Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Reached temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

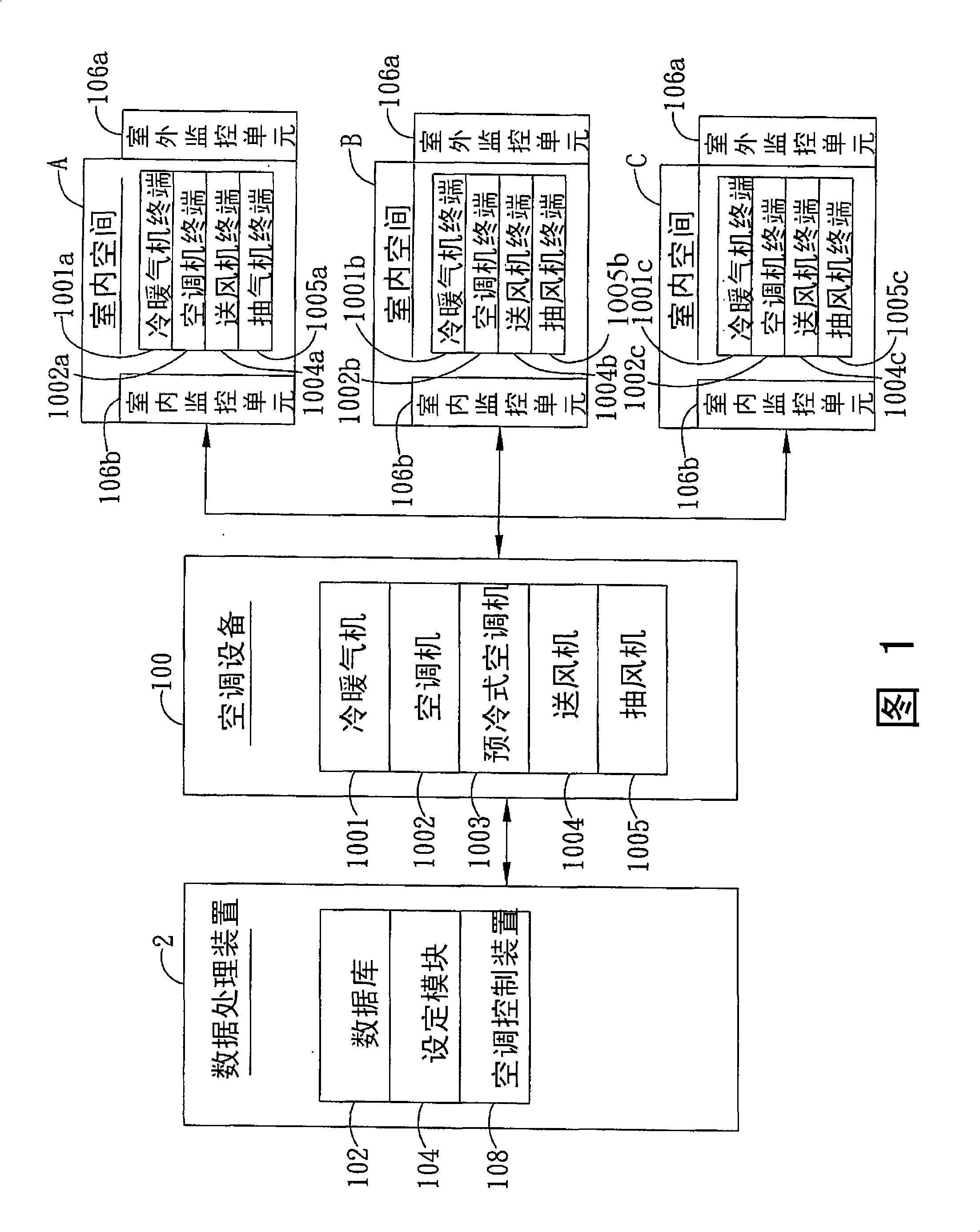

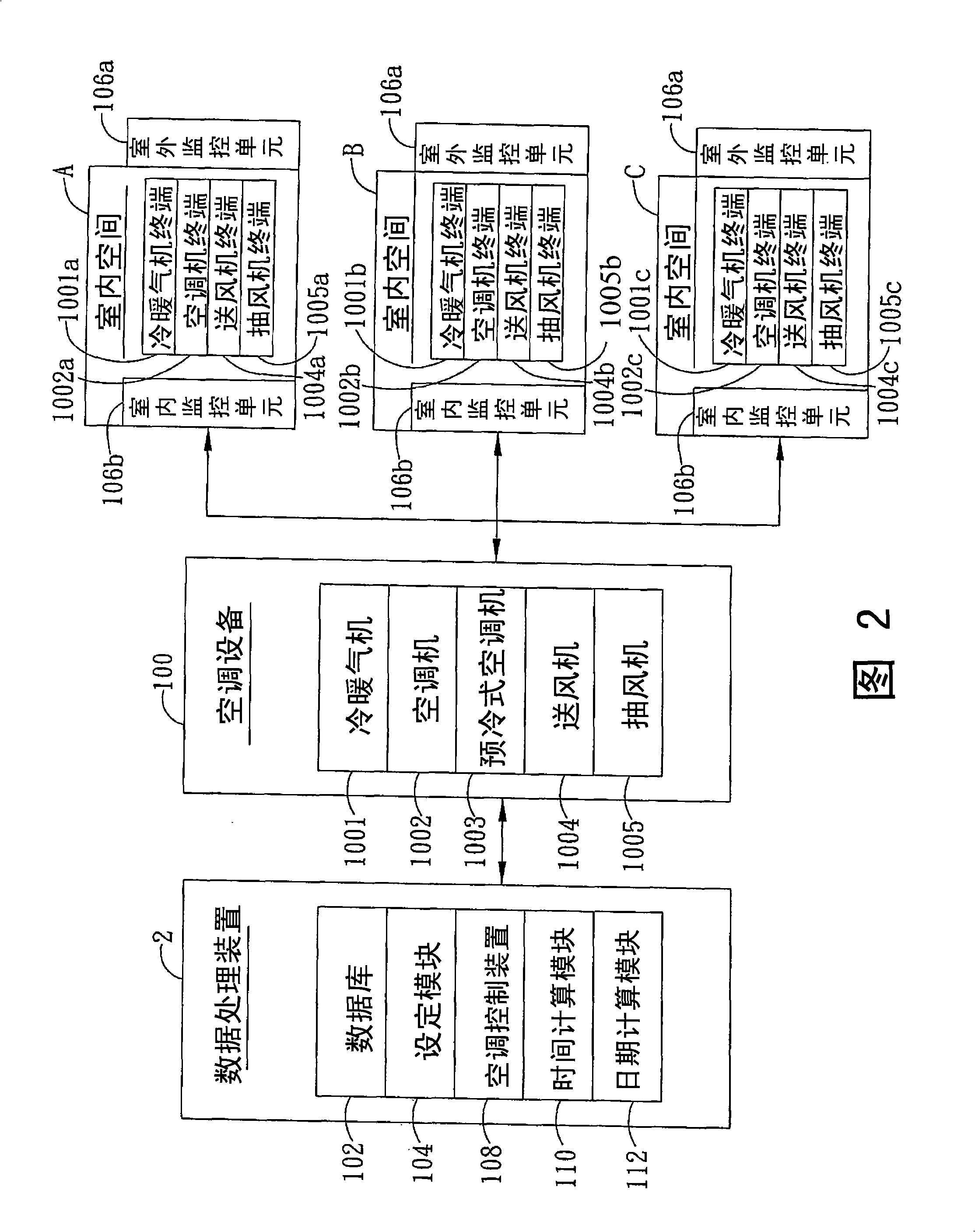

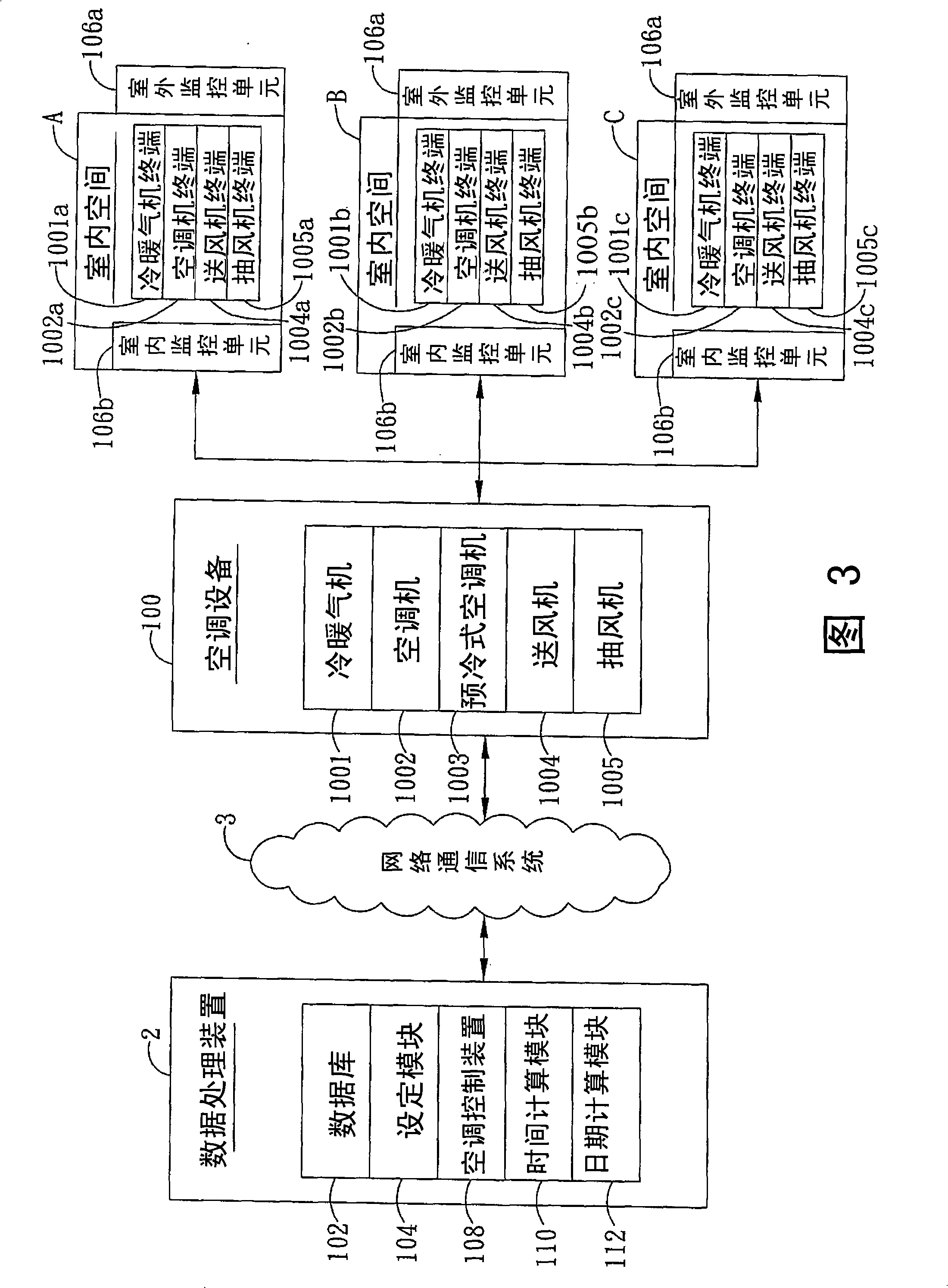

Air conditioning equipment quening regulate and control management system

InactiveCN101493691AReached temperatureTo achieve the purpose of energy managementSpace heating and ventilation safety systemsLighting and heating apparatusManagement systemEnergy resources

The invention provides a system for scheduling regulation management of air conditioning equipment, comprising a database used for memorizing scheduling data, outdoor environment value, indoor environment value, preset indoor environment value and corresponding regulation parameters thereof, a setting module which sets the scheduling, preset indoor environment value and the regulation parameters corresponding to the preset indoor environment value, with the set content being memorized in the database, a monitoring unit which monitors the outdoor environment value and / or the indoor environment value according to the scheduling data, with the monitored outdoor environment value and / or indoor environment value being memorized in the database, and an air conditioner control device which can executes the adjustment and control of the air conditioning equipment according to the scheduling data in the database, the outdoor environment value, the indoor environment data, preset indoor environment value and / or the regulation parameters corresponding to the preset indoor environment value. Therefore, the system can regulate the air conditioning equipment to a suitable use state by the preset scheduling, thus achieving the objective that the air conditioning equipment provides suitable temperature and saving the energy resource.

Owner:CHUNGHWA TELECOM CO LTD

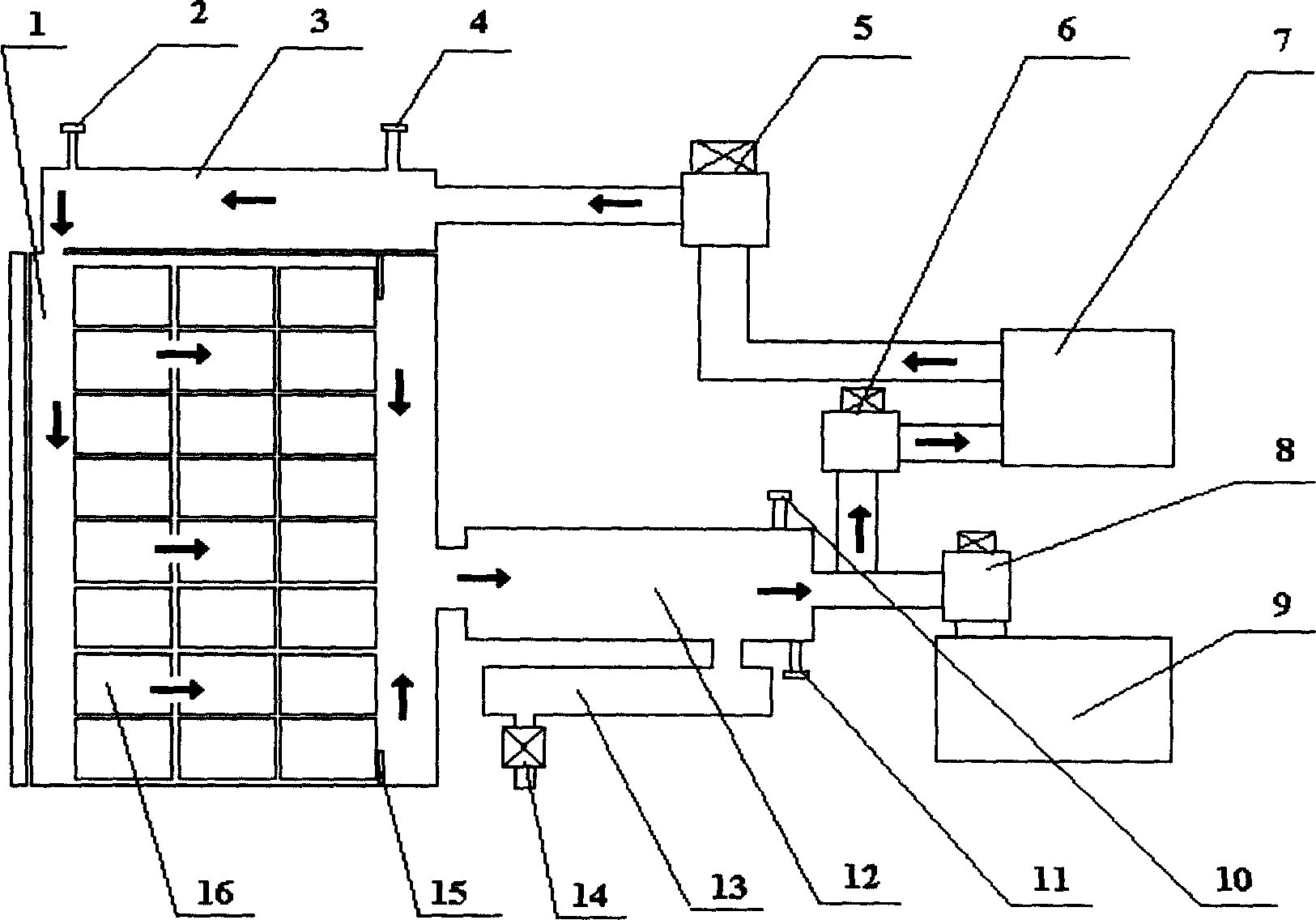

Edible fungus antistaling method and apparatus

InactiveCN1810131ANo pollutionDoes not damage appearanceFruits/vegetable preservation by freezing/coolingBiotechnologyContamination

Edible fungus antistaling method and apparatus are disclosed. The method includes dehumidifying fresh edible fungus with circulating wind inside a sealed vacuum processing chamber to reach set temperature and water content, and fast vacuum freezing to further eliminate water of edible fungus. The said method can maintain the metabolism of edible fungus and reach required temperature and water content of edible fungus without contamination and damage to look of edible fungus. The method and apparatus has low power consumption, results in homogeneous temperature and water content inside and outside the edible fungus, controls water content in edible fungus in 70-88 % and makes edible fungus capable of being preserved and transported at low temperature for long period.

Owner:上海大生泰保鲜设备有限公司

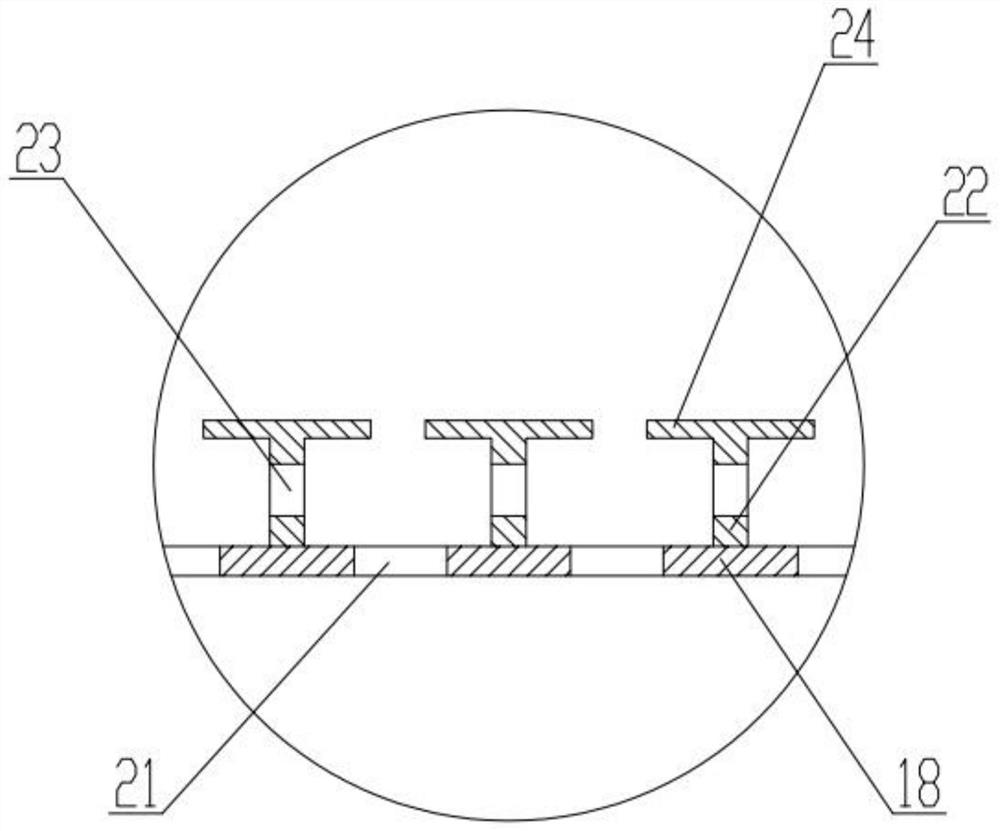

Core making process and core making device of triethylamine cold box

InactiveCN104959543AReduce usageSave phosphoric acid usageFoundry mouldsMoulding machinesExhaust gasPhosphoric acid

The invention discloses a core making process and a core making device of a triethylamine cold box. The core making process comprises a plurality of sequential steps of primary sand shooting, primary gas blowing, primary tail gas recovery, primary core jacking and taking, subsequent sand shooting, subsequent gas blowing, subsequent tail gas collection and compression, subsequent core jacking and taking, and core making finishing or circulating back to subsequent sand shooting; as the triethylamine mixed gas introduced into the box only functions in catalysis and does not joint in reaction, the discharged triethylamine tail gas is the same as the triethylamine mixed gas introduced in components and is capable of directly joining in the subsequent catalytic reaction; the use amount of the triethylamine in the subsequent core making process is saved, the use of phosphoric acid is reduced, and no gas is discharged to the atmosphere; in short, the core making process has the advantages of conservation and environmental protection.

