Grid strain analysis method for thin plate forming and application of method

An analysis method and forming processing technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost, difficult for ordinary personnel to fully grasp, and unable to be promoted on a large scale, and achieve the effect of easy grasp and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] 1. Mesh strain analysis method for thin plate forming:

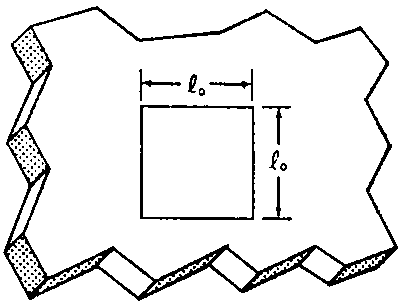

[0046] figure 1 It is a general metal sheet under the condition of no deformation and no load (no external force). The material is marked l 0 × l 0 to measure the deformation of the material. For simplicity, l 0 × l 0 Squares have no specific positioning. It should be mentioned that due to simplification, the strain in the thickness direction is ignored during processing, and the strain in the thickness direction can be calculated based on the strain on the measured surface by assuming that the volume is constant during the deformation process.

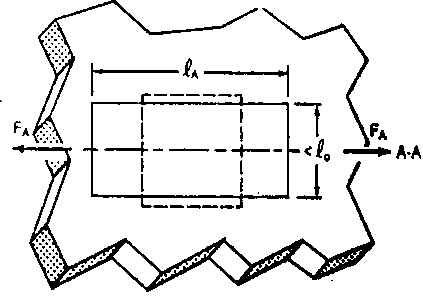

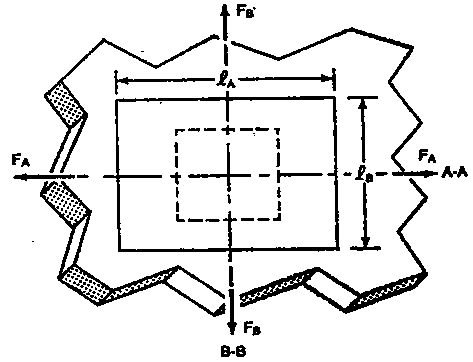

[0047] figure 2 It shows that the above metal plate is subjected to tension F in the direction A-A A The deformed condition. Obviously the metal plate will be under tension F A elongate in the direction of , the side length of the strained metal plate surface becomes l A (Such as figure 2 shown by the solid line in ), and greater than l 0 , l A for and pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com