Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce broken belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

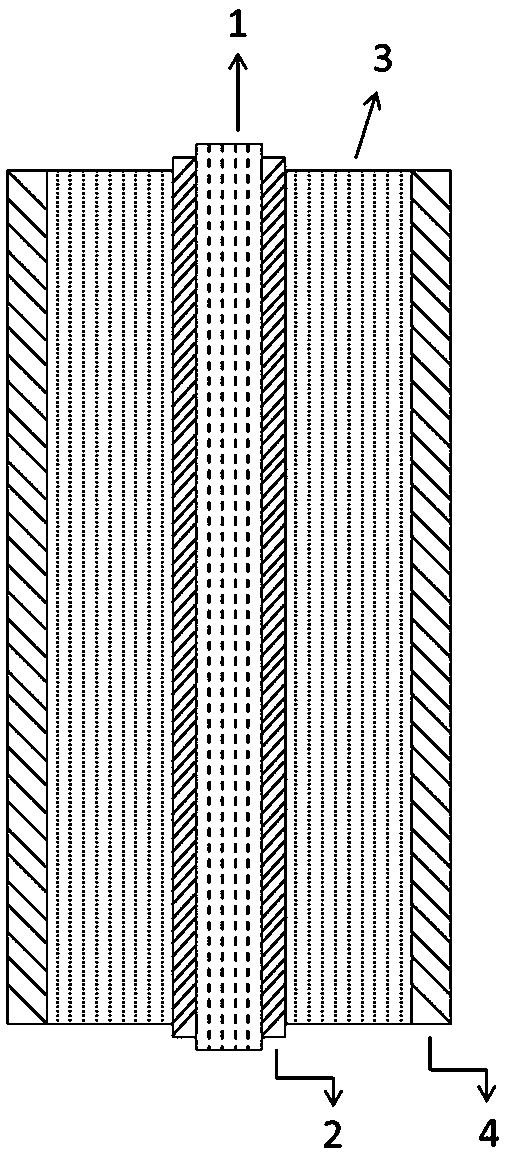

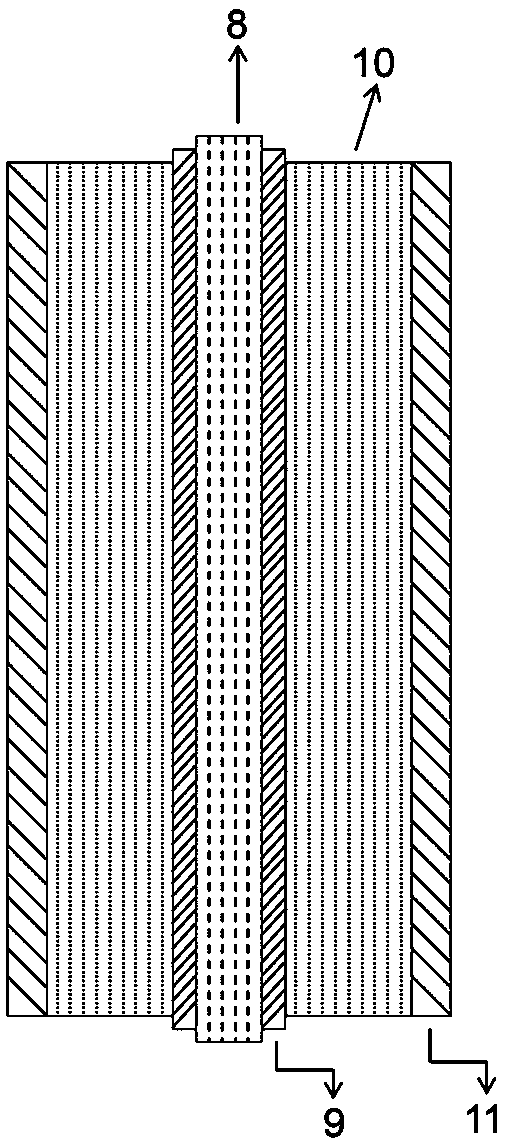

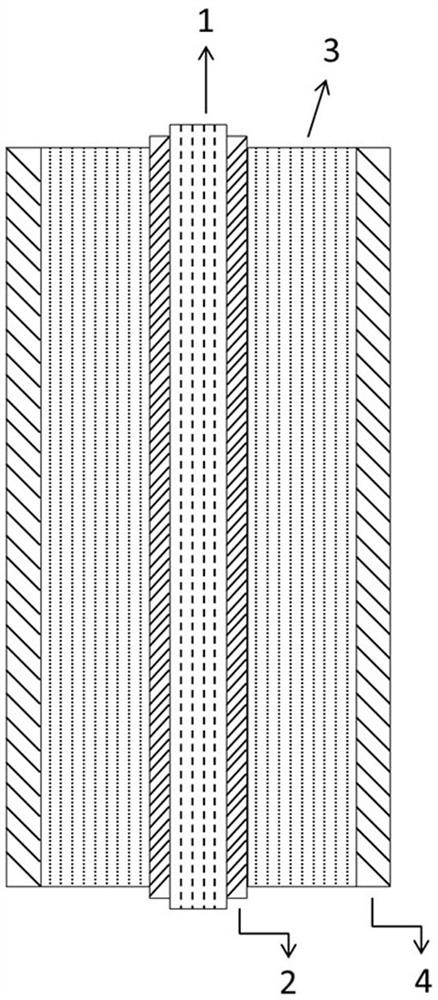

Composite current collector, preparation method thereof and lithium battery pole piece

InactiveCN111883777AImprove physical and chemical propertiesReduce weightElectrode carriers/collectorsSecondary cellsInternal resistancePolymer chemistry

The invention discloses a composite current collector which comprises a porous polymer film, a metal coating attached to the surface of the porous polymer film and a conductive coating attached to thesurface of the metal coating. The invention also discloses a preparation method of the composite current collector. The invention also discloses a lithium battery pole piece. According to the presentinvention, the ultra-thin porous polymer film is adopted, so that the physical and chemical properties of the current collector can be improved, belt breakage is reduced, the weight of the battery can be reduced, and the energy density of the battery is improved; after the ultrathin porous polymer film is plated with metal, micropores in the surface of the ultrathin porous polymer film are filledwith metal, metal plating layers at the two sides are communicated, electronic channels are increased, and the internal resistance is effectively reduced, so that when the battery is prepared, a metal tab does not need to be additionally introduced to a tab, it can be guaranteed that electrode slurry does not leak in the subsequent coating process, and production can be better introduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

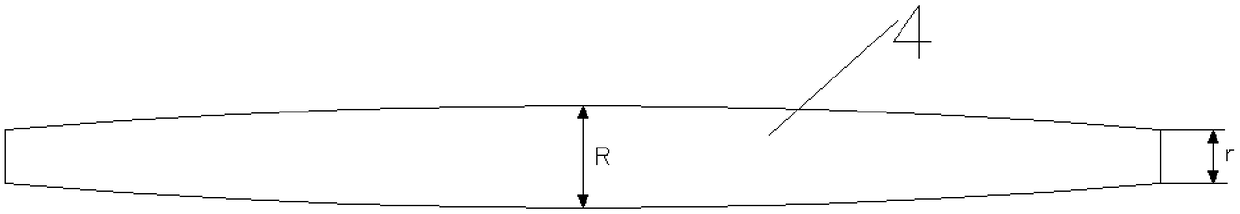

Work roll for cold rolling edge drop control and method for designing roll contour of work roll

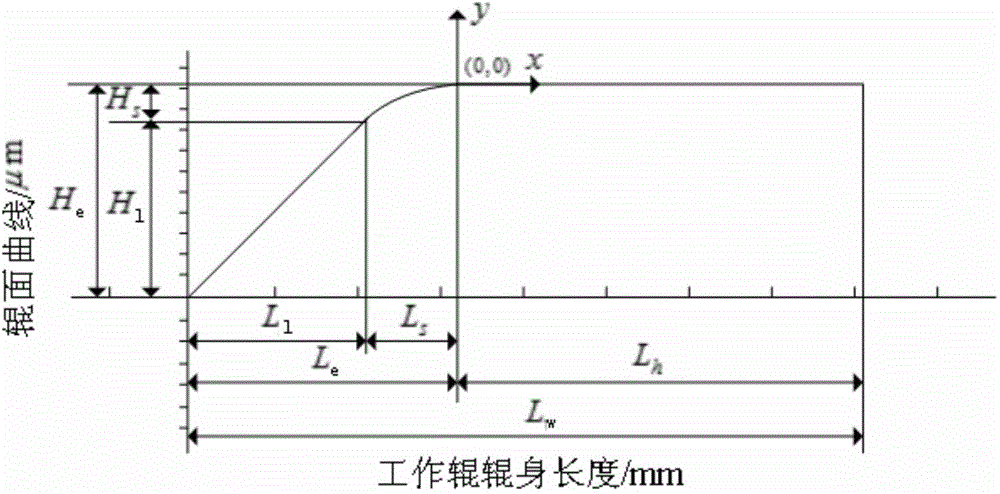

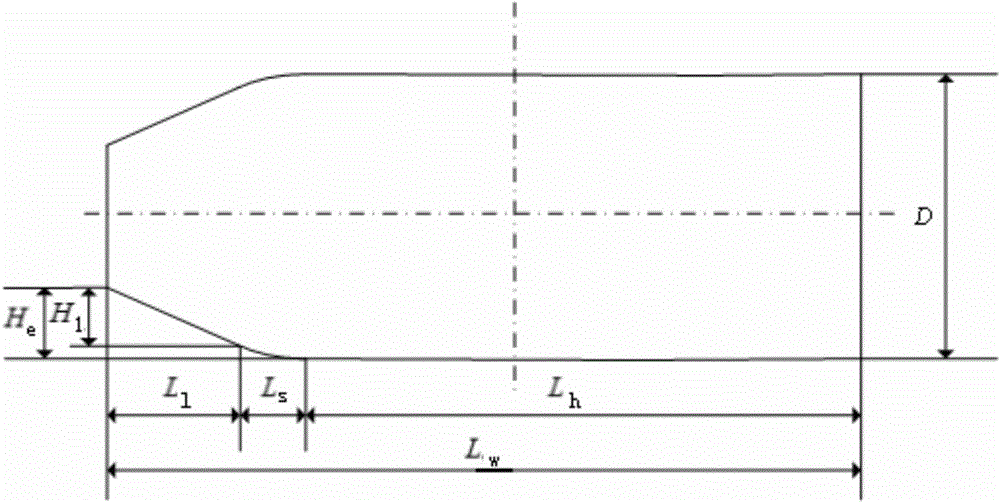

ActiveCN104874607ASolve easy peelingGood self retentionRollsMetal rolling arrangementsStress concentrationWork roll

The invention discloses a work roll for cold rolling edge drop control and a method for designing a roll contour of the work roll. The roll contour of the work roll comprises an oblique line section, a quadratic curve section and a horizontal line section. Two ends of a quadratic curve are respectively tangential to a horizontal line and an oblique line, the roll contour of an end of a side of the work roll is formed by the quadratic curve and the oblique line and participates in edge drop control, the quadratic curve section is short but is high in taper, and the oblique line section is long. The work roll and the method have the advantages that the edge drop control ability of integral edge regions can be guaranteed; regions of the edges of band steel are low in stress value, and accordingly the possibility of band breakage can be reduced; starting positions of the edges of the band steel are in smooth transition, so that stress concentration can be prevented, and the self-preservation property of the shape of the roll can be improved; the probability of band breakage due to deviation of the band steel and excessively high stress at the edges of each single side of the band steel can be reduced, and accordingly the work roll is excellent in deviation resistance; the roll contour is excellent in grinding performance, and the surface quality of the ends of the roll can be guaranteed in grinding procedures.

Owner:UNIV OF SCI & TECH BEIJING

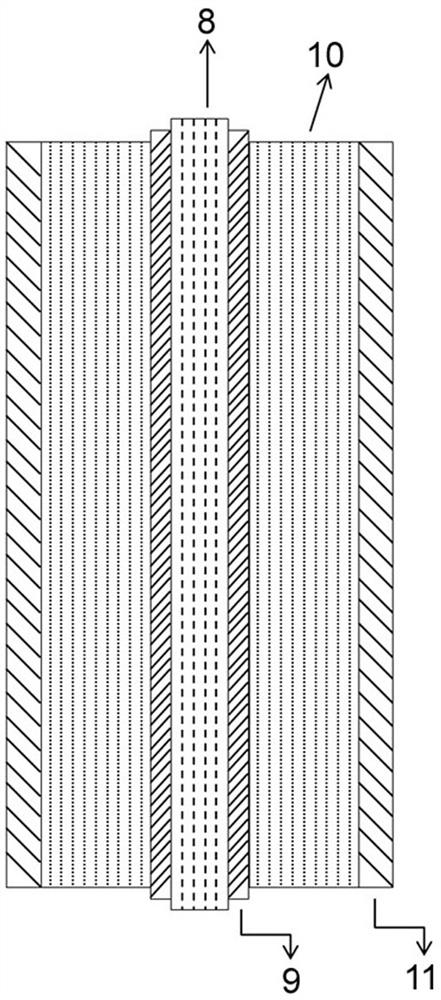

High-energy and high-safety lithium ion battery

ActiveCN110890521AGuaranteed anti-acupuncture safety performanceReduces the risk of internal short circuitsNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceHigh energyCarbon nanotube

The invention discloses a lithium ion battery with high energy and high safety performance, which comprises a negative plate, a diaphragm and a battery cell formed by laminating or winding a positiveplate, and is characterized in that the positive plate contains a positive current collector, a positive active material, a positive conductive agent, a positive binder and a positive additive; the negative plate contains a negative current collector, a negative active substance, a negative conductive agent, a negative binder and a negative additive; the positive electrode current collector is characterized in that coating layers on two sides of the surface of the positive electrode current collector are made of a PTC material, aluminum powder and carbon nanotubes; the positive electrode additive is a mixture of a PTC material, aluminum powder and graphene; coating layers on the two sides of the surface of the positive plate are made of a PTC material and graphene; coating layers on the two sides of the surface of the negative electrode current collector are made of PTC materials, copper powder and carbon nanotubes; the negative electrode additive is a mixture of a PTC material, copperpowder and graphene; and coating layers on two sides of the surface of the negative plate are made of a PTC material and graphene. According to the invention, high safety performance is obtained, thesafety is ensured, the energy density of the battery is improved, the electrical performance of the battery is improved, and the production process level is improved.

Owner:SUZHOU PHYLION BATTERY

Fast sample plate calibration method of gamma-ray thickness gauge

ActiveCN105032953AImprove Thickness QualityImprove calibration accuracyMeasuring devicesMetal rolling arrangementsTime rangeMicrometer

A fast sample plate calibration method of a gamma-ray thickness gauge is mainly used for detecting the thickness of silicon steel. The method comprises the steps that 1, physical measurement is carried out on silicon steel sample plates of different thicknesses to obtain the absolute thickness values of the sample plates of all the thicknesses; 2, the silicon steel sample plates of the different thicknesses are manually measured on the gamma-ray thickness gauge one to five times, and the average manual measurement thickness value is calculated; 3, the thickness deviation value of the sample plates is calculated; 4, a compensation factor is determined, and meets the conditions that the absolute value of the thickness deviation value of the silicon steel sample plates with the thickness of 0.5 mm is not larger than 3 micrometers, and the absolute value of the thickness deviation value of the silicon steel sample plates of other thicknesses is not larger than 6 micrometers; and 5, the compensation factor is stored and calibrated on the gamma-ray thickness gauge. Calibration time ranges from 45 minutes to 1 hour; the number of times of starting a radiation source is 1 / 5 of original calibration time; calibration precision is higher than calibration of an original procedure; and the thickness quality of finished steel plates is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

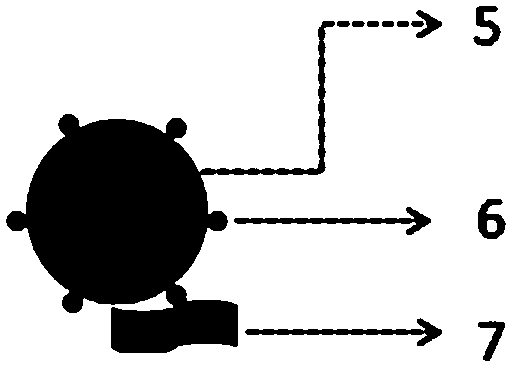

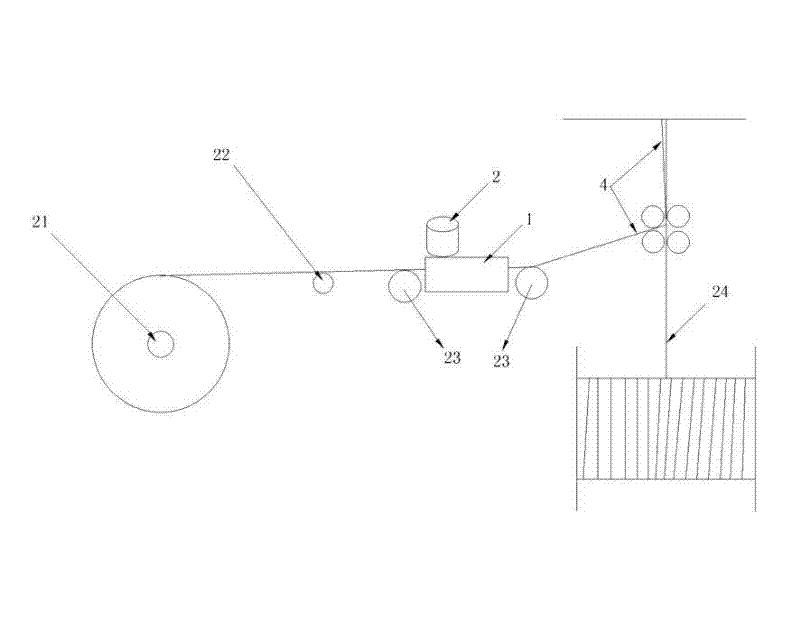

Process for manufacturing outer conductor in coaxial cable production process and special lubricating oil device thereof

InactiveCN102254636AEliminate frictionReduce wearManufacturing co-axial cablesEngineeringWire breakage

The invention discloses a process for manufacturing an outer conductor in a coaxial cable production process. The outer conductor consists of an aluminum foil shielding layer and a woven layer. The process for manufacturing the outer conductor comprises the following steps of: (1) longitudinally wrapping and oiling an aluminum foil: feeding the aluminum foil to a lubricating oil device through an aluminum foil breakage alarm after the aluminum foil in an aluminum foil payoff reel is horizontally released, oiling the aluminum foil, discharging the aluminum foil coated with the lubricating oil from the lubricating oil device, leading out the aluminum foil through a guide wheel, and gradually longitudinally wrapping the aluminum foil on a prepared core wire; and (2) weaving an alloy wire. The friction between the aluminum foil coated with the lubricating oil and the alloy wire is weakened and eliminated, abrasion of the aluminum foil and the alloy wire is reduced, and stability of product performance is ensured. Meanwhile, the probabilities of aluminum foil breakage and alloy wire breakage are reduced, shutdown in the production is reduced, and the production efficiency is greatly increased.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

Six-roller five-rack cold continuous rolling one-time cold rolling process for common oriented silicon steel

ActiveCN112742868ACrystal shape stable and uniformPrevent magnetization from decreasingRoll force/gap control deviceTemperature control deviceContinuous rollingMaterials science

The invention discloses a six-roller five-rack cold continuous rolling one-time cold rolling process for common oriented silicon steel. According to the process, one-time cold rolling of the common oriented silicon steel can also be conducted in a pickling rolling mill combined unit, by means of the process, a hot rolling raw material coil is completed in the pickling rolling mill combined unit, and the hot rolling raw material coil comprises the following components of 0.025wt% to 0.045wt% of C; 3.00wt% to 3.30wt% of Si; 0.15wt% to 0.25wt% of Mn; less than or equal to 0.025wt% of P; 0.004wt% to 0.015wt% of S; 0.010wt% to 0.025wt% of Als; 0.0070wt% to 0.0115wt% of N; 0.45wt% to 0.55wt% of Cu; less than or equal to 0.020wt% of Ti; and the balance Fe and inevitable impurities. According to the process, a compatible function of the pickling rolling mill combined unit is fully exerted, raw materials do not need to be preheated through steam before being uncoiled on line, electromagnetic induction heating is not adopted before the materials enter a rolling mill, investment is saved, and the requirement for research, development and production of cold-rolled common oriented silicon steel is met; and due to continuous rolling, the production efficiency is improved, the yield is improved, and the cost is reduced.

