Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Reduce extrusion deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

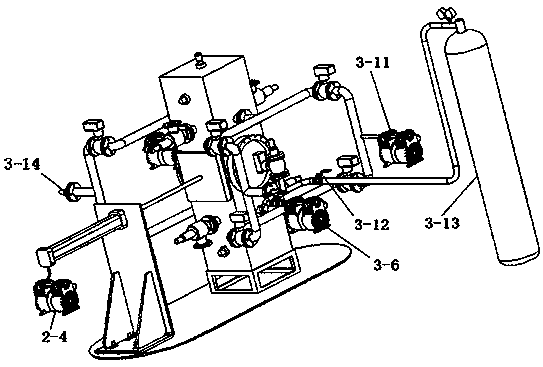

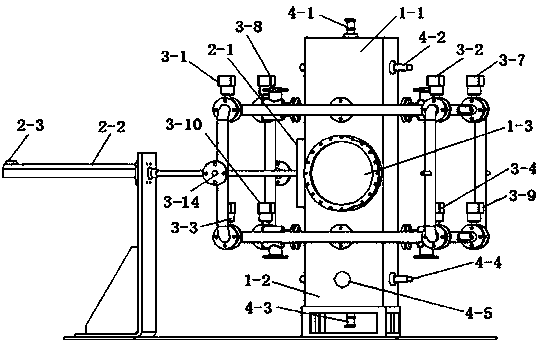

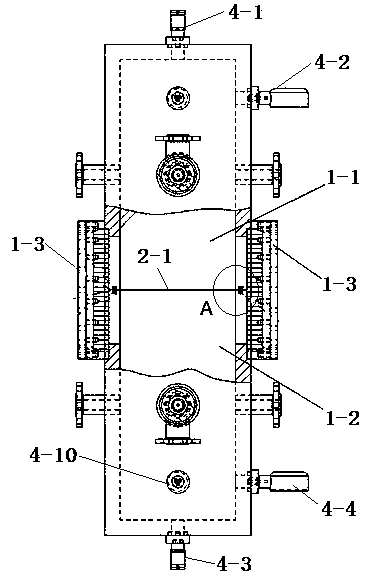

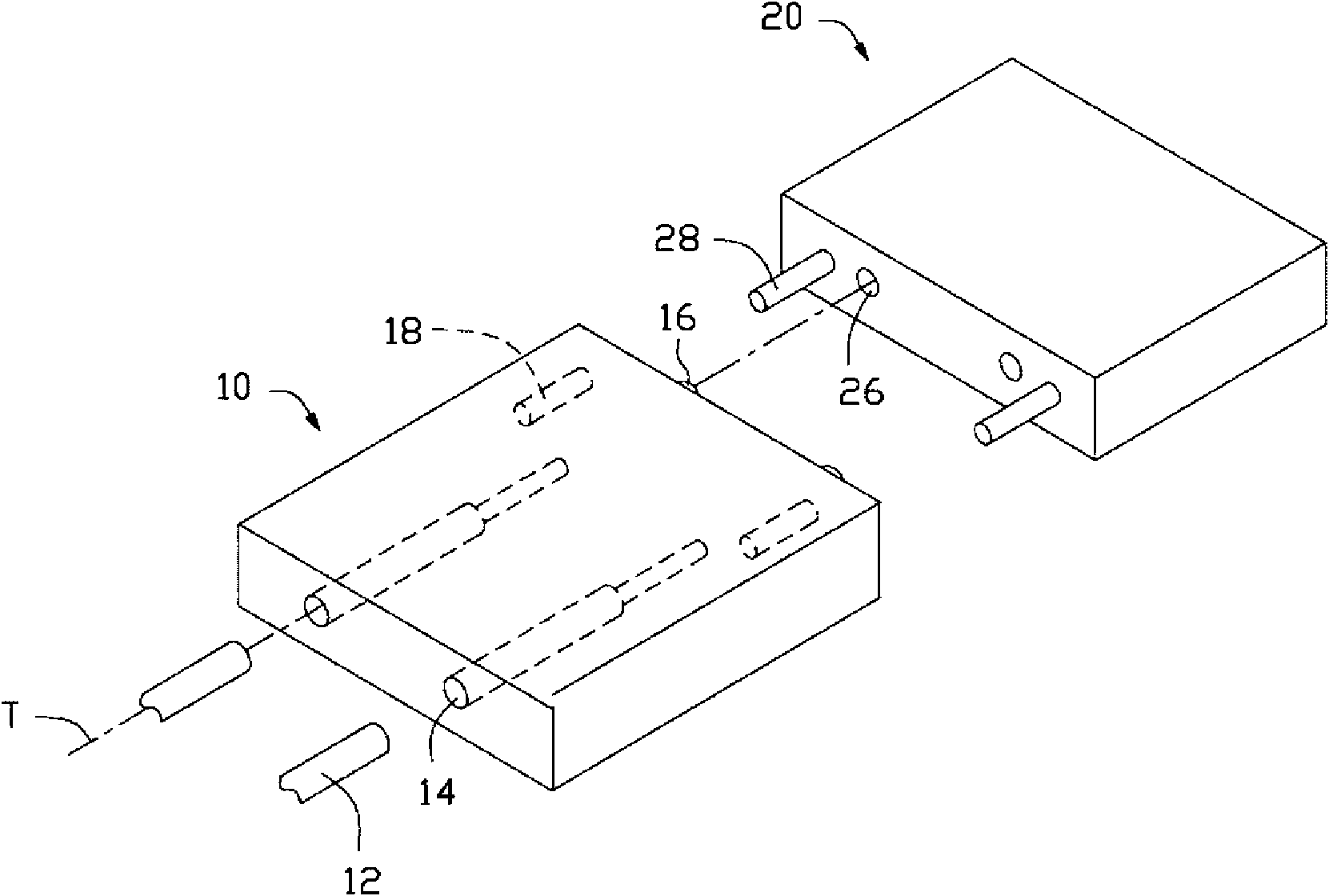

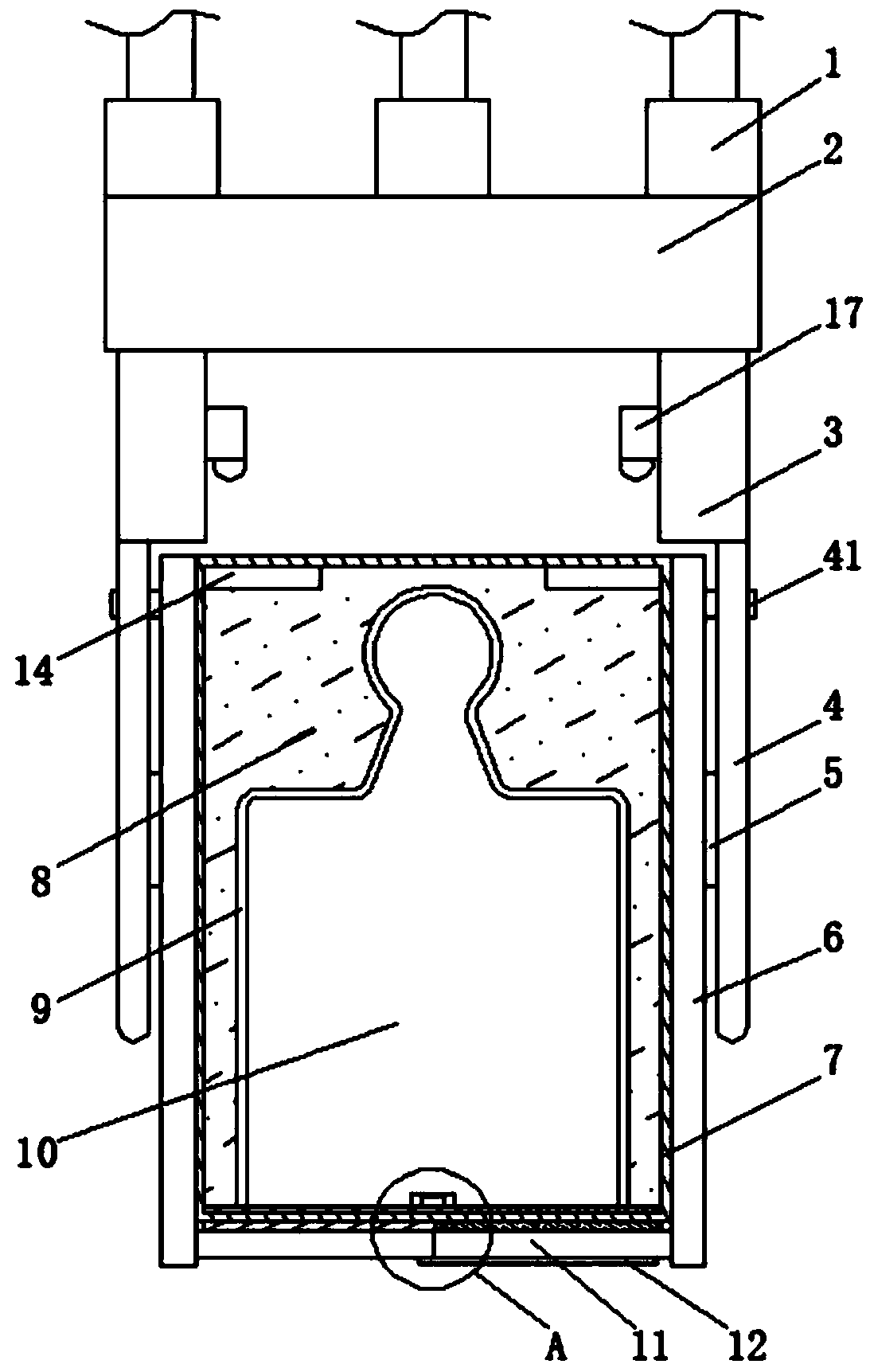

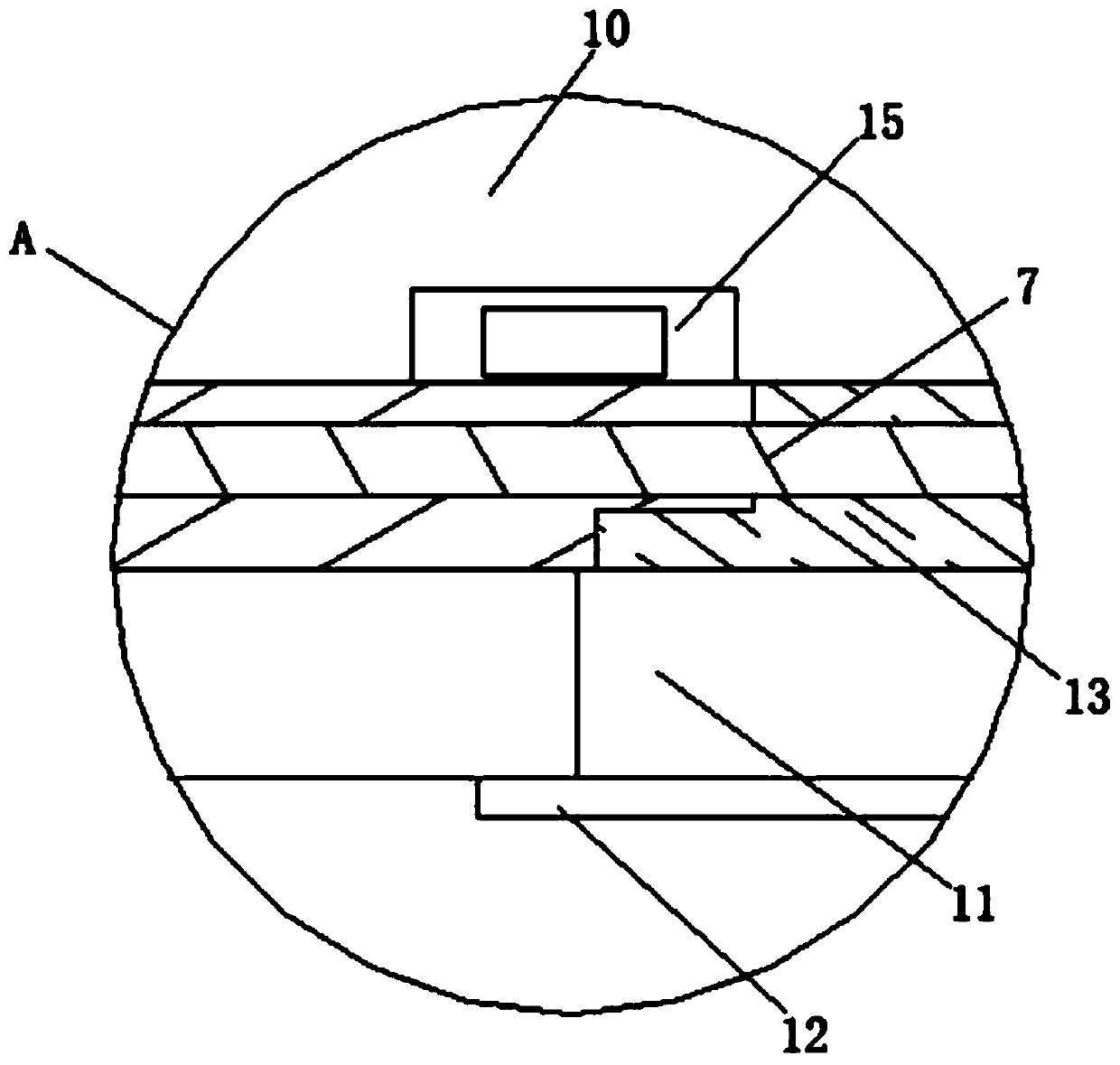

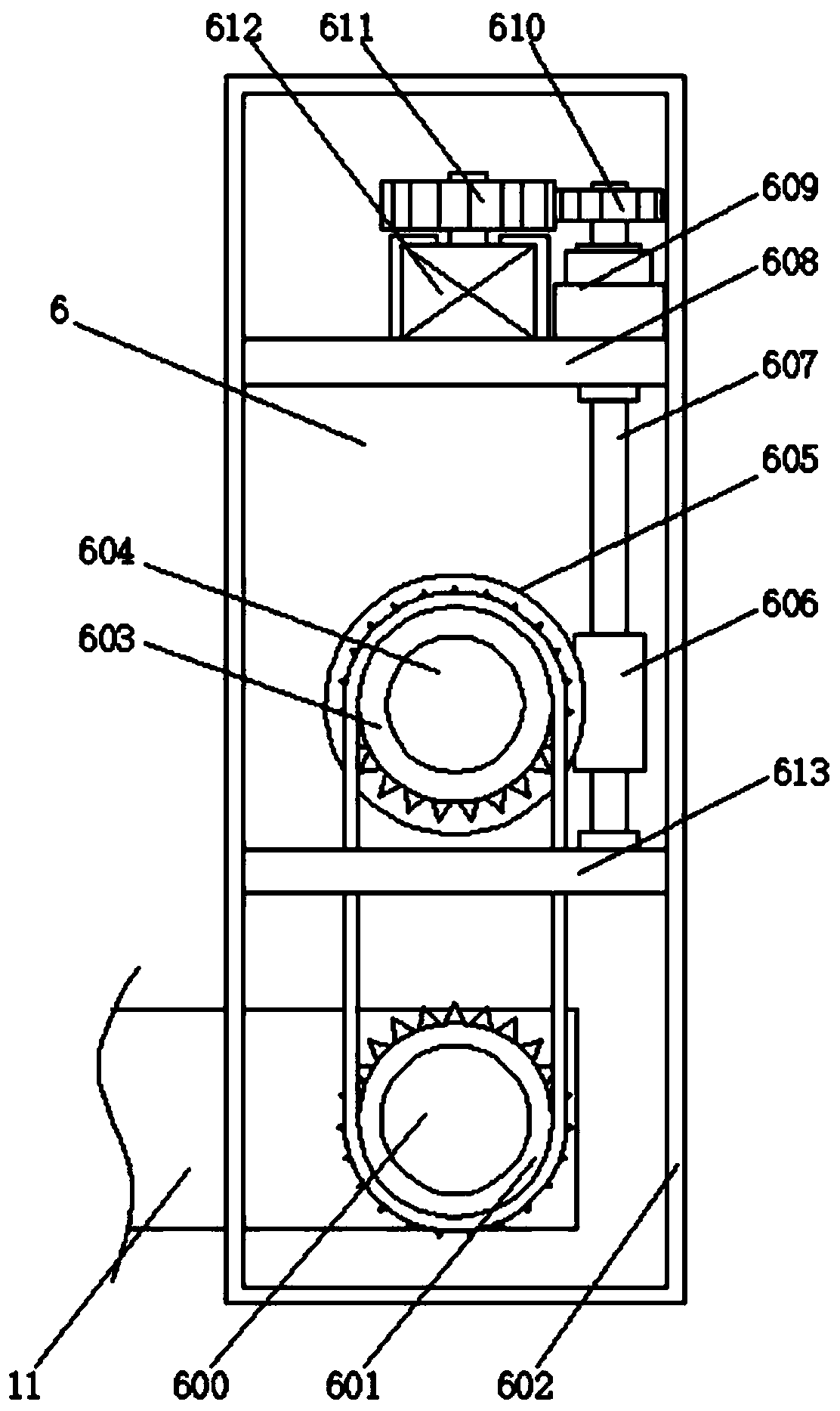

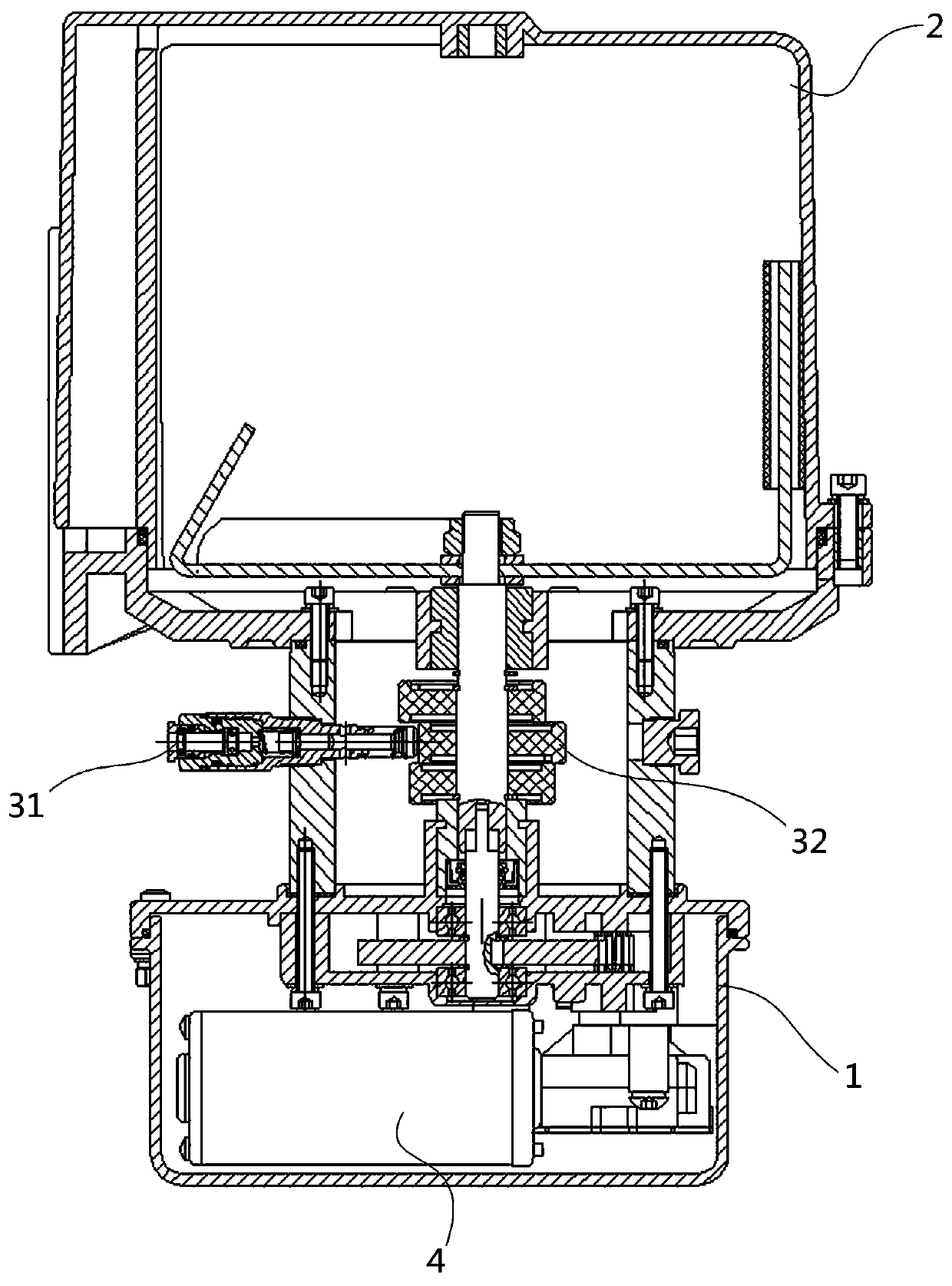

Explosive test device of combustible gas with concentration gradient and using method

ActiveCN108802100AGuaranteed accuracyReduce extrusion deformationMaterial exposibilityCombustible gasPhysical chemistry

The invention provides an explosive test device of combustible gas with the concentration gradient and a using method. The using method comprises the steps that vacuumizing is conducted till the interior of an explosive reaction container is at the vacuum state; negative pressure is matched with the gradient concentration, specifically, the combustible gas with the different concentrations is allocated in an upper reaction container and a lower reaction container, the pressure balance between the upper reaction container and the lower reaction container is always maintained in the gas injection process by controlling the flux speed electrically; an ignition test is conducted, specifically, an air cylinder is pulled out from a separation plate port, so that the upper reaction container andthe lower reaction container are communicated with each other, meanwhile, the ignition test is started, in the ignition process, a high-speed photography and schlieren measuring system analyzes the parameters such as the maximum explosive pressure, the maximum pressure rise speed, the explosive wave transmission rate, the flow field morphology, the flame evolution and the like to do research on the explosive transmission mechanism of the combustible gas with the concentration gradient and analyzes the evolution dynamics process of explosive. The explosive test device has the effects of being used for doing research on the explosive evolution dynamics process and explosive wave transmission mechanism of the combustible gas with the concentration gradient.

Owner:应急管理部天津消防研究所

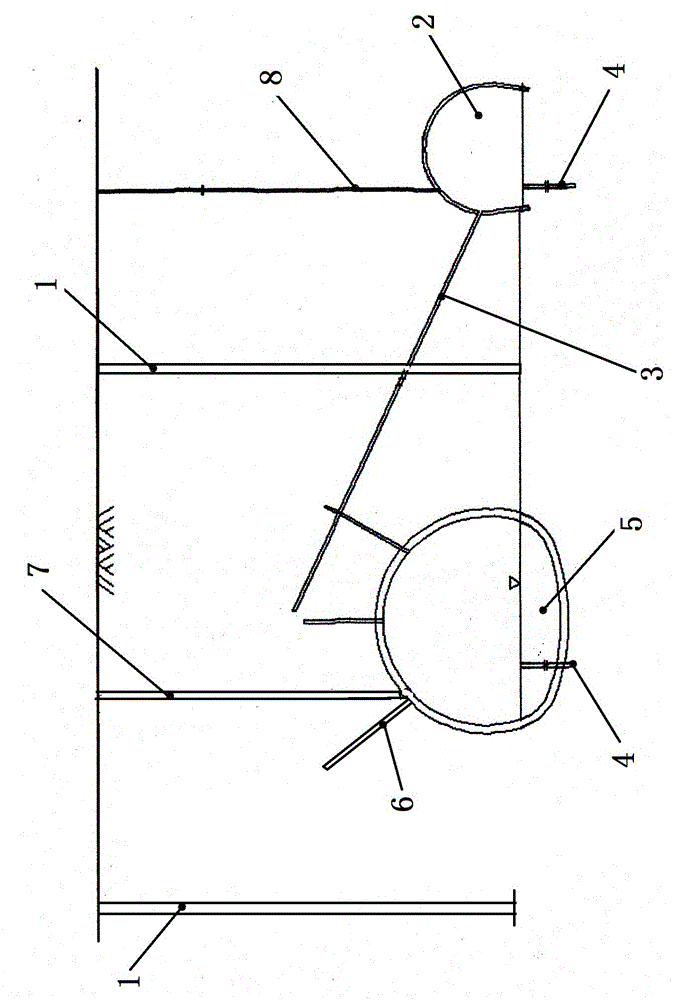

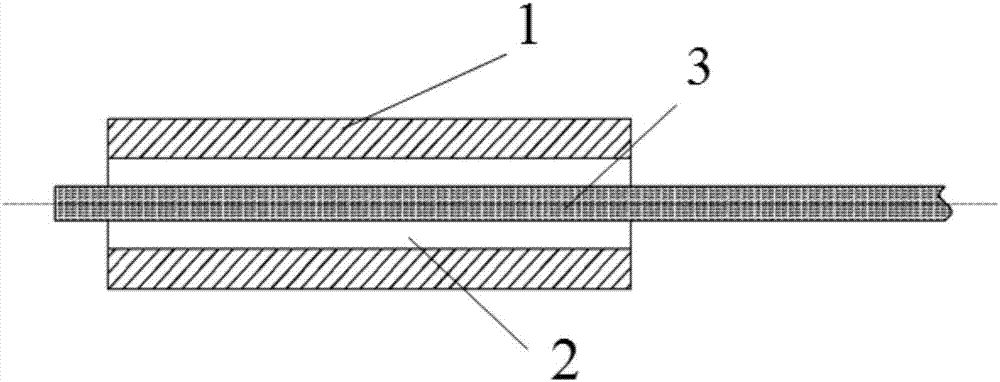

Extruded semi-grouting reinforced sleeve with built-in casing, connective structure, and construction method

InactiveCN105178516AReduce workloadImprove work efficiencyBuilding reinforcementsBuilding material handlingConcrete beamsEngineering

Disclosed are an extruded semi-grouting reinforced sleeve with a built-in casing, a connective structure, and a construction method. The sleeve is a hot-rolled seamless steel tube. The wall of the sleeve is provided with a grout inlet and a grout outlet. The sleeve is provided with circular inner projections. One end of the sleeve is an extruded end, and the rest is a grout-anchoring end. The built-in casing is arranged inside the extruded end. The inner diameter of the built-in casing is equal to the outer diameter of a rebar to be connected, and less than the inner diameter of the grout-anchoring end. All of the grout inlet, the grout outlet and the circular inner projections are located at the grout-anchoring end. By the use of the built-in casing, the deformation of the extruded end is lessened to avoid the extruded end being damaged during crimping; the sleeve is widely applicable to the rebar connection of prefabricated concrete columns in multi-storey and high-rise prefabricated assembled concrete frame structures, shear wall structures or frame shear wall structures, as well as the connection of horizontal rebars in prefabricated concrete beams, the connection of rebars in prefabricated concrete shear walls and the connection of rebars in existing reinforcement projects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Silica gel diaphragm and loudspeaker

ActiveCN107948894AReduce stressUniform stress distributionElectrical transducersLoudspeakersEngineeringSilica gel

The invention provides silica gel diaphragm and a loudspeaker. The silica gel diaphragm has a rectangular folding ring part and a middle adhering part connected with the inner periphery of the foldingring part. The folding ring part is composed of two first folding ring sides which are set oppositely and two second folding ring sides which are set oppositely. A folding ring corner is connected between the adjacent first folding ring side and second folding ring side. Each folding ring corner is equipped with at least one thickness adjustment section. First thickness difference exists among the thickness of the first folding ring sides, the thickness of the second folding ring sides and the thickness of the thickness adjustment sections. According to the silica gel diaphragm and the loudspeaker provided by the invention, the stress at four corners of the silica gel diaphragm is reduced by changing the thickness of the thickness adjustment sections of the folding ring corners of the silica gel diaphragm, so the resonant frequency is reduced and the roll vibration is suppressed.

