Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Meet the forming requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

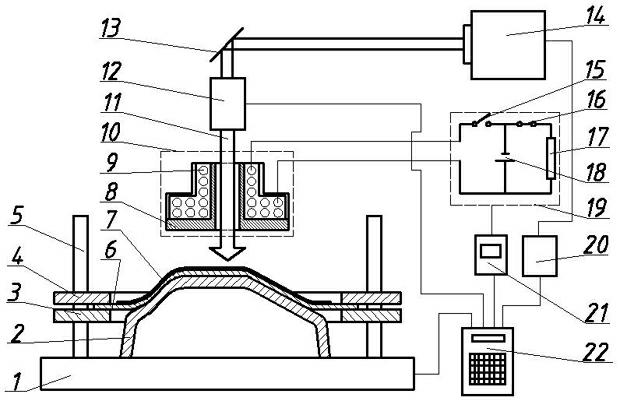

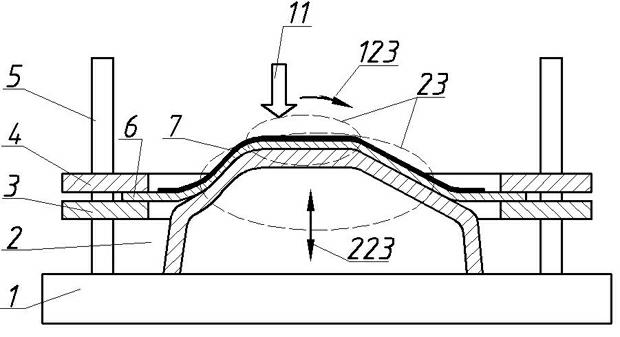

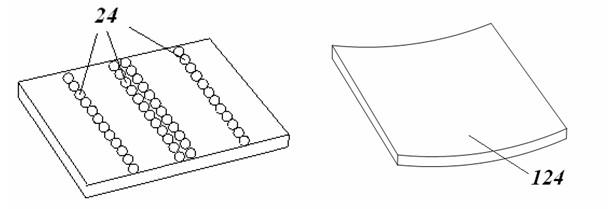

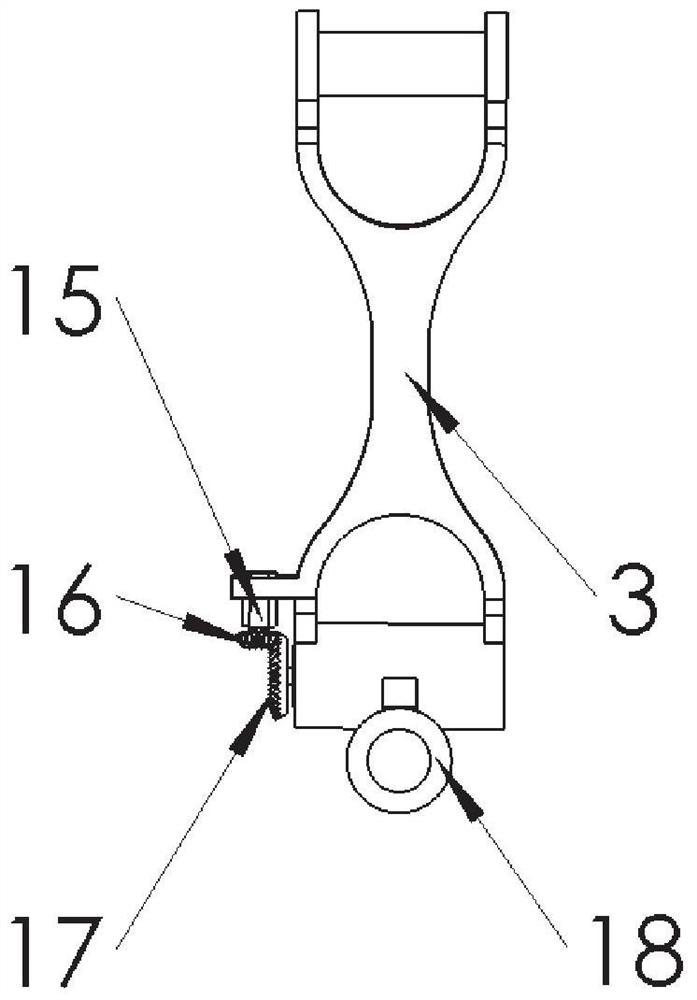

Method and device for laser pulse and electromagnetic pulse composite forming of metal sheet

InactiveCN102125951AMeet the forming requirementsLocality of changeManufacturing technologyEnergy absorption

The invention discloses a method and device for laser pulse and electromagnetic pulse composite forming of a metal sheet and relates to the technical field of processing and manufacturing fastening holes. The head part of an energy absorption rod (10) is a conical surface; a high-power pulse laser outputs an annular laser pulse (8) by means of a light spot regulator (15); the annular laser pulse (8) accommodates the tip part of the conical surface on the head part of the energy absorption rod (10) in a hollow part of a laser beam, and meanwhile, the annular laser pulse (8) is acted on the conical surface on the head part of the energy absorption rod (10) to induce plasma (17) to explode and generate impact waves acted on the internal walls of the fastening holes, so that the fastening holes are strengthened. The method and the device are suitable for strengthening the fastening holes with small diameter; the hollow part of the annular laser pulse (8) keeps away from the tip part of the conical surface of the energy absorption rod (10), so that the energy absorption rod (10) is difficult to damage, which is beneficial to continuously working and achieving a good strengthening effect.

