Polyurethane foam for automobile dry-method ceiling and preparation method thereof

A polyurethane foam and dry process technology is applied in the field of polyurethane foam production to achieve the effects of high molding elongation, improved efficiency and high open cell rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

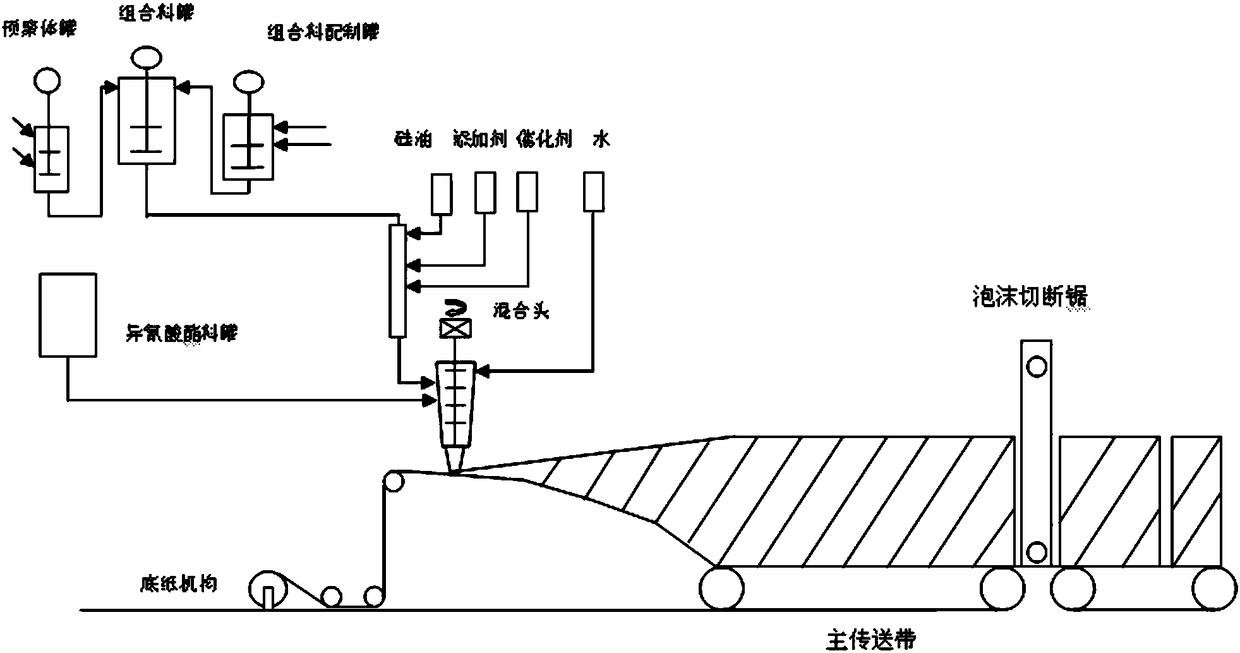

Method used

Image

Examples

Embodiment 1

[0035] The formula of polyurethane foam for automobile dry roof is as follows: polyether polyol (polyether A 20 parts, polyether B 15 parts, polyether C 20 parts, polyether D, chain extender 20 parts); isocyanate mixture: polymerized MDI 100 parts 0.3 parts of catalyst 1, 0.1 part of catalyst 2; 1.8 parts of silicone oil surfactant; 10 parts of solid additive; 1.5 parts of polyurethane antioxidant; 2 parts of black color paste; 3.5 parts of water;

[0036] (1) Preparation of polyether polyol and isocyanate mixture: polyether A, polyether B, polyether C and polyether D; isocyanate mixture, wherein the ratio of the isocyanate equivalent in the isocyanate mixture to the hydroxyl equivalent in the polyether polyol is 1;

[0037] (2) Preparation of premix 1: Take the polyether A, polyether B, and polyether C prepared in step (1), put them into the agitator for premixing, the agitator speed is 10rpm / min, and the mixing time is 70min. premix1;

[0038] (3) Preparation of prepolymer...

Embodiment 2

[0045] The formula of polyurethane foam for automobile dry roof is as follows: polyether polyol (polyether A 20 parts, polyether B 15 parts, polyether C 20 parts, polyether D, chain extender 20 parts); isocyanate mixture 100-150 parts: Polymerized MDI or a mixture of polymerized MDI and pure MDI 50: 50; catalyst 1 0.3 parts, catalyst 2 0.1 parts; silicone oil surfactant 1.8 parts; solid additive 10 parts; polyurethane antioxidant 1.5 parts; black color paste 1.5 parts; water 3.8 servings.

[0046] (1) Preparation of polyether polyol and isocyanate mixture: polyether A, polyether B, polyether C and polyether D; isocyanate mixture, wherein the ratio of the isocyanate equivalent in the isocyanate mixture to the hydroxyl equivalent in the polyether polyol is 1.25;

[0047] (2) Preparation of premix 1: Take the polyether A, polyether B, and polyether C prepared in step (1), put them into the agitator for premixing, the speed of the agitator is 20rpm / min, and the mixing time is 50m...

Embodiment 3

[0054] The formula of polyurethane foam for automobile dry roof is as follows: polyether polyol (polyether A 35 parts, polyether B 15 parts, polyether C 20 parts, polyether D, chain extender 20 parts); isocyanate mixture 100-150 parts: Polymerized MDI or the mixture of polymeric MDI and pure MDI 90: 10 ratio; Catalyst 1 0.3 parts, catalyst 2 0.1 parts; Silicone oil surfactant 1.8 parts; Solid additive 10 parts; Polyurethane antioxidant 1.5 parts; Black color paste 2.5 parts; 4.5 parts of water.

[0055] (1) Preparation of polyether polyol and isocyanate mixture: polyether A, polyether B, polyether C and polyether D; isocyanate mixture, wherein the ratio of the isocyanate equivalent in the isocyanate mixture to the hydroxyl equivalent in the polyether polyol is 1.1;

[0056] (2) Preparation of premix 1: Take the polyether A, polyether B, and polyether C prepared in step (1), put them into the agitator for premixing, the speed of the agitator is 18rpm / min, and the mixing time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com