Owner:SSI NEW MATERIAL (ZHENJIANG) CO LTD

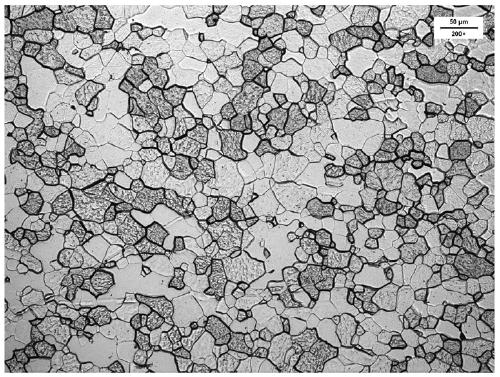

Preparation method of molybdenum tube

InactiveCN110000391AGood deformabilityEasy to processVacuum evaporation coatingSputtering coatingHigh densityVolumetric Mass Density

The invention discloses a preparation method of a molybdenum tube for a rotating target material. The method comprises the following steps: 1, carrying out filling and hot isostatic pressing treatmenton molybdenum powder to obtain a molybdenum tube blank; and 2, extruding and annealing the molybdenum tube blank to obtain the molybdenum tube. The method has the advantages of few process steps, short production period and the like; and the molybdenum tube prepared by the method has high density and fine and uniform crystal grain structure, specifically, the density is greater than or equal to 99% of theoretical density, the average crystal grain size is smaller than or equal to 40 [mu]m, the maximum length can exceed 4 meters, and the molybdenum tube can well meet the sputtering coating requirements in the industries of plane display, solar photovoltaic and the like.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

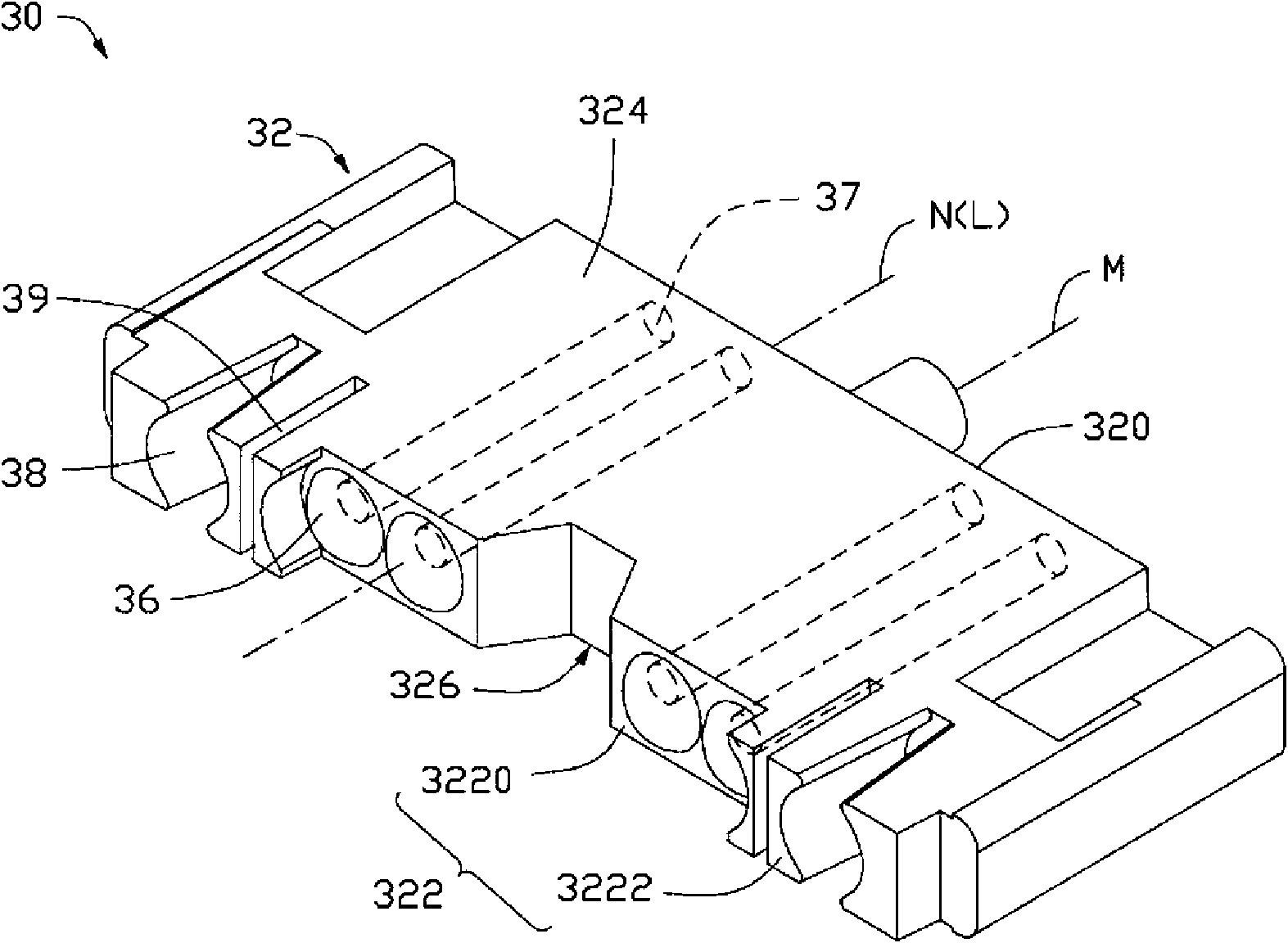

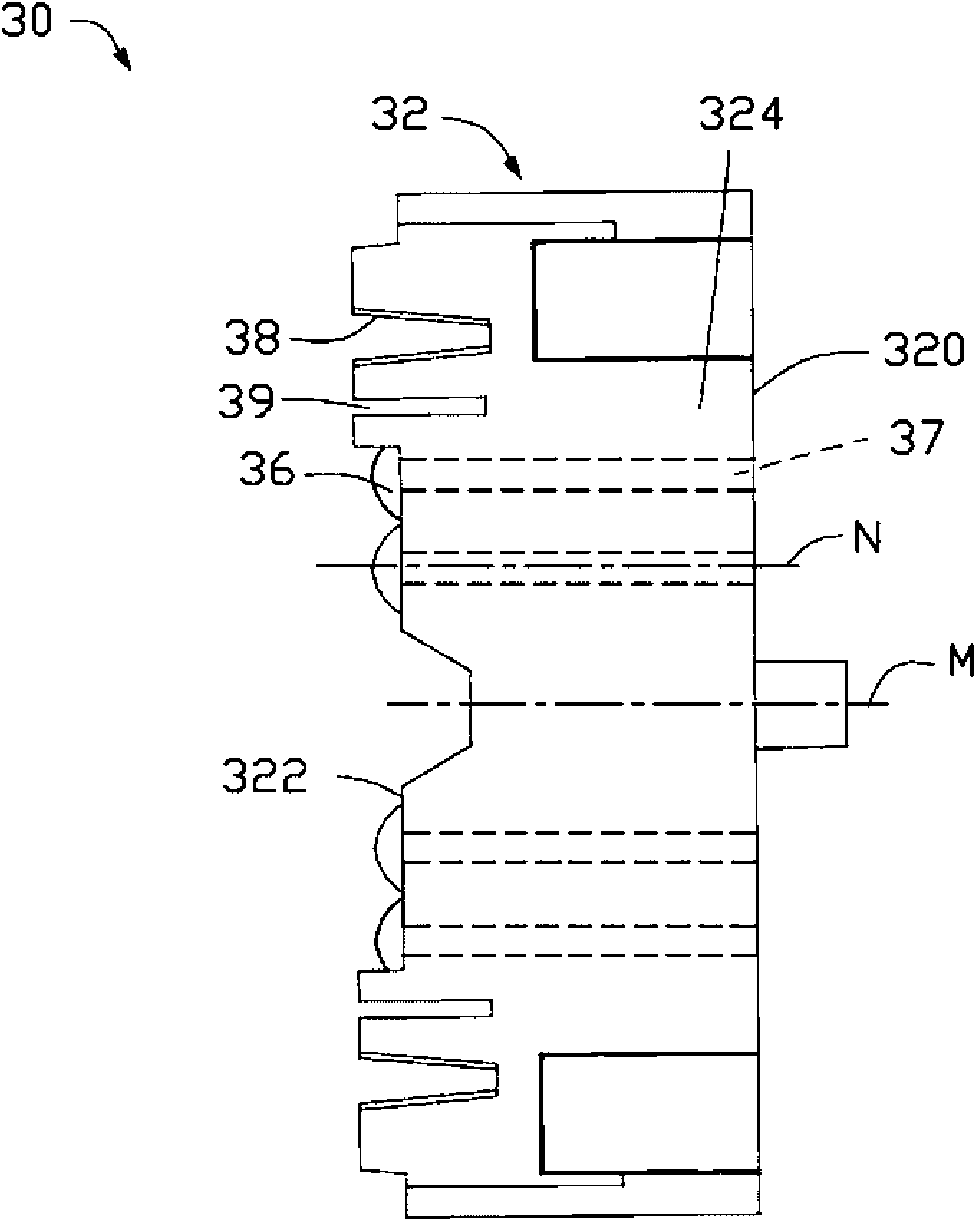

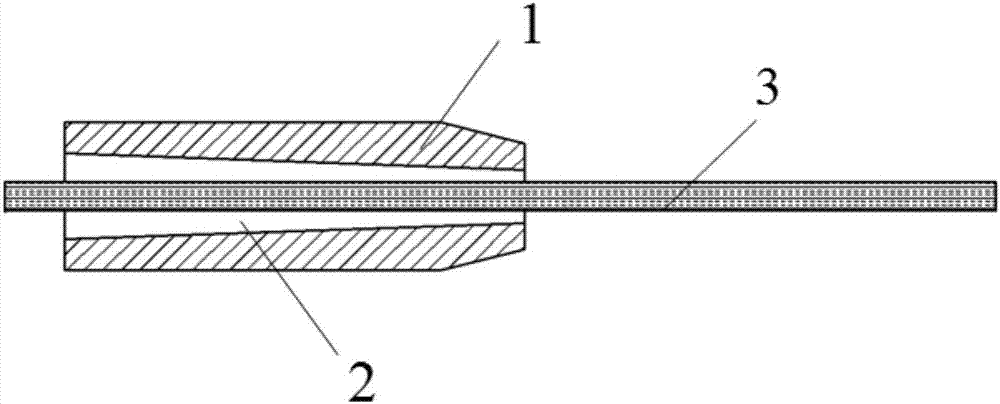

Optical fiber coupling connector

InactiveCN102062903AGuaranteed signal transmission performanceReduce extrusion deformationCoupling light guidesEngineeringOptical fiber cable

The invention relates to an optical fiber coupling connector for coupling and connecting an optical fiber. The optical fiber coupling connector comprises a body and at least one optical lens, wherein the body is provided with a first end surface and a second end surface which are opposite; the first end surface is provided with at least one optical fiber guiding hole to oppositely accommodate at least one optical fiber; at least one optical lens is arranged on the second end surface; the second surface of the body is provided with at least one inserting groove and at least one buffer groove arranged between the inserting groove and the optical lens. According to the optical fiber coupling connector provided by the invention, the buffer groove is arranged between the inserting groove and the optical lens, the compression deformation of a substrate of the inserting groove can be buffered effectively, and the deviation of the position of the optical lens can be avoided, thus the signal transmission performance of the optical fiber coupling connector is guaranteed effectively.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

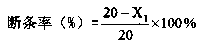

Preparation method of rice flour with low strip breaking rate

ActiveCN110477275ALow sliver breakage rateSolve the problem of high strip breakage rateFood preservationFood shapingToughnessViscosity

The invention relates to a preparation method of rice flour with the low strip breaking rate. The technological process of the preparation method comprises the steps of rice cleaning, soaking, grinding into thick liquid, adding chitosan and protein, adjusting the water content, steaming, flour mixing, extrusion molding, aging, re-steaming, cooling and product finishing. According to the preparation method, a chitosan and protein composite system is added in the preparation process of the rice flour, the chitosan and corn starch are fully mixed first then to be added to rice milk, and the problems of uneven dispersion and easy caking of the chitosan added to the rice milk are solved; and at the same time, due to cross-linking between chitosan molecules with hydrogen bonds of the chitosan molecules into a net structure, entanglement is high, a chitosan solution has a certain viscosity, when added to the rice flour, the chitosan solution can improve toughness of the rice flour, the stripbreaking rate is reduced, the cooking loss of the rice flour can be reduced, at the same time, the shelf life of the rice flour can be prolonged, and nutritional value of the rich flour is improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

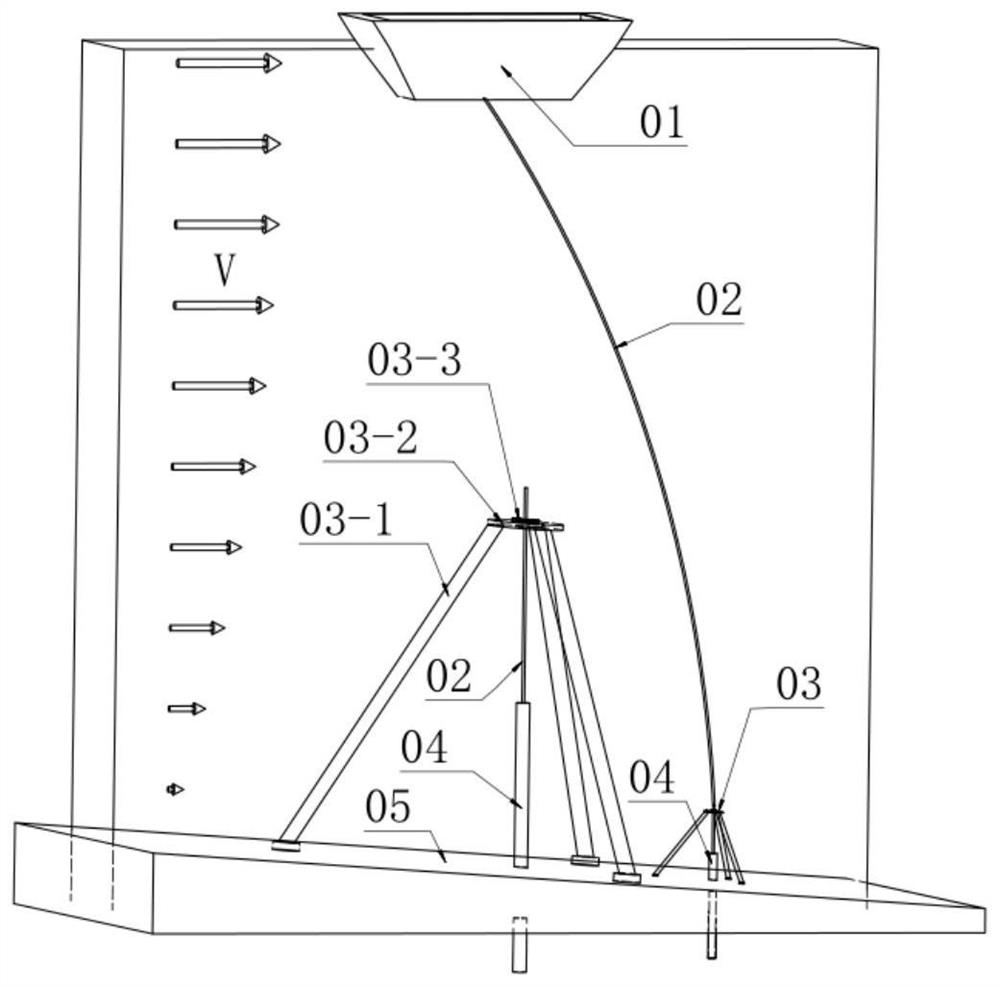

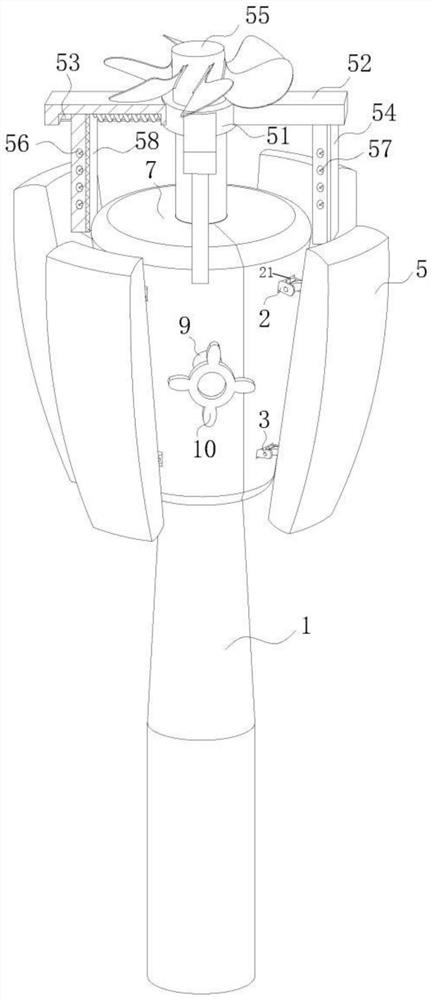

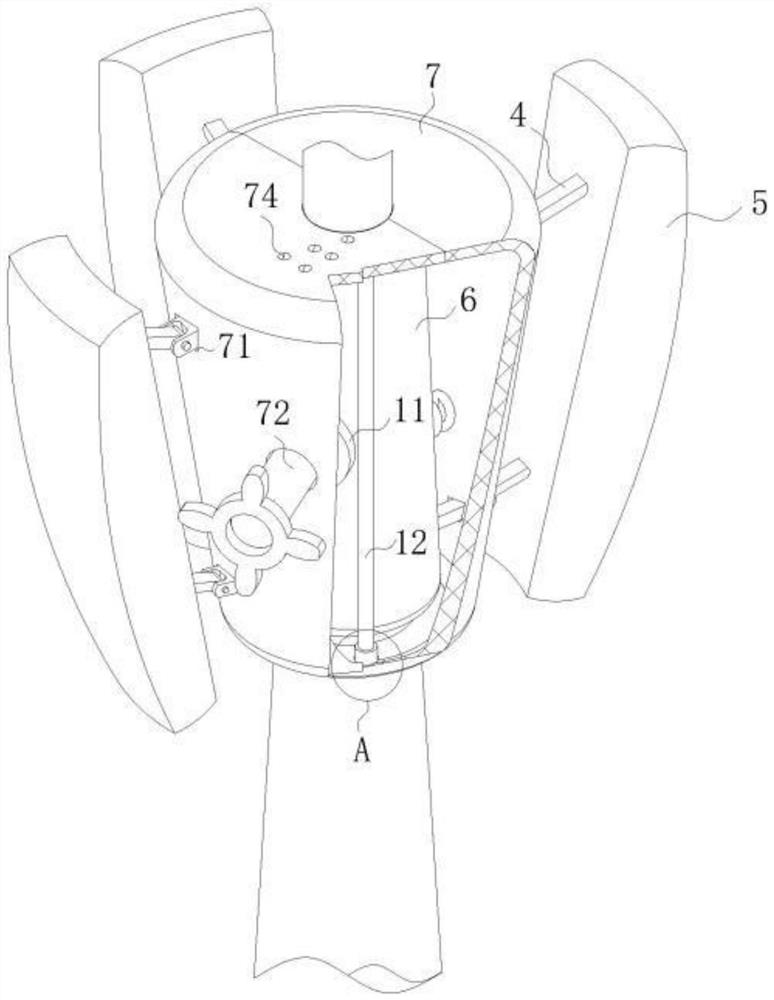

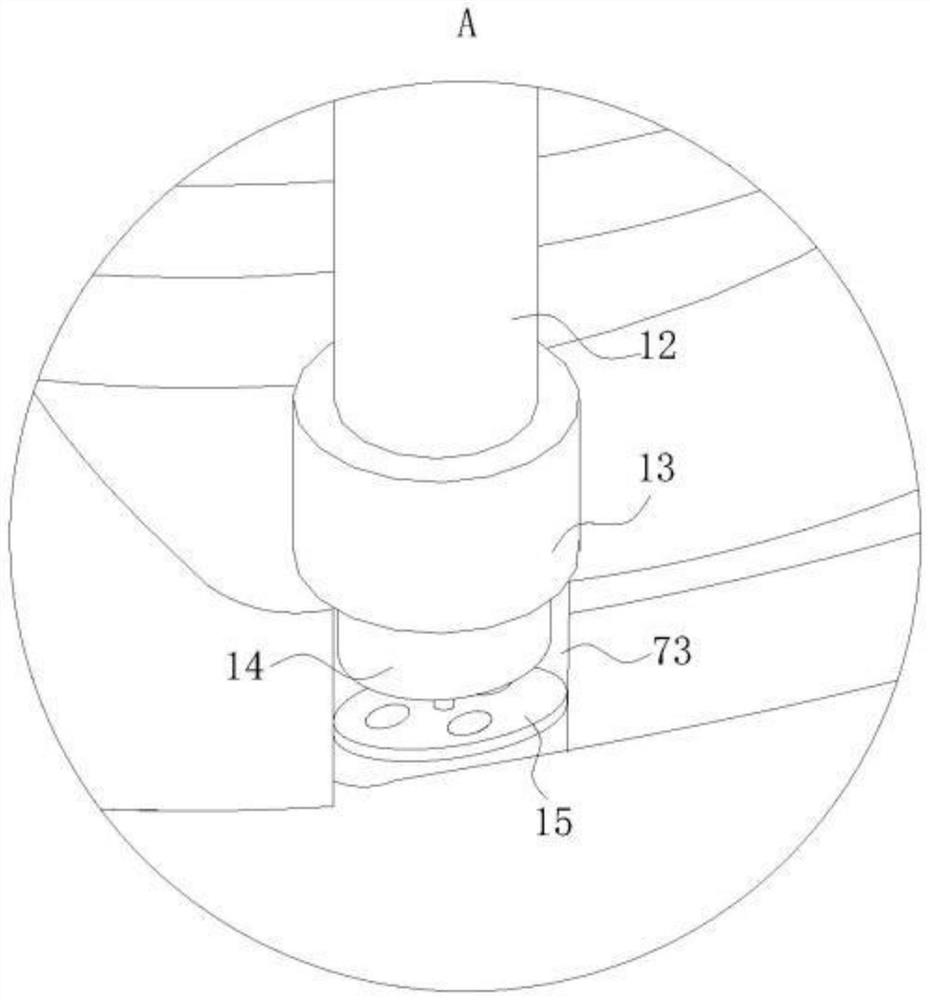

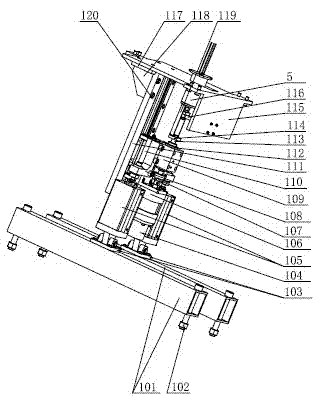

Unlimited depth self-propelled riverbed material sampling device

ActiveCN111624024ASmall driving forceUnlimited sampling depthWaterborne vesselsWithdrawing sample devicesEngineeringRiver bed

The invention relates to an unlimited depth self-propelled riverbed material sampling device. The sampling device comprises a working ship, a composite steel cable, a support frame and a sampler, thesampler comprises an information bin, a power bin, a sample bin, a sand discharging cone and a leakage-proof part. The sampler and the support frame sink together through the composite steel cable onthe working ship, and the water depth is not limited; the sampler can be vertically suspended and automatically and integrally pushed downwards when being close to the bed surface, and the sampling depth is not limited. The counter weight is pulled by the chain to roll along the cylinder wall in a three-point simple supporting mode and ascend and descend in the air, and it is guaranteed that resistance is small; the total length of the thin-wall pipe orifice and the sampler is relatively short so that the energy of push-down driving is relatively small; the extrusion deformation of the sand sample in the short pipe type sample bin is very small, and the bin cover is independently opened and closed to realize high fidelity of sampling; the leakage-proof part ensures that the sand sample does not slip and leak; and a water pressure gauge in the sampler detects the depth of the sampling point away from the bed surface. Sampling of the device is not limited by depth, and the riverbed material sample can be safely, reliably and accurately collected in a high-fidelity mode.

