Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce carboxyl end content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymerizing production method for transparent amorphous copolyester

The invention discloses a polymerizing production method for transparent amorphous copolyester. The method has the advantages of low esterification temperature, short esterification time and high esterification rate. The method comprises the following steps of: carrying out an esterification reaction and a condensation reaction on dihydric alcohol and dicarboxylic acid to obtain the transparent amorphous copolyester, wherein the esterification reaction comprises the following specific procedures of: breaking various materials into pulp by using a pulping machine and carrying out the esterification reaction on the pulp at the temperature of 220-240DEG C for 1.0-1.5 hours to obtain an esterified product; the condensation reaction comprises the following specific procedures of: polymerizing the esterified product obtained by the esterification reaction at the reaction pressure of 0.2-0.5MPa and the temperature of 250-260DEG C for 1.5-2 hours; then reducing the pressure to be less than 200MPa within 0.5 hour; raising the condensation reaction temperature to be 275DEG C from 260DEG C; adding a thermal stabilizer; and after the condensation reaction, obtaining a polyester copolymer with the inherent viscosity of greater than 0.75dL / g and the carboxyl content of less than 10mol / t.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

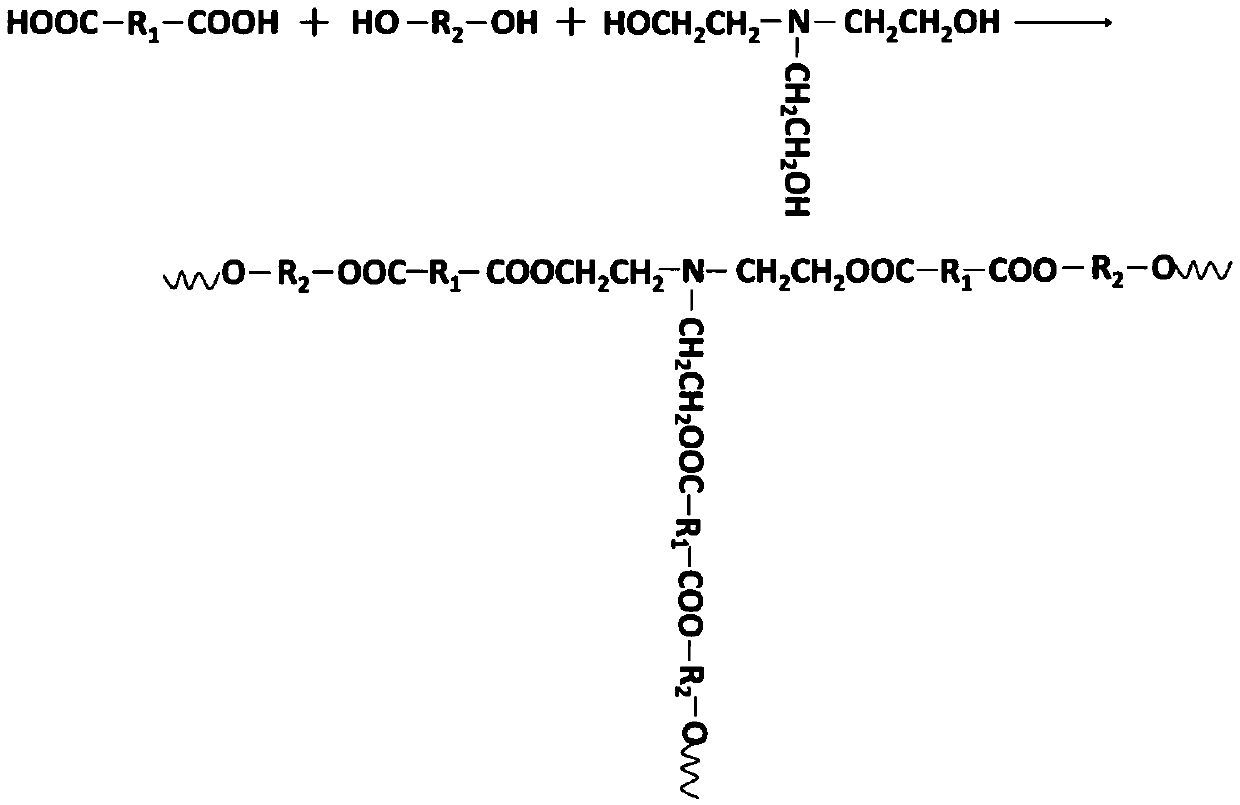

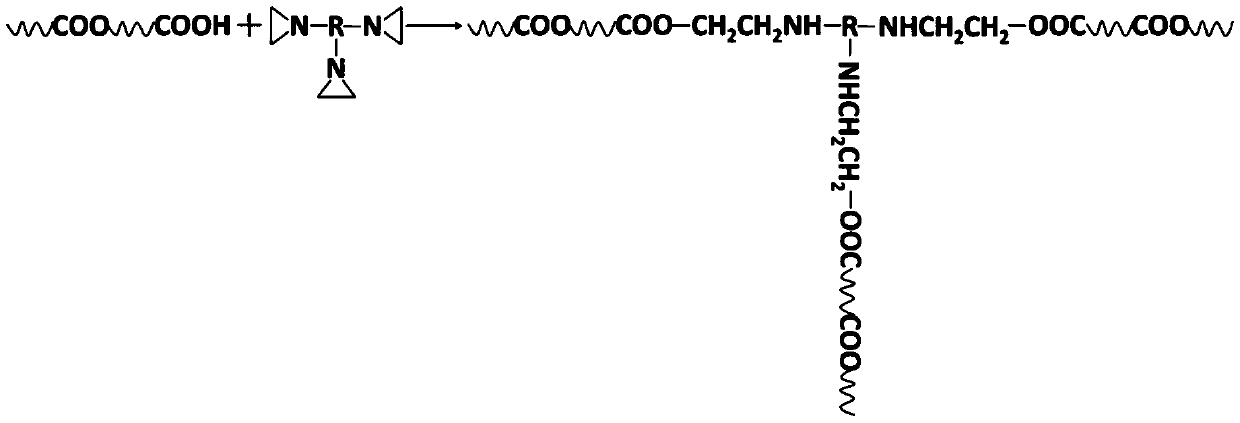

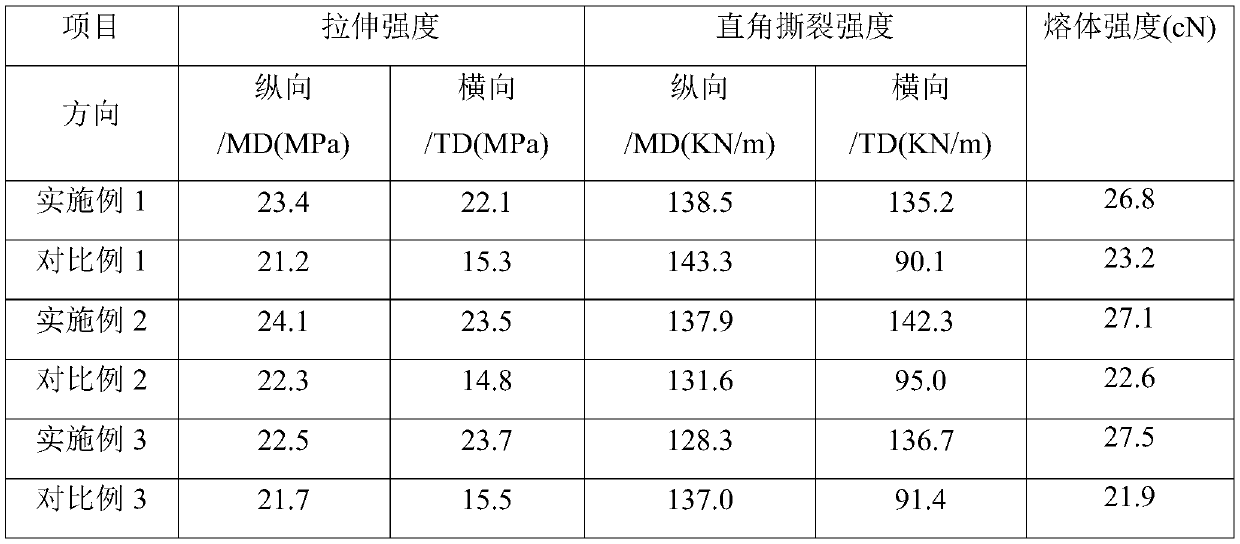

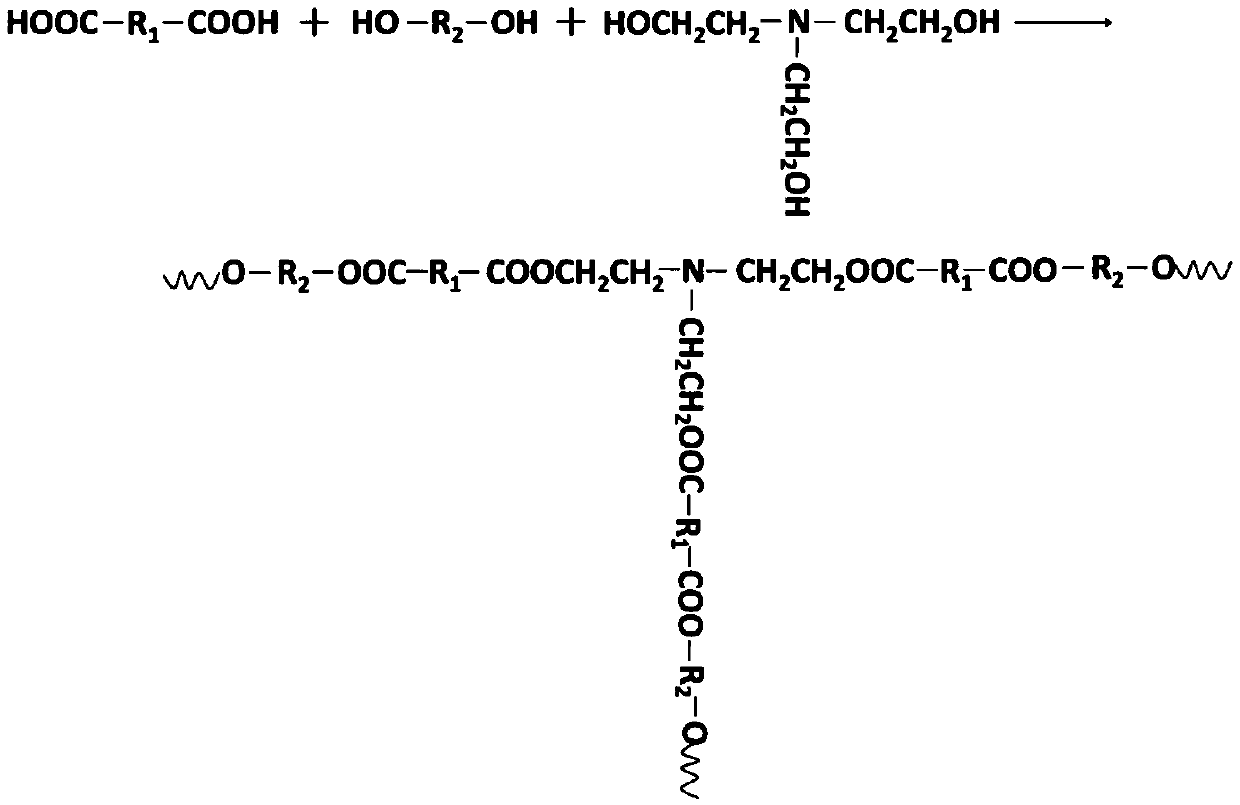

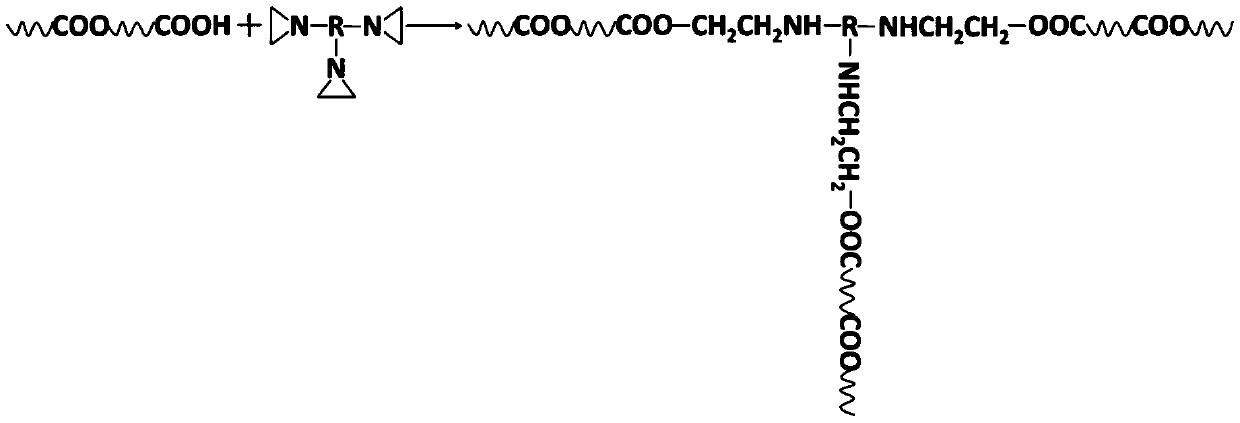

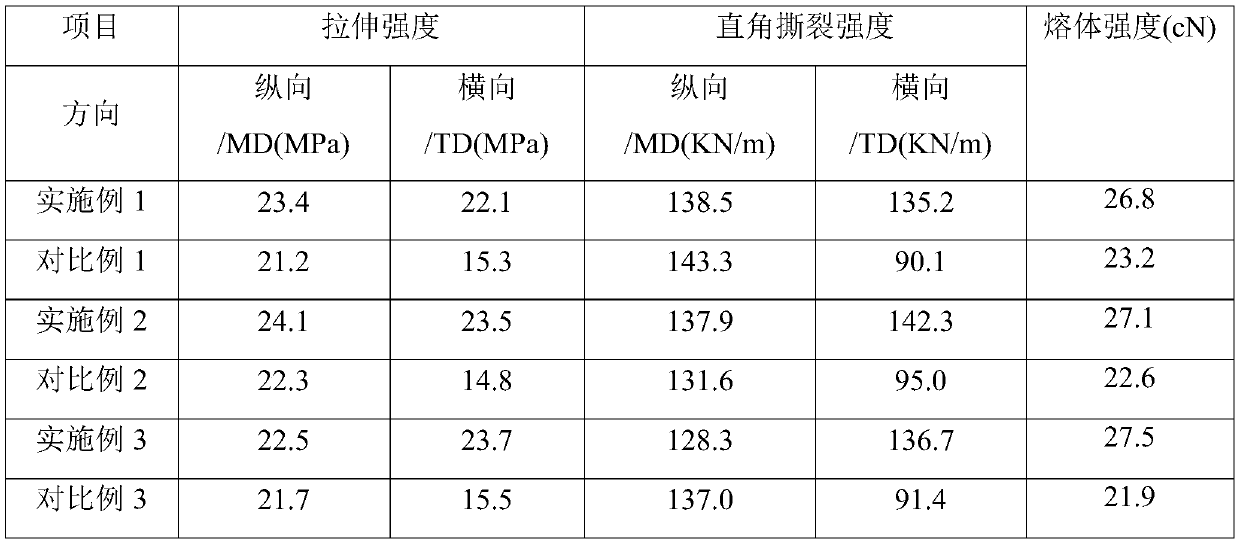

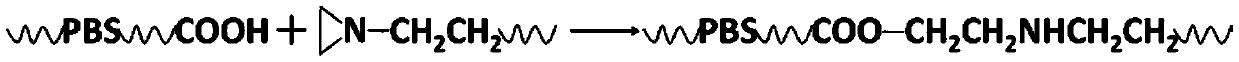

Preparing method of branched biodegradable polyester

The invention belongs to the technical field of macromolecules, and particularly relates to a preparing method of branched biodegradable polyester. The preparing method includes the steps of conducting esterification reaction on dihydric alcohol, a branching aid, aromatic dibasic acid and aliphatic dibasic acid, adding a three-functional-group aziridine group compound after the reaction ends, andfinally conducting condensation polymerization to obtain the branched biodegradable polyester. The branched structure is introduced to polyester molecules sequentially through triethanolamine and thethree-functional-group aziridine group compound; meanwhile, since a tertiary amine structure is formed by triethanolamine and a secondary amine structure is formed by the three-functional-group aziridine group compound, a terminal carboxyl group can be restrained, and the content of the terminal carboxyl group of the material is remarkably reduced. The obtained branched biodegradable polyester ishigh in melt strength and excellent in anti-ageing performance, and the longitudinal and transverse difference between tensile strength and right-angle tearing strength is small.

Owner:惠通北工生物科技(北京)有限公司

Titanium-silicon catalyst, preparation method and uses thereof

The invention discloses a titanium-silicon catalyst and a preparation method as well as an application thereof. The preparation method includes the following steps: (1) organic titanic acid ester and 2 / 3 cubic content of anhydrous alcohol are mixed evenly, and stirred sufficiently to achieve A solution; deionized water is mixed with the remained 1 / 3 cubic content of anhydrous alcohol sufficiently, acid or alkali is added, the acid or alkali concentration is controlled within 0.01-1mol / L, B solution is prepared, and B solution is dripped into A solution by a burette; (2) the mixture is stirred for 3-5 hours after dripping, the precipitate achieved after centrifugal separation is grinded and calcined to achieve titanium-silicon catalyst. The titanium-silicon catalyst achieved by the method is stable during the process of polymerization without hydrolysis reaction; the method can be used to catalytic synthesis of aliphatic and aromatic co-polyester, the titanium-silicon catalyst can reduce the dosage of catalyst, shorten the duration of polymerization, improve the quality of biodegradation co-polyester product, and the terminal carboxyl group content in the product as well as the b value are reduced.

Owner:KINGFA SCI & TECH CO LTD +1

Process for preparing poly trimethylene terephthalate

