Carbon fiber energy-saving heating module and underfloor heating system

A technology of carbon fiber heating and carbon fiber, which is applied in the field of carbon fiber, can solve problems such as increased heating power, increased current, floor layer cracking, etc., and achieves the effects of reduced heating power, increased resistance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

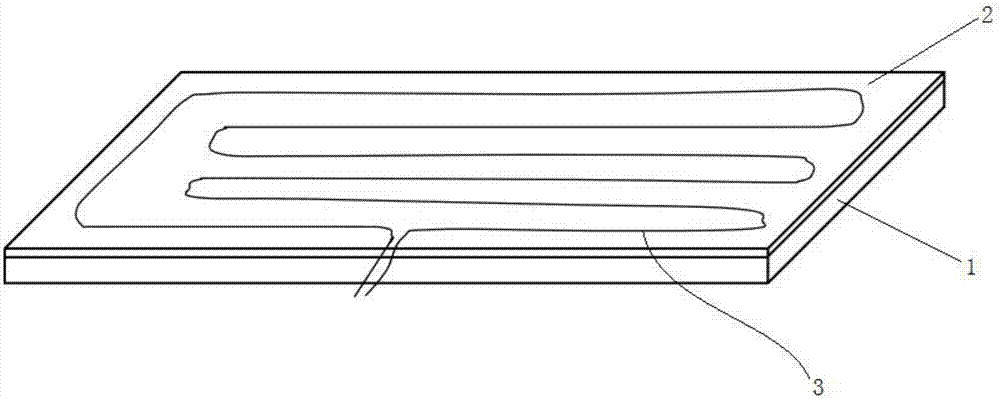

[0031] In one embodiment of the present invention, a carbon fiber energy-saving heating module is provided, see figure 1 , the carbon fiber energy-saving heating module includes a thermal insulation board 1 , a heat conduction plate 2 and a heating wire 3 , the heat conduction plate 2 is arranged above the thermal insulation board 1 , and the heating wire 3 is arranged on the heat conduction plate 2 .

