Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Reduce the number of processing steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

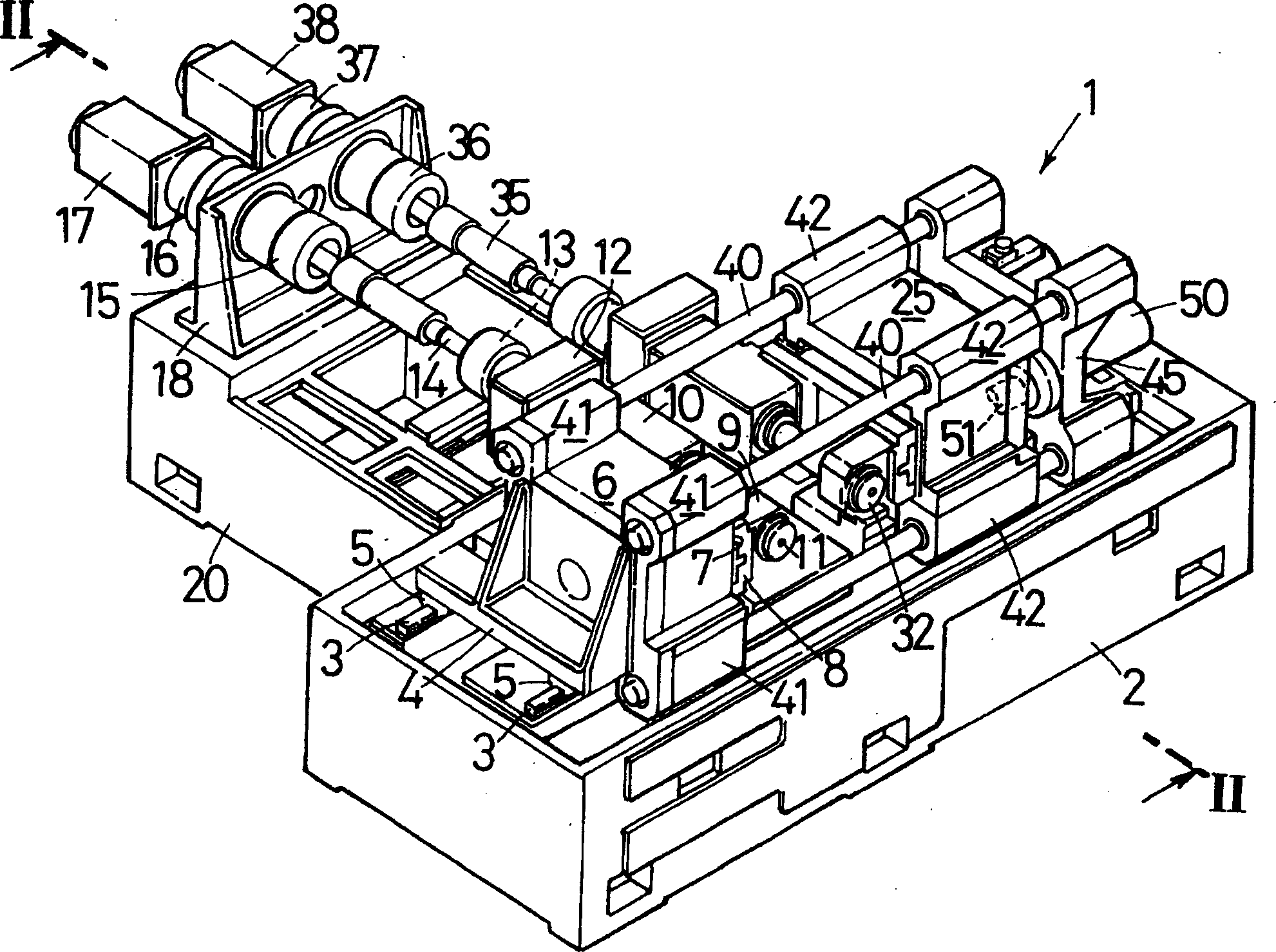

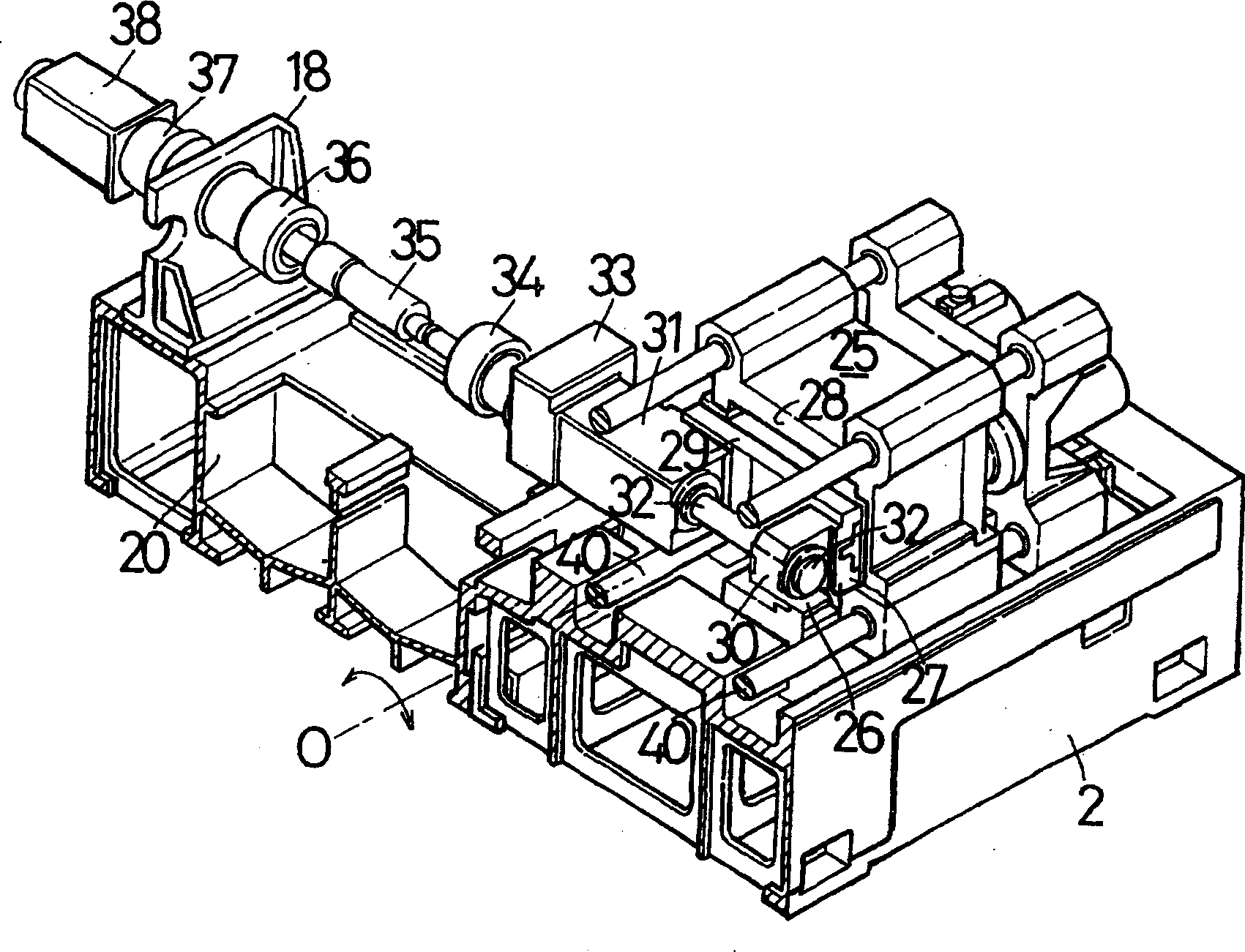

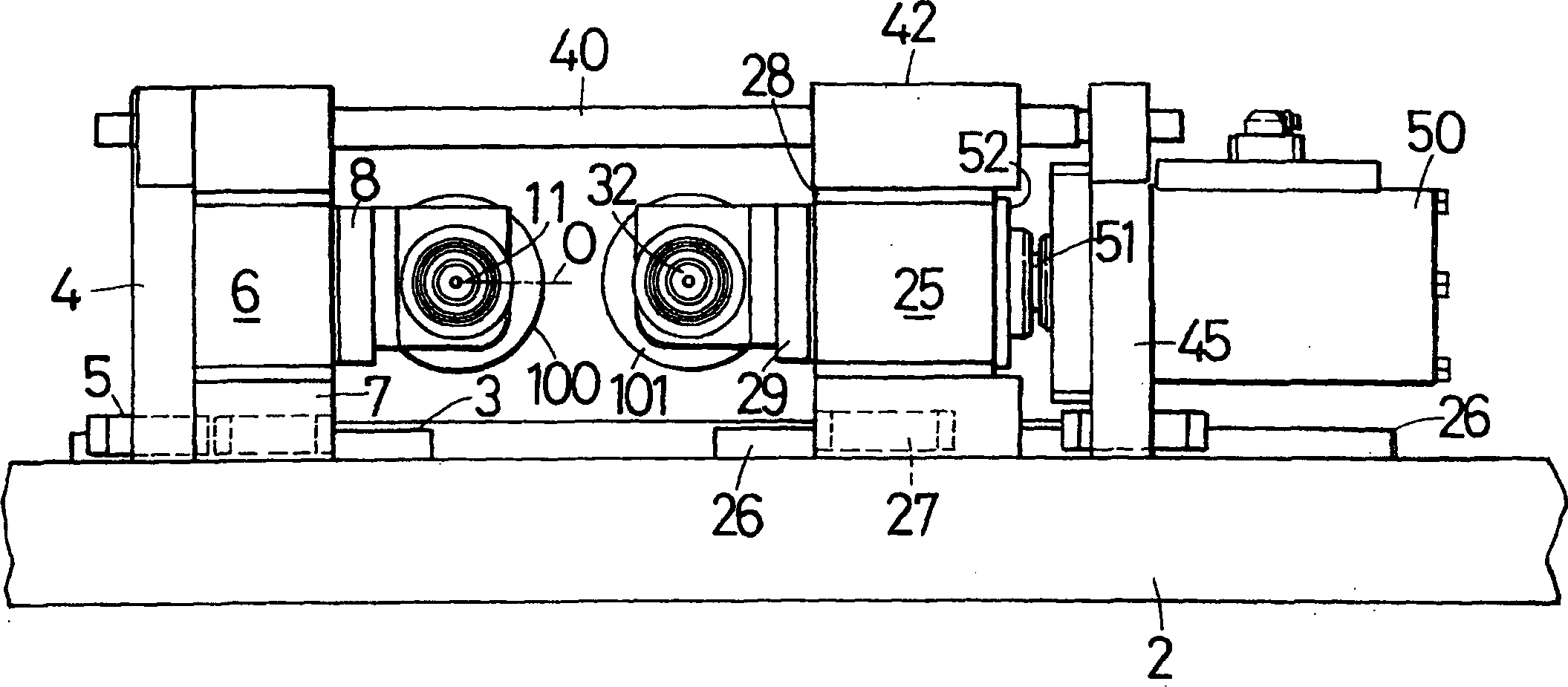

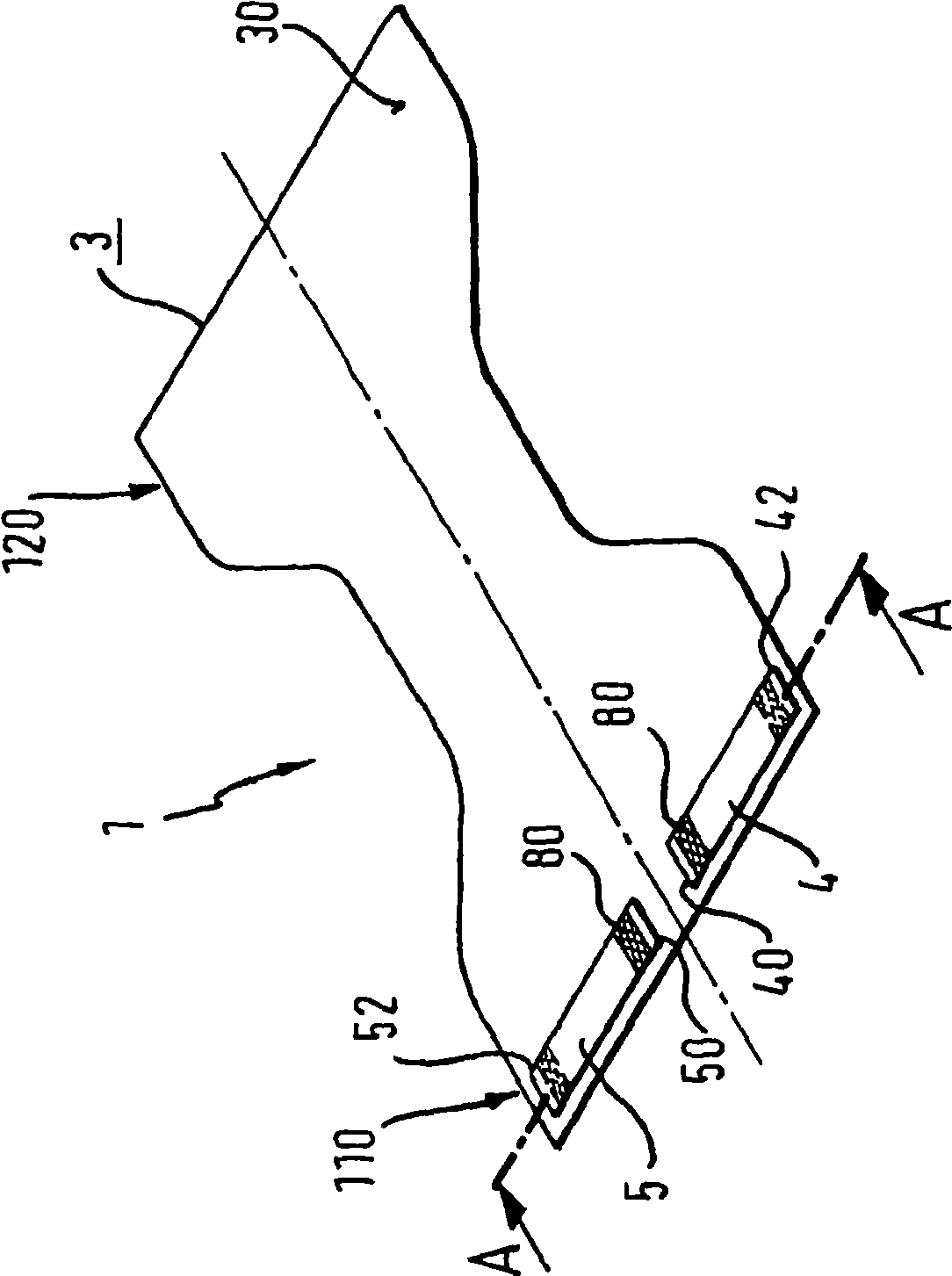

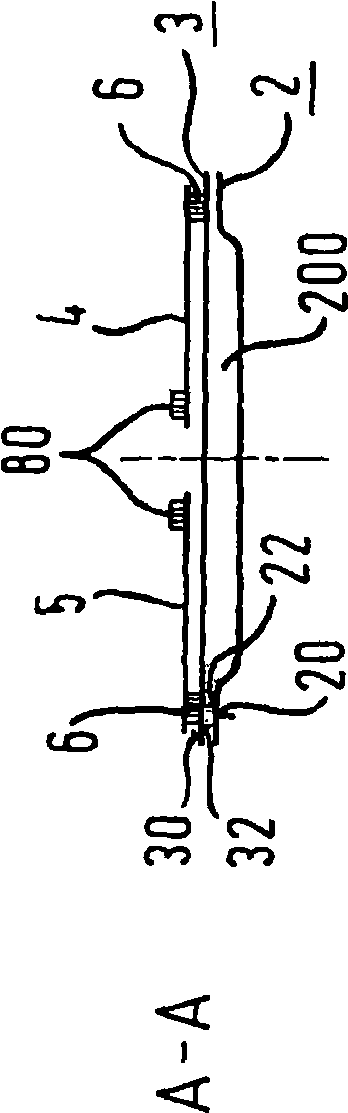

Method of rolling worm gear and worm gear

InactiveCN1463210AReduce the number of processing stepsReduce processing costsPortable liftingGear wheelsSlide plateServomotor

A method of forming a worm gear by rolling to reduce the number of working processes while sufficiently assuring a gear accuracy, comprising the step of positioning a work material between a first rolling die (100) and a second rolling die (101) by the rotation of the rolling dies and a servo-motor (76) for feeding the work material, wherein the lead angle of the worm gear varies to produce a step during form rolling when the lead angle is large enough to produce a large difference between a finished diameter and a material diameter, a slide table (55) is slid freely on a feed table (53) and detected by a detection sensor when the step occurs by the lead angle of the first rolling die (100), second rolling die (101), and the work since the slide plate (55) is allowed to slid freely on the feed table (53), the rotations of the first rolling die (100) and the second rolling die (101) are stopped, the reverse movement of the slide plate (55) is also started to start the rolling simultaneously when the first rolling die (100) and the second rolling die (101) are started to rotate reversely and the same steps are repeated for rolling.

