A method for preventing high-silicon electrical steel cold-rolled strip breakage

A technology of high-silicon electrical steel and broken strips, which is applied to manufacturing tools, metal processing equipment, milling machine equipment details, etc., can solve the problems of long adjustment time, adjustment of trimming amount, and reduction of finished product rate, so as to reduce equipment cost and reduce The effect of breaking the belt and reducing the production cost

Active Publication Date: 2018-04-03

ANGANG STEEL CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the cutting edge of the disc shear is in surface contact with the edge of the steel strip, the trimming amount cannot be adjusted according to the edge during the production process. The trimming amount can only be adjusted before production, and the adjustment time is long, and the shearing amount is the smallest. Generally, it cannot be less than 10mm. If the shearing amount is too small, it cannot be cut, and the hot-rolled edge cracks are generally less than 10mm, and some parts without edge cracks are cut more, which increases the loss and reduces the yield. Can reach about 85%

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

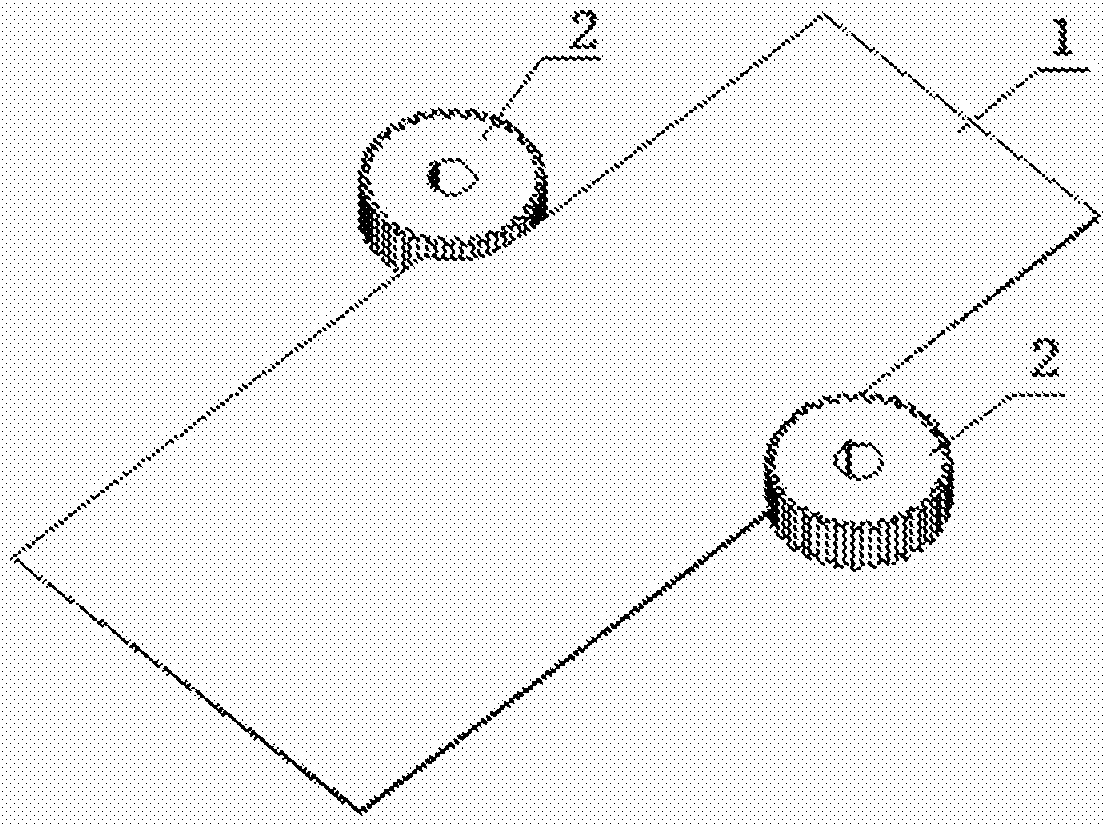

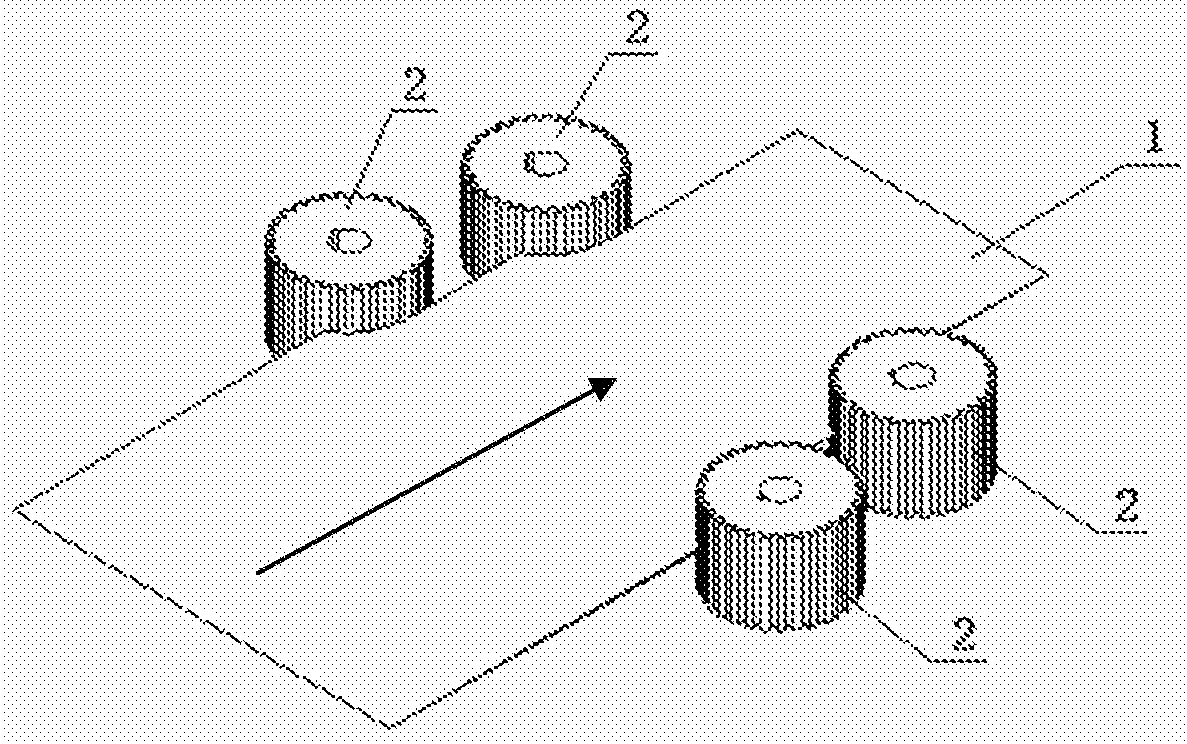

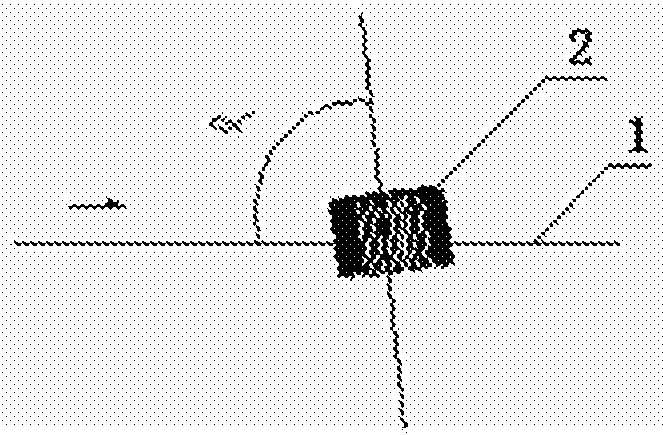

The invention relates to the field of production methods of electrical steel, and particularly relates to a method for preventing high-silicon electrical steel from being broken during cold rolling. The method is characterized in that specific to high-silicon electrical steel with the silicon content of above 2.0 and the thickness of 1.0-4.0 mm, cutters are arranged at the left side and the right side of a hot-rolled strip for performing a milling operation, an included angle alpha is formed between each cutter shaft and the moving direction of the hot-rolled strip, a rotating direction of a blade on each cutter is opposite