Extruded type anchorage device for FRP rib and anchoring method

An extruded anchorage and anchoring technology, which is applied in the direction of sheet pile walls, structural elements, building components, etc., can solve the problems of not giving full play to the high strength of FRP bars, and avoid early fracture damage, high strength, and extrusion deformation Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

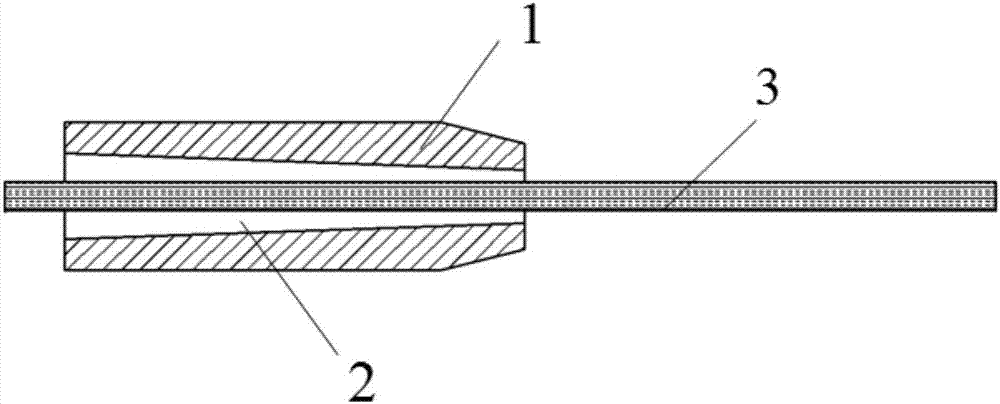

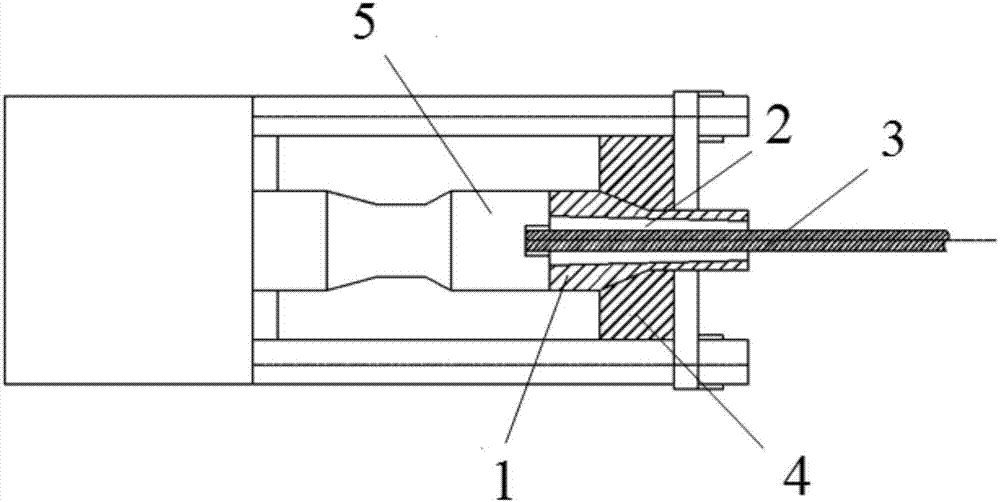

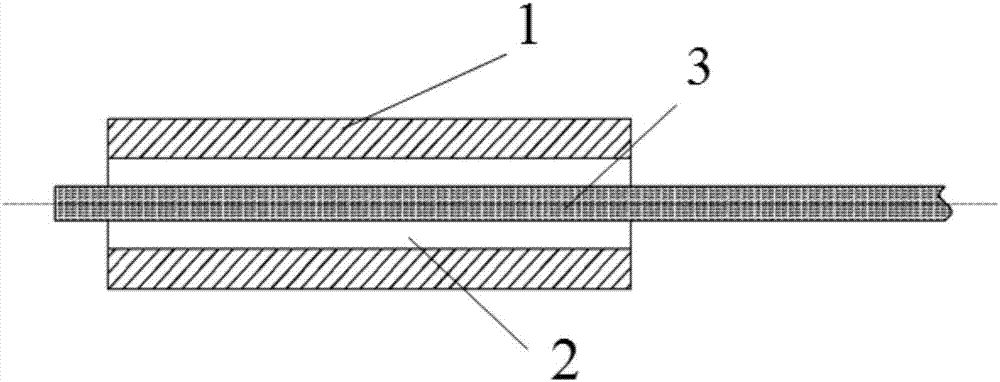

[0027] like figure 1 As shown, the extruded anchor assembly in the embodiment of the present invention includes a steel anchor barrel 1 , an aluminum casing 2 and a CFRP tendon 3 . The inclination angle of the tapered through hole inside the anchor tube 1 is equal to the inclination angle of the wedge-shaped outer surface of the casing, and the inclination angle θ can be 1° to 3°. Since the diameter of the CFRP tendon 3 in the embodiment is 5 mm, the inclination angle θ is 2 °. One end of the anchor cylinder is provided with a chamfer, and the angle of the chamfer is the same as that of the taper hole of the extrusion die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com