Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Shorten the slagging time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for reclaiming and cyclic utilizing residue molten steel slag in steel making

InactiveCN1804047AWell mixedReduce oxidationBlast furnace componentsBlast furnace detailsSulfurSludge

The method to pour residual hot steel sludge for recovery in steel production comprises: a. after casting, pouring the residual steel sludge into empty ladle; b. conveying the sludge to converter and tapping; c. refining; d. casting; repeating. This invention makes full use of the sulfur capacity and strong reducibility to absorb inclusion and improve liquid steel cleanness rapidly, overcomes the consumption for low-melting, and reduces pollution and cost.

Owner:HEBEI IRON AND STEEL

Treatment method for polymetallic alloy formed by arsenic-lead-antimony and noble metal

InactiveCN103194605AReduce the temperatureReduce energy consumptionProcess efficiency improvementLead oxideAlloy

The invention discloses a treatment method for a polymetallic alloy formed by arsenic-lead-antimony and noble metal. In order that the polymetallic alloy formed by arsenic-lead-antimony and noble metal is directly prepared to meet the international standard Sb20399.8, the noble metal is enriched in the noble metal alloy. The treatment method comprises the following steps of: carrying out alkalification and deep dearsenification treatment on the polymetallic alloy formed by arsenic-lead-antimony and noble metal; then converting antimony white at low temperature in a special converting furnace; and finally blasting and highly oxidizing lead slagging to obtain the noble metal alloy. According to the treatment method, the antimony directly satisfies the output requirement of antimony white; the energy consumption is low, and the direct yield rate of the noble metal is improved to more than 98%; and the converting and slagging time of residual alloy after removal of arsenic and antimony is shortened within 30 hours, which is reduced by more than 50% compared with the conventional process.

Owner:CENT SOUTH UNIV +1

Composition for slag formation and preparation and use method thereof

InactiveCN101736114AReduce consumptionEfficient removalManufacturing convertersMolten steelEnergy consumption

The invention provides a composition for slag formation, which comprises the following components based on the total weight of the composition: 45-65wt% of CaO, 10-20wt% of SiO2, 1-5wt% of MnO, 9-25wt% of MgO and 1.5-5wt% of Al2O3. The invention also provides a preparation method and a use method of the composition. The composition for slag formation provided by the invention can promote slagging in the early stage of smelting semisteel, shorten the slag formation time, and obviously remove phosphorus elements. By adopting the composition for slag formation of the invention for smelting the semisteel, the process is simple, the energy consumption is low, the effect of reducing phosphorus is obvious, the phosphorus content in molten steel is lower than 0.007wt%, and consumption of the semisteel is small when the same amount of steel is obtained by smelting.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Converter less-slag smelting method

ActiveCN112646944ALow oxygenCutting costsManufacturing convertersProcess efficiency improvementSmelting processHeat balance

The invention relates to a converter less-slag smelting method. The converter less-slag smelting method uniformly adopts a less-slag single-slag mode under the conditions of high iron consumption or low iron consumption and complex molten iron silicon change. The converter less-slag smelting method comprises the following process flows of: finishing tapping, remaining slags, adjusting the slags, splashing the slags, adding scrap steel, mixing molten iron, conducting calculation, conducting blowing, controlling an end point and tapping. In the smelting process, the lance position and the oxygen supply intensity are controlled by referring to the CO value; the end oxidizability is effectively controlled through heat balance accurate calculation; the molten steel oxidizability is reduced through process low lance position control; the alloying cost is effectively reduced; and meanwhile, the final slag oxidizability is reduced; the slag splashing furnace protection effect is promoted; and the furnace condition maintenance cost is effectively reduced.

Owner:扬州圣莱特冶金科技有限公司

High lead-antimony slag type for anode slime smelting process and its use method

ActiveCN101403040AReduce chemical corrosionReduce the amount of dilutionProcess efficiency improvementSmelting processPrecious metal

The invention relates to a high lead-antimony slag type which is used for smelting technique of anode mud and is used by the anode mud in the process of reduction smelting of an oxygen bottom blowing bullion lead furnace in the technique that an oxygen bottom blowing furnace smelts the anode mud and a using method, belonging to the scope of separation and extraction of precious metal and base metal; a formula thereof is the high lead-antimony slag type with low silicon, low calcium and low sodium; all the materials comprises the following ingredients according to mass ratio: 5 to 22 percent of SiO2, 1 to 8 percent of FeO, 0 to 6 percent of Na2O, 0 to 5 percent of CaO, 10 to 35 percent of PbO and 150 to 45 percent of Sb2O3, wherein, the control range of the mass ratio of the PbO and SiO2 is 1.50 to 6.0. The formula not only has good effect for prolonging the service life of a refractory material and improving the continuous operation rate and processing capacity of the bullion lead, but also leads the reduction and volatilization of arsenic and antimony and oxidation and slag formation of lead to be realized simultaneously, reduces the usage of flux and consumption of fuel and effectively separates the valuable metals.

