Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Meet rigid requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long glass fiber reinforced composite polypropylene material, and preparation method and application thereof

The invention belongs to the technical field of high-molecular materials, and discloses a long glass fiber reinforced composite polypropylene material, and a preparation method and an application thereof The material is prepared by using the following components, by weight, 55-75 parts of polypropylene, 20-40 parts of a continuous glass fiber, 0.1-0.5 parts of a coupling agent, 0.01-0.1 parts of a primary antioxidant, 0.01-0.1 parts of an auxiliary antioxidant, 0.5-1 part of a lubricant and 3.5-4.2 parts of compatilizer. The invention also provides a preparation method of the long glass fiber reinforced composite polypropylene material, and a use of the long glass fiber reinforced composite polypropylene material in automobile components. The long glass fiber reinforced composite polypropylene material can be widely used in automobile components comprising header boards, automobile door panels, inner casings and the like, and has the characteristics of low cost, short injection molding period, low residual stress and small warpage of products, and low fraction defective of the products.

Owner:HEFEI GENIUS NEW MATERIALS

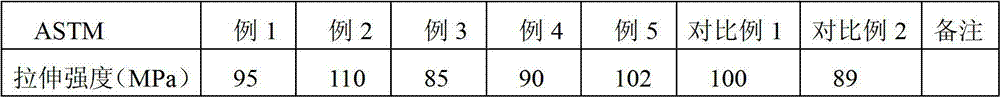

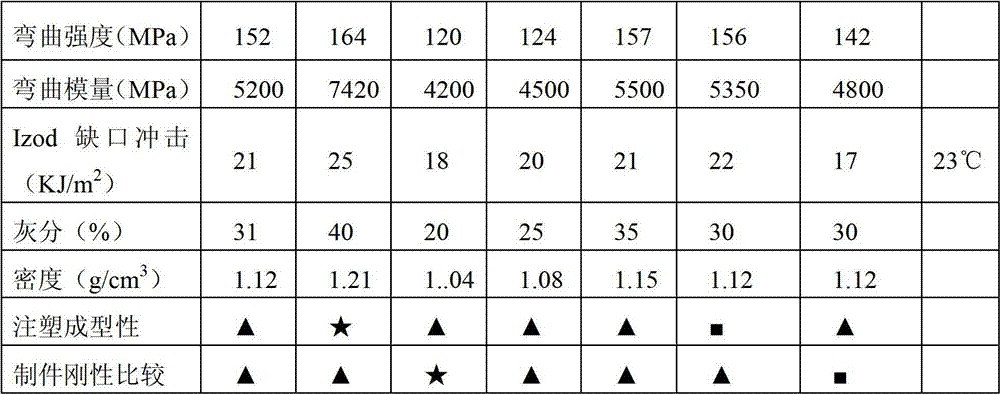

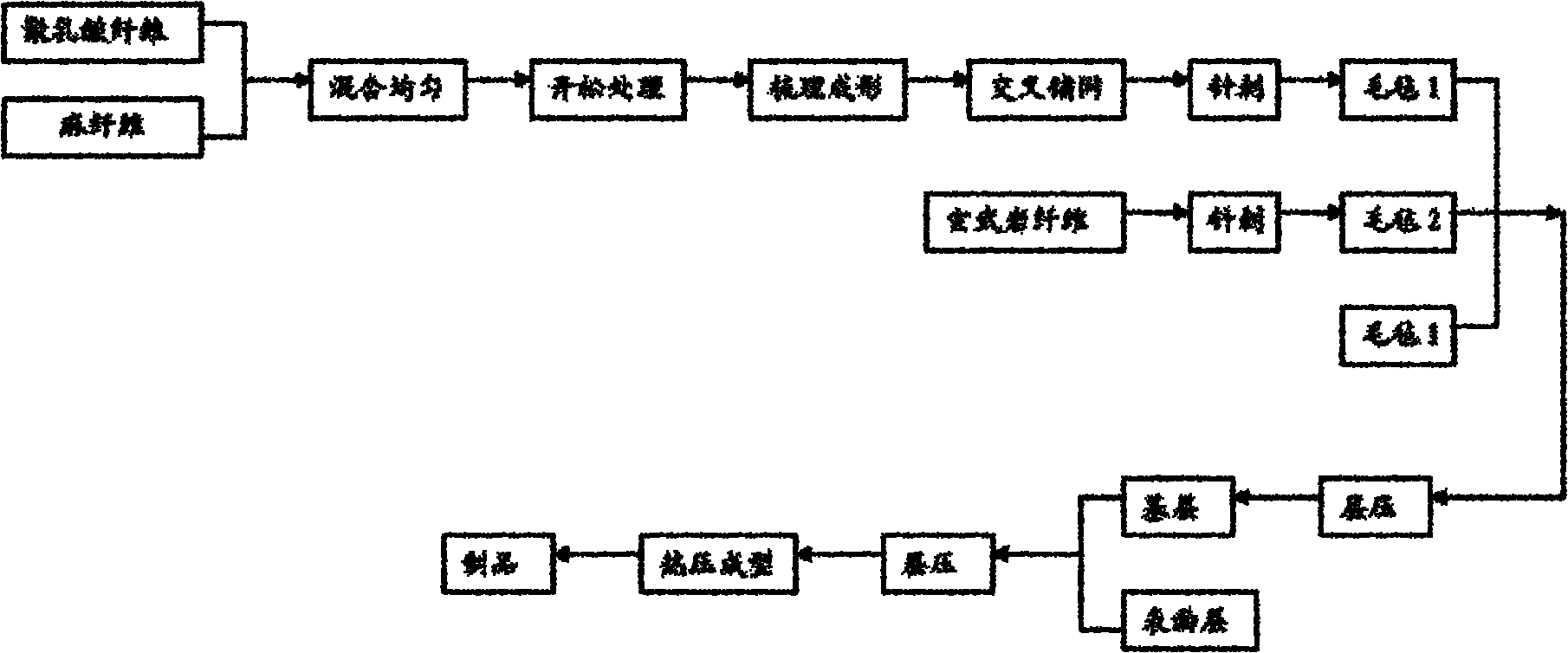

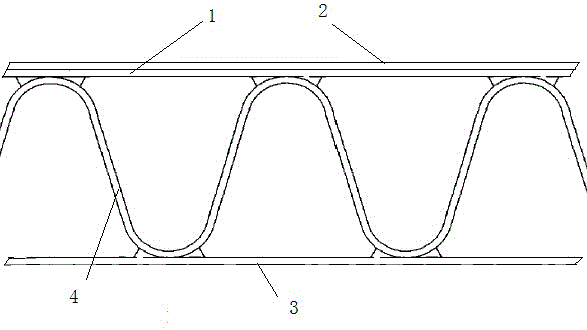

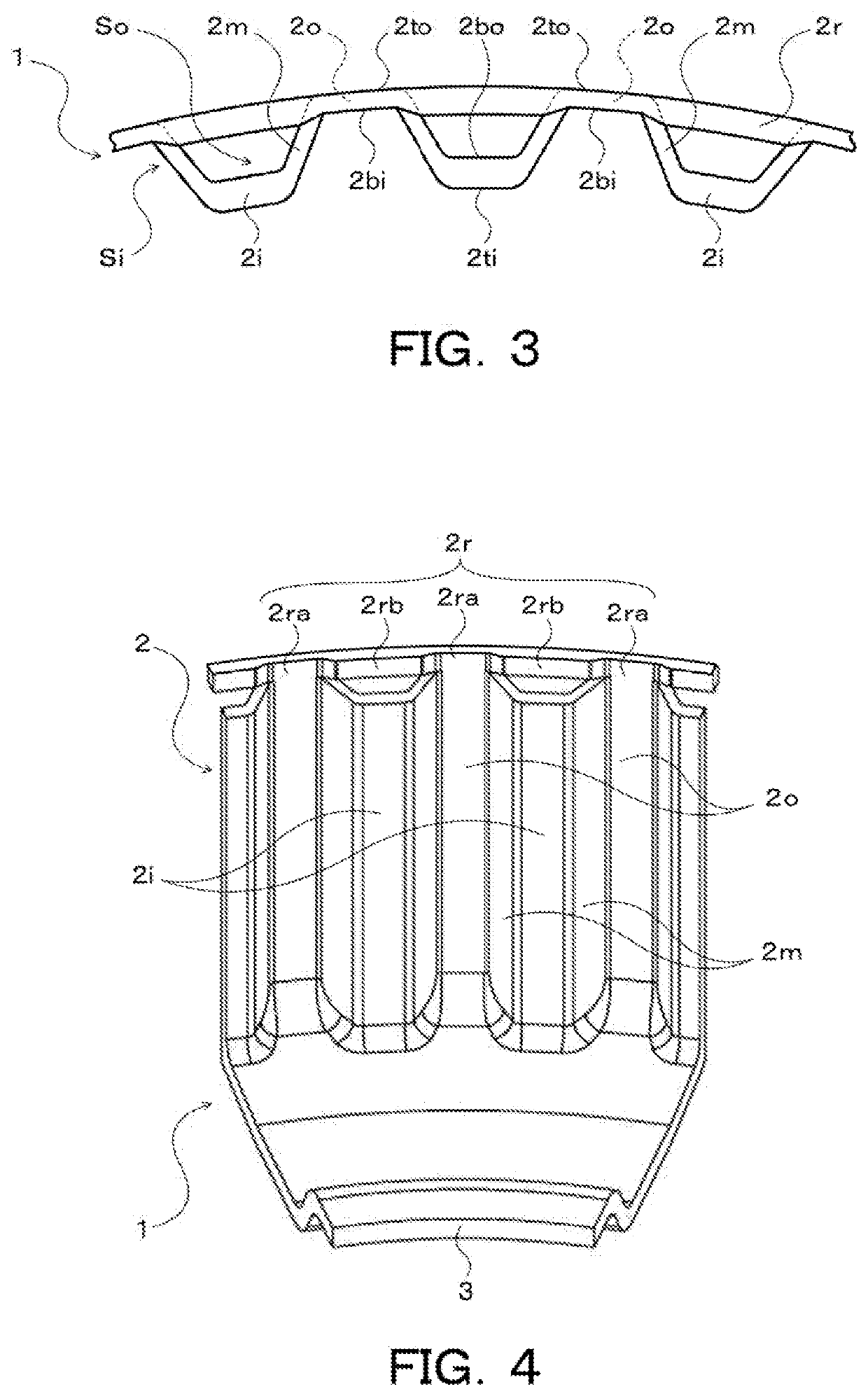

Composite fiber automobile interior board and production method thereof

InactiveCN102166842AImprove tensile propertiesGood filterability at high temperatureLaminationLamination apparatusSurface layerSisal fiber

The invention relates to a composite fiber automobile interior board and a production method thereof. The automobile interior board comprises a base layer and a non-woven or woven surface layer which is laminated on the at least one surface of the base layer, wherein the base layer consists of the following composite fibers: first fibers, namely polylactic acid fibers, second fibers, namely bastose selected from at least one of jute fibers, sisal fibers, ramie fibers, linen fibers, hemp fibers and kenaf fibers, and third fibers, namely basalt fibers in a weight percentage ratio of (20-70):(10-60):(10-60); and the surface layer consists of polylactic acid fibers. The composite fiber automobile interior board can be made into a three-dimensional deep drawing high-strength automobile interior board, and is safe, firm and environment-friendly when used as the base material of an automobile door inner board and a ceiling.

Owner:DALIAN UNIV OF TECH

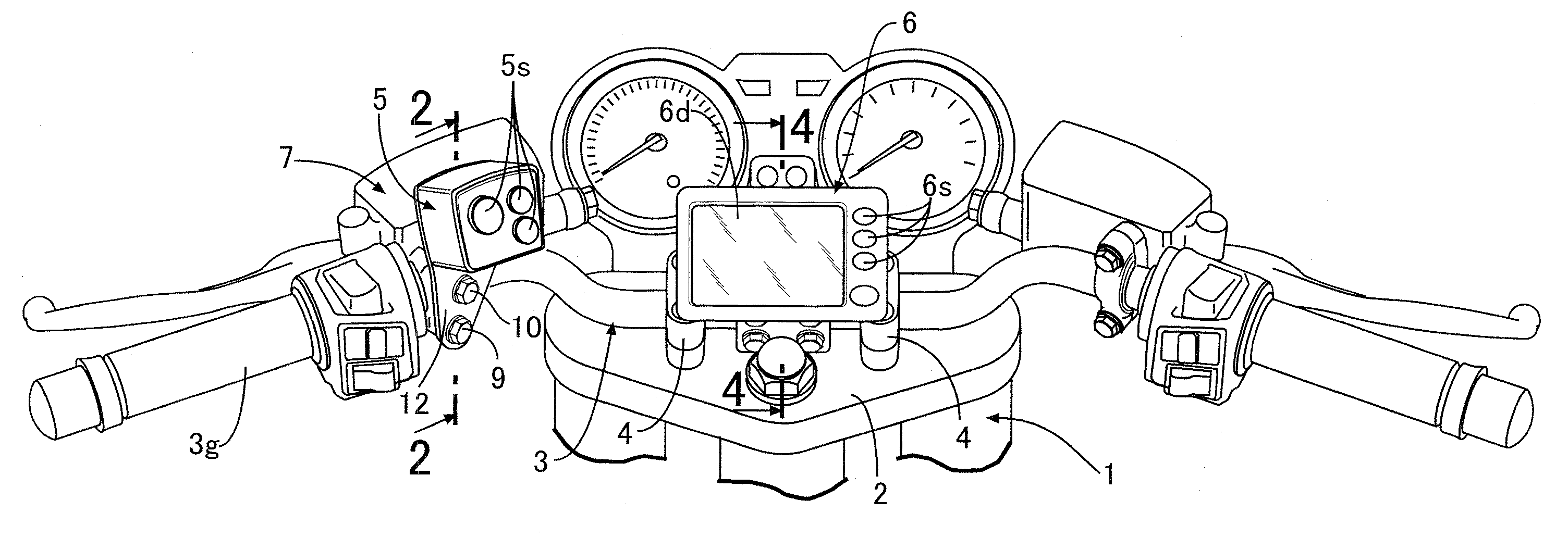

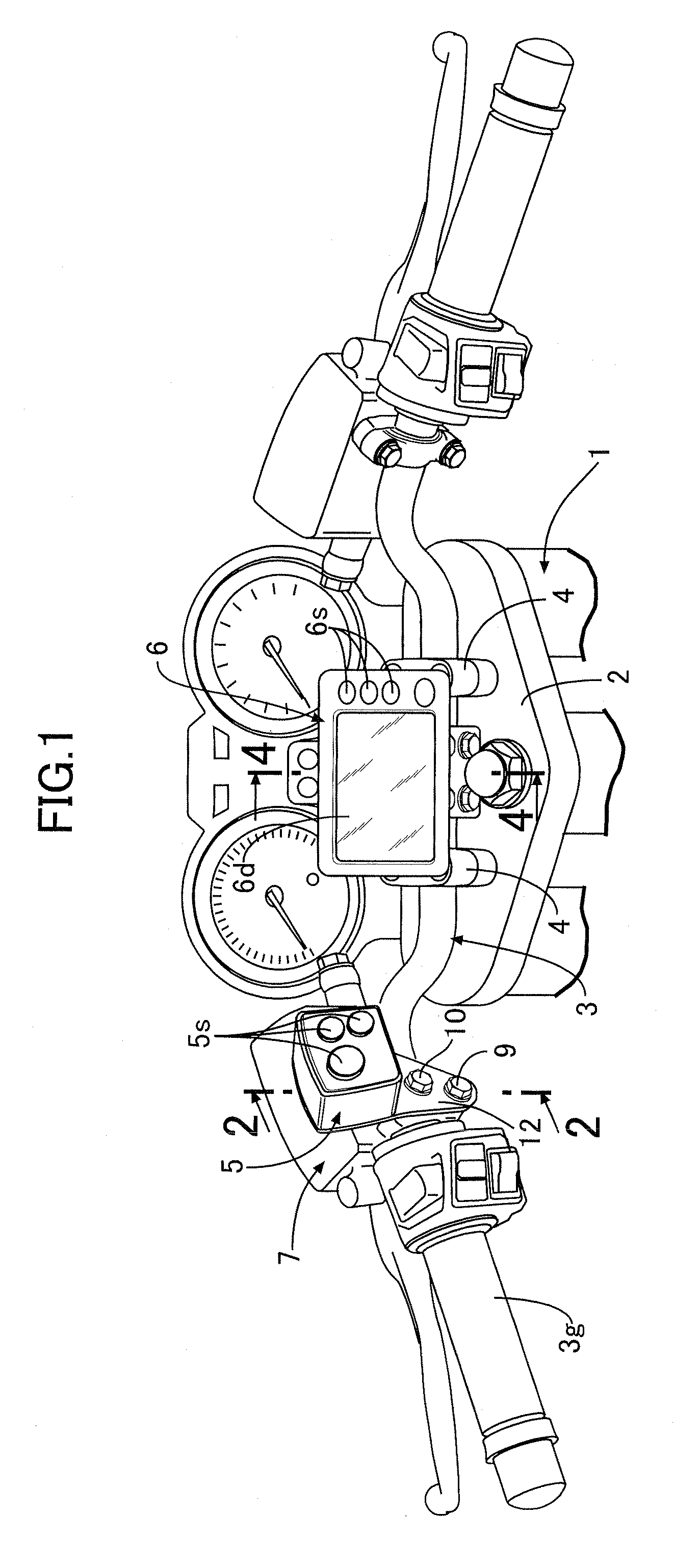

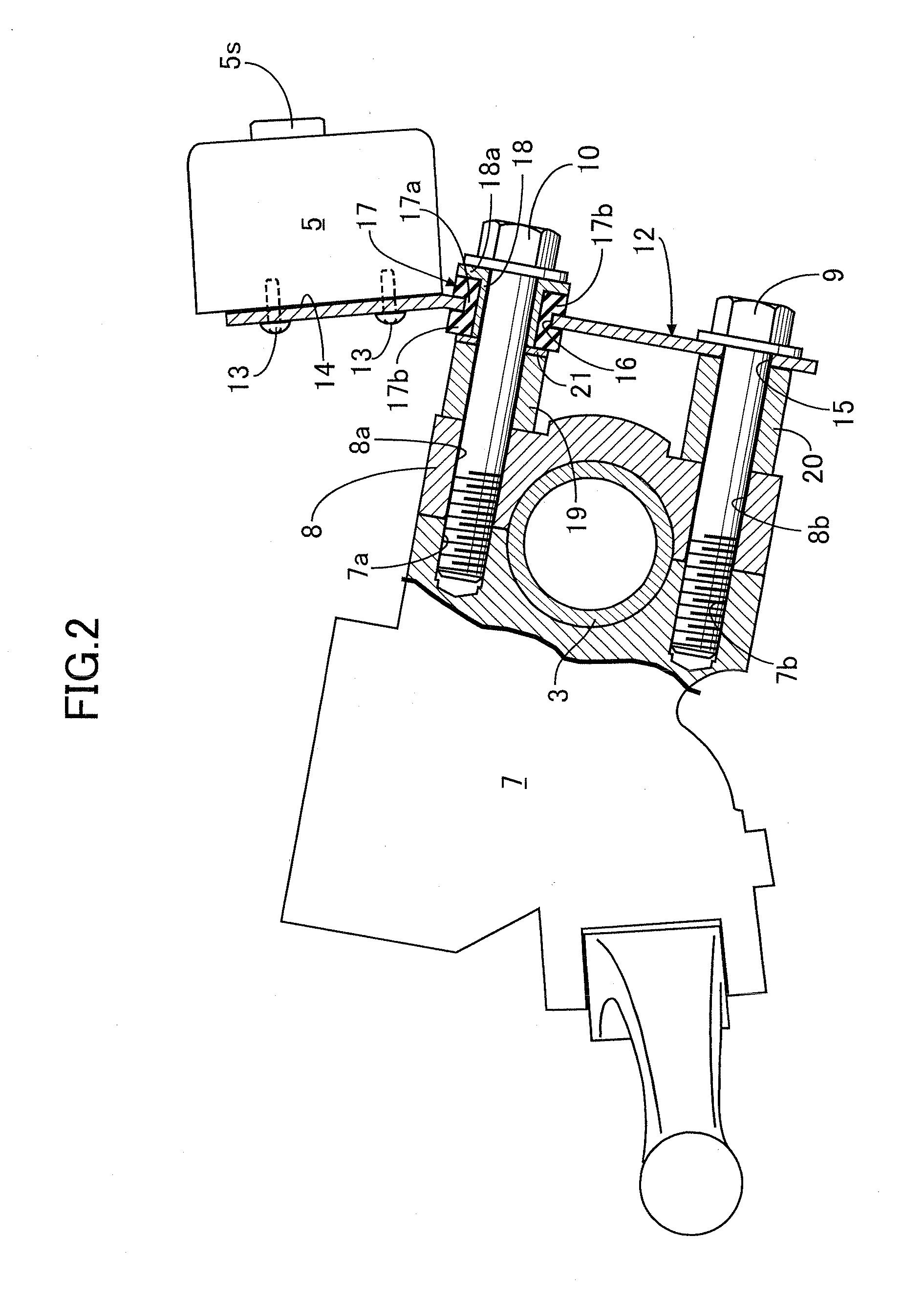

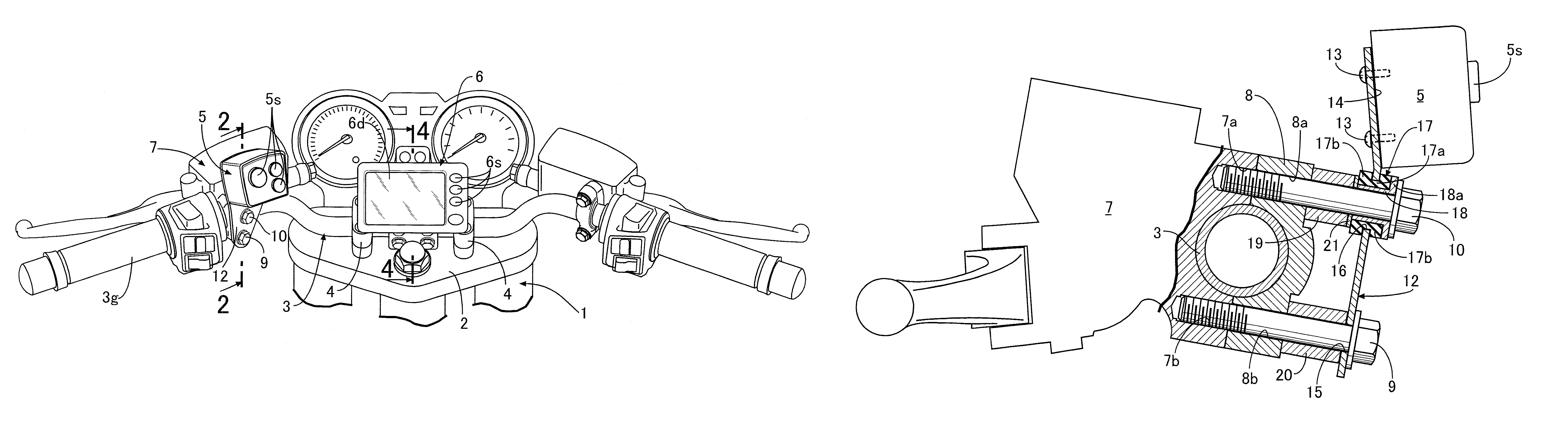

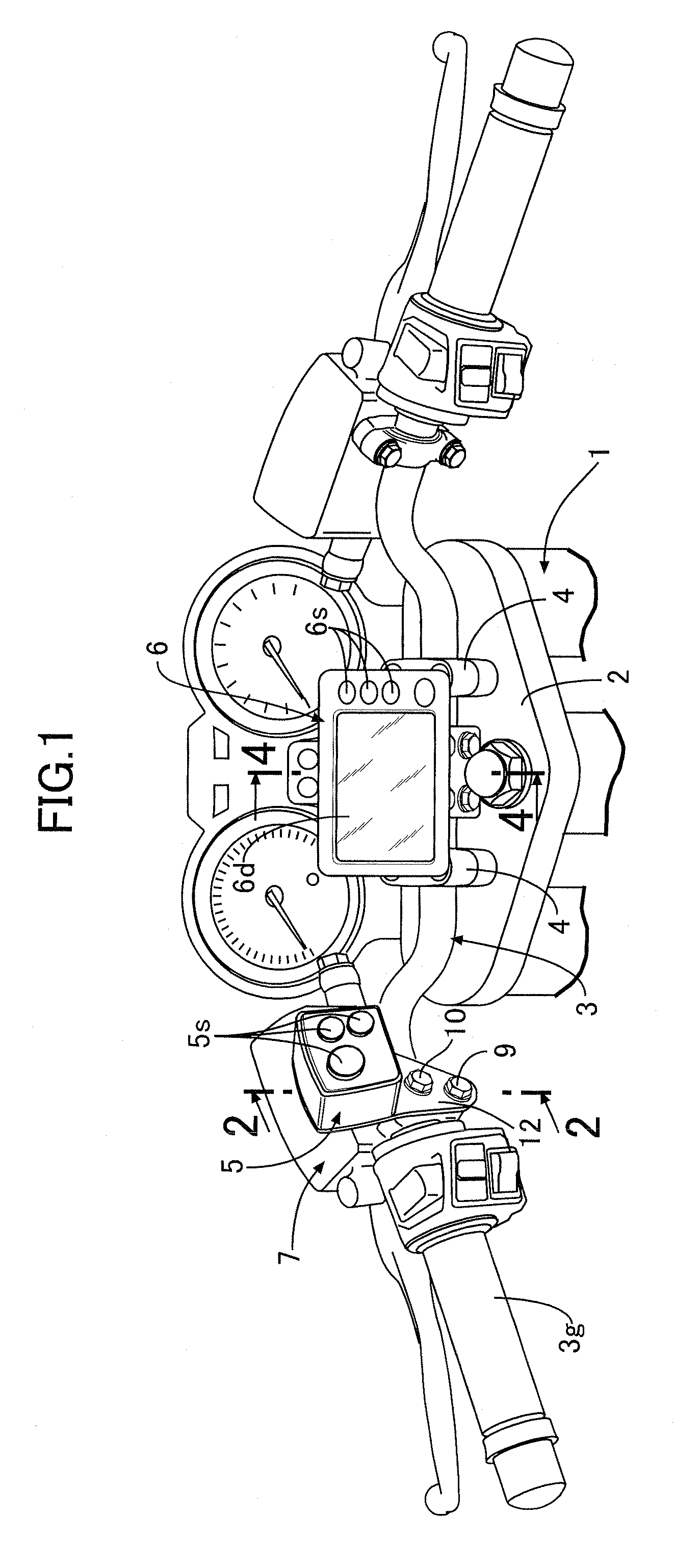

Electrical device mounting structure in motorcycle

InactiveUS20080246247A1Easy to operateSimple designWheel based transmissionTravelling carriersEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