Owner:ANYANG IRON & STEEL +1

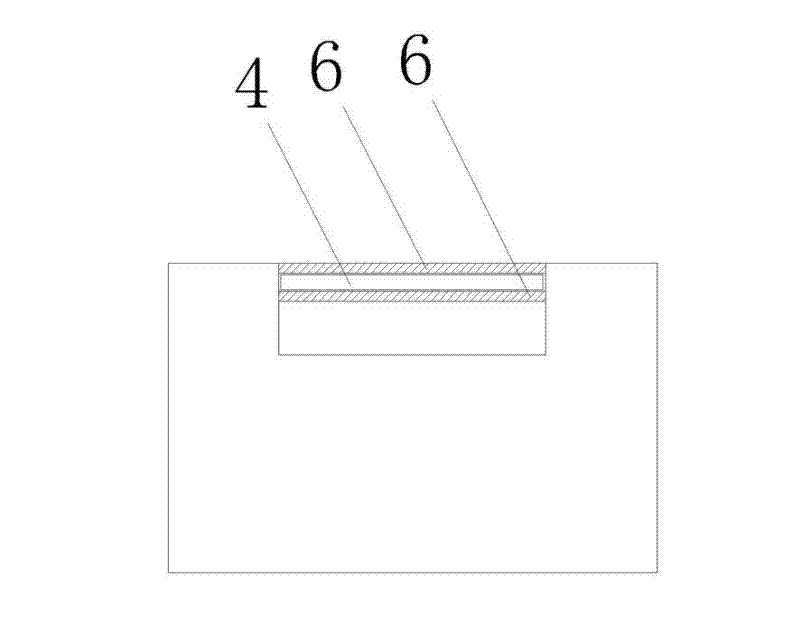

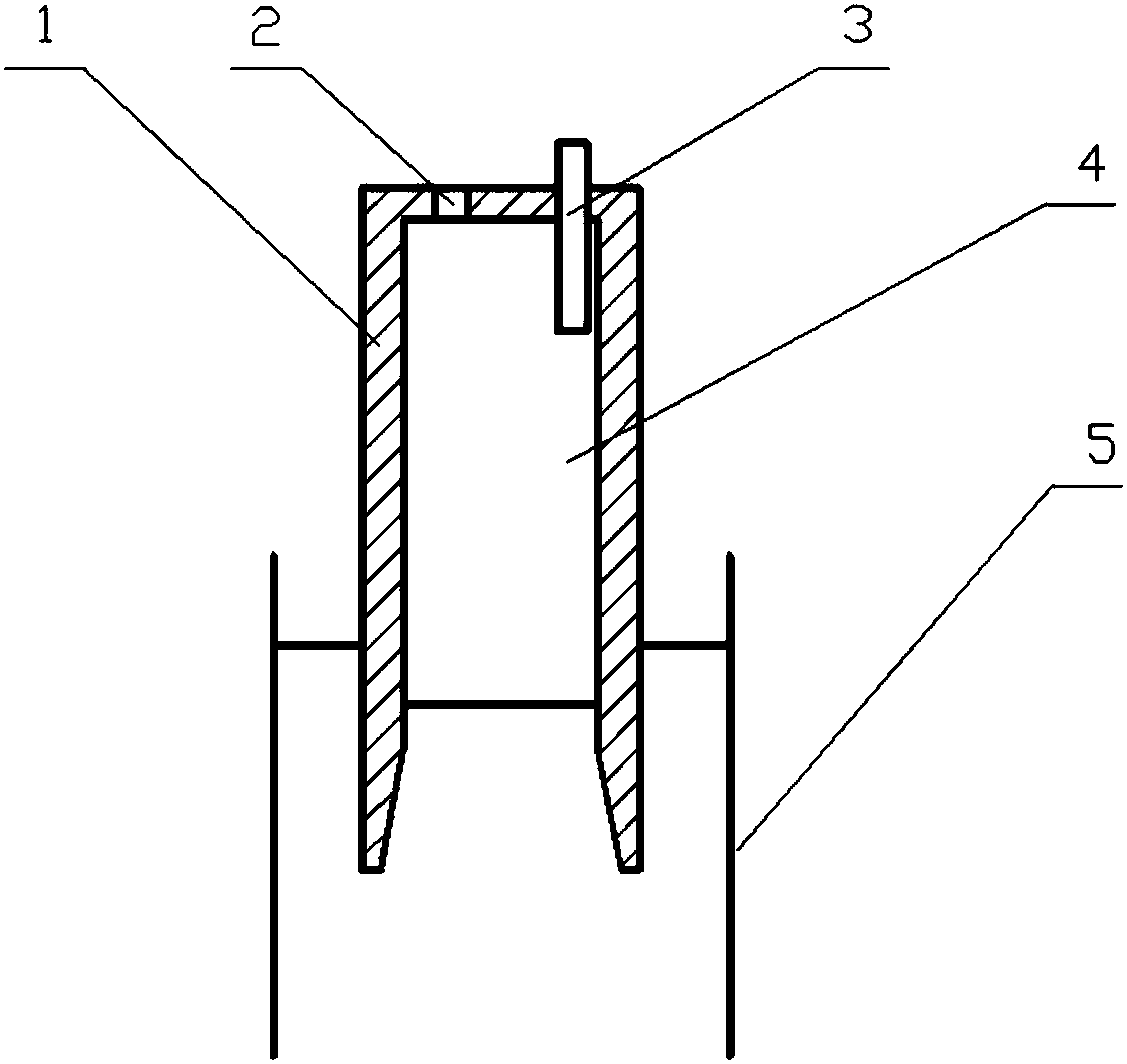

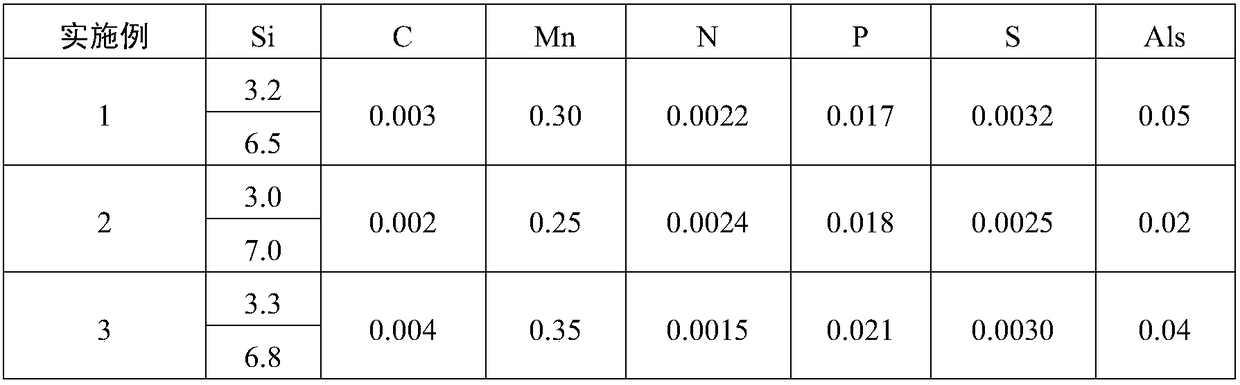

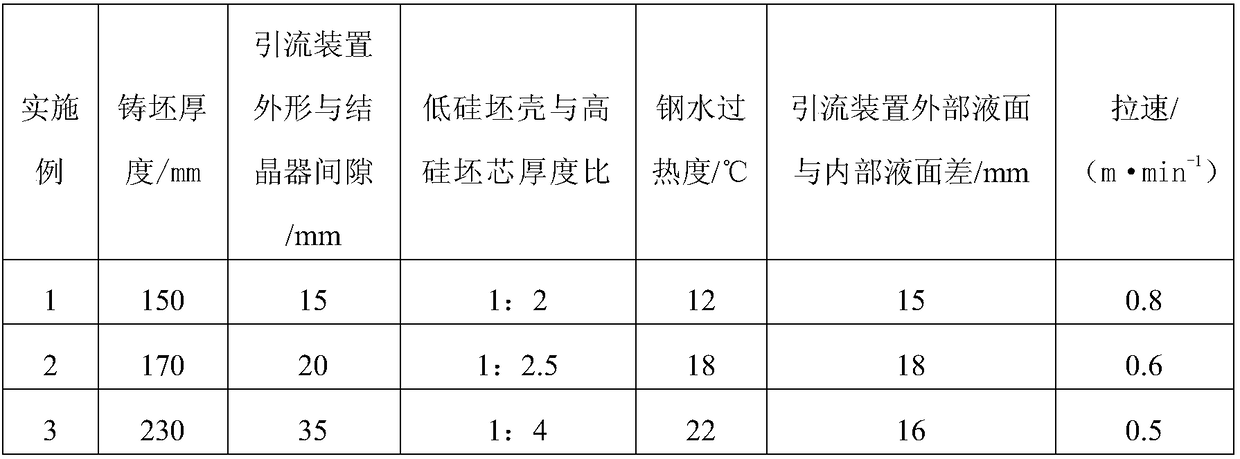

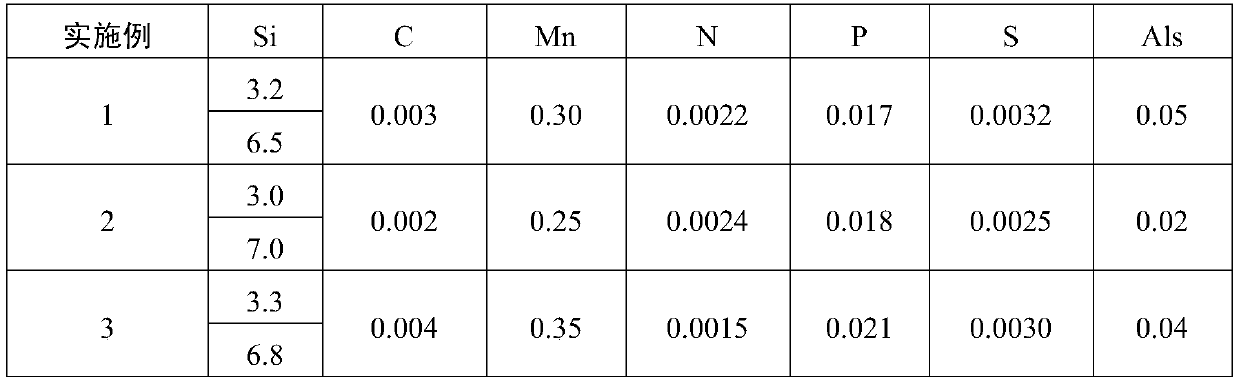

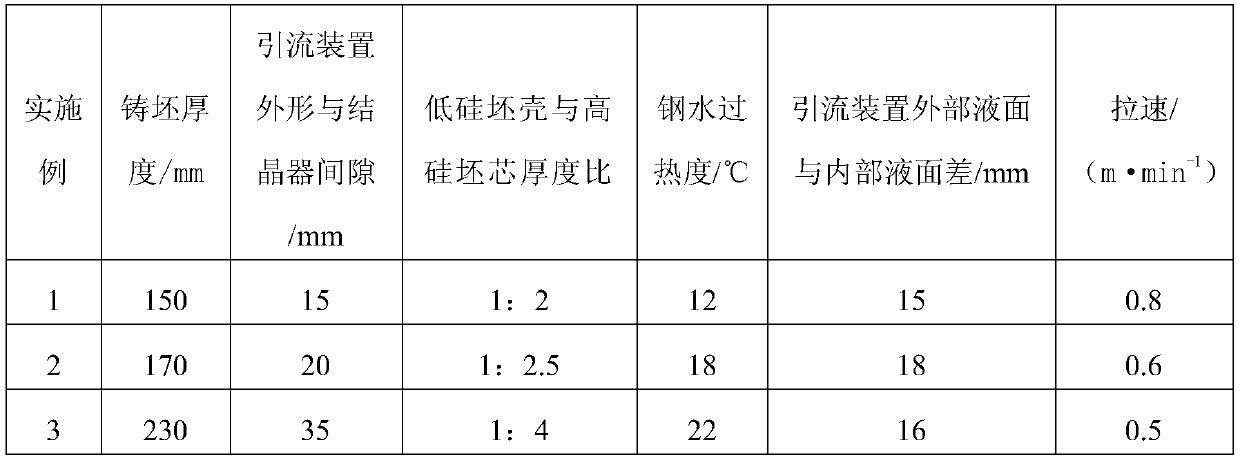

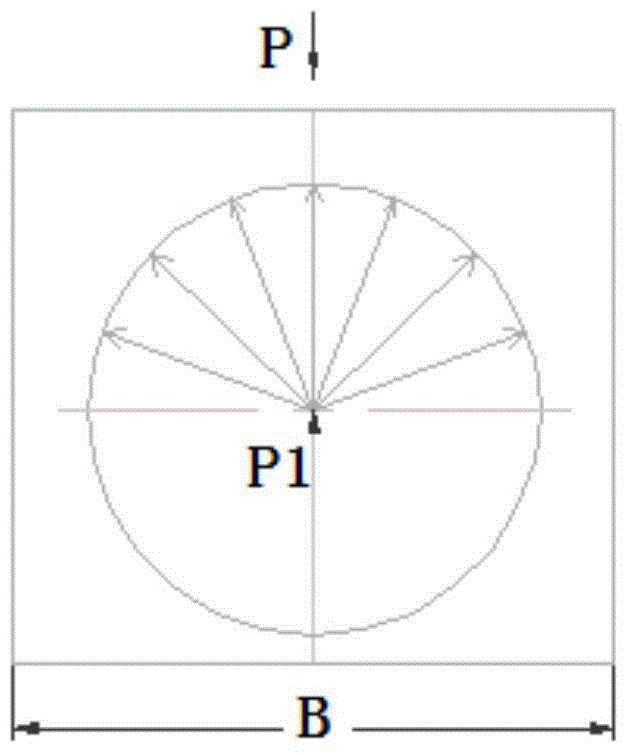

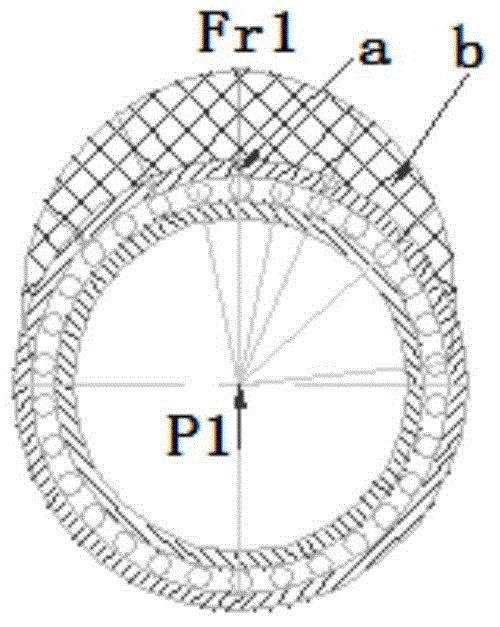

Production method of high-silicon electrical steel

The invention discloses a production method of high-silicon electrical steel. Molten steel with the contents of two kinds of silicon being 2.0%-3.5% and 4.5%-7.0% correspondingly is smelted, and the superheat degree of the molten steel is 10-30 DEG C; a drainage device is arranged in a continuous casting crystallizer, opened downwards and suspended in the molten steel, the gap between the drainagedevice and the crystallizer is 10-40 mm, the high-silicon molten steel is added into the drainage device, low-silicon molten steel flows between the drainage device and the crystallizer, the pullingspeed is 0.4-0.9 m / min, the thickness ratio of a low-silicon blank shell to a high-silicon blank core of a cast blank is 1:2-1:5, inert gas is charged into the drainage device, and thus the internal liquid level of the drainage device is 10-20 mm lower than the external liquid level of the drainage device; the thickness of a hot-rolled roll is 0.8-1.8 mm; and before cold rolling, preheating is carried out to 200-450 DEG C, the annealing temperature is 600-1000 DEG C, and heat-preserving time is 10-200 min. Finished products have good electromagnetic performance and iron loss performance.