Owner:SUZHOU MINGZHI TECH

Preparation method of high-TCR low square resistance linear NTC resistance paste

ActiveCN105321642AWith linear NTC effectHigh TCRNegative temperature coefficient thermistorsManganeseThermistor

The invention discloses a preparation method of a high-TCR low square resistance linear NTC resistance paste. According to the method, nonlinear manganese, nickel and copper NTC ceramic reaction precursors are taken as main body function materials of the linear NTC paste, and the addition amount of precious metals can be effectively reduced by preparing a nonlinear NTC material with suitable B values (material constants) and specific resistance; and moreover, the value of resistance and the influence of temperature on the value of resistance are reduced by using an appropriate amount of nonlinear NTC powder to be mixed with ruthenium powder or ruthenium oxide powder, the linear relation between the value of resistance and the temperature is achieved, and the method is extremely stable in application. The method accords with the miniaturization and lamination development direction of current electronic components, key electronic pastes are independently researched and developed and are produced in large scale, the development of domestic electronic components can be quickened, and the cost of components and parts such as thermistors can be greatly reduced by preparing the low-cost and high-performance linear NTC paste, so that great economic benefits can be brought.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

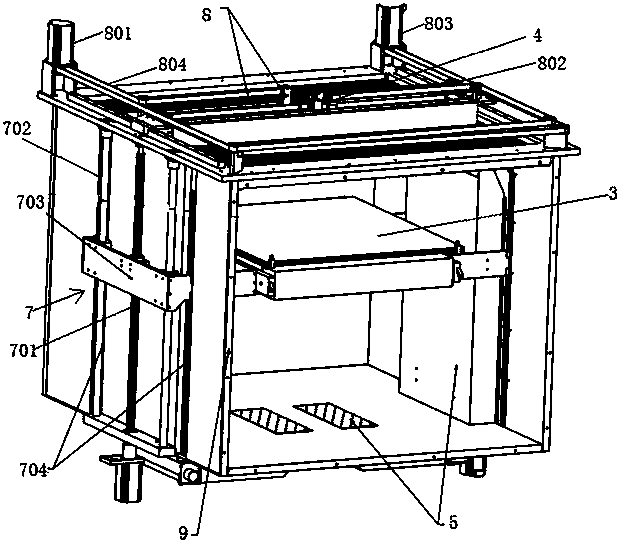

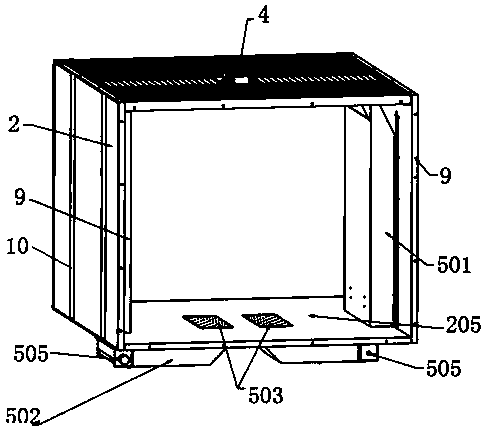

3D printer of double cycle heating constant temperature forming space

PendingCN108582782AGuaranteed accuracyReached temperatureAdditive manufacturing apparatusTemperature controlEngineering

Owner:GUANGZHOU ELECTRONICS TECH

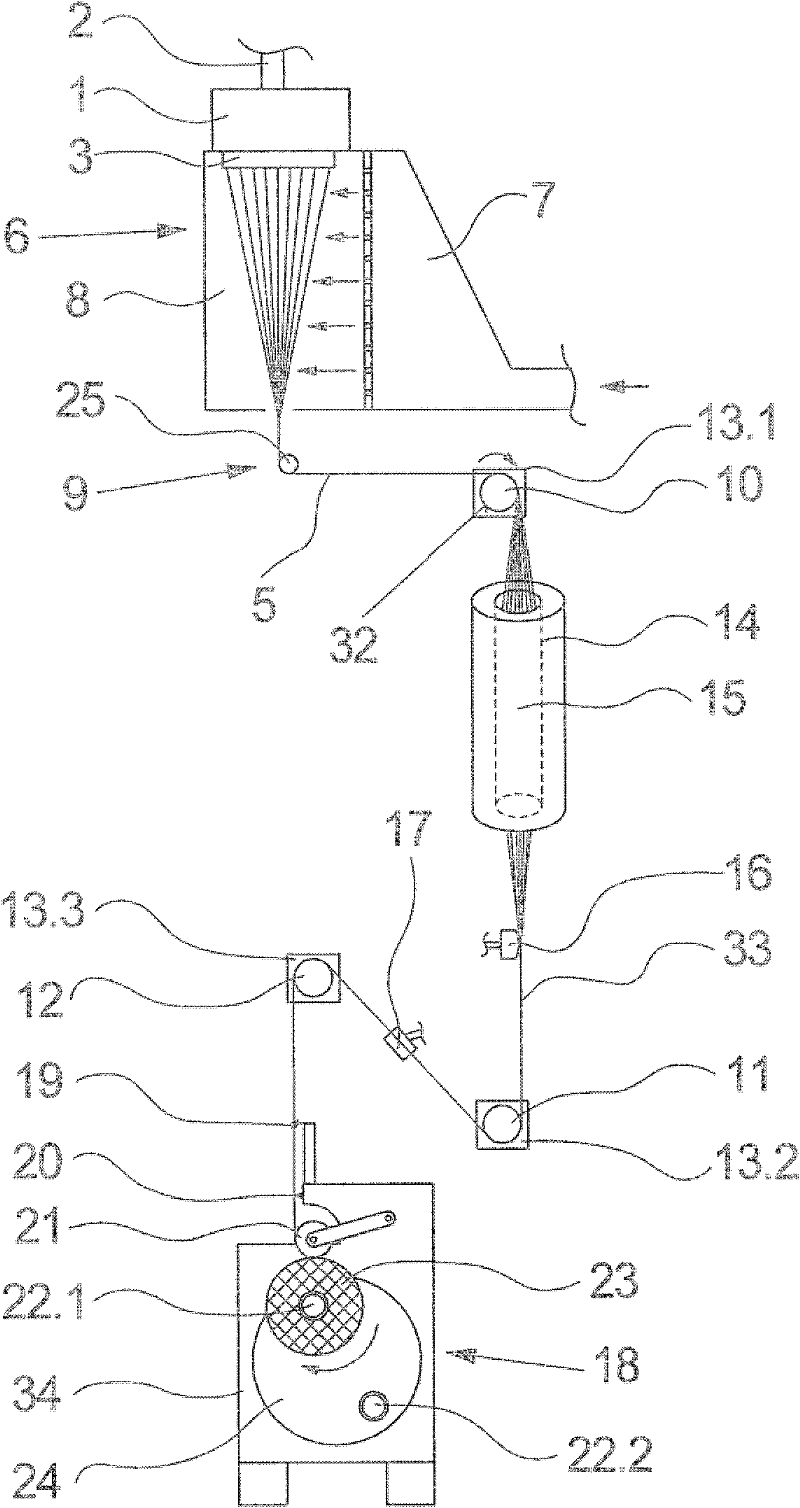

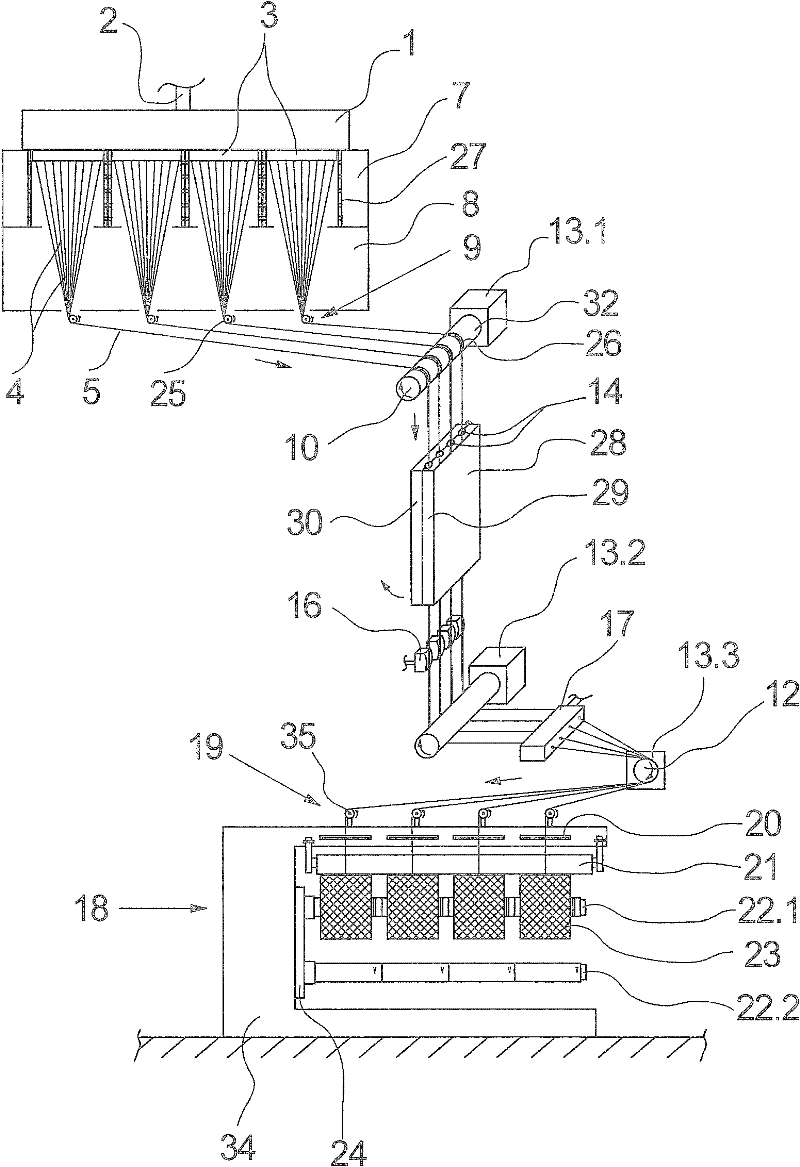

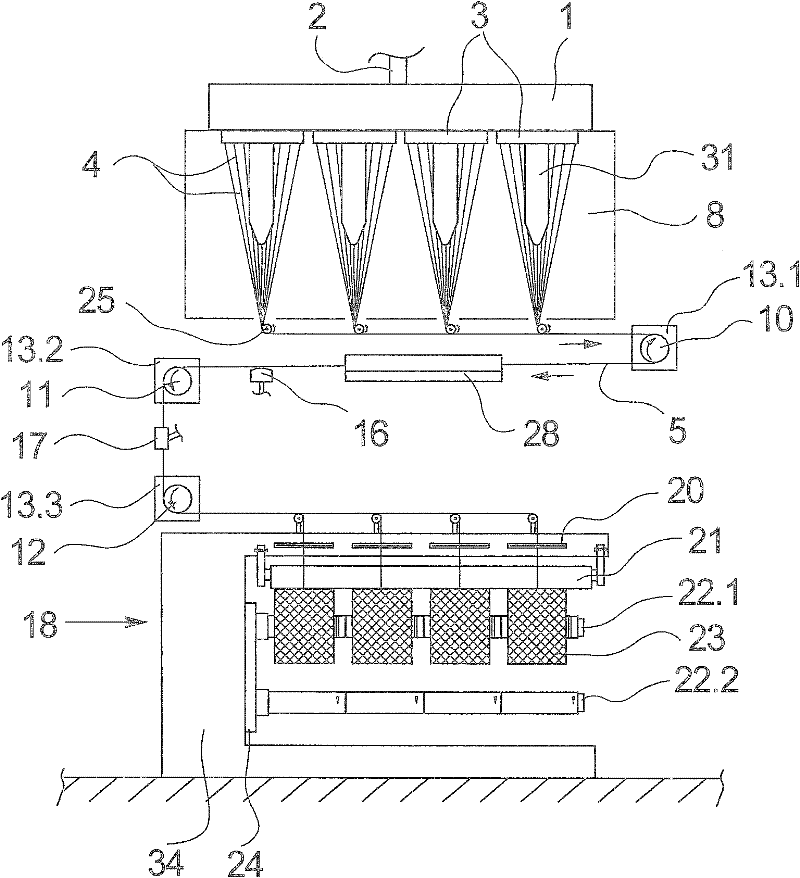

Method for melt spinning, stretching and winding multifilament thread and device for carrying out same

InactiveCN102131965AReached temperatureDesired temperatureArtificial thread manufacturing machinesArtificial filament heat treatmentPolymer sciencePlastic materials

The invention relates to a method for melt spinning, stretching and winding a multifilament thread to form an FDY yarn, and a device for carrying out the method. First, a plurality of filaments made from a thermoplastic melt are extruded, cooled to a temperature below the glass transition temperature of the plastic material, and combined to form a filament bundle with no addition of a preparation fluid. Then, the filament bundle is drawn off at a speed of greater than 1500 m / min, heated to a temperature above the glass transition temperature of the thermoplastic material and stretched at a stretching speed of greater than 4000 m / min. The filament bundle is led through a hot air atmosphere of a heating tube for providing non-contact heating. Then, the filament bundle is prepared with a preparation fluid and the thread is wound into a coil. In the device according to the invention, the preparation device is disposed downstream of the heating means in the thread direction, wherein the heating means, which is a heating tube with a hot air atmosphere for non-contact heating of the filament bundle, is disposed between the drawing-off galette and the stretching galette.

Owner:OERLIKON TEXTILE GMBH & CO KG

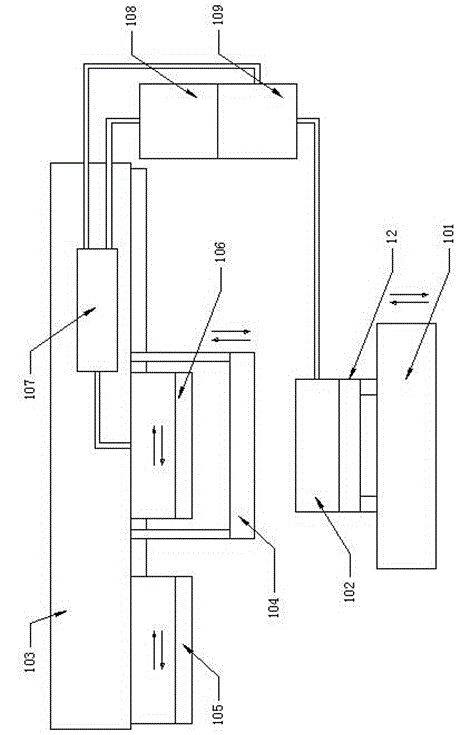

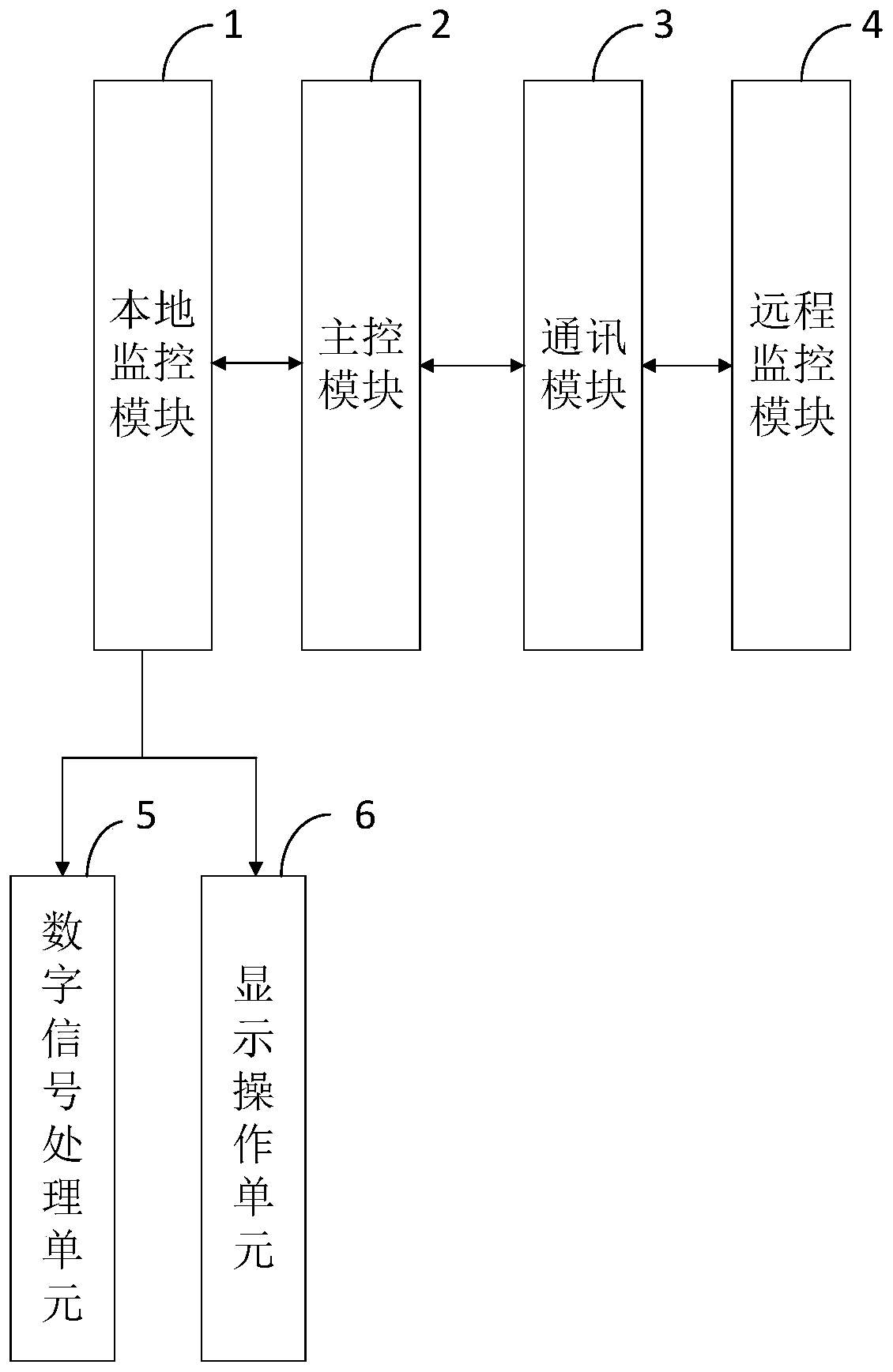

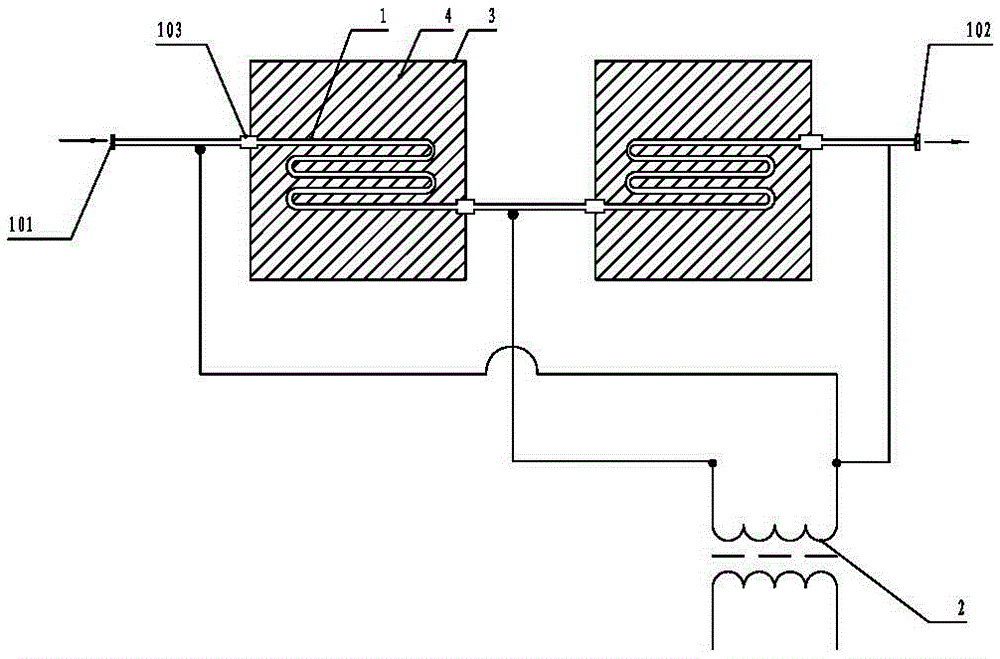

Induction heating distributed control system

InactiveCN110262425AEasy to observe real-time changesImprove reliabilityTotal factory controlProgramme total factory controlDigital signal processingDistributed control system