Owner:HENAN YUGUANG GOLD & LEAD

Slag modifier for converter refining

InactiveCN102002550AReduce oxidationStrong deoxygenation abilityManufacturing convertersProcess efficiency improvementSlagWhite line

The invention relates to a slag modifier for converter refining, which comprises the following components by mass percentage: 0-6.0 of CaO, 48-58 of Al2O3, 0-12 of SiO2, 20-25 of Al, and the balance of inevitable impurities. By adding the slag modifier in the processes of tapping, refining and slagging of a converter, the deoxidation cost in the steel making process can be reduced, the desulfurization degree of steel water in the tapping process of the converter can be increased, the slagging time of white line slag refined by a ladle furnace can be shortened, the refining effect can be improved, the oxidizability of refined early slag can be reduced, and the purity of the steel water can be enhanced.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

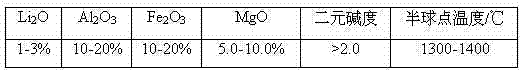

Fluoride-free slagging flux for electric-arc furnace steelmaking

The invention belongs to the technical field of iron and steel smelting and particularly relates to a fluoride-free slagging flux for the electric-arc furnace steelmaking and a preparation method thereof. The invention aims to provide the fluoride-free slagging flux for the electric-arc furnace steelmaking and the preparation method thereof and solve various problems of low slagging speed, poor slag melting effect, fluorine pollution, high cost, serious corrosion of a furnace lining, large dust capacity and the like which are generated due to the case that currently, lime, fluorite, calcium aluminate and iron oxide are used as slags. The fluoride-free slagging flux is characterized by being prepared from the following raw materials in percentage by weight: 20 to 40 percent of spodumene, 15 to 20 percent of red bauxite, 30 to 50 percent of active lime, 5 to 10 percent of iron oxide and 5 to 10 percent of magnesia.

Owner:JIANGSU UNIV

Preparation method of converter steelmaking synthetic slag former

ActiveCN103343180AReduce manufacturing costAvoid secondary processingManufacturing convertersSteelmakingBrick

The invention discloses a preparation method of a converter steelmaking synthetic slag former, belonging to the technical field of converter steelmaking of ferrous metallurgy. The method comprises the following steps of: uniformly mixing 10-18 parts of converter dust, 25-32 parts of scale, 5-10 parts of gas ash, 9-16 parts of waste high-alumina brick and bentonite to obtain a mixture B; adding 30-45 parts of active lime, 6-12 parts of active lime, 5-10 parts of magnesium oxide and bentonite into the mixture B to obtain a mixture C; mixing 10-15 parts of sodium carbonate with the mixture A and the mixture C, and pre-melting at 1,300-1,450 DEG C to obtain a mixture D; and cooling and crushing to obtain the synthetic slag former. According to the synthetic slag former, the metallurgic waste difficult to use is used as a component of the slag former, the prepared slag former has high dephosphorization efficiency, and the slag forming time is short.

Owner:MAANSHAN RUNTONG HEAVY IND TECH CO LTD

Converter or electric furnace steel-making slagging agent and preparation process thereof

InactiveCN101914651AHigh yieldImprove furnace lifeManufacturing convertersProcess efficiency improvementMaterials preparationChemical composition

The invention relates to a steel-making slagging agent, in particular to a converter or electric furnace steel-making slagging agent produced by taking steel slag and magnesium slag as raw materials and blending an additive and a preparation process thereof. The slagging agent comprises the following chemical components in percentage by weight: at least 50 percent of CaO, at least 6 percent of MgO, at least 9 percent of TFe, at most 0.15 percent of S and at most 20 percent of SiO2. The preparation process for the slagging agent comprises the following steps of: material preparation according to the chemical component requirement, material mixing, wetting treatment, die-casting molding and aging reaction. The process solves the problem of the treatment of waste steel slag and metal magnesium slag; the components of the steel slag are basically similar to the components of the steel slag controlled in the steel-making process, so the steel-making slagging time and the slag adjusting time can be shortened; the FeO content of the slagging agent is basically consistent with the FeO content of the actual steel slag, so metal oxidation of molten steel is reduced; the slagging agent contains a certain amount of MgO which has certain assisting effect of protecting the furnace; and because fluorite is added, the corrosion of a furnace lining is reduced, and the service life of the furnace lining is greatly prolonged.

