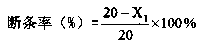

Preparation method of rice flour with low strip breaking rate

A technology of strip breakage and rice noodles, which is applied in the forming of food, the function of food ingredients, and the preservation of food ingredients as anti-microbials, etc., can solve the problems of poor appearance and taste of rice noodles, easy failure of rice noodles, and increased cost of rice noodles. , to achieve the effect of reducing the cooking loss of rice noodles, reducing extrusion deformation, and reducing spoilage and mildew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of preparation method of the low rice flour of breaking rate, comprises the following steps:

[0029] (1) Wash the indica rice in a rice washing machine, mix water and indica rice, and centrifuge in a high-pressure cyclone to separate and remove impurities such as rice husks, weeds, and sediment mixed in the indica rice to obtain clean rice.

[0030] (2) Mix the washed indica rice with deionized water at a ratio of 1:2 to the material, control the temperature of the soaking tank at 20°C, stir at a rate of 30 r / min, and soak for 10 h.

[0031] (3) Mix soaked indica rice with deionized water at a material-to-liquid ratio of 1:1, transfer to a beater to pulverize and refine, and pass the obtained rice milk through an 80-mesh sieve.

[0032] (4) Mix cornstarch and chitosan at a mass ratio of 40:6, and mix and stir evenly at a stirring speed of 150 r / min to obtain a mixed material.

[0033] (5) Add the mixed material obtained in step (4) and soybean pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com