The invention belongs to the technical field of electrical automation control, and discloses an induction heating distributed control system. The induction heating distributed control system comprises a local monitoring module, a main control module, communication module and a remote monitoring module, wherein the local monitoring module processes a set value from a PLC, completes the acquisition, processing and calculation of an electric quantity of induction heating equipment, and outputs a control quantity for controlling the induction heating equipment; the main control module utilizes the PLC for acquiring, receiving and transmitting various data, and transmits the acquired data to a digital signal processing unit; the communication module transmits an electric quantity signal to a display operation unit and the main control module by using circuits such as a serial communication circuit; and the remote monitoring module displays and modifies the status of each induction heating power supply. The induction heating distributed control system adopts an object-oriented design idea, and correctly and effectively divides the functional modules of control software according to the operating characteristics, so that the whole system software has a powerful interface function and good real-time performance; and the induction heating distributed control system has high practicability and reliable operation, and is convenient for field operators to use and overhaul.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

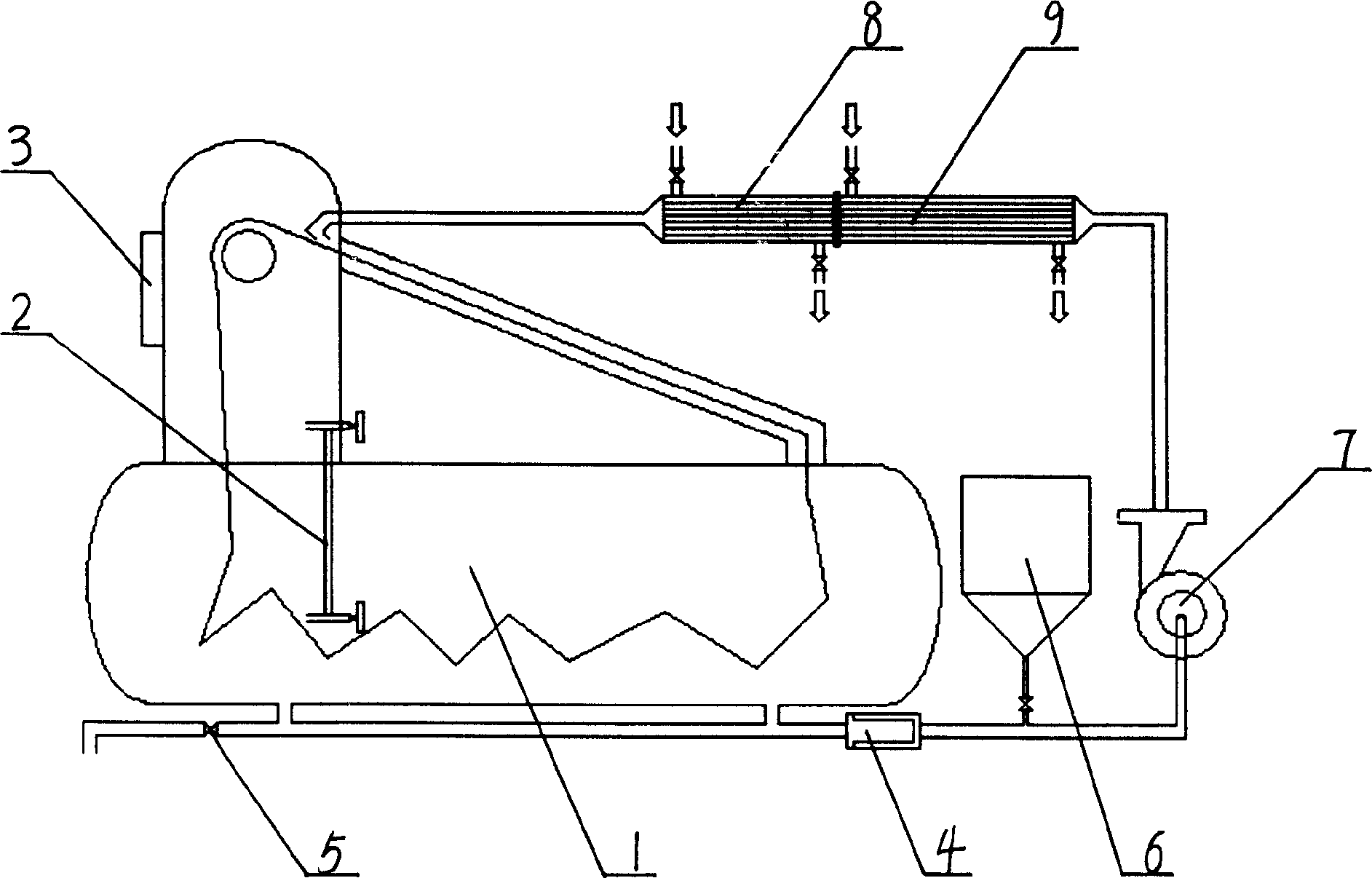

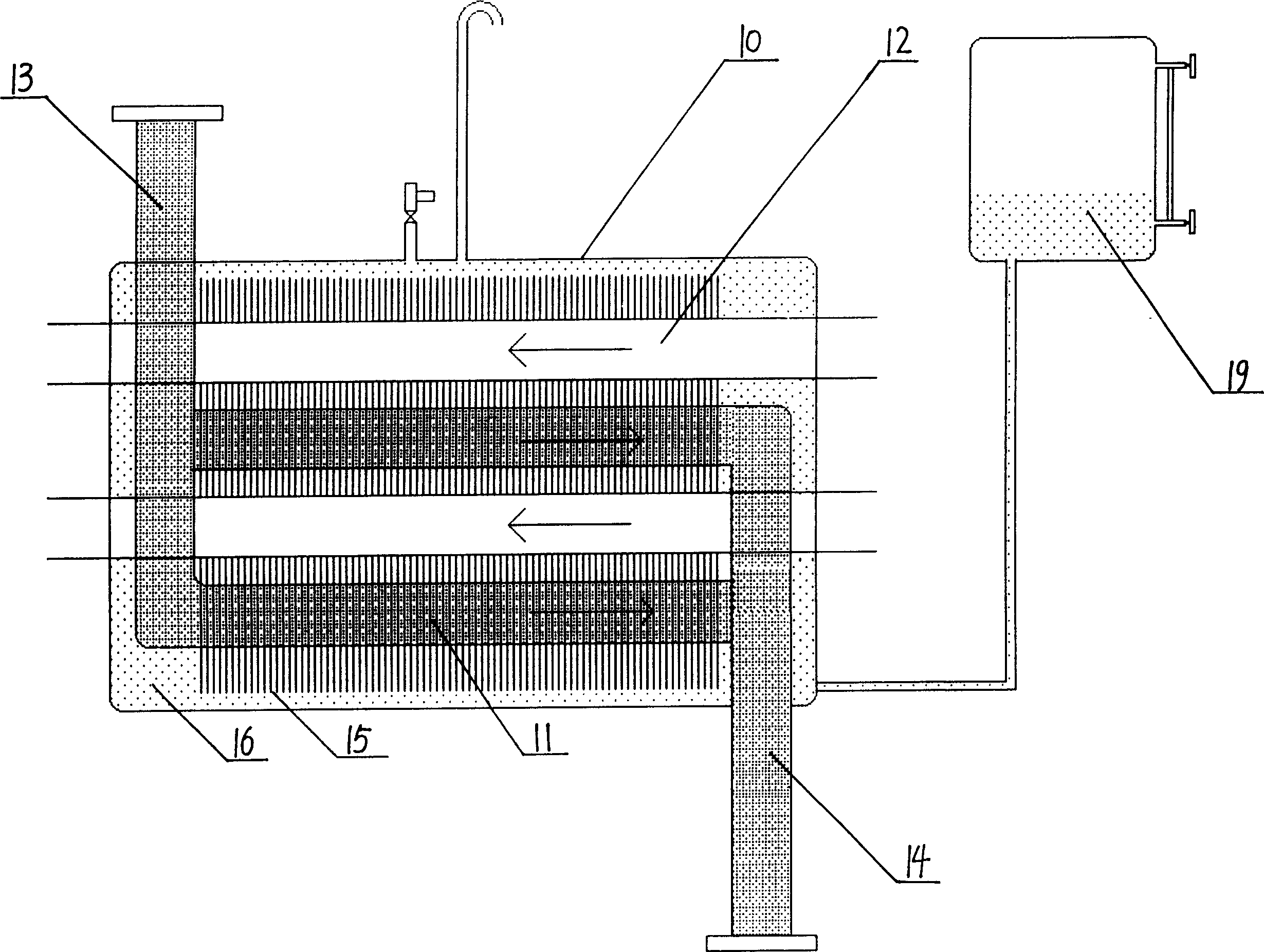

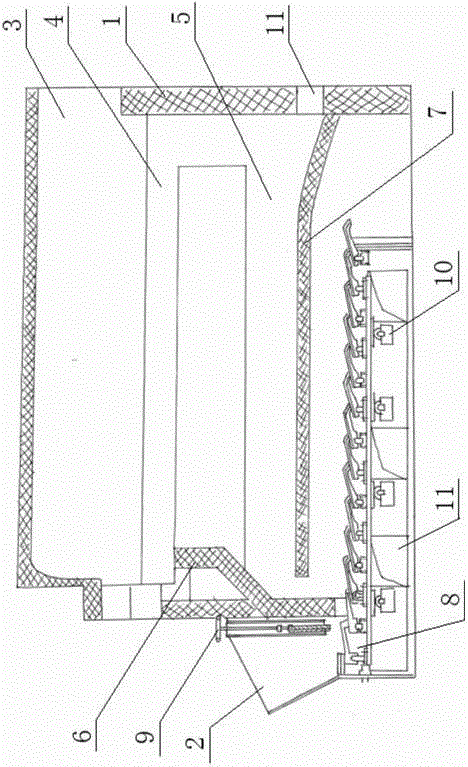

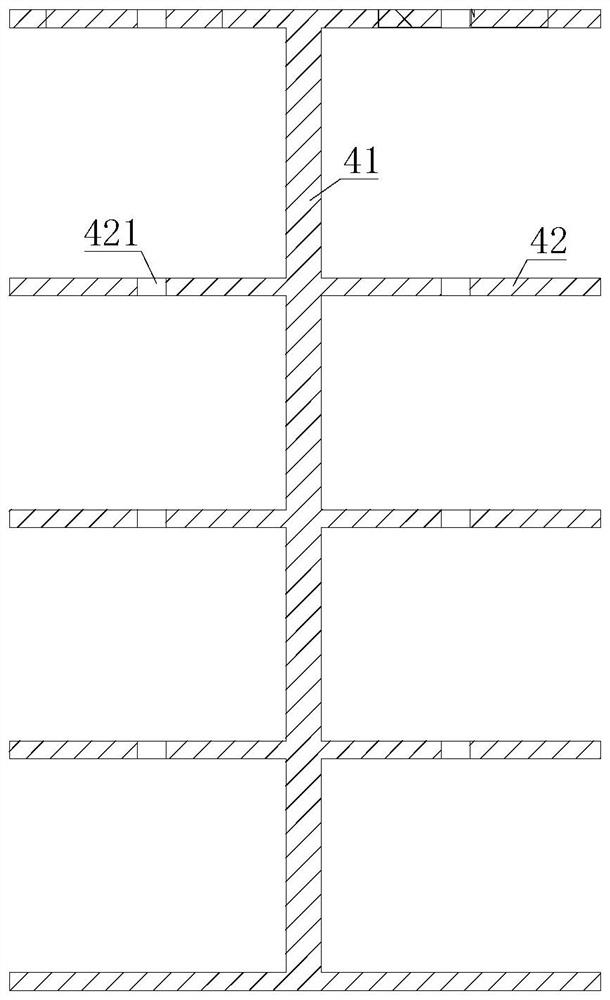

Energy saving type dyeing machine

InactiveCN1648318AIncrease heat exchange rateImprove heating efficiencyTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentLiquid temperatureDyeing

The present invention relates to dyeing machine, and especially a kind of energy saving dyeing machine. The energy saving dyeing machine has cloth dyeing vat with inside water level pipe and cloth inlet and outlet, filter, dyeing liquid inlet and outlet valves, material barrel, dyeing circulating pump connected via pipeline. Between the cloth dyeing vat and the dyeing circulating pump, are connected water cooling exchanger and oil heating exchanger combined integrally with flanges. By means of the water cooling exchanger and the oil heating exchanger combined integrally to cool and heat the dyeing liquid separately, the present invention reaches the technologically required dyeing liquid temperature.

Owner:劳关明

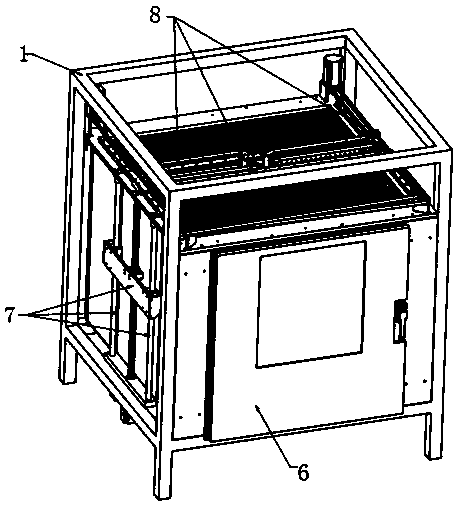

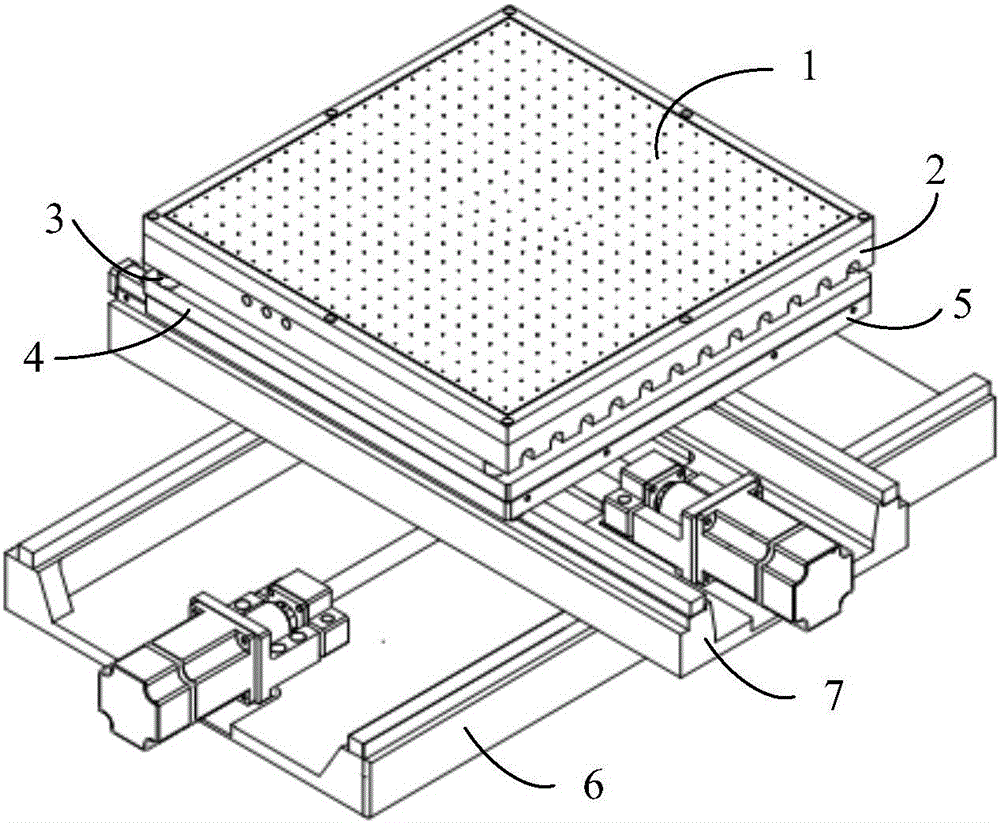

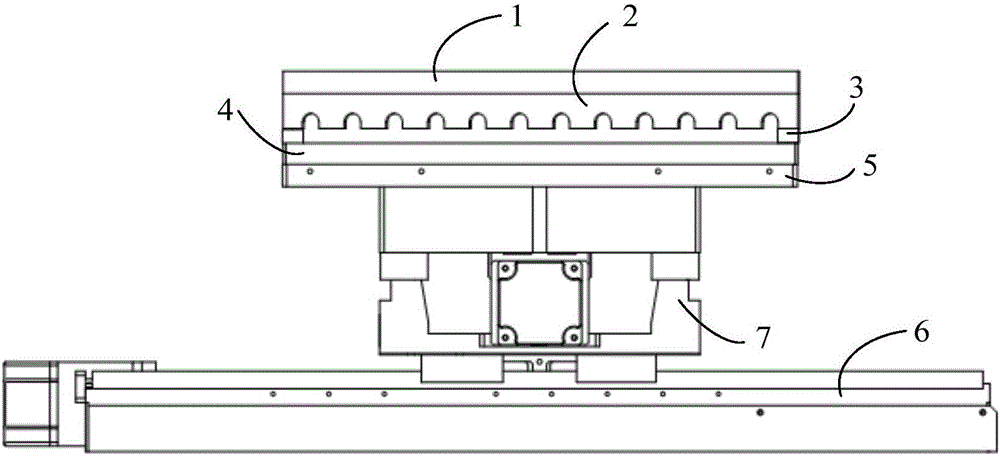

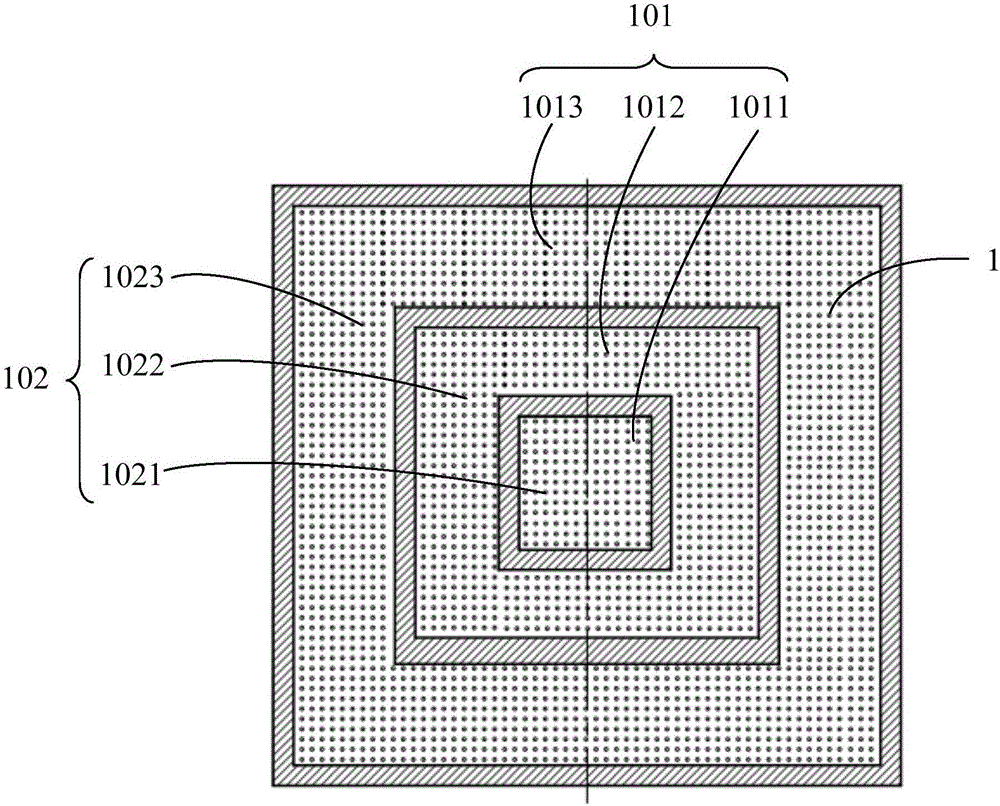

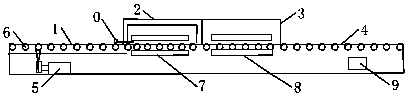

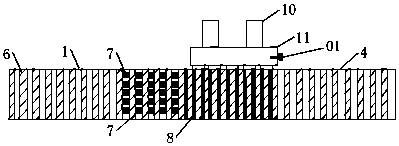

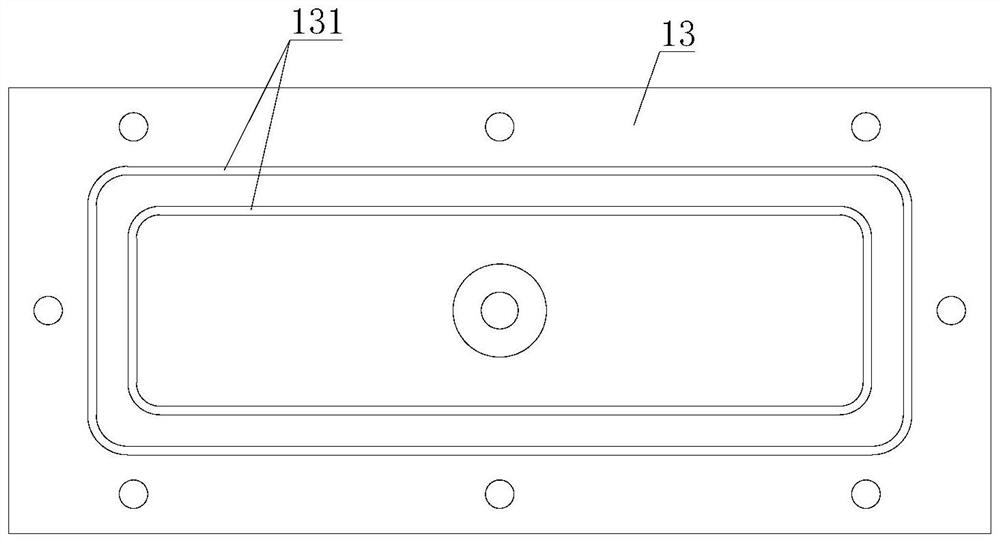

Chip mounting machine and mounting method

InactiveCN106535611AHeating evenlyImprove stabilityElectrical componentsElectrical and Electronics engineeringSurface plate

