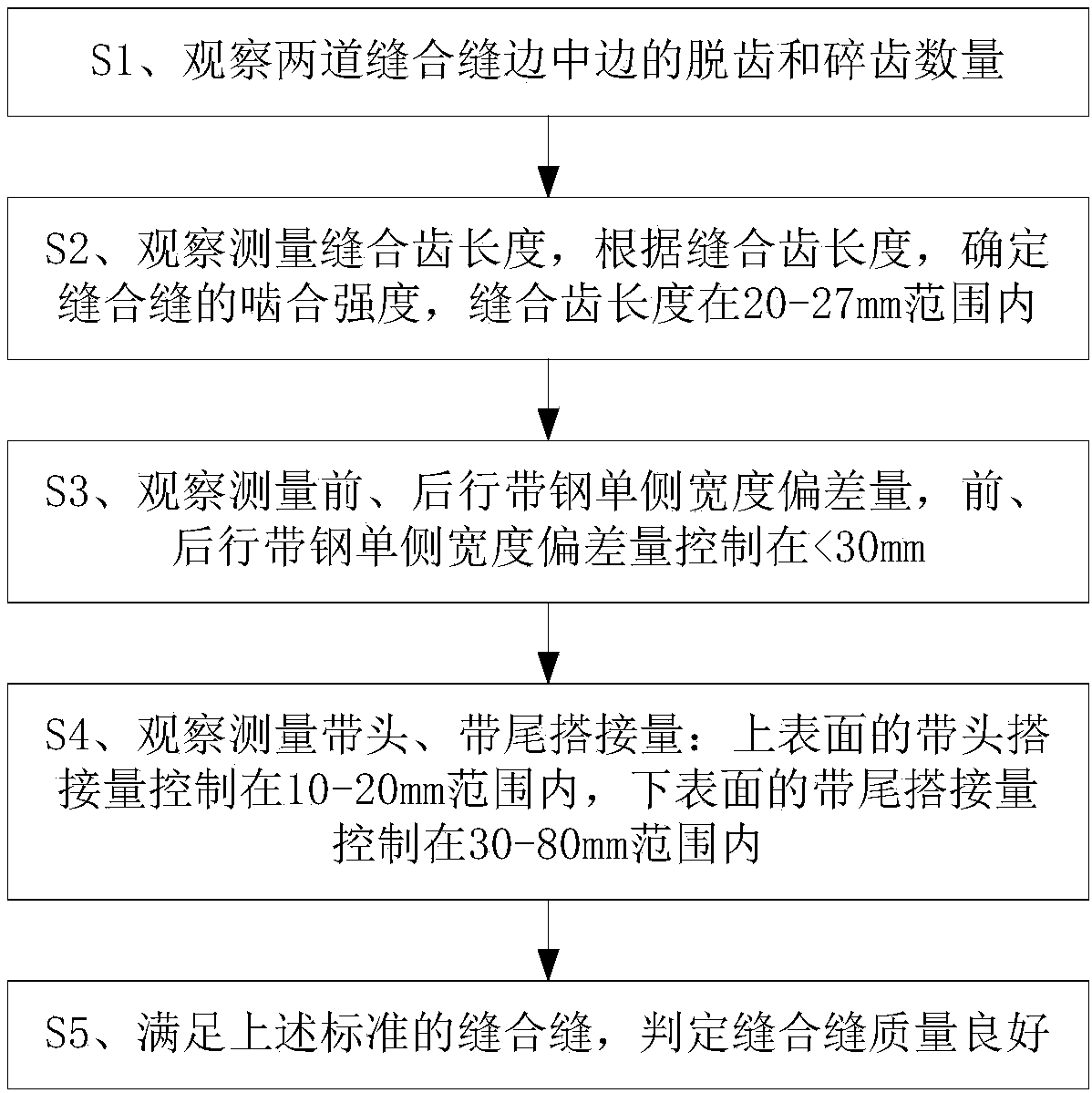

Method for judging quality of oriented silicon steel sutured seam

A kind of oriented silicon steel, quality technology, applied in the direction of measuring devices, instruments, mechanical devices, etc., can solve the problems of slow down, broken belt, no clear standard, etc., to improve the ability of stable operation, easy and fast on-site operation, good quality The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content and advantages of the technical solution of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings.

