Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Prevent top damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

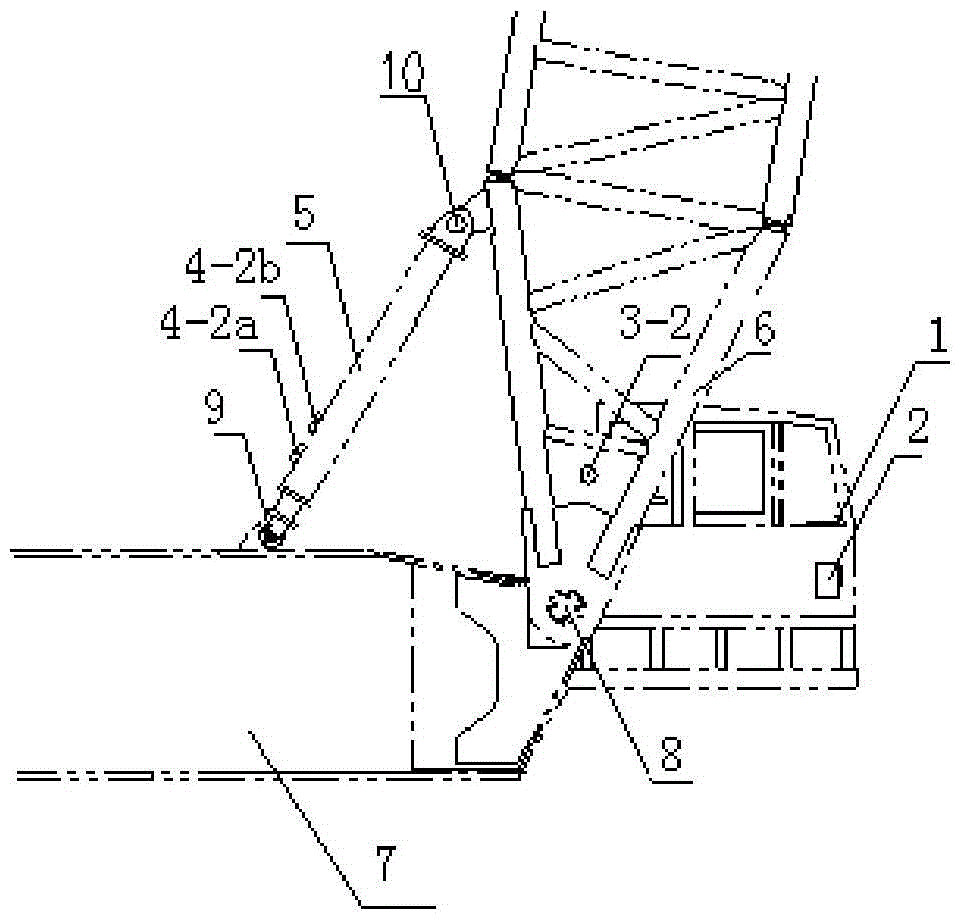

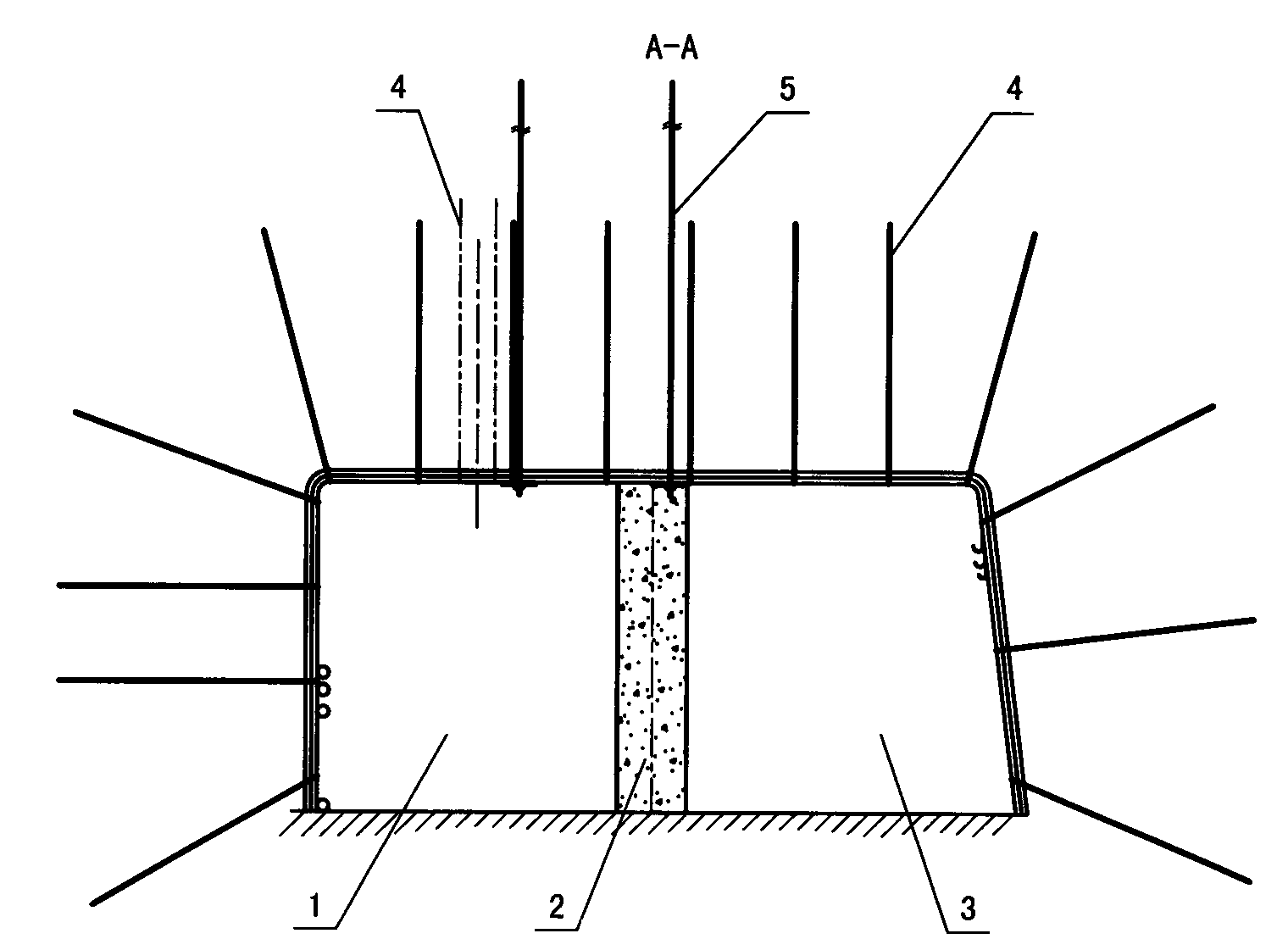

Method for retaining gob-side tunnel

InactiveCN102337904AAchieve miningTake advantage ofMining devicesUnderground chambersEngineeringStructural engineering

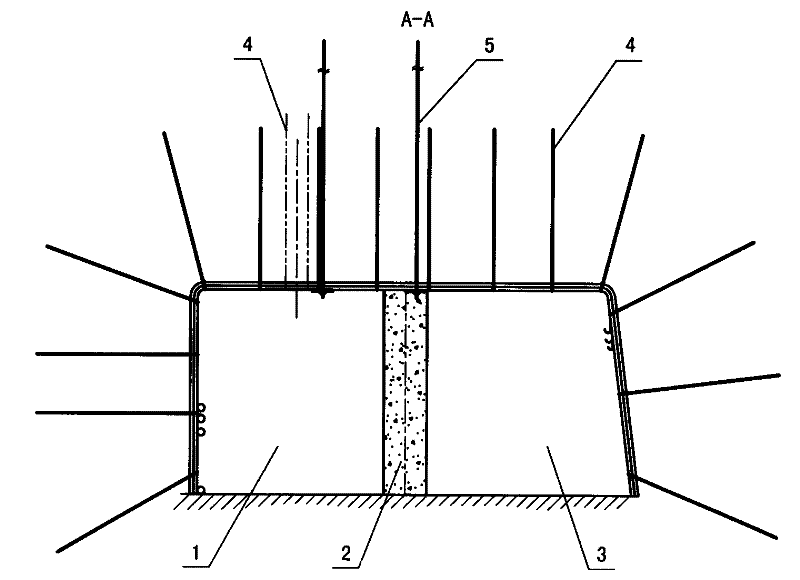

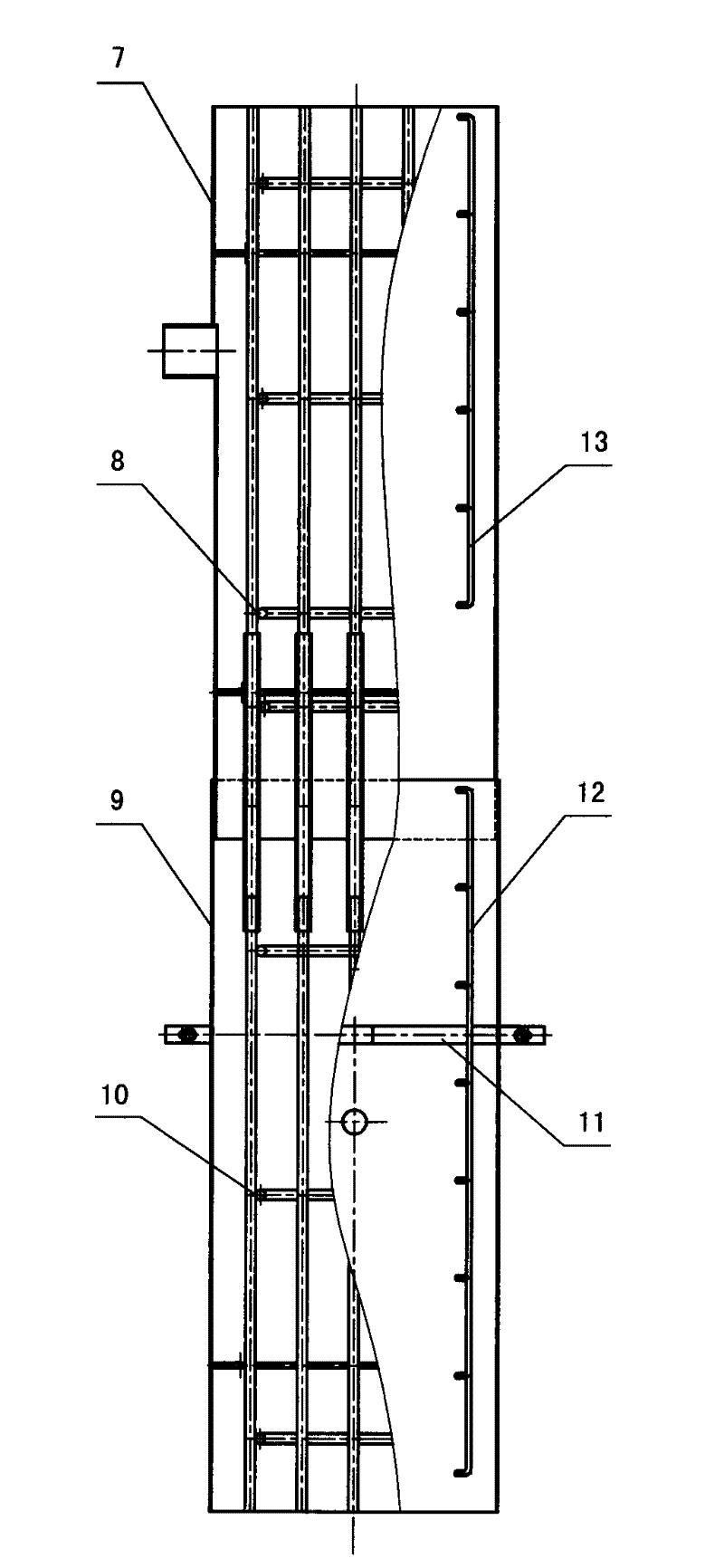

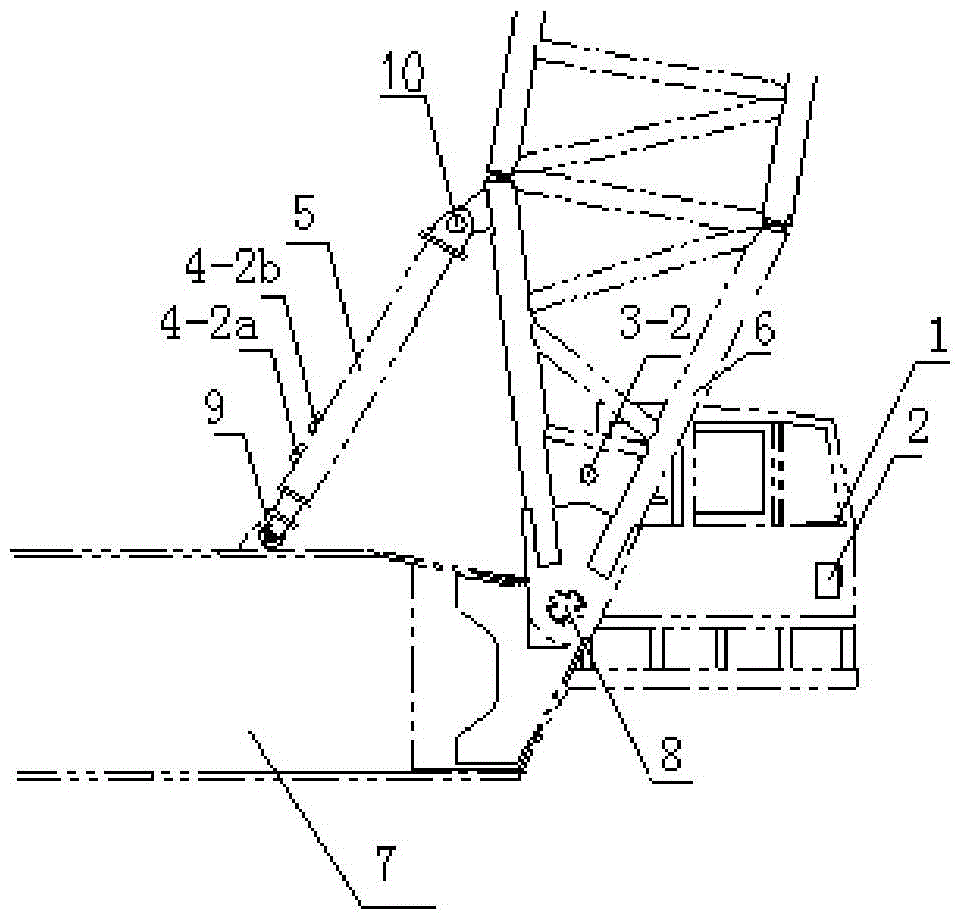

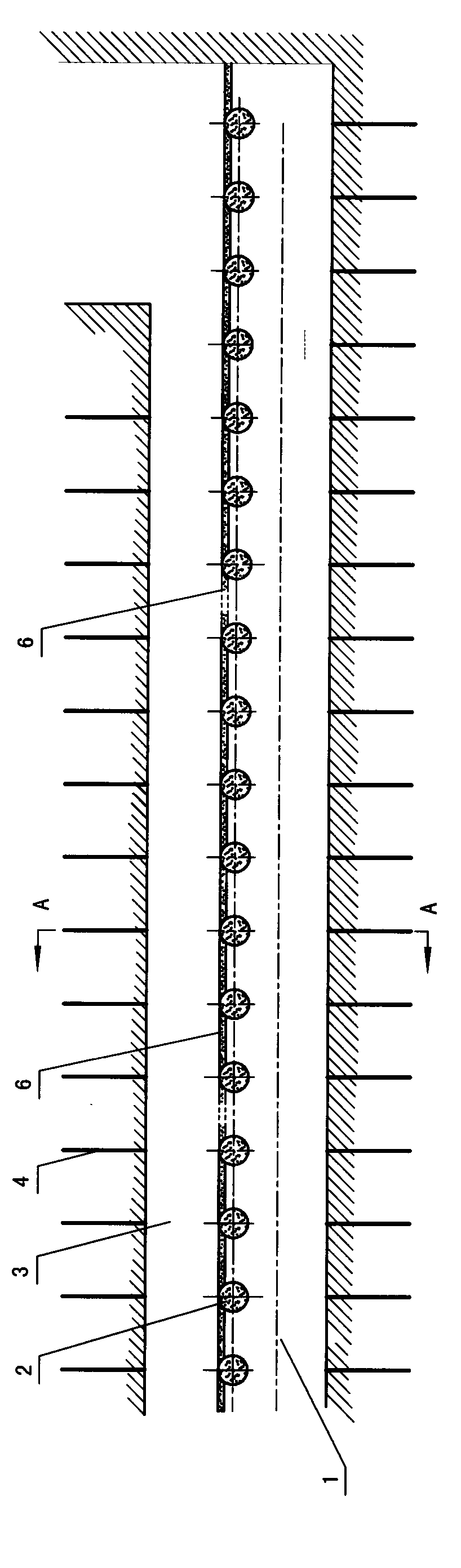

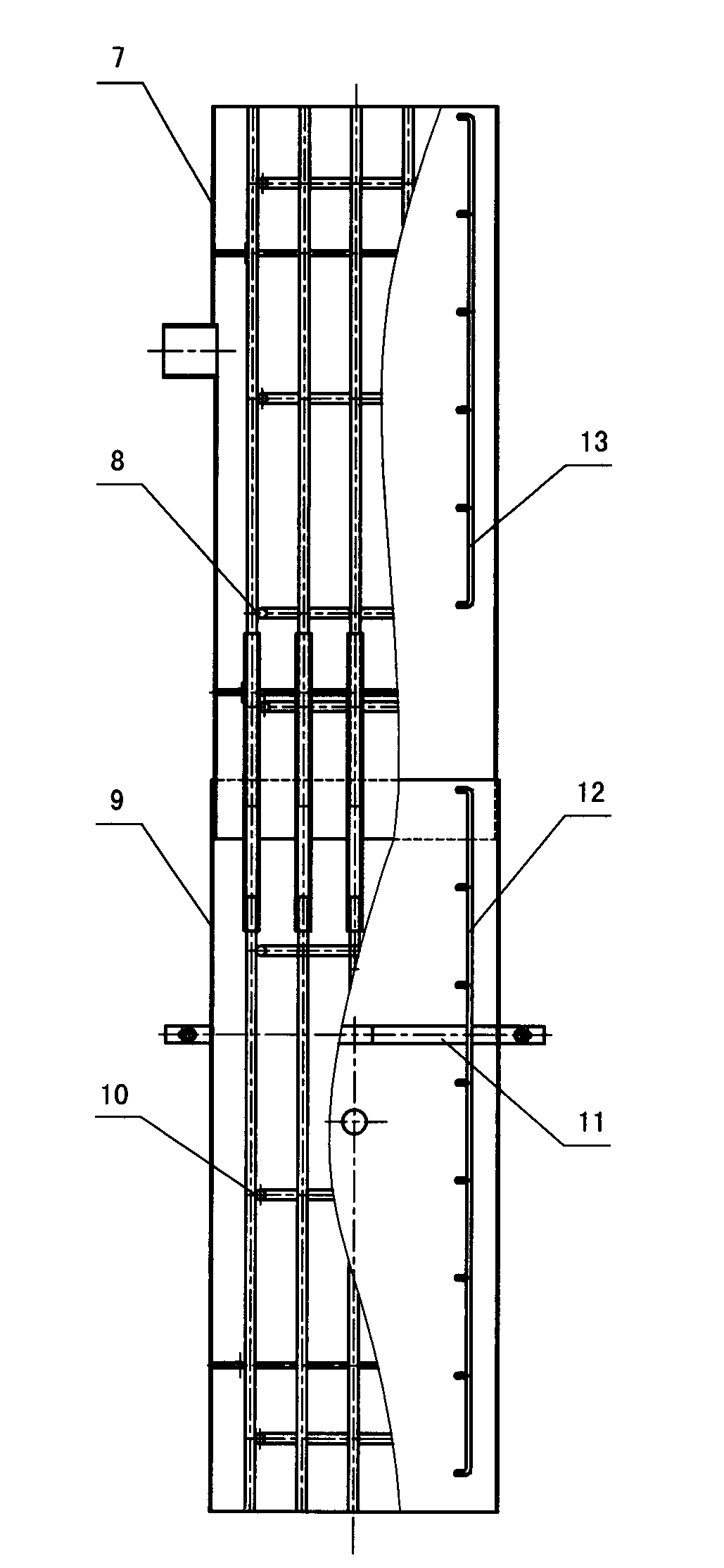

The invention discloses a method for retaining a gob-side tunnel, which overall arranges the retaining of the gob-side tunnel in a stope working face gateway tunneling period, and comprises the steps of: combining the stope working face gateway with the gob-side retained tunnel, namely the next section gateway, together to be served as one tunnel for tunneling; and constructing tunnel concrete pier columns between the stope working face gateway and the gob-side retained tunnel, wherein the tunnel concrete pier columns are served as support in the tunnel and also served as one part of the side support for the gob-side retained tunnel; namely comprising the steps of: widening the section of the tunnel by tunneling, reserving the tunnel section according to the shrinkage factor of the god-side retained tunnel suffering from two times of support pressure, and pouring the reinforcing steel bar concrete pier columns in middle of the transverse direction of the tunnel to match with a cable anchor for supporting. The tunnel concrete pier columns are arranged along the whole length of the tunnel at intervals, and used for dividing the tunnel into two parts. Insulating walls are constructed between two adjacent columns after the columns are constructed. When the stope is starting, the support is needed to be temporarily reinforced at two sides of the columns according to requirements along with the advancing of the stope working face. According to the method for retaining a gob-side tunnel, the retaining of the gob-side tunnel and the tunneling of the stope working face gateway are overall arranged, and the tunnel concrete pier column support is arranged; therefore, the side support intensity and support resistance of the retained tunnel are greatly enhanced, the influence of support pressure in two times of mining is effectively controlled. The method for retaining gob-side tunnel is particularly suitable for using in flexible mining faces of bottom plate and / or top plate.

Owner:贾民

Method of preventing heavy gauge strip steel from being scratched among finishing mill racks

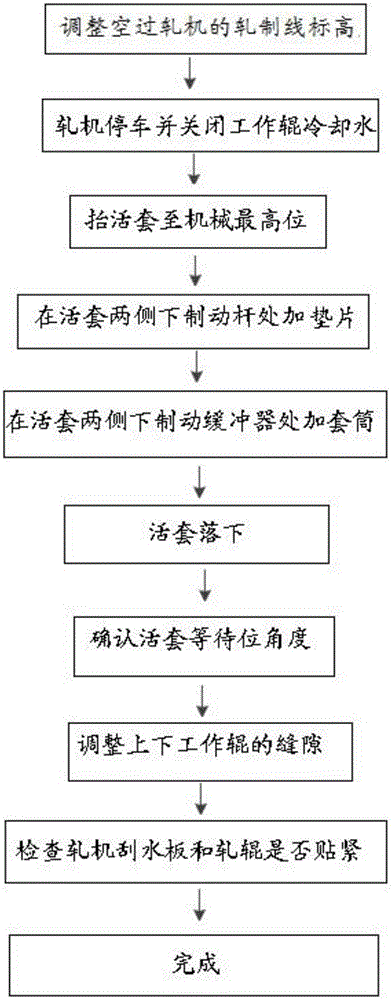

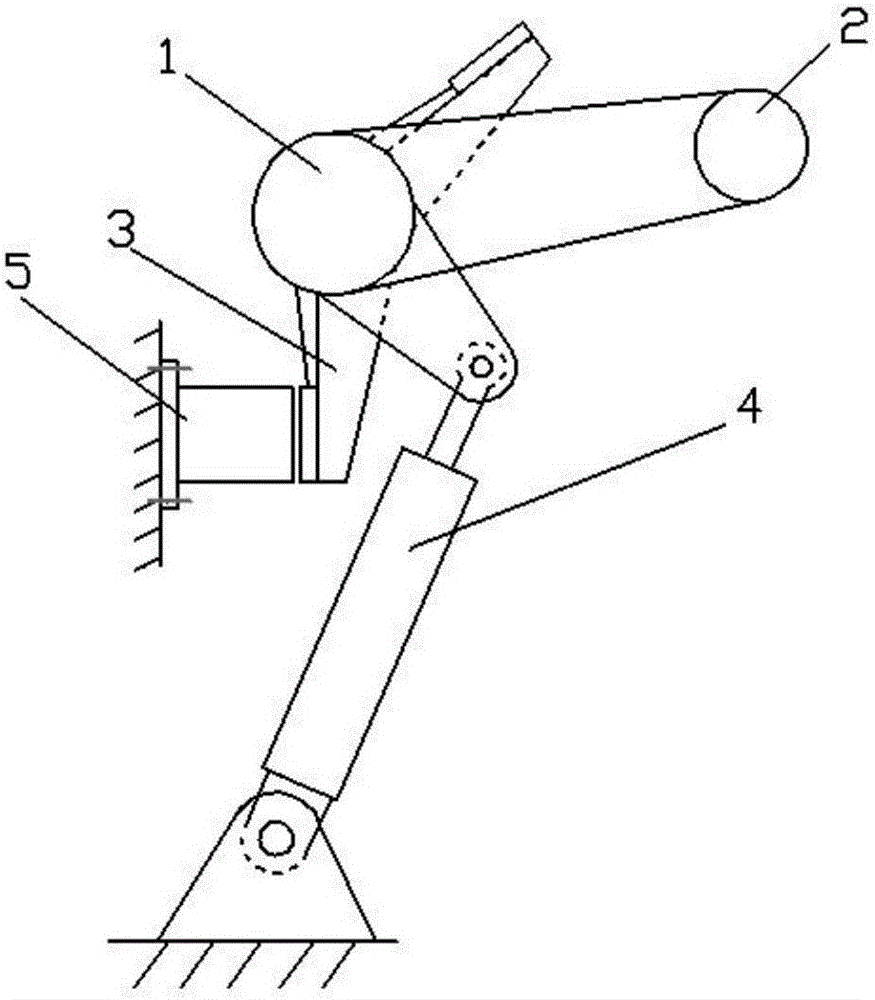

ActiveCN105728460AAvoid compressionSolve the scratchMetal rolling stand detailsFlexible work arrangmentsPosition angleStrip steel

The invention provides a method of preventing heavy gauge strip steel from being scratched among finishing mill racks. The method comprises the following steps of: adjusting the elevation of a rolling line of an idle rolling mill to right elevation; and adjusting the mechanical position of a downstream loop of the idle rolling mill, to be specific, lifting the loop to the mechanical highest position, arranging a gasket on a brake bar below the loop and a sleeve on a buffer below the loop, dropping down the loop, and identifying the waiting position angle of the loop. The method has the beneficial effects that the rolling line is in the right elevation, and strip steel is lifted; the waiting position angle of the loop is increased by adjusting the mechanical position of the downstream loop of the idle rolling mill, thereby preventing the lower surface of the strip steel from scratching a lower guide plate of a rolling mill outlet, completely solving the surface scratching problem of the strip steel, greatly increasing the percent of pass of strip steel quality and ensuring the smooth production.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Flexible die releasing method of closed die forging large irregular profile structure forge piece

ActiveCN106975722AEject evenlyReduce contact areaForging/hammering/pressing machinesPush upsEngineering

The invention discloses a flexible die releasing method of a closed die forging large irregular profile structure forge piece. The flexible die releasing method comprises the steps that an upper forging die is taken out firstly and then force is applied to pushing rods to push up the large irregular profile structure forge piece in a lower forging die; flexible sections of each pushing rod are compressed to the elastic limit, and the compression amount is equal; when push-out force of a certain pushing rod is larger than frictional resistance of the position, located on the pushing rod, of the forging piece and a die mold cavity, the position of the forging piece loosens firstly and produces certain displacement, the pushing rod is not separated from the forging piece, the situation same with the just pushing rod occurs gradually on the other one pushing rod or the other multiple pushing rods, and the process occurs randomly and is conducted continuously; and when the total push-out force of all the pushing rods is larger than the total frictional resistance of the forging piece, the forging piece loosens overall, bears relatively-even force and is steadily pushed out of the die mold cavity. According to the flexible die releasing method, the die releasing process of the forging piece becomes steadier and is not liable to damage, and the flexible die releasing method is mainly used for die releasing after forging of forging pieces such as large aircraft structural pieces.

