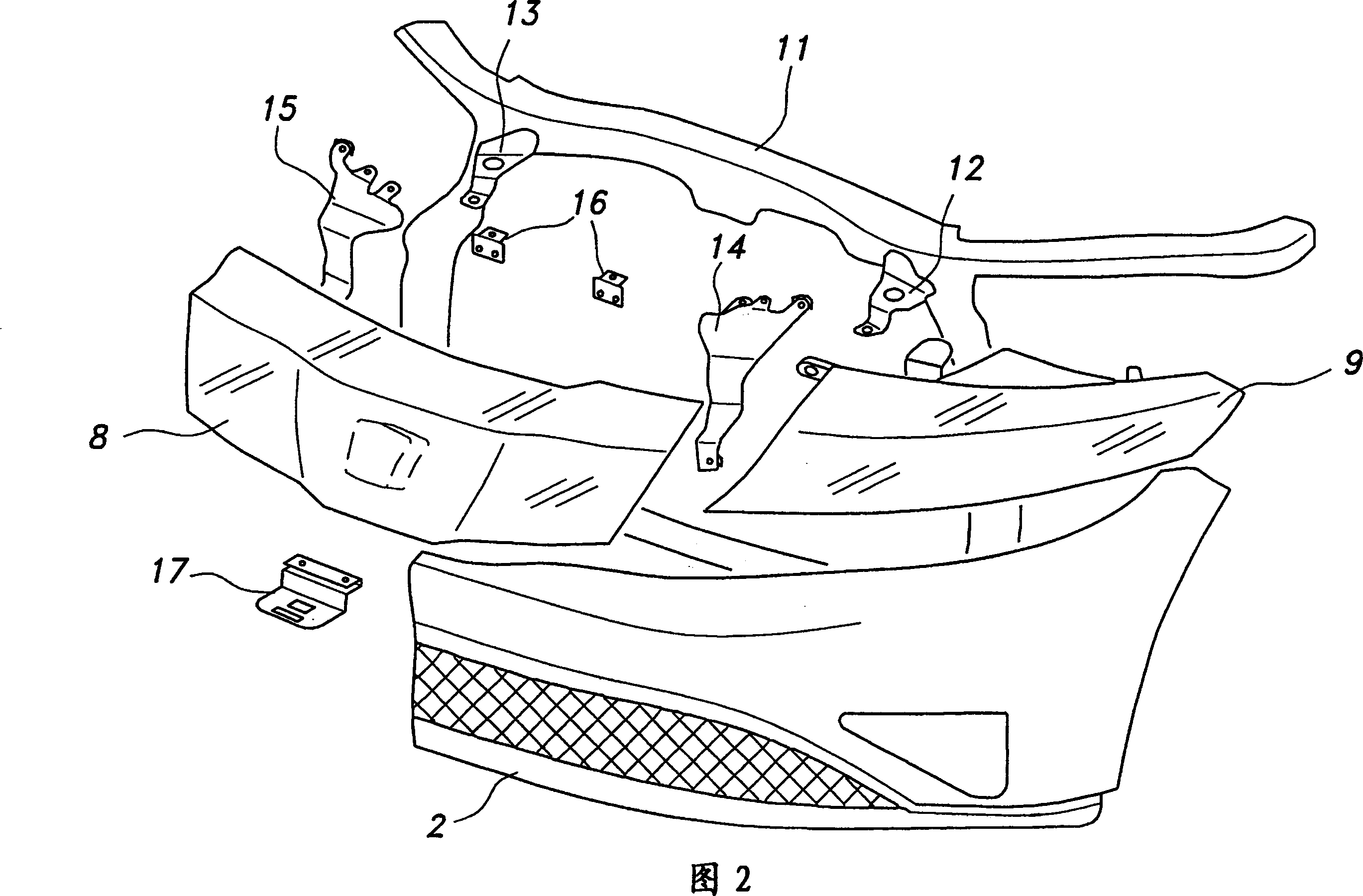

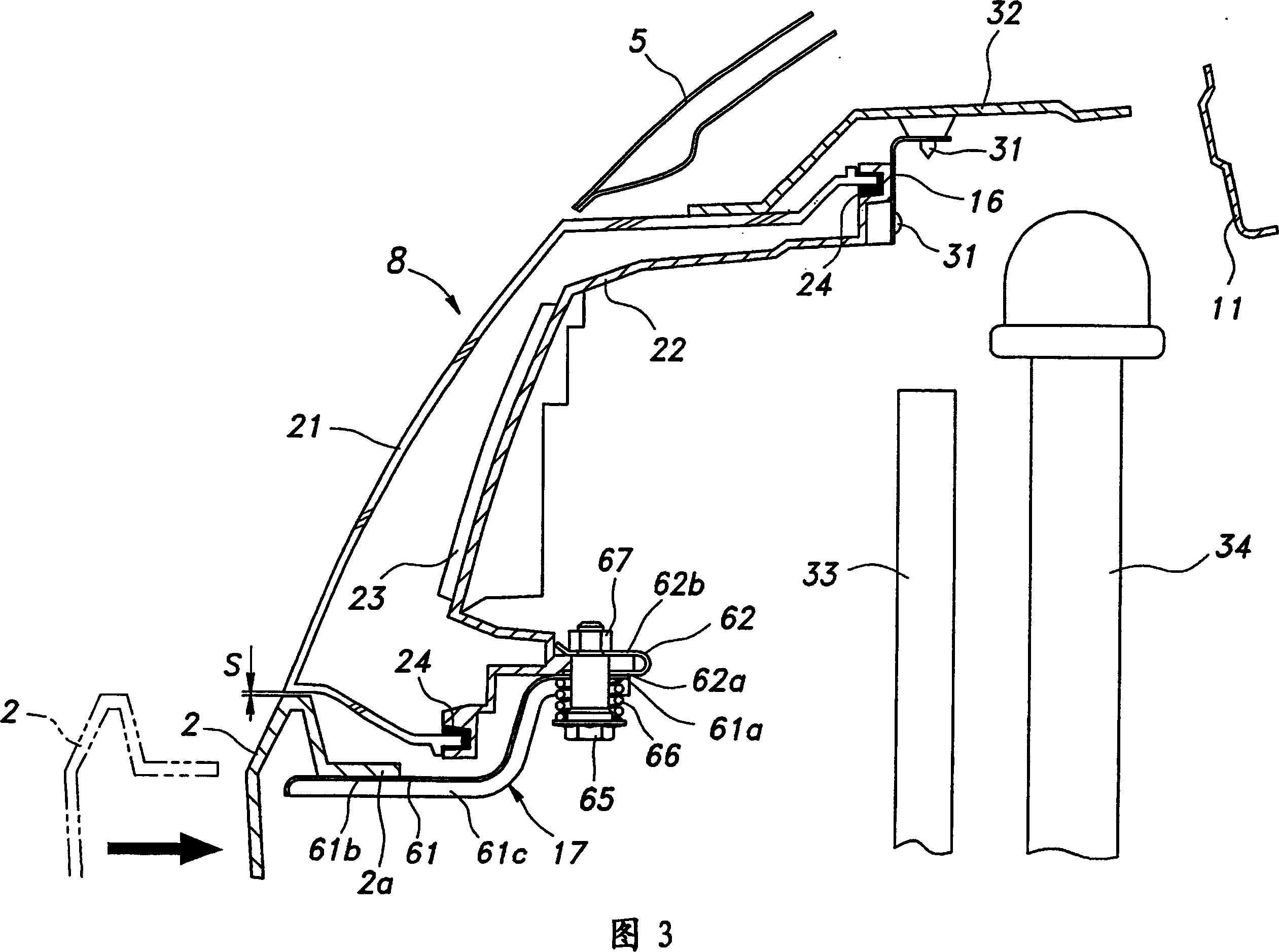

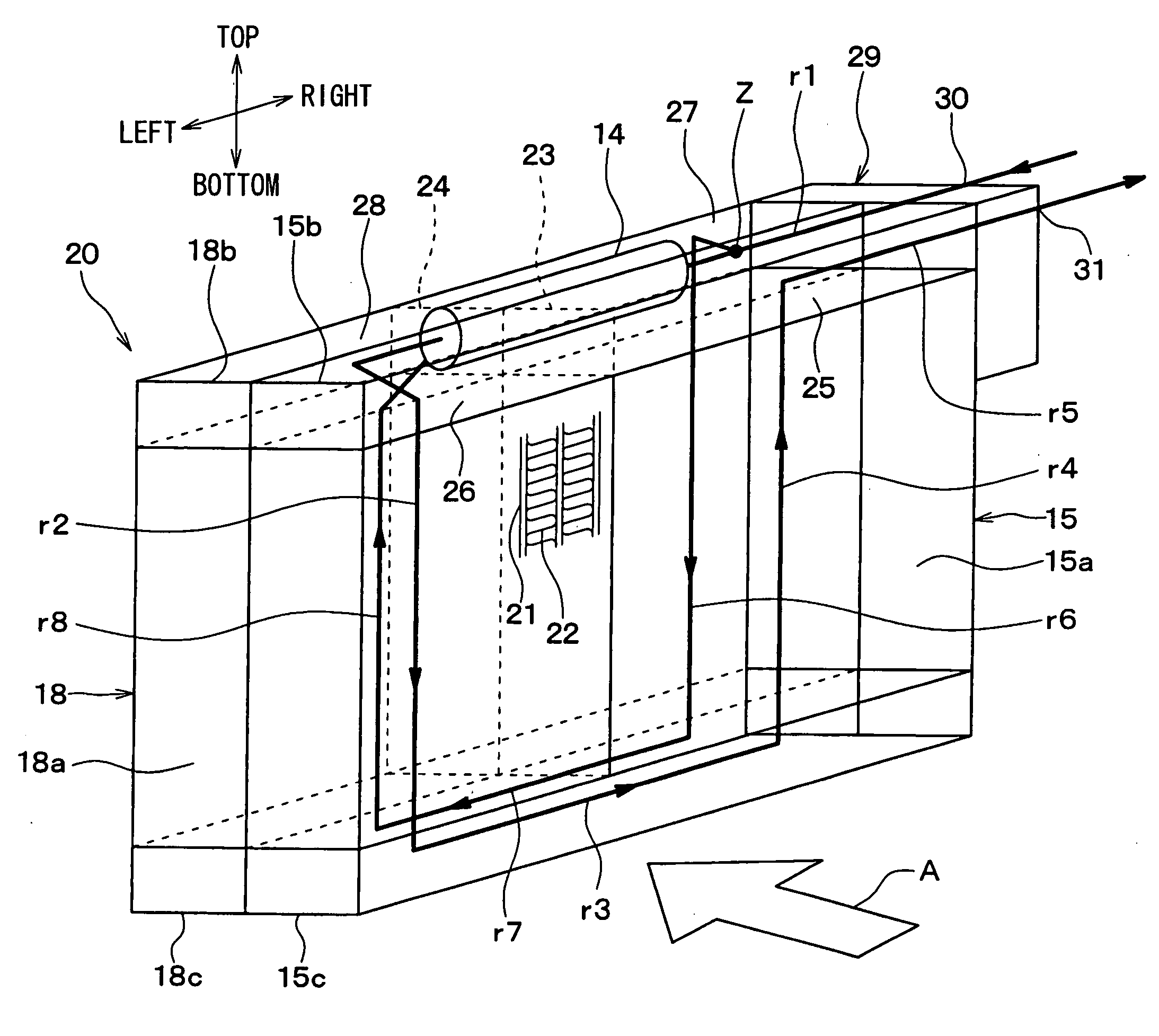

Vehicle front structure

Owner:SUZUKI MOTOR CORP

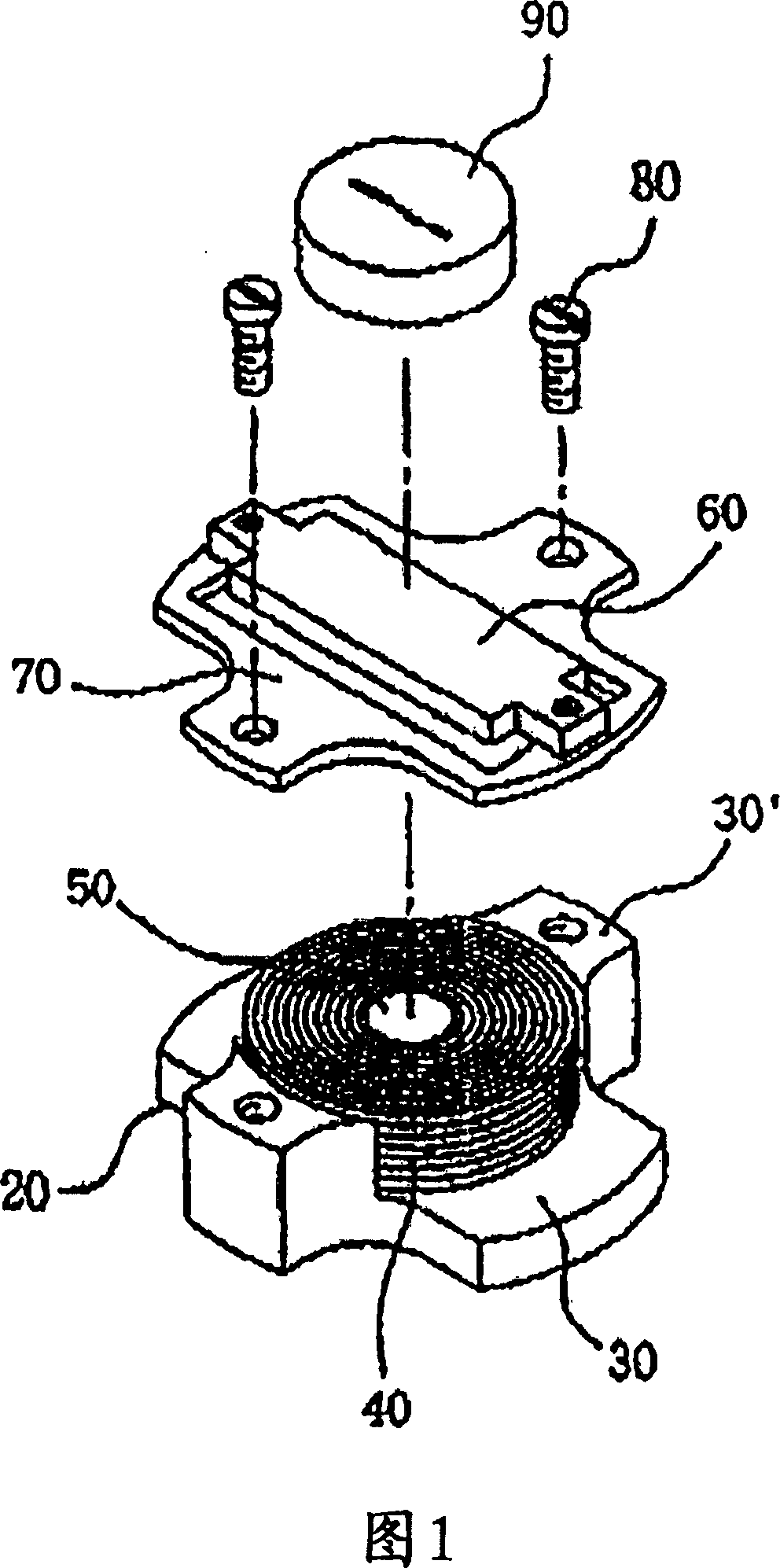

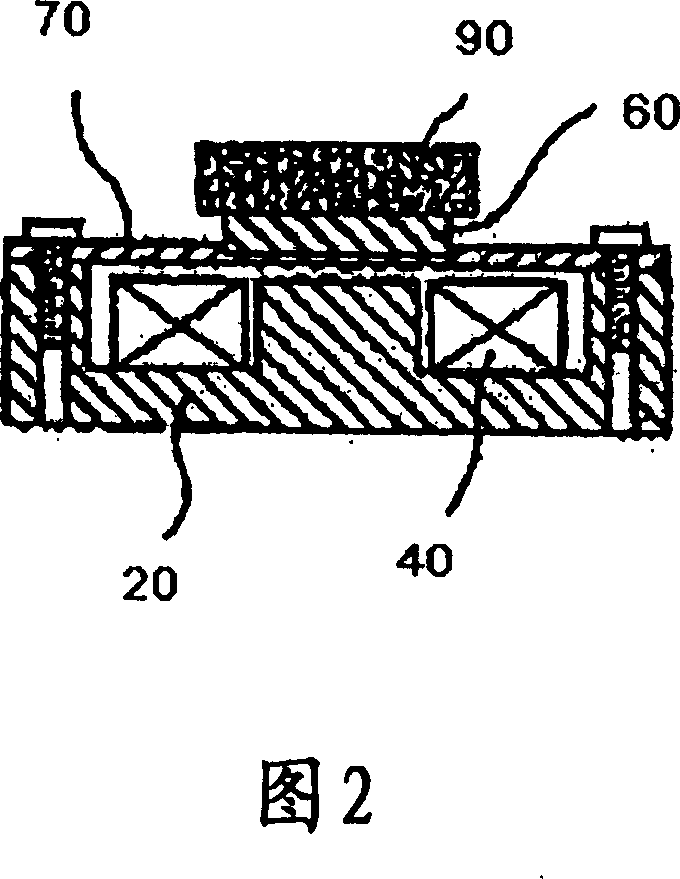

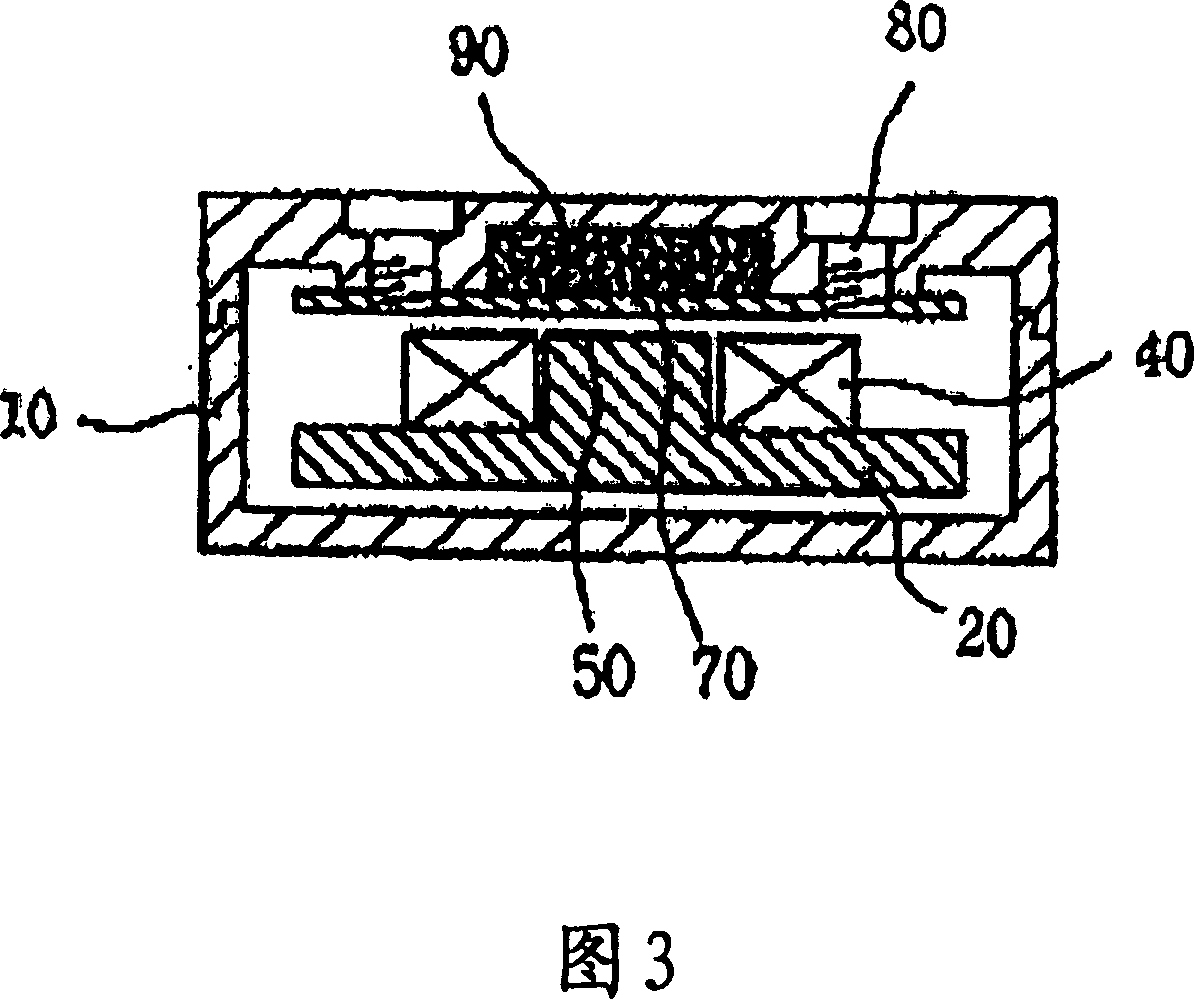

Bone conductive speaker

InactiveCN1976540AAdjustable sizeSimplify assembly workBone conduction transducer hearing devicesContact microphone transducersHuman bodyManufacturing technology

The provide manufacturing technology and method for a bone conductive speaker that enables a person to be aware and recognize audio signal, with the cranial bones of a human body, through the vibrations of a vibrator. In a bone conductive speaker, a magnet is not installed proximately to a voice coil in a configuration box, but one magnet is installed in an upper portion of an iron piece. Thus, the trouble of matching magnet directionality is eliminated, not only characteristics adjustment can be made wider by enlarging the size of the voice coil, but also strength adjustment that depends on the changes in the size of the magnet can be significantly facilitated, and the bone conductive speaker can be made small-sized and lightweight.