Owner:NISSEI CO LTD

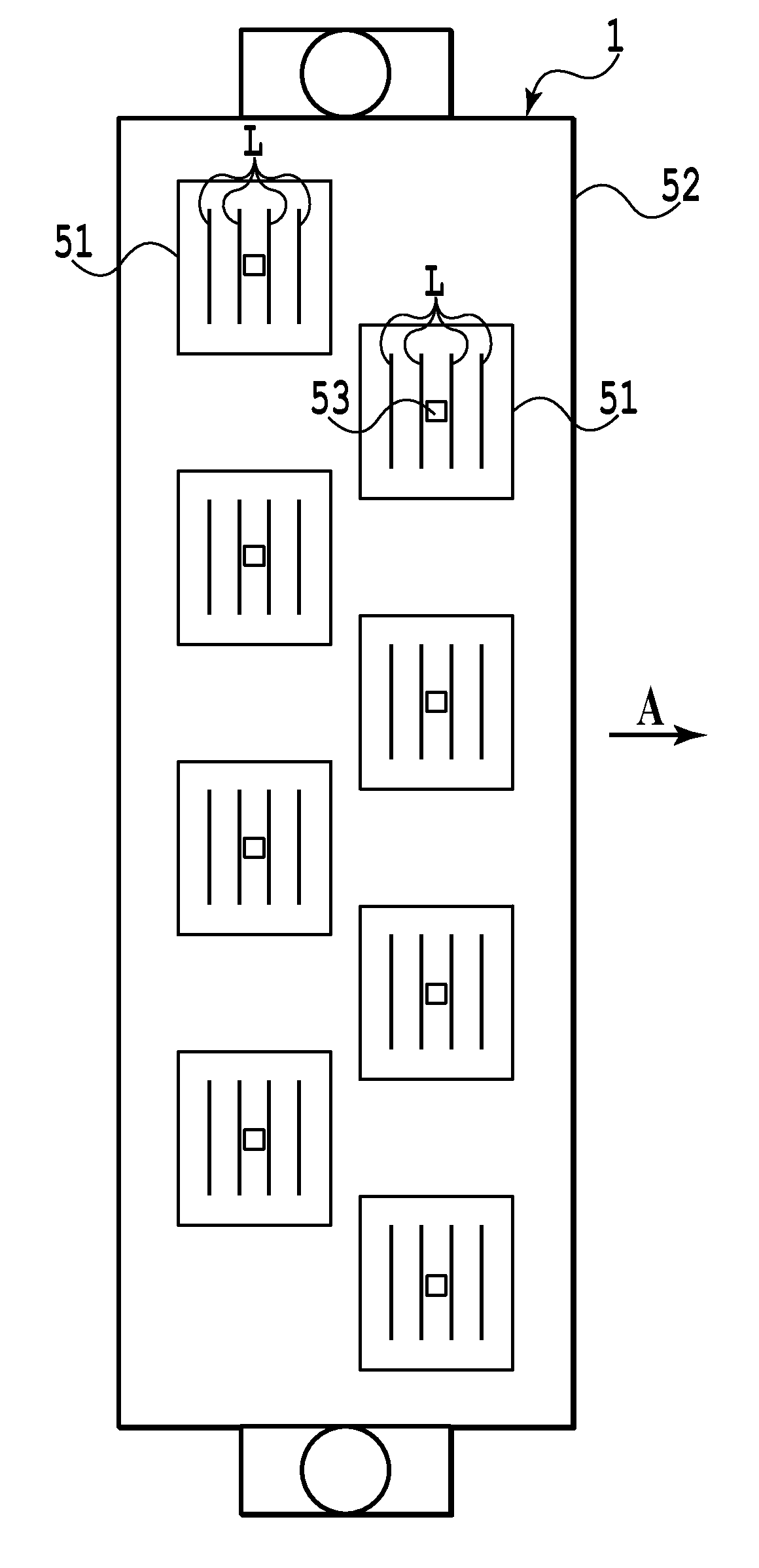

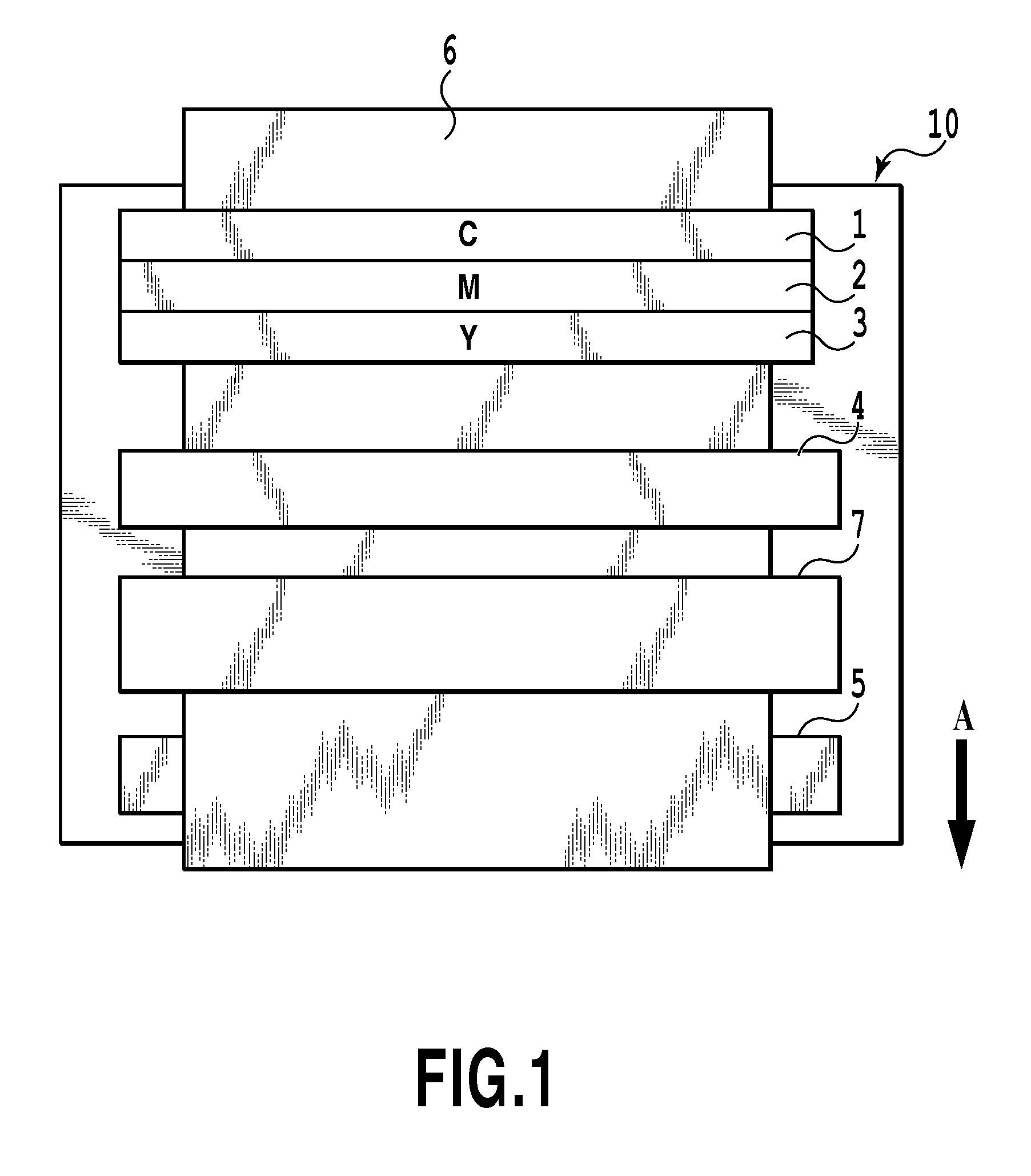

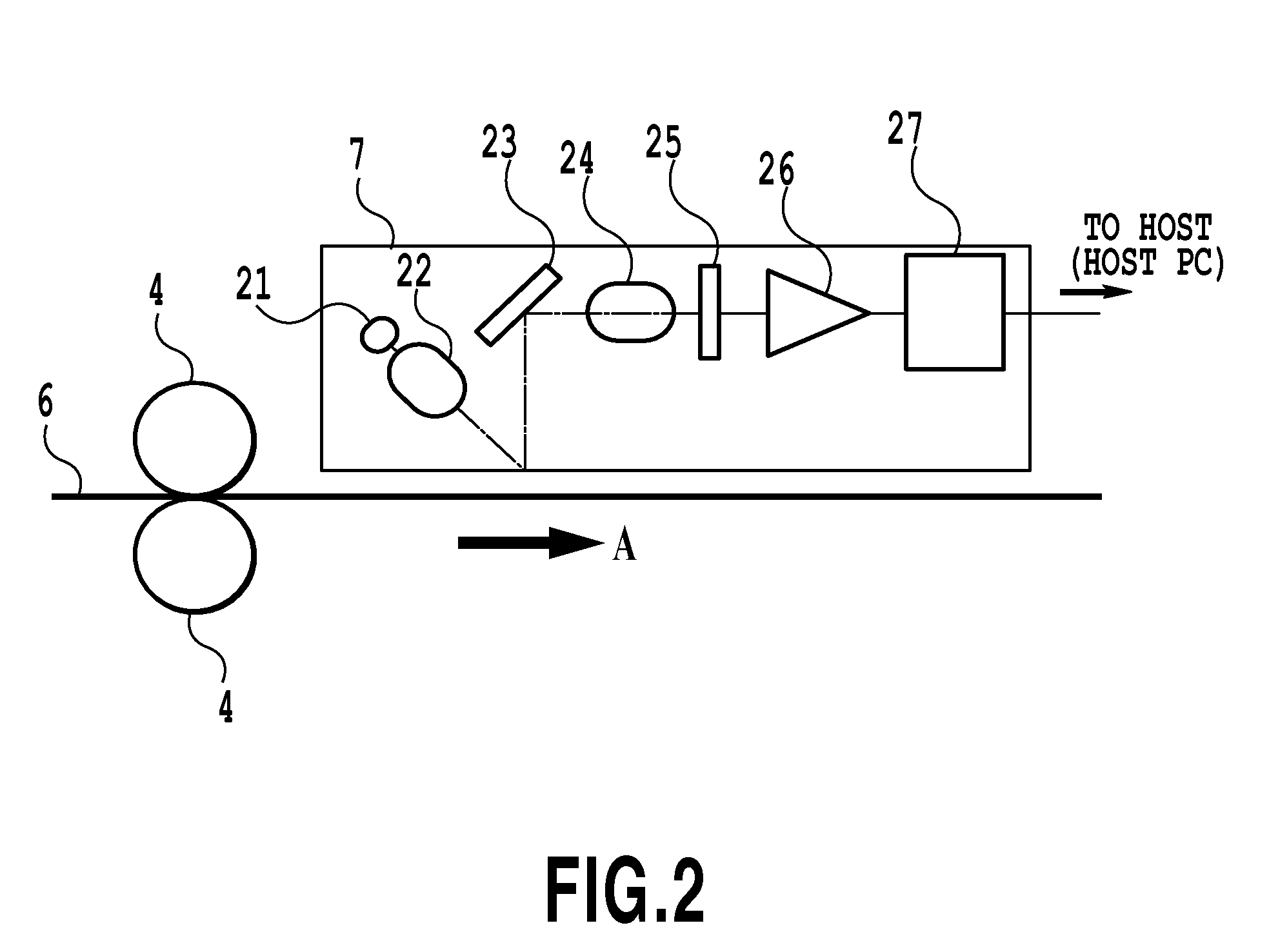

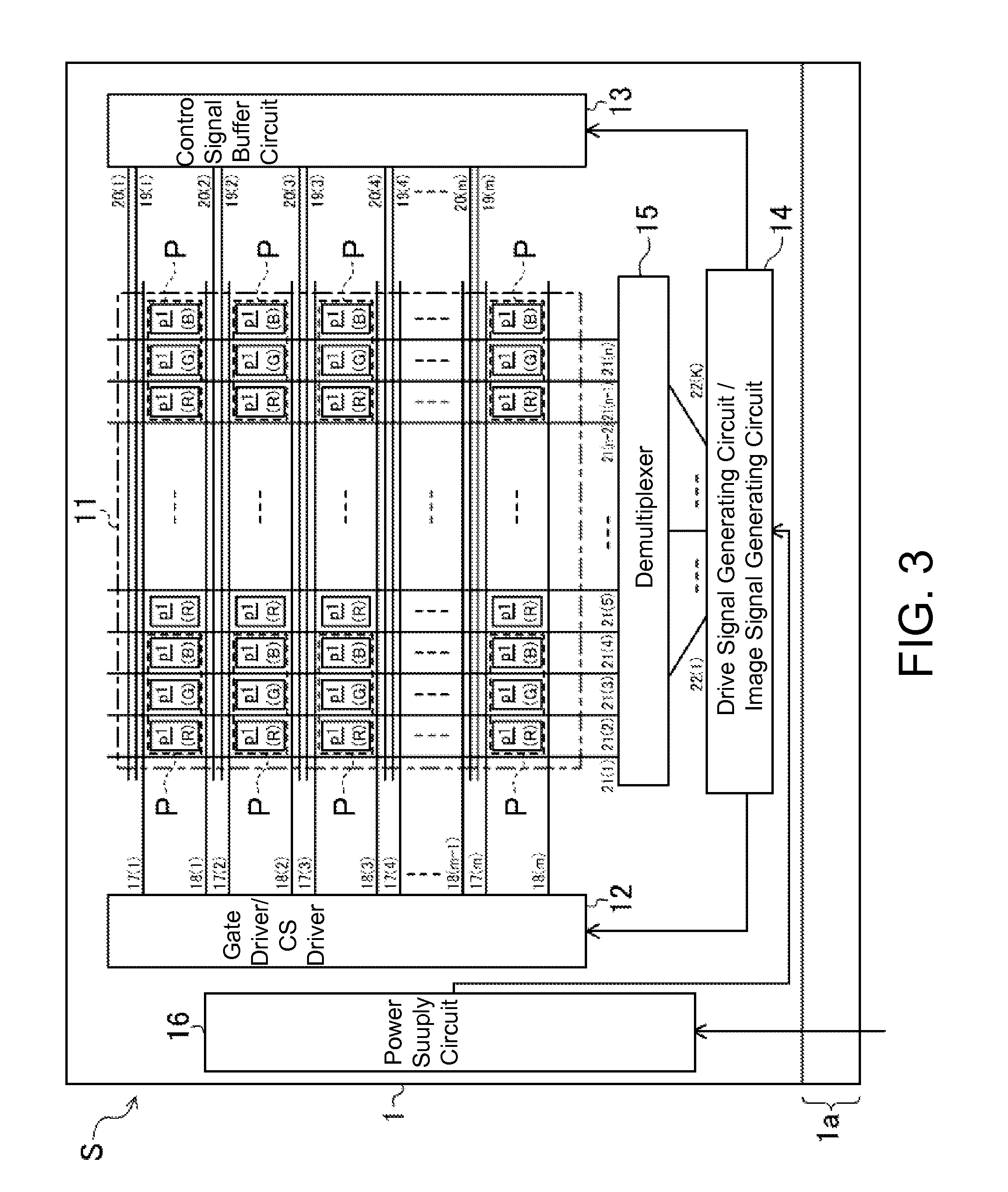

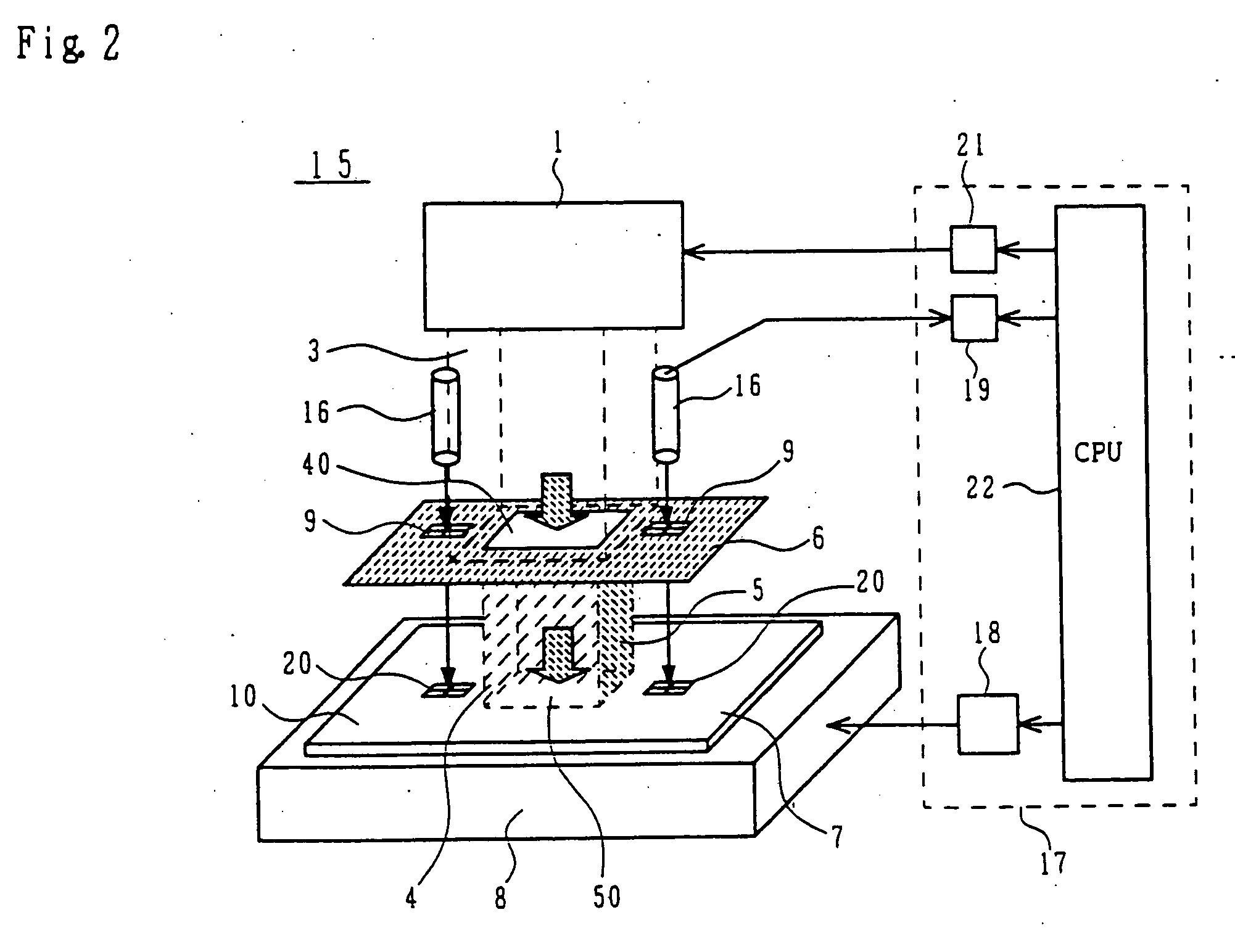

Printing apparatus and method for controlling printing apparatus

InactiveUS20120069067A1Reduce the number of processing stepsDensity unevennessDigitally marking record carriersVisual presentation using printersVolumetric Mass DensityEngineering

According to the present invention, each printing head includes chips wherein a plurality of nozzles are prepared. The density of dots formed by ejecting ink from the nozzles is detected for each chip, and when a density difference between the chips is smaller than a predetermined value, print data are corrected, and the number of dots is adjusted so as to reduce the density difference. When the density difference is equal to or greater than the predetermined value, first, a drive pulse for the nozzles is modulated and the volume of ink to be ejected for one dot is adjusted so as to reduce the density difference. Thereafter, the print data is corrected, and the number of dots to be formed is controlled so as to reduce the density difference.

Owner:CANON KK

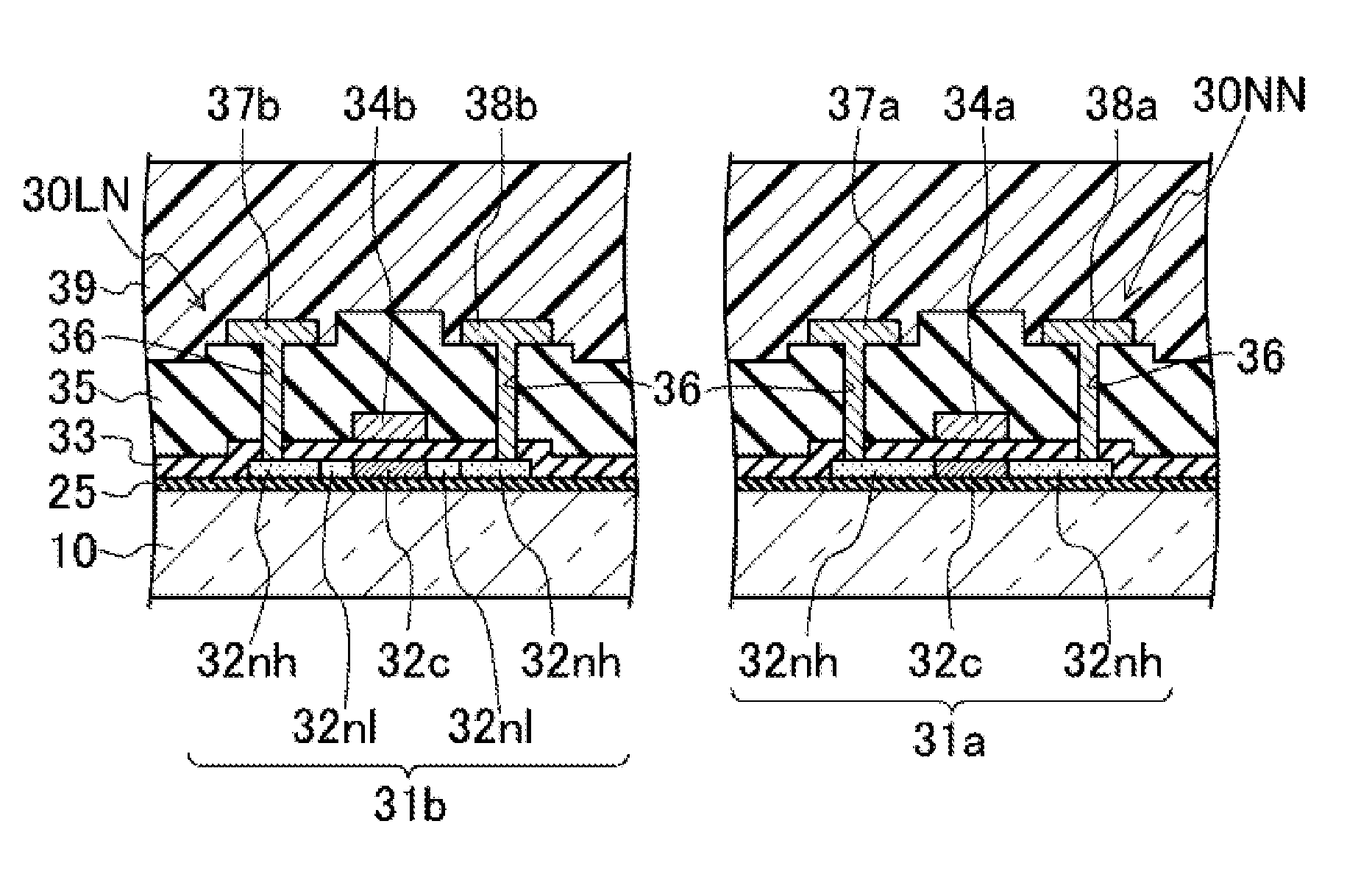

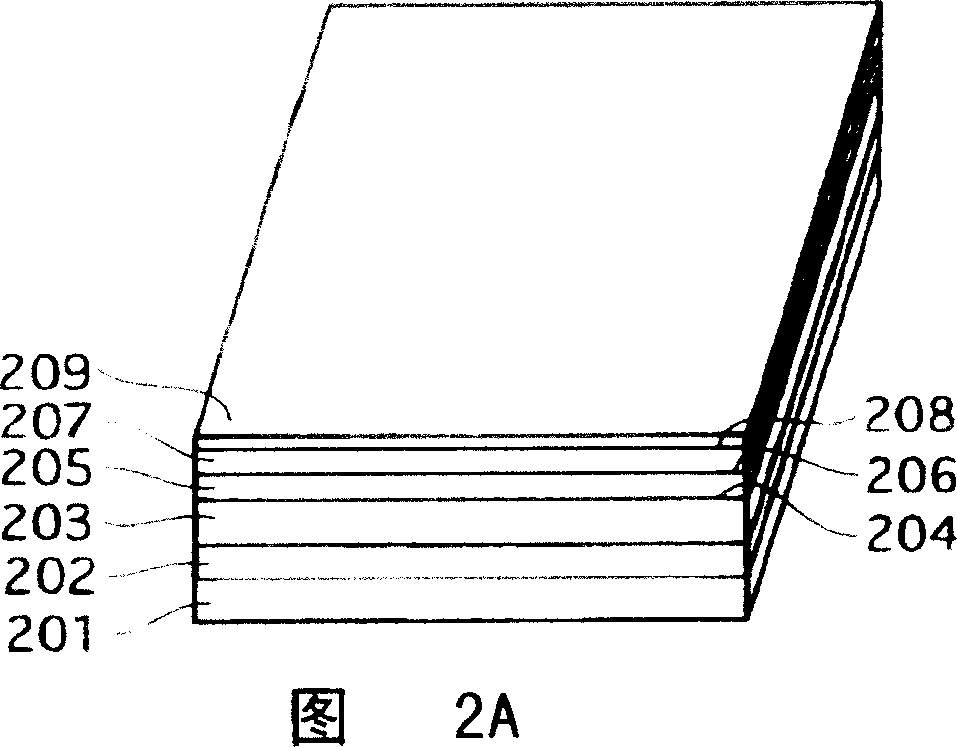

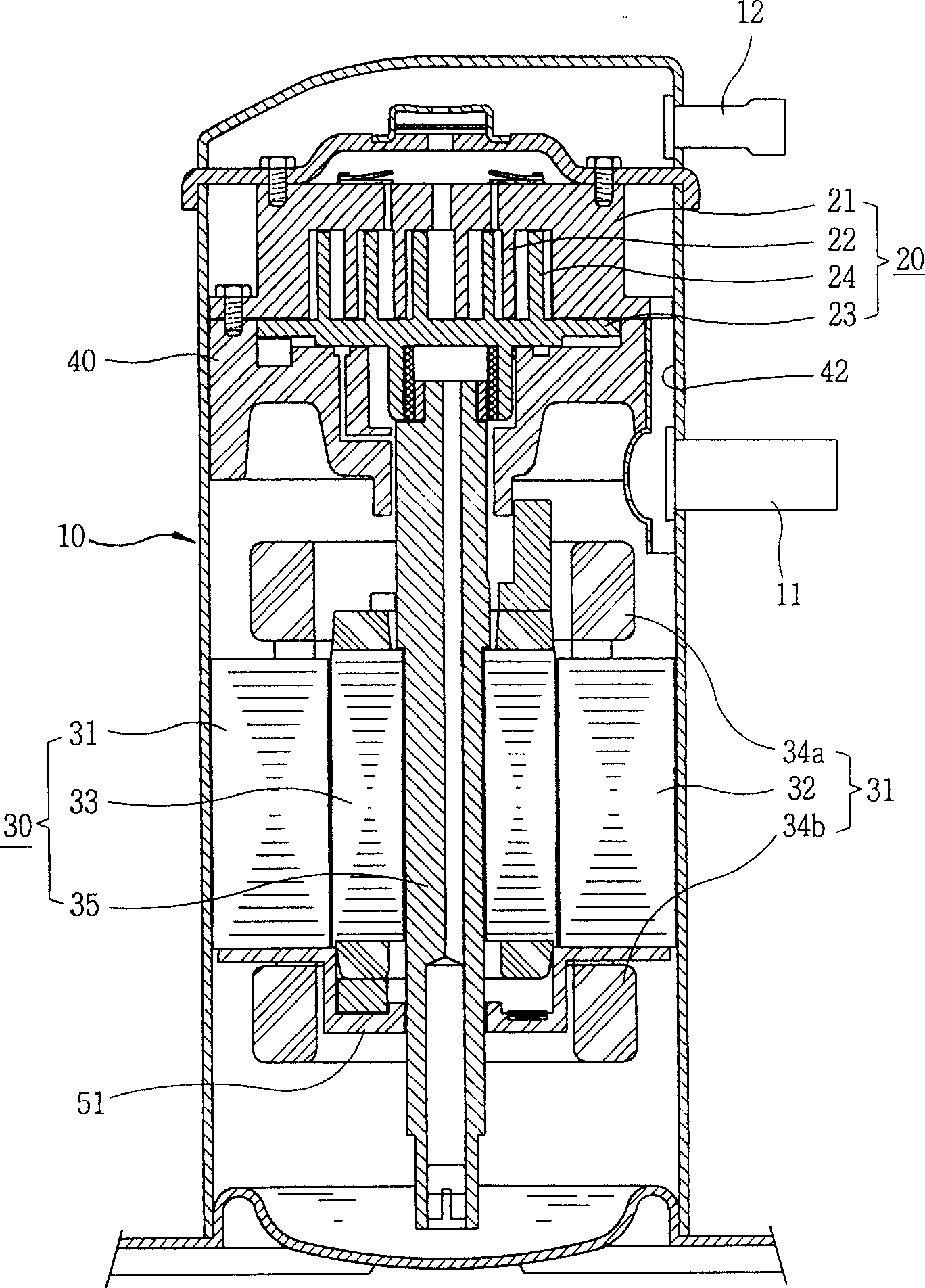

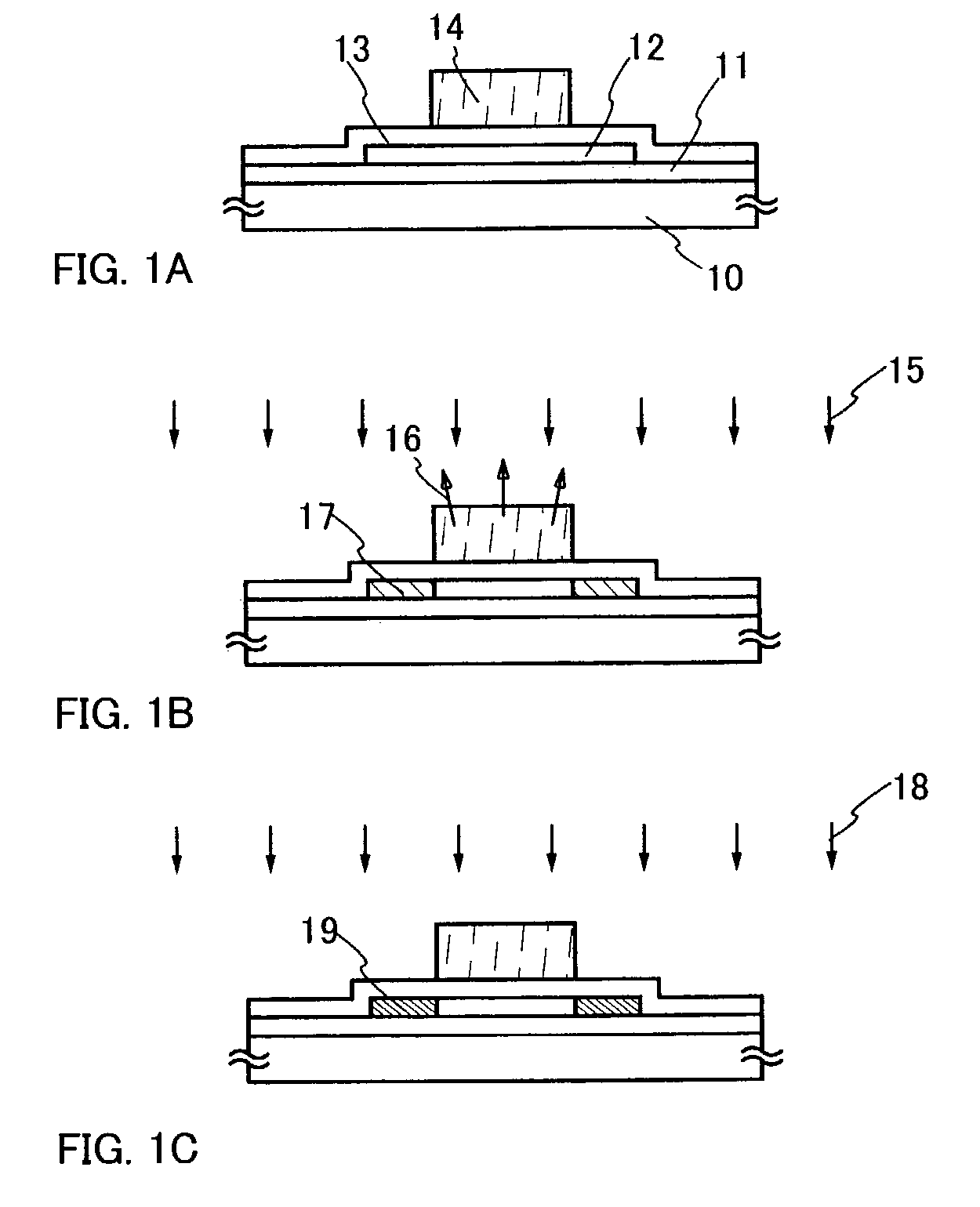

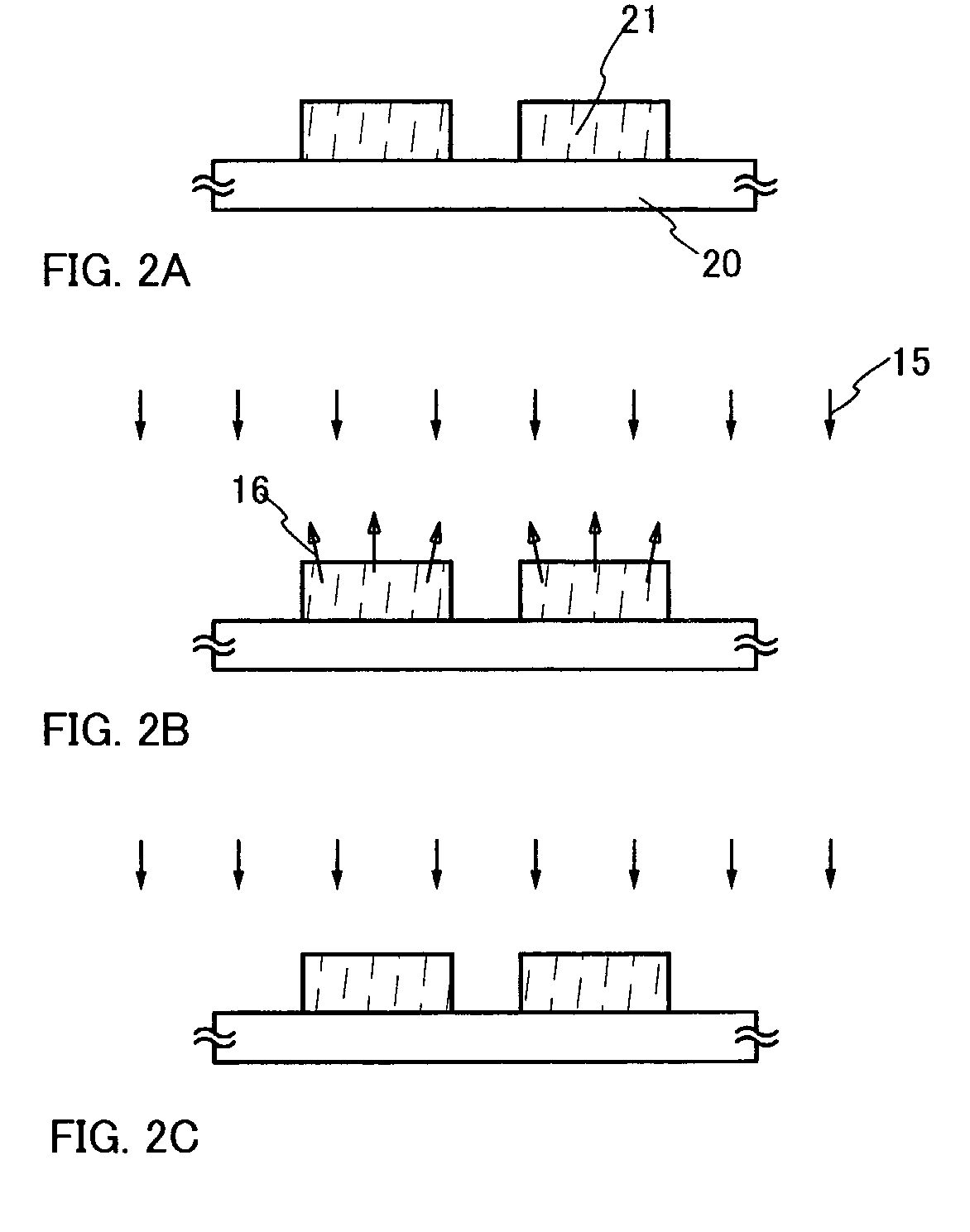

Method for producing semiconductor device

InactiveUS20140051238A1Less photomasksReduce the number of processing stepsSolid-state devicesSemiconductor/solid-state device manufacturingResistImpurity

A first resist layer (46a) and a second resist layer (46b) that is thicker than the first resist layer (46a) are formed using a multi-gradient mask, a conductive film (44) is isotropically etched with both resist layers (46a, 46b) as masks, gate electrodes (34a, 34b) are formed narrower than the resist layers (46a, 46b) at locations corresponding to first and second semiconductor layers (31a, 31b), overhang portions (47) of the resist layers (46a, 46b) are configured at the sides of the gate electrodes (34a, 34b), then the entire first resist layer (46a) is removed and the second resist layer (46b) is thinned into a thin film; and an impurity is injected into the first semiconductor layer (31a) with the gate electrode (34b) as a mask, and into the second semiconductor layer (31b) with the second resist layer (46b) as a mask.

Owner:SHARP KK

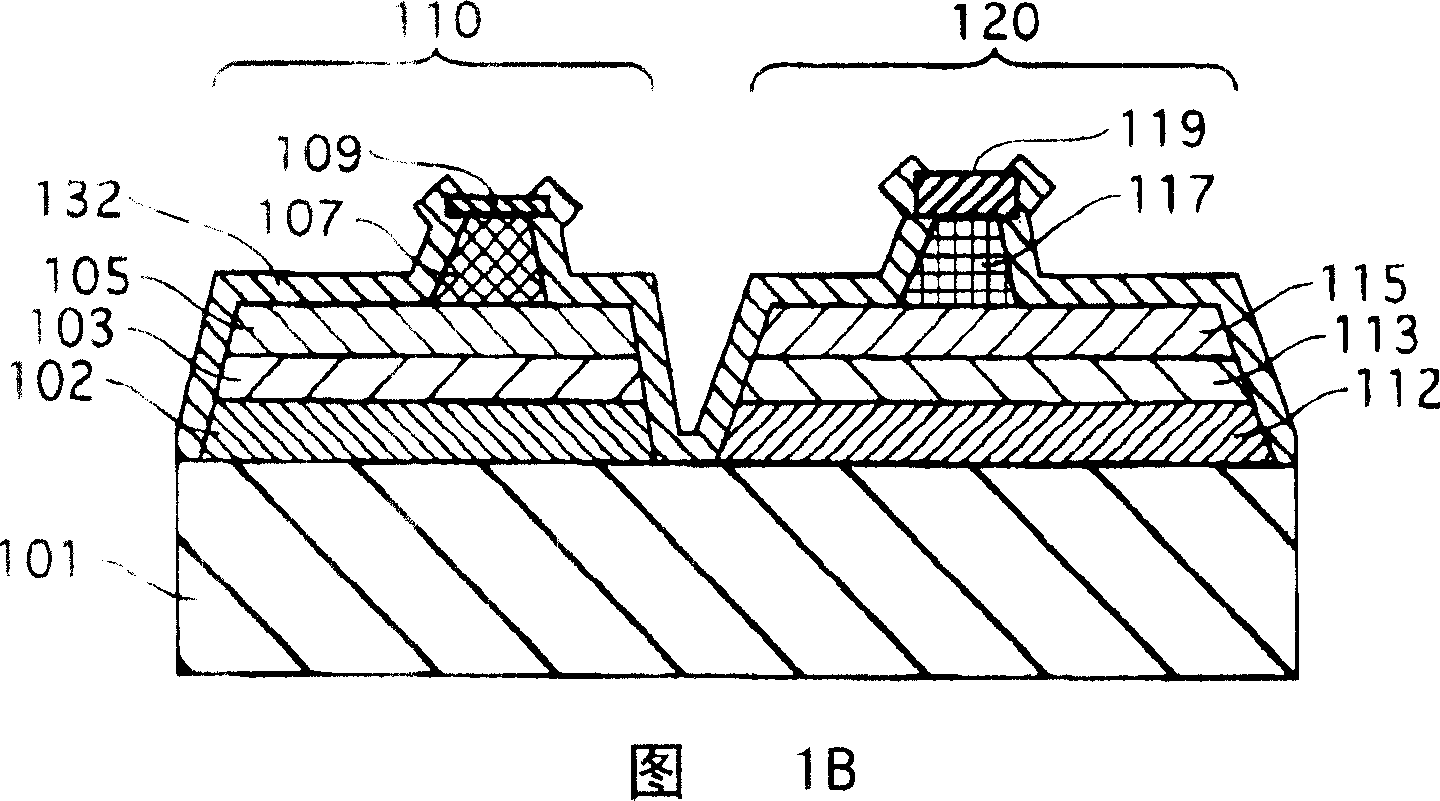

Semiconductor laser device and manufacturing method thereof

InactiveCN101047302ASpread evenlyPrevent proliferationOptical wave guidanceLaser optical resonator constructionRed laserContact layer

A semiconductor laser device is prepared as integrating infrared laser unit and red laser unit on n type of semiconductor substrate in monolithic way, setting ridge waveguide and window both being formed by Zn diffusion on each said infrared laser unit and each said red laser unit, arranging said infrared and red laser units in their own Pa and Pb types of layers on waveguide ridge and setting Pa type of contact layer to be thinner than Pb type of contact layer.