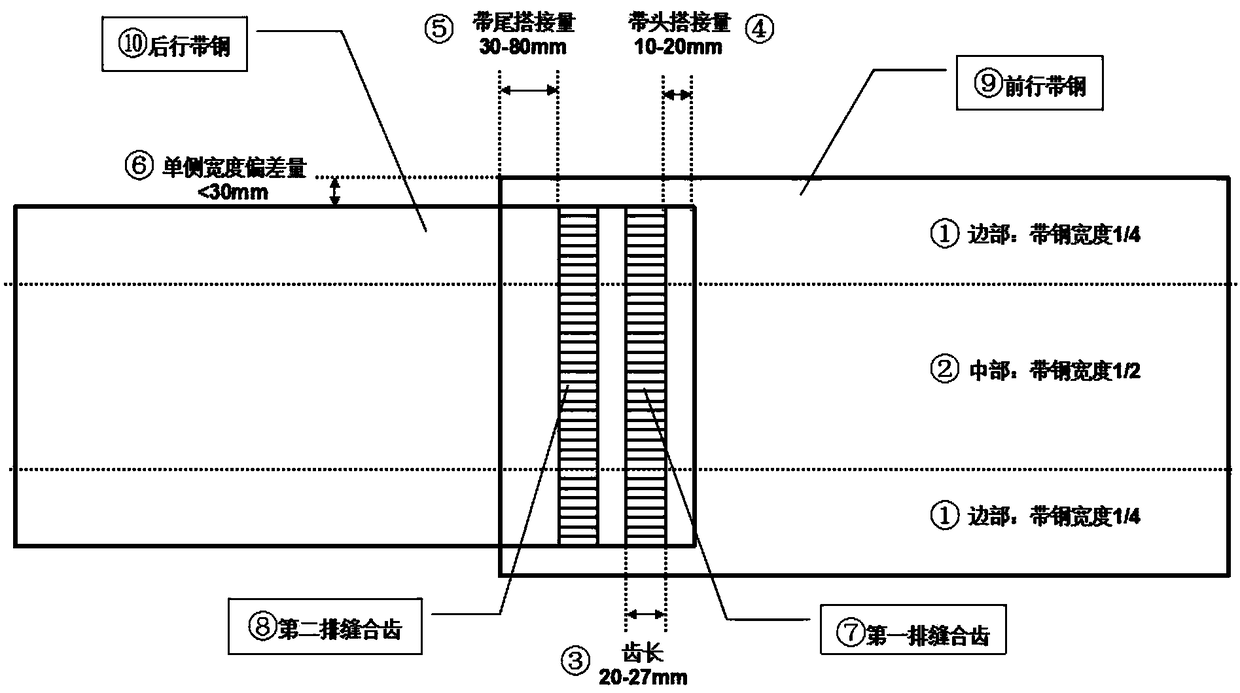

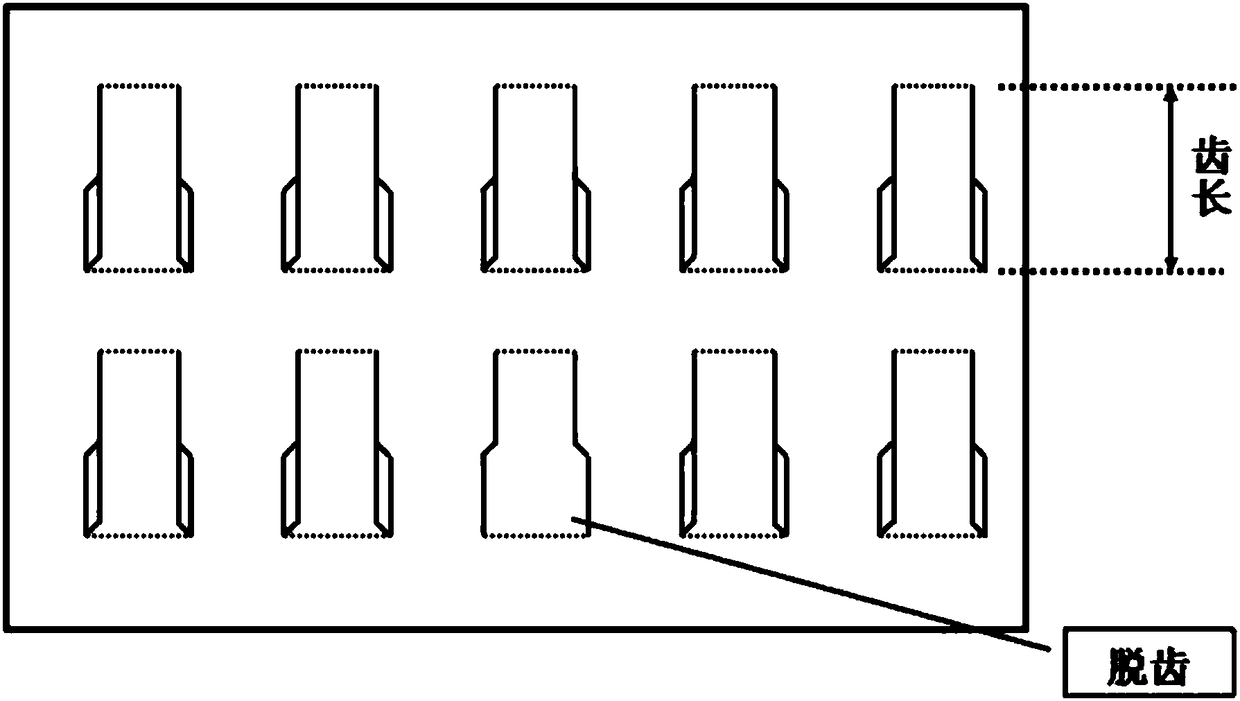

[0030] combine figure 2 Structural diagram of oriented silicon steel suture seam, including ① edge area of strip steel, ② middle area of strip steel, ③ tooth length of suture seam, ④ overlap amount of seam head, ⑤ overlap amount of seam tail, ⑥ front and rear strip sheet Side width deviation, ⑦the first row of seam teeth, ⑧the second row of seam teeth, ⑨forward strip steel, ⑩backward strip steel.

[0031] Before stitching the oriented silicon steel, observe and select the width difference between the forward strip and the rear strip: the width difference between the front strip and the rear strip should be controlled within 60mm, and the front and rear strips should keep the center line aligned, and then Ensure that the width deviation of the front and rear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com