Owner:GOLDENDANCE

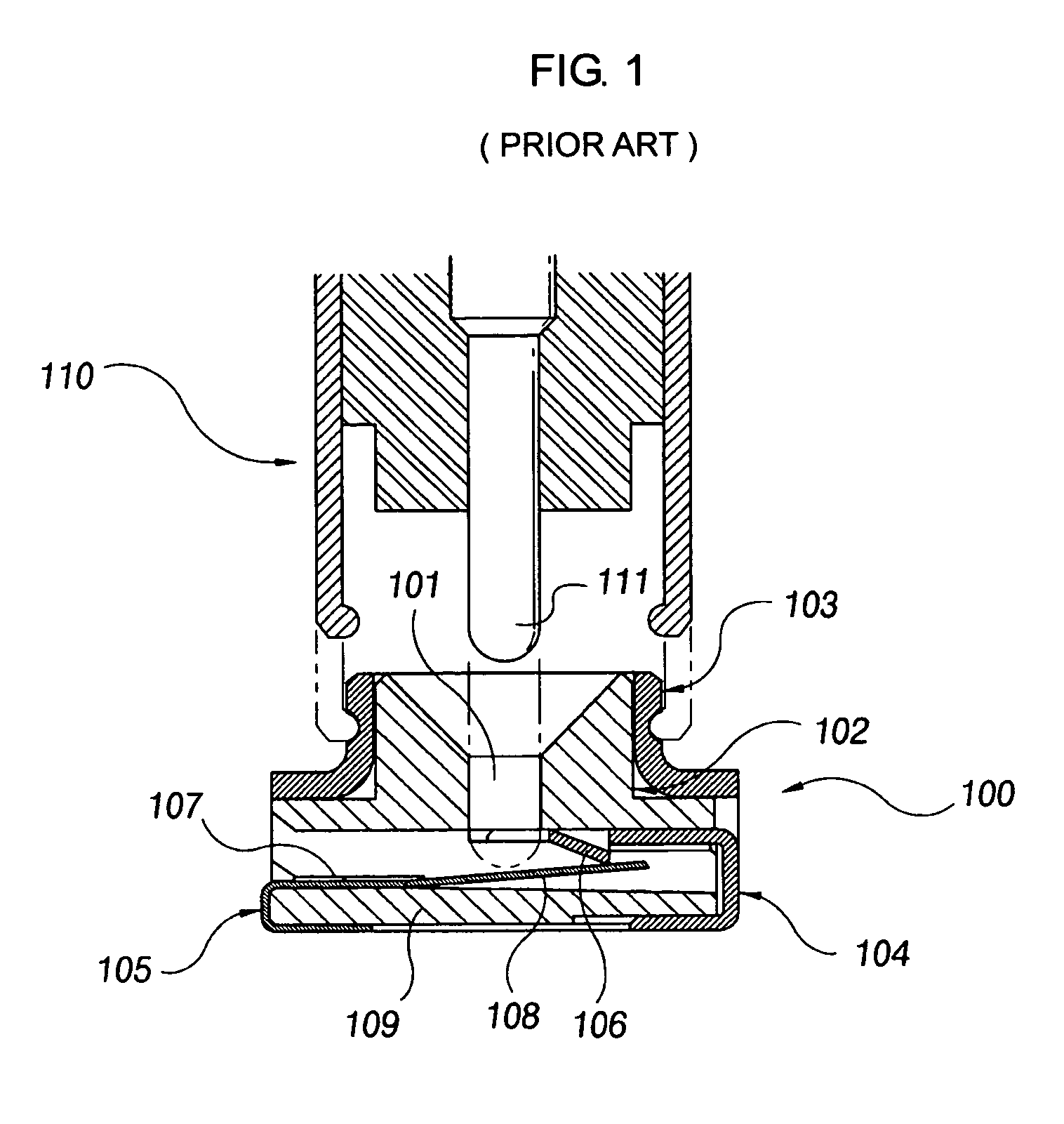

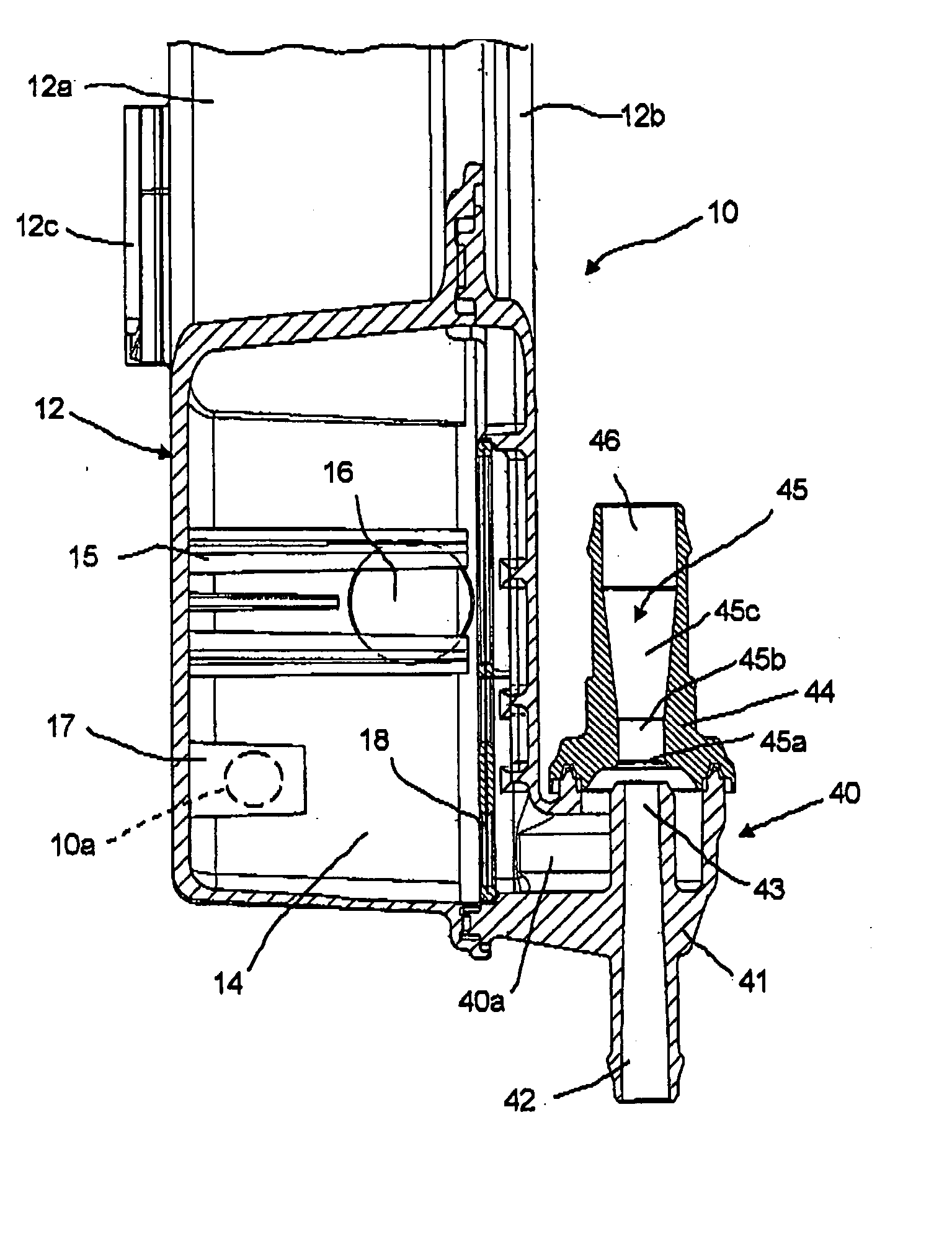

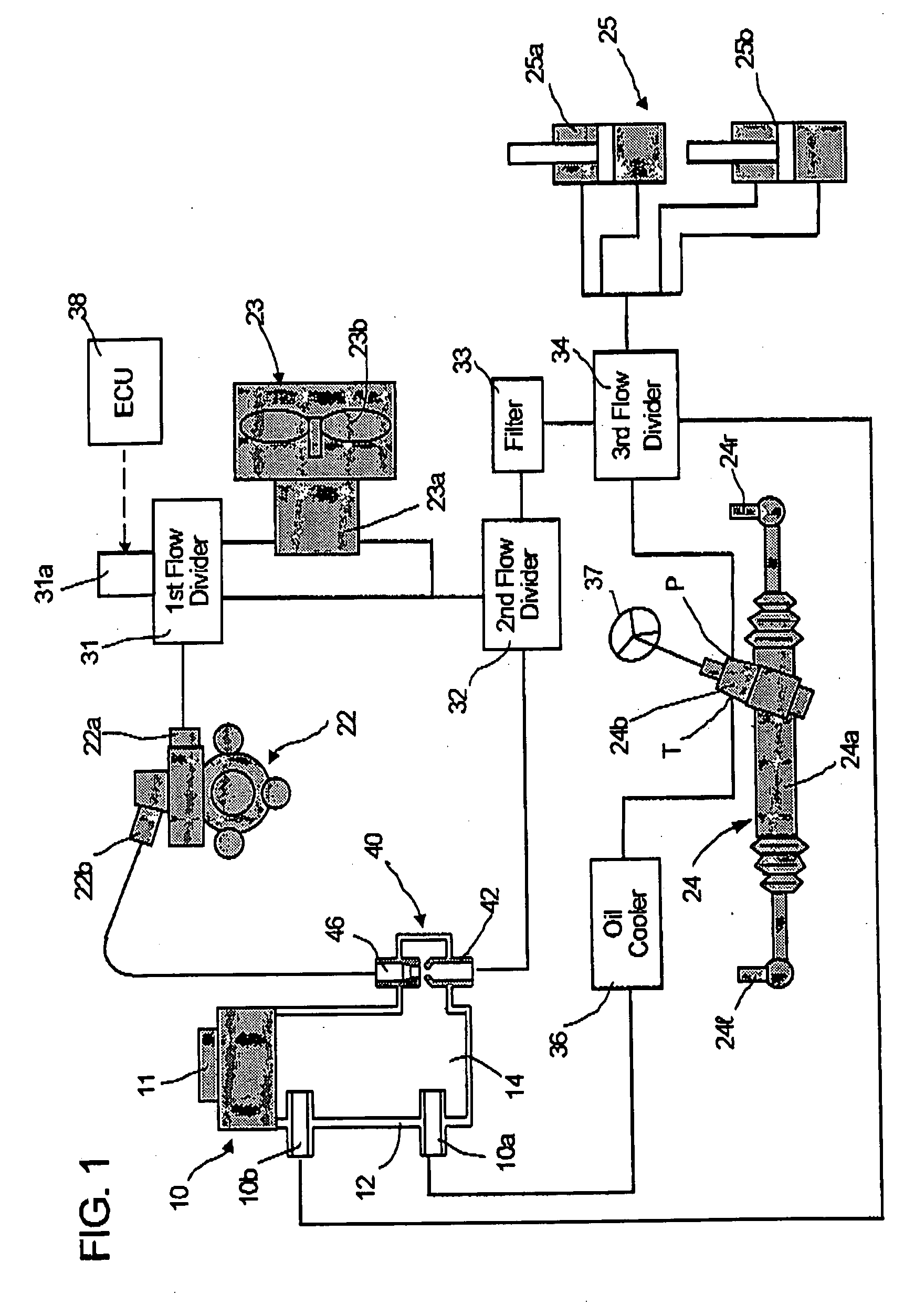

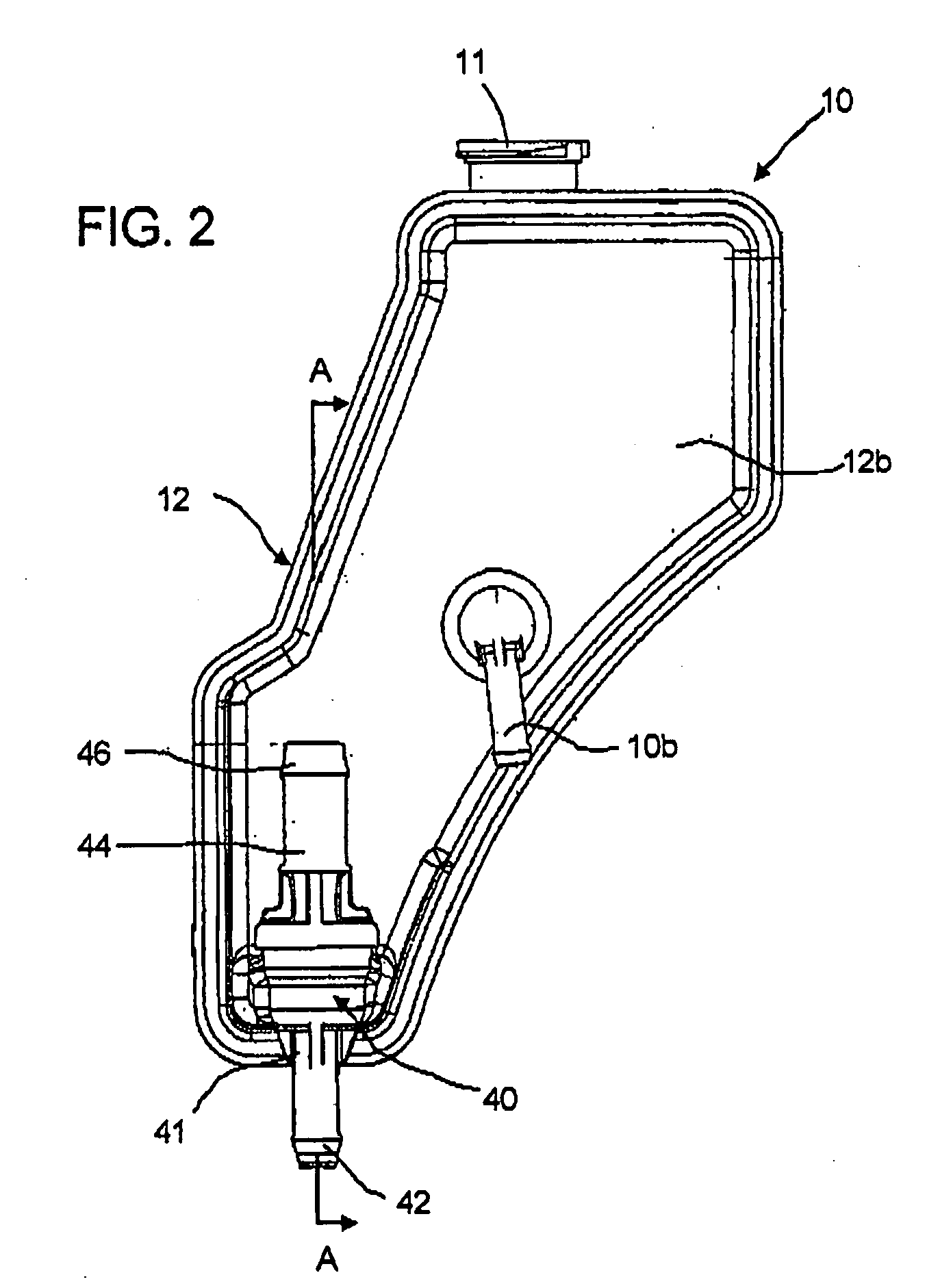

Hydraulic system, reservoir and pump suction enhancer for moror vehicle

InactiveUS20060008356A1Great suctionEasy to assembleFluid couplingsAccumulator installationsFuel tankPower steering

A hydraulic system for a motor vehicle is provided with a pump suction enhancer for boosting the suction of operating oil into a suction port of an oil pump. The pump suction enhancer is composed of a body section for defining a small chamber, a venturi tube passage exposed to the small chamber at an inner end thereof and connected to the suction port of the oil pump, and a nozzle protruding into the small chamber to face the inner end of the venturi tube passage with a space relative to the venturi tube passage in axial alignment with the same for ejecting the operating oil returned from a flow divider into the venturi tube passage thereby to plunge the operating oil from the small chamber into the venturi tube passage. The flow divider divides the operating oil discharged from the oil pump into a return flow to the pump suction enhancer and into a supply flow which passes through a power steering device to return to an oil reservoir. In a first embodiment, the pump suction enhancer is integrally formed with the oil reservoir with the small chamber opening to a reservoir chamber defined in the oil reservoir. In a second embodiment, the pump suction enhancer is provided as a discrete component separated from the oil reservoir, oil pump and the flow divider.

Owner:JTEKT CORP

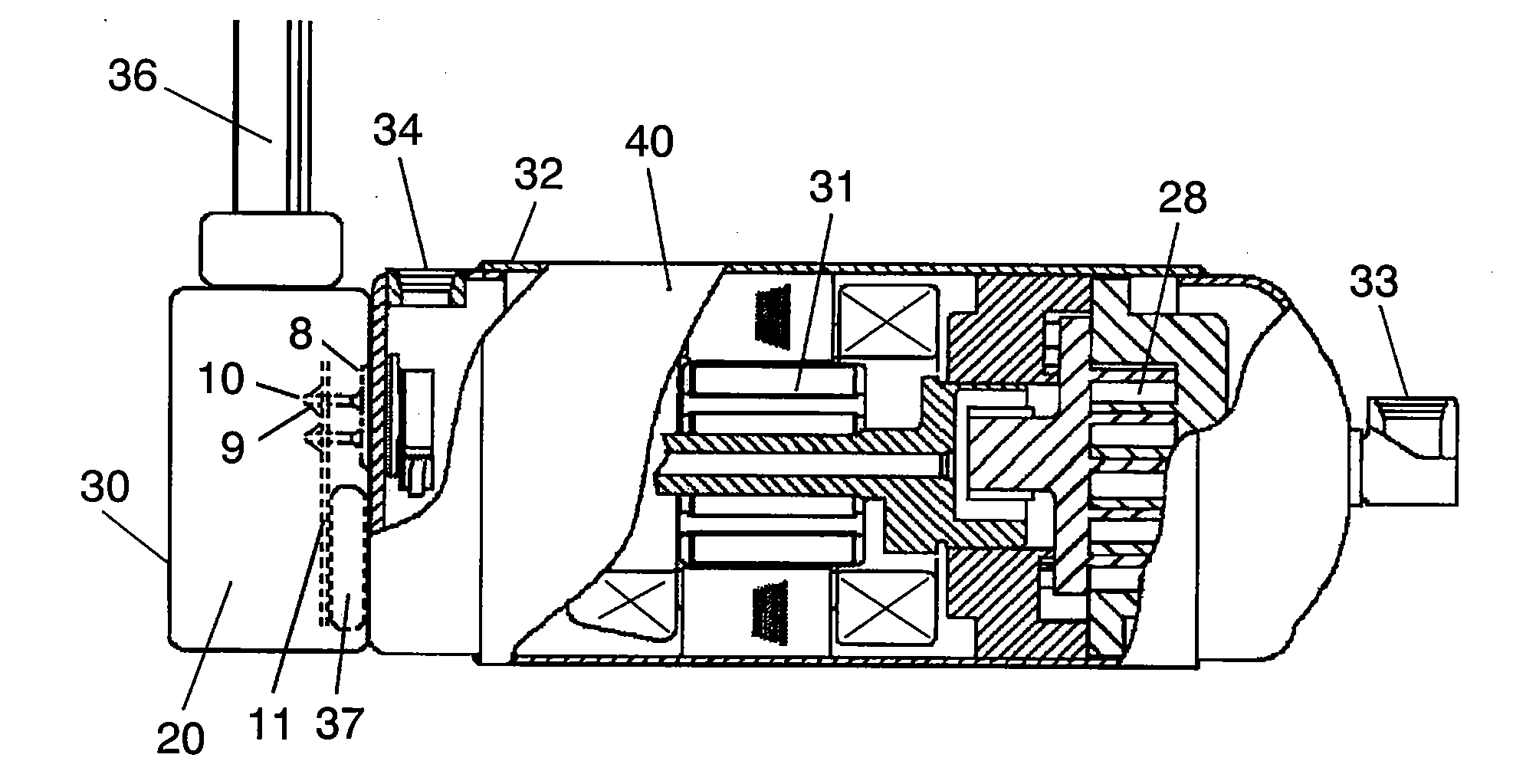

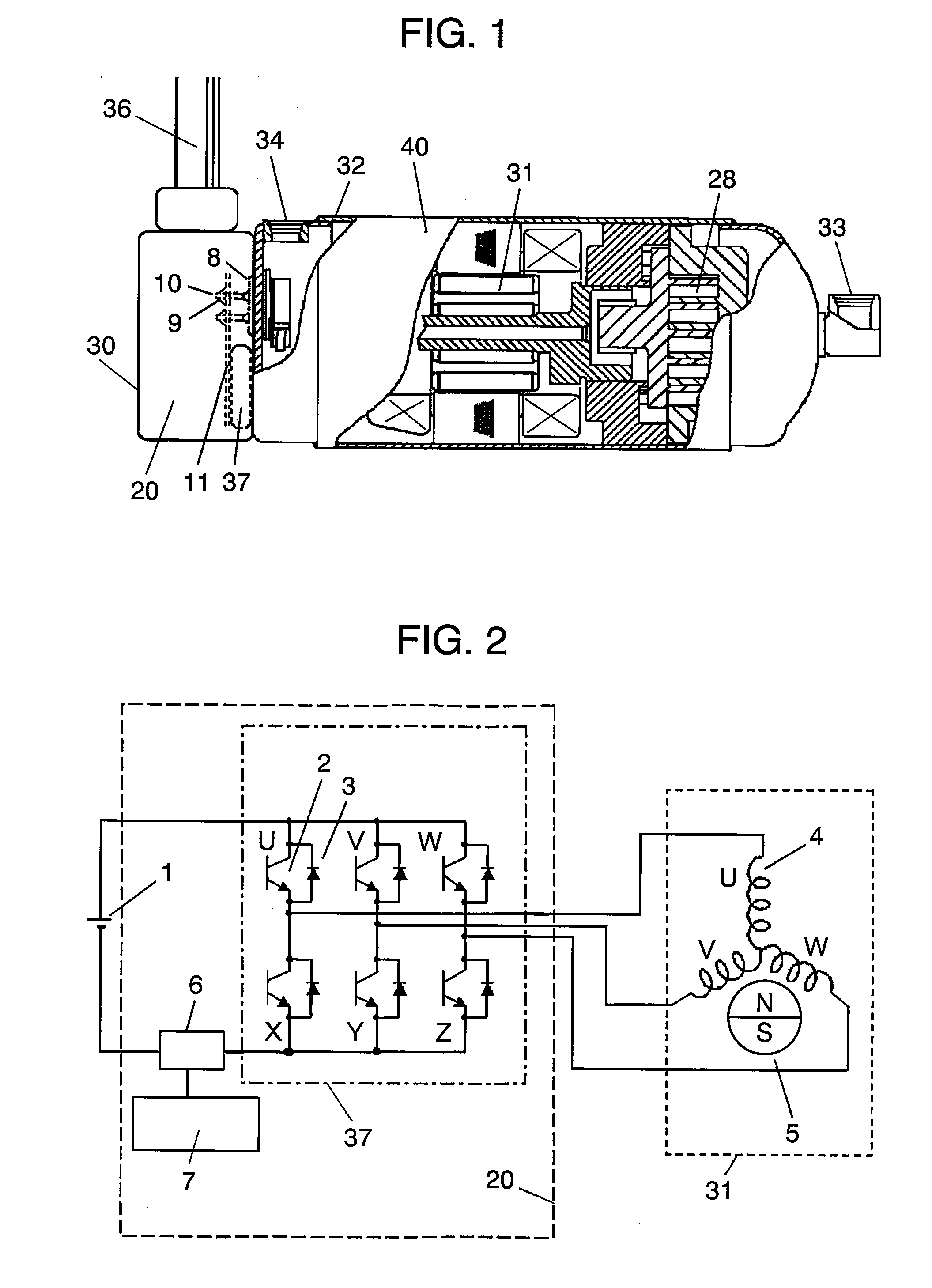

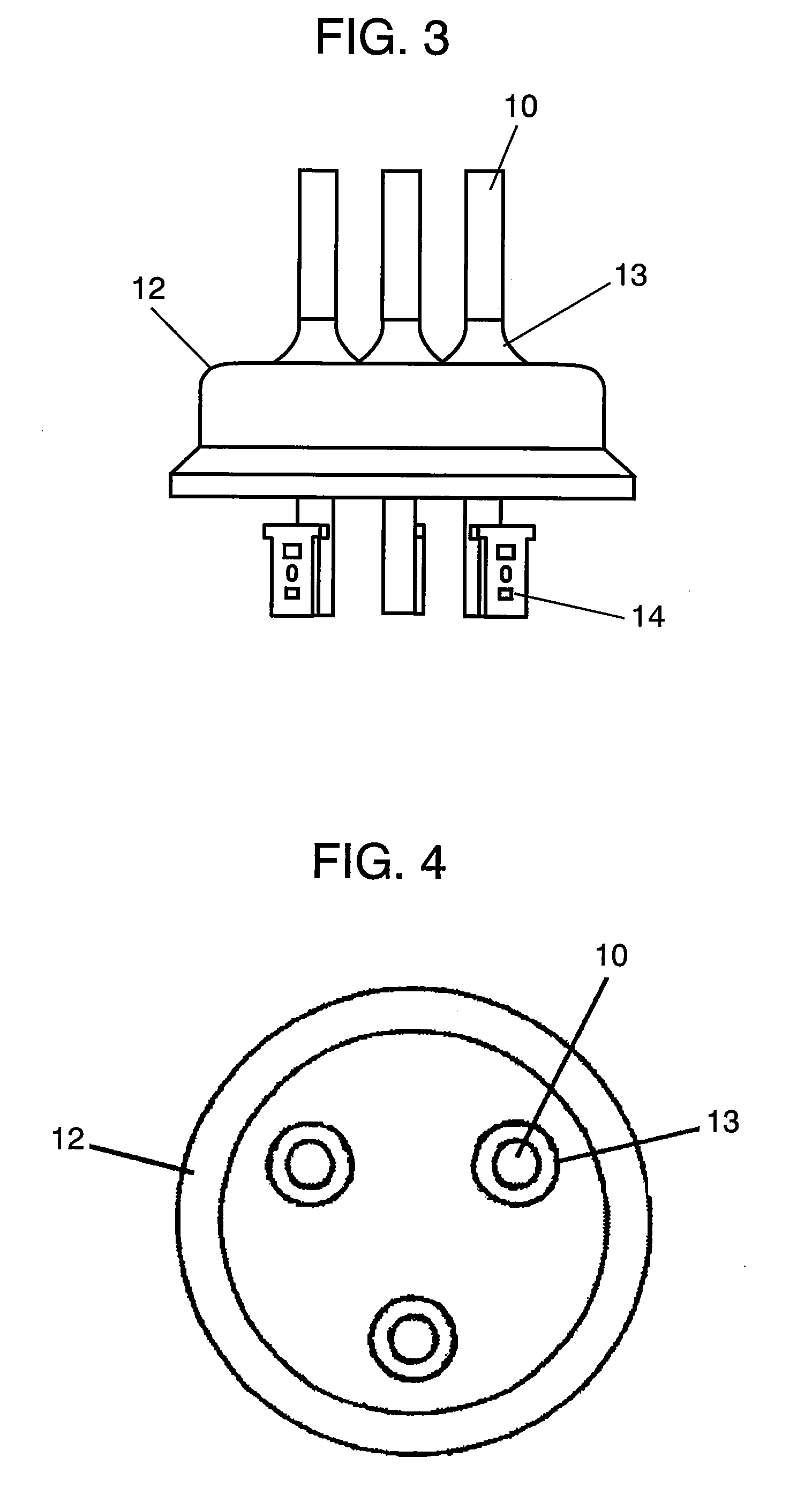

Electrically Driven Compressor Integral with Inverter Device, and Vehicle Air Conditioner Where the Compressor is Used

InactiveUS20080095646A1Simplify assembly workQuickly and easily obtainedRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsThermal conductivityElectricity

The electrically driven compressor integrally formed with an inverter device contains compression mechanism section (28); motor (31) as a power source of the compression mechanism section; metal housing (32) for accommodating the compression mechanism section and the motor; inverter device (20), which is disposed outside the metal housing, for supplying electricity to the motor; and electric connection terminal (8) for electrically connecting between an inside and an outside of the metal housing. The electric connection terminal has pin terminal (10) formed of a metal with low thermal conductivity and a metal with high thermal conductivity plated on the metal with low thermal conductivity. The pin terminal is electrically connected to the inverter device by solder (9).