Owner:ANGANG STEEL CO LTD

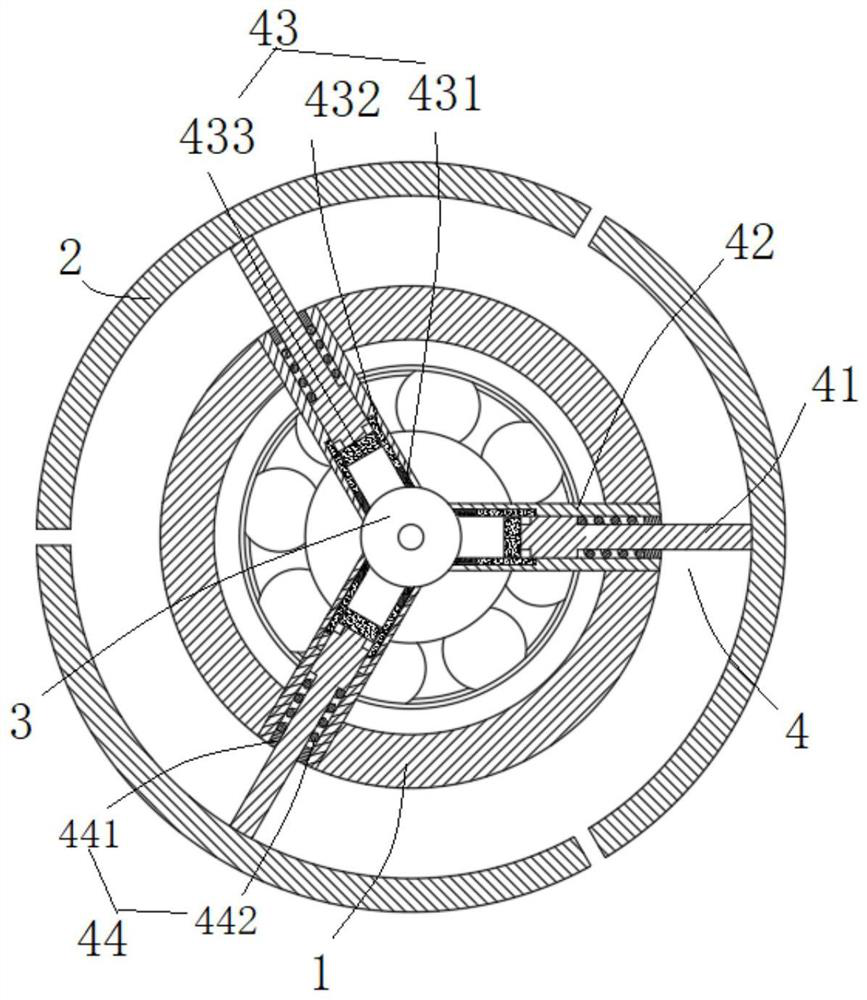

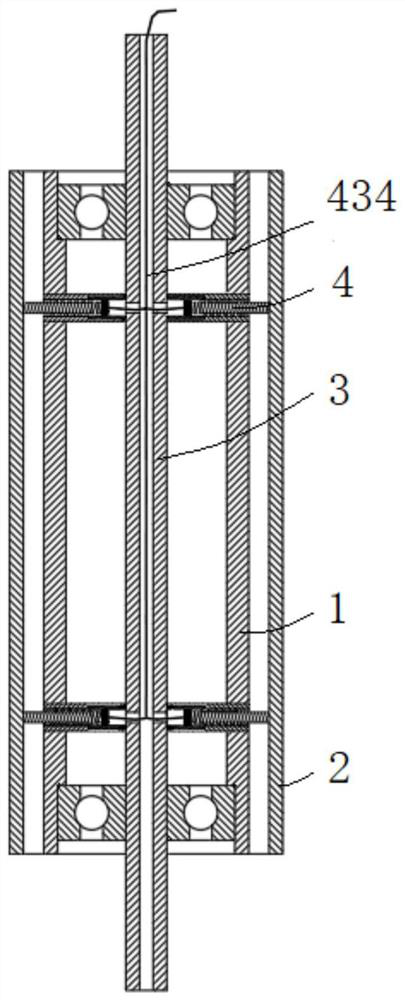

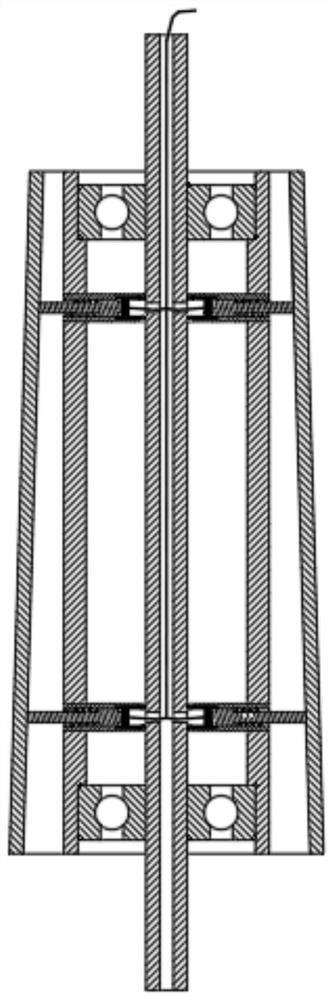

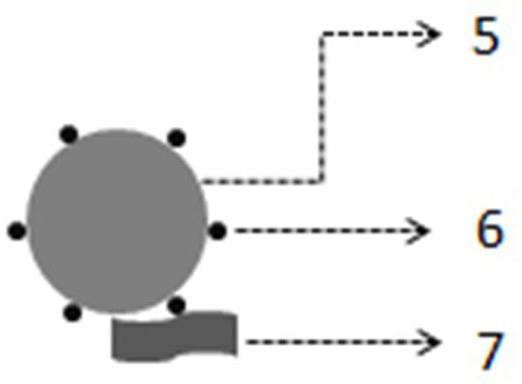

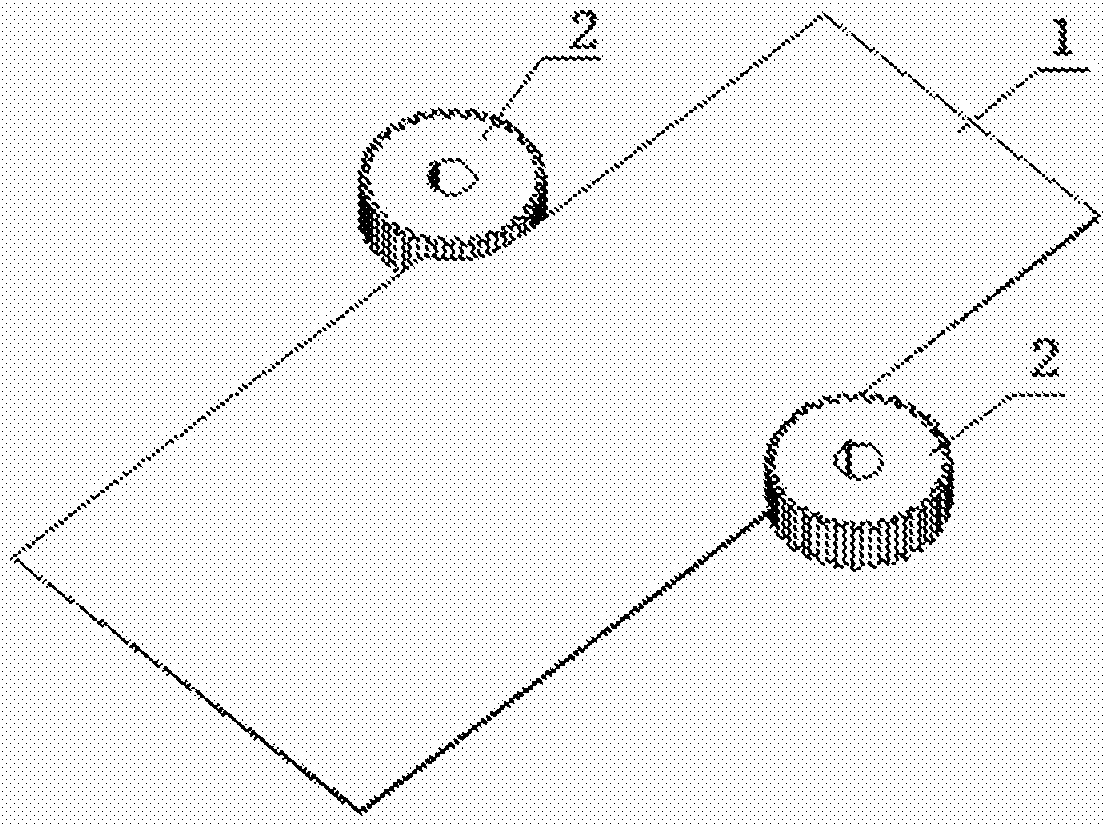

Deformable roller passing structure capable of automatically adjusting tension of pole piece

The invention discloses a deformable roller passing structure capable of automatically adjusting tension of a pole piece, which comprises an inner roller and an outer roller, a center shaft concentric with the inner roller is arranged in the inner roller, and the outer roller is composed of at least two sections of arcs forming a cylindrical structure; a tension adjusting mechanism connected with the inner roller is connected to the center shaft and comprises at least two guide rods correspondingly connected with the at least two sections of arcs and connecting frames connected to the inner roller and the center shaft and corresponding to the guide rods; and the guide rods are connected to the corresponding connecting frames in a sliding mode. The guide rods are displaced in the axial direction through the magnetic force of an electromagnetic rings and the elastic effect of springs, so that the diameter of the outer roller is adjusted, and the problem that the edge of supplied foil in the width direction is loosened in lithium battery piece production is effectively solved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

