Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

222results about How to "Low processing and production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

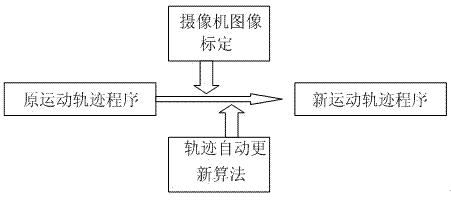

Robot calibration method capable of achieving automatic trajectory correction

ActiveCN102785246AGuaranteed accuracyOvercome the time-consuming and labor-intensive defects of manual correctionProgramme-controlled manipulatorImaging processingActuator

The invention discloses a robot calibration method capable of achieving an automatic trajectory correction and resolves the problems of not only consuming time and labor but also having low correction precision caused by an artificial correction trajectory in prior art. The method comprises the following steps of: (1) shooting a robot clamp and a workpiece by a vidicon, and calibrating the shot image, so as to obtain a newest position relation between the robot clamp and the workpiece; (2) performing an image processing algorithm analysis on the shot image, so as to obtain the position informations of the workpiece and the end effector of the robot clamp; (3) according to the position informations, calculating the moving data required by keeping the consistent positions of the workpiece and the end effector of the robot clamp; and (4) automatically loading the moving data into an original motion trajectory program, thereby automatically obtaining a new motion trajectory program aiming at the new position of the workpiece or the robot, so as to finish the trajectory correction.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

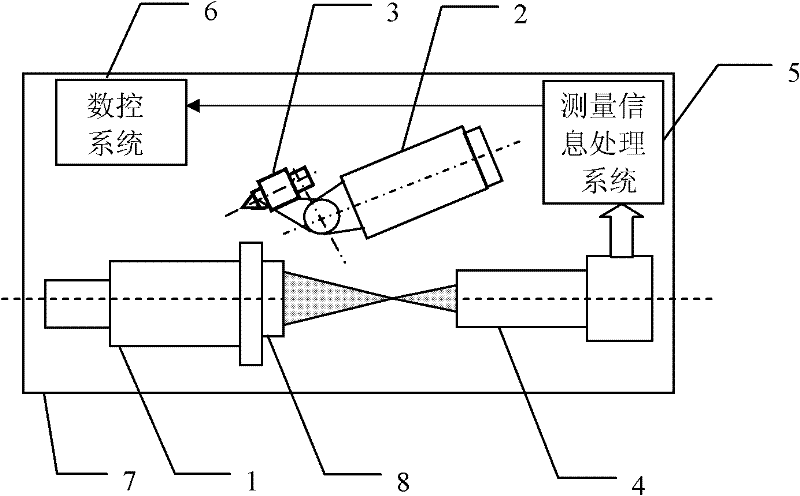

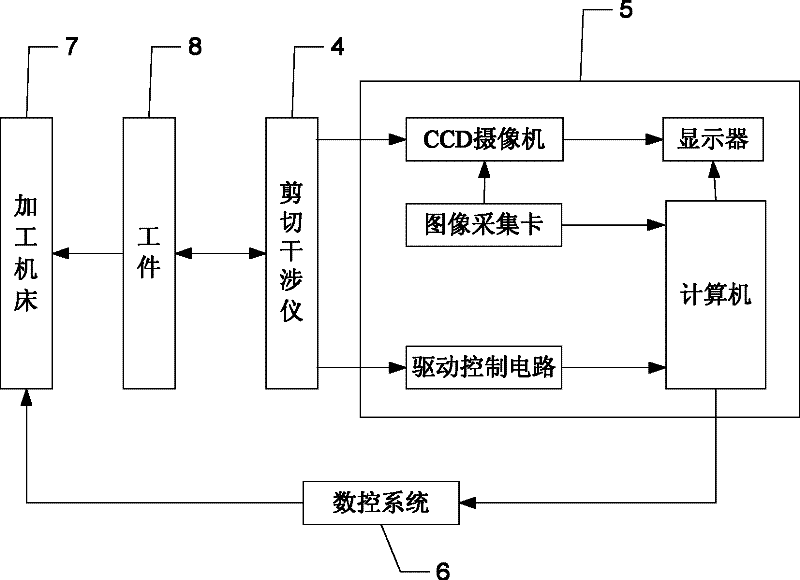

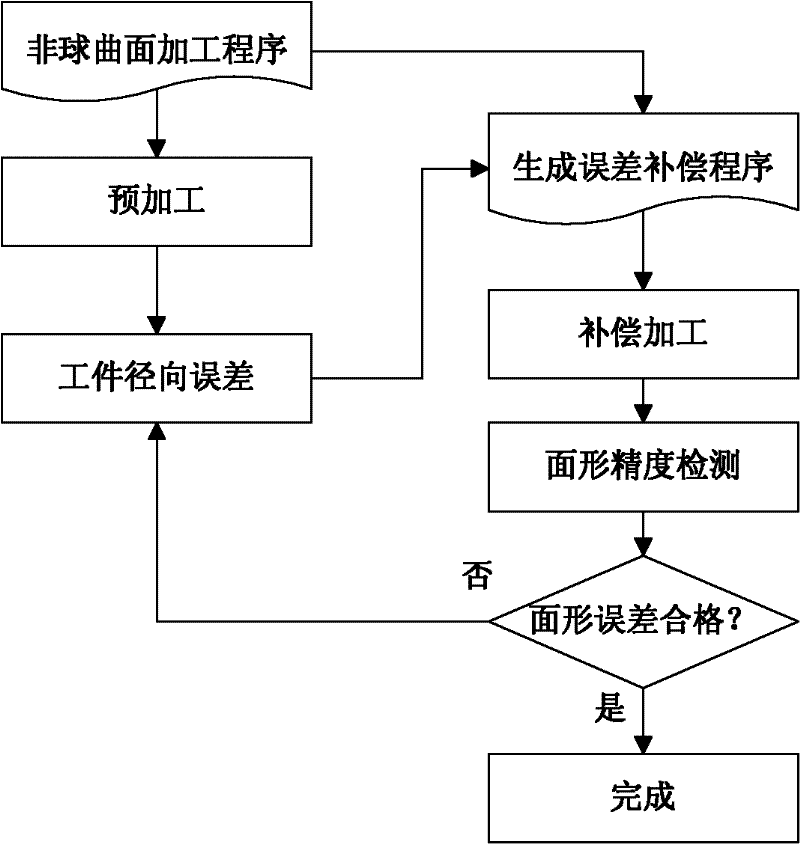

Device and method for integrally machining and measuring optical parts

ActiveCN102303224AReduce intermediate linksRealize feedback compensation machiningMeasurement/indication equipmentsNumerical controlInformation processingOptical axis

The invention relates to a device and method for integrally machining and measuring optical parts, belonging to the field of optical part machining. The invention aims at solving the problems that: an off-line measuring manner is mostly adopted in the traditional optical part machining, thus the machining efficiency is low; and the traditional optical part machining equipment cannot satisfy with the requirement of online measuring. According to the invention, a workpiece main shaft, a cutting tool main shaft and a shearing interferometer are mounted on a worktable surface of a machining machine; a workpiece is mounted on the workpiece main shaft; a cutting tool is mounted on the cutting tool main shaft through an oscillating arm and a tool carrier; a numerical control system is used for driving the cutting tool main shaft to rotate and driving the cutting tool to machine the workpiece; the optical axis of a measuring light beam which is emitted by the shearing interferometer and the central line of the workpiece main shaft are the same straight line; the shearing interferometer is used for emitting the measuring light beam to the workpiece; the shearing interferometer is used for acquiring image information which is returned by the measuring light beam and is used for sending the image information to a measured information processing system; the measured information processingsystem is used for acquiring surface error information of the surface of the workpiece according to the image information and is used for sending the information to the numerical control system; and the numerical control system is used for carrying out compensation machining on the workpiece.