The invention provides a chip mounting machine and a mounting method. The chip mounting machine comprises an adsorption device, a heating device and a vacuum device. At least one layer of vacuum sealing wall and at least one vacuum adsorption region are arranged on the adsorption device. Each of the vacuum adsorption regions is made of special multihole materials. The adsorption device is used for loading a panel. The heating device is arranged under the adsorption device. The upper surface of the heating device is tightly attached to the lower surface of the adsorption device. Multiple uniformly arranged installation holes and heating bodies filling the installation holes are arranged in / on the lower surface of the heating device. Multiple vacuum hole channels are arranged on the heating device and correspond to and communicate with the vacuum adsorption region. The vacuum device is connected with and communicates with the vacuum hole channels. In this way, stable adsorption and uniform heating of big and thin chip panels can be achieved, so stability of mounting temperature and chip mounting precision and efficiency during the chip mounting process are improved.

Owner:CETC BEIJING ELECTRONICS EQUIP

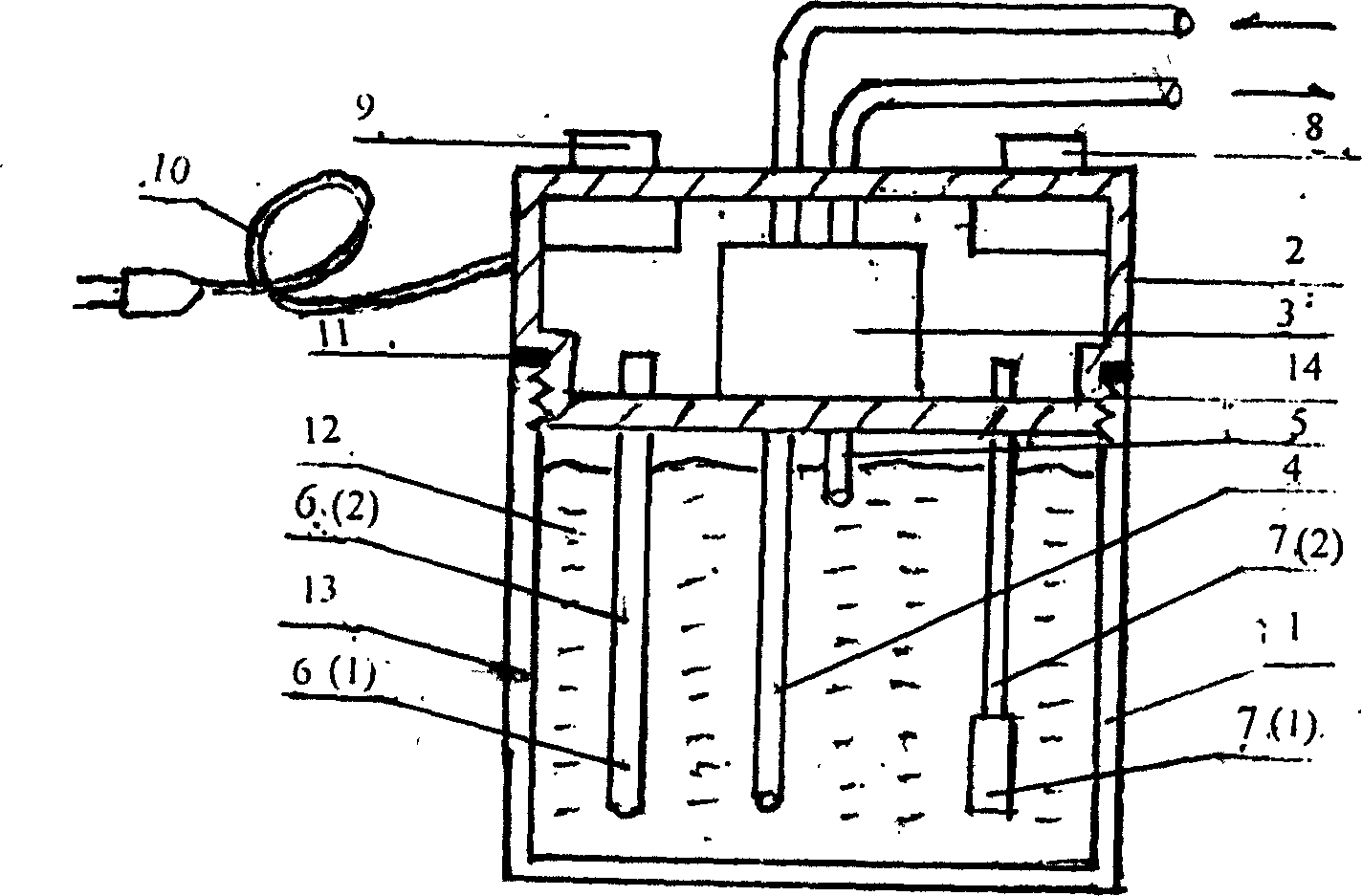

Oil heating type dyeing machine

InactiveCN1635207AReached temperatureCircumstances affecting qualityTextile treatment machine arrangementsPulp and paper industryWater level

The invention relates to a dyeing machine, especially to an oil heating type dyeing machine, comprising a cloth dyeing cylinder, in which a water level pipe is arranged, and on one side of the top of which, a cloth enter-exit port is arranged. The cloth dyeing cylinder is connected to filter apparatus, dye liquor value through channels; the other end of the filter apparatus is connected to a charging bucket, dye liquor circulating water pump through channels; the series water cooling exchanger and oil heating exchanger is connected between cloth dyeing cylinder and dye liquor circulating water pump through channels. The invention can obtain the needed dye liquor temperature by cooling and heating the dye liquor by the water cooling exchanger and oil heating exchanger.

Owner:劳关明

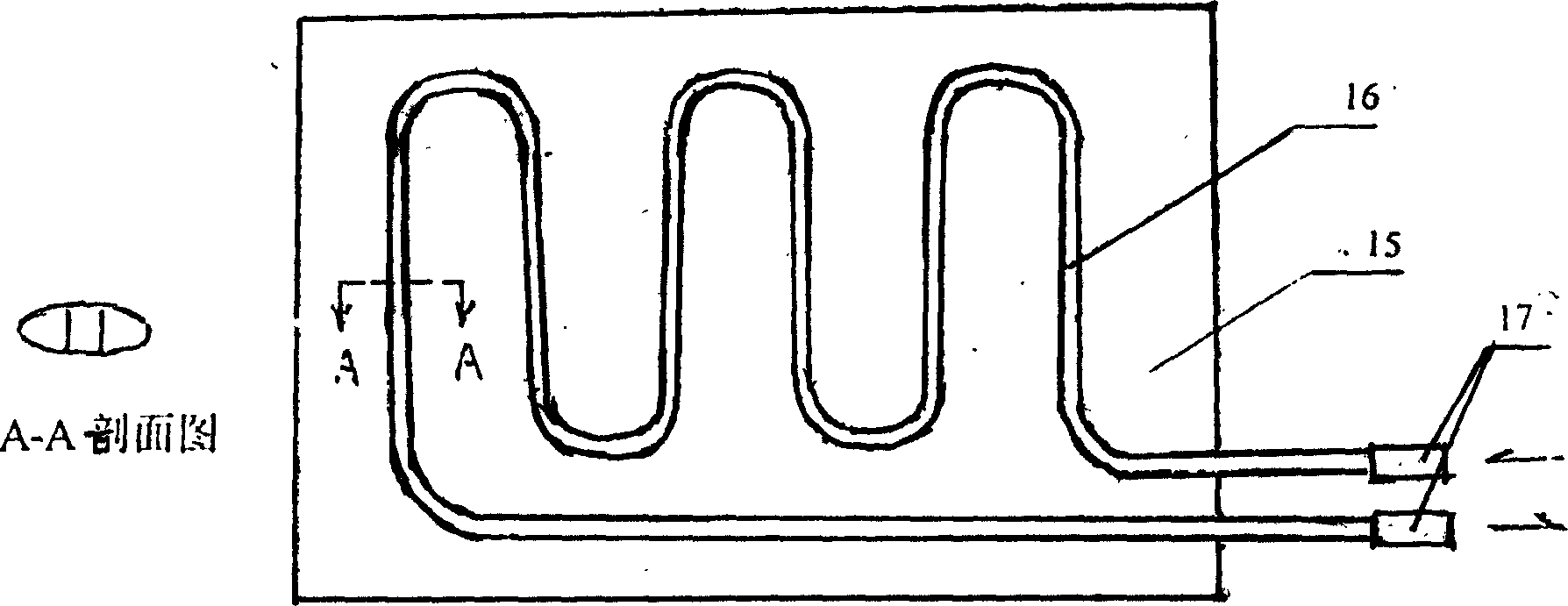

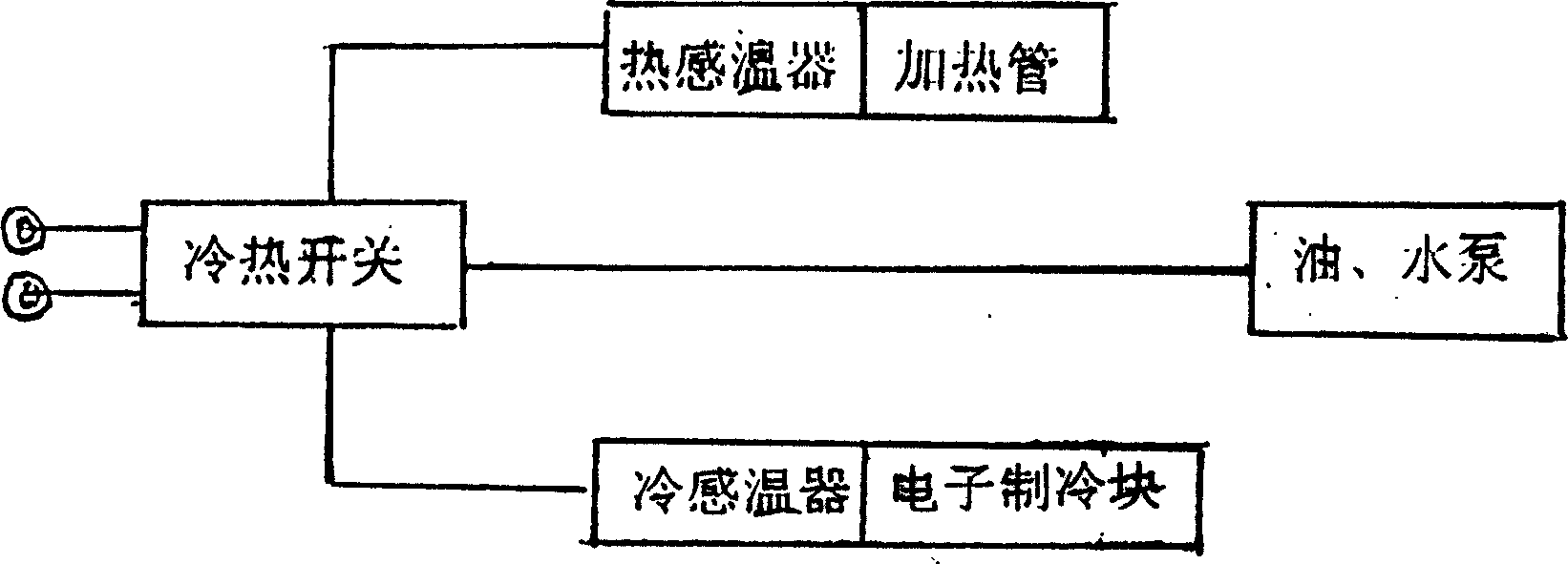

Health protection cold and warm electric blanket

A health-care electric blanket with warming or cooling function is composed of blanket, working container and its cover, oil or water pump, oil or water inlet tube and outlet tube, heating tube, two temp sensors for warming or cooling, electronic refrigerating block, selection switch, temp regulating knob, plug, sealing ring, heat transfer oil or water, insulating vacuum layer, and flat plastic tubes.

Owner:鲍畅 +1

Clean sealed boiler flue gas desulfurization and denitration device with filtering function

InactiveCN109248550AEasy to clean and unclogImprove sealing performanceDispersed particle filtrationHollow article cleaningDrive motorEngineering

The invention discloses a clean sealed boiler flue gas desulfurization and denitration device with a filtering function. The device comprises a boiler body, a placement strip, a cooling tower, a fixing ring, and a water pump, the upper end of the boiler body is seamlessly connected with a smoke-outlet pipe, the outer wall of the cooling tower is seamlessly connected to the input end of a smoke-inlet pipe, the output end of a driving motor is flanged to a rotating shaft, the fixing ring is fixedly welded to the inner bottom end of the cooling tower, and the output end of a condensing tube is injection-connected to a collecting pipe. The clean sealed boiler flue gas desulfurization and denitration device with filtering function has a connection manner of slot connection between the smoke-outlet pipe and the connecting pipe and between the connecting pipe and the smoke-inlet pipe, a user can conveniently perform disassembly and assembly between the smoke-outlet pipe and the connecting pipe and between the connecting pipe and the smoke-inlet pipe, the situation that the pipe connection is too long and the inside is prone to blockage is avoided, so that the user can timely dredge and clean the inside of the pipe, and a sealing gasket is beneficial to increase of the sealing performance between the pipes.

Owner:余汉锡

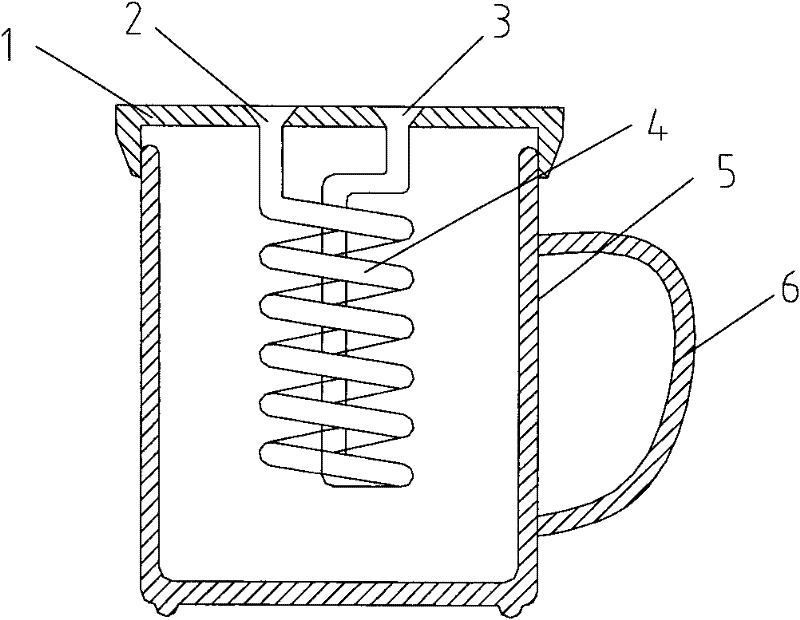

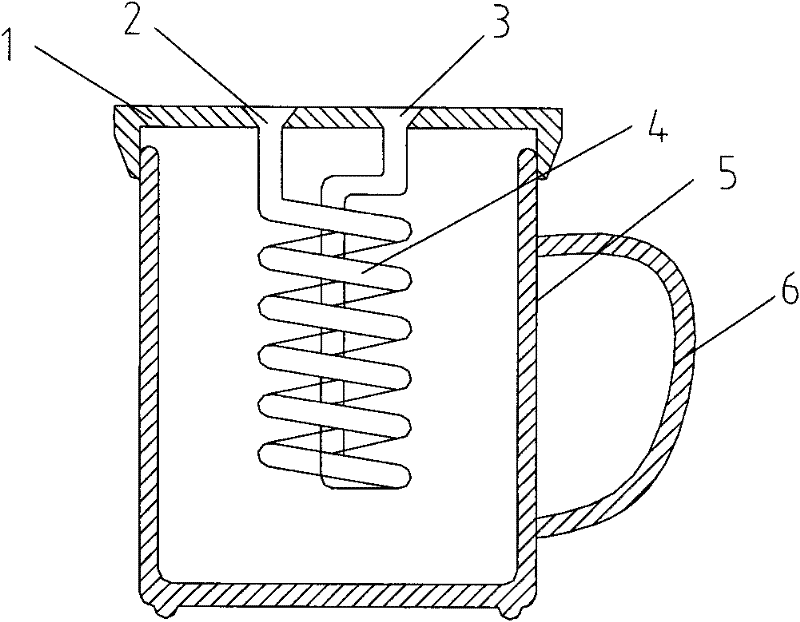

Heat exchange type rapid water cooling cup

InactiveCN102450905AImprove cooling effectReached temperatureDrinking vesselsCooling coilCooling effect

The invention provides a heat exchange type rapid water cooling cup which mainly comprises a cup body, a handle, a cup cover, a cooling coil, a coil water inlet and a coil water outlet. The heat exchange type rapid water cooling cup is characterized in that the cup cover is covered on the cup body; the cooling coil fixed on the cup cover is inserted into the boiled water in the cup body; tap water is connected to the cooling coil water inlet; cold water is led out by the water outlet; and rapid cooling effect is realized through the heat exchange between the tap water and the boiled water. The heat exchange type rapid water cooling cup has the advantages that the boiled water is rapidly cooled to achieve the temperature of drinking and the cooled boiled water is not polluted.