The invention discloses a process for preparing poly trimethylene terephthalate from terephthalic acid and 1,3-propylene glycol which comprises, subjecting terephthalic acid and propylene glycol to esterification reaction, conducting pre-polycondensation reaction to the esterification reactants, cutting the polycondensation polymer into granules, these reactions are conducted at the presence of a composite catalyst, which is a composition comprising titanium dioxide, silica and molybdenum oxidation.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Method for preparing high-viscosity PBT through chain extension modification with polymer

The present invention relates to a method for preparing high-viscosity PBT through chain extension modification with a polymer, wherein PBT is subjected to chain extension by selecting a chain extender containing a functional group capable of reacting with carboxyl and hydroxyl. According to the present invention, the used chain extender reacts with the carboxyl and hydroxyl prepolymer to diffuseand extend the molecular chain, such that the curing molding of the resin is achieved; in the polyester processing process, the molecular weight is decreased and the number of the terminal carboxyl isincreased due to the thermal degradation and the hydrolysis, such that the mechanical performance and the chemical performance of the polymer are reduced; the bifunctional small molecule compounds are added under the reactive blending condition, contain the functional groups capable of easily reacting with carboxyl, hydroxyl and the like, and can directly react with low molecular weight oligomers, such that the bridging is formed between the two polymer chains so as to significantly increase the molecular weight, improve the viscosity of the system, and reduce the terminal carboxyl content; and the polyester chain extension comprises: selecting a compound, and carrying out addition on the compound and hydroxyl or carboxyl.

Owner:YANGZHOU JINSEN OPTOELECTRONICS

Modified PET copolyester and preparation method and application thereof

The invention belongs to the technical field of polyester preparation, and discloses a modified PET copolyester with high viscosity and a low terminal carboxyl group and a preparation method and application thereof. The copolyester contains the following ingredients in parts by weight: 100 parts of low-viscosity PET copolyester, 0.8-2.0 parts of oxazoline compound and 0.6-2.0 parts of a hydroxyl chain extender. The method prepares the high-viscosity modified PET copolyester by adding the oxazoline compound and the hydroxyl chain extender. The oxazoline compound is added to react with the terminal carboxyl group in resin, the terminal carboxyl group content of resin is reduced, therefore, the hot water resisting performance of resin is increased. The hydroxyl chain extender is added, the molecular weight of resin is increased, and the balance between a physical performance and a processing performance is achieved. The viscosity and the melt strength of the modified PET copolyester are increased, the content of terminal carboxyl group is reduced, and the hot water resisting performance is greatly increased. Moreover, the production method shortens the polycondensation time and the production cycle, effectively reduces the thermal degradation reaction, and also increases the output of equipment.

Owner:KINGFA SCI & TECH CO LTD

Polyamide recovery process and polyamide obtained by recovery process

ActiveCN111892743AImprove precipitation efficiencyHigh crystallinityLayered productsPlastic recyclingEndcappingPolyamide

The invention discloses a polyamide waste recovery process, which comprises the following steps: adding polyamide waste into a compound solvent, heating to 50 DEG C to a solution reflux temperature, stirring until the polyamide waste is dissolved, carrying out decolorization treatment, and filtering to obtain a polyamide solution; adding the polyamide solution into water, precipitating polyamide in deionized water to separate out a solid, and separating to obtain recycled polyamide; wherein the compound solvent is prepared from the following components in parts by weight: 10 to 30 parts of phenol and 15 to 40 parts of methylbenzene. According to the invention, the solvent system mainly comprising phenol / toluene has the following advantages: 1, the solvent phenol can carry out secondary endcapping on polyamide, so the end capping rate is improved, and the hydrolysis resistance, alcoholysis resistance and aging resistance are improved; 2, polyamide can be fully separated out when the polyamide solution is added into deionized water, and the obtained polyamide is good in crystallization property; and 3, the phenol / toluene solvent system is low in volatility and irritation, relativelylow in damage to equipment under a high-temperature condition, green, environment-friendly and pollution-free.