Owner:JIANGSU UNIV

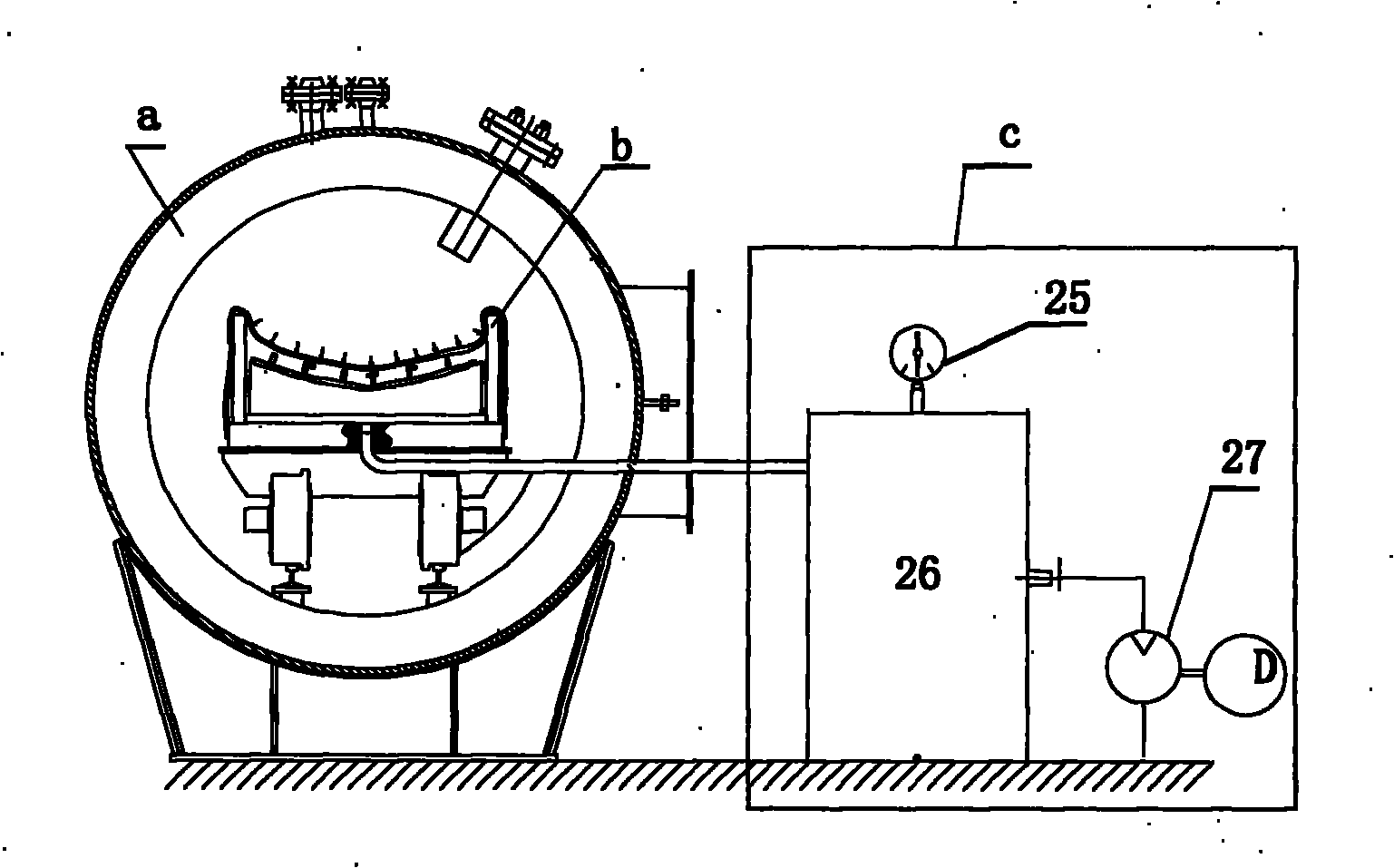

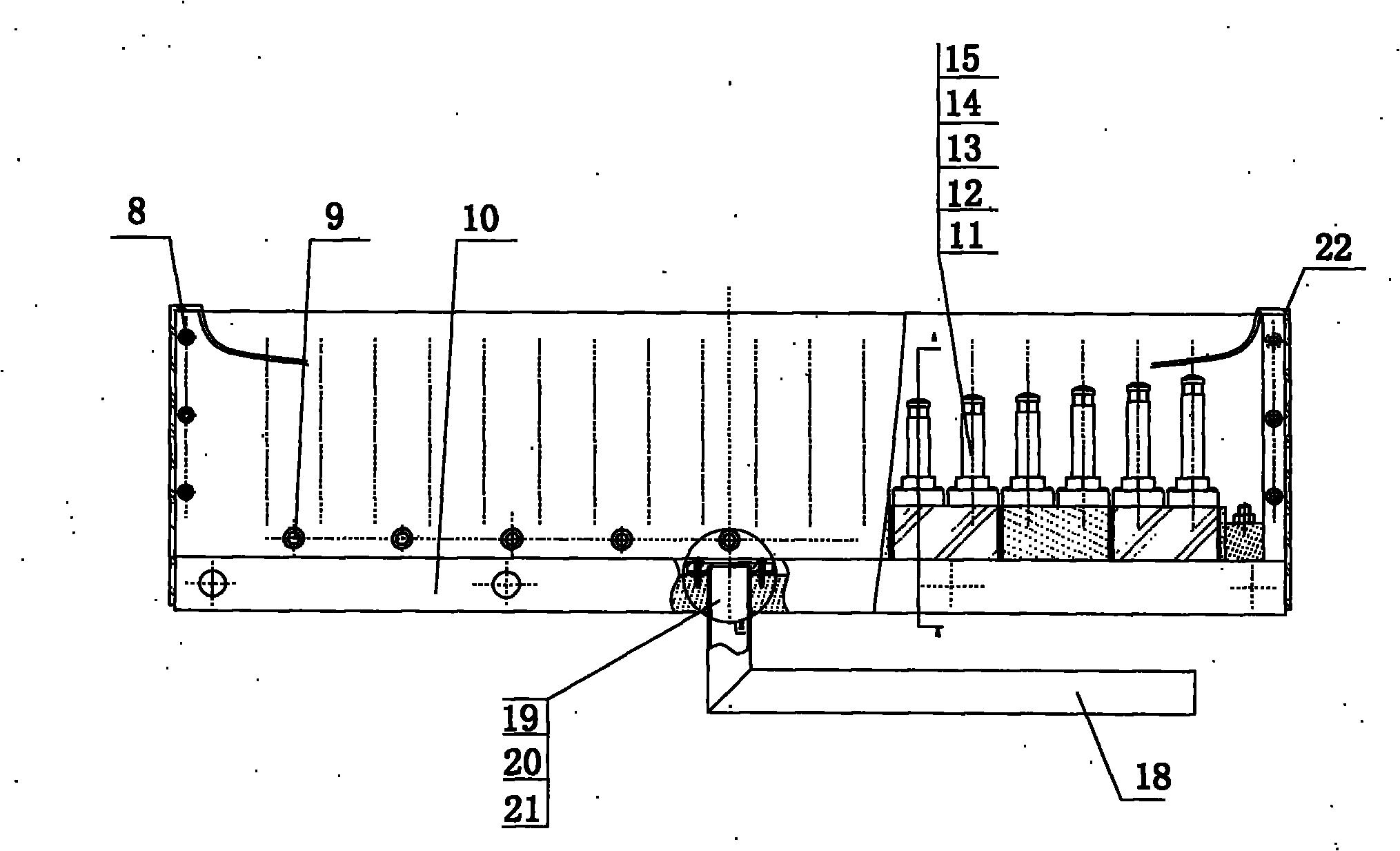

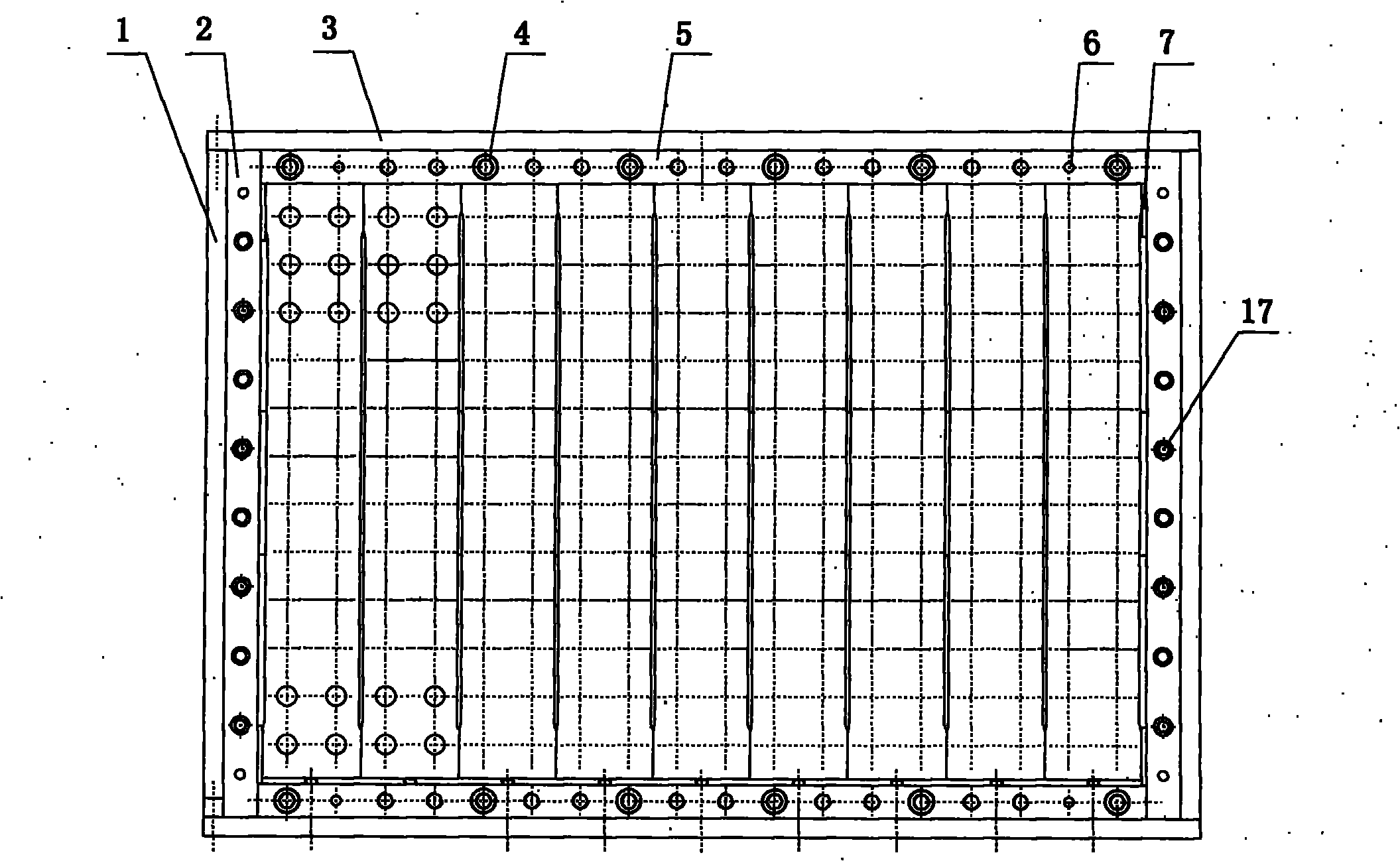

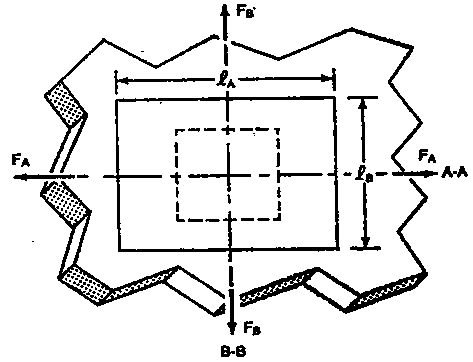

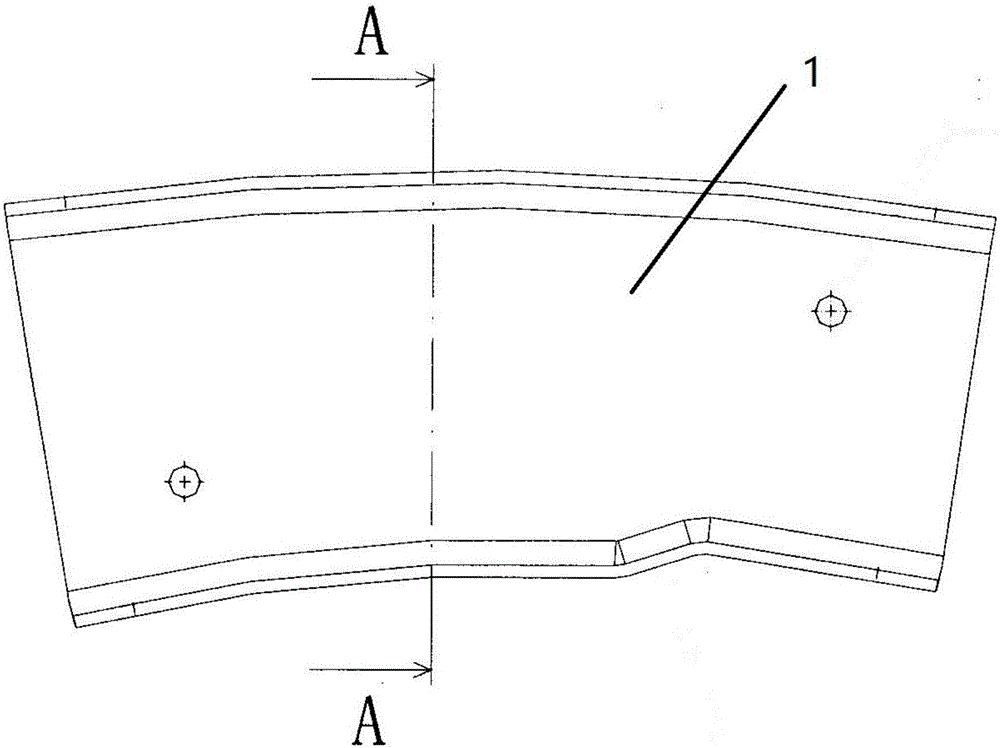

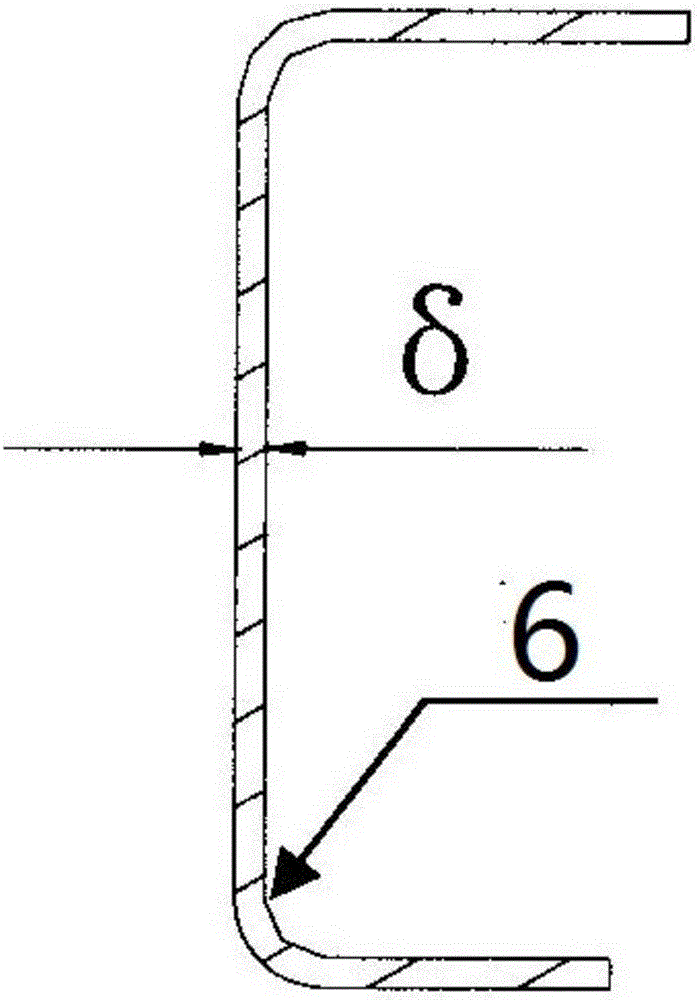

Autoclave-based creep age forming flexible frock

The invention discloses an autoclave-based creep age forming flexible frock, which comprises a vacuum bag, a bottom plate, a high frame, a low frame, nail battens, four gaskets, an adjusting stud, a fixed plate and an air exhaust hose, wherein the bottom plate is provided with a pin hole and a threaded hole; the high frame has a frame body consisting of two short high frames and two long high frames, and the vacuum bag is covered on the high frame and a piece to be formed; the low frame has a frame body consisting of two short low frames and two long low frames, the high frame is fixed at theperiphery of the low frame, and both the high frame and the low frame are fixed on the bottom plate; the nail battens are arranged on the bottom plate in parallel and fixed in the frame body of the low frame through side bolts; the four gaskets are arranged between the inner wall of the low frame and the nail battens; the lower part of the adjusting stud taps the screw thread which is used for forming the fixed plate with a screw thread pair; the central position of the fixed plate taps the screw thread hole which is used for forming the screw thread pair with the adjusting stud, the adjusting stud is fixed on the fixed plate, and then the fixed plate and the adjusting stud are fixed on the nail battens; and the air exhaust hose is connected to an air exhaust tube nozzle which penetrates and is fixed on the corresponding hole of the bottom plate and is hermetically connected through a silicon rubber gasket.

Owner:BEIHANG UNIV +1

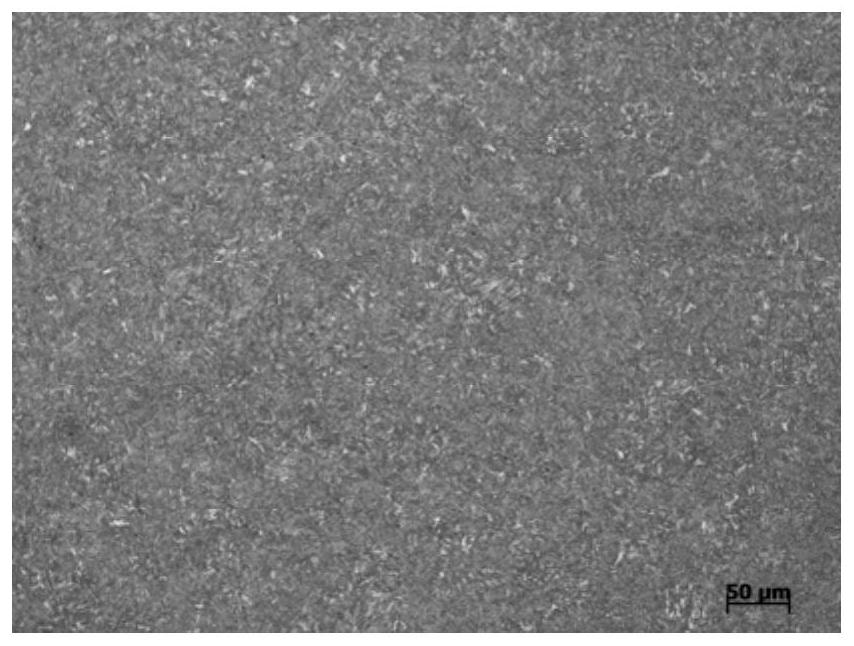

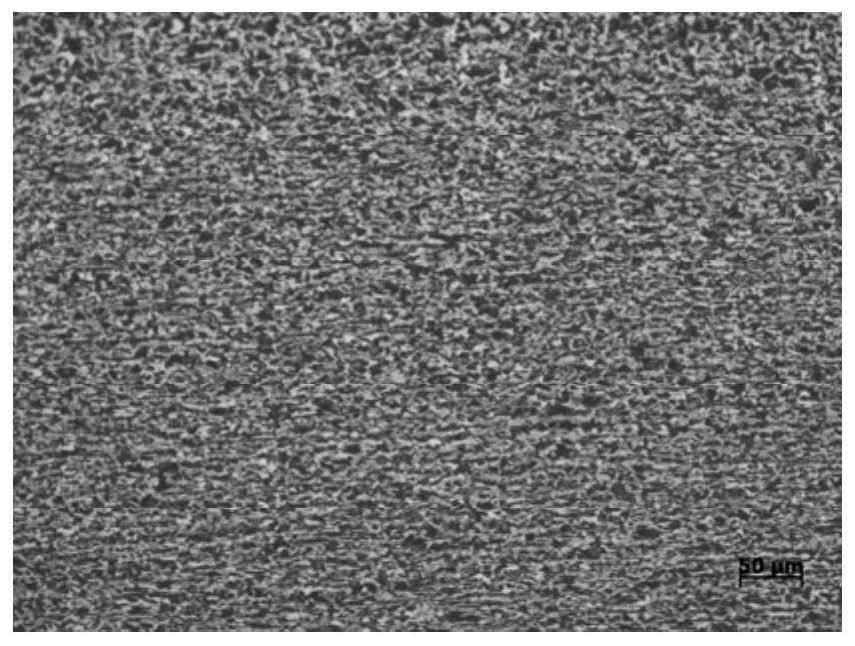

Automotive high manganese steel and manufacturing method thereof

The invention discloses automotive high manganese steel. The steel comprises the following chemical components in percent by weight: 0.55-0.64 percent of C, 0-0.01 percent of Si, 23.5-24.4 percent of Mn, 0-0.015 percent of P, 0.45-0.54 percent of Nb, 0.02-0.06 percent of Als, 0-0.01 percent of S, 0-0.003 percent of N and the balance of Fe and inevitable impurities. The method for manufacturing the steel comprises the following steps of controlling temperature for heating a continuous casting billet to be 1220-1280 DEG C, controlling temperature of rough rolling to be 1050-1100 DEG C, controlling the finishing temperature to be 910-950 DEG C through finish rolling, rolling at the temperature of 680-720 DEG C, controlling a total reduction rate to be 67-80 percent through cold rolling, and controlling the continuous annealing temperature to be 800-850 DEG C through controlled cooling. The steel component design is optimized, and the production process is controlled, so that high-strength Fe-Mn-C-Nb TWIP steel is obtained and can be used for punching automotive safety parts or structural components. The obtained product has relatively high yield strength and plasticity, and the safety of parts in the actual vehicle using process is improved when the requirement for forming complex parts is met.