Owner:ZUNHUA LITUO ENVIRONMENTAL PROTECTION SCI & TECH

Composite slagging agent for converter

InactiveCN102978329AReduce manufacturing costAvoid pollutionManufacturing convertersSteelmakingFluorinated gases

The invention discloses a composite slagging agent for a converter, which belongs to the technical field of slagging agents used in a converter steel-making process. The composite slagging agent comprises, by mass, 68 to 73 parts of calcium-free chromium slag, 12 to 15 parts of white corundum and 20 to 23 parts of limestone. The composite slagging agent for the converter provided by the invention does not contain CaF2, enables pollution to the atmosphere and the water resource by fluorine-containing gas and fluorinions to be avoided and integratedly utilizes waste calcium-free chromium slag which is difficult to recycle as a main raw material, so production cost for the slagging agent is substantially reduced, and elements like Cr and Fe in the calcium-free chromium slag are comprehensively utilized. According to the invention, formation time of the composite slagging agent is short and is reduced by about 30%, high production efficiency is realized, steel consumption is reduced by more than 3 Kg / t, consumption of slagging materials is reduced, and a substantial economic benefit is obtained.

Owner:高金菊

Recycling method of refining hot slag

InactiveCN107858485AImprove liquidityImprove cleanlinessProcess efficiency improvementSlagMolten steel

The invention discloses a recycling method of refining hot slag. The recycling method of the refining hot slag comprises the steps that molten steel subjected to LF white slag refining is cast, casting residual hot steel-making slag and casting residual molten steel generated after LF white slag refining are poured into an empty steel ladle, and to-be-refined molten steel, casting residual moltensteel, casting residual hot steel-making slag with the weight being 40-50% and lime of the next cycle are added into an LF refining furnace for LF white slag refining of the next cycle. By means of the recycling method of the refining hot slag, the problems that an LF refining slag cycling technology of the present stage is not mature yet, the LF refining slag comprehensive utilization rate is low, and severe environment pollution and resource waste are caused are solved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Converter-strengthened slagging agent and preparation method and using method thereof

The invention provides a converter-strengthened slagging agent, which is characterized in that: the converter-strengthened slagging agent comprises the following components in percentage by weight: 55 to 70 percent of poor manganese mineral powder, 15 to 20 percent of iron oxide, 2 to 5 percent of high temperature dispersant, 10 to 15 percent of lime, and 2 to 5 percent of binder. The content of MnO in the poor manganese mineral powder is 15 to 35 percent; the content of FeO in the iron oxide is 55 to 65 percent; the content of Na2CO3 in the high temperature dispersant is 80 to 90 percent; and the content of CaO in the lime is 70 to 80 percent. Due to the use of the converter-strengthened slagging agent, the slagging effect is obviously improved; the slagging time is shortened by 1 to 2 minutes; the blowing process of the converter is stable and has no re-drying and splashing phenomena; the slagging material consumption is reduced; and the service life of the converter lining is prolonged; the content of P at the terminal point of the converter is reduced by 10 to 20 percent; the blowing time of the converter is shortened by 1 to 2 minutes; the smelting cycle is shortened; the converter has no re-drying and splashing phenomena; and the consumption of iron and steel is greatly reduced by 10 kg per ton.

Owner:MAANSHAN IRON & STEEL CO LTD

Environment-friendly converter steel-making slagging agent and preparation method thereof

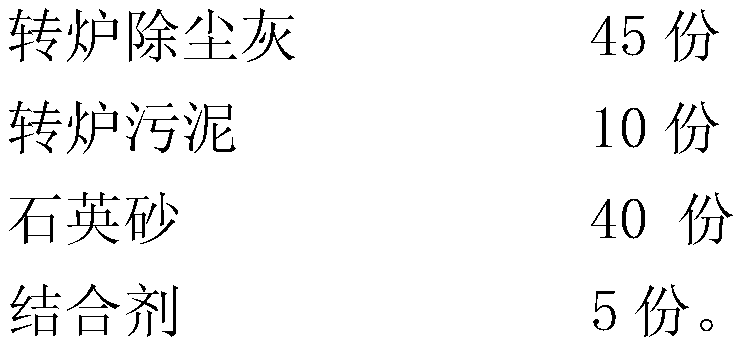

InactiveCN109321705ASolve the pollution problemAchieve recyclingManufacturing convertersProcess efficiency improvementEnvironmental resistanceSocial benefits

The invention relates to an environment-friendly converter steel-making slagging agent and a preparation method thereof, and belongs to the technical field of steel metallurgy converter steel-making.The technical problem that waste comprehensive utilization is difficult in the metallurgical process is solved. The environment-friendly converter steel-making slagging agent is mainly composed of 10-25 parts of steel-making converter sludge, 20-35 parts of steel-making dedust ash, 10-20 parts of tundish waste dry-type material, 40-50 parts of quartz sands and 5-10 parts of binding agents; and themethod comprises the following steps that, firstly, the dedust ash is subjected to the homogenizing treatment, then is uniformly mixed with other raw materials according to the formula, and the pellet slagging agent is prepared by adopting a ball-pressing pelletizing, drying and cooling technology. According to the preparation method, waste resource internal cyclic utilization is realized, and the method has obvious environmental protection and social benefits, the production cost of the steel-making slagging agent product is reduced, and great economic benefits are achieved.