Owner:KINGFA SCI & TECH CO LTD

Modified aliphatic-aromatic copolyester and its preparation method and use

The invention belongs to the technical field of polyesters and discloses a modified aliphatic-aromatic copolyester having high viscosity and low carboxyl end group content and its preparation method and use. The modified aliphatic-aromatic copolyester comprises, by weight, 100 parts of a low-viscosity aliphatic-aromatic copolyester, 0.5-3 parts of an oxazoline compound and 0.4-2.5 parts of a hydroxyl chain extender. Through use of the oxazoline compound and the hydroxyl chain extender, the modified aliphatic-aromatic copolyester is prepared. The used oxazoline compound and the carboxyl end group in the resin undergo a reaction so that resin carboxyl end group content is reduced and resin hot-water resistance is improved. Through use of the hydroxyl chain extender, resin molecular weight is improved and the balance of physical properties and processing properties is realized. Viscosity and the melt-strength of the modified aliphatic-aromatic copolyester are improved, carboxyl end group content is reduced and hot-water resistance is improved. The preparation method has a short production period, reduces polycondensation time and effectively reduces thermal degradation reactions.

Owner:KINGFA SCI & TECH CO LTD

Low-carboxylated biodegradable polyester and production method thereof

ActiveCN103467713AReduce carboxyl end contentGuaranteed low carboxyl levelsPolymer sciencePtru catalyst

The invention relates to the technical field of polyester high-molecular materials, and particularly relates to a low-carboxylated biodegradable polyester and a production method thereof. The low-carboxylated biodegradable polyester comprises1,6-adipic acid or / and terephthalic acid and 1,4-butanediol. According to the preparation method of the low-carboxylated biodegradable polyester, the content of carboxyl end groups in the polyester can be furthest reduced by adopting a compound titanium catalyst and a carboxyl scavenger to produce condensation polymerization in the later period of esterification; the catalytic activity of titanium catalyst can be controlled by adding chelate with stabilizing effect, so as to avoid the side degradation reaction caused by the high activity of the catalyst in the later period of condensation reaction and furthest reduce the side reaction in the later period of the condensation reaction, so that the low-carboxylated level of the finished polyester product can be guaranteed, other additives are not additionally needed for modifying the product, the content of carboxyl end groups in the product can be reduced, and the high production cost of the product can be avoided.

Owner:新疆维格瑞生物科技有限公司

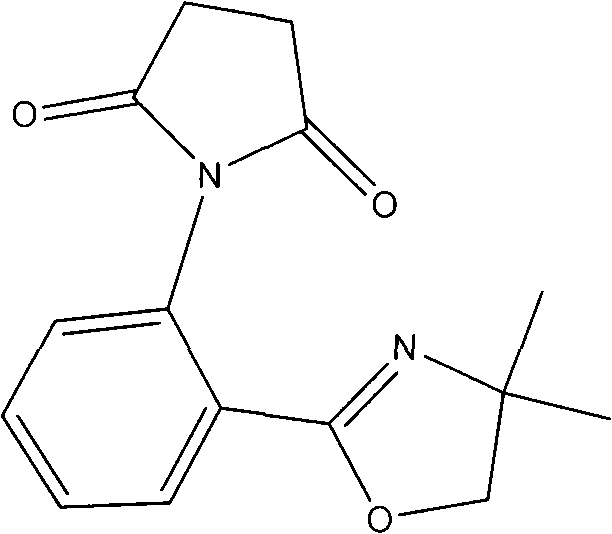

Novel polyester chain extender and preparation method thereof

The invention relates to a novel polyester chain extender and a preparation method thereof. The related novel polyester chain extender can obviously improve the intrinsic viscosity of the polyester and can reduce carboxyl content in the system. The novel polyester chain extender respectively comprises o-(4,4-dimethyl oxazoline) and a butanimide structure at the ortho position of the benzene ring, wherein the imide structure can react with hydroxide radical in the polyester and can obviously improve the intrinsic viscosity of the polyester; and oxazoline can perform the chain extending reaction with carboxyl in the polyester and can reduce the carboxyl content in the system when improving the viscosity. The preparation method for the novel polyester chain extender comprises the following steps: (a) dissolving isatoic anhydride and 2-alkamine in chlorobenzene and adding a catalyst into the mixture to perform a reaction to prepare oxazoline aniline; (b) dissolving the prepared oxazoline aniline in aether, adding succinic anhydride into the mixture to perform a reaction and filtering the reaction solution to obtain an intermediate; and (c) uniformly mixing the intermediate and anhydrous zinc chloride with kieselguhr, carrying out irradiation heating on the mixture by microwave, cooling the obtained product, adding ethyl acetate into the cooled obtained product to dissolve out the product, removing the solvent and crystallizing to obtain the novel polyester chain extender.

Owner:DONGHUA UNIV

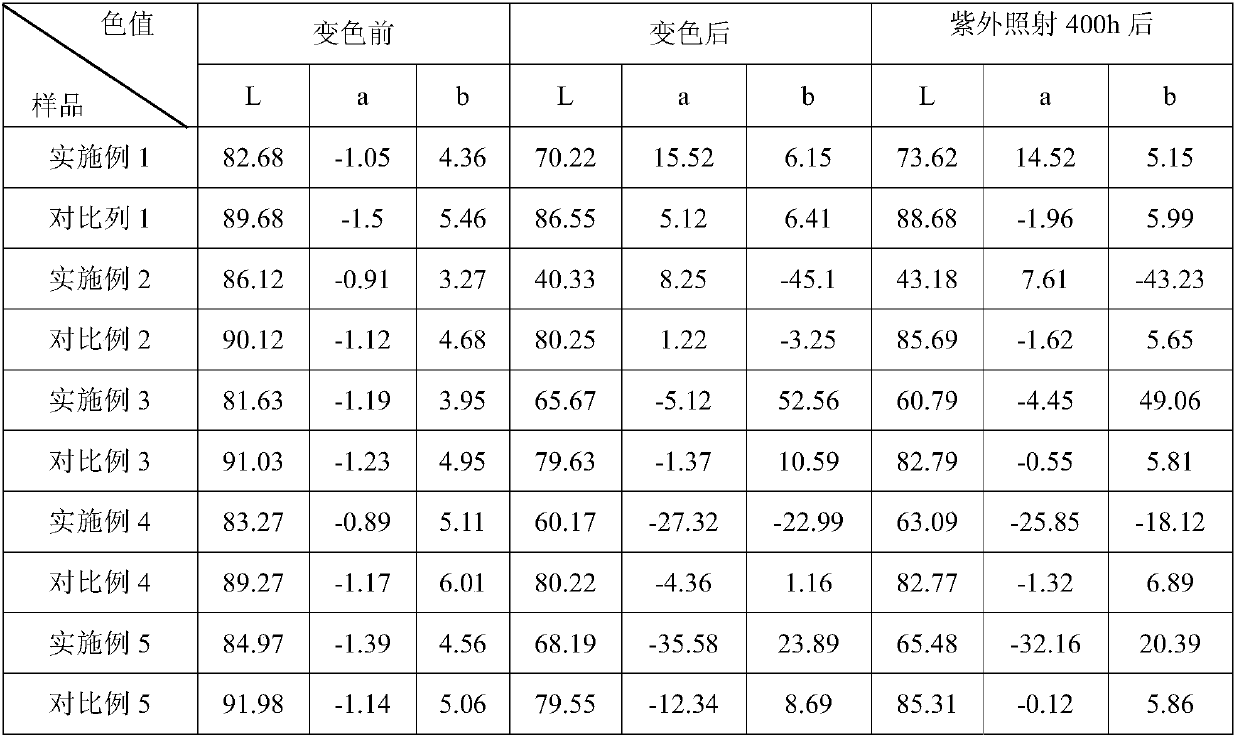

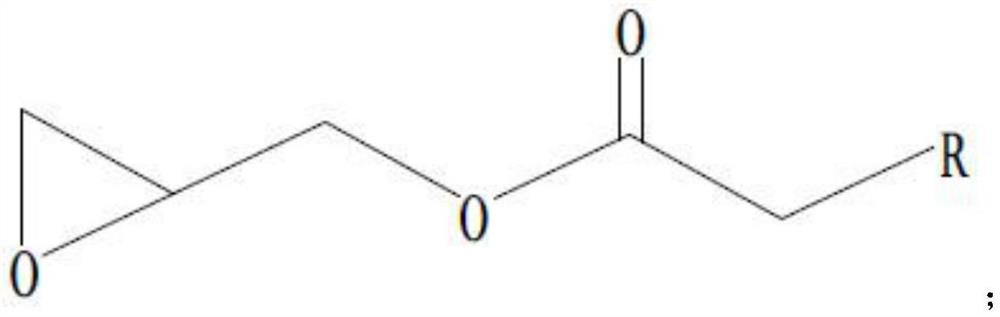

Photochromic low-melting-point polyester master batch and preparation method thereof

The invention discloses a photochromic low-melting-point polyester master batch and a preparation method thereof. The preparation method comprises the following steps: taking terephthalic acid, 1, 4-butanediol or ethylene glycol as raw materials, adding aliphatic dibasic acid, polyester diol and a monohydroxy end-capping reagent by adopting a direct esterification method, and carrying out esterification and polymerization reaction under the action of a catalyst so as to prepare the low-carboxyl-terminated PBT or PET modified copolyester with the melting point range of 140-190 DEG C; and fullycrushing the low-melting-point polyester PET or PBT slices, uniformly mixing with a photochromic material, a heat stabilizer, a light stabilizer and an antioxidant according to a certain ratio in a high-speed mixer, carrying out melt blending by using a double-screw extruder, bracing, and carrying out underwater granulation to obtain the photochromic low-melting-point polyester master batch. The photochromic low-melting-point polyester master batch is good in color-changing effect, good in stability and good in illumination durability, and can be applied to engineering plastics, films, fiber products, 3D printing materials and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