Owner:PANASONIC CORP

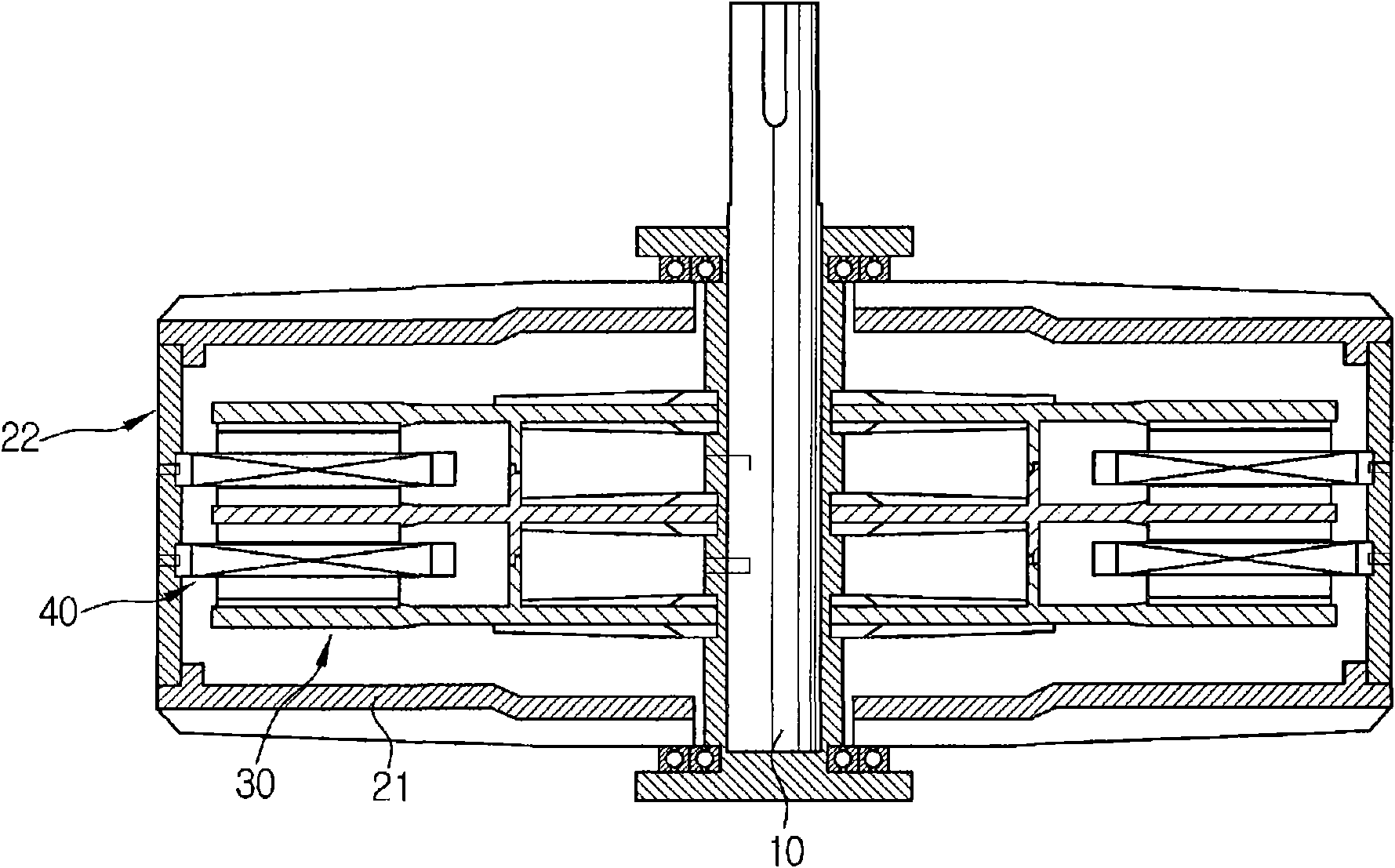

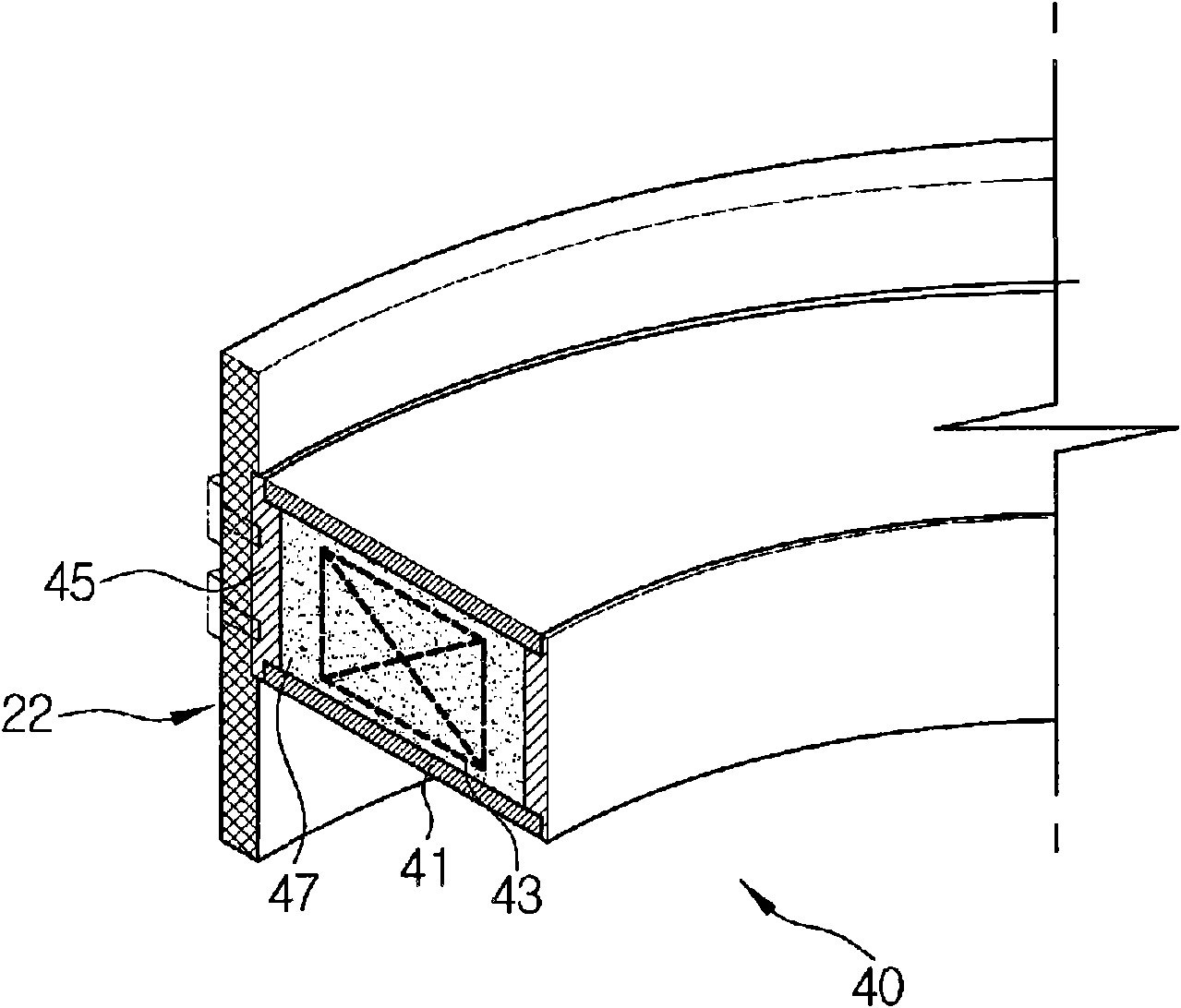

Axial flux permanent magnet (afpm) coreless multi-generator and motor

InactiveCN101578749AAvoid inefficiencySimplify assembly work and processMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsAxial fluxMagnet

The present invention relates to an axial flux permanent magnet (AFPM) coreless multi-generator and motor. The present invention is characterized in that the stator includes coils arranged between upper and lower jig plates made of a non-magnetic material, cooling insulating oil is filled in a space where the coils are mounted between the upper and lower jig plates and is sealed by both lateral plates, and one of the both lateral plates is fixedly coupled to the housing of the generator so as to allow the housing to perform thermal conduction. Also, the rotor includes magnets arranged on a rotor disc in a circular arc shape and a yoke element formed integrally with the rotor disc near a central portion thereof in such a fashion as to vertically protrude by a predetermined height. The rotor disc is fixedly mounted to the rotary shaft, and the yoke element is engaged with a yoke element of another rotor correspondingly adjacent to the rotor so as to allow the engaged yoke elements to serve as a passageway of a magnetic field. The rotor and stator are configured in a multi- structure. The present invention can be applied to a motor having the same structure as that of the generator.

Owner:TAE CHANG N E T

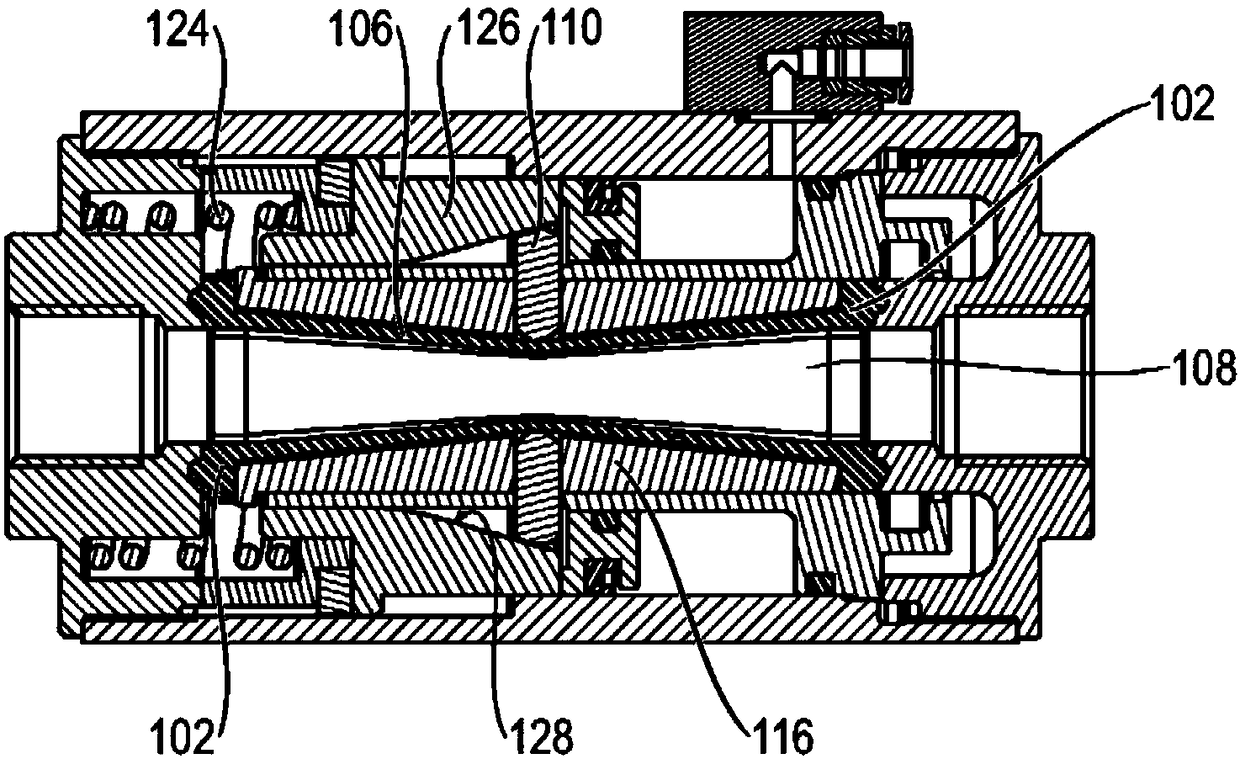

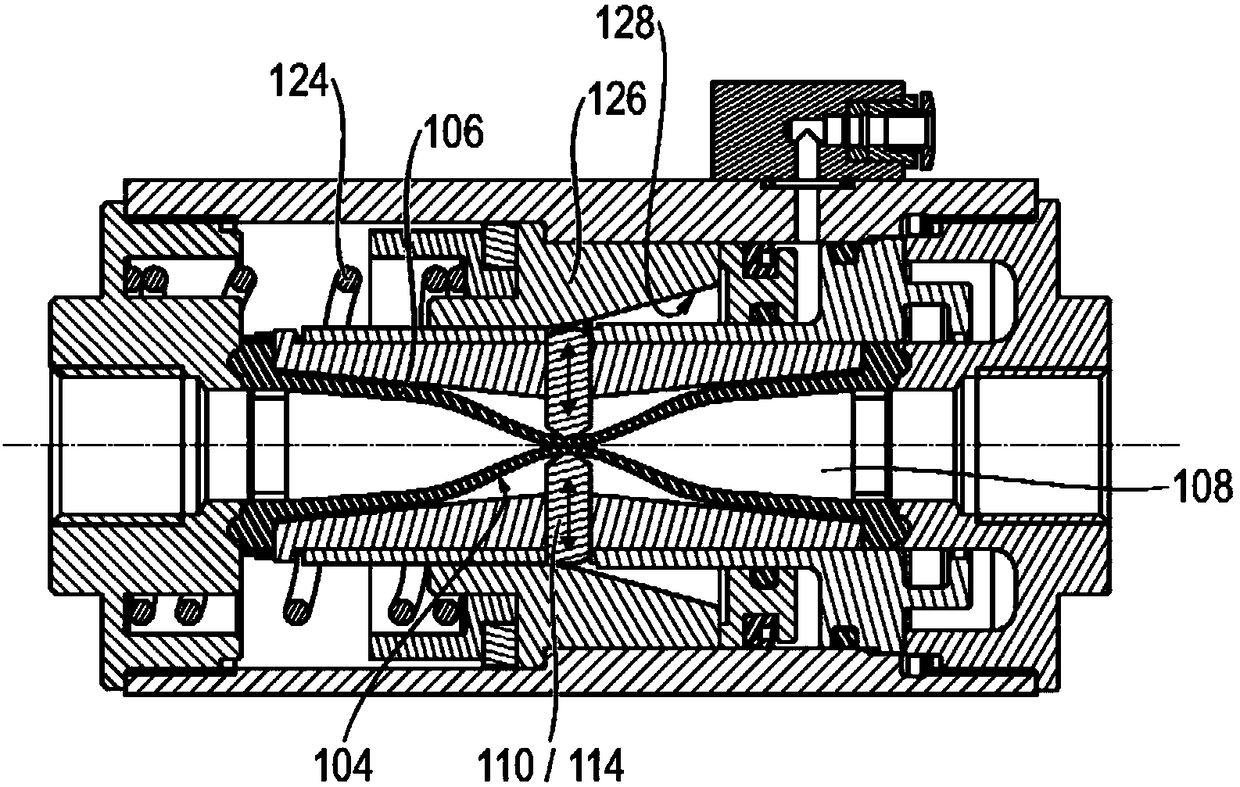

Hybrid drive speed change device

InactiveUS20120090425A1Reduce axial sizeSimplify assembly workGearingFluid actuated clutchesElectric machineEngineering

To provide a hybrid drive speed change device in which a rotation sensor can be disposed appropriately from the viewpoint of reducing the axial dimension of the device. A rotary electric machine MG is disposed coaxially with an input shaft M, and includes a stator St and a rotor Ro provided radially inwardly of the stator St. An oil pump 18 includes a pump case 90, 91 in which a pump chamber 18a is formed, and a pump rotor 18b rotatably housed in the pump chamber 18a. The pump rotor 18b is disposed coaxially with the input shaft M. A rotation sensor 19 is disposed radially outwardly of the pump chamber 18a and radially inwardly of the stator St of the rotary electric machine MG, and disposed to overlap the oil pump 18 as seen from the radial direction of the input shaft M.