Owner:BEIJING JIANGYI TECH

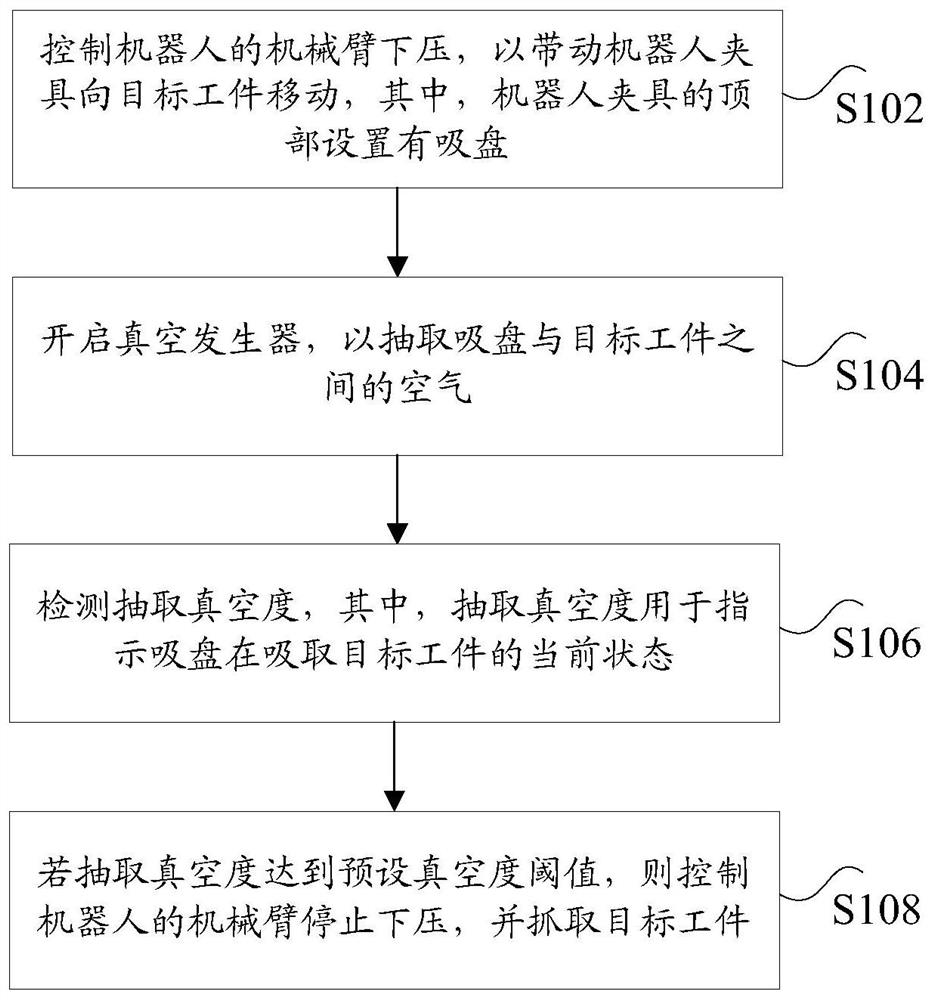

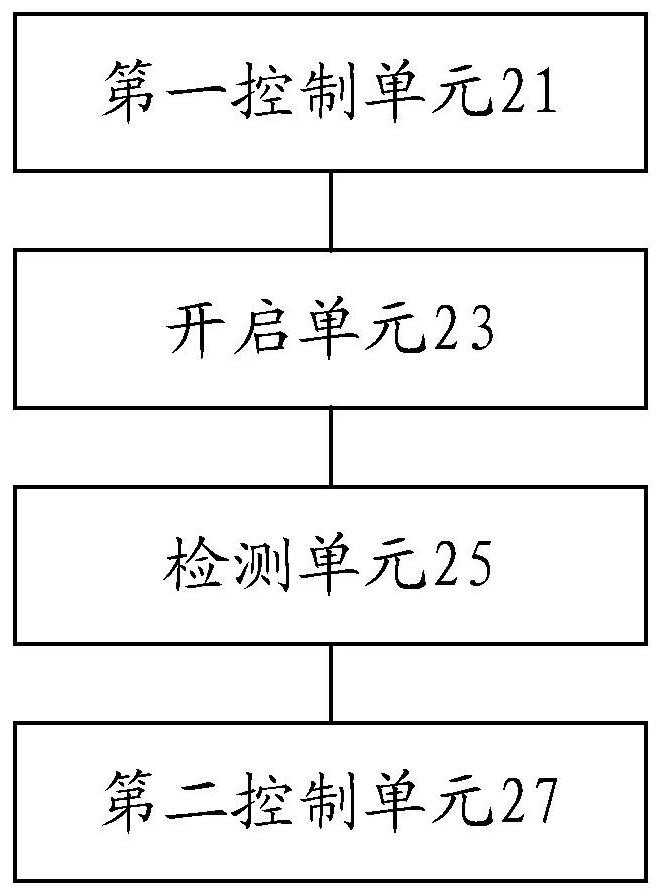

Workpiece grabbing method and device and robot equipment

InactiveCN112025714AReduce extrusion deformationExtended service lifeProgramme-controlled manipulatorGripping headsMechanical engineeringRoboty

The invention discloses a workpiece grabbing method and device and robot equipment. The workpiece grabbing method comprises the steps: a mechanical arm of a robot is controlled to press downward so asto drive a robot clamp to move towards a target workpiece, wherein a suction cup is arranged at the top of the robot clamp; a vacuum generator is started to extract air between the suction cup and the target workpiece; the extracted vacuum is detected, wherein the extracted vacuum is used for indicating the current state of the suction cup sucking the target workpiece; and if the extracted vacuumreaches the preset vacuum threshold value, the mechanical arm of the robot is controlled to stop pressing downward, and the target workpiece is grabbed. According to the workpiece grabbing method, the technical problem that in the related art, when the suction cup at the front end of the robot is controlled to grab the workpiece, the suction cup is easily extruded to deform, and the remaining service life of the suction cup is affected is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Comprehensive tunnel drainage, precipitation and pressure reduction construction method

The invention provides a comprehensive tunnel drainage, precipitation and pressure reduction construction method, relates to an in-tunnel drainage, ground precipitation and comprehensive pressure reduction construction method for a water and mud burst segment of a tertiary system sand shale tunnel and is mainly designed to solve the problems that an existing tunnel is prone to deformation, collapse and even water burst and mud burst in the tertiary system sand shale construction process. Ground precipitation wells are drilled at the positions, eight meters away from the side lines on the two sides, of a ground-direction positive hole, a flat guide hole is formed near the ground-direction positive hole, a drainage hole is formed in the inclined upper direction of the ground-direction positive hole relative to the flat guide hole, tunnel substrate precipitation wells are drilled in both the substrate of the ground-direction positive hole and the substrate of the flat guide hole, a plurality of inclined drainage holes are formed above the inclined front portion of a vault of the ground-direction positive hole, a positive hole vertical drainage hole is formed above the vault of the ground-direction positive hole, and a flat guide hole vertical drainage hole is further formed above the vault of the flat guide hole. The comprehensive tunnel drainage, precipitation and pressure reduction construction method has the advantages that geological disasters such as collapse, deformation, water burst and mud burst are avoided, and tunnel construction safety can be guaranteed.

Owner:CHINA RAILWAY 19TH BUREAU GRP SECOND ENG CO LTD

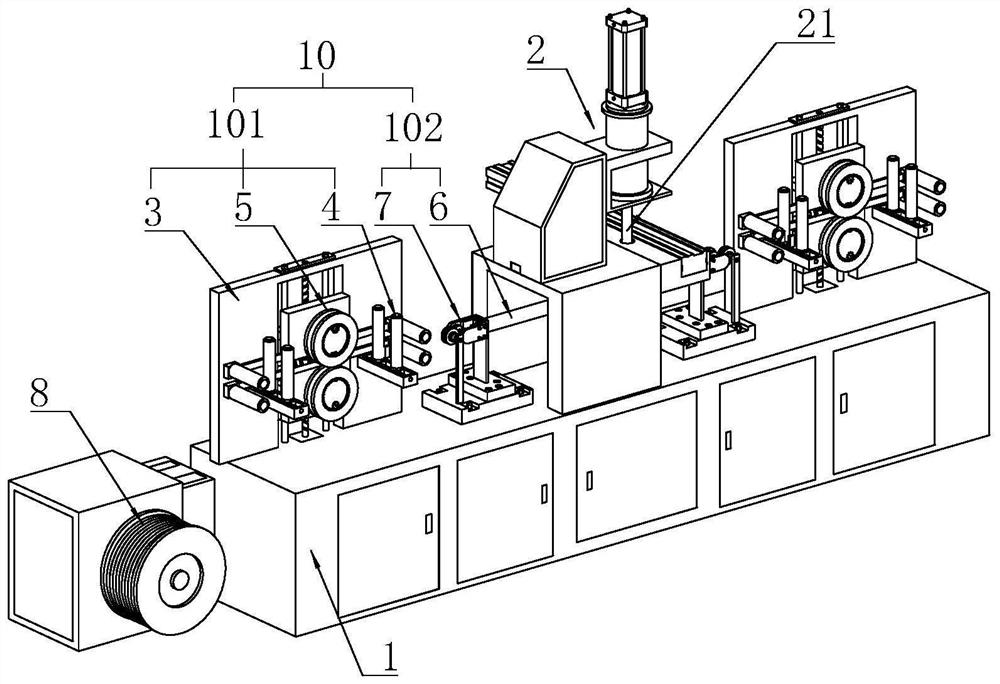

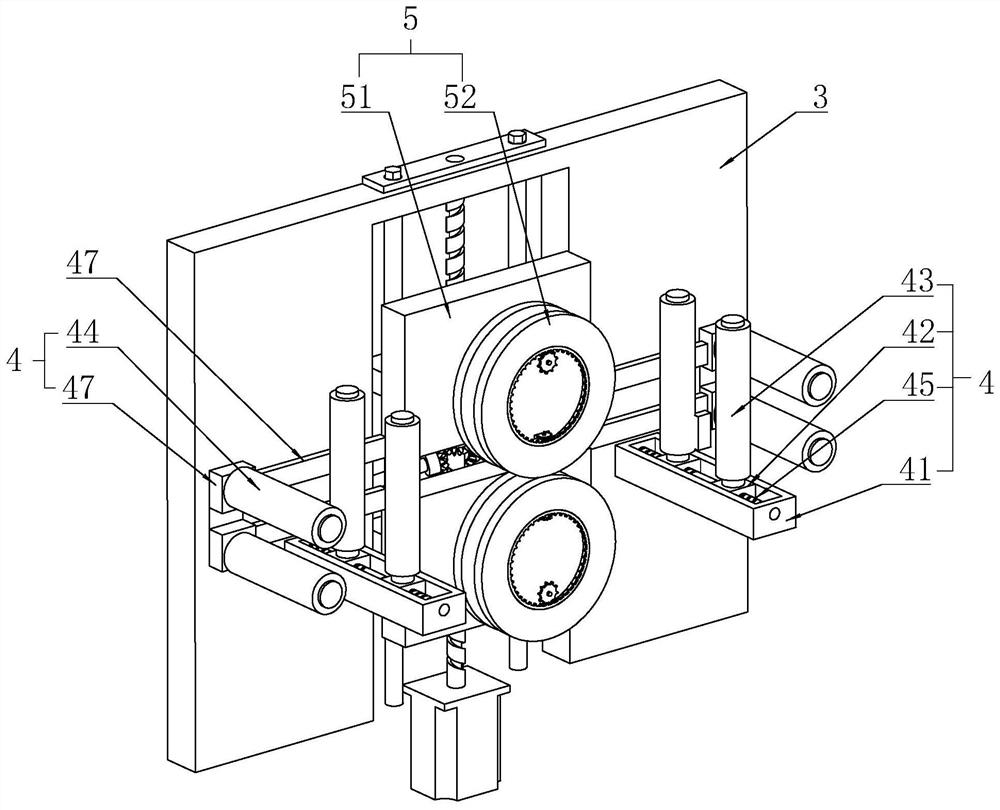

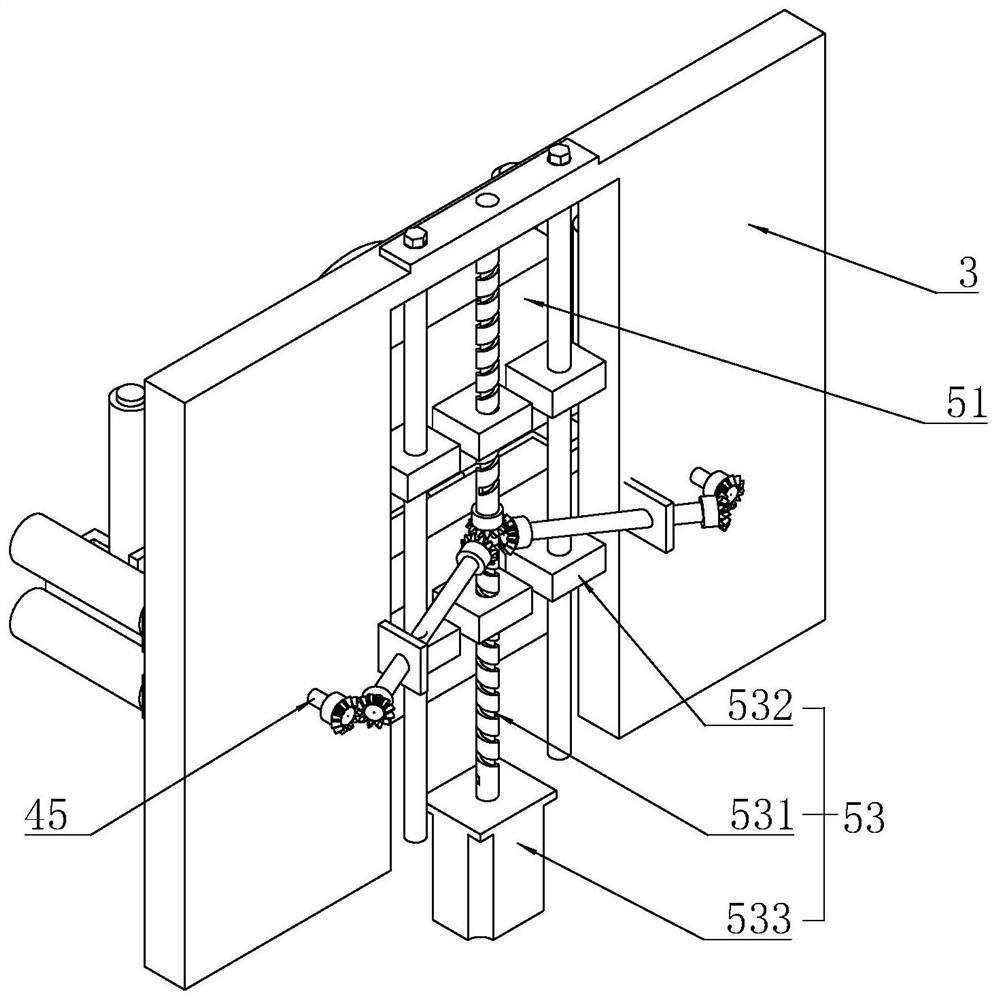

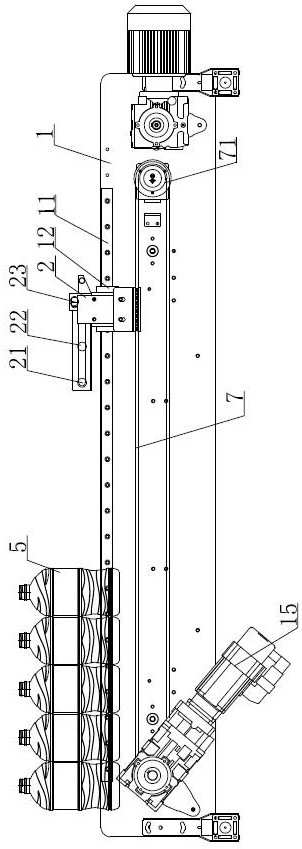

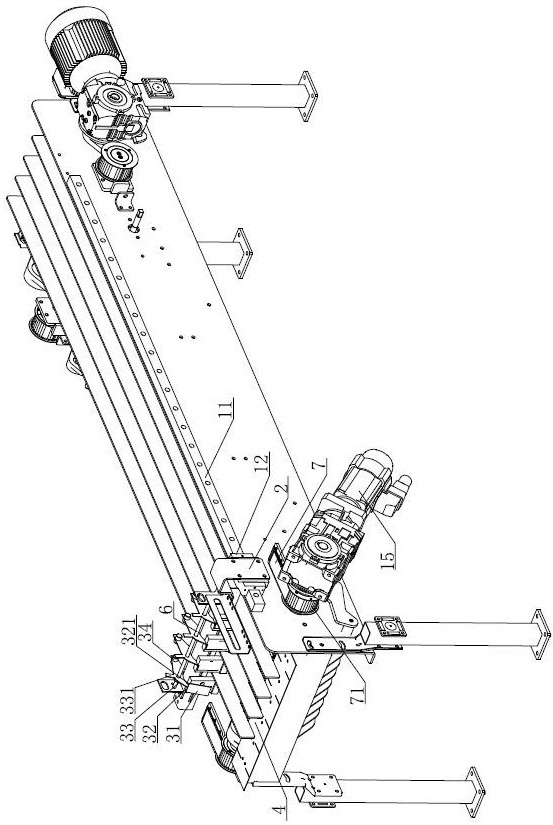

Automatic cable metering and code-spraying production line

ActiveCN112185630AReduce extrusion deformationImprove consistencyCleaning using gasesConductor/cable markingSprayerStructural engineering

The invention relates to an automatic cable metering and code-spraying production line, which comprises a rack, and is characterized in that the rack is provided with a wire guide device and a code sprayer, and the wire guide device comprises a substrate, a guide mechanism and a traction mechanism; and the traction mechanism comprises two lifting plates connected to the base plate in an up-down sliding mode, two traction wheels fixed to the corresponding lifting plates correspondingly and a first driving assembly driving the lifting plates to get close to or get away from each other, and second driving assemblies driving the traction wheels to rotate are arranged on the lifting plates. The guide mechanism comprises a horizontal frame fixed to the base plate, at least two horizontal carrying plates connected to the horizontal frame in a sliding mode, two vertical rollers which are parallel to each other and fixed to the horizontal carrying plates respectively and at least one transverseroller located on the sides, away from the traction wheels, of the vertical rollers, and the horizontal carrying plates are synchronously driven by a first driving assembly. The automatic cable metering and code-spraying production line has the advantages that cables of different specifications can be accurately guided and dragged, and meanwhile extrusion deformation of the cables can be effectively reduced.