to the moving direction of the hot-rolled strip, the moving speed of the hot-rolled strip is 5-40 m / min, when the depth of a side crack is less than 10 mm, a cutter is arranged at one side of the hot-rolled strip, and when the depth of a side crack is more than 10 mm, more than two cutters are arranged at one side of the hot-rolled strip for performing milling simultaneously. Compared with the prior art, the method has the beneficial effects of reducing the probability of strip breakage of high-silicon steel in a cold-rolling process, increasing the yield of high-silicon steel, being free from preheating and capable of realizing cold rolling at normal temperature, further reducing the probability of cracks by removing corner angles of a steel plate which is cut, and being capable of flexibly adjusting the trimming amount.

Description

A method for preventing high-silicon electrical steel cold-rolled strip breakage technical field The invention relates to the field of production methods of electrical steel, in particular to a method for preventing high-silicon electrical steel from being cold-rolled and broken. Background technique In order to give full play to the performance of cold-rolled electrical steel, its hot-rolled sheet needs to be normalized before cold-rolling. In order to avoid strip breakage during cold rolling, the normalization process adopts disc shearing edge treatment. Generally, if there are no cracks at the edge, stress concentration is not easy to occur during cold rolling, and strip breakage can be avoided. When the silicon content reaches more than 2.5, the yield of finished products is seriously affected due to the high rate of broken belts, which greatly increases the production cost. When the silicon content reaches about 3.20, cold rolling is difficult to carry out. For the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23C3/13

Inventor 张智义高振宇李亚东陈春梅张仁波刘文鹏李文权胡洪旭金泰东

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com