Owner:HARBIN INST OF TECH

Method for manufacturing nanometer tungsten/cobalt carbide composite powder

The invention discloses a method for manufacturing nanometer tungsten / cobalt carbide composite powder. The method includes steps of firstly, dissolving, by mass, 55-92% of water-soluble tungsten salt, 3-40% of water-soluble cobalt salt, 3-6% of water-soluble carburizing and nodulizing agents and 0.1-2% of water-soluble composite grain growth inhibitors into water with the mass 3-5 times that of a mixture of the water-soluble tungsten salt, the water-soluble cobalt salt, the water-soluble carburizing and nodulizing agents and the water-soluble composite grain growth inhibitors to prepare mixed aqueous solution; secondly, adding nanometer carbon black accounting for 1-10% of the total mass of the aqueous solution into the mixed aqueous solution obtained in the first step, stirring the nanometer carbon black in the mixed aqueous solution at the rate of 10-30 revolutions per minute for 30-60 minutes so that the nanometer carbon black can be uniformly mixed in the mixed aqueous solution; thirdly, performing quick low-temperature spray drying for mixed aqueous solution obtained in the second step to obtain precursor powder of ultrafine tungsten and cobalt composite salt; and fourthly, performing reduction synthesis and carbon conditioning at the temperature ranging from 900 DEG C to 1000 DEG C for the precursor powder obtained in the third step to manufacture tungsten / cobalt carbide composite powder materials with nanostructures.