Owner:郑州亚华电缆有限公司

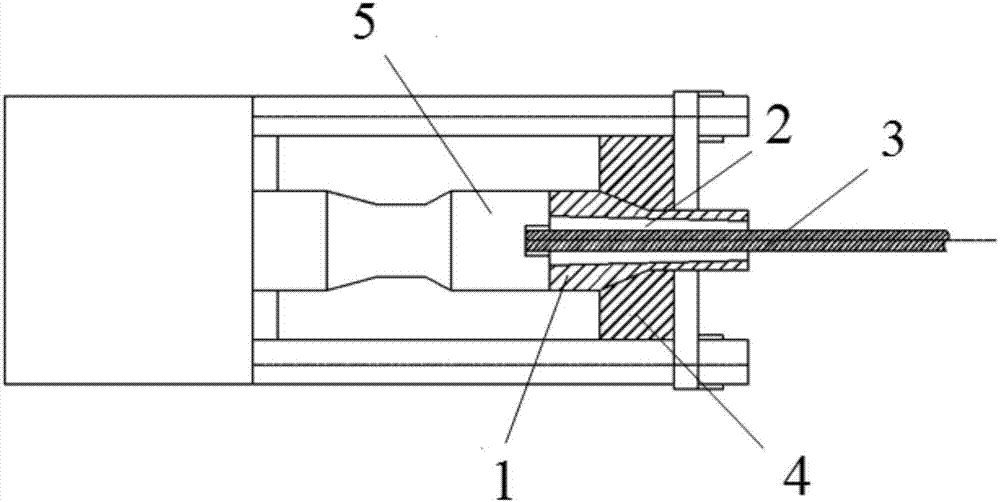

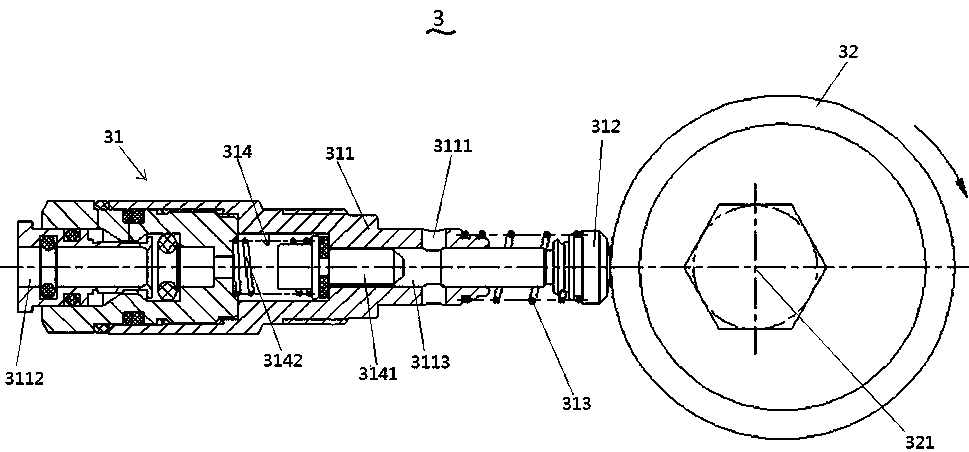

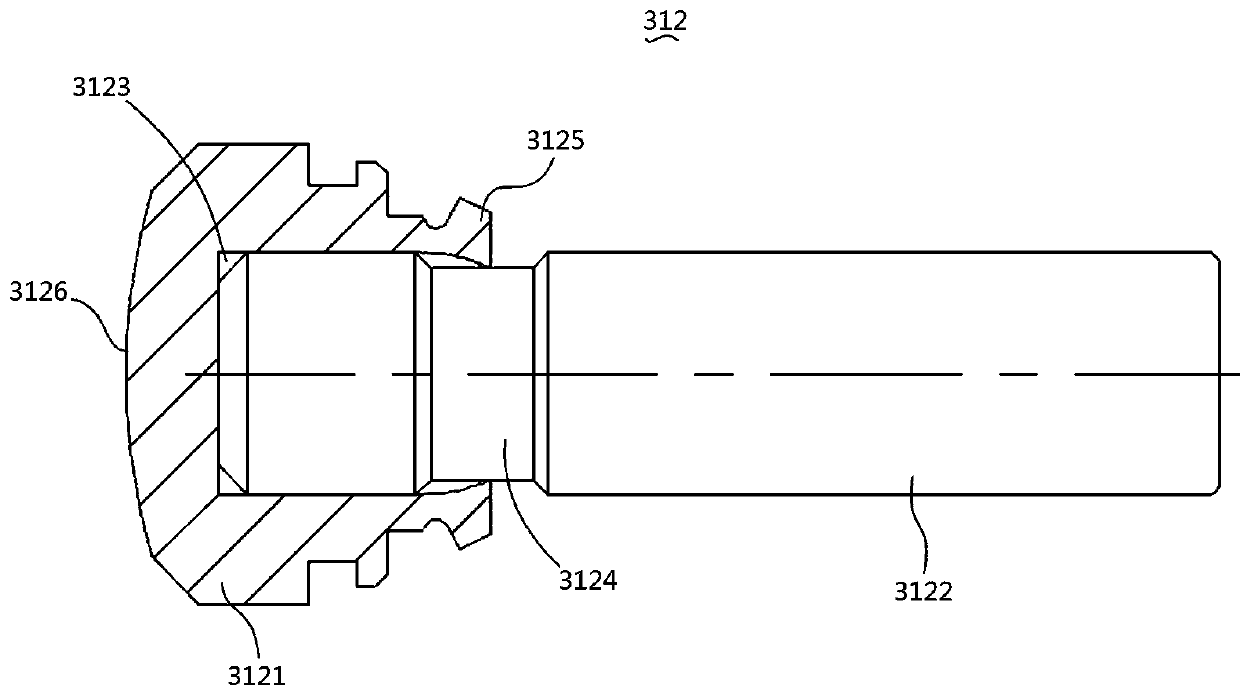

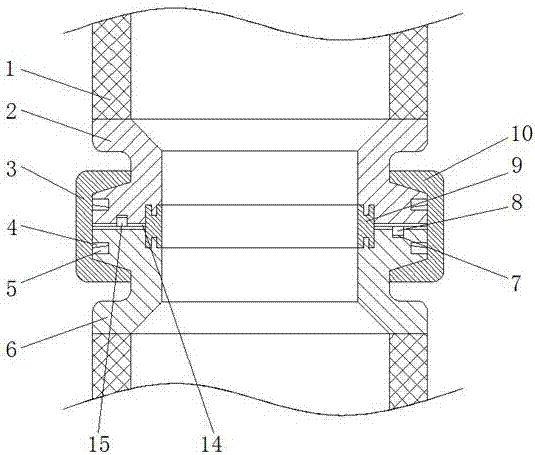

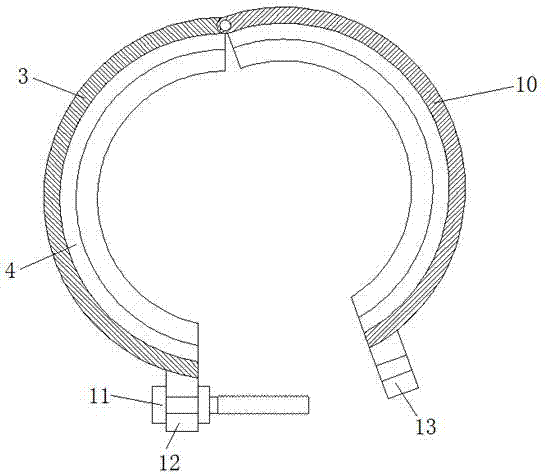

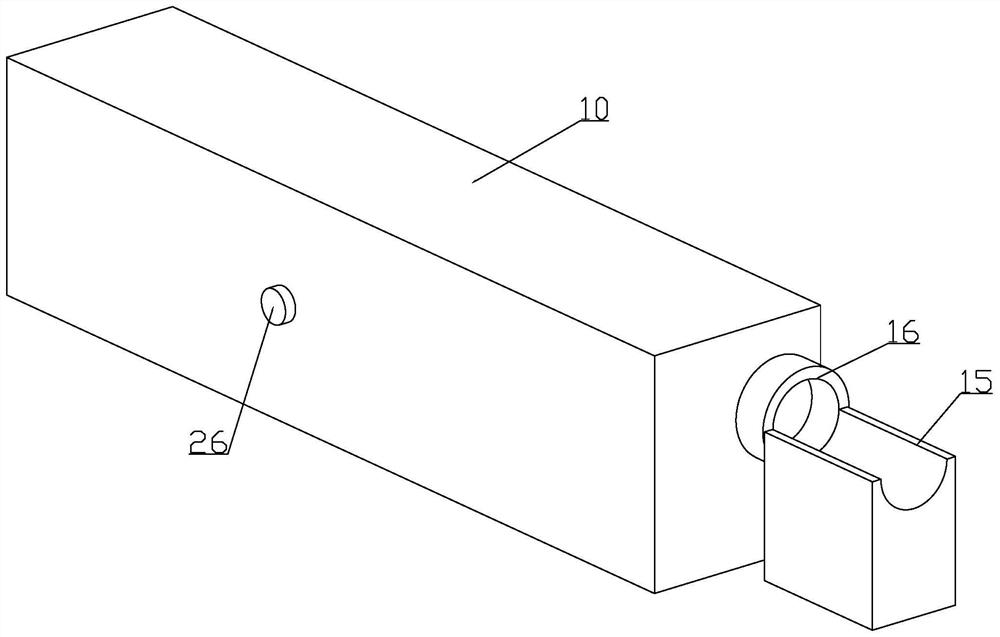

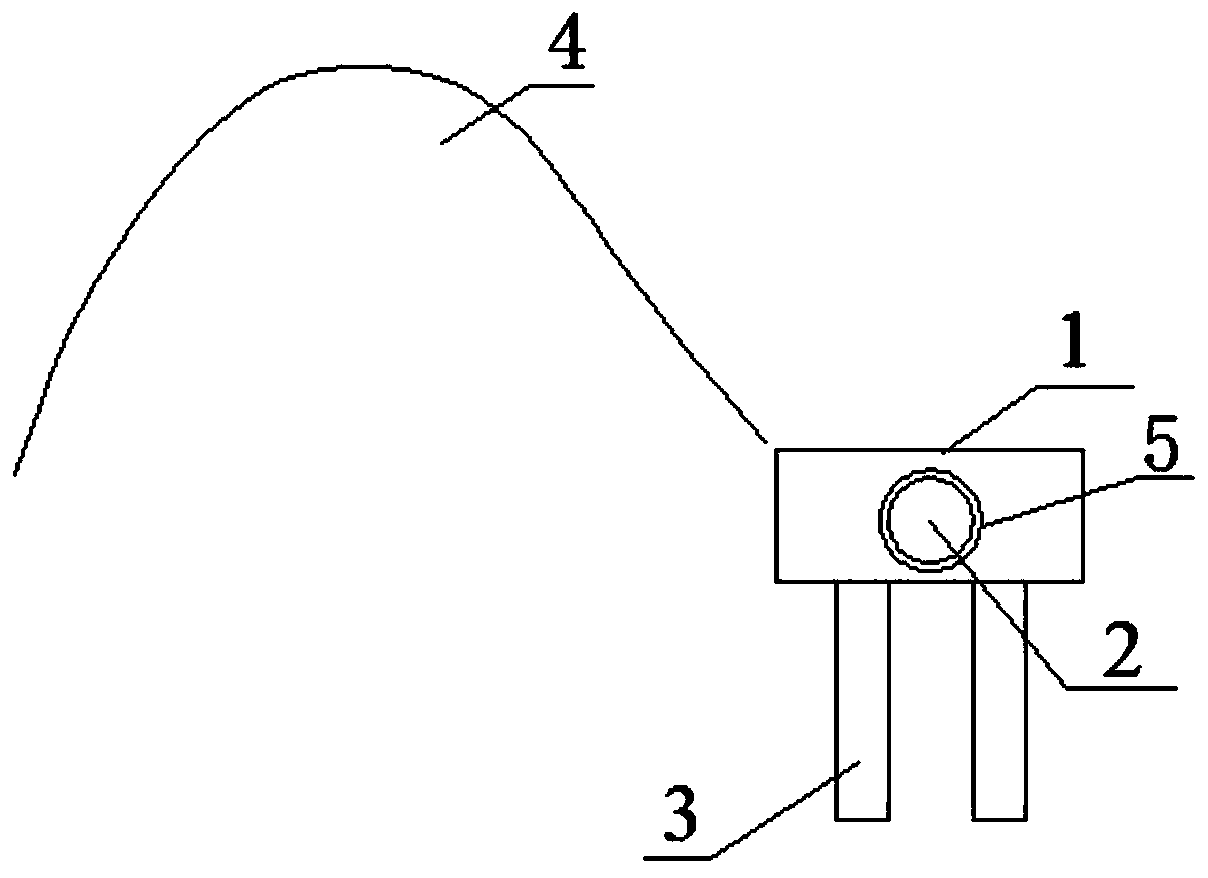

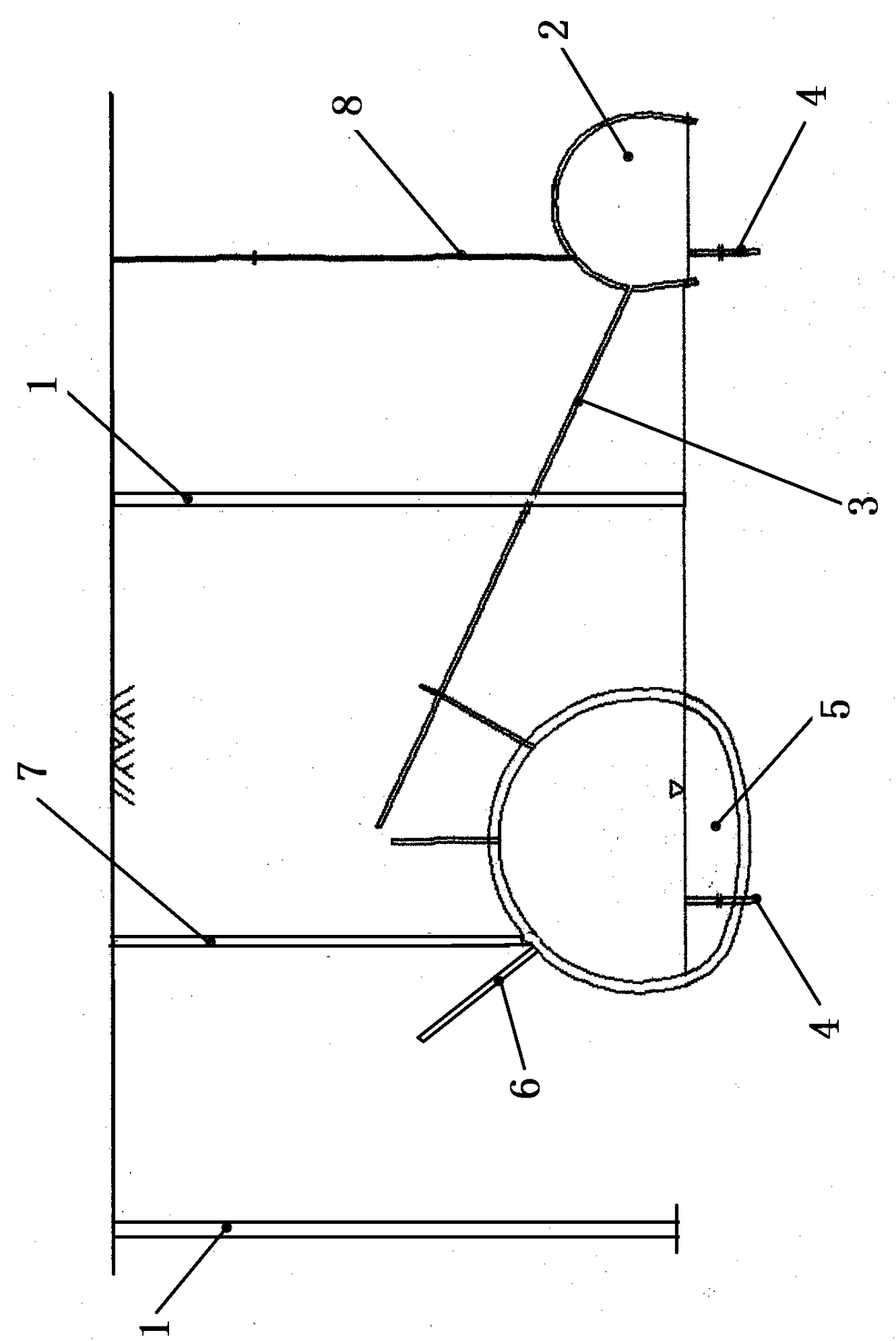

Extruded type anchorage device for FRP rib and anchoring method

ActiveCN107447757AThe amount of extrusion deformation is controllableReduce extrusion deformationBridge structural detailsBuilding reinforcementsBiomedical engineeringConstant speed

The invention discloses an extruded type anchorage device for an FRP rib and an anchoring method. The extruded type anchorage device comprises an anchor barrel, a sleeve, FRP rib, an extrusion die and an extruder, a chamfer is arranged at one end of the anchor barrel, a conical through hole extending in the center line of the anchor barrel is formed in the middle of the anchor barrel, the sleeve matched with the conical through hole is nested in the conical through hole, the outer surface of the sleeve is a wedge surface, a cylindrical center through hole matched with the FRP rib is formed in the middle of the sleeve, and the center lines of the conical through hole, the center through hole and the FRP rib are coincident. The anchoring method comprises the steps that the sleeve penetrates in the anchor barrel, and the wedge surface of the sleeve is attached to the conical through hole of the anchor barrel; the tail end of the FRP rib penetrates through the center hole of the sleeve and extends out of the end surfaces of the anchor barrel and the sleeve; an assembling piece is put in the extruder, and grease is evenly smeared on the outer surface of the anchor barrel; and the assembling piece of the anchor barrel, the sleeve and the FRP rib is jacked into the extrusion die by operating the extruder at a constant speed. The extruded type anchorage device for the FRP rib is safe and reliable, convenient to assemble and reasonable in inner stress and is a new anchorage device capable of exerting advantages of the FRP rib.

Owner:DALIAN UNIV OF TECH

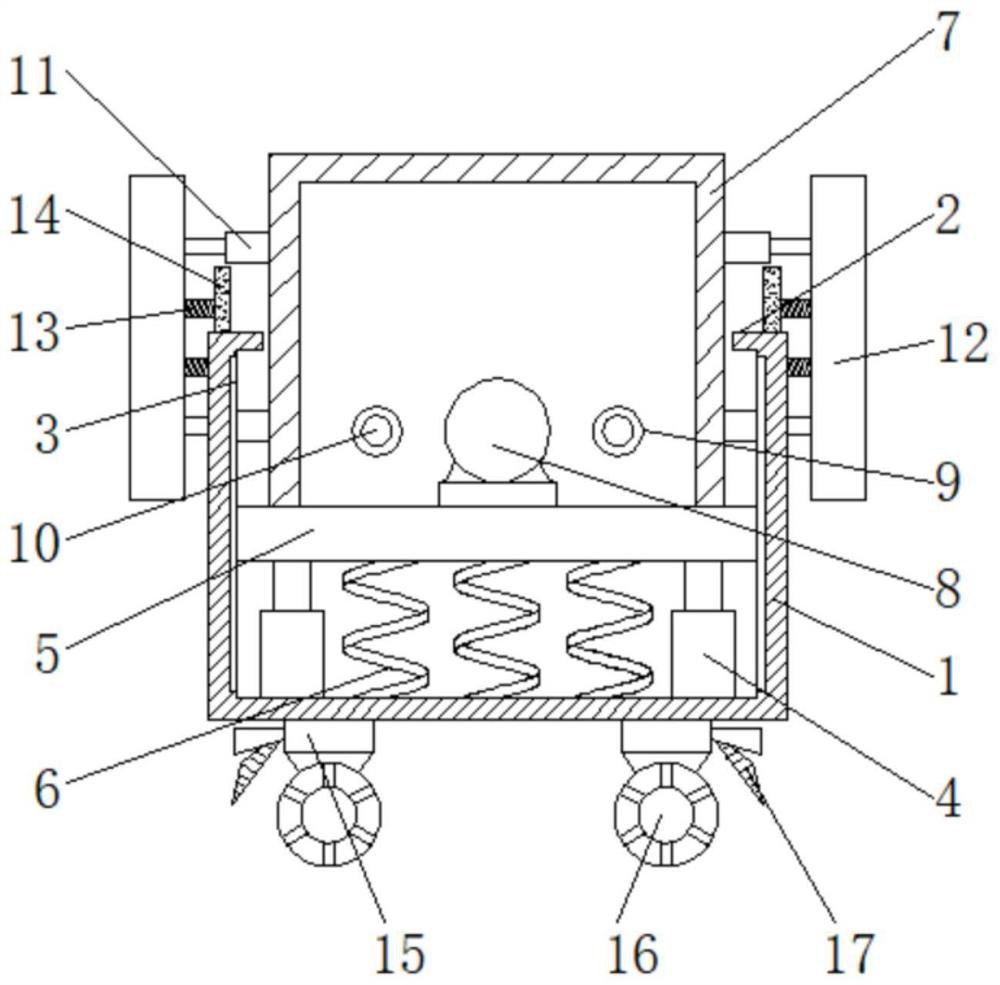

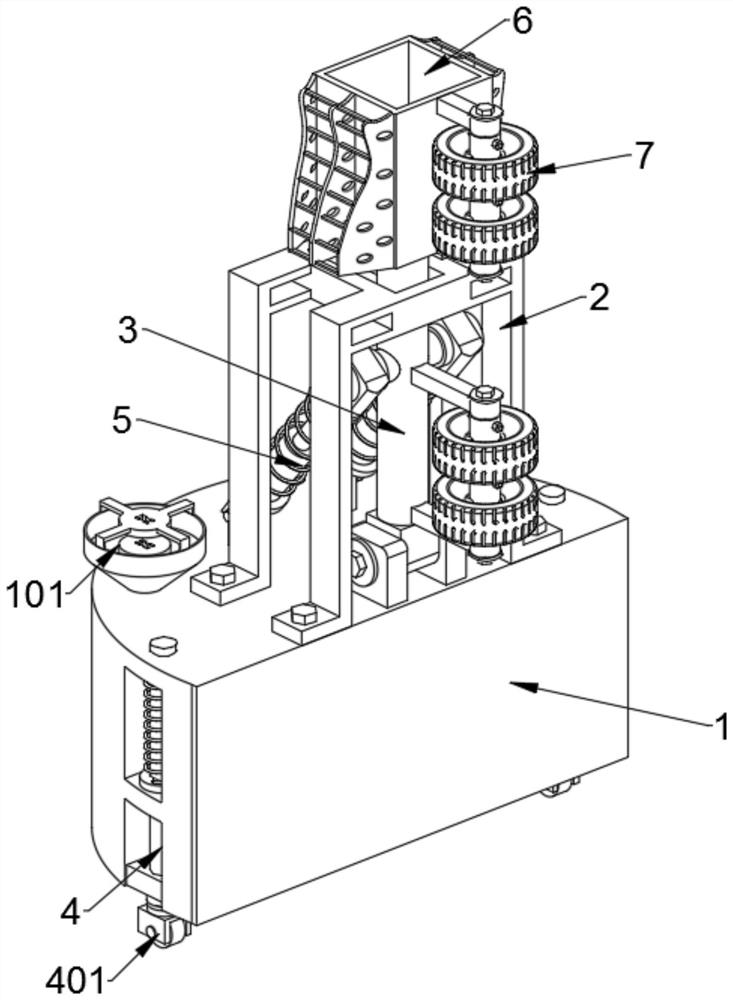

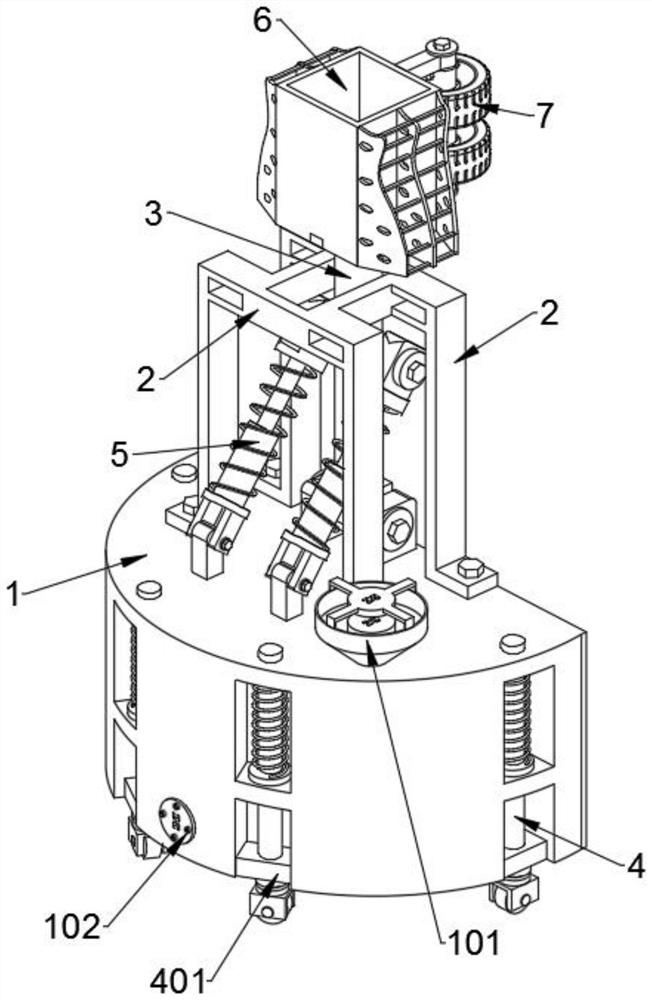

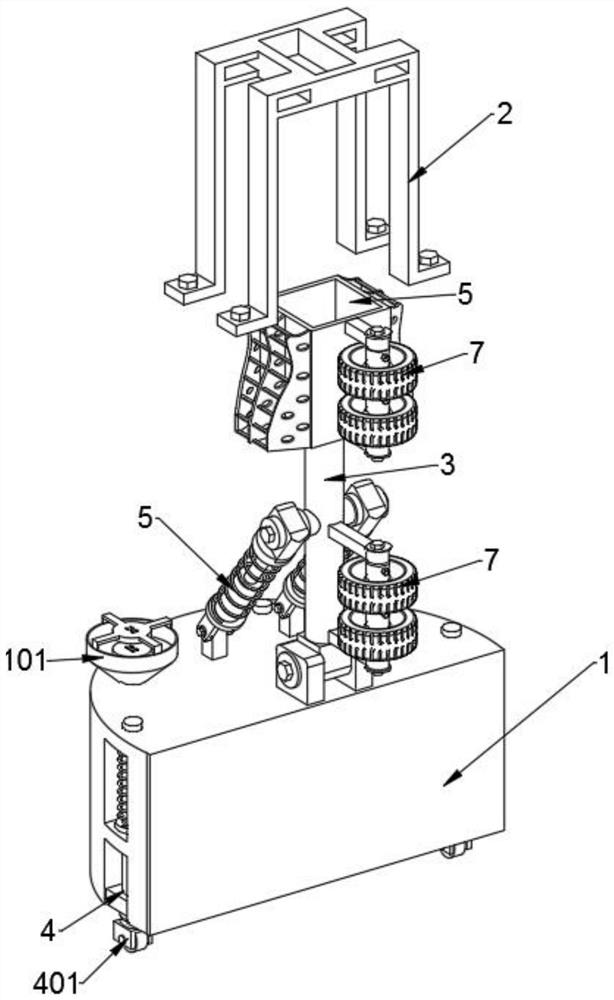

Moving auxiliary device for mounting electromechanical equipment

InactiveCN112178423AEffective clampingReduce extrusion deformationMeasurement devicesStands/trestlesStructural engineeringMechanical engineering

Owner:广州鼎奥科技有限公司

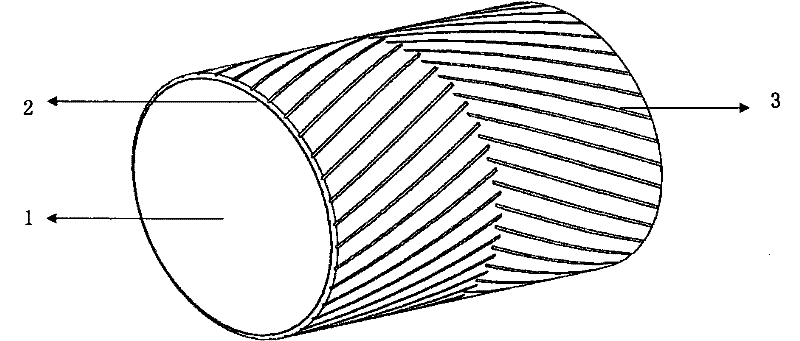

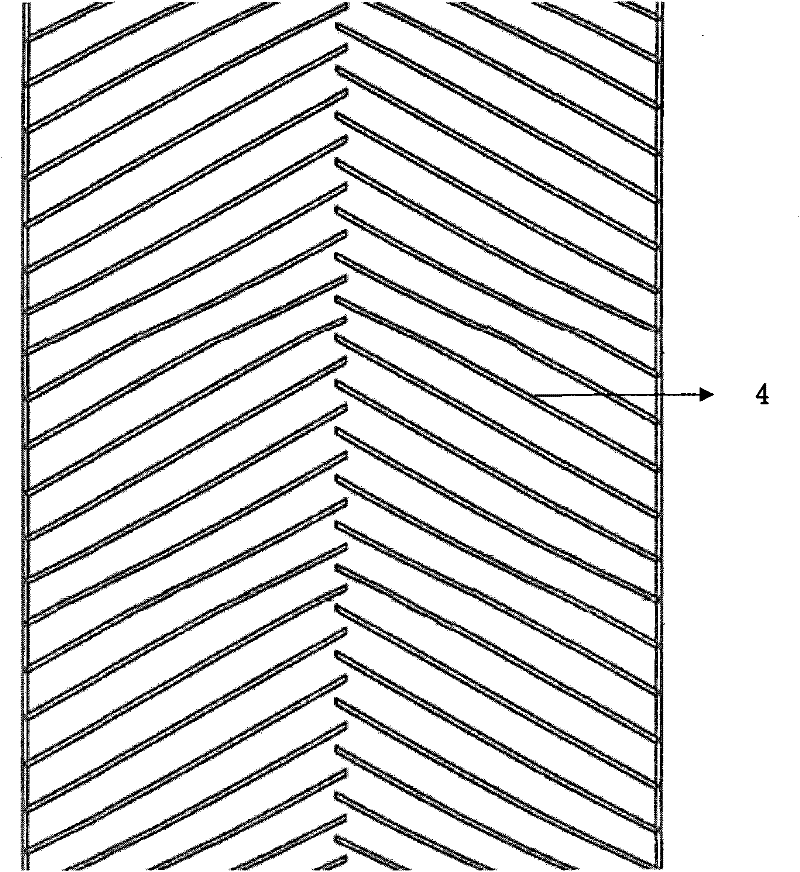

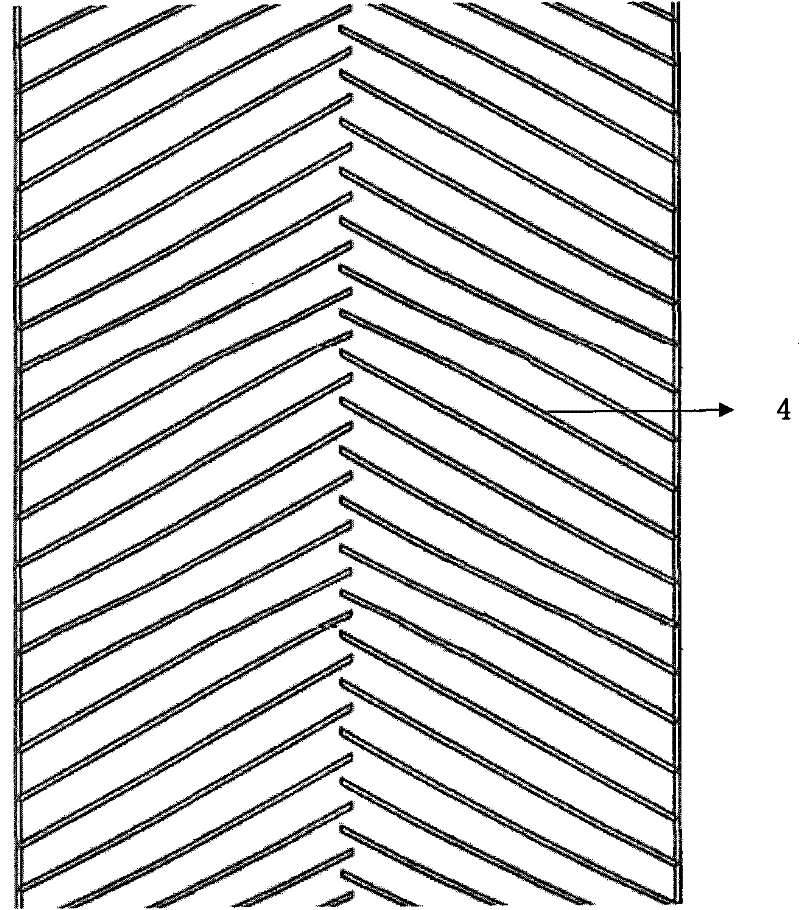

Conveyer belt capable of being matched with fishbone-shaped groove encapsulation roller for use

InactiveCN102234007AGuaranteed fitReduce extrusion deformationConveyorsEngineeringMechanical engineering

The invention relates to a conveyer belt capable of being matched with a fishbone groove encapsulation roller for use. The conveyer belt comprises a conveyer belt body. The conveyer belt is characterized in that strip protuberances matched with encapsulation grooves on the circumferential surface of a roller body are arranged on the lower surface of the conveyer belt body and the protuberances on the lower surface of the conveyer belt body are distributed in a fishbone shape. The strip grooves at the left side and right side of the surface of a roller are not intersected, thus the extrusion deformation of the encapsulation is small and the tearing resistance is improved compared with those of a herringbone groove rubber surface; water and dirt on the surface of the encapsulation roller can be discharged into the strip grooves from the surface of the conveyer belt by virtue of extrusion when the conveyer belt is contacted with the surface of the roller, thus the encapsulation roller can be used in a damp environment and even a worse environment, and the encapsulation roller is ensured to be completely laminated with an adhesive tape while the friction coefficient is not reduced.