Owner:贵州锆石科技发展有限责任公司

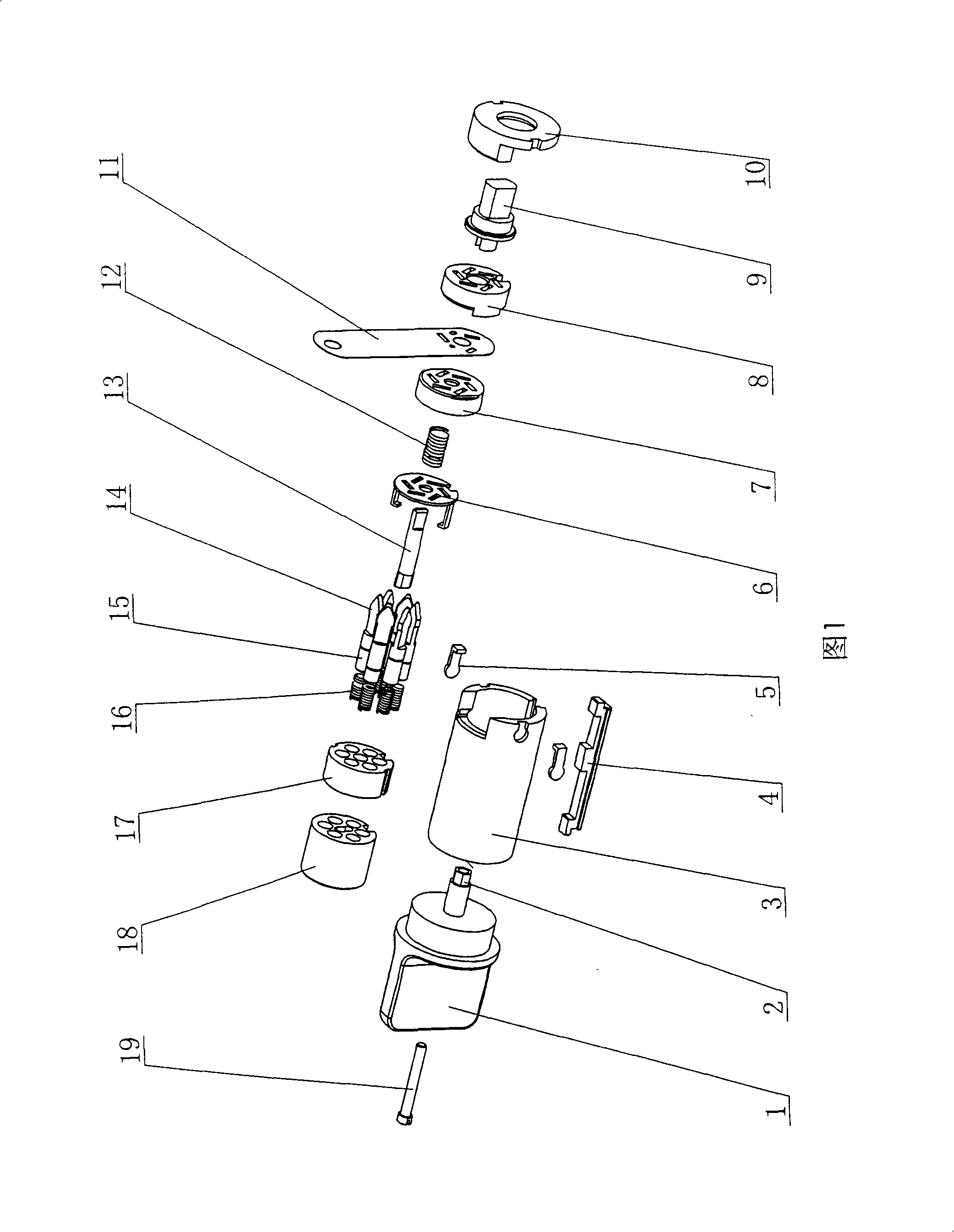

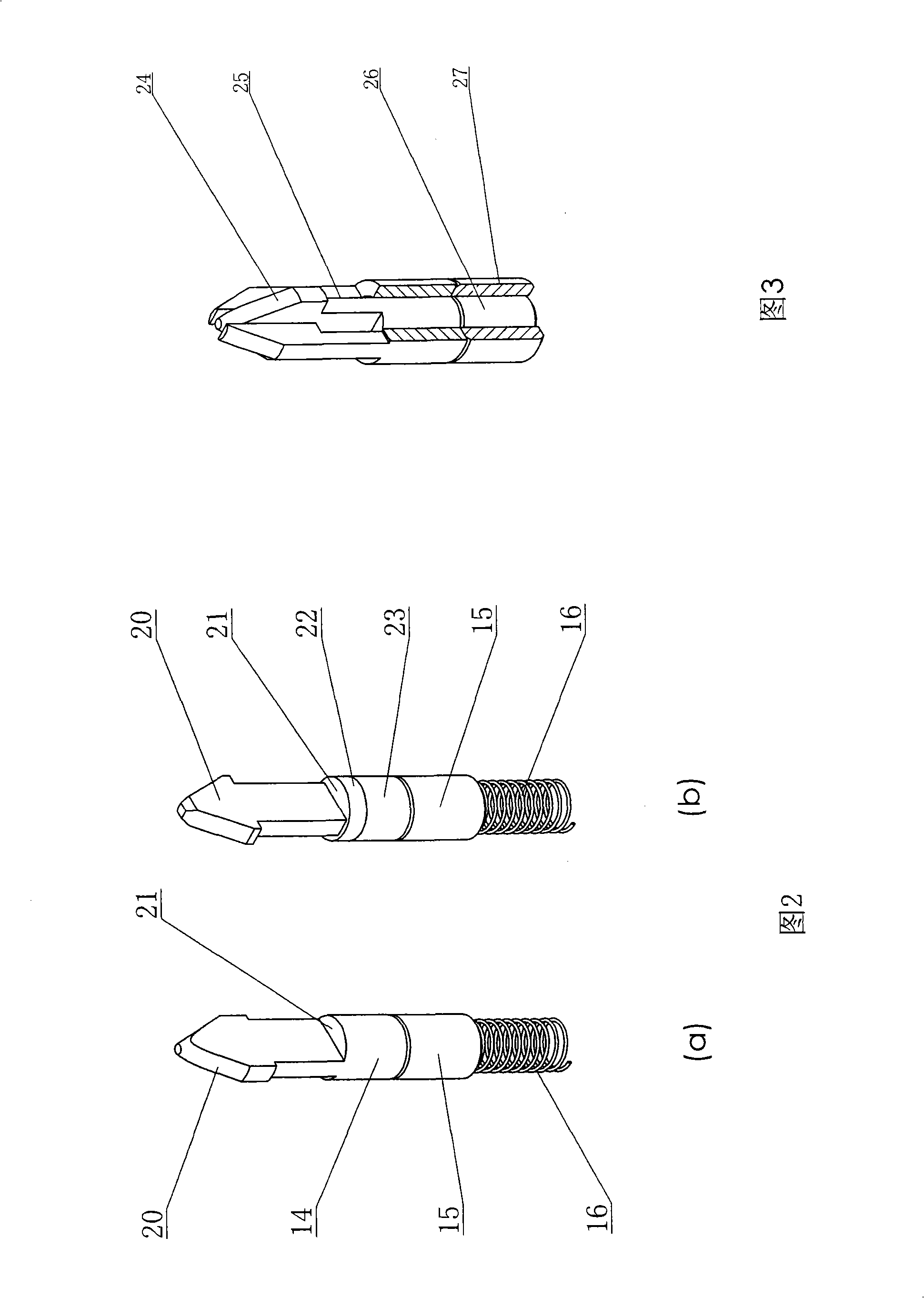

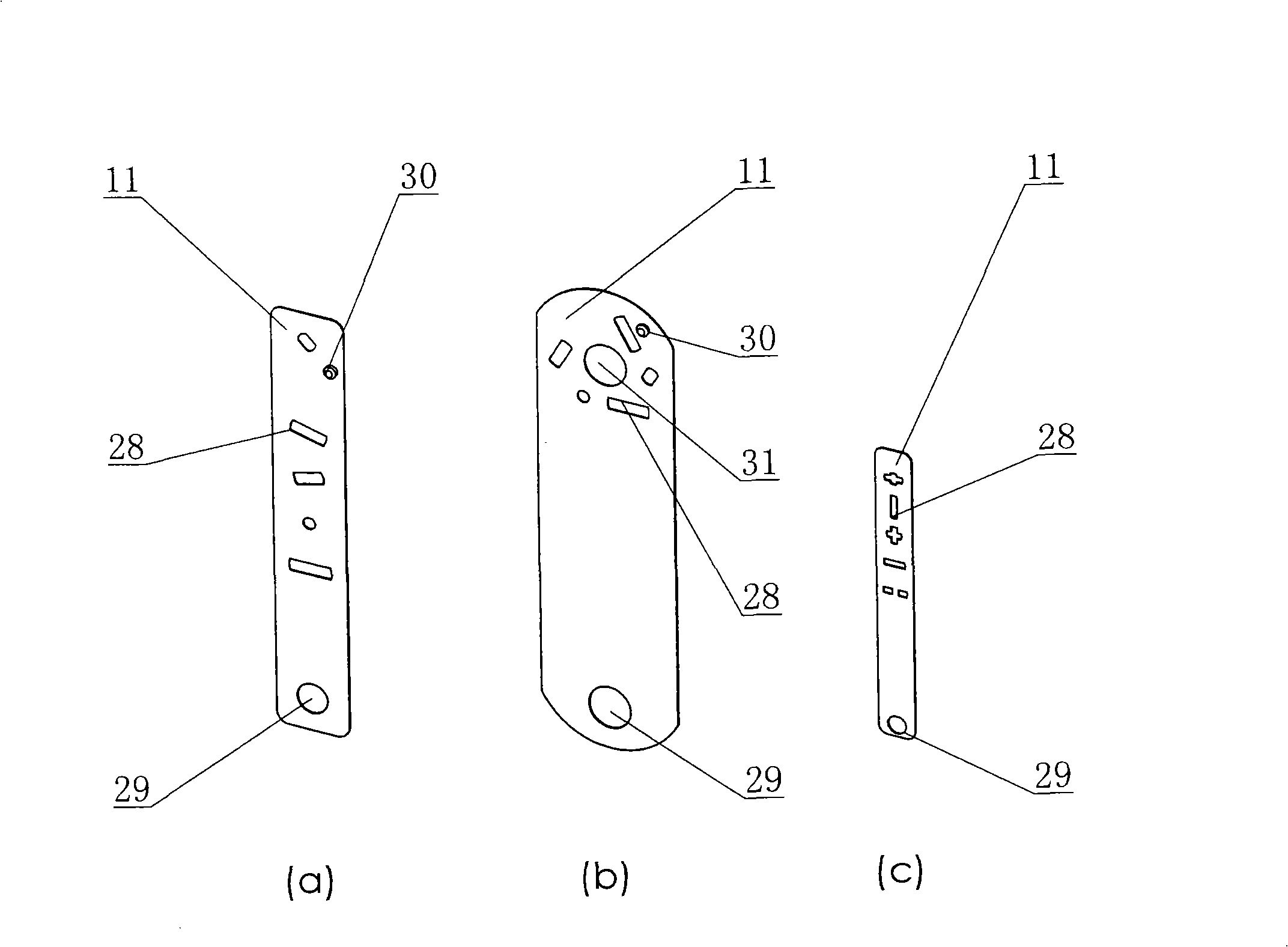

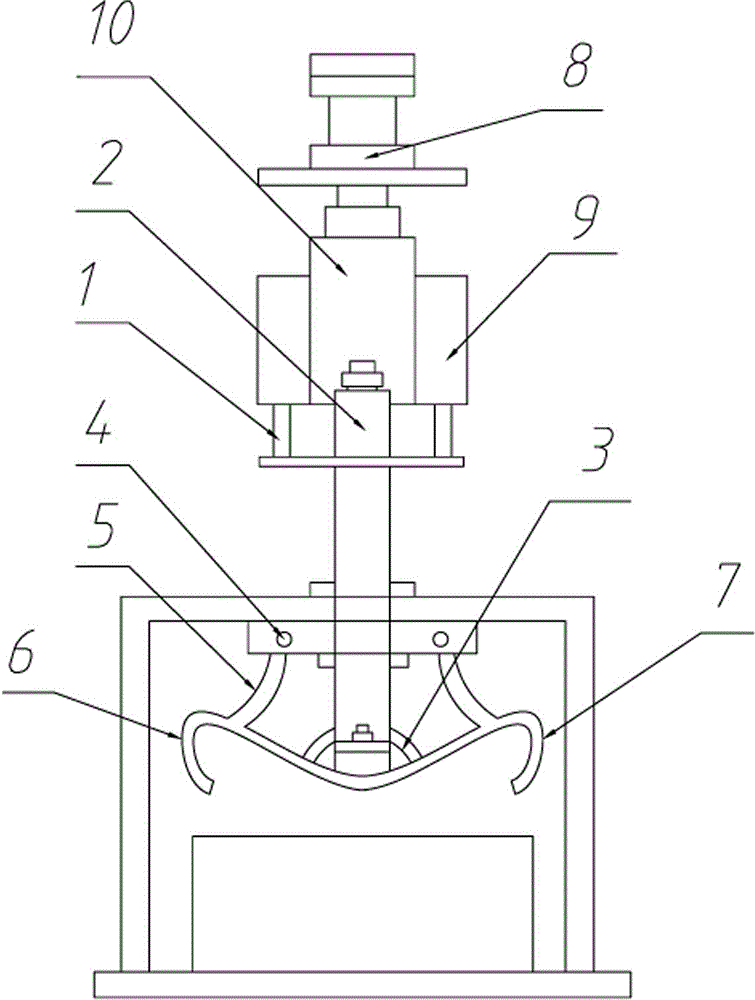

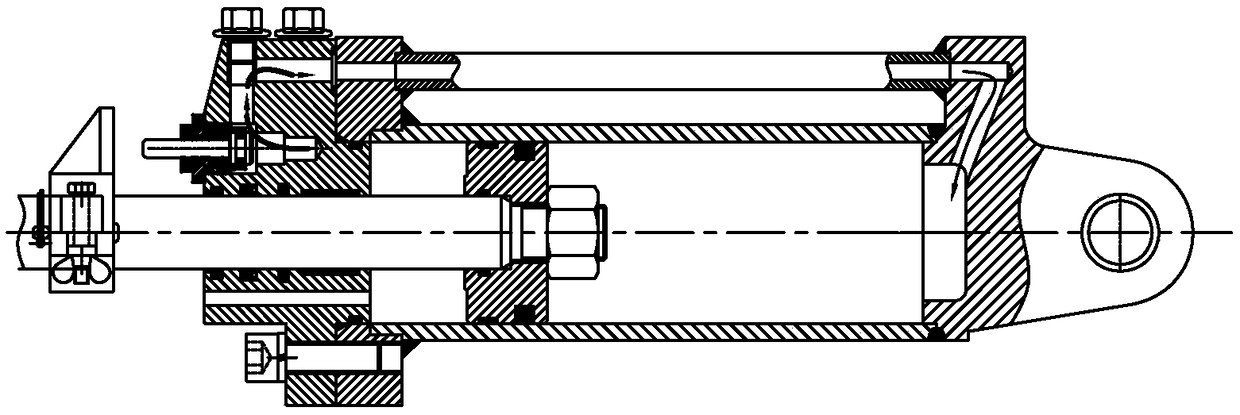

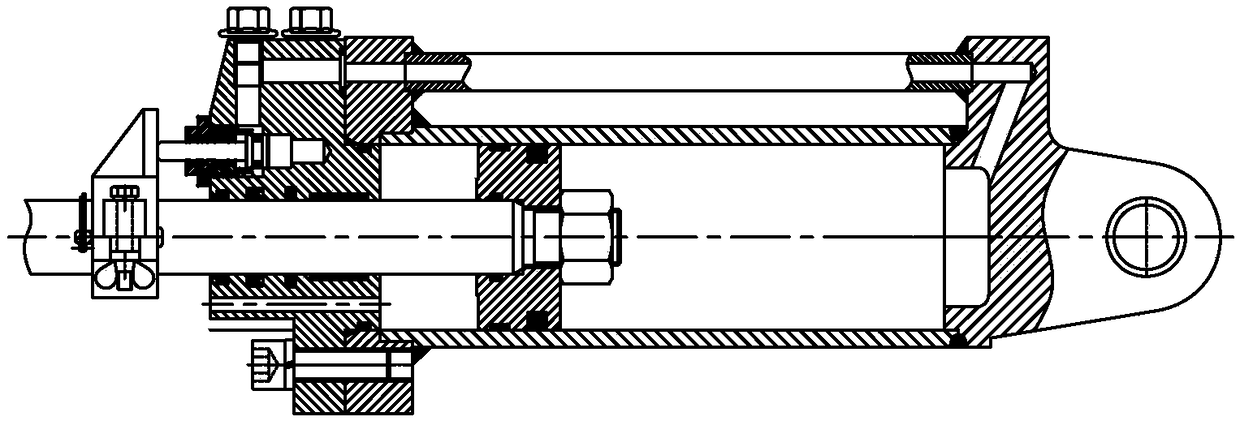

Active sleeve-withdrawing device for hose assembling machine

The invention relates to an active sleeve-withdrawing device for a hose assembling machine. The device comprises a sleeve-taking head, a connecting rod, a cylinder, a cylinder jacking rod, a sleeve-withdrawing jacking rod, a hexagon screw, a sleeve-withdrawing bolt, a pressing spring, a sleeve-withdrawing bolt pin, a sleeve-withdrawing positioning base, a cam, a tension spring, a shifting cylinder and a shifting cylinder base. After a sleeve ring is sent out by the cylinder, the cylinder withdraws, and then the sleeve-withdrawing bolt and the connecting rod withdraw together; after withdrawing for a short time, the lower part of a rear end of the sleeve-withdrawing bolt contacts with the cam and the pressing spring is pressed, but the connecting rod and the sleeve-taking head fixed on the connecting rod continue withdrawing under the pulling of the cylinder jacking rod; the sleeve-withdrawing bolt pin slides in a circular waist through hole of the connecting rod; the sleeve-withdrawing jacking rod is fixed and the sleeve-taking head withdraws; and the hexagon screw which is fixed at the top end of the sleeve-withdrawing jacking rod extends from the sleeve-taking head under the action of the relative motion of the sleeve-withdrawing jacking rod and the sleeve-taking head, so that the sleeve ring which is maintained in the sleeve-taking head can be pushed out and the smooth operation of the next circulation is ensured.

Owner:浙江本发科技有限公司

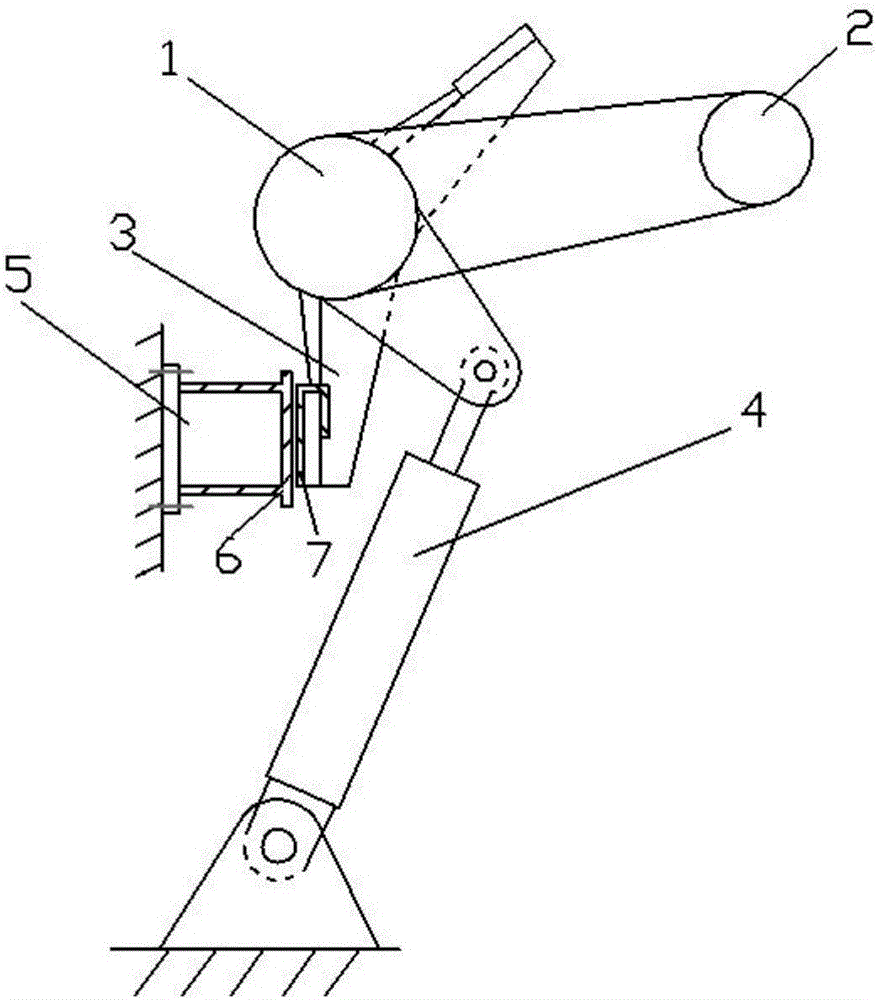

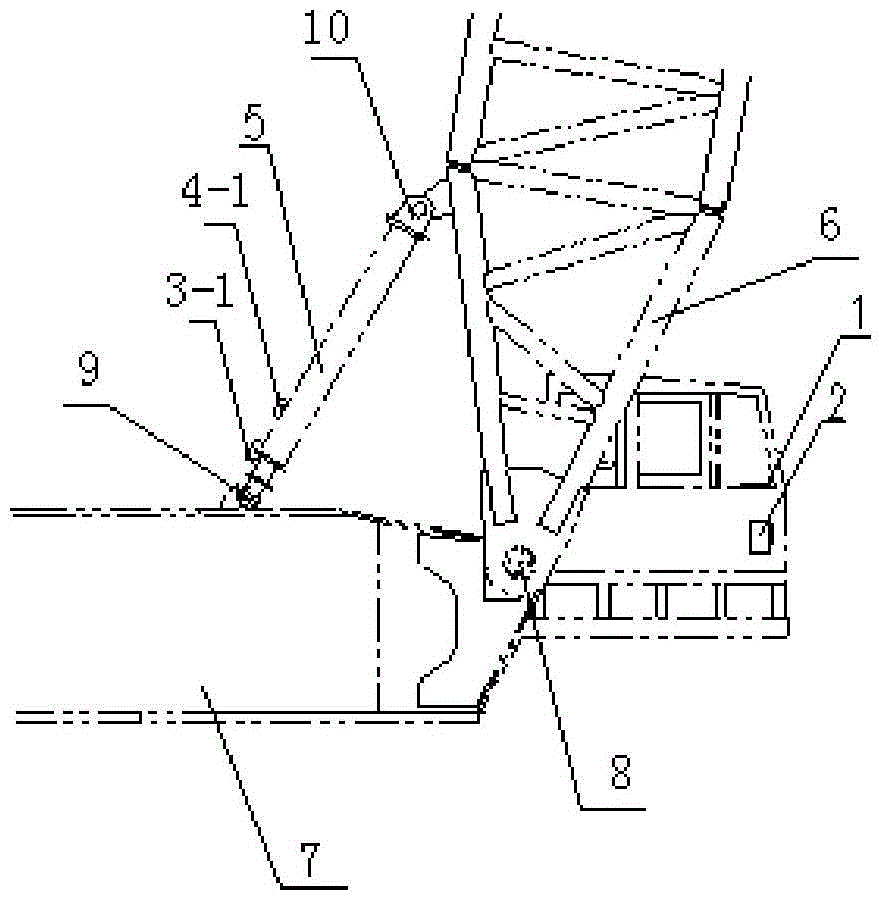

Anti-hypsokinesis safe control device of crane arm frame

The invention discloses an anti-hypsokinesis safe control device of a crane arm frame. The device comprises a displayer, a controller, an angle sensor, a low-pressure alarm pressure switch and a high-pressure alarm pressure switch, wherein the controller is used for calculating the anti-hypsokinesis length and comparing the anti-hypsokinesis length and an anti-hypsokinesis extreme position set value, and sending out an extreme position limited motion signal so as to stop the retraction action of an oil cylinder; the displayer is used for receiving an anti-hypsokinesis length signal sent by the controller; the anti-hypsokinesis length signal is displayed in the displayer in real time, an anti-hypsokinesis extreme pre-alarm range is set in the displayer, when the anti-hypsokinesis reaches the range, an alarm window is popped and used for hinting operators. The problem that the data display is not accurate due to signal interference is avoided, the commonality and operation convenience of the anti-hypsokinesis extreme position detection are improved, an anti-hypsokinesis extreme position pre-alarm function is increased, the precision and reliability of the whole anti-hypsokinesis safety control system are improved, and the cost of the anti-hypsokinesis safety control system is lowered.

Owner:XCMG CONSTR MACHINERY

Mechanical linking lock core started by thin key card

InactiveCN101310085ANot easy to damageReduce volumeKeyhole guardsLock casingsEngineeringMechanical engineering