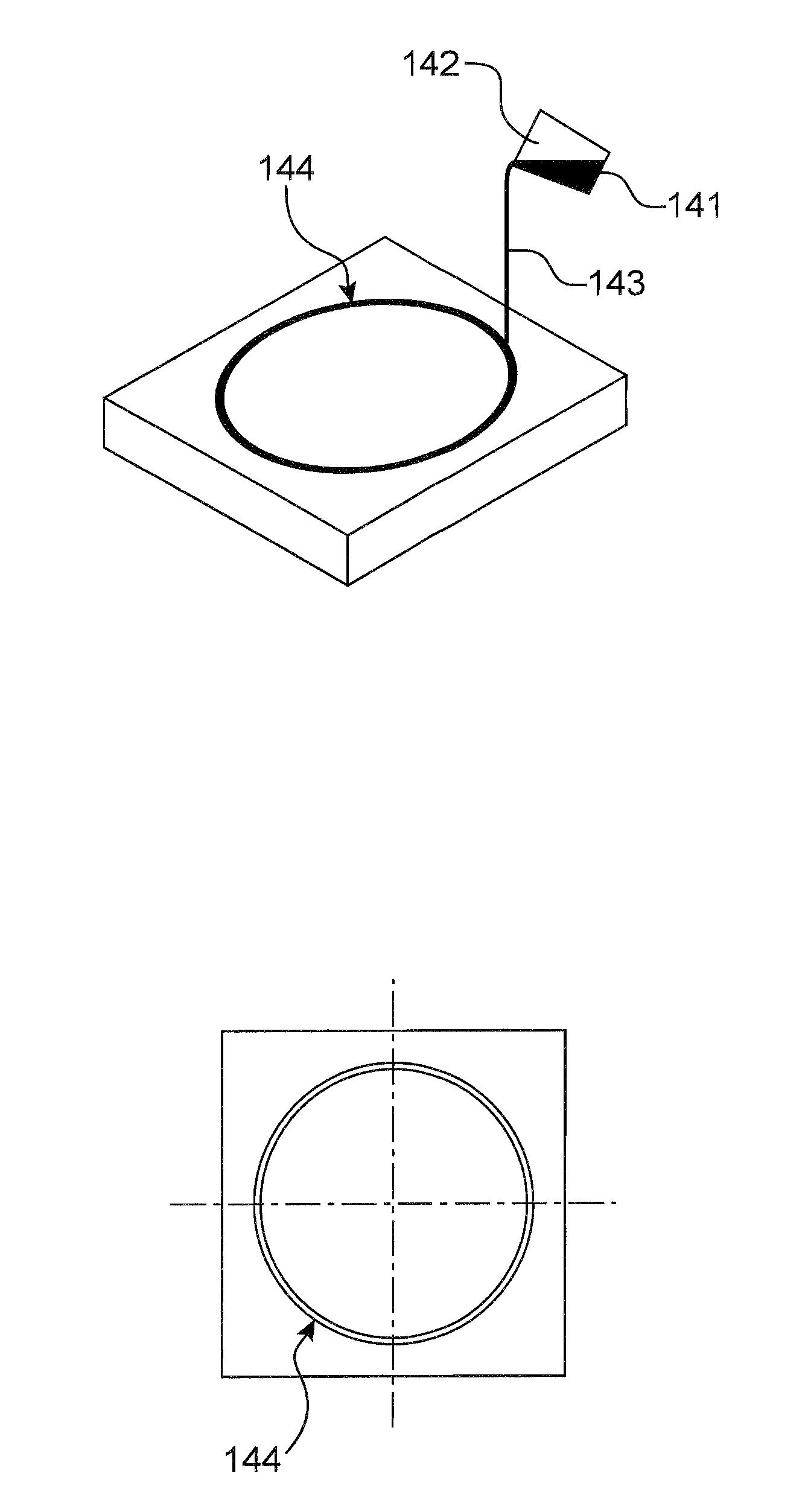

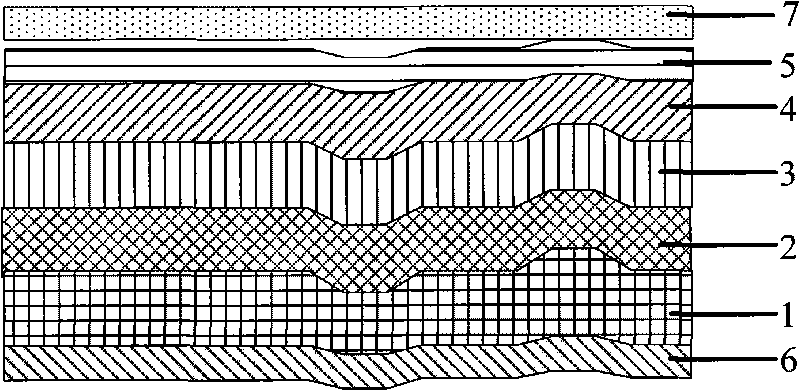

Miniature microphone manufacturing method based on Si-Si bonding process

ActiveCN101854578AThickness is easy to controlWide range of materialsElectrical transducersBiochemical engineeringBonding process

The invention relates to a miniature microphone manufacturing method based on an Si-Si bonding process, which comprises the following steps that: a. a connecting plate and a back plate are provided; b. the back plate and the connecting plate are bonded and fixed; c. the back plate is thinned; d. an insulating bonding layer is grown on the thinned back plate; e. a substrate is provided; f. an insulating supporting layer is grown on the substrate; g. a vibrating diaphragm is precipitated on the substrate; h. the vibrating diaphragm which is arranged in a groove is obtained; i. the back plate and the substrate are bonded and fixed; j. the connecting plate and an oxidization layer above the substrate are etched; k. a lower electrode hole is obtained on the back plate; l. an electrode layer isprecipitated on the back plate; m. electrodes on the back plate and the vibrating diaphragm are obtained; n. a plurality of sound holes on the back plate are obtained; and o. the other end of the substrate which corresponds to the back plate is etched to obtain a vocal cavity below the vibrating diaphragm. The miniature microphone manufacturing method based on the Si-Si bonding process has the advantages of high sensitivity, low cost, wide frequency band, high finished product rate and simple manufacturing process.

Owner:无锡芯感智半导体有限公司

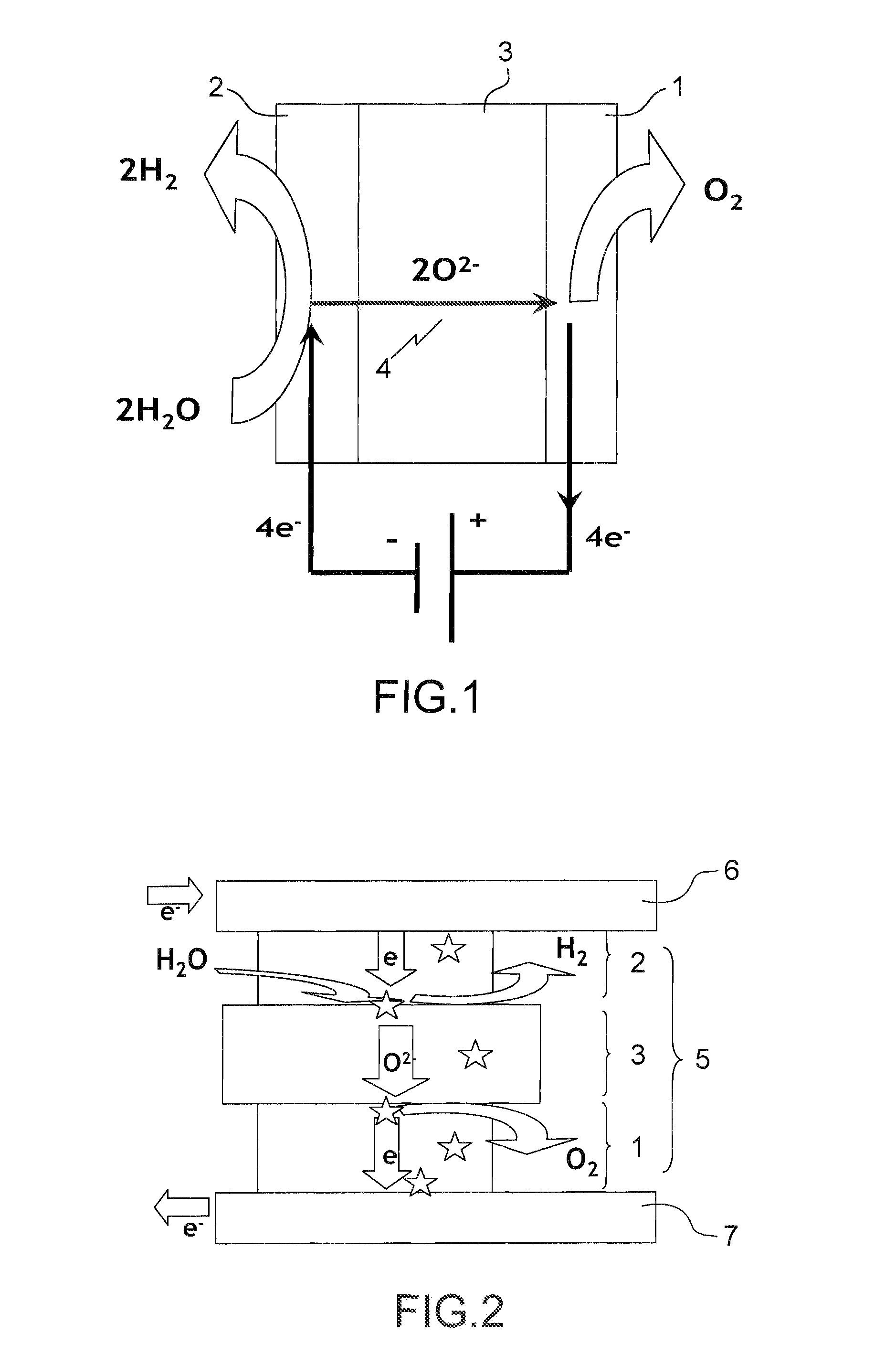

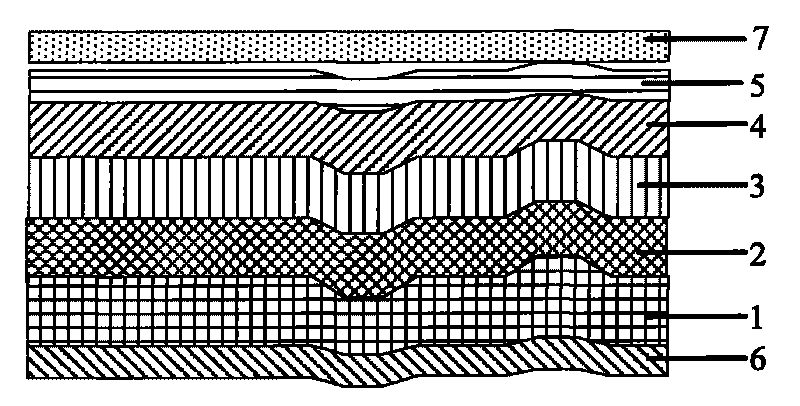

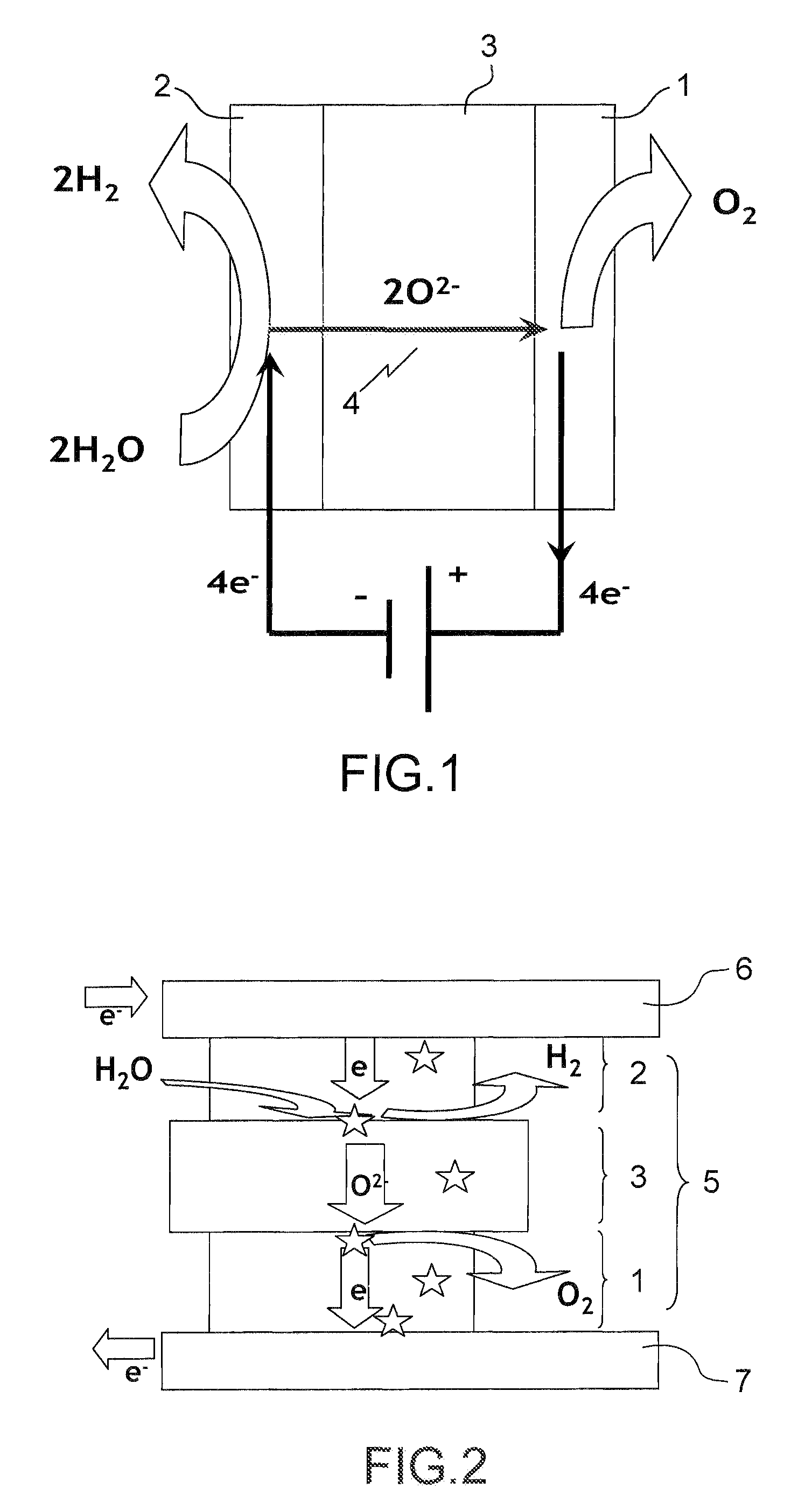

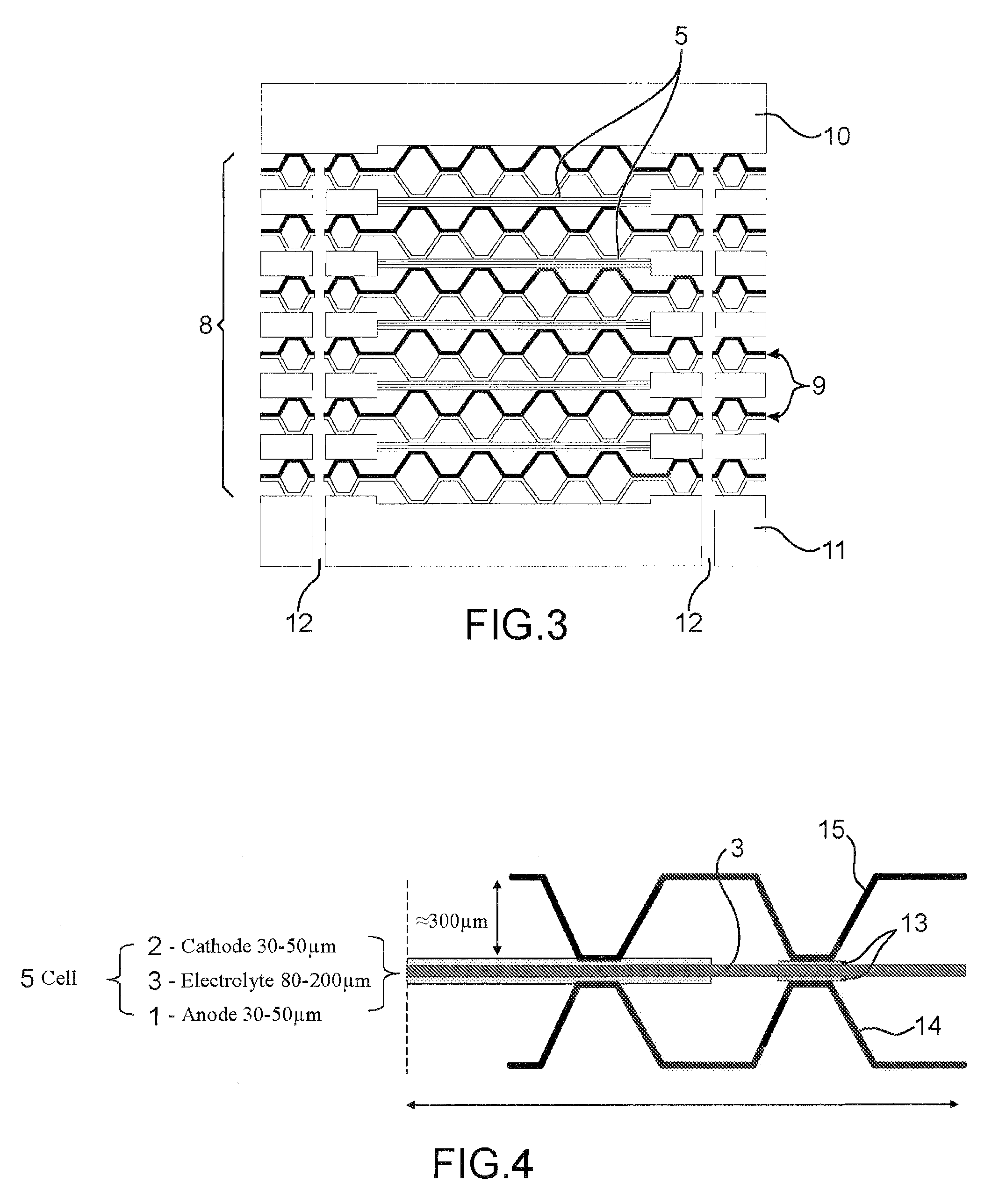

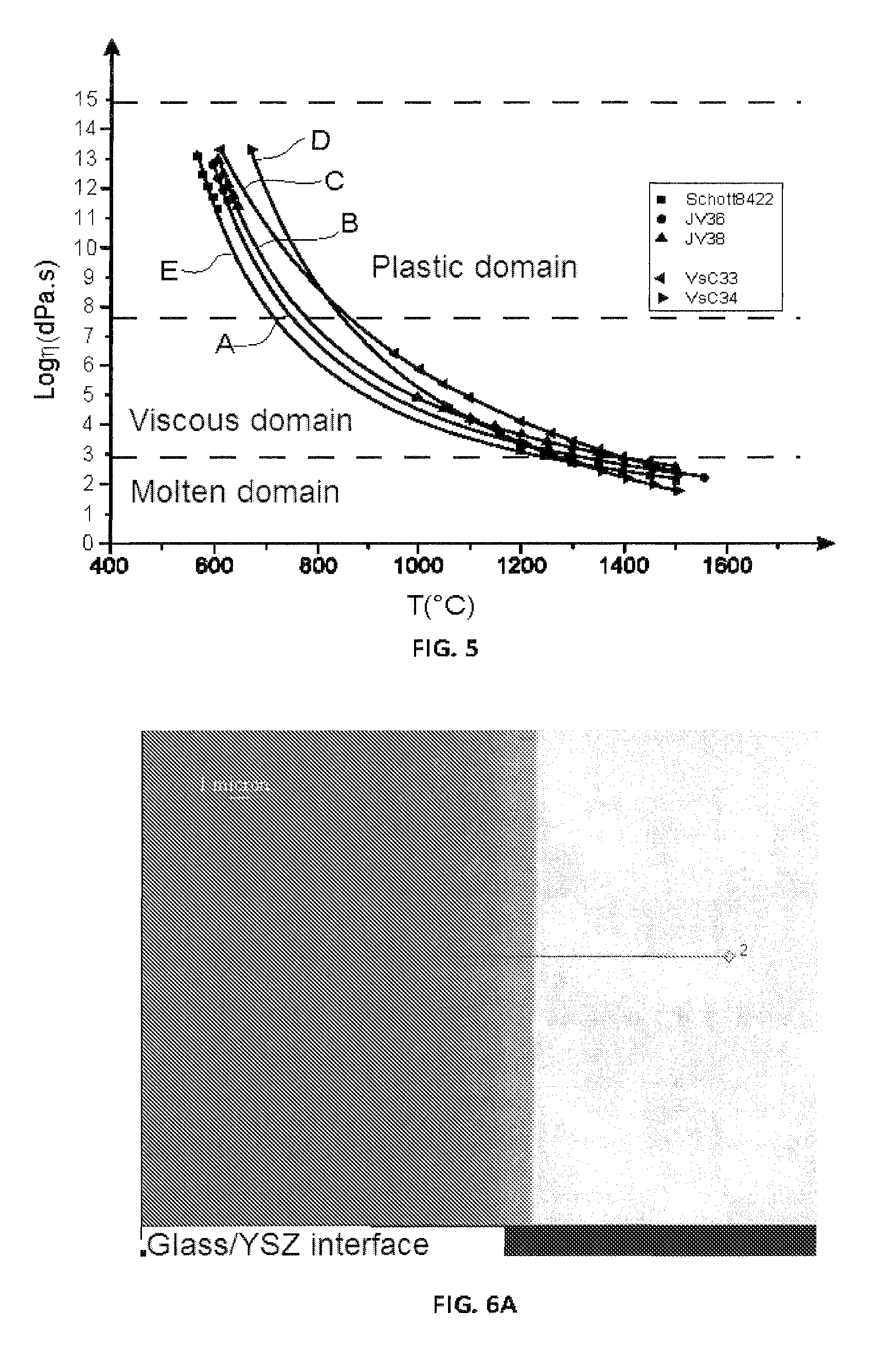

Glass compositions for gaskets of apparatuses operating at high temperatures and assembling method using them