Owner:AISIN AW CO LTD

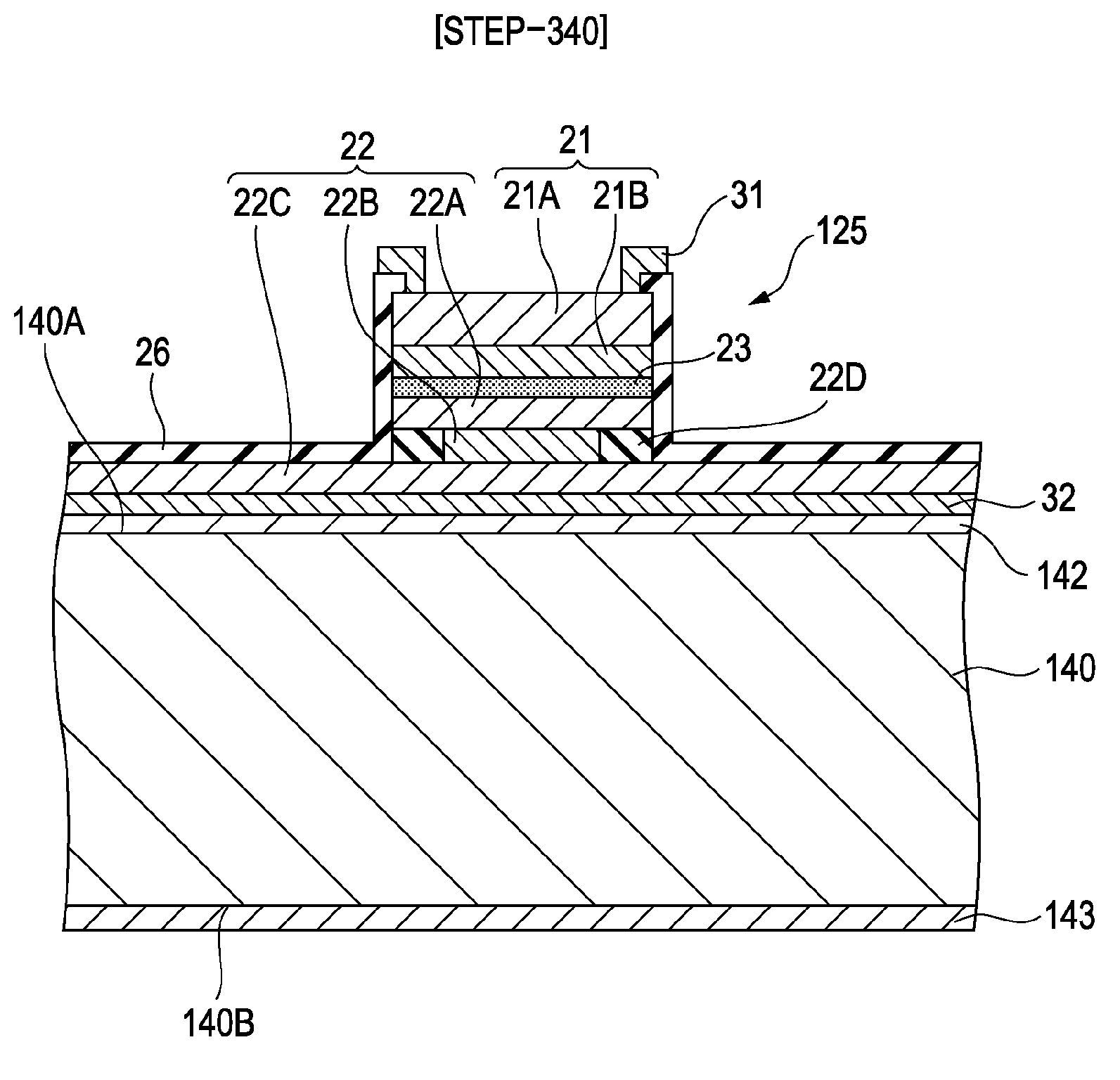

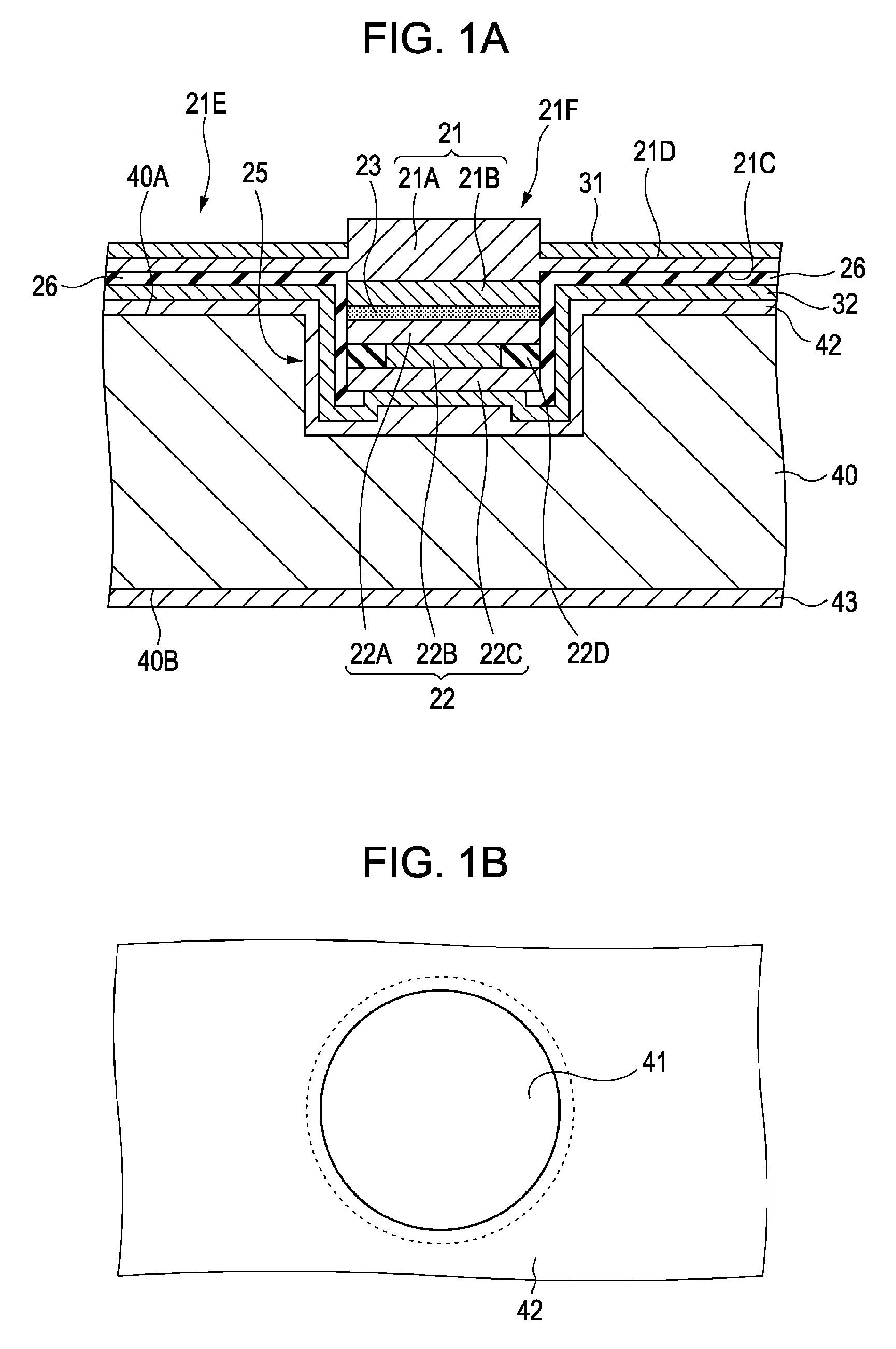

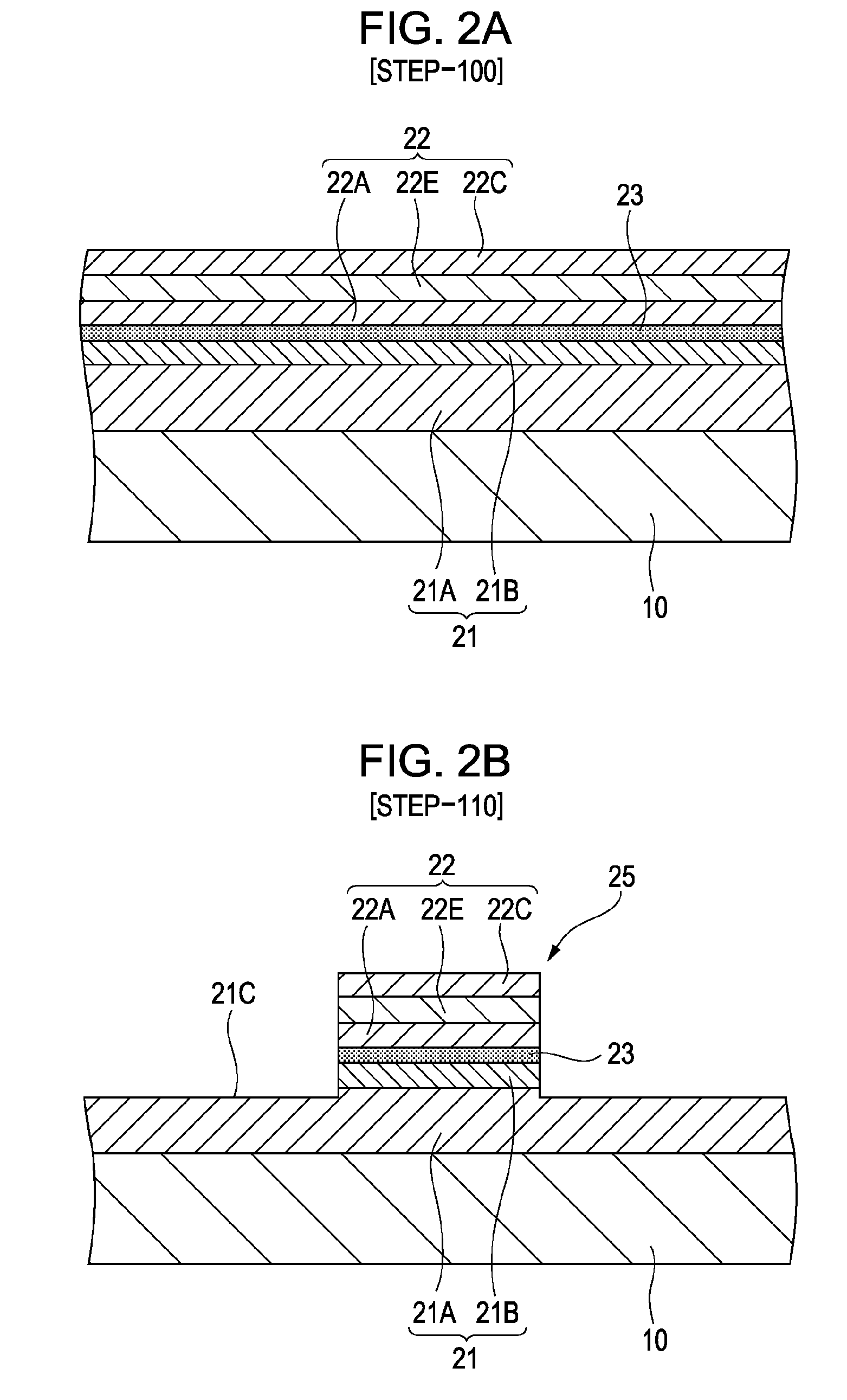

Light-emitting element assembly and method for manufacturing the same

ActiveUS20090168825A1Emission Reduction EfficiencyExtended operating temperature rangeLaser detailsSolid-state devicesConductive materialsEngineering

A light-emitting element assembly includes a support substrate having a first surface, a second surface facing the first surface, a recessed portion, and a conductive material layer formed over the first surface and the inner surface of the recessed portion, and a light-emitting element. The light-emitting element has a laminated structure including a first compound semiconductor layer, a light-emitting portion, and a second compound semiconductor layer, at least the second compound semiconductor layer and the light-emitting portion constituting a mesa structure. The light-emitting element further includes an insulating layer formed, a second electrode, and a first electrode. The mesa structure is placed in the recessed portion so that the conductive material layer and the second electrode are in at least partial contact with each other, and light emitted from the light-emitting portion is emitted from the second surface side of the first compound semiconductor layer.

Owner:SONY CORP

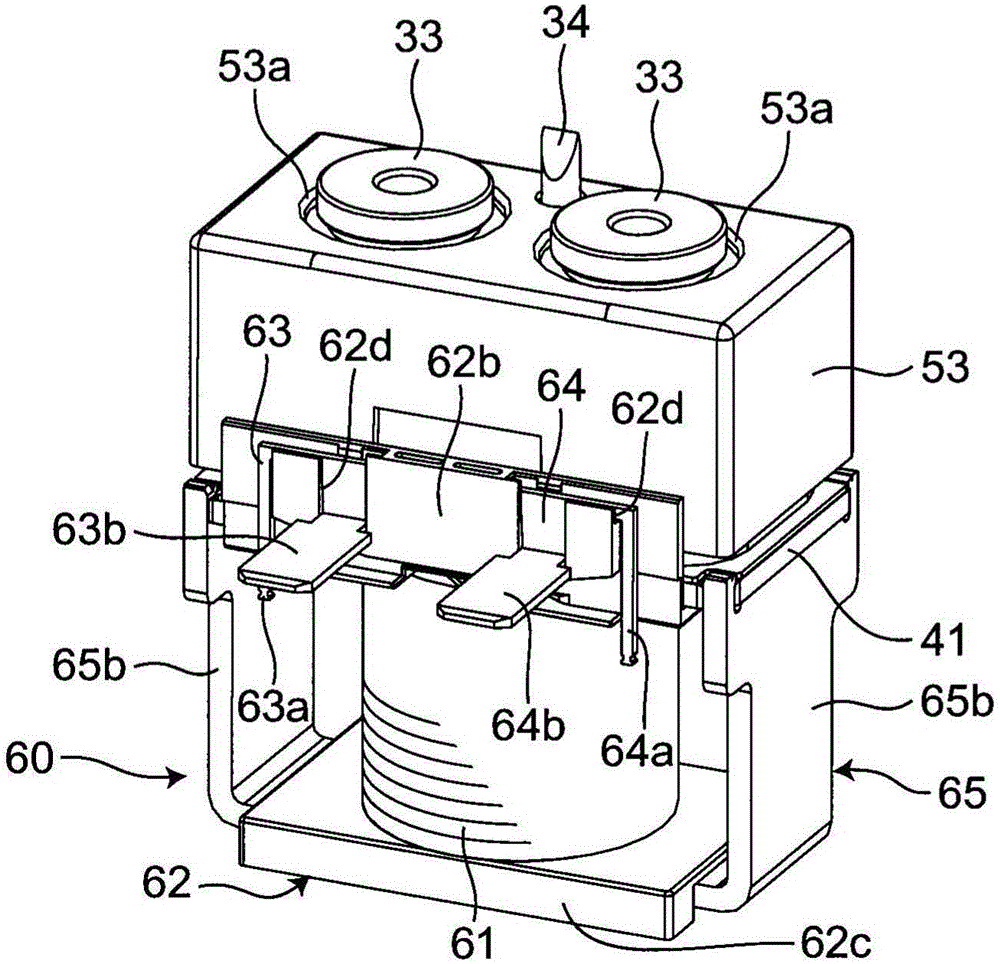

Contact switching device

ActiveCN106504948ASimplify assembly workIncrease productivityElectromagnetic relay detailsEngineeringPower flow

There is provided a contact switching device which has high productivity and in which operation characteristics hardly vary. The contact switching device includes an electromagnetic unit (60), a holder (35), a movable shaft (43), a movable yoke (48), a movable contact piece (49) having movable contacts (49a) at both ends, fixed contacts (33a), and a fixed yoke (51). At the time of excitation of the electromagnetic unit (60), the movable shaft (43) moves to the holder (35) side along a direction of an axis center. A magnetic circuit is formed of the fixed yoke (51) and the movable yoke (48) due to a magnetic field generated by a current that flows into the movable contact piece (49) as a result of the movable contacts (49a) coming into contact with the fixed contacts (33a). The movable yoke (48) is then attracted to the fixed yoke (51).

Owner:ORMON CORPORATION

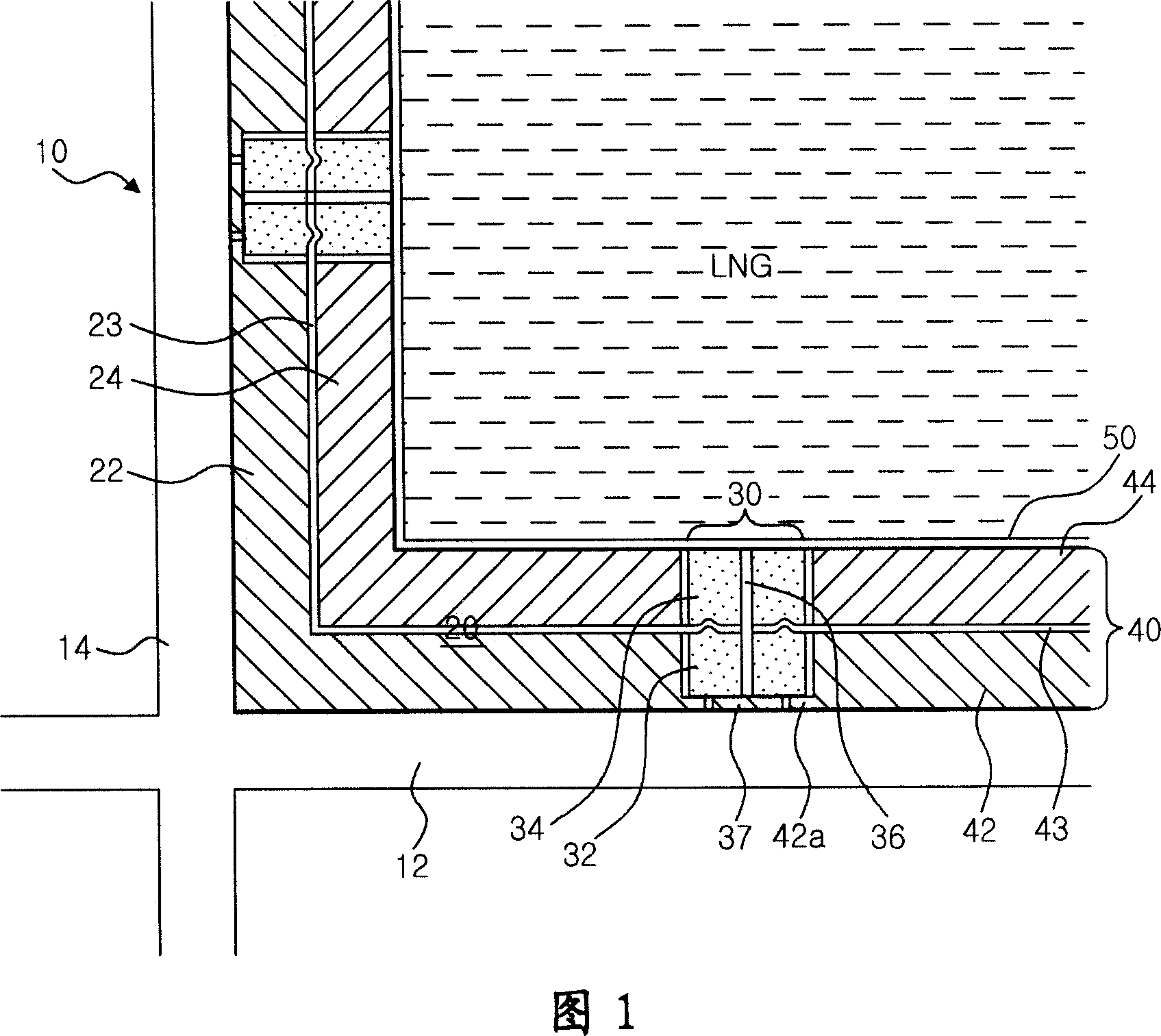

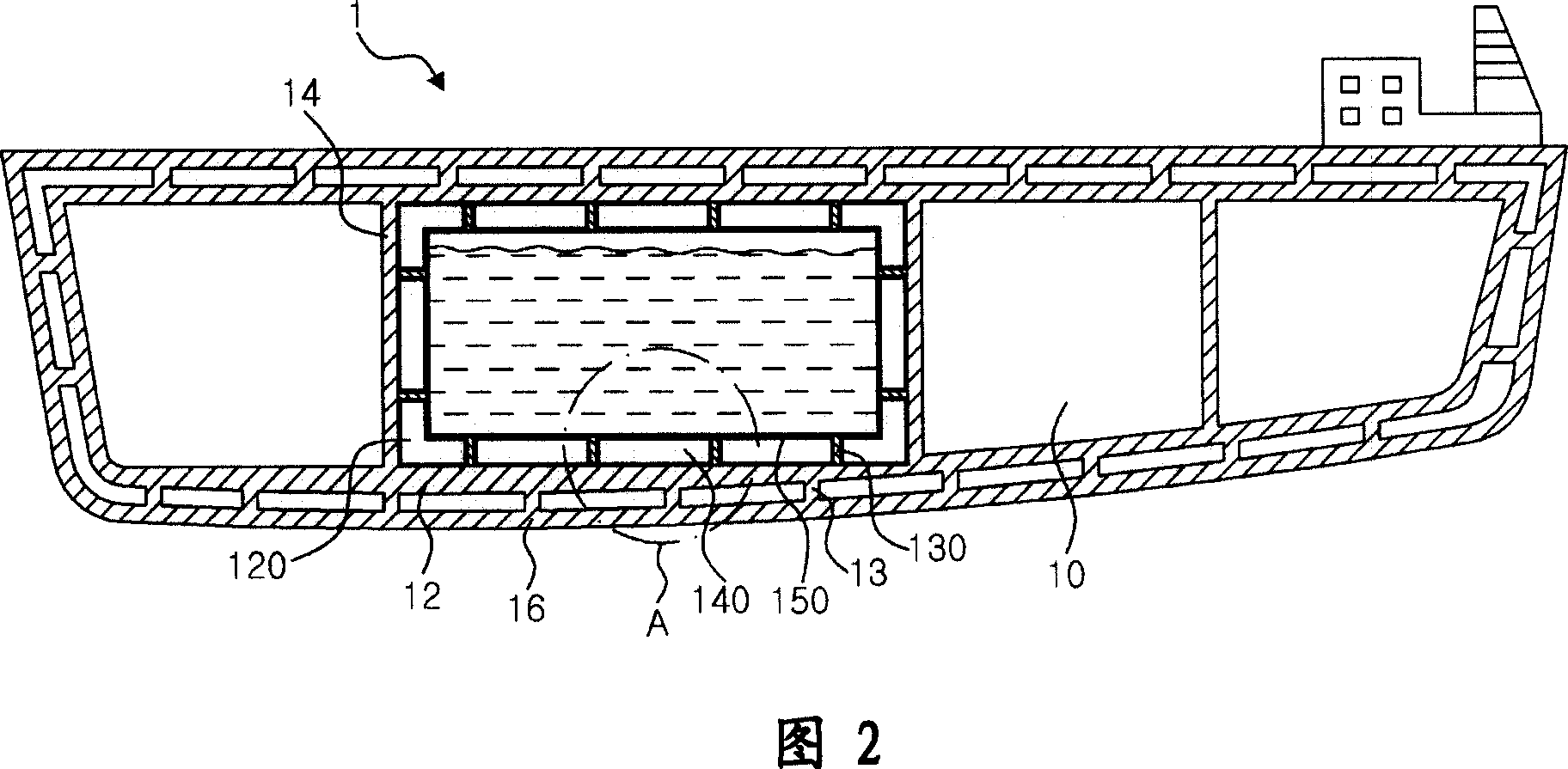

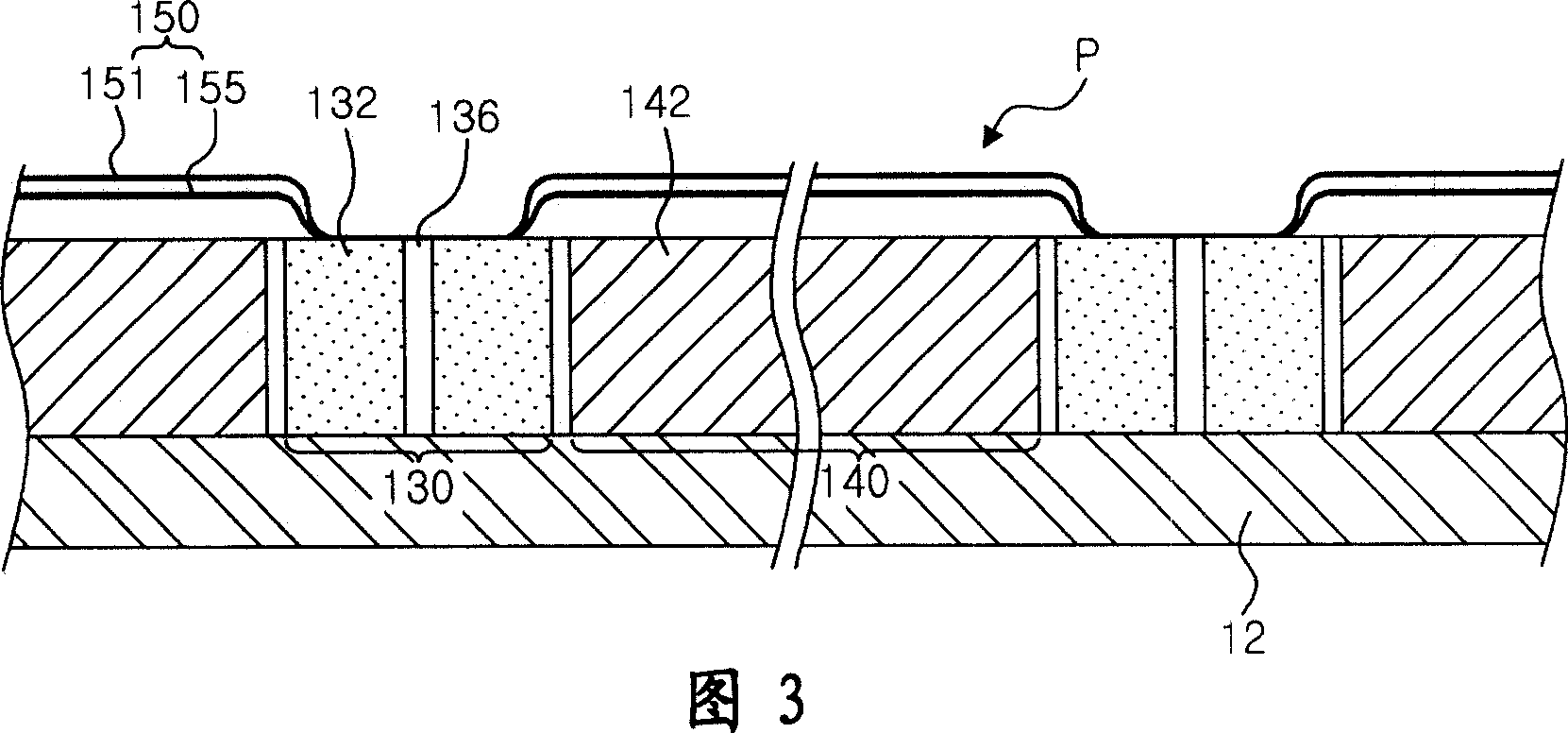

Liquefied natural gas storage tank having improved insulation structure and method of manufacturing the same

ActiveCN101059202ASimple configurationRemove complexityVessel mounting detailsVessel manufacturingPetroleum engineeringStorage tank

The invention relates to a liquefied natural gas storage tank with improved separation structure and a manufacture method thereof; furthermore, the liquefied natural gas storage tank is arranged in the structure such as a ship, a ground storage tank, a vehicle and similar objects. The invention aims at providing the liquefied natural gas storage tank with the improved separation structure and the manufacture method thereof; wherein, the sealing reliability can be increased by simplifying the structure of the separation body and a sealing wall and the assembly mechanism between the sealing walls and improving the assembly operation; furthermore, the time that is used for constructing the storage tank can be reduced by simplifying the manufacture structure and the process. In order to achieve the objects of the invention, the invention provides the liquefied natural gas storage tank with the improved separation structure. The invention comprises the separation wall which is arranged on the internal wall of the storage tank, the sealing wall which is arranged on the upper surface of the separation wall and is directly contacted with the liquefied natural gas, and a plurality of anchorage structures which are arranged on the internal wall of the storage tank so as to supporting the sealing wall by passing through the separation wall.

