Heavy load tolerance regulator

A regulator and tolerance technology, which is applied in the field of tolerance regulators and tolerance regulators for fixing automotive battery packs, can solve the problems of inability to ensure battery pack fit, inability to withstand heavy loads, and difficult assembly, and achieve convenient and fast adjustment operations. , The assembly difficulty is low, the effect of improving the installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

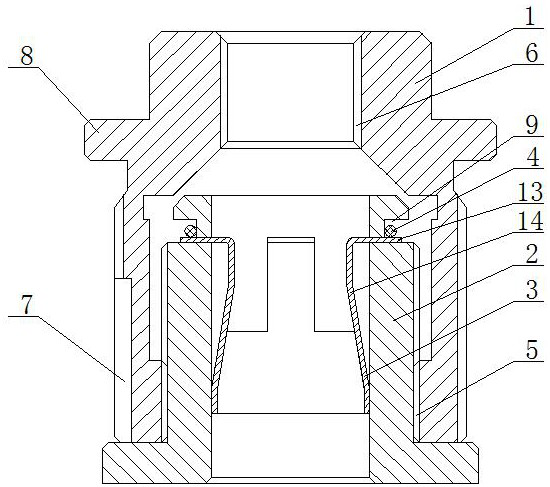

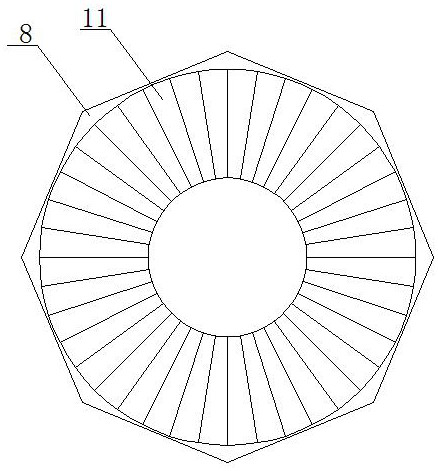

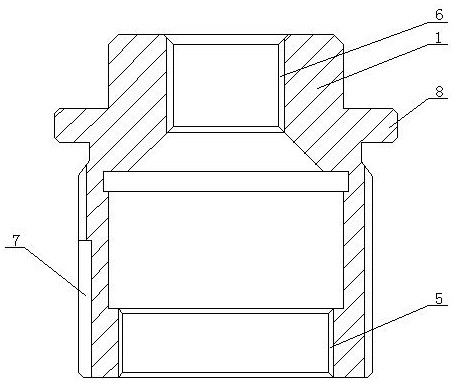

[0026] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the heavy-duty tolerance adjuster is composed of a hollow nut 1, a hollow screw rod 2, a retaining ring 3 and a positioning ring 4. The hollow nut 1 is provided with a lower thread 5 and an upper thread 6, and the upper thread 6 The diameter of the hollow nut 1 is smaller than the diameter of the lower thread 5, and the thread of the hollow nut 1 is provided with lock grooves 7, and the number of the lock grooves 7 is 1-4, and they are evenly distributed along the circumferential direction. The upper part of the hollow nut 1 is provided with polygonal protrusions. Platform 8, on the one hand, is beneficial to limit, and on the other hand, it is beneficial to the force of the fork wrench. The upper end of the hollow screw 2 is provided with a ring groove 9, and the upper end of the hollow screw 2 is also provided with a ring groove 9. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com