Owner:PANZHIHUA GANGCHENG GROUP

Device for production of magnesium by thermite process and magnesium production process

PendingCN111748691AReduce loading and slag discharge timeIncrease productivitySlagProcess engineering

The invention discloses a device for production of magnesium by a thermite process. The device comprises a vacuum induction furnace, a vacuumizing device and a condensation collecting system. A feeding system is arranged at the top of the vacuum induction furnace, a residue collecting system is arranged at the bottom of the vacuum induction furnace, the condensation collecting system comprises a condensation pipe and a collecting tank, the first end of the condensation pipe communicates with the vacuum induction furnace, and the second end of the condensation pipe communicates with the collecting tank. During magnesium production, raw materials for magnesium production are first filled in the vacuum induction furnace through the feeding system, then the vacuum induction furnace is vacuumized by means of the vacuumizing device, the vacuum induction furnace is heated to the reaction temperature, magnesium oxides are reduced to produce magnesium vapor, the produced magnesium vapor is cooled by the condensation pipe and conveyed to the collecting tank for condensation, after the reduction reaction is over, waste slag in the vacuum induction furnace can be discharged from the bottom through a slag collecting system, feeding and deslagging are easy and convenient, time and labor are saved, and the efficiency is high. The invention further discloses a magnesium production process forproducing magnesium by using the device for production of the magnesium by the thermite process.

Owner:狄保法

Low-cost slag washing method

ActiveCN108018402ANo crusting on the bottom of the bagNo sintering on the bottom of the bagProcess efficiency improvementSlagSulfur

The invention belongs to the technical field of iron and steel metallurgy and in particular relates to a low-cost slag washing method. The low-cost slag washing method comprises the following steps: producing synthetic slag for slag washing in a steel ladle, obtained by casting molten steel, by utilizing refining slag and a deoxidant; then utilizing the produced solid-state synthetic slag with relatively high temperature for slag washing operation of a steel tapping process of the next heat. The method provided by the invention has a simple technology and is low in cost; the consumption of slag production materials is less and the heat of the refining slag is recycled; smooth production is not influenced; compared with cyclic utilization of heat-state refining slag, the low-cost slag washing method has remarkable advantages. Sulfur is effectively removed.

Owner:SHANDONG IRON & STEEL CO LTD

Method for efficiently using converter precipitator dust

InactiveCN106282475AReduce the phosphorus content in the furnacePromote rapid slaggingManufacturing convertersProcess efficiency improvementSlagLiquid surfaces

The invention discloses a method for efficiently using converter precipitator dust, belongs to the technical field of converter steel making methods, and is used for efficient reuse of the precipitator dust. The method is characterized in that the precipitator dust is added along with a chute in the process of extracting vanadium to discharge from semisteel; when the vanadium is extracted to discharge from the semisteel by 1 / 5, a secondary dust removing valve is opened; the chute rotates to add the precipitator dust by one time or two times; after the precipitator dust is added, the precipitator dust is accelerated to melt through front-back movement; the dust removing valve is recovered to a normal state; and after the semisteel is discharged, the iron mixing for converter steel making is prepared. The precipitator dust totally covers the liquid surface of the semisteel to achieve the effect of inhibiting the smoke discharge; the pecipitator dust is molten in a semisteel ladle to form slag to improve the difficulties of making steel slag by the semisteel; and the problems of non-ignition of a converter and explosion venting of an electric field in direct returning of the precipitator dust along with waste steel are solved. The method is an initiate in converter steel making, solves the problem, of capability of effectively using the precipitator dust, not thoroughly solved for a long time, and has the advantages of short flow, high metal yield and low cost.

Owner:HEBEI IRON AND STEEL

Converter composite exothermic agent and preparation method

ActiveCN113005260AEasy to fixHigh calorific valueChemical industryManufacturing convertersPtru catalystCombustion

The invention discloses a converter composite exothermic agent and a preparation method. The converter composite exothermic agent comprises the following raw materials in percentage by mass of 50-60% of a heat supplementing agent, 10-15% of a regulator, 1-3% of a catalyst, 10-20% of a weighting agent, 5-10% of a heat increasing agent and 2-4% of a binding agent. By optimizing the raw materials of the converter composite exothermic agent and the mass percent thereof, the converter composite exothermic agent has the characteristics of stable oxygen-blowing combustion, high heat supplementing efficiency, low cost, convenience in preparation and the like, and finally, the purpose of high-efficiency and low-cost smelting of a converter with a large scrap steel ratio is achieved. Through optimization of process parameters in the preparation method, the consistency of the quality reliability of a heating agent pressing ball and the in-furnace heat compensation effect is ensured.