Owner:KC LNG TECH CO LTD ENTIRE RIGHT

Automotive front body structure

A front body structure of an automobile, capable of preventing damage to exterior trim parts and the like in light collision situations, and at the same time, normally fixing the exterior trim parts to the front bumper with an appropriate fastening force. A lower bracket (17) made of stamped and formed steel plate is provided between the lower part of the exterior trim and the upper part of the front bumper, and the lower bracket includes a bracket body (61) having a substantially Z-shaped cross-section and a The clamping portion (62) is made of stamped and formed steel sheet and has a substantially U-shaped cross-section. The clamping part (62) includes a first clamping part (62) fixed on the upper wall part (61a) of the bracket body (61) and cooperates with the first clamping part (62a) to clamp the inner panel (22) The second clamping member (62b) of the rib (22a). The clamping portion (62) of the lower bracket (17) is provided with a pair of clamping force generating mechanisms (68) in a transversely spaced relationship, and each clamping force generating mechanism includes a stepped bolt (65), a coil spring (66) and Nut (67). Thus, a relatively large elastic clamping force is generated to clamp the rib (22a) of the front trim (8) with the clamping portion (62).

Owner:HONDA MOTOR CO LTD

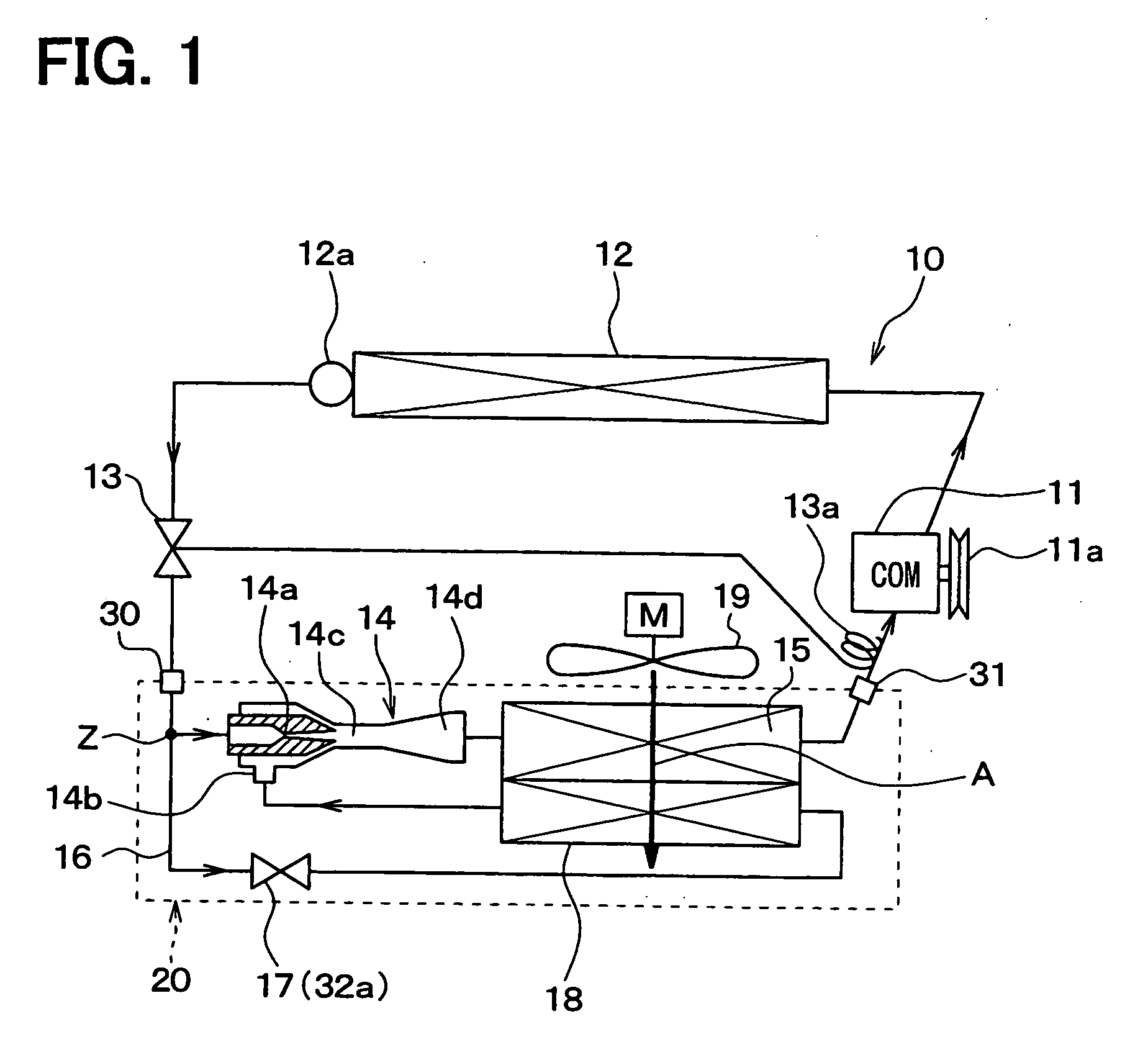

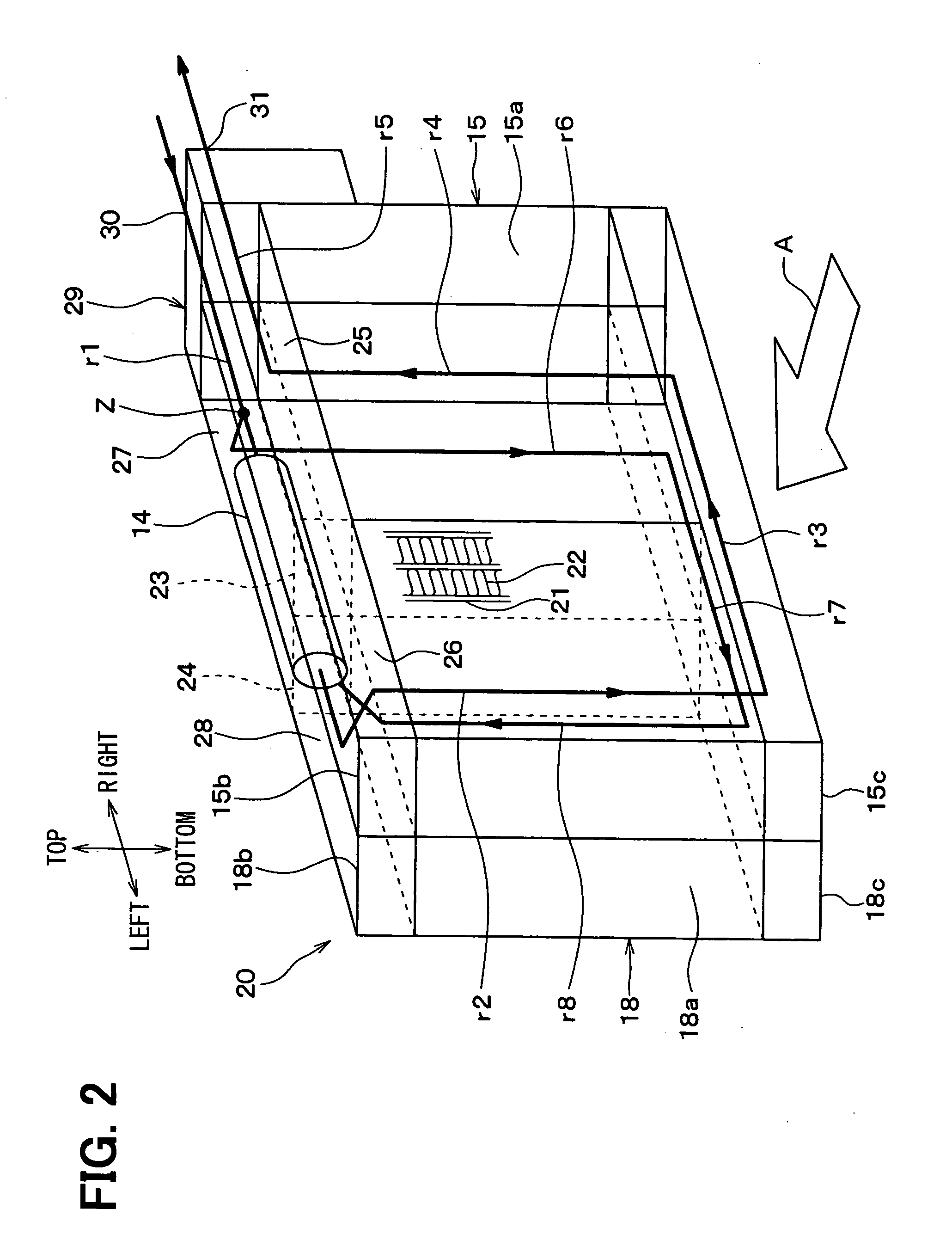

Evaporator unit

InactiveUS20090107171A1Improve productivityReduce manufacturing costCompression machines with non-reversible cycleEvaporators/condensersInjectorEvaporator

In an evaporator unit for a refrigerant cycle device, an evaporator is connected to an ejector to evaporate refrigerant to be drawn into a refrigerant suction port of the ejector or the refrigerant flowing out of the outlet of the ejector. The evaporator includes a plurality of tubes in which the refrigerant flows, and a tank configured to distribute the refrigerant into the tubes or to collect the refrigerant from the tubes. The ejector is located in the tank, and the nozzle portion is brazed to the tank to be fixed into the tank. The tank may be a header tank directly connected to the tubes or may be a separate tank separated from the header tank.

Owner:DENSO CORP

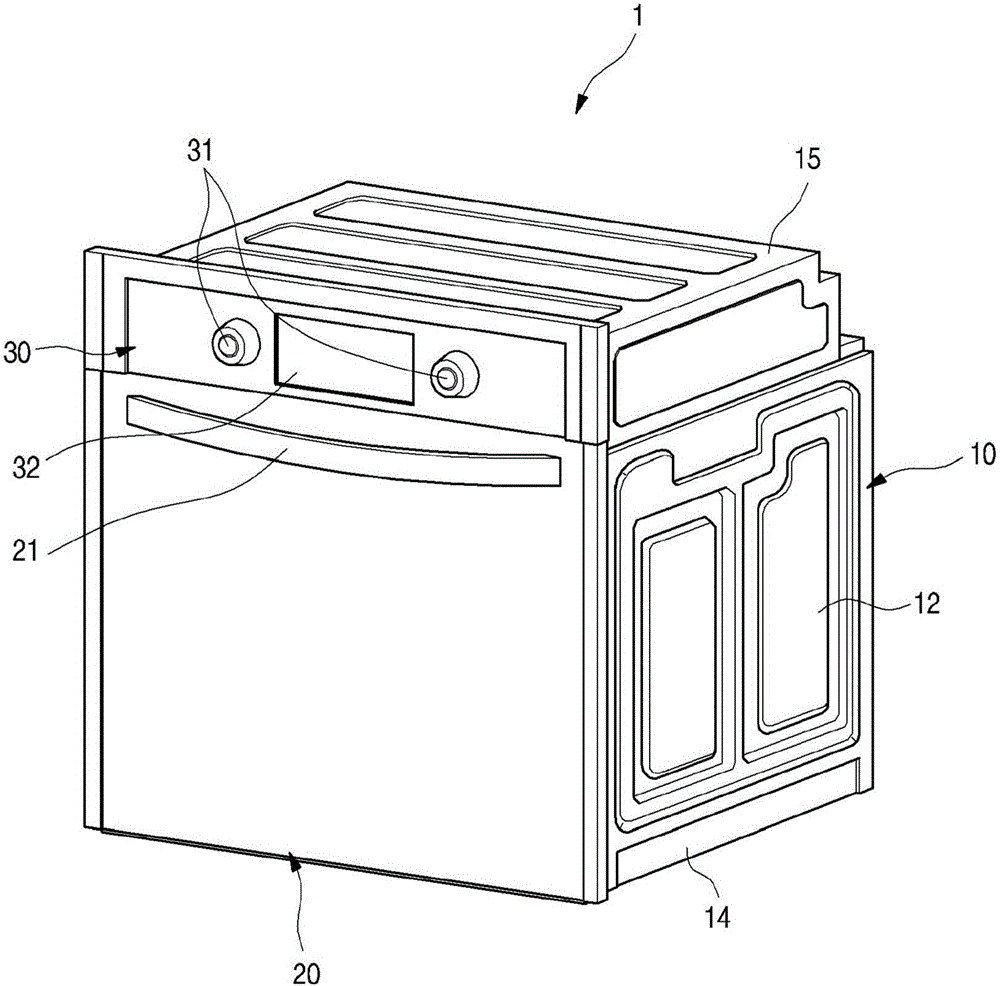

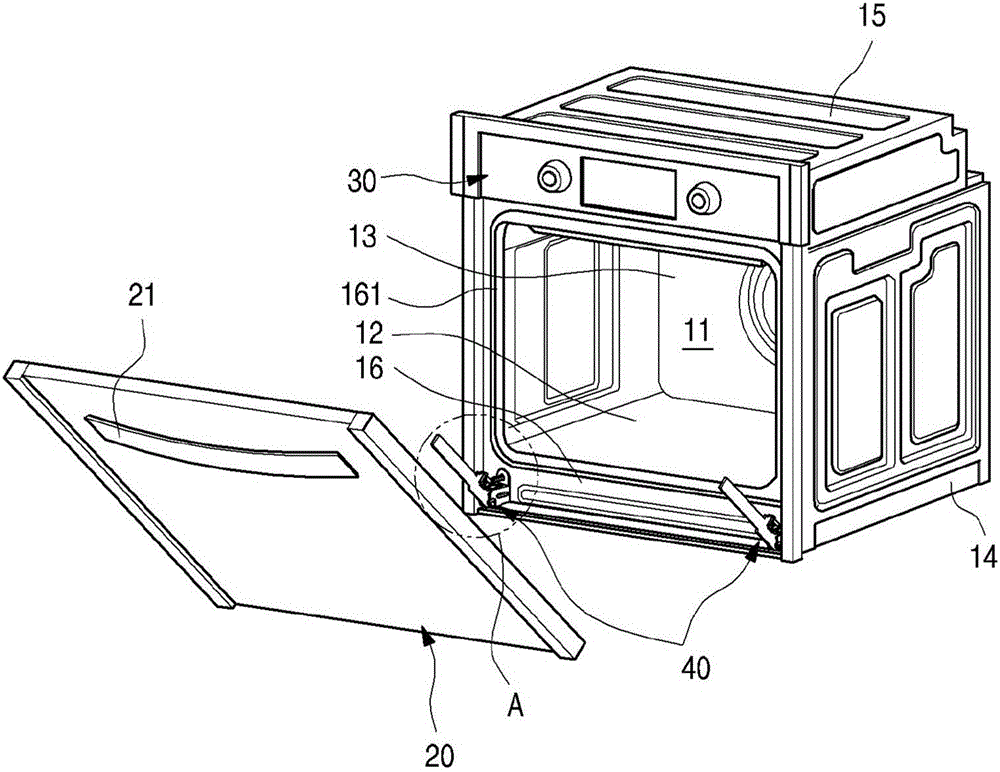

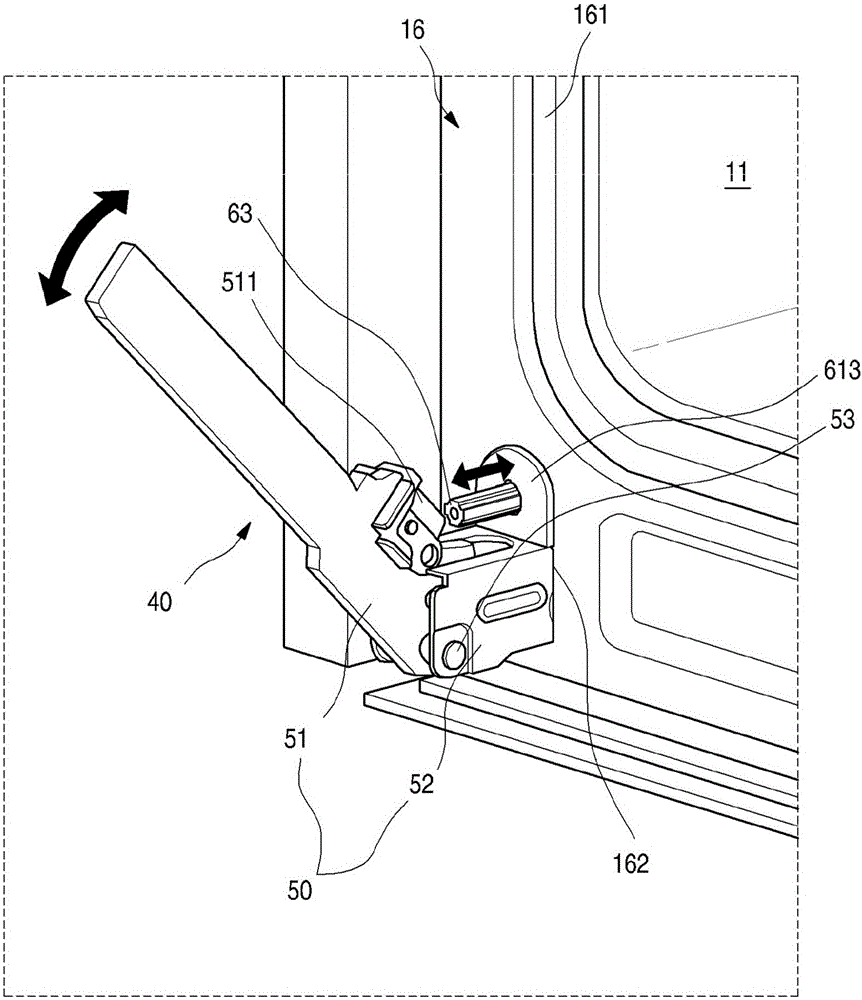

Hinge apparatus and oven with the same

ActiveCN105986724ANo need to change the internal structureSimple structureDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

An oven includes a main body having a cooking space; a door configured to open and close the cooking space; and a hinge apparatus configured to connect the main body with the door, and at which the door is rotatably installed. The hinge apparatus includes a hinge unit which includes a hinge body fixed to the main body, and a hinge lever which is coupled to the door and also rotatably shaft-coupled to the hinge body by a hinge pin; and a damping unit which is installed at an outer surface of the hinge body within a radius of rotation of the hinge lever, and is in contact with the hinge lever to reduce a rotating speed of the hinge lever when the hinge lever is rotated.

Owner:LG ELECTRONICS INC

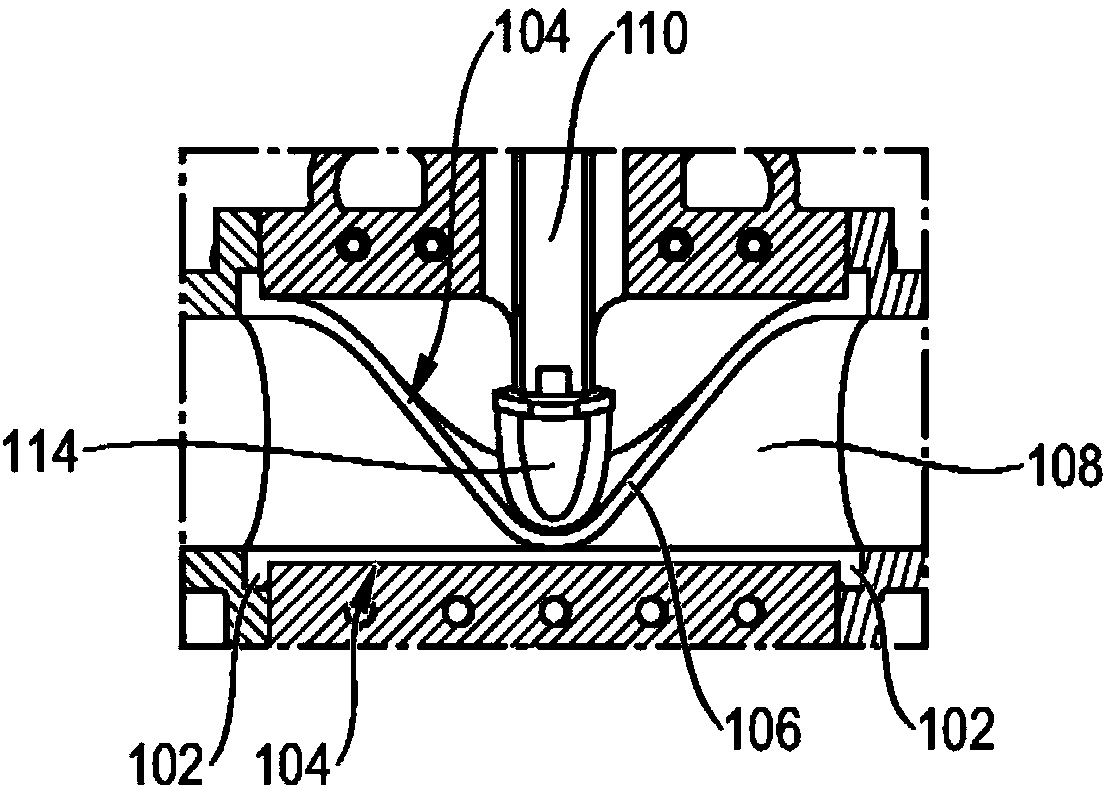

Pinch valve

ActiveCN108223831AIncreased durabilityAccurate operationDiaphragm valvesOperating means/releasing devices for valvesPinch valveEngineering

The invention relates to a pinch valve (100), comprising a tubular valve member (106), which has a flexible peripheral wall (104) and defines a flow channel (108) for a fluid between two connection elements (102), and a closing device (110) arranged outside the peripheral wall (104), which is switchable between an open position where the flow channel (108) defines a fluid-permeable state, and a closed position where the flow channel (108) defines a fluid-closed state, characterized in that the closing device (110) has a stopping block (112) which restricts the transfer of the closing device (110) to the closed position.