Owner:PANASONIC CORP

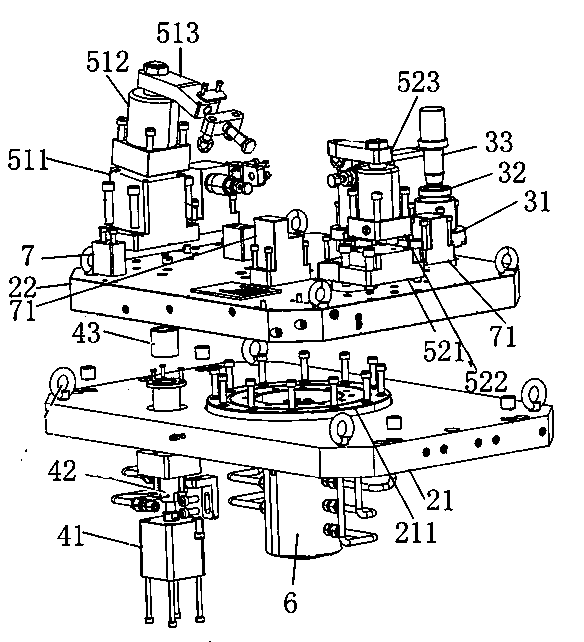

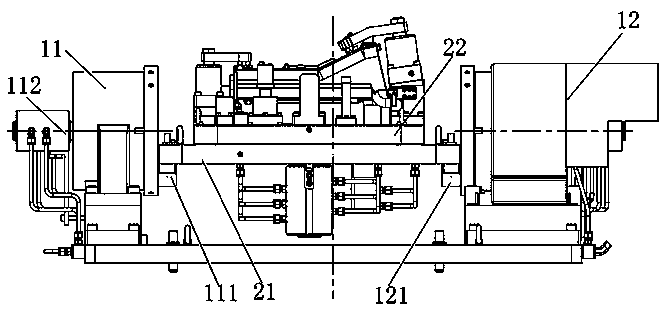

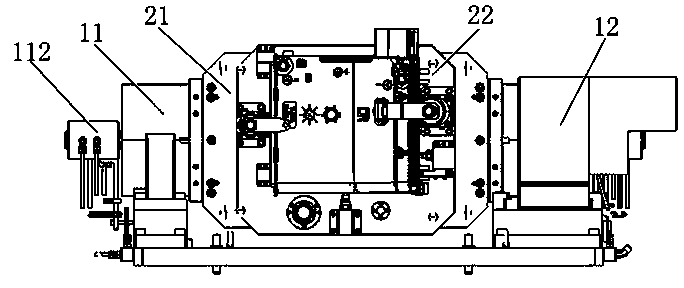

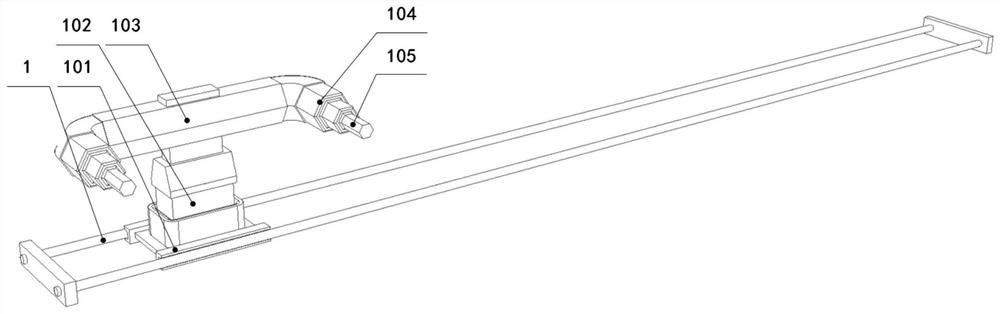

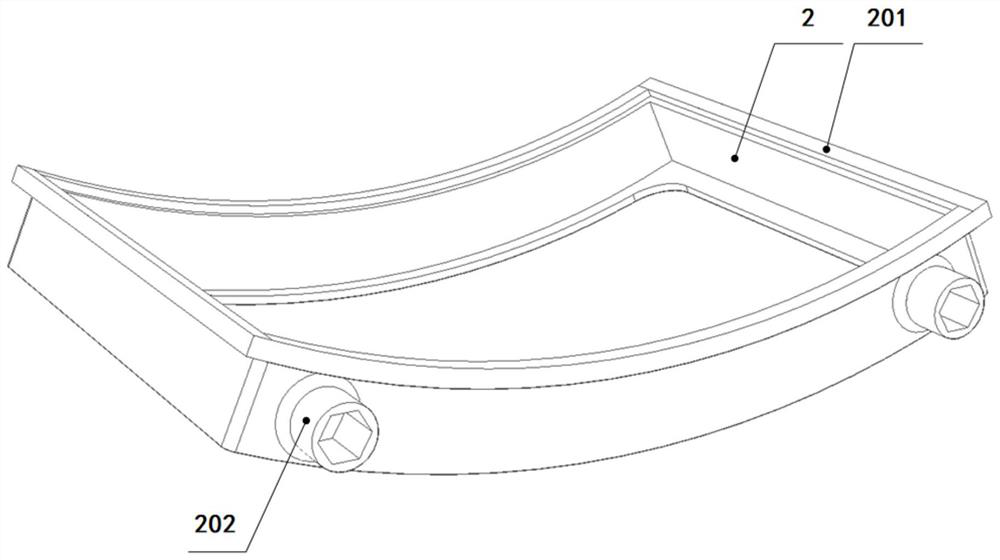

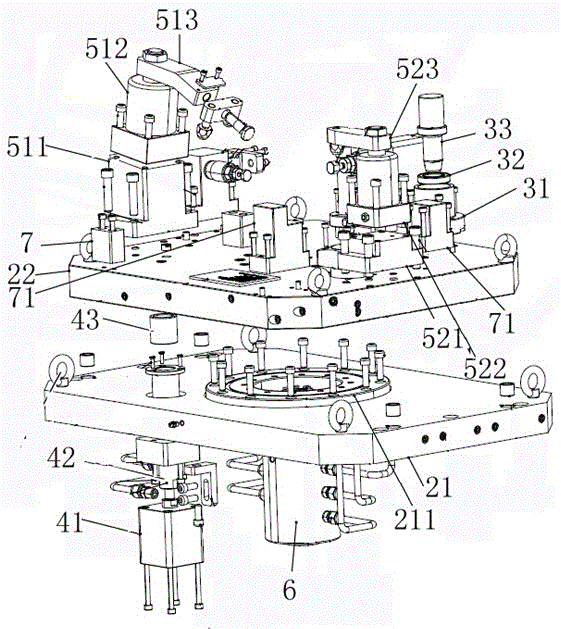

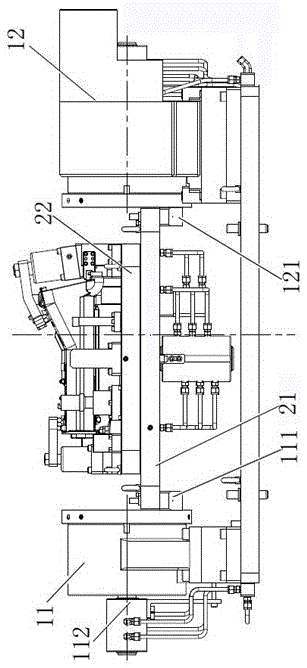

Quasi-five-axis machining centre and machining method thereof

ActiveCN104097072AGuaranteed rotation accuracyGuaranteed rigidityLarge fixed membersPositioning apparatusMachine toolMachining

The invention discloses a quasi-five-axis machining centre and a machining method thereof. The quasi-five-axis machining centre comprises an AC rotary table structure, wherein the AC rotary table structure comprises a C-axis rotary table, the C-axis rotary table comprises a bridge frame plate with one end which is supported and connected to a first support table, and the other end which is supported and connected to a second support table, and a crossing shaft ring capable of freely rotating around a C-axis is further assembled on the bridge frame plate; a rotary plate is arranged by being parallel to the axis direction of an A-axis, and supported and connected to the rotary end surface of the crossing shaft ring, a shaft sleeve is further arranged on the rotary plate, and a rotary bearing capable of freely rotating around the C-axis is arranged in the shaft sleeve; a machining main shaft is detachably connected with a drive pin, and when the rotary bearing moves to be below the drive pin, the drive pin is inserted in the middle hole of the rotary bearing. According to the quasi-five-axis machining centre and the machining method thereof disclosed by the invention, the rotary power source of the C-axis is from the machining main shaft of a common vertical machine, and the existing common vertical XYZ three-axis machine can be utilized, thus furthest reducing the machining cost of polyhedral components; moreover, the machining accuracy is high and the equipment structure is simple.

Owner:SUZHOU MINGZHI TECH

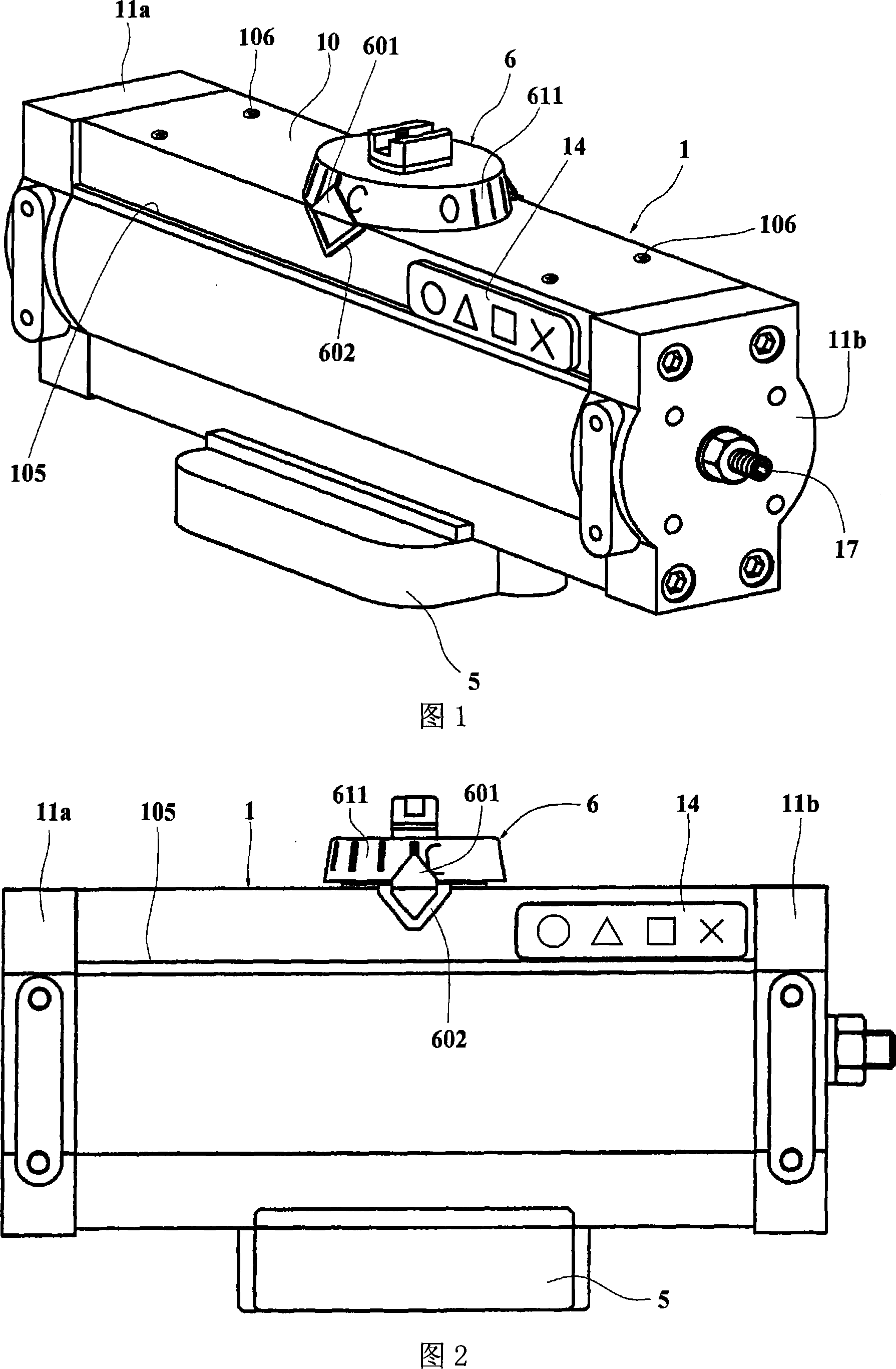

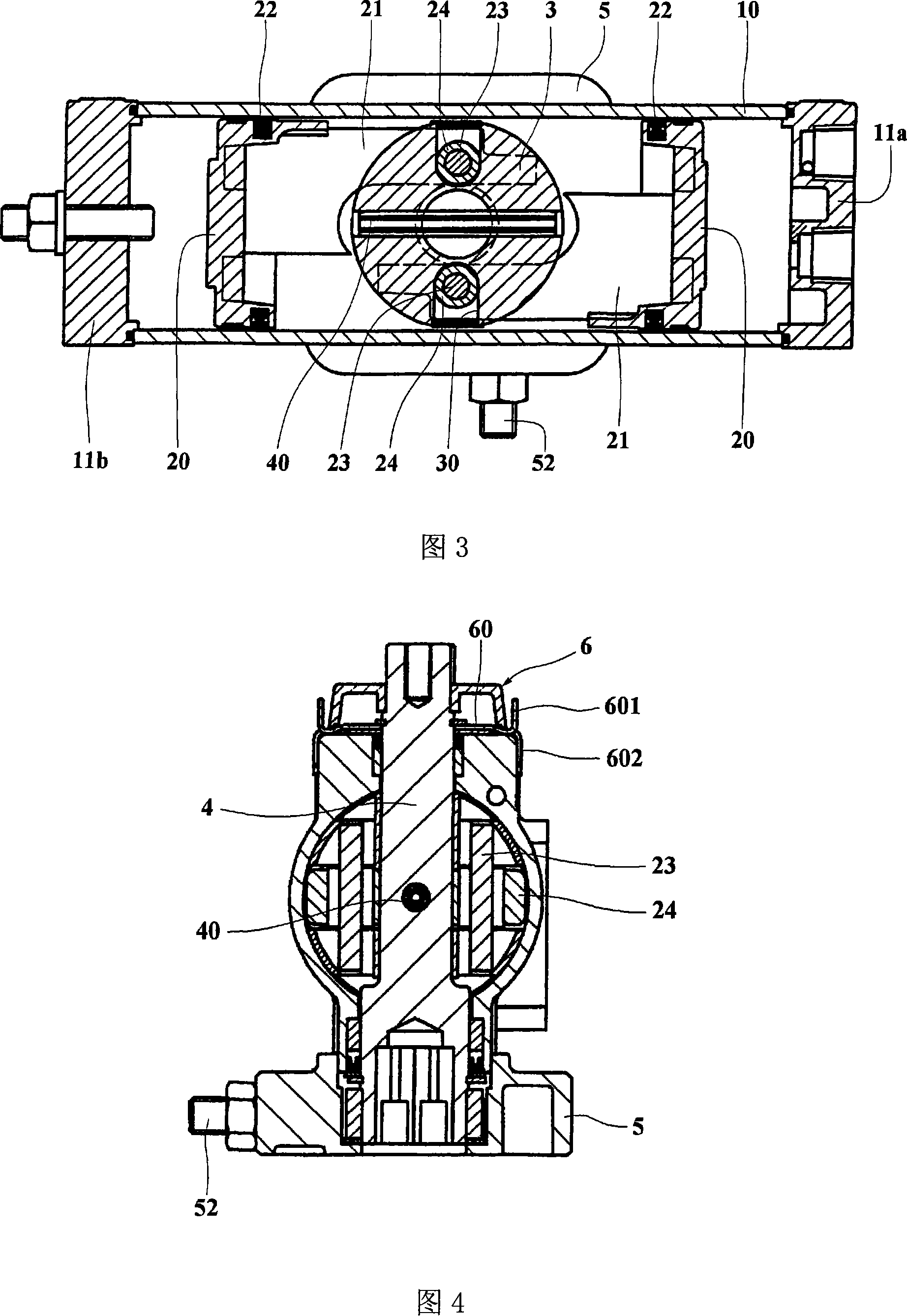

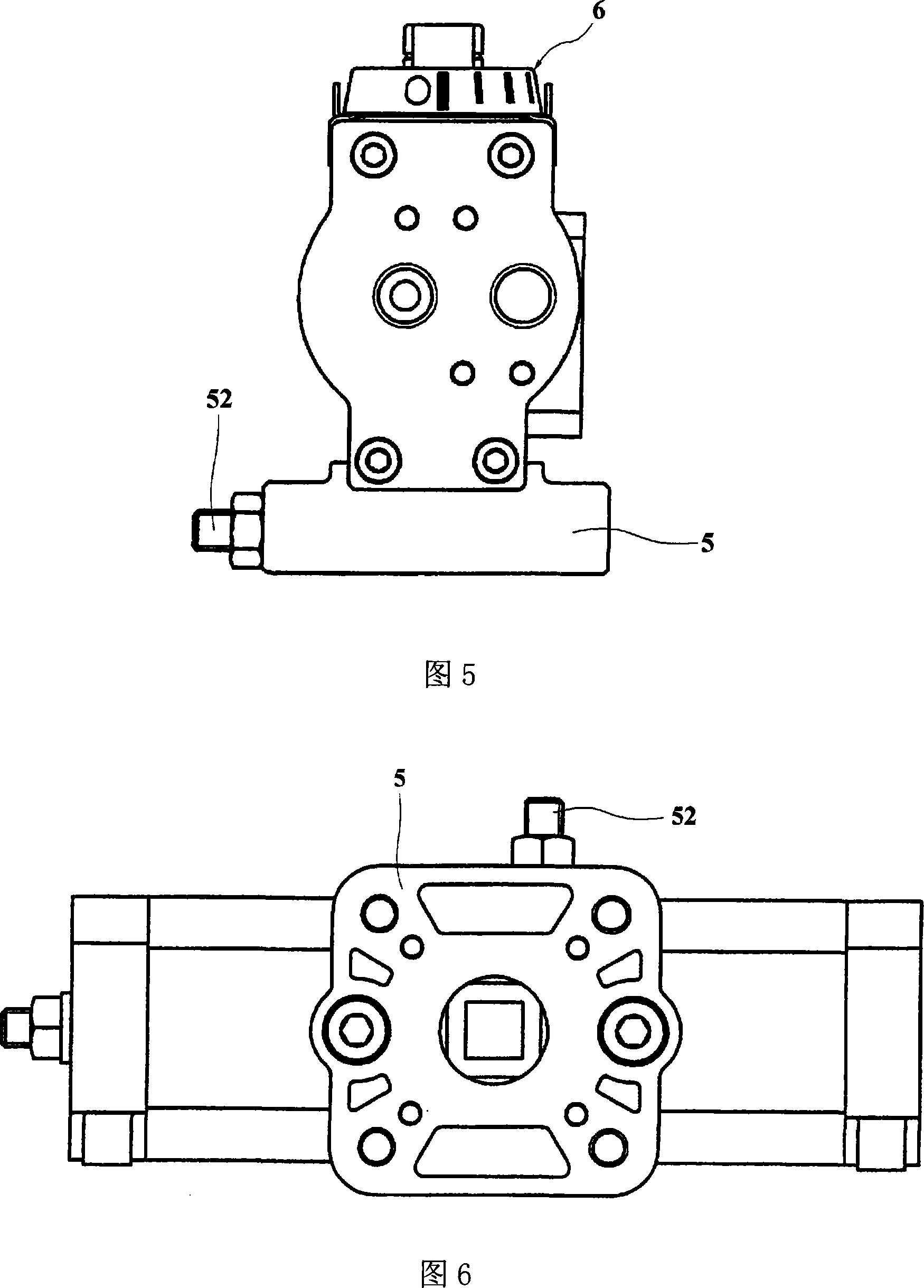

Rotary actuator

ActiveCN101091064ASimple structurePrevent pulling outValve arrangementsFluid-pressure actuatorsComing outOpen adjustment

Conventional coming-out of a trunnion pin is prevented to assure stable and smooth movement of a piston. Further, a rotary actuator, a rotary valve, and a connection structure that correspond to a cylinder output and a valve bore diameter are appropriately selectable, the number of parts is reduced, and a cylinder body is shaped so as to have the same cross-sectional shape in its axial direction. Coming-out of a trunnion pin is effectively prevented by a simple structure, a rotary actuator and a rotary valve are connected via an intermediate part, torque is received by the intermediate part, an opening adjustment means is incorporated to simplify the structure of the rotary actuator, and the intermediate part is made replaceable. Further, an indicator section for displaying the degree of opening of the rotary actuator is made to take thrust force occurring when an output is produced. In addition, open side and closed side air passages communicating an air passage are arranged in a side cover.

