Fluoride-free slagging flux for electric-arc furnace steelmaking

An electric arc furnace and slag making technology, applied in the field of iron and steel smelting, can solve the problems of slow slagging speed, poor slagging effect, and large amount of dust, and achieve the effects of fast slagging speed, fast melting speed and improving the life of furnace lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

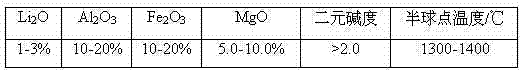

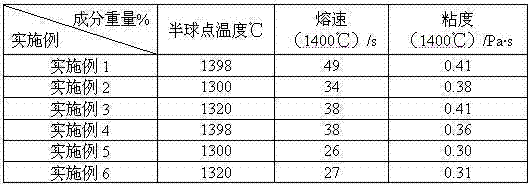

Embodiment 1

[0050] Ingredients: Spodumene 20Kg, Bauxite 20Kg, Active Lime 50Kg, Iron Oxide 5Kg, Magnesia 5Kg.

[0051] Preparation process: Mix the materials well, press the balls with a ball press, dry at 150°C, sinter at 600°C, sieve and pack the finished product after cooling; see Table 2 for the main composition indexes of the product, and see Table 2 for the main performance indexes table 3.

Embodiment 2

[0053] Ingredients: 40Kg of spodumene, 15Kg of bauxite, 30Kg of active lime, 10Kg of iron oxide, 5Kg of magnesia.

[0054] Preparation process: Mix the materials well, press the balls with a ball press, dry at 150°C, sinter at 600°C, sieve and pack the finished product after cooling; see Table 2 for the main composition indexes of the product, and see Table 2 for the main performance indexes table 3.

Embodiment 3

[0056] Ingredients: Spodumene 35Kg, Bauxite 15Kg, Active Lime 30Kg, Iron Oxide 10Kg, Magnesia 10Kg.

[0057] Preparation process: Mix the materials well, press the balls with a ball press, dry at 150°C, sinter at 600°C, sieve and pack the finished product after cooling; see Table 2 for the main composition indexes of the product, and see Table 2 for the main performance indexes table 3.

[0058] Second set of examples

[0059] The raw materials used in this group of examples are the same as those in the first group of examples. The difference is that this group of examples is prepared by pre-melting, that is, the raw materials are fully dried first, and then the ingredients are weighed according to the weight ratio and ground to below 3mm. Mix evenly, and then pre-melt, cool, crush and sieve to make finished products in sequence, and the particle size range of the finished products is 1-30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com