Owner:孙曙光

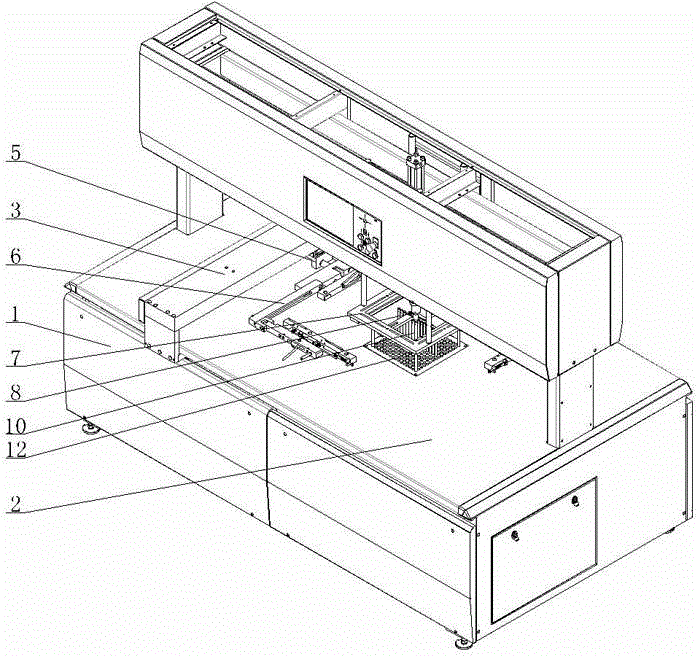

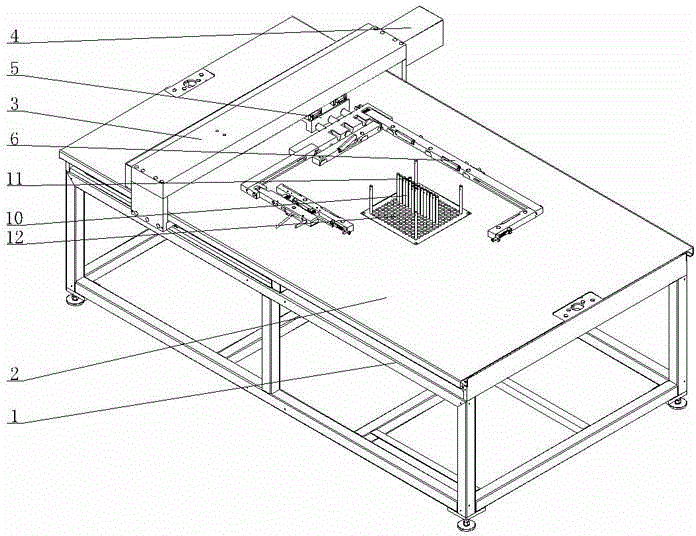

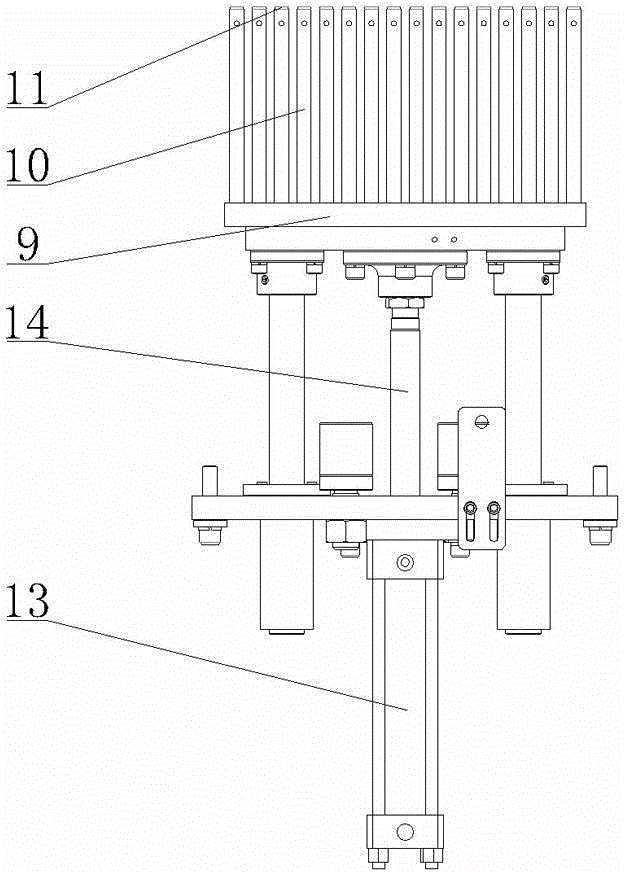

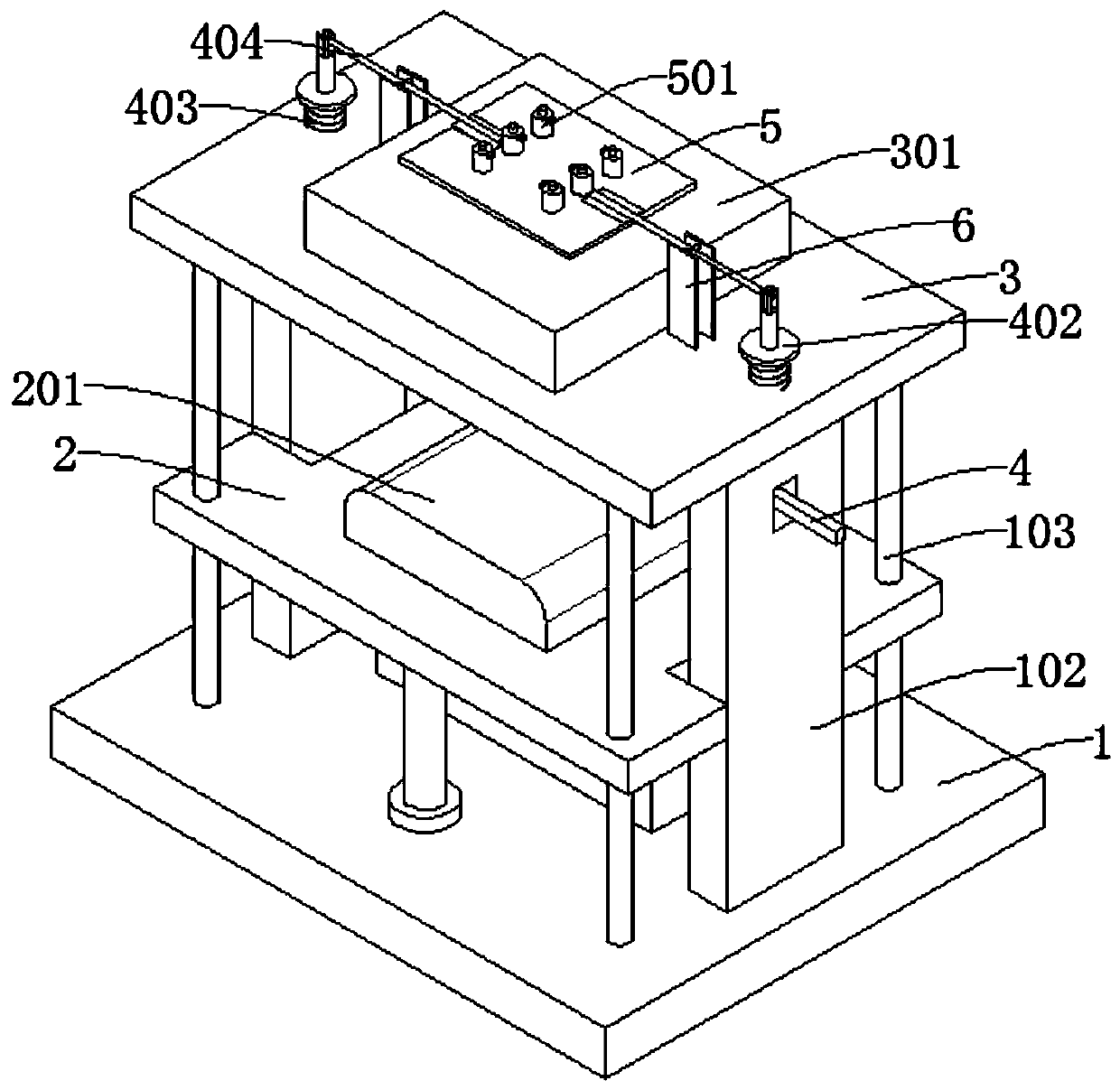

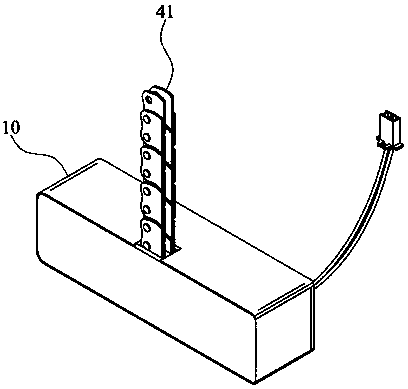

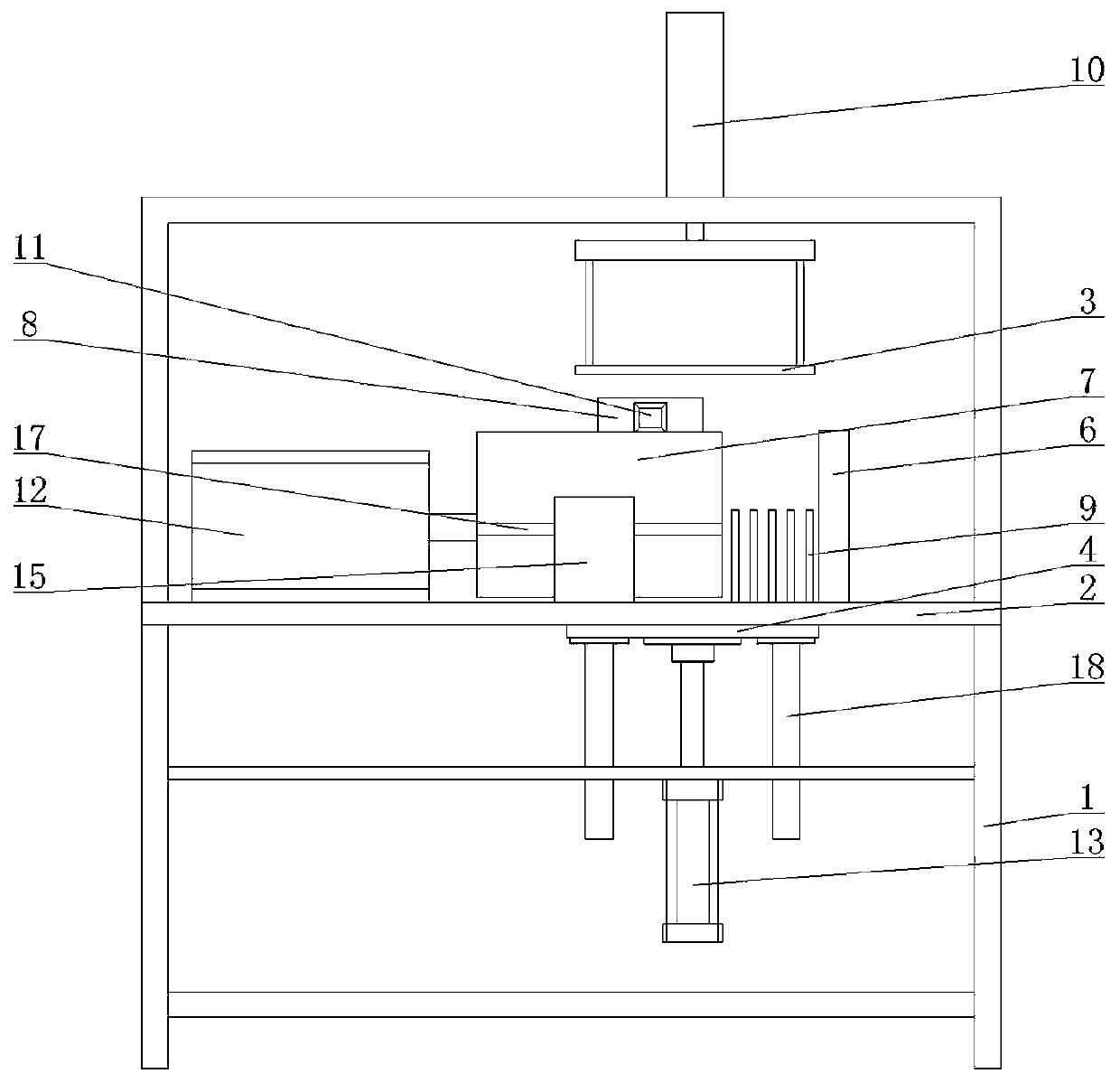

Intelligent product taking machine

InactiveCN104669351AAccurate and safe ejectionPrevent top damageMetal working apparatusWork in processInductor

The invention discloses an intelligent product taking machine which comprises a rack, an operating platform, a transmission mechanism and a pressure head mechanism, wherein the operating platform and the pressure head mechanism are arranged on the rack, the transmission mechanism is arranged on the operating platform, the pressure head mechanism is provided with a pressing frame and an ejector rod, the pressing frame can move up and down, the ejector rod is driven by an air cylinder with a pressure self inductor, the air cylinder is fixed on an upper pressing plate, the transmission mechanism comprises a transverse driving device and a longitudinal driving device, the transverse driving device is in sliding connection with the rack, the longitudinal driving device is in sliding connection with the transverse driving device, and the longitudinal driving device is provided with a fixed frame which is connected with a paper retaining frame. The intelligent product taking machine is characterized in that an ejector pin disc is arranged below the pressure head mechanism, the ejector pin disc can move up and down, a plurality of removable ejector pins are arranged on the ejector pin disc, and through holes which are used for the plurality of ejector pins to pass through are formed in the operating platform. The intelligent product taking machine is suitable for semi-finished products in various shapes and has the advantages of high product taking efficiency and strong versatility.

Owner:国望科技(浙江)有限公司

Lagging mechanism for drawing die and application method

The invention discloses a hysteresis mechanism for a drawing die and an application method thereof. The hysteresis mechanism includes a hysteresis cylinder and a hysteresis cushion block, the hysteresis cushion block is connected with the piston rod of the hysteresis cylinder, the hysteresis cylinder is mounted on a blank holder, and the blank holder is installed On the lower die, the drawing die also includes an upper die, the upper die is provided with a binder body, a limit cover plate is arranged above the binder body, a nitrogen cylinder is arranged on the limit cover plate, and the ejector rod of the nitrogen cylinder and the binder body The height of the contact and hysteresis pads is the same as the movement stroke of the binder body; the application method of the hysteresis mechanism: 1. Place the sheet; 2. Clamp the mold and stamp the sheet into a finished product; 3. Start the hysteresis mechanism; 4. Delay the mold opening press body Exit; 5. Take out the stamping part. In the process of mold opening, the binder body starts to withdraw after the end of the binder ring stroke, so that the binder ring and the binder body move first and then later, avoiding the two moving at the same time and damaging the stamping part, and it can be used without air cushion The delay function is used on the press to save resources and reduce stamping costs.

Owner:烟台泰利汽车模具股份有限公司

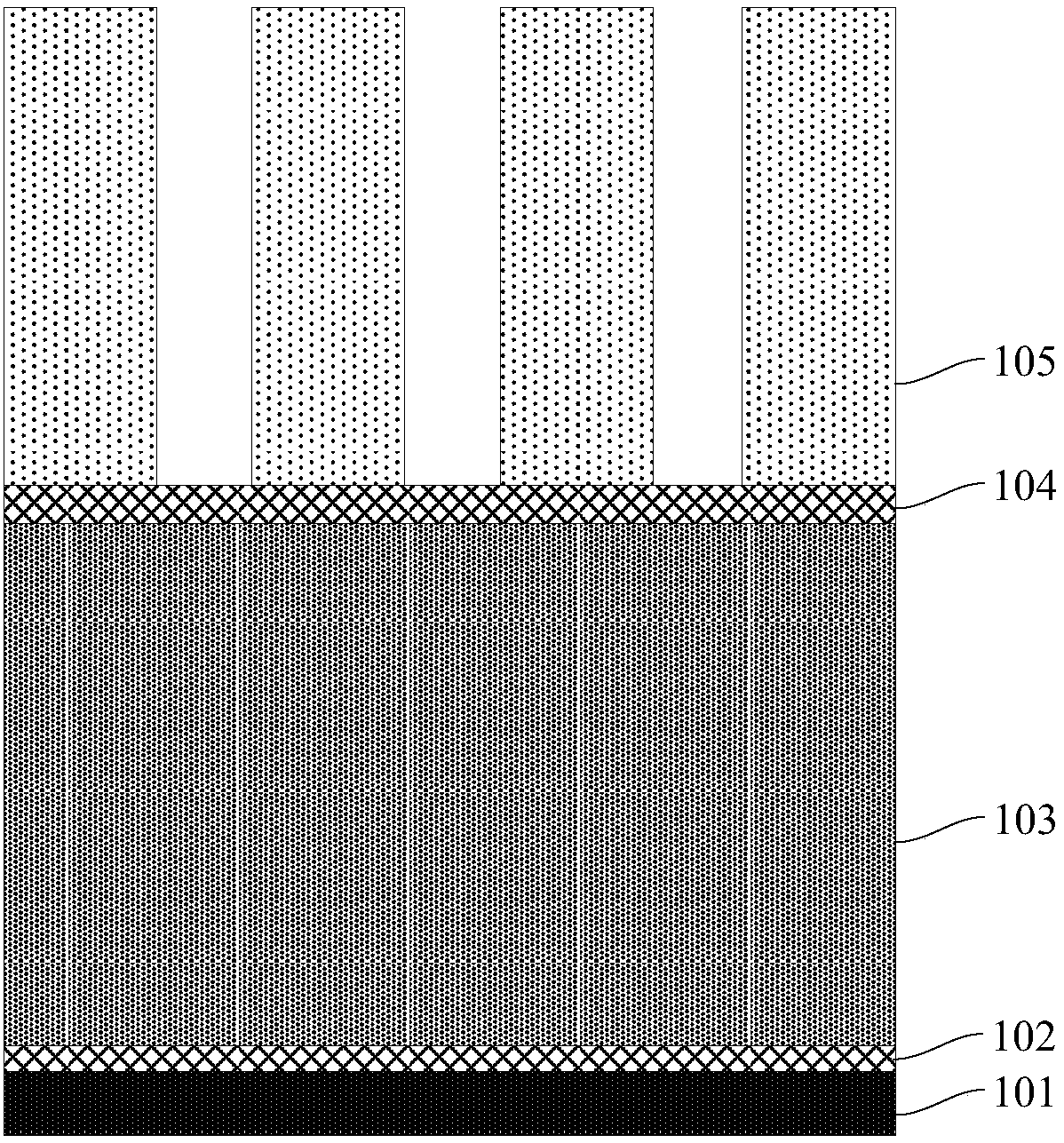

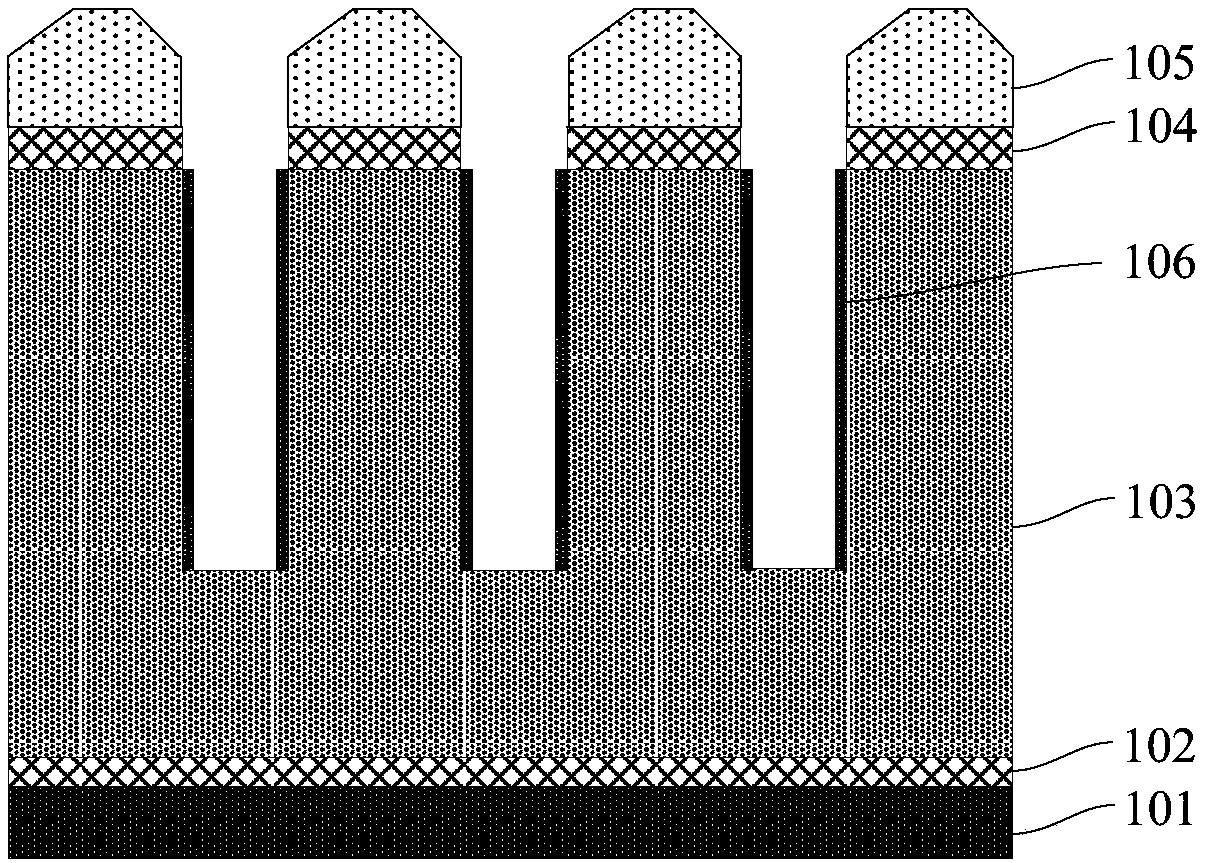

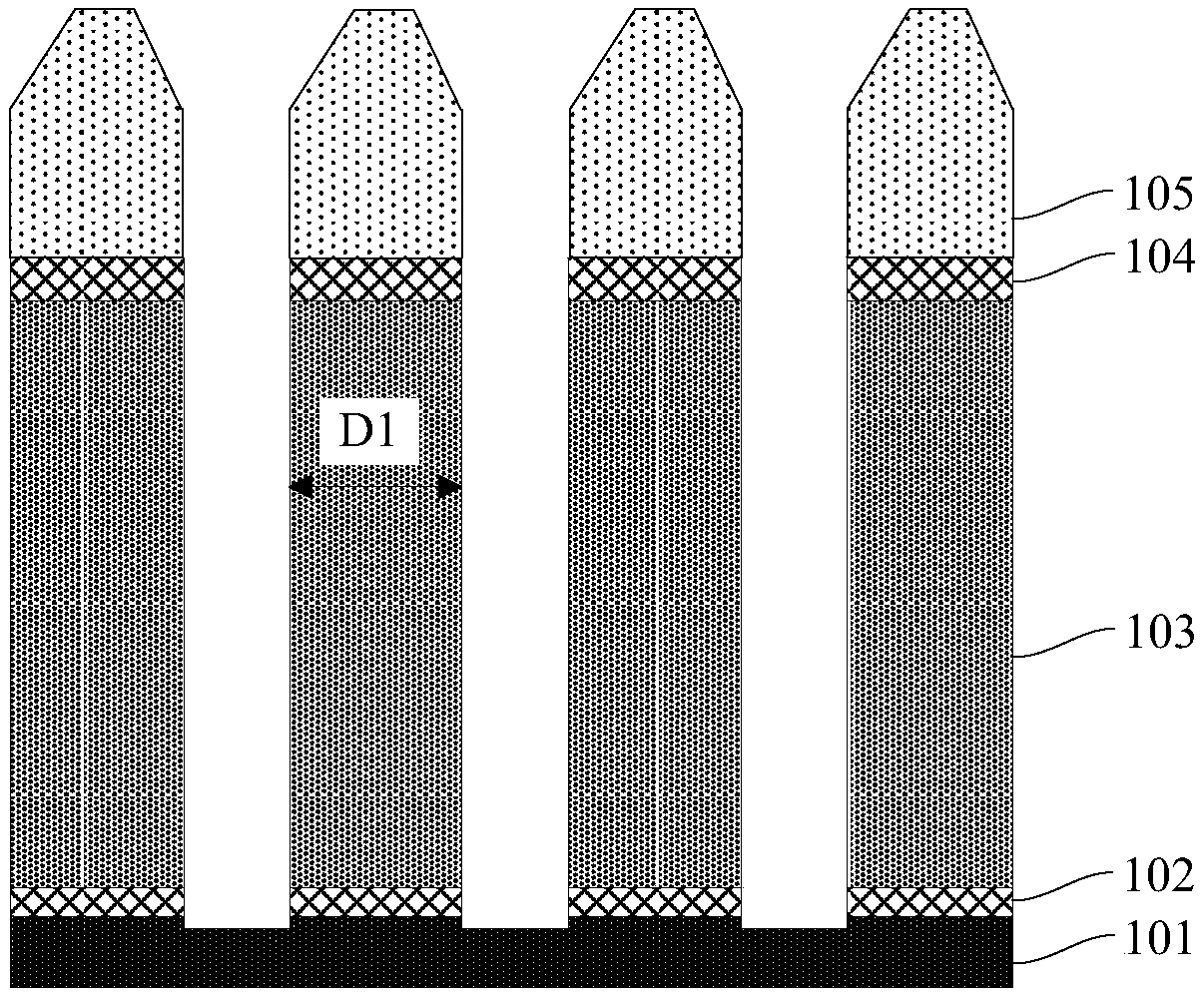

Metal wire manufacturing method and metal wire isolating method

InactiveCN107910258AEtch rate reductionIncrease residueSemiconductor/solid-state device manufacturingLine widthPhotoresist

The invention provides a metal wire manufacturing method and a metal wire isolating method. The method comprises the steps that 1) an anti-reflection layer is formed on a metal layer; 2) a photoresistlayer is formed on the anti-reflection layer, and an etching window is formed in the photoresist layer; and 3) a halogen-containing gas is used and an alkane-based gas is added to etch the metal layer to separate the metal layer into a number of metal lines. The alkane-based gas reacts with the halogen-containing gas to generate an auxiliary carbon halogen compound, so as to avoid the side etching of the sidewall of the metal lines and reduce the consumption rate of the photoresist layer during the etching process. According to the invention, the added alkane-based gas is used as the source of an etching aluminum by-product CClx, which can effectively reduce the etching rate of the photoresist layer; reduced line width of the metal lines and top damage, which are caused by insufficient residue of the photoresist layer, are avoided; side etching of the sidewall of the metal lines is avoided through the by-product CClx; and the overall width of the metal lines is the same as the targetwidth.