Owner:武汉钢铁有限公司

Superplastic forming method of 1Cr21Ni5Ti duplex stainless steel complex section ring piece

The invention discloses a superplastic forming method of a 1Cr21Ni5Ti duplex stainless steel complex section ring piece. The superplastic forming method comprises the following steps: heating 1Cr21Ni5Ti duplex stainless steel to 1,000-1,200 DEG C, repetitively conducting upsetting and drawing until total forging deformation reaches 55-70 percent, heating to 1,250 DEG C at the heating speed of 2 DEG C per second, and preserving heat for 30 minutes to obtain a fine-grained 1Cr21Ni5Ti duplex stainless steel blank; heating the blank to forging temperature, and conducting upsetting, punching and height flattening to obtain an alloy ring blank; at temperature of 940-980 DEG C, rolling the alloy ring blank at the maximum feeding speed of 2.8mm / s to obtain the 1Cr21Ni5Ti duplex stainless steel complex section ring piece. The method can enable 1Cr21Ni5Ti duplex stainless steel to be in a superplastic state during formation, and thus the 1Cr21Ni5Ti duplex stainless steel complex section ring piece with performance and dimension which satisfy the requirements is obtained. The ring piece is mainly used as a connecting ring, a bearing ring or the like and is widely used on mechanical equipment in the industrial fields such as aviation and space flight.

Owner:GUIZHOU ANDA AVIATION FORGING

Grid strain analysis method for thin plate forming and application of method

The invention discloses a grid strain analysis method for thin plate forming and an application of the method, and relates to forming production techniques of metal materials such as automobiles and small metal components. The method comprises the following steps: firstly, directly drawing grid lines with the same length in a centralized limited strain area for forming metal plate workpieces and on the surface of metal plates, after stamping deforming, measuring direct deformation values of the grid lines with wrinkles or cracks in the centralized limited strain area, and respectively adjusting the process according to the calculated deformation situations. The method can be applied to stamping sites at any time, and is generally not limited by conditions. The method can be widely popularized and used in production lines, and is low in cost and easy to master.

Owner:YIZHENG SHENWEI STAMPING

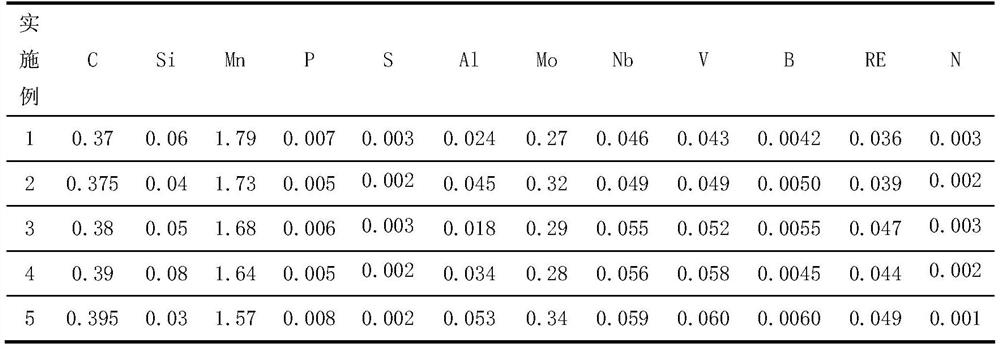

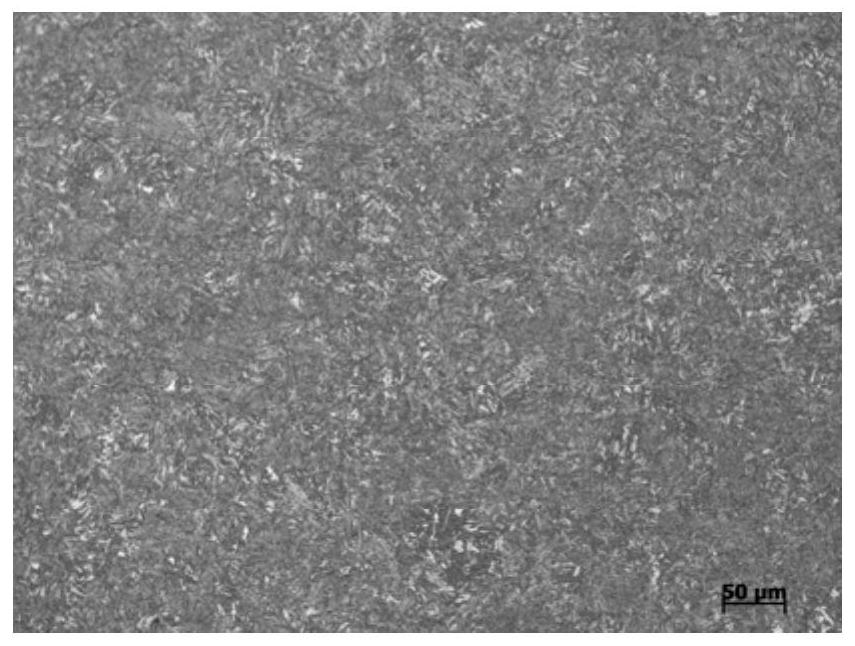

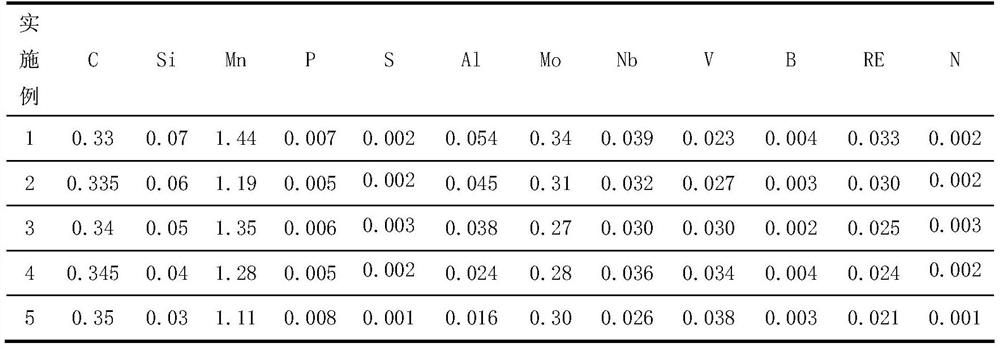

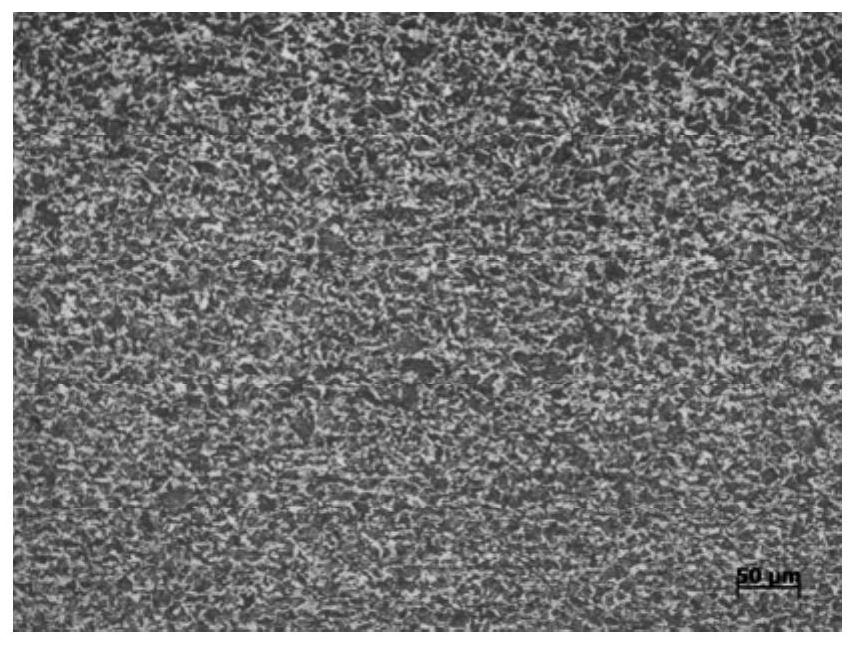

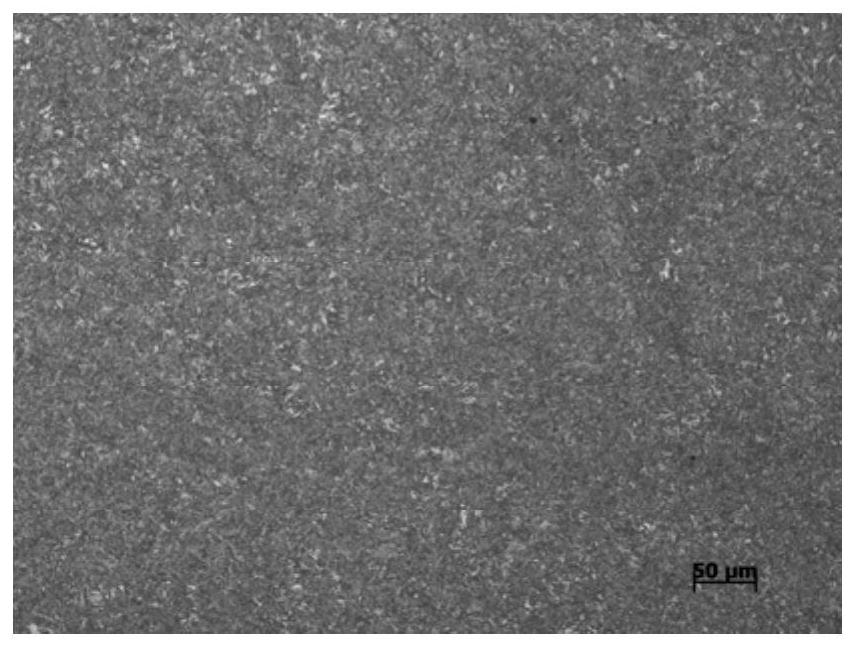

2,000 MPa-grade acid pickling steel plate for hot stamping wheel rim and manufacturing method of acid pickling steel plate

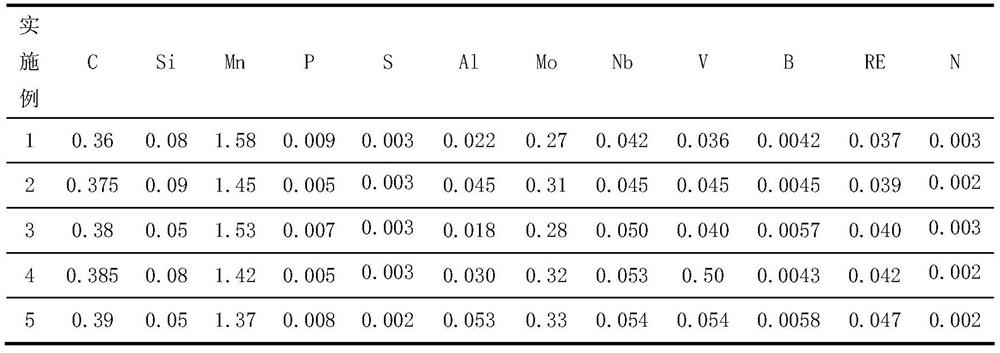

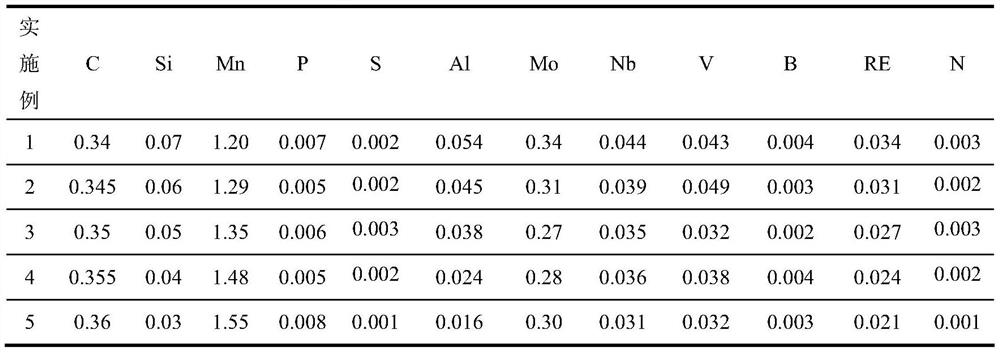

The invention discloses a 2,000 MPa-grade acid pickling steel plate for a hot stamping wheel rim and a manufacturing method of the acid pickling steel plate. The 2,000 MPa-grade pickled steel plate comprises 0.36%-0.39% of C, 0.01%-0.10% of Si, 1.36%-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.015%-0.055% of Al, 0.041%-0.055% of Nb, 0.035%-0.055% of V, 0.26%-0.35% of Mo, 0.0041%-0.006% of B, 0.035%-0.050% of rare earth elements La and Ce, equal to or less than 0.003% of N and the balance of Fe and unavoidable impurities.

Owner:ANGANG STEEL CO LTD

800MPa-grade high-cold-bending cold-rolling dual-phase steel plate and preparation method thereof

The invention relates to 800MPa-grade high-cold-bending cold-rolling dual-phase steel. A steel plate comprises the following chemical components in percentage by weight: 0.05-0.09 of C, 0.01-0.05 of Si, 1.7-2.2 of Mn, 0.01-0.04 of Nb, 0.01-0.04 of Ti, 0.1-0.5 of Cr, 0.15-0.3 of Mo, 0.015 of P or less, 0.01 of S or less, 0.3-0.8 of Als, 0.005 of N or less, and the balance of Fe and inevitable impurities. The invention further relates to a preparation method of the 800MPa-grade high-cold-bending cold-rolling dual-phase steel, wherein an annealing process is a continuous annealing process, the strip steel is heated to 800-850 DEG C at a heating rate of 1-3 DEG C / s, and slow cooling is conducted to 700-750 DEG C at the speed of 2-4 DEG C / s after heat preservation is conducted for 120-150 s; air cooling is adopted for rapid cooling, and then rapid cooling is conducted to 250-300 DEG C at the cooling speed of 10-20 DEG C / s; and overaging treatment is conducted for 250-400 s, wherein the smooth elongation is 0.2%-0.5%.