Owner:武汉钢铁有限公司

Slag adding and slagging method of high-temperature alloy short-electrode electroslag furnace

The invention belongs to the technical field of slag adding of electroslag furnaces, and particularly relates to a slag adding and slagging method of a high-temperature alloy short-electrode electroslag furnace. The slag adding and slagging method of the high-temperature alloy short-electrode electroslag furnace comprises the steps that firstly, slag is placed in a slag adding machine, the slag adding machine is started, and the slag enters a lower smoke hood along a slag adding pipe, then reaches a lower flange, is gathered and aligned on the lower flange, enters a crystallizer, is guided through an electrode cap, finally reaches a bottom pad and starts to be slagged. The slag adding and slagging method of the high-temperature alloy short-electrode electroslag furnace is a simple and smooth feeding mode, the slag can evenly enter the bottom pad of the crystallizer without delay, and the utilization rate of the slag can be increased through the arrangement of the electrode cap; and bysetting proper parameters, the slagging process is smooth, the smelting rhythm can be accelerated, the slag crust thickness is small, the slag inclusion condition is light, and therefore the alloy quality is improved.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

Comprehensive utilization method of converter dust removal ash

InactiveCN110951934ASolve the pollution problemAchieve recyclingManufacturing convertersProcess efficiency improvementSteelmakingDigestion Treatment

The invention discloses a comprehensive utilization method of converter dust removal ash, relates to the technical field of environmental protection, and provides the comprehensive utilization methodof the converter dust removal ash. The comprehensive utilization method of the converter dust removal ash comprises the following steps that A, digestion treatment is carried out on the converter dustremoval ash in a spray water mode; and B, the digested converter dust removal ash is uniformly mixed with other ingredients according to a formula, and a balling environment-friendly converter steelmaking slagging agent is prepared by using a compression ball granulation, drying and cooling process, wherein the converter steelmaking slagging agent raw material comprises the following components of, in part by mass, 40-50 parts of converter dust removal ash, 10-15 parts of furnace sludge, 40-50 parts of quartz sand, and 5-10 parts of binder. According to the comprehensive utilization method, waste which is difficult to comprehensively utilized in the converter dust removal ash, converter sludge and the like of an iron and steel plant is taken as an important components for preparing a slagremover, so that the waste can be recycled, the problem of environmental pollution caused by stacking or burying of the materials is solved, and internal recycling of the waste resources is realized.

Owner:PANZHIHUA GANGCHENG GROUP

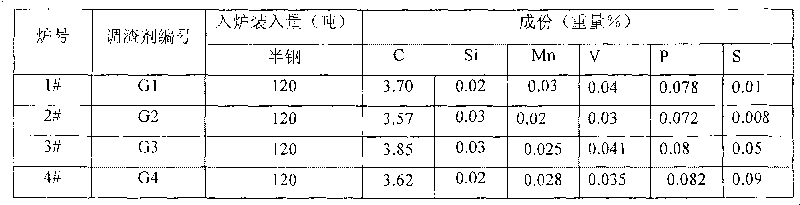

Semi-steel less slagging dephosphorization smelting method capable of rapid slagging

ActiveCN109913613AShorten the formation timeReduce consumptionManufacturing convertersProcess efficiency improvementHigh magnesiumMolten steel

The invention discloses a semi-steel less slagging dephosphorization smelting method capable of rapid slagging, and belongs to the technical field of steel smelting. The semi-steel less slagging dephosphorization smelting method includes the following steps that (1) under the condition that slag exists in a converter, the basicity of the slag is adjusted to be 2-2.5 by adding a composite slag forming agent after converter protection by slag splashing, semi-steel is blended, then under the condition of top blowing oxygen supply and bottom blowing gas supply, blowing and slag forming are conducted, the basicity of the slag is controlled to be 1.5-2 by adding the composite slag forming agent in the process of blowing, and after blowing is completed, turning down and slagging are conducted; (2) after slagging in the step (1), the basicity of the final slag is controlled to be 3-4 by adding high-magnesium lime and active lime into the converter under the condition of top blowing oxygen supply and bottom blowing gas supply, blowing is conducted until qualified molten steel is obtained, and slag B existing in the converter is obtained after steel tapping and all slag remaining; and (3) the step (1) and the step (2) are cycled, wherein the original slag existing in the converter in step (1) is the slag B obtained in the step (2).

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Integrated embedding type skewback foundation excavation construction method

InactiveCN109868746AReduce displacementSolve the construction problem of eccentric compressionBridge erection/assemblyExcavationsComputer scienceBuilding construction

The invention discloses an integrated embedding type skewback foundation excavation construction method, and relates to bridges. The method comprises the steps that at least two steps are excavated ona slope, specifically, the first step is excavated on the slope at first, then, the second step is excavated below the first step, and the rest steps continue being excavated downwards in sequence, wherein the excavation depth of the first step is the largest, and the excavation depth of the follow-up steps is gradually decreased. The method has the beneficial effects that by arranging the multiple steps, the construction problems of large-gradient excavation and hole opening eccentric compression can be solved, and surrounding soil body displacement can be reduced advantageously; and the construction method is reasonable and reliable, the deslagging time can be shortened, and construction progress is accelerated.