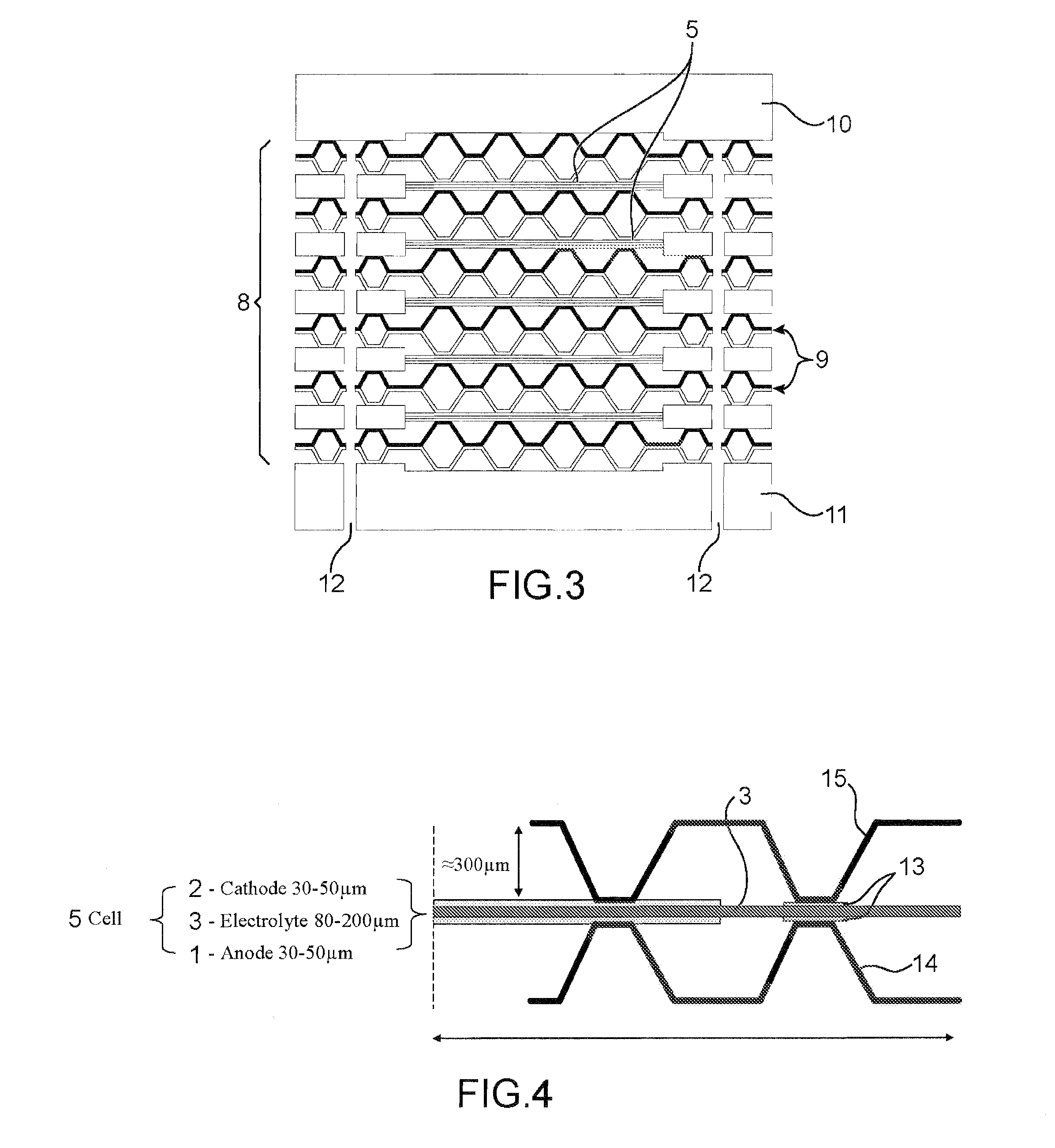

ActiveUS20120318022A1Meet rigid requirementsImprove balanceCellsFinal product manufactureFuel cellsPhotochemistry

A glass composition, characterized in that it is selected from the group consisting of: a glass composition (A) with the following molar percentages: 70 to 76% of SiO2, 7 to 8% of B2O3, 5 to 6% of Al2O3, and 10 to 17% of Na2O; and a glass composition (B) with the following molar percentages: 63 to 76% of SiO2, 5 to 12% of ZrO2, 0 to 12% of B2O3, 0 to 2% of La2O3, 11 to 14% of Na2O, and 3 to 5% of K2O. The glass composition can be used in a method for assembling parts, in particular for a method of manufacturing high-temperature electrolyzers (HTEs) or high-temperature fuel cells (SOFCs).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