Owner:CHANGXIN MEMORY TECH INC

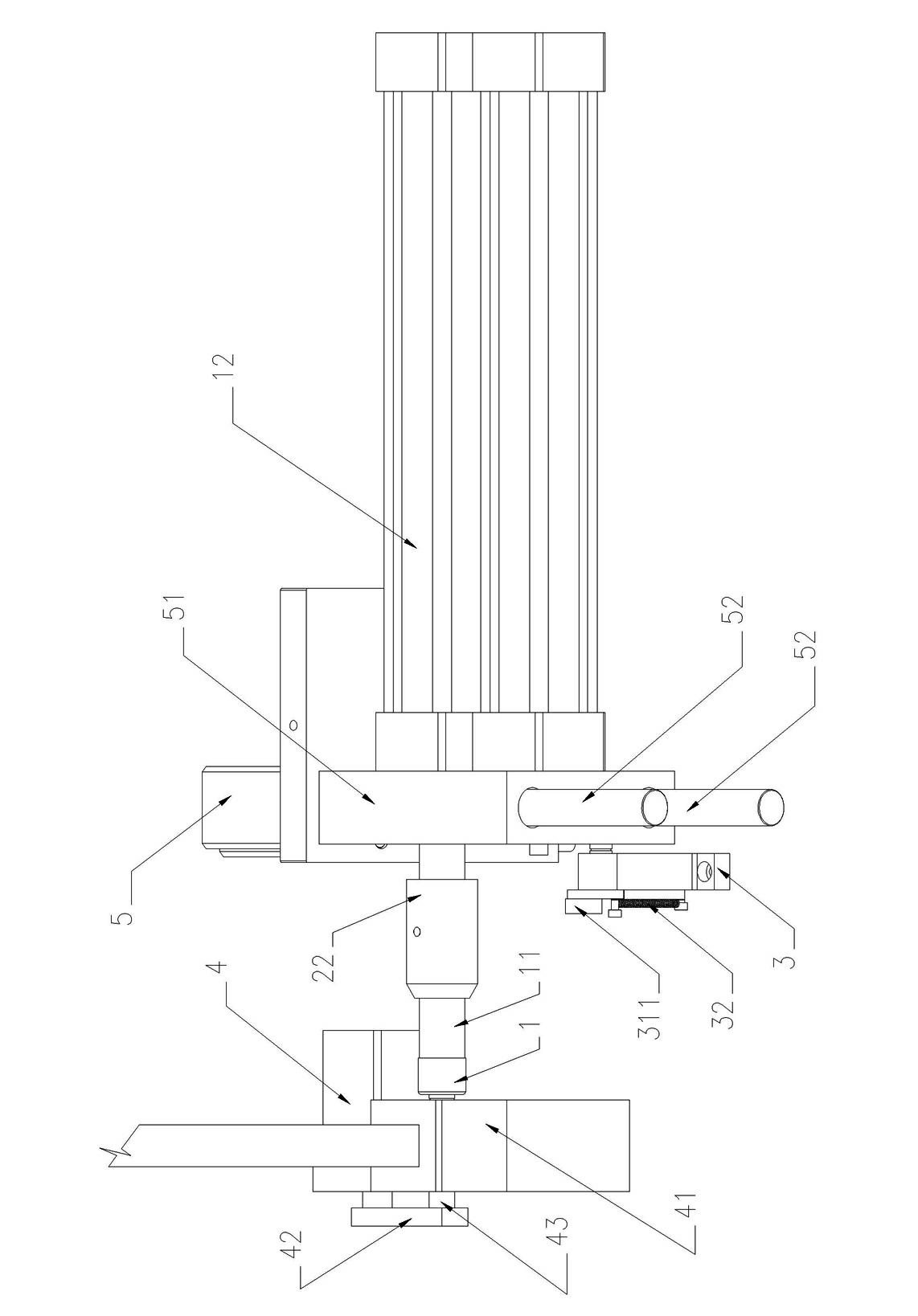

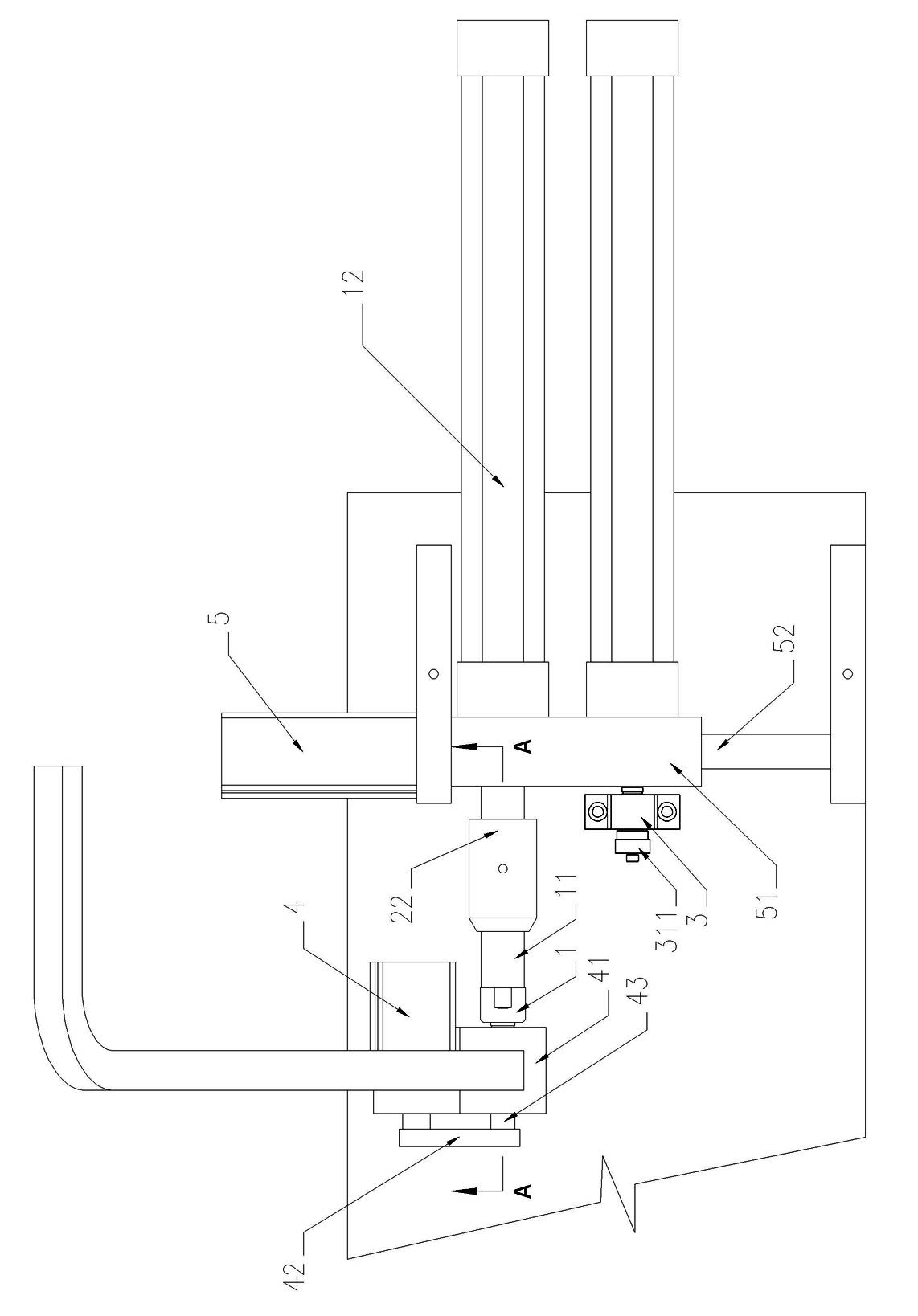

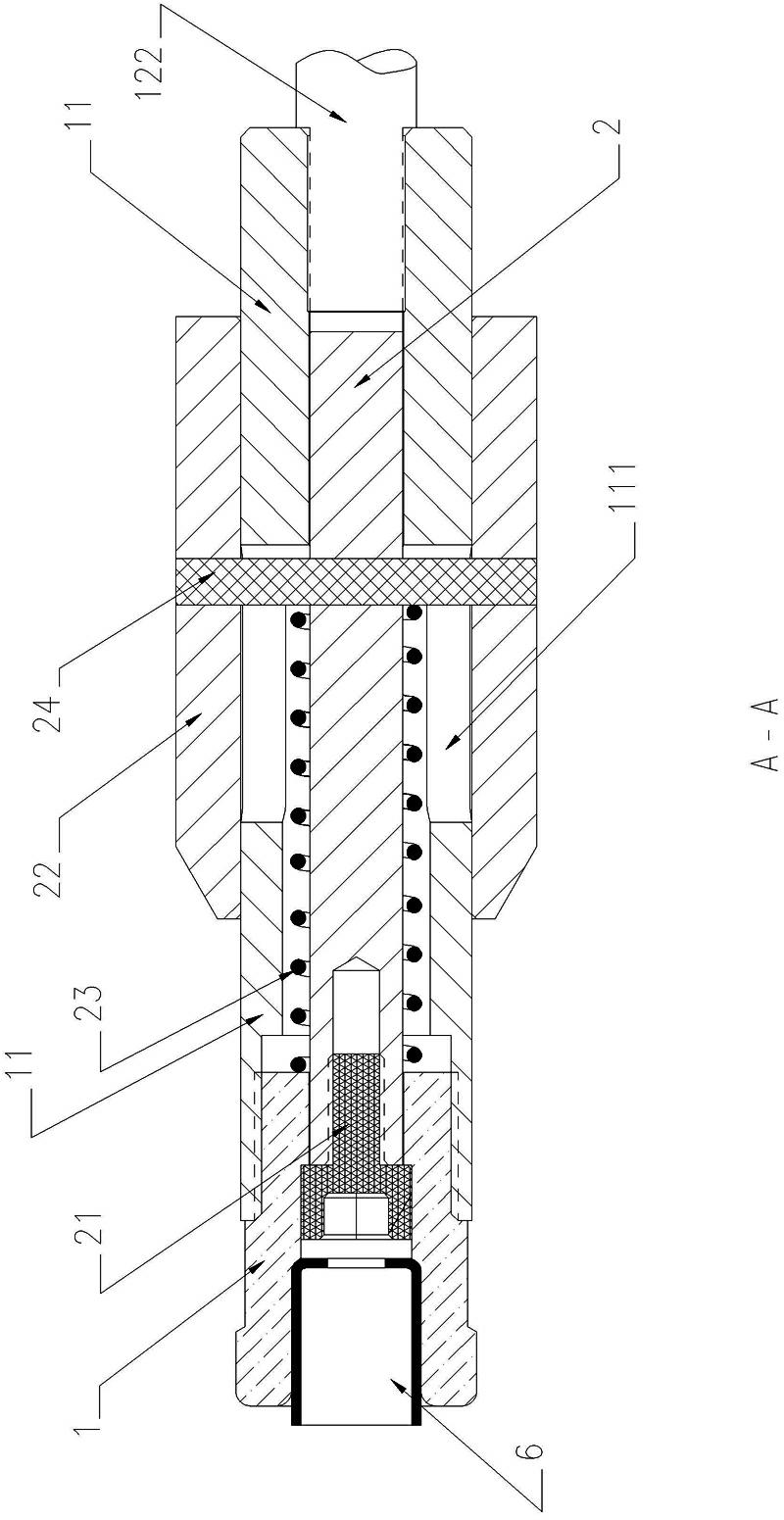

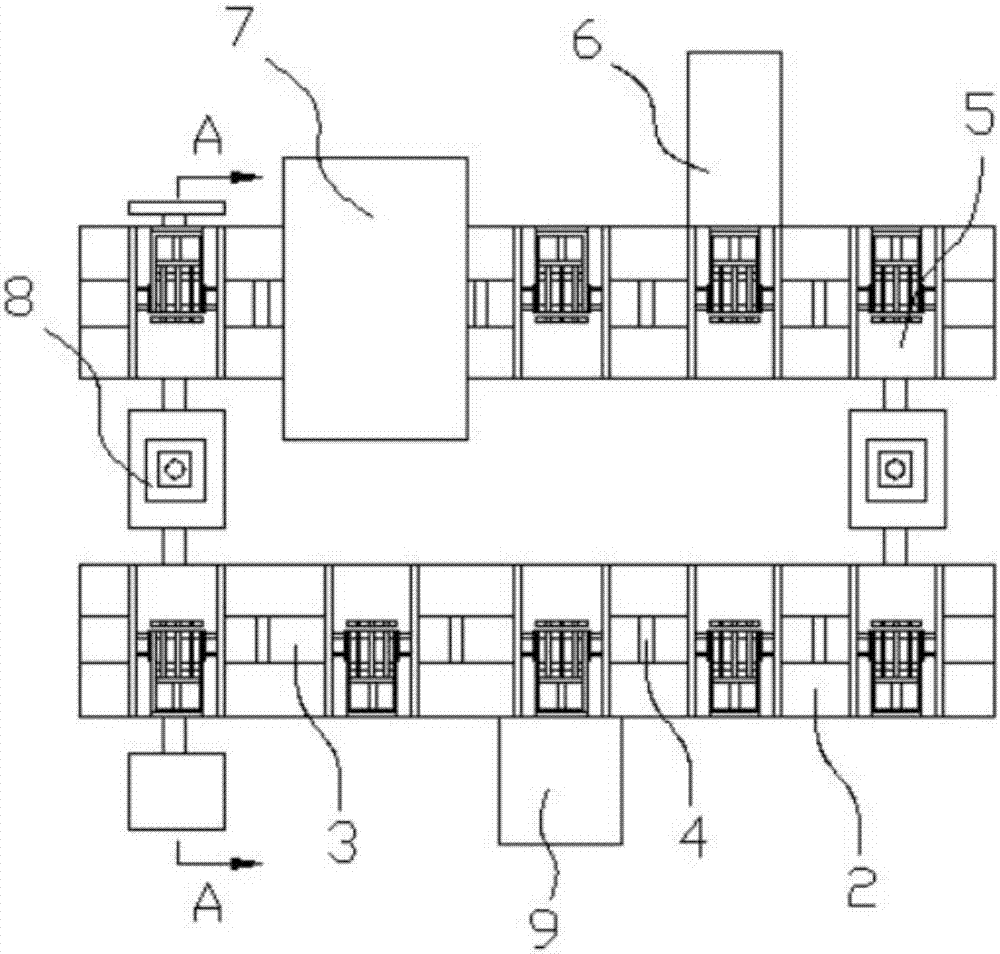

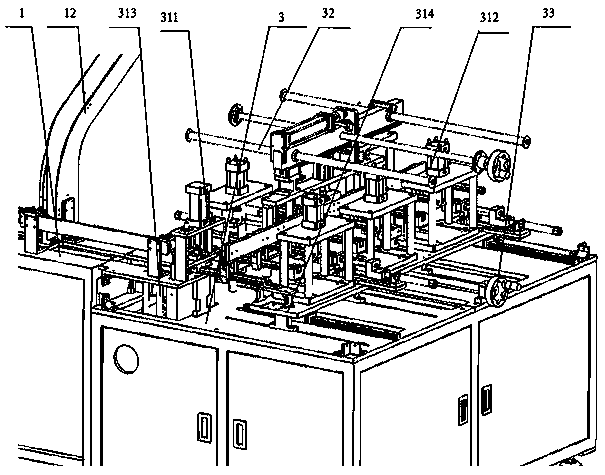

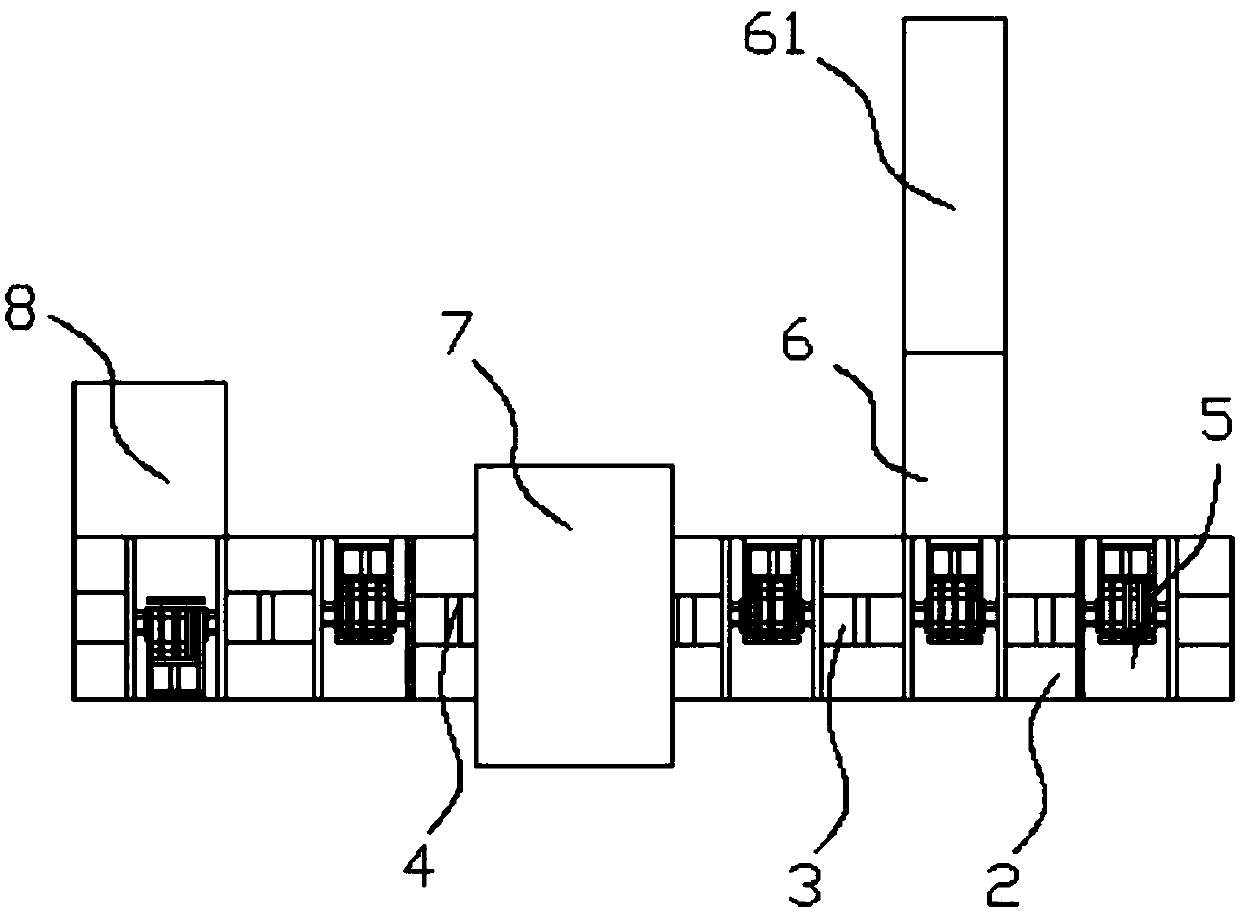

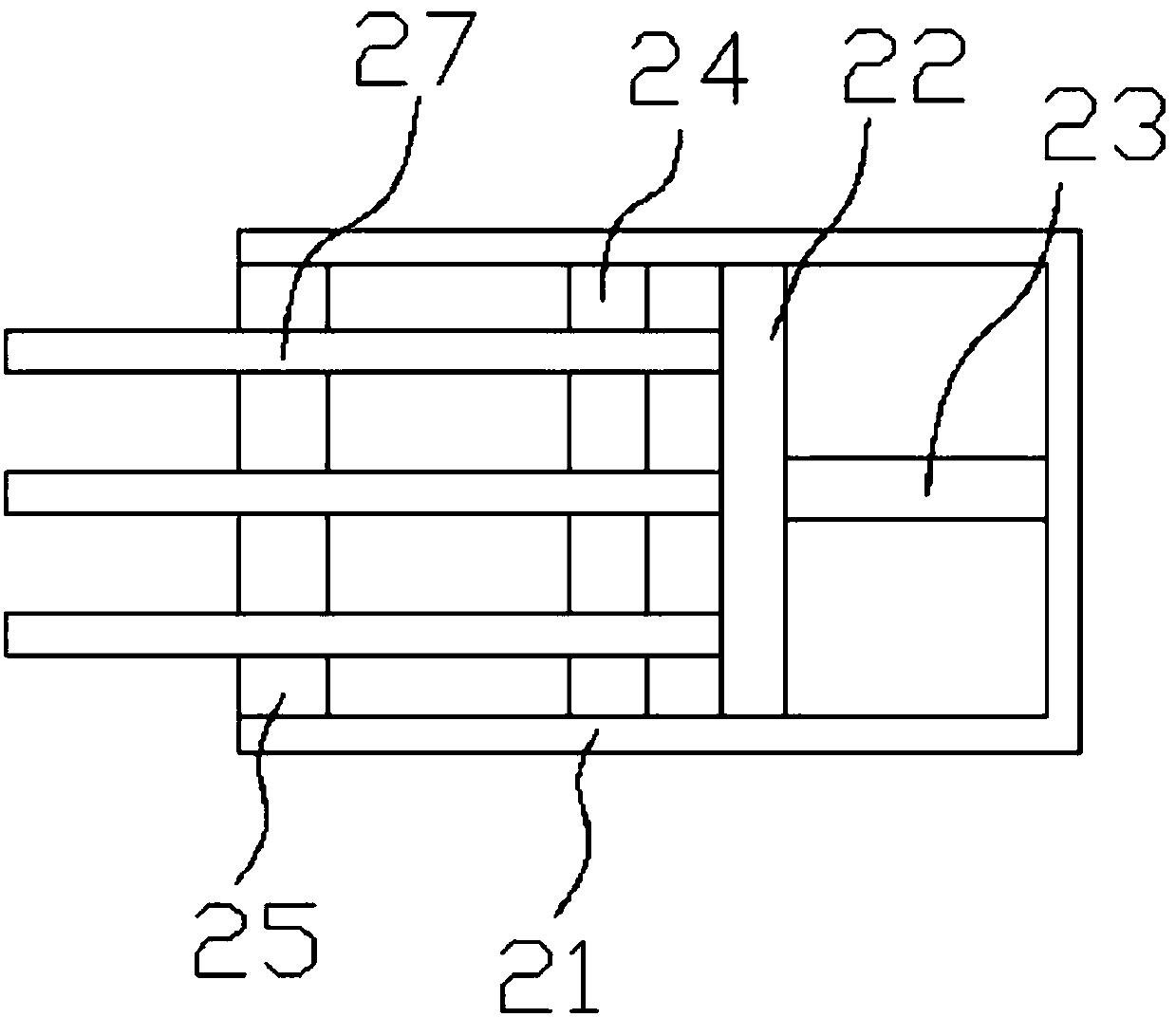

Double-layer metal pin assembling machine for plug

InactiveCN107959215AExtrudeImprove efficiencyContact member assembly/disassemblyBiomedical engineeringAssembly machine

The invention relates to a double-layer metal pin assembly machine for plugs, comprising a frame, a conveying mechanism, a pin device, a welding device and a blanking device. Lifting cylinder and pin pick and place device. The pin pick and place device includes a pick and place body. The center of the lower part of the pick and place body is provided with an arc-shaped groove with an arc of 180 degrees. The lower part of the arc-shaped groove is equipped with an opening and closing device. There is a pressing slot on the main body of the device, the upper part of the pressing slot is provided with a pin pressing cylinder, the lower part of the pin pressing cylinder is connected to a pin pressing block, and the front side of the pick-and-placer is provided with a pin pushing installation block. The lower part of the pin push-in mounting block is provided with a pin push-in lift cylinder, and the pin push-in lift cylinder is connected with the pin push-in lift block. The present invention can not only realize the downward pressing of the pin, but also realize the metal pin The needle insertion operation is realized through the jack, which can meet the two-layer metal needle insertion of the double-layer and half-socket.

Owner:DONGGUAN UNIV OF TECH

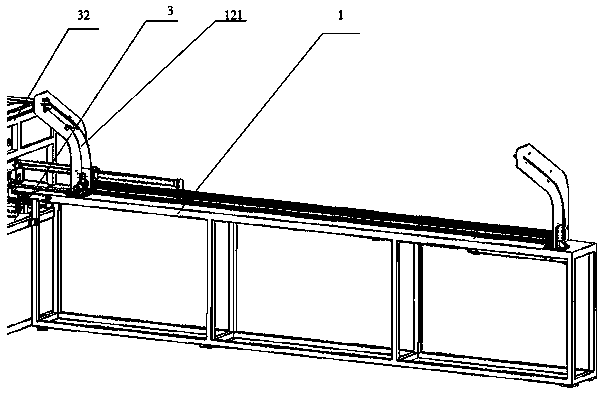

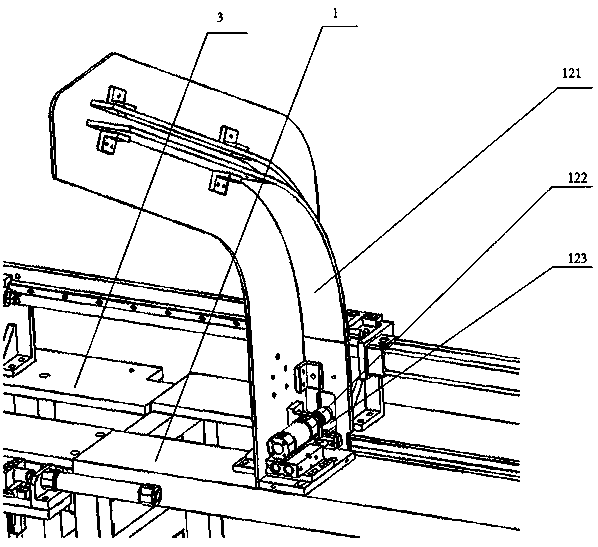

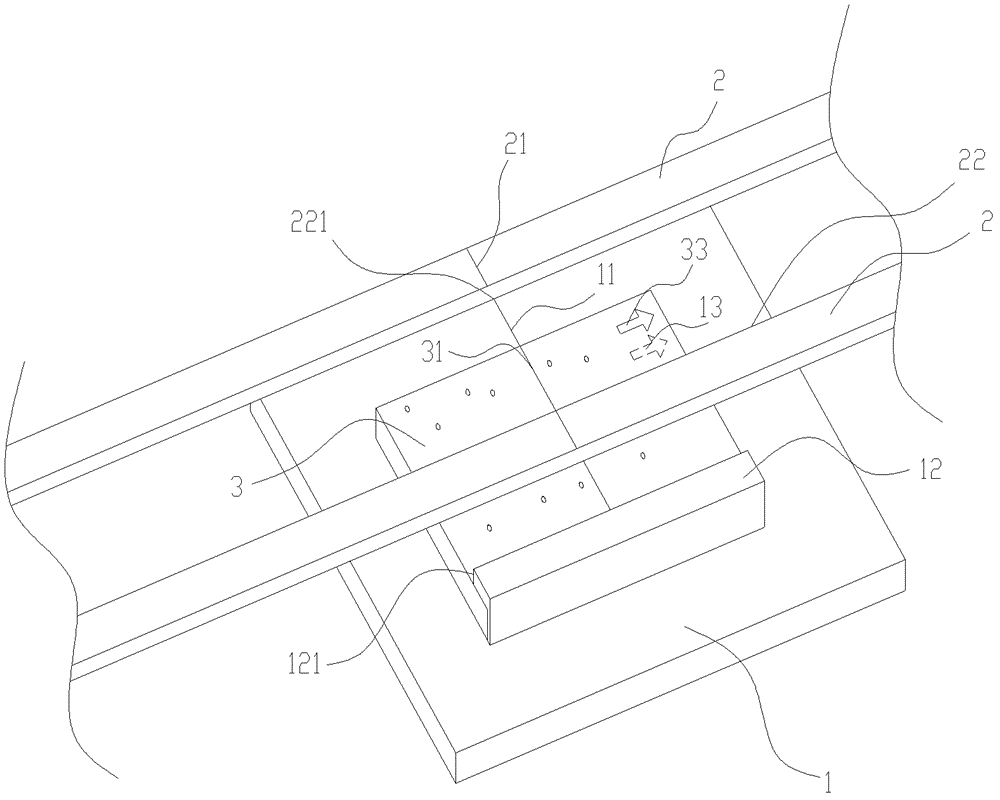

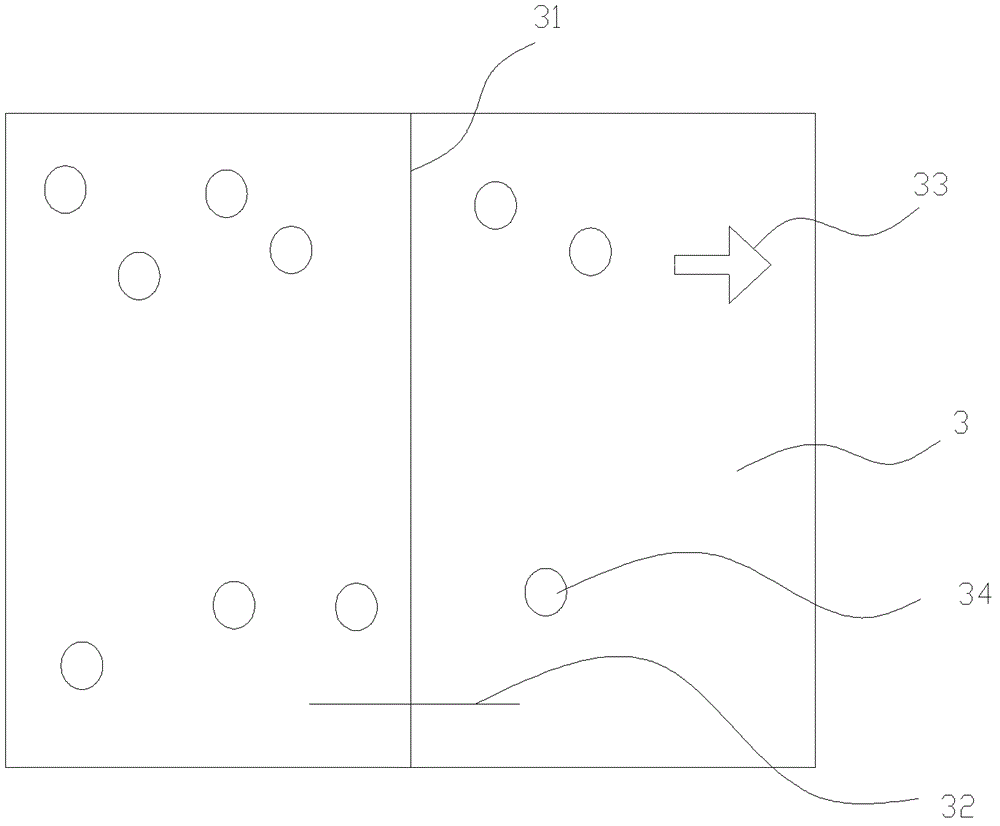

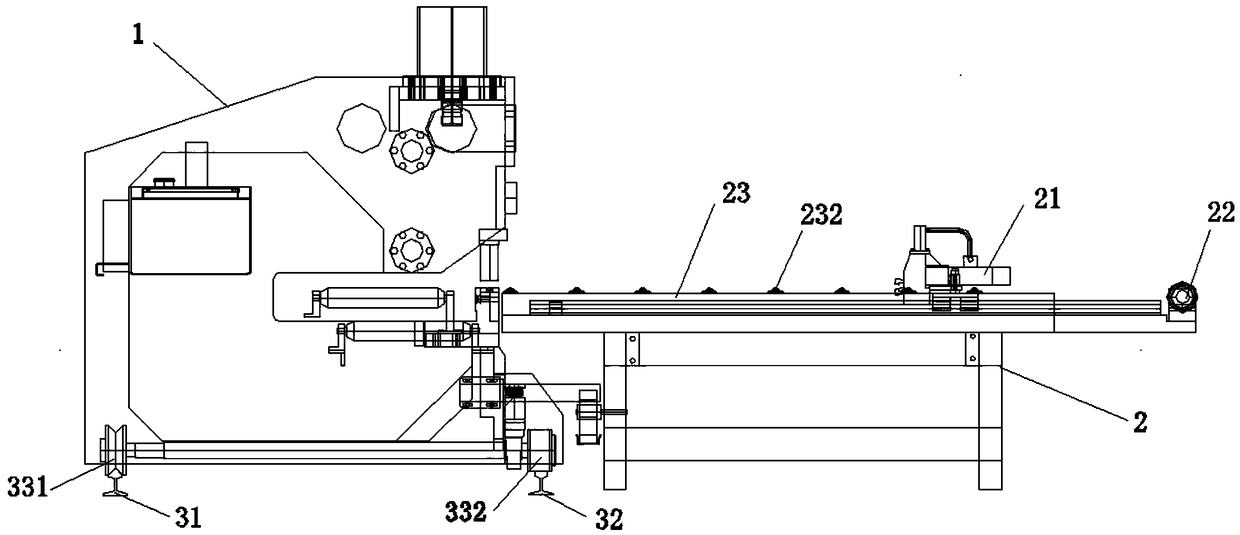

Novel full-automatic pipe cutting and punching integrated device

PendingCN108655746AImprove processing qualityImprove stabilityPerforating toolsOther manufacturing equipments/toolsPunchingEngineering

The invention discloses a novel full-automatic pipe cutting and punching integrated device which comprises a long pipe feeding platform, a pipe cutting assembly and a punching platform, wherein the long pipe feeding platform is used for feeding a long tubular material and comprises a pushing assembly; the pipe cutting assembly is arranged between the long pipe feeding platform and the punching platform for cutting the long tubular material conveyed by the long pipe feeding platform; the punching platform at least comprises a conveyor line, at least a feeding station, a punching station and a discharging station are arranged on the conveyor belt, and a punching die is arranged on the punching platform; and a conveying assembly of the conveyor line is arranged on the upper part of the punching platform. The novel full-automatic pipe cutting and punching integrated device disclosed by the invention is suitable for integrated processing of pipe cutting and perforating of different sectionbars, loads and unloads materials automatically, is high in processing efficiency, solves the problem of collision of the materials effectively, prevents the surface from being scraped and damaged, and is high in processing quality and convenient to detach. Problems of equipment in a production process can be found immediately, and the equipment is maintained quickly, so that the maintenance costis lowered.