Owner:SHANGHAI KEDA HEAVY IND GROUP

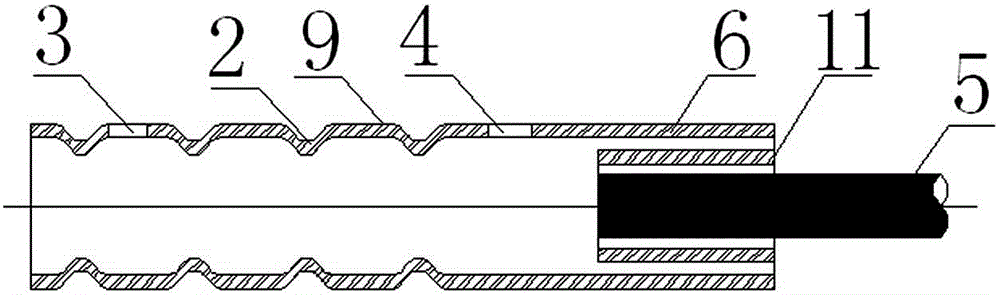

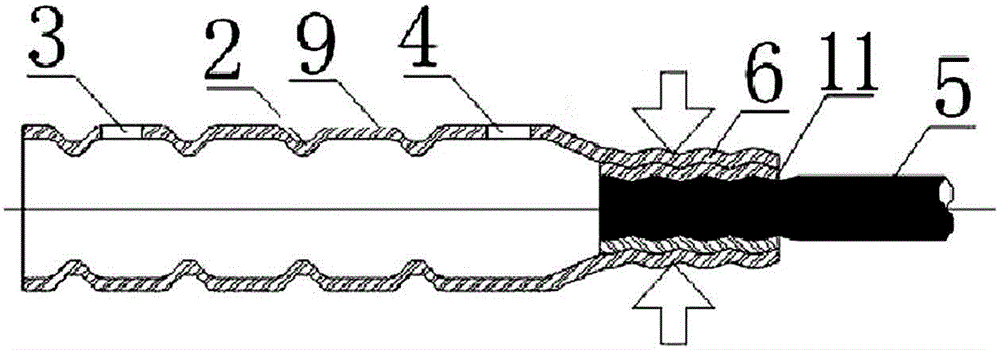

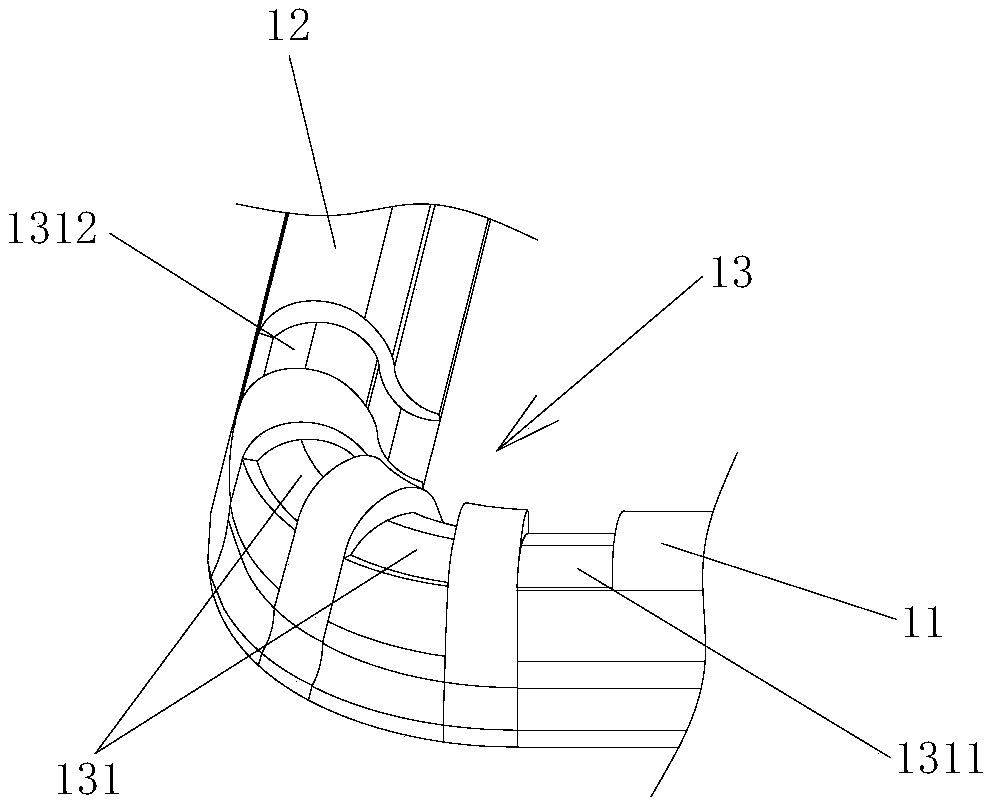

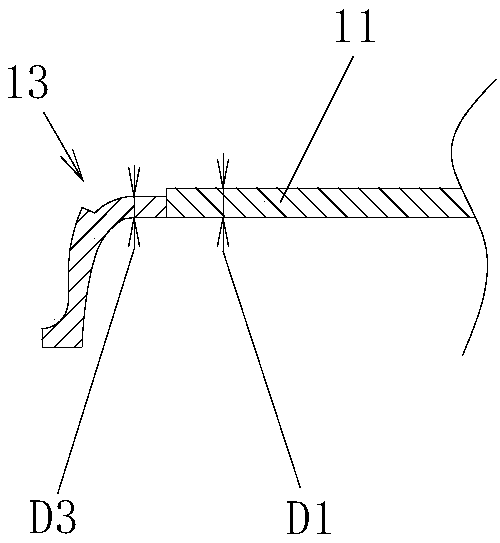

UHF digital communication cable and its preparation method

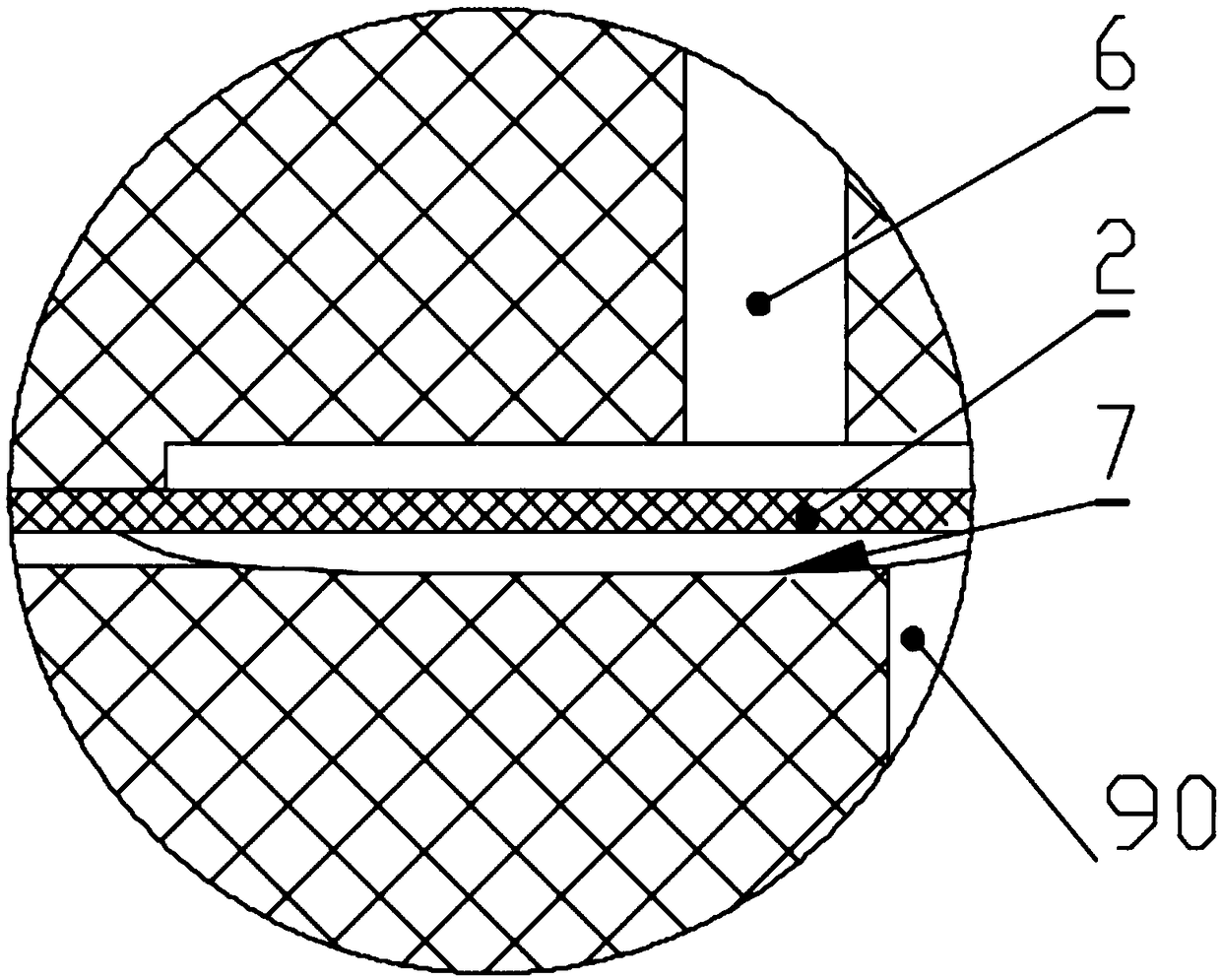

ActiveCN105551677BReduce contact stressPrevent intrusionInsulated cablesCable/conductor manufactureCopper conductorInsulation layer

An ultra-high frequency digital communication cable, comprising a cable core, a total shielding layer (6), an outer protection layer (7) and branch shielding layers (4) on twisted pair wire groups (3), wherein overlapping sides of the branch shielding layers (4) are clamped between two adjacent insulated single wires to form a branch shielding overlapping wire (8); the branch shielding overlapping wires (8) corresponding to two adjacent pairs of twisted pair wire groups (3) are arranged in a staggered manner; and the length for overlapping, outward-stretching sides of the branch shielding layers (4) to extend outwards from the branch shielding overlapping wires (8) is L1, L1 being 10%-15% of the width of a clad foil band of the branch shielding layers (4). The preparation method comprises the following steps: (1), drawing a copper conductor (1); (2), extruding an insulation layer; (3), twisting twisted pair wire groups (3); (4), cladding branch shielding layers (4); (5), twisting same into a cable; (6), weaving a total shielding layer (6); and (7), extruding an outer protection layer (7) into a finished cable. The communication cable not only has a good shielding effect and can effectively prevent intrusion and leakage of an electromagnetic wave, but also has a firm cable structure and stable transmission performance, and is particularly applicable to transmitting an ultra-high frequency band digital signal.

Owner:JIANGSU DONGQIANG

a communication base station

ActiveCN110792312BReduce the problem of poor crushing effectAvoid safety hazardsAntenna supports/mountingsTowersStructural engineeringMechanical engineering

The invention belongs to the technical field of communication base stations, and particularly relates to a communication base station. The communication base station comprises an upright rod, a plurality of supporting rods are fixedly arranged at the top of the upright rod in the peripheral direction, and supporting columns are hinged into swing grooves through threaded hinge columns. Base stationantennae are installed at the ends of the supporting columns, the base station antennae are arranged in the peripheral direction of the upright rod through the supporting columns, the upright rod issleeved with a rubber annular sleeve, and the outer portion of the rubber annular sleeve is wrapped with a cavity supporting sleeve. The cavity supporting sleeve is formed by splicing elastic rubber plates; a plurality of limiting springs are uniformly arranged between the cavity supporting sleeve and the rubber annular sleeve. The phenomenon that when the antennae swing in a strong wind environment, the base station antennae are blown by wind power to hit against one another or the base station antennae impact on the upright rod, the base station antennae are damaged due to impact is prevented so that the base station antennae can stably send and receive signals. It is achieved that birds are effectively expelled for a long time, labor is saved, and the service life is prolonged.

Owner:上海国城科绿色照明科技研究中心有限公司

Protective fishing device and fishing method for deep well corpse fishing

InactiveCN111301637ATo achieve the effect of position space transformationReduce extrusion deformationVessel salvagingDead bodyZoology

The invention relates to the technical field of deep well corpse fishing and further discloses a protective fishing device and method for deep well corpse fishing. The device comprises a steel wire rope fixing body and an orientation stabilizer, wherein a bottom of the steel wire rope fixing body is welded to an upper surface of the orientation stabilizer, a connecting body is welded at the bottomof the orientation stabilizer, an arc-shaped positioning side protection body is welded at the bottom of the connecting body, the arc-shaped positioning side protection body is movably connected withone side of a positioning sealing mechanism through a rotating shaft, the positioning sealing mechanism is provided with a lower baffle through a conduction mechanism, and a box body is welded on theother side of the positioning sealing mechanism. The device is advantaged in that the characteristic that a corpse is easy to damage, the effect that the corpse collides with the interior of the wellbody to be damaged can be effectively reduced, the bottom of a box body is sealed, so the effect of corpse position space conversion can be achieved, the corpse fishing protection effect is greatly improved, a memory protection body can better protect the placed corpse, and extrusion deformation of the corpse due to influence of gravity during corpse fishing is effectively reduced.

Owner:杨春光

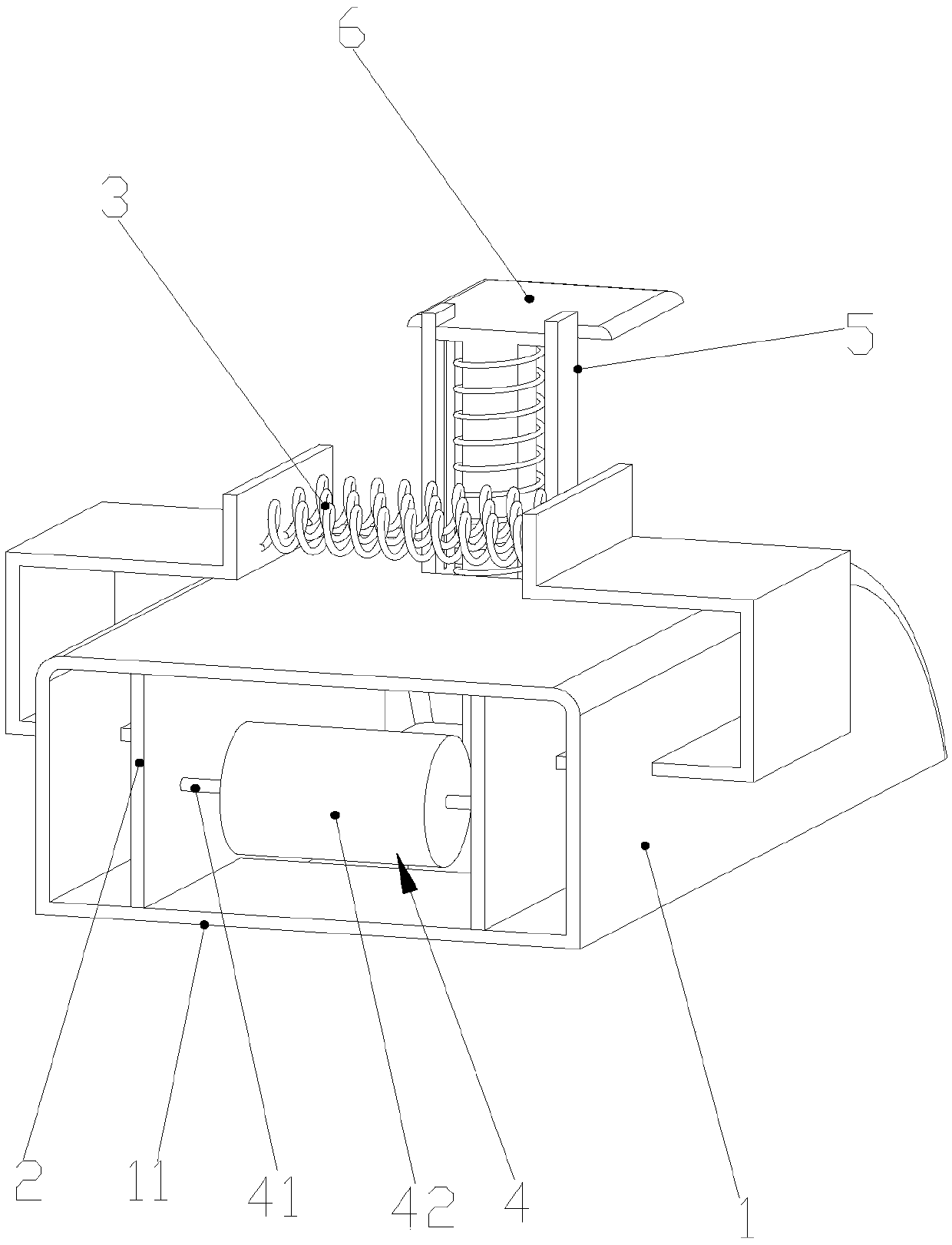

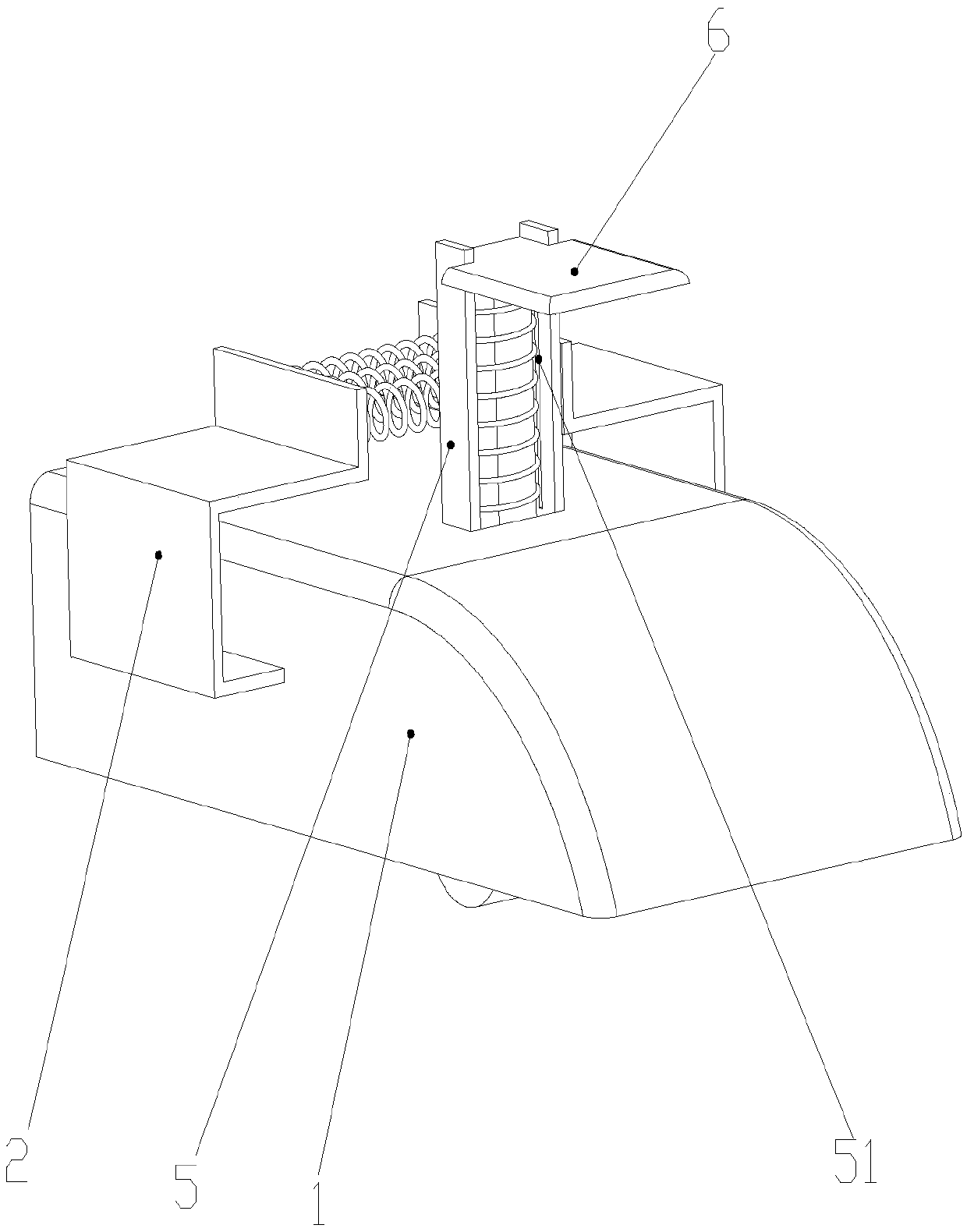

Plunger assembly, lubricating pump, plunger and plunger machining method

InactiveCN110608165AImprove pressure bearing capacityReduce consumptionPositive displacement pump componentsLubricating pumpsEngineeringMachining

The invention relates to a plunger assembly, a lubricating pump, a plunger and a plunger machining method. The plunger comprises a large-diameter section and a small-diameter section. The large-diameter section and the small-diameter section are separately arranged and respectively machined. The large-diameter section is formed by turning and machining. The small-diameter section is formed throughmachining by a centerless excircle grinding machine. The large-diameter section and the small-diameter section are connected with each other after being separately machined. According to the plungerassembly, the lubricating pump, the plunger and the plunger machining method, through ingenious conception and simple structures, machining consumables are saved, the machining efficiency is improved,and more importantly, the machining precision of the plunger is improved, so that the pressure bearing capacity of the plunger is further improved, the pressure bearing capacity of the lubricating pump is improved, and a very important significance is embodied.

Owner:AUTOL TECH

Greenhouse snap spring mounting tool

InactiveCN109623734AReduce extrusion deformationAvoid leaningMetal-working hand toolsGreenhouseEngineering

The invention discloses a greenhouse snap spring mounting tool which comprises a shell. A connecting block is arranged at the lower end of the shell and provided with clamping units, an elastic pieceis arranged between the clamping units, and an anti-warping unit is arranged between the clamping units. A slide rail is arranged at the upper end of the shell and provided with a slide groove, and apressing unit is arranged on the slide rail. The handheld shell is held by hand to place the mounting tool on a clamping groove filled with a thin film, the clamping units are attached to an opening of the clamping groove, the handheld shell is pushed with force at an even speed, greenhouse snap springs are downwards extruded by the pressing unit to enter the clamping groove one by one, the pressing unit is pressed to flatten the snap springs in the clamping groove, and the handheld shell is continuously pushed until all the greenhouse snap springs are plugged into the clamping groove.