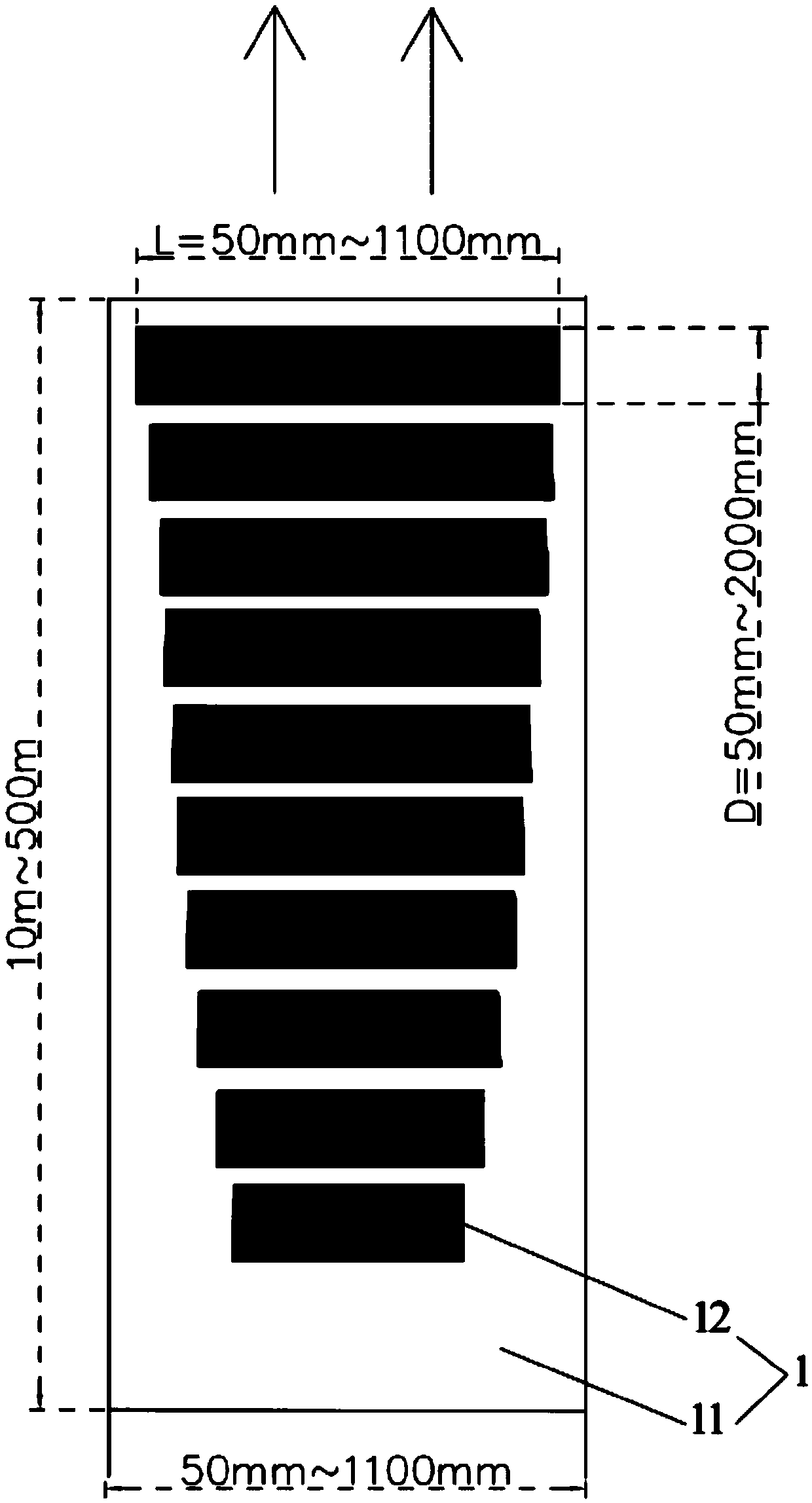

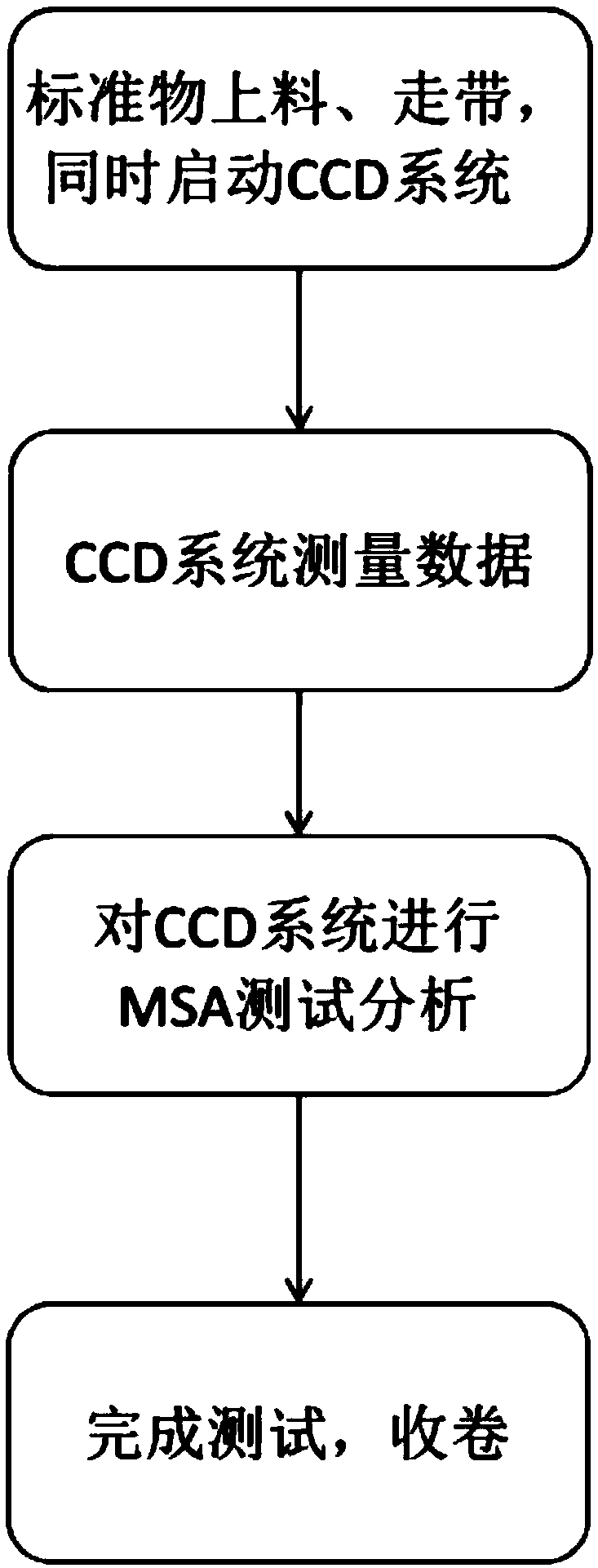

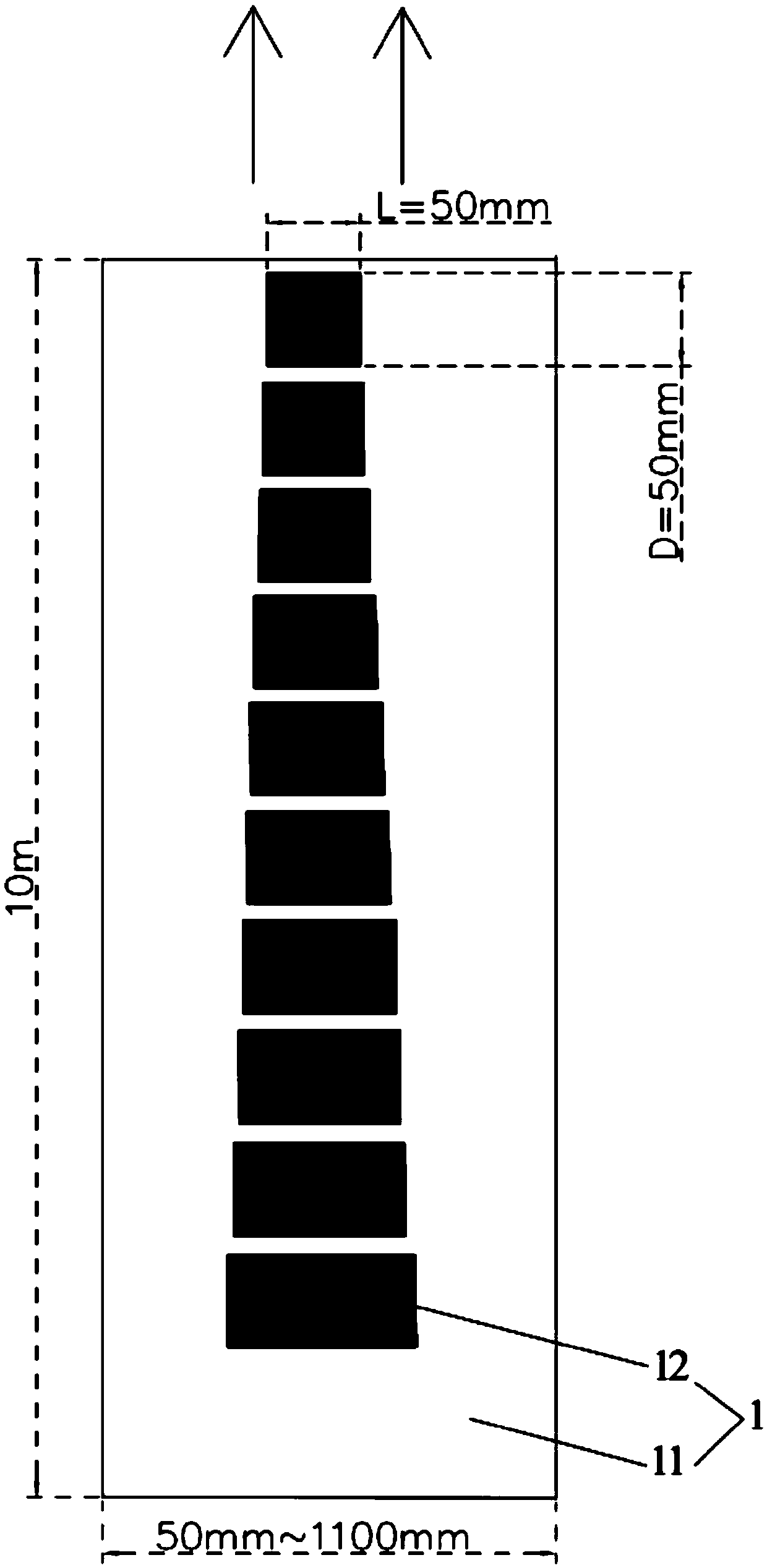

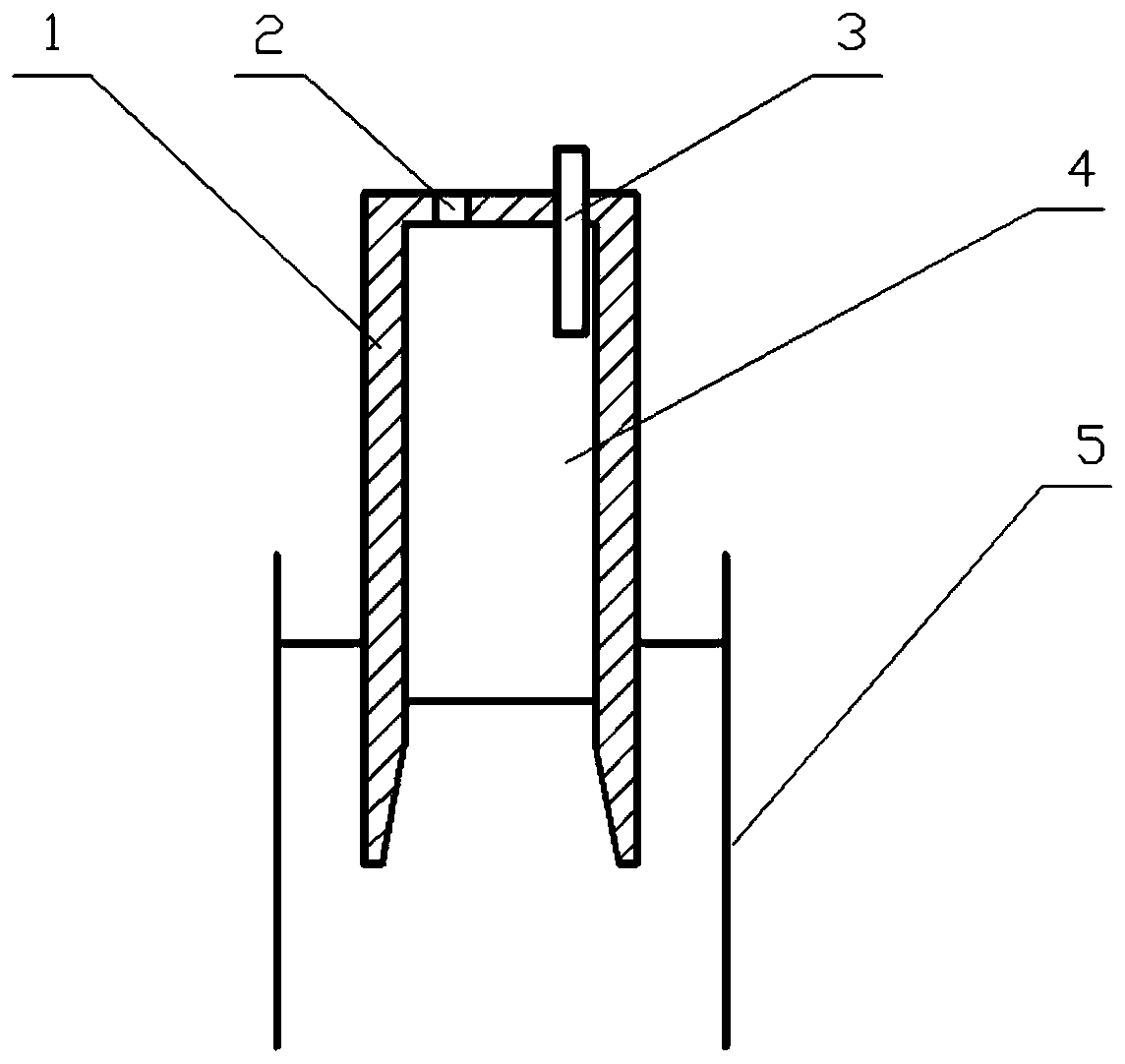

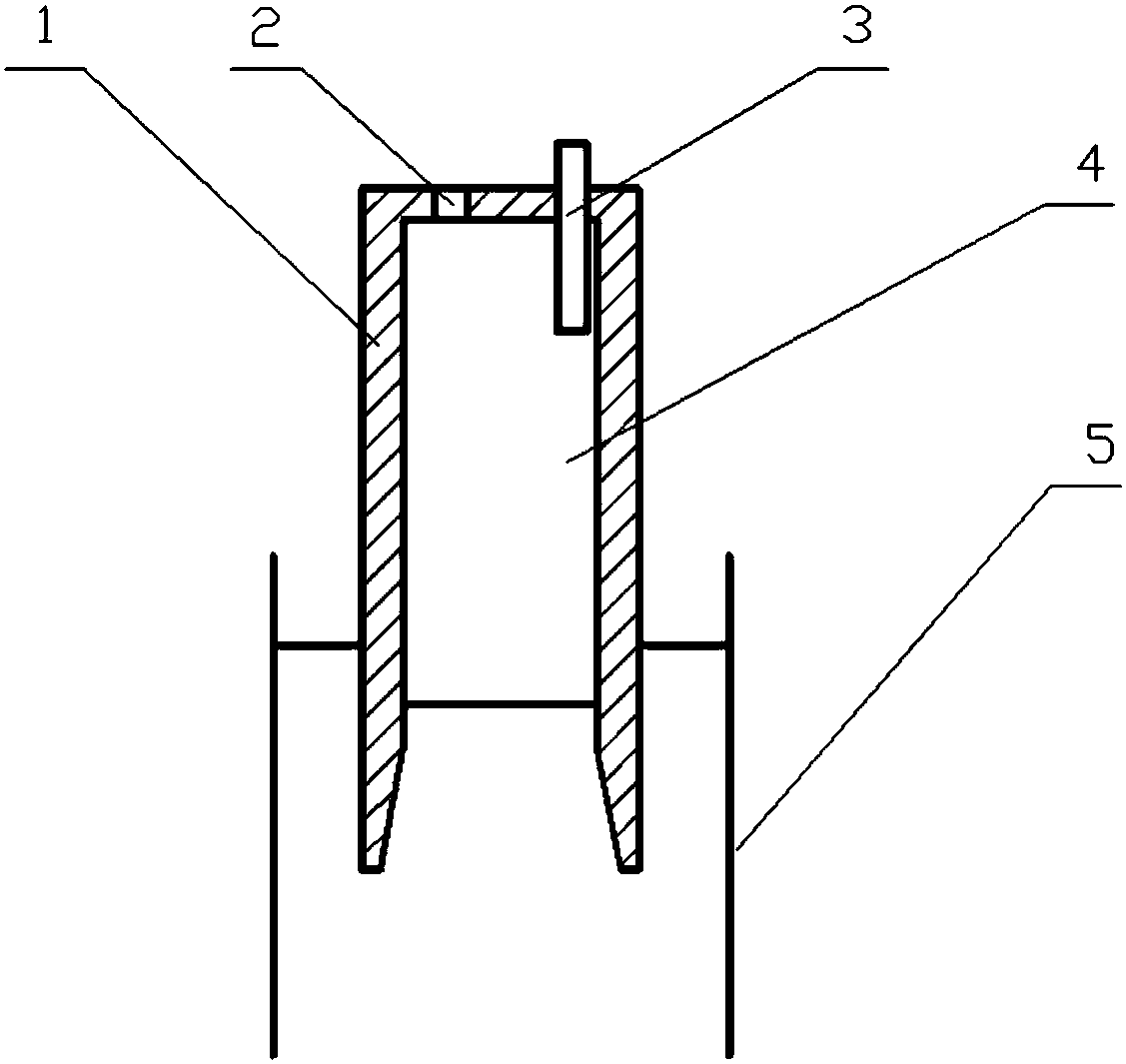

Standard member for pole plate width testing, preparation method and application method thereof

The invention belongs to the technical field of a lithium ion battery, and particularly to a standard member for pole plate width testing. The standard member comprises a polyester high-molecular filmand a plurality of segments of square coatings which are plated on the belt moving surface of the polyester high-molecular film. The widths D of the segments of the coating are same. Furthermore thewidths D are 50-2000 mm. The length L of each segment of the coating is 50-1100 mm. Furthermore the lengths L of the segments of the coating gradually increase or gradually reduce. The difference between the lengths of two adjacent segments of coating is 0.1-2mm. The standard member for testing the CCD system pole plate is prepared through utilizing the polyester high-molecular film and the coating with relatively high adhesion force. The standard member has advantages of excellent physical property, no easy folding or breakage, effective reduction of a measurement result error of the CCD system, and higher data reliability in performing MSA by the CCD system. Furthermore the invention discloses a preparation method of the standard member for pole plate width testing, and an application method thereof.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

A kind of production method of medium frequency magnetic shielding silicon steel

The invention provides a production method for intermediate-frequency magnetic shielding silicon steel. The production method comprises the steps of smelting, continuous casting, hot rolling, pickling, cold rolling, annealing, coating, performance testing and packaging; as for smelting, molten steel is smelted until the silicon content is 2.0%-3.5%, and other element ingredients are smelted to target ingredients; as for continuous casting, the molten steel superheat degree is 20-60 DEG C, a charging device is arranged in a continuous casting crystallizer, steel particles are added into the molten steel in the charging device, the added steel particles need to be heated to 400 DEG C or above, the mass percentage content of steel particle silicon is 0.5%-2.0% higher than the mass percentagecontent of target ingredient silicon, other element ingredients are the same as the target element ingredients, and the particle size of steel particles is 1.0-5.0 mm; the steel particles exist in a casting blank in a molten state or semi-solid state; and as for annealing, the annealing temperature is 600-1000 DEG C, and the temperature holding time is 10-400 min. The production method adopts lowsilicon electric steel to protect hot rolling heating oxidation of high silicon electric steel, and the yield is improved.

Owner:ANGANG STEEL CO LTD

Control method for preventing high-magnetic-induction oriented silicon steel cold rolling strip breakage

PendingCN114453430AReduce consumptionReduce broken beltRoll mill control devicesWork heating devicesSteel beltSilicon

The invention relates to the technical field of steel and iron smelting, discloses a control method for preventing high-magnetic-induction oriented silicon steel cold rolling strip breakage, and aims at solving the problems that in the prior art, high-magnetic-induction oriented silicon steel is prone to breakage, oxidation and the like during cold rolling, the following scheme is provided, the control method comprises the following steps that firstly, a circle shear is used for trimming, and a steel strip is obtained; edge defects possibly existing in the hot-rolled steel strip are cut off; secondly, a bell-type furnace is adopted for gas protection preheating before cold rolling, the preheating temperature of a steel coil is 40-100 DEG C, and the preheating time is 6-18 h; and thirdly, transverse temperature distribution of the steel strip is controlled through emulsion cooling in the rolling process. According to the method, the edge tension is prevented from being too large through trimming before cold rolling, gas protection preheating of the steel coil and control over transverse temperature distribution of the steel strip in the rolling process, and therefore the steel strip is effectively prevented from being broken in the rolling process.

Owner:ANYANG IRON & STEEL +1

Production method for intermediate-frequency magnetic shielding silicon steel

The invention provides a production method for intermediate-frequency magnetic shielding silicon steel. The production method comprises the steps of smelting, continuous casting, hot rolling, pickling, cold rolling, annealing, coating, performance testing and packaging; as for smelting, molten steel is smelted until the silicon content is 2.0%-3.5%, and other element ingredients are smelted to target ingredients; as for continuous casting, the molten steel superheat degree is 20-60 DEG C, a charging device is arranged in a continuous casting crystallizer, steel particles are added into the molten steel in the charging device, the added steel particles need to be heated to 400 DEG C or above, the mass percentage content of steel particle silicon is 0.5%-2.0% higher than the mass percentagecontent of target ingredient silicon, other element ingredients are the same as the target element ingredients, and the particle size of steel particles is 1.0-5.0 mm; the steel particles exist in a casting blank in a molten state or semi-solid state; and as for annealing, the annealing temperature is 600-1000 DEG C, and the temperature holding time is 10-400 min. The production method adopts lowsilicon electric steel to protect hot rolling heating oxidation of high silicon electric steel, and the yield is improved.

Owner:ANGANG STEEL CO LTD

Rapid Calibration Method of γ-ray Thickness Gauge Sample

ActiveCN105032953BImprove Thickness QualityImprove calibration accuracyMeasuring devicesMetal rolling arrangementsTime rangeMicrometer

A fast sample plate calibration method of a gamma-ray thickness gauge is mainly used for detecting the thickness of silicon steel. The method comprises the steps that 1, physical measurement is carried out on silicon steel sample plates of different thicknesses to obtain the absolute thickness values of the sample plates of all the thicknesses; 2, the silicon steel sample plates of the different thicknesses are manually measured on the gamma-ray thickness gauge one to five times, and the average manual measurement thickness value is calculated; 3, the thickness deviation value of the sample plates is calculated; 4, a compensation factor is determined, and meets the conditions that the absolute value of the thickness deviation value of the silicon steel sample plates with the thickness of 0.5 mm is not larger than 3 micrometers, and the absolute value of the thickness deviation value of the silicon steel sample plates of other thicknesses is not larger than 6 micrometers; and 5, the compensation factor is stored and calibrated on the gamma-ray thickness gauge. Calibration time ranges from 45 minutes to 1 hour; the number of times of starting a radiation source is 1 / 5 of original calibration time; calibration precision is higher than calibration of an original procedure; and the thickness quality of finished steel plates is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

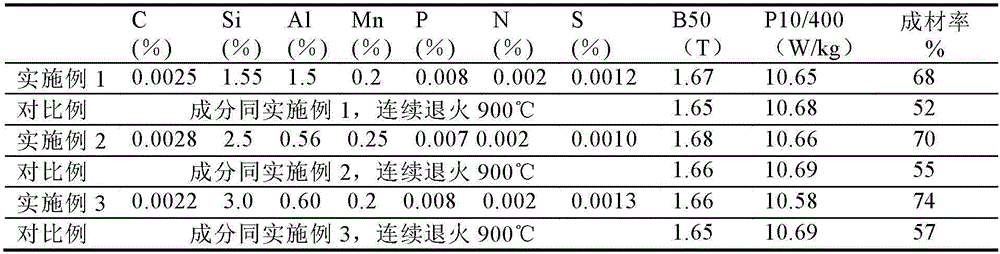

Annealing method of cold-rolled non-oriented electrical steel thin strip

ActiveCN103882211BImprove electromagnetic performanceEasy to shapeFurnace typesHeat treatment furnacesElectrical steelStress relieving

The invention provides an annealing method of cold-rolled non-oriented electrical steel thin strips, which comprises the following steps: 1) performing normalized acid pickling, then performing cold rolling to reach a thickness of 0.15-0.20 mm, uniformly spraying a MgO aqueous solution on a steel plate surface in a cold rolling final finished product pass process; 2) after cold rolling, performing cover annealing by coils under the protection of N2+H2, wherein the volume percent of N2 is 10%-90% and the volume percent of H2 is 10%-90%, performing heat preservation at 400-500 DEG C for 2-10 hours, then performing recrystallization annealing at 850-1000 DEG C for 8-20 hours; 3) washing off the MgO coating with 3%-8% diluted H2SO4 before stretching annealing, performing stress-relieving annealing at 500-900 DEG C, and applying tension force which is controlled to be 0.8-5 KN. The method of the invention adopts cover furnace annealing, and performs a stretching flattening process after annealing, which not only obtains excellent electromagnetic performance, but also ensures good plate shape, greatly increases the yield, reduces strip breaking, and increases the yield by 10%-20%. The method of the invention is widely applicable to variable frequency motors, and extends the application field of electrical steel.

Owner:ANGANG STEEL CO LTD

A kind of preparation method of micron titanium foil

ActiveCN107442570BEliminate internal processing stressUniform internal structureRollsProfile control deviceWork in processEnergy consumption

The invention discloses a preparation method for micron-grade titanium foil. The preparation method comprises the steps that firstly, a titanium belt is fed into a rolling mill to be subjected to primary rolling, and a primary rolled titanium foil semi-finished product is obtained; second, after being washed, the primary rolled titanium foil semi-finished product is fed into a vacuum furnace to be subjected to heat preservation treatment; thirdly, the primary rolled titanium foil semi-finished product is fed into the rolling mill to be subjected to secondary rolling, and a secondary rolled titanium foil semi-finished product is obtained; fourthly, after being washed, the secondary rolled titanium foil semi-finished product is fed into the vacuum furnace to be subjected to heat preservation treatment; fifthly, the secondary rolled titanium foil semi-finished product is fed into the rolling mill to be subjected to tertiary rolling, and a tertiary rolled titanium foil semi-finished product is obtained; and sixthly, after being washed, the tertiary rolled titanium foil semi-finished product is fed into the vacuum furnace to be subjected to heat preservation treatment, and the finished titanium foil product is obtained. According to the preparation method, the technological process is simple, energy sources are saved, the energy consumption is low, the production efficiency is effectively improved, the titanium foil with the thickness only being 0.007 mm-0.009 mm can be prepared, the titanium foil is smooth in surface, the defects of cracking, peeling, folding, obvious oxidation and impurity pressing-in are not caused, the titanium foil can replace an existing titanium foil product, and the titanium foil has wide market space and development prospects.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

