Explosive test device of combustible gas with concentration gradient and using method

A gas explosion and concentration gradient technology, applied in the direction of material explosion, can solve the problems of incomplete mixing of combustible gas and oxygen, and less space research on approximate length, width and height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

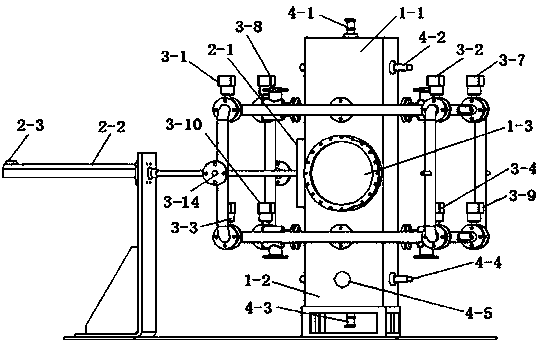

[0053] Such as Figure 1 to Figure 10 As shown, a combustible gas explosion experiment device with a concentration gradient includes an explosion reaction vessel 1 , a partition extraction device 2 , a gas distribution system 3 , and a control system 4 .

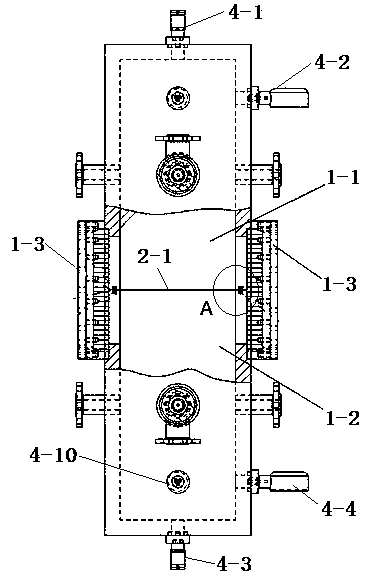

[0054] The explosion reaction vessel 1 includes an upper reaction vessel 1-1, a lower reaction vessel 1-2, an observation window 1-3, an upper gray ring 1-4, a lower gray ring 1-5, and a dovetail-shaped sealing strip 1-6.

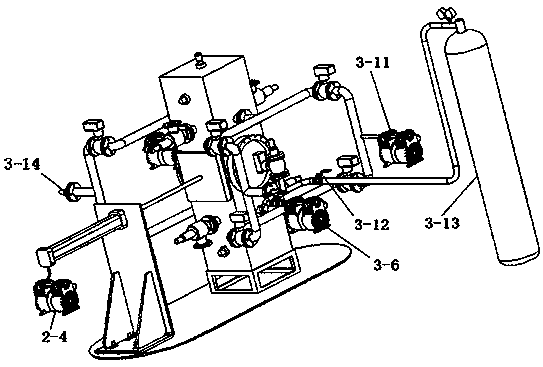

[0055] The separator separating device 2 comprises a separator 2-1, a cylinder 2-2, a muffler I2-3, and a compressor 2-4.

[0056] Gas distribution device 3 includes solenoid valve Ⅰ3-1, solenoid valve Ⅱ3-2, solenoid valve Ⅲ3-3, solenoid valve Ⅳ3-4, muffler Ⅱ3-5, vacuum pump Ⅰ3-6, solenoid valve Ⅴ3-7, solenoid valve Ⅵ3-8 , Solenoid valve VII 3-9, Solenoid valve VIII 3-10, Air pump 3-11, Manual ball valve 3-12, Air source 3-13.

[0057] The control system 4 includes PCB pressure sensor I4-1, pressure sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com