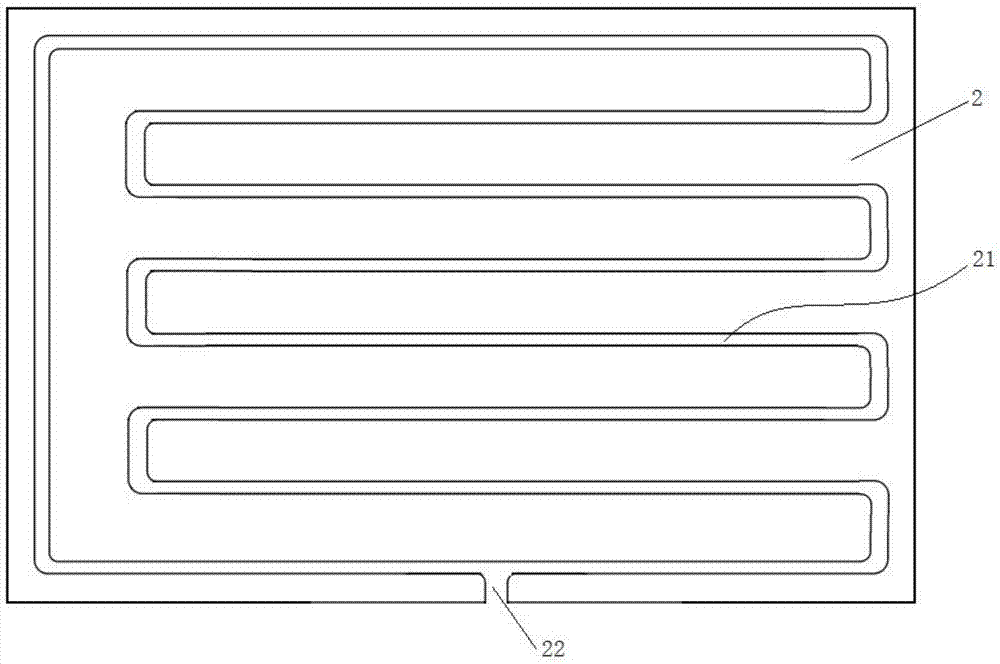

[0032] In order to facilitate the arrangement of the heating wires 3 on the heat conducting plate 2, the heat conducting plate 2 is provided with a wiring groove 21, and the heating wires 3 are arranged in the wiring groove 21, see figure 2 , the wire trough 21 is arranged in a serpentine shape or in a round shape, the wire trough 21 has a wire groove outlet 22, and the wire groove outlet 22 is arranged on the edge of the heat conducting plate 2, and the heating wire 3 Both ends of the wire slot are drawn out from the outlet 22 of the wire slot, but the above is a preferred e...

Embodiment 2

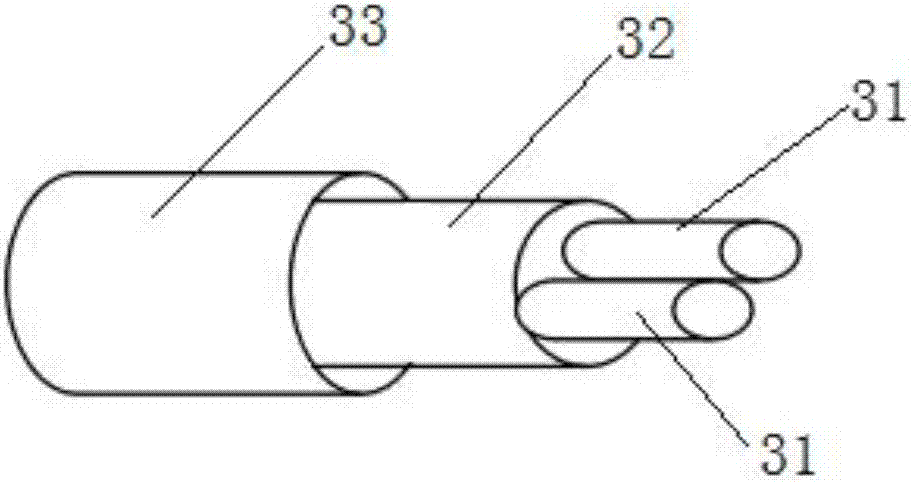

[0040] Different from Embodiment 1, there are three carbon fiber heating unit wires 31 in this embodiment, and each carbon fiber heating unit wire 31 includes 4000 carbon fiber filaments. Compared with the single 12K carbon fiber heating wire (12000 carbon fiber heating wires) in the prior art, it can also reduce the power consumption.

[0041] Correspondingly, the carbon fiber heating wires of the three carbon fiber heating unit lines 31 are all wrapped by the insulating layer 32, and the thermally conductive protective layer 33 is wrapped around the three carbon fiber heating unit lines 31, and the carbon fiber energy-saving heating modules made of other numbers of carbon fiber heating unit lines 31 are in the This is not listed one by one.

Embodiment 3

[0043] In one embodiment of the present invention, a floor heating system is provided, including a floor, a power supply interface and a plurality of carbon fiber energy-saving heating modules as described in the above-mentioned embodiments, and the power supply interface is used to supply the heating wires of the carbon fiber energy-saving heating modules Power supply, a plurality of carbon fiber energy-saving heating modules are laid side by side, and the floor is laid on the carbon fiber energy-saving heating modules.

[0044] The floor heating system provided by the embodiment of the present invention does not need to set up a cable trough on the floor body, so there will be no layered cracks on the floor body due to slotting or direct contact with the heating wires, and the cable trough of the heat insulation board can be installed on the insulation board. It is formed during hot layer forming without subsequent slotting. Therefore, the liner can be mass-produced in the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com