Owner:ANHUI RONGDA COMPOSITE POWDERS TECH

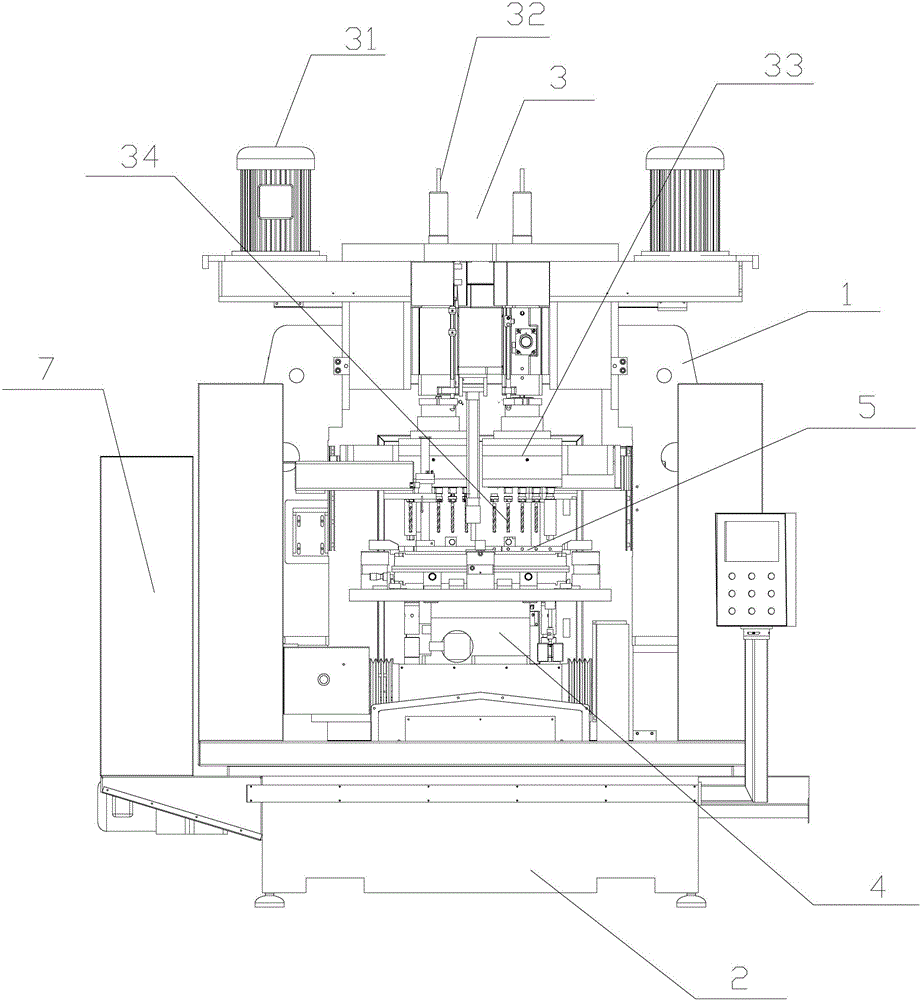

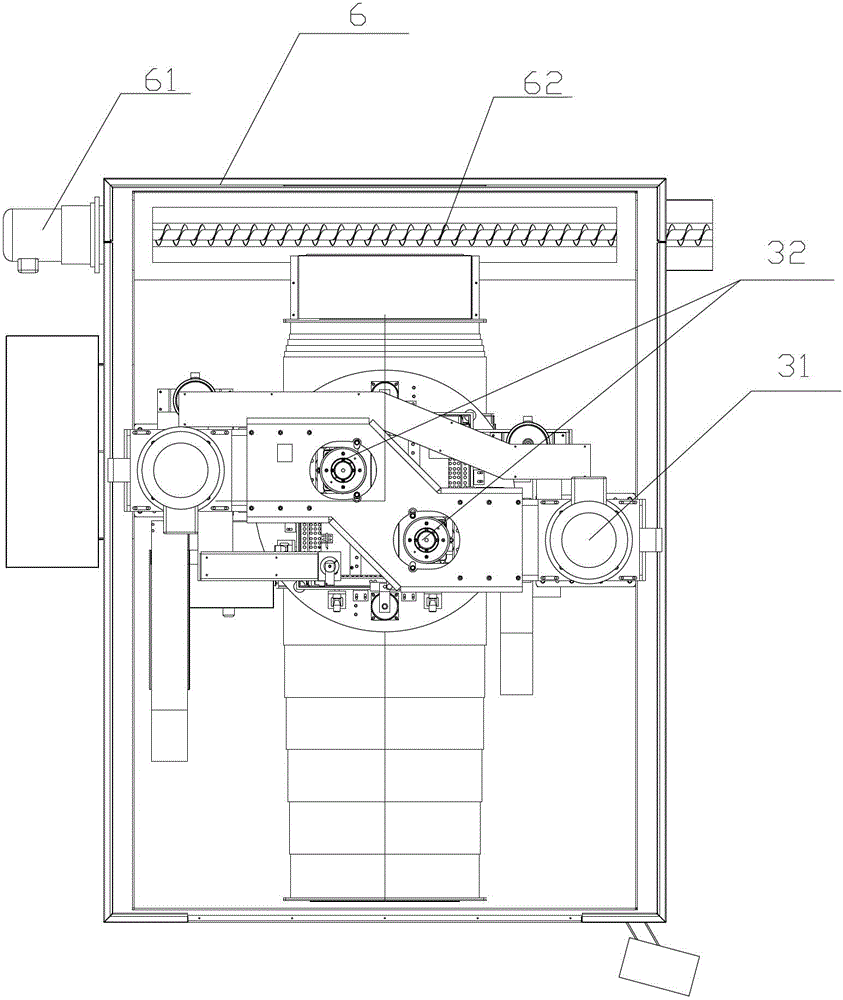

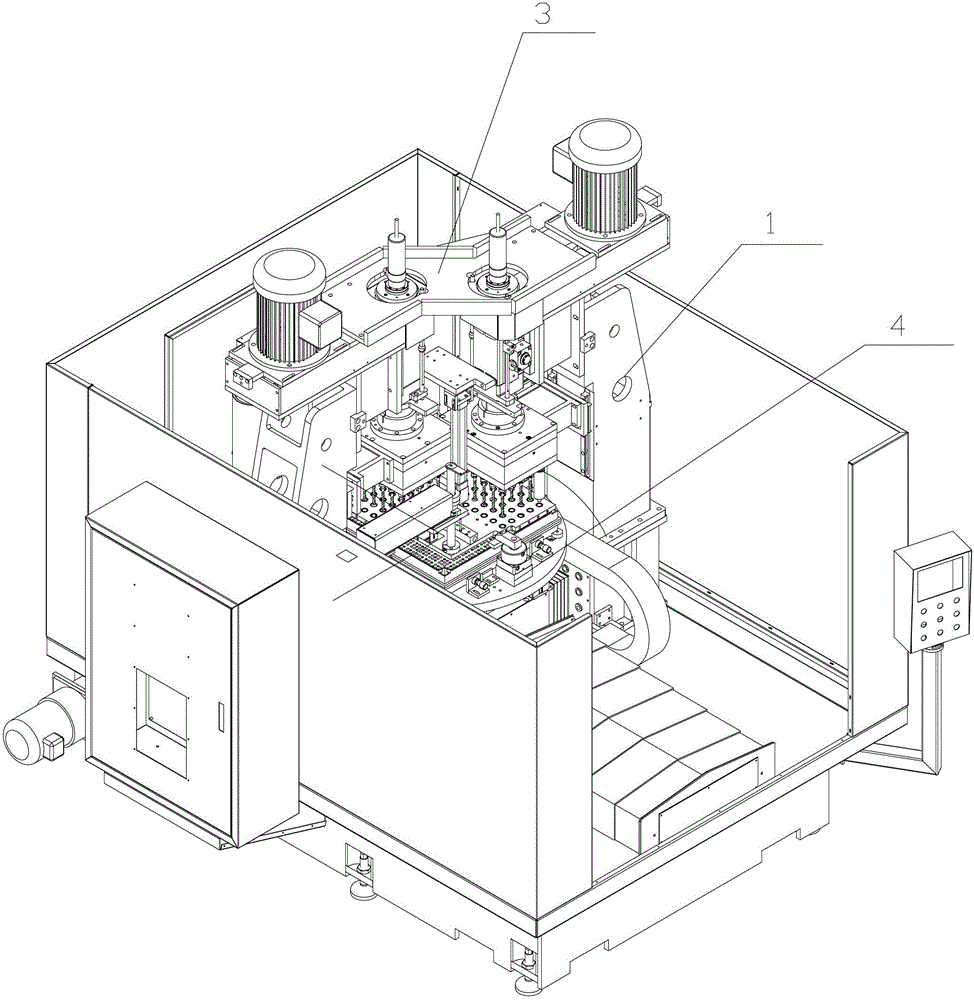

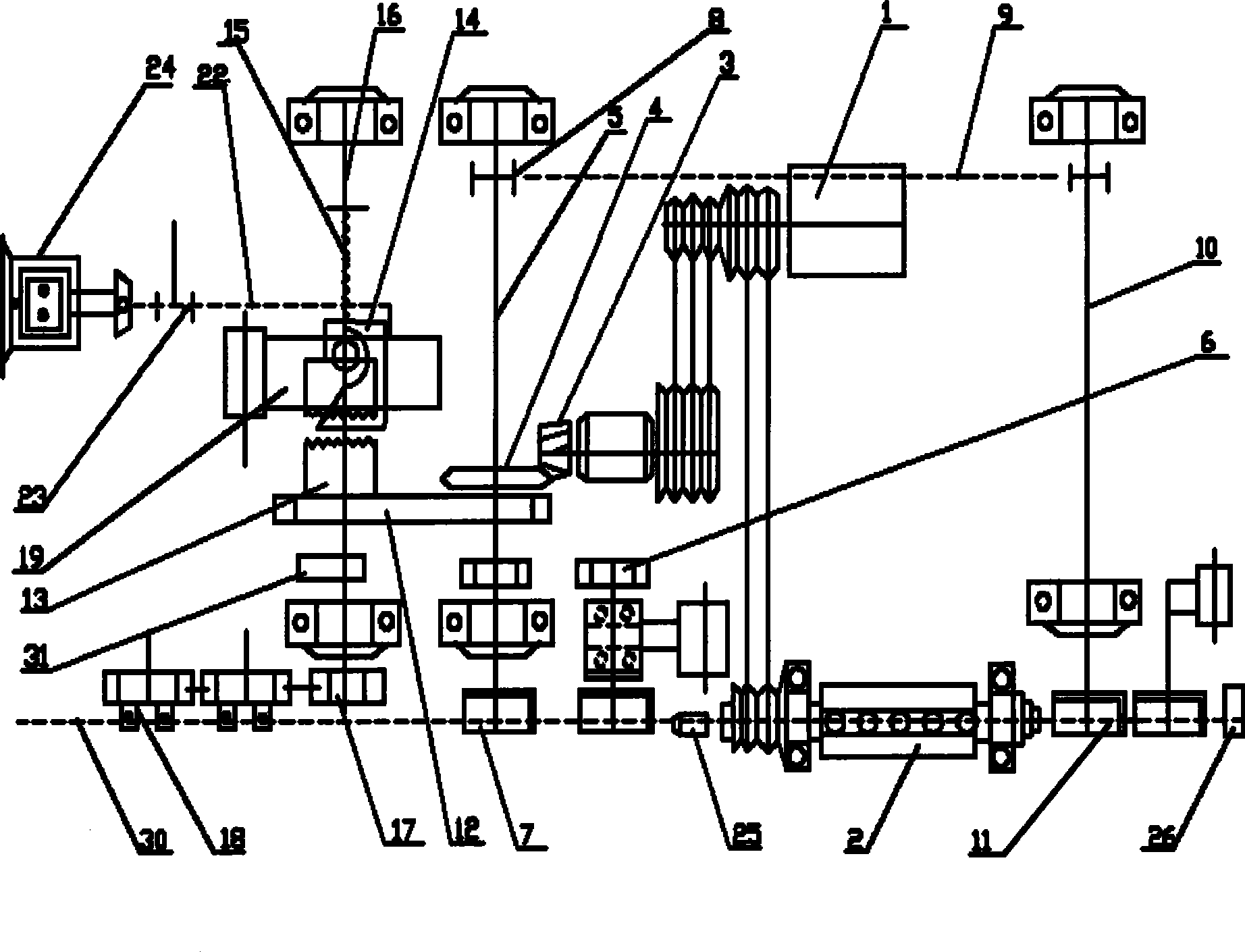

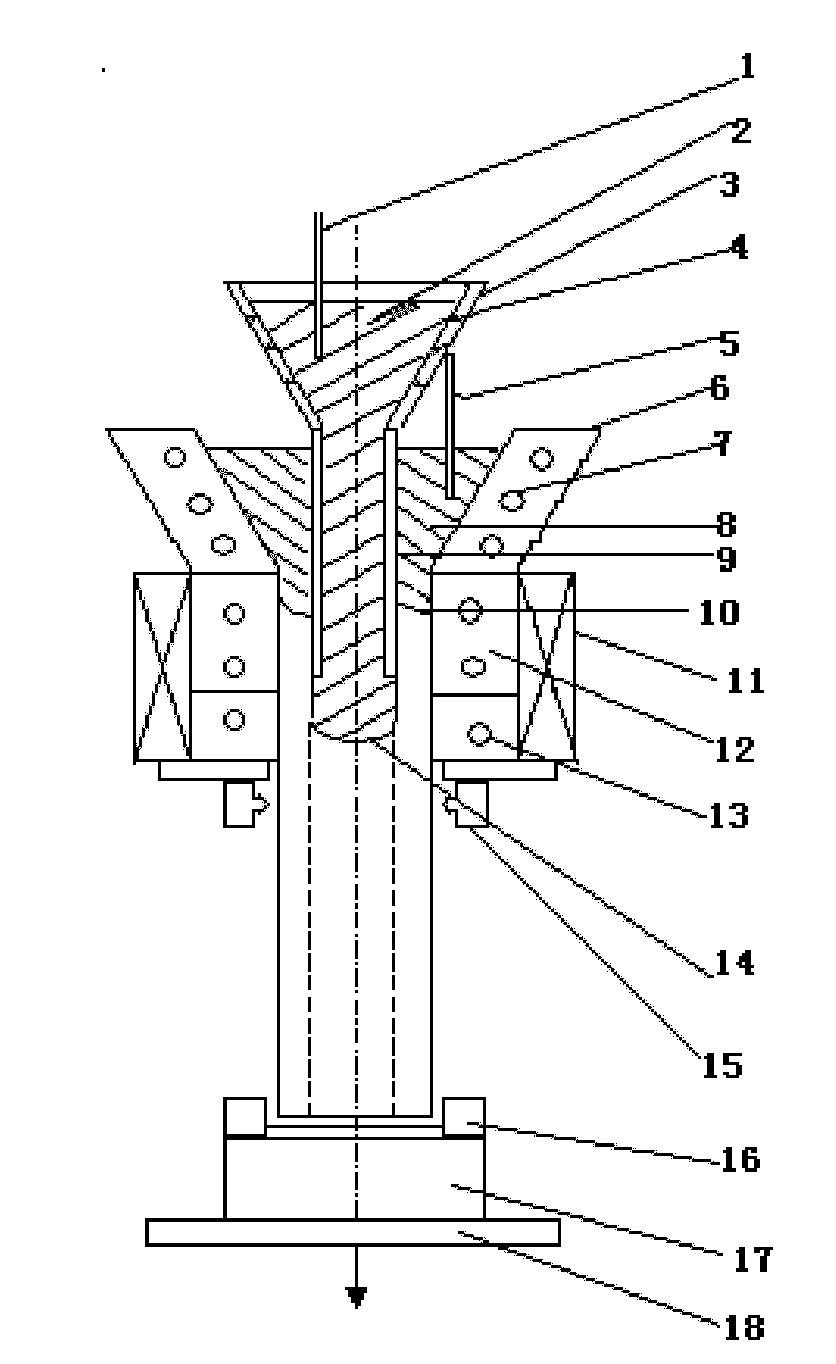

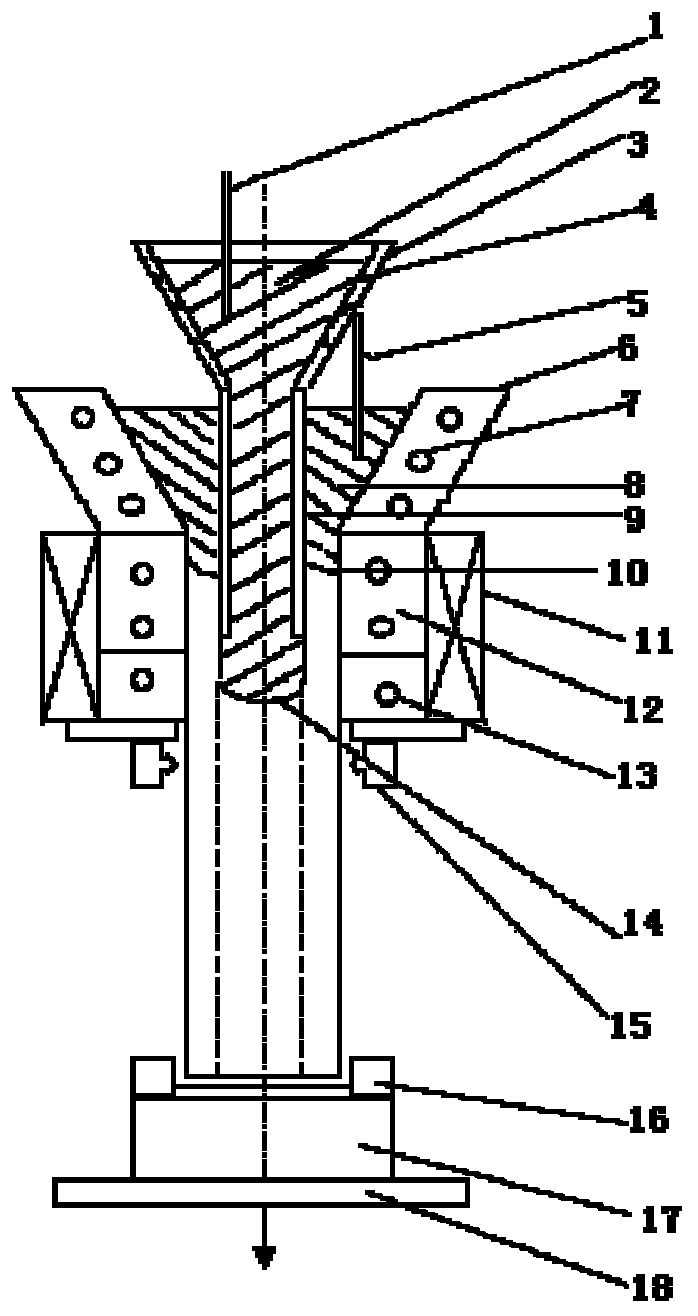

Full-automatic drilling machine

InactiveCN103143746AGuaranteed central locationImprove work efficiencyPrecision positioning equipmentPositioning apparatusMulti axisWorkload

The invention discloses a full-automatic drilling machine. A multi-axis device is arranged and a plurality of drill bits are mounted on the multi-axis device according to a drilling requirement, so that the simultaneous processing of multiple sets of drilling mechanisms is realized, the working efficiency is increased and the processing production cost is lowered. A workpiece is positioned on a rotatable index plate in a