Automotive front body structure

A front body, car technology, applied in vehicle components, vehicle safety arrangements, bumpers, etc., to solve problems such as noise, increased labor, and clicks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

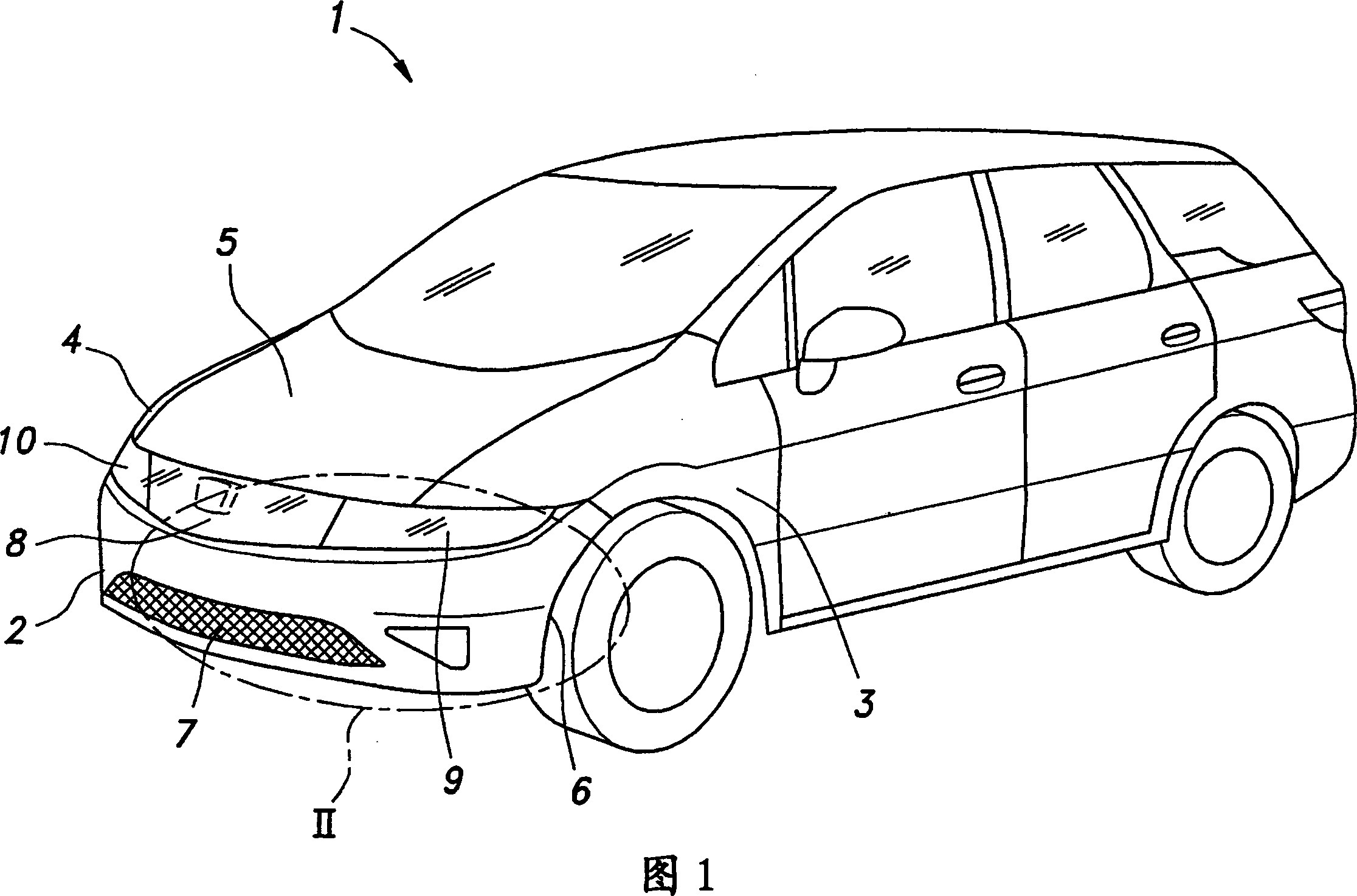

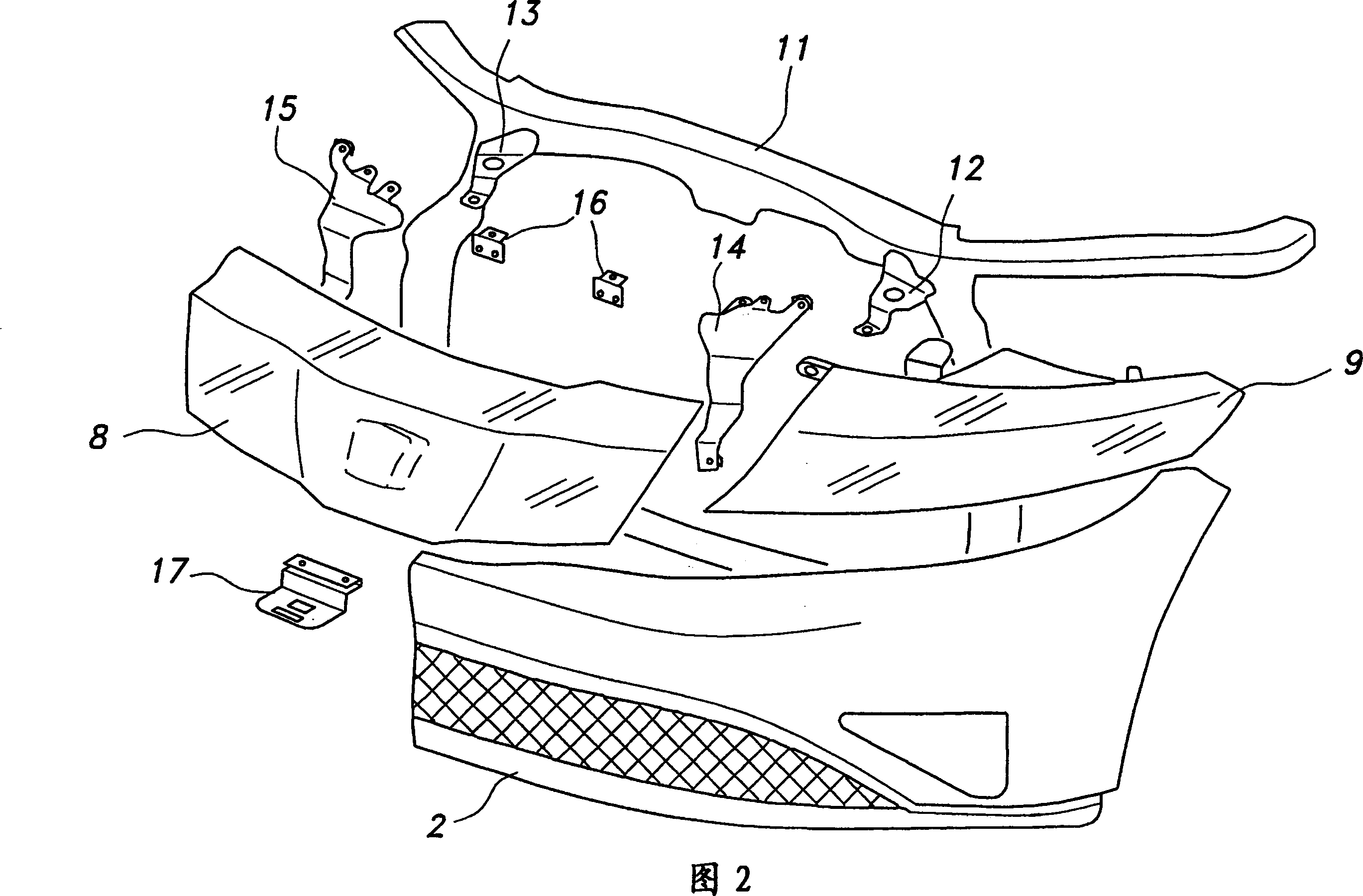

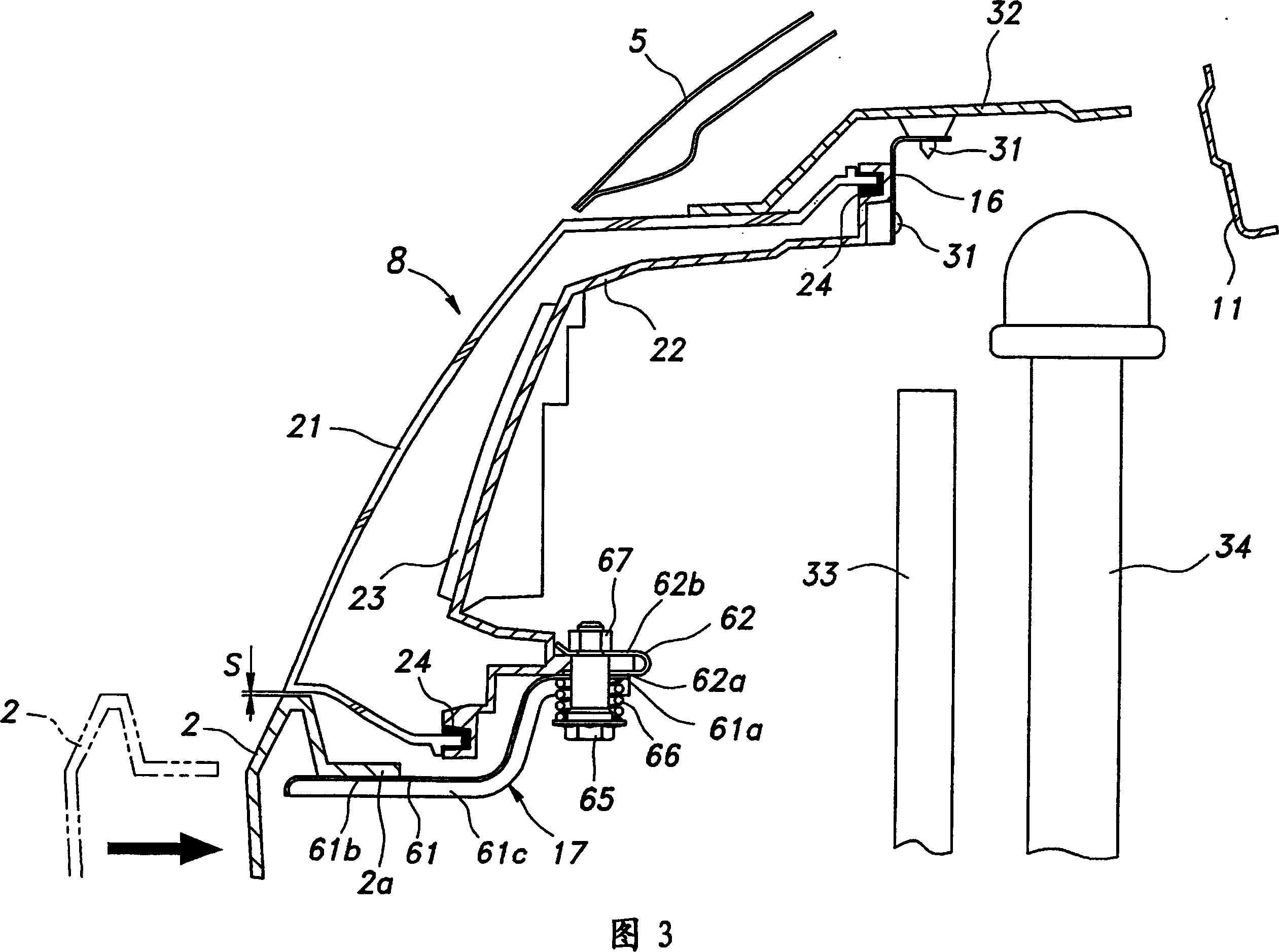

[0021] 1 is a perspective view of an automobile embodying the present invention; FIG. 2 is an exploded perspective view of a part represented by II in FIG. 1 ; ; Figure 4 is an exploded perspective view of the structure used to connect the front trim member to the lower bracket; Figure 5 is a perspective view showing the way the front trim member is installed on the side bracket; Figure 6 is a vertical sectional view , showing the manner in which the front trim member is mounted on the side bracket; and FIGS. 7 and 8 are views showing the manner of operation of the illustrated embodiment.

[0022] "Structure of Embodiment"

[0023]

[0024] Referring to Figure 1, the illustrated embodiment consists of a sedan (hereinafter referred to as an automobile) embodying the present invention. The vehicle body 1 of the illustrated embodiment is composed of a monocoque formed by welding steel plates together, and is provided with a front portion defined by a front bumper 2, a pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com