Owner:广州英固特智能装备有限公司

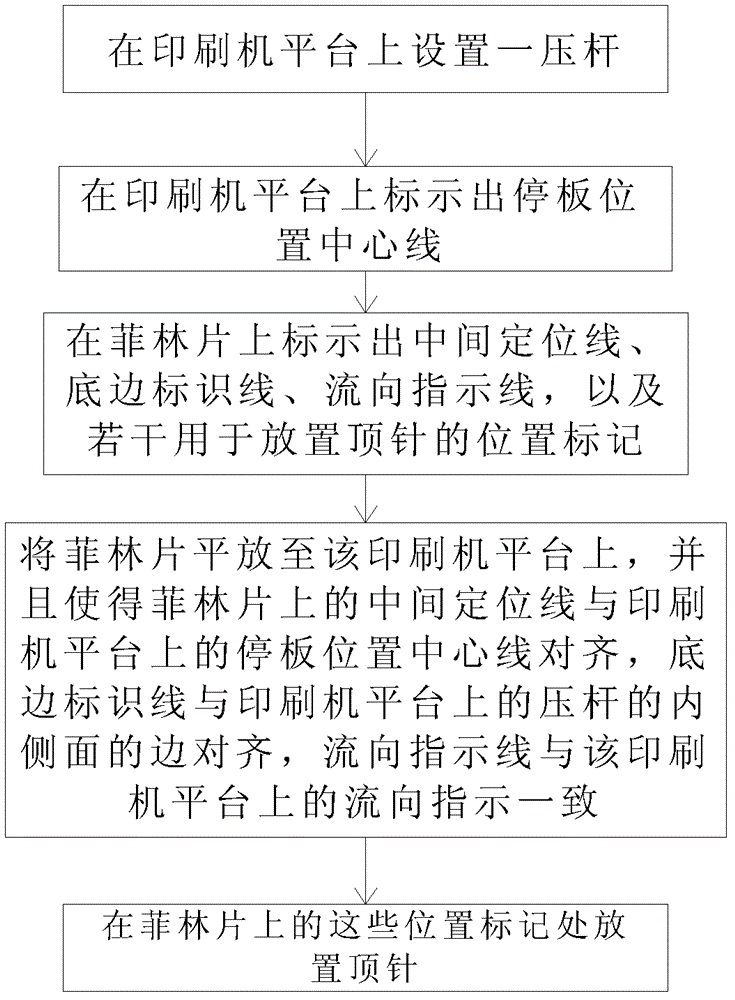

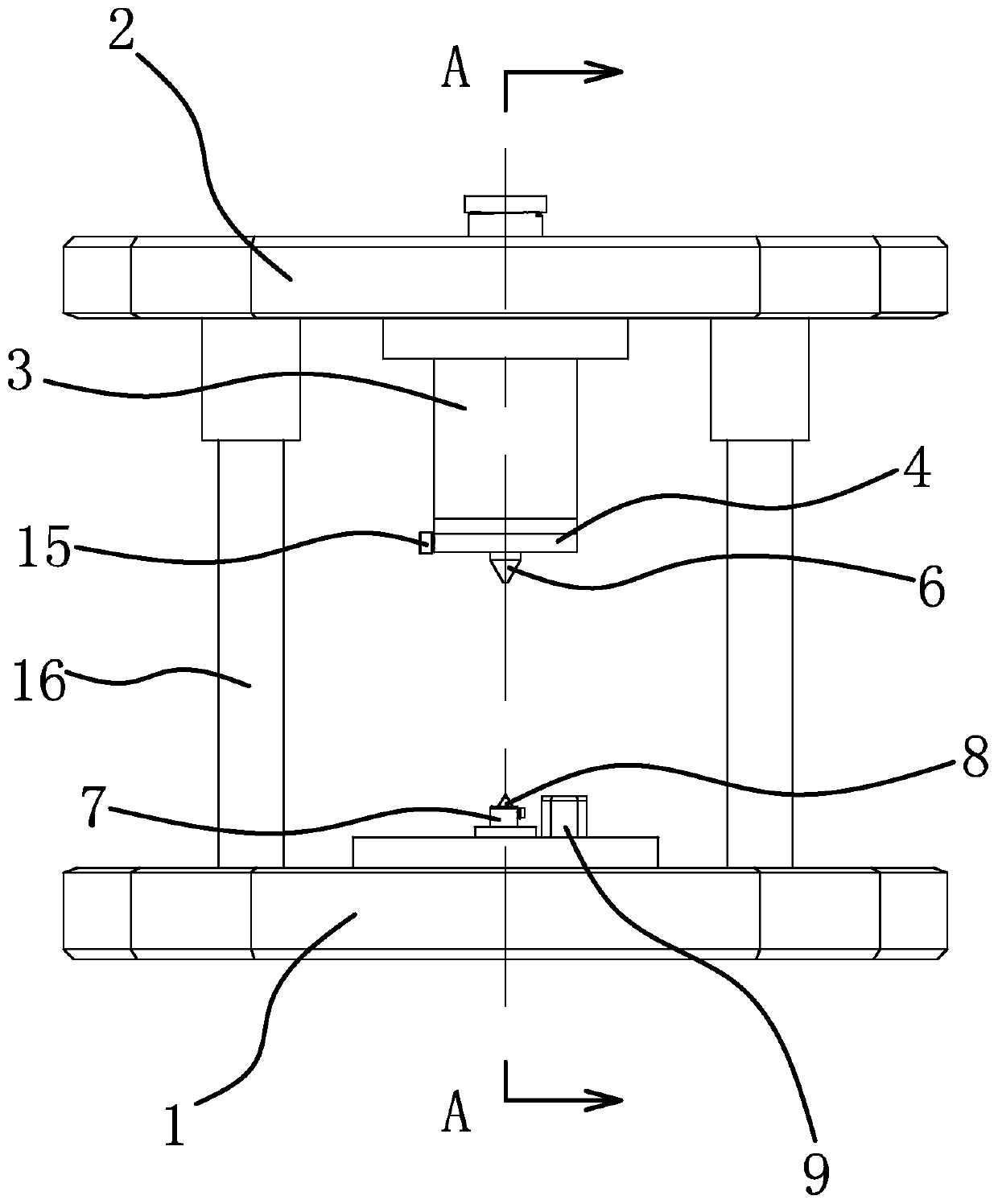

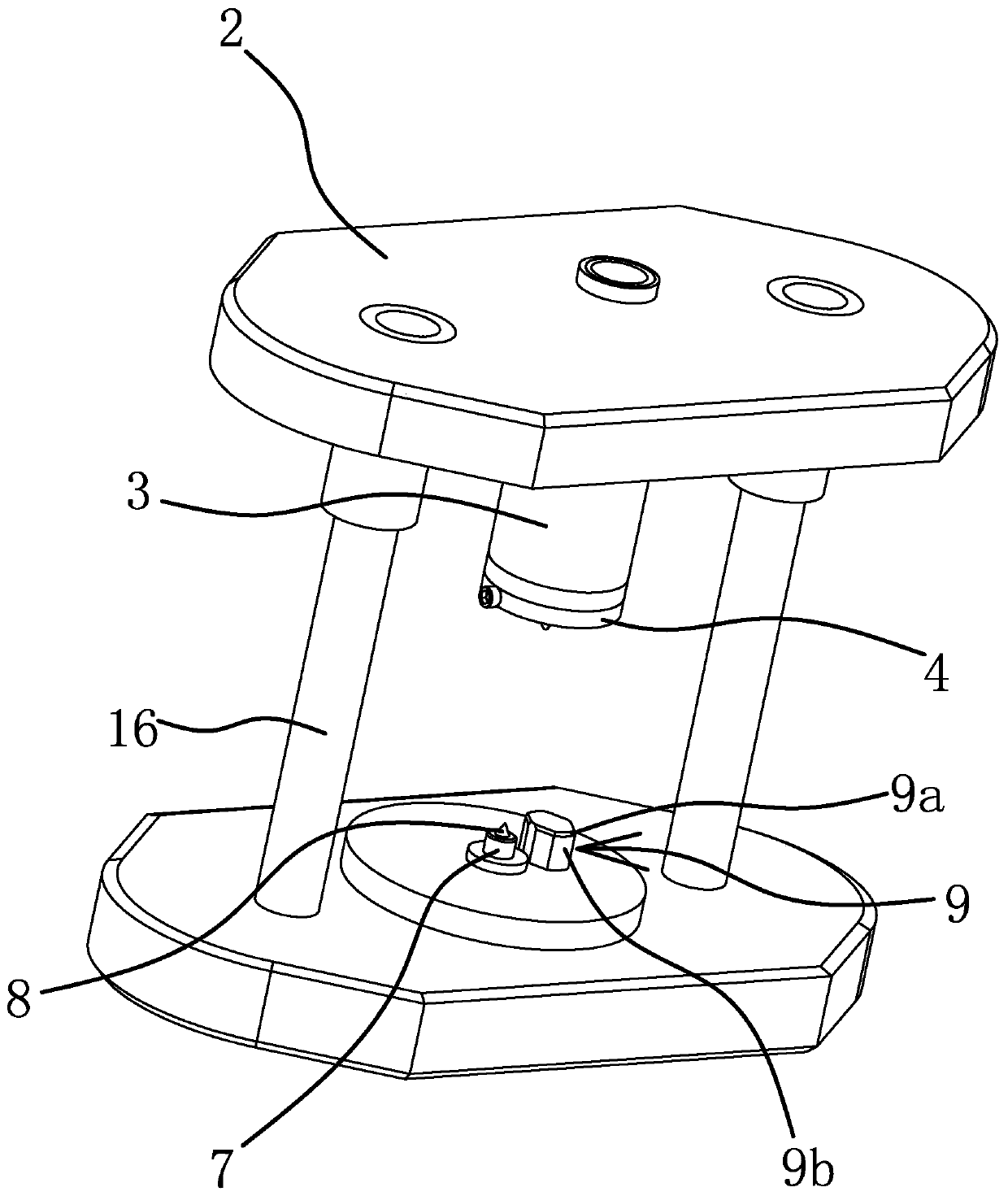

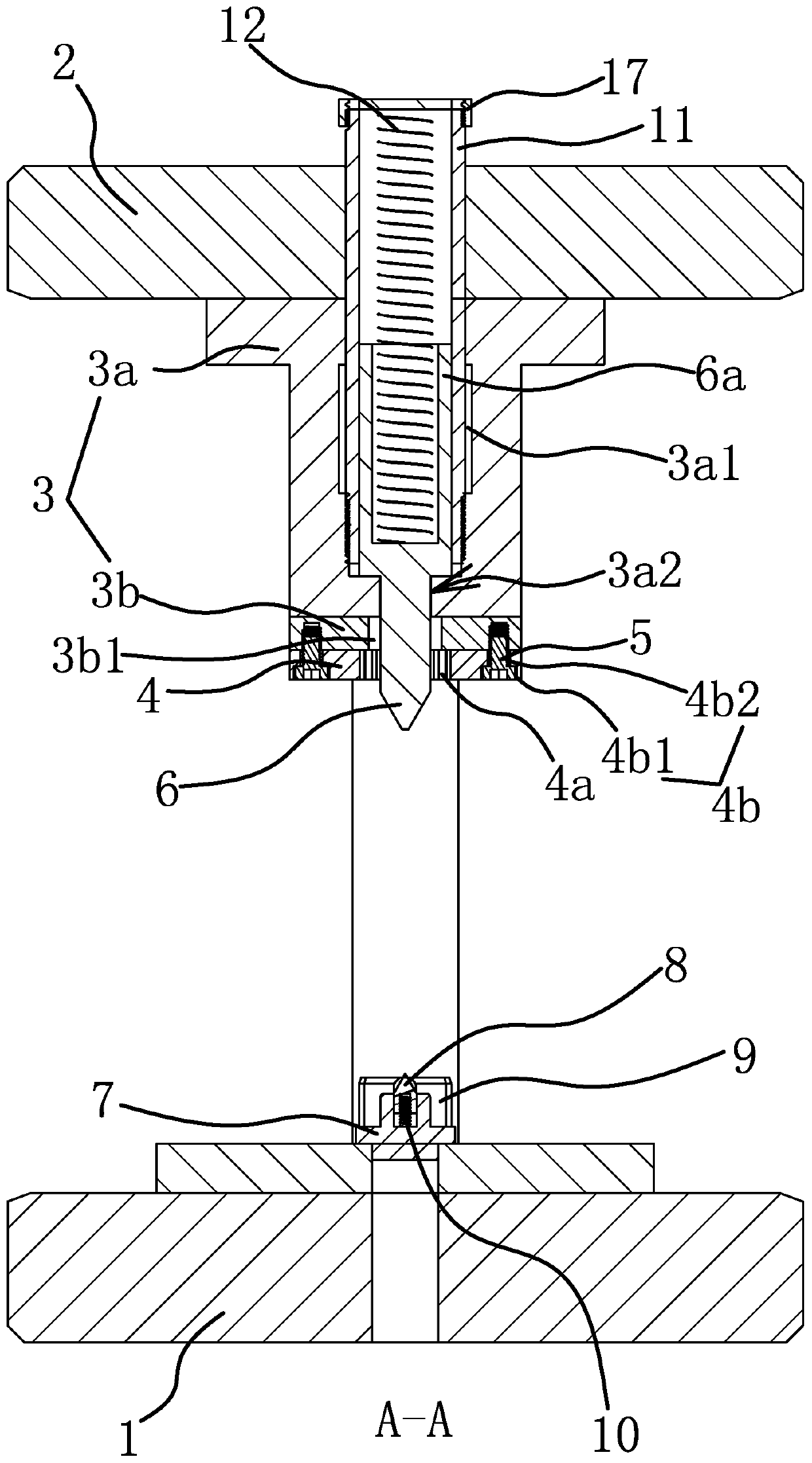

Device capable of precisely placing thimbles and method

InactiveCN103068180AFast and flatFast and precise placementPrinted circuit assemblingEngineeringPrinted circuit board

The invention provides a device capable of precisely placing thimbles and a method. The device is applied to a printing machine platform. A rail used for conveying a printed circuit board (PCB) is arranged above the printing machine platform. Due to the fact that a center positioning line on a film is aligned to a center line of a plate stopping position on the printing machine platform, and a bottom marking line on the film is aligned to one side edge of a pressing rod on the printing machine platform. Besides, due to arrangement that a flow direction index line on the film is in accordance with a flow direction indication on the printing machine platform, the film is rapidly and flatly placed on the printing machine platform, then the thimbles are arranged in a plurality of position marks on the film, and therefore fast and precise placement of the thimbles is realized. Besides, the phenomenon that the thimbles damage devices on the PCB is prevented from occurring.

Owner:MITAC COMP (SHUN DE) LTD

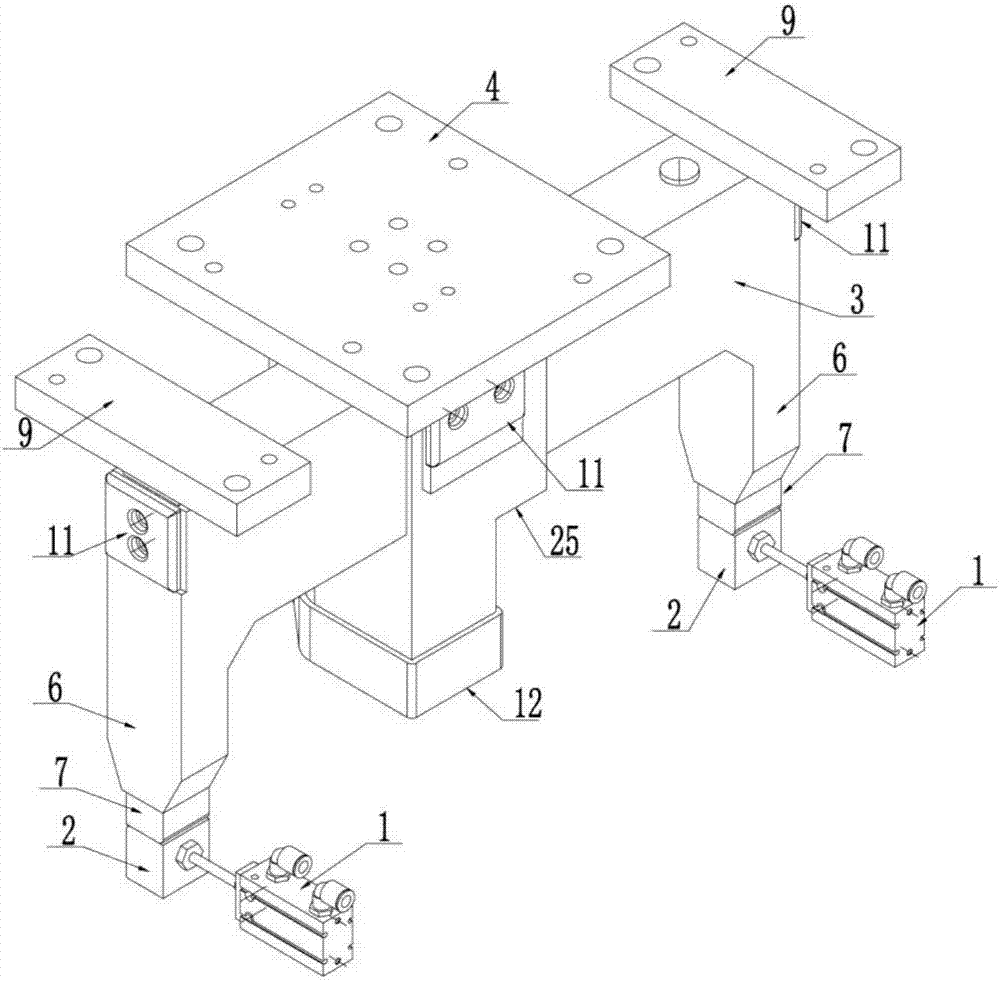

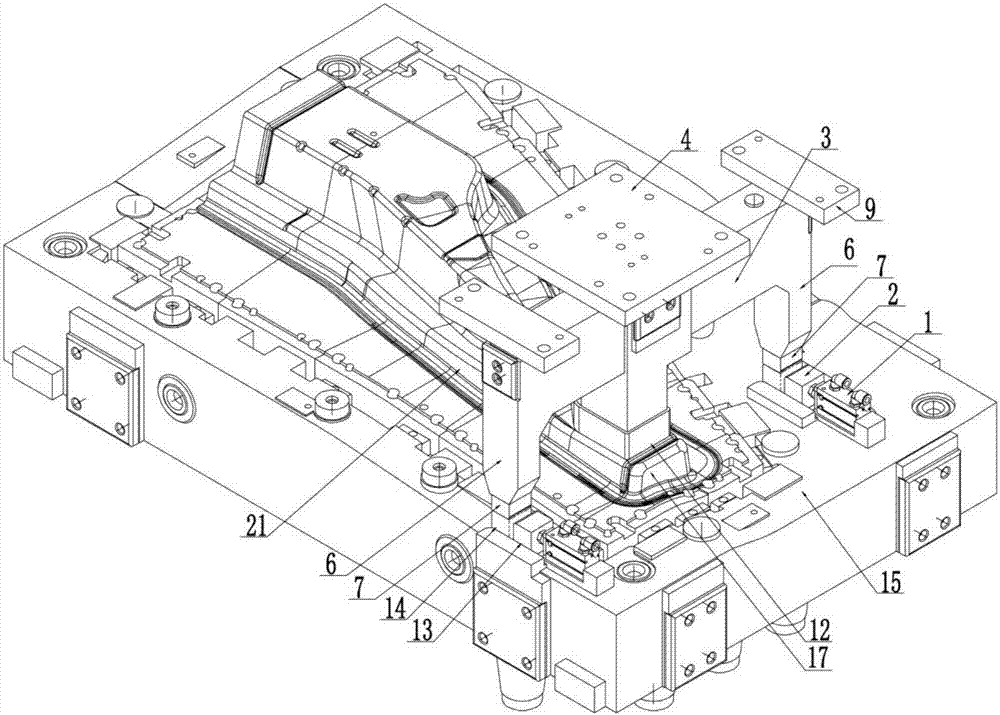

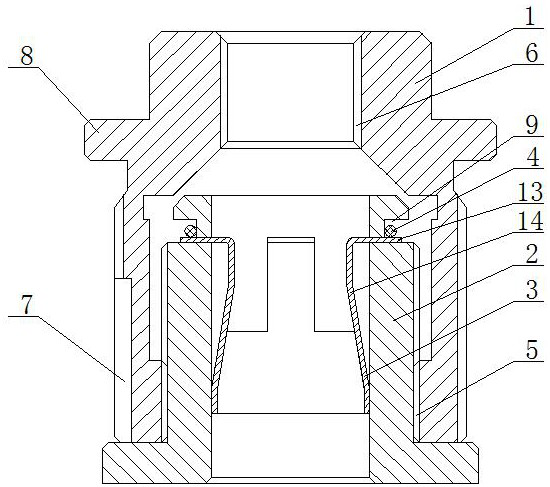

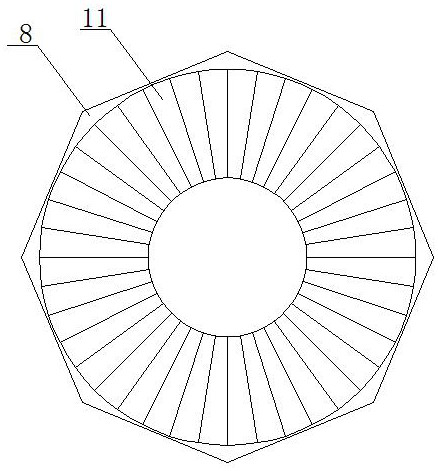

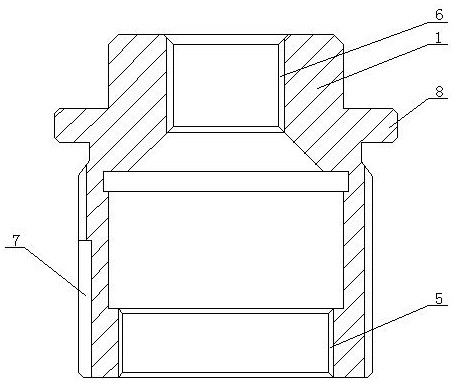

Crankshaft throw timing sprocket press-fitting device

The invention provides a crankshaft throw timing sprocket press-fitting device and belongs to the technical field of press-fitting equipment. Through the crankshaft throw timing sprocket press-fittingdevice, the problems that the timing angle is not easy to control and the product qualified rate is low during press-fitting are solved. The crankshaft throw timing sprocket press-fitting device comprises a base and a die carrier. A die head is fixed to the die carrier. A mounting block is fixed to the lower end face of the die head through fasteners. The center of the mounting block is providedwith a mounting groove in the same shape with a timing sprocket in a through mode. A floating center is slidably arranged in the die head in the vertical direction. The lower end of the floating center penetrates through the center of the mounting groove. A locating block is fixed to the base. A lower center is arranged in the center of the locating block. The axis of the lower center and the axisof the floating center are collinear. A pin capable of being inserted into a throw pin hole of a throw is arranged in the position, close to the locating block, of the base. A friction structure usedfor preventing the timing sprocket from going out is arranged in the mounting groove. The crankshaft throw timing sprocket press-fitting device has the advantages that the timing angle is easy to control, the press-fitting precision is high, the qualified rate is high, the structure is simple and the like.

Owner:TAIZHOU HONGXIN CRANKSHAFT

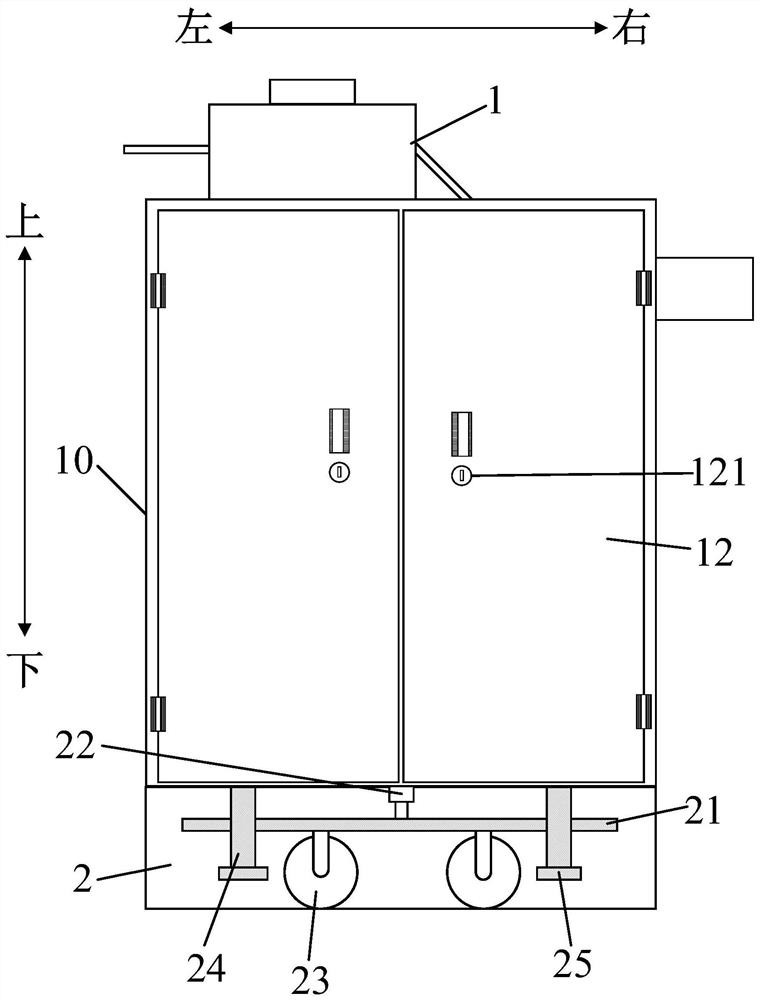

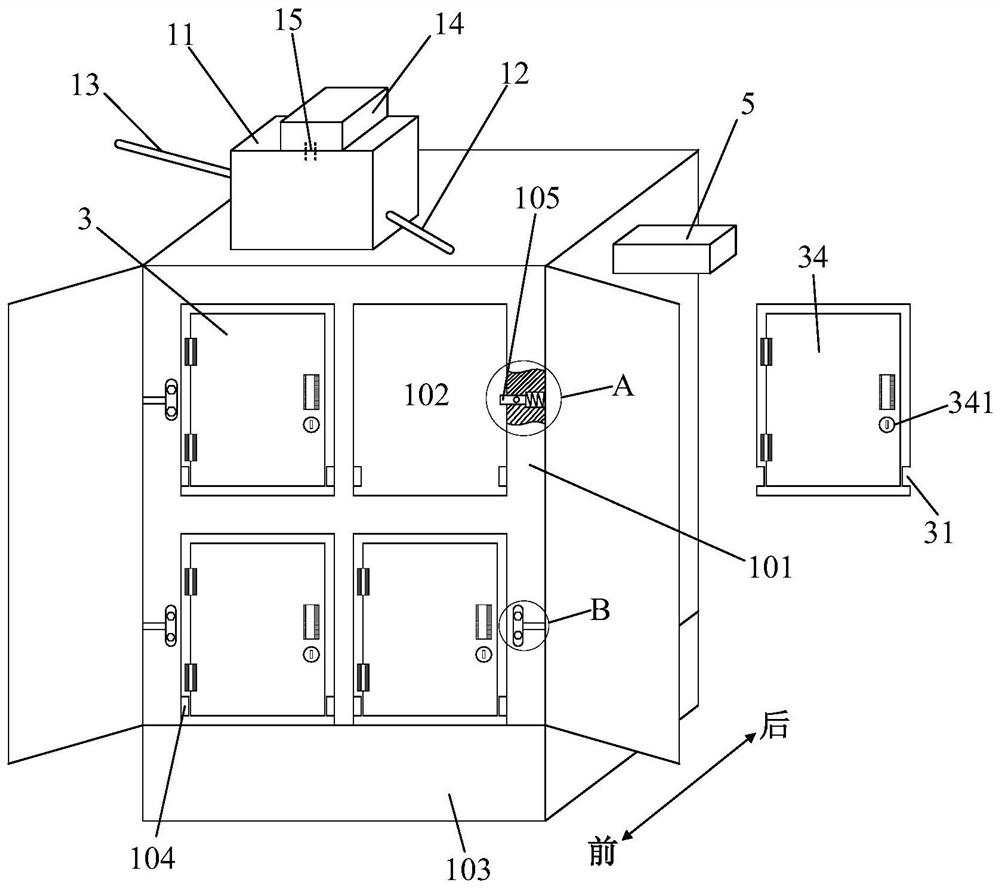

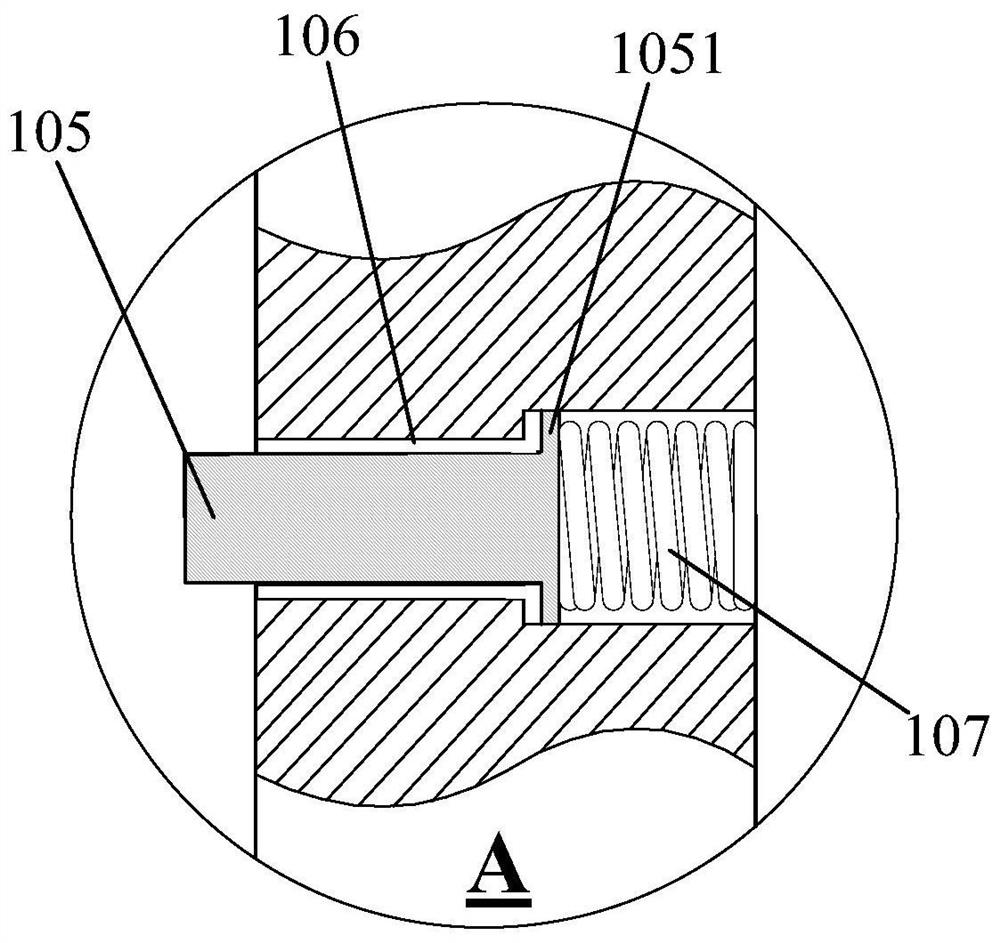

Fireproof cabinet capable of automatically destroying high-confidentiality files and automatic control system thereof

PendingCN113693381AReduce the temperatureAvoid burnsBook cabinetsBuilding locksAutomatic controlConfidentiality

The invention discloses a fireproof cabinet capable of automatically destroying high-confidentiality files, which comprises a cabinet body, a cabinet door mounted at the front end of the cabinet body, a first anti-theft lock mounted on the cabinet door and a file destroying storage box mounted in the cabinet body. When the first anti-theft lock is abnormally opened, the high-confidentiality files in the file destroying storage box are automatically crushed. The fireproof cabinet further comprises a fireproof system installed on the cabinet body and an auxiliary moving mechanism installed on the cabinet body, wherein the fireproof system comprises a water tank, the bottom of the water tank is connected with a water outlet pipe communicated with a cavity in the cabinet body, a dry ice box storing dry ice particles is further arranged above the box, and the bottom of the dry ice box is connected with a conveying channel guiding the dry ice particles into the water tank. By arranging the fireproof system, when a fire disaster occurs, cold water is injected into the cavity of the cabinet body, the temperature of the cabinet body is reduced through water, high-confidentiality files are prevented from being damaged by baking due to the fact that the temperature of the inner wall of the cabinet body is too high, redundant heat is guided out through the water, the water can be recycled, no chemical materials are used for cooling, the environment is not polluted, and more environment friendliness is achieved.

Owner:中盾创新数字科技(北京)有限公司

An anti-tilt safety control device for crane jib

The invention discloses a safety control device for anti-backward tilting of a crane jib, comprising a display, a controller, an angle sensor, a low-pressure alarm pressure switch, and a high-voltage alarm pressure switch; Compared with the setting value of the tilt limit position, a limit position limit signal is sent to stop the oil cylinder from retracting; the display is used to receive the anti-backward length signal sent by the controller, display it in real time on the display, and set it in the display Set a pre-alarm range for anti-backward limit, and when the anti-backward length reaches this range, an alarm window will pop up to remind the operator. The invention avoids the problem of inaccurate data display caused by signal interference; improves the generality and operation convenience of the detection of the limit position of anti-backward tilt; increases the pre-alarm function of the limit position of anti-backward tilt; improves the accuracy and accuracy of the entire anti-backward tilt safety control system. Reliability; reduce the cost of the anti-roll safety control system.

Owner:XCMG CONSTR MACHINERY

U-shaped tube smoke guiding car uncovery gripper device

InactiveCN104152159AIncrease contact areaAccurate gripOven incrustations prevention/removalCharging devicesEngineeringPressure reduction

The invention relates to the field of machinery equipment, and in particular relates to a U-shaped tube smoke guiding car uncovery gripper device. The device comprises an outer rod, an inner rod, a lifting lug, a hoop, a connecting rod, a first gripper, a second gripper, a gripper lifting oil cylinder, a gripper opening / closing oil cylinder and an opening / closing oil cylinder bracket, wherein the inner rod is connected with the lifting lug; two gripping plates are symmetrically arranged on the lifting lug and are hinged with the lifting lug; the action sequence of each gripper and a guide sleeve is as follows: the gripper falls off firstly, and then the guide sleeve falls off after a water sealing cover is clamped by the gripper, so that the whole actions of the grinder are clear and visible; a guiding rack and an auxiliary guide roller device are additionally arranged at each gripper, so that the gripper which acts up and down is prevented from being deflected; the oil cylinder for driving each gripper to move up and down and the oil cylinder for opening and closing each gripper are designed in a single-cavity and pressure-reducing manner, i.e., the speed deceleration and the pressure reduction are realized during the falling of the grippers and the closing of mechanical claws, so that the mechanical claws are prevented from being damaged by the oil cylinders in an ejection manner when the grippers are not accurately aligned or civil engineering errors are large.