Owner:HANDAN IRON & STEEL GROUP +1

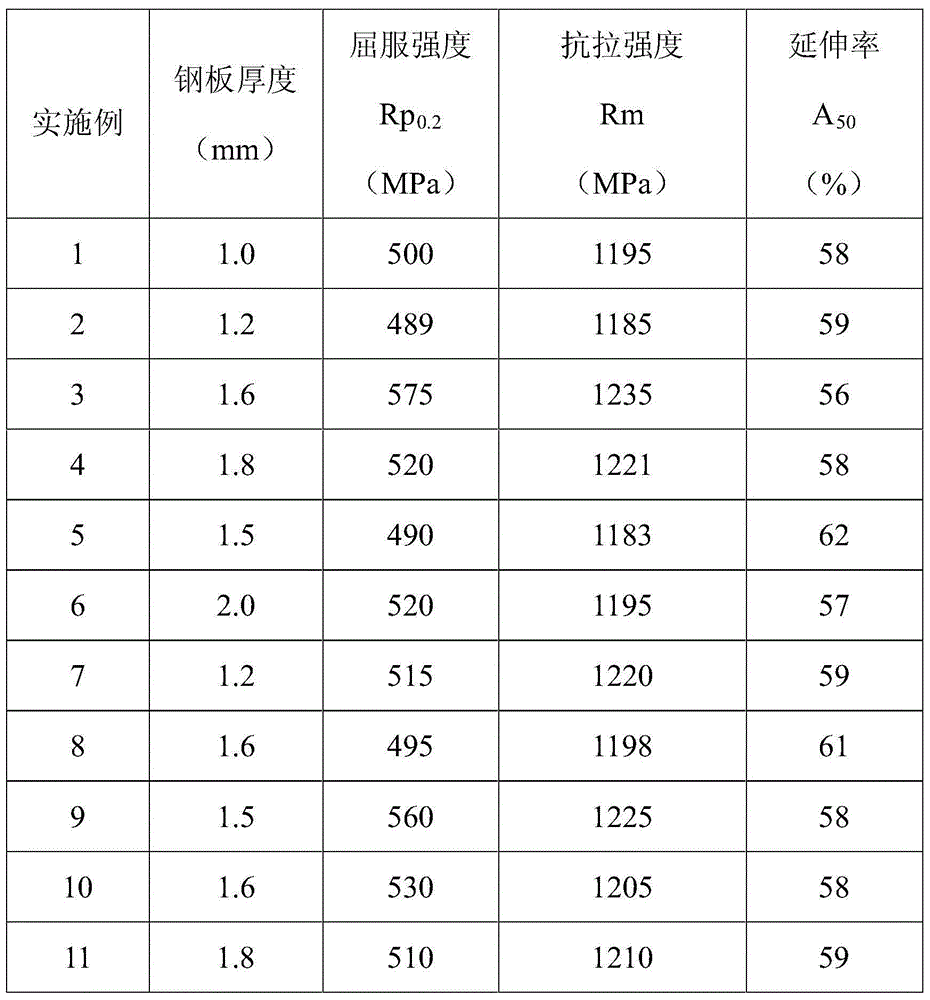

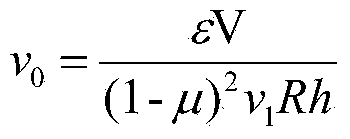

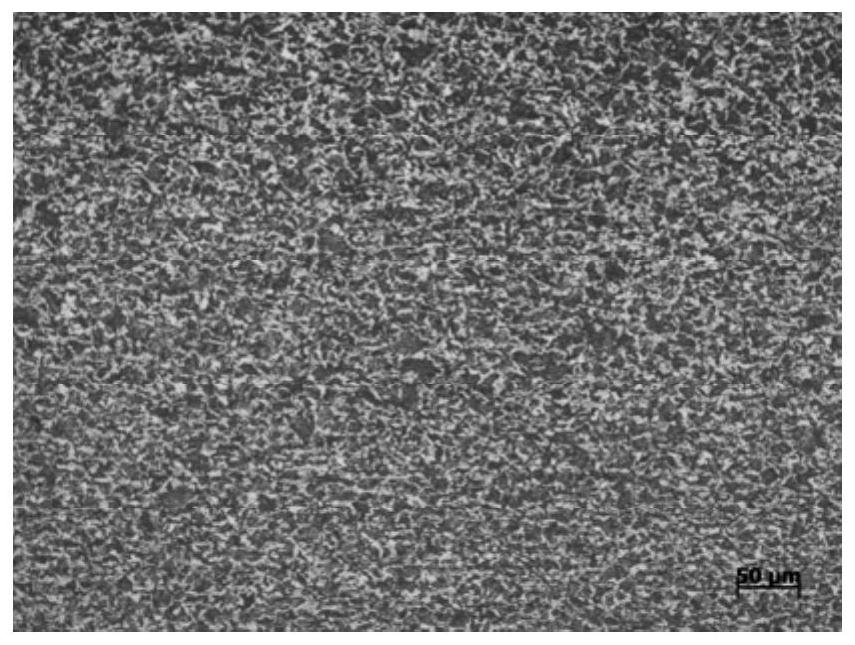

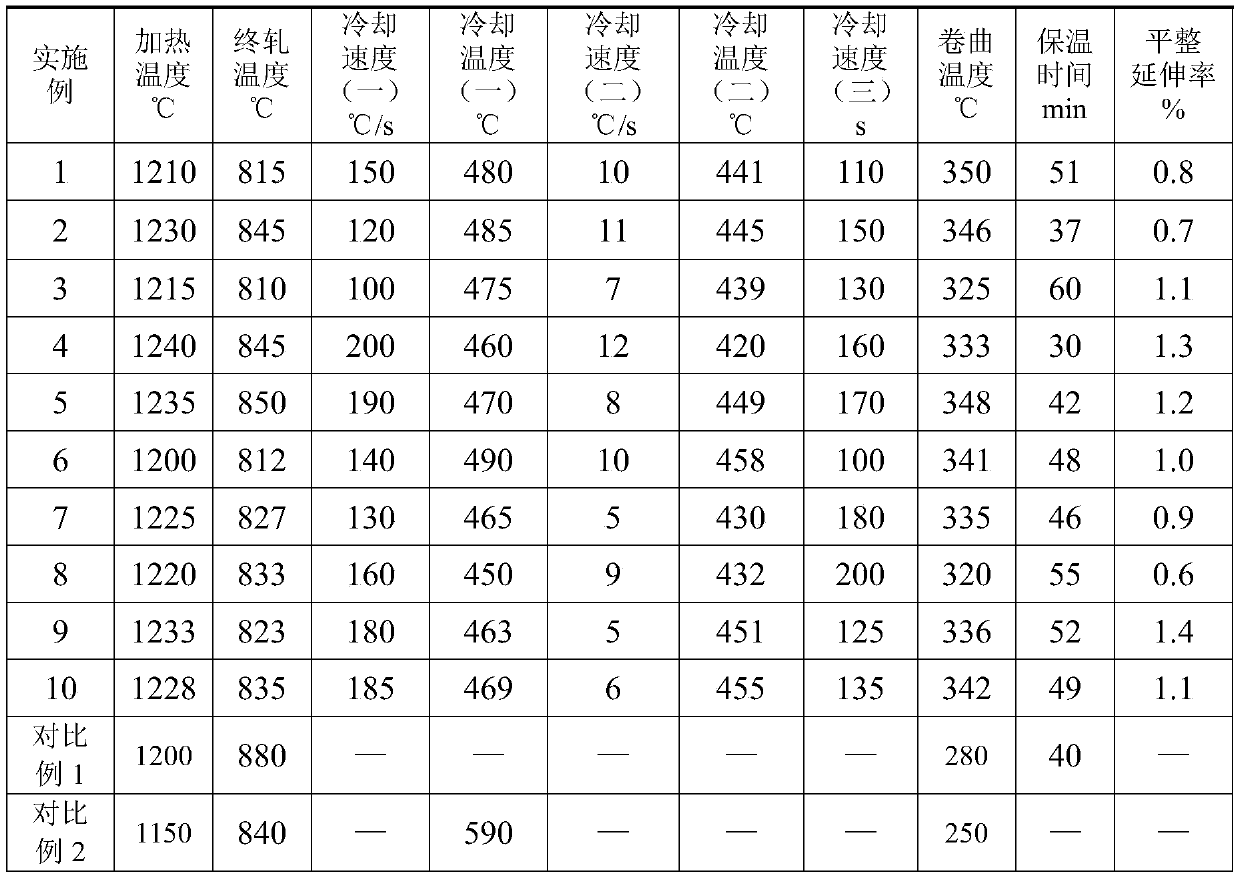

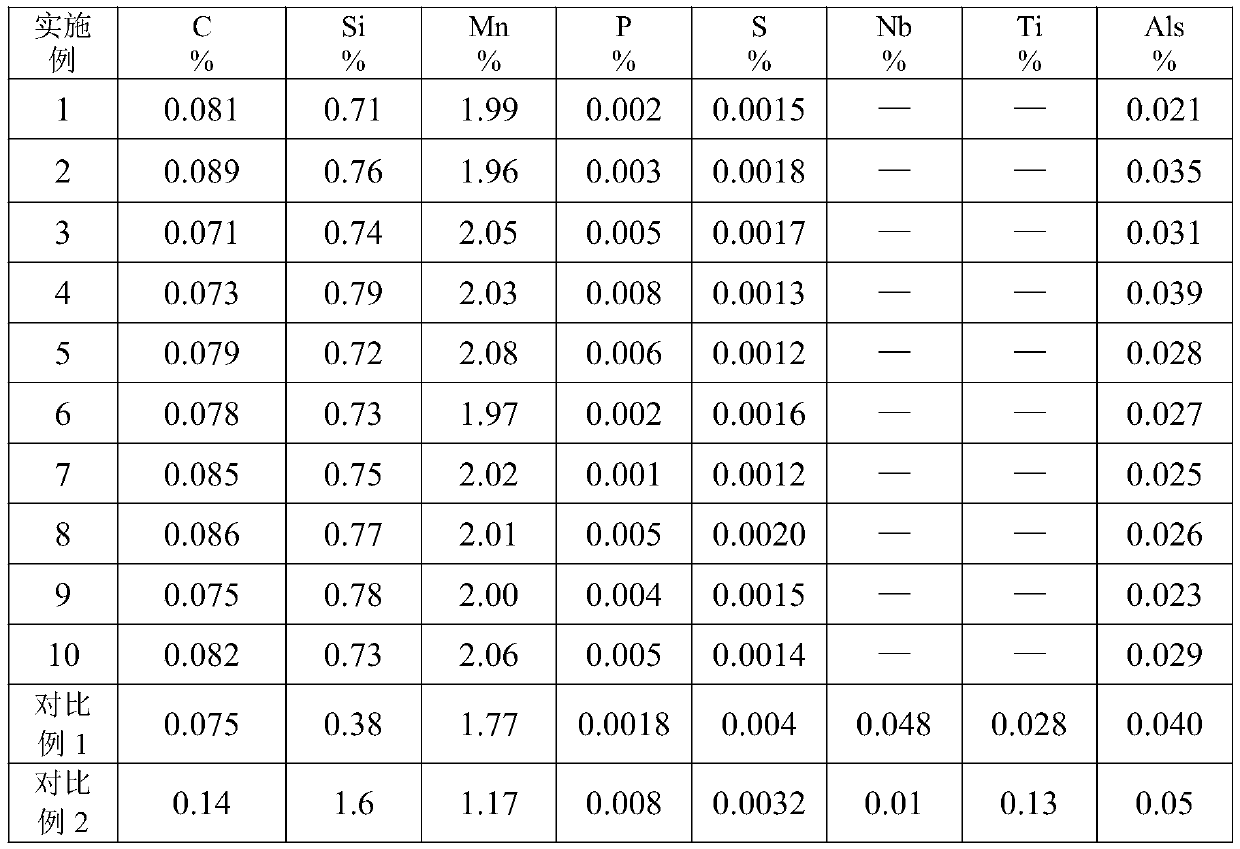

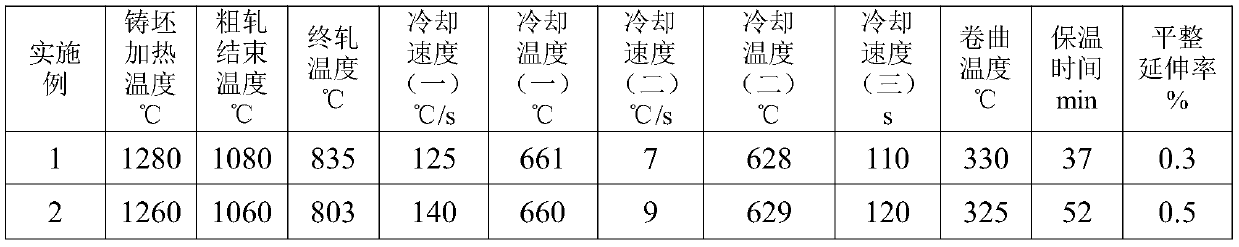

High-elongation hot-rolled structure regulated and controlled steel with tensile strength greater than or equal to 1200 MPa and production method

