Low-precipitation matte polyester chip for laminating flexible circuit board and preparation method of low-precipitation matte polyester chip

A technology for flexible circuit boards and polyester chips, applied in the field of polyester chips, can solve the problems of reduced mechanical and chemical properties of polymers, pollution of polyester film film surface, and increase in the number of terminal carboxyl groups, etc., to achieve high insulation, improve Intrinsic viscosity of raw materials and the effect of increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

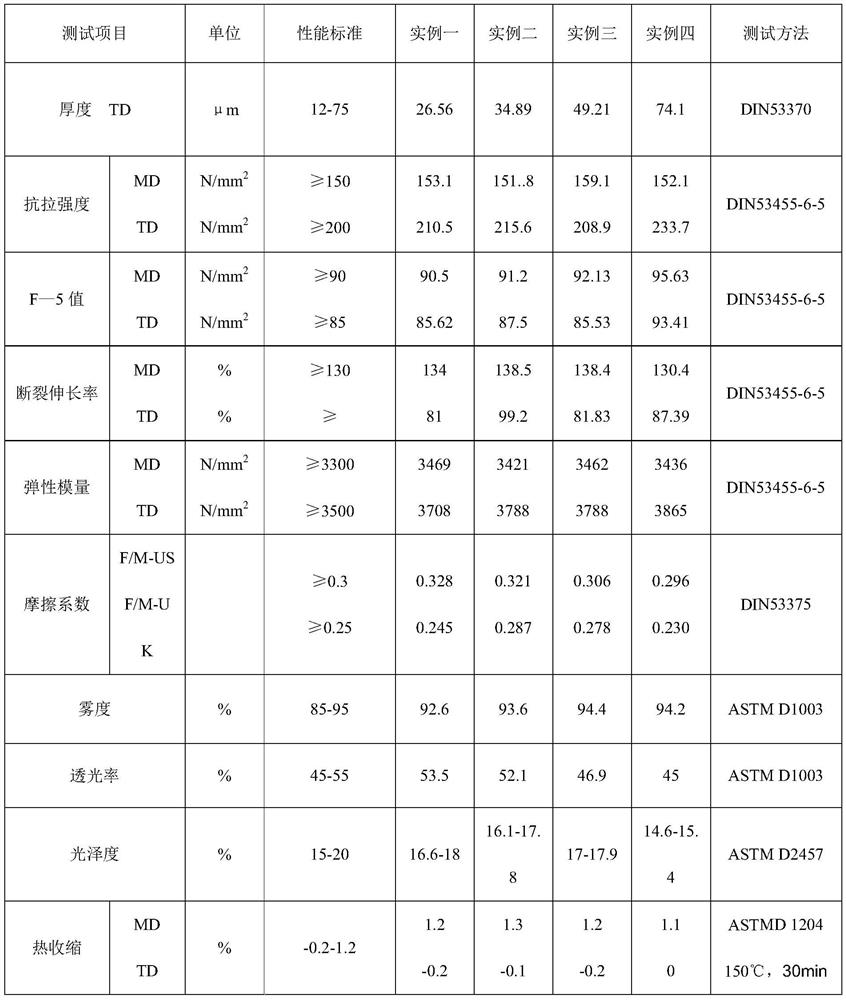

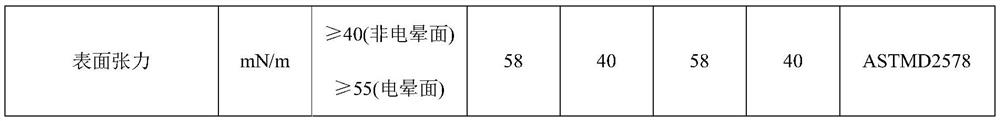

Examples

preparation example Construction

[0017] The preparation method of the low-separation matt polyester chips used for lamination of flexible circuit boards of the present invention comprises the following steps:

[0018] (1) Mix ethylene glycol and catalyst evenly and add to the reactor for pre-esterification reaction at a temperature of 175-188°C and a pre-esterification time of 3-5 hours;

[0019] (2) Add the feed liquid and terephthalic acid after the pre-esterification reaction to a stirrer and stir evenly into the reactor, feed nitrogen gas, turn on the circulating water, and carry out the esterification reaction. The esterification temperature is controlled at 265-280°C, The curing time is 5~7h;

[0020] (3) After the esterification reaction is finished, start vacuuming, and carry out the precondensation reaction at a pressure of 2500 to 3500Pa and a temperature of 275 to 285°C for 1.5 to 3 hours;

[0021] (4) At a temperature of 280-320°C and a vacuum pressure of 45-85Pa, the chain extender PMDA is added...

Embodiment 1

[0028] A kind of production method of low precipitation matte polyester chips, described low precipitation matt polyester chip preparation steps are as follows:

[0029] (1) Mix ethylene glycol and catalyst ethylene glycol antimony and add them evenly into the reactor for pre-esterification reaction at a temperature of 175-188°C and a pre-esterification time of 3-5 hours;

[0030] (2) Add the feed liquid and terephthalic acid after the pre-esterification reaction to a stirrer and stir evenly into the reactor, feed nitrogen gas, turn on the circulating water, and carry out the esterification reaction. The esterification temperature is controlled at 265-280°C, The curing time is 5~7h;

[0031] (3) After the esterification reaction is finished, start vacuuming, and carry out the precondensation reaction at a pressure of 2500 to 3500Pa and a temperature of 275 to 285°C for 1.5 to 3 hours;

[0032] (4) Add the chain extender pyromellitic dianhydride (PMDA) at a temperature of 280-...

Embodiment 2

[0036] A kind of production method of low precipitation matte polyester chips, described low precipitation matt polyester chip preparation steps are as follows:

[0037] (1) Mix ethylene glycol and catalyst ethylene glycol antimony and add them evenly into the reactor for pre-esterification reaction at a temperature of 175-188°C and a pre-esterification time of 3-5 hours;

[0038] (2) Add the feed liquid and terephthalic acid after the pre-esterification reaction to a stirrer and stir evenly into the reactor, feed nitrogen gas, turn on the circulating water, and carry out the esterification reaction. The esterification temperature is controlled at 265-280°C, The curing time is 5~7h;

[0039] (3) After the esterification reaction is finished, start vacuuming, and carry out the precondensation reaction at a pressure of 2500 to 3500Pa and a temperature of 275 to 285°C for 1.5 to 3 hours;

[0040] (4) Add the chain extender pyromellitic dianhydride (PMDA) at a temperature of 280-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com