Owner:FESTO AG & CO KG

Hinge connector, and circuit board connected to connector

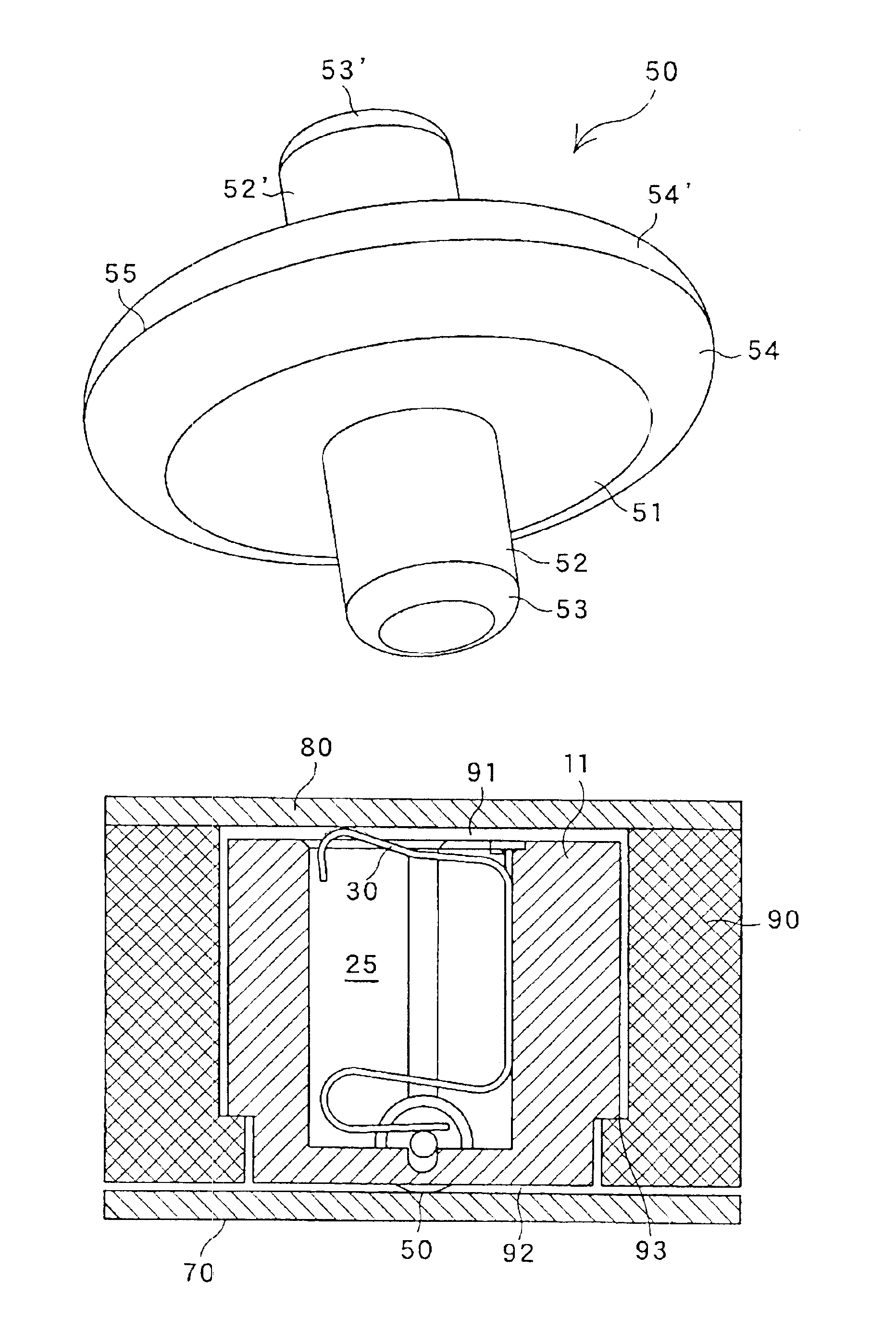

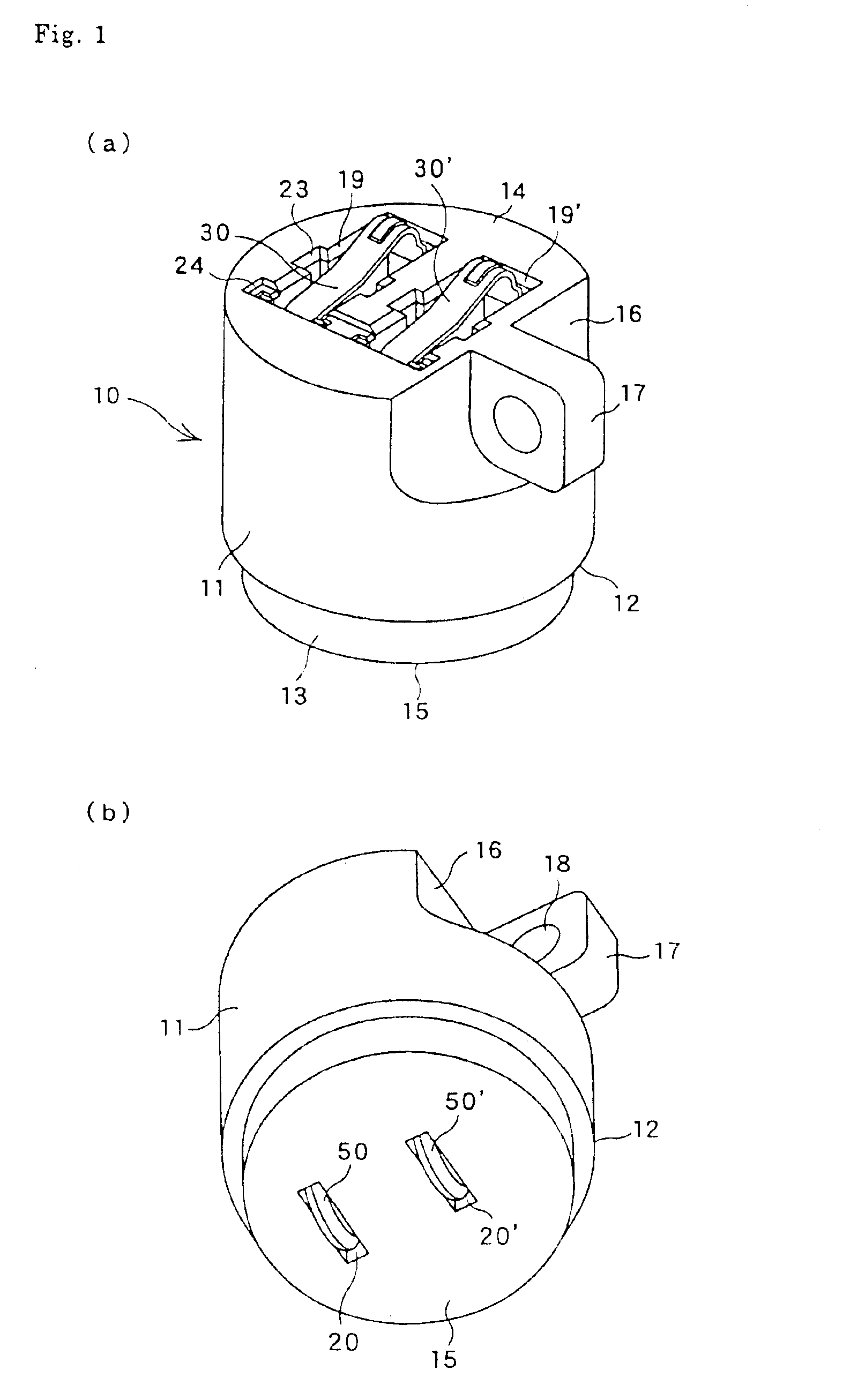

InactiveUS6896522B2Simplify assembly workRotary current collectorCoupling contact membersContact pressureEngineering

A hinge connector comprising an insulative connector housing (10) having a predetermined shape, a through hole extending through the connector housing, a receiving chamber defined in the through hole, and an elastic contact member (30) having electric conductivity and a rotatable contact member (50) that are received in the receiving chamber, wherein the elastic contact member (30) is elastically contacted at one end thereof with the rotatable contact member (50), and projects at the other end out of the through hole to form an external contact. This hinge connector is mounted on the main body housing (90) of an electronic device, a circuit board (70) is connected to a cover body, and the contact member (50) is disposed to make rotation contact with the pattern on the circuit board. Such arrangement provides a hinge connector wherein the contact smoothly rotates even if the contact pressure on the circuit board is increased, and good contact can be maintained.

Owner:JST MFG CO LTD

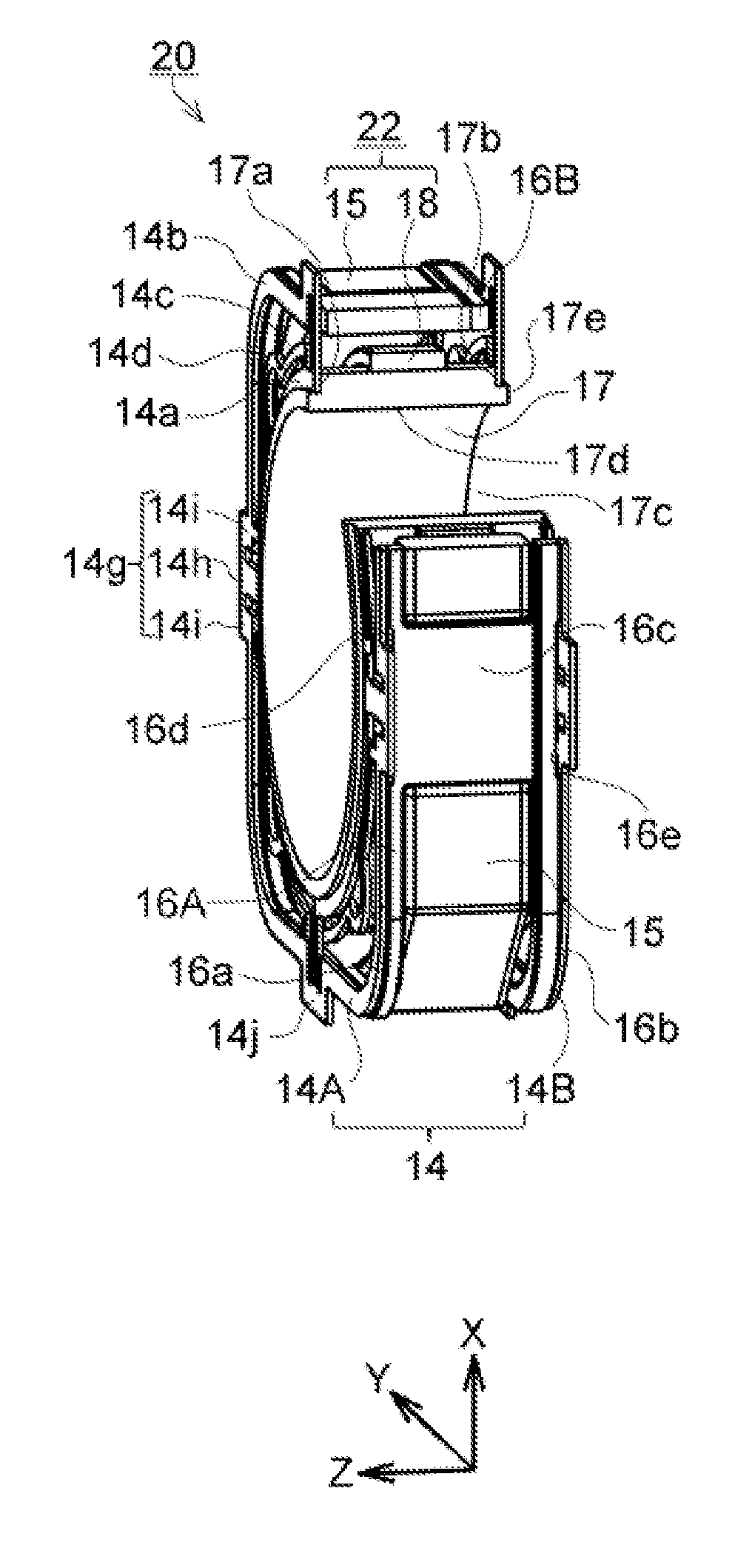

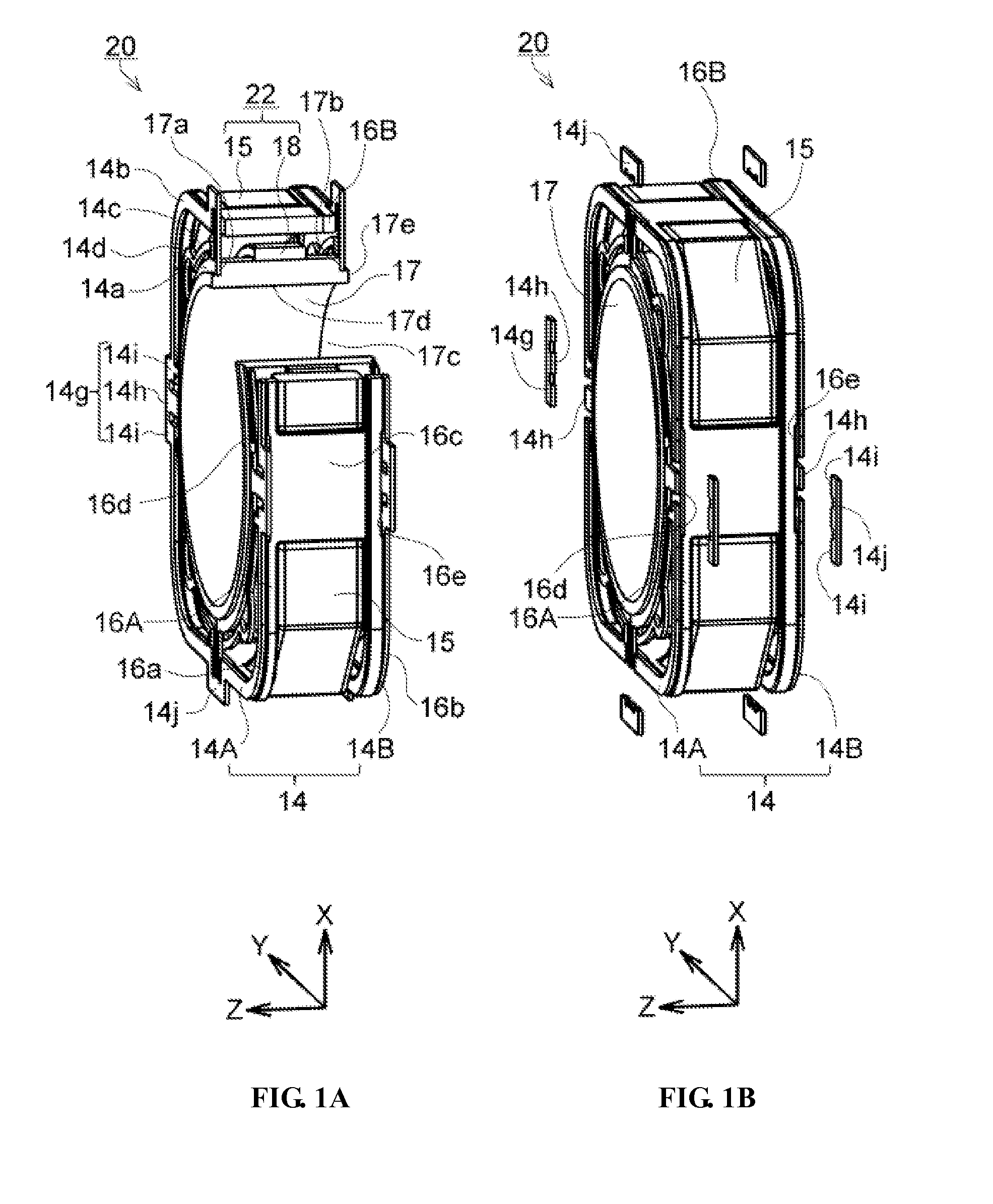

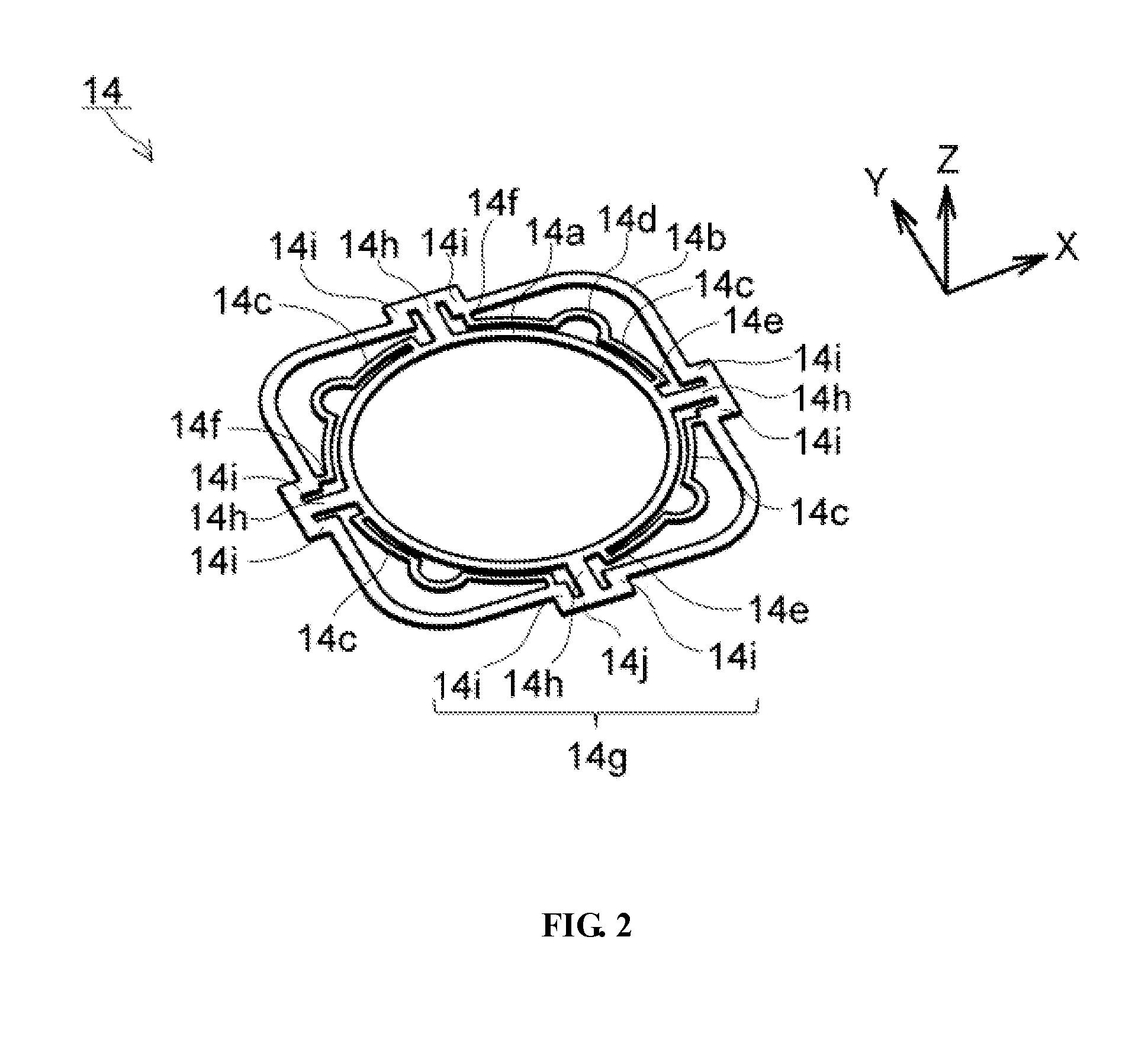

Actuator unit

InactiveUS20150070792A1Easy to separateSimplify assembly workMountingsPropulsion systemsEngineeringActuator

The present invention aims to provide an actuator unit. When the actuator unit is assembled in a lens driving device and works, a lens support beginning to move cannot be inclined. A spring component (14) is provided with an inner side retaining part (14a), an outer side retaining part (14b), a plurality of wrist parts (14c), a plurality of inner side connecting parts (14e), a plurality of outer side connecting parts (14f) and spoke parts (14g) for connecting the inner side retaining part (14a) with the outer side retaining part (14b) in a releasable manner, wherein the lens support (17) is supported by the spring components (14), and an electromagnetic driving mechanism (22) is utilized for enabling the lens support (17) to move.

Owner:HUIZHOU DAYAWAY EVER BRIGHT ELECTRONICS IND CO LTD +2

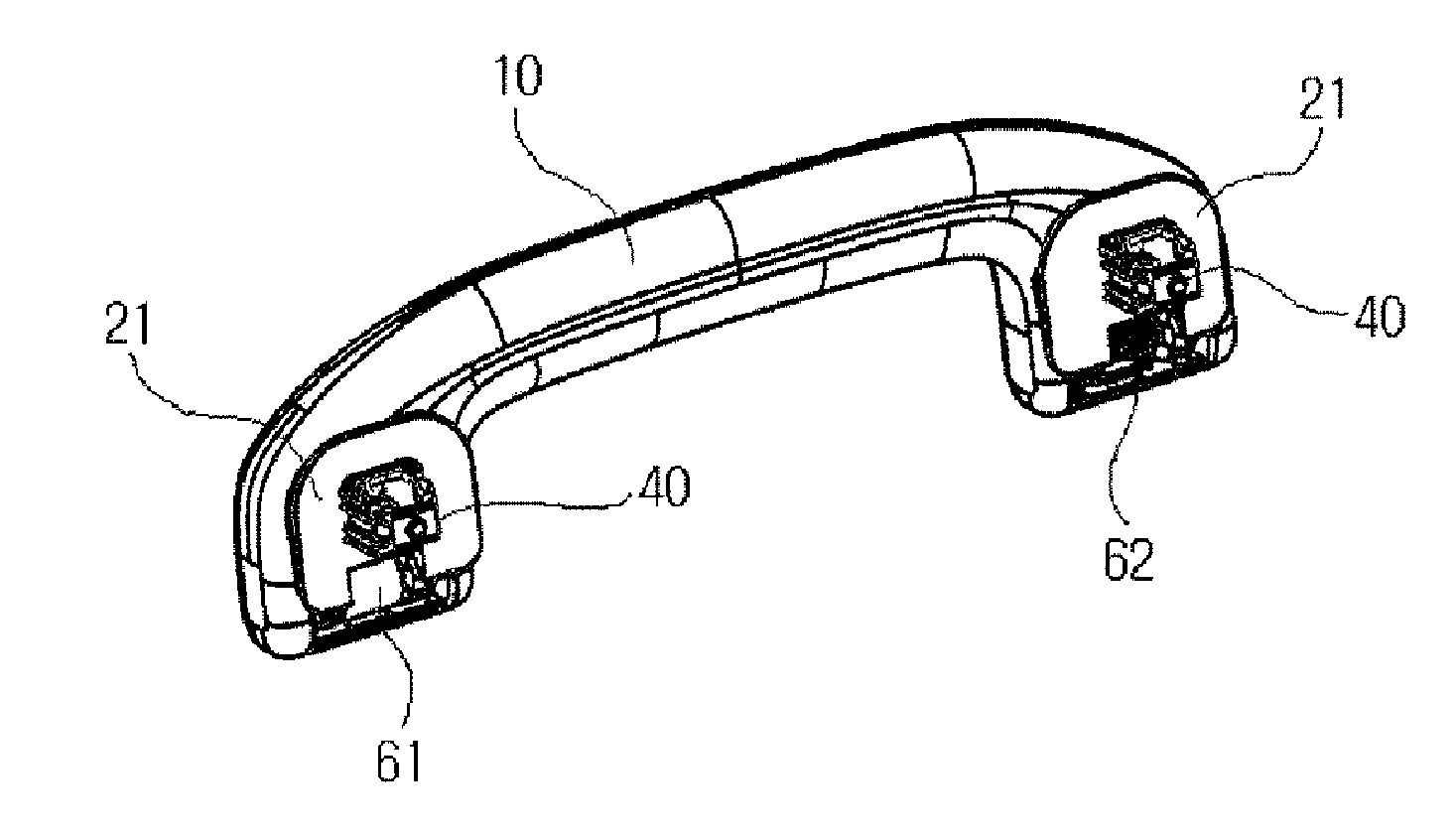

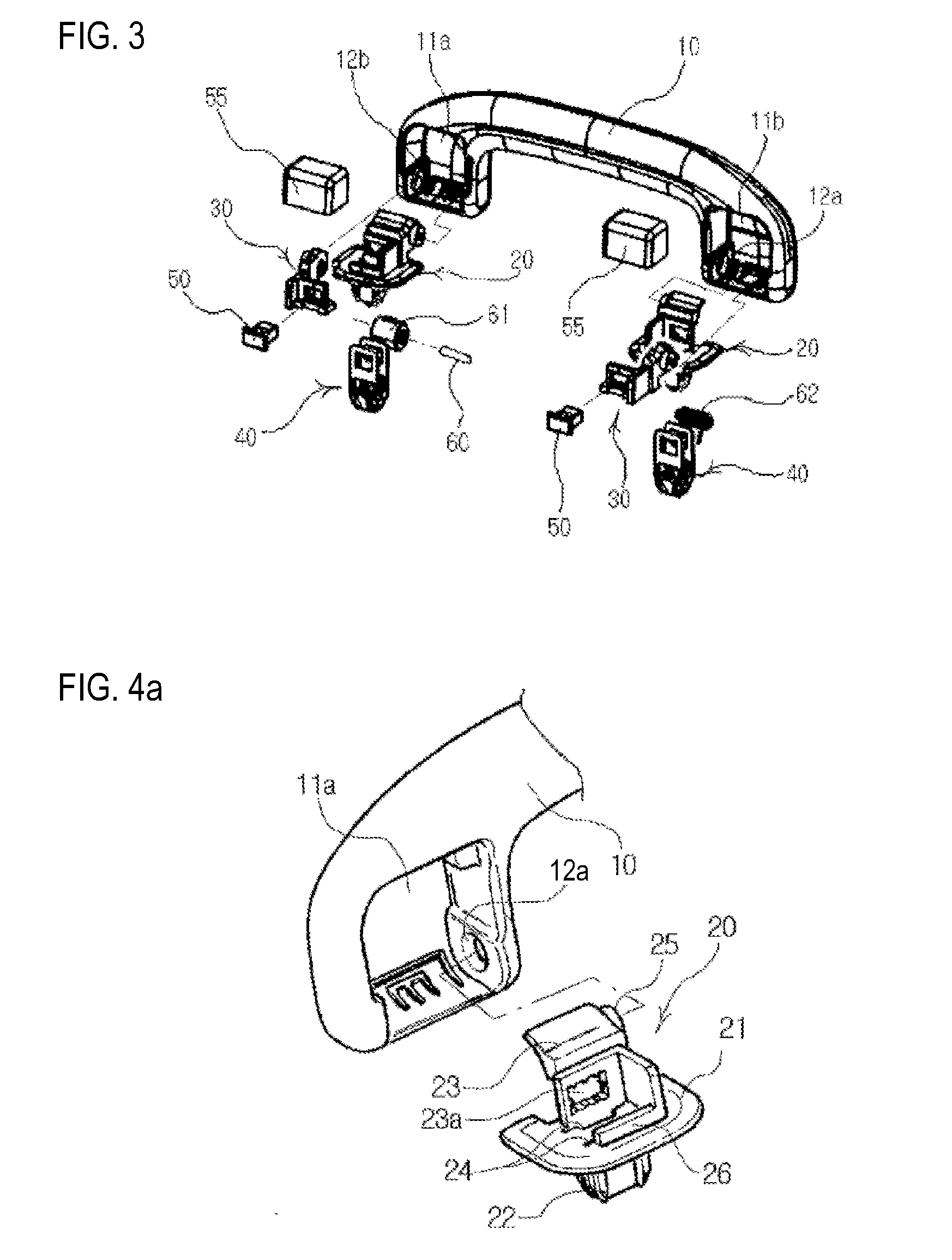

Assist handle for car

InactiveUS20160297340A1Good lookingProcess stabilityVehicle arrangementsSuperstructure subunitsEngineeringMechanical engineering

An assist handle for a car includes an assist handle having mounting spaces and hinge grooves; main brackets positioned in the mounting spaces of the assist handle and having fitting protrusions, clip insertion holes and hinge shafts fitted into the hinge grooves on one side of the mounting spaces; auxiliary brackets having coupling plates provided with hook fixing holes overlapping front portions of body portions of the main brackets and hinge shafts fitted into the hinge grooves on another side of the mounting spaces; fixing clips adapted to couple to the body panel of the car at one side and inserted into the clip insertion holes at the other side such that holding pieces are placed at the same positions as the hook fixing holes; and hooks fitted into the holding pieces and the hook fixing holes to fix the fixing clips, the main brackets and the auxiliary brackets.