Owner:中铁广州工程局集团桥梁工程有限公司 +1

RH furnace refining hydrogen oxygen control process

The invention discloses a RH furnace refining hydrogen oxygen control process. The RH furnace refining hydrogen oxygen control process is characterized by comprising the following steps that temperature measurement is carried out on molten steel; sampling and measuring N, C content are carried out; vacuumizing operation is carried out; high-pressure nitrogen gas and oxygen are adopted for mixing or argon gas and oxygen are used as lifting gas; the vacuum degree is kept at 3-4.5 kPa, and refining slag is added; then a decarbonization process is carried out; ferrochrome is added in the early stage of vacuum circulation degassing refining to perform chromium alloying; and steel liquid temperature measurement and oxygen measurement are carried out; deoxidation operation is carried out by adding low-carbon silicon iron, and alloying adjustment is carried out; dehydrogenation and tranquilizing treatment are carried out; the vacuum is broken, and argon blowing from the bottom and soft stirring is carried out on a steel ladle.

Owner:JINGYE STEEL CO LTD

Composition for slag formation and preparation and use method thereof

The invention provides a composition for slag formation, which comprises the following components based on the total weight of the composition: 45-65wt% of CaO, 10-20wt% of SiO2, 1-5wt% of MnO, 9-25wt% of MgO and 1.5-5wt% of Al2O3. The invention also provides a preparation method and a use method of the composition. The composition for slag formation provided by the invention can promote slaggingin the early stage of smelting semisteel, shorten the slag formation time, and obviously remove phosphorus elements. By adopting the composition for slag formation of the invention for smelting the semisteel, the process is simple, the energy consumption is low, the effect of reducing phosphorus is obvious, the phosphorus content in molten steel is lower than 0.007wt%, and consumption of the semisteel is small when the same amount of steel is obtained by smelting.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

