Work roll for cold rolling edge drop control and method for designing roll contour of work roll

A work roll and roll shape technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of uneven force on the roll system, reduced grinding capacity of the grinder, and asymmetric control of the edge drop on both sides. , to avoid the easy peeling of the roll and the effect of good self-retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

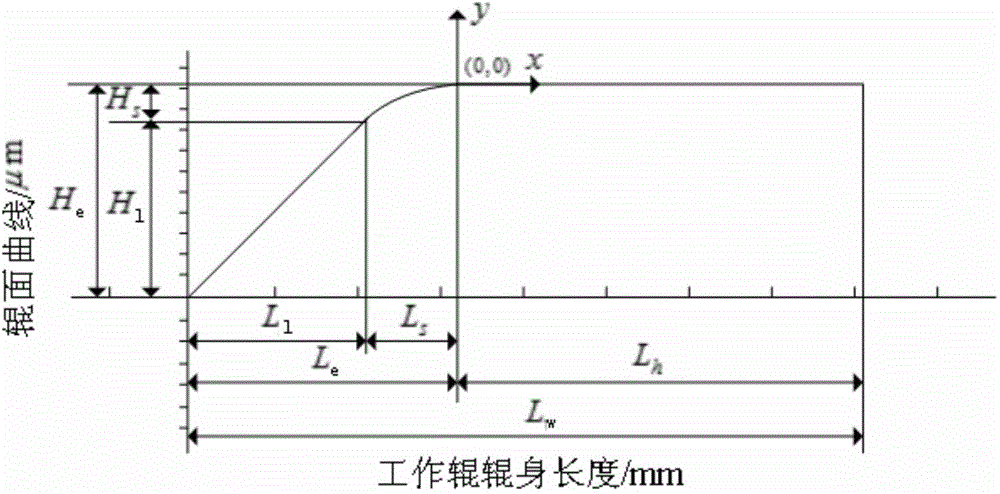

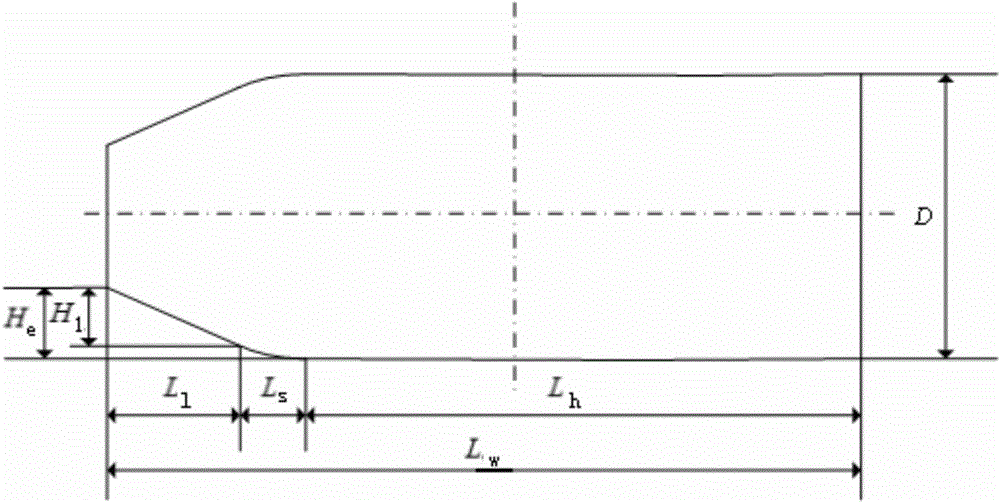

[0067] See attached figure 1 , in the two-dimensional coordinate system in the figure, the roll shape of the work roll used for cold rolling edge drop control provided by the embodiment of the present invention includes an oblique straight line segment, a quadratic curve segment and a horizontal straight line segment, and the quadratic curve segment is at its two ends They are respectively tangent to the oblique straight line segment and the horizontal straight line segment, and the roll curve equation is:

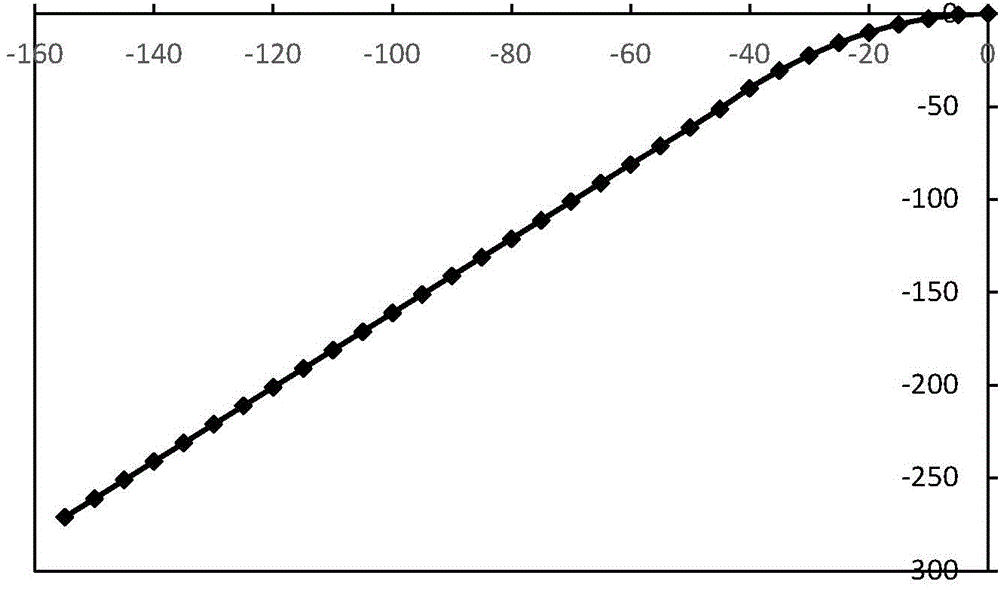

[0068] y ( x ) = 2 x + 40 - 155 ≤ x - 40 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com