Polyester for hydrolysis-resistant high-speed-spun spunbonded non-woven fabric and synthesis method thereof

A synthesis method and non-woven fabric technology are applied in the field of polyester for hydrolysis-resistant high-speed spunbond non-woven fabric and its synthesis, which can solve the problem of easy hydrolysis of polyester, reduce the content of terminal carboxyl groups, increase viscosity, and increase fiber powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

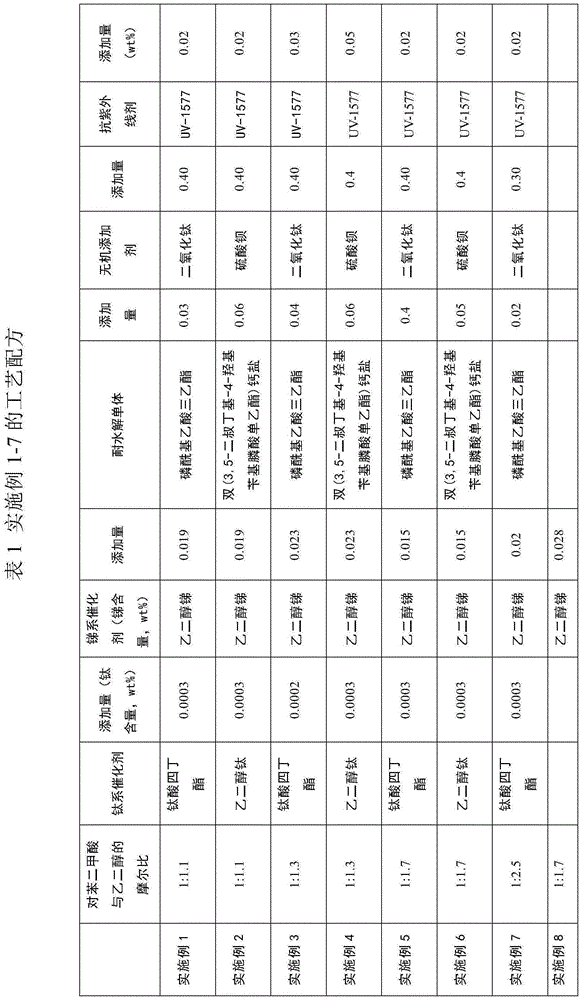

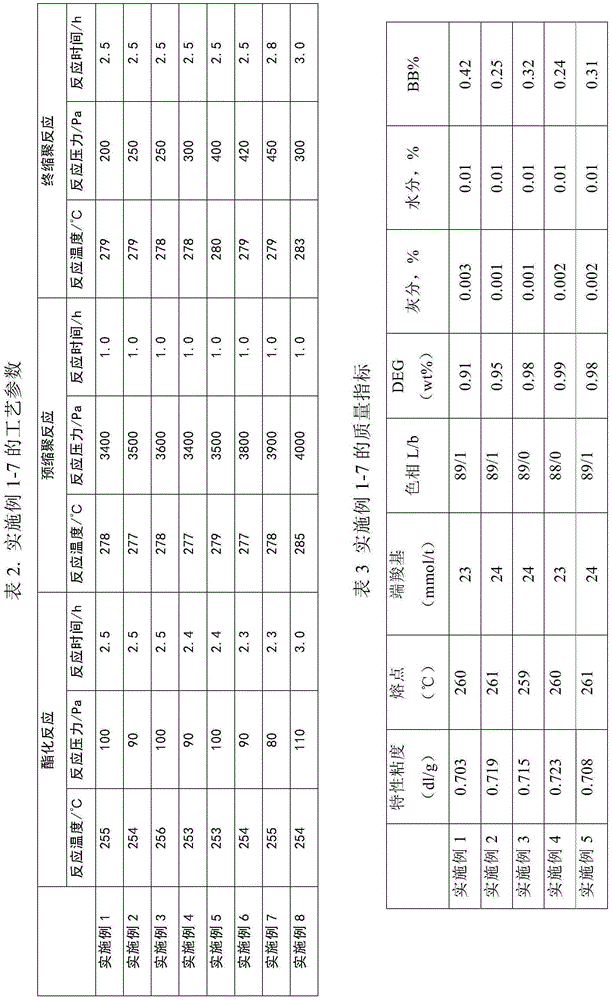

Embodiment 1-8

[0026] Add terephthalic acid and ethylene glycol in proportion to the slurry mixing tank with stirring, after the titanium-based catalyst (titanium glycolate) enters the preparation area, add ethylene glycol to dilute the catalyst concentration to 0.04wt% , after being prepared, it is transported to the slurry blending tank to participate in the slurry preparation, and after being metered through the slurry supply tank, it is quantitatively and continuously sent to the horizontal belt stirring esterification reaction kettle with a gauge pressure of 0.08-0.12MPa and a temperature of 230 Stir at -265°C for esterification to produce the intermediate bishydroxyethyl terephthalate, react until the esterification rate is at least 92%, the water generated during the esterification process is distilled out with ethylene glycol, and the water is separated through the fractionating tower Finally, 99 wt% of ethylene glycol is refluxed in the kettle, and the residence time of the esterific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com