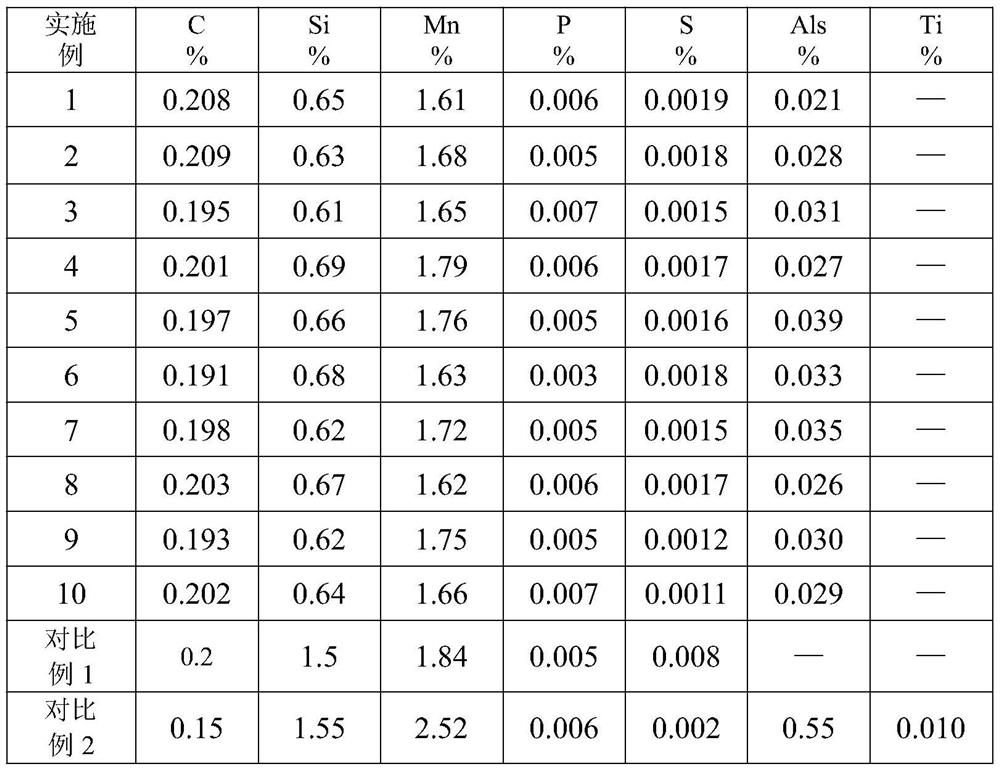

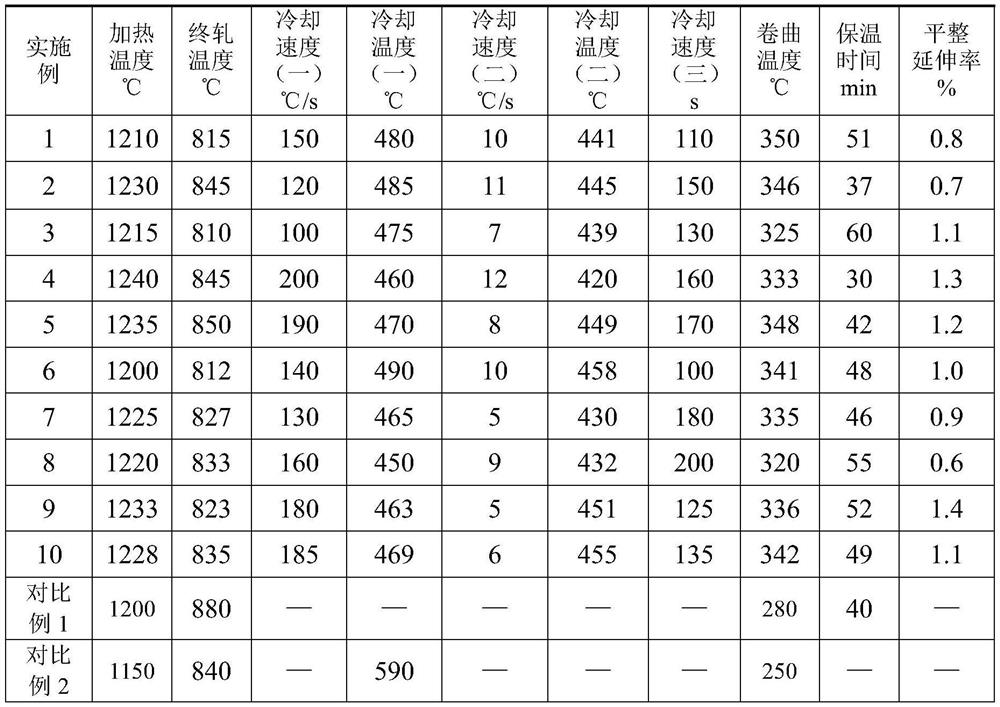

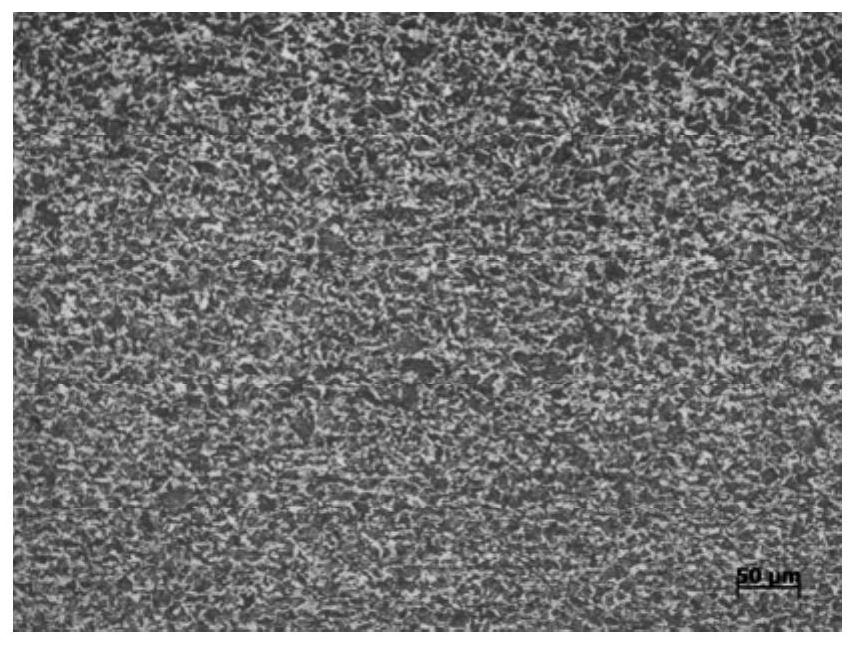

The invention discloses high-elongation hot-rolled structure regulated and controlled steel with the tensile strength greater than or equal to 1200 MPa. The steel comprises the following components of, by weight, 0.19%-0.21% of C, 1.60%-1.80% of Mn, 0.60%-0.70% of Si, less than or equal to 0.008% of P, less than or equal to 0.002% of S and 0.02%-0.04% of Als. The production method comprises the following steps that smelting is performed by a converter, and then RH vacuum furnace treatment is performed; a casting blank is heated; staged rolling is performed; staged variable-speed cooling is performed; coiling is performed; heat preservation is performed; and leveling treatment is performed. According to the steel and the production method, under the condition that Nb, V, Mo and other alloysare not added, it can be guaranteed that the tensile strength is 1200 MPa or above, the elongation is greater than or equal to 15%, the thickness of a steel plate is 7-12 mm, then the forming requirement of thick-specification high-strength steel can be met, and the alloy cost is reduced by at least 10%.

Owner:武汉钢铁有限公司

2000MPa-grade hot-stamped vehicle wheel spoke hot-rolled steel plate and fabrication method thereof

The invention discloses a 2000MPa-grade hot-stamped vehicle wheel spoke hot-rolled steel plate and a fabrication method thereof. The hot rolled steel plate comprises the chemical ingredients of, in percentage by mass, 0.37-0.40% of C, 0.01-0.10% of Si, 1.56-1.80% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.015-0.055% of Al, 0.046%-0.060% of Nb, 0.041-0.060% of V,0.26-0.35% of Mo, 0.0041-0.006% of B, 0.035-0.050% of rare earth elements La+Ce, less than or equal to 0.003% of N and the balance Fe and inevitable impurities.

Owner:ANGANG STEEL CO LTD

Super-plasticity forming method for GH4169 alloy ring part with complex section

The invention discloses a super-plasticity forming method for a GH4169 alloy ring part with a complex section. The method comprises the steps that GH4169 alloy is heated to the temperature of 1000+ / -10 DEG C, after forge deformation with deflection of 40%-50%, the temperature is kept at 890 DEG C for 10 hours, then raised to 950 DEG C and kept for 3 hours, and a crystal GH4169 alloy blank is obtained; the GH4169 alloy blank is heated to forge temperature, and an alloy ring blank is obtained through upsetting, punching and levelling; the alloy ring blank is rapidly rolled and formed at the maximum feed speed of 1.7 mm / s at the temperature of 1060-1080 DEG C, and the GH4169 alloy ring part with the complex section is obtained. According to the method, the GH4169 alloy can be in a super-plasticity state in the forming process, so that the GH4169 alloy ring part with the complex section and both the performance and the size meeting requirements is obtained. The ring part is mainly taken as a connection ring, a bearing ring and the like to be widely applied to mechanized equipment in the industry areas such as aviation and aerospace.

Owner:GUIZHOU ANDA AVIATION FORGING

Superplastic forming method of complex section ring part of TC11 titanium alloy

The invention discloses a superplastic forming method of a complex section ring part of a TC11 titanium alloy. The superplastic forming method comprises the following steps: the TC11 titanium alloy is heated to 1030-1050 DEG C for undergoing one-way elongation with the total deformation being 20%-40%, and then is air-cooled; the TC11 titanium alloy is heated again to 950-980 DEG C for undergoing repeated upsetting and elongation with the total deformation being 40-65%, and then is air-cooled; the TC11 titanium alloy is kept at the temperature of 950 DEG C for 1.5 hours and then is air-cooled; the TC11 titanium alloy is kept at the temperature of 530 DEG C for 6 hours and then is air-cooled; a fine-grain TC11 titanium alloy blank is thus obtained, and then is heated to the forging temperature, and is upset, punched and leveled to obtain an alloy ring blank; and the rolling formation is performed at the temperature of 880-900 DEG C at the maximal feeding speed of 2.0 mm / s to obtain the complex section ring part of the TC11 titanium alloy. The method can enable the TC11 titanium alloy to be in a superplastic state in the forming process so as to obtain the complex section ring part of the TC11 titanium alloy; and the properties and the size of the complex section ring part both satisfy the requirements. The ring part, mainly serving as a connecting ring and a bearing ring, is widely applied to mechanical equipment of such industrial fields as the aviation field and the aerospace field.

Owner:GUIZHOU ANDA AVIATION FORGING

2000MPa-grade hot-rolled steel plate for hot-stamped wheel rim and manufacturing method of 2000MPa-grade hot-rolled steel plate

The invention discloses a 2000MPa-grade hot-rolled steel plate for a hot-stamped wheel rim and a manufacturing method of the 2000MPa-grade hot-rolled steel plate. The 2000MPa-grade hot-rolled steel plate comprises 0.36%-0.39% of C, 0.01%-0.10% of Si, 1.46%-1.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.015%-0.055% of Al, 0.041%-0.055% of Nb, 0.030%-0.050% of V, 0.26%-0.35% of Mo, 0.0041-0.006% of B, 0.035%-0.050% of of rare earth elements La+Ce, less than or equal to 0.003% of N, and the balance Fe and inevitable impurities.

Owner:ANGANG STEEL CO LTD

Sheet metal part sagging compensation design method

ActiveCN105046035AMeet the forming requirementsGuaranteed expanded sizeSpecial data processing applicationsBorder lineDesign methods

The invention discloses a sheet metal part sagging compensation design method comprising steps of first, expanding a data set of a sagging sheet material part, second, selecting a critical point of sagging end head deformation of a bend side of the sheet material part in the data set as a sagging compensation start point (C), third, designing a maximum value point (B) of expansion value of the sheet material part in the data set to acquire a line section (BC) and connecting points (B, C) to form a line section (BC), fourth, acquiring a tangent line to a sagging arc of the sheet material part via the B point in the data set, and fifth, chamfering between the line section (BC) and a line section (BD) to form a sealed area, then achieving sagging expansion compensation. In the first step, an outline border line of the sagging part in the data set is designated to be L3; the outline border line of one side of the sagging part of the sheet material part is designated to be L1; L1 and L3 are adjacent to each other; a tangency point between the tangent line and the sagging arc is D; and points (D, B) are connected to form a line section (BD). Sheet material part blanking accuracy and work efficiency can be improved; and manufacturing cost can be reduced.

Owner:SHENYANG AIRCRAFT CORP

High manganese steel for automobiles and manufacturing method thereof

The invention discloses automotive high manganese steel. The steel comprises the following chemical components in percent by weight: 0.55-0.64 percent of C, 0-0.01 percent of Si, 23.5-24.4 percent of Mn, 0-0.015 percent of P, 0.45-0.54 percent of Nb, 0.02-0.06 percent of Als, 0-0.01 percent of S, 0-0.003 percent of N and the balance of Fe and inevitable impurities. The method for manufacturing the steel comprises the following steps of controlling temperature for heating a continuous casting billet to be 1220-1280 DEG C, controlling temperature of rough rolling to be 1050-1100 DEG C, controlling the finishing temperature to be 910-950 DEG C through finish rolling, rolling at the temperature of 680-720 DEG C, controlling a total reduction rate to be 67-80 percent through cold rolling, and controlling the continuous annealing temperature to be 800-850 DEG C through controlled cooling. The steel component design is optimized, and the production process is controlled, so that high-strength Fe-Mn-C-Nb TWIP steel is obtained and can be used for punching automotive safety parts or structural components. The obtained product has relatively high yield strength and plasticity, and the safety of parts in the actual vehicle using process is improved when the requirement for forming complex parts is met.