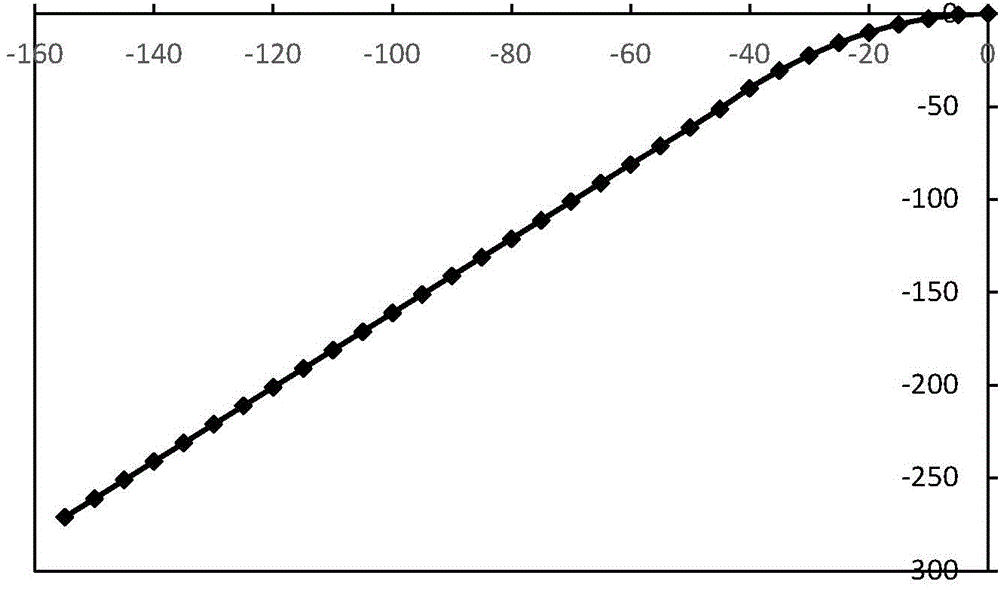

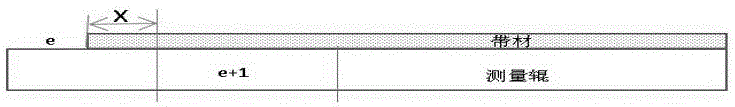

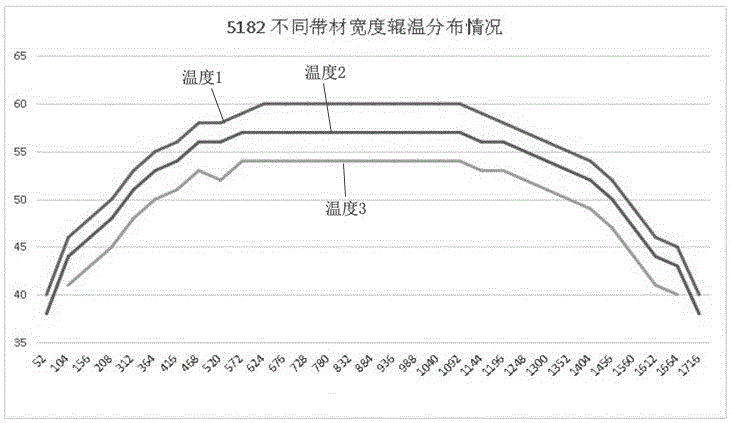

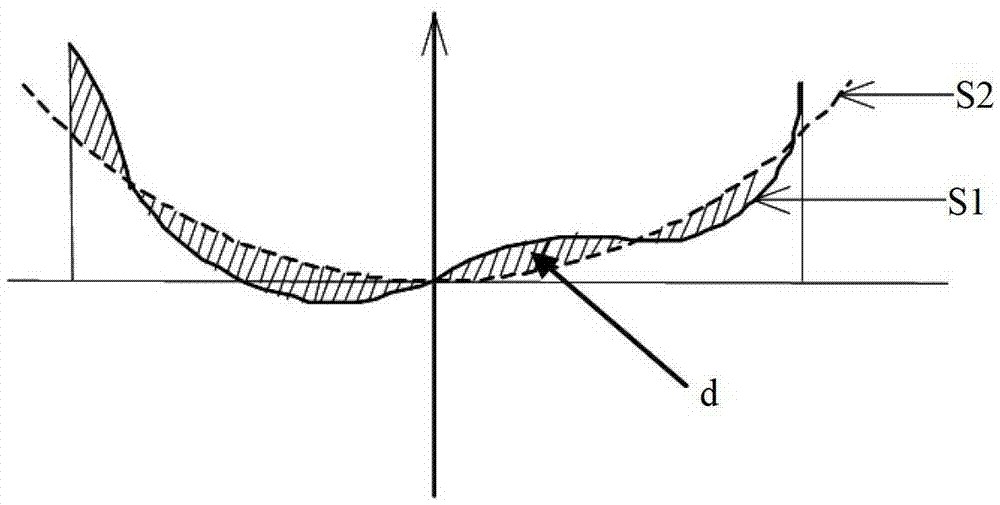

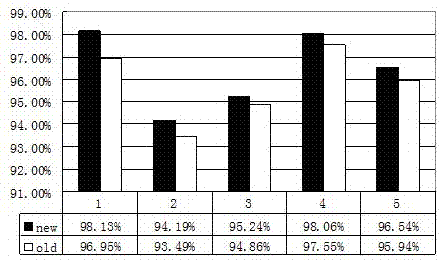

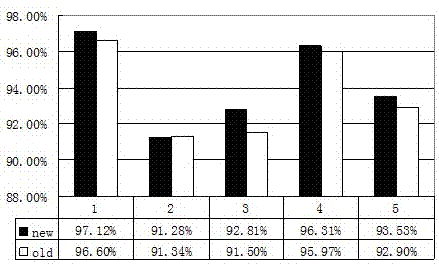

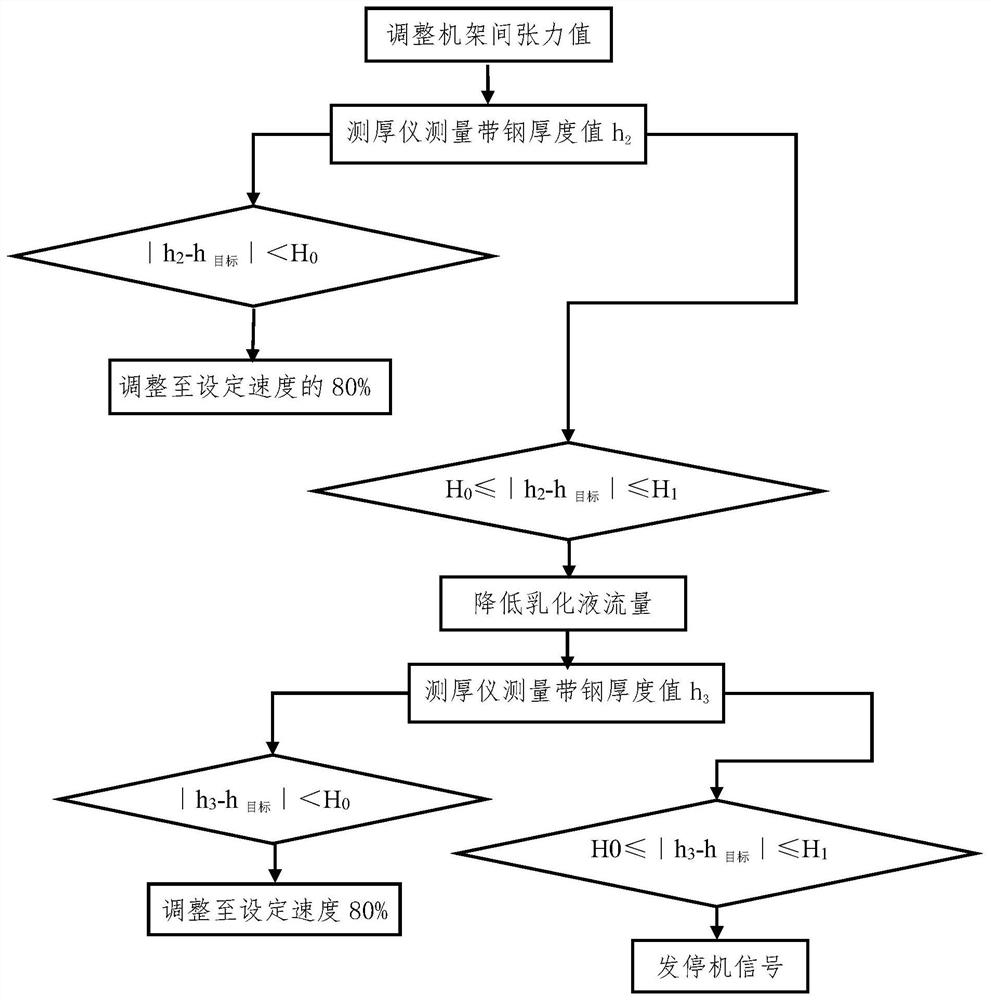

Broken-belt reduction control method for cold rolling production of 5182 aluminum alloys

ActiveCN106734236AReduce broken beltIncrease productivityGeometric CADRoll mill control devicesDistortion functionRolling mill

The invention relates to a broken-belt reduction control method for cold rolling production of 5182 aluminum alloys. The control method includes the steps: building side covering weight of belt materials to obtain a plate shape distortion function based on original rolling process of the 5182 aluminum alloys; optimizing rolling reduction and rolling oil parameters. According to control method, the 5182 aluminum alloys have the advantages that belt breaking frequency of a cold-rolling mill can be reduced, production efficiency is improved, production safety is ensured, and product quality is stabilized.

Owner:CHINALCO RUIMIN

A kind of production method of high silicon electrical steel

The invention discloses a production method of high-silicon electrical steel. Molten steel with the contents of two kinds of silicon being 2.0%-3.5% and 4.5%-7.0% correspondingly is smelted, and the superheat degree of the molten steel is 10-30 DEG C; a drainage device is arranged in a continuous casting crystallizer, opened downwards and suspended in the molten steel, the gap between the drainagedevice and the crystallizer is 10-40 mm, the high-silicon molten steel is added into the drainage device, low-silicon molten steel flows between the drainage device and the crystallizer, the pullingspeed is 0.4-0.9 m / min, the thickness ratio of a low-silicon blank shell to a high-silicon blank core of a cast blank is 1:2-1:5, inert gas is charged into the drainage device, and thus the internal liquid level of the drainage device is 10-20 mm lower than the external liquid level of the drainage device; the thickness of a hot-rolled roll is 0.8-1.8 mm; and before cold rolling, preheating is carried out to 200-450 DEG C, the annealing temperature is 600-1000 DEG C, and heat-preserving time is 10-200 min. Finished products have good electromagnetic performance and iron loss performance.

Owner:ANGANG STEEL CO LTD

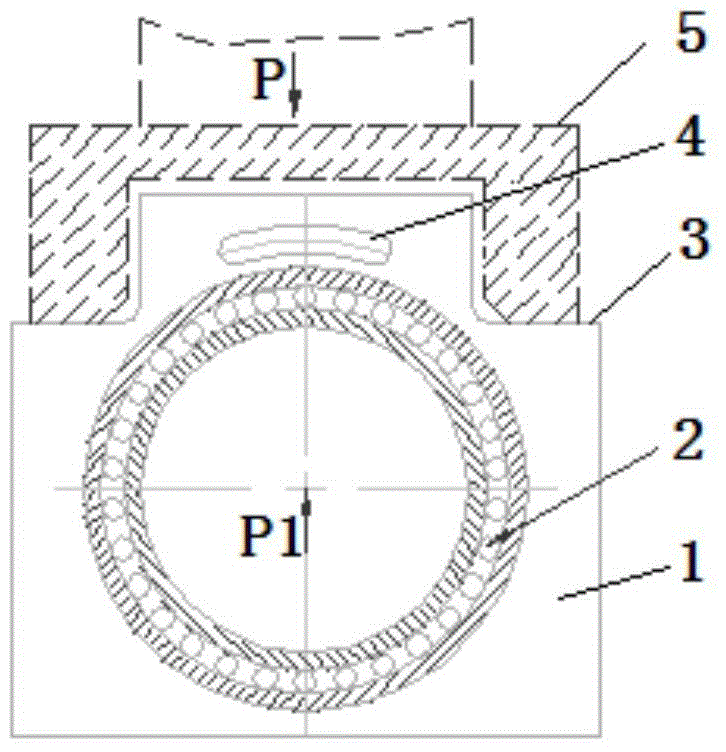

Supporting roll bearing base

InactiveCN104879390AExtended service lifeReduce use costMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

The invention discloses a supporting roll bearing base. A bearing hole is formed in the bearing base, the bearing hole is internally provided with a bearing, the bearing parallel with the upper part of the bearing hole is axially provided with a transparent arc-shaped through hole, the upper edges of two sides of the bearing base are respectively provided with a step along the axial direction of the bearing, the height of each step is 2 / 3 of the radius of a bearing outer ring. According to the structure, under the existing conditions that the size of the reduction force P and the direction of the roll force can not be changed, the force bearing point location of the bearing base is partly changed, part of supporting stiffness of the bearing base is changed on the maximal stress location of the bearing, so that the loading is uniformly bore by a roller in the bearing as far as possible, the peak load of a bearing rolling body is greatly reduced, the problems that the bearing is untimely burned and the life is obviously shortened are avoided.

Owner:MCC SFRE HEAVY IND EQUIP

A lithium-ion battery with high energy and high safety performance

ActiveCN110890521BGuaranteed anti-acupuncture safety performanceReduces the risk of internal short circuitsElectrode carriers/collectorsSecondary cells servicing/maintenanceHigh energyCarbon nanotube

The invention discloses a lithium-ion battery with high energy and high safety performance, which comprises a negative electrode sheet, a separator, a positive electrode sheet laminated or a wound electric core, wherein the positive electrode sheet contains a positive electrode current collector, a positive electrode active material, and a positive electrode conductive agent. , positive electrode binder and positive electrode additive; the negative electrode sheet contains negative electrode current collector, negative electrode active material, negative electrode conductive agent, negative electrode binder and negative electrode additive; it is characterized in that: the coating layer on both sides of the surface of the positive electrode current collector is PTC material, Aluminum powder and carbon nanotubes; the positive electrode additive is a mixture of PTC material, aluminum powder and graphene; the coating layer on both sides of the positive electrode sheet is PTC material and graphene; the coating layer on both sides of the negative electrode current collector surface is PTC material , copper powder and carbon nanotubes; the negative electrode additive is a mixture of PTC material, copper powder and graphene; the coating layers on both sides of the negative electrode surface are PTC material and graphene. The invention obtains high safety performance, ensures safety and at the same time improves the energy density of the battery, improves the electrical performance of the battery and improves the level of the production process.

Owner:SUZHOU PHYLION BATTERY

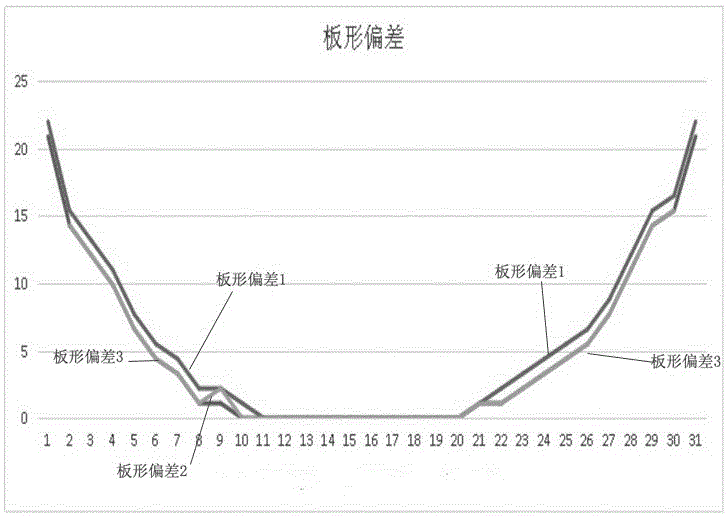

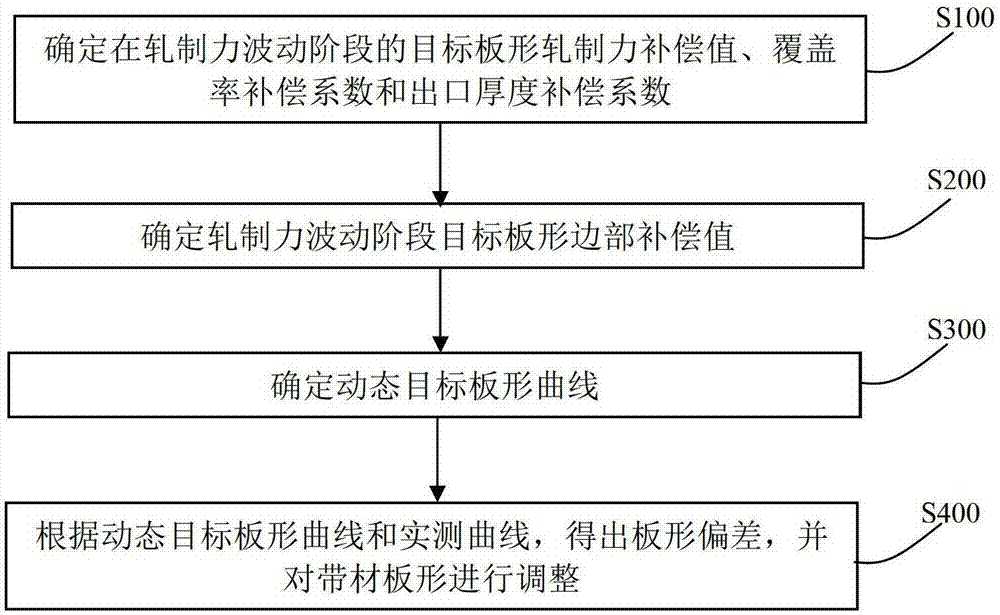

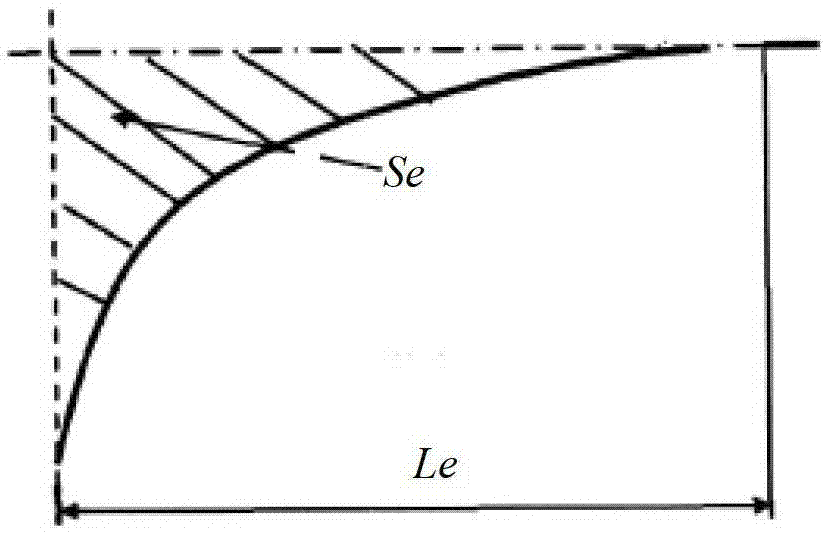

Target shape setting method

The invention discloses a target board shape setting method. The target board shape setting method comprises: step S100, confirming a target board shape rolling force compensation value, a coverage rate compensation factor and an outlet thickness compensation factor at a rolling force fluctuation stage; step S200, confirming a target board shape side portion compensation value at the rolling force fluctuation stage; step S300, confirming a dynamic target board shape curve; finally step S400, obtaining board shape deviation according to the dynamic target board shape curve and a measured curve and performing belt material board shape adjustment. The target board shape setting method can improve the board shape material object mass of belt material side portion at the rolling force fluctuation stage and ensures the rolling stability and decrease broken belt situation and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