Owner:厚志刚

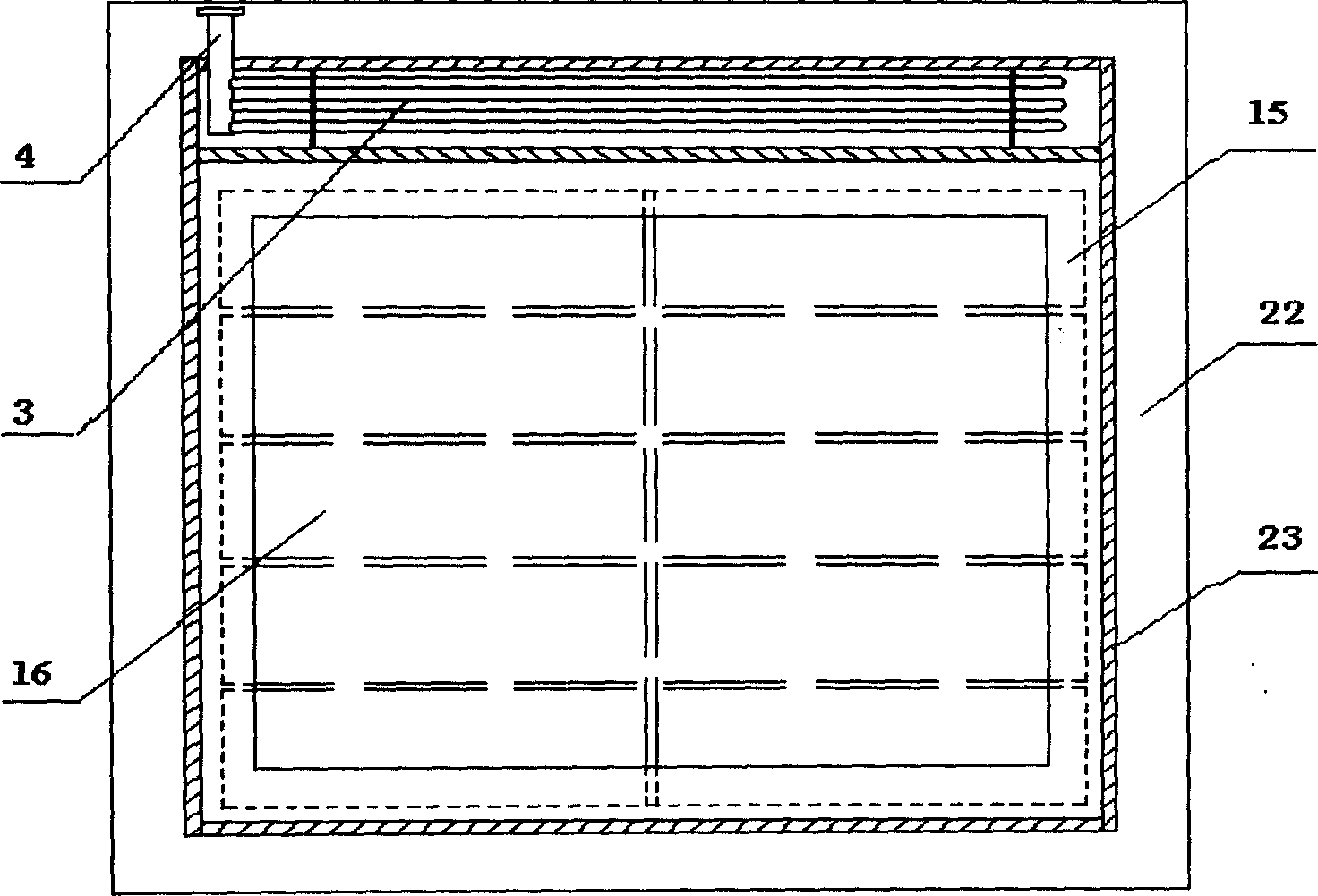

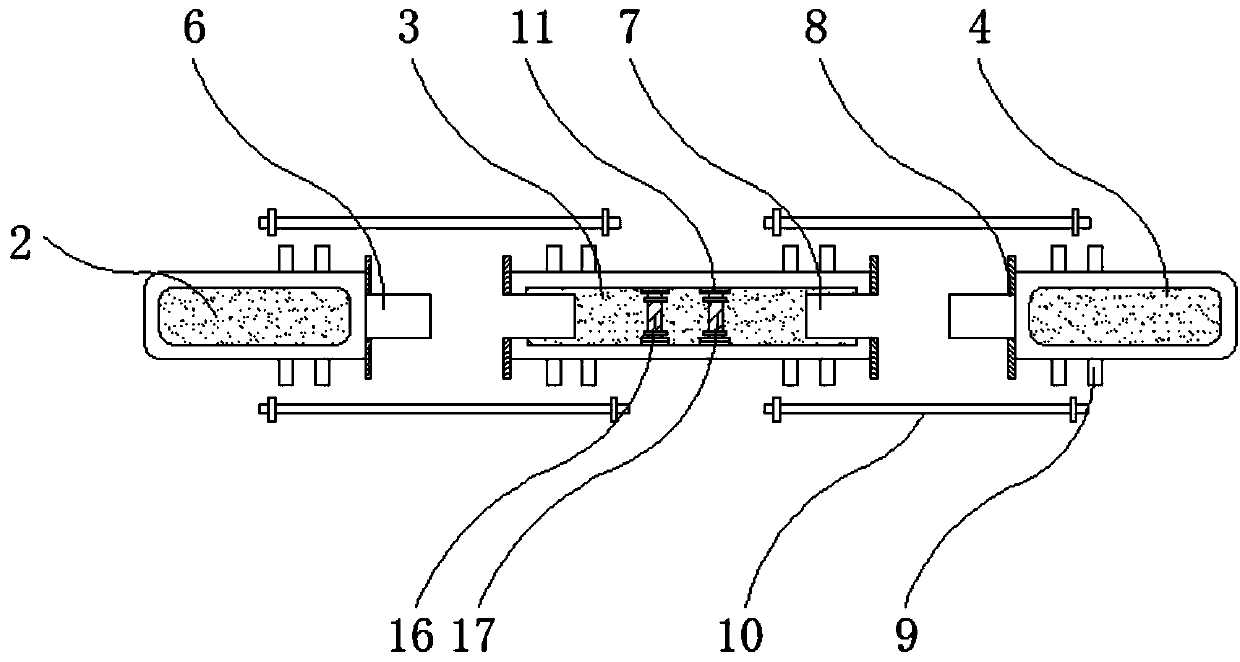

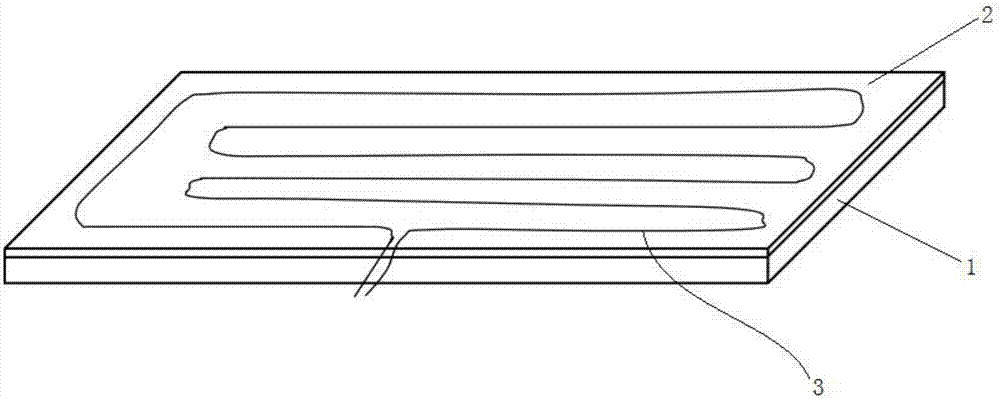

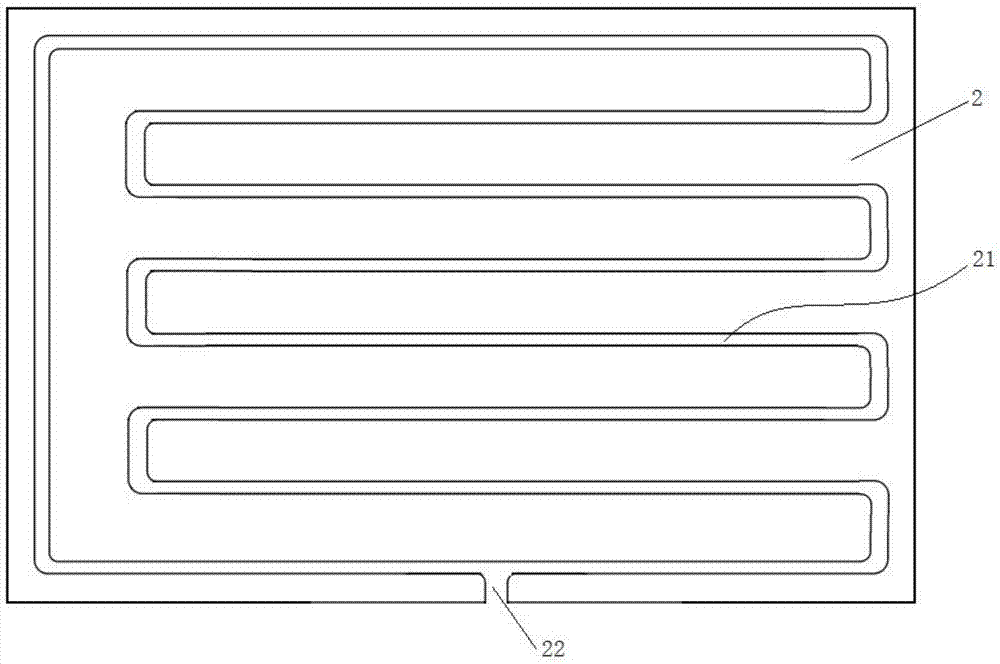

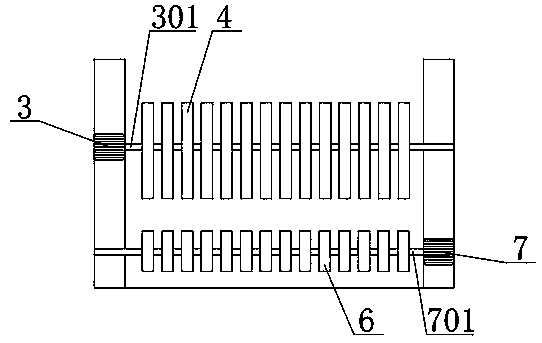

Carbon fiber energy-saving heating module and underfloor heating system

InactiveCN107172728AReduce in quantityIncrease resistanceHeating fuelLighting and heating apparatusFiberElectricity

The invention discloses a carbon fiber energy-saving heating module and an underfloor heating system. The carbon fiber energy-saving heating module includes a heat preservation plate, a heat conduction plate and a heating wire. The heat conduction plate is disposed above the heat preservation plate. The heating wire is routed on the heat conduction plate. The heating wire includes at least two carbon fire heating cell lines which are in a bundle shape. Each carbon fiber heating cell line includes a plurality of carbon fiber filaments and insulating layers which are configured in a bundle shape. The plurality of carbon fiber filaments are arranged inside the insulating layers. Different carbon fiber heating cell lines have identical or different number of carbon fiber filaments. According to the invention, the heating wire in the carbon energy-saving heating module uses two or more than two carbon fiber heating cell lines which can laminate heat so as to reach a required temperature. Single carbon fiber heating cell line has reduced number of carbon fiber filaments, lower heating power and reduced electricity consumption.

Owner:SUZHOU DONGFANG KANGTAN NEN ENERGY TECH

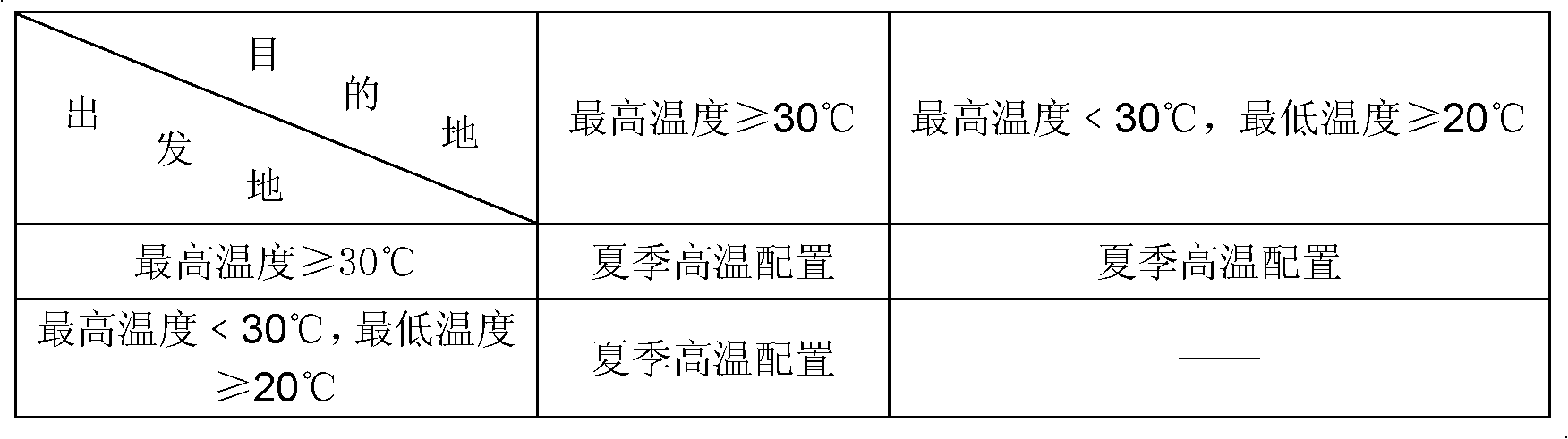

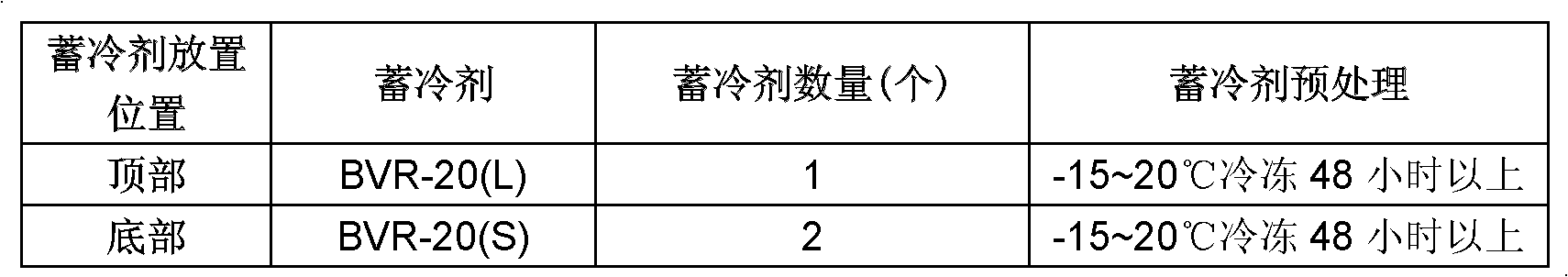

Insulation can configuration method

InactiveCN102490991ASignificant advantagesSignificant beneficial effectShock-sensitive articlesEngineeringCoolant

The invention relates to an insulation can configuration method, comprising the following steps of: (1) setting an insulation can configuration table; (2) determining conditions when an insulation object is transported; (3) selecting a corresponding configuration scheme according to the set insulation can configuration table, determining type and quantity of coolant, a processing method and an assembly method; and (4) packing the coolant and the insulation object according to the insulation can configuration table, and making preparation for transportation. The insulation can configuration method provided by the invention can flexibly control temperature of an insulation can as required, is not influenced by variation of seasons and ambient temperature and can reliably guarantee that specified preservation effect or transportation temperature of medicines can be reached.