Owner:巴阀门株式会社

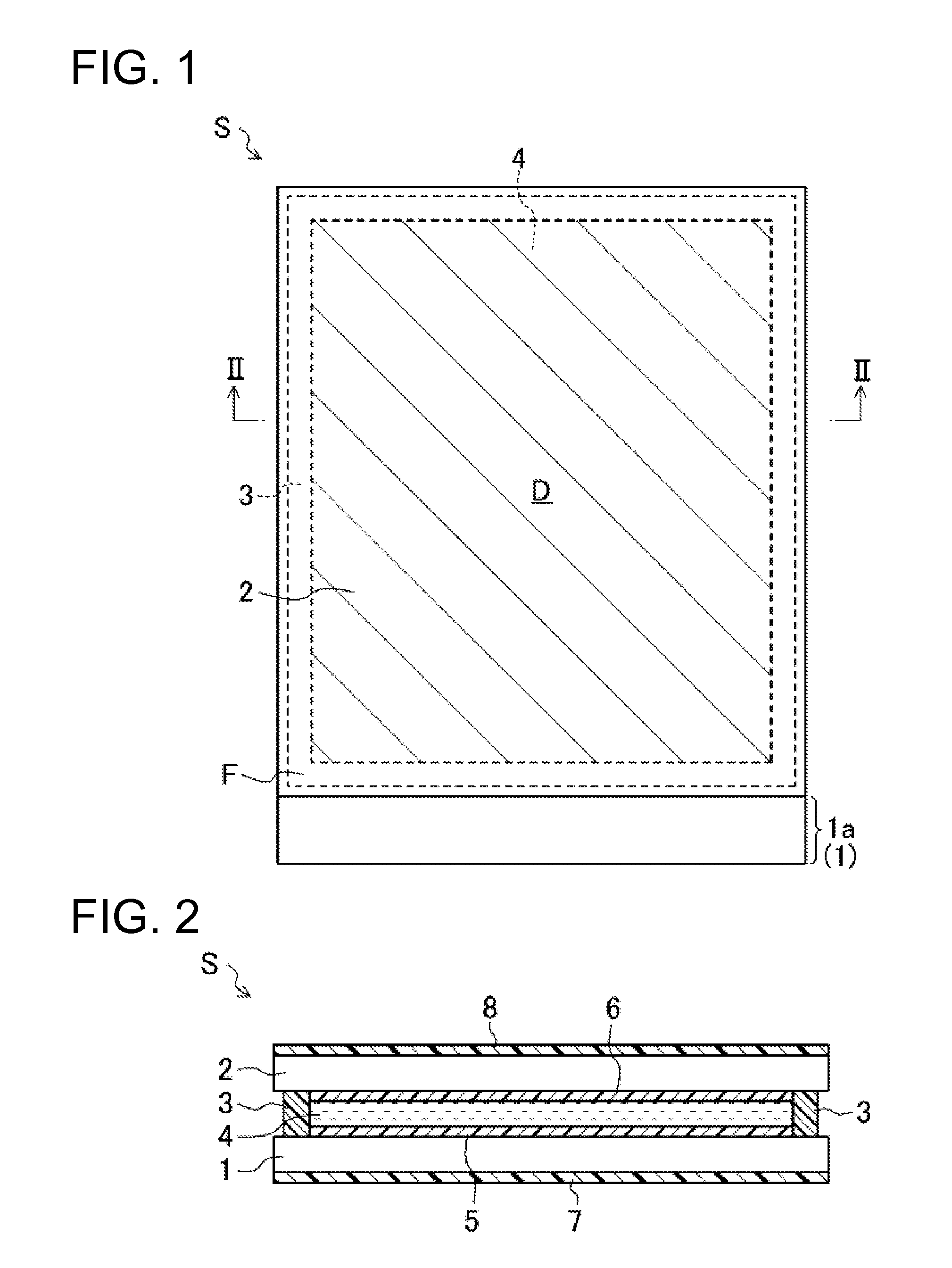

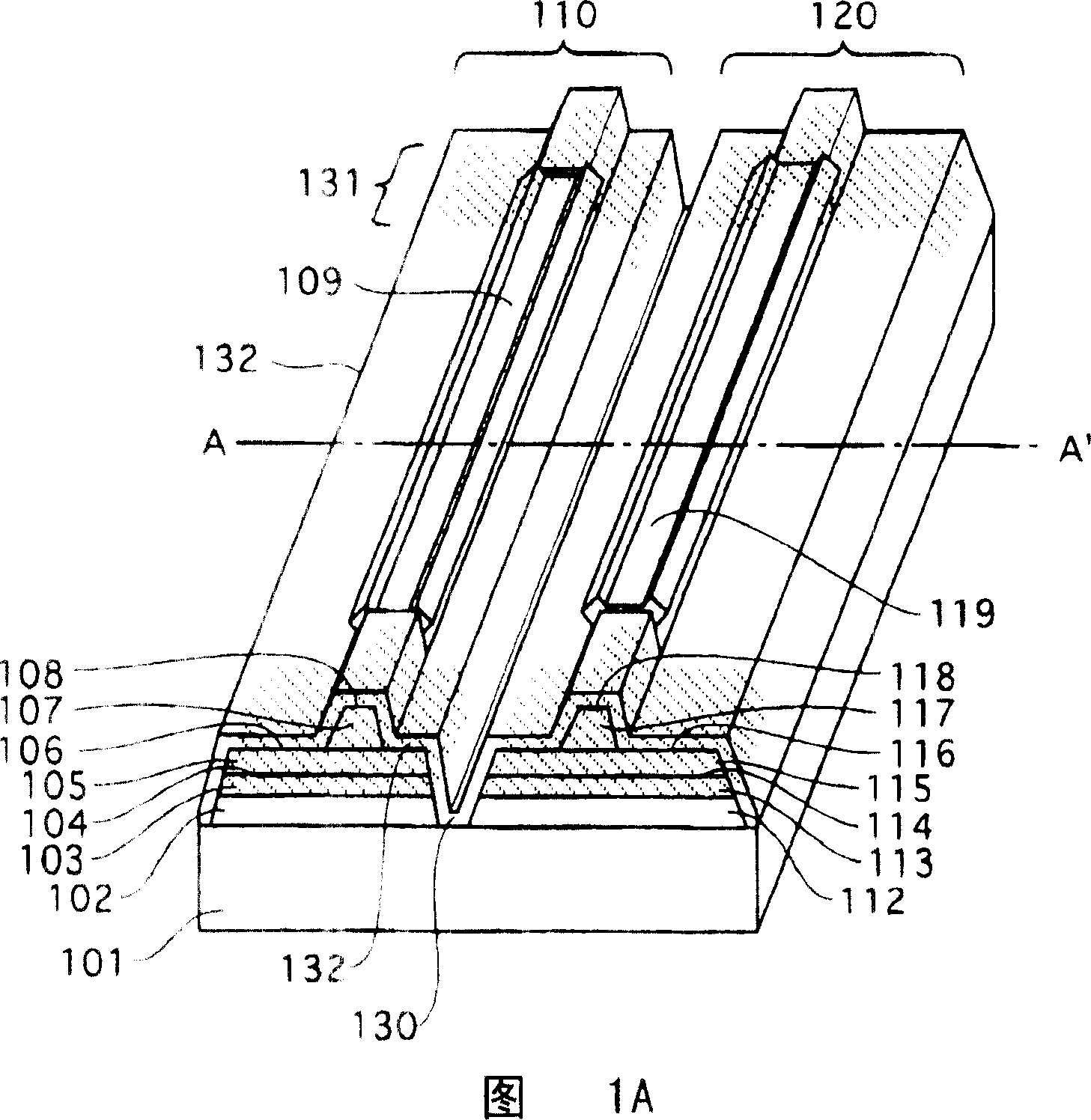

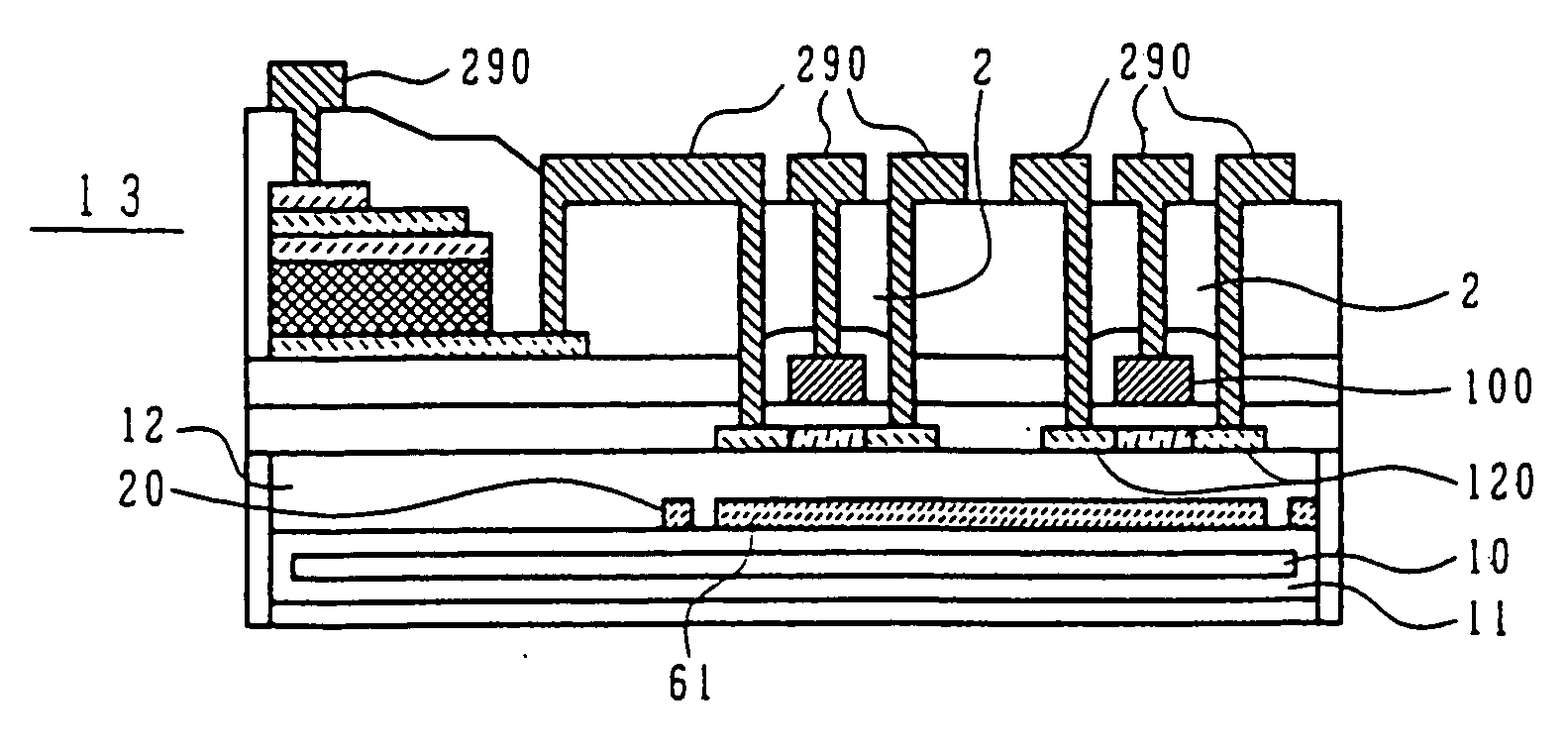

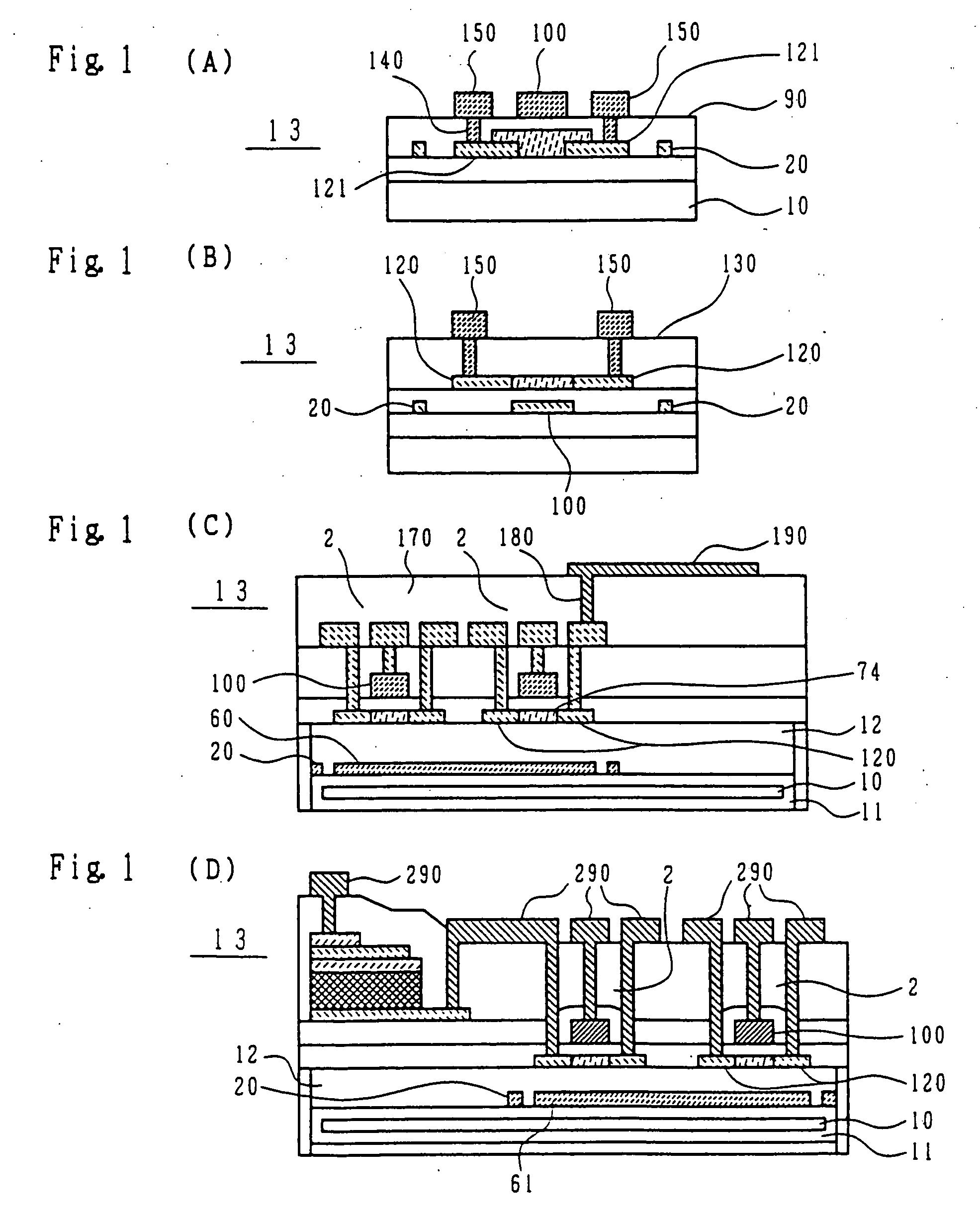

Thin film transistor formed on a transparent substrate

InactiveUS20050012098A1Improve throughputSimple configurationTransistorSemiconductor/solid-state device detailsOptoelectronicsTransistor

A thin-film transistor is formed on a transparent substrate and has a gate electrode film layer and a source and drain regions, and further has an alignment mark made of one and the same constituent material as a constituent material of at least one of the gate electrode film layer and source and drain regions and formed at one and the same position as the gate electrode film layer or source and drain region.

Owner:VISTA PEAK VENTURES LLC

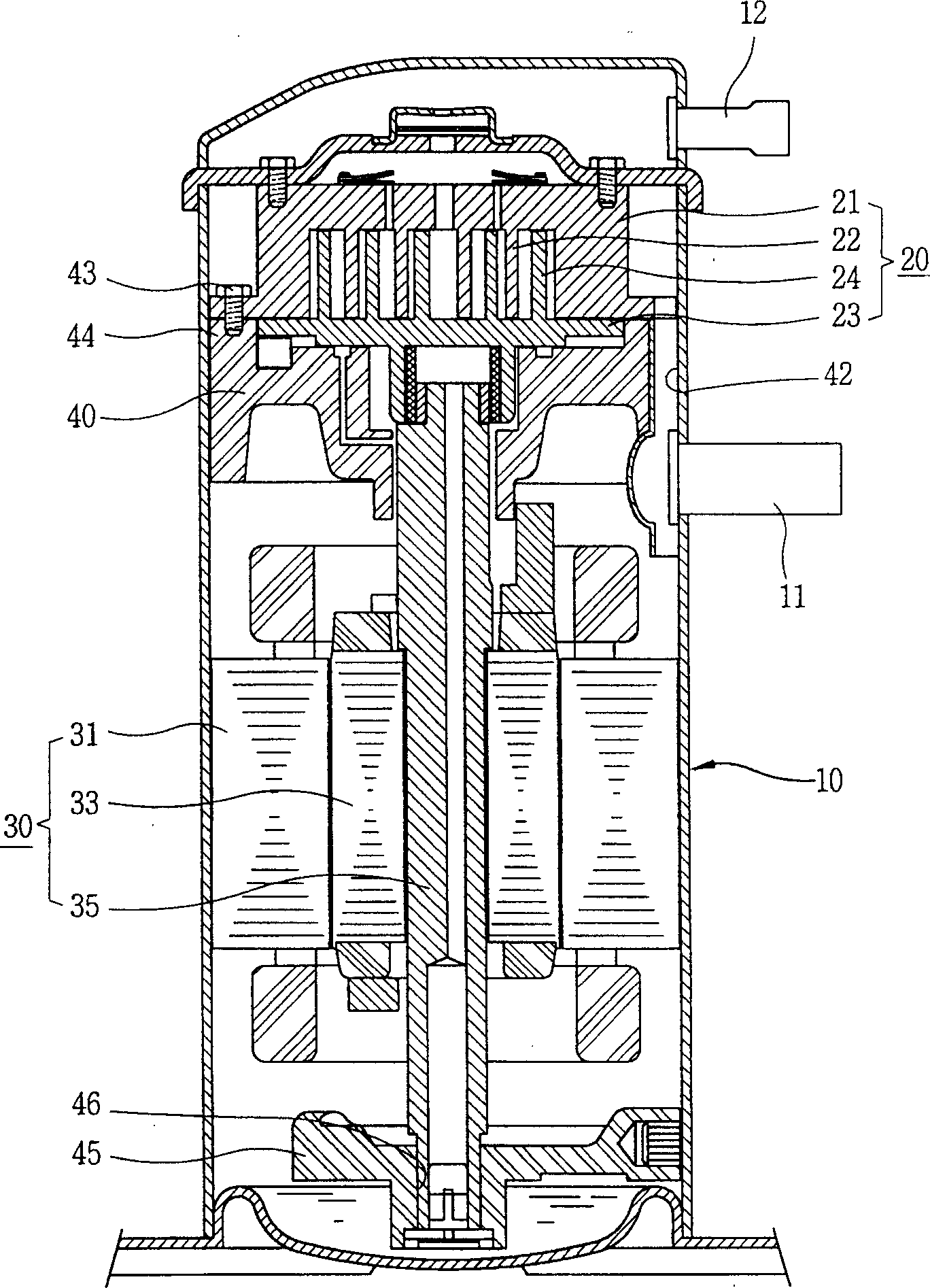

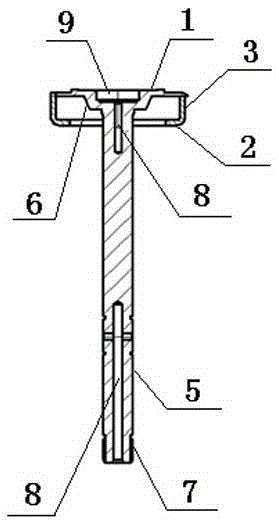

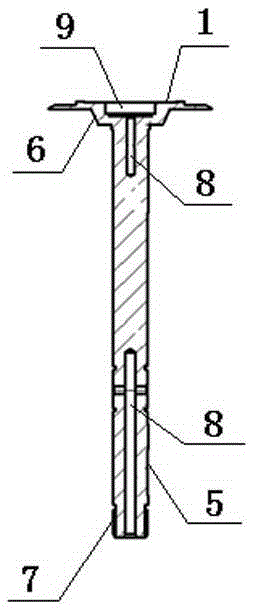

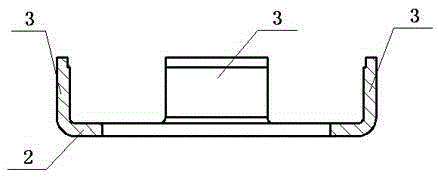

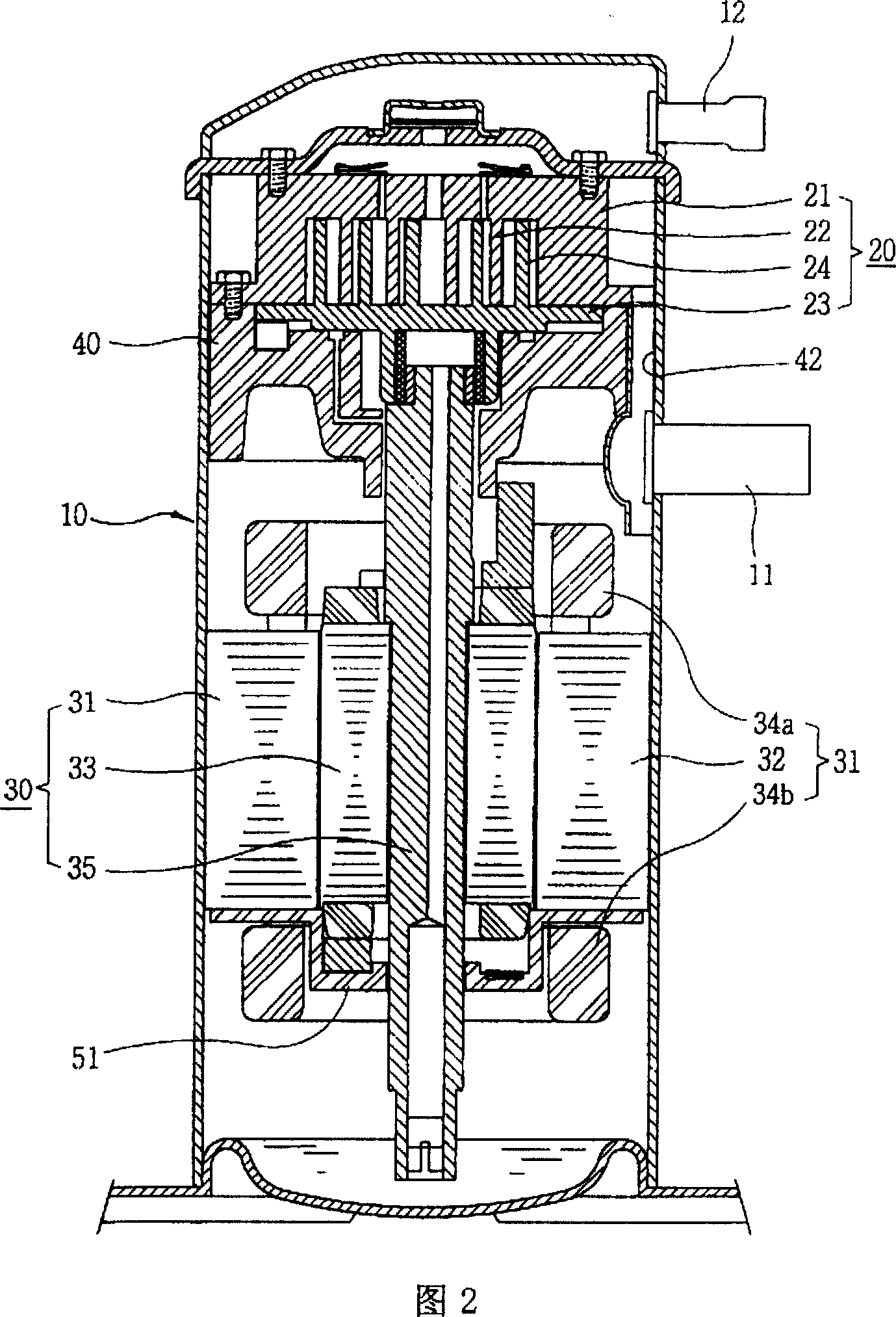

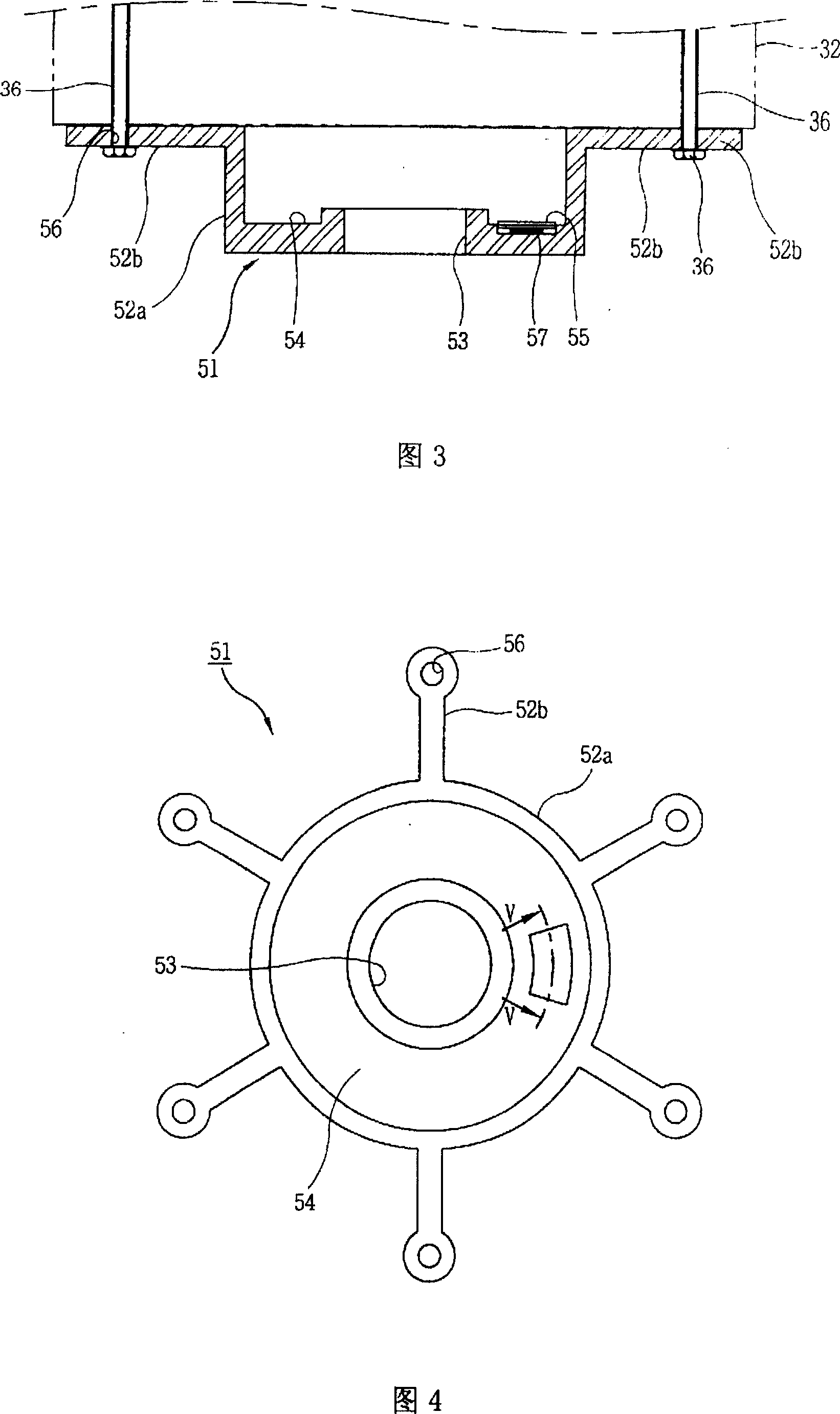

Vortex compressor

InactiveCN1427173AReduce weldingReduce the number of processing stepsRotary piston pumpsRotary piston liquid enginesMotor shaftFlange

A vortex-type compressor with detachable lower supporter is disclosed. Its cylindrical lower supporter under stator and rotor has flange jaws on its top. Said flange jaws have screen hole for fixing iron core of stator. The lower part of motor shaft is positioned in the central hole on bottom of lower supporter. A ring recess on the bottom of lower supporter is used to recept a lower balance block of lower end of rotor. Its advantages are low cost and preventing reverse rotation.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

