Novel full-automatic pipe cutting and punching integrated device

A fully automatic, punching technology, used in punching tools, other manufacturing equipment/tools, metal processing, etc., can solve problems such as easy collision, unreasonable structural design, low processing efficiency, etc., to avoid surface scratches and damages , The effect of ensuring safety and stability and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

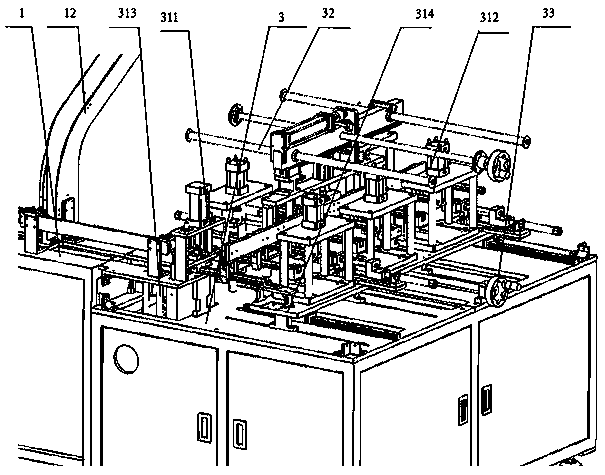

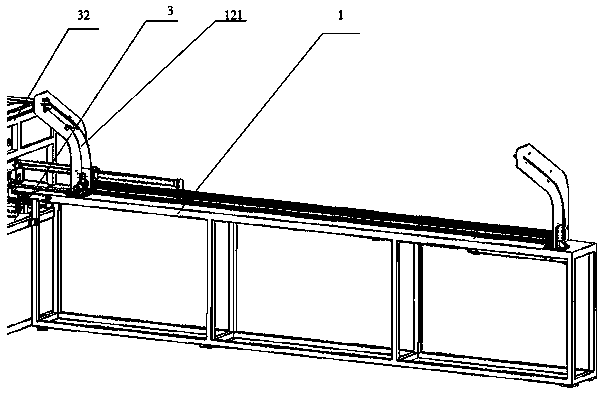

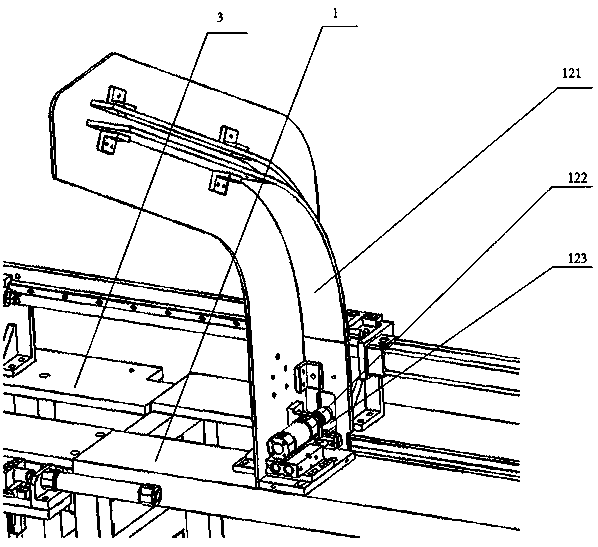

[0027] Such as Figure 1 to Figure 8 As shown, a new type of fully automatic pipe cutting and punching integrated device, a long pipe automatic feeding platform 1, a pipe cutting assembly 2 and a punching platform 3; the long pipe automatic feeding platform 1 includes a push assembly and an automatic material limiting assembly 12, The automatic material limiting assembly 12 includes an arc-shaped blanking frame 121, a rotary clamping head 122 and a blanking baffle 123, and the rotary clamping head 122 is arranged at the bottom of the arc-shaped blanking frame 121. The blanking baffle 123 is arranged below the rotary clamping head 122; the pipe cutting assembly 2 is arranged between the long pipe automatic feeding platform 1 and the punching platform 3, and the punching platform 3 Comprising a lower frame 31 and an upper frame 32, the lower frame 31 includes a feeding station, a first punching station, a turning station, a second punching station and a discharging station, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com