Owner:SHANGHAI VISION INDS

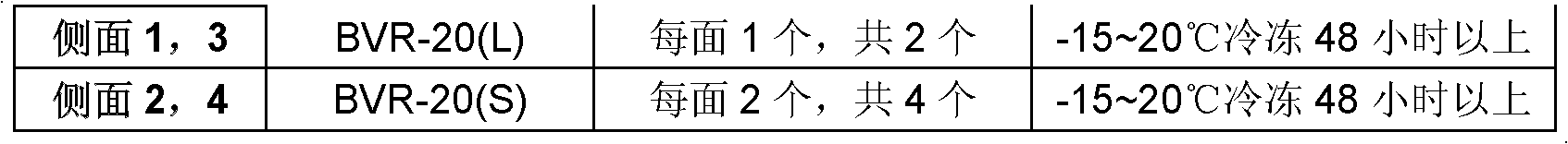

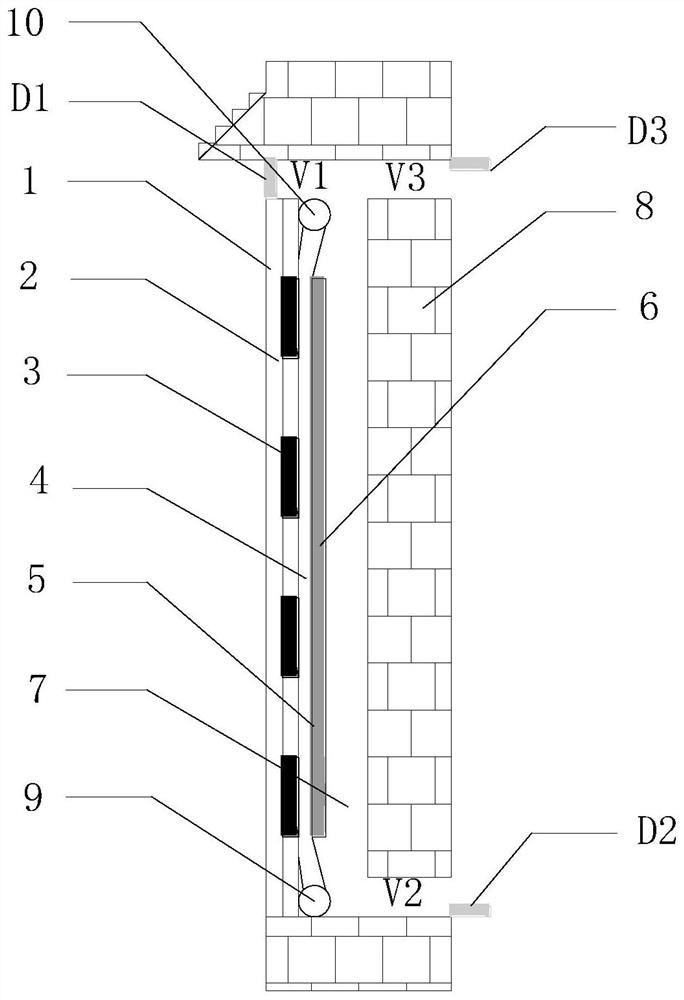

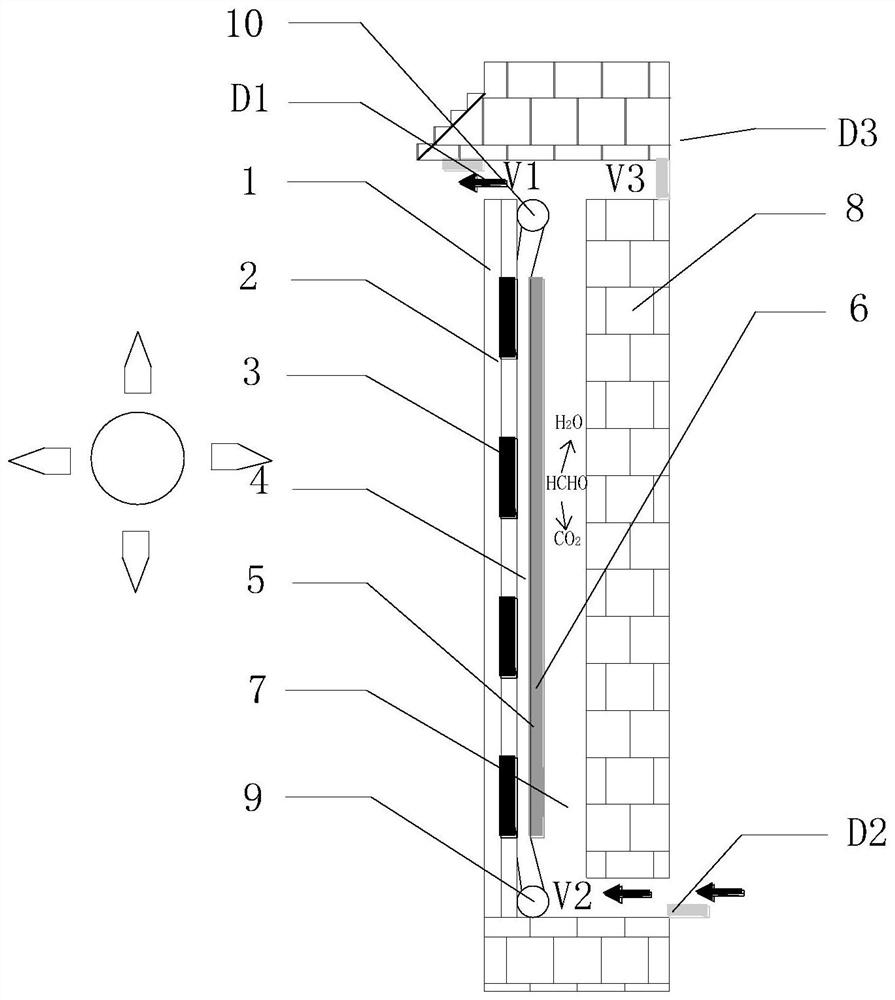

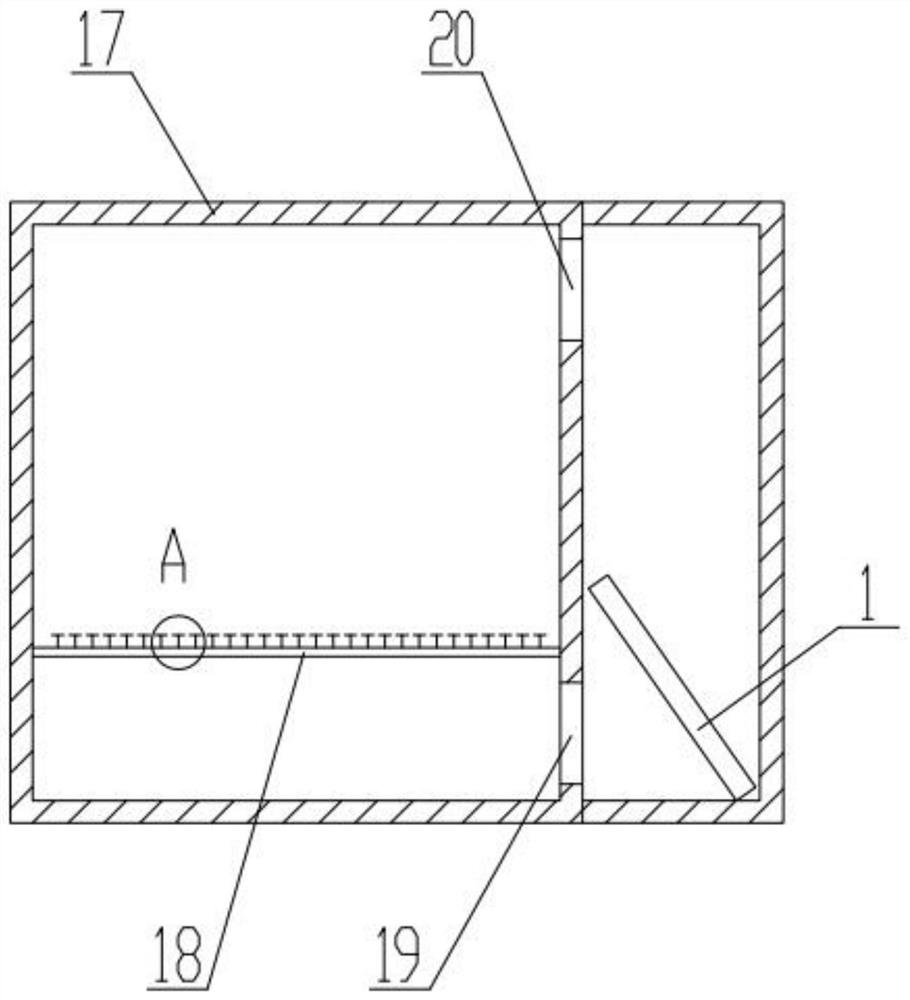

Catalytic purification-sterilization disinfection type multifunctional photovoltaic passive ventilation wall

PendingCN112049280AFlexible implementation of preparationFlexibility to achieve activityPhotovoltaic supportsSolar heating energyHeating seasonPassive ventilation

The invention discloses a catalytic purification-sterilization disinfection type multifunctional photovolatic passive ventilation wall. Different modes are switched by controlling opening and closingof baffles at all ventilation openings. The ventilation baffles comprise an outdoor ventilation baffle (D1), an indoor lower ventilation baffle (D2) and an indoor upper ventilation baffle (D3). The ventilation openings comprise an outdoor ventilation opening (V1), an indoor lower ventilation opening (V2) and an indoor upper ventilation opening (V3). The back face of a heat absorption plate (5) issprayed with an adsorption-thermal catalysis coating. According to the catalytic purification-sterilization disinfection type multifunctional photovolatic passive ventilation wall, the thermal catalysis technology, the thermal sterilization disinfection technology and the solar photovolatic photo-thermal technology are innovatively combined and utilized, the functions of power generation in the heating season, passive heating ventilation, air purification and thermal sterilization disinfection can be achieved, and the functions of power generation in the non-heating season, domestic hot waterpreparation, passive cooling, purification and thermal sterilization disinfection are achieved; and in the transition season, according to the building requirements, the functions of domestic hot water preparation and passive heating can be flexibly achieved by adjusting the ventilation baffles while power generation, thermal catalytic degradation of formaldehyde and thermal sterilization disinfection are conducted.

Owner:UNIV OF SCI & TECH OF CHINA

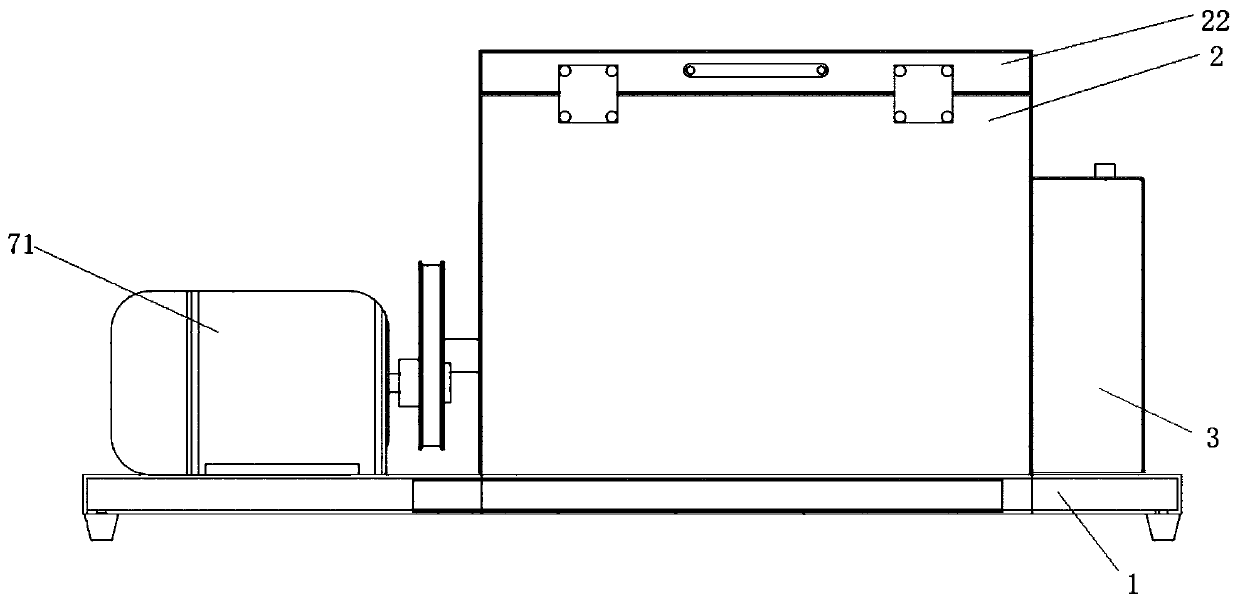

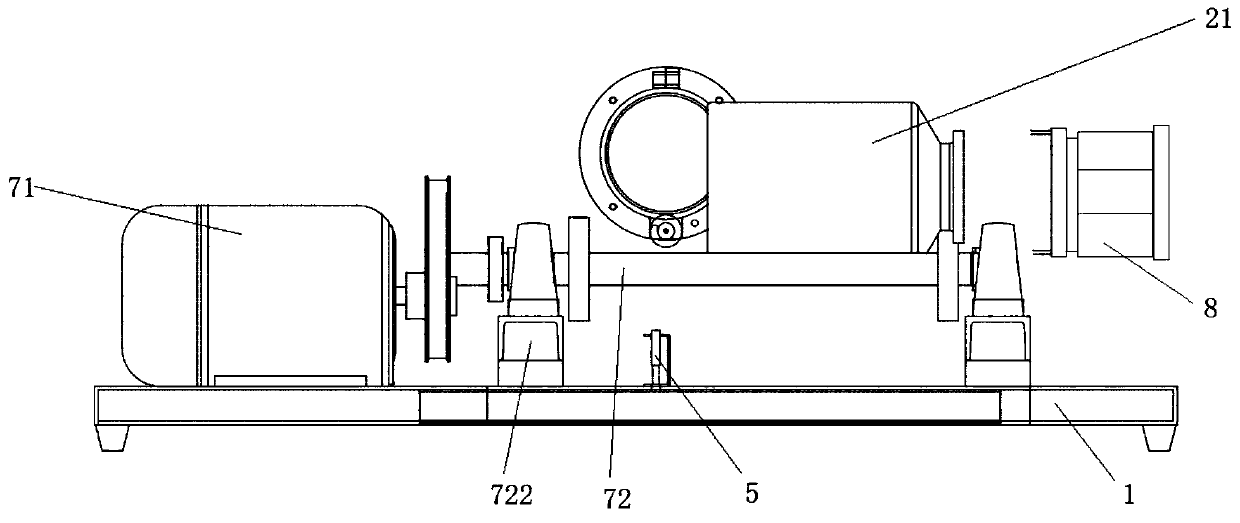

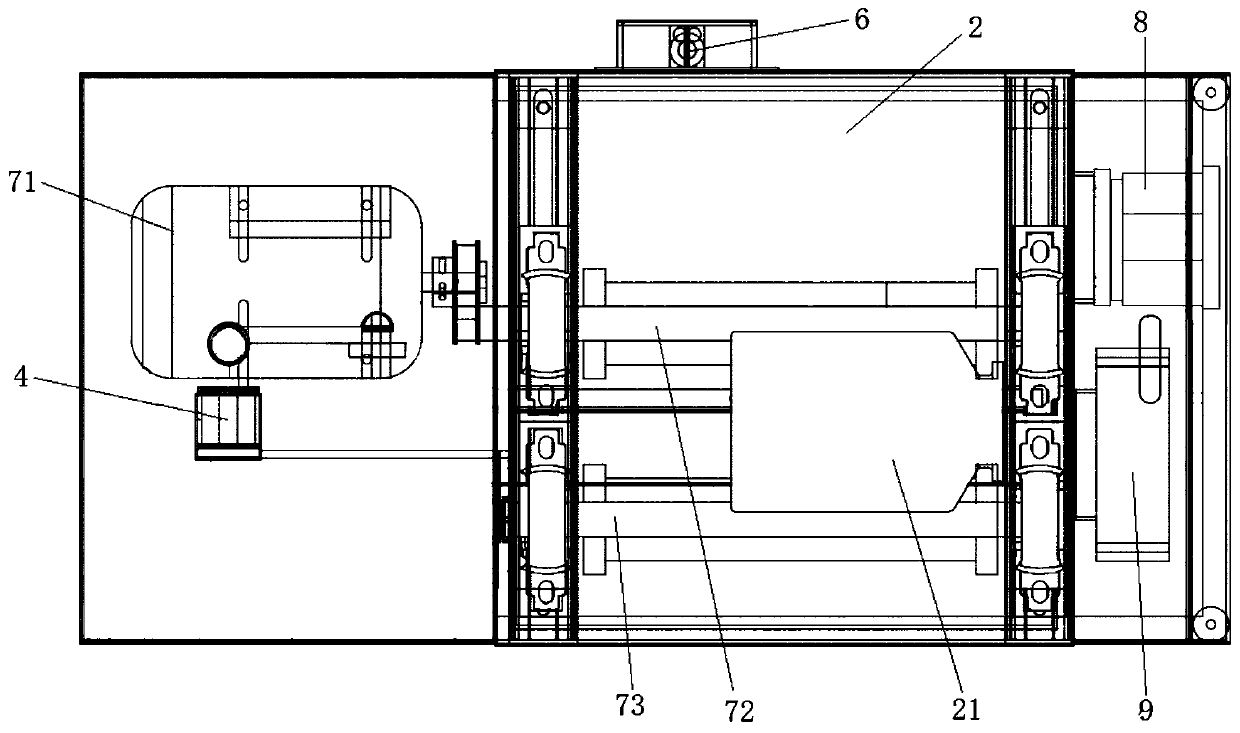

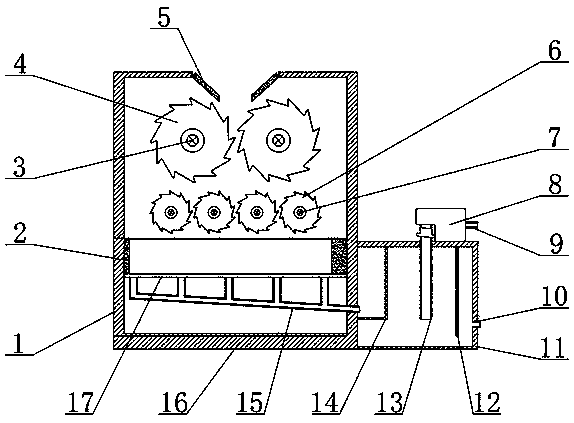

Constant-temperature ball mill

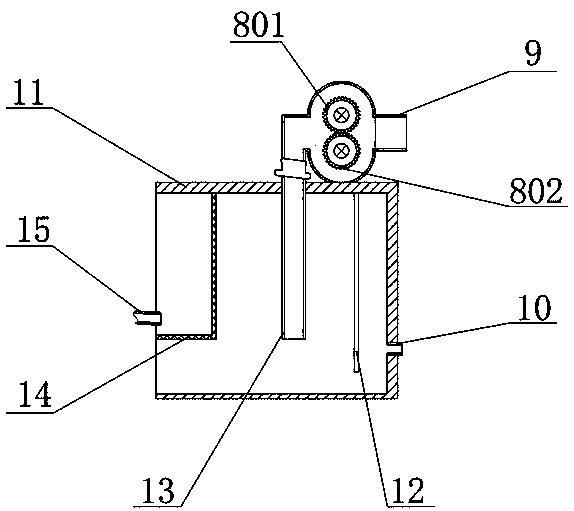

PendingCN111250226AUniform temperatureReached temperatureMachines using electric/magnetic effectsRefrigeration safety arrangementTemperature controlEngineering

The invention discloses a constant-temperature ball mill, which comprises a frame, and the frame is provided with a driving device, a ball mill protective cover, a temperature control box and a controller, wherein the ball mill protective cover is internally provided with a ball mill tank driven to rotate by the driving device and a temperature sensor connected with the controller, the ball mill protective cover is provided with a protective cover air inlet and a protective cover air outlet, and the temperature control box is provided with a temperature control air outlet and a temperature control air inlet which are respectively connected with the protective cover air inlet and the protective cover air outlet; the temperature control box is internally provided with a refrigerating part connected with the controller and / or a heating part connected with the controller and a circulating fan enabling air to circulate between the ball mill protective cover and the temperature control box,and the refrigerating power of the refrigerating part or the heating power of the heating part is controlled by the controller according to signals of the temperature sensor. According to the invention, monitoring signals of the temperature sensor can be obtained in real time by the controller, and the refrigerating power of the refrigerating part or the heating power of the heating part is controlled according to signals of the temperature sensor and the requirement of the grinding environment temperature, so that the temperature required by the grinding material in the grinding process can be better met.

Owner:长沙天创粉末技术有限公司

Fireproof glass tempering furnace

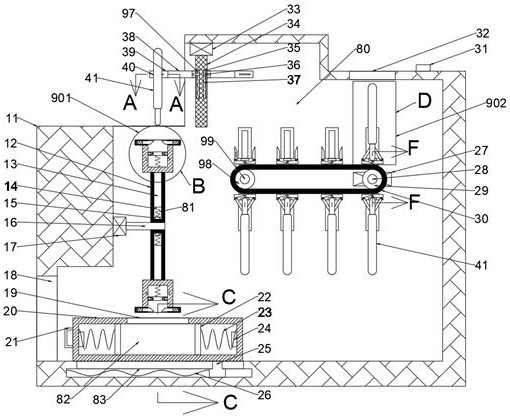

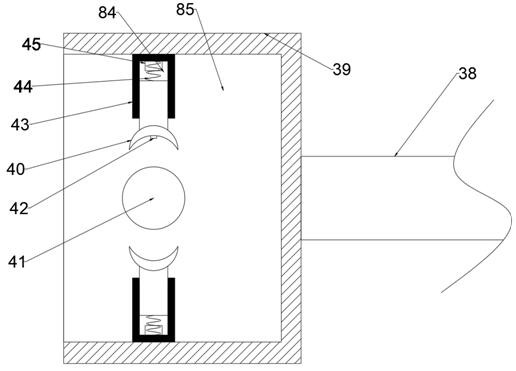

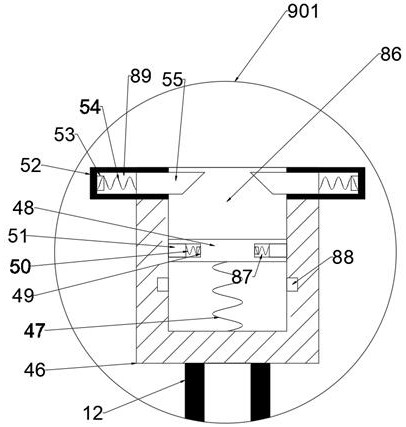

PendingCN110078361AReached temperatureMeet the requirementsGlass tempering apparatusFire preventionToughened glass

The invention provides a fireproof glass tempering furnace. The fireproof glass tempering furnace consists of an upper section, a heating section, a tempering section and a lower section, wherein theheating section controls the heating temperature of glass to be 650-1000 DEG C; and the tempering section controls the blowing pressure to be 12000-20000 Pa. The furnace is used for tempering fireproof glass, so that the tempered glass meets the technical requirements of fire prevention and no cracking at a high temperature for a long time. The fireproof glass tempering furnace is suitable for being applied to equipment for producing fireproof tempered glass.

