Prediction method of friction coefficient of cold rolling mill

A technology of friction coefficient and prediction method, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems affecting the calculation accuracy of rolling force, affecting the control accuracy of strip thickness, and broken strips in rolling mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

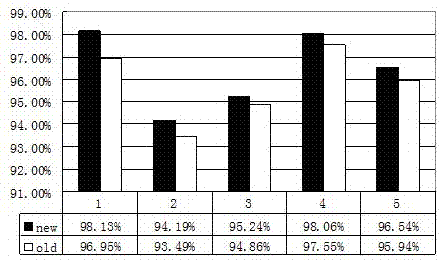

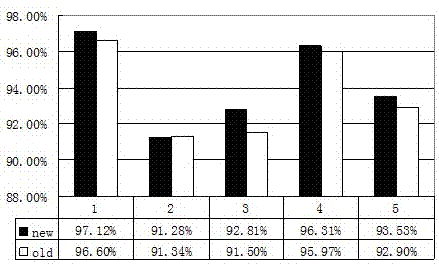

Examples

Embodiment Construction

[0034] A method for predicting the coefficient of friction of a cold tandem rolling mill, the method comprising the following steps:

[0035] (1) Screening of relevant data: Find out the main factors affecting the friction coefficient from the influencing factors of the friction coefficient, including steel grade, rolling speed, original roughness of the roll, and rolling kilometers;

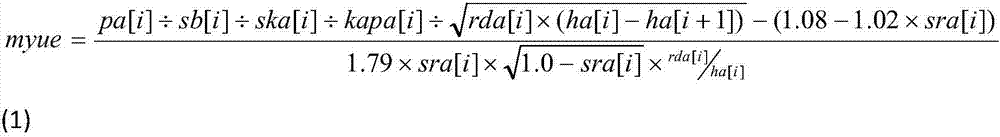

[0036] (2) Calculation of the empirical friction coefficient: the empirical friction coefficient is obtained by inverse calculation based on other actual performance data related to the rolling process using the rolling principle, and the calculation method is as follows:

[0037]

[0038] In the formula (1): myue is the historical experience actual performance friction coefficient obtained by using the actual rolling performance data back calculation;

[0039] sra[i] is the actual performance load of the current rack;

[0040] rda[i] is the flattening radius of the current rack;

[0041] h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com