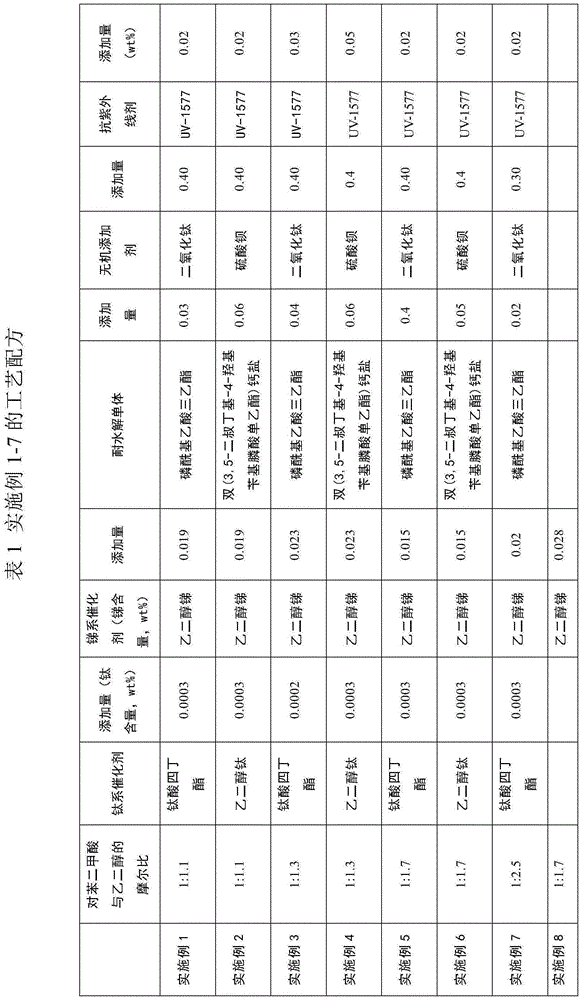

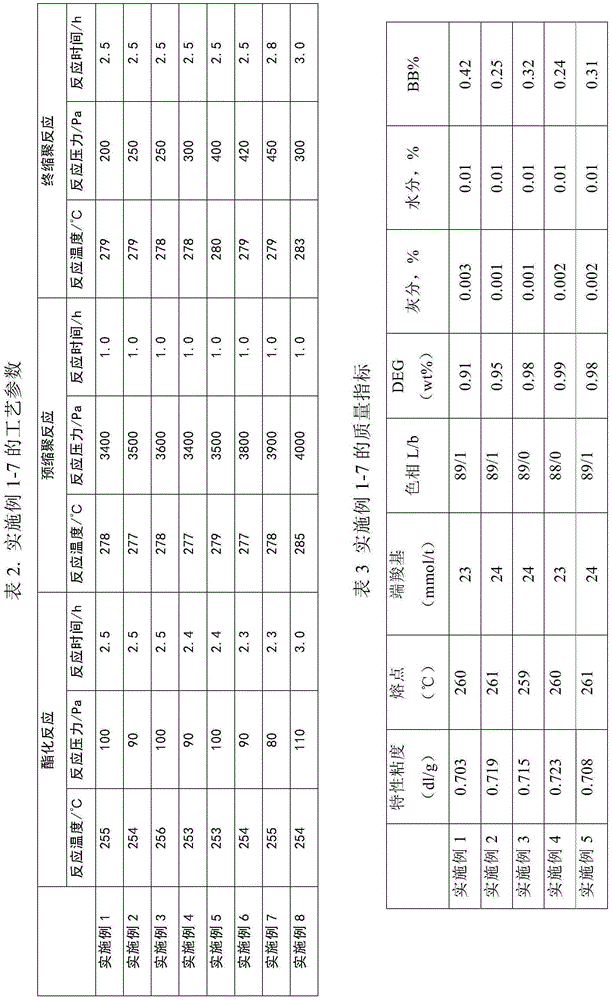

Polyester for hydrolysis-resistant high-speed-spun spunbonded non-woven fabric and synthesis method thereof

The invention discloses polyester for a hydrolysis-resistant high-speed-spun spunbonded non-woven fabric and a synthesis method thereof. The polyester for the hydrolysis-resistant high-speed-spun spunbonded non-woven fabric is prepared by PTA and EG low temperature esterification by using a Ti-Sb composite catalyst, adding a hydrolysis-resistant monomer and an inorganic additive for supplementing spun-bonding high-speed high-ratio stretching, and adding an anti UV agent for pre polycondensation and final polycondensation reaction, and the polyester for the hydrolysis-resistant high-speed-spun spunbonded non-woven fabric has the intrinsic viscosity of 0.68-0.72 dl / g, the end carboxyl group content of 28-34 mmol / t, the DEG content of less than 0.8%, the melting point of higher than 260 DEG C, the water content of less than 0.1%, the powder content of less than 0.01%, the ash content of less than 0.01% and the suitable spinning stretching speed of 5000-6000 m / min.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of branched biodegradable polyester

The invention belongs to the technical field of macromolecules, and particularly relates to a preparing method of branched biodegradable polyester. The preparing method includes the steps of conducting esterification reaction on dihydric alcohol, a branching aid, aromatic dibasic acid and aliphatic dibasic acid, adding a three-functional-group aziridine group compound after the reaction ends, andfinally conducting condensation polymerization to obtain the branched biodegradable polyester. The branched structure is introduced to polyester molecules sequentially through triethanolamine and thethree-functional-group aziridine group compound; meanwhile, since a tertiary amine structure is formed by triethanolamine and a secondary amine structure is formed by the three-functional-group aziridine group compound, a terminal carboxyl group can be restrained, and the content of the terminal carboxyl group of the material is remarkably reduced. The obtained branched biodegradable polyester ishigh in melt strength and excellent in anti-ageing performance, and the longitudinal and transverse difference between tensile strength and right-angle tearing strength is small.

Owner:惠通北工生物科技(北京)有限公司

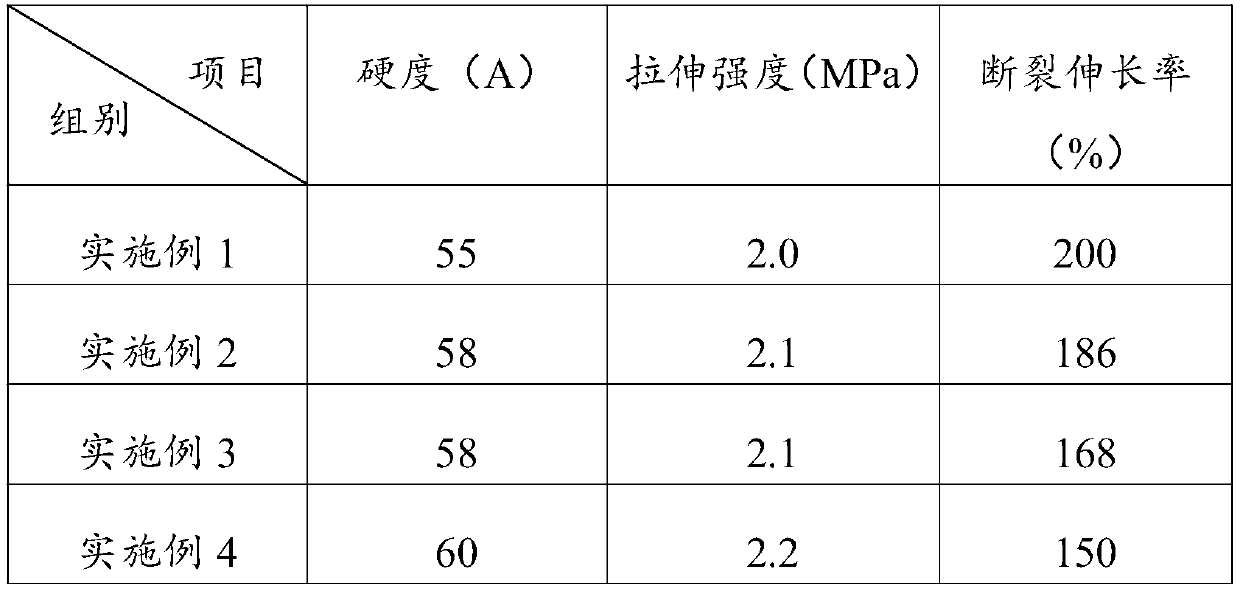

Manufacturing process of polyurethane prefabricated runway coiled material and obtained runway coiled material

The invention provides a manufacturing process of a polyurethane prefabricated runway coiled material. The manufacturing process comprises the following steps: firstly, paving a plastic film on a platform; then uniformly paving a polyurethane material on the plastic film; and carrying out high-temperature compounding on the two layers of materials to form the prefabricated runway coiled material.The manufacturing process is simple in process, short in production period and low in energy consumption. The manufacturing process is used for preparing polyurethane materials of the prefabricated runway coiled material. Polyether polyol and MDI are taken as main raw materials, the 3 ,3'-dichloro-4,4'-diaminodiphenylmethane is taken as a chain extender, and amino groups in the chain extender react with isocyanate end group prepolymer, so that the mechanical property of polyurethane is improved. By use of the white carbon black, the strength, the toughness, the heat resistance, the wear resistance and the aging resistance of the polyurethane can be improved. By use of the calcium carbonate, the mechanical property of the polyurethane is further enhanced. By use of the plasticizer, the processability of the polyurethane is improved. Pentaerythritol diphosphite distearyl ester is used as an antioxidant, so that the service life of polyurethane is prolonged. The prefabricated runway coiled material provided by the invention is high in safety performance and high in durability.

Owner:天津鼎兴橡塑有限公司

Method for synthesizing PBT polyester

The invention belongs to the technical field of polyester production, and particularly discloses a method. The method comprises the following steps: Step 1: preparation of a catalyst: firstly continuously stirring a hydroxycarboxylic acid, dropwise adding titanium alkoxide into the hydroxycarboxylic acid at the same time to carry out stirring reaction, adding an alkali solution, and controlling the pH to be less than or equal to 7, then allowing standing still to layer the solution to obtain lower supernate which is a hydrolysis-resistant titanium-based liquid catalyst, and taking out the lower supernate; Step 2: polyester synthesis: placing terephthalic acid and 1,4-butanediol in a reactor, catalyzing the terephthalic acid and the 1,4-butanediol by using the hydrolysis-resistant titanium-based liquid catalyst prepared in Step 1 for esterification for 60 to 240 min to synthesize a PBT oligomer, lowering the pressure of the PBT oligomer within 30 to 120 min to 1 to 100 Pa, adjusting thetemperature to 240 to 260 DEG C, and performing condensation for 60 to 300 min to synthesize the PBT polyester. The catalyst preparation process used in the method is simple, and no hydrolytic precipitations are produced in the synthesis process; furthermore, the titanium-based liquid catalyst is uniform and high in flowability.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