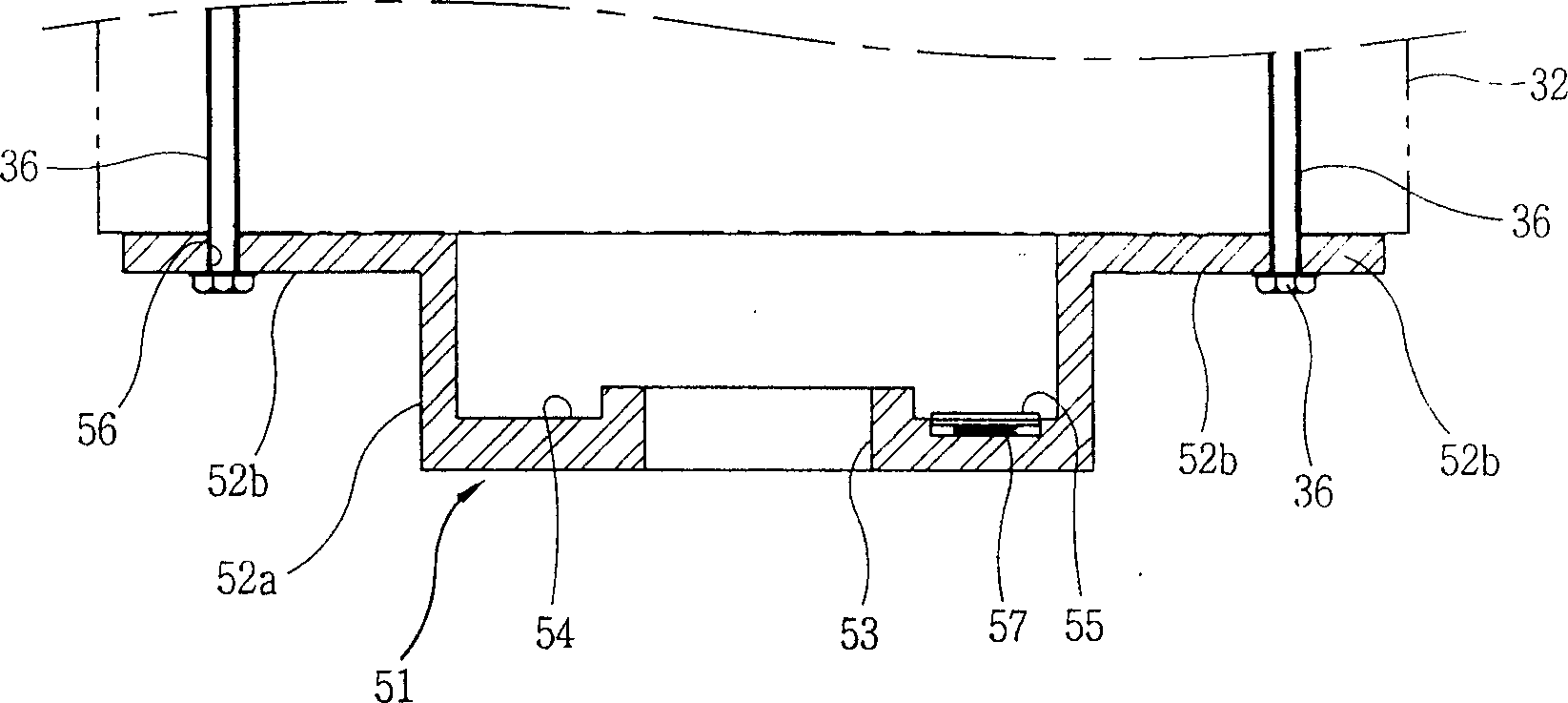

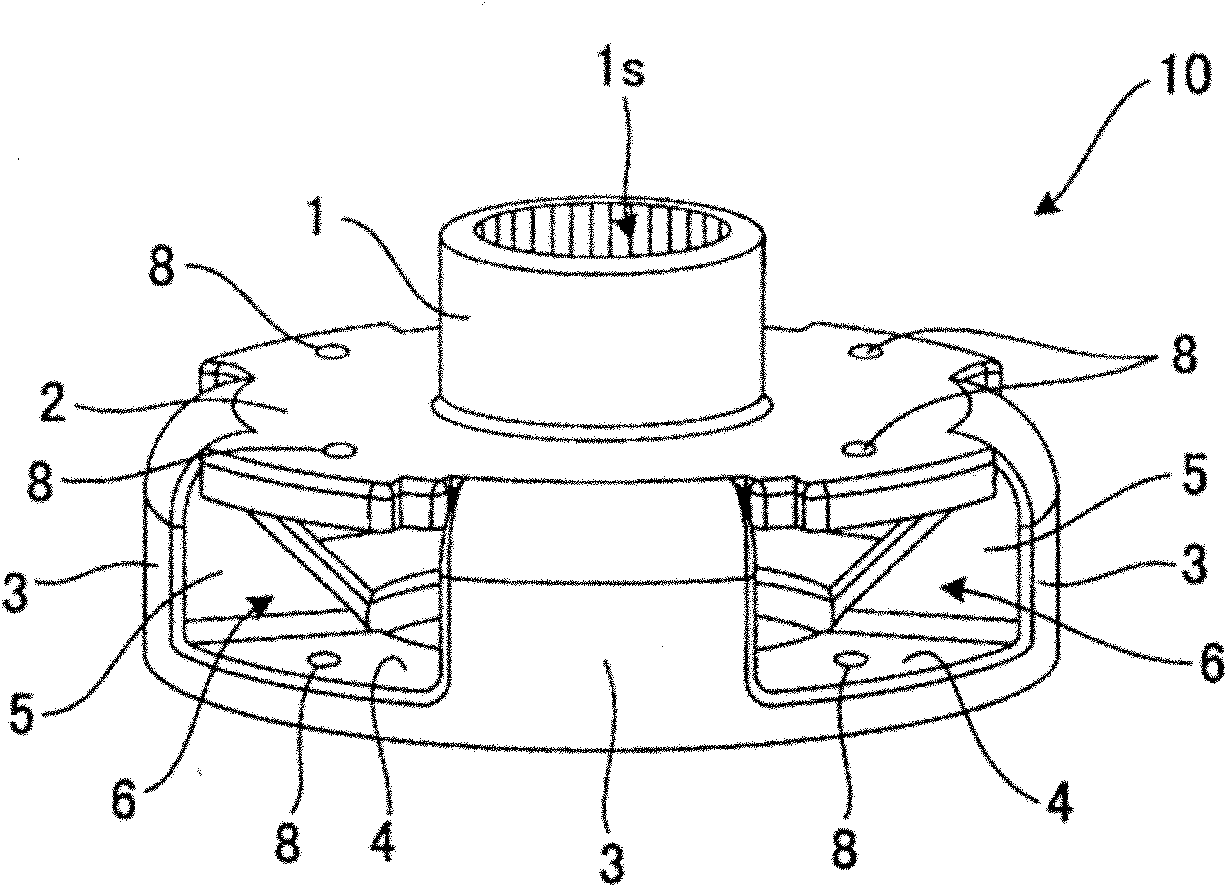

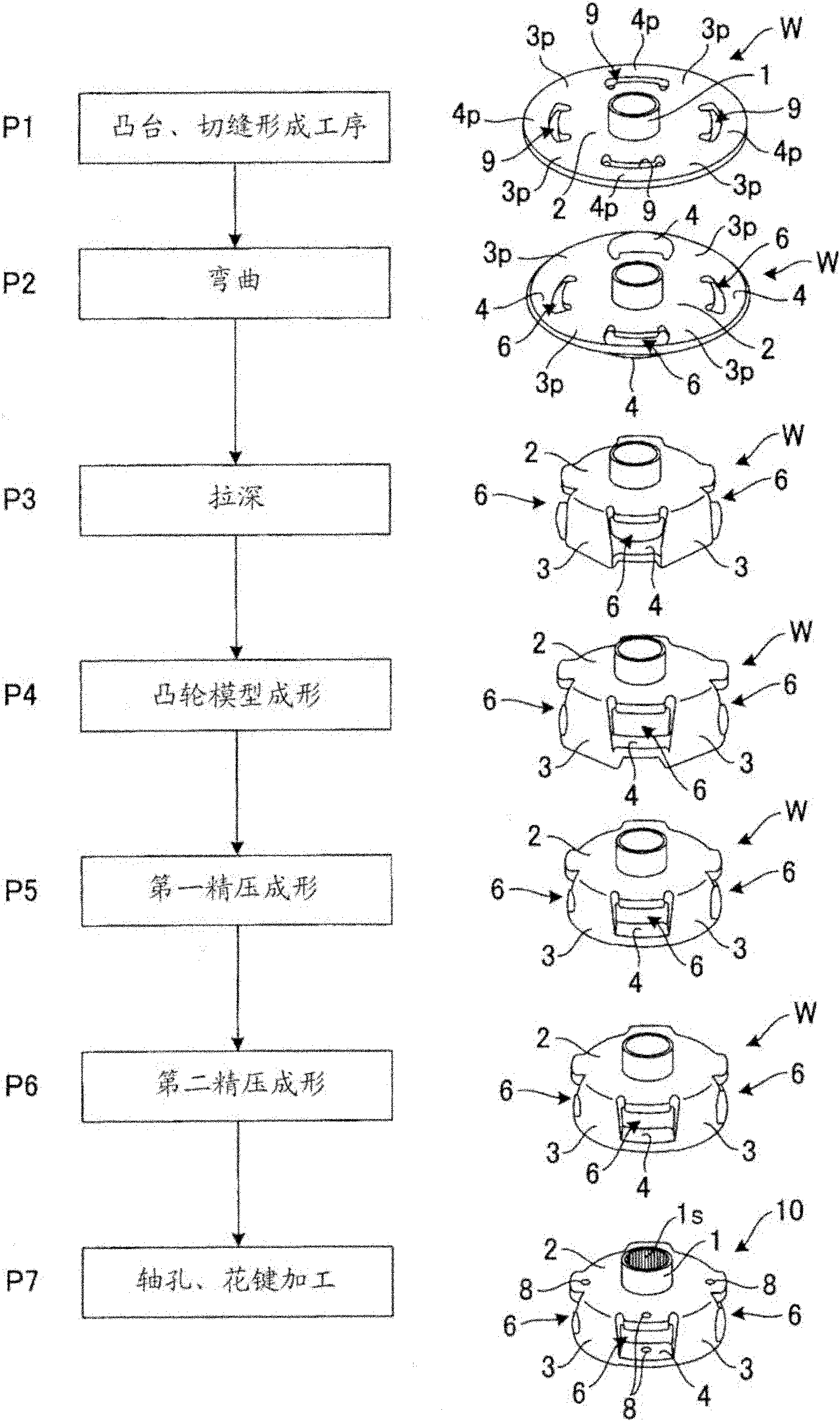

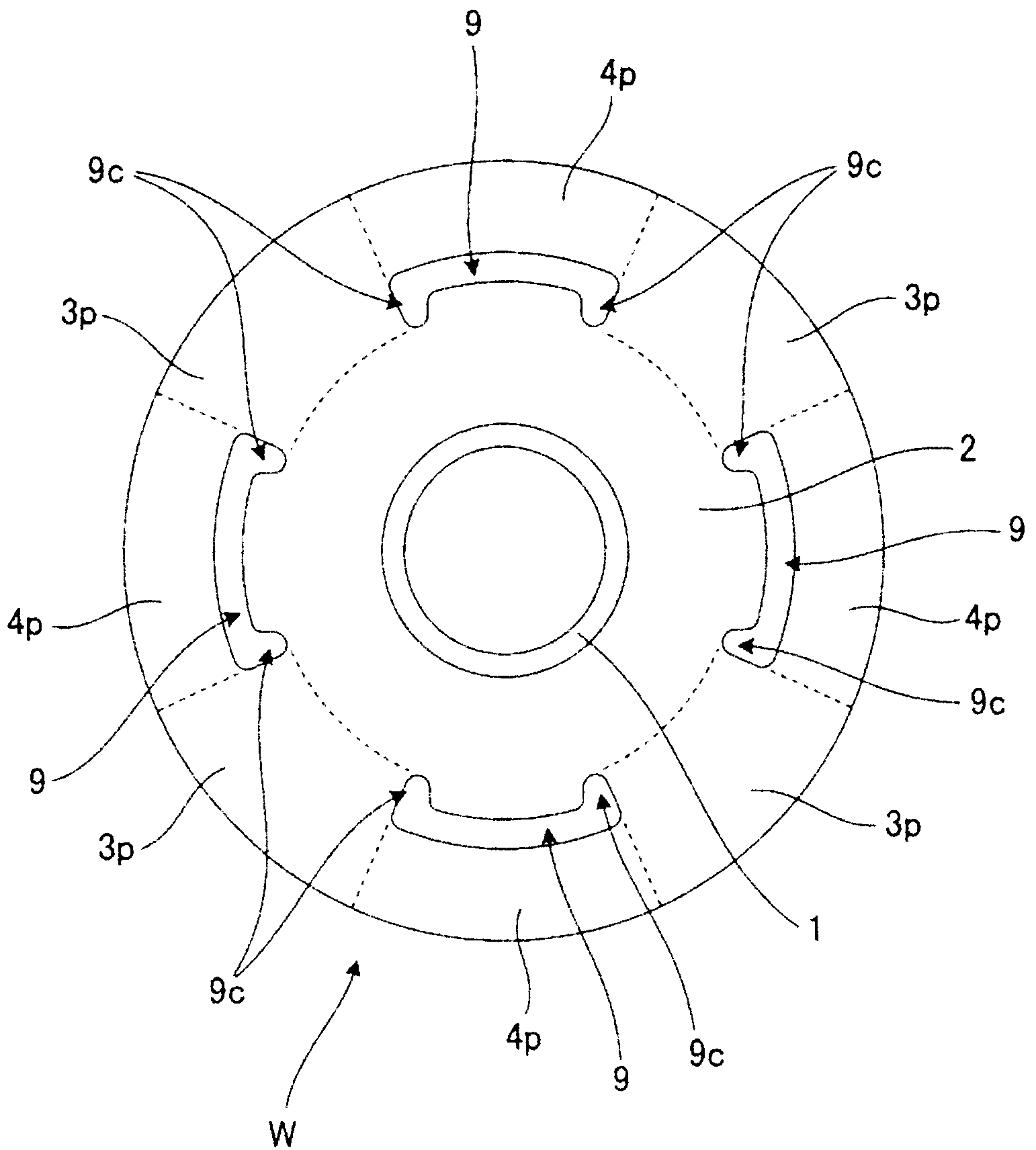

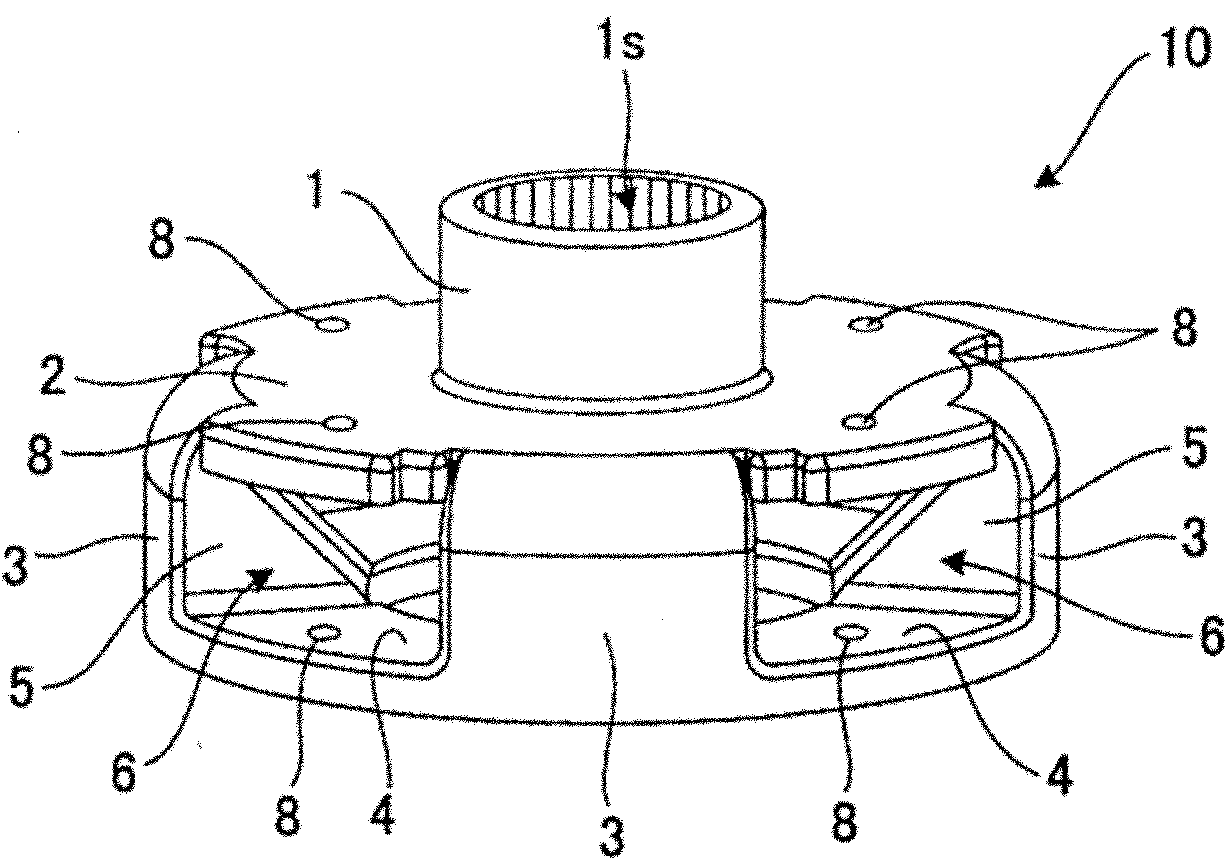

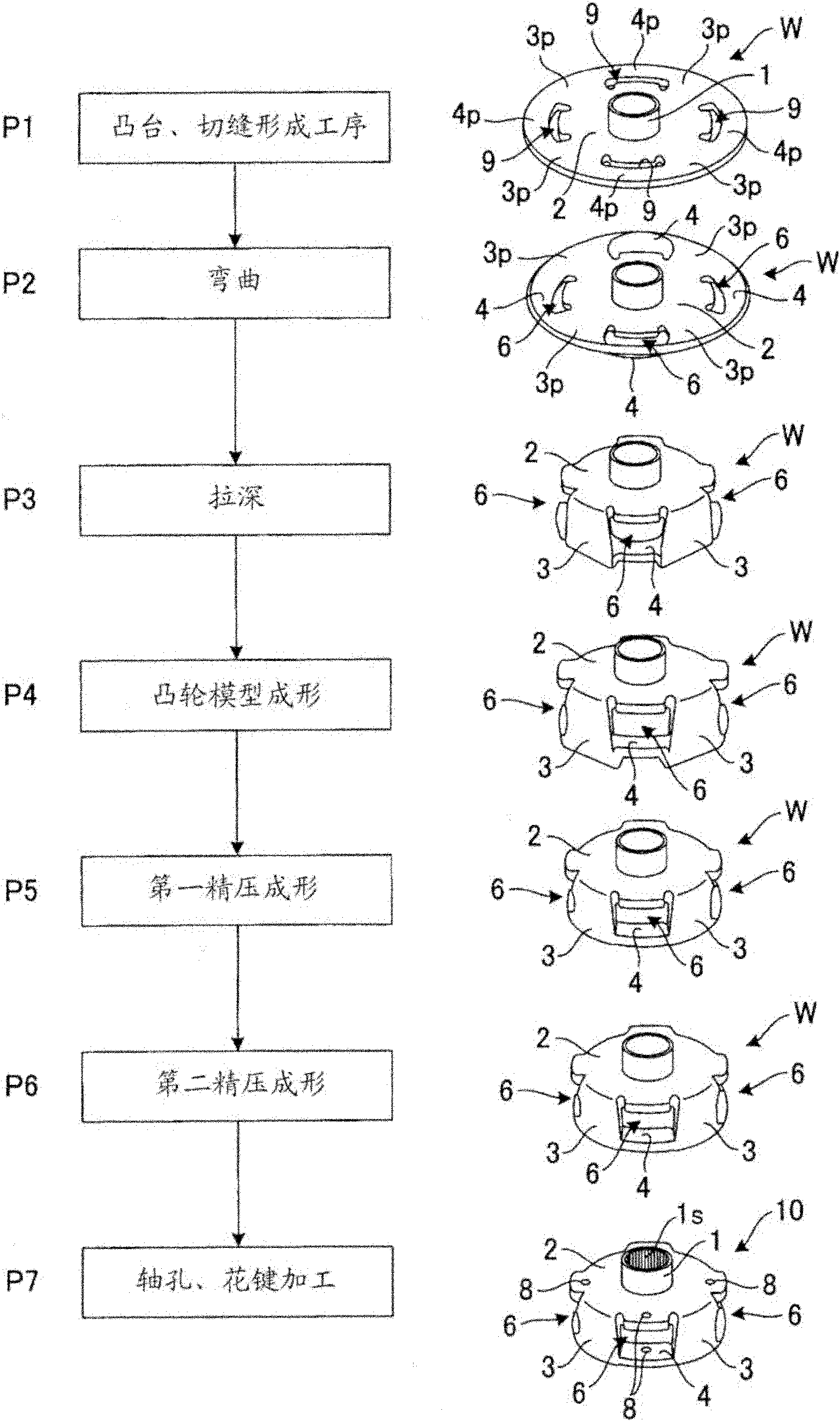

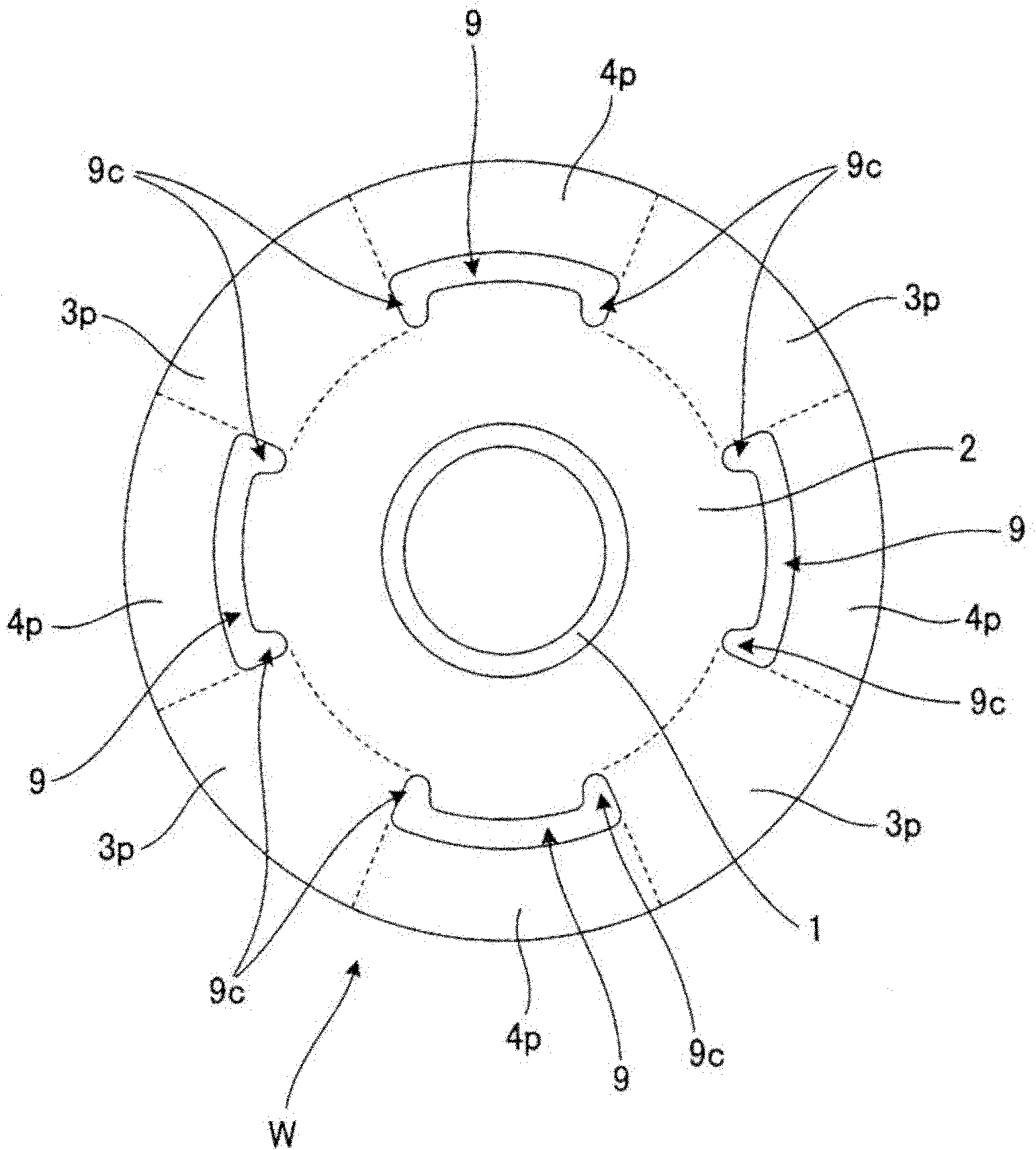

Planetary gear rack and manufacture method thereof

InactiveCN102233394AReduce in quantityReduce the number of processing stepsMetal-working apparatusGearing detailsEngineeringMechanical engineering

The invention provides a planetary gear rack and a manufacture method thereof, which are capable of reducing component number and processing steps during manufacture of a planetary gear rack, and improving yield of materials. Raw materials (W) of a side wall preset part (3p) and a seat surface preset position (4p) are alternatively configured at the surrounding of a protruding edge (2), via expansion of the seat surface preset position (4p), a seat surface (4) of a small gear is formed, and an opening (6) used for making the small gear be exposed is formed. Via stretching of the side wall preset part (3p), the side wall preset part (3p) is formed to be a side wall (3) connected with the protruding edge (2), and also the seat surface (4) is made to move toward the lower part of the protruding edge (2).

Owner:JATCO LTD

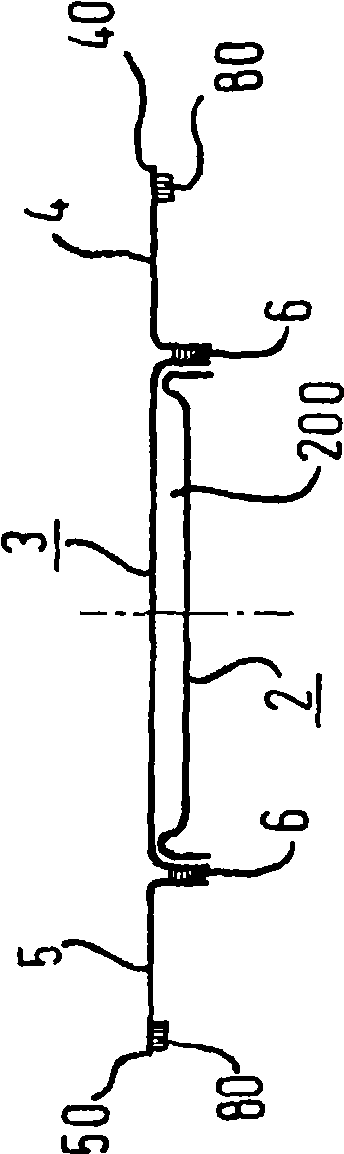

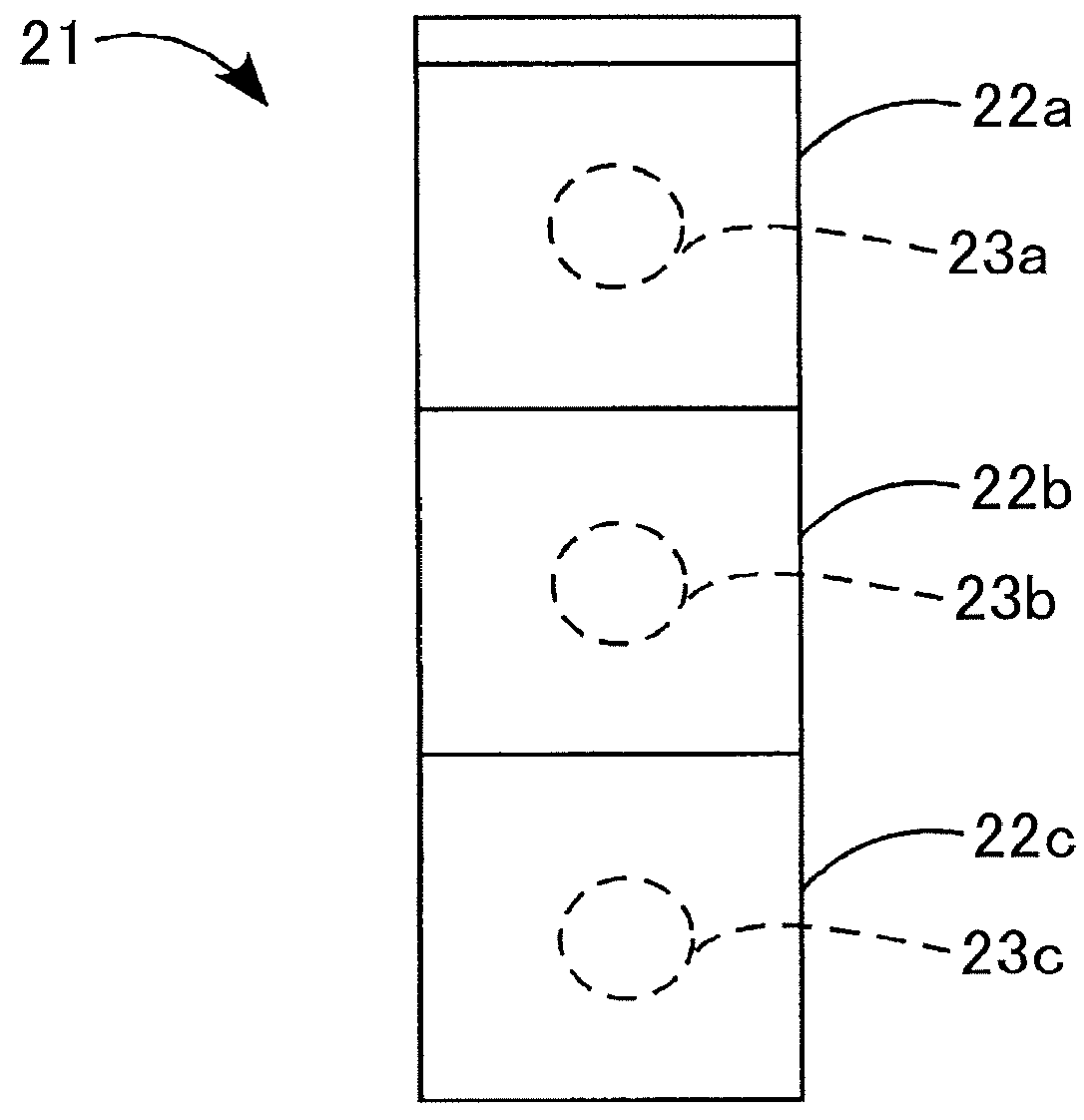

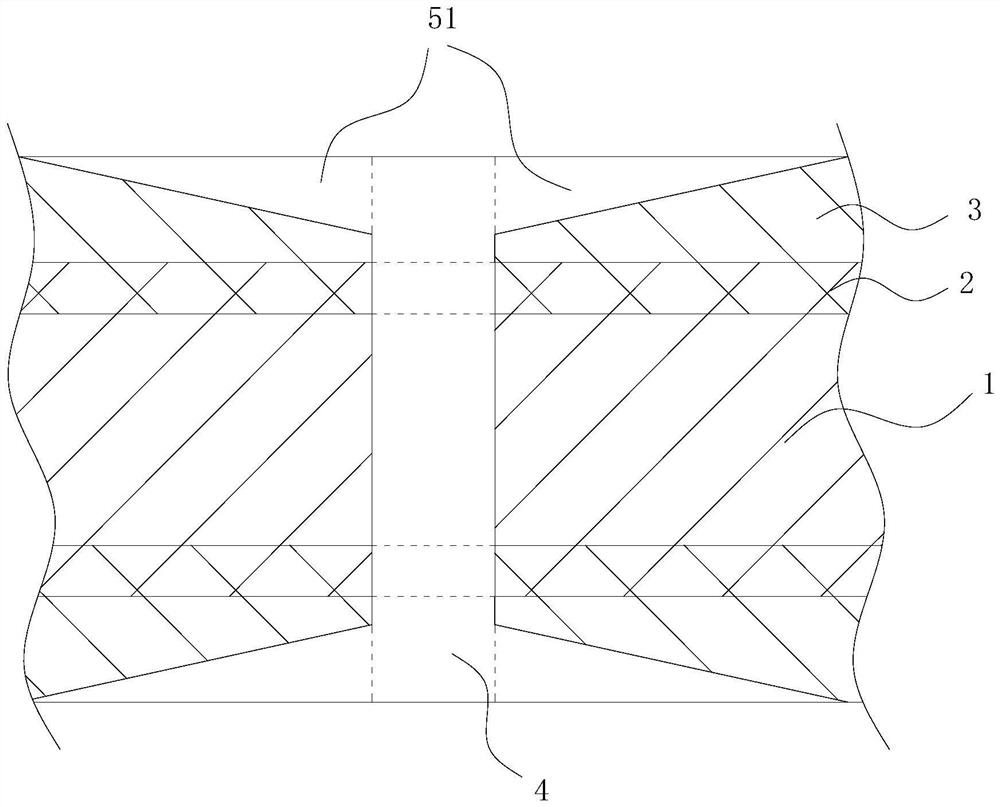

Absorbability article, belt structure, method for manufacturing belt structure and absorbability article

InactiveCN101511317AReduce the number of processing stepsEasy to operateAbsorbent padsAdhesivesEngineeringSheet material

The disclosure relates to an absorbent article (1'') comprising a top-sheet (2) having an inner side (22) and an outside (20) and a back-sheet (3) having an inner side (32) and an outside (30) and the inner side of the back-sheet being directed towards the inner side of the top-sheet. At least one elongate belt (74, 76) is provided which has a free end portion (740, 760) for fastening the absorbent article around the waist of a wearer and an attachment end portion (742, 762) that is fixedly attached to the outside of the back-sheet or to the outside of the top-sheet, whereas the free end portion is arranged within the boundaries of the top-sheet and / or the back-sheet.

Owner:SCA HYGIENE PROD AB

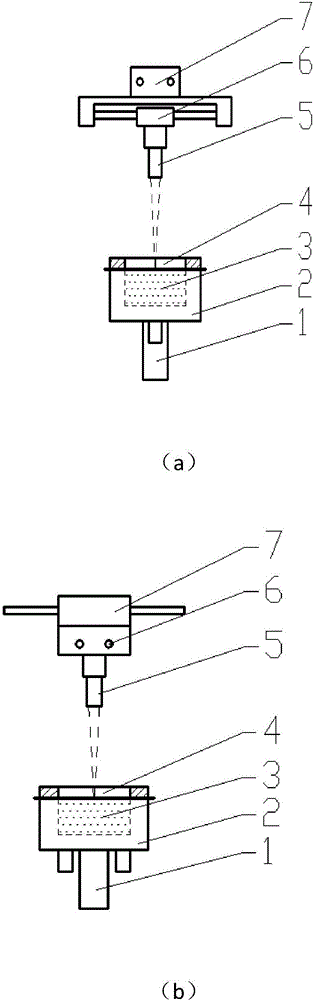

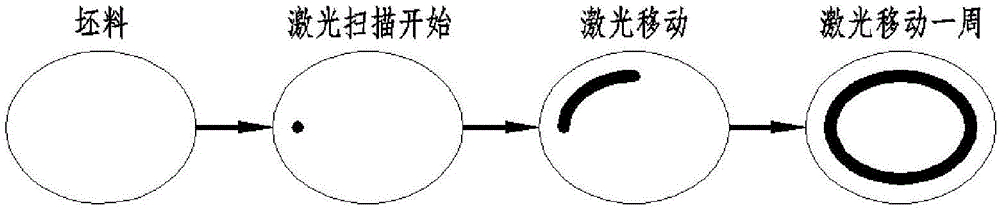

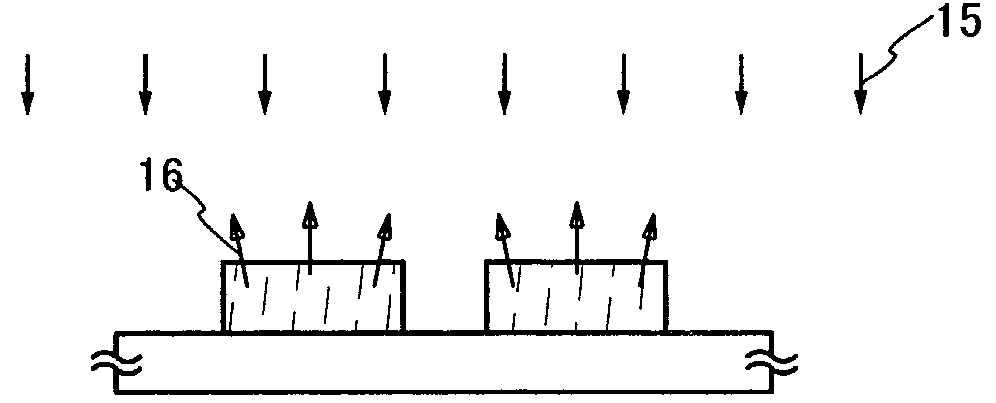

Laser heating induced isostatic pressing loading type die-less forming method of plates

InactiveCN104646479AFacilitates the formation of fine featuresEasy to shapeShaping toolsLiquid mediumOptoelectronics

The invention discloses a laser heating induced isostatic pressing loading type die-less forming method of plates. The method comprises the following steps of: partially heating the plates through laser; applying isostatic pressing on liquid mediums; finishing the die-less forming of the plates by accumulating partial deformations of the plates. According to the laser heating induced isostatic pressing loading type die-less forming method of the plates, the shortcomings that the forming accuracy of a laser thermal stress forming method is not high and intricately shaped parts are difficult to form are overcome, and the machining speed and accuracy are accurately controlled, so that the size accuracy and good surface quality of the formed plates are higher, and the intricately shaped parts can be formed; the forming limit is improved, thus the machining procedures are simplified, the number of the machining procedures is reduced, and the machining efficiency is improved.

Owner:ZHEJIANG SCI-TECH UNIV

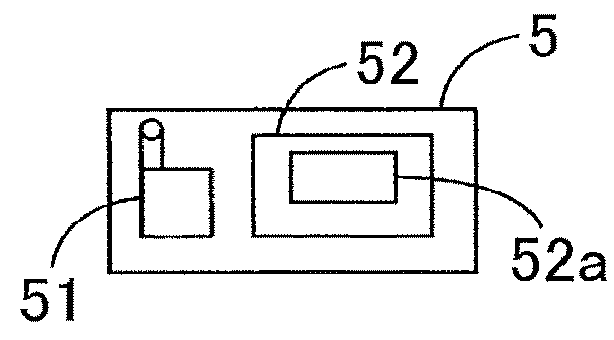

Optical detection device and facility management system

InactiveUS20180165955A1Low costReduce the number of processing stepsControlling traffic signalsElectromagnetic transmissionElectric forceCommunication unit

An optical detection device includes: an optical sensor configured to detect light from a light source of an indication lamp; an optical-detection-side communication unit configured to wirelessly transmit at least an optical detection signal of the optical sensor; and a photoelectric conversion unit configured to convert light from the light source into power and to store the power. The optical sensor and the optical-detection-side communication unit operate using the power stored in the photoelectric conversion unit.