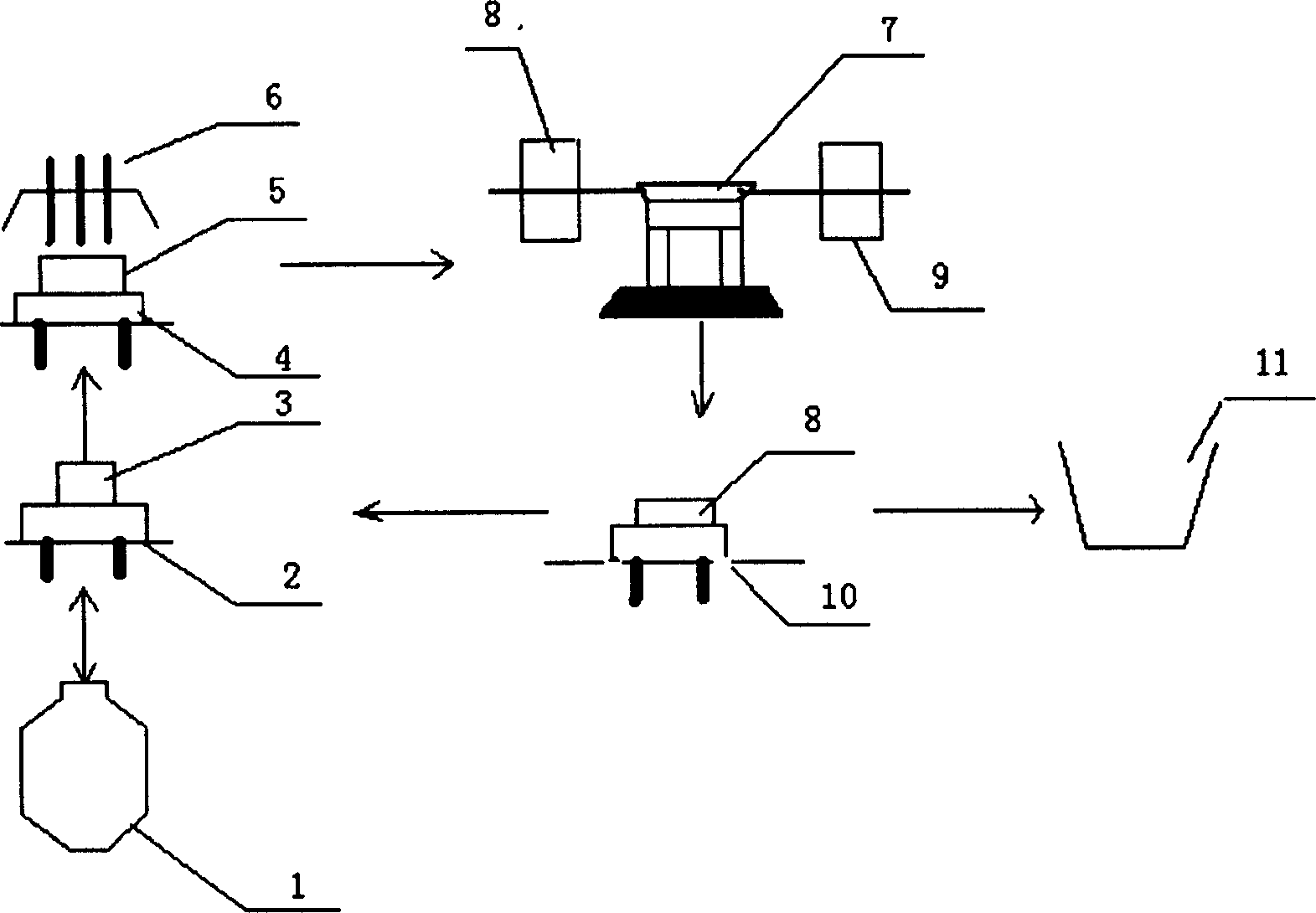

Method for producing steel by using limestone in semisteel steelmaking of top-bottom combined blowing converter

InactiveCN110016534AShorten the slagging timeReduce dosageManufacturing convertersLime productionSteelmakingDecomposition

The invention discloses a method for producing steel by using limestone in semisteel steelmaking of top-bottom combined blowing converter. The method comprises the following steps that semisteel is added into a converter, limestone, lime and light-burned dolomite materials are added in batches for slagging and oxygen supply blowing, and after a converter smelting control end point is reached, thesteel is discharged. According to the method, the limestone is used for replacing part of the lime to carry out converter steelmaking production, so that the use amount of the lime and the dependenceof converter semisteel steelmaking on lime slagging are reduced, meanwhile, the production cost can be reduced, and the purposes of energy conservation, emission reduction and environmental friendliness are achieved; in the limestone decomposition process, the generated CO2 reacts with CO generated in the C in the steel in the floating escaping process, so that not only can the adsorption upward floating of the impurities be promoted, but also the effect of the steel slag interface is promoted, the slagging time of the converter is shortened by 0.5-2.0min, the dephosphorization efficiency is improved, and the final dephosphorization rate is more than or equal to 90%.

Owner:CHENGDE IRON & STEEL GRP

Blowing method of converter and oxygen lance

The invention discloses a blowing method of a converter and an oxygen lance. The blowing method of the converter comprises the following steps: additionally arranging a nitrogen branch on an oxygen supply pipeline of the oxygen lance; and enabling the oxygen lance to simultaneously blow oxygen and high-pressure nitrogen into steel liquid in the converter in the earlier, middle and later stages of blowing. The blowing method and the oxygen lance have the following advantages that the change for equipment is small, and the cost is relatively low; the implementation and operation costs are low, and the operation is simple and convenient; the metal yield is increased, the service life of a copper head of the oxygen lance is prolonged, and the possibility of explosion venting caused by electric dust removal is reduced; the slag discharging time is shortened; the effect of carbon content retaining steel tapping in the final stage of blowing is obvious; meanwhile, the temperature and components in a molten pool are evened; and the problem that the bottom blowing effect of a conventional top and bottom combined blowing converter in the intermediate campaign is not obvious can be solved.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

High-efficiency water precipitation and concentration system and traditional Chinese medicine extraction system

PendingCN107088312AReduce workloadImprove work efficiencyFiltration circuitsMultiple-effect evaporationEnvironmental engineeringHooking

The invention relates to the field of pharmaceutical equipment and provides a high-efficiency water precipitation and concentration system. The high-efficiency water precipitation and concentration system comprises a water precipitation refrigeration pot, a plate and frame filter and a multi-effect concentration system, which are connected in sequence, wherein a dreg discharging hole and a dreg discharging hole cover for closing the dreg discharging hole are arranged at the bottom of the water precipitation refrigeration pot; the dreg discharging hole cover is connected with a discharging assisting part; the discharging assisting part comprises a connecting rod and a backward hooking part which are connected with each other; the connecting rod is connected with the dreg discharging hole cover; the backward hooking part is located in the water precipitation refrigeration pot; a liquid inlet pipe is arranged at the top of the water precipitation refrigeration pot and a liquid outlet pipe is arranged at the lower part of the water precipitation refrigeration pot; one end of the liquid outlet pipe is communicated with the plate and frame filter and a filter is arranged at the other end of the liquid outlet pipe; the filter is located in the water precipitation refrigeration pot. The high-efficiency water precipitation and concentration system has high working efficiency. The invention further provides a traditional Chinese medicine extraction system; the traditional Chinese medicine extraction system comprises the high-efficiency water precipitation and concentration system provided by the invention and has high working efficiency.