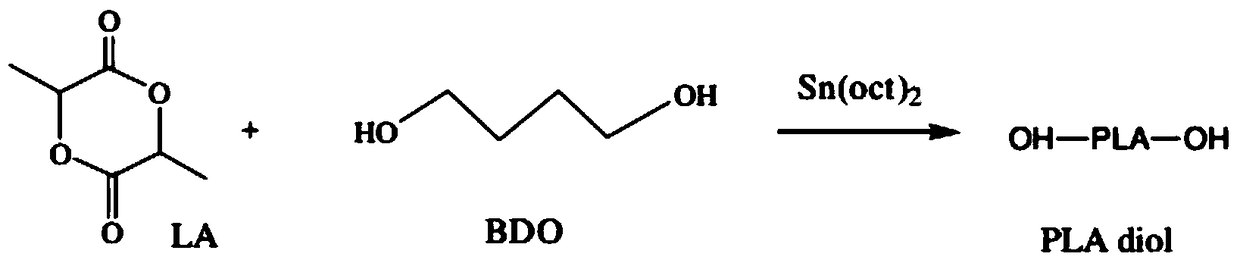

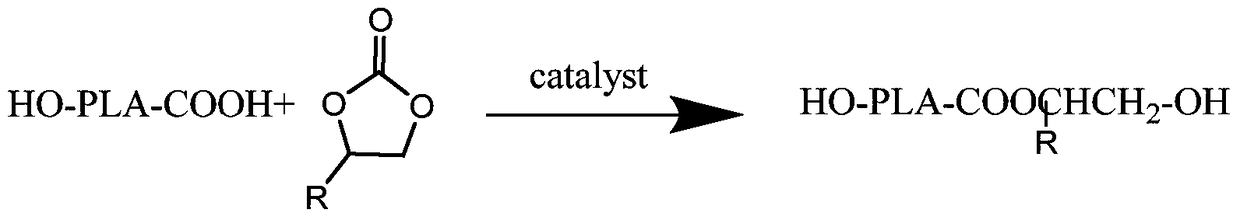

A kind of preparation method of polylactic acid polyol with low acid value

Owner:SHENZHEN ESUN IND +1

Preparation method of durable polybutylene succinate

The invention belongs to the technical field of macromolecules, and particularly relates to a preparation method of durable polybutylene succinate. The preparation method comprises the following stepsof utilizing a compounded homogeneous catalyst firstly to catalyze1,4-butanediol and succinic acid to polymerize, and then extruding to obtain the durable polybutylene succinate; during extrusion, injecting a compound, which contains aziridine groups, into polybutylene succinate melt so as to be used for end-capping. The terminal carboxyl group content of the durable polybutylene succinate prepared by the invention is as low as less than or equal to 15mmol / kg, and the durability and heat stability of the durable polybutylene succinate are greatly improved.

Owner:庞买只

Low carboxyl biodegradable polyester and its production method

The invention relates to the technical field of polyester high-molecular materials, and particularly relates to a low-carboxylated biodegradable polyester and a production method thereof. The low-carboxylated biodegradable polyester comprises1,6-adipic acid or / and terephthalic acid and 1,4-butanediol. According to the preparation method of the low-carboxylated biodegradable polyester, the content of carboxyl end groups in the polyester can be furthest reduced by adopting a compound titanium catalyst and a carboxyl scavenger to produce condensation polymerization in the later period of esterification; the catalytic activity of titanium catalyst can be controlled by adding chelate with stabilizing effect, so as to avoid the side degradation reaction caused by the high activity of the catalyst in the later period of condensation reaction and furthest reduce the side reaction in the later period of the condensation reaction, so that the low-carboxylated level of the finished polyester product can be guaranteed, other additives are not additionally needed for modifying the product, the content of carboxyl end groups in the product can be reduced, and the high production cost of the product can be avoided.

Owner:新疆维格瑞生物科技有限公司

Preparation method of ultraviolet-resistant and damp-heat aging-resistant copolyester

ActiveCN113583221AImproves UV resistanceImprove water vapor barrier performanceBio-packagingPhotovoltaic energy generationPolycyclic aromatic hydrocarbonCopolyester

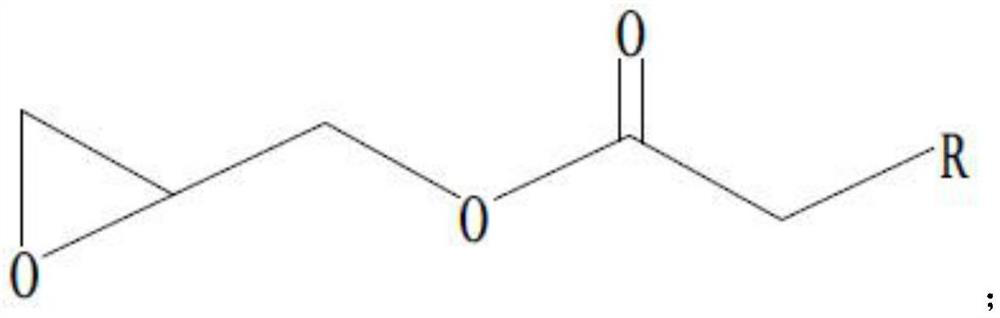

A preparation method of ultraviolet-resistant and damp-heat-aging-resistant copolyester is characterized in that the copolyester is prepared by controlling the charging ratio of polycyclic aromatic hydrocarbon derivative monomers to dibasic acid to dihydric alcohol to perform esterification and polycondensation and then performing end capping through monofunctional epoxy substances, and the end capping step is performed at the end of the polycondensation reaction. Compared with the prior art, the preparation method has the advantages of ultraviolet resistance, damp-heat aging resistance, water vapor barrier property and dimensional stability.

Owner:浙江凯普奇新材料科技有限公司

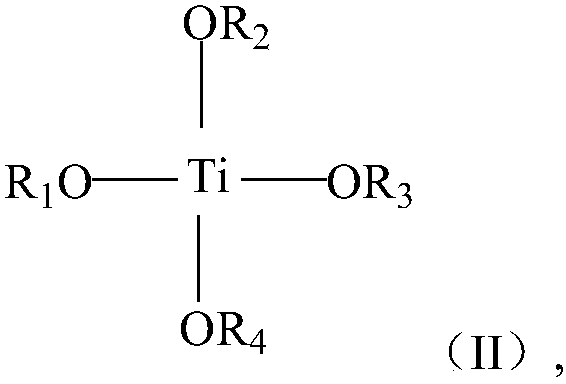

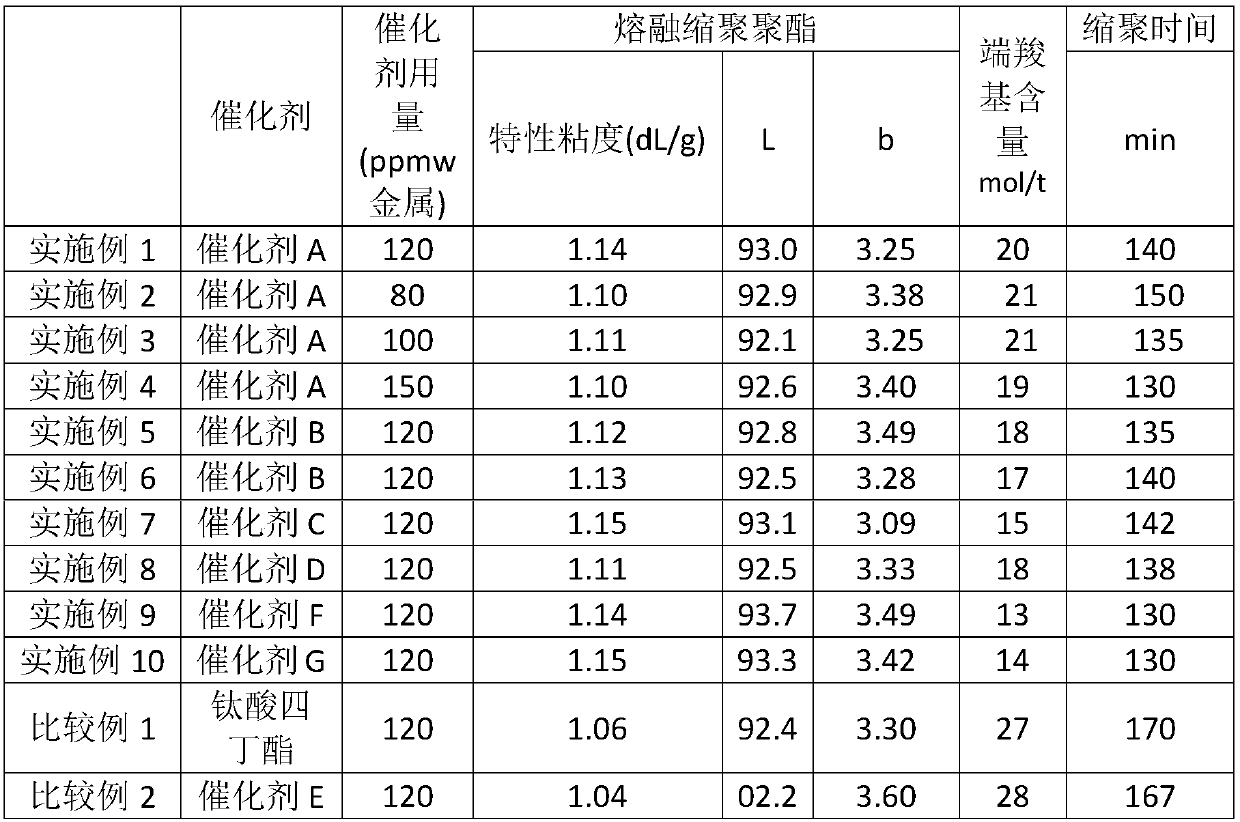

Preparation method of low terminal carboxyl PBT resin

ActiveCN111087583AReduce carboxyl end contentQuick responsePolytetramethylene terephthalateOrganic acid

The invention relates to a preparation method of low terminal carboxyl PBT resin. In the prior art, the terminal carboxyl group is not easy to control during the PBT polymerization process, the viscosity of slices is reduced, the color becomes yellow, and thus the quality of PBT resin is influenced. The preparation method of the low terminal carboxyl PBT resin is adopted, and a catalyst obtained after reaction of the following raw materials is adopted to prepare the low terminal carboxyl PBT resin: (1) a titanium compound Ti(OR)4 with a general formula shown in the specification; (2) diol B having 2 to 10 carbon atoms; (3) a metal compound C selected from the periodic table IIA of elements; and (4) at least one aliphatic organic acid D. Refined terephthalic acid and 1,4-butanediol are taken as raw materials, the catalyst is added to carry out reactions to obtain the low terminal carboxyl PBT (polybutylene terephthalate) resin, the problems mentioned above are solved, and the preparation method can be applied to industrial production of PBT.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of modified PET copolyester and its preparation method and application

The invention belongs to the technical field of polyester preparation, and discloses a modified PET copolyester with high viscosity and a low terminal carboxyl group and a preparation method and application thereof. The copolyester contains the following ingredients in parts by weight: 100 parts of low-viscosity PET copolyester, 0.8-2.0 parts of oxazoline compound and 0.6-2.0 parts of a hydroxyl chain extender. The method prepares the high-viscosity modified PET copolyester by adding the oxazoline compound and the hydroxyl chain extender. The oxazoline compound is added to react with the terminal carboxyl group in resin, the terminal carboxyl group content of resin is reduced, therefore, the hot water resisting performance of resin is increased. The hydroxyl chain extender is added, the molecular weight of resin is increased, and the balance between a physical performance and a processing performance is achieved. The viscosity and the melt strength of the modified PET copolyester are increased, the content of terminal carboxyl group is reduced, and the hot water resisting performance is greatly increased. Moreover, the production method shortens the polycondensation time and the production cycle, effectively reduces the thermal degradation reaction, and also increases the output of equipment.