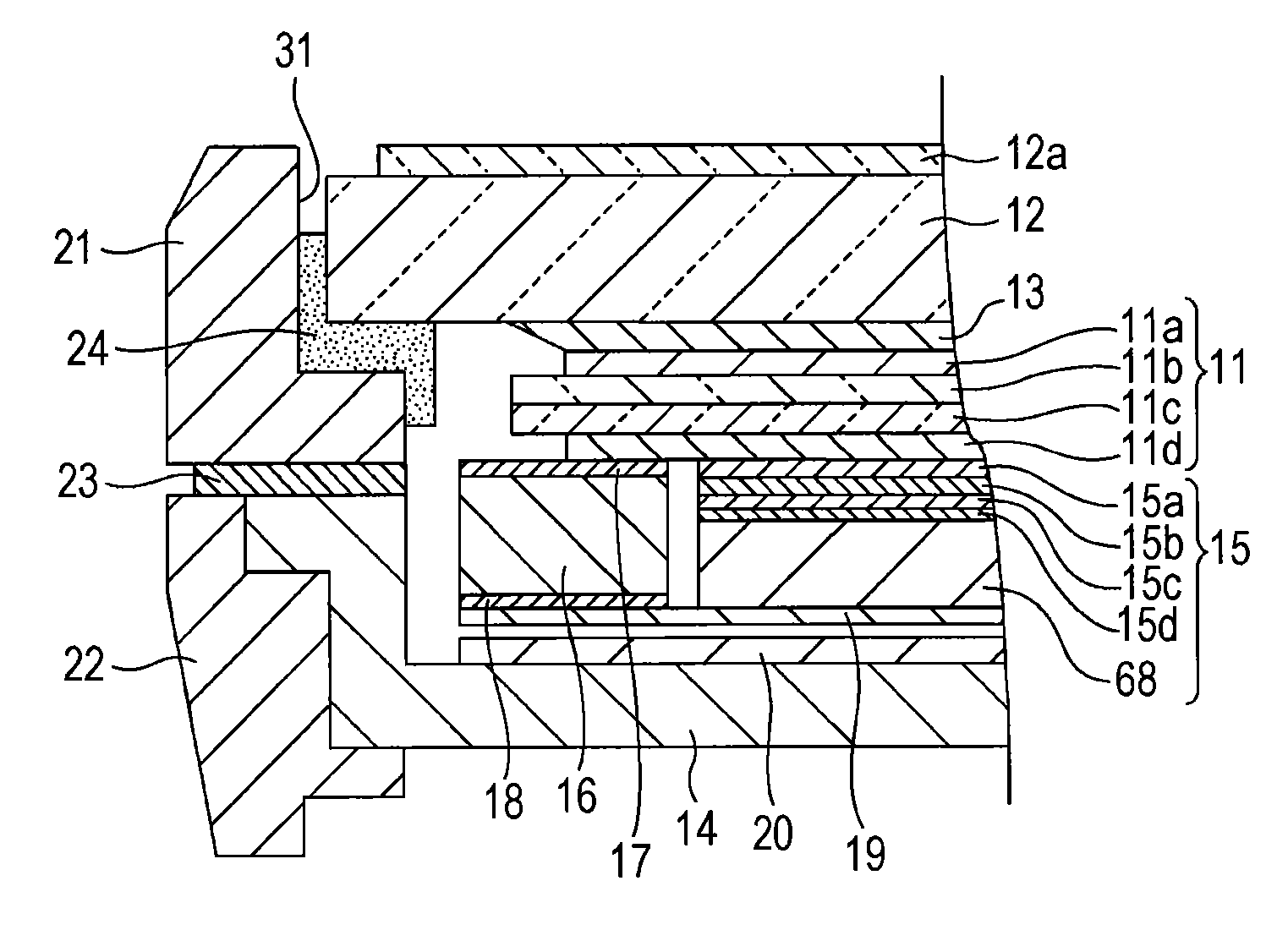

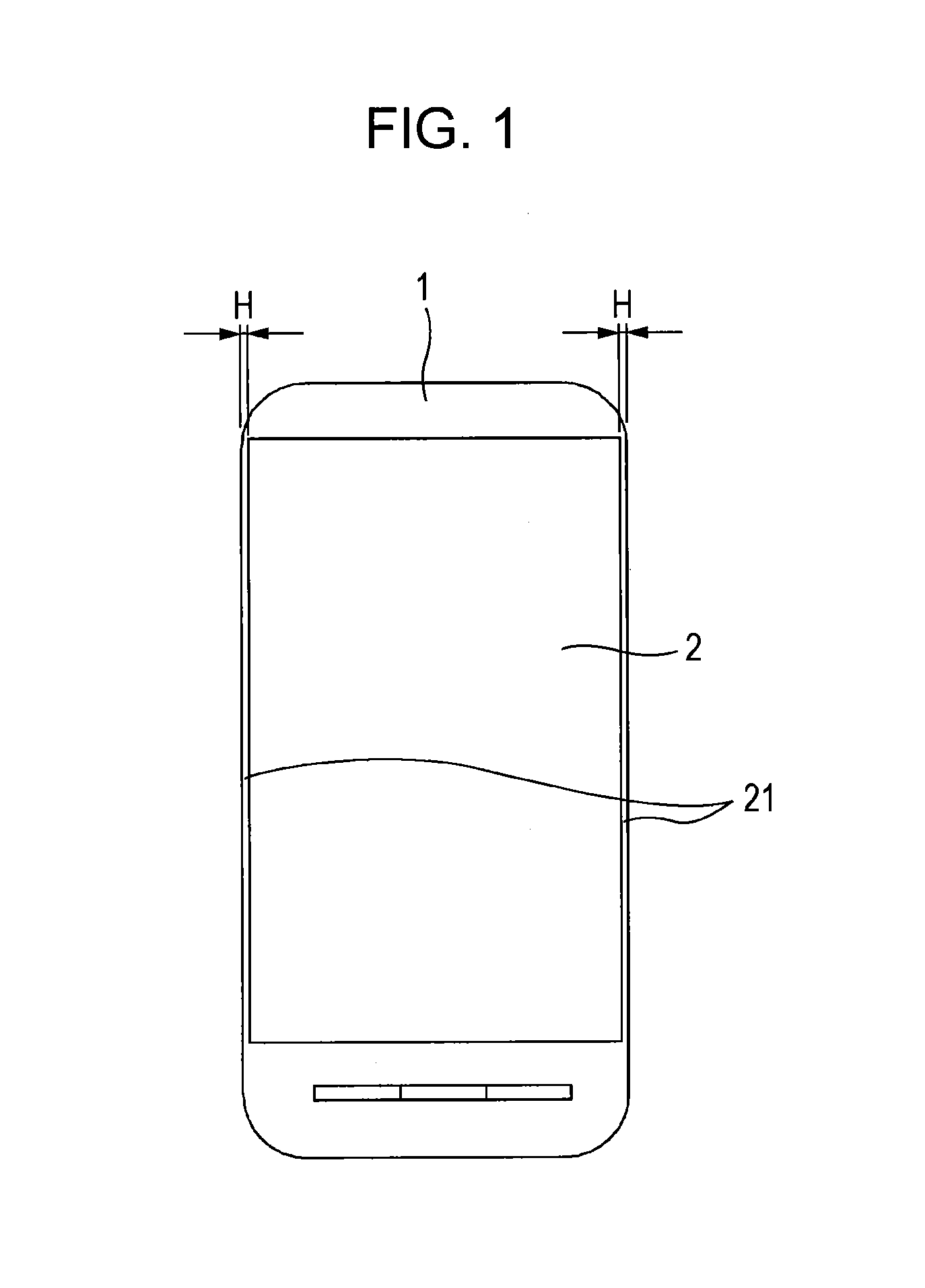

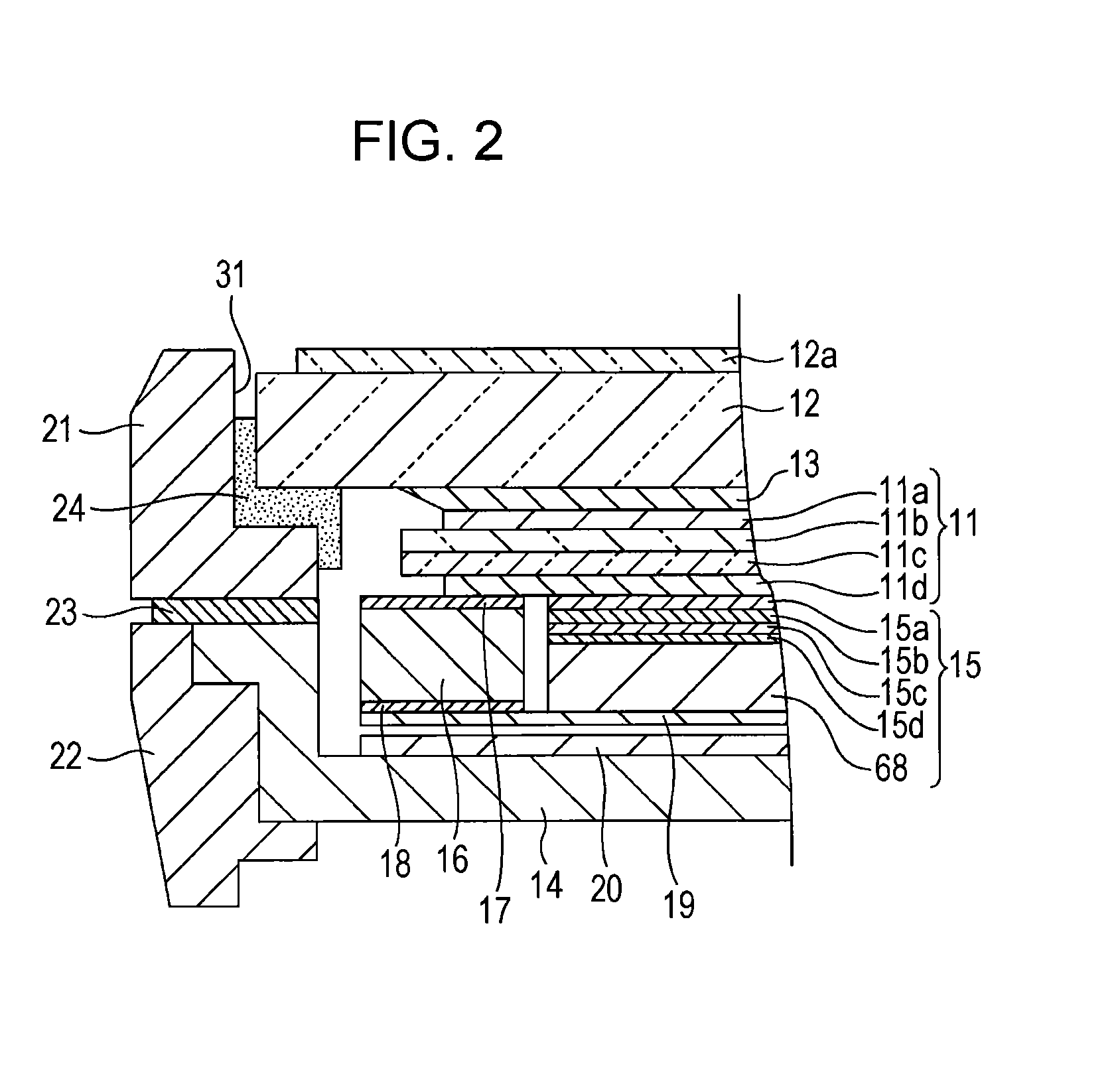

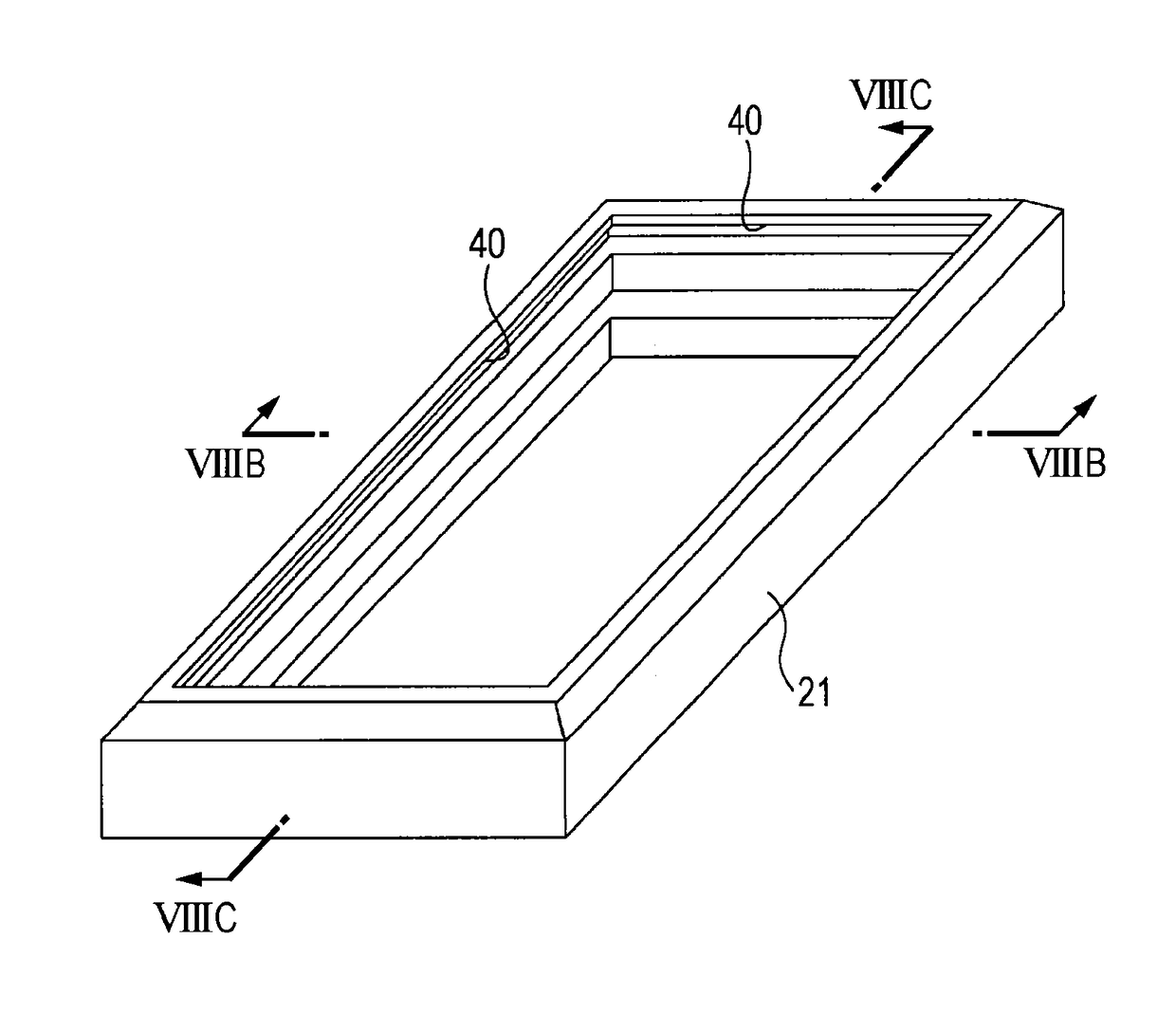

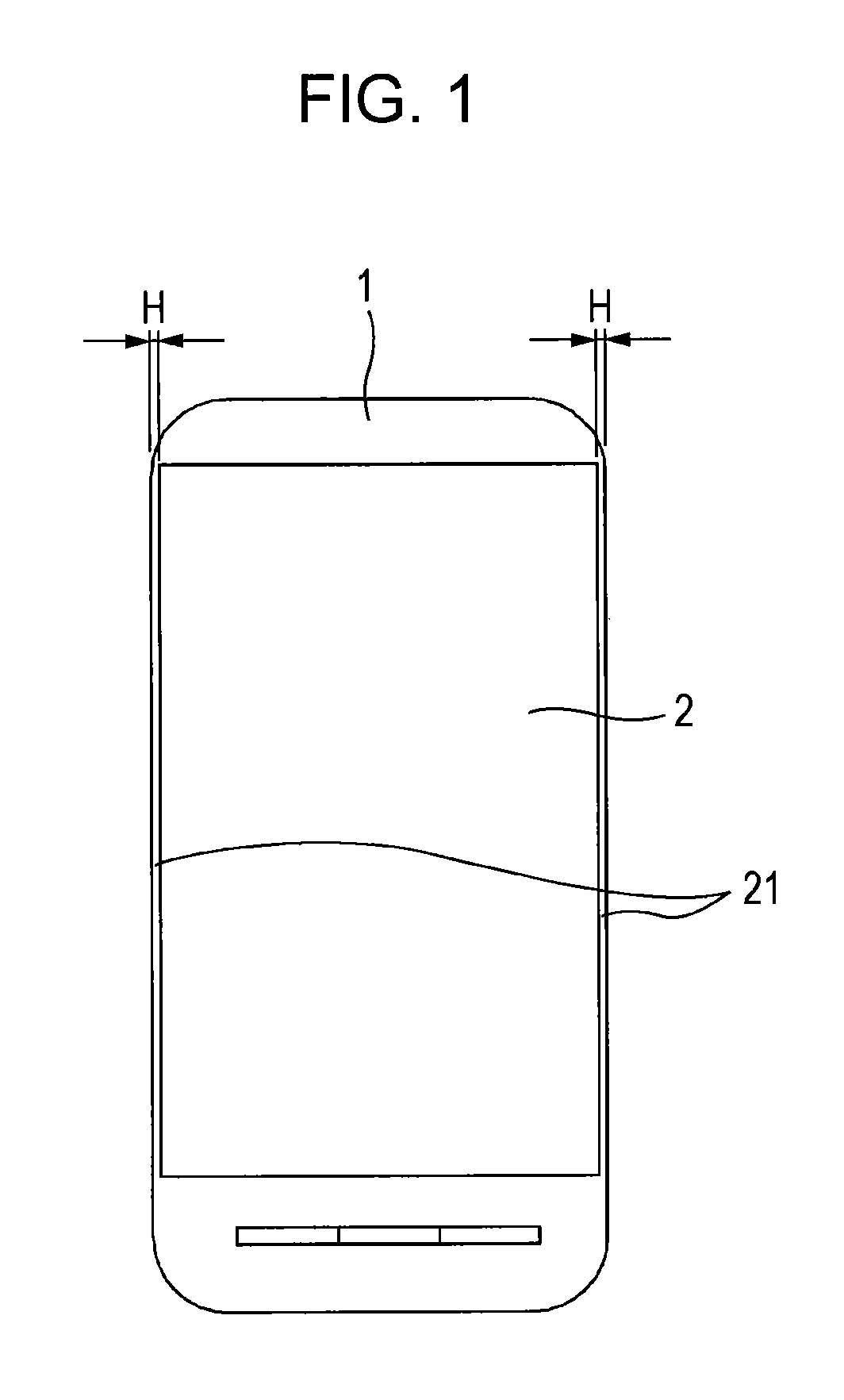

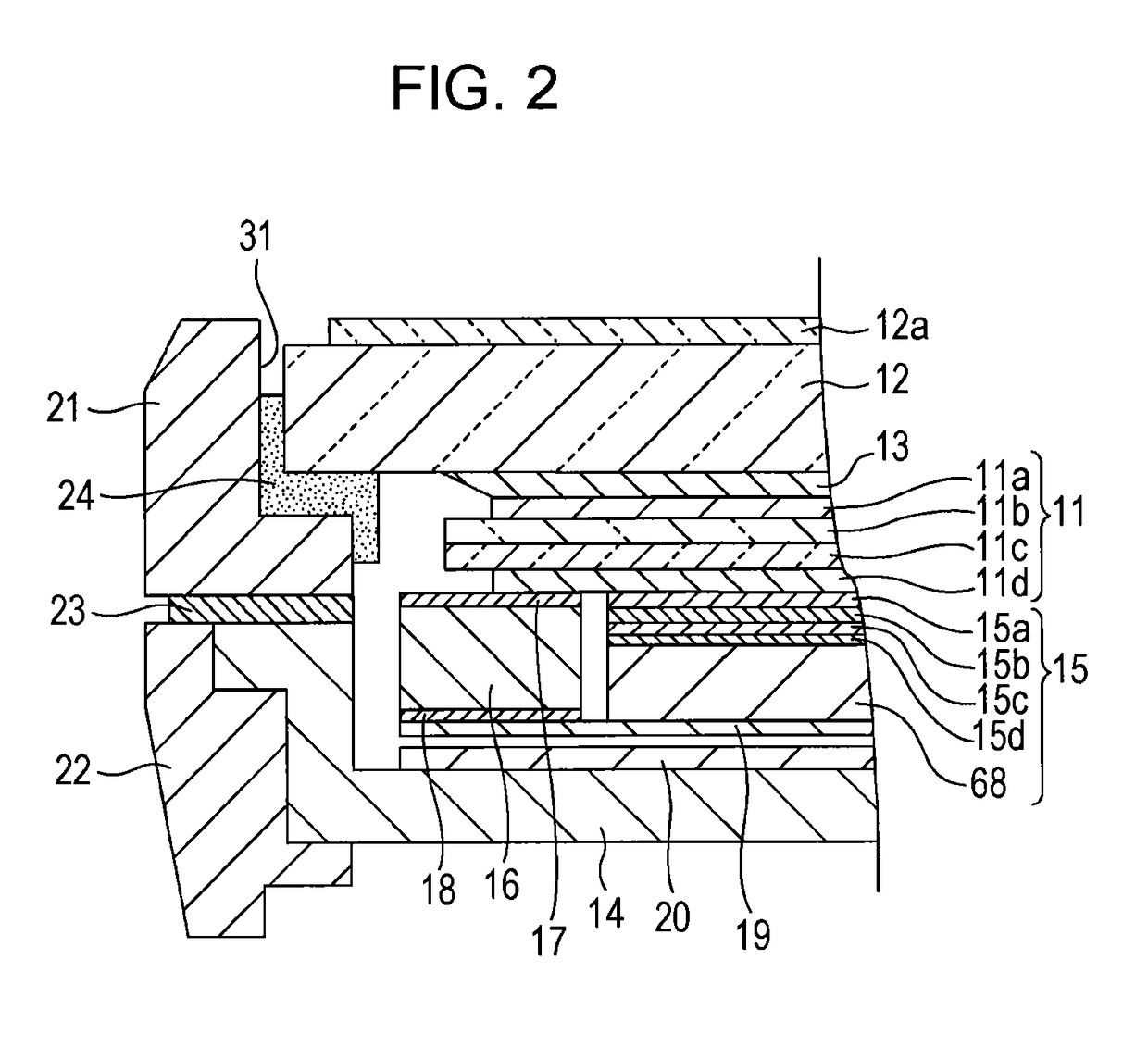

Personal digital assistant apparatus

ActiveUS20130208412A1Meet rigid requirementsNarrow frameDigital data processing detailsElectrical apparatus contructional detailsInformation processingEngineering

An information processing apparatus including a display portion, and a casing including an inner circumference wall portion that faces a side wall of the display portion and an inner circumference bottom plane portion that faces a rear surface of the display portion. The display portion is secured to the inner circumference wall portion and the inner circumference bottom plane portion of the casing with an adhesive agent.

Owner:SONY CORP

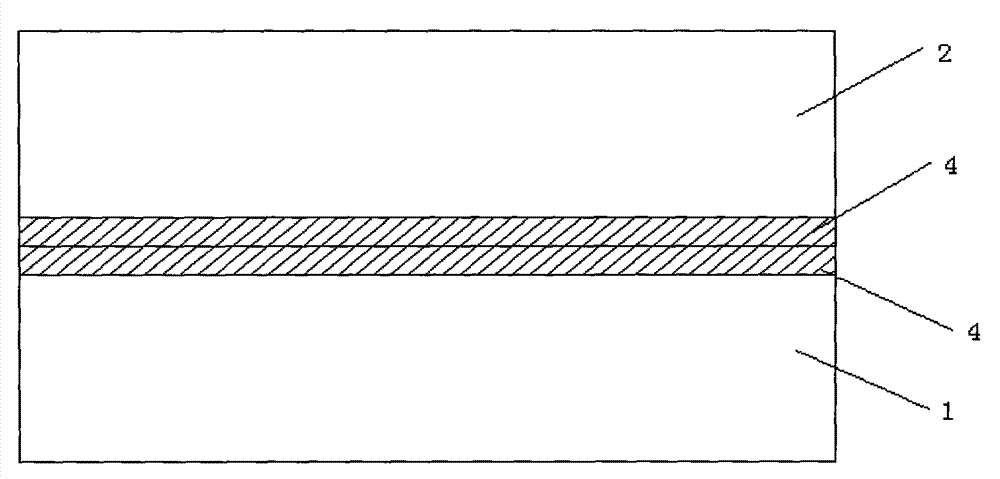

Double-layer PVC (Poly Vinyl Chloride) composite material and preparation method thereof

InactiveCN102604254AIncrease costLow costSynthetic resin layered productsPlasticizerPolyvinyl chloride

The invention provides a double-layer PVC (Poly Vinyl Chloride) composite material and a preparation method thereof. The composite material comprises an upper layer and a bottom layer which are formed by up-down co-extrusion. The upper layer comprises the following components in mass percent of 13-17% of PET (Poly Ethylene Terephthalate) resin, 2-4% of plasticizer, 4.5-5.5% of aluminum silver powder, 0.9-1.1% of stabilizing agent, 0.3-1.5% of lubricating agent and residual amount of polyvinyl chloride resin; the lower layer comprises the following components in mass percent of 2-4% of the plasticizer, 0.3-1% of the stabilizing agent, 25-35% of filling agent and residual amount of the polyvinyl chloride resin. The upper layer of the double-layer PVC composite material provided by the invention comprises the aluminum silver powder, and the aluminum silver powder is applicable to filling pits on the surface of the upper layer, so that the surface of the upper layer has high fineness and brightness to satisfy the decorating effect on the surface of the household appliances. The bottom layer is a hard PVC layer and has preferable mechanical properties and product stability, so that the rigid requirements of the entire product can be met.

Owner:江苏伊特复合新材料有限公司

PVC (Poly Vinyl Chloride) composite material

ActiveCN102582185AIncrease costLow costSynthetic resin layered productsPlasticizerPolyvinyl chloride

The invention provides a PVC (Poly Vinyl Chloride) composite material and a preparation method thereof. The composite material comprises an upper layer and a bottom layer which are subjected to up-and-down co-extrusion forming; the upper layer comprises the following components in percentage by mass: 15 percent of PET (polyethylene glycol terephthalate) resin, 3 percent of plasticizer, 5 percent of aluminium silver powder, 1 percent of stabilizer, 0.3 to 1.5 percent of lubricant and the balance of PVC resin; and the bottom layer comprises the following components in percentage by mass: 3 percent of plasticizer, 0.3 to 1 percent of stabilizer, 0.3 to 1 percent of lubricant, 24 to 36 percent of filler and the balance of PVC resin. The upper layer of the double-layer PVC composite material provided by the invention comprises the aluminium silver powder, and the aluminium silver powder is suitable for filling concave pits on the surface of the upper layer, so that the surface of the upper layer has high smooth finish and brightness to meet the surface decoration effect of household appliance equipment; and the bottom layer is a hard PVC layer, has good mechanical performance and product stability, and is suitable for meeting the integral rigidity requirement of the product.

Owner:江苏伊特复合新材料有限公司

Electrical device mounting structure on a motorcycle

InactiveUS8800830B2Easy to operateSimple designWheel based transmissionTravelling carriersElectrical devicesEngineering

Owner:HONDA MOTOR CO LTD

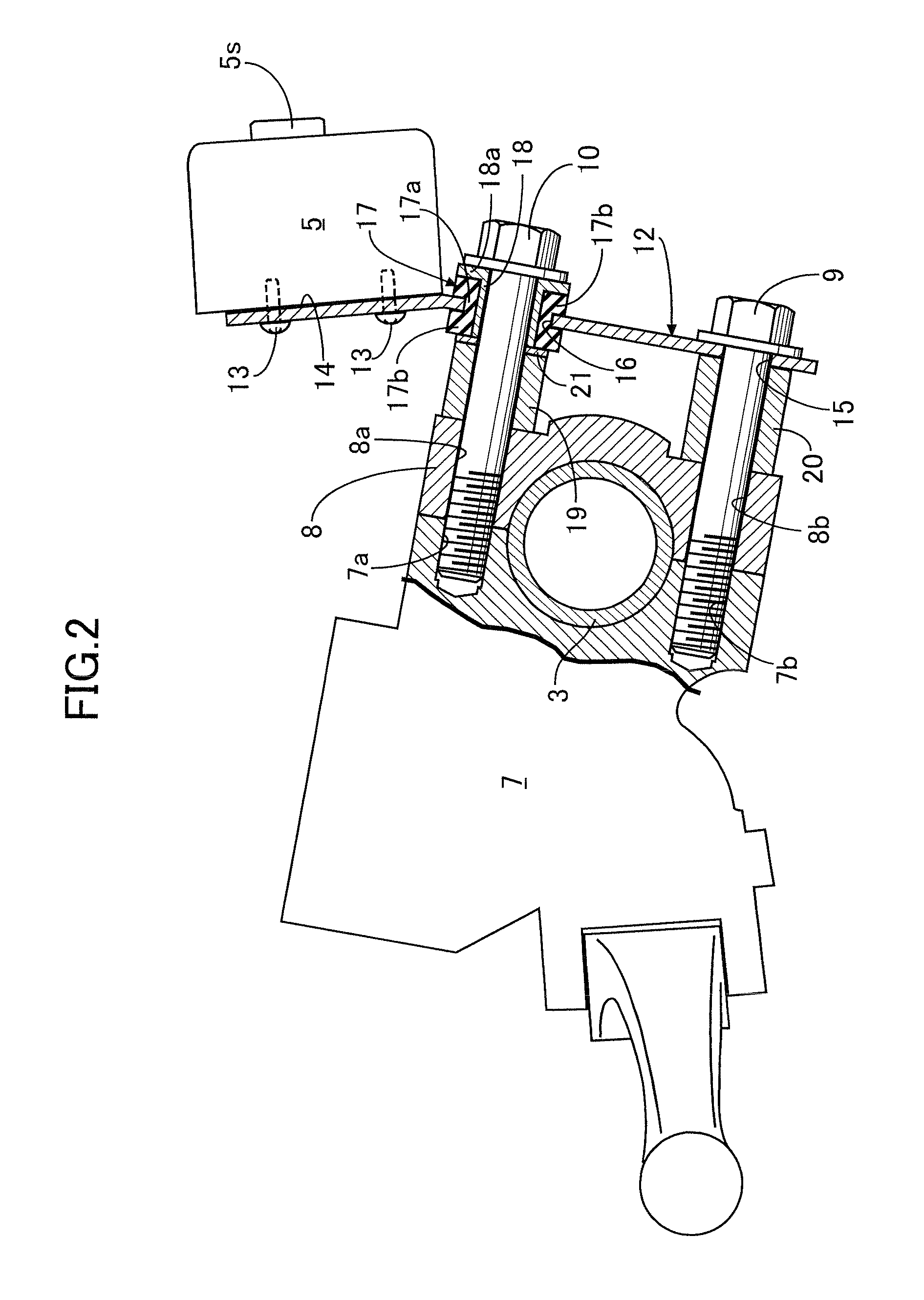

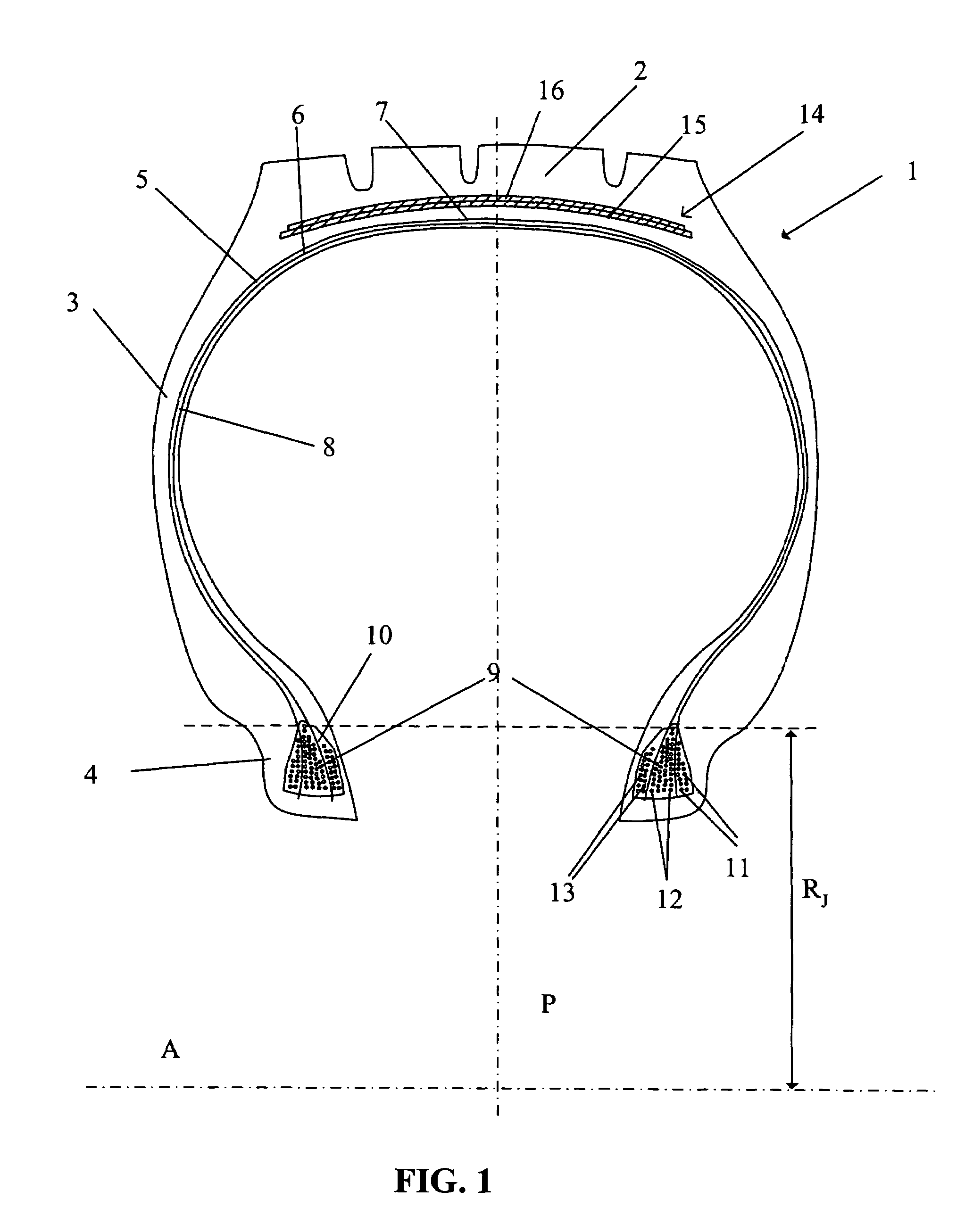

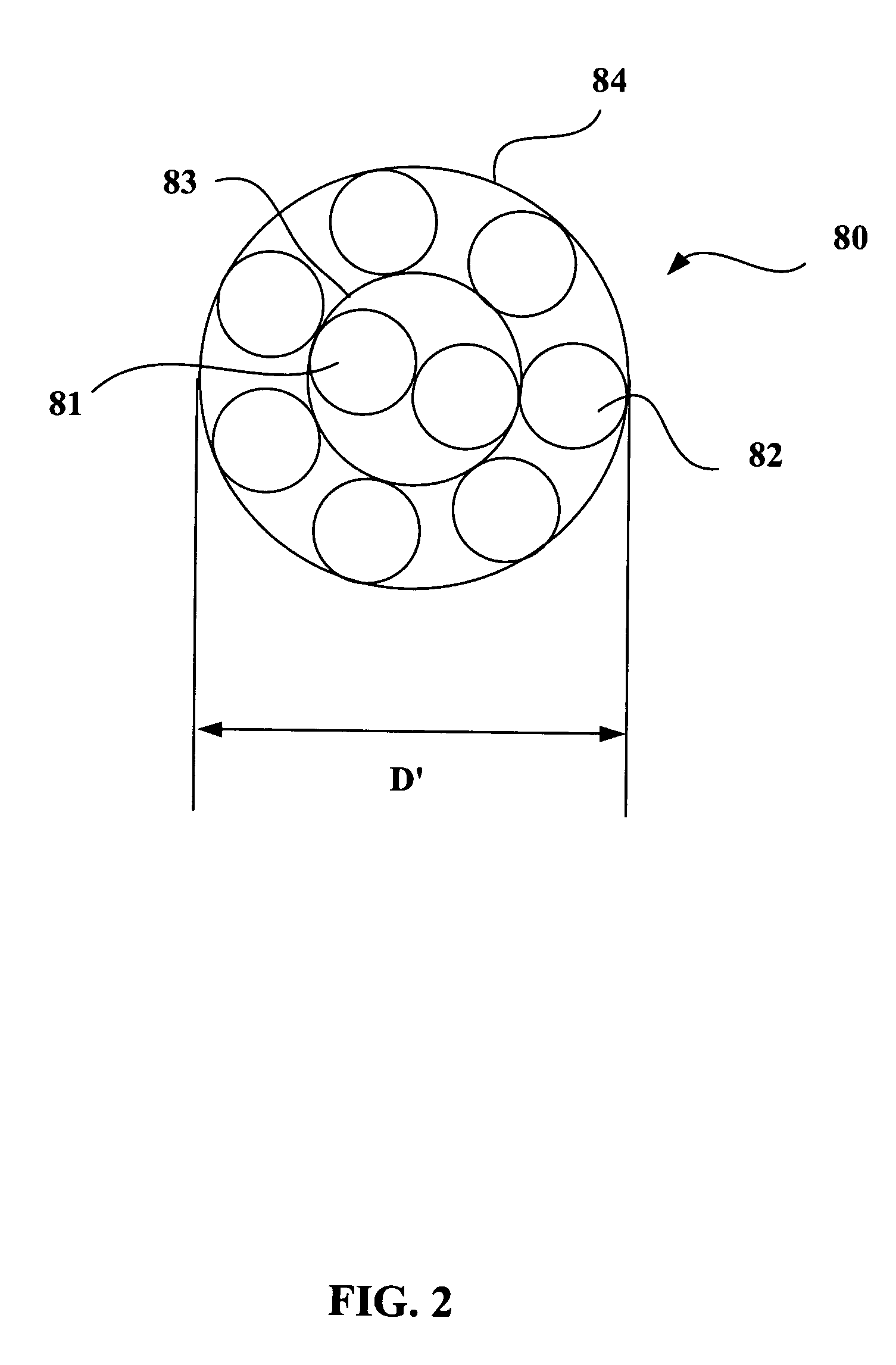

Aircraft tire

InactiveUS7278457B2Reduce deformationHigh modulusPneumatic tyre reinforcementsTyre beadsElastic modulusAirplane

