Preparation method of lithium yttrium halide and application thereof in solid electrolyte and battery

A technology of solid electrolyte and lithium battery, which is applied in chemical instruments and methods, secondary batteries, circuits, etc. It can solve the problems that 4V level cathodes cannot be used together, the lithium ion diffusion mobility is greatly affected, and it does not have thermodynamic stability. Achieve the effect of facilitating assembly, improving ion mobility, and not easy to react

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

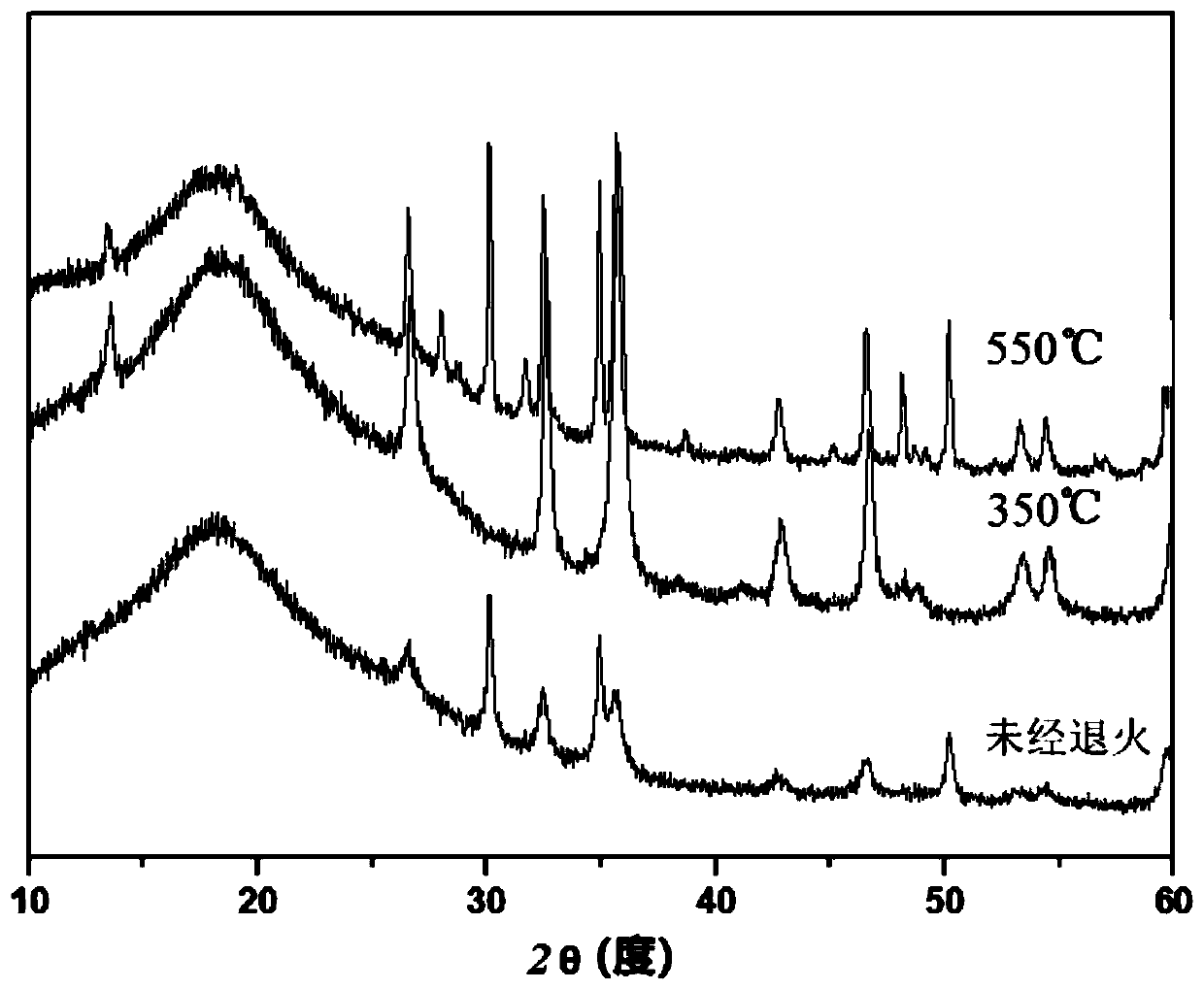

Embodiment 1

[0047] YCl will be subjected to vacuum conditions at 350 degrees Celsius 3 ·8H 2 O is subjected to high temperature dehydration to obtain YCl 31. After vacuum drying, LiCl and 3mm zirconia balls were filled into a ball mill