clamped way and two sets of drilling mechanisms are corresponding to two spaced areas on the index plate, so that the workpiece in a relative central position during a processing process is ensured and the stability at the drilling moment is ensured. The index plate is rotatable, and after one side of the workpiece is processed, the index plate is rotated for 90 degrees under the driving of a transmission mechanism and the other side of the workpiece is processed, so that the workpiece is not detached, the processing time is saved, the workload is reduced and the working efficiency is increased. A limiting mechanism is arranged, so that the position of the workpiece is effectively limited, the adjusting precision is higher, the fixed central position of the workpiece is ensured, the processing error is avoided and the product quality is increased.

Owner:惠亚科技(苏州)有限公司

New method for preparing pine nut oil by squeezing raw material of pine nut

InactiveCN101050398ALow processing and production costsGuaranteed qualityFatty-oils/fats productionOrganic solventHusk

This invention relates to a method for extracting pine seed oil from pine seeds without the need for solvent or complex apparatus. The method largely reduces the extraction cost, and does not use solvent, thus can maintain the natural quality of pine seed oil. The method comprises: crushing the husks of pine seeds, taking out the kernels, mixing with screened and cleaned rice hulls, wheat hulls or segments of rice straws and wheat straws at a volume ratio of (70 plus and minus 30) :(20 plus and minus 19), adding into an oil mill, extracting to obtain pine seed oil, and naturally precipitating at 10-50 deg.C for 1-15 days to separate oil and residues. The obtained pine seed oil is yellow, clear and fragrant.