Owner:安徽丰絮农业科技股份有限公司

Metal filter bag capable of being conveniently spliced and mounted

InactiveCN107875757AQuick stitchingImprove connection strengthDispersed particle filtrationEngineeringUltimate tensile strength

The invention discloses a metal filter bag which is convenient for splicing and installation. It comprises an upper connector and a lower connector. Both the bottom of the inner wall of one side of the upper connector and the top of the inner wall of one side of the lower connector are provided with I-shaped connecting grooves. And the inner walls of the two I-shaped connecting grooves are sleeved with the same sealing ring, the bottom outer wall of the upper connector and the top outer wall of the lower connector are fixed with elastic pads by screws, and one part of the bottom outer wall of the upper connector There is a connecting groove on the side, and the same connecting ring is sleeved on one side of the outer wall of the upper connecting head and one side of the lower connecting head, and the connecting ring includes a left sub-connecting ring and a right sub-connecting ring. The invention can quickly splice two metal filter bags, which can be easily disassembled while ensuring the connection strength, can improve the coaxiality, can improve the sealing performance of the joint, and can eliminate part of the extrusion force while ensuring sufficient pre-tightening force , helps to protect product performance and prolong service life.

Owner:江苏凯诺滤袋有限公司

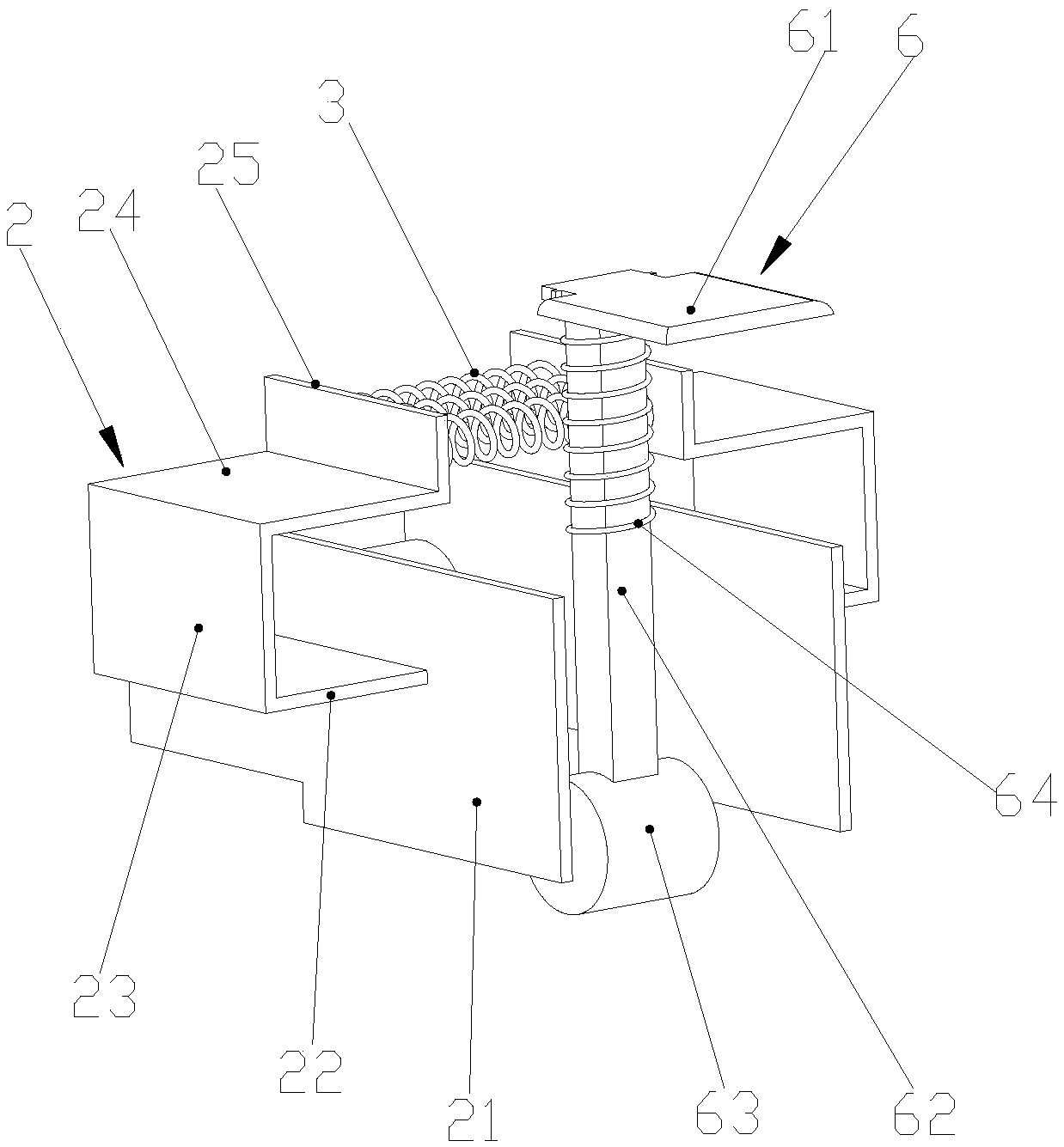

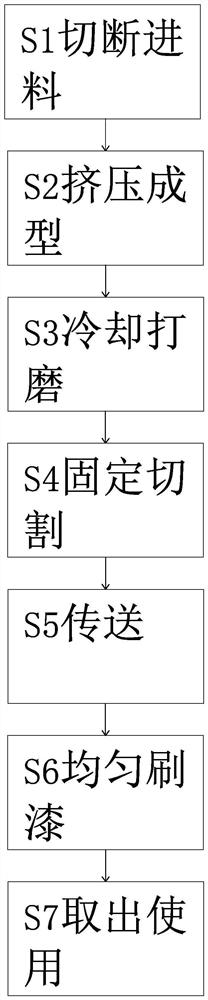

Aluminum profile production equipment and process

PendingCN113953843AAvoid deformationImprove stabilityOther manufacturing equipments/toolsMachiningGrinding

The invention belongs to the technical field of aluminum profile machining, and particularly relates to aluminum profile production equipment and process. The aluminum profile production equipment is adopted for being matched for completion. The aluminum profile production equipment comprises a machining box, and a feeding part is arranged at one end of the machining box and used for cutting aluminum casting rods into sections and feeding and conveying the aluminum casting rods. An extrusion forming part is arranged on one side of the feeding part and used for conducting fixed extrusion forming on the aluminum casting rods, a cutting part is arranged on the rear side of the extrusion forming part and used for cooling, grinding and cutting aluminum profiles into sections, and a paint brushing part is arranged in the direction, away from the extrusion forming part, of the cutting part and used for evenly brushing paint on the aluminum profiles and drying and conveying the aluminum profiles. According to the aluminum profile production equipment and process, the aluminum casting rods can be firstly tightened, the center is removed, then extrusion forming is conducted, and extrusion deformation of the aluminum casting rods is reduced; the aluminum profiles are subjected to rotary cooling, grinding and powder suction, and the aluminum profiles are subjected to fixed cutting; and the paint brushing part rotates comprehensively to brush paint and is matched with the movement of the aluminum profiles, so that uniform paint brushing is performed.

Owner:乐清精注机械有限公司

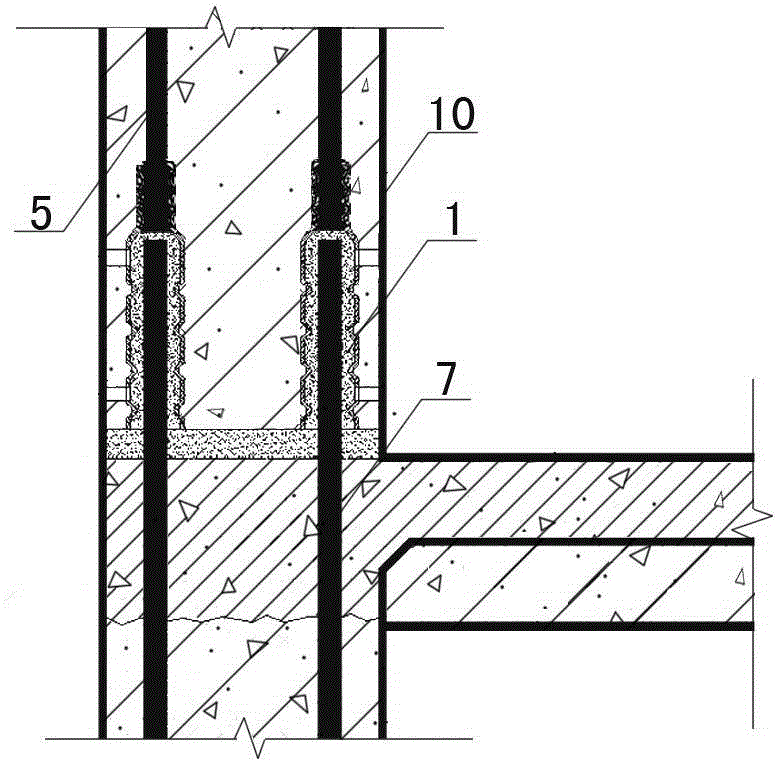

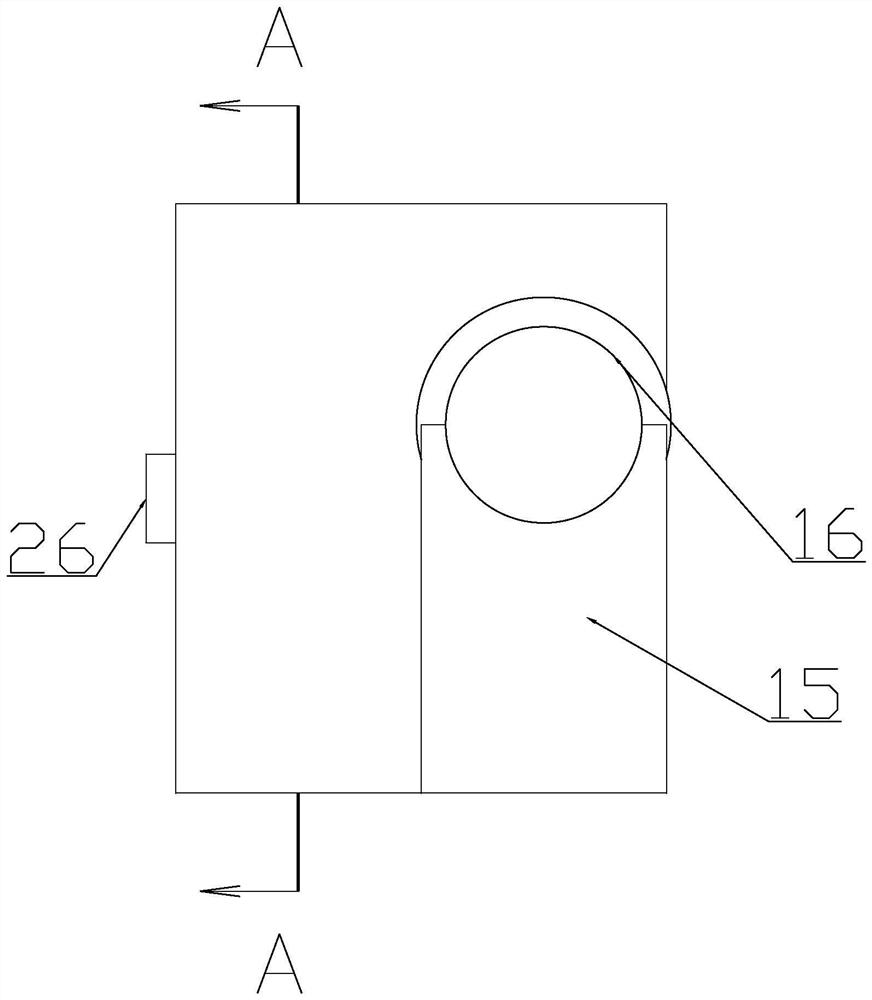

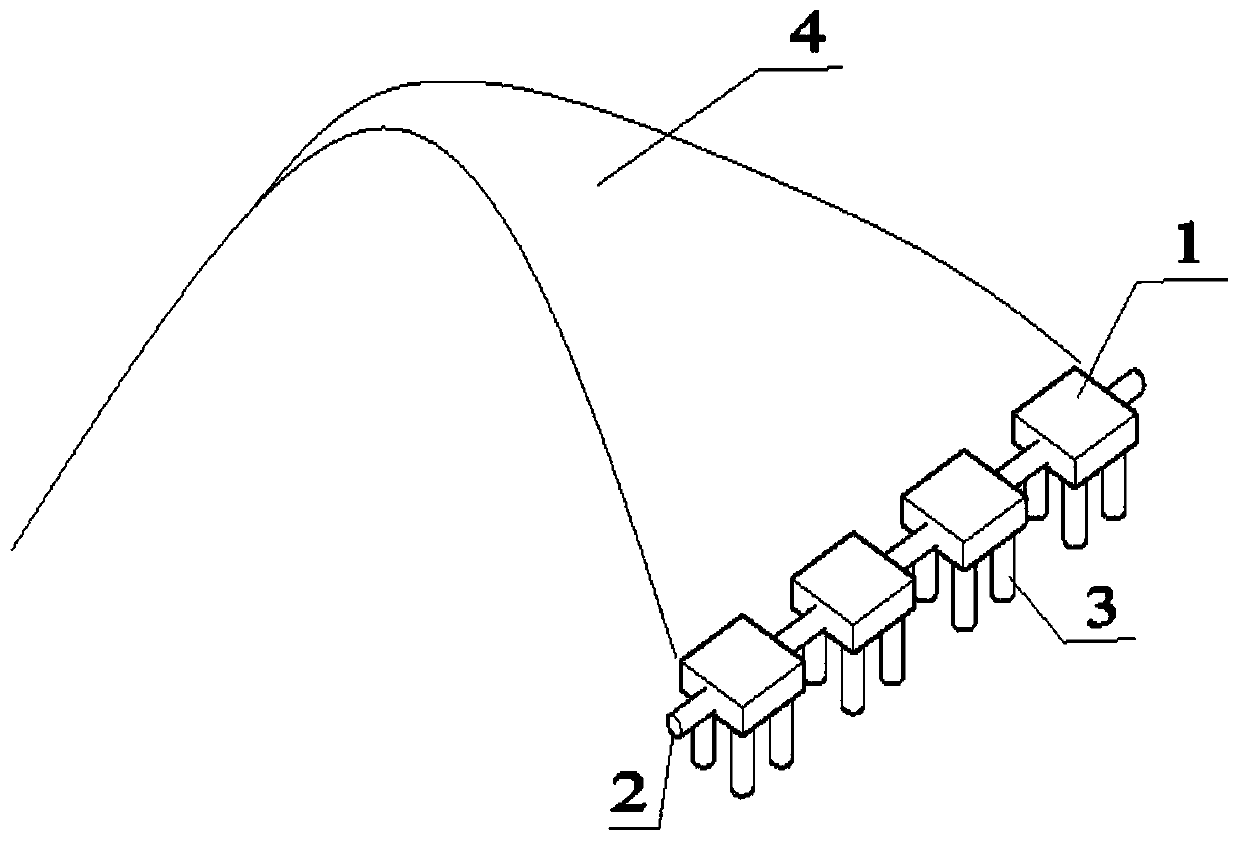

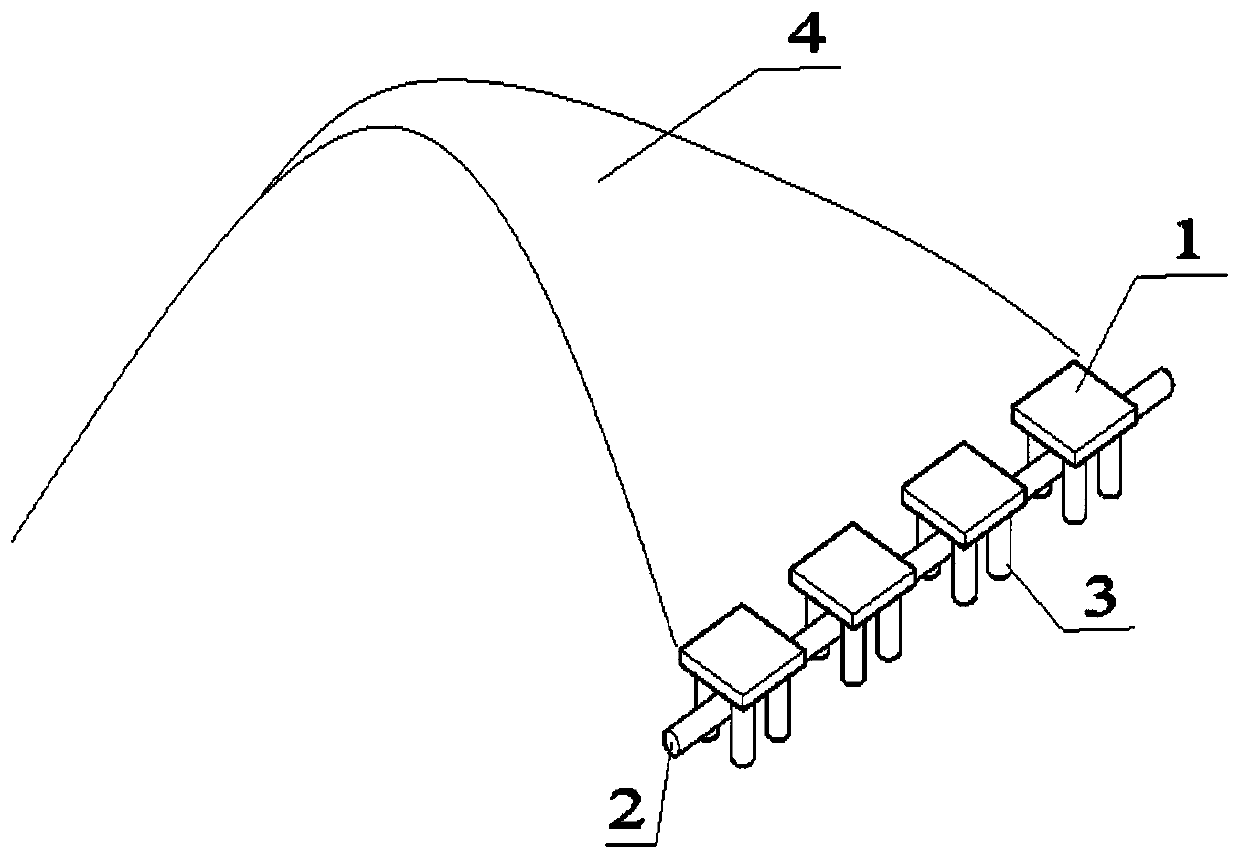

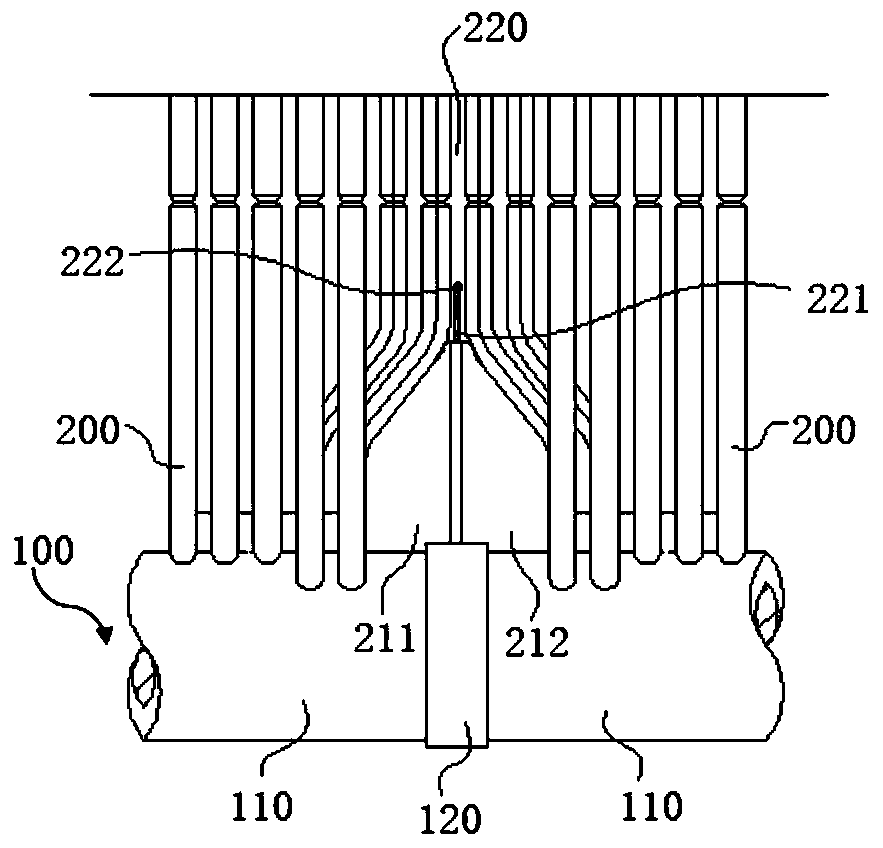

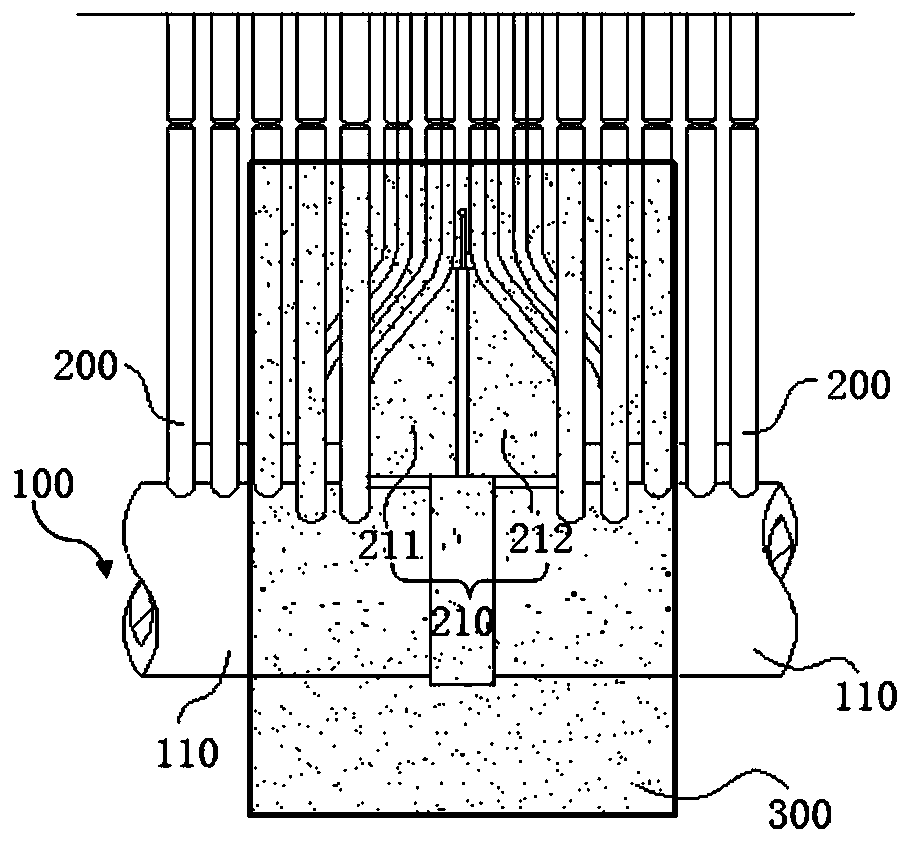

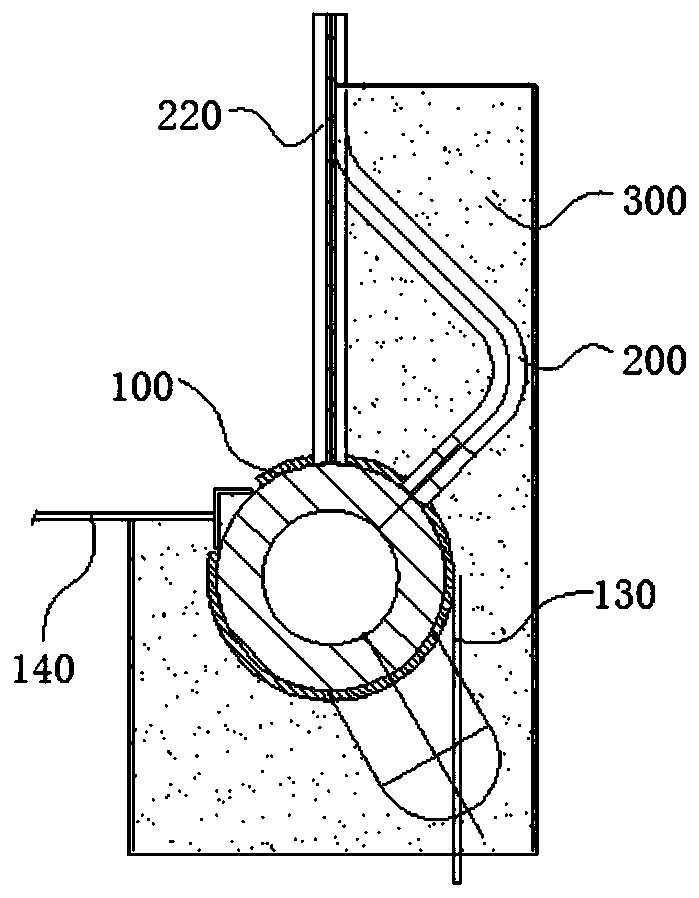

Anti-seismic protection structure of micro-pile frame pipeline

PendingCN111520565AReduce extrusion deformationAvoid damagePipe supportsPipe elementsSeismic protectionSpace frame

The invention relates to pipeline construction, in particular to an anti-seismic protection structure of a micro-pile frame pipeline. The anti-seismic protection structure comprises top plates and micro-piles driven into soil, and the micro-piles are fixed in the top plates; a space frame structure is formed by the micro-piles and the top plate overall, and the top plates are arranged at the footof a mountain; the frame structure used for arranging a pipeline in a sleeving mode is formed by one top plate and at least four micro-piles; and the frame structure is a protective unit, and the protective units are arranged in a certain direction to form a channel used for protecting the pipeline. Through arrangement of the anti-seismic protection structure of the micro-pile frame pipeline, longoil and gas pipelines laid at the foot of the mountain are protected, so that damage or larger deformation risks of the pipeline are reduced under the strong earthquake action.