Owner:KINGFA SCI & TECH CO LTD

Composite esterification and polycondensation catalyst for preparing poly trimethylene terephthalate

InactiveCN1272360CReduce carboxyl end contentLow ether contentPolyethylene terephthalatePolymer science

The invention discloses a composite esterification and polycondensation catalyst for preparing poly trimethylene terephthalate, wherein the composite catalyst is a composition containing titanium dioxide, silicon dioxide and molybdenum trioxide. The prepared PTT product has very low end carboxyl content, ether content and rather high characteristic viscosity.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

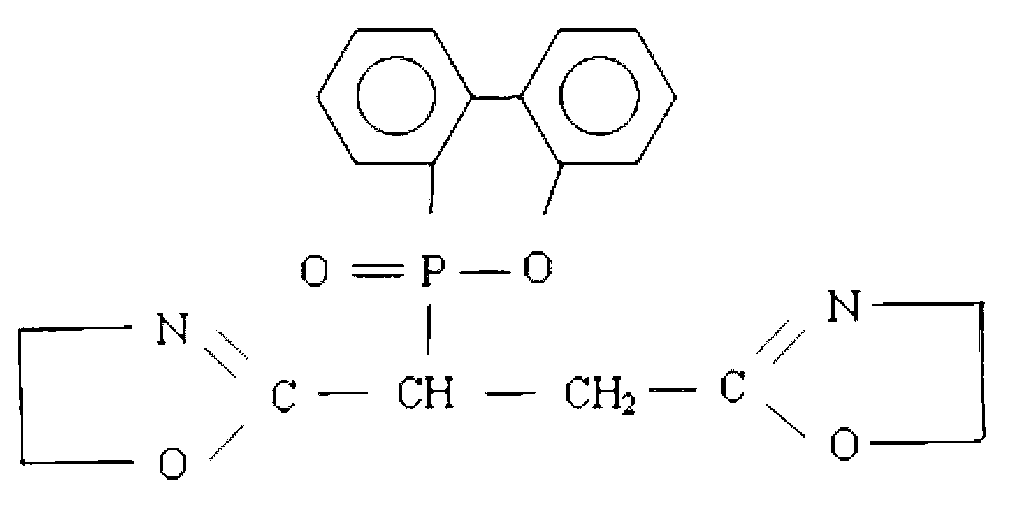

Phosphorus-containing flame retardant, flame-retarding polyester thin film and preparation methods thereof

ActiveCN102634064BAdd lessReduce carboxyl end contentGroup 5/15 element organic compoundsPolyesterPolymer science

The invention relates to the technical field of flame-retarding polyester thin film, and particularly relates to a phosphorus-containing flame retardant, a flame-retarding thin film and preparation methods thereof. In order to solve the problems of large flame retardant adding amount, low compatibility with a thin film substrate and unstable mechanical performance, the invention provides the phosphorus-containing flame retardant, the flame-retarding thin film and preparation methods thereof. The phosphorus-containing flame retardant has the following structural formula as shown in the specification, wherein the flame retardant has an oxazoline structure; R1 is alkylidene; and the number of C atoms is 2-6. The phosphorus-containing flame retardant has functions of expanding the chain and improving the viscosity of polyester molecules; and the flame-retarding polyester thin film with the flame retardant has high flame-retarding performance, relatively high mechanical property, high heat stability and higher light transmittance. The preparation methods are easy to operate and simple.

Owner:NINGBO CHANGYANG TECH

Low-precipitation matte polyester chip for laminating flexible circuit board and preparation method of low-precipitation matte polyester chip

PendingCN114195990AHigh intrinsic viscosityAvoid pollutionBulk chemical productionPolyesterPolymer science

The invention discloses a low-precipitation matte polyester chip for laminating a flexible circuit board and a preparation method of the low-precipitation matte polyester chip, which comprises the following steps: (1) increasing the molecular weight of PET (polyethylene terephthalate) and increasing the intrinsic viscosity by expanding a molecular chain to prepare a low-precipitation PET matte polyester chip; (2) raw materials are extracted by adopting supercritical CO2 fluid, oligomers and residues in the preparation process are removed, and environmental pollution is avoided by adopting an environment-friendly extraction and purification mode. According to the low-precipitation matte polyester chip disclosed by the invention, a chain extension and tackifying manner is adopted, so that the phenomenon of precipitation of a common matte polyester film in a long-time high-temperature working environment of high-temperature lamination of a flexible circuit board is overcome. By adopting a CO2 fluid extraction mode, the purity of the raw materials is further improved, and oligomers and other impurities are reduced.

Owner:TIANJIN WANHUA CO LTD

Liquid-phase titanium composite catalyst and preparation method and application of liquid-phase titanium composite catalyst in preparation of polyester compound

The invention discloses a liquid-phase titanium composite catalyst and a preparation method and application of the liquid-phase titanium composite catalyst in preparation of polyester compounds. The invention belongs to the technical field of preparation of titanium catalysts. The catalyst is prepared by mixing the following components in percentage by mass: 2-10% of a titanium compound, 0.5-2% ofa ruthenium compound, 5-25% of a polyether polyol compound, 2.5-13% of ethylene glycol and 50-90% of ethanol. In the polyester polymerization process, the addition amount of the catalyst is one thousandth to five thousandths of the mass of the carboxylic acid monomer based on the titanium compound. The liquid-phase composite catalyst prepared by the invention is a compound mainly formed by mixinga titanium compound, a ruthenium compound, a polyether polyol compound, ethylene glycol and ethanol, and has the advantages of high catalytic rate, high activity, low residual carboxyl-terminated content, good product hue and the like compared with the existing polyester catalyst.

Owner:JINLIN MEDICAL COLLEGE

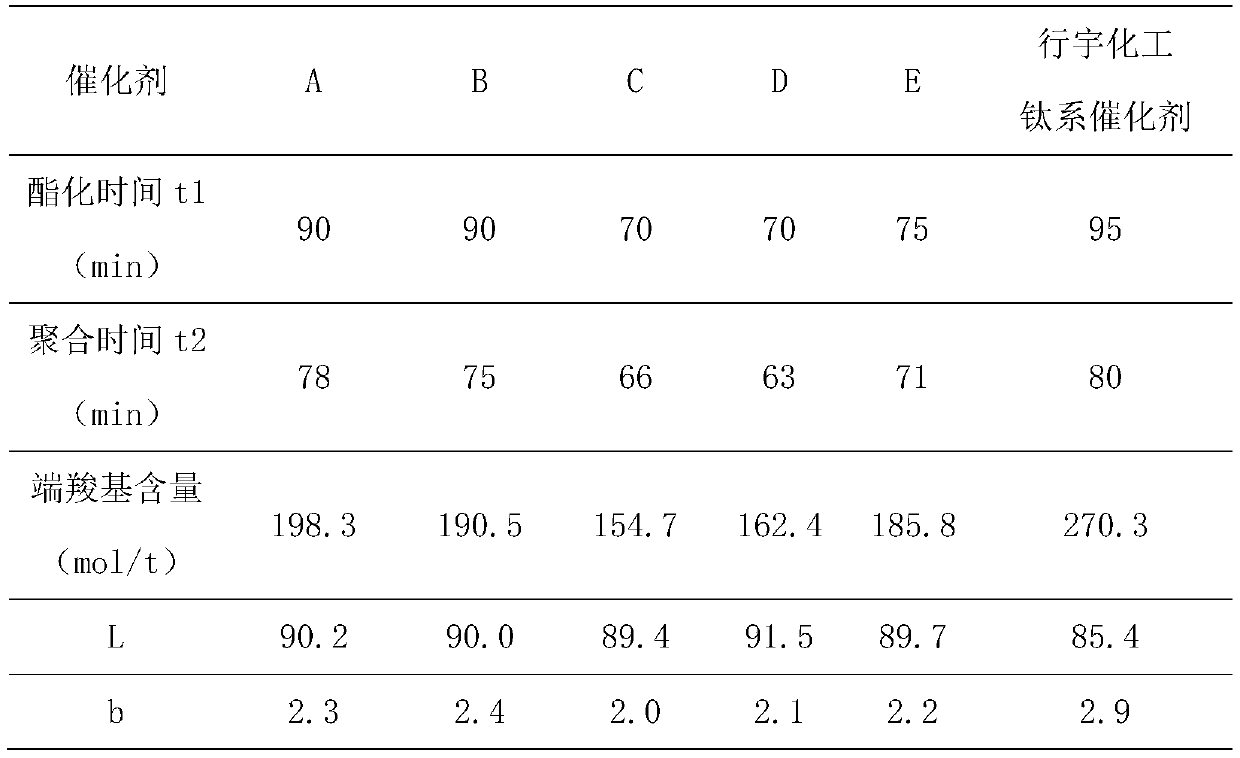

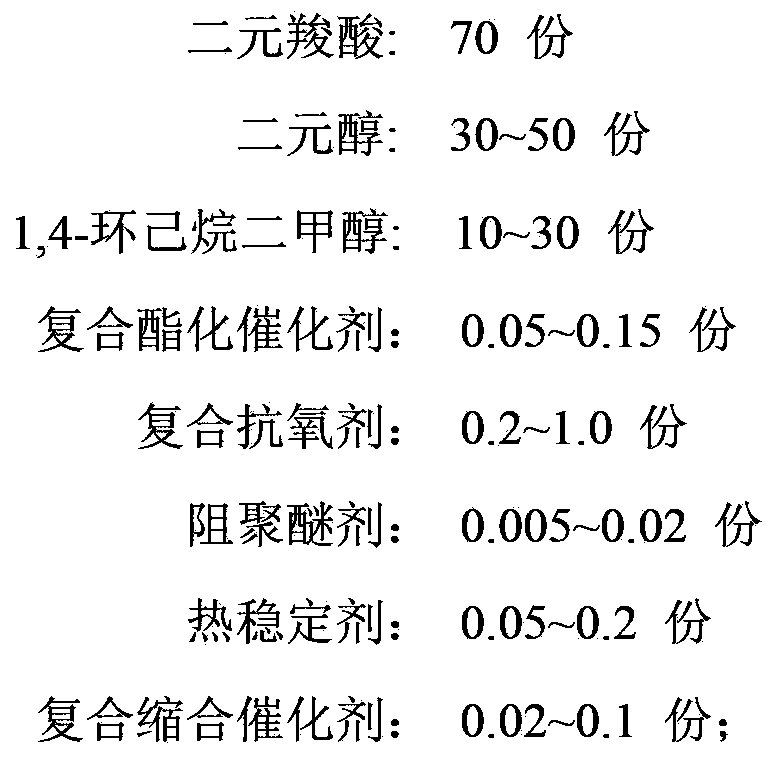

Polymerizing production method for transparent amorphous copolyester

The invention discloses a polymerizing production method for transparent amorphous copolyester. The method has the advantages of low esterification temperature, short esterification time and high esterification rate. The method comprises the following steps of: carrying out an esterification reaction and a condensation reaction on dihydric alcohol and dicarboxylic acid to obtain the transparent amorphous copolyester, wherein the esterification reaction comprises the following specific procedures of: breaking various materials into pulp by using a pulping machine and carrying out the esterification reaction on the pulp at the temperature of 220-240DEG C for 1.0-1.5 hours to obtain an esterified product; the condensation reaction comprises the following specific procedures of: polymerizing the esterified product obtained by the esterification reaction at the reaction pressure of 0.2-0.5MPa and the temperature of 250-260DEG C for 1.5-2 hours; then reducing the pressure to be less than 200MPa within 0.5 hour; raising the condensation reaction temperature to be 275DEG C from 260DEG C; adding a thermal stabilizer; and after the condensation reaction, obtaining a polyester copolymer with the inherent viscosity of greater than 0.75dL / g and the carboxyl content of less than 10mol / t.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