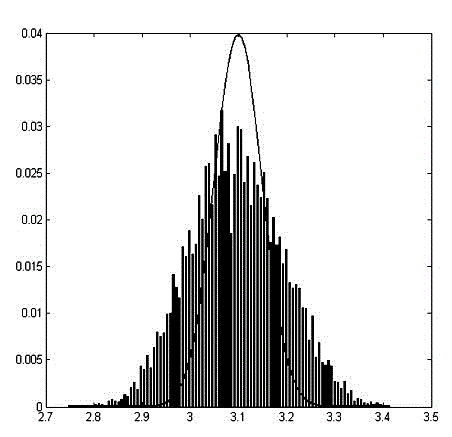

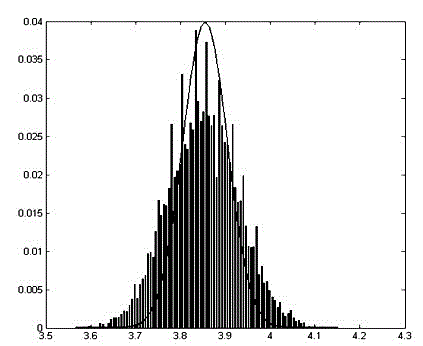

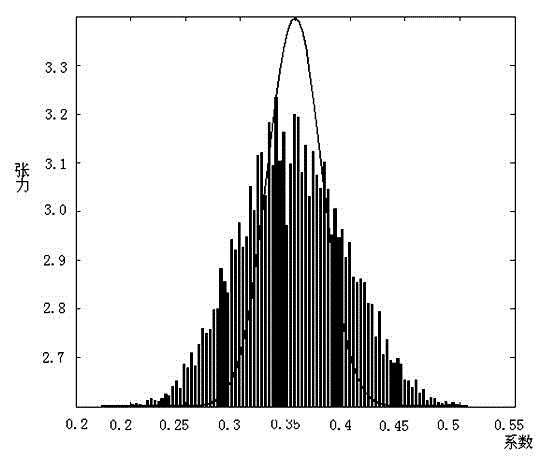

Prediction method of friction coefficient of cold rolling mill

ActiveCN104346505BHigh precisionReduce broken beltSpecial data processing applicationsRegression analysisPrediction methods

The invention provides a cold continuous rolling mill friction coefficient forecasting method which includes the steps: (1) screening related data; (2) calculating an empirical practical friction coefficient; (3) building a friction coefficient forecasting model; (4) building the forecasting method. Main factors influencing the friction coefficient are found out from influence factors of the friction coefficient and include steel grades, rolling speed, original roughness of rollers and rolling mileages, the data are divided into an experimental data set and a testing data set based on acquired rolling process data according to different steel grades and different frames, the experimental data set is used for fitting a curve and building a new calculation formula, and the testing data set is used for testing and verifying a calculation result. The cold continuous rolling mill friction coefficient forecasting method performs multivariate regression analysis for the data by the aid of a Mathematica7.0 analysis tool, and set accuracy of the frames can be improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

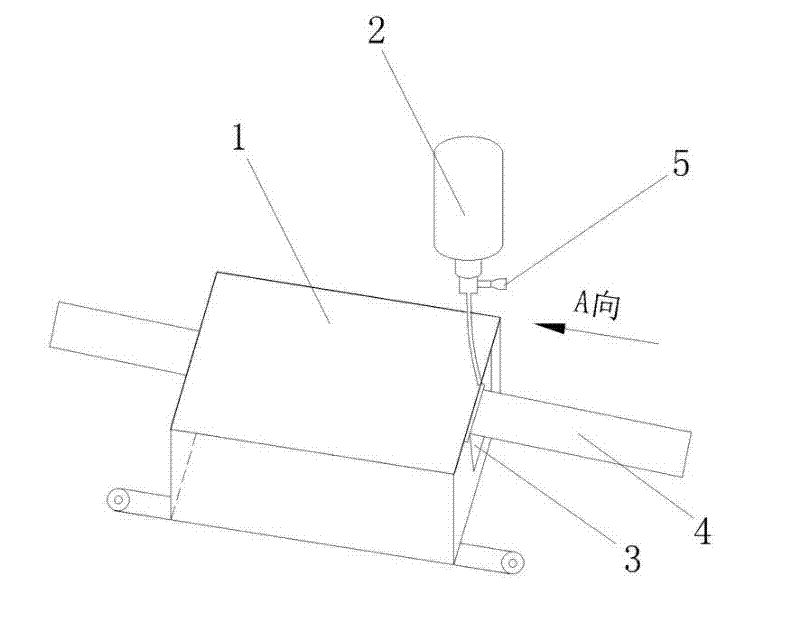

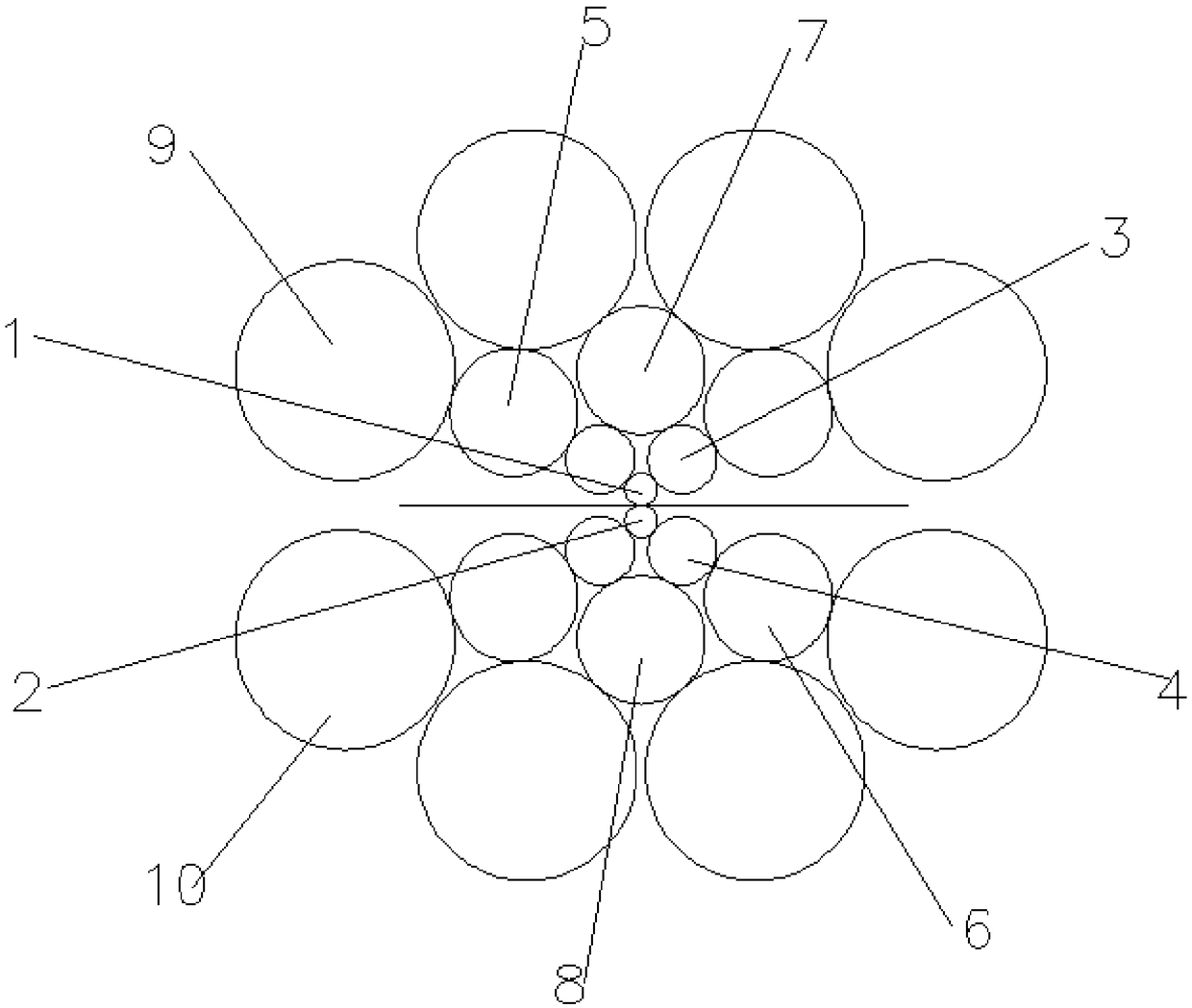

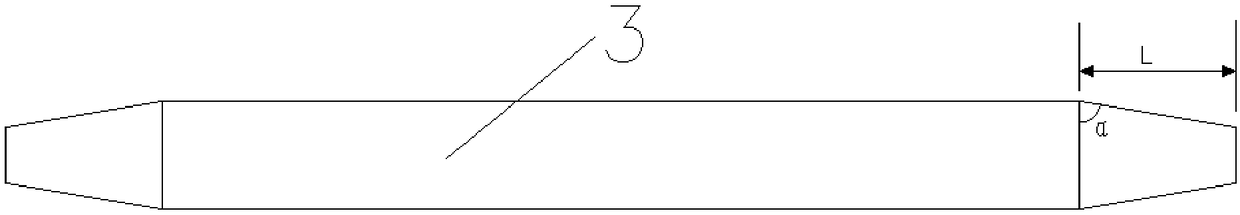

A method for preventing high-silicon electrical steel cold-rolled strip breakage

ActiveCN104014855BReduce broken beltReduce crackingMilling equipment detailsElectrical steelSheet steel

The invention relates to the field of production methods of electrical steel, and particularly relates to a method for preventing high-silicon electrical steel from being broken during cold rolling. The method is characterized in that specific to high-silicon electrical steel with the silicon content of above 2.0 and the thickness of 1.0-4.0 mm, cutters are arranged at the left side and the right side of a hot-rolled strip for performing a milling operation, an included angle alpha is formed between each cutter shaft and the moving direction of the hot-rolled strip, a rotating direction of a blade on each cutter is opposite to the moving direction of the hot-rolled strip, the moving speed of the hot-rolled strip is 5-40 m / min, when the depth of a side crack is less than 10 mm, a cutter is arranged at one side of the hot-rolled strip, and when the depth of a side crack is more than 10 mm, more than two cutters are arranged at one side of the hot-rolled strip for performing milling simultaneously. Compared with the prior art, the method has the beneficial effects of reducing the probability of strip breakage of high-silicon steel in a cold-rolling process, increasing the yield of high-silicon steel, being free from preheating and capable of realizing cold rolling at normal temperature, further reducing the probability of cracks by removing corner angles of a steel plate which is cut, and being capable of flexibly adjusting the trimming amount.

Owner:ANGANG STEEL CO LTD

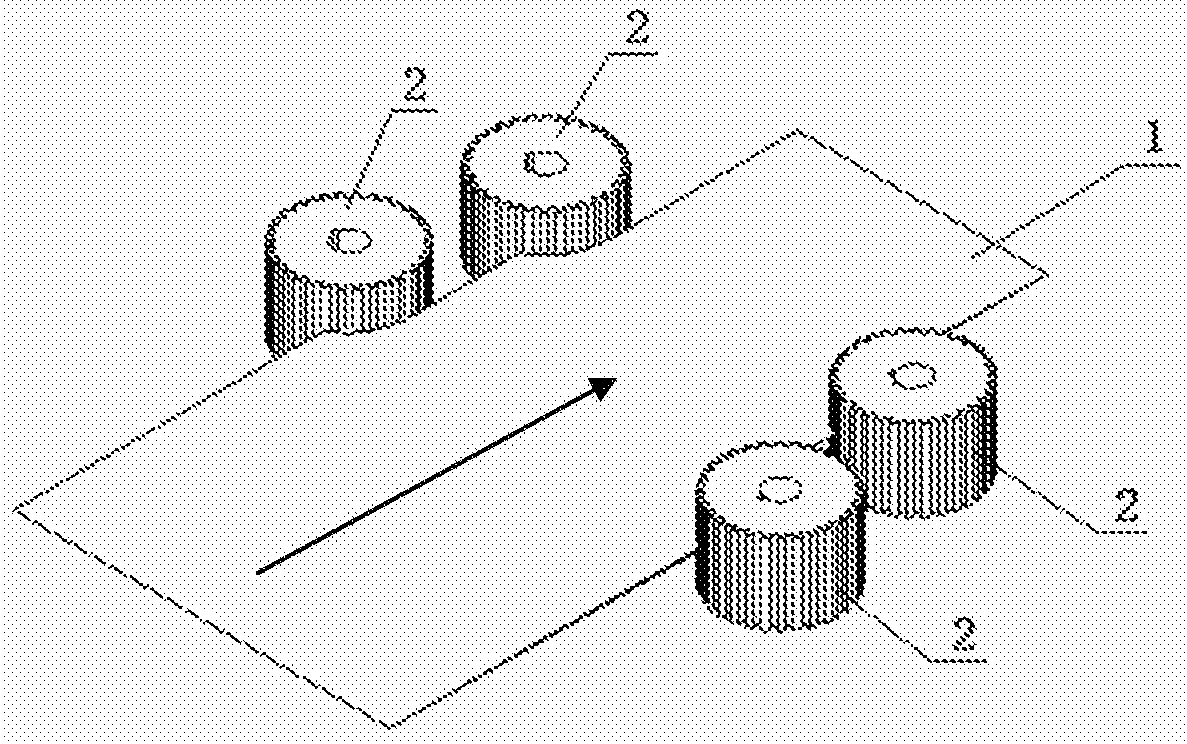

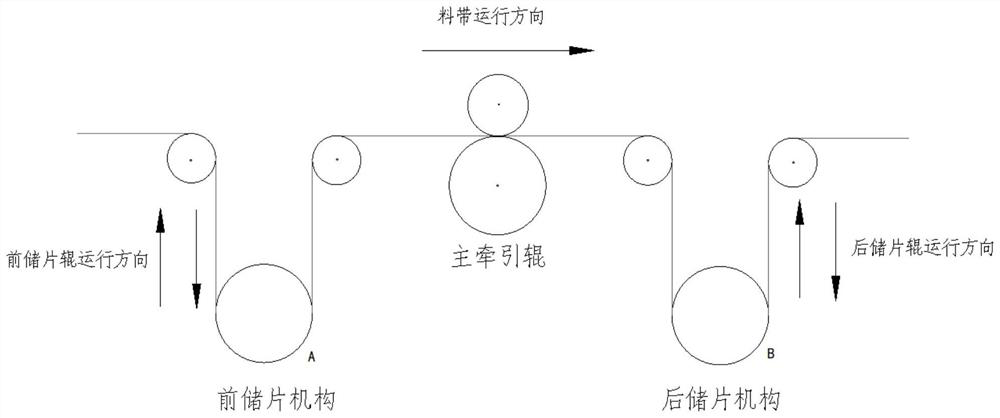

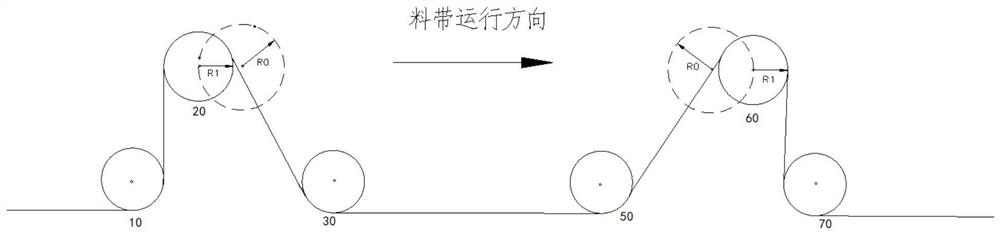

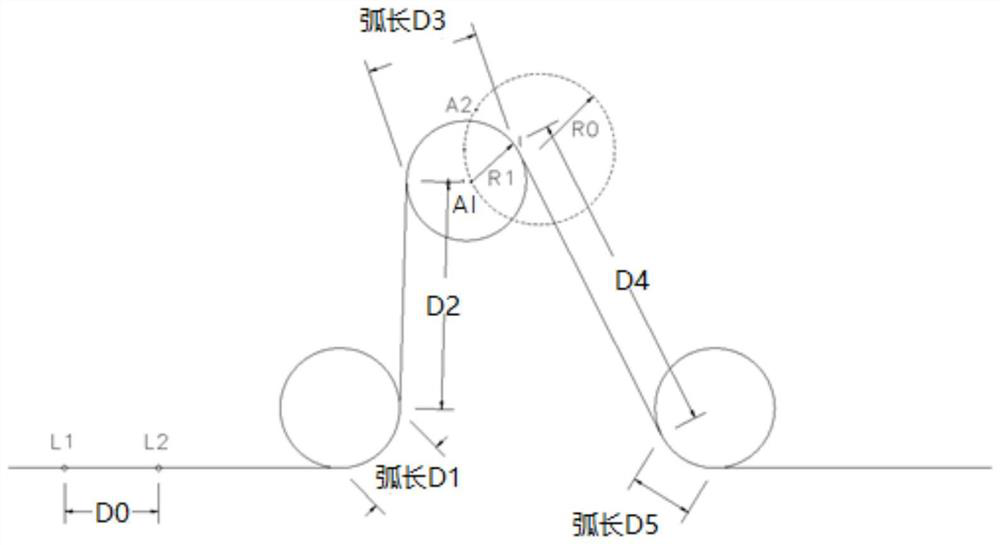

Buffering mechanism and material conveying device

PendingCN114873165AReduce jitterReduce broken beltConveyorsFinal product manufactureEngineeringControl theory

The invention relates to a temporary storage mechanism and a material conveying device. The temporary storage mechanism comprises a first front fixing roller, a first temporary storage roller, a first rear fixing roller, a second front fixing roller, a second temporary storage roller and a second rear fixing roller which are sequentially arranged in the running direction of a material conveying belt. The first front fixed roller, the first rear fixed roller, the second front fixed roller and the second rear fixed roller are located at the same horizontal position, the first buffer roller and the second buffer roller are located at the positions except the horizontal position where the first front fixed roller is located, and the first buffer roller and the second buffer roller are arranged in a mirror symmetry mode; the first buffer roller does non-uniform circular motion around a first preset circle center and a circle with a preset radius after being started; and the second buffer roller does non-uniform circular motion around a second preset circle center and a circle with a preset radius after being started. By adopting the method, the equipment operation stability can be improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