Owner:中国石化销售股份有限公司

Treatment method for preventing expansion and cracking of boiler

The invention discloses a treatment method for preventing expansion and cracking of a boiler, and belongs to the technical field of expansion and cracking of boilers. The treatment method includes structural improvement of a tube seat part of a water wall lower collecting box. An improvement method includes the following steps that joint of two adjacent water wall diversity collecting boxes is cut, a locating hold hoop is added on the joint, one side of the locating hold hoop is welded to the water wall diversity collecting boxes, and the other side of the locating hold hoop is only erected with the water wall diversity collecting boxed; a water wall sealing plate is formed by mutually lap-jointing and splicing a first water wall sealing plate and a second water wall sealing plate, and theouter sides of the first water wall sealing plate and the second water wall sealing plate are correspondingly welded to a light-pipe water wall pipe. According to the treatment method for preventingexpansion and cracking of the boiler, the propose is to overcome the problems of existing pipe bursting of the boiler of a supercritical W flame boiler due to expansion and cracking and the like are overcome, the treatment method for preventing expansion and cracking of the boiler is provided, a passive situation of frequency pipe bursting of the boiler with the supercritical W flame boiler is changed advantageously, and experience guiding is provided for renovation of the supercritical W flame boiler.

Owner:DATANG HUAYIN ELECTRIC POWER

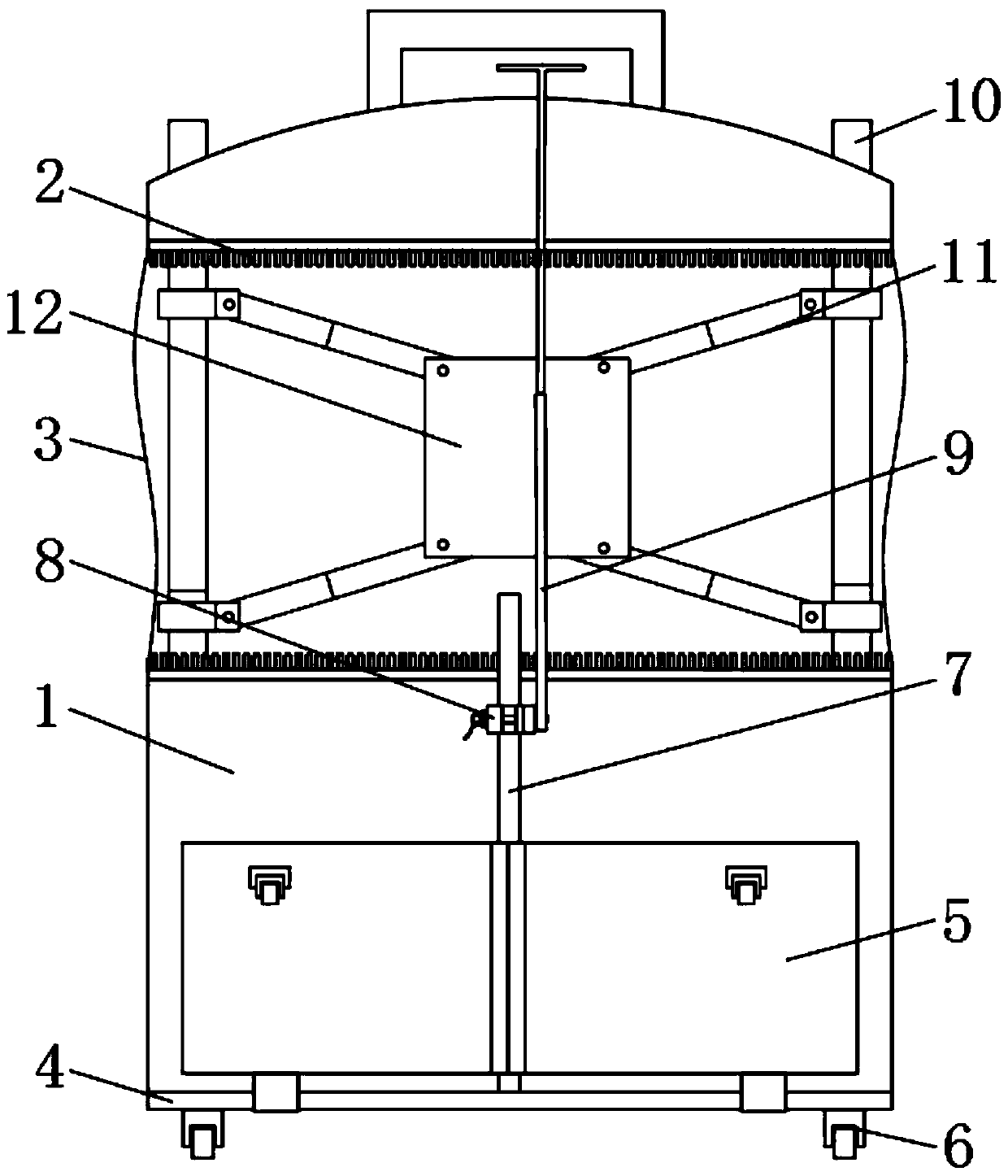

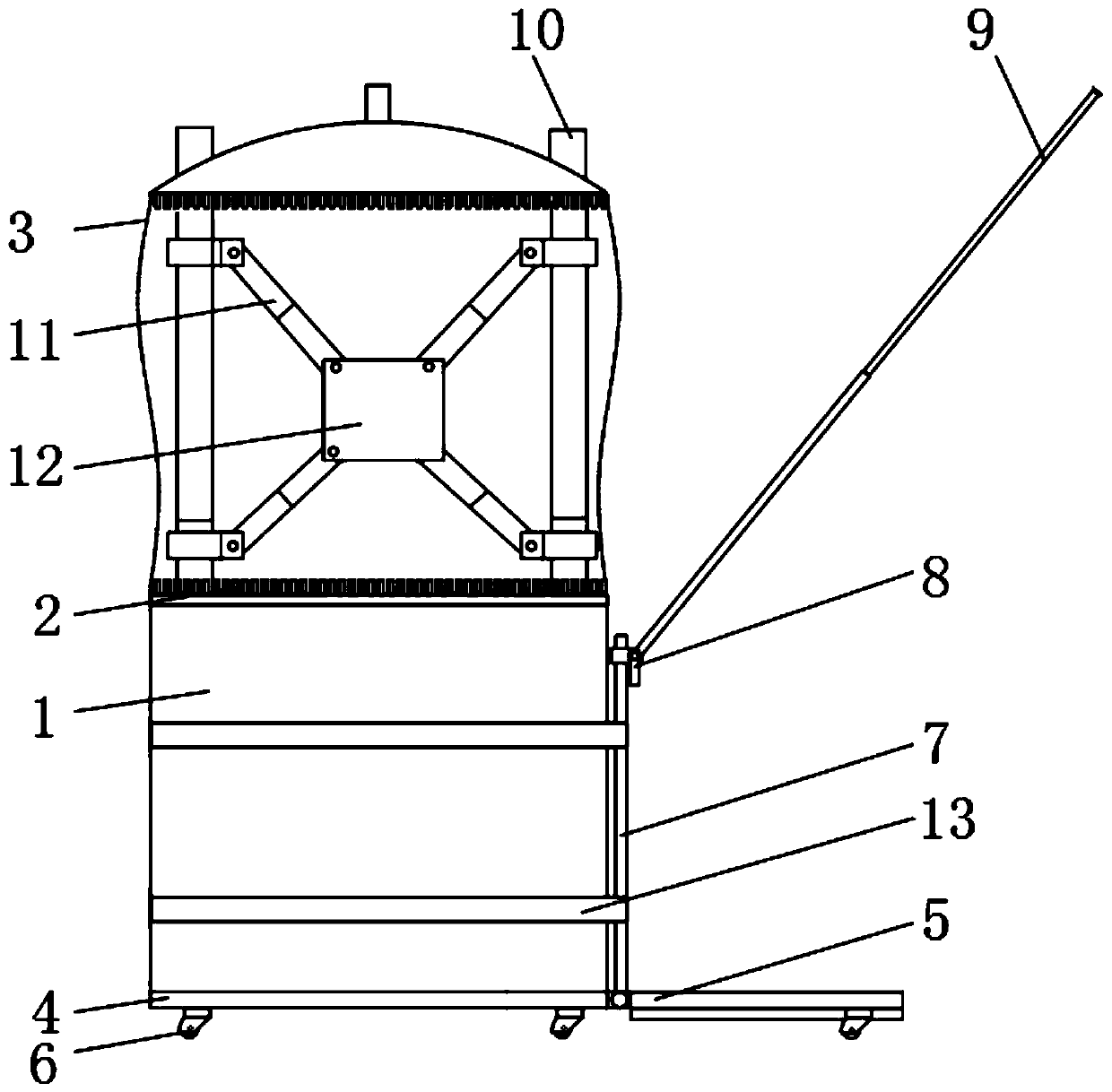

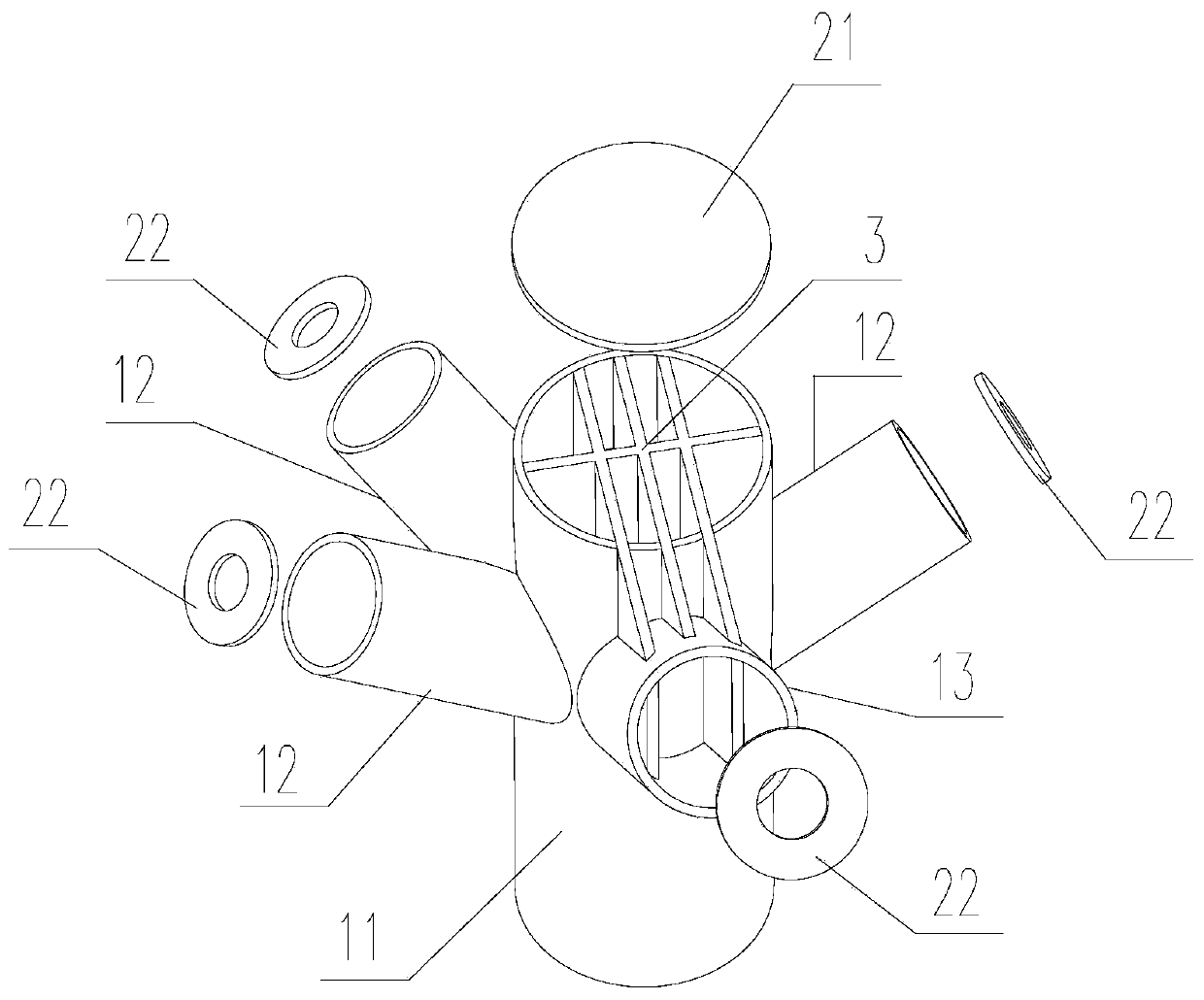

Folding-type storage luggage

The invention relates to the technical field of home equipment, and discloses a folding-type storage luggage. The folding-type storage luggage comprises a basic part; a folding part is arranged at theupper end of the basic part, and the upper end and the lower end of the folding part are movably connected through a folding zipper; and a bottom plate is assembled at the lower end of the basic part, and one side of the bottom plate is movably connected with a folding plate. According to the folding-type storage luggage, a supporting plate and a supporting rod are assembled in the folding part to support the folded part of the folding-type storage luggage to prevent the exterior of the luggage from deforming, the probability of occurrence of extrusion deformation of objects in the luggage isdecreased, meanwhile the inclining risk of the luggage is reduced, secondly force bearing during moving of the luggage is more reasonable, and thus the service life of a push-pull rod is prolonged; and moreover, the folding plate can be used for storing other objects after being unfolded, the volume of the luggage is increased, the using efficiency of the luggage is improved, meanwhile the overall gravity center of the luggage is lowered by placing the other objects on the folding plate, and thus the stability of the luggage during moving is further improved.

Owner:沈阳炳恒科技有限公司

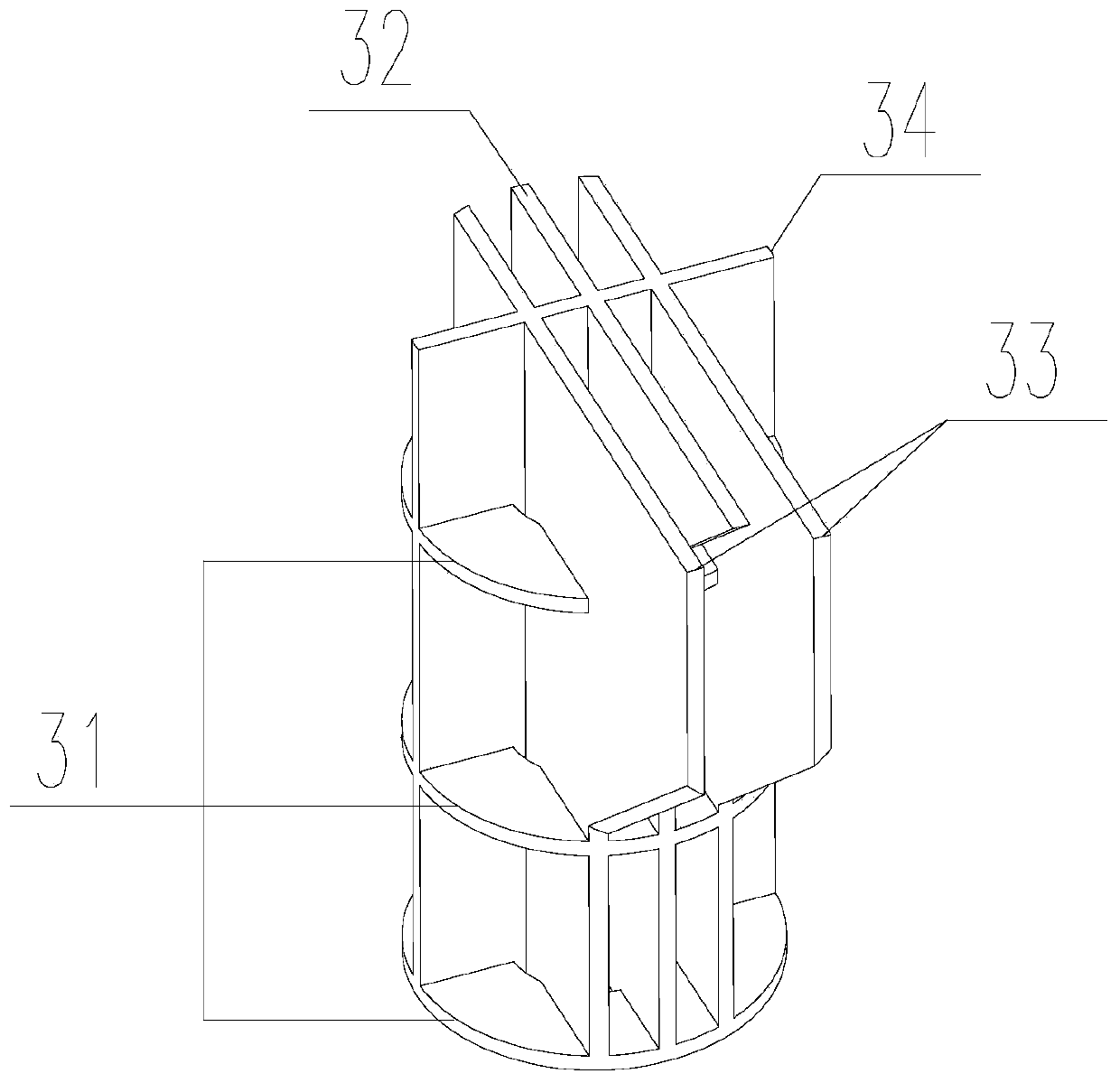

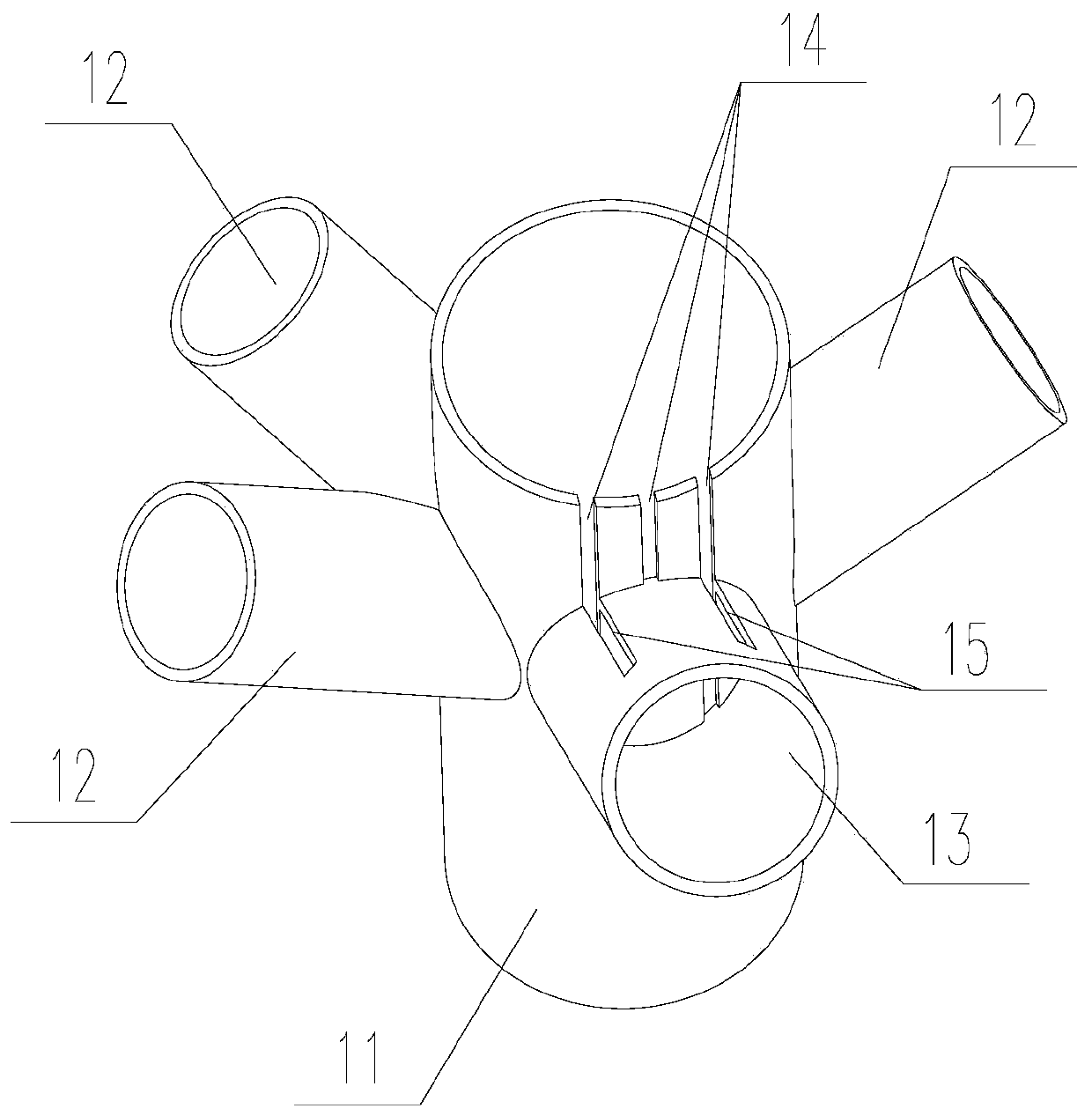

Steel pipe structure tree-shaped column bifurcated joint with bidirectional stiffening plates

ActiveCN111287317AIncrease stiffnessEasy to operateBuilding constructionsStress concentrationClassical mechanics

The invention belongs to the field of constructional engineering, and particularly relates to a steel pipe structure tree-shaped column bifurcated joint with bidirectional stiffening plates. The steelpipe structure tree-shaped column bifurcated joint with the bidirectional stiffening plates comprises a steel pipe structure, joint end plates and the bidirectional stiffening plates, wherein the each bidirectional stiffening plate comprises a plurality of transverse annular stiffening plates arranged inside a main rod in parallel and a plurality of vertical stiffening plates which are perpendicular to the transverse annular stiffening plates and extend out of the main rod to intersect with the pipe walls of supporting rods. According to the steel pipe structure tree-shaped column bifurcatedjoint with the bidirectional stiffening plates, the bidirectional stiffening plates are welded in the steel pipe structure tree-shaped column joint, so that the rigidity of the joint is effectively improved, stress concentration and rod piece deformation of intersecting parts are reduced, and the steel pipe structure tree-shaped column bifurcated joint has the advantages of being simple in structure, low in engineering cost, wide in application range and the like.

Owner:上海杰地建筑设计有限公司

Dynamic bottle blocking device in bottle conveying mechanism in box filling machine

The invention discloses a dynamic bottle blocking device in a bottle conveying mechanism in a box filling machine. The dynamic bottle blocking device comprises a bottle blocking support arranged on arack, wherein a plurality of bottle blocking assemblies are arranged on the bottle blocking support, and each bottle blocking assembly is correspondingly blocked in one conveying channel; the bottle blocking support is connected with the rack in a sliding mode, a driving mechanism is arranged on the rack, the bottle blocking support can be driven by the driving mechanism to slide back and forth onthe rack, and therefore each bottle blocking assembly is driven to move back and forth in the corresponding conveying channel; and a first position sensor, a second position sensor and a third position sensor are arranged on the bottle blocking support at intervals, bottles closest to the bottle blocking assemblies in the conveying channels can be detected by the first position sensor, the secondposition sensor and the third position sensor in sequence in the process of moving towards the bottle blocking assemblies until the bottles are blocked in place. The dynamic bottle blocking device inthe bottle conveying mechanism in the box filling machine has the advantages that bottle deformation is greatly reduced, and therefore the bottle grabbing accuracy is improved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

A width limiting device for small road section construction used in traffic engineering

The invention provides a width-limiting device for construction of small road sections used in traffic engineering, which includes rollers, shock absorbers, square pipe sleeves, guide wheels and tight release rods; the peripheral outer wall of the semicircular water tank is arranged in a circular array There are four rectangular slots, where two quarters of the height of the four rectangular slots are supported and welded with a positioning plate with a central jack, and each of the four rectangular slots is slidably inserted with a roller support shaft; The upper support sleeve of the lower half of the support tube has two guide wheels arranged at intervals up and down; there is a positioning disc on the outer opening of the tube hole, which is screw-locked, and the position of the positioning disc and the center of the plug is equal. An I-shaped notch is provided; an I-shaped elastic block is provided at the tail end of the tight unloading lever. The setting of the guide wheel of the present invention can prevent the rubber tire on the guide wheel from being damaged when the vehicle accidentally touches the guide wheel. The exterior paint of the vehicle is scratched.