Owner:SHAANXI QIYUAN TECH DEV

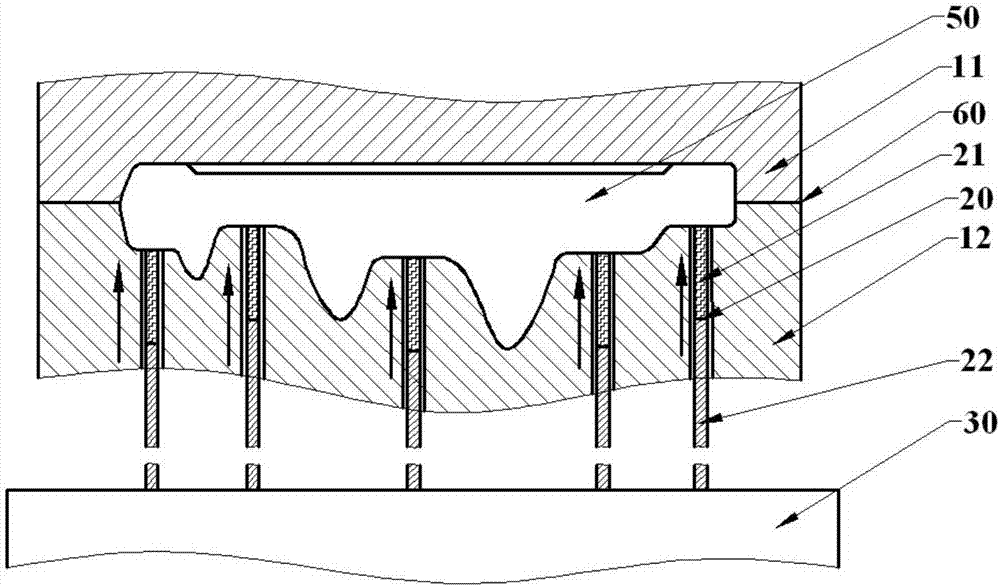

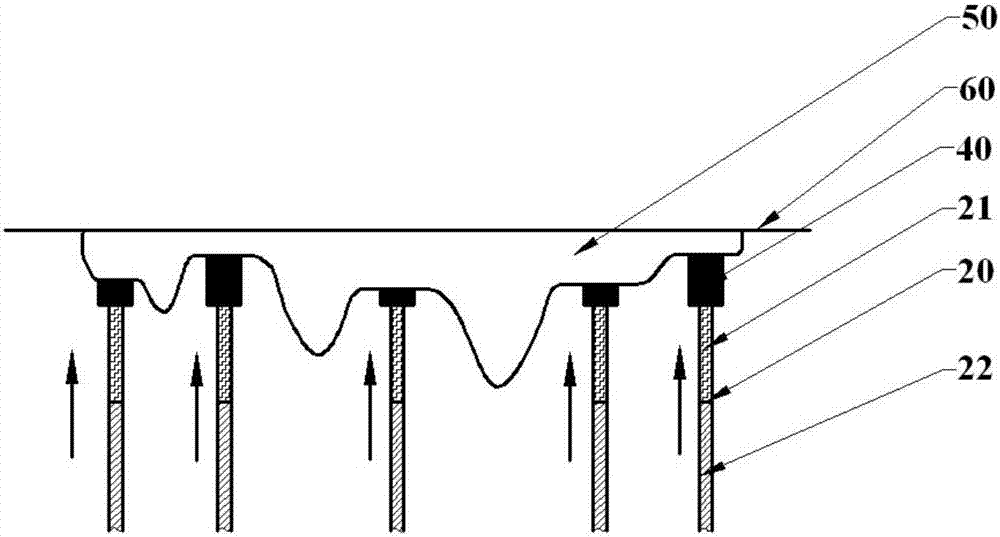

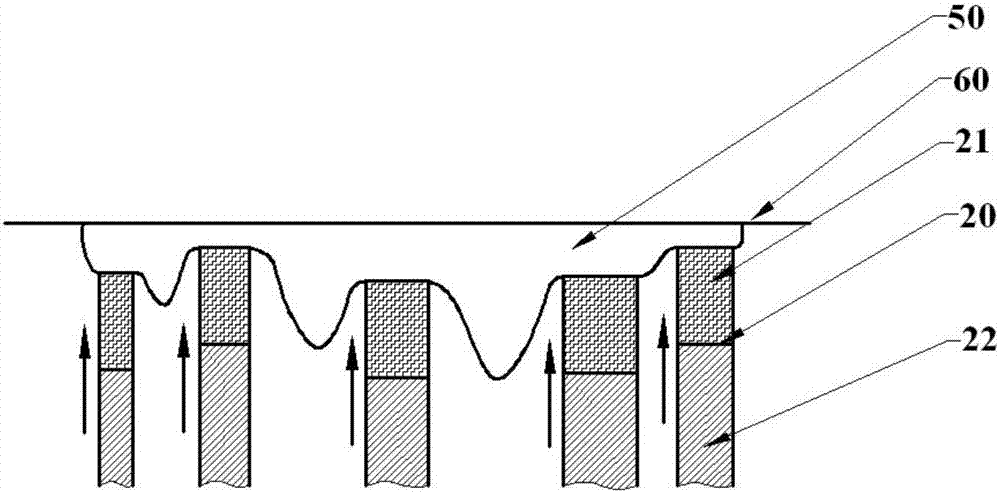

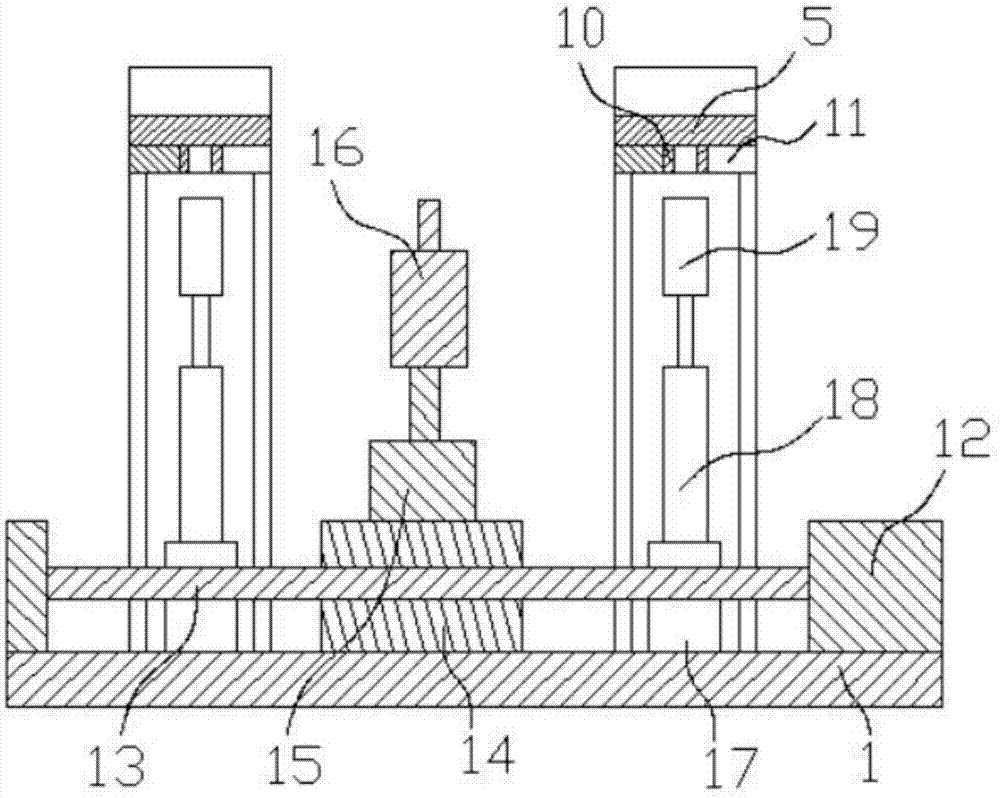

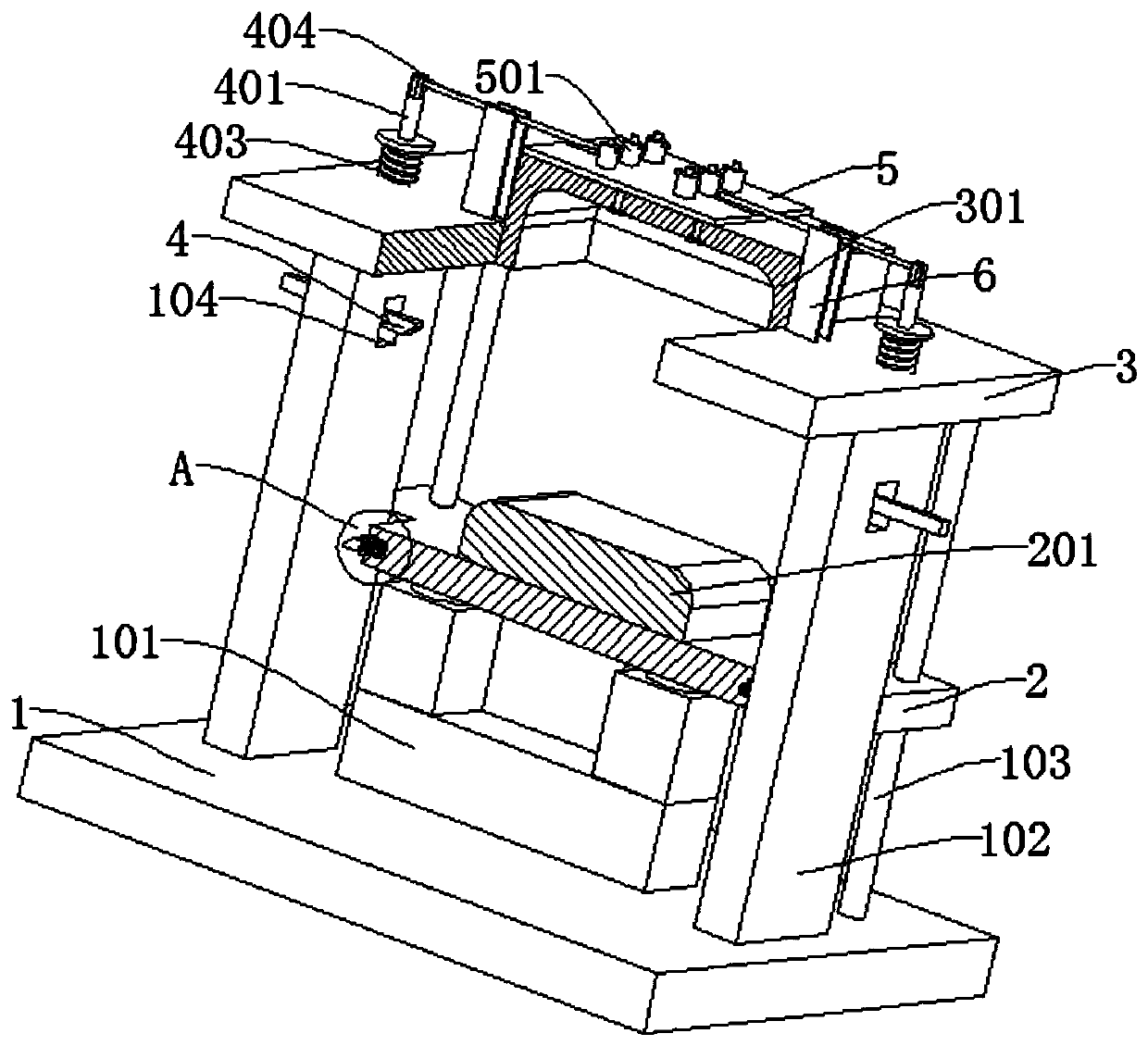

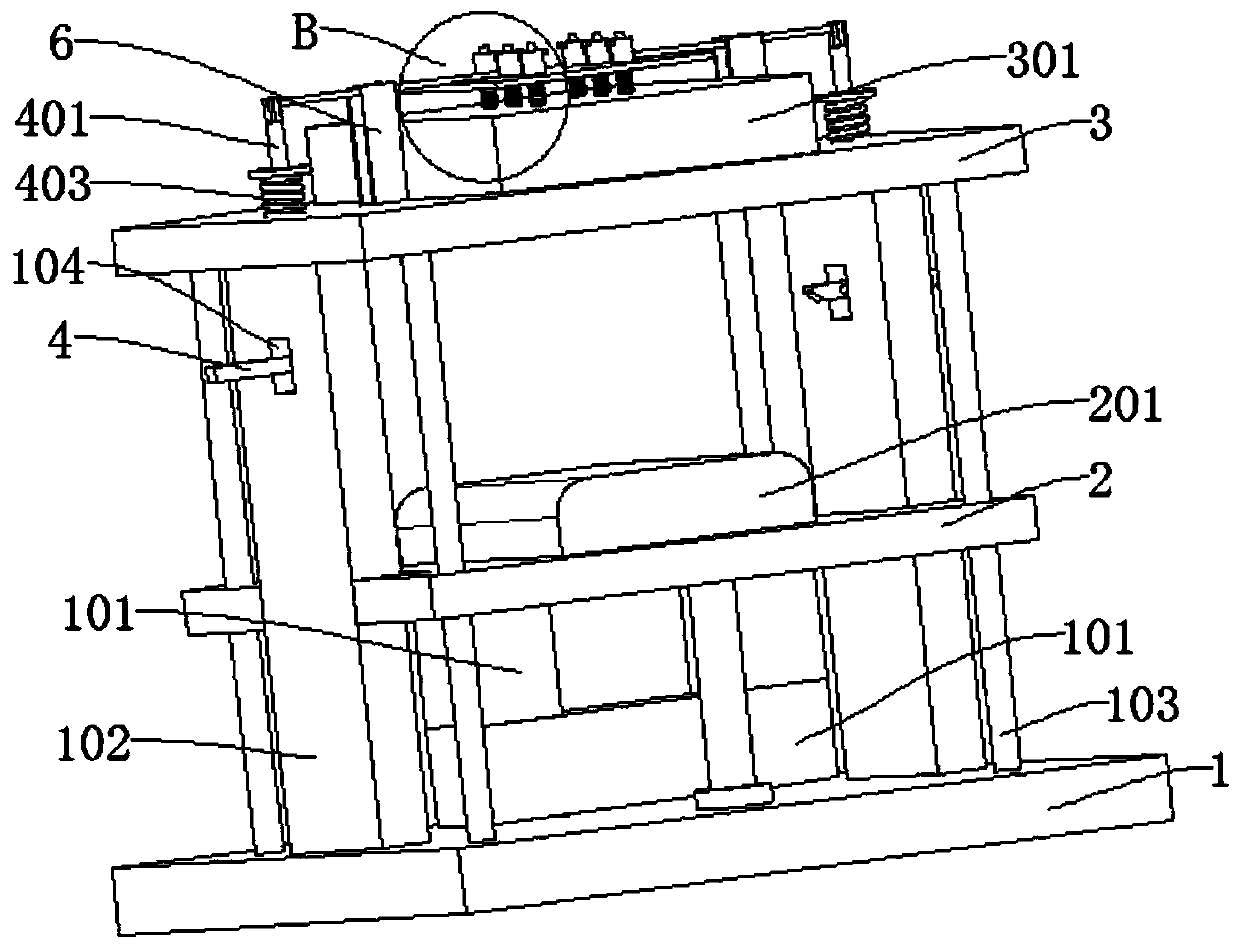

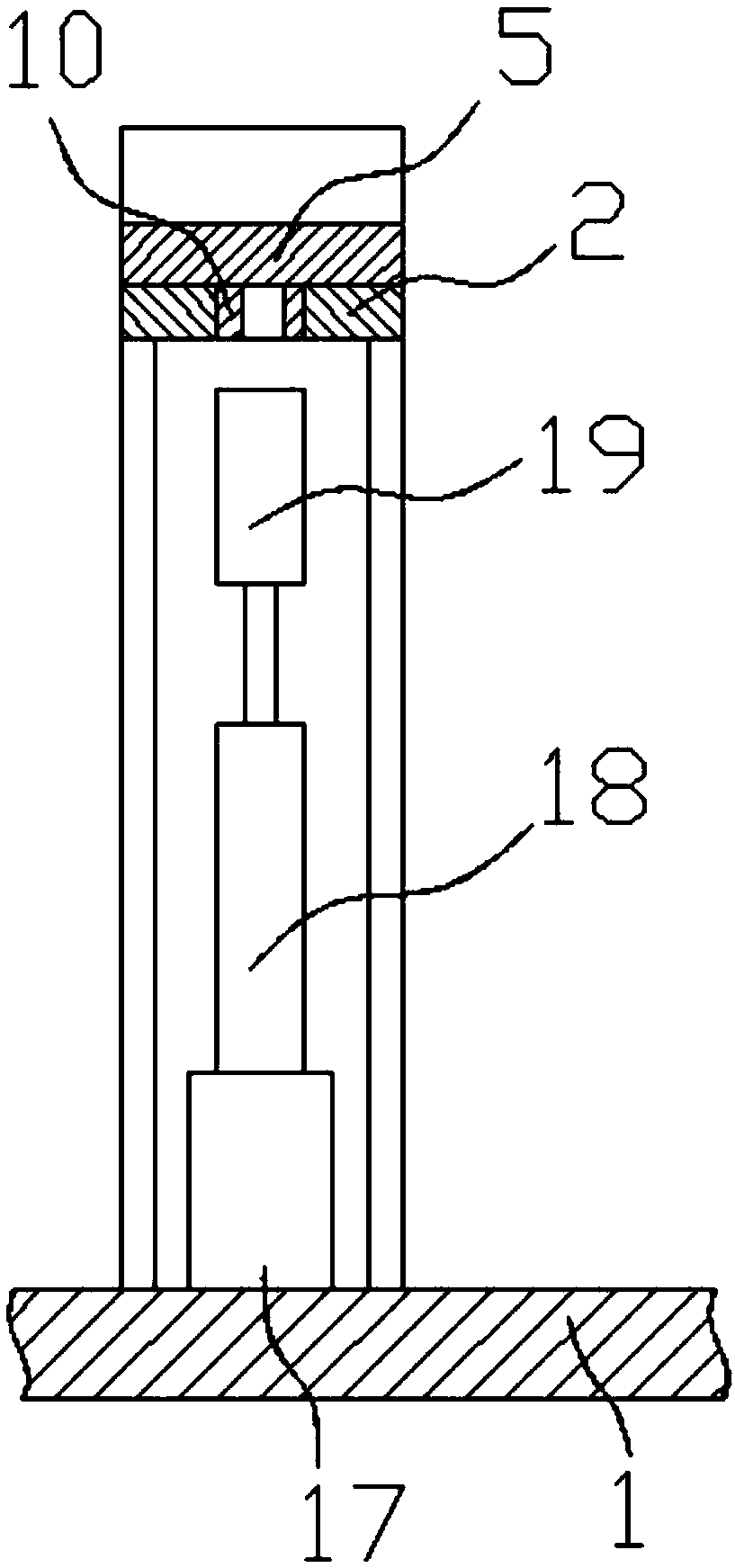

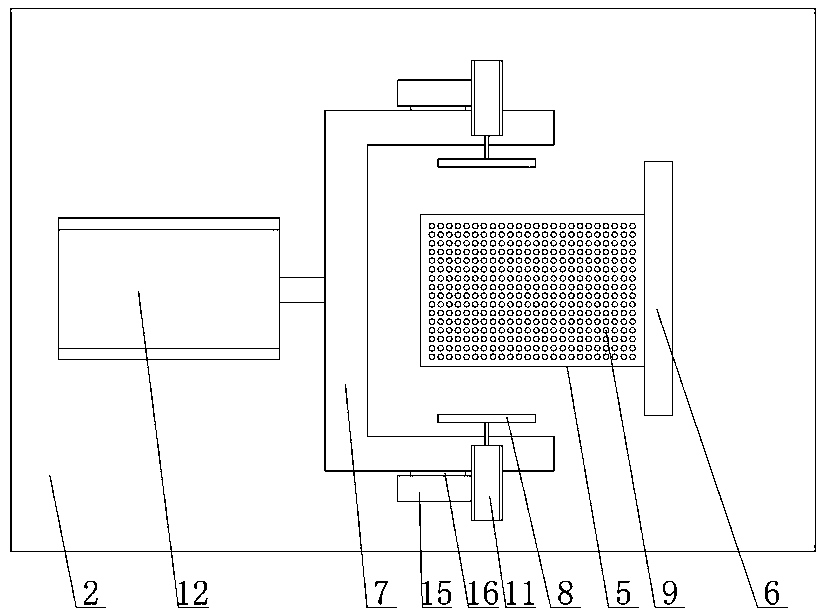

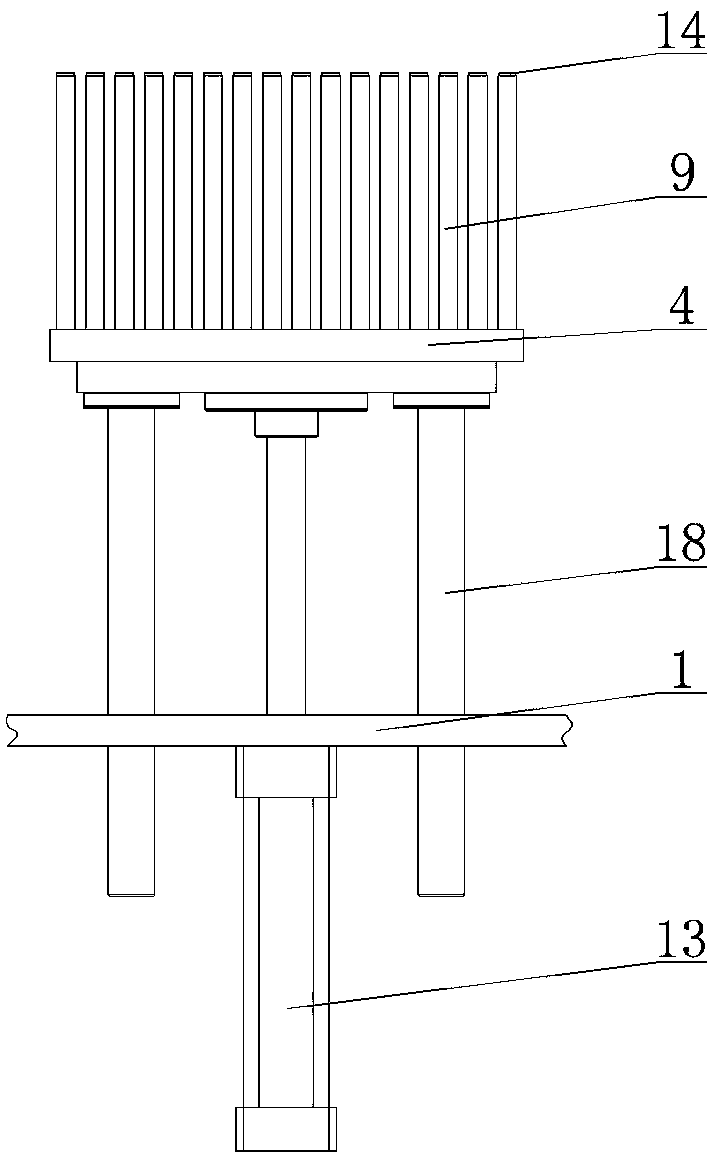

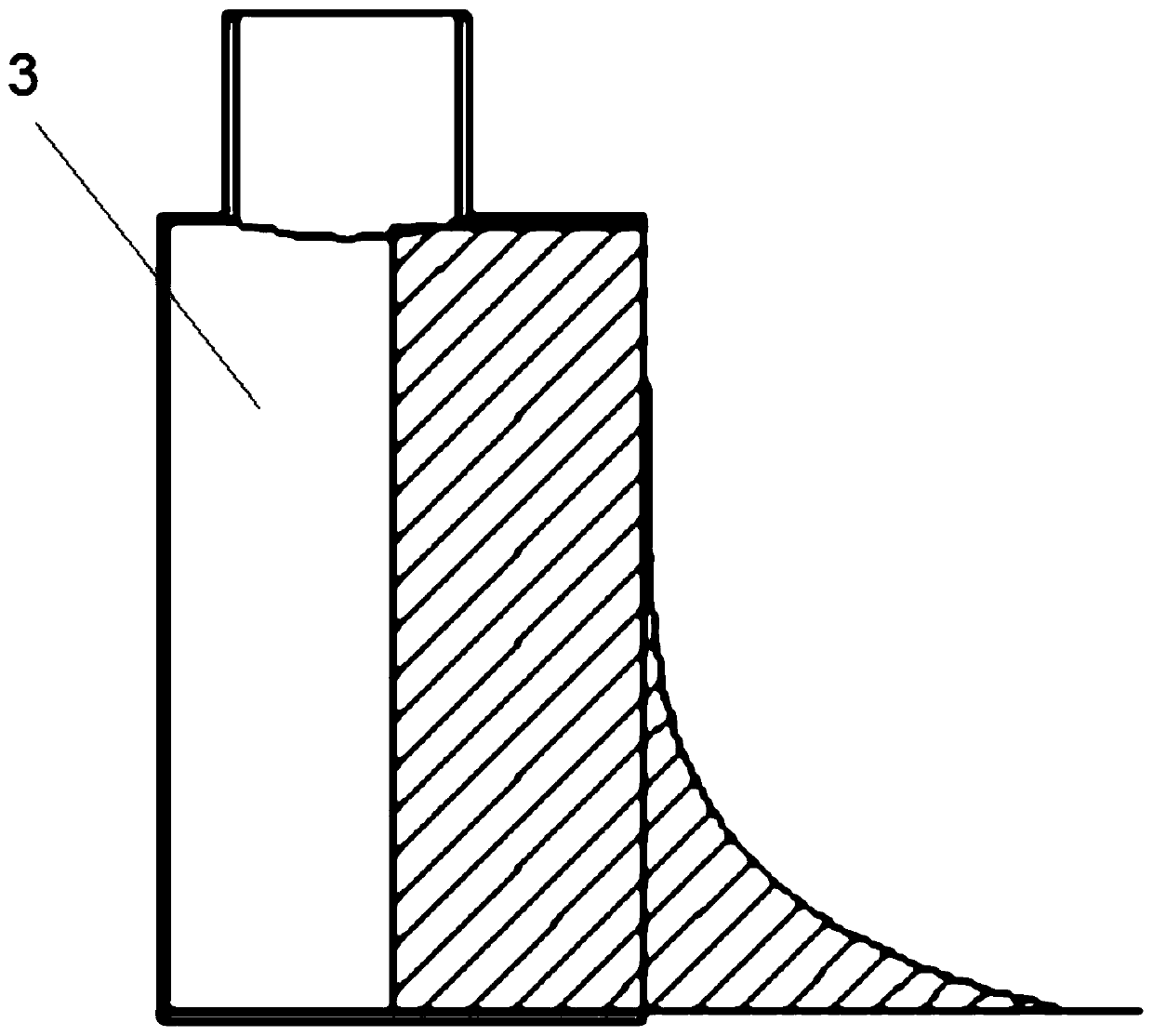

A stamping mold for auto parts

ActiveCN109967622BSufficient gas volumePrevent top damageShaping toolsShaping safety devicesPunchingEngineering

The invention discloses an automobile component punching forming die, and belongs to the technical field of automobile component punching. The automobile component punching forming die comprises a bottom plate, a first air pump, a male die, a top plate and a female die. The first air pump is connected to the top of the bottom plate, the female die is connected to the top plate, the end, away fromthe bottom plate, of the first air pump is connected with a sliding plate, the male die is connected to the outer wall of the sliding plate, ejector pins are connected to the inner wall of the femaledie, the tops of the ejector pins are connected with a pressing plate, the top of the pressing plate is connected with second air pumps, and the outer wall of each second air pump is connected with agas releasing valve and a one-way valve; and the ends, away from the female die, of the ejector pins penetrate through the second air pumps and are connected with pistons, and the ends, arranged in the female die, of the ejector pins are connected with ejector sheets. Through the arrangement of the second air pumps, it can be guaranteed that the stretching length of the ejector pins in the motionprocess is proper, and the situation that the ejector pins jack the dies to damage is avoided; and cost is reduced, manual drawing is avoided, the labor intensity is lowered, the work efficiency is improved, and repeated operation is convenient.