High-performance flame-retardant reinforced hydrolysis-resistant PBT (polybutylene terephthalate) material and preparation method thereof

InactiveCN103525030AReduce carboxyl end contentImprove hydrolysis resistanceGlass fiberPolyethylene terephthalate

The invention discloses a high-performance flame-retardant reinforced hydrolysis-resistant PBT (polybutylene terephthalate) material and a preparation method thereof. The high-performance flame-retardant reinforced hydrolysis-resistant PBT material comprises the following components in percentage by mass: 45-60% of PBT, 5-10% of flame retardant, 1-10% of antimony trioxide, 20-35% of glass fiber, 0.2-1.5% of coupling agent, 0.1-2% of chain extender, 0.2-0.5% of antioxidant, 0.5-5% of toughener and 0.3-1% of lubrication dispersing agent. According to the invention, on the basis of performing glass fiber reinforced flame retardance on the PBT material, a proper amount of chain extender is added, thus greatly reducing the terminal carboxyl content of the PBT, and enhancing the hydrolysis resistance, compatibility and toughening and reinforcing performance of the PBT. The preparation method provided by the invention adopts a secondary extrusion process, and the PBT material meeting flame-retardant and hydrolysis-resistant requirements and having excellent comprehensive performance can be obtained; and the preparation process is simple and easy to operate.

Owner:QINGDAO XINZHAN PLASTIC

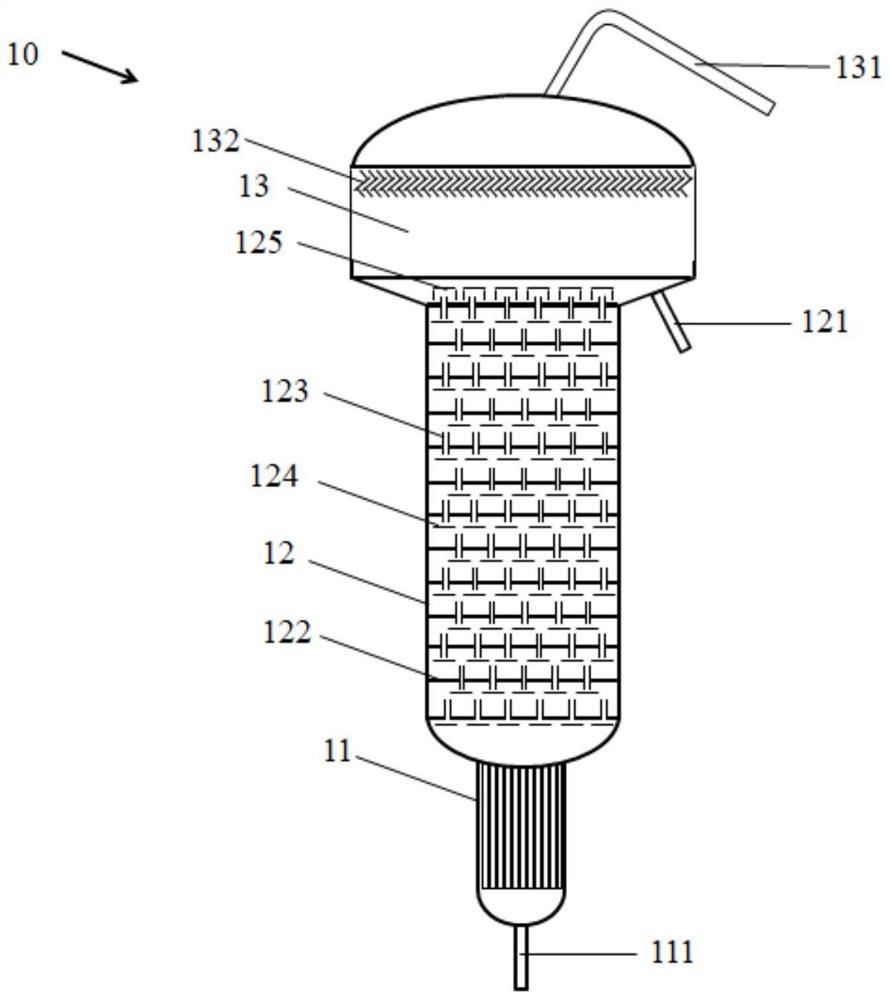

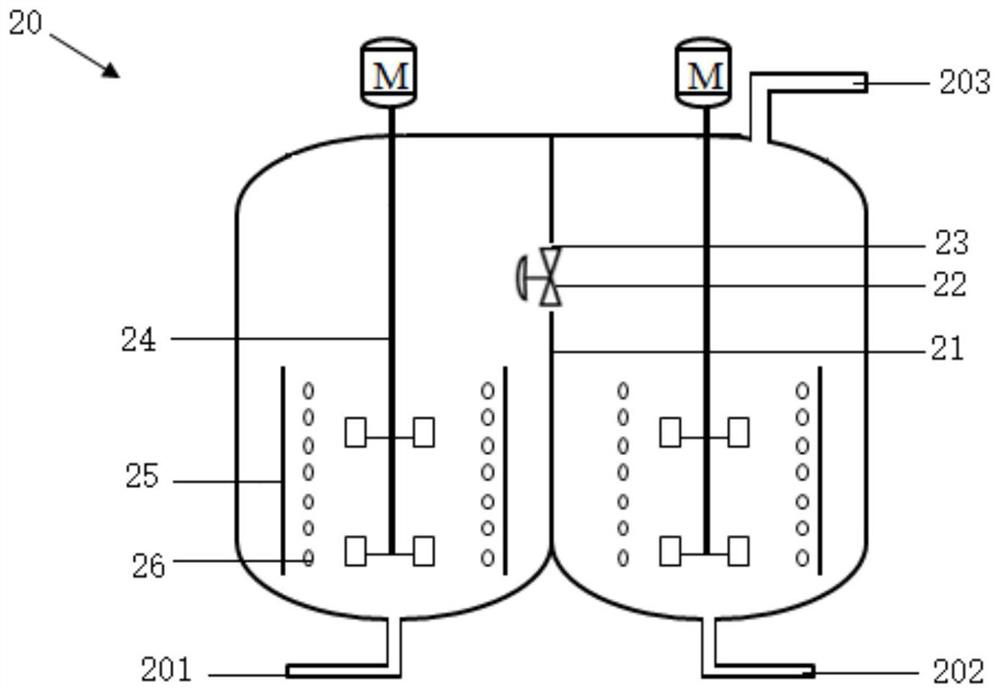

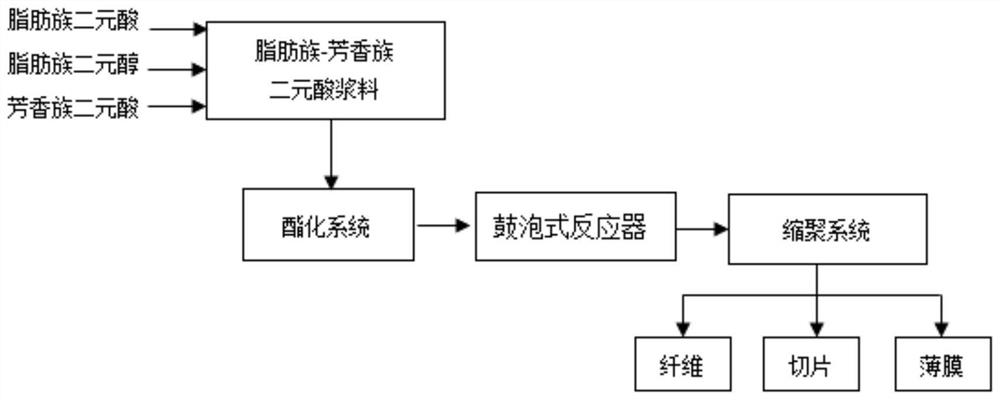

Preparation system and preparation method of biodegradable copolyester and copolyester thereof

ActiveCN112794996AEfficient DepthEfficient melt polycondensationBio-packagingChemical/physical/physico-chemical stationary reactorsPolymer scienceCopolyester

The invention discloses a preparation system and a preparation method of biodegradable copolyester and the copolyester thereof. The preparation system comprises an esterification system and a polycondensation system which are connected in sequence, and a bubbling type reactor is further arranged between the esterification system and the polycondensation system. Materials flowing out of the esterification system are subjected to deep esterification and pre-polycondensation through the bubbling type reactor and then are fed into the polycondensation system. According to the preparation system of the biodegradable copolyester, the simultaneous occurrence of efficient deep esterification and melt polycondensation of aliphatic-aromatic copolyester ester is realized, and the esterification time of aliphatic-aromatic binary acid slurry is greatly shortened; the aliphatic-aromatic copolyester prepolymer meeting the requirements of a subsequent final polycondensation reaction is prepared; the aliphatic-aromatic copolyester continuously produced by using the system has the characteristics of good biodegradability, low terminal carboxyl group content and good hue.