Owner:JTEKT CORP

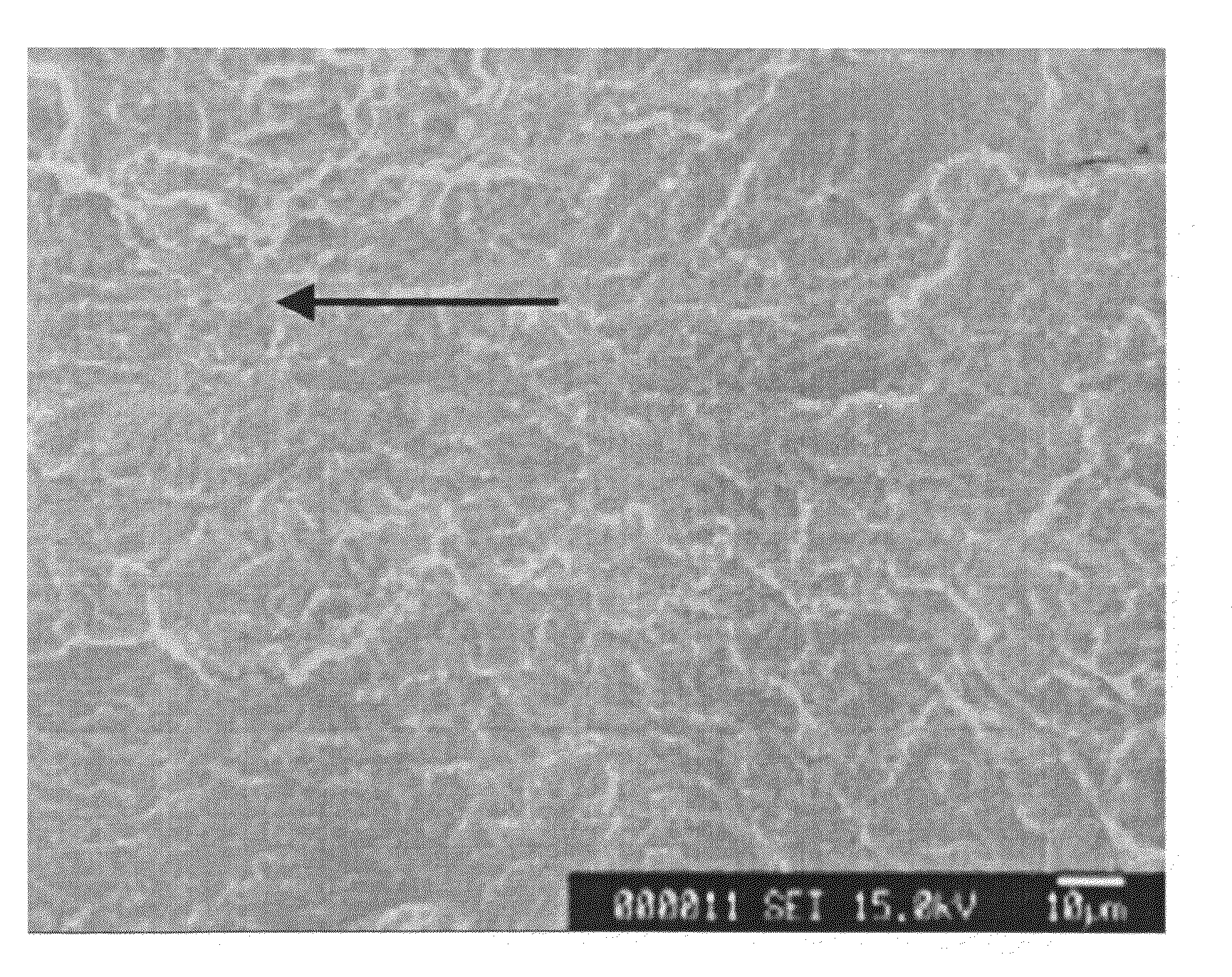

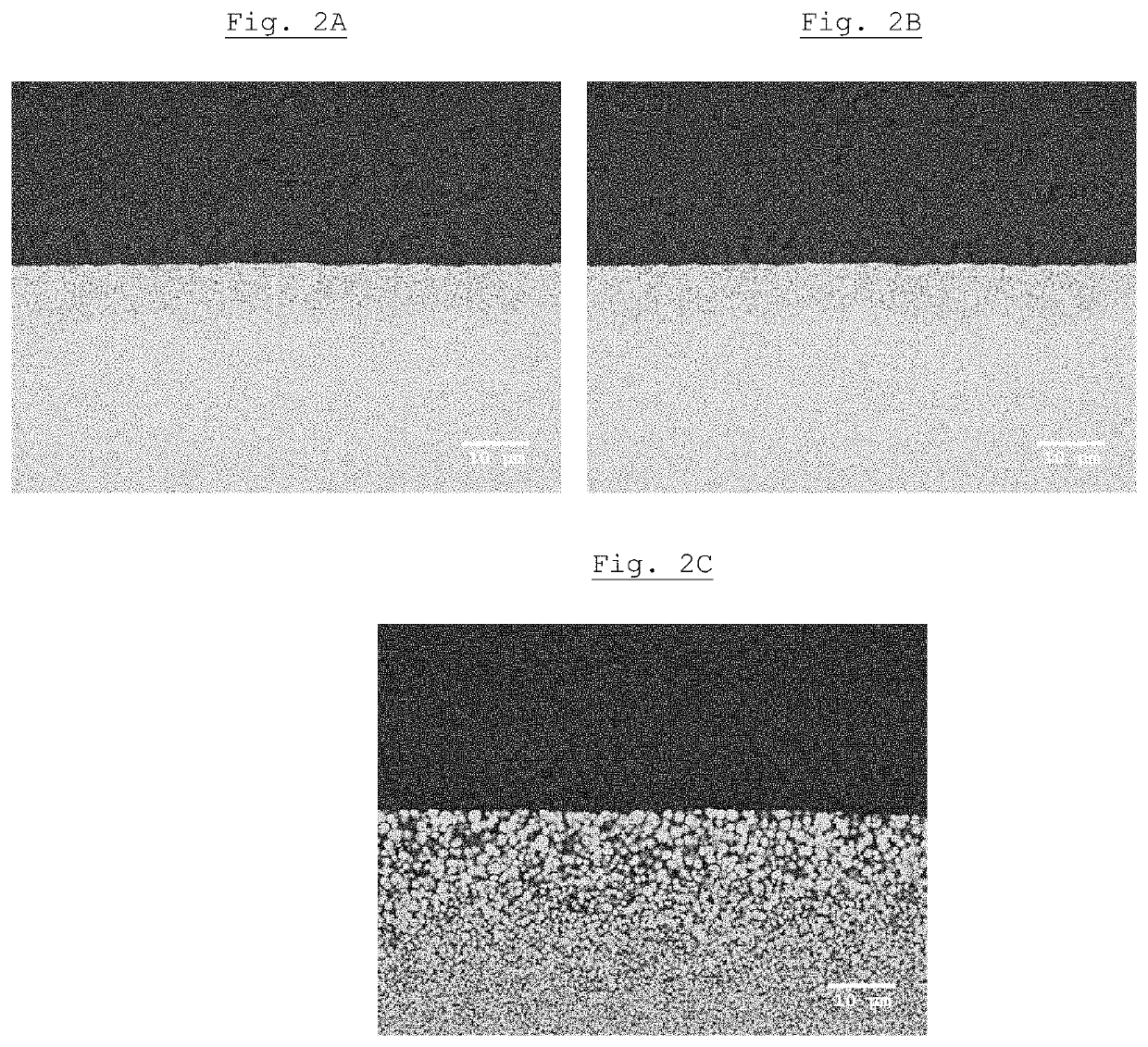

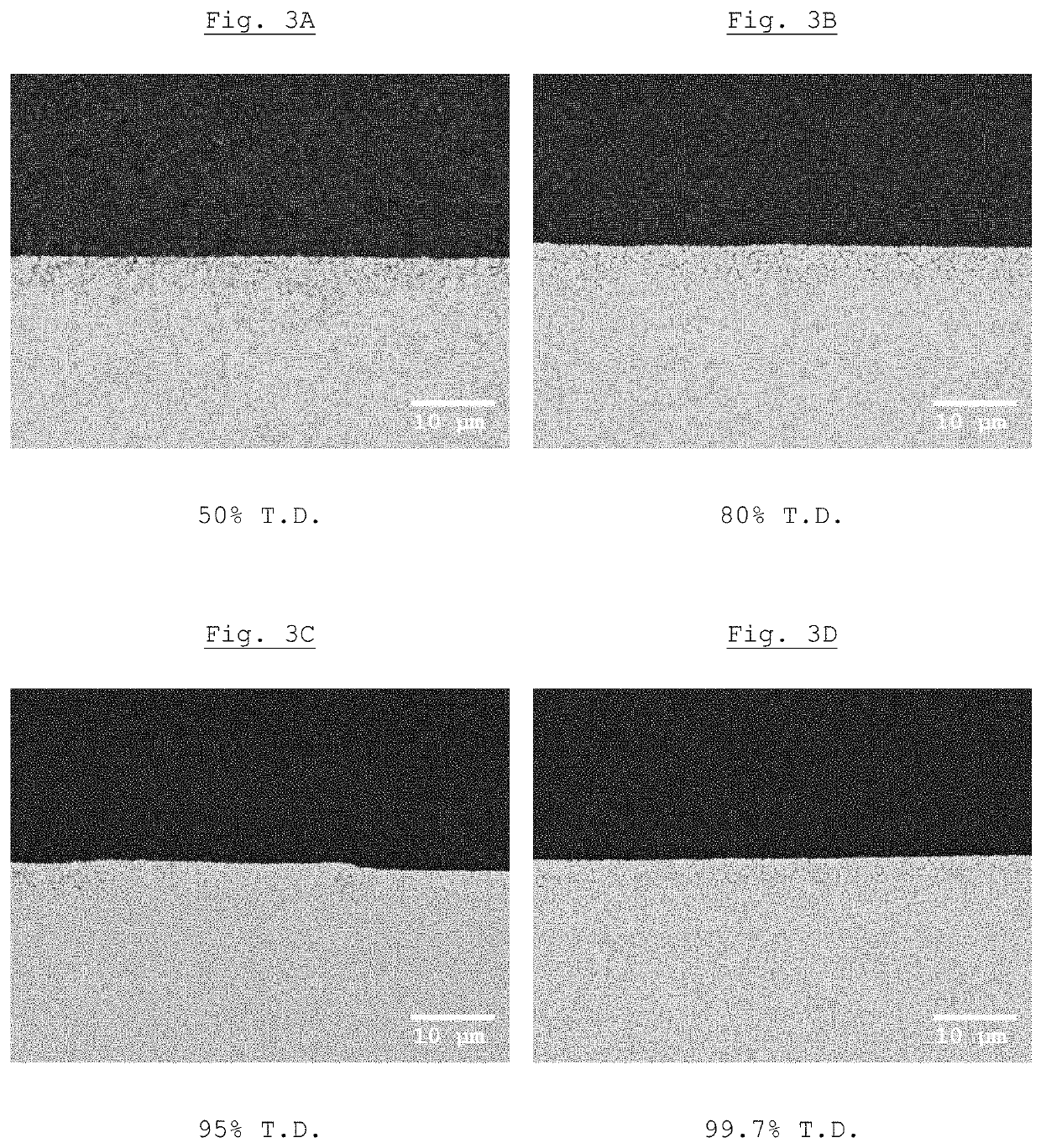

Process for Producing Metallic Component and Structural Member

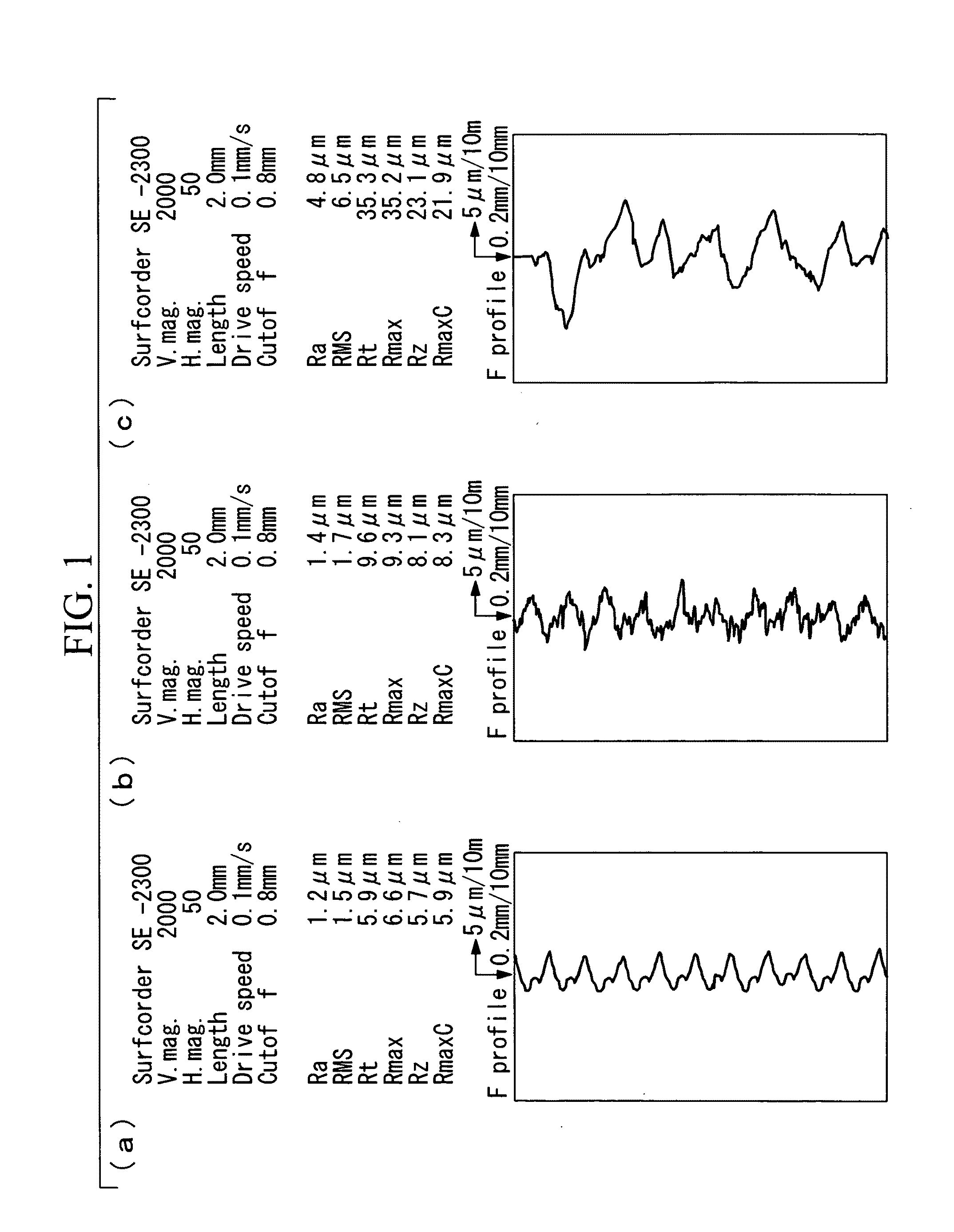

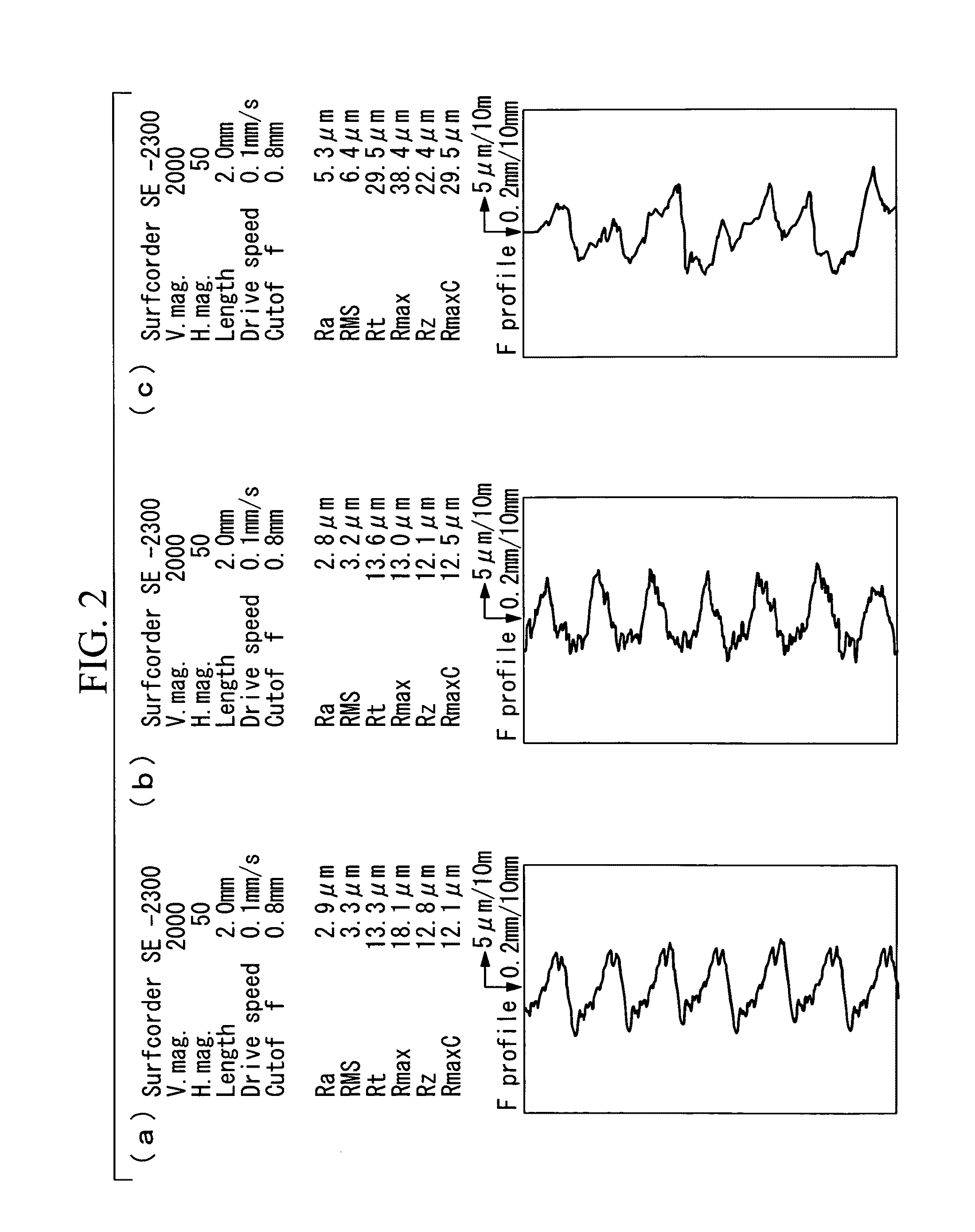

InactiveUS20090023014A1Improve fatigue performanceNo excessive surface roughnessLayered productsAbrasion apparatusSurface roughnessMetallic materials

A process for producing a metallic component of a structural member or the like used in an aircraft or automobile or the like, the process including shot peening the surface of a metallic material, wherein the fatigue properties of the metallic material are improved with almost no variation in the surface roughness over the course of shot peening. Shot peening the metallic material surface uses a shot material having an average particle size of not more than 200 μm, and the ratio of the surface roughness of the metallic material surface following the projection step relative to the surface roughness of the metallic material surface prior to the projection step is not less than 0.8 and not more than 1.5.

Owner:MITSUBISHI HEAVY IND LTD

Compressor unit

InactiveCN101535648AReduce weightLow costPositive displacement pump componentsPiston pumpsCrankcaseMechanical engineering

The invention relates to a compressor unit which comprises a motor and a reciprocating piston compressor, driven by a slider crank mechanism that is arranged inside a crankcase. The invention is characterized in that the crankcase and the cylinder for the piston are configured as one piece and are secured to the motor as one unit at the output thereof.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

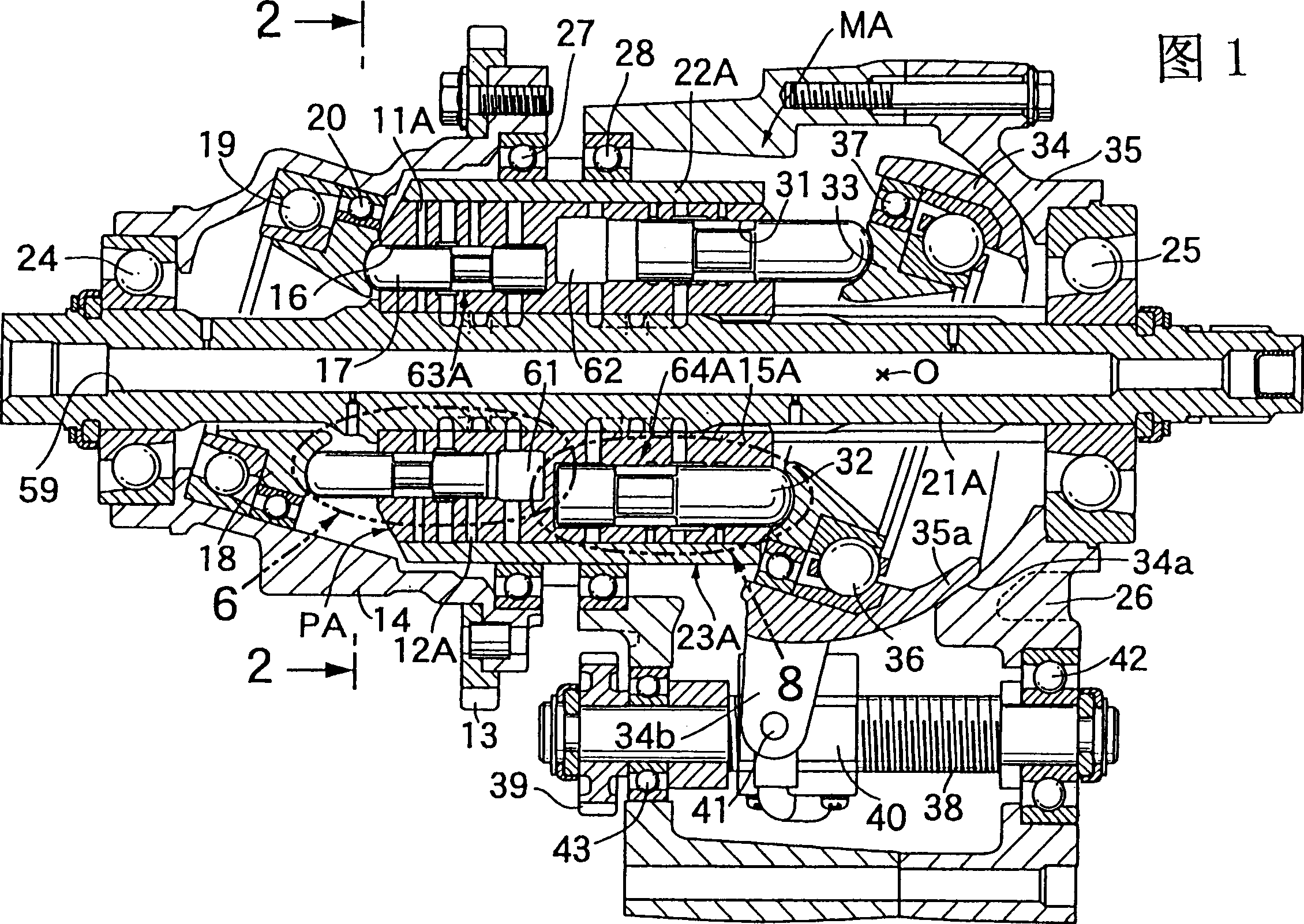

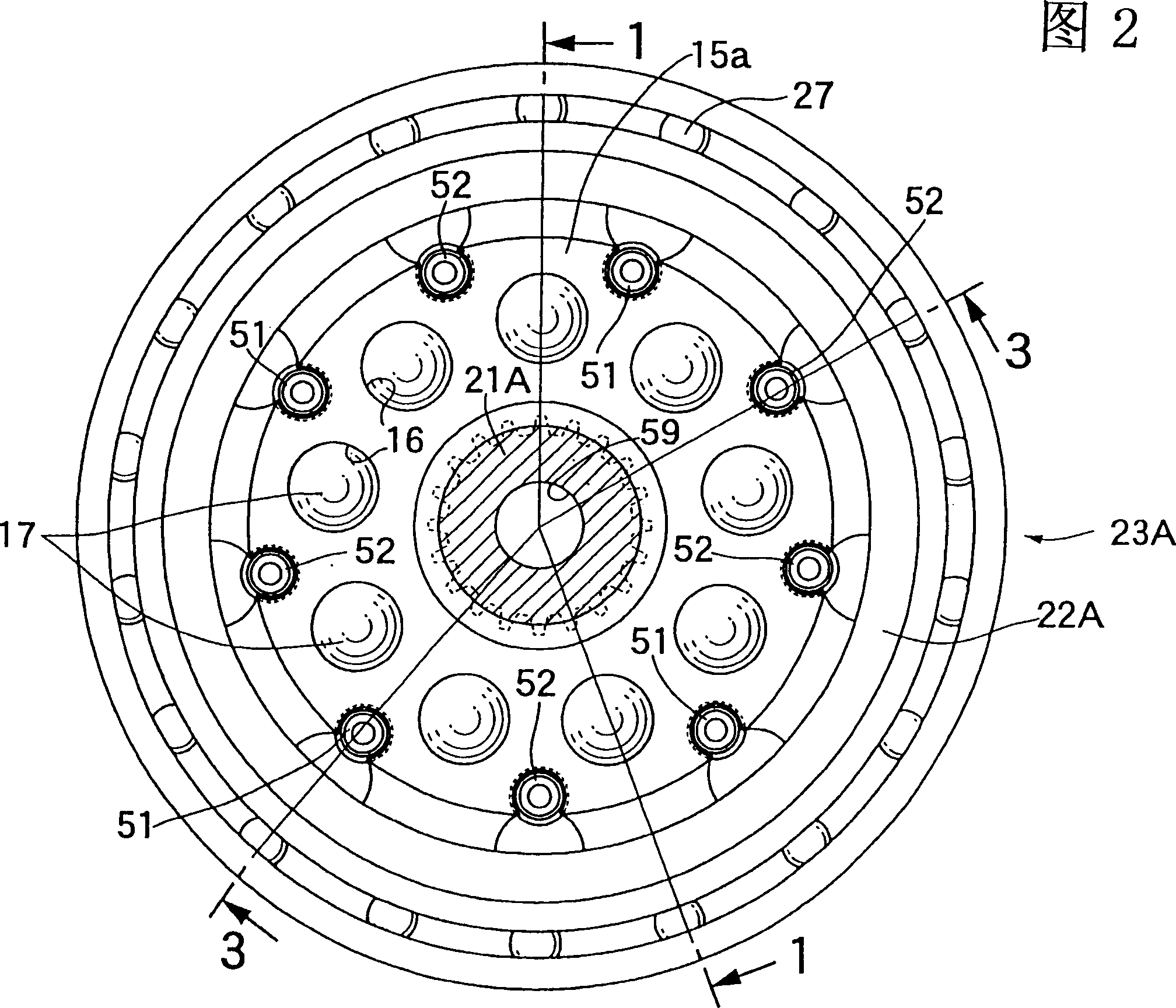

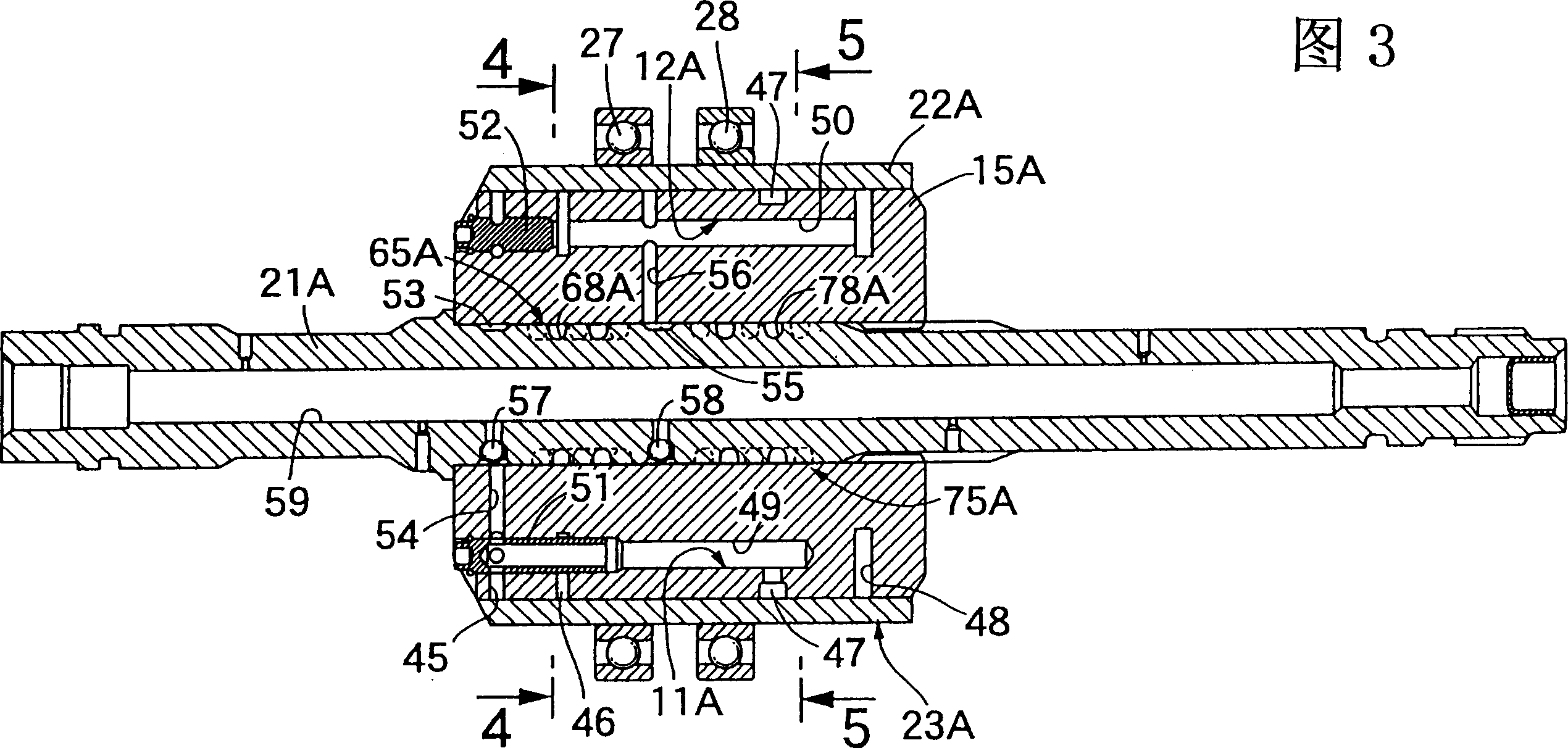

Slope plate type hydraulic action device and static pressure stepless speed variator