jar, and mechanically synthesized at a speed of 400 rpm. The ball milling time was 48 hours. The ball milled product was divided into four equal parts, one of which was used as a control group , under an argon atmosphere, the mechanically synthesized product was pressed at a pressure of 300Mpa to obtain pellets; the remaining three parts were respectively placed on alumina crucibles in three different argon atmosphere glove boxes and heated for 12 hours, and the annealing temperature was 350 °C, 550 °C and 630 °C, the reaction product was crushed with a pestle and mortar in the glove box, and the reaction product was pressed at a pressure of 300 MPa in the glove box to obtain pellets.

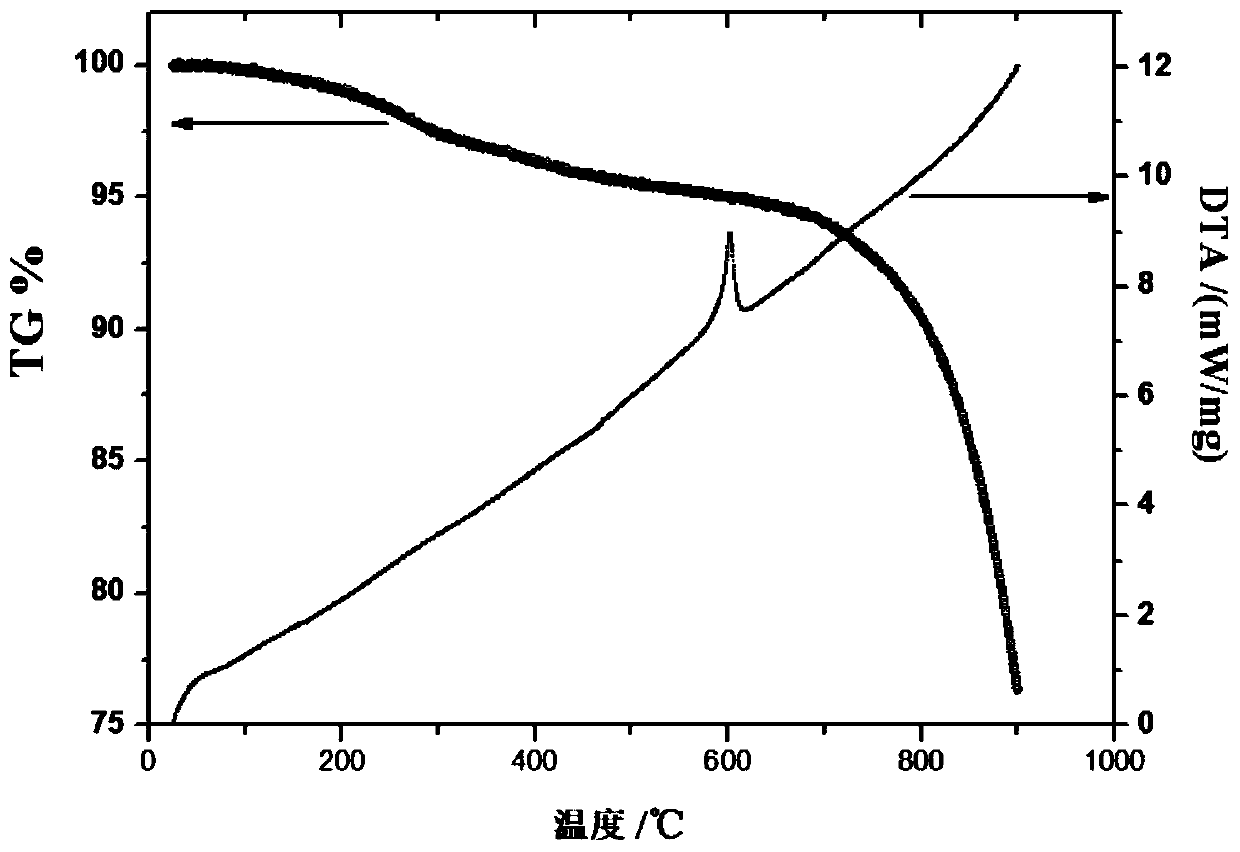

[0048] in, figure 1 At 350°C, YCl 3 ·8H 2 50% removal of water in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com