Owner:徐海波

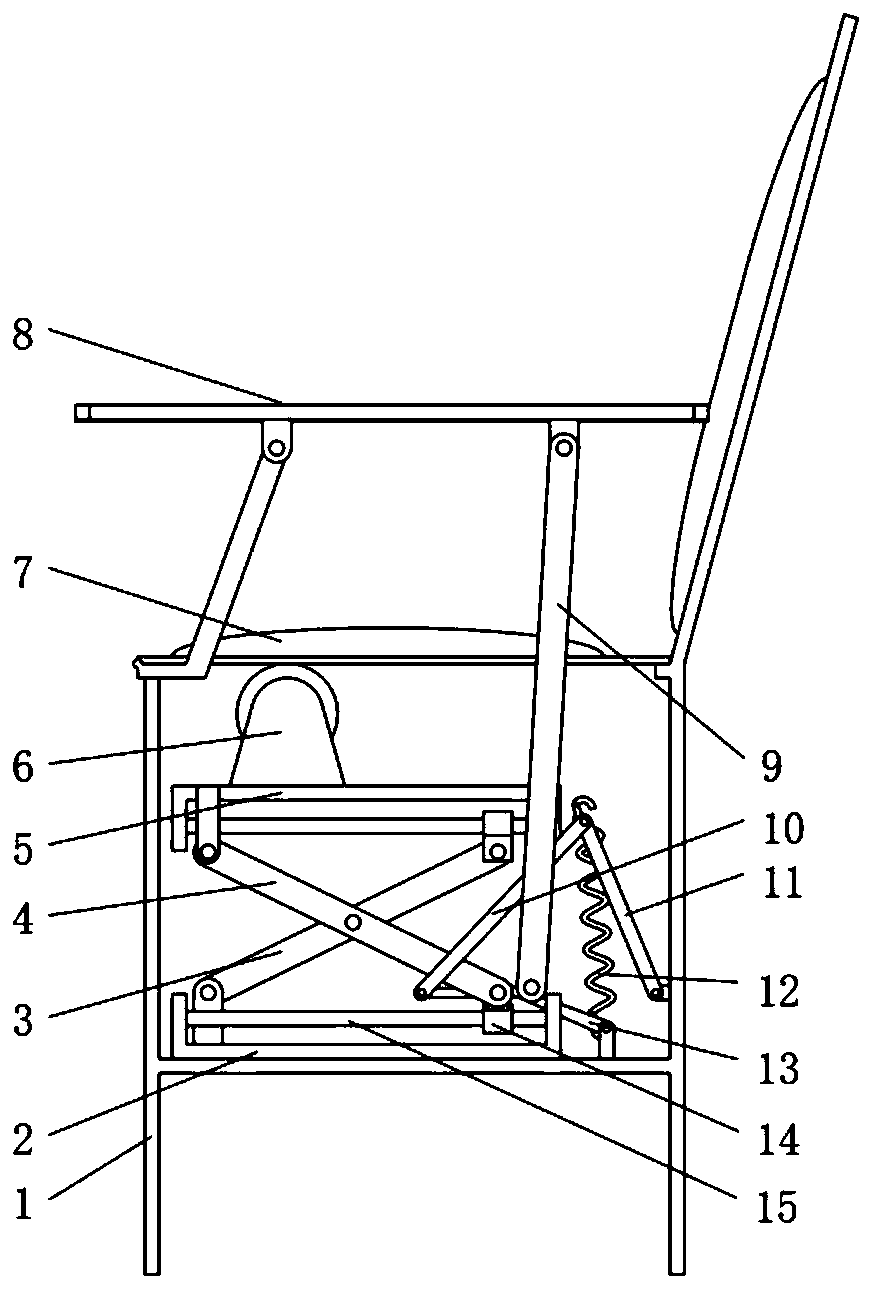

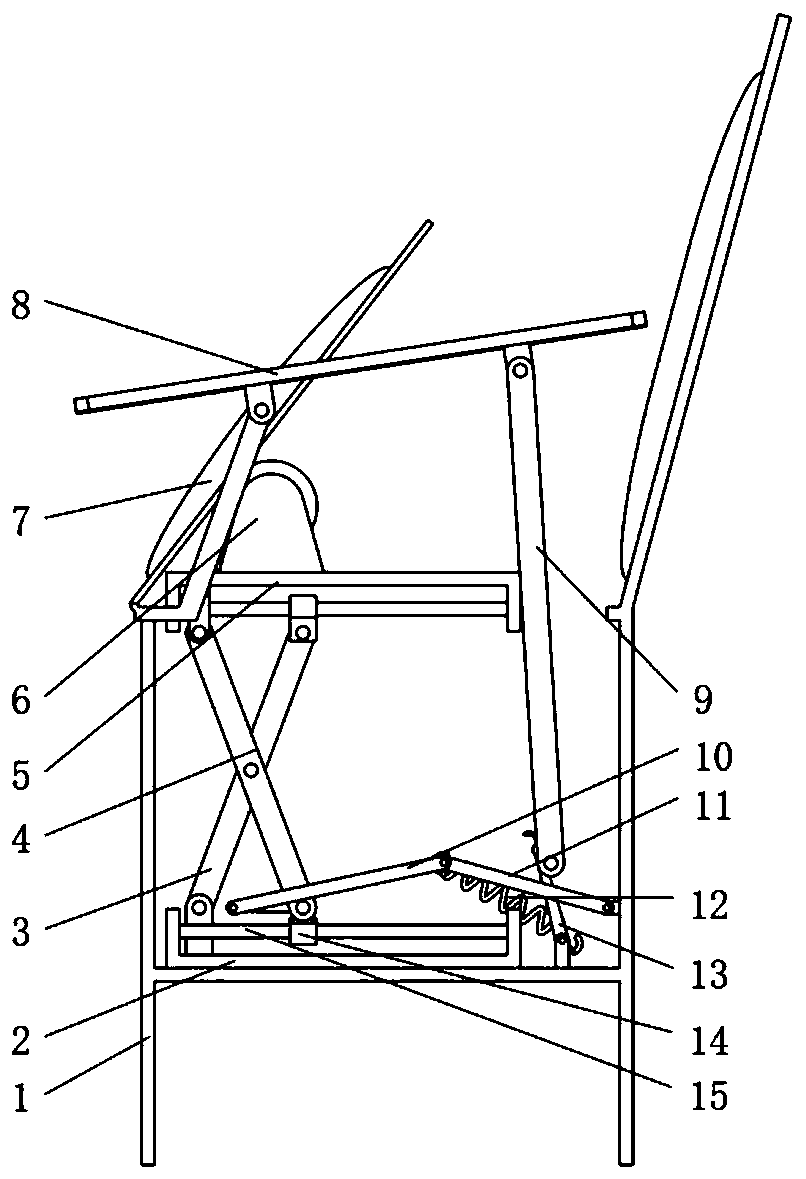

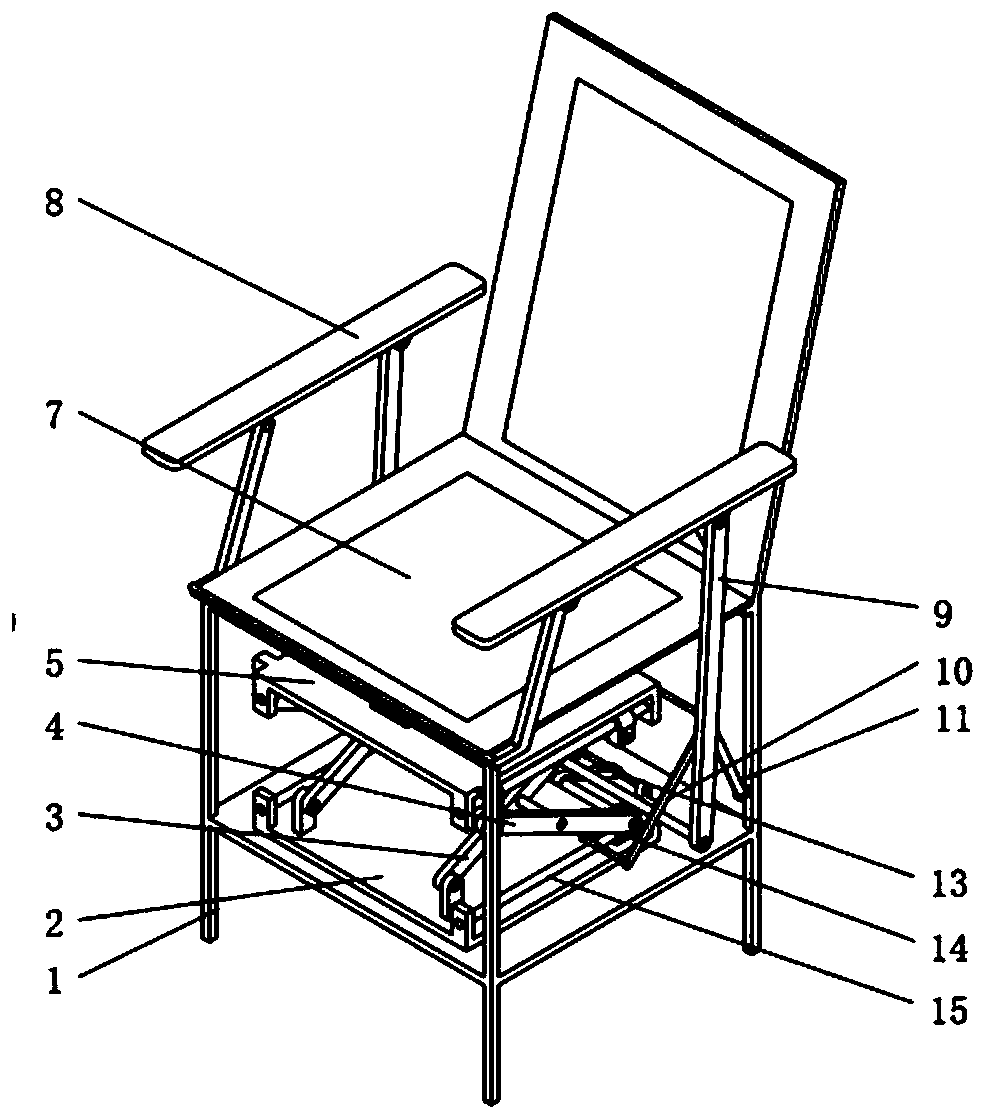

Standing assisting chair for old people

InactiveCN110353903ALow skill level requiredSuitable for mass deliveryWheelchairs/patient conveyanceOlder peopleMechanical engineering

The invention discloses a standing assisting chair for old people. The standing assisting chair comprises chair bodies and a seat plate, wherein the space between the seat plate and a plate at the lower portions of the chair bodies is internally and fixedly provided with a scissors fork mechanism, the scissors fork mechanism is symmetrically distributed, the upper and lower ends of the left and right sides of the scissors fork mechanism are all fixedly provided with a slide rail, the slide rails are provided with sliding blocks, the left and right sides of the scissors fork mechanism are bothprovided with a pair of cross-distributed scissors fork links, the upper and lower ends of the scissors fork links are connected with the sliding blocks respectively, the sliding blocks are further connected with a crank sliding block mechanism, and a tension spring is connected between the top end of the crank sliding block mechanism and the chair bodies; the top of the scissors fork mechanism isfurther fixedly provided with a roller, and the roller is in contact with the seat plate. The standing assisting chair has the advantages of pure mechanical structure, convenient maintenance, simpleoperation, simple structure and strong adaptability, and is suitable for indoor places and outdoor places with frequent use and complicated environment.