Owner:武汉钢铁有限公司

Method for preparing high-entropy reinforced amorphous alloy composite material

PendingCN113953528AGood physical and chemical compatibilityImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysPowder

The invention belongs to the technical field of amorphous alloy preparation, and relates to a method for preparing a high-entropy reinforced amorphous alloy composite material. The method comprises the following steps that amorphous alloy powder and high-melting-point high-entropy alloy powder with high toughness are evenly mixed according to a designed volume fraction, the mixed powder is conveyed out through airflow with supersonic speed, and the mixed powder and a laser focus are converged at a position 2-30mm above a deposition substrate; the amorphous alloy powder is heated to be in a molten state through laser suspension, meanwhile, the amorphous alloy powder is blown and cooled to be in a supercooled liquid state through supersonic airflow in the process of flying to the deposition substrate, an amorphous alloy matrix is deposited on the substrate, the high-entropy alloy powder is kept not molten all the time in the process, and finally, the high-entropy alloy powder is uniformly distributed in amorphous alloy formed by deposition in a reinforced phase form; the melting point of the high-entropy alloy powder is higher than that of the amorphous alloy powder; and an amorphous alloy composite material part without size constraint can be prepared, and the material has the performance advantages of high strength and high toughness.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Superplastic Forming Method of tc11 Titanium Alloy Complicated Cross Section Annular Parts

The invention discloses a method for superplastic forming of a TC11 titanium alloy ring with complex cross-section. The steps are as follows: heating the TC11 titanium alloy to 1030-1050°C, elongating in one direction, with a total deformation of 20%-40%, and air cooling ; Reheat to 950-980°C, repeatedly upsetting and elongating, the total deformation is 40%-65%, air cooling; then keep at 950°C for 1.5 hours, air-cooling; keep at 530°C for 6 hours, air-cooling; get fine crystal TC11 titanium alloy blank; reheated to forging temperature, through upsetting, punching, and flat height, to obtain the alloy ring blank; at a temperature of 880-900°C, rolling at a maximum feed speed of 2.0mm / s Forming to obtain TC11 titanium alloy complex section ring. The method enables the TC11 titanium alloy to be in a superplastic state during the forming process, thereby obtaining a TC11 titanium alloy complex cross-section annular part that meets requirements in performance and size. The ring is mainly used as a connecting ring, a bearing ring, etc., and is widely used in mechanical equipment in aviation, aerospace and other industrial fields.

Owner:GUIZHOU ANDA AVIATION FORGING

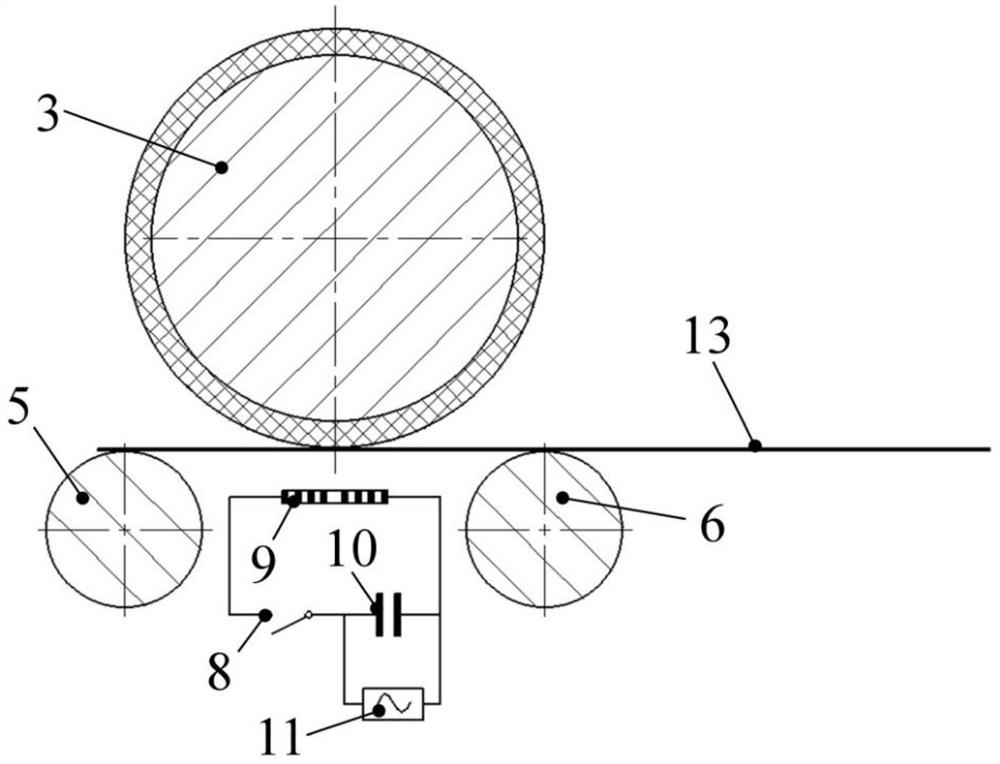

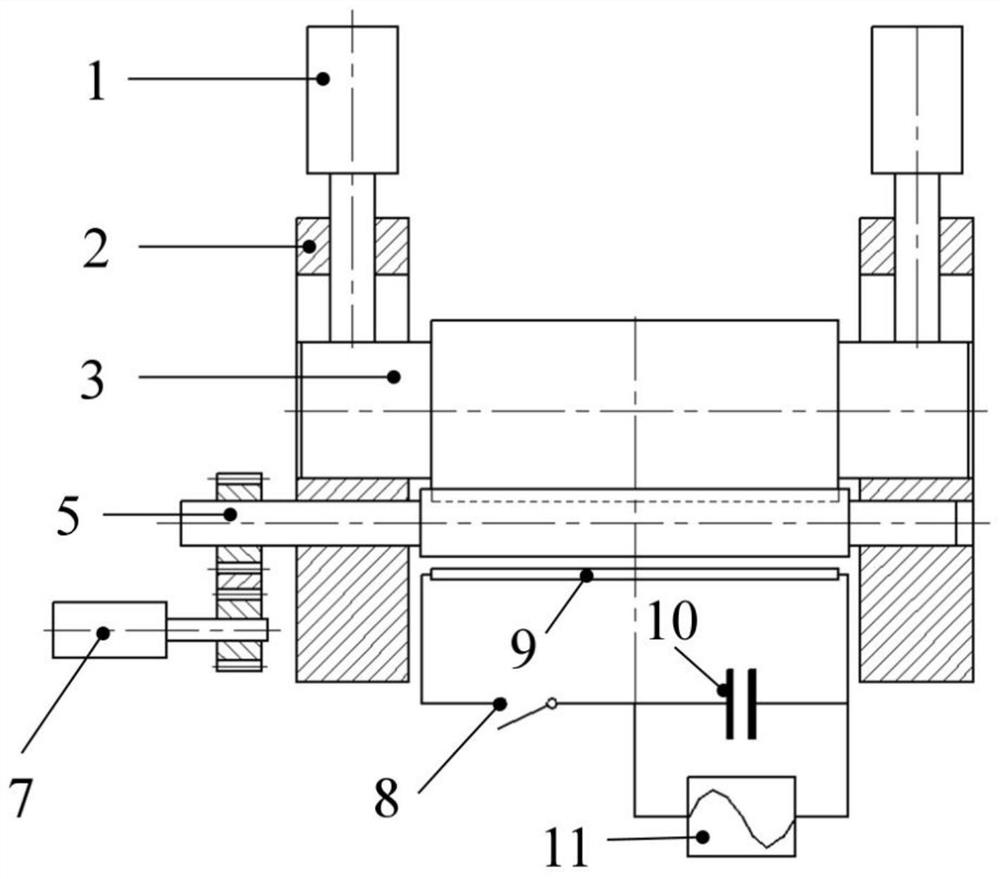

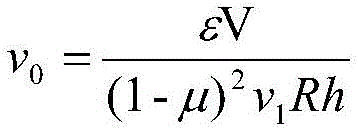

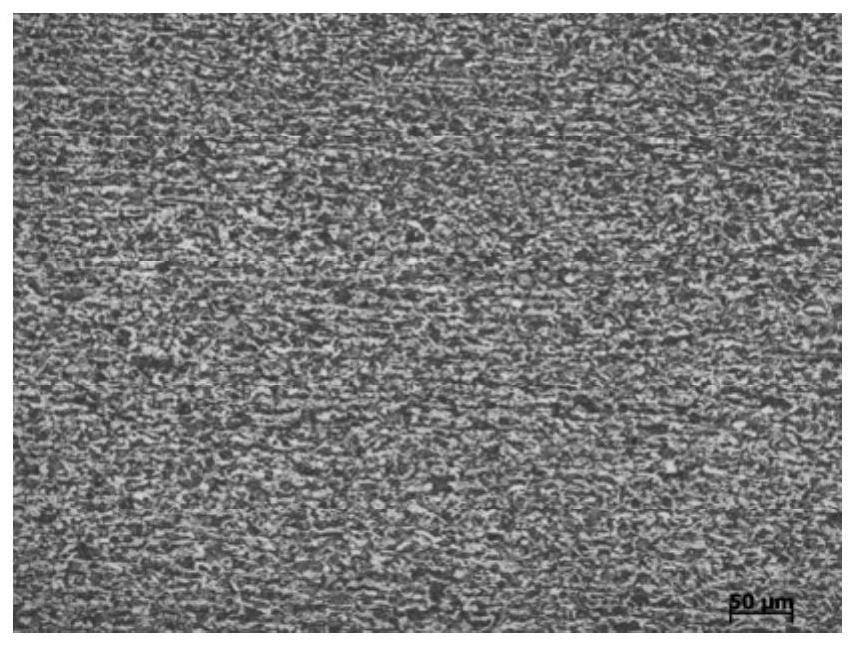

Electromagnetic auxiliary roll bending forming method and forming device thereof

The electromagnetic auxiliary roll bending forming method comprises the following steps that an elastic roller is used for pressing a plate to be bent and deformed, and the plate with an inner arc face and an outer arc face is formed; the downward pressing position of the elastic roller is kept, and periodic electromagnetic pulse discharging is conducted on the plate on the outer cambered surface of the plate; during discharge amplification, the plate is reversely bent and deformed under electromagnetic loading, and meanwhile, the elastic surface of the compression elastic roller is deformed; during discharge attenuation, the elastic surface of the elastic roller recovers deformation and forces the plate to reset; and the plate is driven to continuously move in the roll bending direction, and meanwhile periodic electromagnetic pulse discharging is continuously conducted till the continuous roll bending arc length of the plate is larger than or equal to the forming target arc length. Local reverse bending and local bending are periodically and alternately carried out on the plate, the plastic forming performance of the plate can be improved, rebound of the plate after roll bending is restrained, and the surface quality and forming precision of the formed small-curvature thin-wall bent part are improved.

Owner:NANJING FORESTRY UNIV

Superplastic Forming Method of LC4 Aluminum Alloy Ring with Complicated Section

The invention discloses a super-plasticity forming method for an LC4 aluminum alloy ring part with a complex section. The method comprises the steps that an LC4 aluminum alloy is heated to the temperature of 460+ / -10 DEG C, the temperature is kept for 2 hours, and water cooling is performed; the LC4 aluminum alloy is heated to the temperature of 380+ / -10 DEG C, the temperature is kept for 6 hours, and water cooling is performed; the alloy is heated to the temperature of 200+ / -10 DEG C, after forge deformation with deflection larger than or equal to 80%, the temperature is kept at 460+ / -10 DEG C for 30 minutes, water cooling is performed, and a crystal LC4 aluminum alloy blank is obtained; the LC4 aluminum alloy blank is rapidly rolled and formed at the maximum feed speed of 2.6 mm / s at the temperature of 480-510 DEG C, and the LC4 aluminum alloy ring part with the complex section is obtained. According to the method, the LC4 aluminum alloy can be in a super-plasticity state in the forming process, so that the LC4 aluminum alloy ring part with the complex section and both the performance and the size meeting requirements is obtained. The ring part is mainly taken as a connection ring, a bearing ring and the like to be widely applied to mechanized equipment in the industry areas such as aviation and aerospace.

Owner:GUIZHOU ANDA AVIATION FORGING

Hot-rolled steel plate for 2000mpa class hot-stamped wheel spokes and manufacturing method thereof

The invention discloses a hot-rolled steel plate for 2000MPa grade hot stamping wheel spokes and a preparation method thereof, C: 0.37%-0.40%, Si: 0.01%-0.10%, Mn: 1.56%-1.80%, P: ≤0.010%, S: ≤0.004%, Al: 0.015%‑0.055%, Nb: 0.046‑0.060%, V: 0.041‑0.060%, Mo: 0.26‑0.35%, B: 0.0041‑0.006%, rare earth element La+Ce: 0.035% ‑0.050%, N≤0.003%, the balance is Fe and unavoidable impurities.

Owner:ANGANG STEEL CO LTD

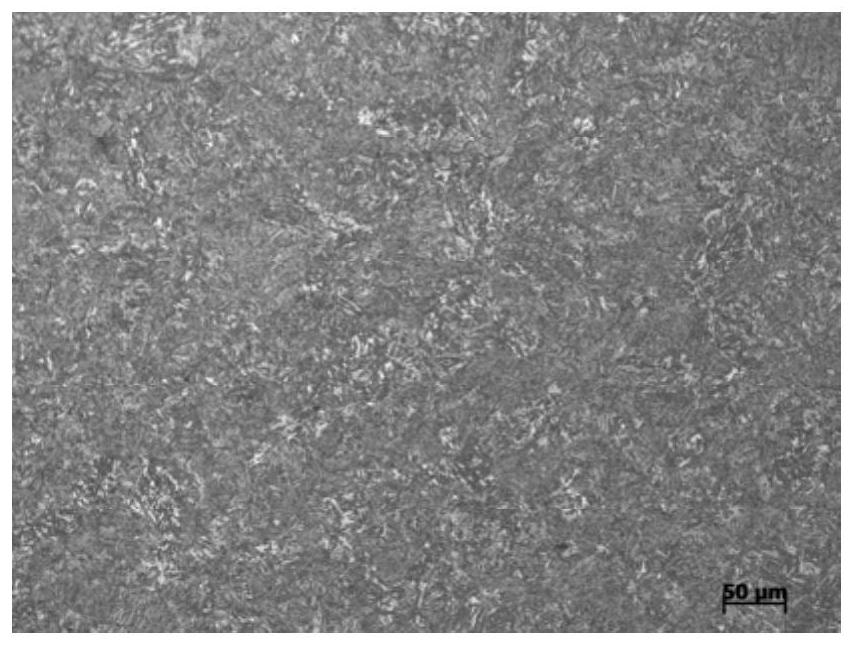

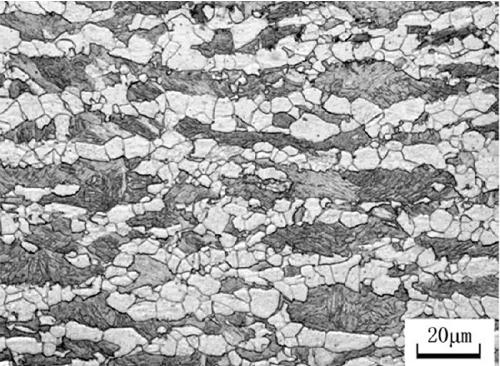

A high-elongation hot-rolled structure control steel with tensile strength ≥ 800mpa and production method

ActiveCN111334701BMeet the forming requirementsLow costTemperature control deviceFurnace typesUltimate tensile strengthMicrostructure

A high-elongation hot-rolled structure control steel with a tensile strength ≥ 800MPa, the composition and weight percentage of which are: C: 0.07-0.09%, Mn: 1.95-2.10%, Si: 0.70-0.80%, P≤0.008 %, S≤0.002%, Als: 0.02~0.04%; production method: RH vacuum furnace treatment after converter smelting; heating of cast slab; segmental rolling; segmental variable speed cooling: coiling; Under the premise of ensuring the tensile strength above 800MPa, the present invention makes the yield strength ≥ 500MPa, the elongation ≥ 25%, the strength-plastic product ≥ 20GPa%, and the yield-strength ratio < 0.65, which can meet the forming requirements of thick-gauge high-strength steel. Moreover, the alloying elements are simple, and precious alloys such as Nb, V, and Mo are not added, and the cost of the alloy can be reduced by at least 10%.