Owner:NIFCO KOREA

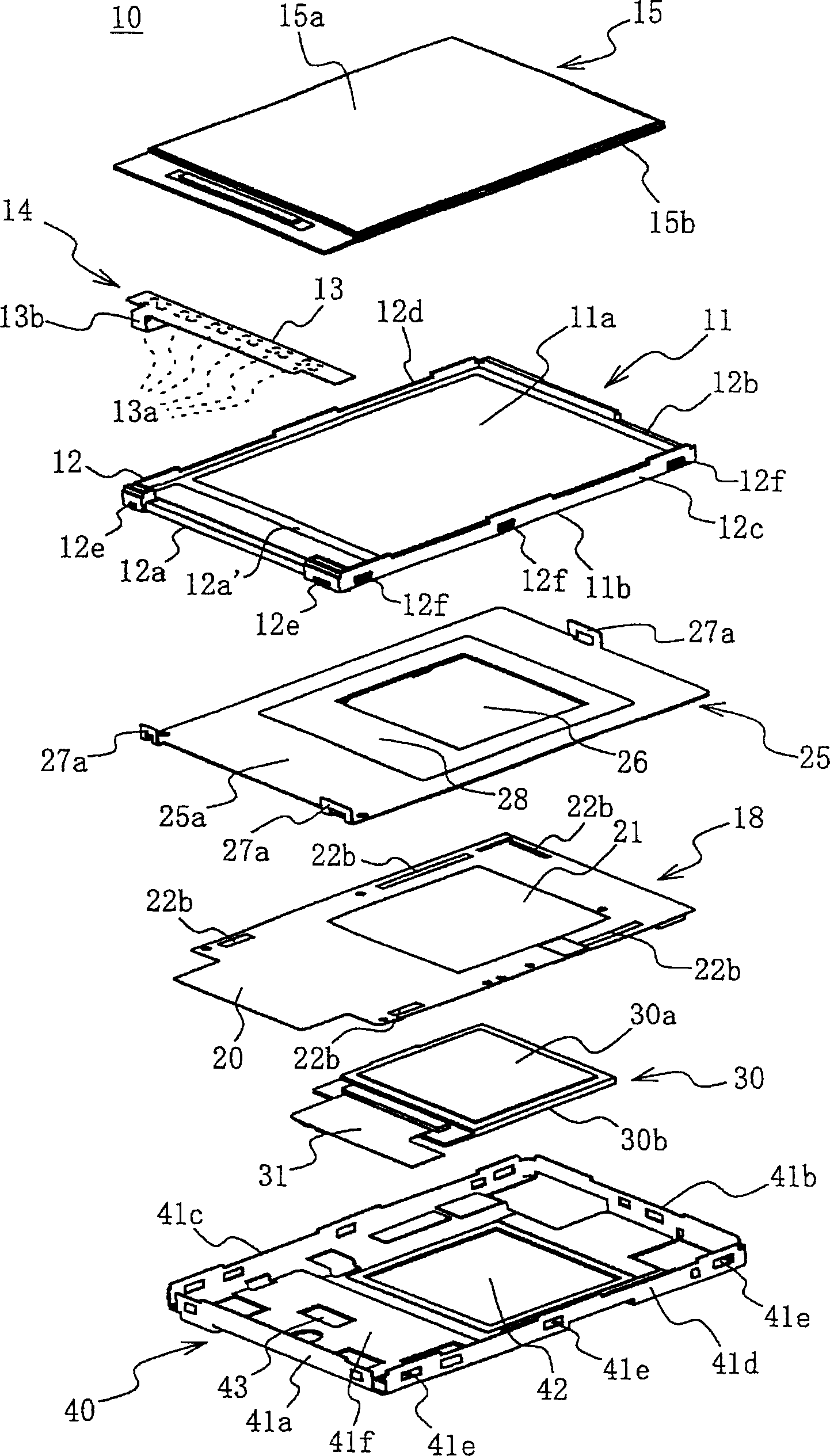

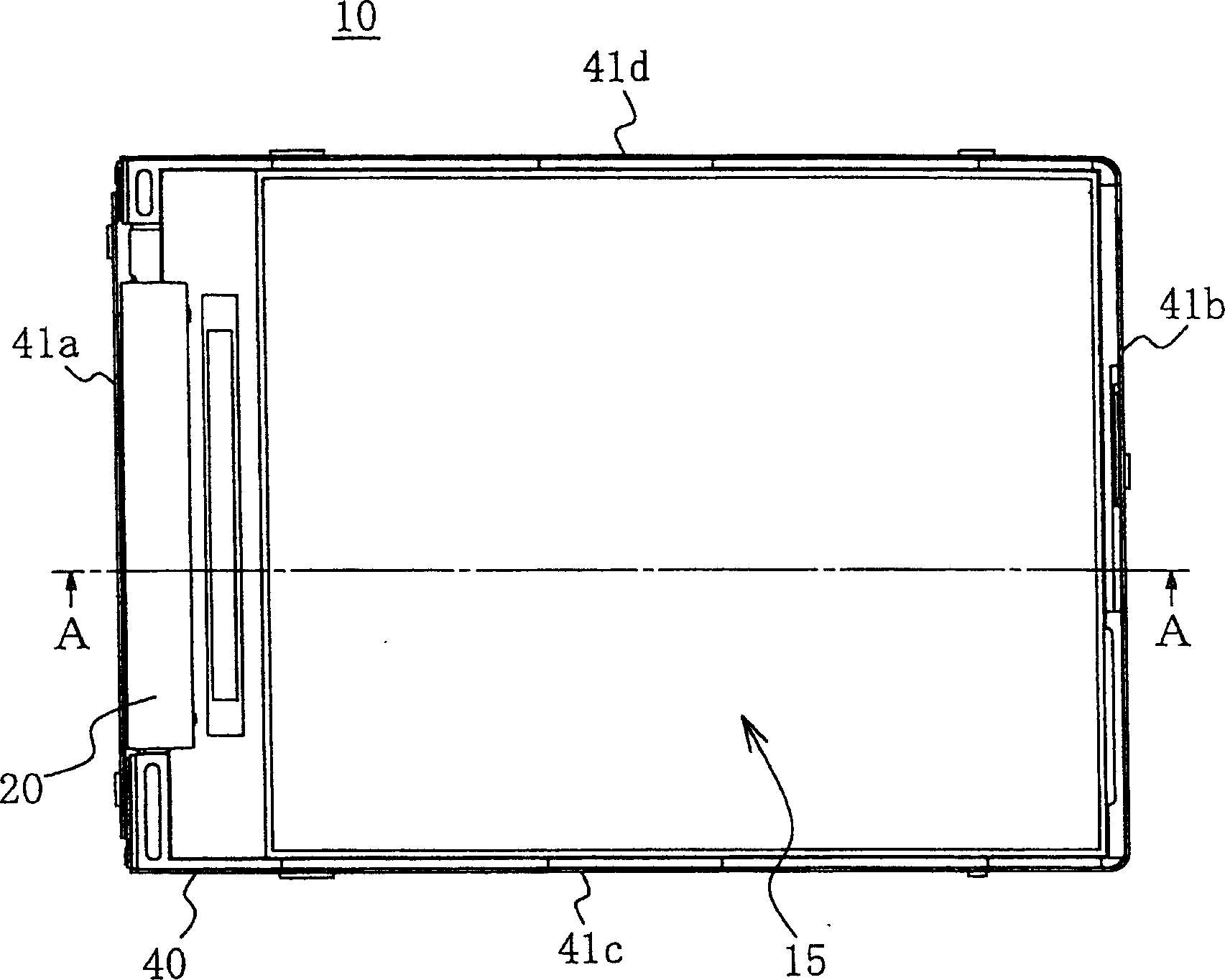

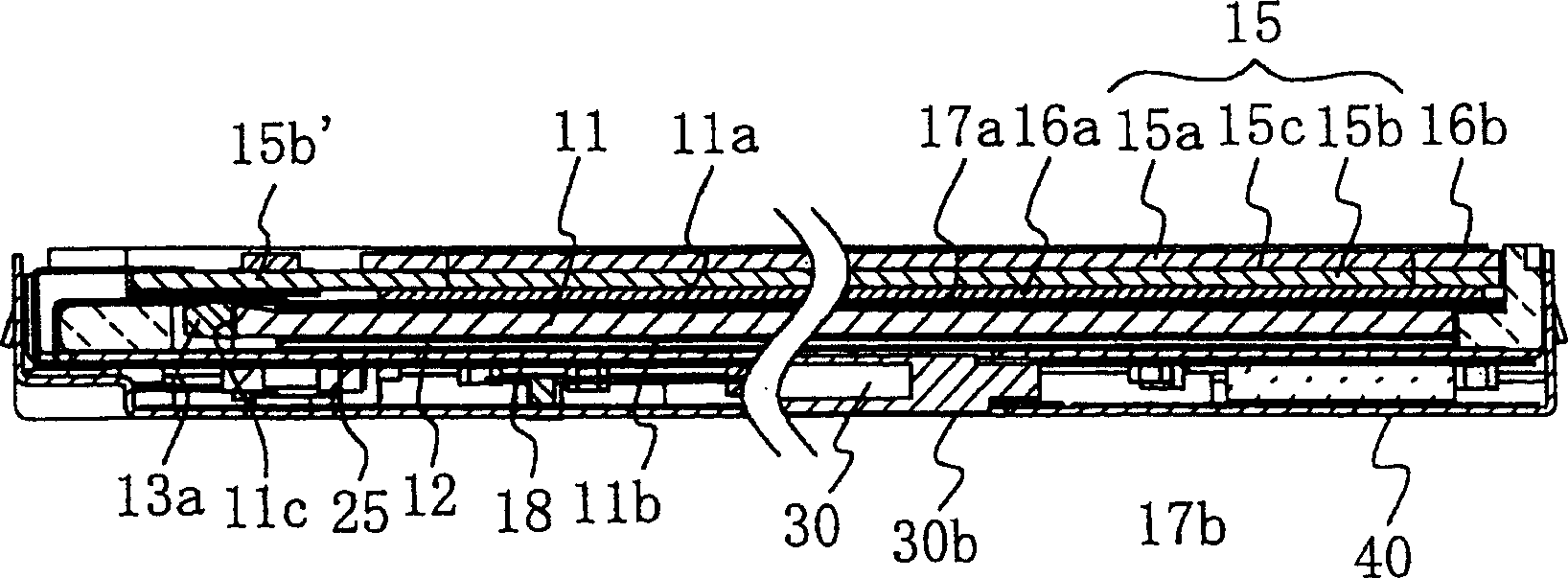

Liquid crystal display device

ActiveCN1755454AEasy to packEasy to makeStatic indicating devicesNon-linear opticsLiquid-crystal displayLight guide

The invention provides a liquid crystal display device which causes the withdraw of various apparatus such as handset, etc to become simple. The display device has a stacked body, and the stacked body is formed by the overlapping of a first liquid crystal display panel (15) which is arranged on one face side of a light guide plate (11) which respectively guides the light to the internal and external faces and a second liquid crystal display panel (30) which is smaller than the first liquid crystal display panel (15) and is arranged on the other face side of the light guide plate (11). The face with the second liquid crystal display panel (30) is covered by a metal casing, and the casing has a flat face which is supported to a height being roughly identical with the display face of the second liquid crystal display panel (30). A body casing (40) covers a circuit substrate (20) which is arranged at the circumference of the second liquid crystal display panel (30), causing the display face (30b) of the second liquid crystal display panel (30) to show up from the opening (42) on the body casing (40).

Owner:JAPAN DISPLAY INC

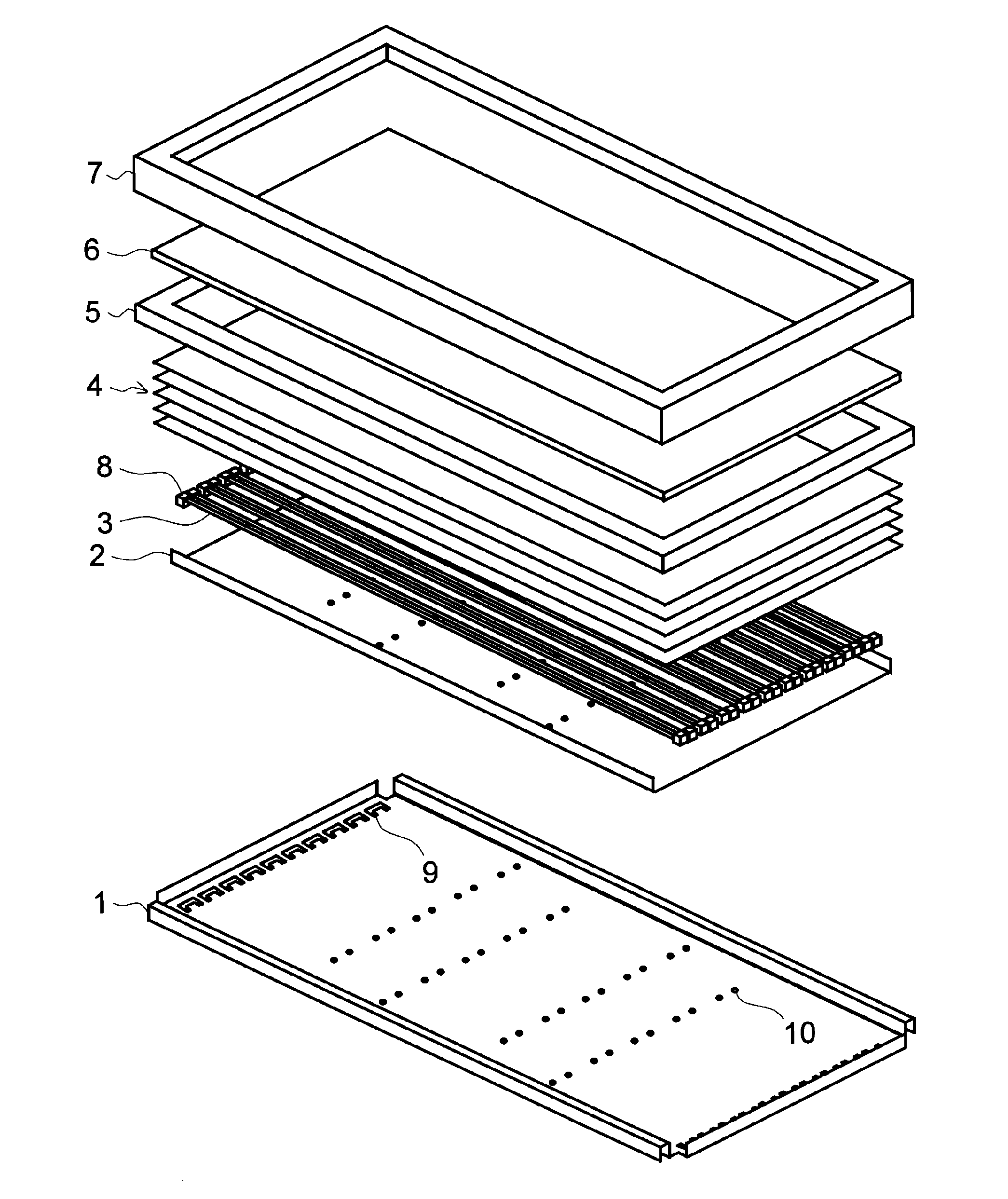

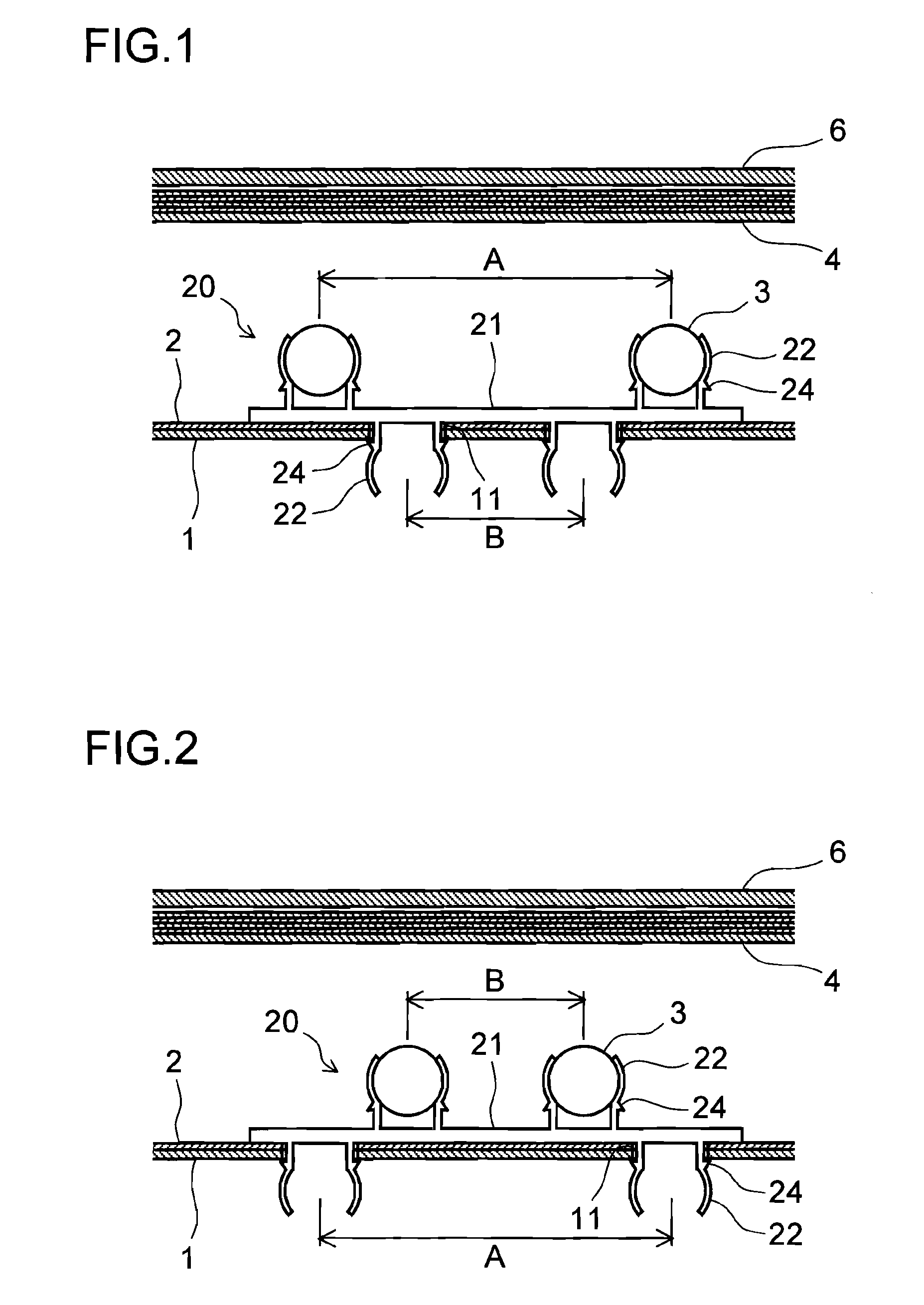

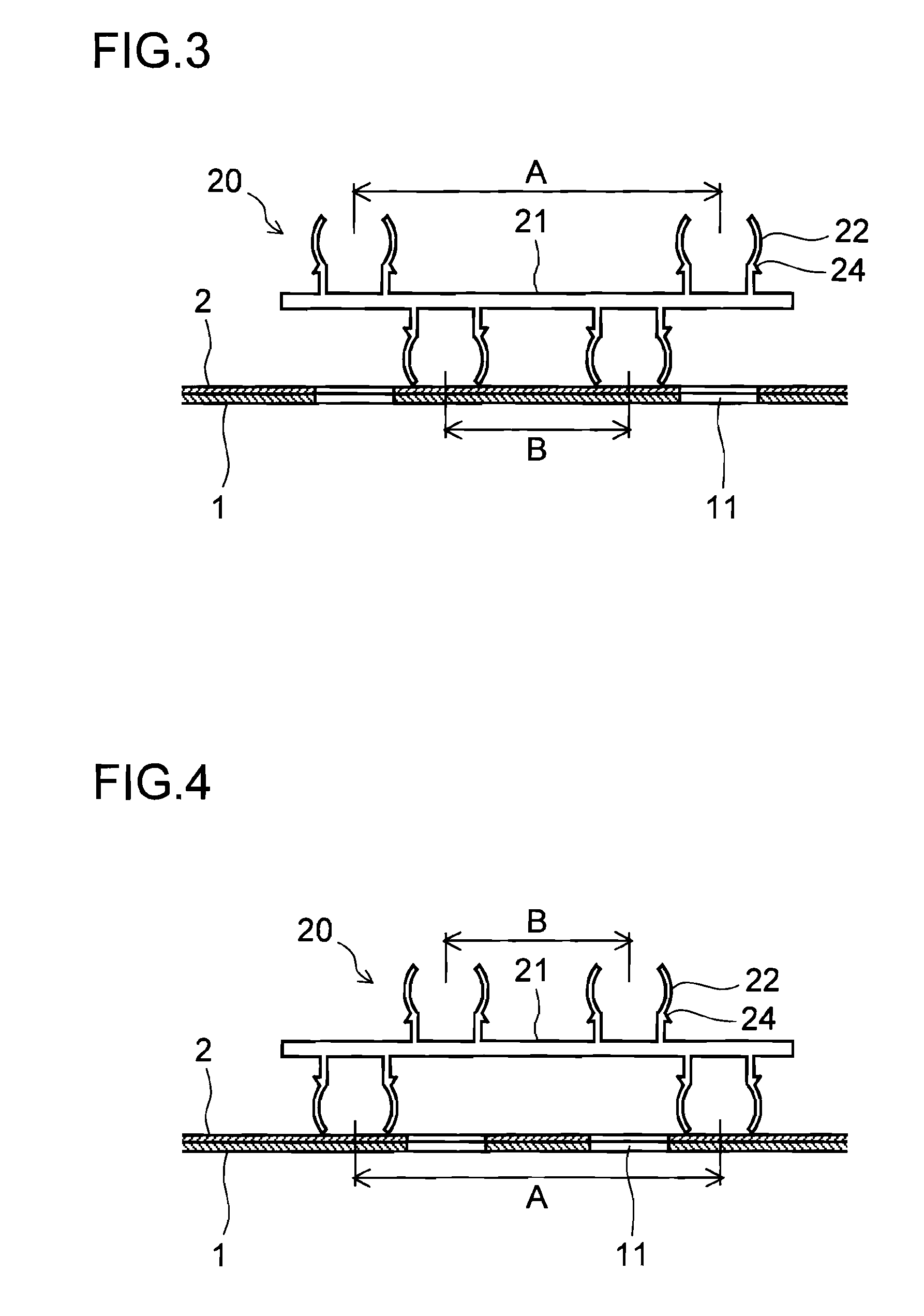

Backlight for liquid crystal display

InactiveUS20100321926A1Low production costReduce storage costsIlluminated signsNon-linear opticsLiquid-crystal displayStraight tube

Light source lamps can be held at different interval by a single kind of lamp clip. A straight tube light source lamp (3) arranged on the surface of a backlight chassis (1) is held by a lamp clip (20) fixed to the backlight chassis (1). The lamp clip (20) comprises a base (21) placed on the surface of the backlight chassis (1), and lamp grippers (22) formed on the opposite sides of the base (21). A plurality of lamp grippers (22) are formed on both sides of the base (21) at respective intervals different from each other. A through hole (11) for passing the lamp gripper (22) on the surface of the lamp clip (20) not pertaining to lamp holding is formed in the backlight chassis (1). The lamp gripper (22) passed through the through hole (11) serves to fix the lamp clip (20) to the backlight chassis (1).