Owner:MICHELIN RECH & TECH SA

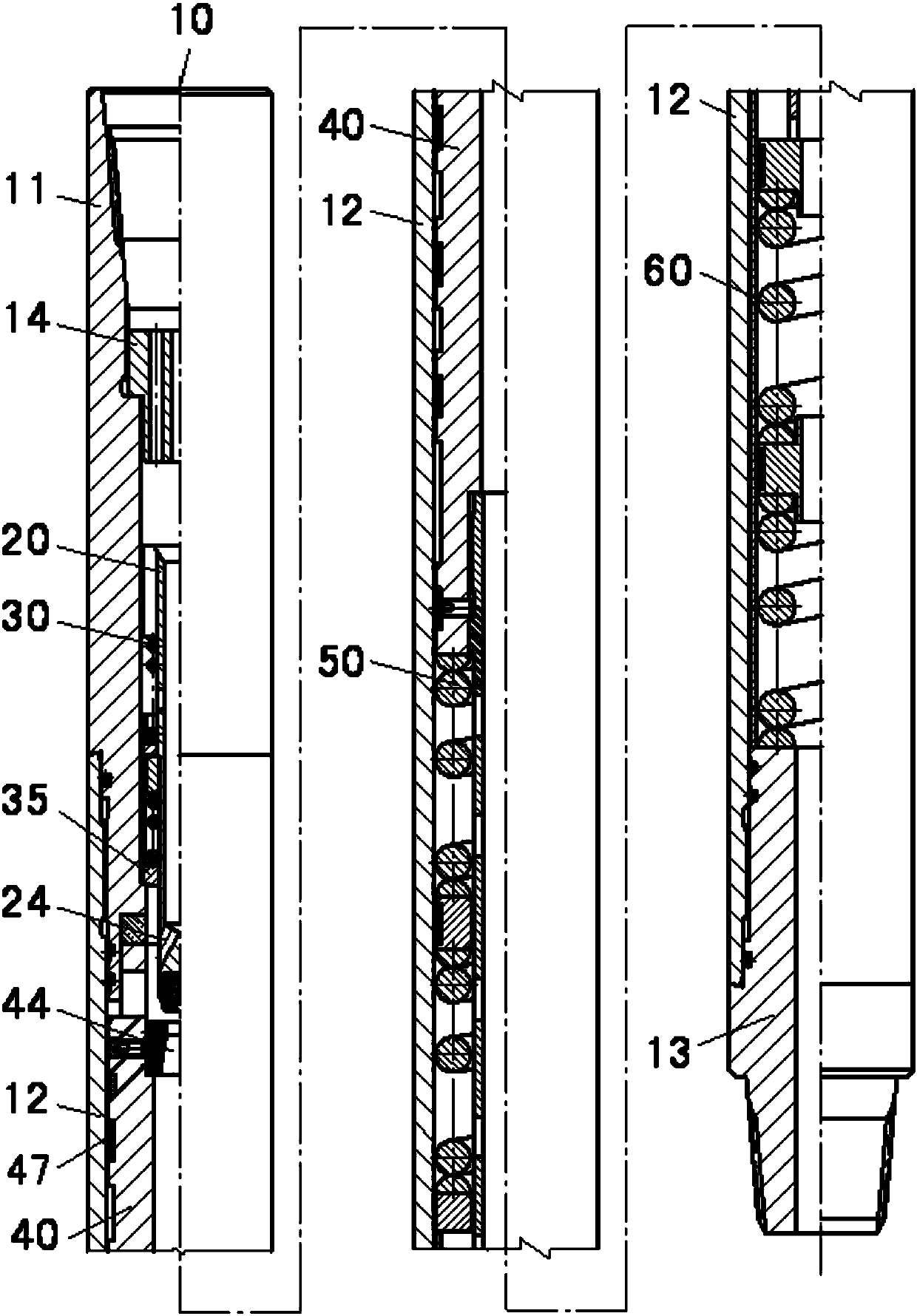

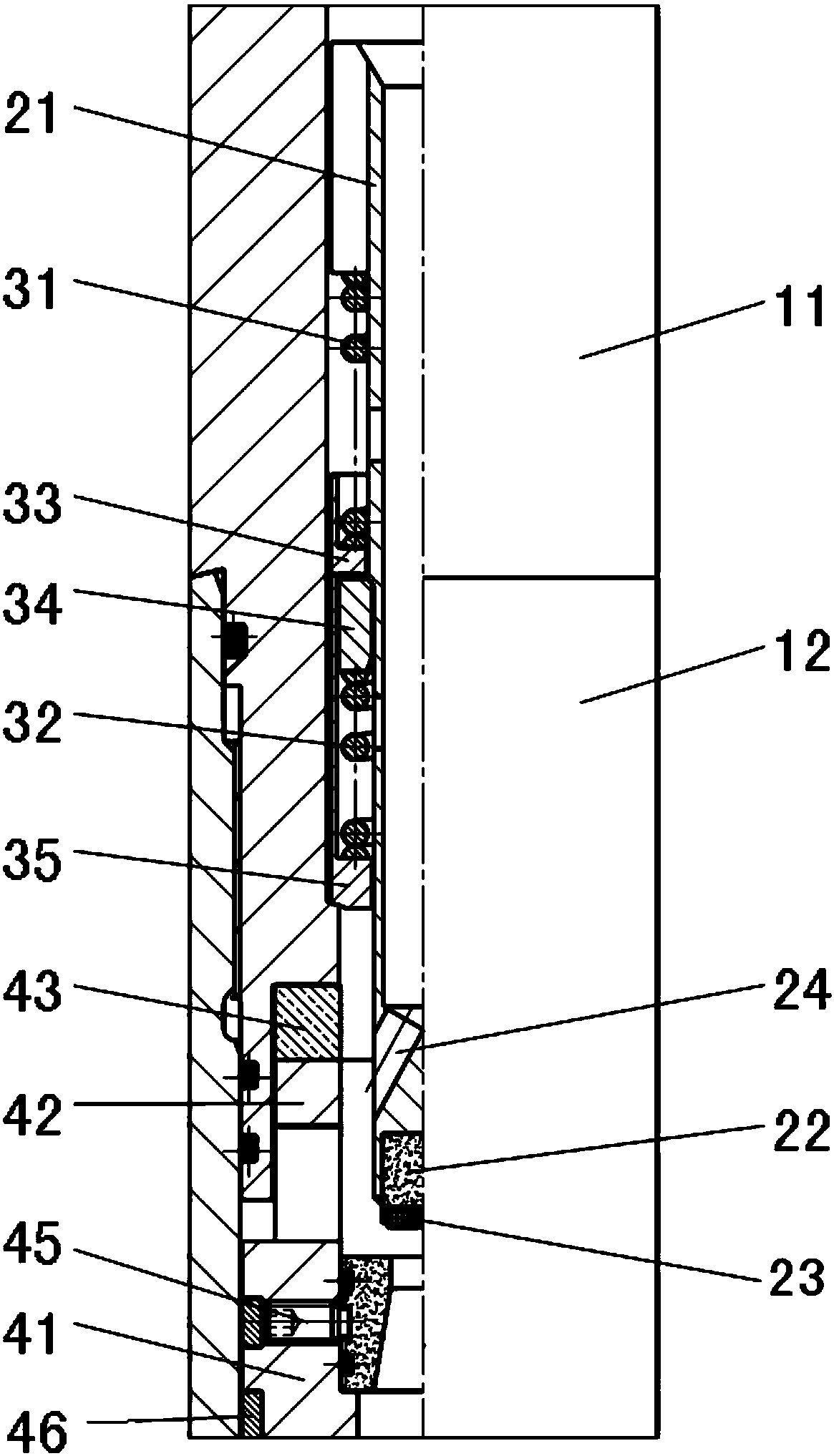

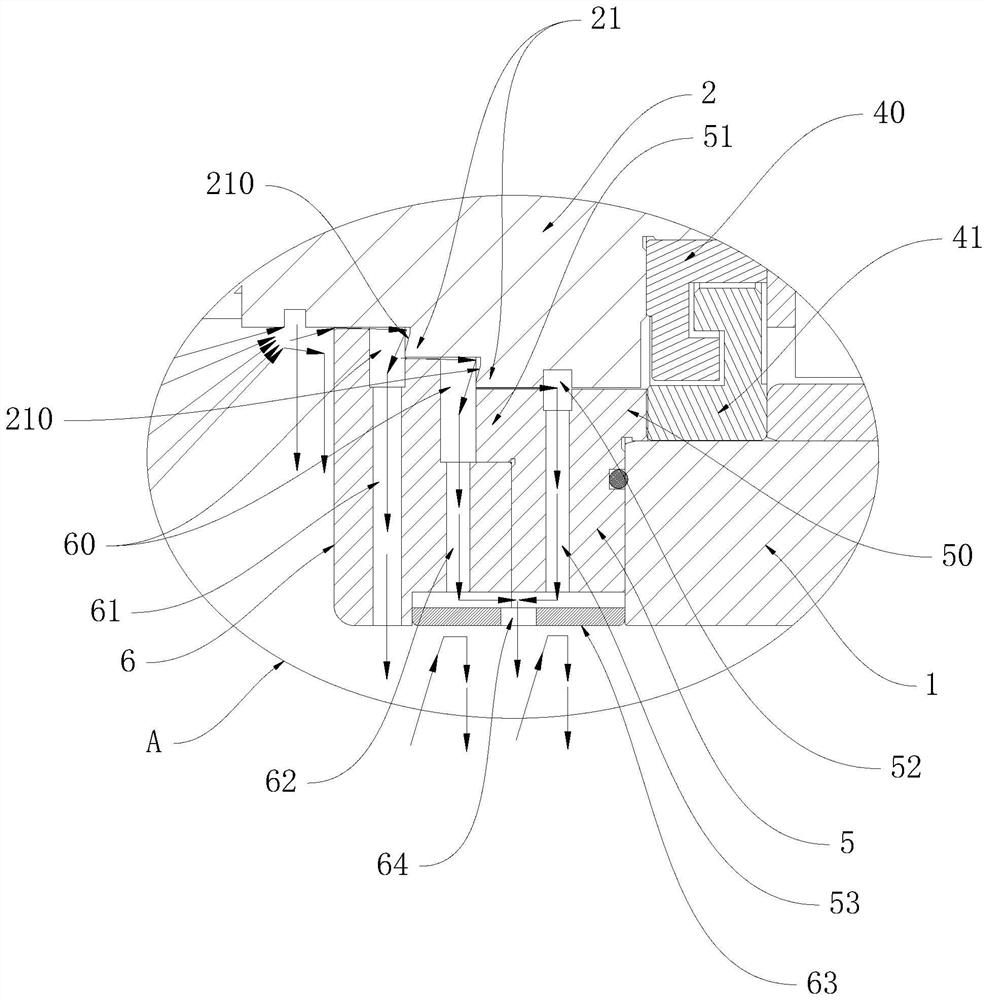

Unclamping method and device adopting continuous jarring through spring periodically stretching out and drawing back

PendingCN107687328AMeet rigid requirementsMeet travel requirementsBorehole/well accessoriesInternal pressureHorizontal wells

The invention discloses an unclamping method and device adopting continuous jarring through spring periodically stretching out and drawing back. According to the unclamping method and device, a valveis arranged in a tubular column, when the pressure of circulating fluid entering the tubular column is larger than the counter-acting force of a spring inside the tubular column and a valve hole is closed, the pressure of the circulating fluid compresses the spring and is converted into compressed elastic potential energy of the spring, when the compressed elastic potential energy of the spring isincreased gradually and equal to the pressure of the circulating fluid, the valve hole is opened, the pressure inside the tubular column is unbalanced instantly, the compressed elastic potential energy of the spring is released instantly and drives a jar weight inside the tubular column to upwards impact suddenly, and impacting kinetic energy is transmitted to the clamping point through the tubular column; after one-time impacting is completed, all components inside the tubular column are reset simultaneously to well prepare for energy storage impact of the next time, the process is repeated,and periodical repeat jarring is formed till unclamping is achieved. The unclamping method and device can be used for salvage operation of vertical wells and can also be used for unclamping and salvage operation of deviated wells, greatly-displaced wells and horizontal wells; and during operation, manual resetting operation is not needed, continuous jarring can be achieved till unclamping is achieved, and the unclamping method and device are more efficient and quicker than a conventional technology.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

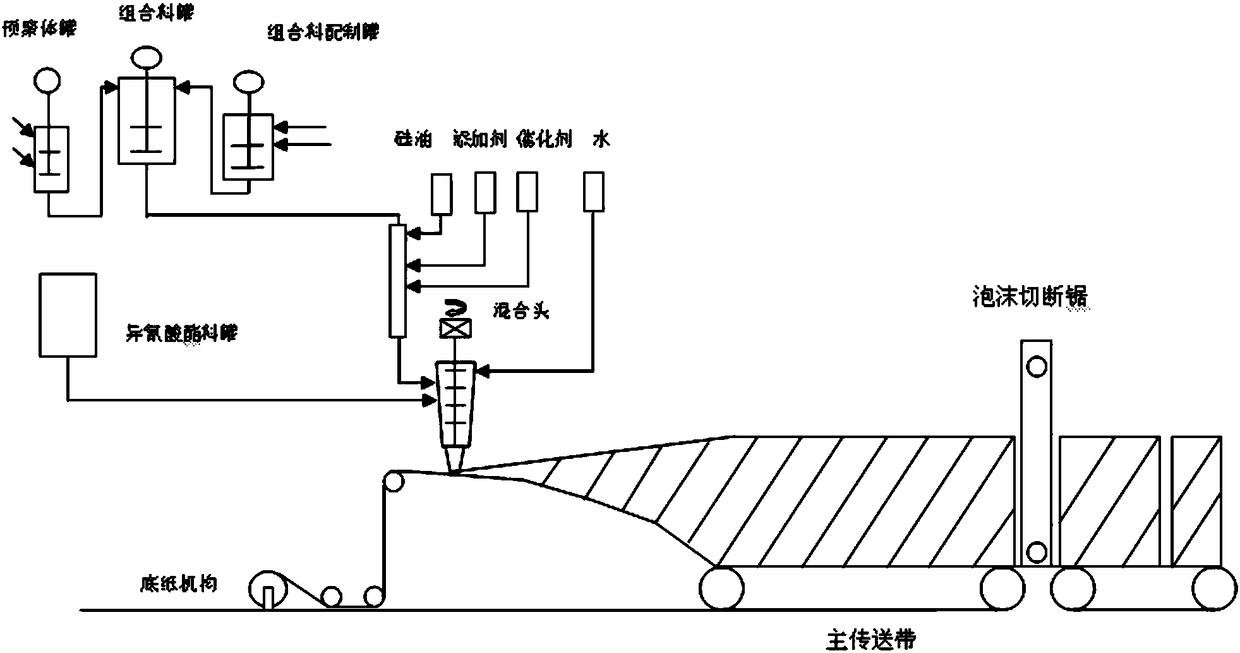

Polyurethane foam for automobile dry-method ceiling and preparation method thereof

The invention relates to polyurethane foam for an automobile dry-method ceiling and a preparation method thereof and belongs to the technical field of production of the polyurethane foam. The polyurethane foam is prepared from polyether glycol, an isocyanate mixture, a catalyst 1, a catalyst 2, a silicone oil type surfactant, a solid additive, a polyurethane antioxidant, a pore opening agent and water through mixing and foaming. The technology provided by the invention is suitable for large-batch and multi-scale production; manpower of a foaming line can be used in other posts so that the production efficiency is effectively improved. Furthermore, when the yield is greater, the foaming rate is higher. Continuous foaming and box type foaming, which are universally accepted in an industry, have better advantages in the aspect of foam block quality; raw materials are accurately metered and foam holes are uniform; the difference of upper, middle and lower parts of the foam blocks is reduced; unavailable parts of the tops and bottoms of the foam blocks are controlled; the yield of products and the like can be improved by adopting various ceiling technologies.

Owner:无锡吉兴高分子材料科技有限公司

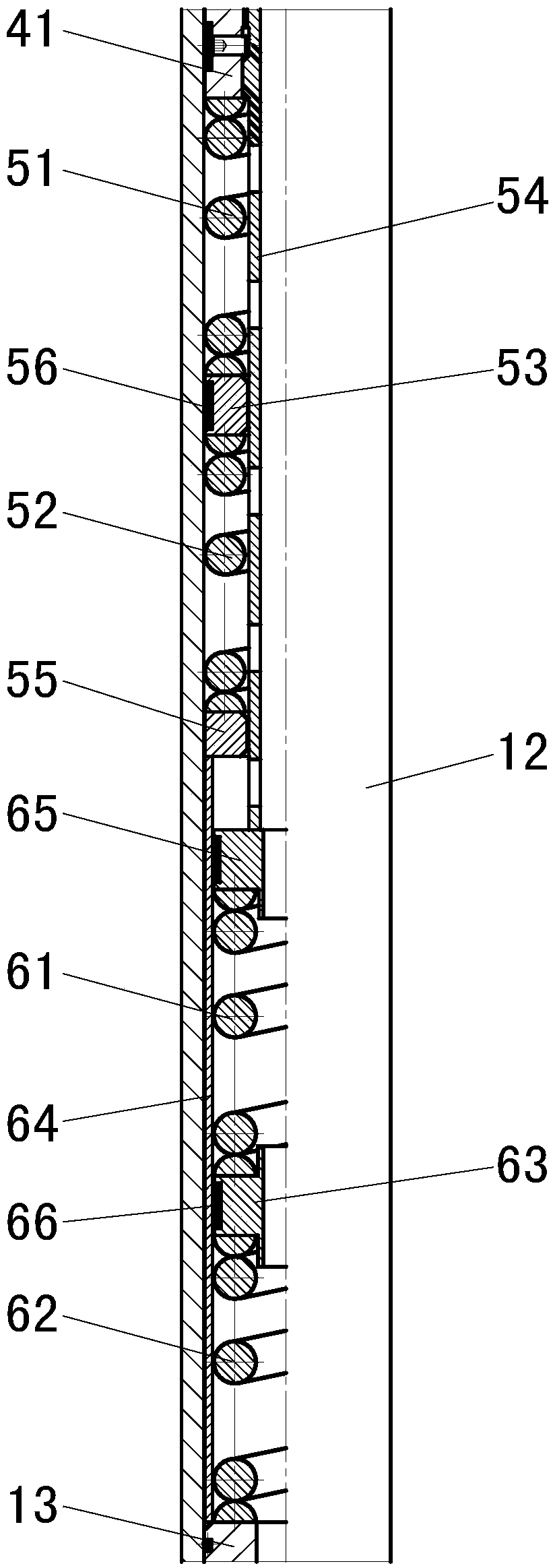

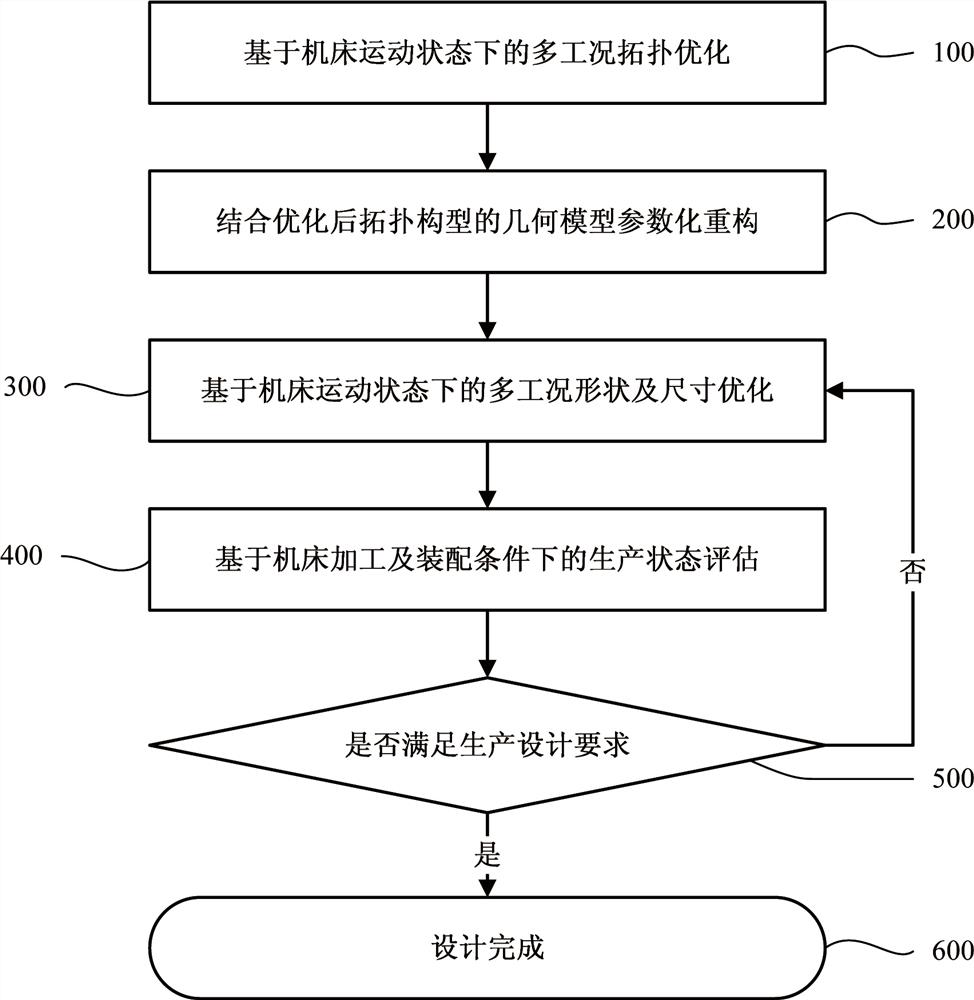

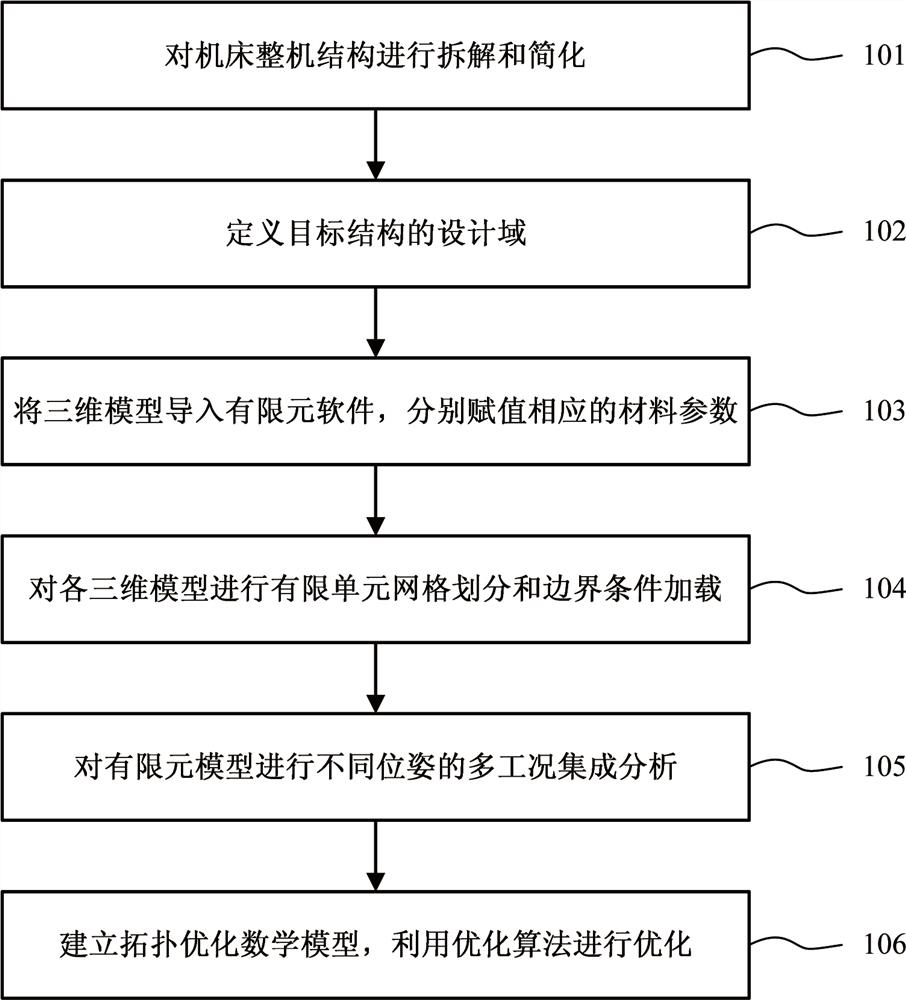

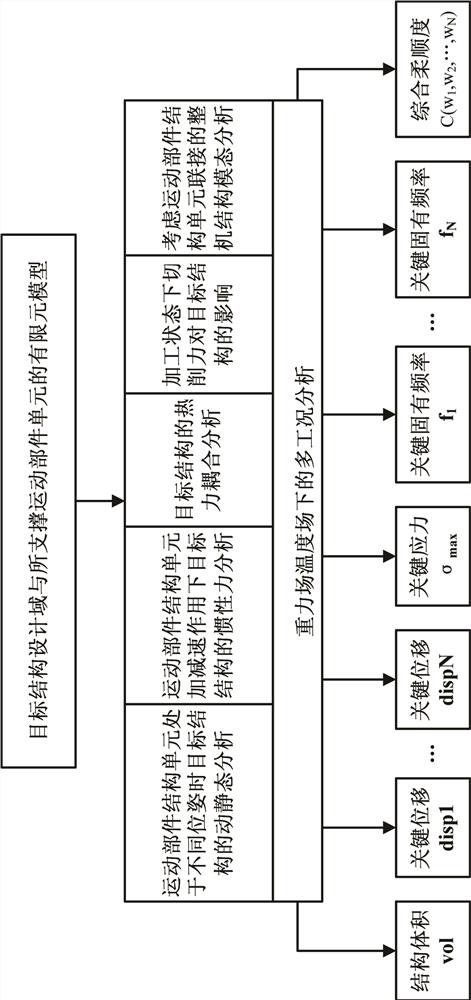

Key host assembly structure optimization design method based on machine tool working state

PendingCN112487673AIn line with the actual working statusMeet rigid requirementsGeometric CADDesign optimisation/simulationGeometric modelingProcess engineering

The invention relates to a structure optimization design method of a machine tool component, in particular to a key host component structure optimization design method based on a machine tool workingstate. The method comprises the following steps: A, performing multi-working-condition topological optimization based on a machine tool motion state; B, parameterization reconstruction is carried outon the geometric model combined with the optimized topological structure; C, optimizing the shape and the size based on multiple working conditions of the machine tool in the motion state; D, performing production state evaluation based on machine tool machining and assembling conditions. The method is not limited to an assembly structure needing to be optimized, but comprehensively considers complete machine mounting structures such as the motion connecting piece and the supported piece, and fully considers various motion states and various working conditions of the machine tool, so that theoptimized design index is closer to the actual working state of the machine tool, and the optimized structure is higher in reliability.