Owner:武汉钢铁有限公司

A high-elongation hot-rolled structure control steel with tensile strength ≥ 1200mpa and production method

ActiveCN111270160BLow costMeet the forming requirementsHeat treatment process controlAlloyMicrostructure

A high-elongation hot-rolled structure control steel with a tensile strength ≥ 1200MPa, the composition and weight percentage of which are: C: 0.19-0.21%, Mn: 1.60-1.80%, Si: 0.60-0.70%, P≤0.008 %, S≤0.002%, Als: 0.02%~0.04%; production method: RH vacuum furnace treatment after converter smelting; heating of billet; segmental rolling; segmental variable speed cooling: coiling; . Without adding Nb, V, Mo and other alloys, the invention can not only ensure the tensile strength above 1200MPa, but also make the elongation ≥ 15%, and the thickness of the steel plate is 7~12mm, so as to meet the forming requirements of thick gauge high strength steel. , and reduce the alloy cost by at least 10%.

Owner:武汉钢铁有限公司

Pickled steel plate for 2000mpa grade hot stamping wheel rim and manufacturing method thereof

The invention discloses a 2000MPa grade hot stamping wheel rim pickling steel plate and a preparation method thereof, C: 0.36%-0.39%, Si: 0.01%-0.10%, Mn: 1.36%-1.60%, P: ≤0.010%, S: ≤0.004%, Al: 0.015%‑0.055%, Nb: 0.041‑0.055%, V: 0.035‑0.055%, Mo: 0.26‑0.35%, B: 0.0041‑0.006%, rare earth element La+Ce: 0.035% ‑0.050%, N≤0.003%, the balance is Fe and unavoidable impurities.

Owner:ANGANG STEEL CO LTD

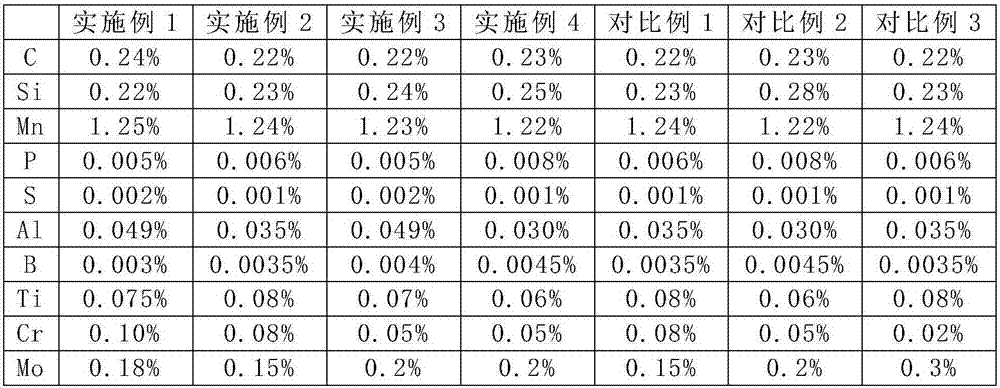

A method of manufacturing a torsion beam

ActiveCN105568140BHigh elongationNot exceed yield strengthLoad-supporting pillarsMetallurgyThermal treatment

The invention belongs to the technical field of forming and relates to a torsion beam preparation method which comprises the steps of pipe bending, performing, hydraulic forming and thermal treatment. The pipe is prepared from the following chemical components in parts by weight: 0.22-0.24% of C, 0.22-0.25% of Si, 1.22-1.25% of Mn, 0.005-0.008% of P, 0.001-0.002% of S, 0.030-0.049% of Al, 0.003-0.0045% of B, 0.06-0.08% of Ti, 0.05-0.10% of Cr, 0.15-0.2% of Mo, 0.15-0.2% of Ni, less than or equal to 0.05% of Cu, 0.1-0.2% of Co, and the balance of Fe. According to the invention, the pipe has good elongation in a forming state so as to meet a forming requirement; while after material forming is completed, the pipe has relatively high tensile strength through thermal treatment.

Owner:JIANGSU JOYLONG AUTOMOBILE

Method for preparing amorphous alloy

PendingCN114131039AAchieving net shape without shape constraintsSimple processAdditive manufacturing apparatusIncreasing energy efficiencyAlloyMetal powder

The invention belongs to the technical field of amorphous alloy preparation, and relates to a method for preparing an amorphous alloy. The metal powder is sent out through airflow with supersonic speed, laser is utilized to suspend and melt the powder at the position away from a substrate by a certain distance, and the powder is deposited in a supercooled liquid form after being blown and cooled by the airflow to form amorphous alloy; according to the method, the amorphous alloy block material without size limitation is obtained by controlling the powder feeding, melting and deposition positions in a mode of combining laser suspension melting of alloy powder and supersonic airflow high-speed deposition, meanwhile, the movement track of the substrate can be programmed in the preparation process according to the shape requirement of a workpiece, and the production efficiency is improved. Three-dimensional forming of amorphous alloy workpieces in different shapes is achieved; according to the method, the amorphous alloy size limitation can be solved, the amorphous alloy workpiece without size constraint can be prepared, and the method is particularly suitable for preparing the amorphous alloy workpiece of a large-area thin-wall structure.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

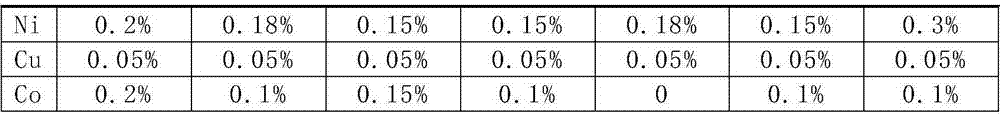

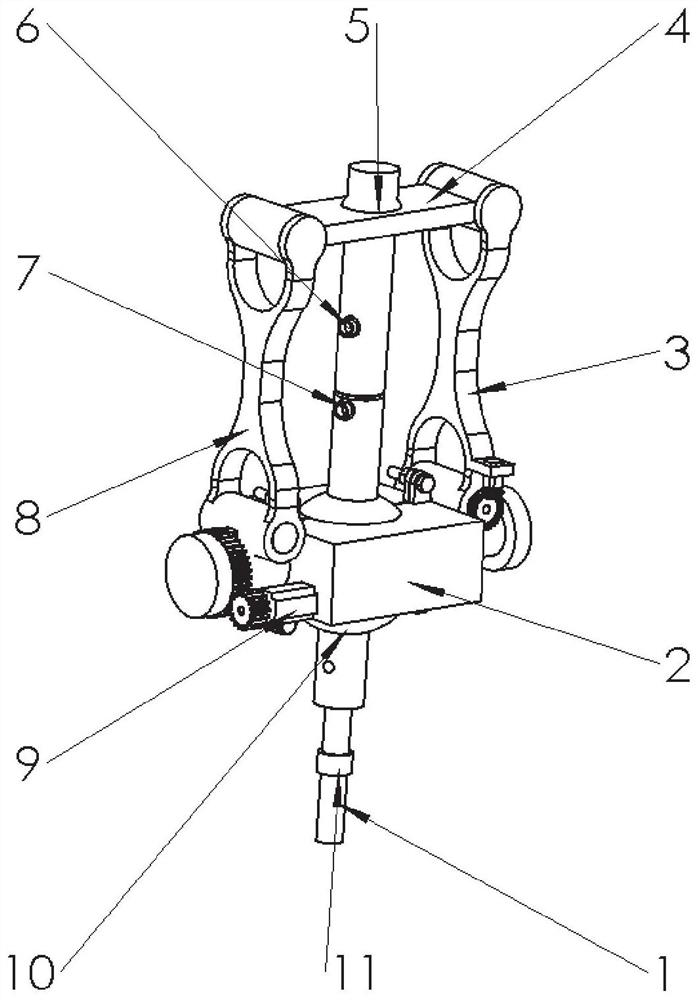

A multi-angle deflectable tool head and a processing device comprising the same

The invention discloses a multi-angle deflectable tool head and a processing device including the tool head, including a first deflection control mechanism, a second deflection control mechanism, a first rocker, a second rocker, a ball joint support, a telescopic Rods, connecting rods and tool heads; the lower ends of the first rocker and the second rocker are connected to the two ends of the spherical joint support, and the upper ends of the first rocker and the second rocker are connected to the two ends of the connecting rod in rotation. The middle part is provided with a through hole, and the tail of the telescopic rod is connected with the first through-hole metal ball, and the first through-hole metal ball is in clearance fit with the through-hole; the middle part of the telescopic rod is fixed with a second through-hole metal ball, and the second through-hole metal ball The ball is tangentially matched with the through hole in the middle of the ball hinge support; the head of the telescopic rod is connected to the tool head; the first deflection control mechanism controls the first rocker and the second rocker to drive the telescopic rod and the tool head to rotate in the first plane ; The second deflection control mechanism controls the first rocker and the second rocker to drive the telescopic rod and the tool head to rotate in the second plane perpendicular to the first plane.

Owner:SHANDONG UNIV

High-elongation hot-rolled microstructure regulating steel with tensile strength greater than or less than 800MPa and production method thereof

ActiveCN111334701AMeet the forming requirementsLow costTemperature control deviceFurnace typesUltimate tensile strengthMicrostructure

The invention discloses high-elongation hot-rolled microstructure regulating steel with tensile strength greater than or less than 800MPa. The steel comprises the following components in percentage byweight: 0.07-0.09% of C, 1.95-2.10% of Mn, 0.70%-0.80% of Si, less than or equal to 0.008% of P, less than or equal to 0.002% of S and 0.02-0.04% of Als; the production method comprises the followingsteps of: carrying out RH vacuum furnace treatment after converter smelting; heating a casting blank; rolling in sections; variable speed cooling in sections: coiling; heat insulation; smoothing treatment. Under the premise of ensuring the tensile strength above 800MPa, the steel can make the yield strength be greater than or equal to 500MPa, elongation greater than or equal to 25%, product of strength and elongation greater than or equal to 20GPa% and yield ratio less than 0.65, the steel can meet the forming requirement of thick specifications and high strength steel, and alloy elements aresimple without adding precious alloys such as Nb, V, Mo, etc.; and the alloy cost can be reduced by at least 10%.

