Crankshaft throw timing sprocket press-fitting device

A timing sprocket and press-fitting device technology, which is applied in the field of press-fitting devices, can solve problems such as low product qualification rate and difficult timing angle control, and achieve the effects of improving qualification rate, avoiding skew, and improving press-fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

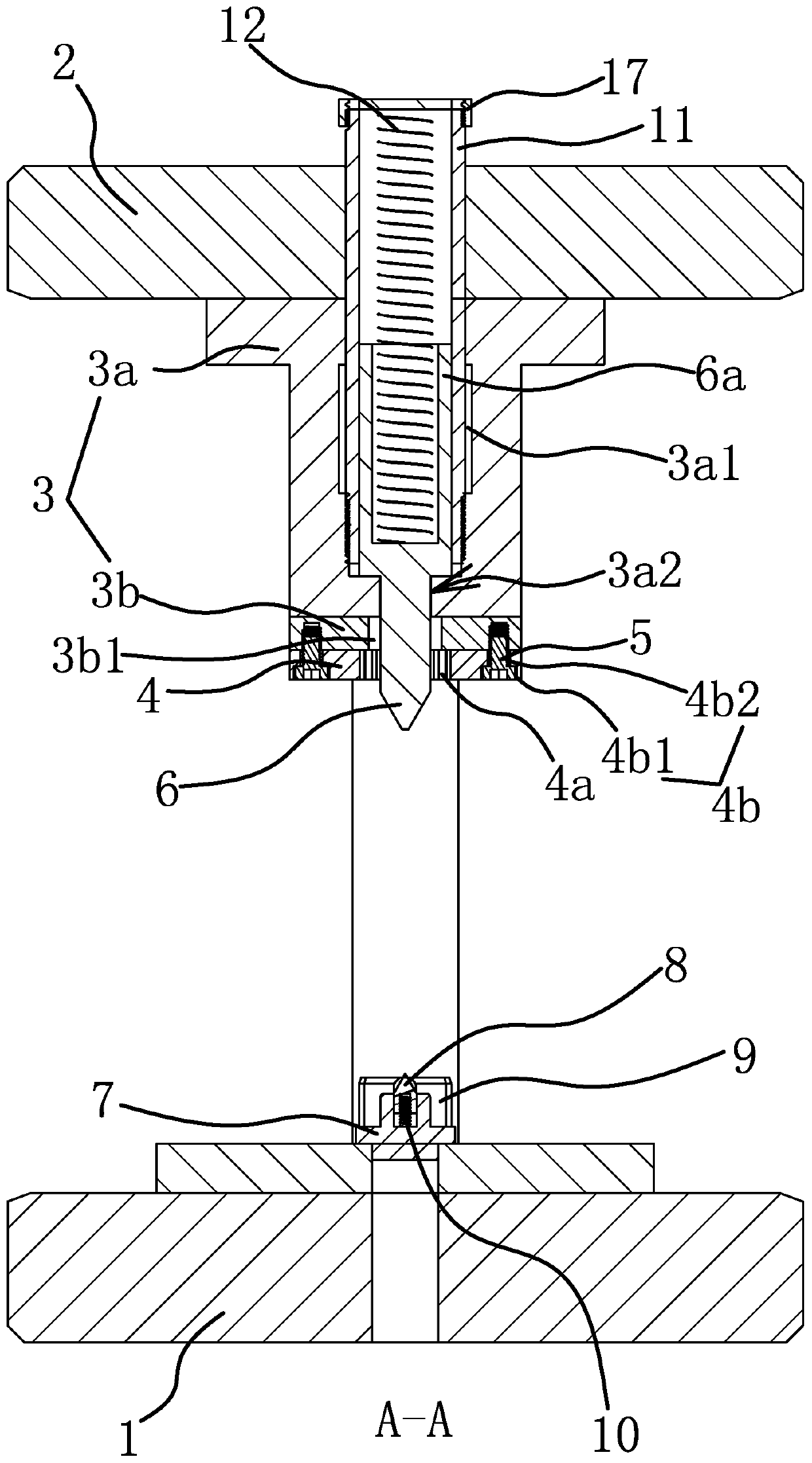