InactiveCN1380496AMiniaturizationReduce the numberLaser using scattering effectsServomotor componentsReciprocating motionEngineering

Distributing valves of a swash plate type hydraulic drive transmission can make a cylinder block smaller and reduce the number of processes and the number of parts. <??>Distributing valves 63A alternately switch, corresponding to the axial reciprocating motion of plungers 17, communication and cutoff between communication passages 65A communicated to oil chambers 61 opening to the inner surface of cylinder holes 16 and low pressure ports 66A and high pressure ports 67A communicated to a low pressure oil passage 11A and a high pressure oil passage 12A opening to the inner surface of the cylinder holes 16. <IMAGE>

Owner:HONDA MOTOR CO LTD

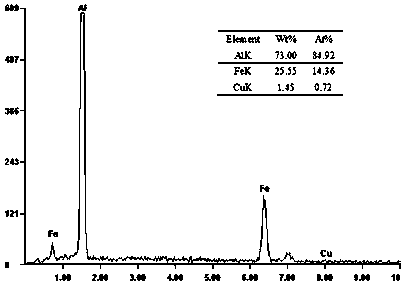

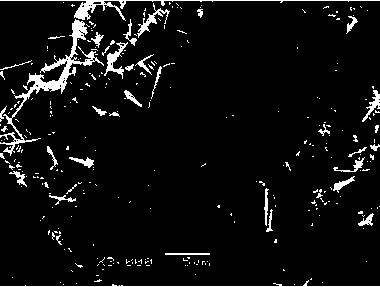

A pre-treatment method for hot-dip aluminizing of uncoated ultra-high-strength steel plates for vehicles

ActiveCN105925927BImprove corrosion resistanceSolve the leakage problemHot-dipping/immersion processesHot stampingPretreatment method

Owner:NANJING INST OF TECH

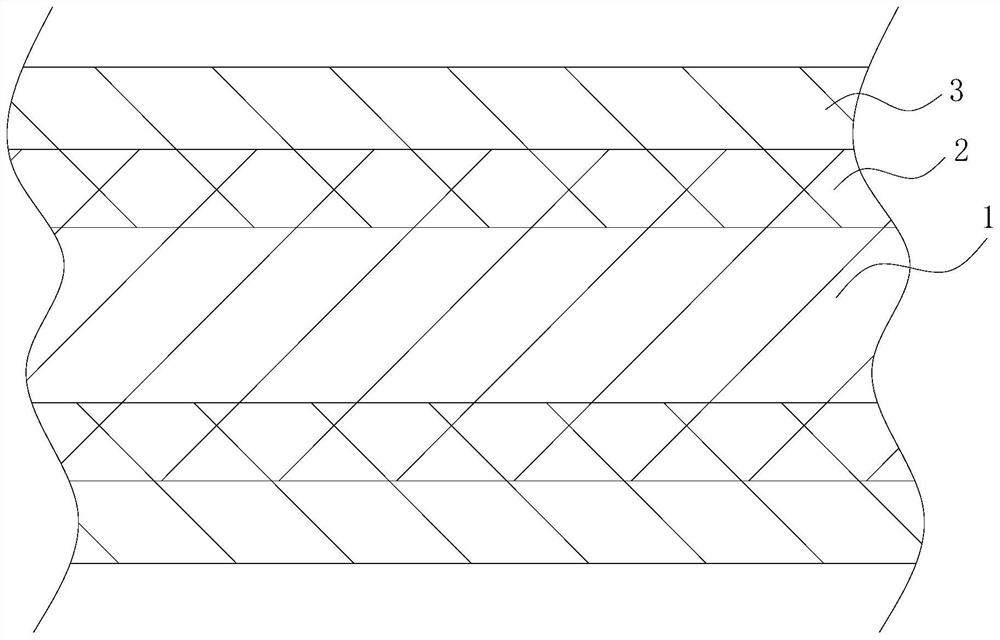

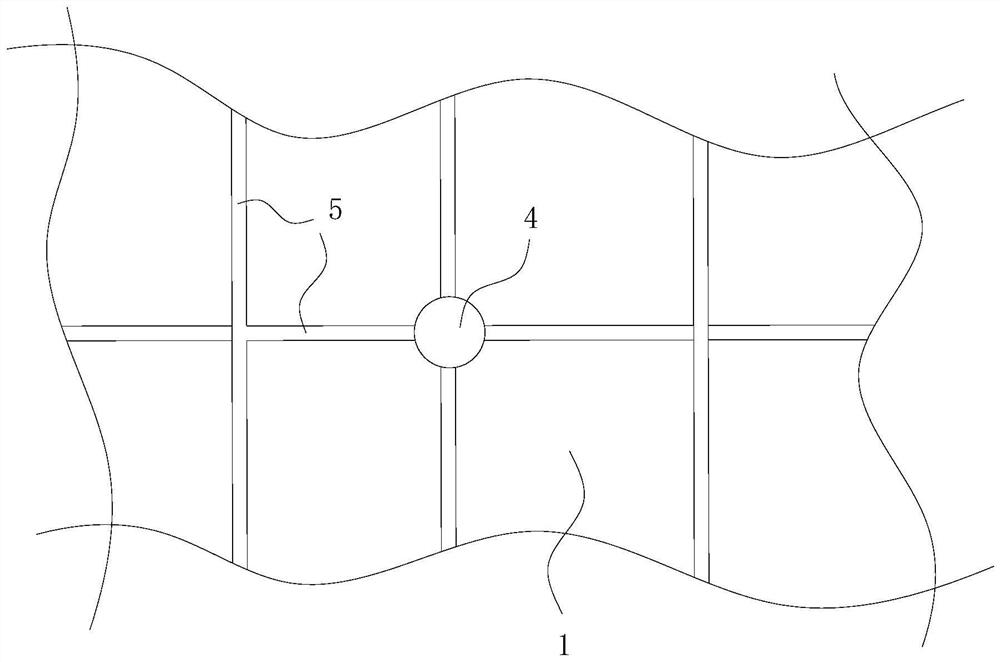

Sandwich aluminum-based printed circuit board laminating method

ActiveCN113079645AImprove performanceImprove stabilityPrinted circuit manufactureMegasonic cleaningCopper foil

The invention belongs to the technical field of printed circuit boards, and particularly relates to a sandwich aluminum-based printed circuit board laminating method which comprises the following steps: S1, after an aluminum substrate is fixed on a clamp, performing drilling on the aluminum substrate to obtain a through hole; S2, on the basis of the step S1, immersing the aluminum substrate in DI water at the temperature of 50-60 DEG C for ultrasonic cleaning, after cleaning is completed and drying is conducted, attaching prepregs to the upper surface and the lower surface of the aluminum substrate respectively, and then covering the surfaces of the prepregs with a layer of copper foil; S3, on the basis of the step S3, feeding the aluminum substrate into a laminating machine, and laminating the aluminum substrate to obtain a semi-finished circuit board; S4, on the basis of the step S3, conducting drilling again at the position of the through hole in the aluminum substrate, obtaining a working hole, and conducting metallization treatment on the inner wall of the working hole. The prepared circuit board is low in production cost and good in performance and stability.

Owner:SHANGHAI UNIV

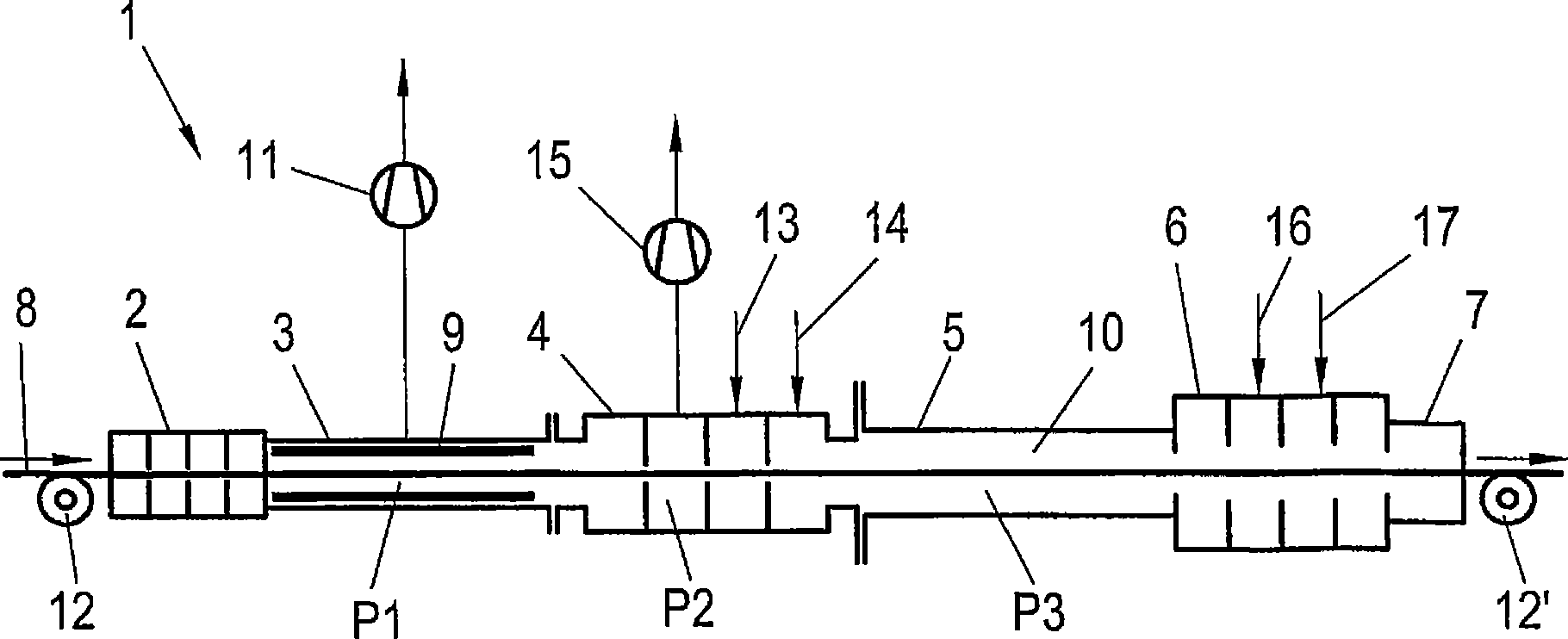

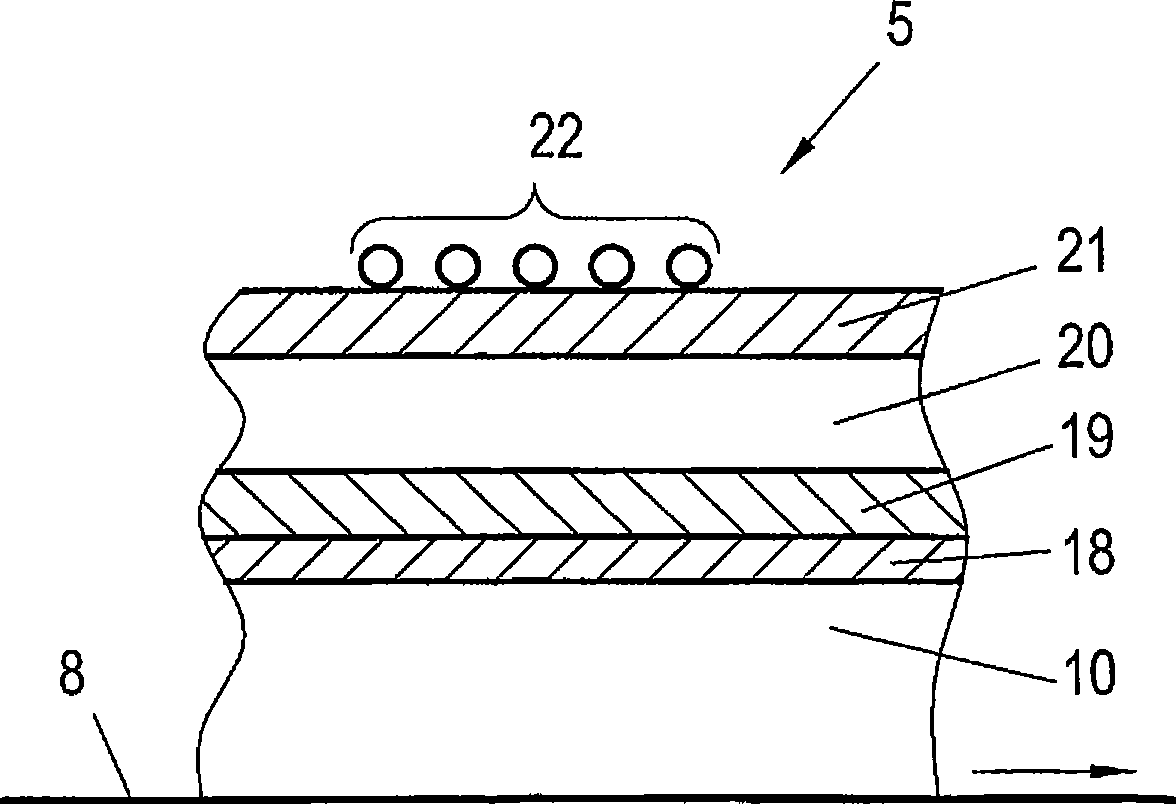

Method and device for the continuous plasma treatment of materials, in particular for the descaling of a metal strand

InactiveCN101394948AAvoid lostReduce wearElectric discharge tubesWork treatment devicesPlasma reactorMetal

The invention relates to a method and a device (1) for the treatment of materials, in particular endless materials, such as wires, rods, tubes, etc. The device comprises a heating chamber (3) for heating fed material (8) during its movement through the heating chamber (3) and a plasma reactor (5) which is arranged upstream of the heating chamber and has at least one discharge chamber (10), through which the material (8) can be transported continuously and in which the material can be subjected to a plasma treatment while it is moving through.

Owner:普利莫兹·艾泽尔特 +2

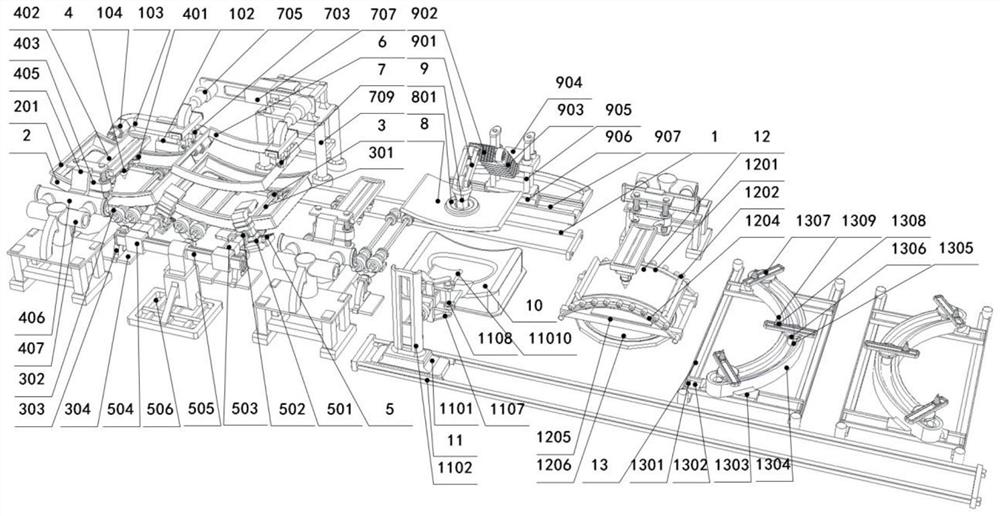

An intelligent turning device for shield segment steel skeleton

ActiveCN111545981BReduce the possibilityNo human intervention requiredWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention discloses an intelligent overturning device for a steel bar skeleton of a shield segment, comprising a magnetic displacement system, a mold frame 1, a rolling system, a welding system, a locking system, a mold frame 2, a frame placing system, a placing table 1, and a displacement system , inversion system, and side welding system; the invention can realize the positioning and fixed point of the steel frame through the mutual cooperation of the magnetic displacement system and the rolling system, which is accurate and does not require manual intervention, saves time and effort in operation and can carry out all-round inspection of the steel frame Welding, greatly reducing the possibility of missing key welding points, while ensuring uniform quality of welding points. The mold frame combination can be locked through the locking system, and then the steel cage and the steel mold can be welded synchronously. Through the cooperation of the displacement system and the side welding system, it is possible to weld difficult, deep or weak points without welding. Affected by the position or orientation of the steel skeleton, the work intensity is reduced and the possibility of processing accidents is reduced.

Owner:济南轨道中铁管片制造有限公司

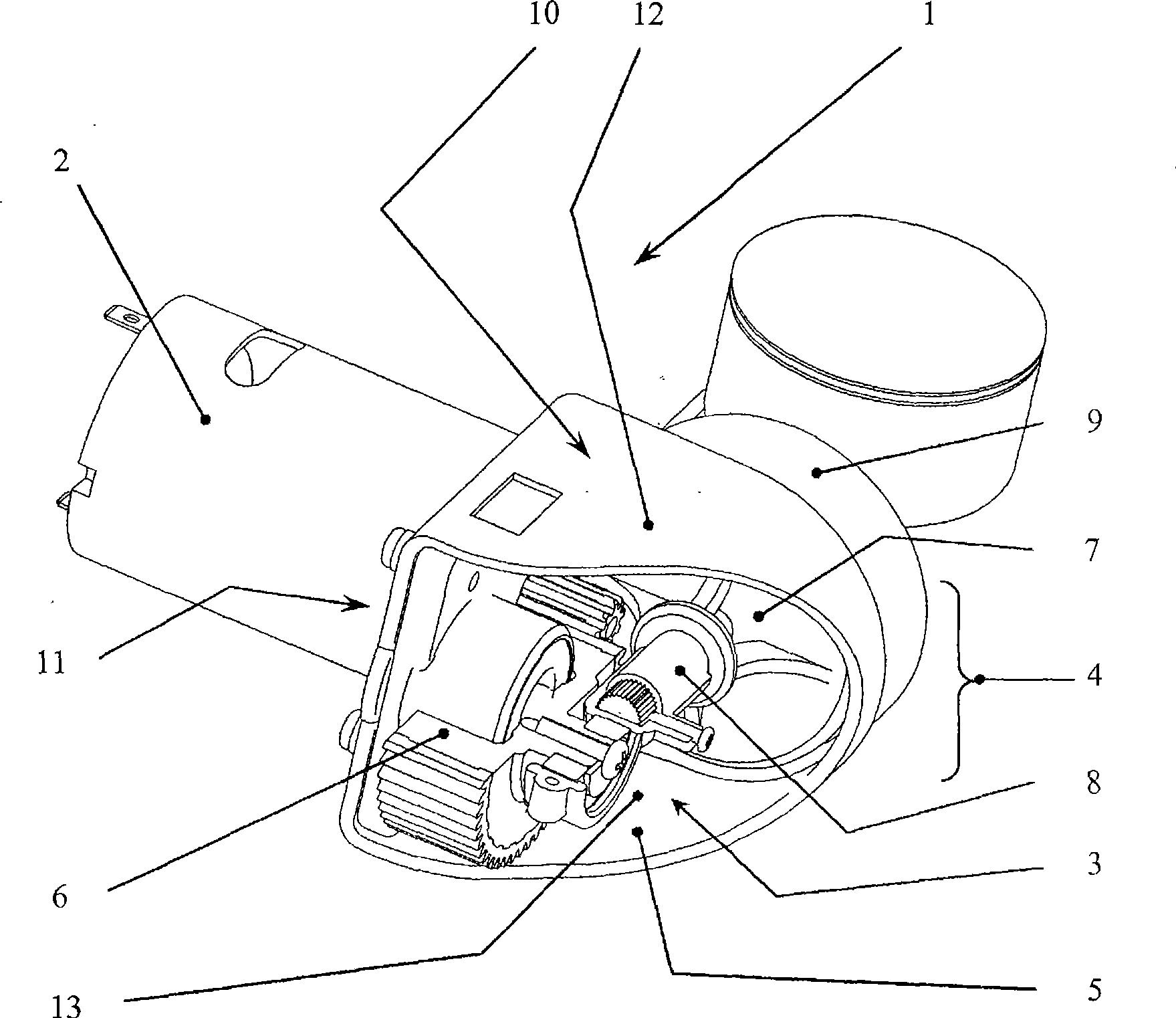

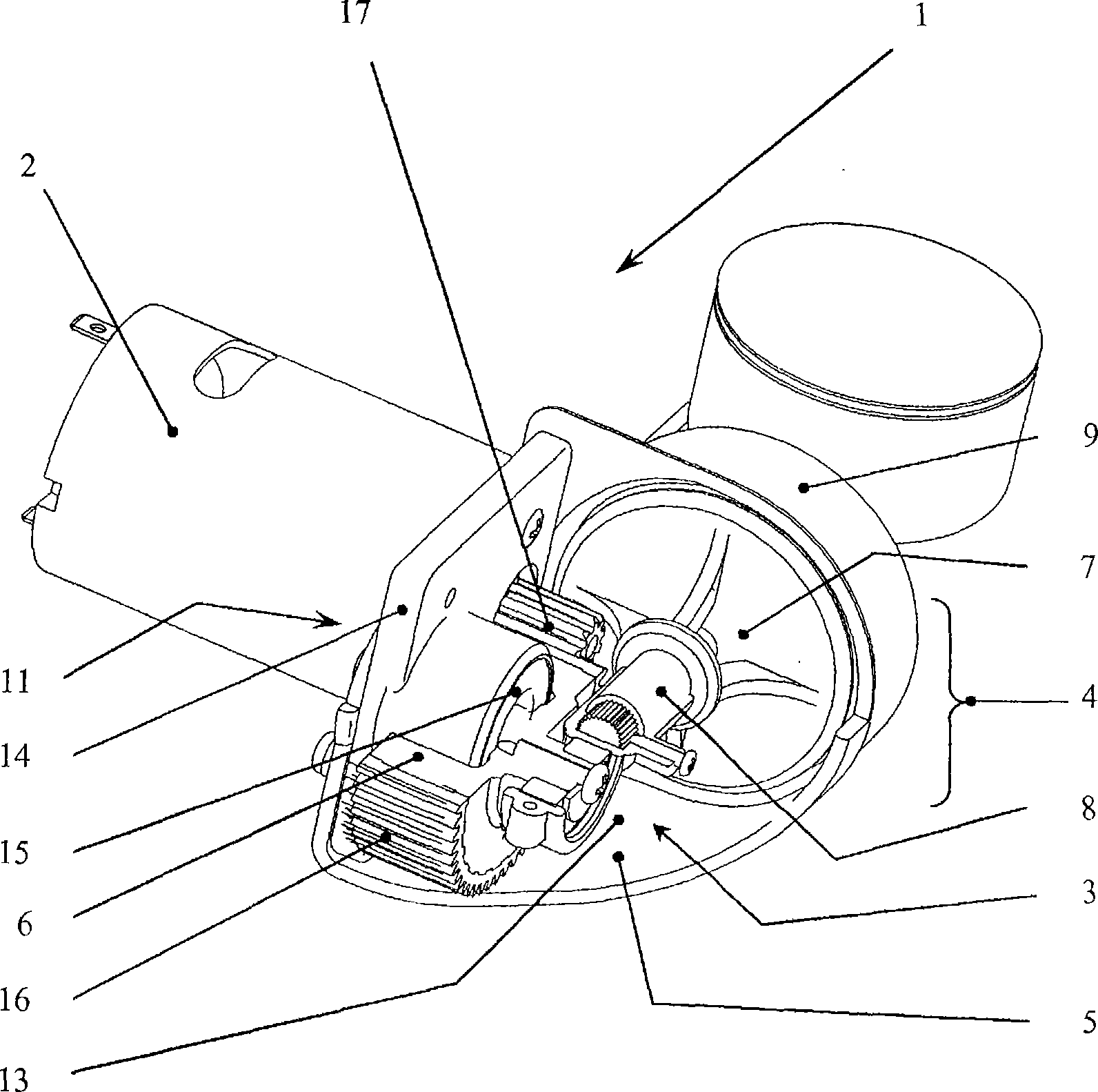

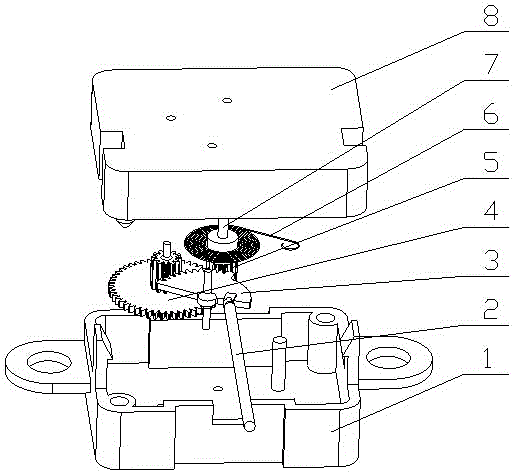

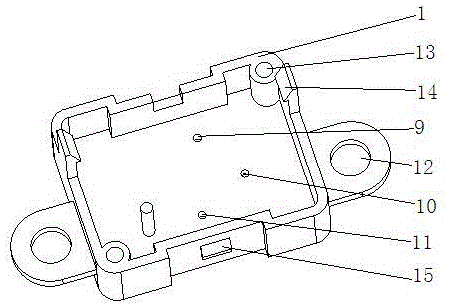

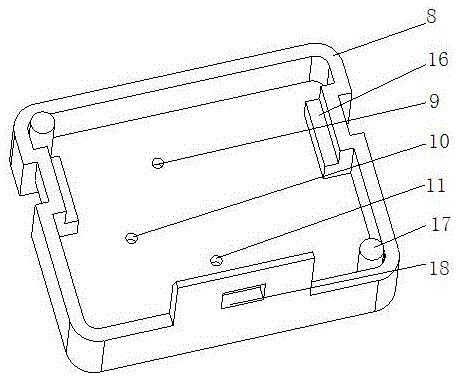

Novel mechanical blood pressure meter movement

ActiveCN105147270ASimplified quantityWith dustproof effectEvaluation of blood vesselsAngiographyGear wheelBlood pressure

The invention relates to a novel mechanical blood pressure meter movement. The movement is characterized in that the blood pressure meter movement is composed of a lower box cover, an ejector pin, a gear assembly, a pointer shaft, a torsion spring and an upper box cover. The ejector pin is arranged on the gear assembly, the pointer shaft is sleeved with the torsion spring, and the gear assembly is arranged between the upper box cover and the lower box cover which are fixed together through a buckle structure. According to the technical scheme, the overall structural design is ingenious, and the structure is compact and simple. Main parts of the movement are made of plastic good in forming performance. The mechanical blood pressure meter movement is optimized through the brand new design suitable for characteristics of the plastic parts, production efficiency is greatly improved, and performance is more stable.