Owner:BEIJING JINGDIAO GRP CO LTD

Sound-absorbing aluminum plate

ActiveCN103603436AImprove the decorative effectEasy to viewSound proofingMetal layered productsMetallurgy

Owner:ZHANGJIAGANG RUNSHENG SCI & TECH MATERIAL

Printing color management (PCM) compound steel plate

InactiveCN101758737AImprove rigidityImprove molding pass rateSpecial ornamental structuresSheet steelLacquer

The invention provides a PCM compound steel plate. The front face of the steel plate is coated with a primer layer, an upper roller of the primer layer is coated with a finish layer, an upper roller of the finish layer is coated with a pattern printing layer, the surface of which is embossed with a decorative pattern, and an upper roller of the pattern printing layer embossed with the decorative pattern is coated with a protective paint layer. The pattern printing layer realizes the visual effect of various colors and patterns, the surface embossing forms concavo-convex stereoscopic impression, the rigidity of the steel plate is increased, the rigidity requirement can be satisfied through selecting a thin base material so that the cost is reduced, the forming qualification rate of a finished product is enhanced, and the PCM compound steel plate is extensively used for the industries of home appliances, decoration and the like.

Owner:SUZHOU HESHENG NEW MATERIALS

Glass compositions for gaskets of apparatuses operating at high temperatures and assembling method using them

ActiveUS9309144B2Meet rigid requirementsImprove balanceCellsFuel cell manufactureFuel cellsPhotochemistry

A glass composition, characterized in that it is selected from the group consisting of: a glass composition (A) with the following molar percentages: 70 to 76% of SiO2, 7 to 8% of B2O3, 5 to 6% of Al2O3, and 10 to 17% of Na2O; and a glass composition (B) with the following molar percentages: 63 to 76% of SiO2, 5 to 12% of ZrO2, 0 to 12% of B2O3, 0 to 2% of La2O3, 11 to 14% of Na2O, and 3 to 5% of K2O. The glass composition can be used in a method for assembling parts, in particular for a method of manufacturing high-temperature electrolyzers (HTEs) or high-temperature fuel cells (SOFCs).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

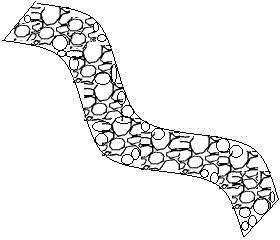

Surgical thread

ActiveUS20200281588A1Without reducing fastening capabilityEasy to getSuture equipmentsCosmetic implantsReoperative surgeryMedical device

The present invention relates to a surgical thread comprising at least a first portion extending longitudinally and comprising a central thread covered with a sheath, said sheath comprising fastening means each comprising at least one conical barb. The present invention also relates to a medical device comprising such a surgical thread and a surgical needle.

Owner:THREAD & LIFT

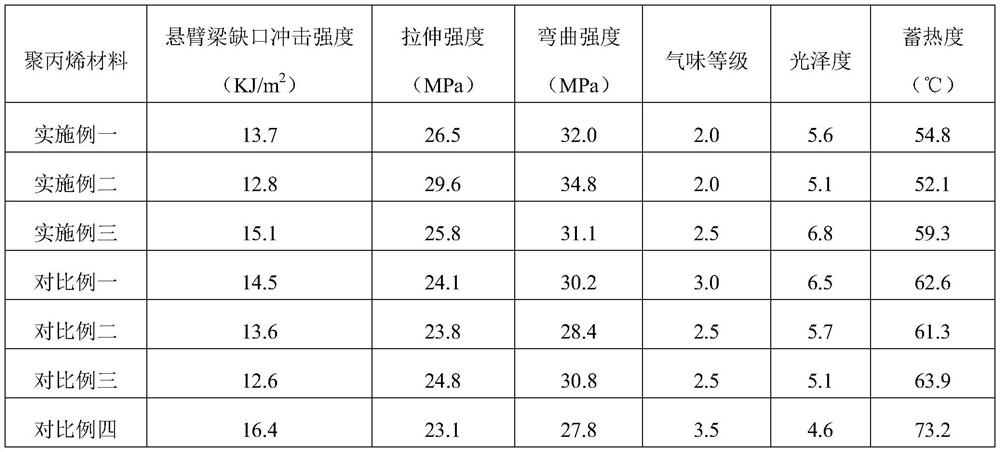

Low-heat-storage-degree polypropylene composite material for automotive upholstery and preparation method thereof

ActiveCN112011123AReduces the ability to absorb solar radiation energyImprove surface heat storage valueIr reflectionElastomer

The invention discloses a low-heat-storage-degree polypropylene composite material for automotive upholstery and a preparation method thereof. The material comprises the following raw materials: 55-75parts of polypropylene, 5-15 parts of polyolefin elastomer, 10-20 parts of talcum powder, 3-10 parts of infrared reflection filler A, 3-10 parts of infrared reflection filler B, 0.6-1.0 part of antioxidant, 0.3-0.5 part of dispersing agent, 0.5-3 parts of deodorant, 0.3-3 parts of scratch-resistant agent, 0.5-2 parts of stabilizer and 1-3 parts of infrared reflection pigment. The invention also provides the preparation method of the polypropylene composite material. The infrared reflection filler A, the infrared reflection filler B and the infrared reflection pigment are compatible with polypropylene, the blending effect is good, reflection of the polypropylene composite material to visible light, infrared light and ultraviolet light radiation energy is improved, the capacity of absorbingillumination radiation energy is reduced, the temperature in an automobile is reduced, and the comfort of passengers is improved.

Owner:QINGDAO GON TECHNOLOGY CO LTD

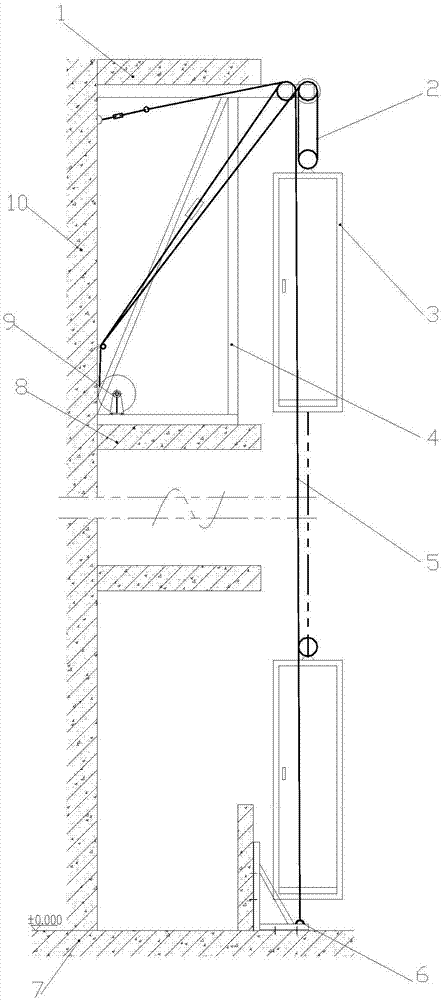

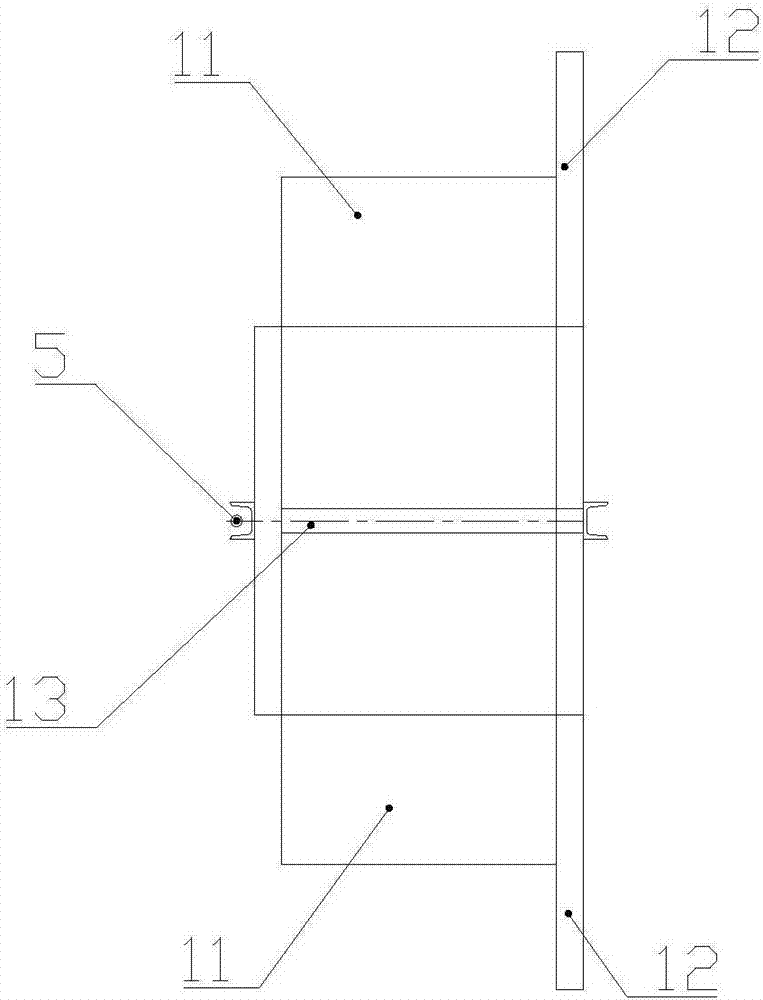

Tensioning flexible guide rail type domestic simple elevator

PendingCN107265255APrevent the elevator from fallingProtection against fall hazardsElevatorsBuilding liftsElectric machineryDrive motor

The invention discloses a tensioning flexible guide rail type domestic simple elevator comprising a lift car, a lifting traction mechanism and a power source; two sides of the lift car are connected with the lifting traction mechanism by a guide rail and a guide roller; a pulley at the top end of the lifting traction mechanism is fixedly arranged on the outer eave of a roof by a supporting beam; hoisting equipment of the lifting traction mechanism is fixedly arranged by virtue of a load bearing wall; a driving motor in the hoisting equipment is electrically connected with the power source; the lift car is internally provided with a control switch for controlling the operation of the driving motor; and the guide rail adopts a flexible guide rail. The simple elevator disclosed by the invention is mounted on a balcony or a windowsill and occupies no public spaces or an extremely small public space; due to the adoption of the flexible guide rail, not only can the rigidity requirement be met under the action of a tension, but also the elevator can be shrunk to be stored when not being used; due to the arrangement of a rope breaking protection device, a protecting effect can be achieved, so that the risk that the elevator falls down is avoided; and the simple elevator has the characteristics of space saving, convenience in mounting and operation as well as safety and reliability.

Owner:上海同演建筑科技有限公司 +2

Embossing enhanced PCM galvanized sheet

InactiveCN104354385AImprove visual effectsImprove rigiditySpecial ornamental structuresDecorative articlesFrontageAnti ageing

The invention provides an embossing enhanced PCM galvanized sheet. The base material is a galvanized sheet, a second passivation layer is formed on the back of the galvanized sheet the second passivation layer is subjected to roll-coating by a back paint layer, a first passivation layer is formed on the frontage of the galvanized plate, the first passivation layer is subjected to roll-coating by a primer layer, the primer layer is subjected to roll-coating by an anti-ageing paint coating, and patterns are pressed on the surface of the anti-ageing paint coating. The embossed anti-ageing coating is enhanced to achieve the visual effect of various colors and patterns, the surface embossing has concavo-convex stereoscopic impression, the rigidity of the galvanized sheet is enhanced, thinner base materials can be selected to meet the rigidity requirement, the cost is lowered, the finished product forming pass percent is improved, and the galvanized sheet is widely applied to the industries of household appliances, decoration and the like.