Owner:JIANGSU XIANGHE ELECTRONICS SCI & TECH

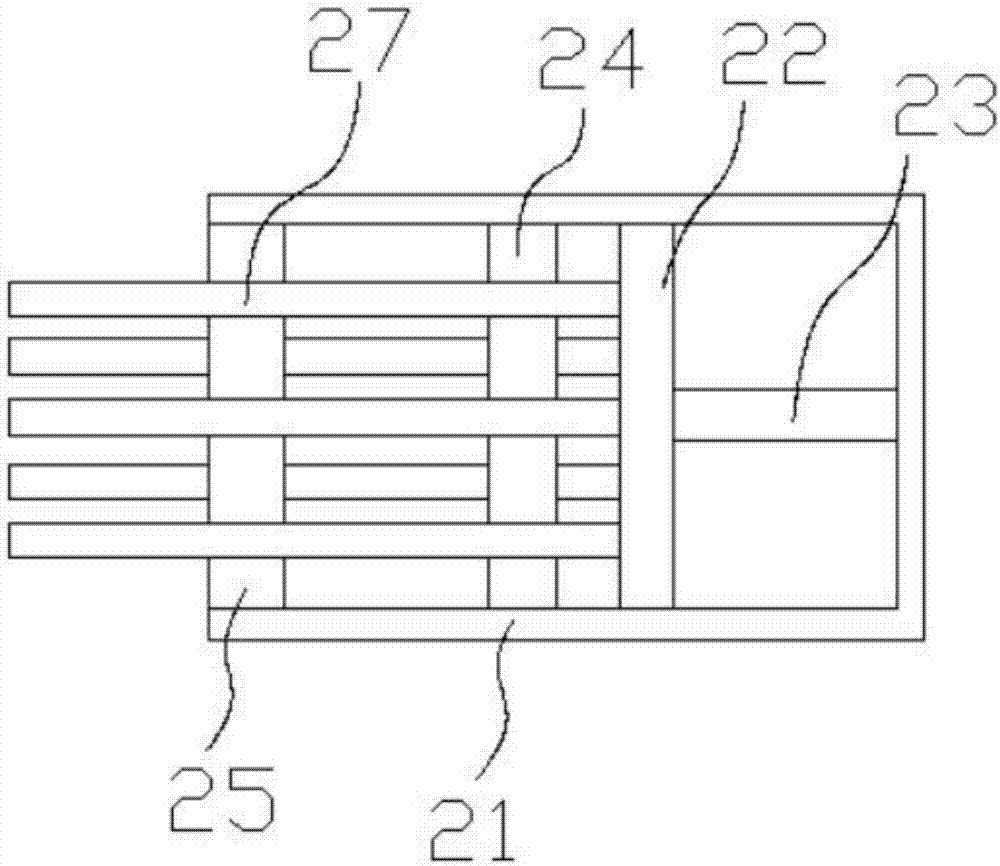

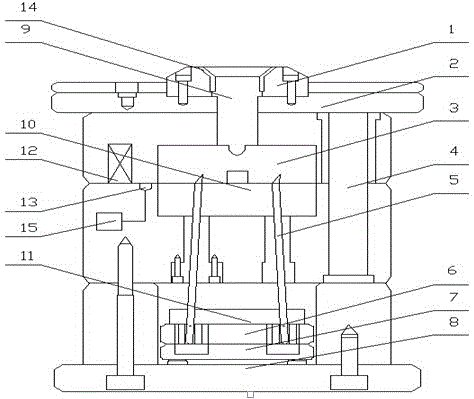

Novel anticollision injection mold

InactiveCN106378903APrevent top damageAchieve the effect of automatic piece countingEngineeringIndustrial engineering

The invention provides a novel anticollision injection mold including a positioning ring, an upper fixed plate and the like and characterized in that the novel anticollision injection mold also includes a limit controller, a limit block, a photoelectric switch, a detachable sprue bush and a counter; the upper fixed plate is provided with the positioning ring; the positioning ring is provided with the detachable sprue bush; a pouring gate is arranged below the detachable sprue bush; a female mold is arranged below the upper fixed plate, one side of the female mold is provided with a guide pillar, and the other side of the female mold is provided with the limit block. The limit controller, the limit block, the photoelectric switch, the detachable sprue bush and the counter are added; if an ejection rod is not reset, a case that the ejection rod is not reset and the mold is assembled again to eject the mold to be bad is avoided; the photoelectric switch is triggered when the mold is opened, the counter is allowed to count, the effectiveness of piece automatic counting is achieved, artificial recording is not needed, and the manpower is saved; after injection molding, the sprue bush can be dismounted alone and is cleaned, the whole positioning ring is not required to be dismounted, and a plenty of time is saved.

Owner:TIANJIN LIANXINYING PLASTIC TECH

Plug metal assembly machine capable of integrally pulling and cutting metal strip

InactiveCN108054615ACut offSimple structureContact member manufacturingContact member assembly/disassemblyMetal stripsMetal

The invention relates to a plug metal assembly machine capable of integrally pulling and cutting a metal strip. The plug metal assembly machine comprises a rack, a transmission mechanism, a pin device, a welding device, a discharging device and a pulling and cutting device, wherein the pulling and cutting device comprises a pull groove seat and a metal roll rotation shaft, a metal roll is arrangedon the metal roll rotation shaft, the groove depth of the pull groove seat is half of the diameter of a metal needle, a cutter device comprises a pulling and cutting seat, a pull motor and a pull lead screw are arranged on the pulling and cutting seat, the pull lead screw is sleeved by a pull movable block, a cutting lifting air cylinder is arranged at a lower part of the pull movable block, a cutting lifting seat is connected with the cutting lifting air cylinder, a vertical cutter is connected with the cutting lifting seat, and an edge of the cutter is a semi-circular notch with the diameter larger than that of the metal needle. By special structure design on the cutter and the pull groove seat, the cutter can complete pulling of the metal strip, the metal strip also can be cut, the pulling and cutting structure is simplified, automatic pulling and cutting is achieved, and the processing efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

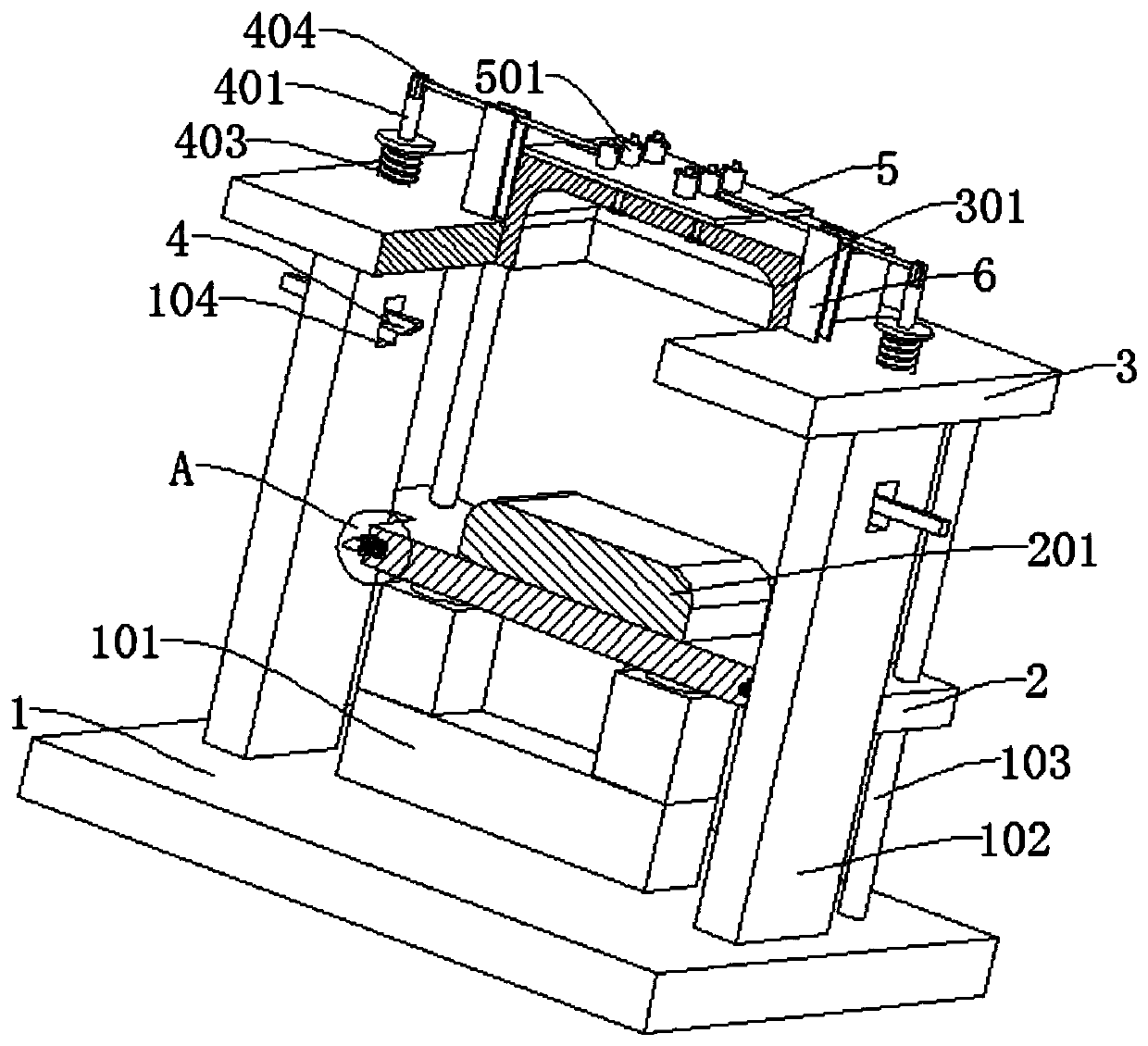

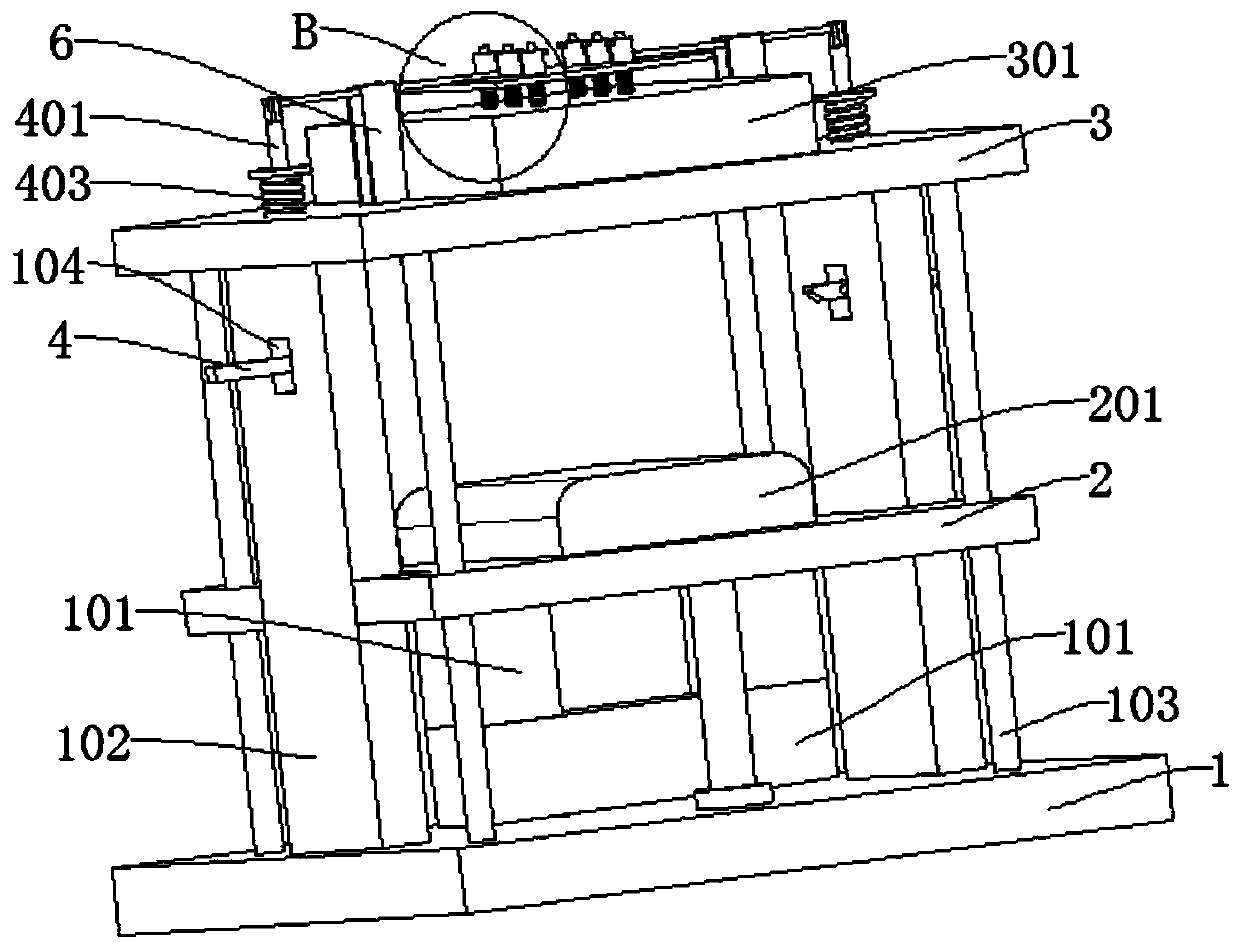

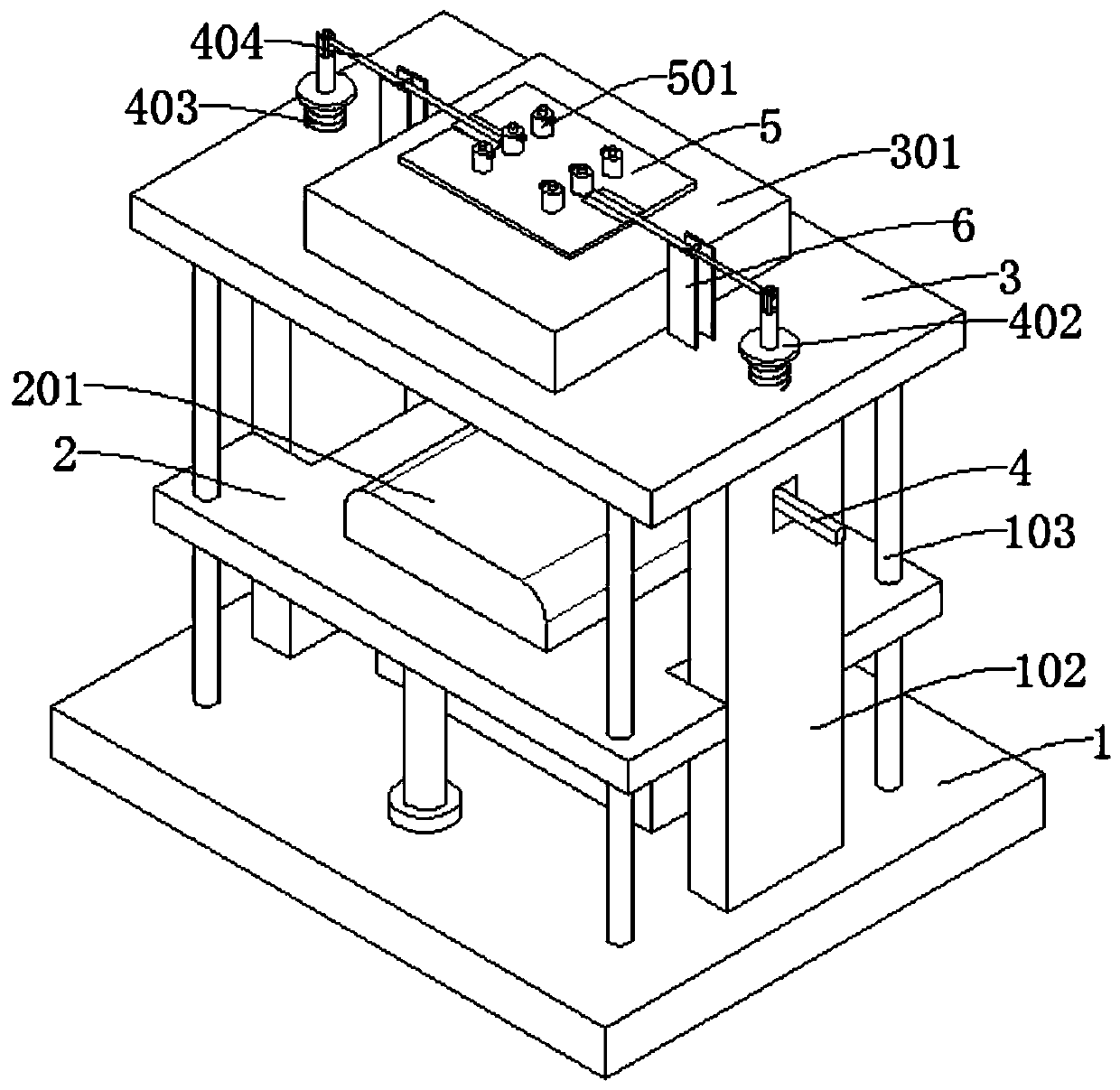

Automobile component punching forming die

ActiveCN109967622ASufficient gas volumePrevent top damageShaping toolsShaping safety devicesPunchingSlide plate

The invention discloses an automobile component punching forming die, and belongs to the technical field of automobile component punching. The automobile component punching forming die comprises a bottom plate, a first air pump, a male die, a top plate and a female die. The first air pump is connected to the top of the bottom plate, the female die is connected to the top plate, the end, away fromthe bottom plate, of the first air pump is connected with a sliding plate, the male die is connected to the outer wall of the sliding plate, ejector pins are connected to the inner wall of the femaledie, the tops of the ejector pins are connected with a pressing plate, the top of the pressing plate is connected with second air pumps, and the outer wall of each second air pump is connected with agas releasing valve and a one-way valve; and the ends, away from the female die, of the ejector pins penetrate through the second air pumps and are connected with pistons, and the ends, arranged in the female die, of the ejector pins are connected with ejector sheets. Through the arrangement of the second air pumps, it can be guaranteed that the stretching length of the ejector pins in the motionprocess is proper, and the situation that the ejector pins jack the dies to damage is avoided; and cost is reduced, manual drawing is avoided, the labor intensity is lowered, the work efficiency is improved, and repeated operation is convenient.

Owner:JIANGSU XIANGHE ELECTRONICS SCI & TECH

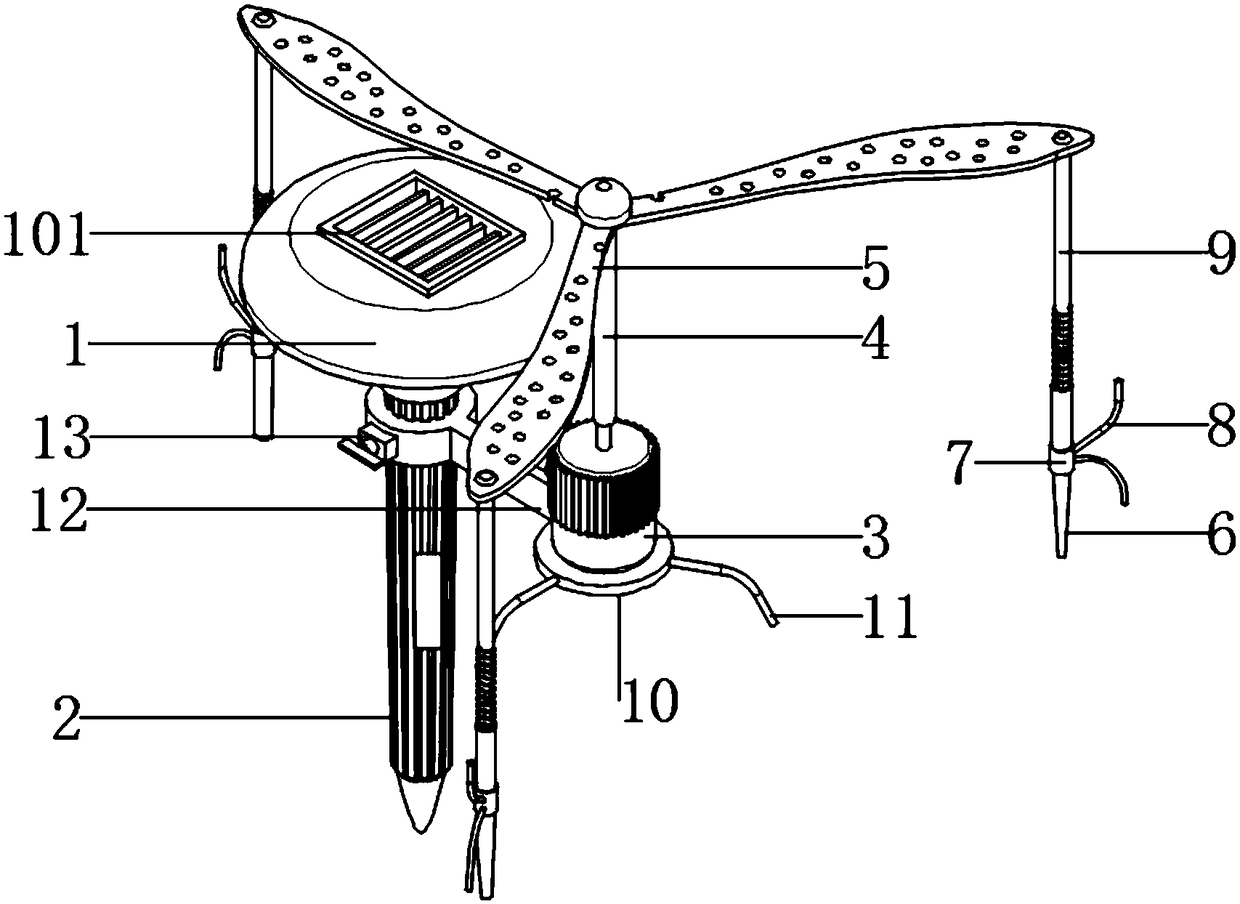

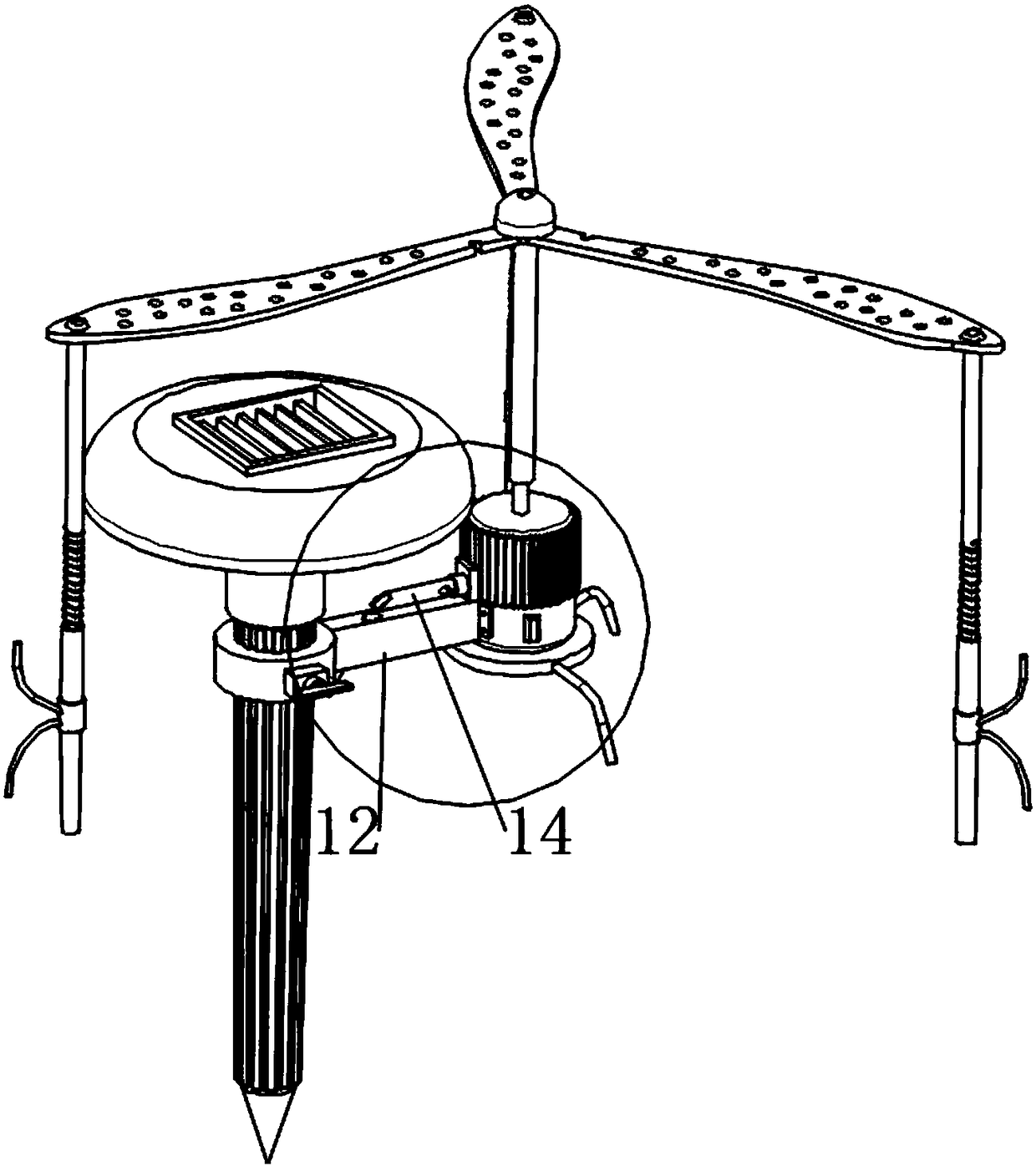

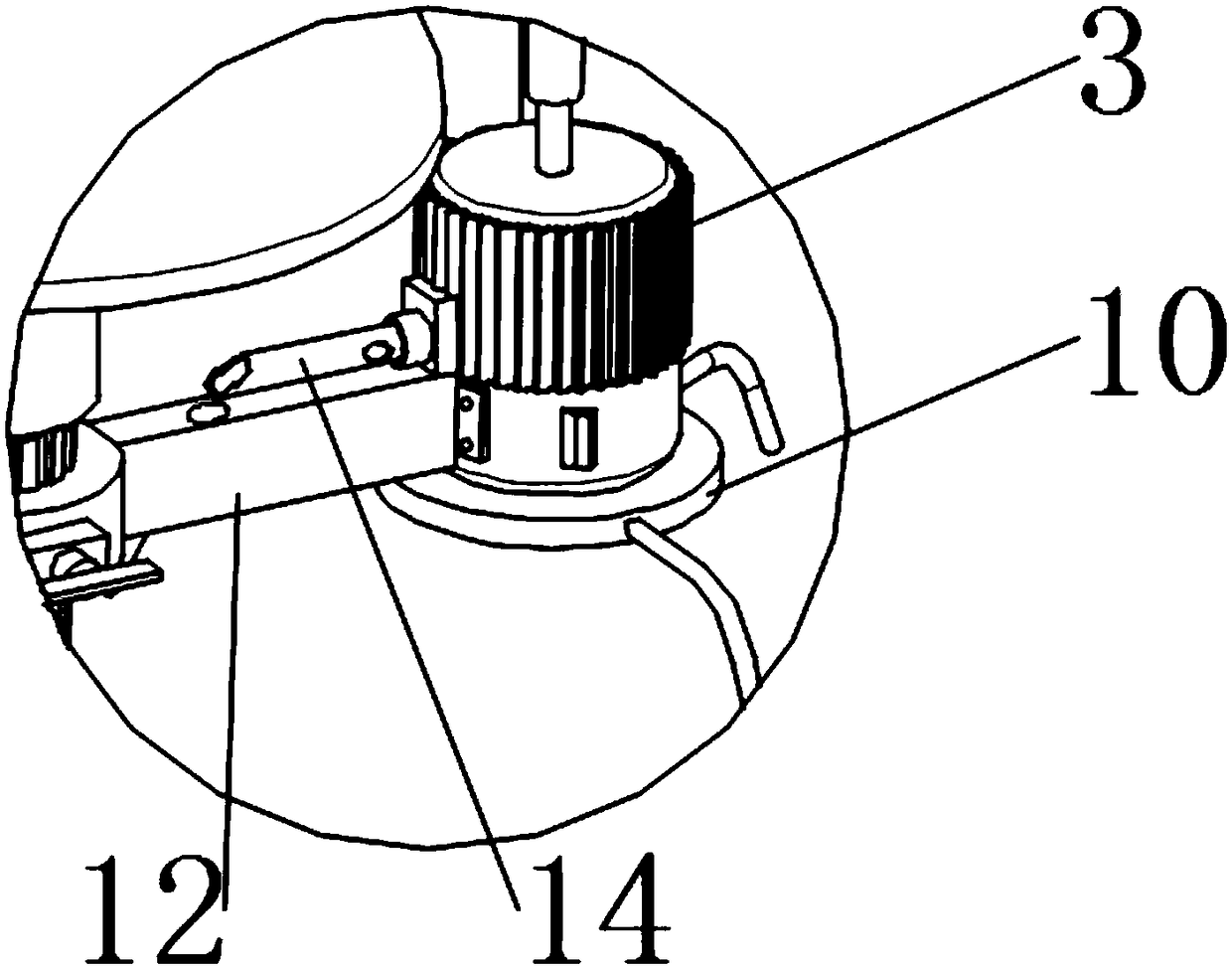

Ultrasonic wave rat control device for agriculture and forestry

The invention provides an ultrasonic wave rat control device for agriculture and forestry. The device comprises a straight rod, a ground supporting base, supporting feet, a connecting rod, a screwingbase and a wire arranging tube; an ultrasonic wave rat controller body is subjected to energy conservation and power supply by adopting a solar cell panel arranged on the top face, a PVC ground insertion pipe at the bottom end of the ultrasonic wave rat controller body is provided with a loudspeaker and a switch assembly which are used for being connected with a storage battery inside the solar cell panel; on the existing basis, a motor is connected to the side edge through the connecting rod, three fan blades are connected to a power output shaft of the motor, when the blades rotate, a top interference preventer is formed on the top side of the solar cell panel of the existing device, the phenomenon that the top is damaged due to the fact that aerial birds fall on the device is avoided, the motor is also powered by a solar assembly installed on the existing device, and the device saves energy and is environmentally friendly.