Owner:江苏北松健康产业有限公司

LF furnace smelting method for improving continuous casting castability of low-silicon molten steel

The invention provides an LF furnace smelting method for improving the continuous casting castability of low-silicon molten steel. Compared with the prior art, the LF furnace smelting method has the following advantages that the lime washing amount of converter slag is increased, and the slagging time of the LF furnace is shortened; the slag is deeply deoxidized by adding a molten steel purifyingagent, so that the problem of high oxygen content of low-silicon molten steel slag is solved; secondary oxidation of the low-silicon molten steel and slag is effectively avoided by adjusting the dustremoval opening degree in the soft blowing process; and finally, the flowability of the smelted low-silicon molten steel in continuous casting is improved, and inclusions in the steel are remarkably reduced.

Owner:新余钢铁股份有限公司

Rapid slag-forming method for dephosphorization of semi-steel with less slag

ActiveCN109913613BShorten the formation timeReduce consumptionManufacturing convertersProcess efficiency improvementMolten steelGas supply

The invention discloses a rapid slag-forming semi-steel and less slag dephosphorization smelting method, belonging to the technical field of iron and steel smelting, comprising the following steps: (1) adding a composite slagging agent after splashing slag to protect the furnace under the condition that there is slag in the converter Adjust the basicity of the slag to 2-2.5, mix it with semi-steel, and then carry out blowing and slagging under the conditions of top blowing oxygen supply and bottom blowing gas supply. During the blowing process, add a compound slagging agent to control the slag basicity 1.5‑2, after the blowing is completed, pour the furnace and discharge the slag; (2) Step (1) After the slag discharge, add high-magnesia lime and active lime to the converter under the condition of top-blowing oxygen supply and bottom-blowing gas supply to control the end-point slag The basicity is 3-4, blowing to obtain qualified molten steel, tapping, all slag, obtain the slag B that exists in the converter; (3) step (1)-(2) is carried out in circulation, wherein, step ( In 1), the slag initially present in the converter is the slag B obtained in step (2).

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for blowing high-grade matte through horizontal rotary furnace

The invention relates to a method for blowing high-grade matte through a horizontal rotary furnace. The technical problem is solved that an existing matte blowing method is long in blowing cycle, lowin air supply time rate and low in single furnace output. According to the technical scheme, the method includes the following steps of firstly, selecting the matte at the grade of 70-75% as the blowing raw material; secondly, conducting thermal insulation on a hearth through natural gas when the empty rotary furnace waits for the material; thirdly, adding 50 tonnages of the raw material into therotary furnace for blowing; fourthly, conducting blowing for 30-50 minutes, and then adding 25 tonnages of the raw material into the rotary furnace to continue the blowing; fifthly, conducting blowingfor 25-35 minutes, and then adding 25 tonnages of the raw material into the rotary furnace for blowing for 5 minutes, and then adding quartz stone into the furnace to continue the blowing; sixthly, continuing the blowing for 65-75 minutes, then conducting depositing for 5 minutes, and then discharging residues. When the high-grade matte is blown in the horizontal rotary furnace, a traditional two-cycle blowing method is changed into a single-cycle blowing method, the blowing time is shortened, and the method has the advantages of high safety coefficient, large cold material throughput, low inproduction cost and the like.

Owner:山西北方铜业有限公司

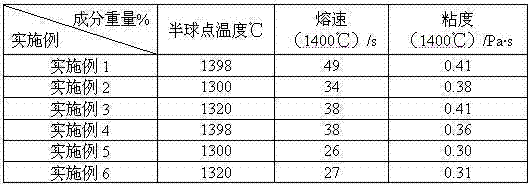

Efficient boron-removing slag former and preparation method thereof and method for removing boron and slagging

ActiveCN104016351ARich range of materialsHigh purityMaterial nanotechnologySilicaSodium carbonateSlag

The invention relates to the technical field of polysilicon purification, and particularly relates to an efficient boron-removing slag former and a preparation method thereof, and a method for removing boron and slagging. The boron-removing slag former comprises the following components: 40-60wt% of nanosilicon dioxide and 40-60wt% of sodium carbonate, preferably, 40-50wt% of nanosilicon dioxide and 50-60wt% of sodium carbonate, wherein the grain diameter of the nanosilicon dioxide is 50-130nm, preferably 60-120nm. By using common silicon dioxide, the proportion of a component B of a slag system is 4; by using the nanosilicon dioxide, the proportion of the component B is increased to 7-10. The nanosilicon dioxide is large in surface activity, high in boron-removing distribution coefficient, and significant in effect; the dosage of the slag former can be effectively reduced, the slagging time is shortened, and the cost is greatly reduced.

Owner:福建上杭兴恒硅品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com