Owner:SUZHOU HESHENG NEW MATERIALS

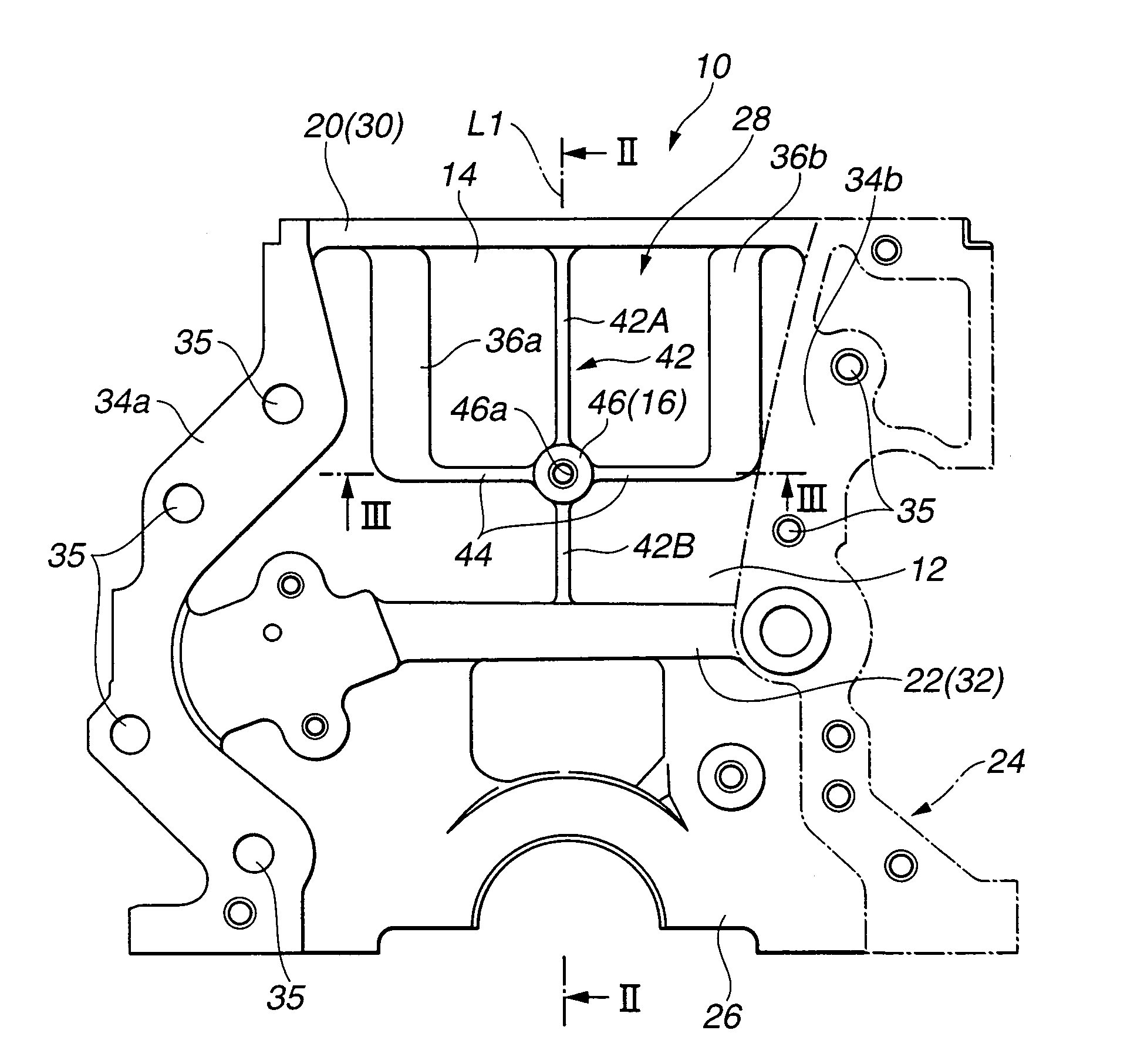

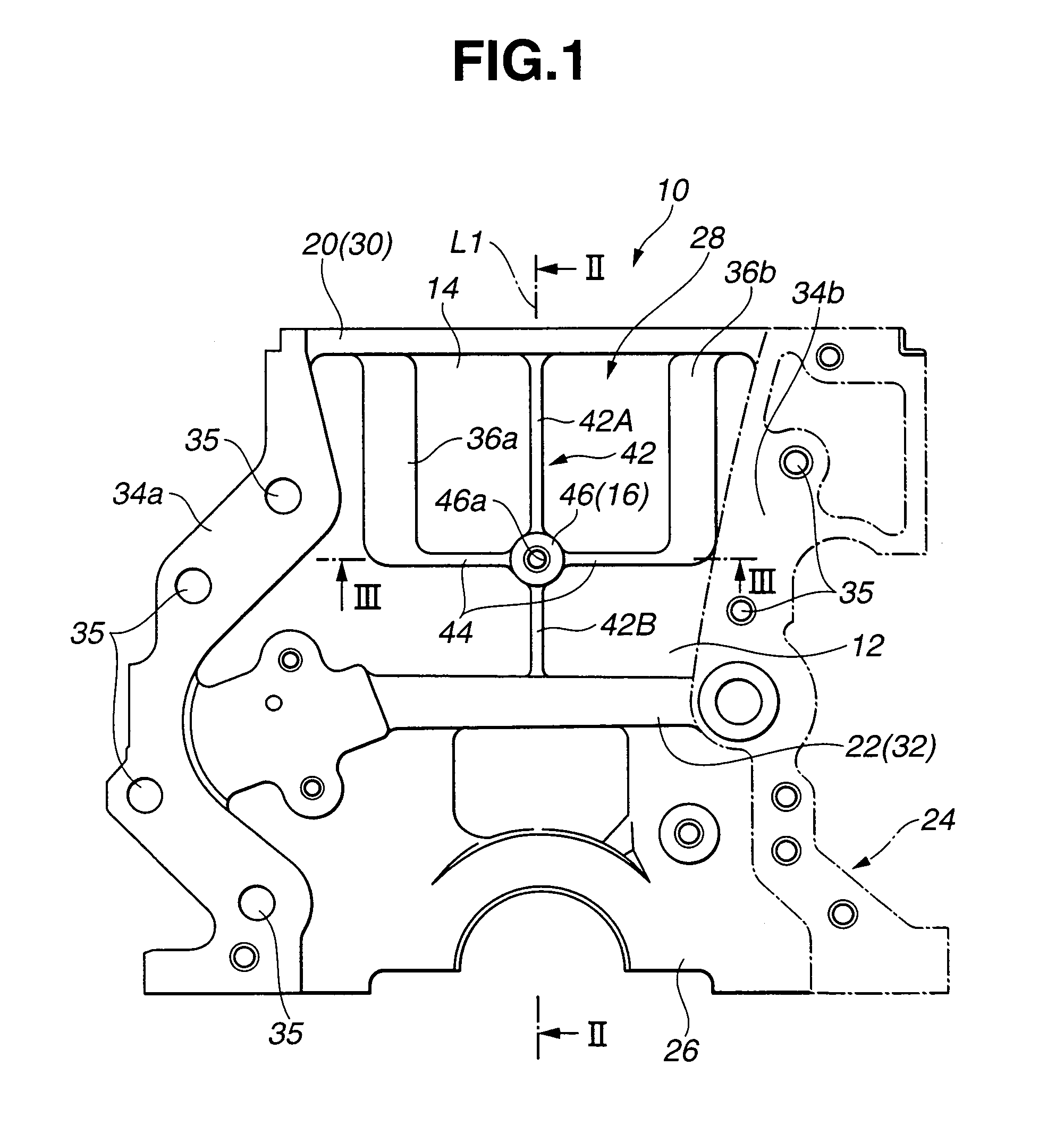

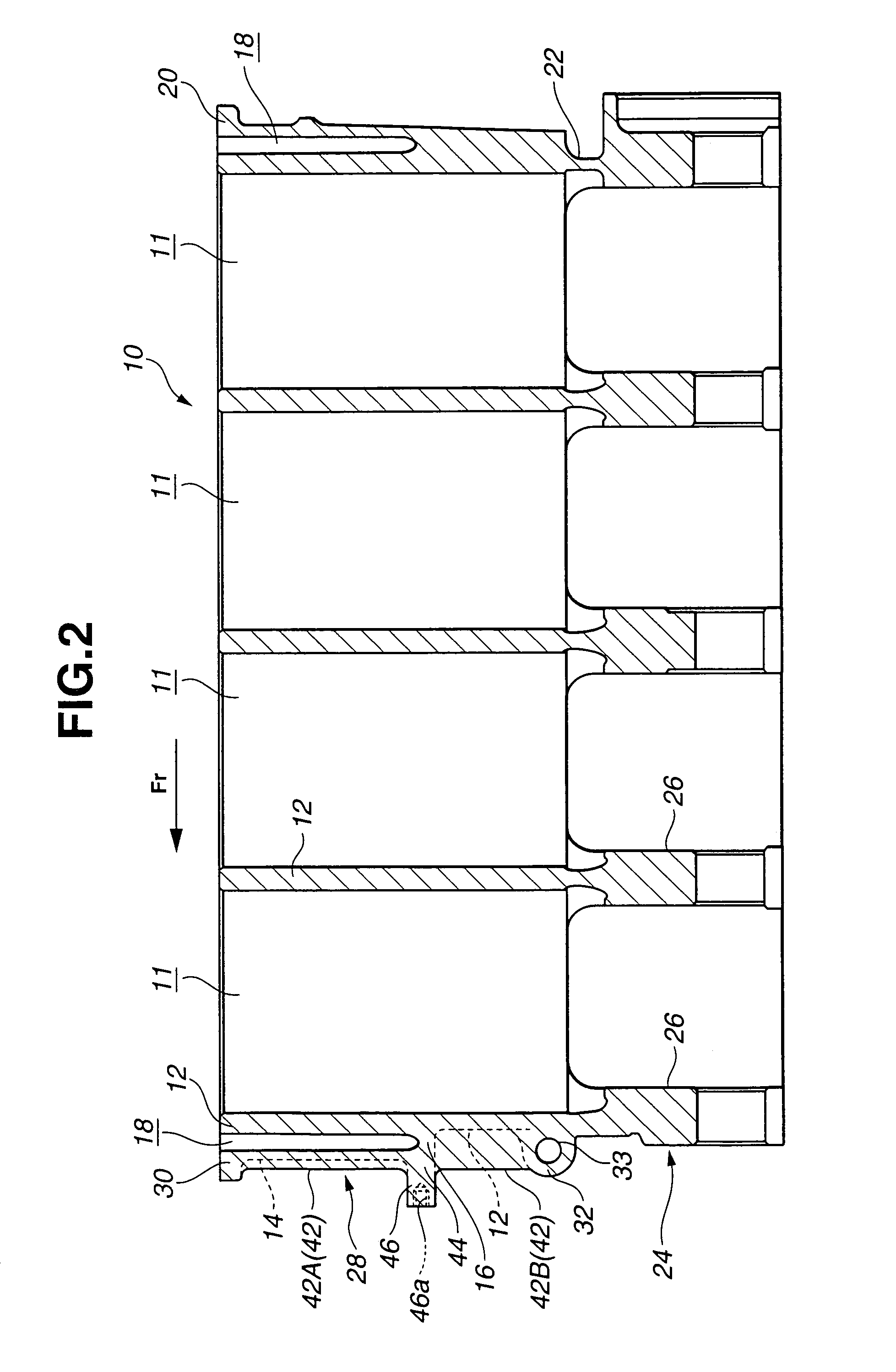

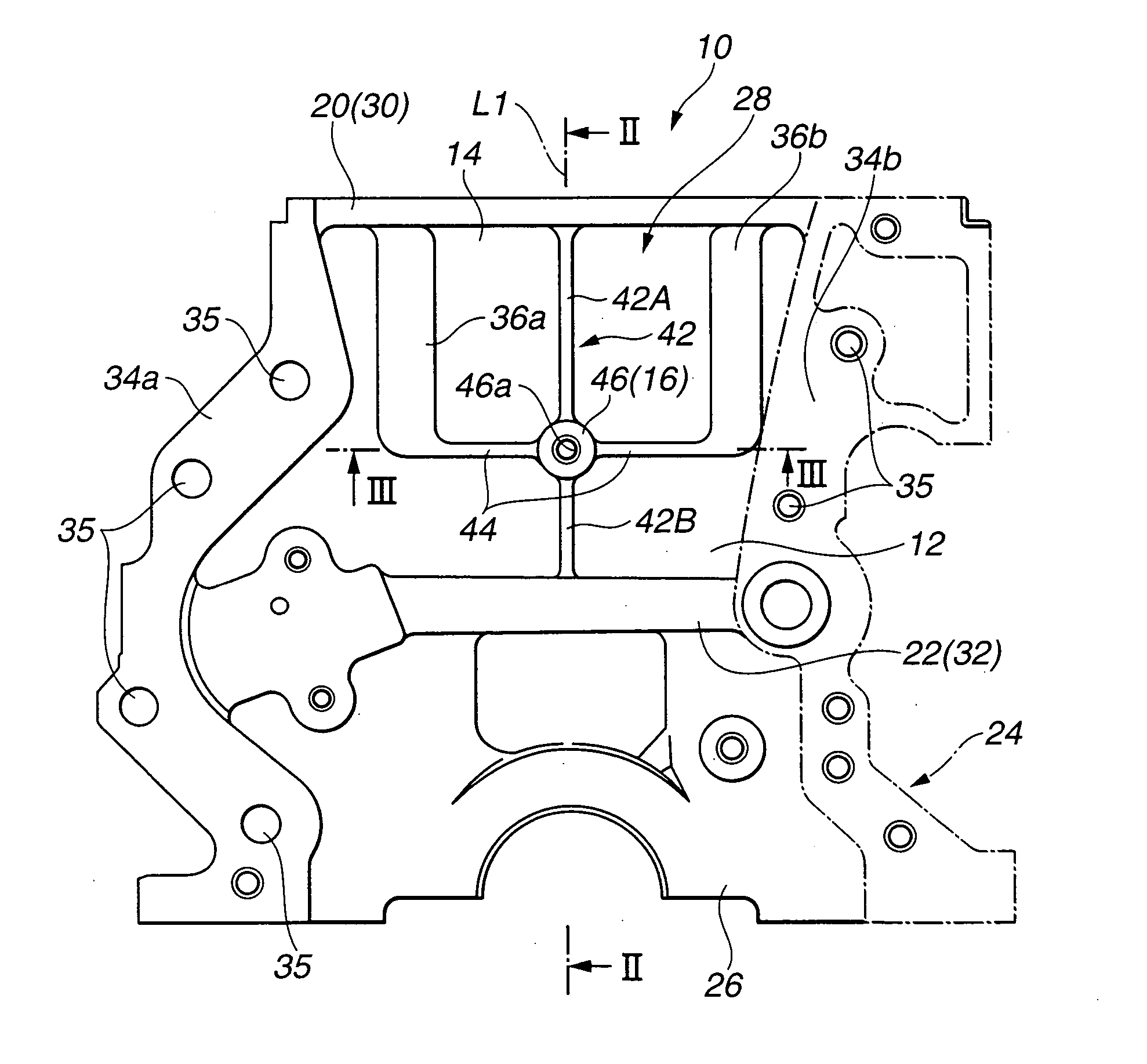

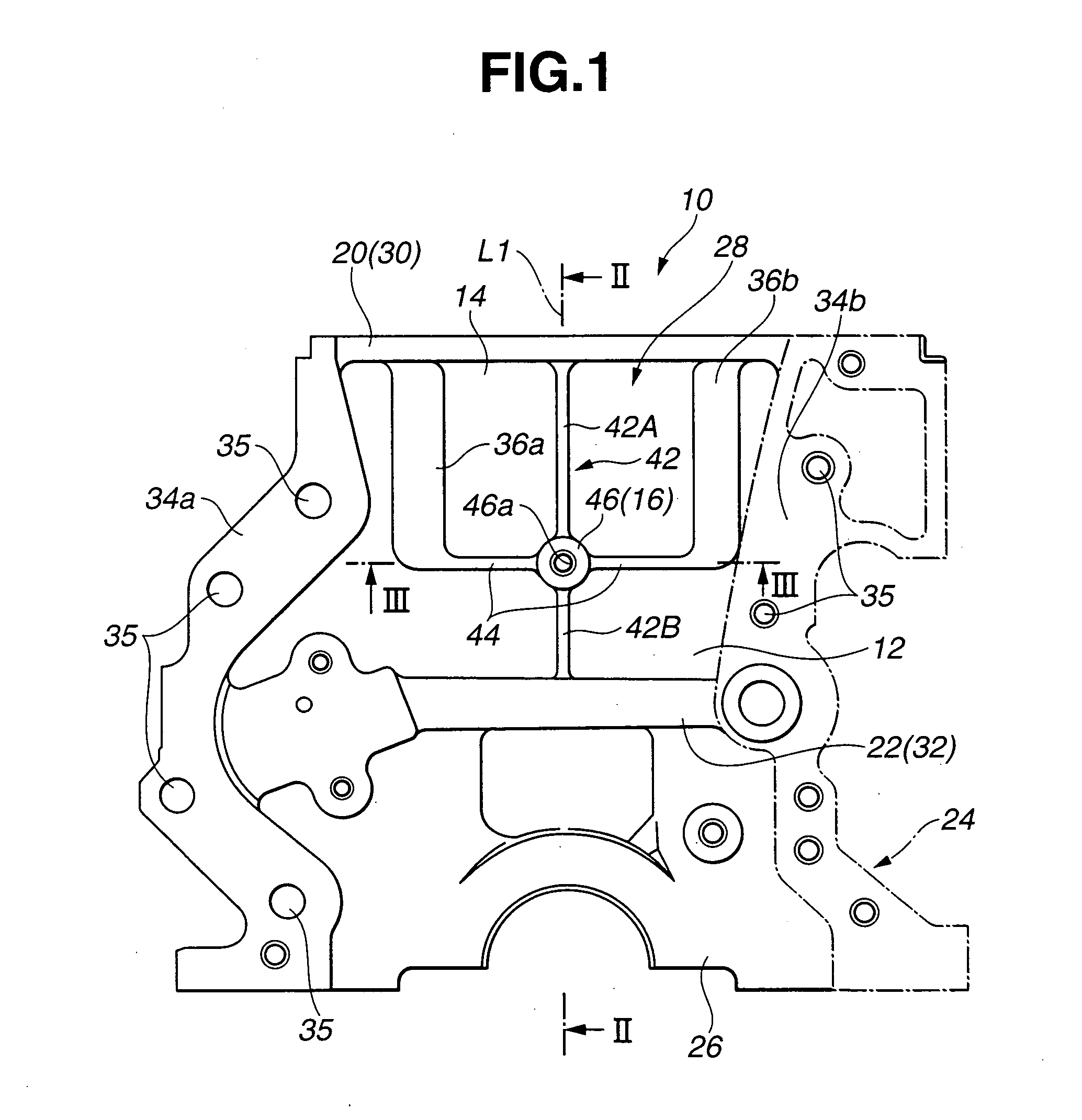

Cylinder block of internal combustion engine

ActiveUS7077079B2Meet rigid requirementsImprove rigidityCasingsCylinder headsStructural engineeringInternal combustion engine

A reinforcing structure is integrally formed on a front wall of a cylinder block of shallow water jacket type. The reinforcing structure comprises mutually crossing vertical and lateral ribs. The vertical rib extends vertically between upper and lower deck portions of the cylinder block, and the lateral rib is constructed to constitute a raised ridge of a front one of jacket bottom wall. Alternatively, the reinforcing structure comprises a raised bolt boss that is integrally formed on a front one of jacket bottom walls to catch a connecting bolt used for securing a middle portion of a front cover to the front wall.

Owner:NISSAN MOTOR CO LTD

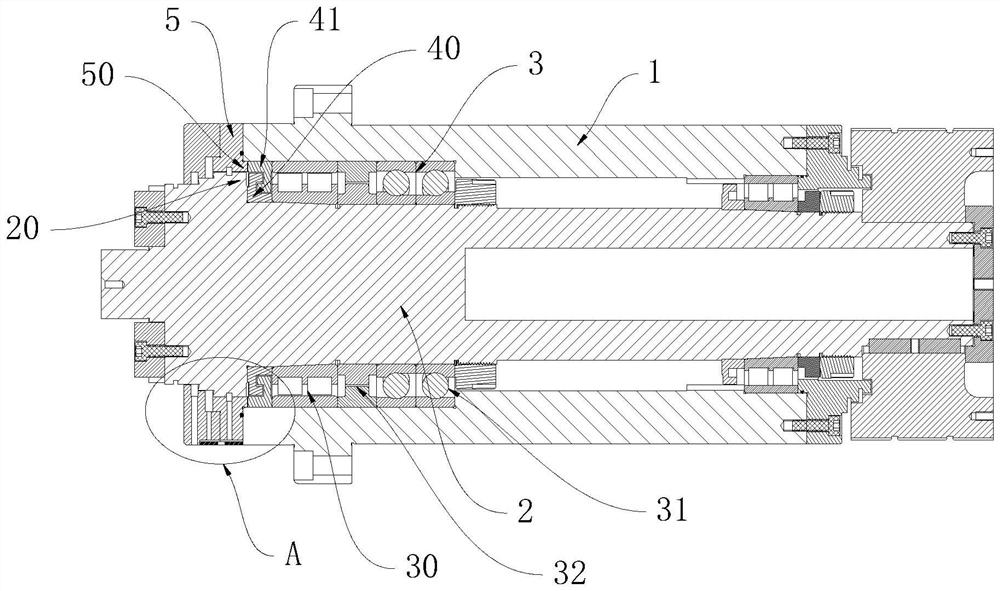

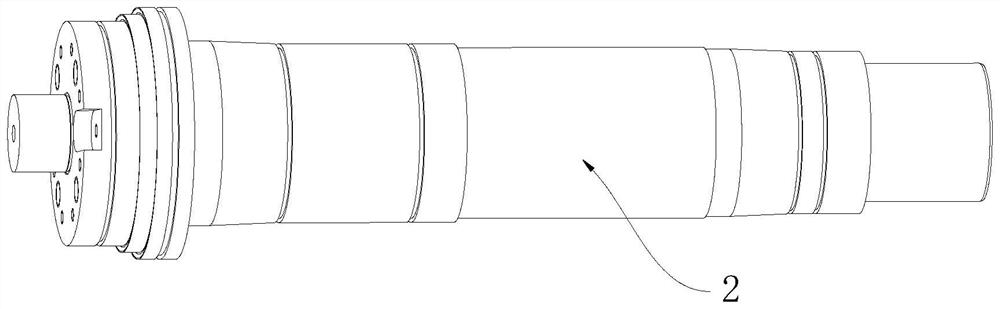

Horizontal milling machine spindle

PendingCN114453602AReduce the difficulty of assemblyReduce maintenance costsLarge fixed membersStructural engineeringMechanical engineering

The invention discloses a horizontal milling machine spindle which comprises a bearing chamber and a spindle core arranged in the bearing chamber in a penetrating mode, the spindle core is sleeved with a front bearing assembly and an inner spacer ring, a front step part is formed at the front end of the spindle core, and the inner spacer ring is arranged between the front step part and the front bearing assembly in a clamped mode. The outer side of the inner spacer ring is sleeved with an outer spacer ring, a gap is formed between the inner spacer ring and the outer spacer ring, a front bearing gland is fixed to the front end of the bearing chamber, a gap is formed between the front bearing gland and the shaft core, and a rear resisting convex ring is formed at the rear end of the front bearing gland. The rear resisting convex ring is clamped between the inner wall of the opening in the front end of the bearing chamber and the front step part, and the rear resisting convex ring is in abutting fit with the outer spacer ring. Compared with the prior art, the front bearing gland can be pushed from the front end of the shaft core, so that the assembly difficulty is reduced, the maintenance cost is saved, and meanwhile, the rigidity requirement can be met.

Owner:深圳市爱贝科精密工业股份有限公司

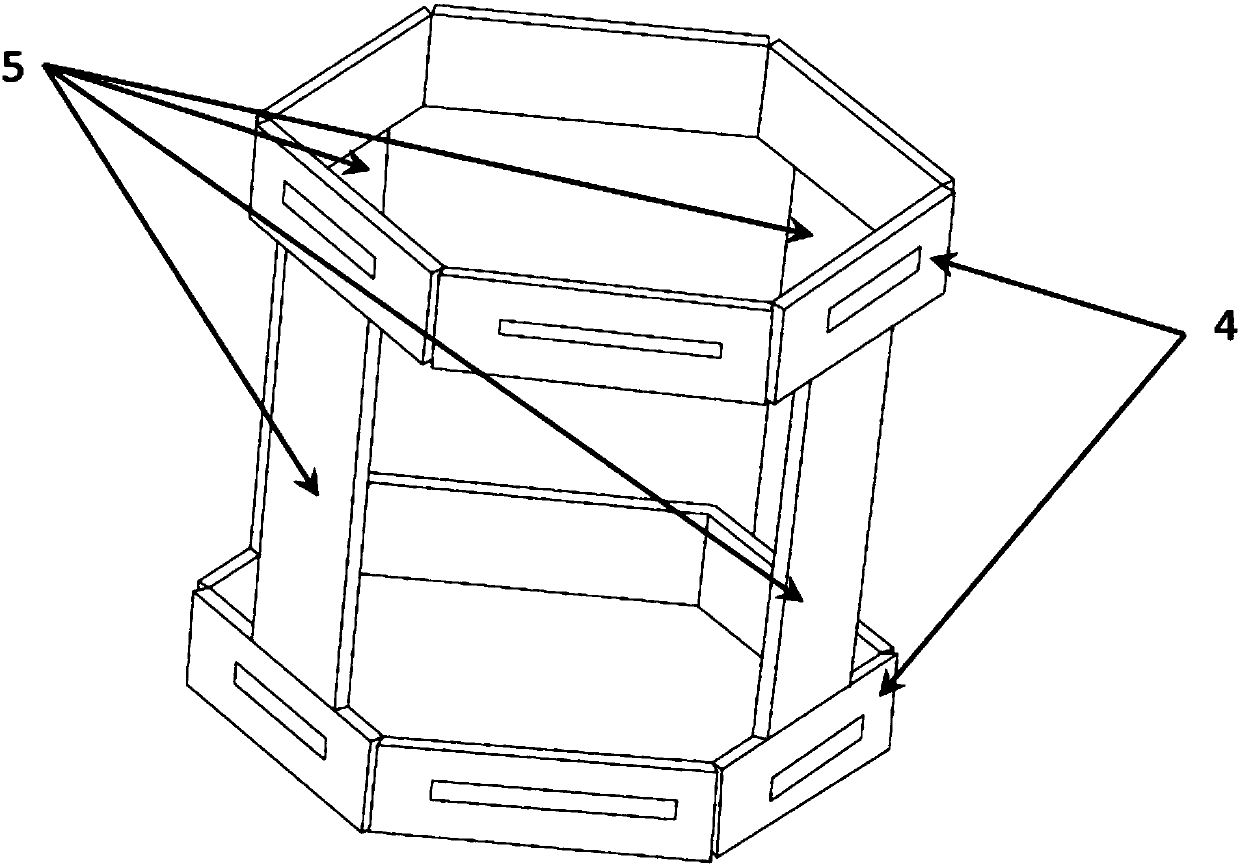

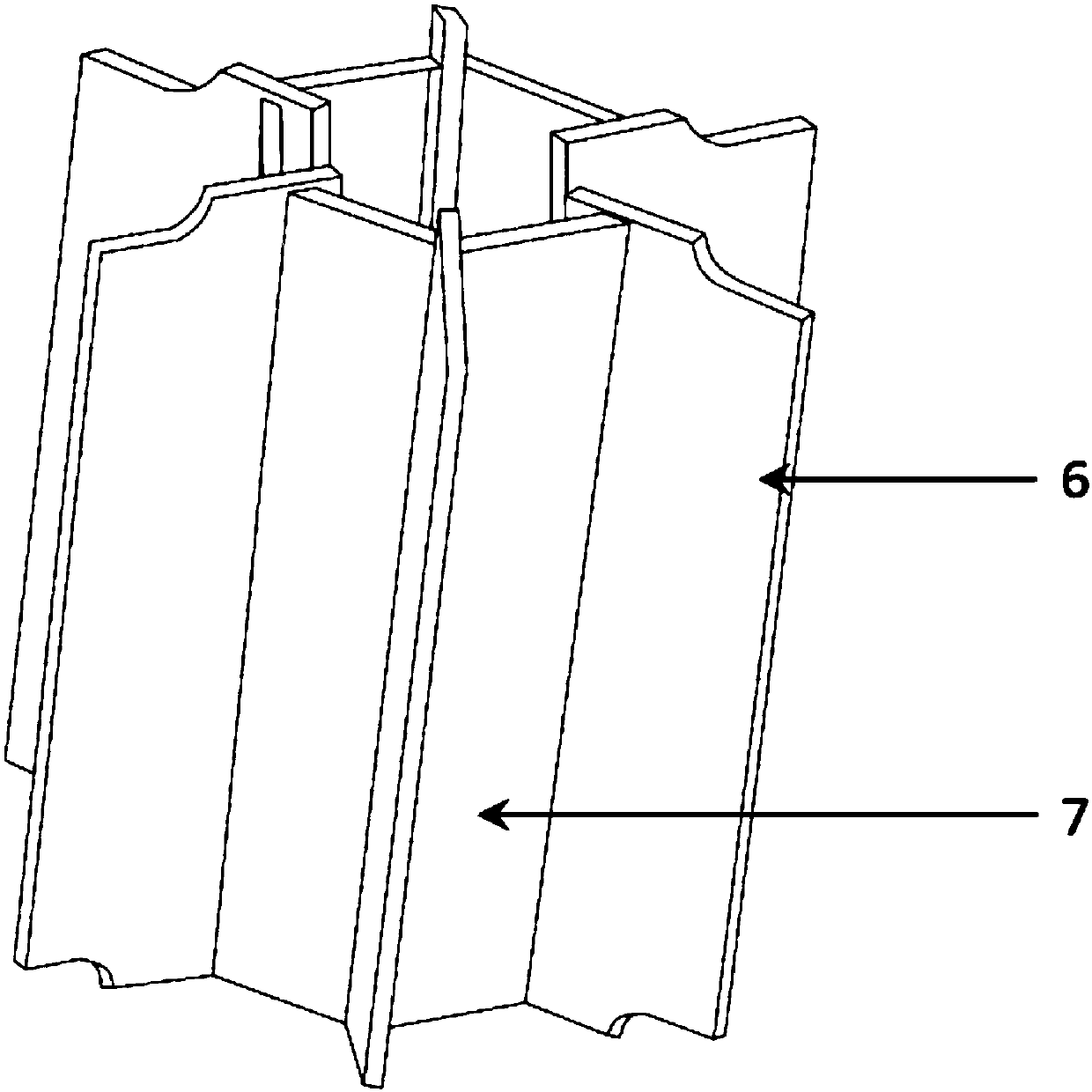

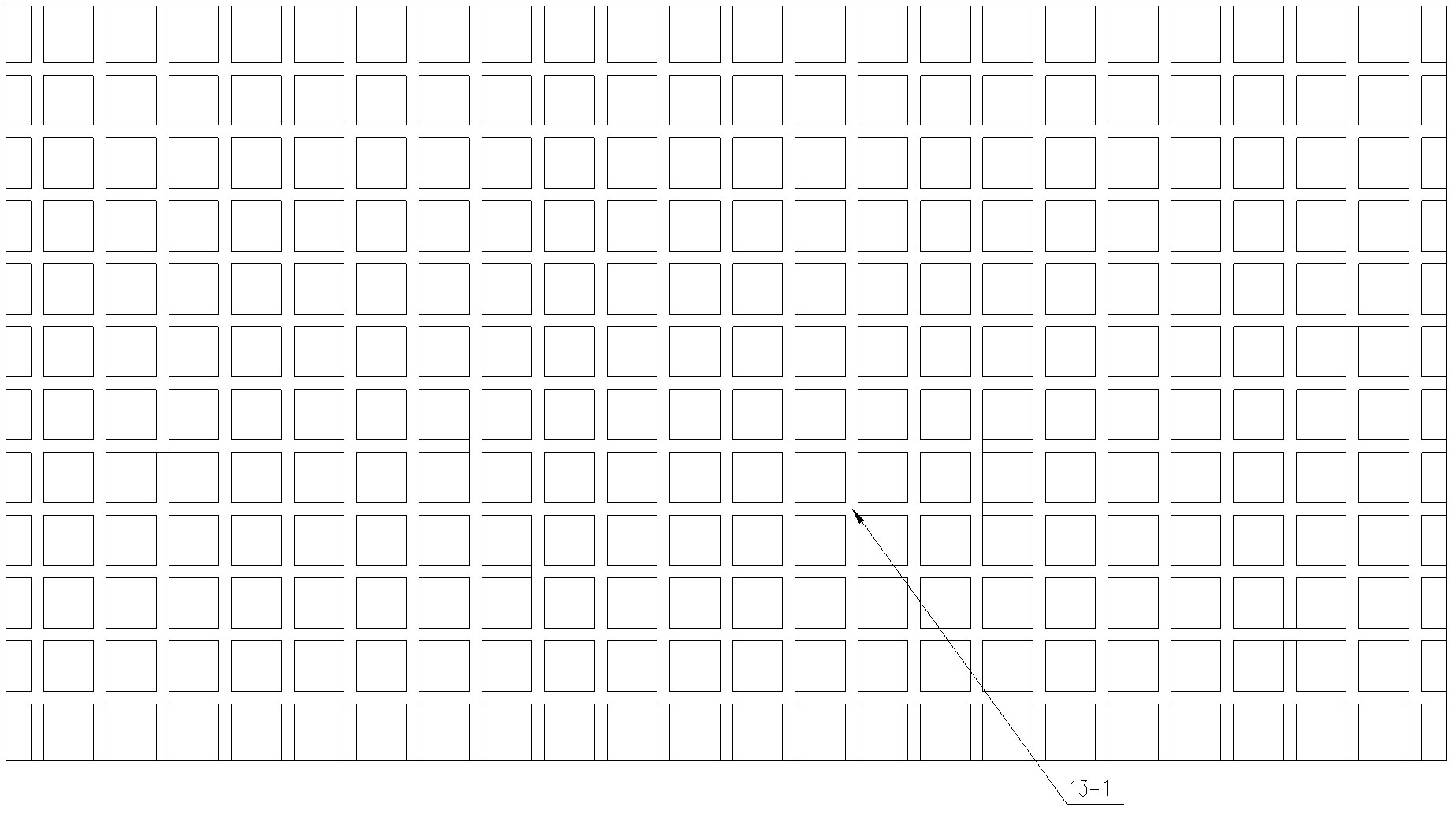

Reticulated shell structure and box type joint support of reticulated shell structure

The invention discloses a reticulated shell structure and a box type joint support of the reticulated shell structure. The box type joint support includes a web plate and a joint plate arranged in thesupport, the joint plate is connected with the adjacent web plate, a hollow inner box is formed, the web plate extends outward from the center of the hollow inner box, the upper end of the outer sideof the web plate and the lower end of the outer side of the web plate are provided with transverse plates, the outer sides of the transverse plates are connected with flange plates of main beam-and-rod piece, and connection parts of the joint plate, the web plate and the transverse plates are welded to one another and fixed. The reticulated shell structure can be used for jointing and splicing ofH-shaped-steel main beam-and-rod pieces different in size, angle and rotation angle, connection of the joints is simple and feasible, and stress is reasonable.

Owner:CHINA CONSTR ENG HONG KONG

Personal digital assistant apparatus

ActiveUS9678533B2Meet rigid requirementsNarrow frameDigital data processing detailsElectrical apparatus contructional detailsInformation processingEngineering

An information processing apparatus including a display portion, and a casing including an inner circumference wall portion that faces a side wall of the display portion and an inner circumference bottom plane portion that faces a rear surface of the display portion. The display portion is secured to the inner circumference wall portion and the inner circumference bottom plane portion of the casing with an adhesive agent.

Owner:SONY CORP

Cylinder block of internal combustion engine

ActiveUS20050076861A1Satisfy the rigidity requirementImprove rigidityLiquid coolingCasingsCylinder blockInternal combustion engine

A reinforcing structure is integrally formed on a front wall of a cylinder block of shallow water jacket type. The reinforcing structure comprises mutually crossing vertical and lateral ribs. The vertical rib extends vertically between upper and lower deck portions of the cylinder block, and the lateral rib is constructed to constitute a raised ridge of a front one of jacket bottom wall. Alternatively, the reinforcing structure comprises a raised bolt boss that is integrally formed on a front one of jacket bottom walls to catch a connecting bolt used for securing a middle portion of a front cover to the front wall.