Owner:SUIZHONG YUANTU TECH DEV

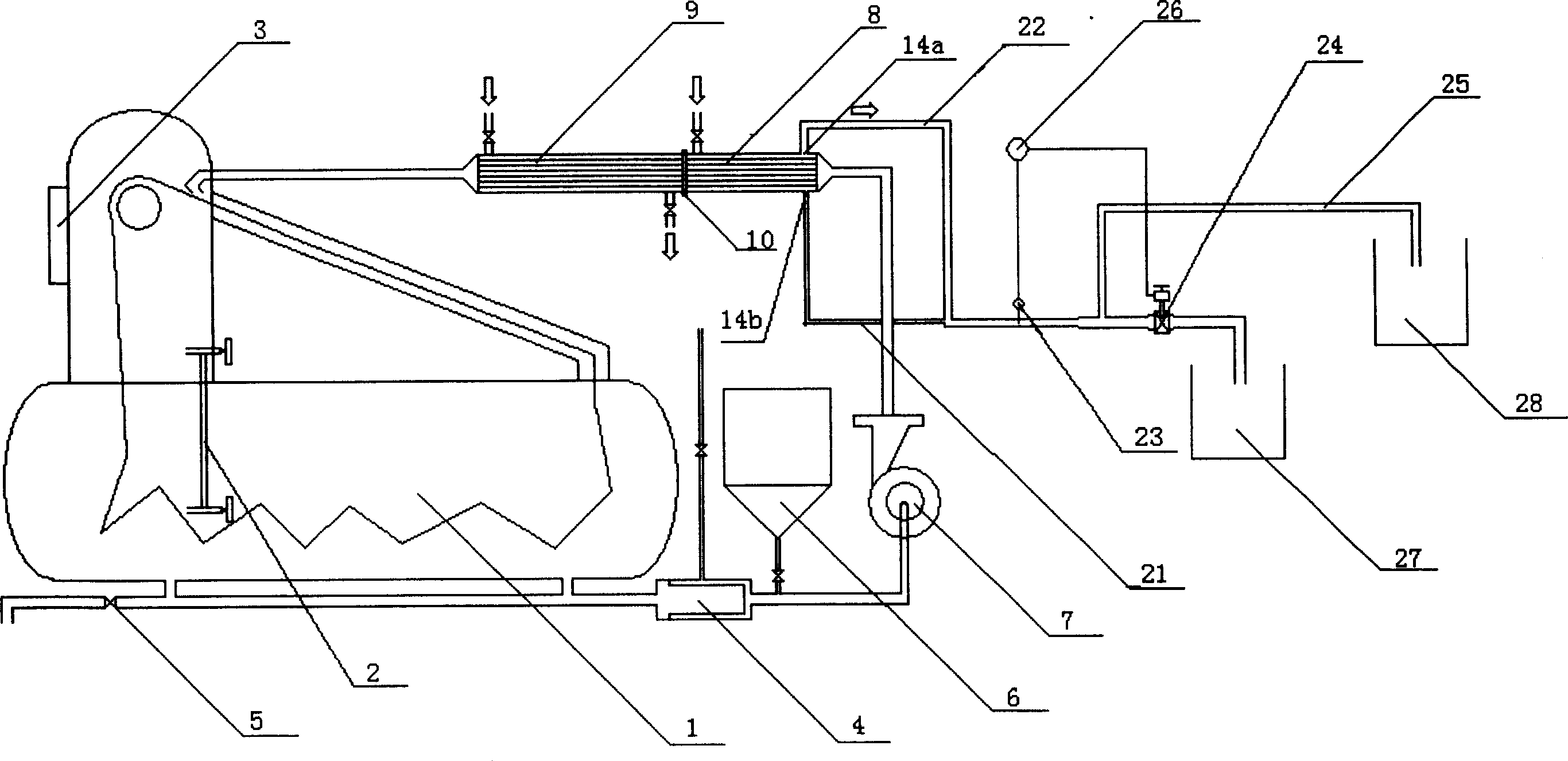

Oil-heating and heat-recovery type dyeing machine

InactiveCN1766195AReached temperatureEnhanced agitationTextile treatment machine arrangementsTextile/flexible product manufactureShunt DevicePulp and paper industry

The invention discloses a oil-heat thermal recovery dyeing machine, which comprises: a dyeing cylinder body connected with a filtrator that links to a circulating water pump, linking a water-cool exchanger with a shunt device and oil-heat exchangeer integrated by flange or in series between said cylinder body and pump. This invention can make good use of hot water, and increases utility for heat energy.

Owner:劳关明 +1

Disinfecting and collecting device for glass thermometers

InactiveCN112076332APlay the effect of automatic wiping and disinfectionThe effect of automatic wiping and disinfection is achievedConveyorsLavatory sanitoryElectric machineryEngineering

The invention discloses a disinfecting and collecting device for glass thermometers. The disinfecting and collecting device comprises a machine body, wherein a working cavity with an upward opening and a leftward opening is formed in the machine body; a first motor is fixedly arranged on the inner wall of the upper side of the working cavity; a first rotating shaft is rotationally arranged on thelower end surface of the first motor; first sliding cavities with leftward and rightward openings are symmetrically formed in the left end surface and the right end surface of the first rotating shaft; and a first electromagnet is fixedly arranged on the inner wall of the upper side of each first sliding cavity. According to the disinfecting and collecting device, a distance sensor is used for controlling a thermometer magnetic chuck to collect the used thermometers, and under the action of a disinfecting mechanism, the effect of automatically wiping and disinfecting the thermometers is achieved through alcohol cotton; and in addition, clamping plates in a thermometer collecting mechanism are used for orderly collecting the used thermometers, and the disinfected thermometers are popped outunder the action of a cam for workers to use, so that the effects of automatically disinfecting and storing the thermometers and providing the thermometers are achieved.

Owner:JINAN HUICHUAN CLOTHING CO LTD

Novel energy-saving hotel water supply system

InactiveCN105333490ATo achieve the effect of heatingLow costLighting and heating apparatusSpace heating and ventilation detailsEngineeringHydraulic pressure

The invention relates to the field of water supply, particularly to a novel energy-saving hotel water supply system which comprises a building above a ground plate and a basement below the ground plate, wherein a heating boiler is arranged in the basement; a cold water tank is arranged at the top of the building; the heating boiler is connected with a heat exchanging box through an upper circulating pipe and a lower circulating pipe; a heat exchanging pipe is arranged in the heat exchanging box; the inlet end of the heat exchanging pipe is connected with a water inlet pipe; a heat outlet pipe is connected with the outlet end of the heat exchanging pipe; the water inlet pipe is connected onto the cold water tank; the heat outlet pipe is connected into rooms through branched heat outlet pipes. The invention aims to provide the novel energy-saving hotel water supply system; the heat exchanging pipe connected with the boiler is arranged and directly heats the cold water outputted by the cold water tank at the top of the building, and the heated water is directly conveyed to the building through the hydraulic pressure principle, so that the equipment cost is reduced, and the hot water conveying path is shortened at the same time to further reduce energy loss.

Owner:HUAIHUA QIXIAO ENERGY SAVING TECH

Reciprocating grate-fired furnace

InactiveCN104421928ASimple structureEasy maintenanceSolid fuel combustionCasings/liningsCombustion chamberEngineering

The invention belongs to the technical field of combustion furnaces, and particularly relates to a reciprocating grate-fired furnace. The reciprocating grate-fired furnace comprises a furnace body, a coal hopper, a front arch, a rear arch and a grate, wherein a boiler barrel is arranged on the upper portion of the interior of the furnace body, a combustion chamber is arranged on the lower portion of the interior of the furnace body, and a flue is formed between the boiler barrel and the combustion chamber; an opening is formed in the inner wall of the side, with the combustion chamber, of the furnace body, and the coal hopper is arranged outside the opening; the front arch, the rear arch and the grate are arranged in the combustion chamber, the front arch is arranged above the opening, one end of the rear arch is installed on the inner wall of the other side of the furnace body, the other end of the rear arch is a free end and is arranged between the opening and the front arch, and a gap is reserved between the free end and the inner wall on one side of the furnace body; the grate is installed at the bottom of the furnace body, and the coal inlet end of the grate penetrates out of the opening and is arranged below the coal hopper. According to the reciprocating grate-fired furnace, anthracite serves as fuel of the reciprocating grate-fired furnace instead of secondary soft coal, the purposes of energy saving, emission reduction and consumption reduction are achieved, and the production cost can be reduced to a large extent.