Owner:汤惠增

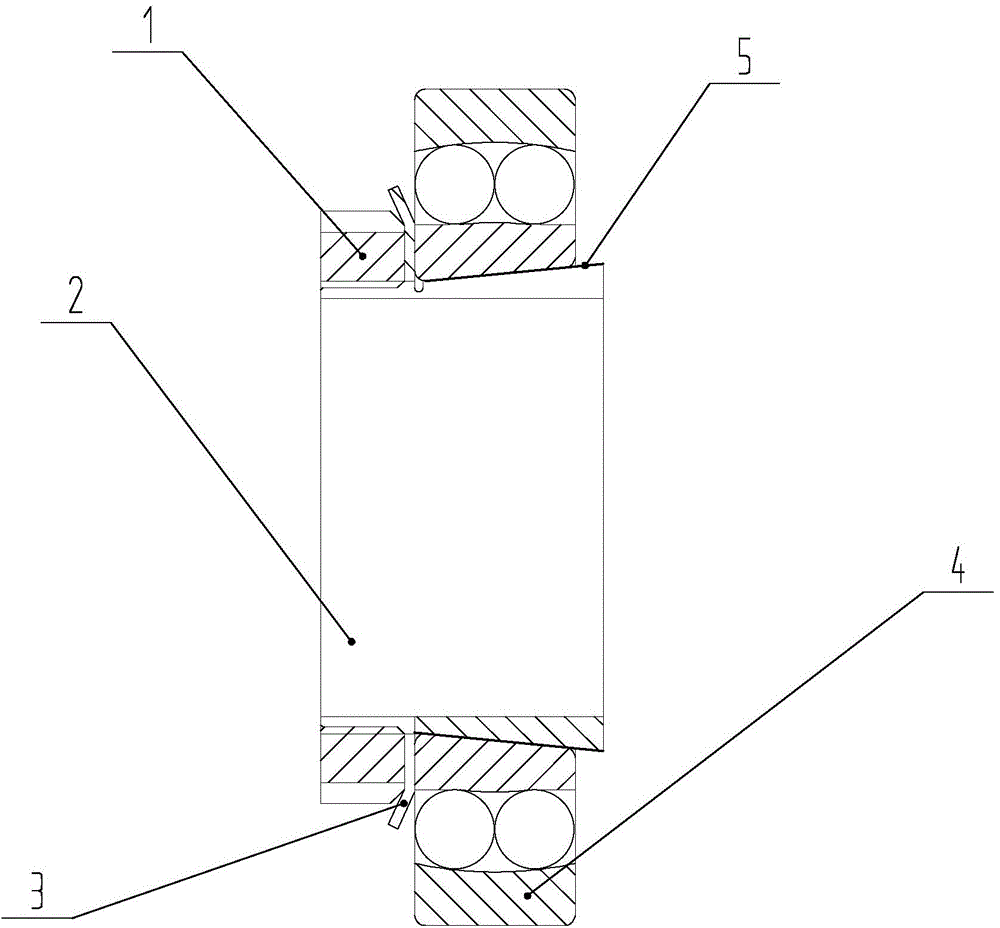

Device for adjusting bearing gap

InactiveCN104653636AEasy to install and disassembleEasy maintenanceBearing unit rigid supportEngineeringConical surface

The invention discloses a device for adjusting a bearing gap. The device comprises an adapter sleeve, a locknut, a conical bore self-aligning bearing and a locking gasket. The device is characterized in that the periphery of the right side of the adapter sleeve is provided with a conical surface, the periphery of the conical surface is provided with the conical bore self-aligning bearing, and the left side of the conical bore self-aligning bearing is provided with the locking gasket; the locking gasket sleeves the adapter sleeve, the left side of the adapter sleeve is provided with the locknut, and the locknut is connected with the adapter sleeve. The device for adjusting the bearing gap has the beneficial effects of adjusting the bearing gap, preventing a bearing from being damaged duo to shaft swelling and facilitating dismantling.

Owner:诸城市盛奥机械有限公司

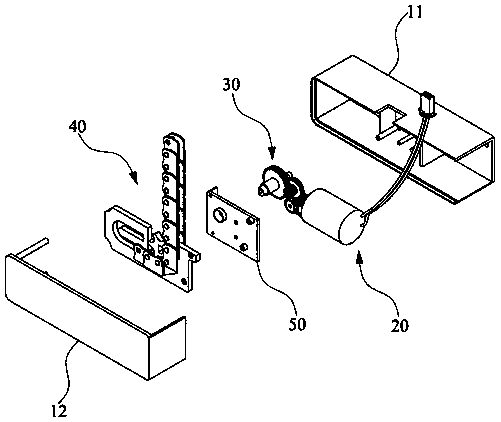

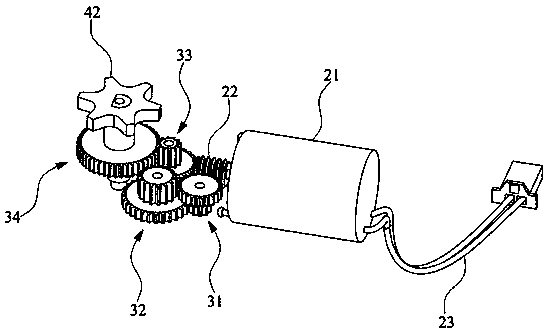

Automobile skylight opener

InactiveCN107795223AAvoid troubleAvoid the hassle of openingPower-operated mechanismPower supplyEngineeringSkylight

The application discloses an automobile sunroof opener, which comprises an outer casing, the outer casing includes a box body and a cover plate covering the box body; a driving mechanism built in the box body; a gear transmission mechanism driven by the driving mechanism; and connecting gears The transmission chain mechanism of the speed change mechanism, a support partition is set between the transmission chain mechanism and the gear transmission mechanism, and the chain of the transmission chain mechanism is exposed to the outer shell; wherein, the drive mechanism drives the gear transmission mechanism to drive the transmission chain mechanism, so that the chain is retracted Outer casing or release outer casing. The invention uses the chain of the transmission chain mechanism to open and close the sunroof of the car, so as to avoid the problem that the sunroof will only be lifted abruptly when it is stuck by foreign matter, and the sunroof is easily broken or the motor is damaged.

Owner:钟新国

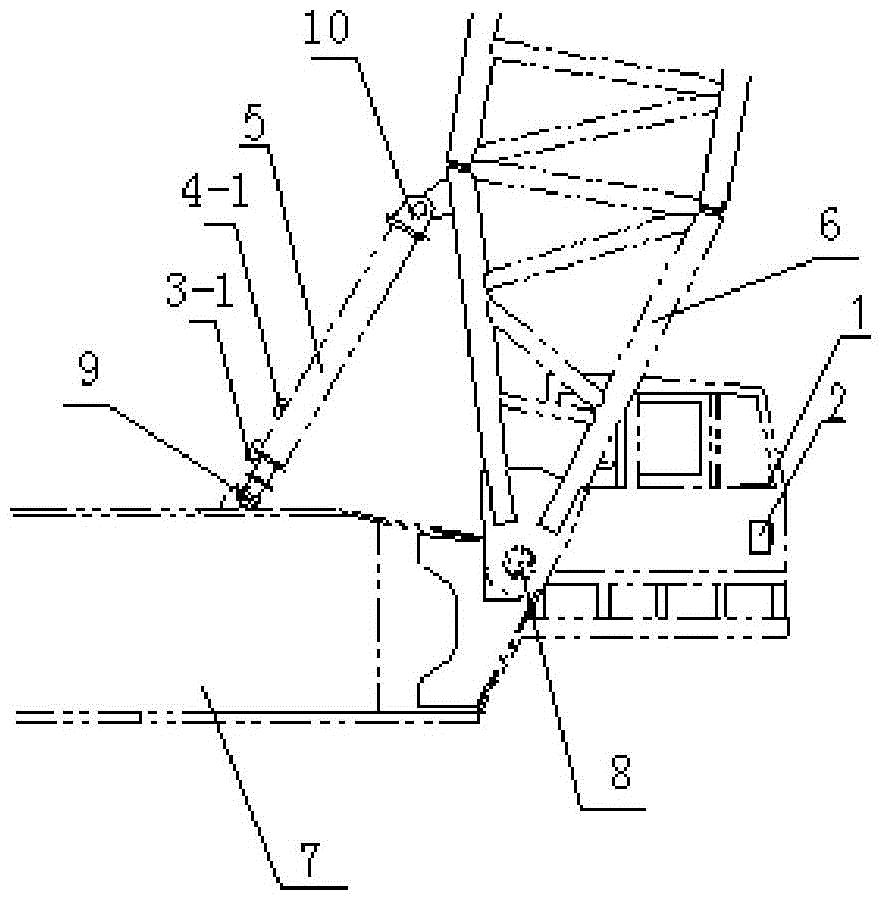

Method for retaining gob-side tunnel

InactiveCN102337904BAchieve miningTake advantage ofMining devicesUnderground chambersArchitectural engineeringRebar

The invention discloses a method for retaining a gob-side tunnel, which overall arranges the retaining of the gob-side tunnel in a stope working face gateway tunneling period, and comprises the steps of: combining the stope working face gateway with the gob-side retained tunnel, namely the next section gateway, together to be served as one tunnel for tunneling; and constructing tunnel concrete pier columns between the stope working face gateway and the gob-side retained tunnel, wherein the tunnel concrete pier columns are served as support in the tunnel and also served as one part of the side support for the gob-side retained tunnel; namely comprising the steps of: widening the section of the tunnel by tunneling, reserving the tunnel section according to the shrinkage factor of the god-side retained tunnel suffering from two times of support pressure, and pouring the reinforcing steel bar concrete pier columns in middle of the transverse direction of the tunnel to match with a cable anchor for supporting. The tunnel concrete pier columns are arranged along the whole length of the tunnel at intervals, and used for dividing the tunnel into two parts. Insulating walls are constructed between two adjacent columns after the columns are constructed. When the stope is starting, the support is needed to be temporarily reinforced at two sides of the columns according to requirements along with the advancing of the stope working face. According to the method for retaining a gob-side tunnel, the retaining of the gob-side tunnel and the tunneling of the stope working face gateway are overall arranged, and the tunnel concrete pier column support is arranged; therefore, the side support intensity and support resistance of the retained tunnel are greatly enhanced, the influence of support pressure in two times of mining is effectively controlled. The method for retaining gob-side tunnel is particularly suitable for using in flexible mining faces of bottom plate and / or top plate.

Owner:贾民

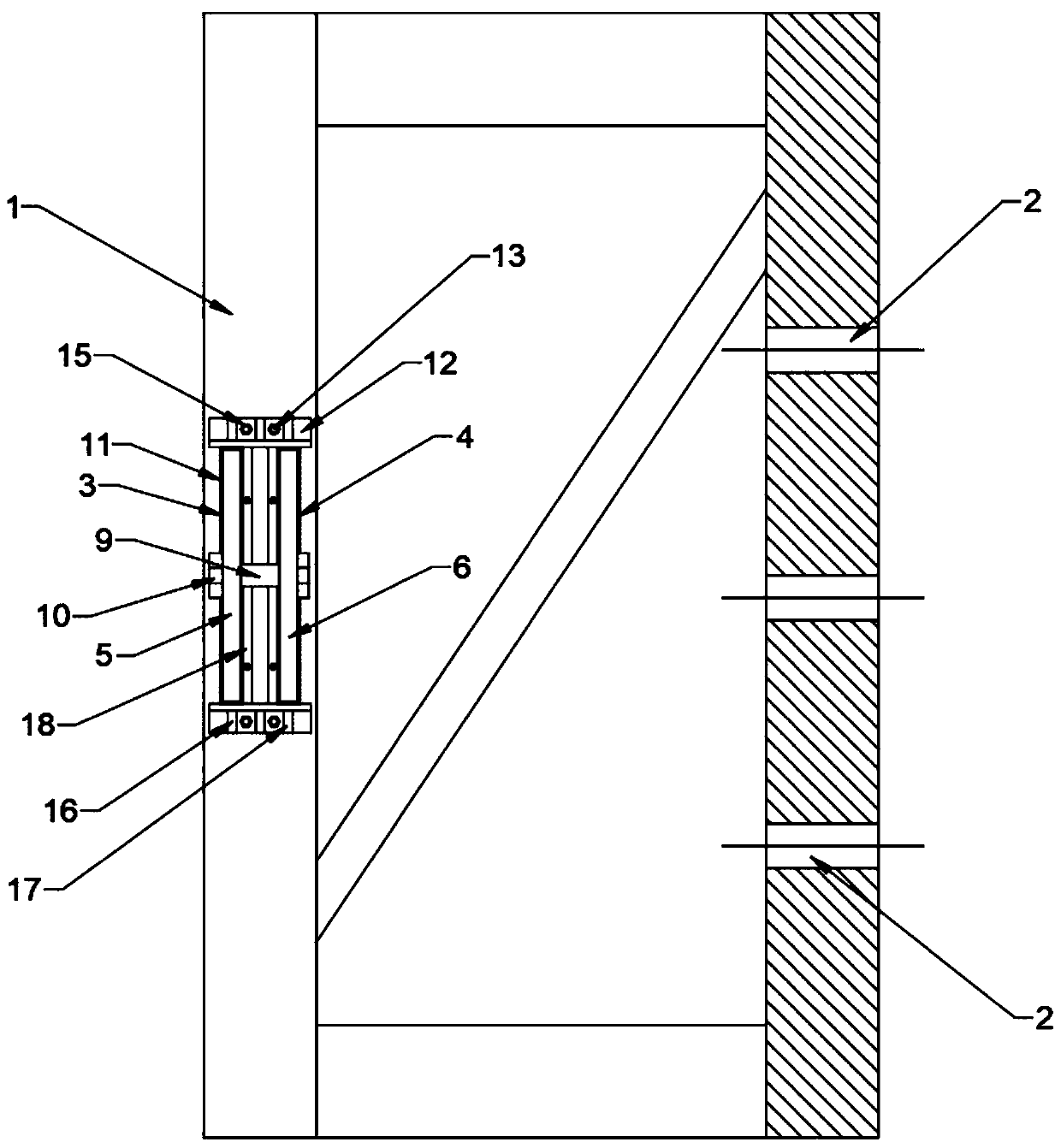

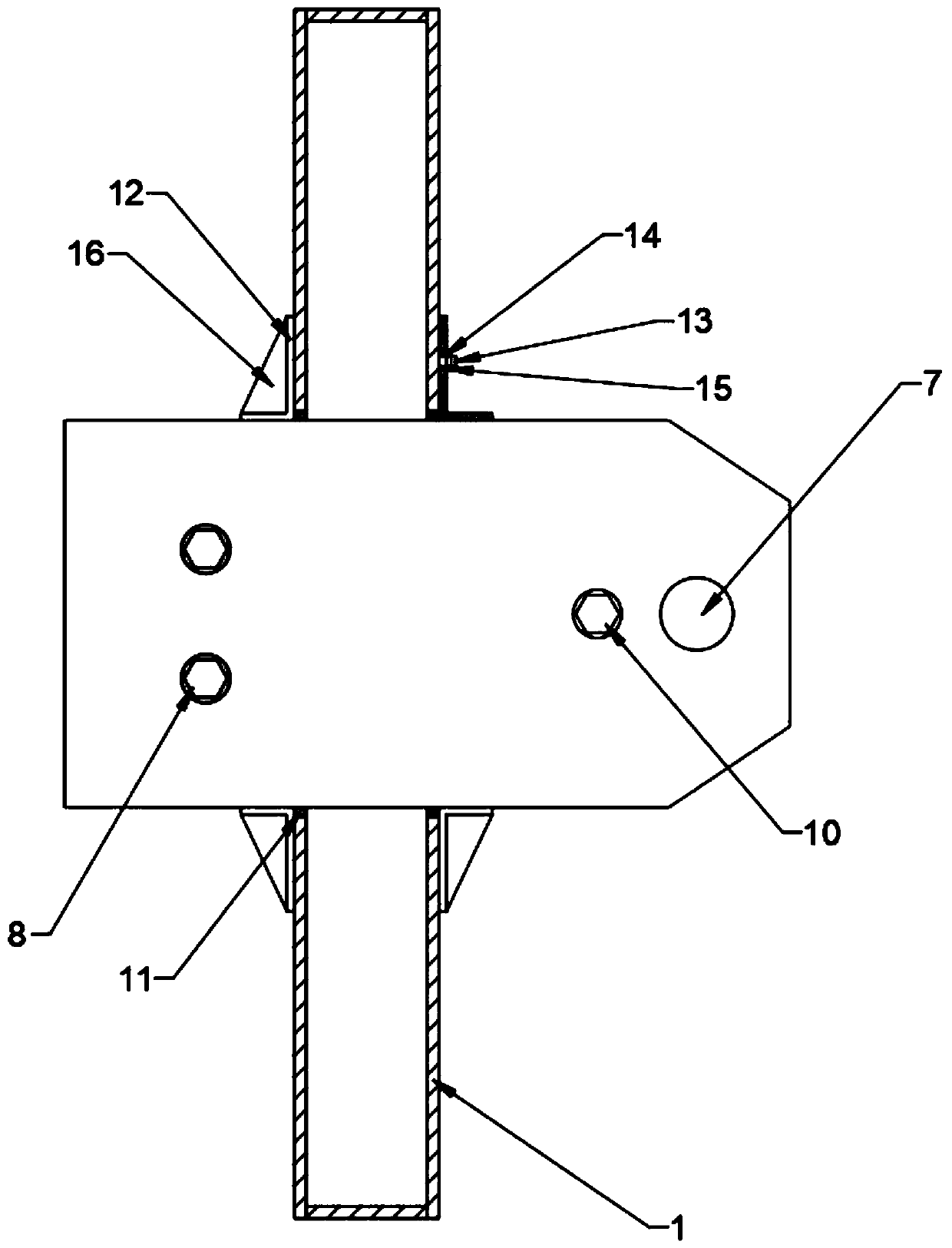

Hoisting assembly applied to an attached lifting scaffold

ActiveCN110700551AImprove replacement efficiencyImprove maintenance efficiencyBuilding support scaffoldsControl theoryScaffolder

The invention discloses a hoisting assembly applied to an attached lifting scaffold. The hoisting assembly comprises a supporting frame, a left hoisting plate and a right hoisting plate, wherein the left hoisting plate and the right hoisting plate are inserted into a left inserting groove and a right inserting groove respectively, and the two ends of the left hoisting plate and the two ends of theright hoisting plate are fixed through fastening bolts. Compared with an integrally-welded type hoisting piece in the prior art, the hoisting assembly is of an assembled structure, when different hoisting assemblies need to be replaced, the replacement efficiency is high, meanwhile, when parts are damaged, the whole hoisting assembly does not need to be replaced, the equipment is easy to maintain, the maintenance efficiency is high, meanwhile, the maintenance cost of the equipment is reduced, and the construction cost can be reduced.

Owner:ZHEJIANG YUZHIHANG TECH ENG

Intelligent takeout device for semi-finished product with tear mark

The invention discloses an intelligent takeout device for a semi-finished product with a tear mark. The device is characterized by comprising a frame, and a working platform, a pressing frame and a top plate arranged on the frame; the pressing frame can move on the frame up and down; the working platform is provided with a working area aligned to the pressing frame, and the working area is provided with a first vertical baffle plate on one side and a similarly C-shaped plate on the other side; the similarly C-shaped plate can move on the working platform left and right, and second vertical baffle plates are respectively arranged on the front and back sides of the similarly C-shaped plate; the second vertical baffle plates can move on the similarly C-shaped plate front and back; the top plate is positioned under the working area, and is provided with multiple detachable thimbles; and a through hole capable of allowing a thimble to penetrate through is formed in the working platform. Theintelligent takeout device for the semi-finished product with the tear mark is high in automation degree, high in working efficiency and wide in applicability.

Owner:WENZHOU POLYTECHNIC

Linear traveling sheet metal shearing machine

ActiveCN106881495BGuaranteed uptimePrevent left and right shiftShearing machine accessoriesAgricultural engineeringMachining

The invention discloses a straight walking type plate shearing machine, which belongs to the field of machining equipment. The straight walking type plate shearing machine comprises a shearing machine and a feeding device, wherein the feeding device is matched with the shearing machine, a straight walking mechanism is arranged at the bottom of the shearing machine, and the straight walking mechanism comprises a switch rail, a flat rail and a plurality of groups of roller assemblies; double inclined planes are formed on both sides of the upper part of the switch rail, the distance of the top ends of the double inclined planes is less than that of the bottom ends of the double inclined planes, and the center line of the flat rail is parallel to that of the switch rail; and the roller assemblies include concave rollers which are matched with the switch rail and flat rollers which are matched with the flat rail, and grooves which are matched with the upper part of the switch rail are formed in the surfaces of the concave rollers. The straight walking type plate shearing machine has the advantages of low cost and high practicability, the problem of incapability of straight walking of an existing walking type shearing machine is effectively solved, the structural design is optimized, the straight walking of the walking type shearing machine is realized by adopting a simple structure, and the plate shearing accuracy is guaranteed.

Owner:无锡通美机械科技有限公司

Heavy load tolerance regulator

PendingCN114084250AImprove installation efficiencyReduce the difficulty of assemblyCell component detailsVehiclesElectrical batteryClassical mechanics

The invention provides a heavy load tolerance regulator, a lower thread is arranged in the hollow portion of a hollow nut, an annular groove is formed in the upper end of a hollow screw rod, a longitudinal receding groove communicated with the annular groove is further formed in the upper end face of the hollow screw rod, a closing-in arc-shaped elastic piece with a limiting plate is arranged at the upper end of a clamping spring, the limiting plate corresponds to the receding groove in the upper end face of the hollow screw rod, the clamping spring is clamped in the hollow screw rod, the limiting plate at the upper end of the clamping spring is located in the receding groove of the hollow screw rod, a positioning ring is installed in the annular groove in the upper end of the hollow screw rod, the clamping spring is locked in the hollow screw rod through the limiting plate, the hollow screw rod is screwed at the lower thread in the hollow part of the hollow nut through the thread of the hollow screw rod, and a locking groove is formed in the thread of the hollow nut. The regulator has the advantages that the good adjusting effect is achieved, the adjusting operation is very convenient and rapid, the mounting efficiency of a battery pack is effectively improved, and the adjustable loading capacity is improved.

Owner:HUBEI BOSHILONG TECH

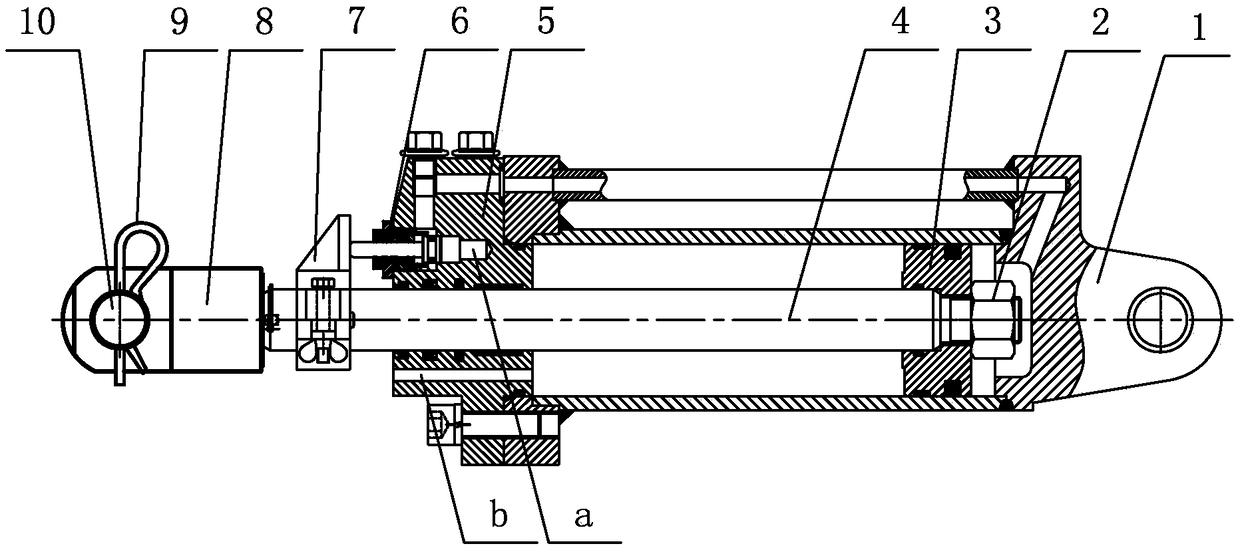

Lift cylinders for agricultural machinery

Owner:LOVOL HEAVY IND CO LTD

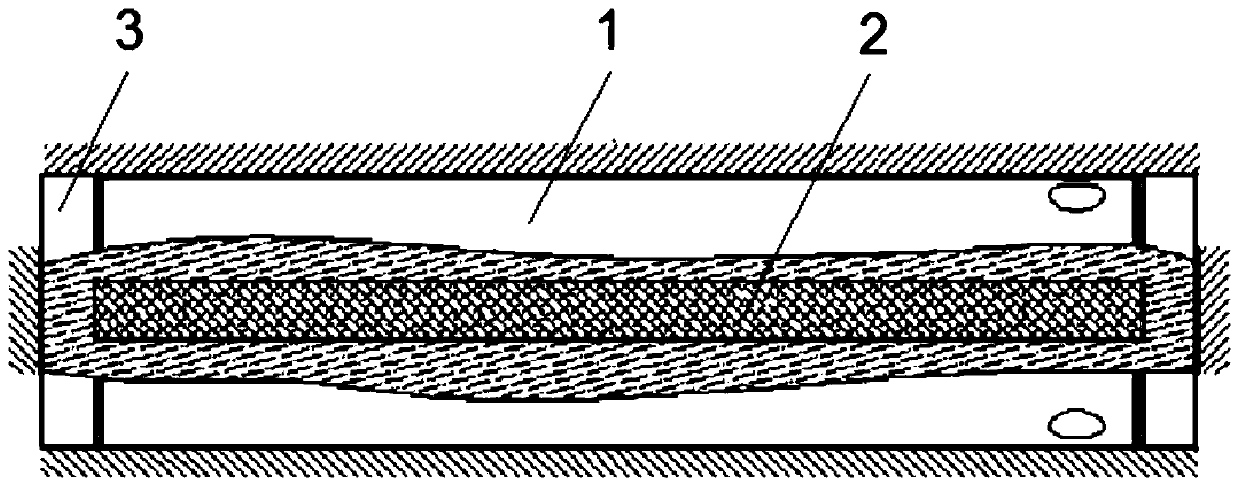

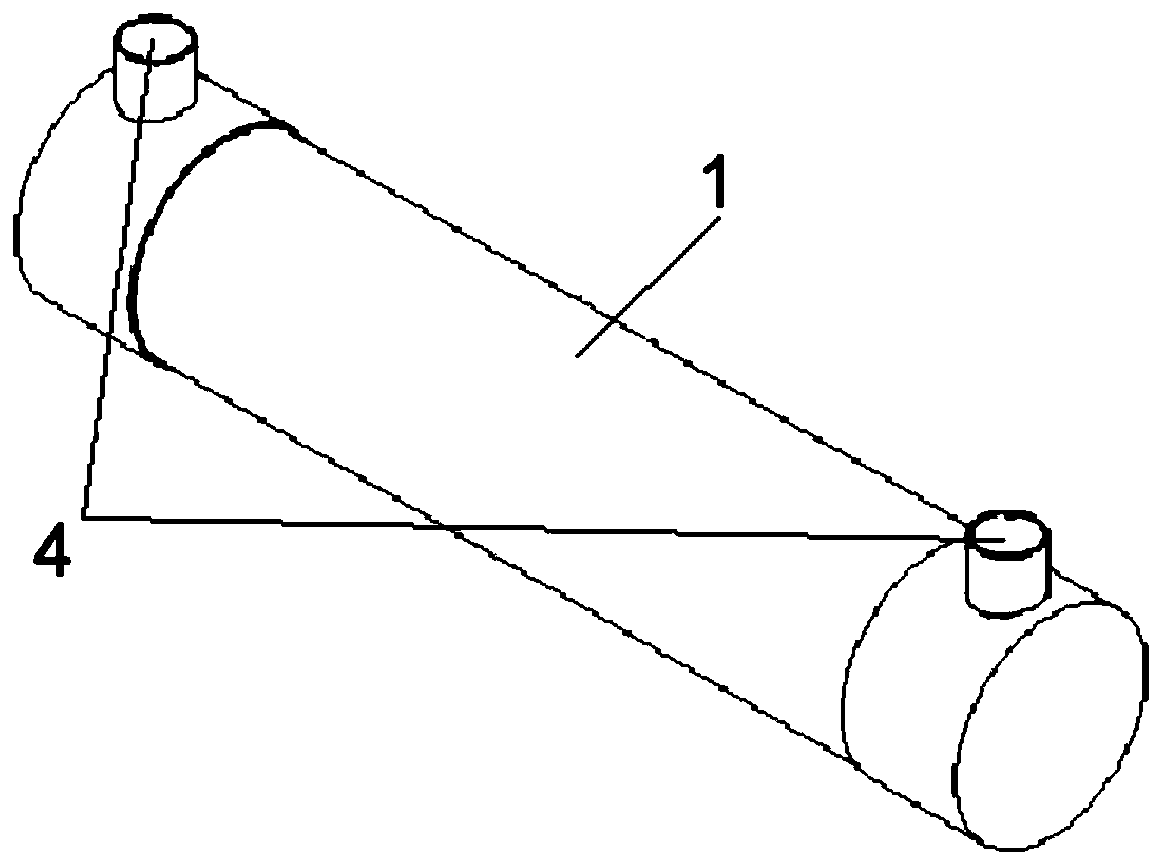

Manufacturing process of long-life nitrogen generator

InactiveCN111170286AAvoid displacementPrevent top damageNitrogen purification/separationSemi-permeable membranesNitrogen generatorProcess engineering

The invention discloses a manufacturing process of a long-life nitrogen generator. The manufacturing process comprises the following steps: taking materials, processing end sockets, cutting, winding of film, tapping, mounting a shell, pouring glue, and mounting a sealing cover and a tail cover to obtain the long-life nitrogen generator. The manufacturing process has the advantages of improving theseparation efficiency, prolonging the service life and the like.

Owner:SHENZHEN ZHONGLIAN AEROSPACE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com