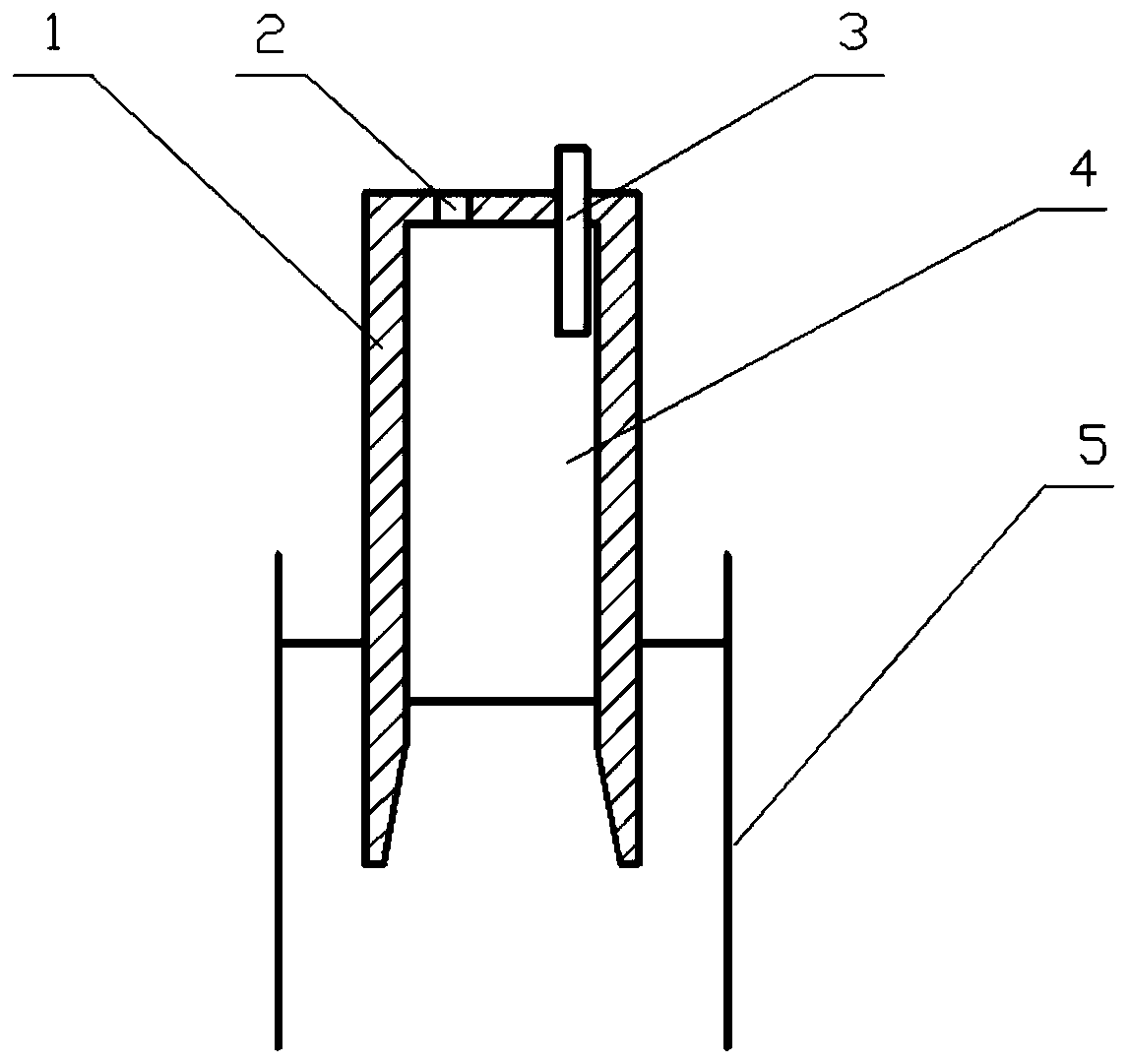

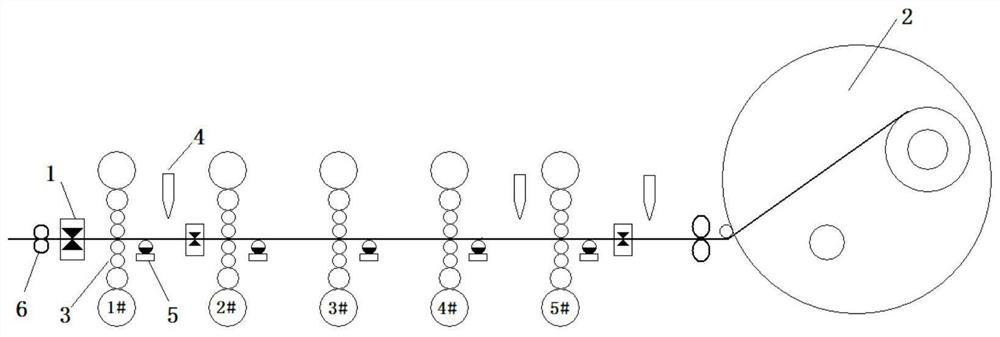

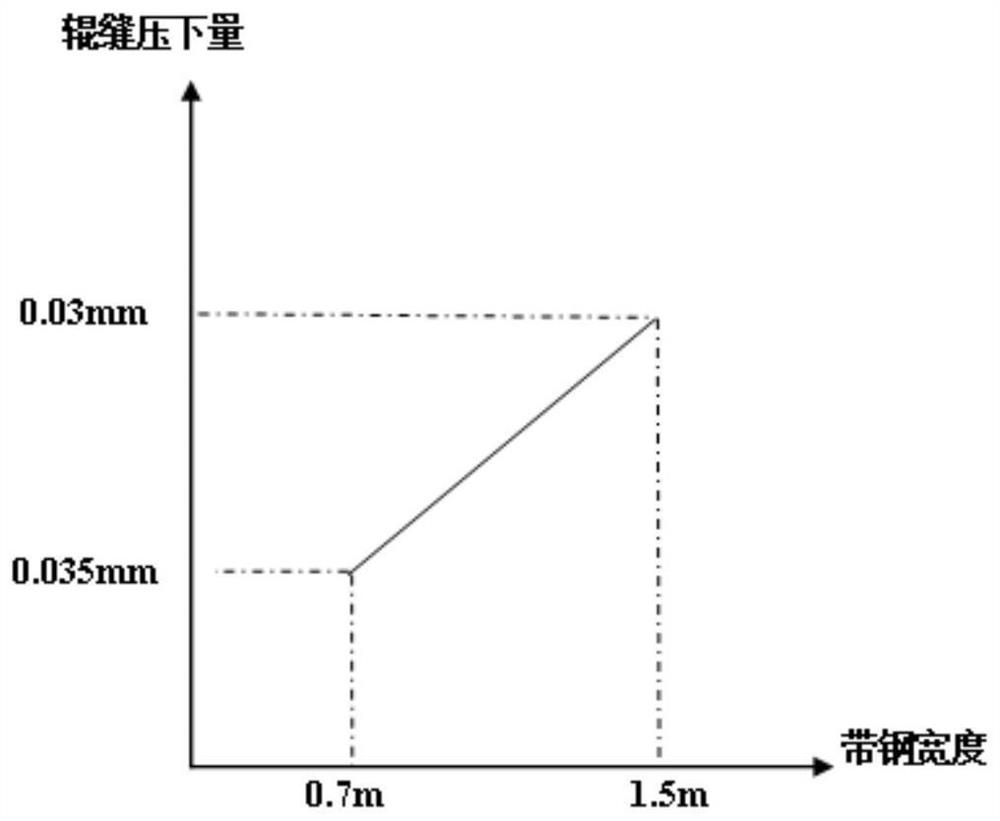

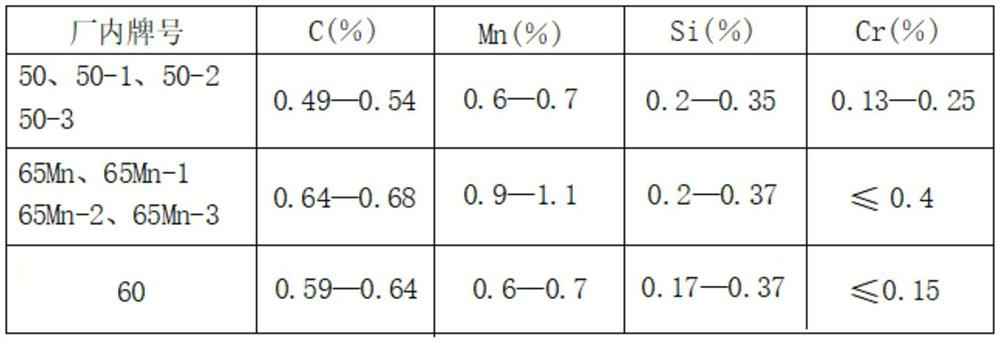

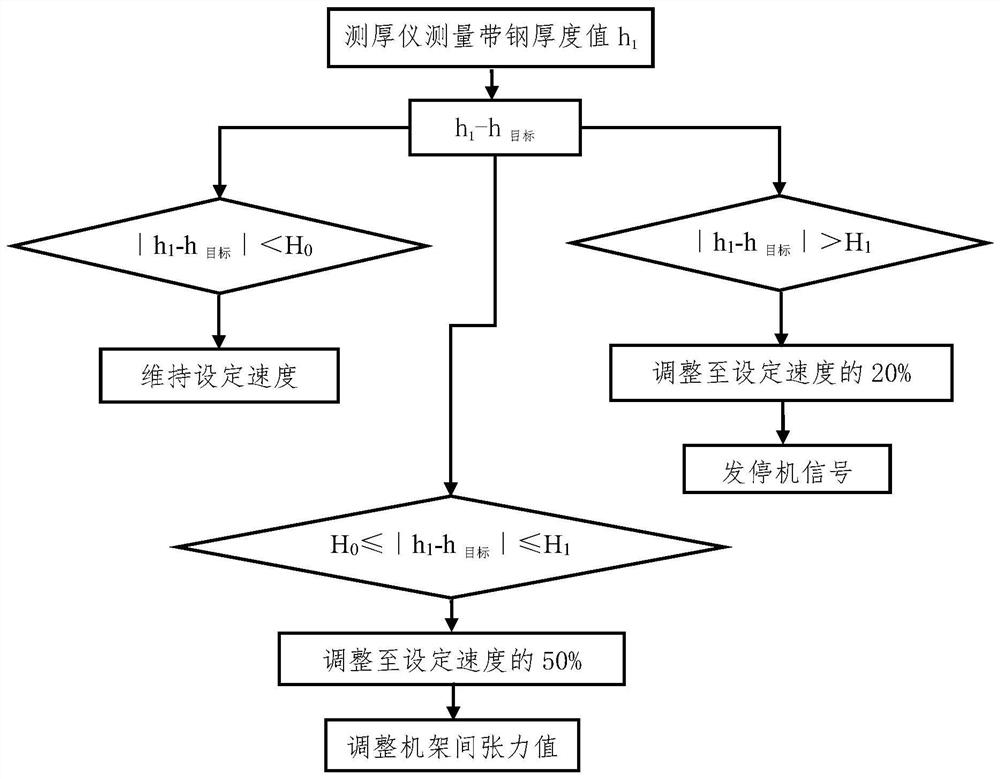

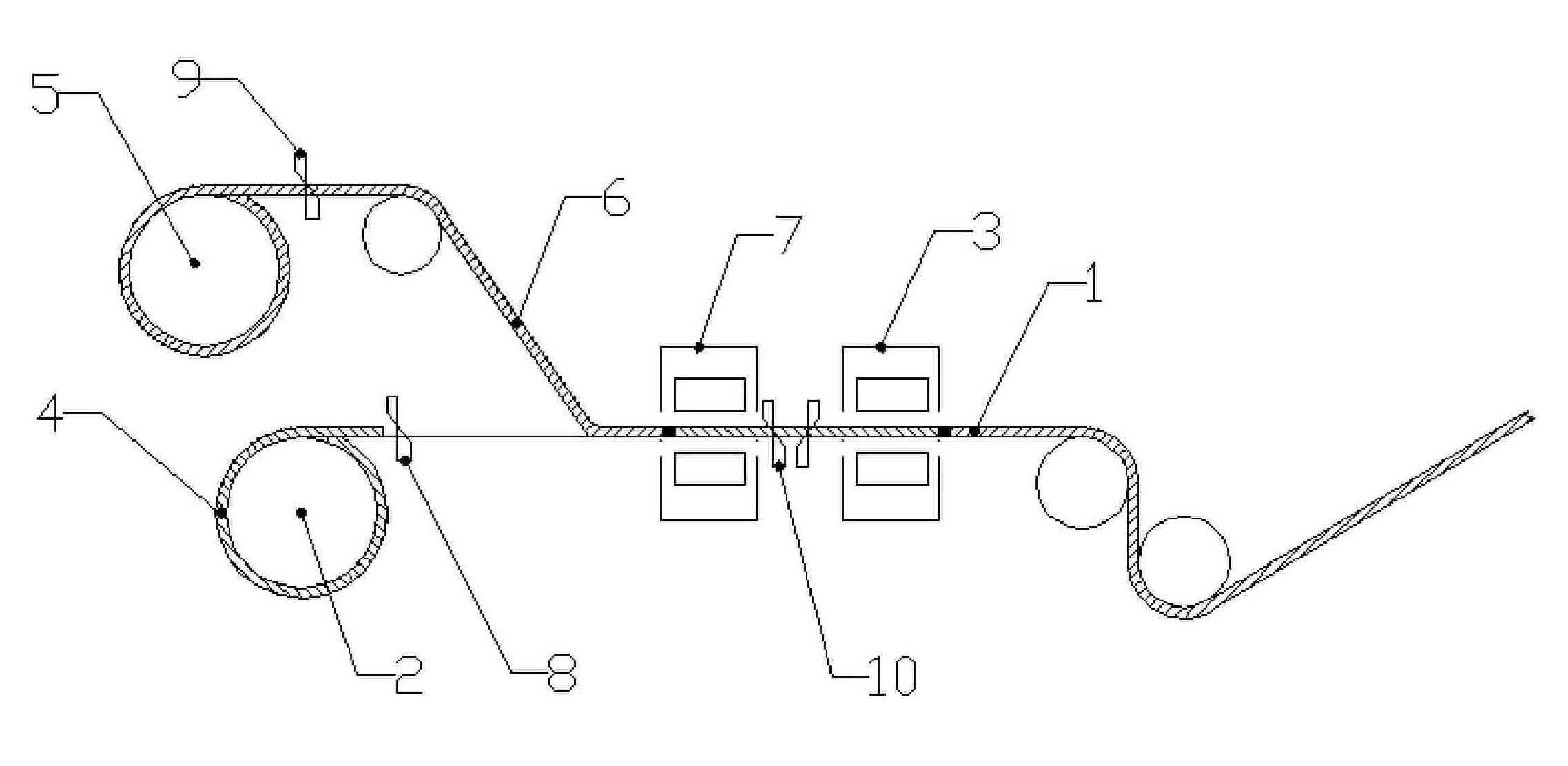

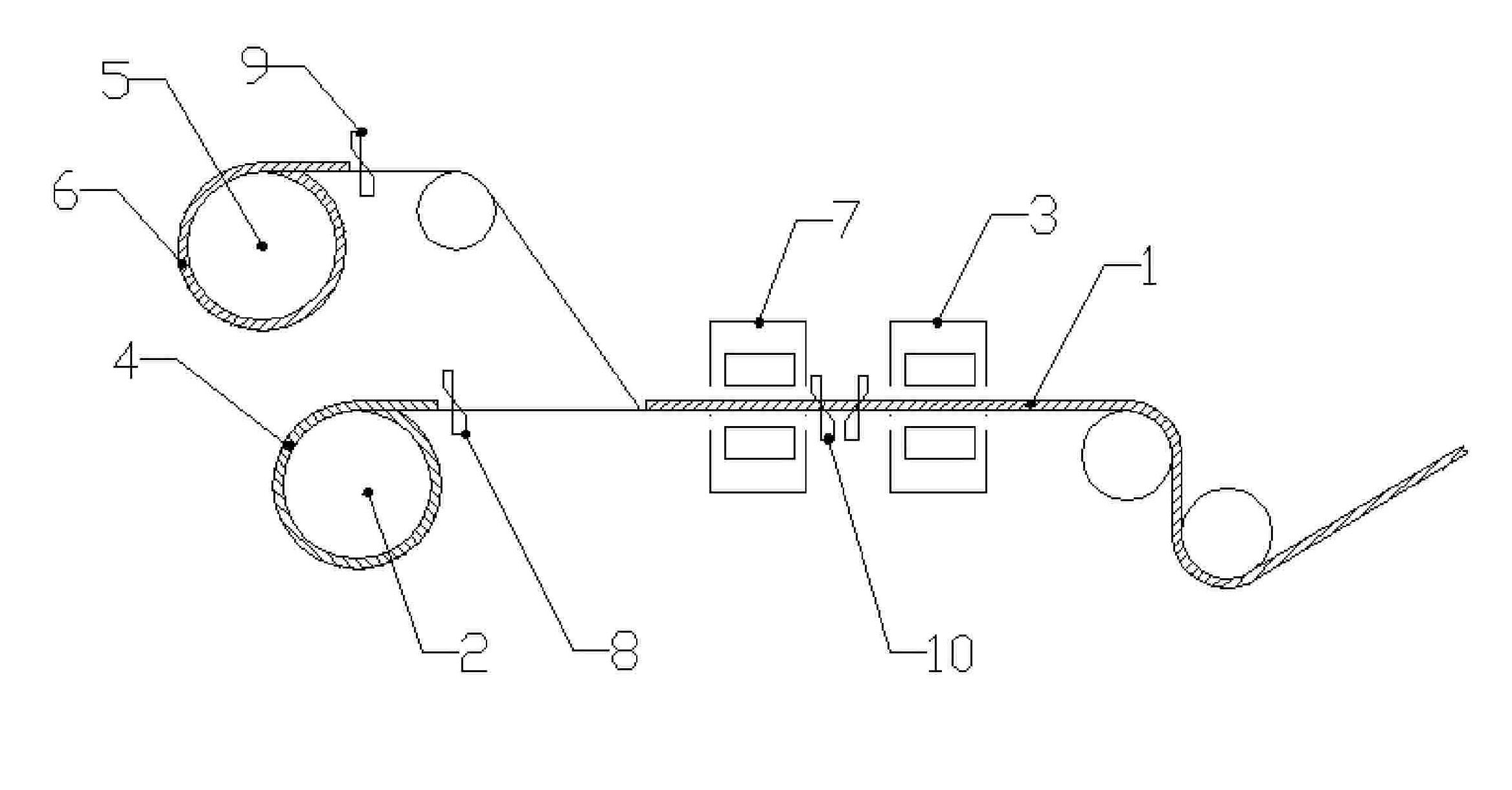

Rolling belt breakage prevention system for continuous rolling of high-carbon steel and control method thereof

PendingCN113118210AReduce broken beltImprove efficiencyMeasuring devicesMetal rolling arrangementsBreakage rateContinuous rolling

The invention discloses a rolling belt breakage prevention system for continuous rolling of high-carbon steel. At least two rolling mills are arranged at a rolling mill section of an acid rolling mill group, a tensiometer roller in contact with a product is arranged at an outlet of each rolling mill, the lower portions of an operation side bearing seat and a transmission side bearing seat of each tensiometer roller are each provided with a tension sensor, and the tension sensors output an induction signal to control equipment. According to the rolling belt breakage prevention system and method for continuous rolling of high-carbon steel, the occurrence of belt breakage during continuous rolling of the high-carbon steel can be reduced, meanwhile, the efficiency and the cost of continuous rolling of the high-carbon steel are improved, batch production of the high-carbon steel on a continuous rolling mill is realized, and the belt breakage rate is reduced within 3%.