Owner:丹东玉龙镁业有限公司

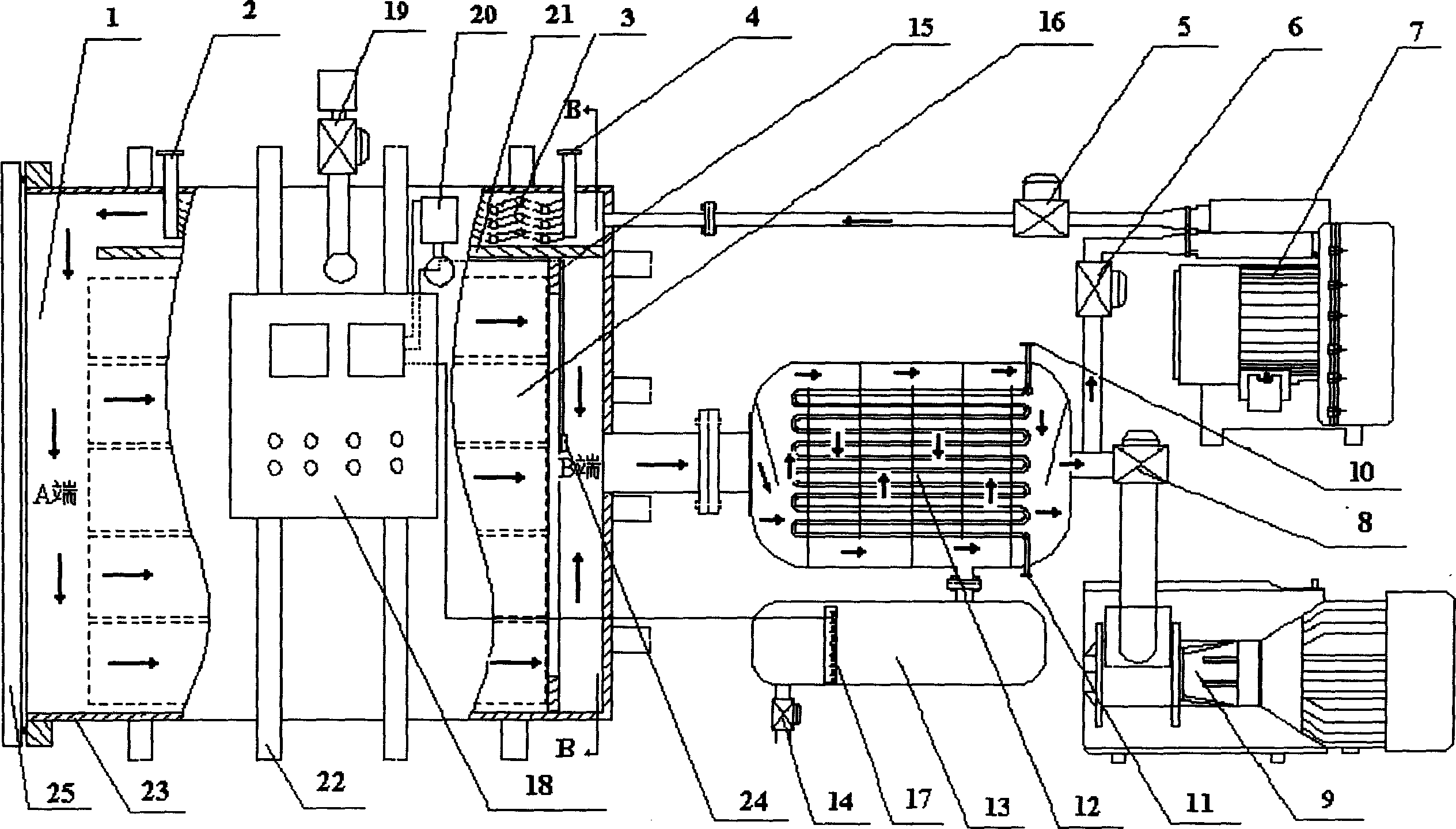

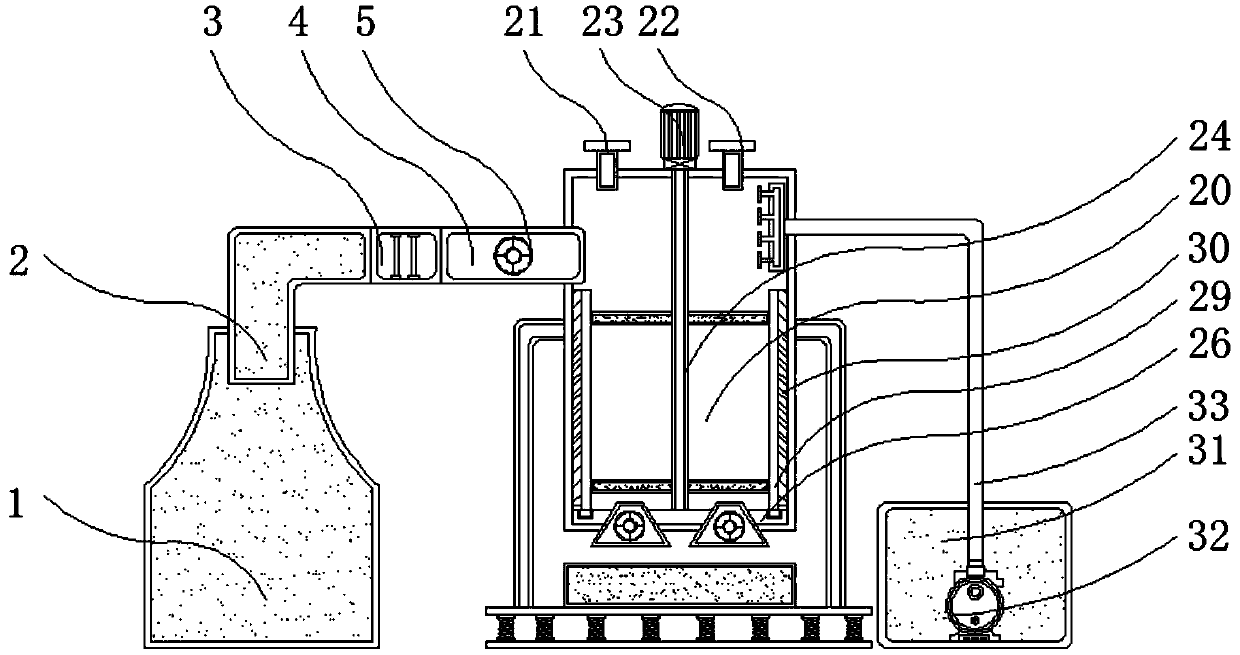

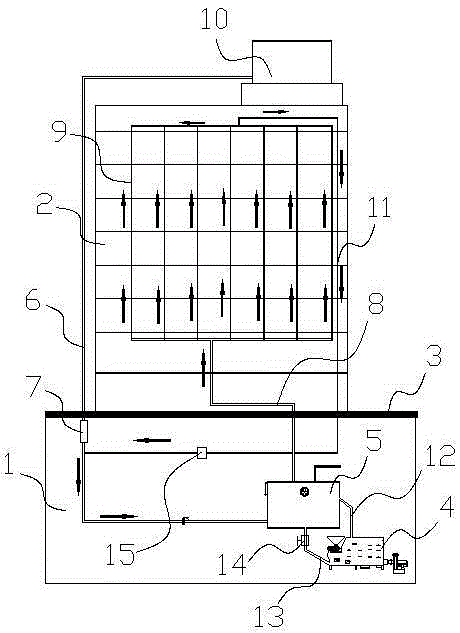

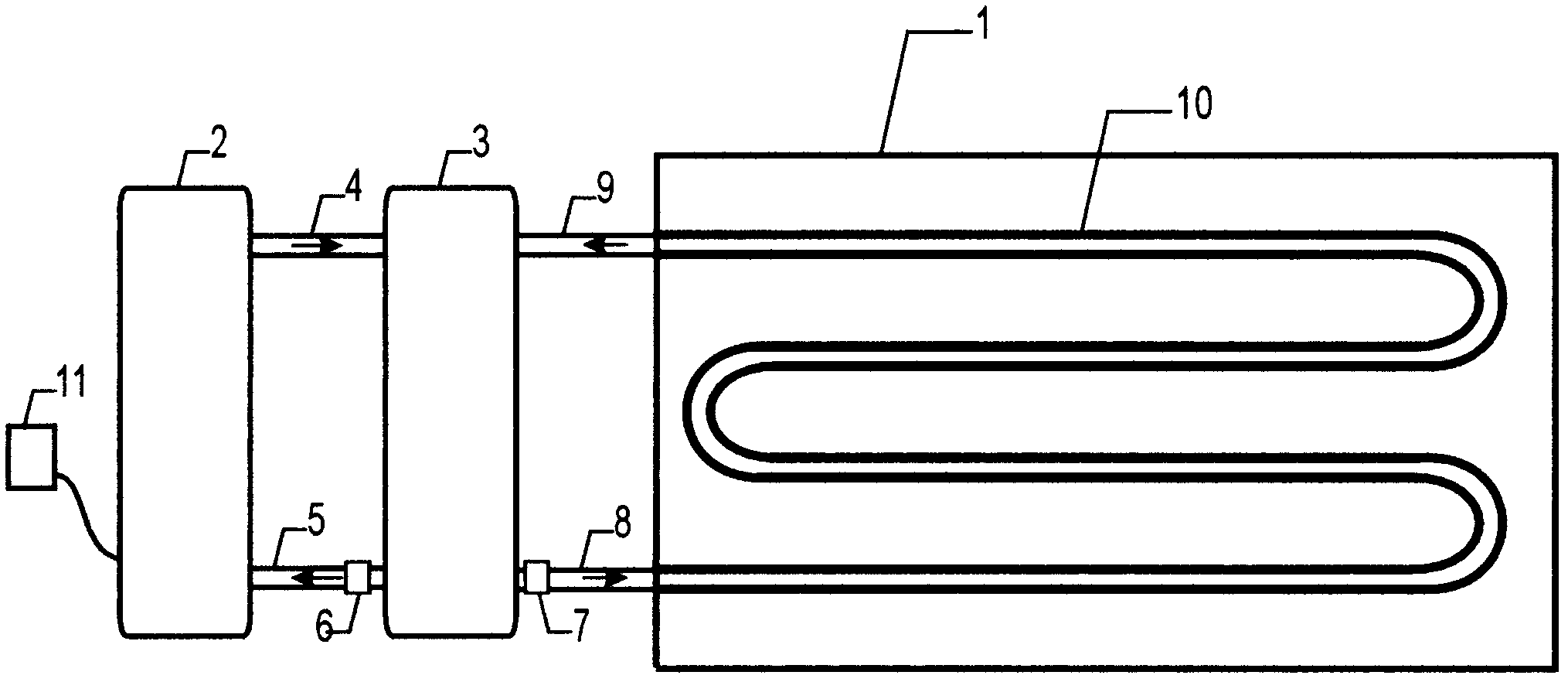

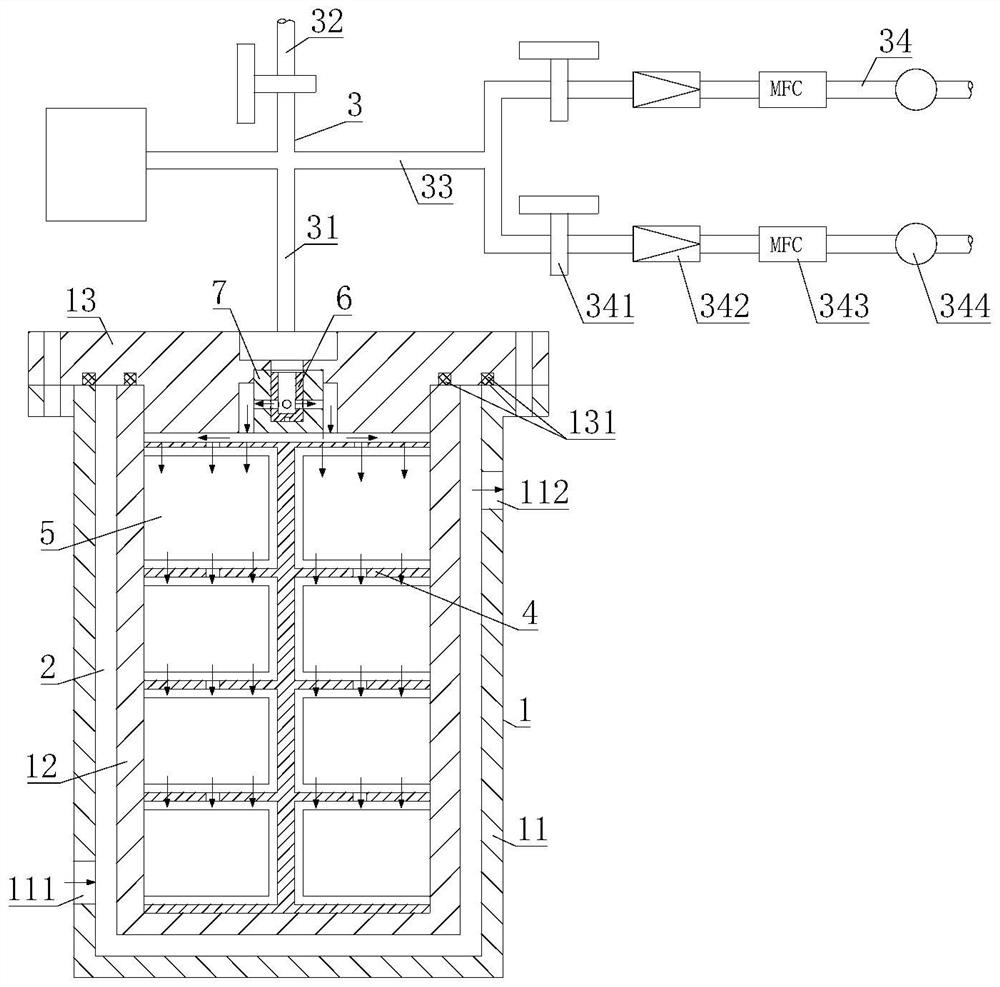

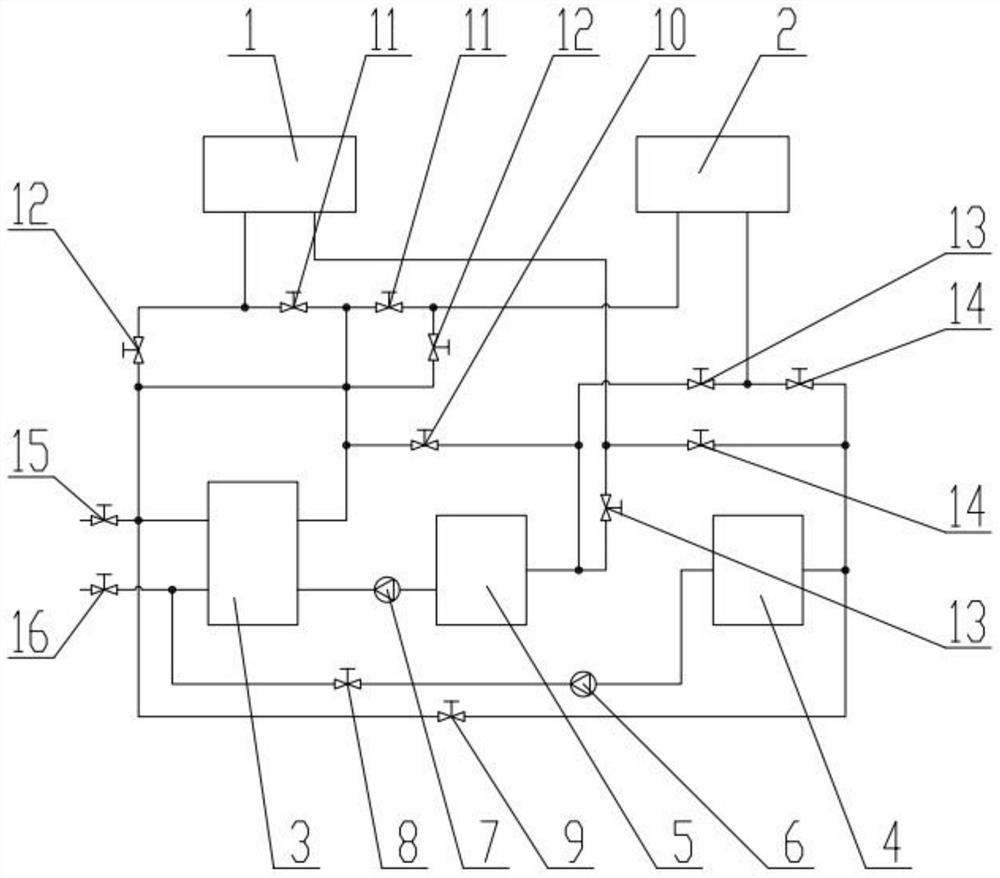

Full-automatic double-channel water-heating constant-temperature ground heating system for farm

InactiveCN102620335AReduce manufacturing costGuaranteed uptimeLighting and heating apparatusAnimal housingContactorHeating system

The invention provides a full-automatic double-channel water-heating constant-temperature ground heating system for a farm, which adopts a technical scheme that the full-automatic double-channel water-heating constant-temperature ground heating system includes a cultivation house, an air energy water heater, a water heating furnace, a hot water outlet pipeline, a hot water return pipeline, two circulating water pumps, a hot water inlet pipeline of a heat sink, a water return pipeline of the heat sink, the heat sink and a control system. The full-automatic double-channel water-heating constant-temperature ground heating system is characterized in that the air energy water heater, the water heating furnace, the hot water outlet pipeline, the hot water return pipeline, the circulating water pumps, the hot water inlet pipeline of the heat sink, the water return pipeline of the heat sink and the control system are mounted outside the cultivation house, and the floor of the cultivation house is made of a cement plaster layer and a heat preservation waterproof layer; the heat sink is mounted in the cement plaster layer; and the control system comprises a temperature control device, a leakage switch, and an alternating current contactor. The system employs the air energy water heater and the water heating furnace double-channel heat supply manner, is energy-saving and environment-friendly, and is suitable for a heating system or a drinking water heating system in the farm.

Owner:谢松林

High-voltage vacuum circuit breaker with protection function

InactiveCN109461617AReached temperatureDetectableBatteries circuit arrangementsElectric powerEngineeringHigh pressure

The invention discloses a high-voltage vacuum circuit breaker with a protection function. The high-voltage vacuum circuit breaker comprises a box body, wherein the bottom of the inner cavity of the box body is fixedly connected with a first fixing board; a second fixing board is movably connected in the first fixing board; the top of the second fixing board is fixedly connected with a vacuum circuit breaker body; and the top of the surface of the box body is fixedly connected with a supporting board. The high-voltage vacuum circuit breaker is provided with the box body and the first fixing board to achieve an effect on placing the second fixing board and the vacuum circuit breaker body, an effect on detecting temperature and humidity in the box body is achieved through a temperature sensorand a humidity sensor, an effect on providing energy is achieved through a solar panel and a storage battery, and an effect of the temperature and humidity regulation of the box body is achieved through a connecting pipe and a fan, and an effect on blocking dust is achieved through a static electricity dust screen. By use of the device, the vacuum circuit breaker can be effectively protected so as to bring convenience to people in use.

Owner:HENAN CHANGZHENG ELECTRIC

Environment-friendly treatment device for animal carcasses

InactiveCN108838192ASave resourcesEasy to closeFatty/oily/floating substances removal devicesTransportation and packagingMarket needsWater pipe

The invention relates to the technical field of environment protection and energy saving, and particularly relates to an environment-friendly treatment device for animal carcasses. The environment-friendly treatment device for the animal carcasses comprises a humidification case, a gear pump, an oil outlet pipe, an oil-water separation box and a box body, wherein the gear pump is fixedly connectedto the left end of the oil outlet pipe; the gear pump is fixedly connected to the top end of the oil-water separation box; a water outlet pipe, a partition, an oil absorption pipe and a filter screenare sequentially arranged in the oil-water separation box from right to left; the humidification case is slidably connected to the bottom end of the inner side of the box body; an oil collection water pipe is arranged at a lower part in the humidification case; a collection plate is fixedly connected above the oil collection water pipe; steam generators are fixedly connected above the two ends ofthe collection plate; a large blade is fixedly connected to a first rotary shaft; a small blade is fixedly connected to a second rotary shaft; and a charge plate is connected to the top end of the box body in a hinging manner. The environment-friendly treatment device for the animal carcasses is scientific and reasonable in structure, reutilizes the animal carcasses to achieve the effects of environment protection and energy saving, has great economic benefits, meets a wide market need, and is worthy of popularization.

Owner:张雪燕

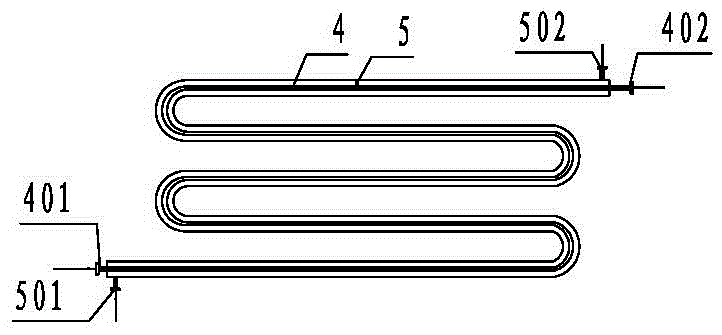

Rosin heater

The invention discloses a rosin heater and relates to the technical field of rosin processing. The rosin heater comprises a heating pipeline. At least one pipeline section of the heating pipeline is arranged in a loopback mode. The pipeline sections arranged in the loopback modes are installed in a heat-preservation box filled with asbestine. The heating pipeline is in insulating connection with the heat-preservation box. The two ends of the heating pipeline are connected with a transformer. The heater disclosed by the invention is connected with the transformer through a wire; heating is conducted by means of a rosin heating pipeline body resistor; the structure is simple; the device is small in occupied area, easy to install, low in cost and good in heating effect; and a temperature regulating valve is arranged so that the temperature of the rosin heater can be regulated in real time.

Owner:广西梧州日成林产化工股份有限公司

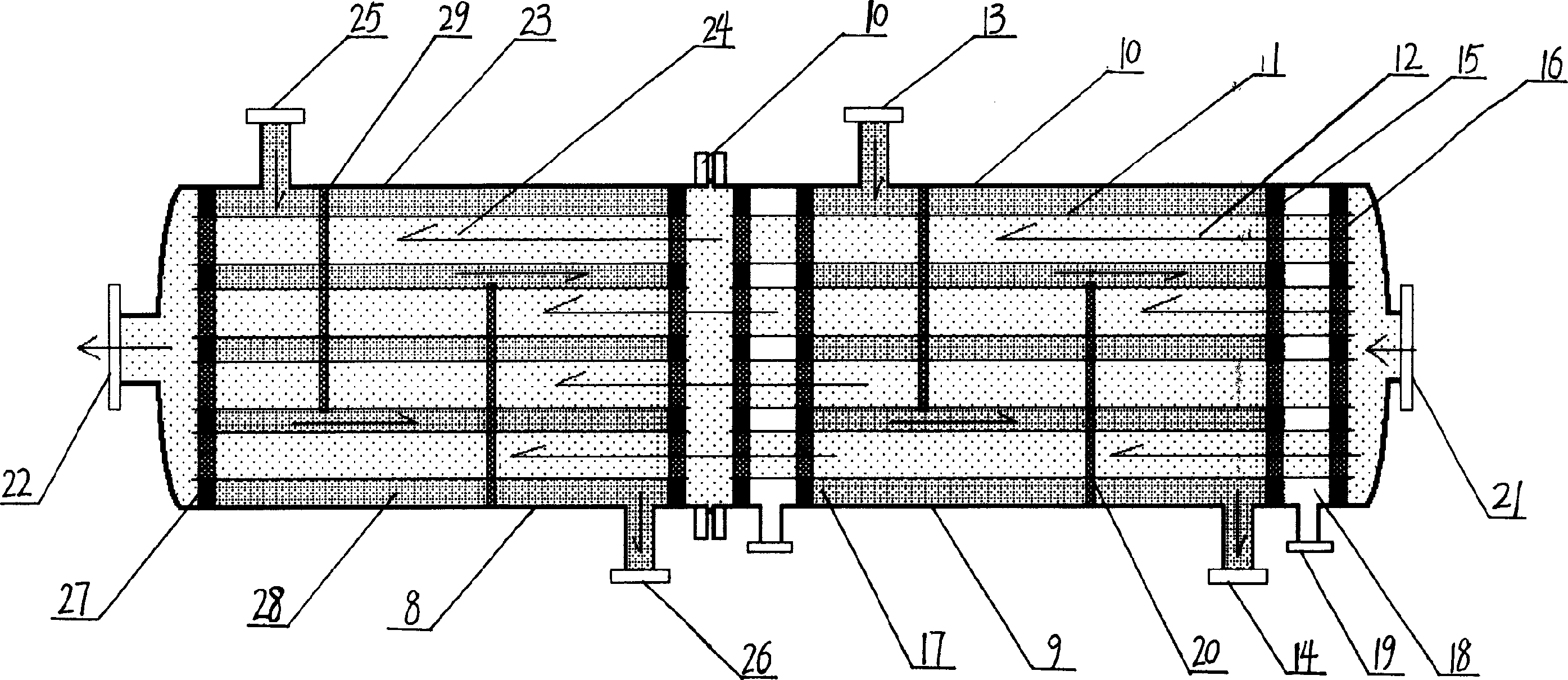

Solid hydrogen storage and supply device for hydrogen refueling station

PendingCN114508694AFast deliveryRapid temperatureVessel mounting detailsPressure vesselsEngineeringMechanical engineering

The invention belongs to the technical field of hydrogen storage and supply devices, and particularly relates to a solid hydrogen storage and supply device for a hydrogen refueling station. According to the technical scheme, the solid hydrogen storage and supply device for the hydrogen refueling station comprises a device body, a circulating water cavity is formed in the device body, a hydrogen charging and discharging pipeline is communicated to the device body, a heat conduction frame is arranged in the device body and makes contact with the inner wall of the device body, an alloy container is placed on the heat conduction frame, and alloy materials are contained in the alloy container. The solid hydrogen storage device is good in mass transfer and heat transfer, and stable hydrogen storage and supply are achieved.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Heat exchange drying device

ActiveCN111678303AIncrease profitReduce temperature differenceDrying gas arrangementsDrying chambers/containersHeat exchangerRefrigeration

The invention relates to the field of drying equipment, in particular to a heat exchange drying device. Heating drying and dehumidification functions can be achieved at the same time, and energy can be saved. The heat exchange drying device comprises a drying chamber and a heat exchange device. The drying chamber is provided with a drying heat exchanger. The heat exchange device is connected withthe drying heat exchanger and comprises a heat exchange unit and a cold and hot switching device. The cold and hot switching device is arranged between the heat exchange unit and a drying heat exchanger. The heat exchange unit can use a compressor unit, and refrigeration and heating are conducted simultaneously. Working states of the drying heat exchanger can be changed directly through the cold and hot switching device. Products can be dried through the heating mode. The refrigeration mode can be used for dehumidification.

Owner:山东东工新能源科技有限公司

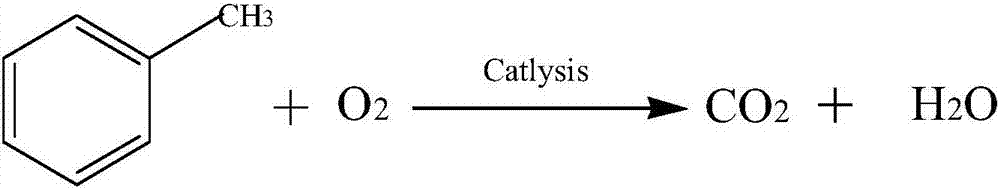

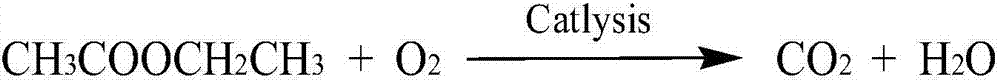

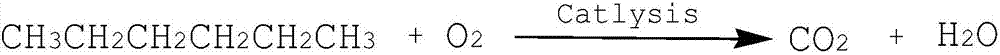

Application of integral type electrothermal wire mesh catalyst in catalytic combustion of volatile organic waste gas

ActiveCN107191948AHigh strengthEasy to prepareIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsEngineeringHigh activity

The invention relates to application of an integral type electrothermal wire mesh catalyst in catalytic combustion of volatile organic waste gas. The catalyst is prepared by the following steps: (1) placing a wire mesh material in acetone, removing oil in an ultrasonic manner, washing the wire mesh material thoroughly with distilled water, placing a wire mesh in a NaOH solution, carrying out ultrasonic treatment on the wire mesh, washing the wire mesh thoroughly with the distilled water, finally, placing the wire mesh in an HNO3 solution, carrying out ultrasonic treatment on the wire mesh to remove oxide on the surface of the wire mesh, washing the wire mesh thoroughly with the distilled water, and then drying the wire mesh; (2) calcining the pretreated wire mesh in pure oxygen; and (3) spraying Pt or Pd nano-particle sol dispersion liquid to the calcined wire mesh, then drying the wire mesh, and calcining the wire mesh to obtain the Pt or Pd nano-particle-loaded integral type electrothermal wire mesh catalyst. The active components of the catalyst are dispersed highly, and cannot be agglomerated easily, the ability of the catalyst which is combined to a carrier is high, the catalyst has the characteristics of small use amount of precious metal, high activity, and capability of spontaneously heating after the catalyst is electrified, and therefore, the application has the characteristics of energy conservation, high efficiency and rapid reaction.

Owner:ZHEJIANG UNIV OF TECH

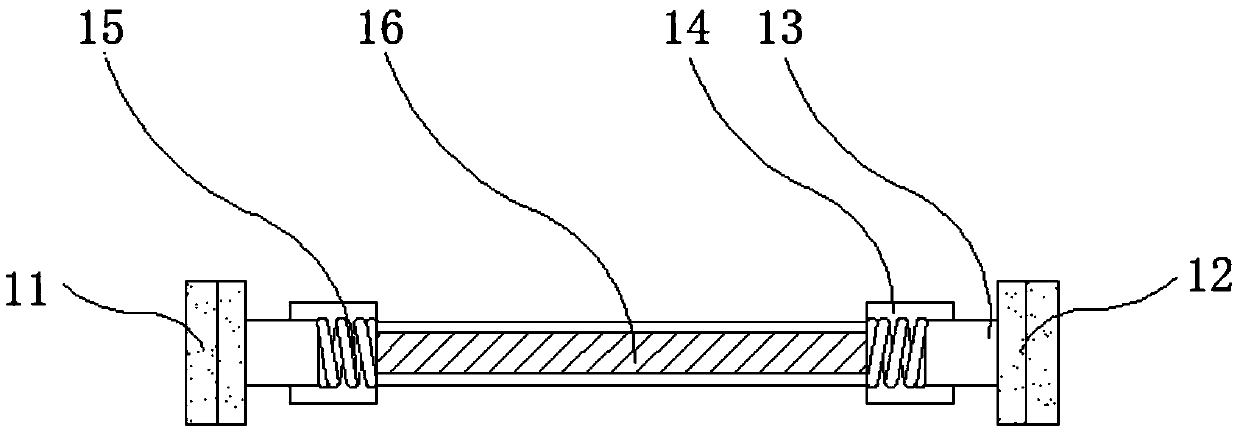

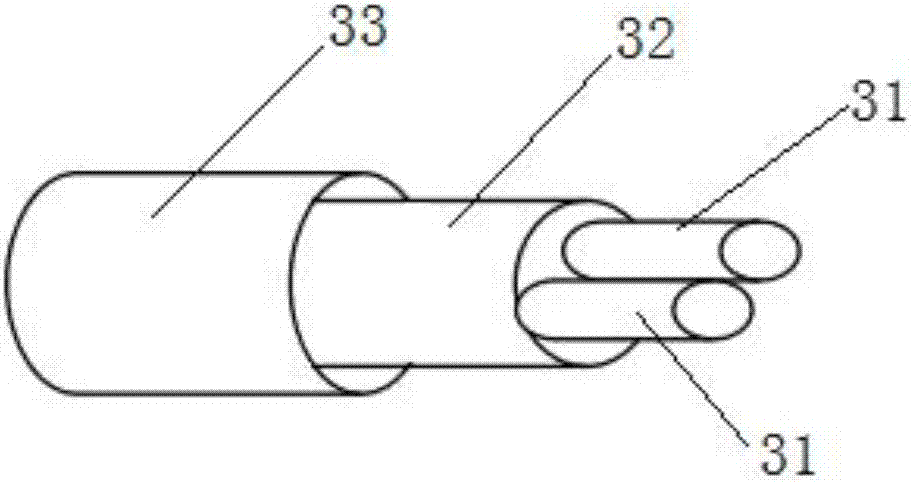

Carbon fiber energy-saving heat generation line and fabrication method thereof

InactiveCN107148100AReduce in quantityIncrease resistanceHeating element shapesHeating element materialsYarnFiber

The invention discloses a carbon fiber energy-saving heat generation line and a fabrication method thereof. The carbon fiber energy-saving heat generation line comprises at least two carbon fiber heat generation unit lines arranged in a bundle shape, wherein each carbon fiber heat generation unit line comprises a plurality of carbon fiber yarns in a bundle shape and an insulation layer, the plurality of carbon fiber yarns are arranged in the insulation layer, and the numbers of carbon fiber yarns in different carbon fiber heat generation unit line lines are same or different. The carbon fiber energy-saving heat generation line employs two or multiple carbon fiber heat generation unit lines, the number of the carbon fiber yarns of a single carbon fiber heat generation unit line is reduced, the heat generation power is reduced, electric energy is saved, a heat superposition effect of multiple carbon fiber heat generation unit lines is developed, and a required temperature is reached.

Owner:SUZHOU DONGFANG KANGTAN NEN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com