Owner:武汉钢铁有限公司

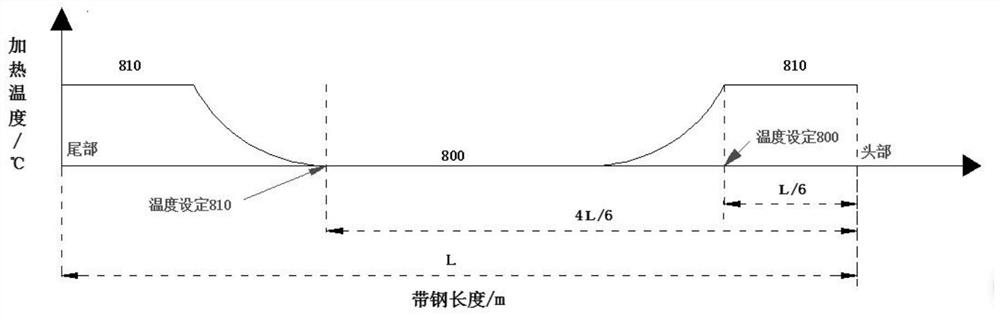

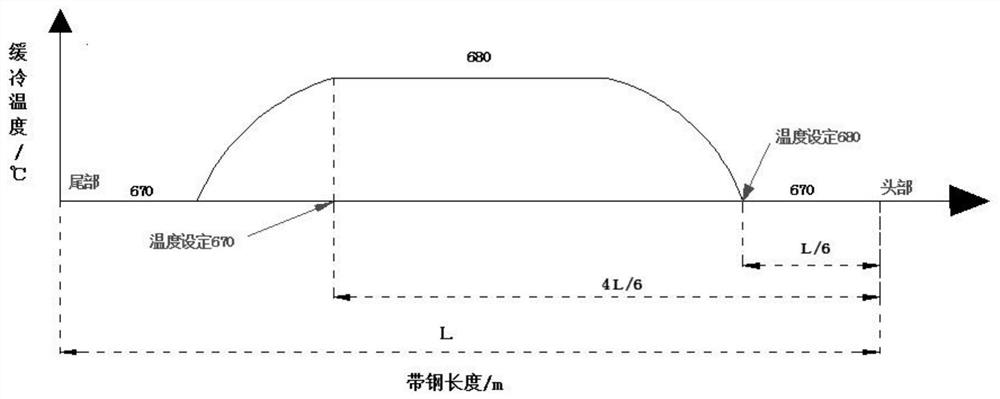

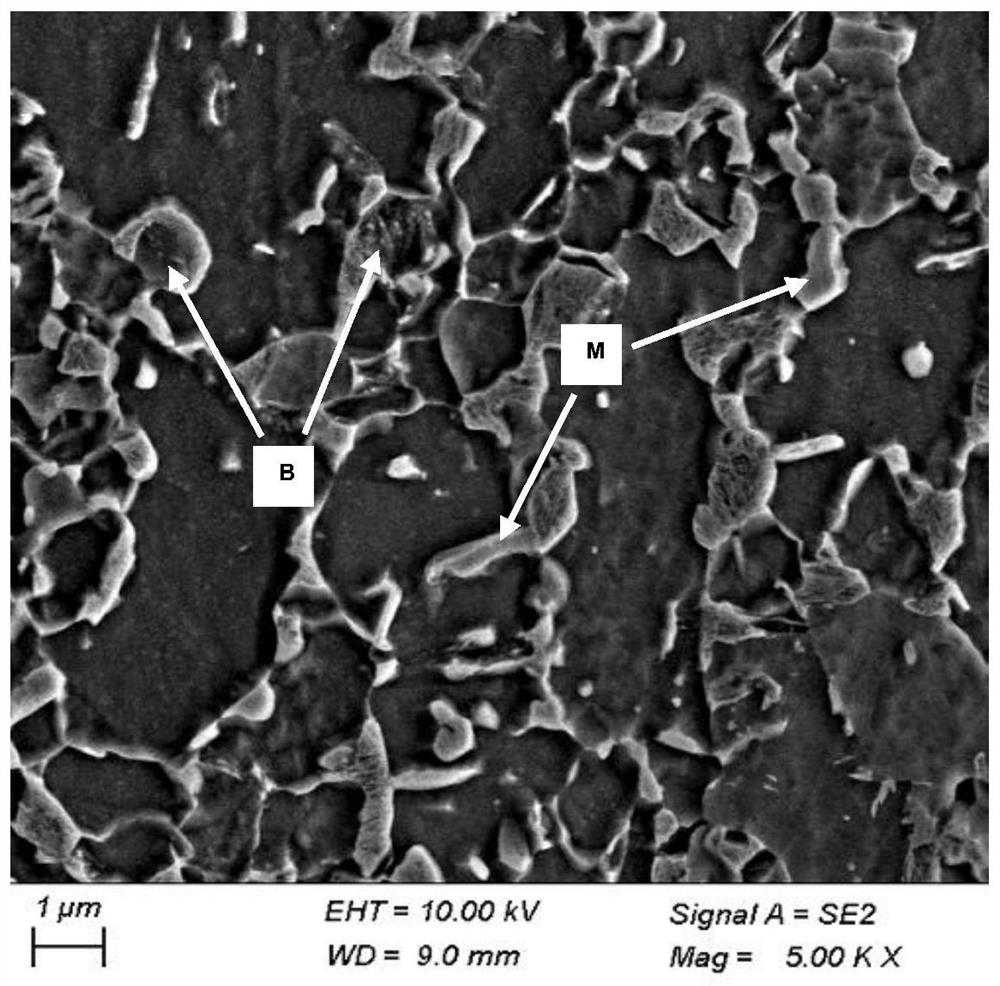

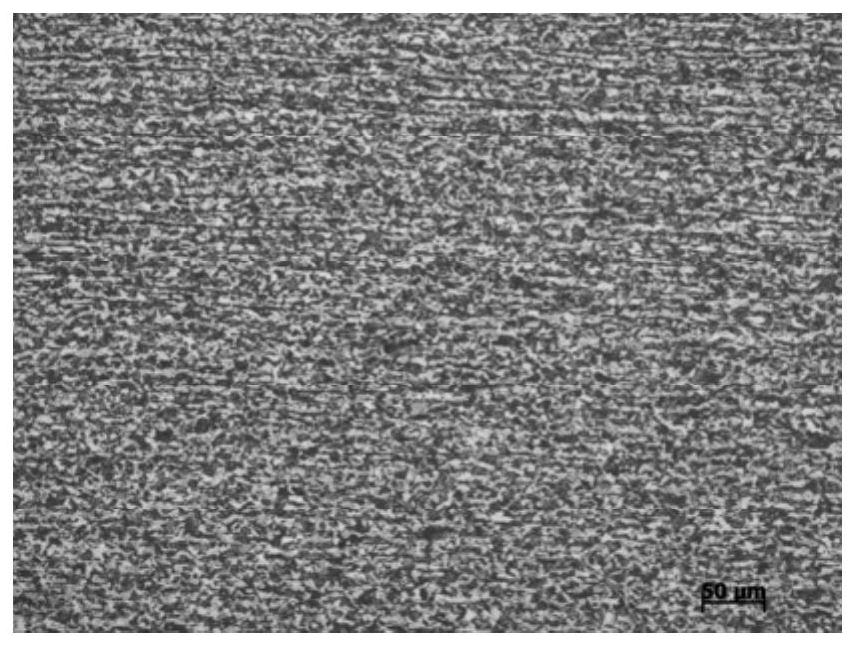

A continuous annealing method for 780mpa micro-alloyed dual-phase steel

ActiveCN112760463BMeet the forming requirementsSmall fluctuations in intensityFurnace typesHeat treatment process controlProduction lineContinuous annealing

The invention discloses a continuous annealing method for 780MPa grade microalloyed dual-phase steel. The invention adopts a "U-shaped" control strategy for the heating temperature and soaking temperature, a "∩-type" control strategy for the slow cooling temperature, and a "∩" control strategy for the rapid cooling section. The segmental cooling strategy of rapid cooling Ⅰ and rapid cooling Ⅱ reduces the strength fluctuation of the product and improves the local forming performance of the product. The strength difference in the inner head of the obtained product roll does not exceed 40MPa, and the elongation after breaking is 16-23%. The hole expansion rate is not lower than 20%. The method of the invention is simple and effective, and conforms to the actual production line of a continuous annealing unit.

Owner:MAANSHAN IRON & STEEL CO LTD

Hot-rolled steel plate for 1800mpa class hot-stamped wheel rim and manufacturing method thereof

The invention discloses a hot-rolled steel plate for 1800MPa hot stamping wheel rims and a preparation method thereof, C: 0.33%-0.35%, Si: 0.01%-0.10%, Mn: 1.10%-1.45%, P: ≤0.010%, S: ≤0.004%, Al: 0.015%‑0.055%, Nb: 0.025‑0.040%, V: 0.02‑0.04%, Mo: 0.26‑0.35%, B: 0.002‑0.004%, rare earth element La+Ce: 0.020% ‑0.034%, N≤0.003%, the balance is Fe and unavoidable impurities.

Owner:ANGANG STEEL CO LTD

Hot-rolled steel plate for 1800mpa class hot-stamped wheel spokes and manufacturing method thereof

The invention discloses a hot-rolled steel plate for 1800MPa hot stamping wheel spokes and a preparation method thereof, C: 0.34%-0.36%, Si: 0.01%-0.10%, Mn: 1.20%-1.55%, P: ≤0.010%, S: ≤0.004%, Al: 0.015%‑0.055%, Nb: 0.03‑0.045%, V: 0.031‑0.050%, Mo: 0.26‑0.35%, B: 0.002‑0.004%, rare earth element La+Ce: 0.020% ‑0.034%, N: ≤0.003%, the balance is Fe and unavoidable impurities.

Owner:ANGANG STEEL CO LTD

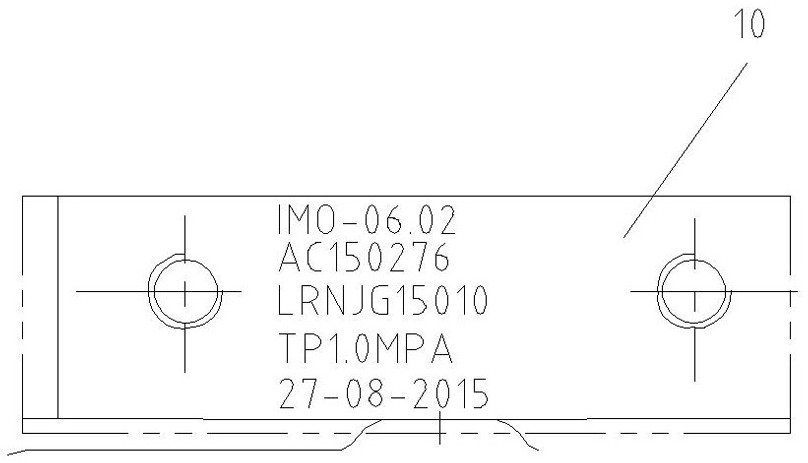

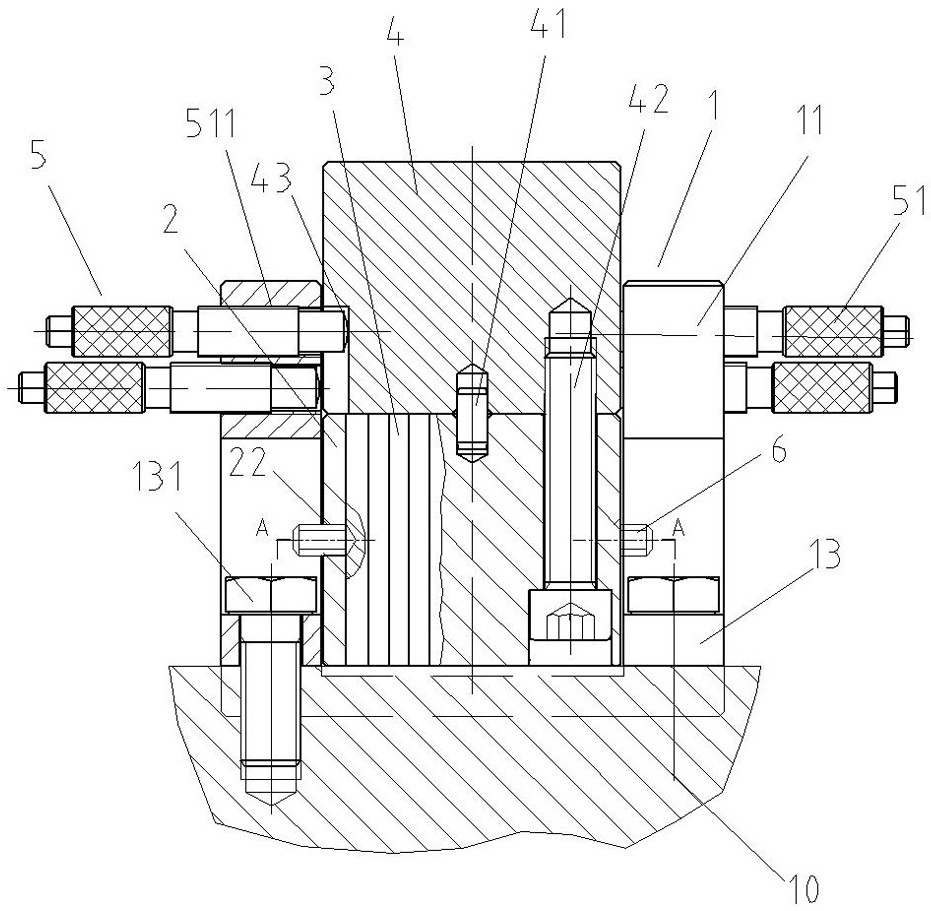

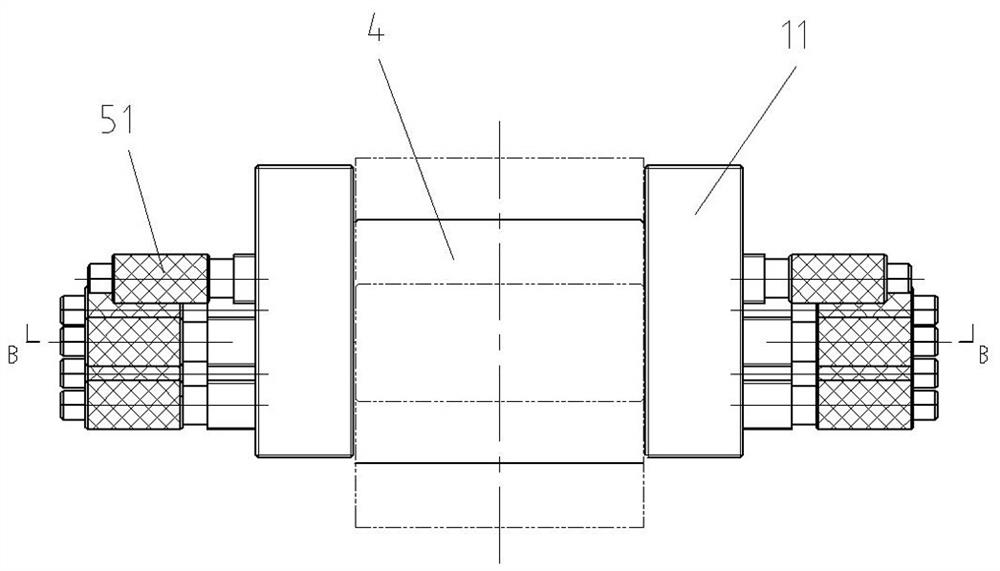

Cylinder head stamping mark pressing tool and method

ActiveCN109835076BHigh suppression efficiencyImprove appearance qualityStampingCylinder headDieseling

The invention discloses a cylinder cover steel seal mark pressing tool. The cylinder cover steel seal mark pressing tool comprises a positioning support, a steel seal matrix supporting block, a plurality of steel seal matrixes, a pressing block and a steel seal matrix line spacing adjusting mechanism, wherein the bottom of the positioning support is fixed on the two sides of a steel seal mark partof a cylinder cover, the plurality of transversely-adjacent steel seal matrixes are fixed in the steel seal matrix supporting block side by side, the pressing block and the steel seal matrix supporting block are embedded into a notch of the positioning support, and the bottoms of the plurality of steel seal matrixes abut against the corresponding steel seal mark part to be pressed of the cylindercover; and the two sides of the lower part of the pressing block are supported in the positioning support through the steel seal matrix line spacing adjusting mechanism. The method comprises the following steps of 1) assembling the tool; and 2) sequentially pressing steel seal marks on the cylinder cover line by line. The tool is small and exquisite in structure, convenient to use and low in manufacturing cost. According to the method, the working efficiency and quality of steel seal mark pressing are greatly improved, the appearance quality of a marine diesel engine is improved, and the labor cost is reduced.

Owner:CSSC MARINE POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com