Owner:CHINESE TEXTILE ACAD

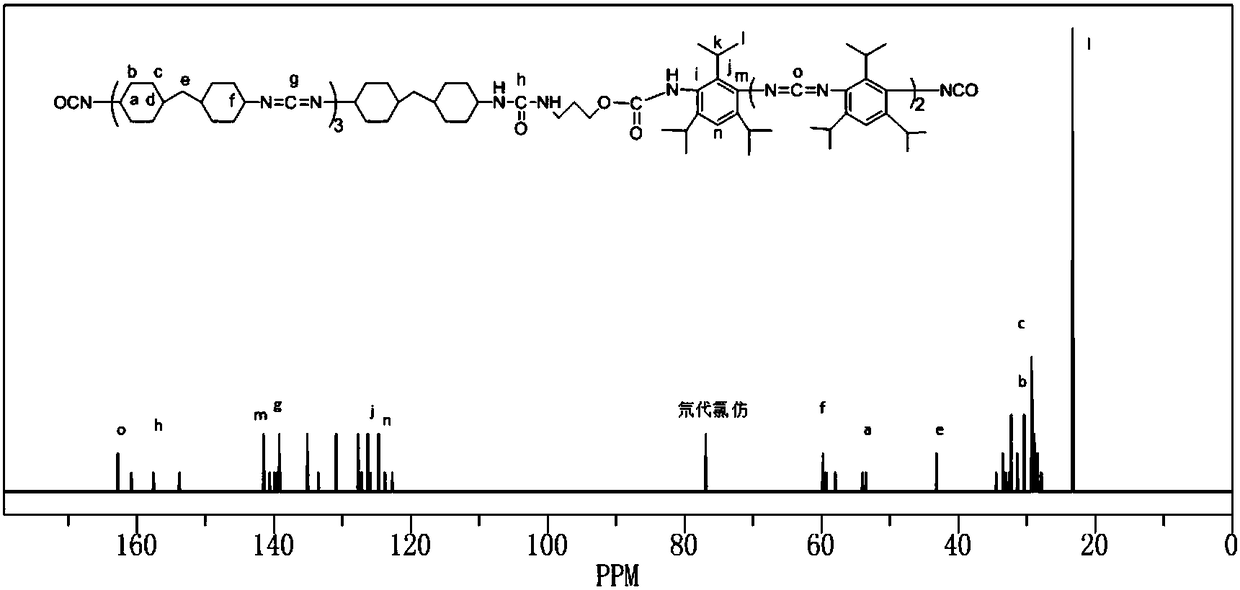

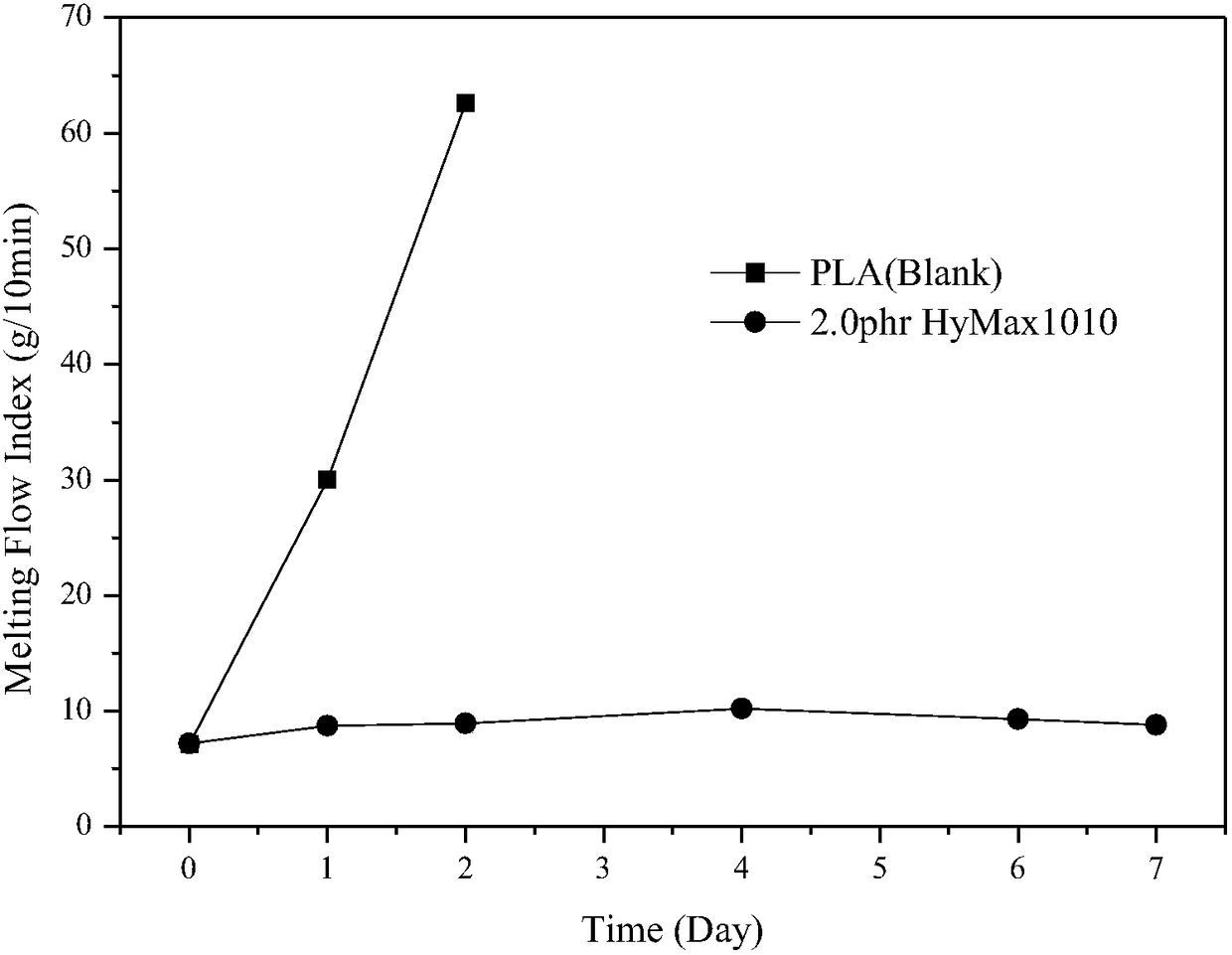

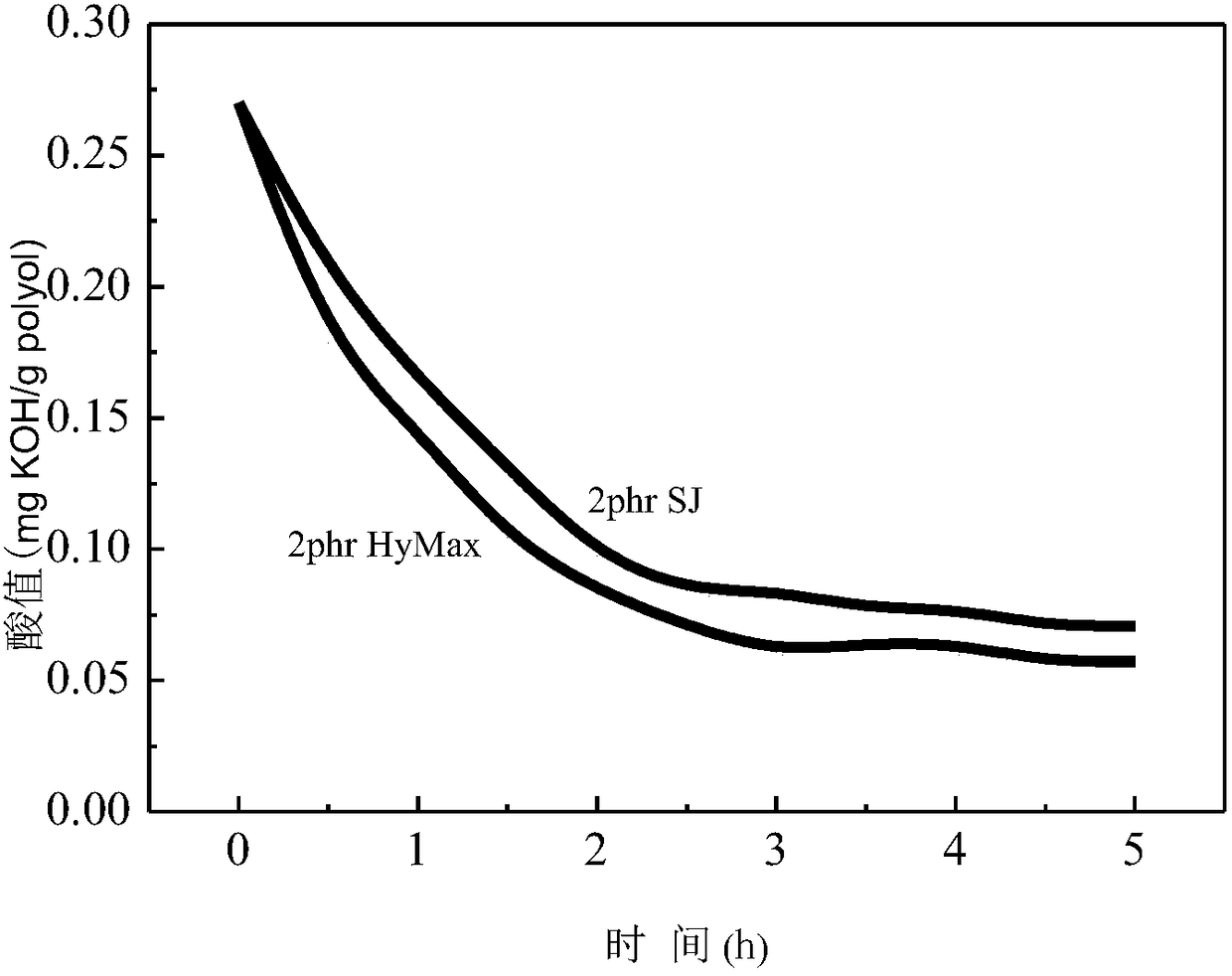

Block-copolymerized carbodiimide compound and preparation method thereof

InactiveCN108084056AGuaranteed long-lasting resistance to hydrolysisReduce carboxyl end contentOrganic chemistryDiaminePolyamide

The invention relates to a block-copolymerized carbodiimide compound. The block-copolymerized carbodiimide compound has the structural formula as shown in the description, and is prepared by a condensation polymerization between an aromatic carbonized diamine oligomer and an aliphatic or alicyclic carbodiimide oligomer. The obtained block-copolymerized carbodiimide compound can serve as a hydrolysis-resistant stabilizer, a chain extender and a processing aid to be used for polyester and polyamide compounds, particularly special polyester materials for thin films in the photovoltaic industry, bio-degradable materials for mulching films, automobile polyamide materials and the like, can effectively prevent polyester materials from hydrolysis, and compared with traditional haplotype and aggregate-type carbodiimide, can not only guarantee the material performance under hot and humid conditions but also greatly inhibit plastics from being degraded during processing.

Owner:SHANGHAI LANGYI FUNCTIONAL MATERIALS

Preparation method of high molecular weight polybutylene adipate-terephthalate

The invention belongs to the technology in the preparation field of completely biodegradable fat-aromatic copolyester and in particular relates to a preparation method of polyadipic acid-butylene terephthalate with high molecular weight. The preparation method comprises the following steps of: adding butanediol, adipic acid and terephthalic acid into a reactor; adding a composite catalyst to the reactor for carrying out esterification reaction; and carrying out polycondensation to obtain a product, wherein the composite catalyst is a mixture of metal oxide and titanium organic esters, and the metal oxide is at least one of oxides of Li, Na, K, Mg, Al, Ca, Mn and Co. The composite catalyst is adopted, so that the catalytic efficiency is high, the polymerization reaction velocity is greatly increased and the cost of the product is technically reduced. A stabilizer is added during the polycondensation stage, so that the high-temperature degradation side reaction is reduced, the molecular weight of the polymer is improved, the product color phase is improved, the terminal carboxyl content of the polymer is effectively reduced, the post-processing heat resistant performance of the product is improved, and the using value is greater.

Owner:山东悦泰生物新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com