Owner:新余钢铁股份有限公司

A method for monitoring and adjusting the vibration of a cold tandem rolling mill

ActiveCN111085543BStable productionIncrease productivityRoll mill control devicesMetal rolling arrangementsProduction lineControl engineering

Owner:BAOSHAN IRON & STEEL CO LTD

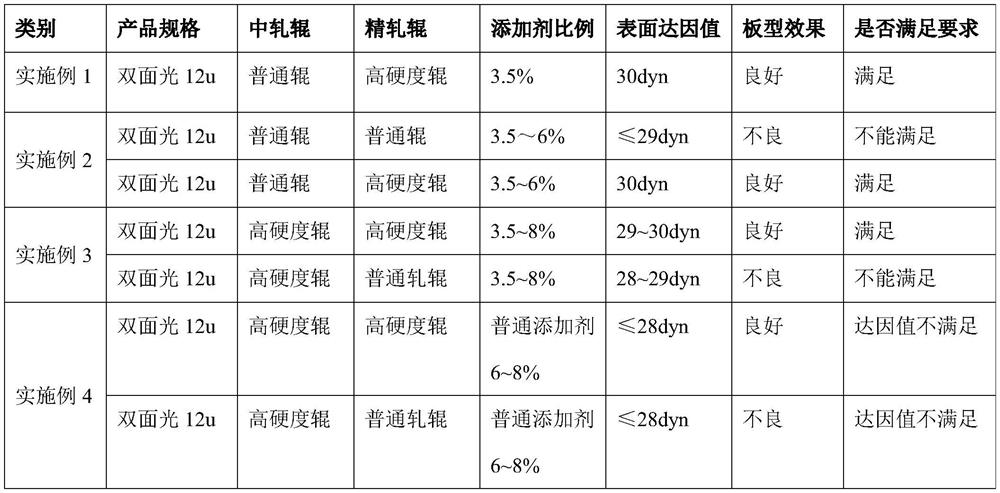

Production process of aluminum foil for lithium battery prepared by high hardness roll

ActiveCN111438187BImprove deformation resistanceEnhanced roll profile stabilityRoll mill control devicesRollsNonferrous metalAluminum foil

Owner:江苏大亚电子新材料科技有限公司

Non-oriented electrical steel head and tail flash welding technique

InactiveCN101264549BImprove plasticityImprove toughnessResistance welding apparatusElectrical steelLap joint

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

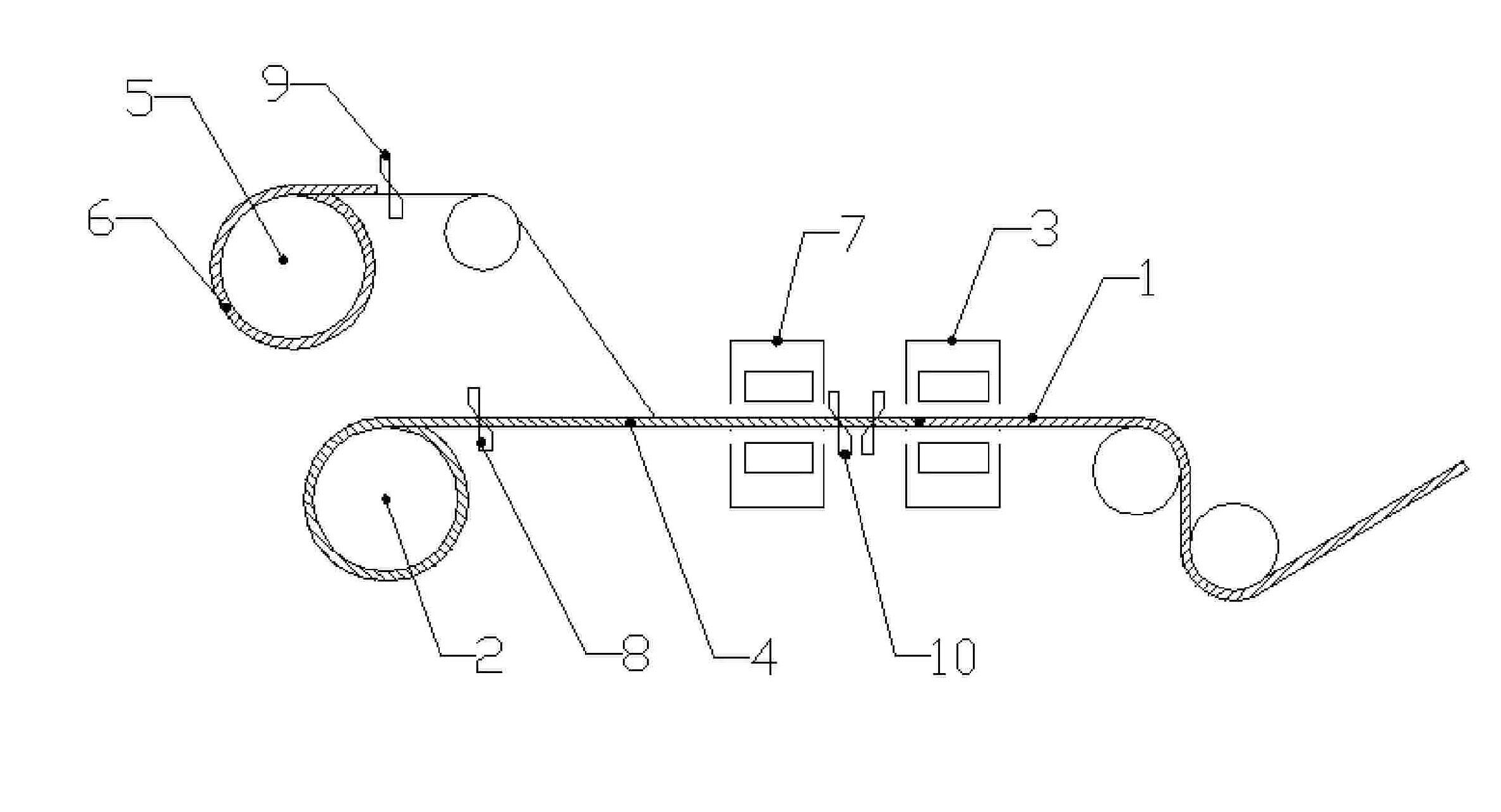

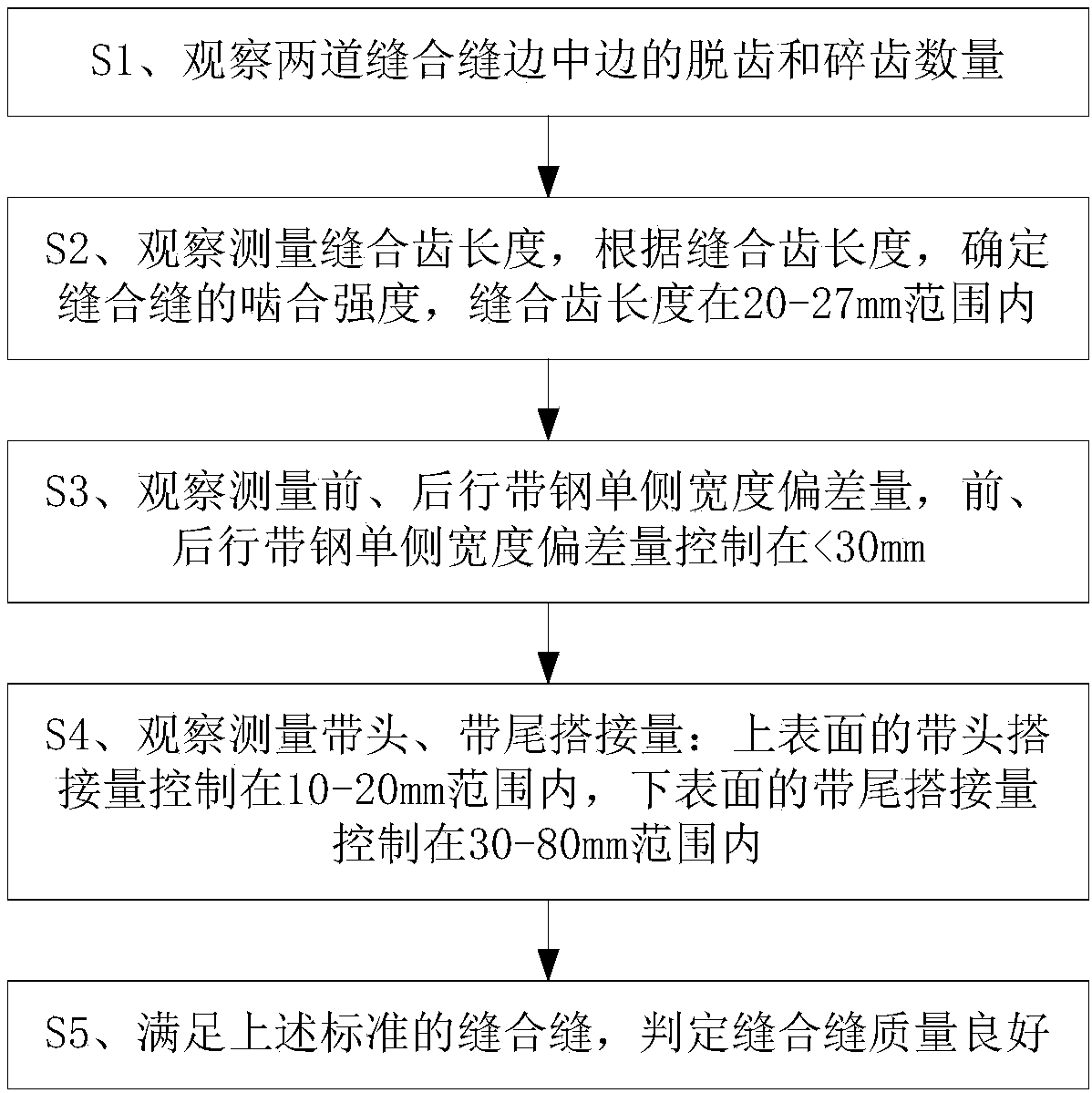

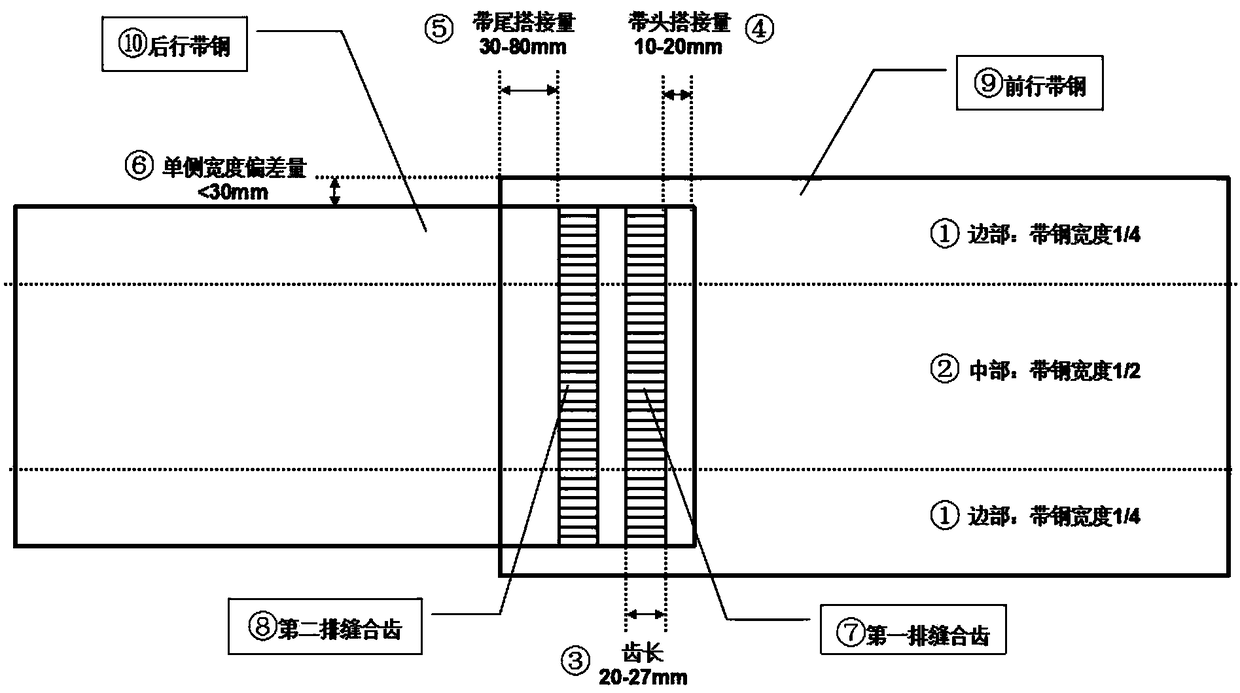

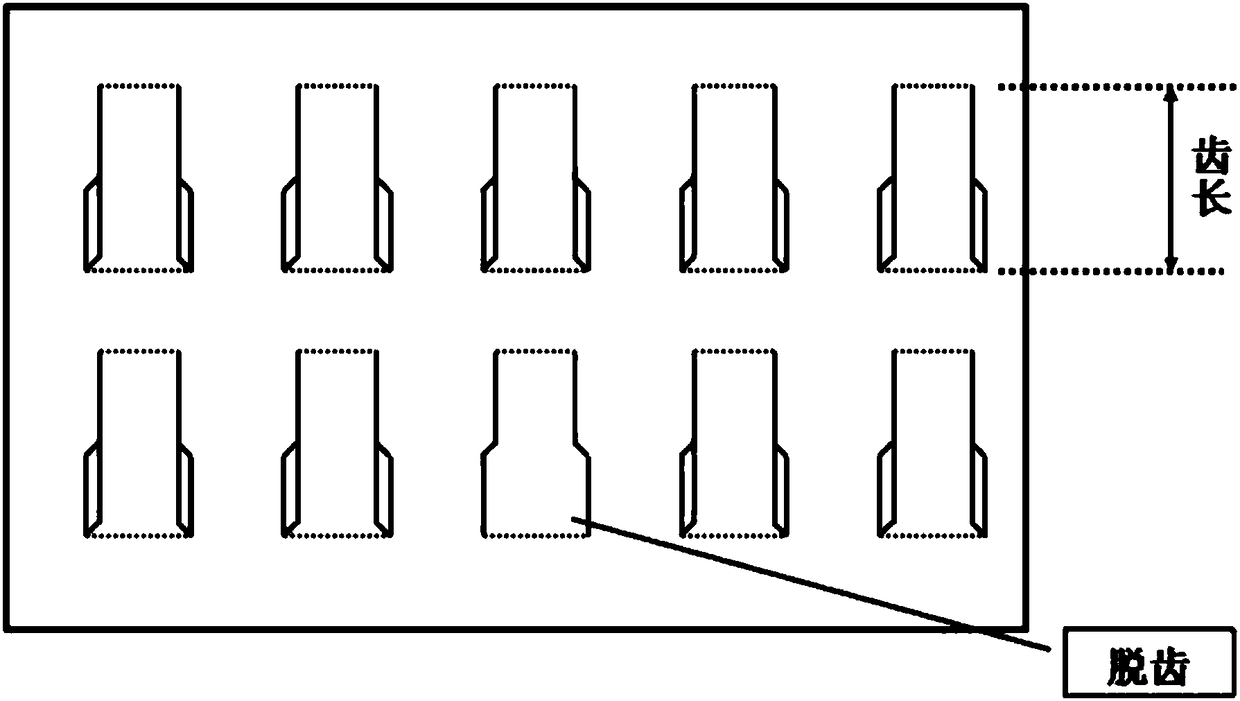

Method for judging quality of oriented silicon steel sutured seam

ActiveCN108931476AGuaranteed uptimeReduce broken beltUsing mechanical meansMaterial analysisTooth lengthBroken teeth

The invention discloses a method for judging the quality of an oriented silicon steel sutured seam; the quality of the sutured seam can be quickly judged according to conditions of removed tooth, broken teeth, tooth length, overlap quantity and deviation of unilateral width of the suture seam; the method can find out a suture seam with poor quality in time, performs re-suture in time, reduces thespeed-down shutdown or even band breakage caused by rewinding re-suturing, ensures the stable operation of the unit, and increases the unit output. After only observing and measuring need to be performed according to the standards, the quality of the suture seam can be judged, the breakage and shutdown caused by the suture seam can be effectively reduced, and the ability of stable operation of theunit can be improved; the field operation is simple, fast and strongly pertinent, and the method has good promotion value.

Owner:BAOSHAN IRON & STEEL CO LTD

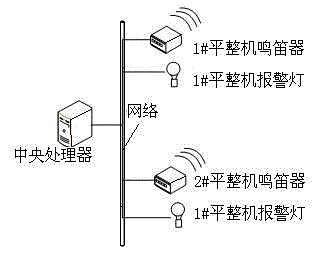

Pre-warning system and pre-warning method for inclination of temper mill

InactiveCN104550253AReduce the human factorReduce broken beltRoll mill control devicesMeasuring devicesEngineeringStrip steel

The invention relates to a cold-rolled sheet production system, in particular to a temper mill. A pre-warning system for inclination of the temper mill is characterized in that whether the temper mill may be in inclination or not can be subjected to computation processing by a central processing machine; a result can be sent to the temper mill if an abnormal situation appears, and whistling warning can be carried out while a lamp flashes. The pre-warning system is formed by two parts, wherein one part is provided with the central processing machine which is responsible for analyzing and forecasting the inclination of the temper mill, and the other part is provided with a warning lamp and a buzzer which are distributed in a roller group of the temper mill; flashing and whistling can be carried out for reminding a worker to operate when an inclination alarm of the temper mill is received. According to the pre-warning system disclosed by the invention, the problem of the inclination of the temper mill can be effectively solved; the quality of strip steel products is ensured, and further generation of strip steel defects is reduced by increasing the production benefit through the effective improvement.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

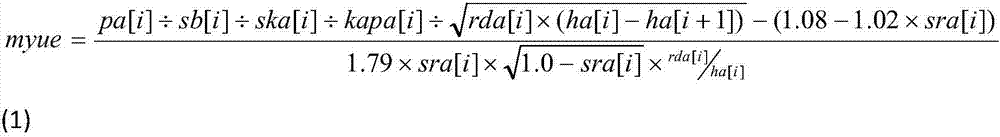

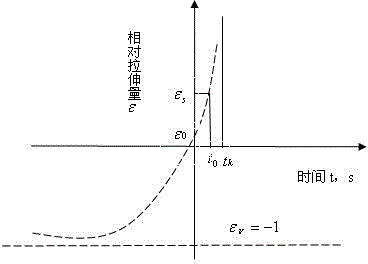

Quick early warning method of in-furnace tension fluctuation of cold rolled production line

InactiveCN104550242AReduce the human factorReduce broken beltRolling equipment maintainenceMeasuring devicesTension controlDistributed control system

The invention relates to a cold rolled production line monitoring method, in particular to a quick early warning method of the in-furnace tension fluctuation of a cold rolled production line. The quick early warning method of the in-furnace tension fluctuation of the cold rolled production line comprises the following steps: setting an early warning value in a level-2 machine, wherein a computational formula of band steel early warning tension sigma Omicron1 is as follows (shown in the specification); collecting and transmitting a tension signal to a DCS (distributed control system); comparing the tension signal with the preset early warning value by the level-2 machine; if the tension signal is greater than the early warning value, giving out an early warning signal. A situation that faults are caused since an operator sets a tension value from feelings can be avoided, and more optimal tension control values can be quickly set.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com