Owner:NISSAN MOTOR CO LTD

High-precision net-free ultrathin resin grinding wheel cutting blade and manufacturing method thereof

InactiveCN108214333AReasonable production processUniform structureAbrasion apparatusGrinding devicesEngineeringHardness

The invention provides a high-precision net-free ultrathin resin grinding wheel cutting blade which does not adopt a conventional grinding wheel blade ring glass fiber reinforced net. The grinding wheel cutting blade manufactured by the manufacturing method belongs to a high-environment-friendliness innocuous and harmless product, and can meet environment-friendly requirements such as SGS; a producing process is reasonable, rigorous and scientific; the manufactured grinding wheel cutting blade has a thickness ranging from 0.1 mm to 1.0 mm, is uniform in structural organization, is extremely low in hardness deviation, has flatness within + / -0.02mm, has lot thickness error within + / -0.03mm, is good in self-sharpening performance, is sharp in cutting, is high in cutting efficiency, is free ofburrs during workpiece cutting, is free of burns, is flat and bright in cut end opening, and even achieves the mirror effect; and cut materials can be saved to the greatest extent, and material wastecost is greatly reduced for enterprises.

Owner:GUANGZHOU AUTOFOR ENERGY SAVING TECH CO LTD

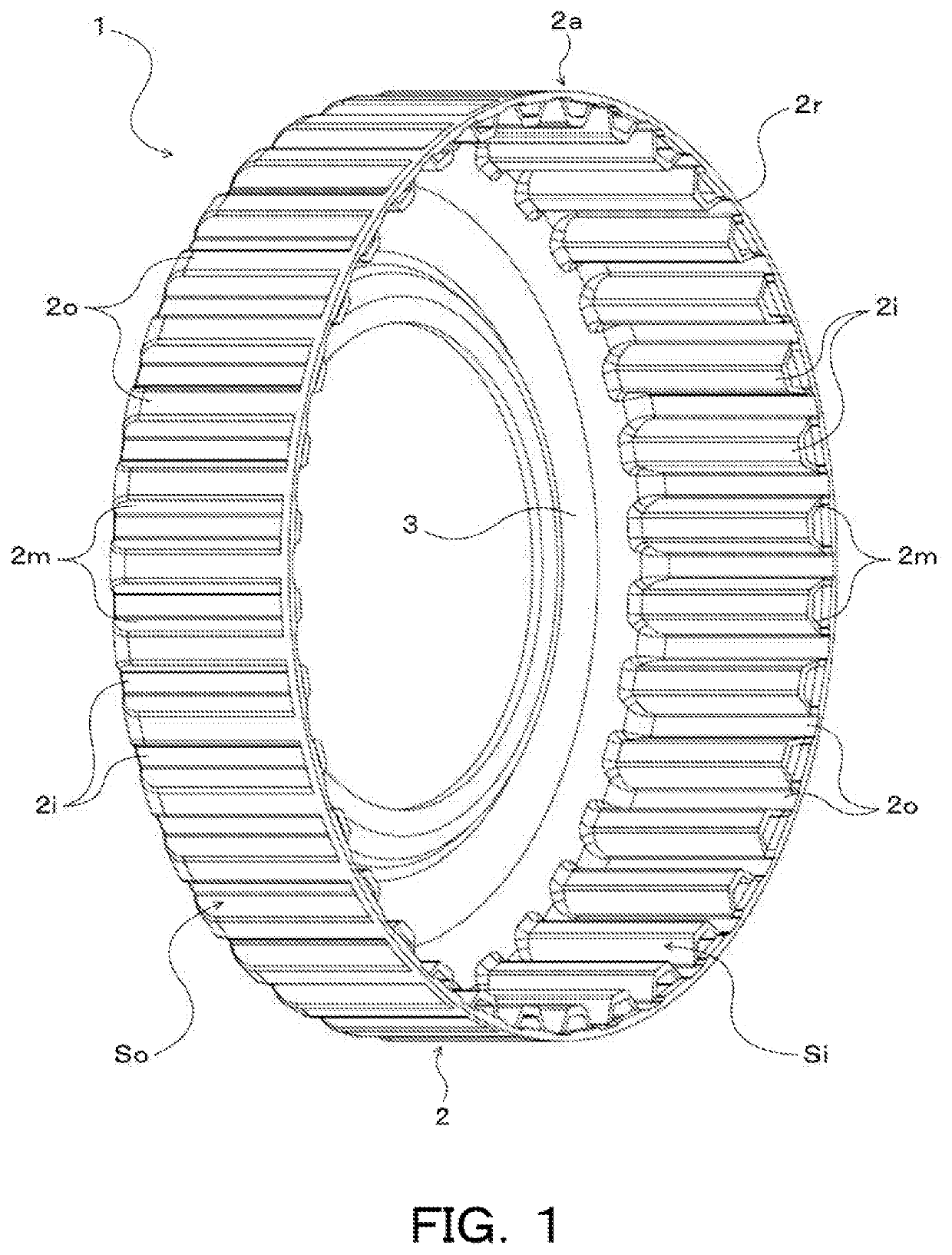

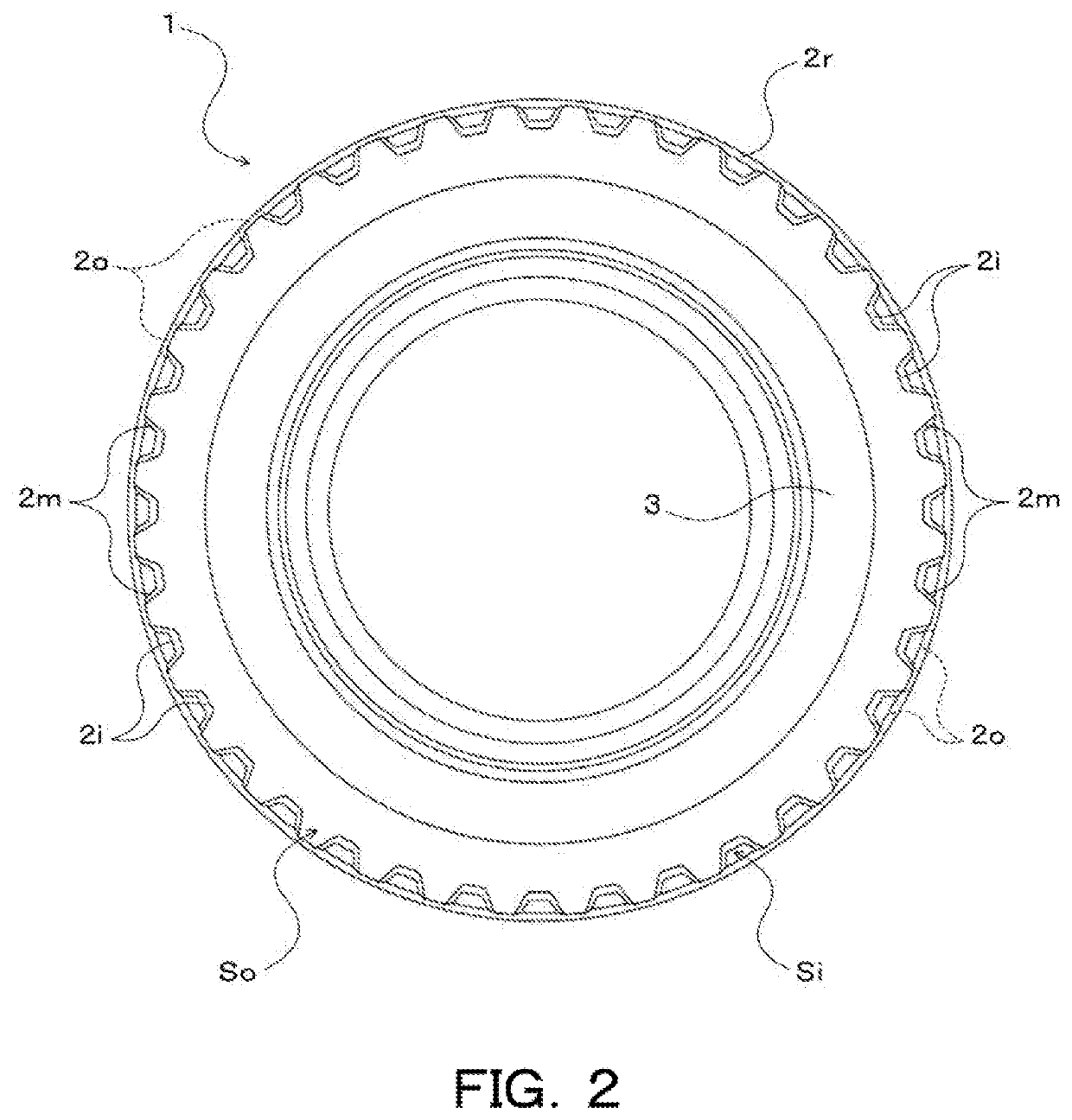

Manufacturing method of tooth part, tooth part, and processing device of tooth part

ActiveUS20200393003A1High strengthIncreasing the thicknessShaping toolsFriction clutchesEngineeringMouth opening

The tooth part includes: a tubular portion having an inner tooth portion formed on an inner peripheral surface and an outer tooth portion formed on an outer peripheral surface; a plurality of inner peripheral wall portions that each extend in an axial direction of the tubular portion and form a tooth tip portion of the inner tooth portion and a tooth bottom portion of the outer tooth portion; a plurality of outer peripheral wall portions that each extend in the axial direction and form a tooth bottom portion of the inner tooth portion and a tooth tip portion of the outer tooth portion; and an annular rib that is joined to the outer peripheral wall portions and that extends in an annular shape on an open end side with respect to the inner peripheral wall portions in the axial direction and radially outward from the inner peripheral wall portions, at an open end of the tubular portion.

Owner:AISIN CORP

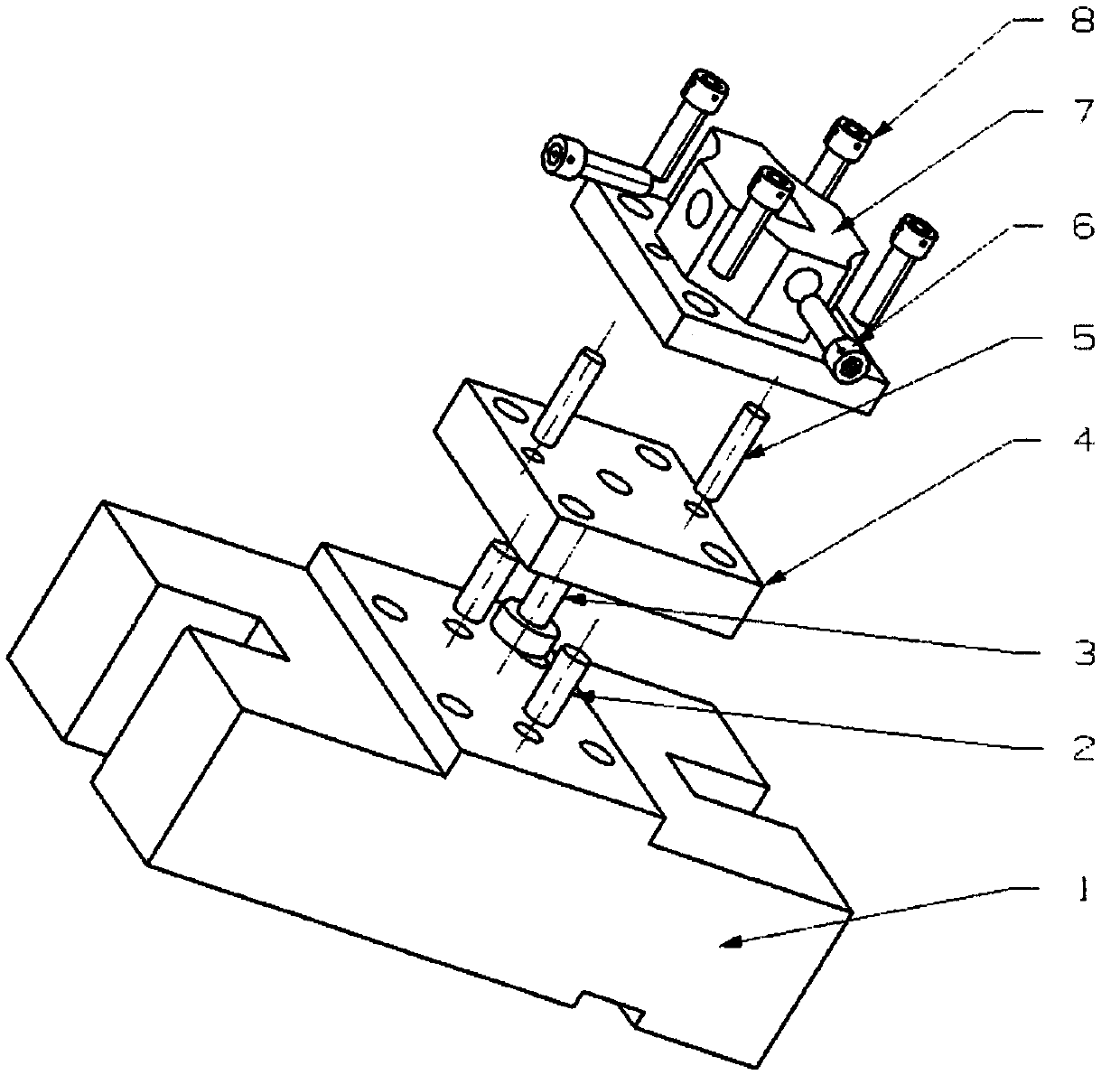

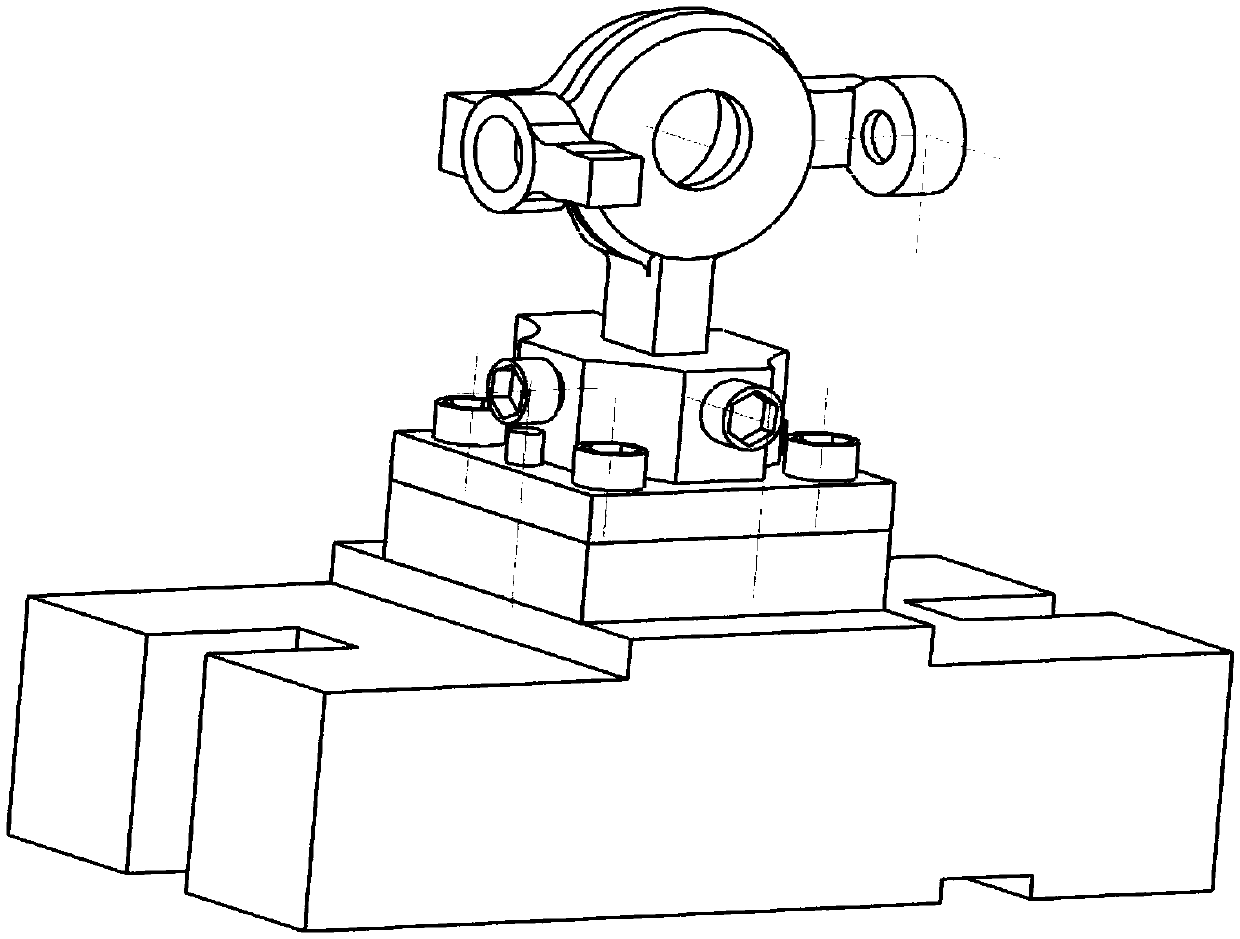

Precision CNC milling fixture for servo mechanism oil pump swash plate parts

ActiveCN104057336BMeet rigid requirementsAvoid interferenceWork clamping meansPositioning apparatusNumerical controlEngineering

The invention discloses a precise numerical control milling machining clamp for swash plate type parts of a servo mechanism oil pump. The precise numerical control milling machining clamp comprises an installing seat, a pull block and a chuck seat, wherein the lower end surface of the installing seat is provided with a cross key slot, the installing seat and the pull block as well as the pull block and the chuck seat are respectively positioned through pins and are fixedly connected through screw bolts, the middle of the pull block is provided with a step hole, the hole diameter of the hole, near the upper end surface, of the step hole is smaller than that of the hole near the lower end surface, a downward pull screw bolt is arranged in the step hole, a lug boss is arranged on a bottom plate of the chuck seat, the middle of the chuck seat is provided with a through square hole, the periphery of the lug boss is provided with screw holes penetrating through the square hole, and lateral fastening screws are arranged in the screw holes, wherein the downward pull screw bolt extends into the square hole. The precise numerical control milling machining clamp has the advantages that the positioning is stable, the installation and the clamping are convenient, in addition, the multi-molded-surface processing can be completed through once installation and clamping, and the dimensional precision and the form and position precision of the parts can be guaranteed.

Owner:NANJING CHENGUANG GRP

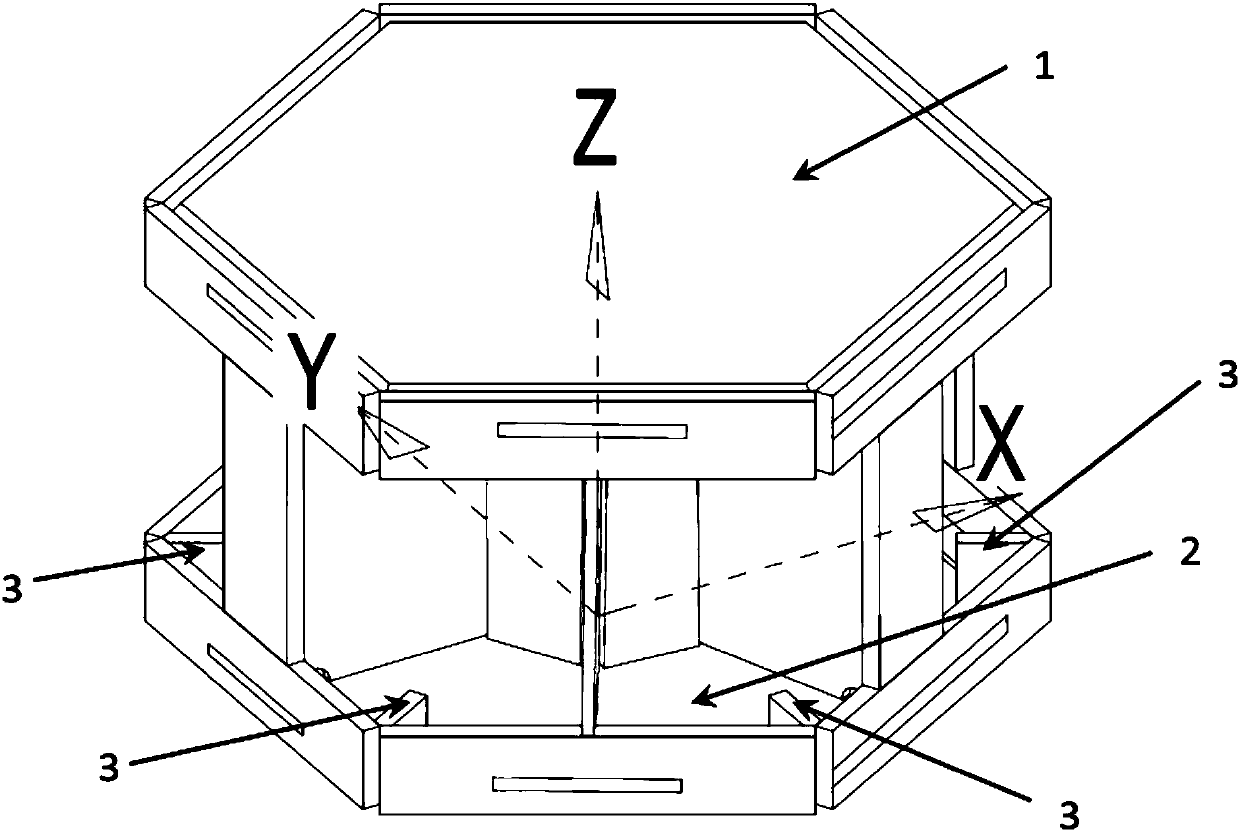

Multi-station triaxial force application testing machine

ActiveCN102607830BScientific and reasonable designMeet rigid requirementsVehicle testingMachine part testingTest efficiencyMultiple forms

The invention relates to the technical field of machinery, in particular to a multi-station triaxial force application testing machine. The multi-station triaxial force application testing machine is characterized in that two cylinder brackets and a cylinder supporting plate are arranged on a platform, and each cylinder bracket adopts a T-type plate structure formed by vertically connecting a vertical plate on a horizontal bottom plate; the horizontal bottom plates of the two cylinder brackets are arranged on the platform respectively in an X direction and a Y direction; and the side surfaces on the upper parts of the vertical plates of the cylinder brackets arranged in the X direction and the Y direction and the upper part of the cylinder supporting plate are respectively hinged with the tail ends of cylinders in a drive mechanism to respectively form an X-direction force application mechanism, a Y-direction force application mechanism and a Z-direction force application mechanism. Compared with the prior art, the multi-station triaxial force application testing machine has the advantages that the force application mechanisms are light and can meet the rigidity requirement, so that the real train states of force application in the X direction, the Y direction and the Z direction can be guaranteed; and grooves are distributed on the platform in a shape like a Chinese character jing, so that an adjustable sample piece fixing mechanism and the force mechanisms can be set up as required to meet the requirements of tests of force application directions in multiple forms, and the test efficiency can be improved.

Owner:YANFENG AUTOMOTIVE SAFETY SYST CO LTD +1

Miniature microphone manufacturing method based on Si-Si bonding process

ActiveCN101854578BThickness is easy to controlWide range of materialsElectrical transducersBiochemical engineeringBonding process

The invention relates to a miniature microphone manufacturing method based on an Si-Si bonding process, which comprises the following steps that: a. a connecting plate and a back plate are provided; b. the back plate and the connecting plate are bonded and fixed; c. the back plate is thinned; d. an insulating bonding layer is grown on the thinned back plate; e. a substrate is provided; f. an insulating supporting layer is grown on the substrate; g. a vibrating diaphragm is precipitated on the substrate; h. the vibrating diaphragm which is arranged in a groove is obtained; i. the back plate and the substrate are bonded and fixed; j. the connecting plate and an oxidization layer above the substrate are etched; k. a lower electrode hole is obtained on the back plate; l. an electrode layer is precipitated on the back plate; m. electrodes on the back plate and the vibrating diaphragm are obtained; n. a plurality of sound holes on the back plate are obtained; and o. the other end of the substrate which corresponds to the back plate is etched to obtain a vocal cavity below the vibrating diaphragm. The miniature microphone manufacturing method based on the Si-Si bonding process has the advantages of high sensitivity, low cost, wide frequency band, high finished product rate and simple manufacturing process.

Owner:无锡芯感智半导体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com