Owner:新昌县凌智机械有限公司

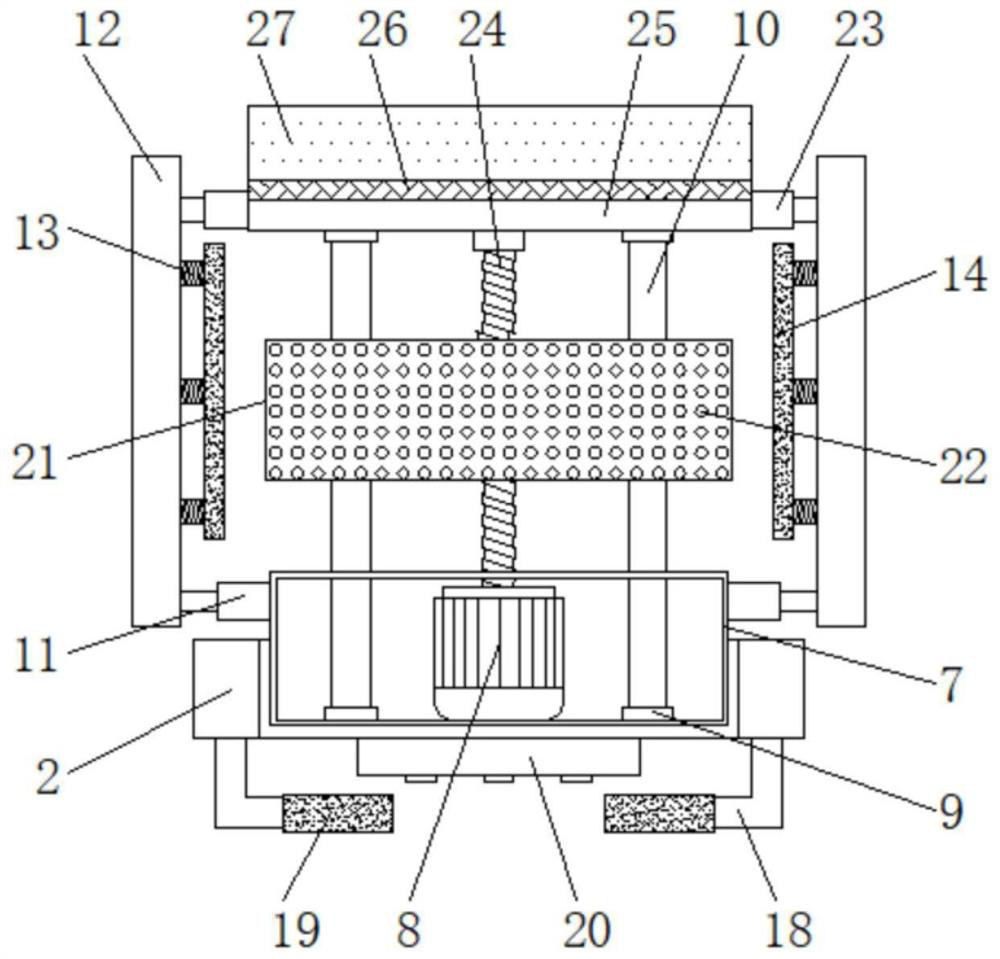

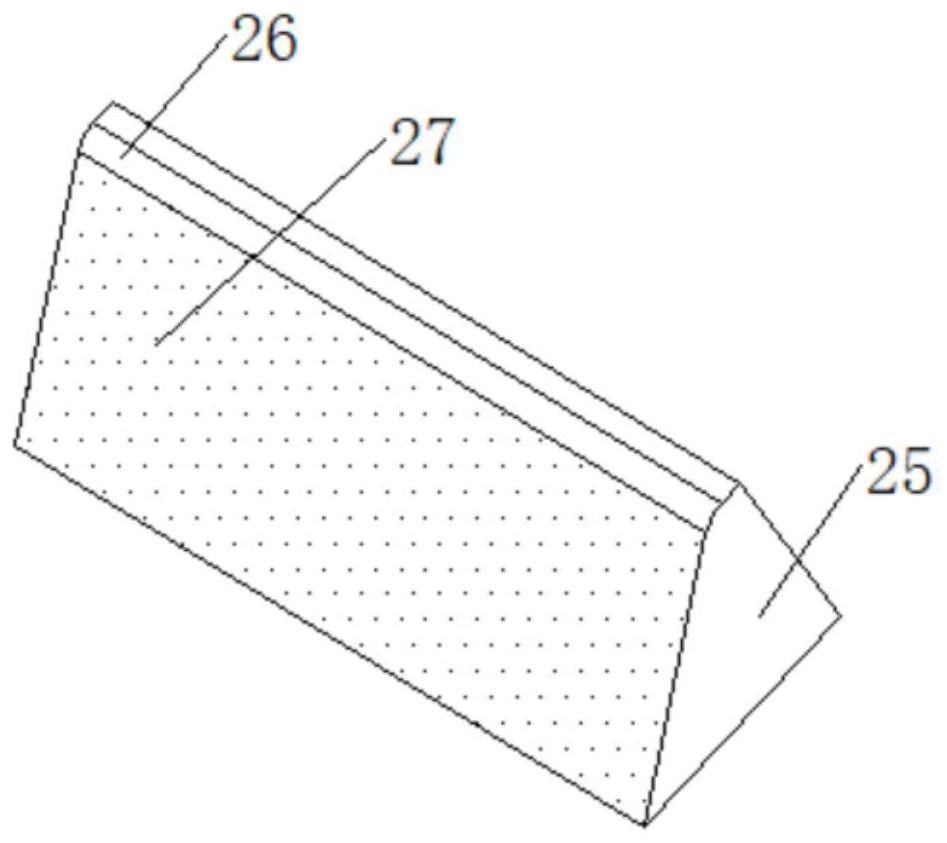

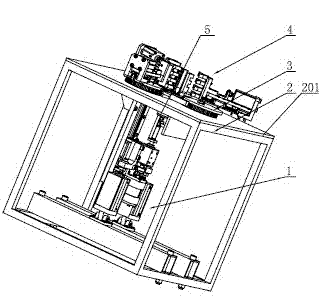

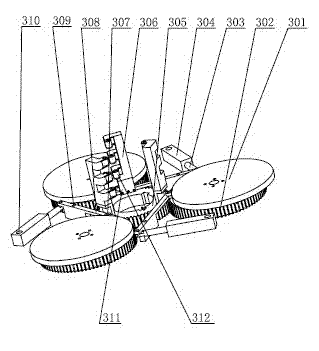

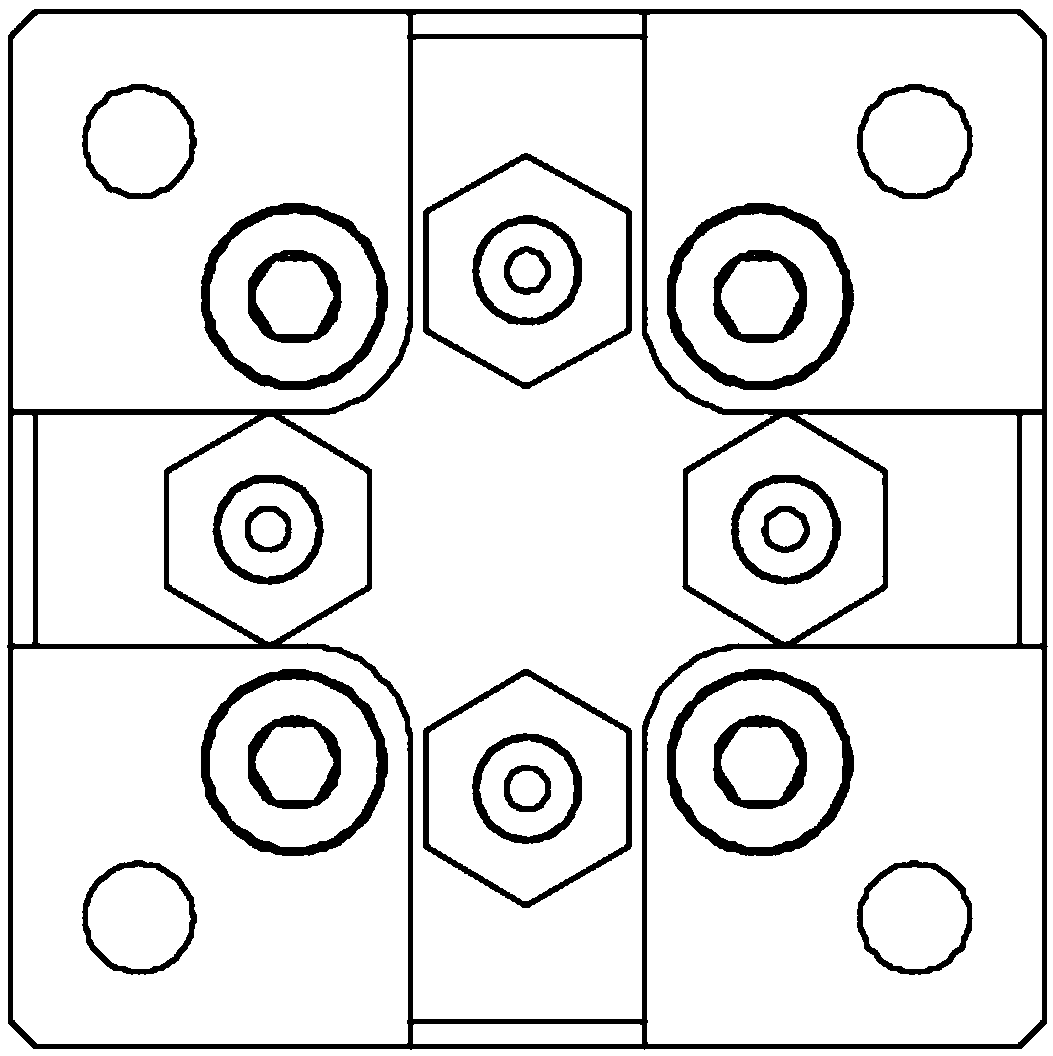

Device for forming metal carrier

InactiveCN103042081AImprove the flatness of the end faceReduce extrusion deformationEngineeringPoor quality

The invention relates to a device for forming a metal carrier. The device comprises a push-turn mechanism which is installed in a rack, an output end of the push-turn mechanism is connected with a needle rolling mechanism, and the push-turn mechanism drives the needle rolling mechanism to perform vertical motion and rotational motion; the needle rolling mechanism is movably connected with a forming mechanism, and the forming mechanism is installed on a work table board of the rack; and an operation platform is installed above the forming mechanism, and a clamping mechanism is installed on the operation platform. The push-turn mechanism, the forming mechanism and the clamping mechanism cooperatively work to finish rolling of the three-core metal carrier, the degree of automation is high in the whole work process, moulding and deformation of materials in the rolling forming process are greatly reduced, and problems of low qualification rates, poor qualities and low efficiencies which are caused by manual forming production of operators in the past are solved, and production efficiencies are improved.

Owner:JIANGNAN UNIV

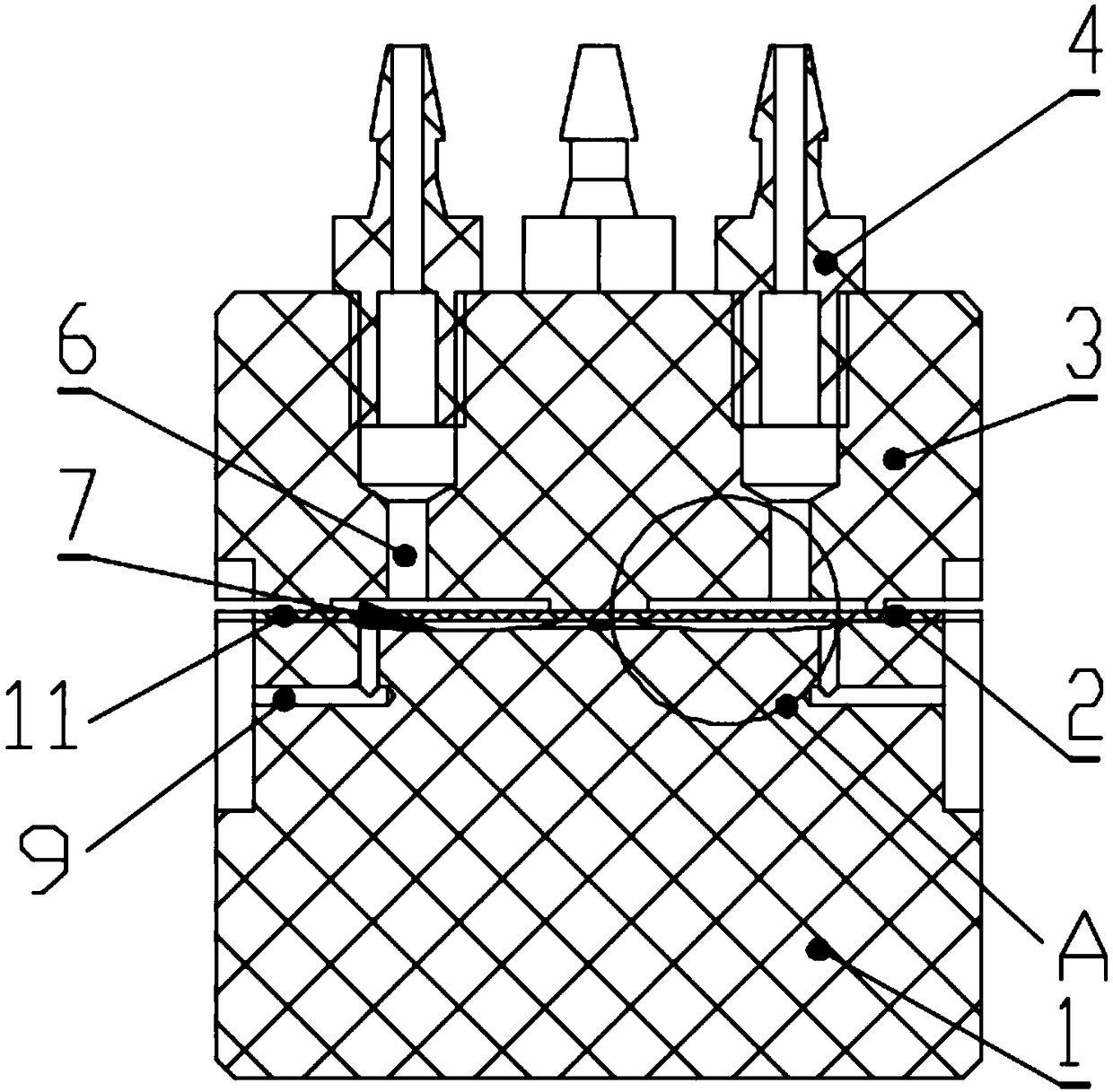

An Improved Miniaturized Membrane Valve

ActiveCN106499841BSimple compositionEasy to disassembleDiaphragm valvesEngine diaphragmsMedicineMembrane configuration

The invention relates to the technical field of valves, and particularly discloses a small improved membrane valve. The small improved membrane valve comprises an upper valve body, a lower valve body and a flexible membrane, wherein the upper valve body and the lower valve body are connected with each other, and the flexible membrane is clamped between the upper valve body and the lower valve body. The upper valve body and the lower valve body are further provided with a valve system. The valve system comprises connectors, air pipelines, fluid cavities and fluid pipelines. The fluid cavities are formed in the lower valve body and communicate with one ends of the corresponding fluid pipelines, and the other ends of the fluid pipelines transversely extend to the outer side wall of the membrane valve. The fluid pipelines are arranged inside the lower valve body and bent in an L shape. Connecting ports corresponding to outlets of the fluid pipelines are arranged in the outer side face of the membrane valve. The inner surface of the upper valve body or the lower valve body is provided with bosses, and the height of the bosses is slightly smaller than the thickness of the flexible membrane in the natural relaxation process. The bosses are arranged at the positions corresponding to the outer sides of the edges of the fluid cavities in a surrounding mode, so that an enclosed space is formed. By the adoption of the membrane valve, the problem of channel blockage caused by elastic film compressional deformation can be better solved, the resistance of liquid flowing past channels is reduced, and the membrane valve performance is improved.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

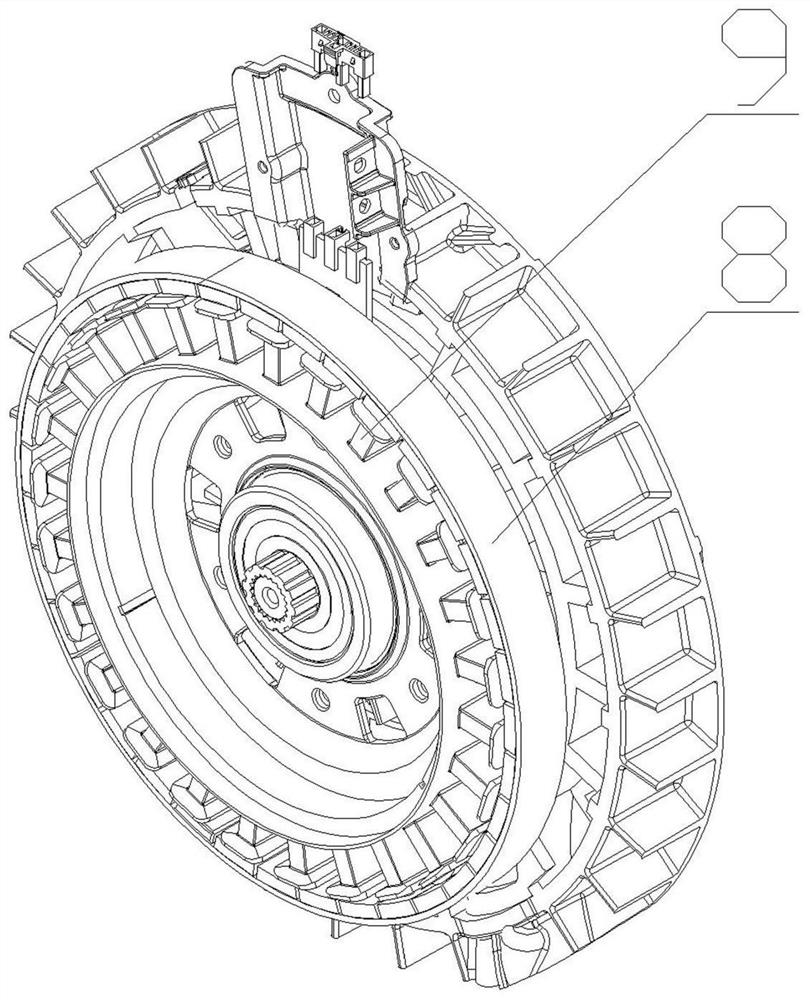

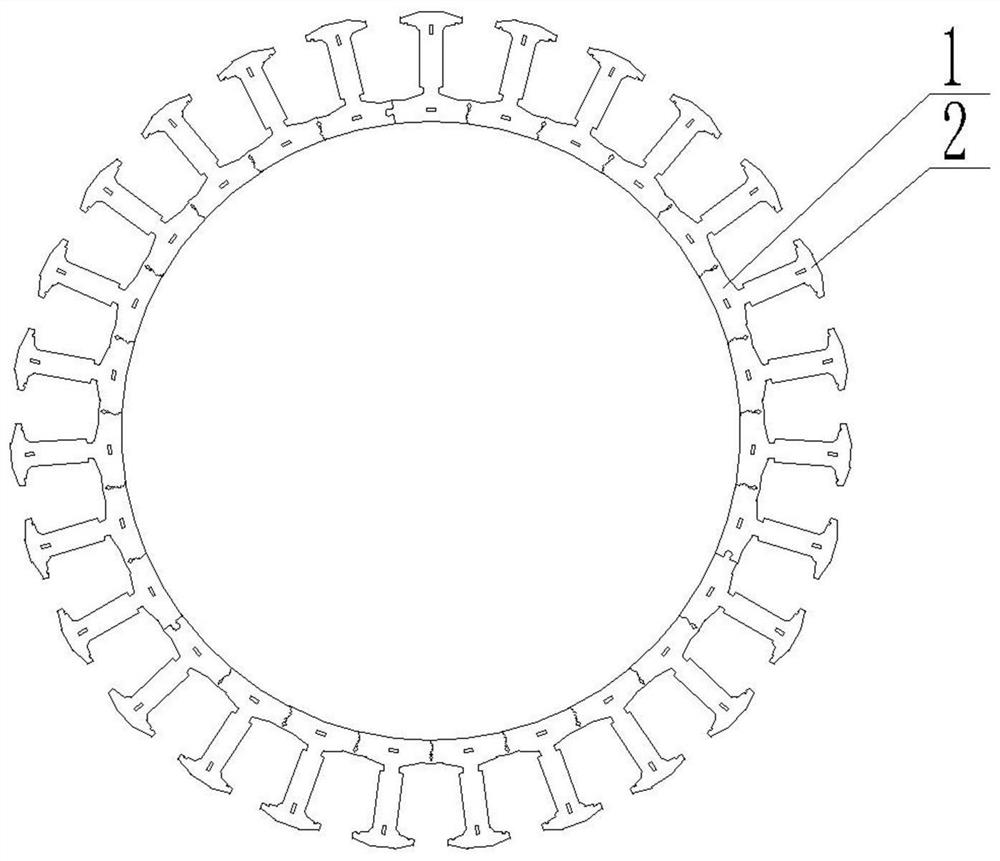

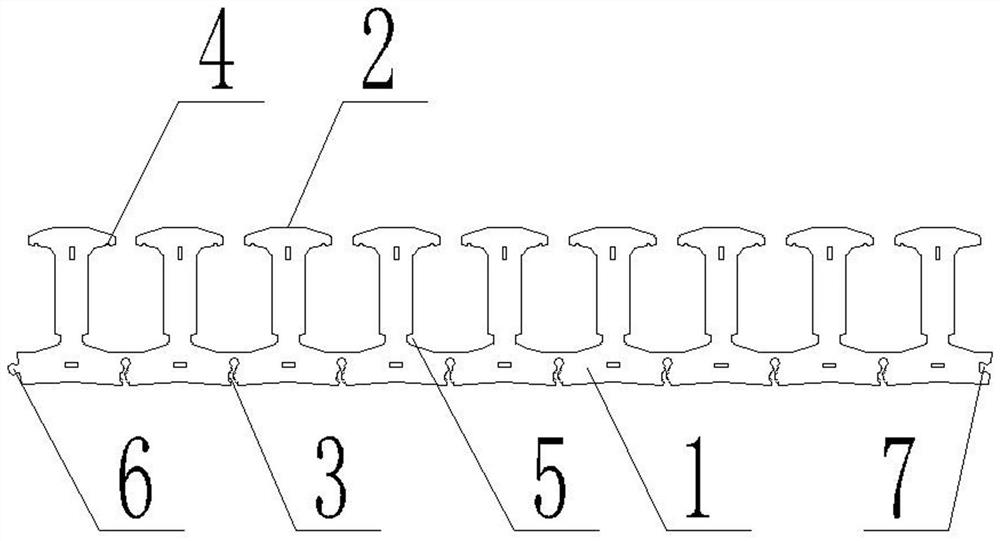

Stator punching sheet structure and motor comprising same

PendingCN112636495AReduce processing costsIncrease usageMagnetic circuit stationary partsWindings conductor shape/form/constructionPunchingElectric machine

The invention discloses a stator punching sheet structure and a motor comprising the same. The stator punching sheet structure comprises a plurality of stator iron core groups; one stator iron core group is provided with 9-12 stator iron core pieces; a stator bending groove is arranged between every two adjacent stator iron core pieces; each stator bending groove comprises a curved surface A, a curved surface B and a curved surface C, wherein the curved surface A and the curved surface B are each provided with multiple arcs with the same number, and the curved surface C is in an arc shape; after each stator iron core group is bent, the multiple arcs on the curved surface A can coincide with the multiple arcs on the curved surface B; and the multiple stator iron core groups are connected end to end to form stator iron core layers. The motor comprising the stator punching sheet structure comprises a rotor body; and the stator core layers are stacked in sequence to form a stator body; the stator body is wound and then put into a mold so as to be subjected to injection molding; and the rotor body is also put into the mold so as to be subjected to injection molding.

Owner:HUZHOU YONGCHANG BEISHITUO ELECTRIC APPLIANCE INDAL

A tunnel comprehensive drainage, precipitation, decompression construction method

The invention provides a comprehensive tunnel drainage, precipitation and pressure reduction construction method, relates to an in-tunnel drainage, ground precipitation and comprehensive pressure reduction construction method for a water and mud burst segment of a tertiary system sand shale tunnel and is mainly designed to solve the problems that an existing tunnel is prone to deformation, collapse and even water burst and mud burst in the tertiary system sand shale construction process. Ground precipitation wells are drilled at the positions, eight meters away from the side lines on the two sides, of a ground-direction positive hole, a flat guide hole is formed near the ground-direction positive hole, a drainage hole is formed in the inclined upper direction of the ground-direction positive hole relative to the flat guide hole, tunnel substrate precipitation wells are drilled in both the substrate of the ground-direction positive hole and the substrate of the flat guide hole, a plurality of inclined drainage holes are formed above the inclined front portion of a vault of the ground-direction positive hole, a positive hole vertical drainage hole is formed above the vault of the ground-direction positive hole, and a flat guide hole vertical drainage hole is further formed above the vault of the flat guide hole. The comprehensive tunnel drainage, precipitation and pressure reduction construction method has the advantages that geological disasters such as collapse, deformation, water burst and mud burst are avoided, and tunnel construction safety can be guaranteed.

Owner:CHINA RAILWAY 19TH BUREAU GRP SECOND ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com