High-precision net-free ultrathin resin grinding wheel cutting blade and manufacturing method thereof

A resin grinding wheel and cutting disc technology, used in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of poor cutting ports, not to mention precision and sharpness, and achieve high cutting efficiency and smooth cutting ports. Bright, razor-sharp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

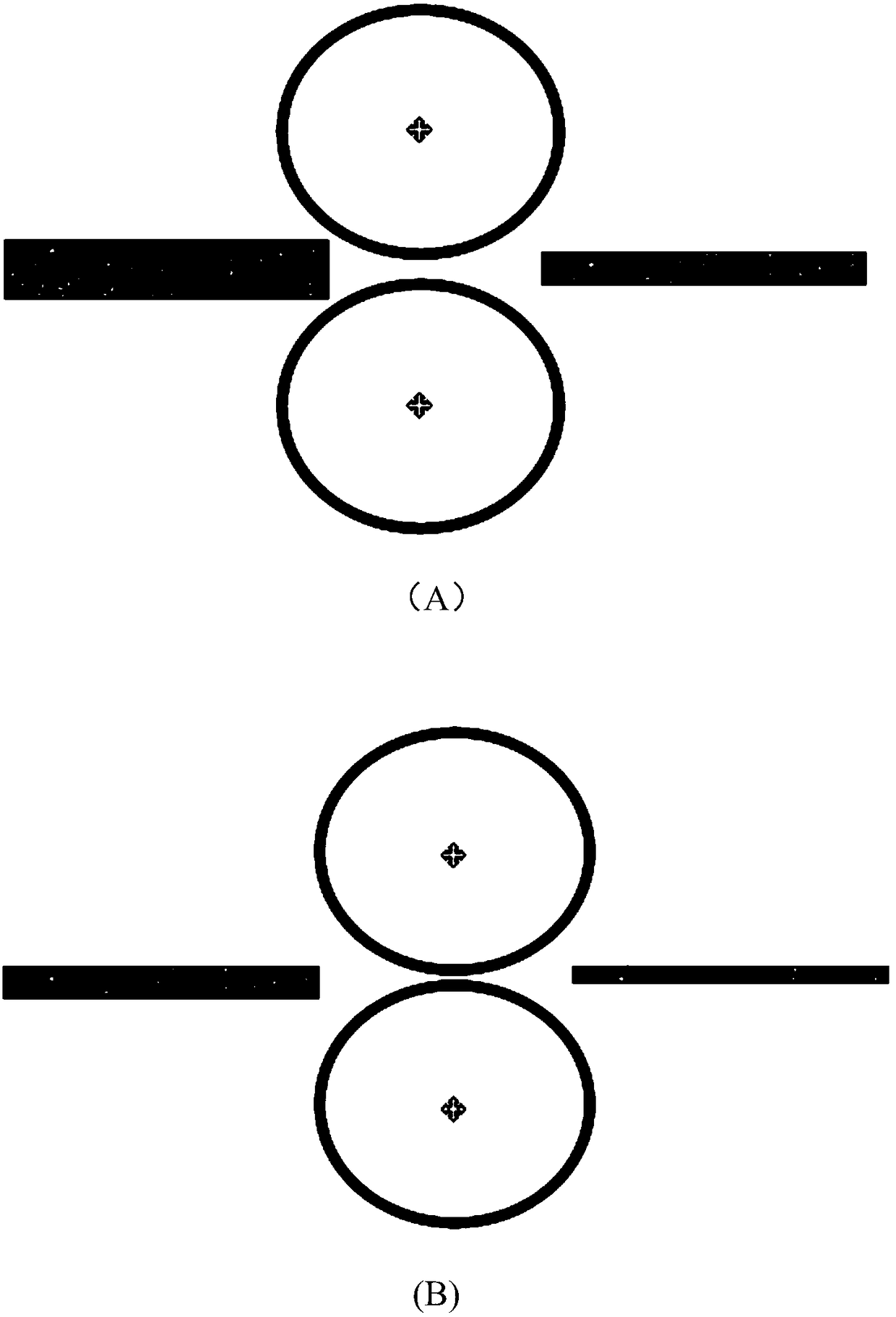

Method used

Image

Examples

Embodiment 1

[0047] The preferred formula of the high-precision non-network ultra-thin resin grinding wheel cutting sheet of the present invention comprises the raw materials of the following weight percentages:

[0048] Abrasive: 38% white corundum powder,

[0050] 12% green silicon carbide,

[0051] 10% monocrystalline silicon powder;

[0052] Resin binder: 11% powdered phenolic resin,

[0053] 14% liquid phenolic resin;

[0054] Excipients: 7% carbon black.

[0055] The preparation method is as follows:

[0056] (1) Stir the raw materials evenly in an automatic mixer for more than 6 hours, and then let them stand naturally for 8-10 hours, during which the substances inside are continuously fused, interpenetrated and decomposed;

[0057] (2) Carry out 72-96 hour storage molecular static in the constant temperature and humidity preservation cabinet that temperature is 25 degrees centigrade then, and humidity is 45%;

[0058] (3) Then, at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com