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

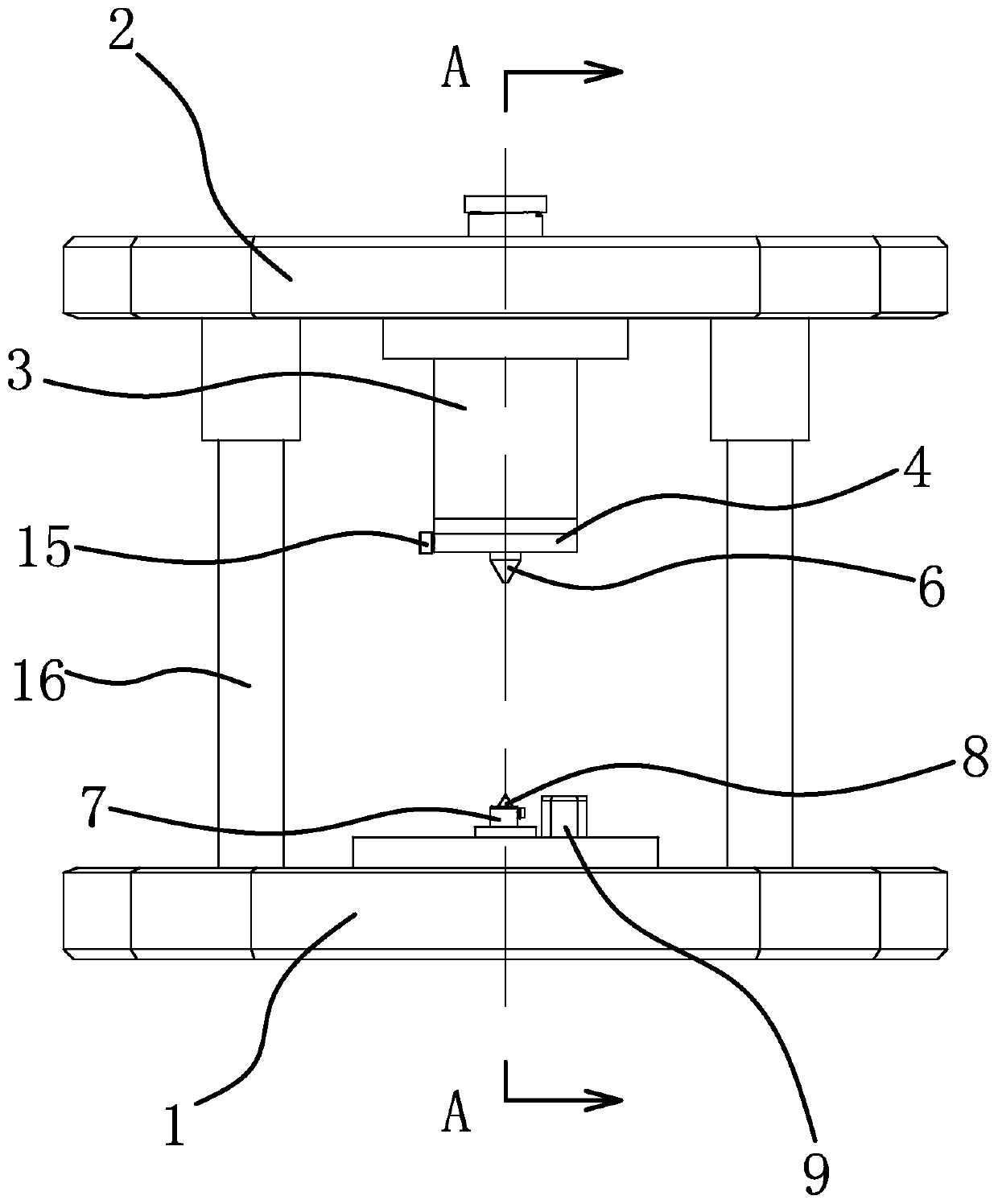

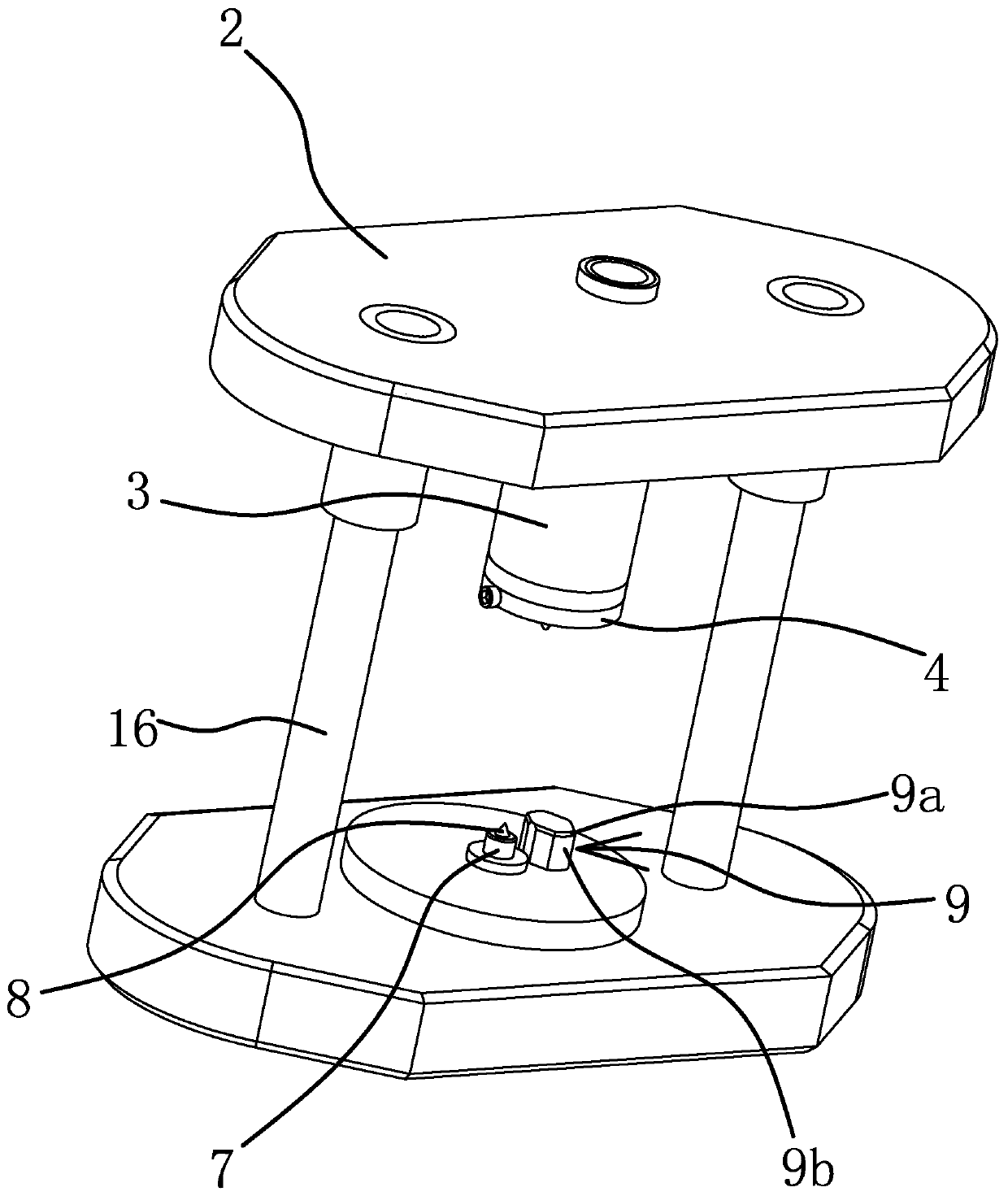

[0038] Such as Figure 1-Figure 3 As shown, the press-fitting device for the timing sprocket on the crank of the crankshaft includes a base 1 and a mold frame 2 that can be driven by a driving member to move to the base 1, wherein two parallel columns 16 are fixed on the base 1, and the mold The frame 2 is slidably arranged on the two columns 16, and the mold frame 2 is specifically driven by a cylinder or hydraulic pressure. A die head 3 is fixed on the mold frame 2, and the lower end surface of the die head 3 is fixed with a mounting block 4 by a fastener 5, and the center of the mounting block 4 is provided with a mounting groove 4 having the same shape as the timing sprocket 19. A floating top 6 is slidingly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com