Horizontal milling machine spindle

A milling machine spindle, horizontal technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools and other directions, can solve the problems of bearing damage, complicated installation, time-consuming knockout process, etc., to meet rigid requirements, save maintenance costs, The effect of reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

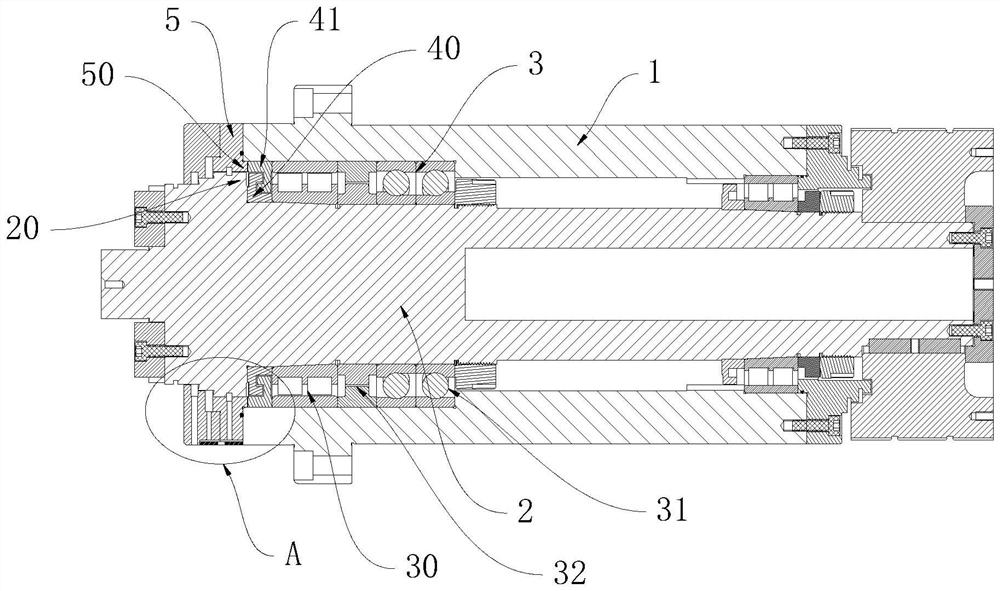

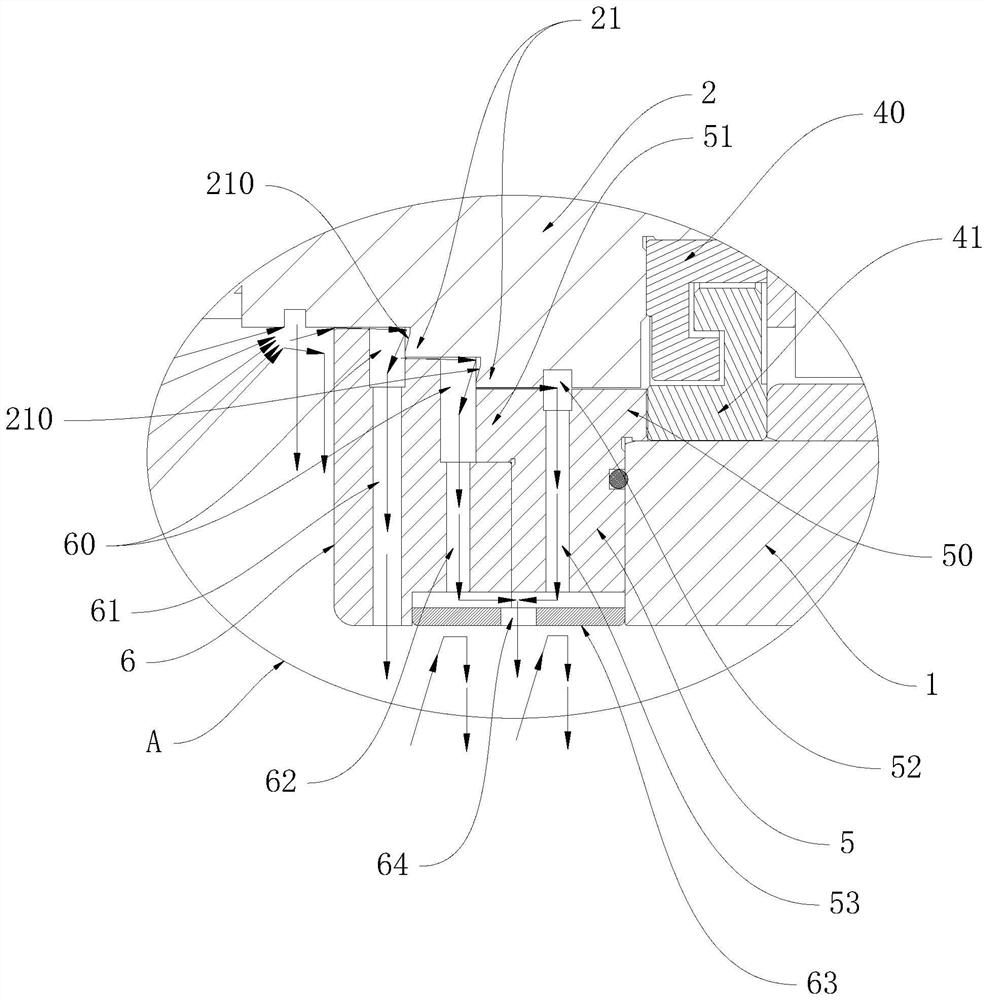

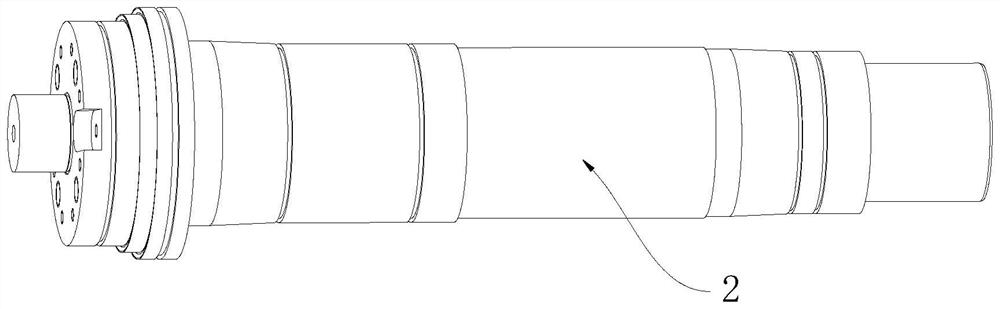

[0033] The invention discloses a horizontal milling machine spindle, which combines Figure 1 to Figure 8 As shown, it includes a bearing chamber 1 and a shaft core 2 passing through the bearing chamber 1. The front bearing assembly 3 and an inner spacer ring 40 are sleeved on the shaft core 2. The front end of the shaft core 2 A front step portion 20 is formed, and the inner spacer ring 40 is sandwiched between the front step portion 20 and the front bearing assembly 3 , the outer side of the inner spacer ring 40 is sleeved with an outer spacer ring 41 and both There is a gap between them, the front end of the bearing chamber 1 is fixed with a front bearing cover 5, a gap is provided between the front bearing cover 5 and the shaft core 2, and the rear end of the front bearing cover 5 A rear resisting convex ring 50 is formed, and the rear resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com