Owner:HONSUN NANTONG

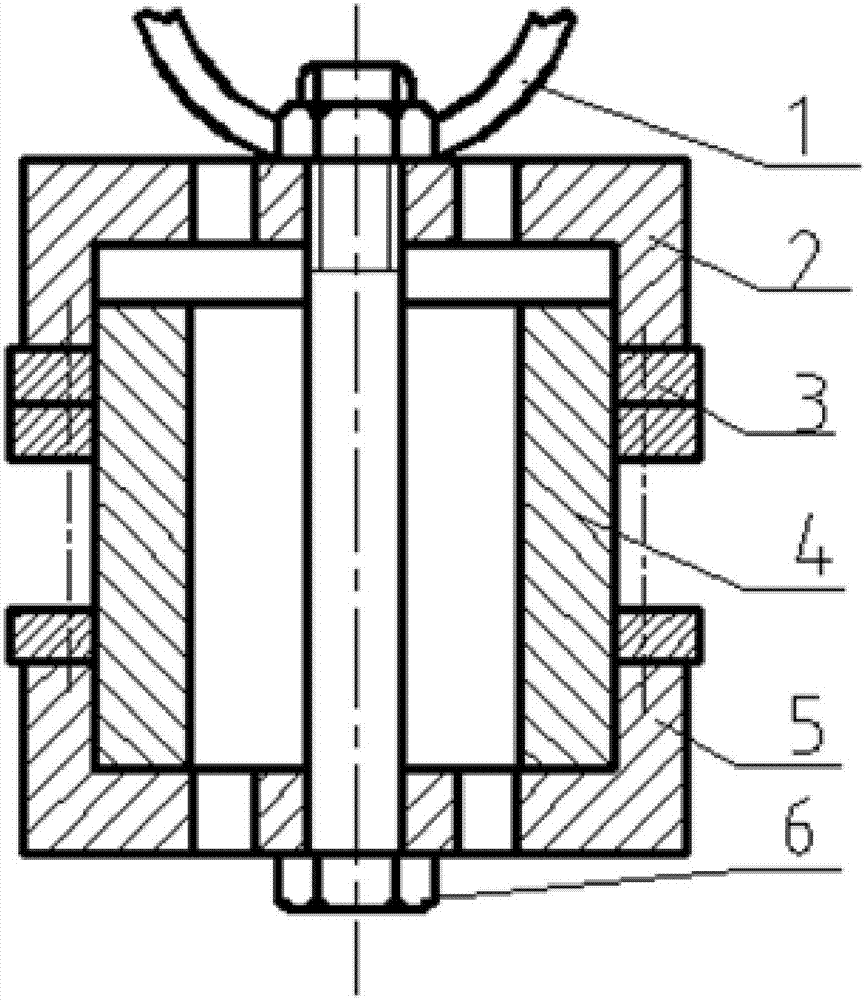

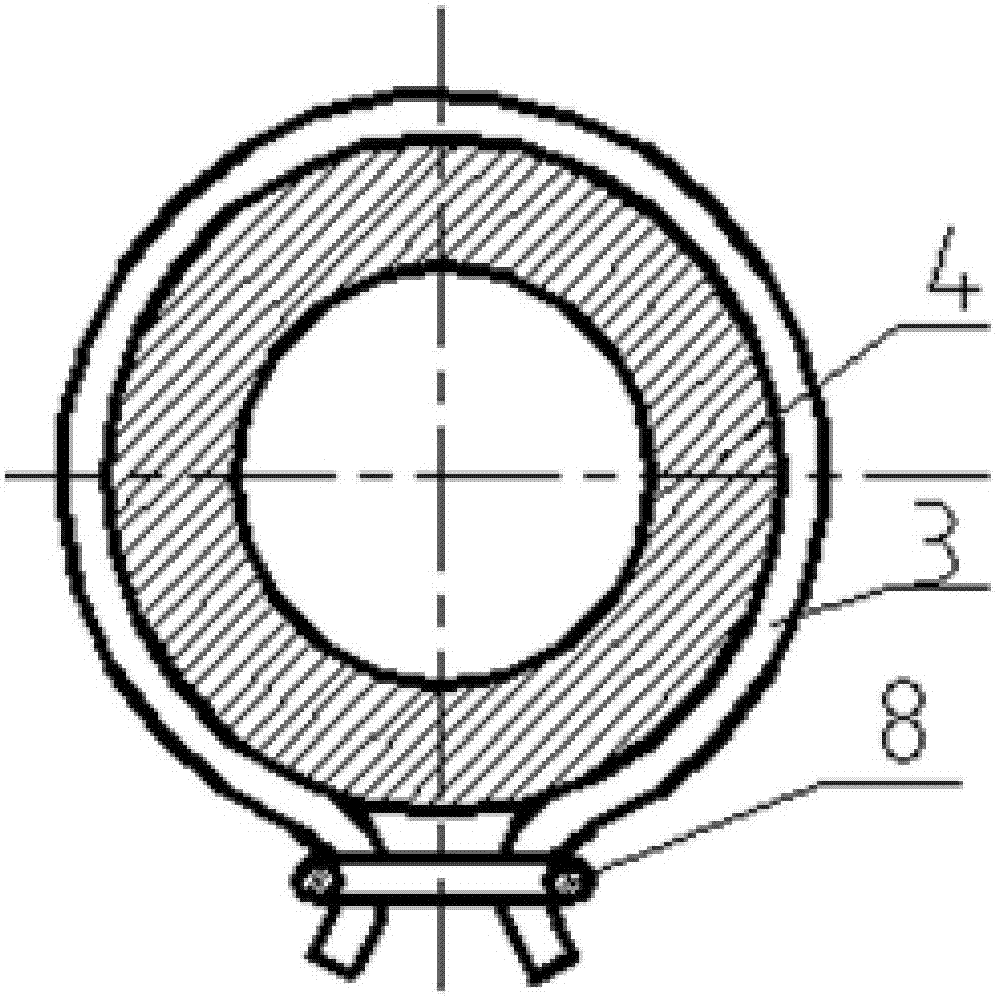

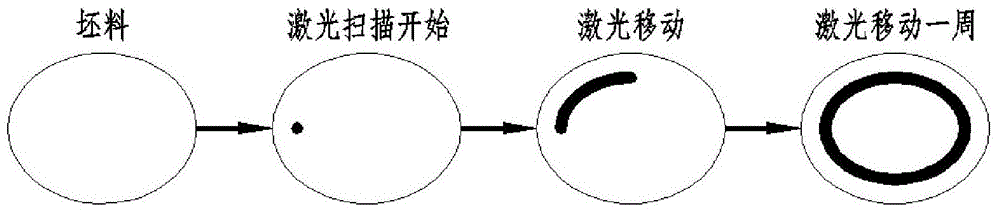

A processing method of a steel split ring and a device for realizing the method

ActiveCN105690044BSimple processing methodReduce the number of processing stepsCoil springMachining time

The invention discloses a method for machining a steel snap ring and a device for realizing the method, relates to a machining technique of a steel snap ring, and aims to solve the problems that a conventional machining method is complex, numerous in procedure, low in pass percent, high in cost and long in production period. The method comprises the following steps: coiling a blank profile which is appropriate in cross section size and length into a multi-circle ring part by using a method for manufacturing a tightly coiled helical spring, wherein the multi-circle ring part has multiple circles and the circles are tightly contacted; cutting the multi-circle ring part into a single-circle snap ring blank; setting clamping heads at two ends of the blank; tightening an iron wire hooping knot on the outer circle of a cylindrical barrel, inserting a fastening bolt and a lifting eye nut into the cylindrical barrel, a top cover and a bottom cover so as to connect and tightly press the cylindrical barrel, the top cover and the bottom cover, tempering, remaking the iron wire hooping knot, tempering again, and cutting. By adopting the method, the beneficial effects that 7 procedures are reduced to 3 procedures, the pass percent is increased by 20%, the machining cost is halved and the machining time is halved can be achieved, and the method is applicable to the field of snap ring machining, and particularly to machining of steel snap rings.

Owner:HARBIN TURBINE

Method of introducing ion and method of manufacturing semiconductor device

InactiveUS7615473B2Light weightIncreased durabilitySolid-state devicesSemiconductor/solid-state device manufacturingResistOrganic film

When an ion is introduced into a semiconductor on which a resist is formed, the ion and the resist react with each other to generate a gas (dissociated gas) and a component of the thus-generated dissociated gas is introduced into the semiconductor, which becomes a factor to deteriorate properties of the semiconductor. According to the invention, the dissociated gas to be generated from an organic film is treated. Particularly, the dissociated gas is treated before an ion introduction is performed. As a method of performing such a treatment, the ion introduction is performed by dividing ion introduction processing itself into a plurality of times. The dissociated gas is generated in a maximum quantity just after the ion introduction is started. For this reason, it is possible to decrease an introduction of a component of the dissociated gas into the semiconductor or prevent the component of the dissociated gas from being introduced into the semiconductor, when ion introduction processing is divided into a plurality of times and, in each of the thus-divided ion introduction processing after a second time thereof, the ion is introduced while removing the dissociated gas from a treatment chamber by performing evacuation.

Owner:SEMICON ENERGY LAB CO LTD

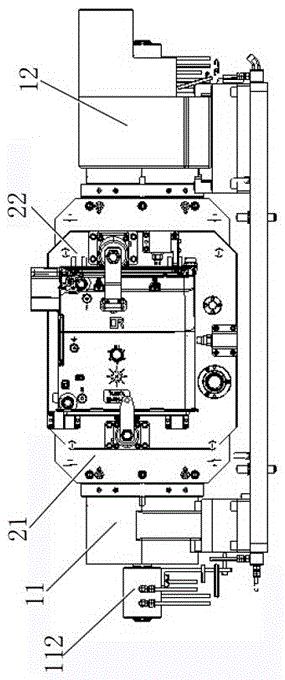

A quasi-five-axis machining center and its machining method

ActiveCN104097072BGuaranteed rotation accuracyGuaranteed rigidityLarge fixed membersPositioning apparatusEngineeringShaft collar

The invention discloses a quasi-five-axis machining centre and a machining method thereof. The quasi-five-axis machining centre comprises an AC rotary table structure, wherein the AC rotary table structure comprises a C-axis rotary table, the C-axis rotary table comprises a bridge frame plate with one end which is supported and connected to a first support table, and the other end which is supported and connected to a second support table, and a crossing shaft ring capable of freely rotating around a C-axis is further assembled on the bridge frame plate; a rotary plate is arranged by being parallel to the axis direction of an A-axis, and supported and connected to the rotary end surface of the crossing shaft ring, a shaft sleeve is further arranged on the rotary plate, and a rotary bearing capable of freely rotating around the C-axis is arranged in the shaft sleeve; a machining main shaft is detachably connected with a drive pin, and when the rotary bearing moves to be below the drive pin, the drive pin is inserted in the middle hole of the rotary bearing. According to the quasi-five-axis machining centre and the machining method thereof disclosed by the invention, the rotary power source of the C-axis is from the machining main shaft of a common vertical machine, and the existing common vertical XYZ three-axis machine can be utilized, thus furthest reducing the machining cost of polyhedral components; moreover, the machining accuracy is high and the equipment structure is simple.

Owner:SUZHOU MINGZHI TECH

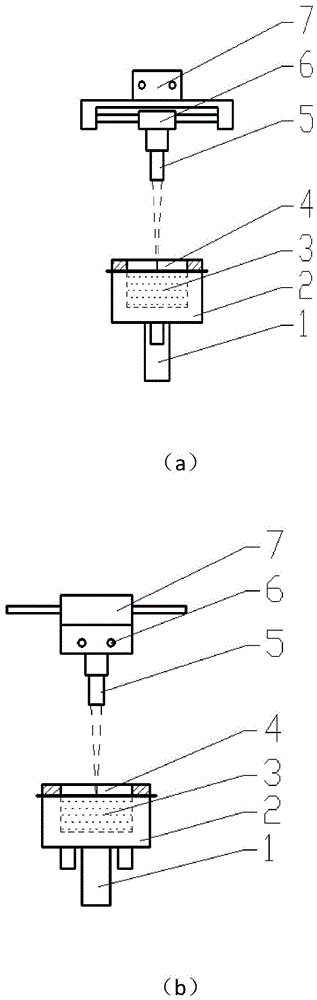

A method for dieless forming of laser heating induced isostatically loaded sheet metal

InactiveCN104646479BFacilitates the formation of fine featuresEasy to shapeShaping toolsLiquid mediumLaser heating

The invention discloses a laser heating induced isostatic pressing loading type die-less forming method of plates. The method comprises the following steps of: partially heating the plates through laser; applying isostatic pressing on liquid mediums; finishing the die-less forming of the plates by accumulating partial deformations of the plates. According to the laser heating induced isostatic pressing loading type die-less forming method of the plates, the shortcomings that the forming accuracy of a laser thermal stress forming method is not high and intricately shaped parts are difficult to form are overcome, and the machining speed and accuracy are accurately controlled, so that the size accuracy and good surface quality of the formed plates are higher, and the intricately shaped parts can be formed; the forming limit is improved, thus the machining procedures are simplified, the number of the machining procedures is reduced, and the machining efficiency is improved.

Owner:ZHEJIANG SCI-TECH UNIV

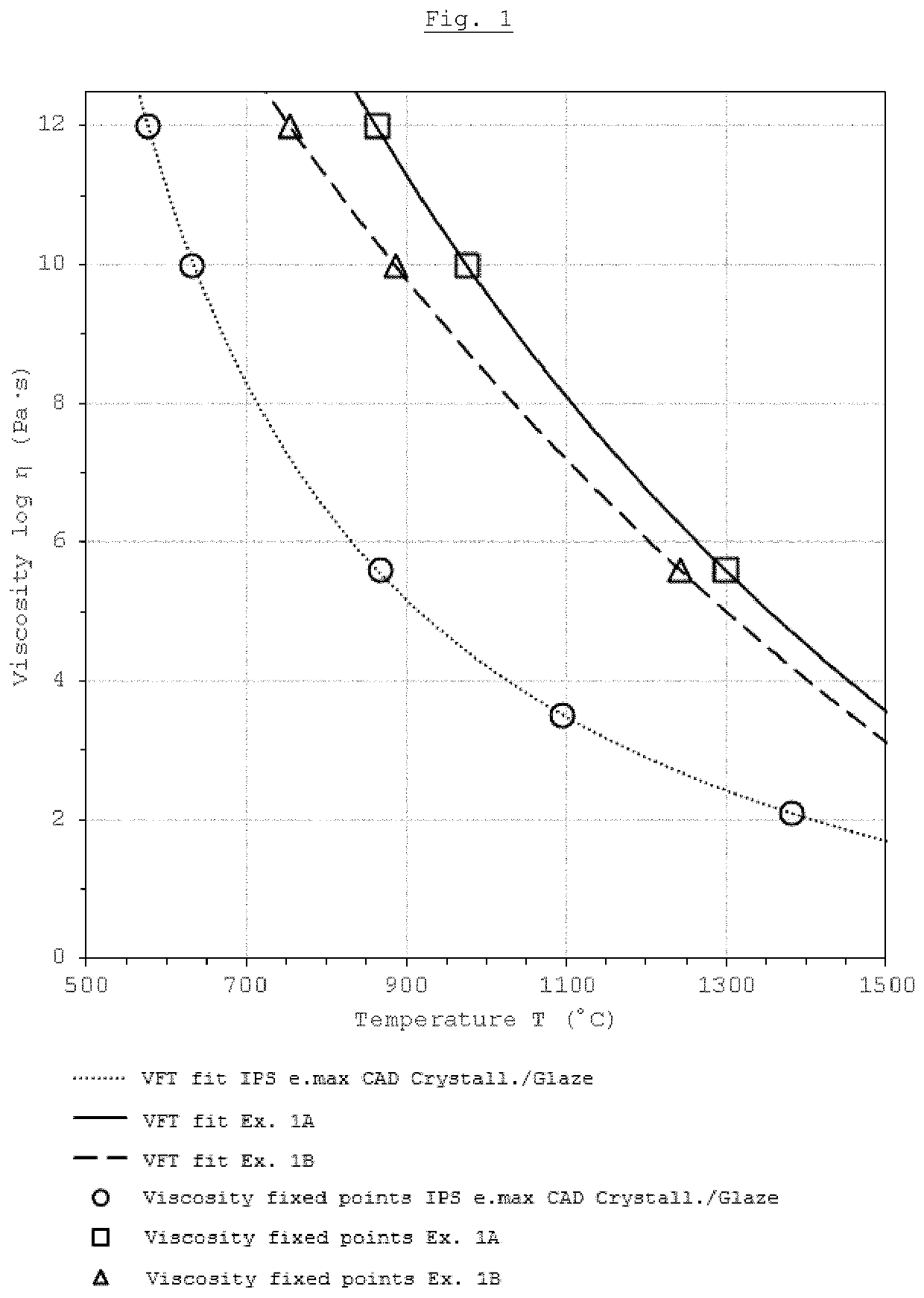

Process for producing a glazed ceramic body

ActiveUS11254618B2Reduce the number of processing stepsImpairing opticalArtificial teethHeat treatingSi substrate

Owner:IVOCLAR VIVADENT AG

Metallization of dielectrics

ActiveCN1982503BImprove bindingReduce usageLiquid/solution decomposition chemical coatingSuperimposed coating processDielectricElectron

A composition and method are disclosed. The composition both conditions and activates a dielectric material for metal deposition. The metal may be deposited on the dielectric by electroless methods. The metallized dielectric may be used in electronic devices.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Planetary gear rack and manufacture method thereof

InactiveCN102233394BReduce in quantityReduce the number of processing stepsMetal-working apparatusGearing detailsGear wheelEngineering

The invention provides a planetary gear rack and a manufacture method thereof, which are capable of reducing component number and processing steps during manufacture of a planetary gear rack, and improving yield of materials. Raw materials (W) of a side wall preset part (3p) and a seat surface preset position (4p) are alternatively configured at the surrounding of a protruding edge (2), via expansion of the seat surface preset position (4p), a seat surface (4) of a small gear is formed, and an opening (6) used for making the small gear be exposed is formed. Via stretching of the side wall preset part (3p), the side wall preset part (3p) is formed to be a side wall (3) connected with the protruding edge (2), and also the seat surface (4) is made to move toward the lower part of the protruding edge (2).

Owner:JATCO LTD

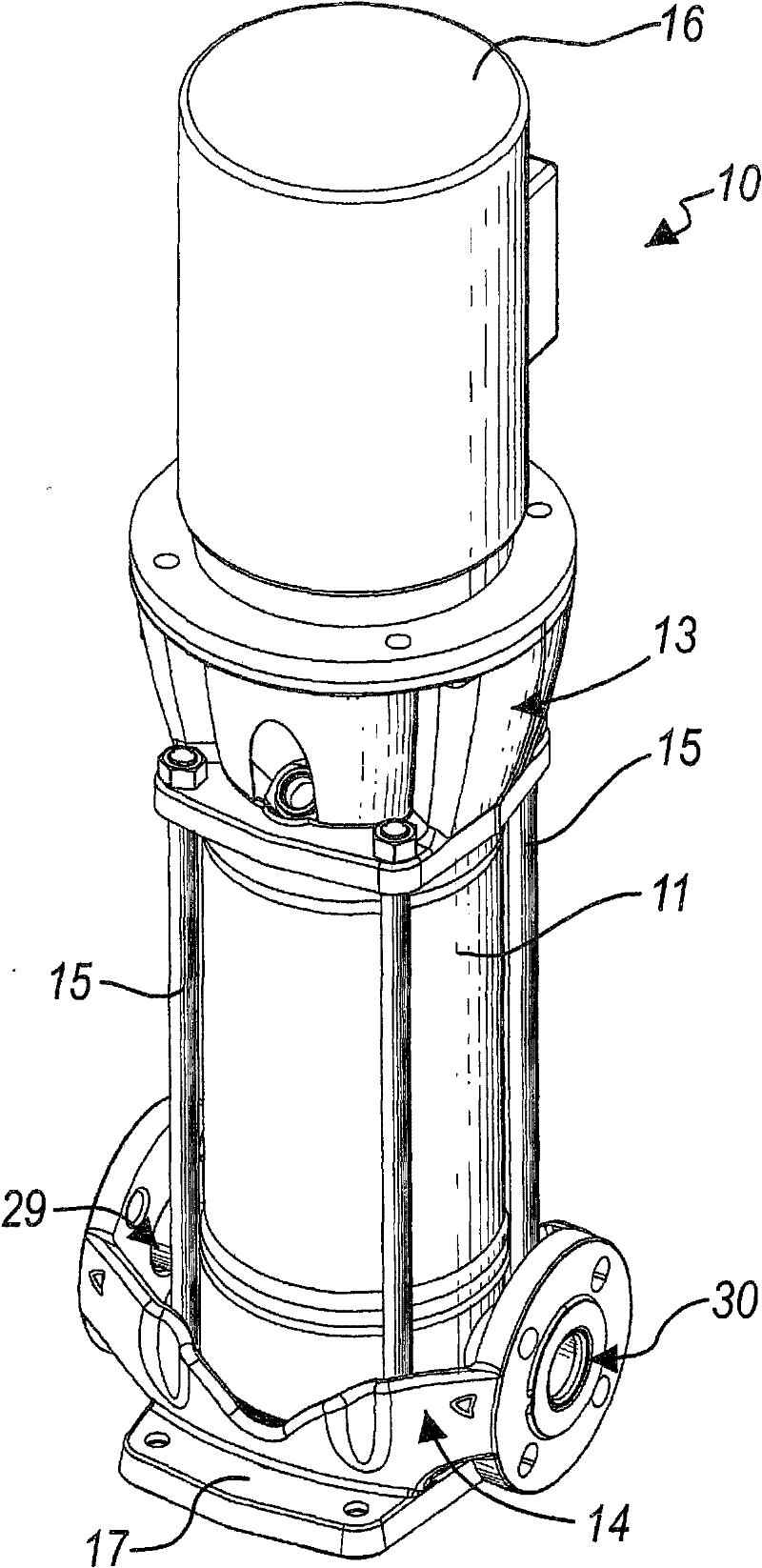

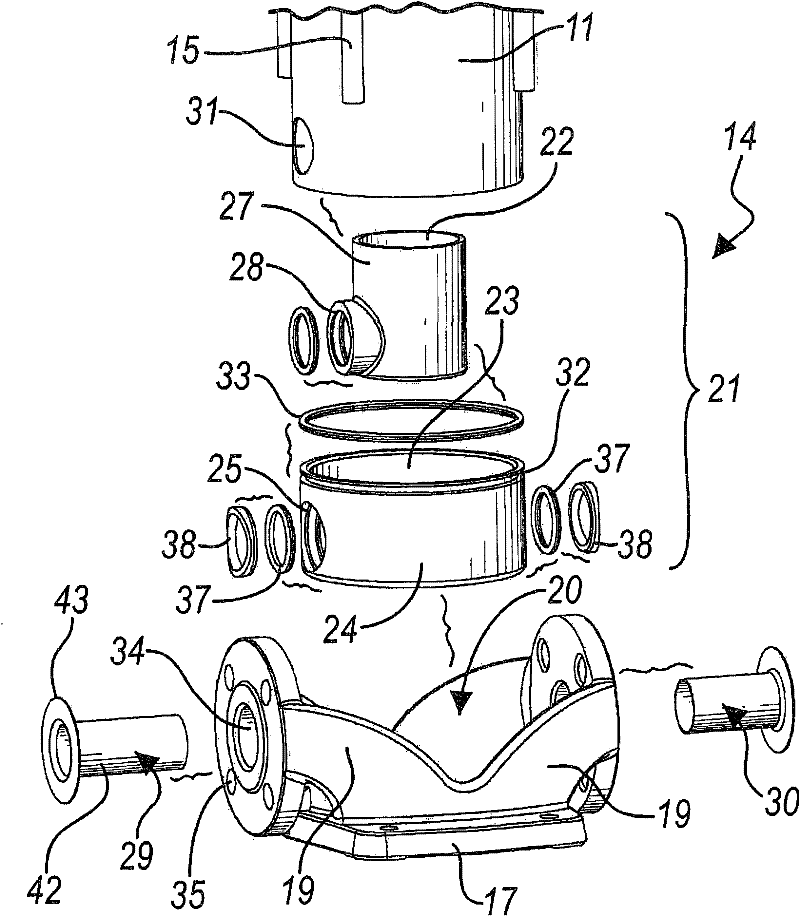

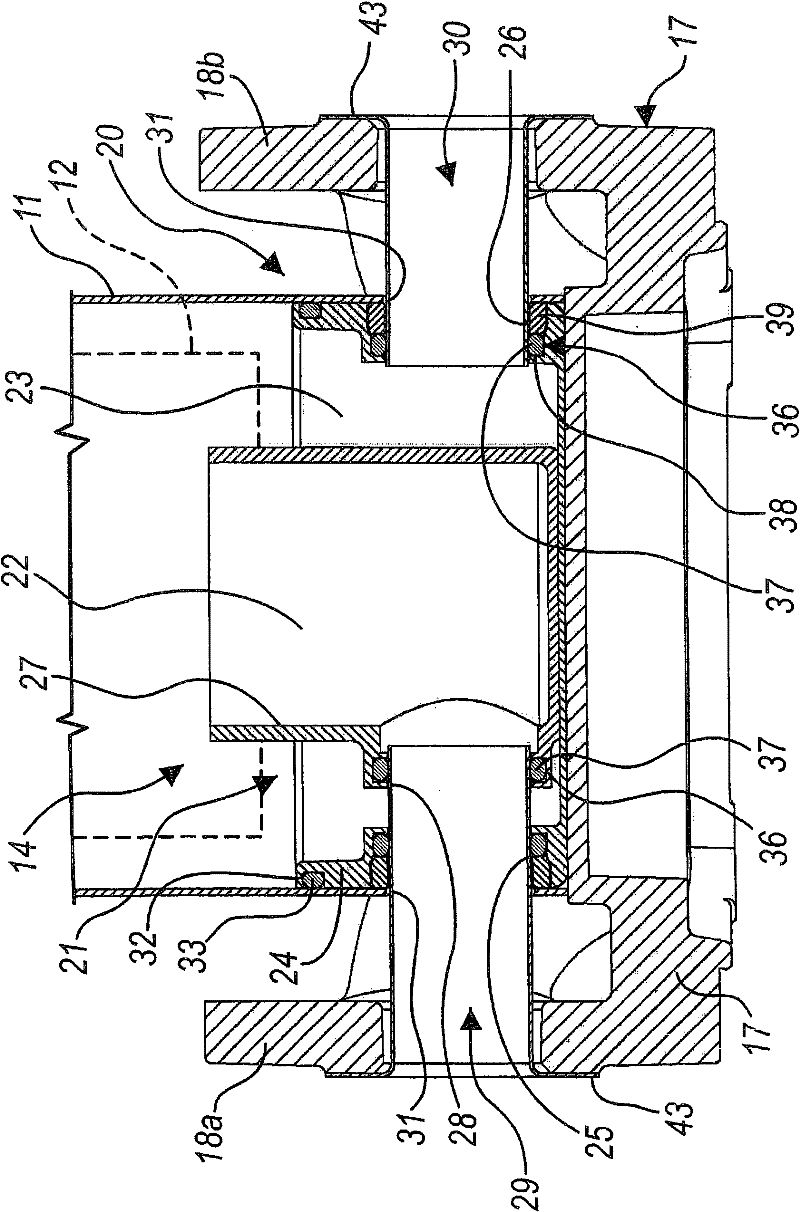

Hydraulic pump

A hydraulic pump (10), of the type which comprises a jacket (11) for containing an impeller assembly (12), which is closed at its ends respectively by a closure head (13) and by a pump body (14) for connection to the hydraulic system. The pump body (14) comprises a footing (17) from which two mutually opposite flanges (18a, 18b) for fixing the pump to the hydraulic system protrude monolithically with respect to the footing ( 17). A box-like body (21 ) is arranged on the footing (17) and forms internally two mutually isolated chambers (22, 23) which are open upward, respectively a first chamber(22) for sending fluid into the impeller assembly (12) and a second chamber (23) for collecting the fluid that arrives from the impeller assembly ( 12). The pump body ( 14) further comprises two sleeves (29, 30), a first intake sleeve (29), which protrudes from the first chamber (22) and is associated at one end with a first one (18a) of the flanges, and a second delivery sleeve (30), which protrudes from the second chamber (23) and is associated at one end with the second ( 18b) of the flanges. The space formed by the contour of the footing (17) which is comprised between the jacket ( 11) and the flanges (18a, 18b) and is occupied by the sleeves (29, 30) is open upward.

Owner:DAB PUMPS SPA

Transmission planetary gear carrier with support shaft and its production process

The invention discloses a transmission planetary gear carrier with a support shaft. The transmission planetary gear carrier comprises a support plate, a hollow cover plate parallel to the support plate and supporting legs connected with the support plate and the hollow cover plate, wherein the support plate and the hollow cover plate are correspondingly provided with multiple gear holes for small gears to be installed, the middle of the support plate penetrates the hollow cover plate and is provided with the support shaft, and the support plate and the support shaft form an integral structure. A production process of the transmission planetary gear carrier comprises the steps of (a) forming the support plate disc portion and a support shaft rod through warm-cold forging, forming the support plate and the support shaft through spline machining and rolling and performing carburizing treatment; (b) forming the hollow cover plate and the supporting legs through machining; (c) welding the hollow cover plate, the supporting legs and the support plate. The defect brought by assembly during classified manufacture of the planetary gear carrier and the support shaft in the prior art in a friction welding or press-fitting mode is overcome, the cutting-milling machining frequency and machining step number are decreased, the production efficiency is high, the production cost is low, the product quality is stable, the internal tissue density is high, the comprehensive mechanical performance is good, and the service life is long.

Owner:江苏威鹰机械有限公司

Vortex compressor

InactiveCN1329662CReduce weldingReduce the number of processing stepsRotary piston pumpsRotary piston liquid enginesMotor shaftFlange

A vortex-type compressor with detachable lower supporter is disclosed. Its cylindrical lower supporter under stator and rotor has flange jaws on its top. Said flange jaws have screen hole for fixing iron core of stator. The lower part of motor shaft is positioned in the central hole on bottom of lower supporter. A ring recess on the bottom of lower supporter is used to recept a lower balance block of lower end of rotor. Its advantages are low cost and preventing reverse rotation.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com