Owner:SHARP KK

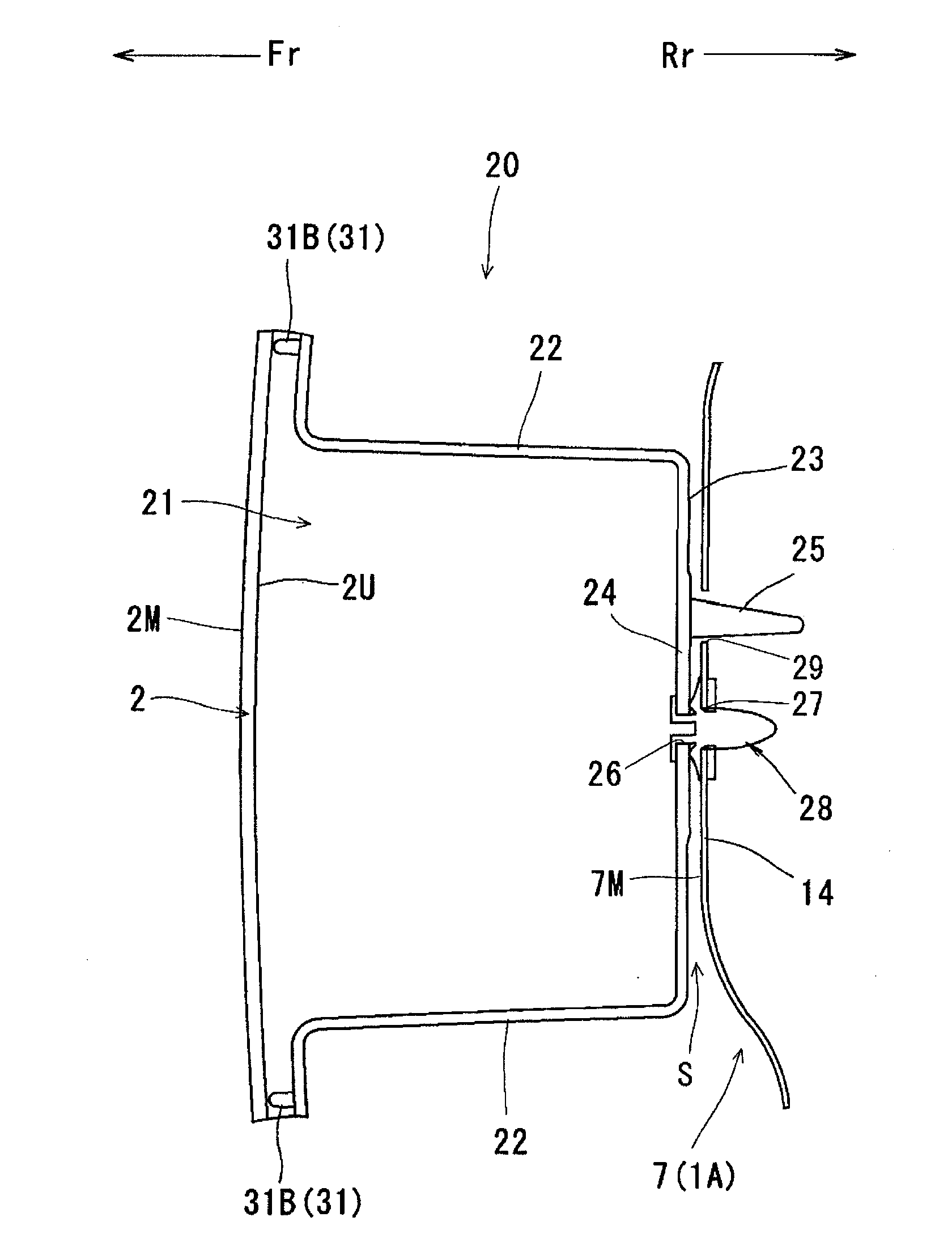

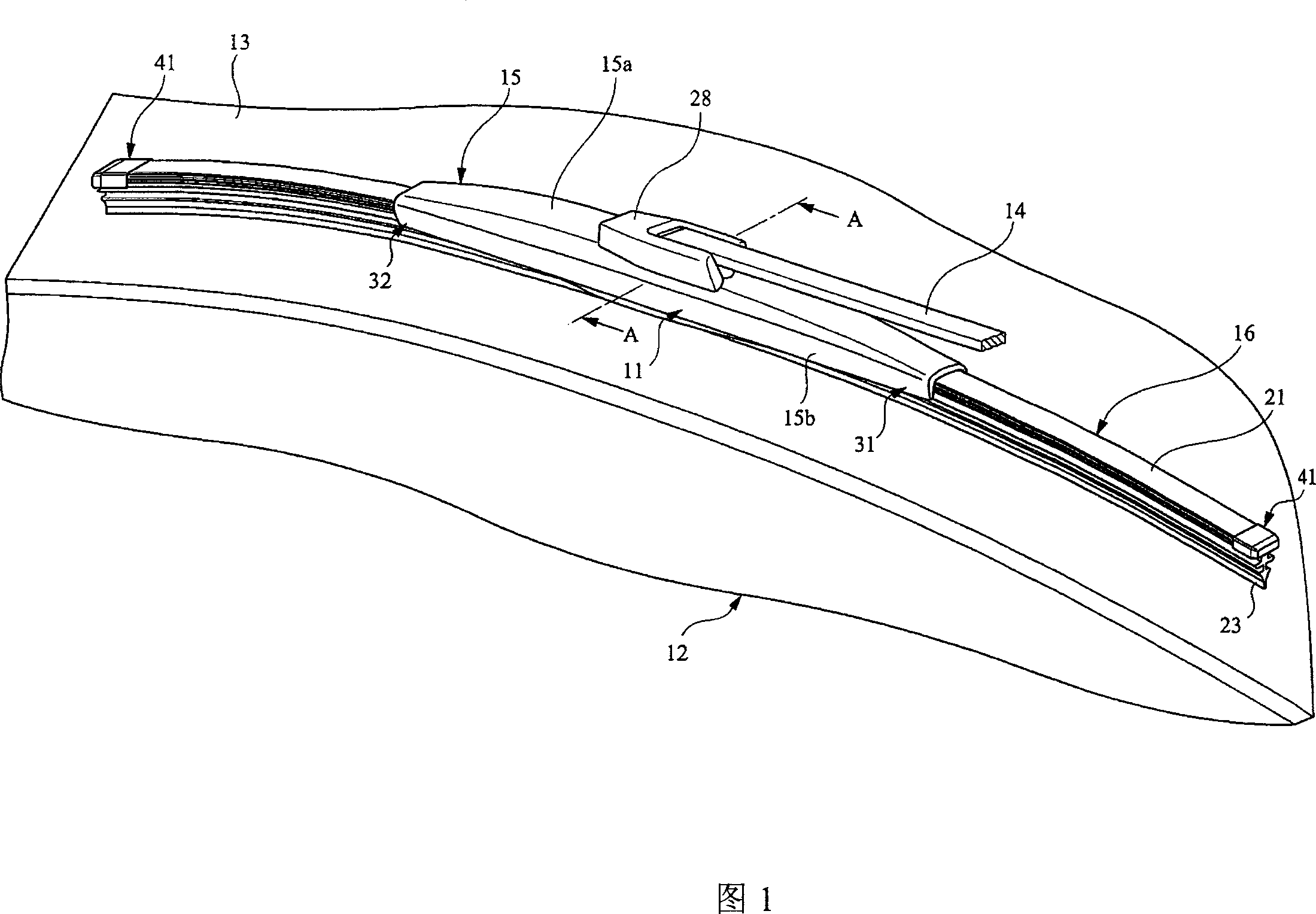

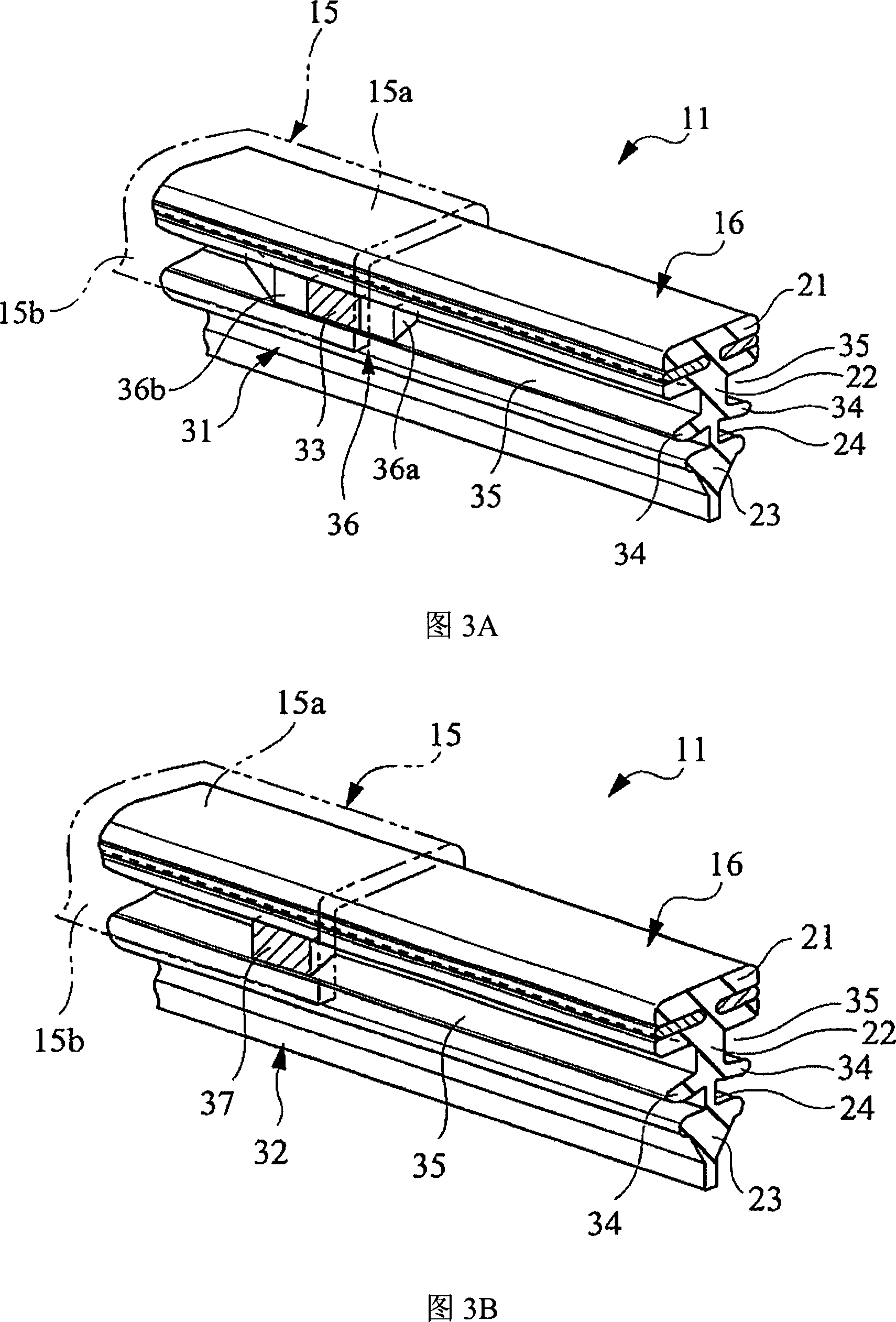

Wiper blade

ActiveCN101098804ASimple structureSimplify assembly workVehicle cleaningEngineeringMechanical engineering

A wiper blade 11 linked to a wiper arm 14 has a blade rubber 16 and a rubber holder 15 with a U-shaped section, wherein the rubber holder 15 is formed shorter in axial length than the blade rubber 16 and surrounds an intermediate portion of the blade rubber 16. Both end portions in a longitudinal direction of the rubber holder 15 are provided with a pair of holding portions 31 and 32, wherein the holding portion 31 has a holding claw 33 engaged with a stopper portion 36 provided in a holding groove 35 of the blade rubber 16 and the holding portion 32 has a holding claw 37 engaged slidably with the holding groove 35 of the blade rubber 16 and the rubber holder 15 is linked to the blade rubber 16 by two position of these holding portions 31 and 32.

Owner:MITSUBA CORP

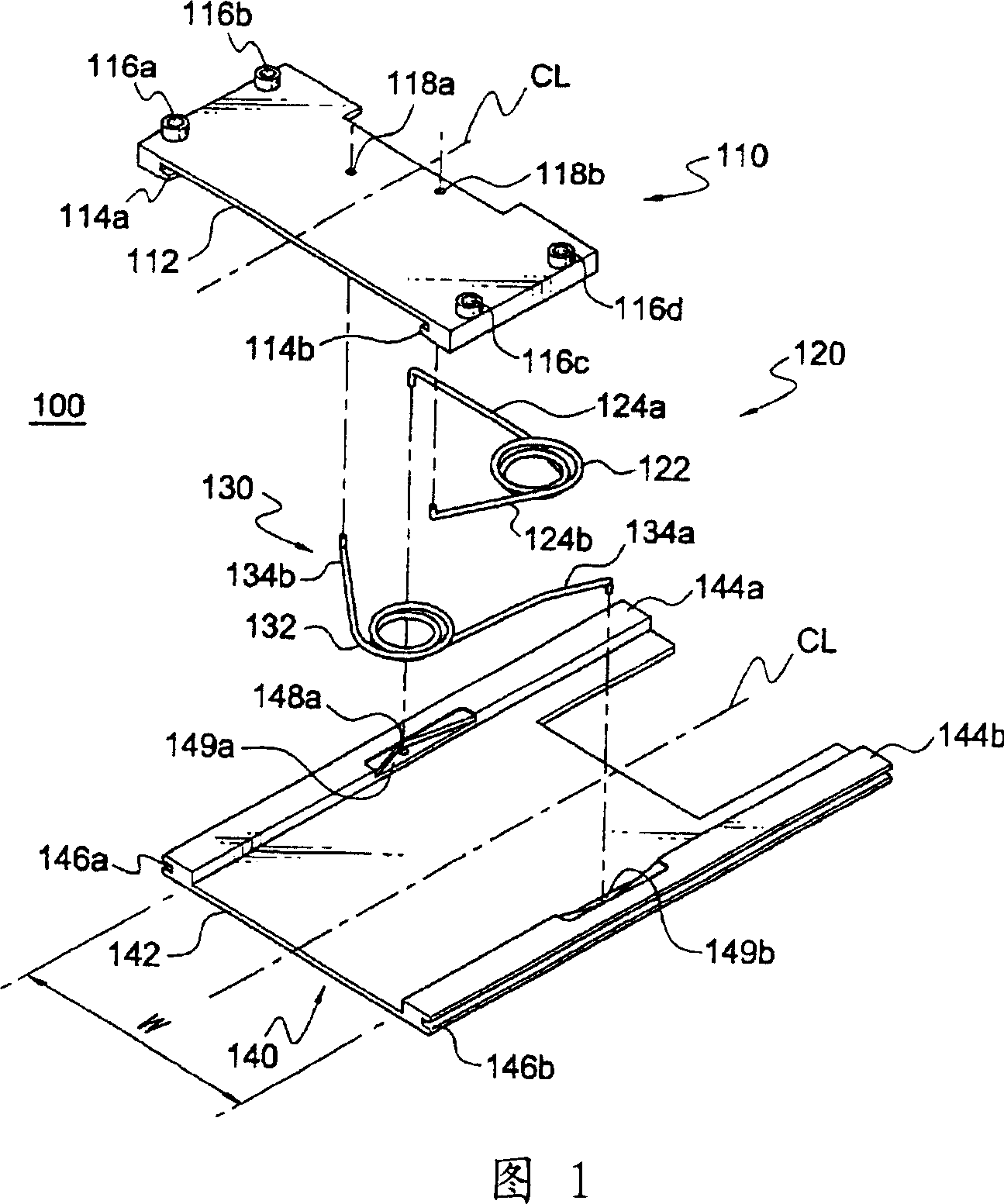

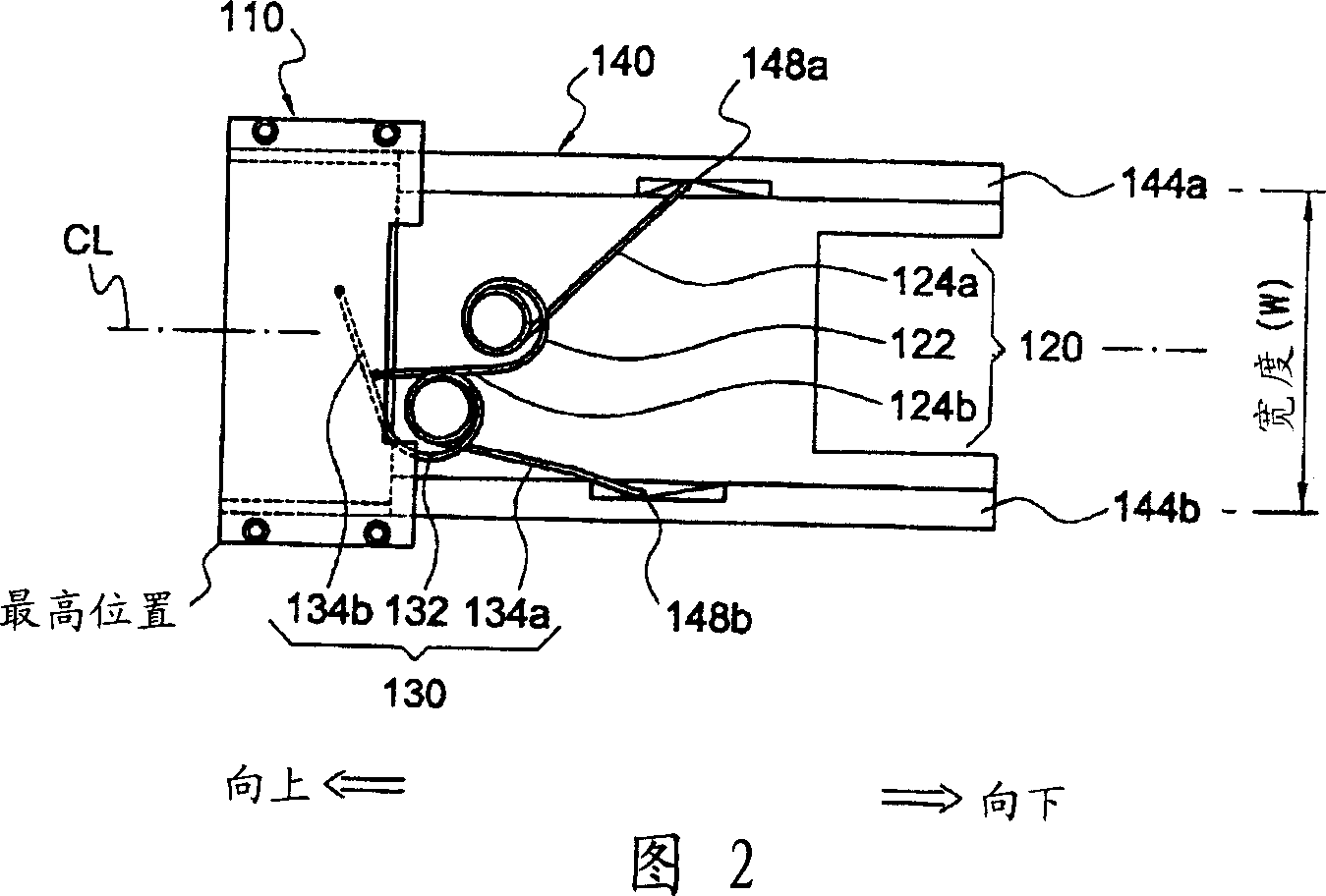

Sliding mechanism apparatus and appliance integrated with the same

InactiveCN1930787AMeet design needsSmooth sliding movementTransmissionTelephone set constructionsLeft halfAcute angle

A sliding mechanism device for sliding open and Gubeikou slide type cellular phones is disclosed. The guide member and the slide member are engaged with each other to be able to slide relative to each other. The end of one arm of the first torsion spring is connected to the slide member near the left edge of the slide member. The end of its other arm is connected in the right half of the guide. The end of one arm of the second torsion spring is connected to the slide member near the right edge of the slide member. The end of its other arm is connected in the left half of the guide. From the original state where the first and second torsion springs are expanded, if an external force acts on the slide member or the guide member, the torsion springs are compressed to an acute angle and then expanded again by their elastic force. In this way, the slide member can be moved to the lowermost or uppermost position. In the first and second torsion springs, the distance between the ends of the two arms is greater than at least half the width of the slide member. Therefore, the first and second torsion springs can make maximum use of the width of the guide member when rotating, thereby extending the maximum travel distance of the slide member.

Owner:李汉相 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com