Owner:SOUTHEAST UNIV

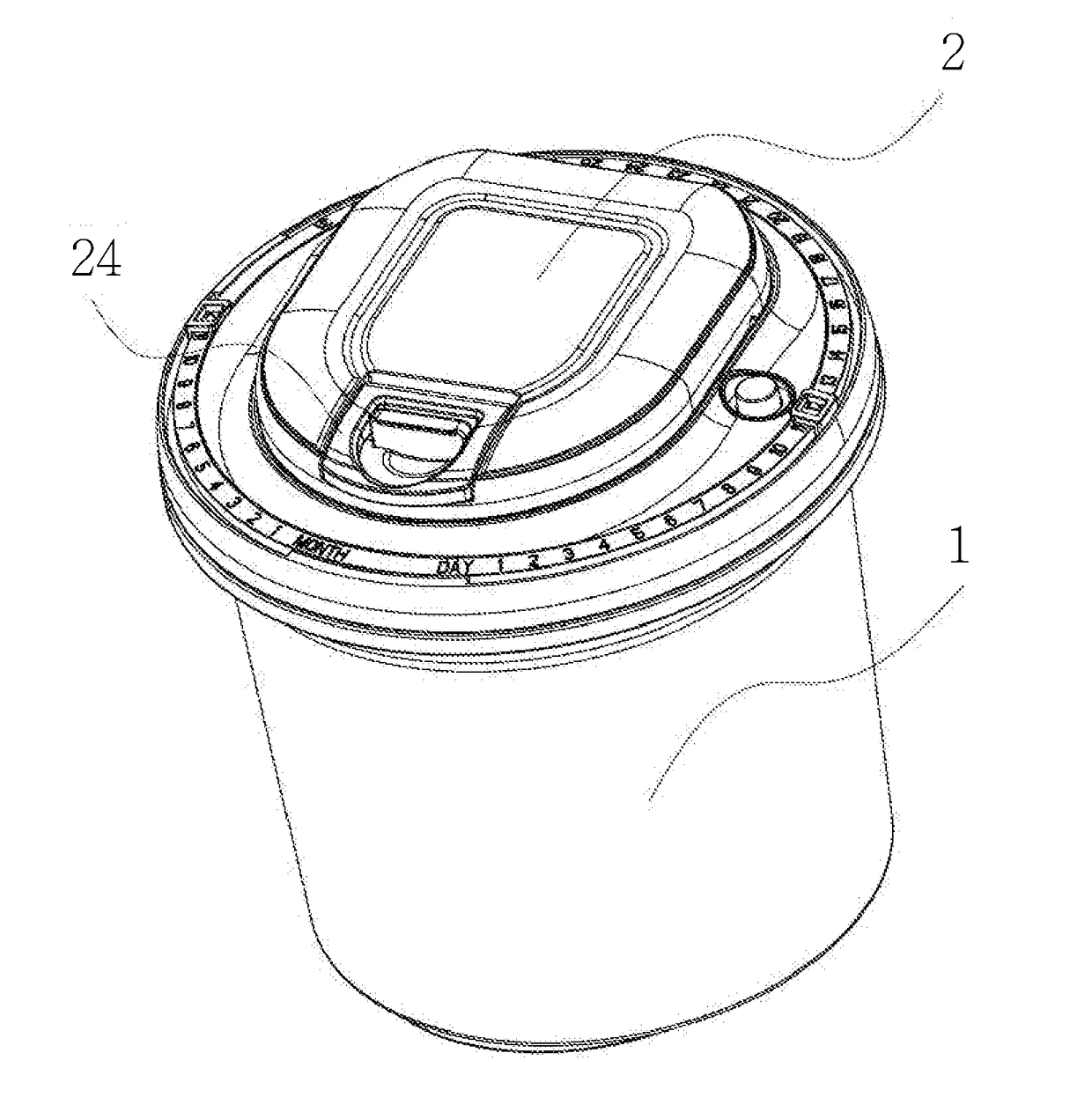

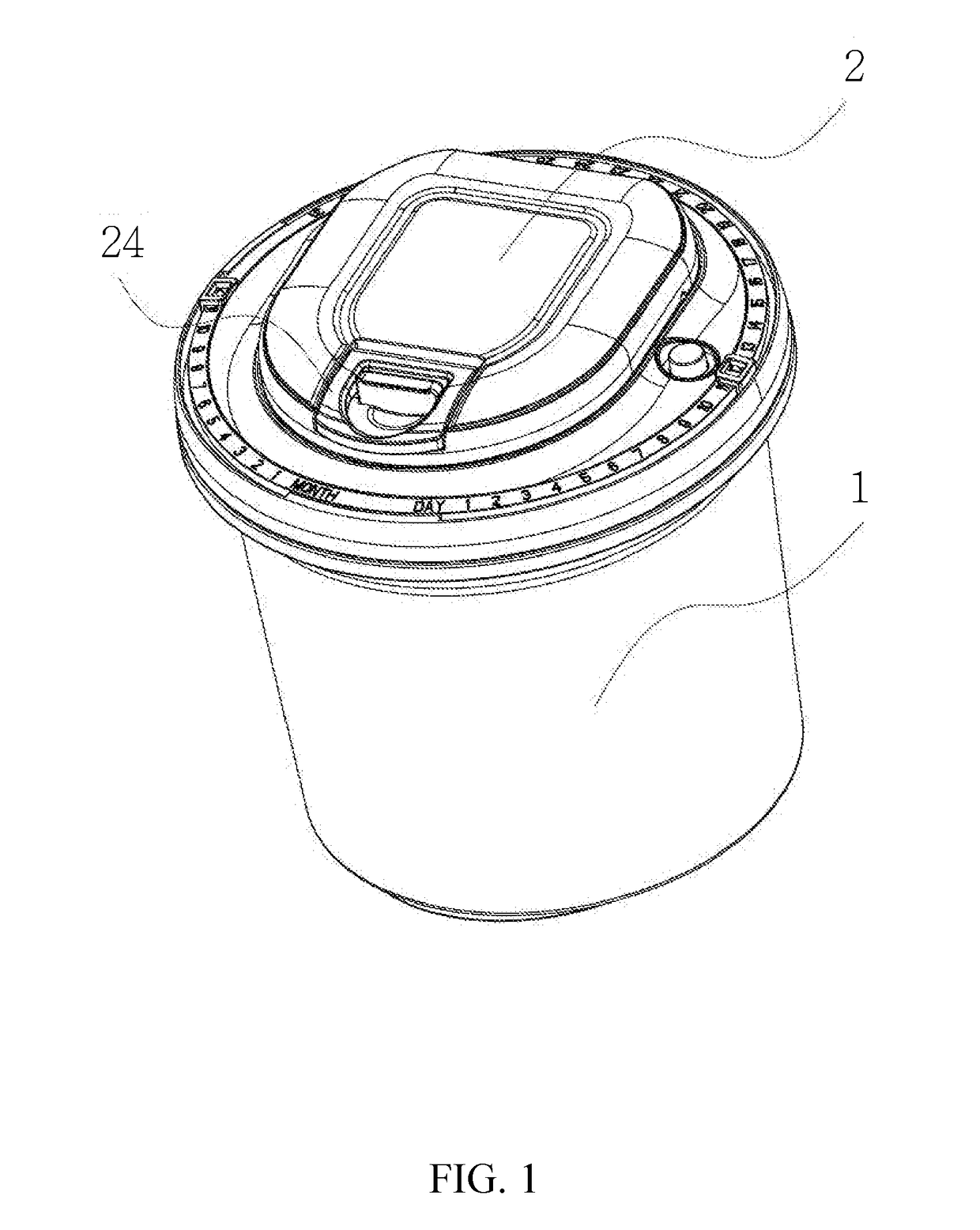

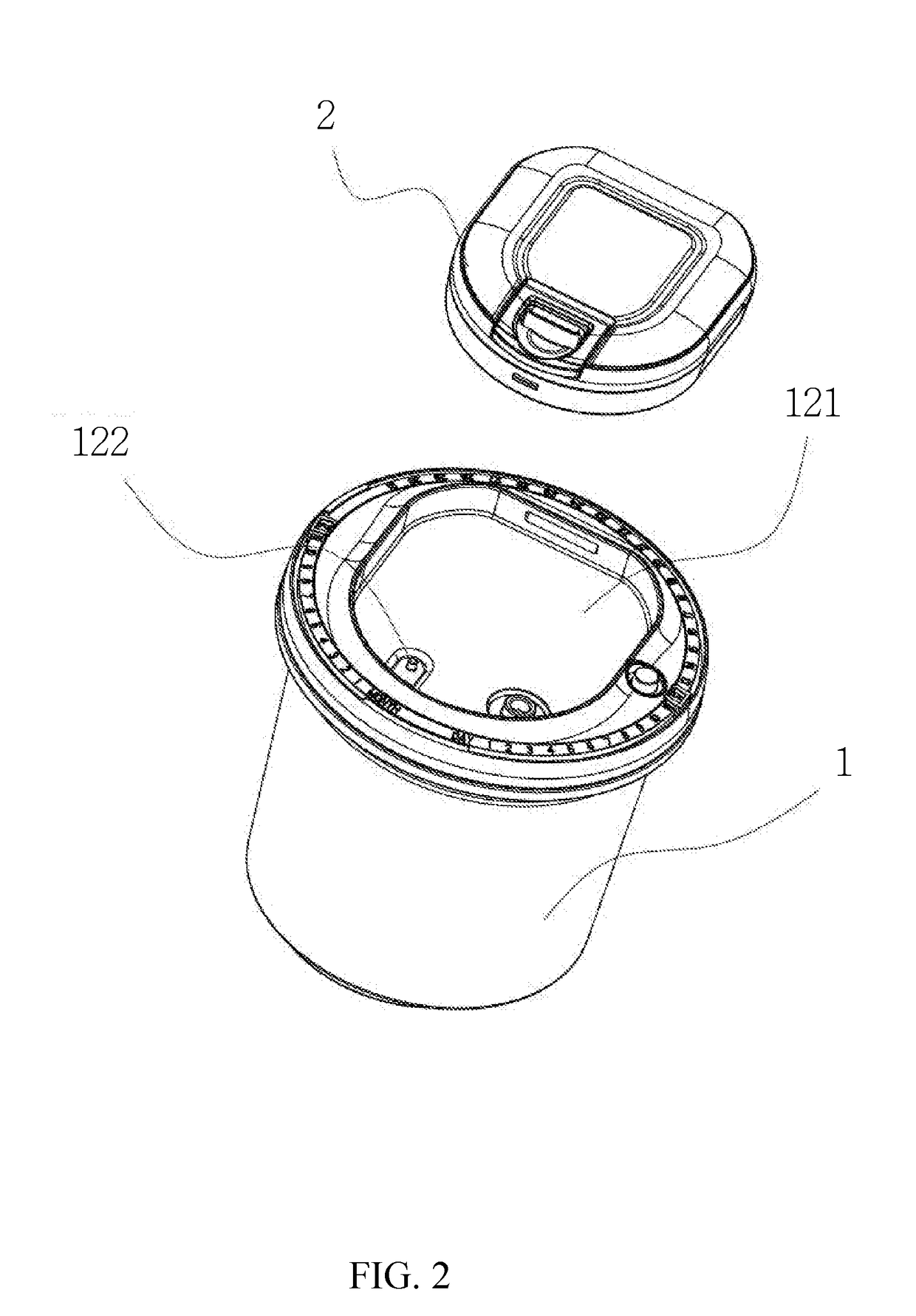

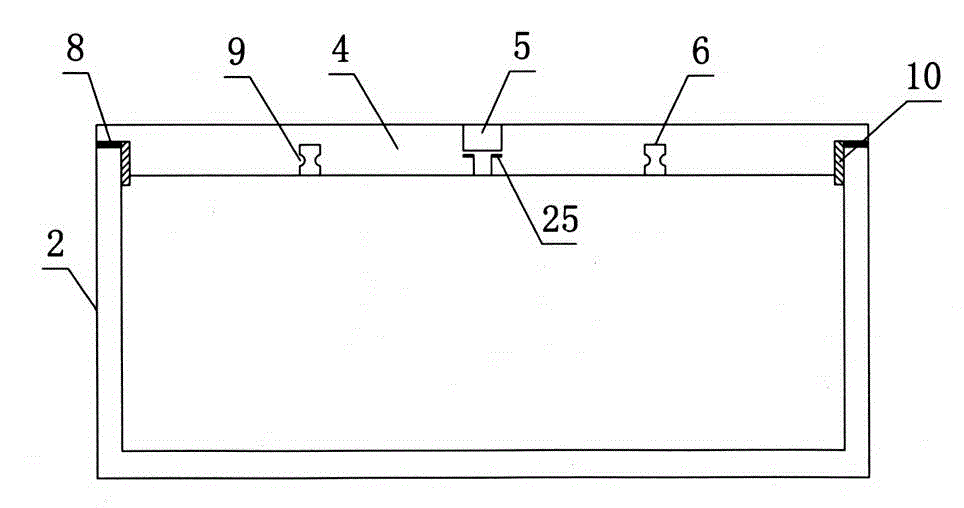

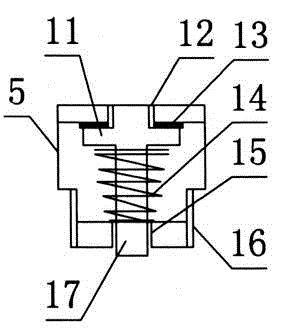

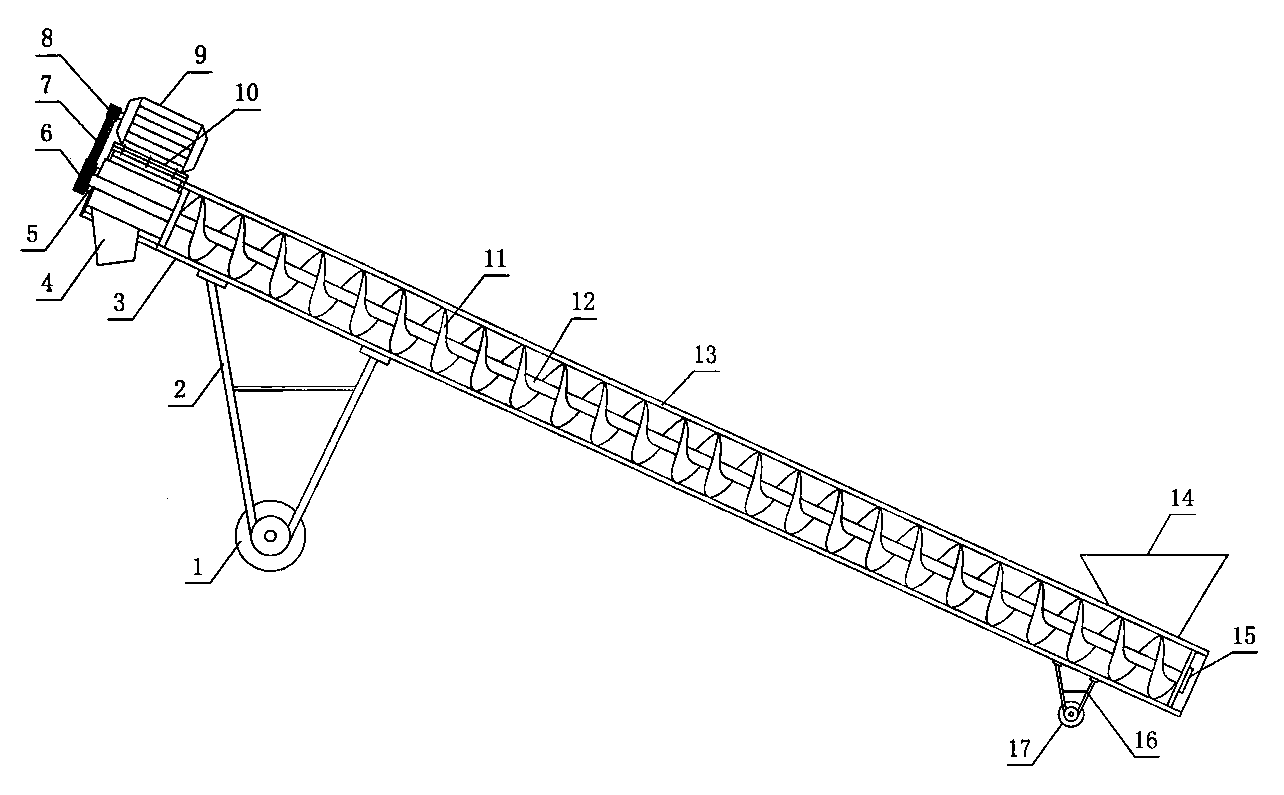

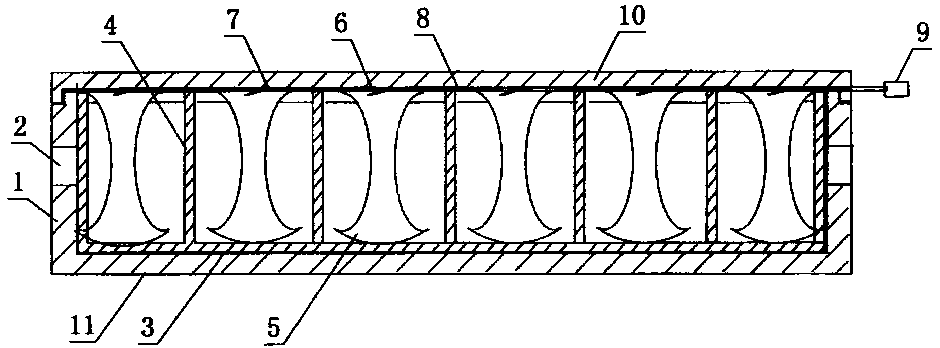

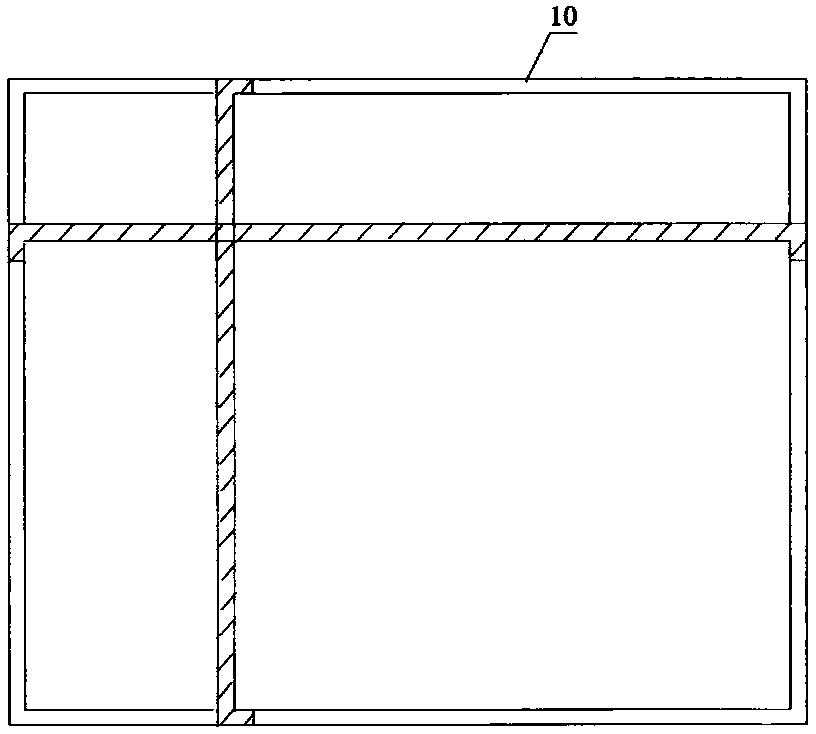

Detachable automatic vacuum storage container

InactiveUS20170190496A1Reduce processLow production costRemovable lids/coversPackaging under vacuum/special atmosphereAtmospheric pressureElectrical and Electronics engineering

A detachable automatic vacuum storage container comprises a box body and a vacuum control device, the box body being provided with a vacuumizing channel, and the vacuum control device being connected with the vacuumizing channel in a removable manner; one end of the vacuumizing channel is connected to the inner chamber of the box body, and the other end is provided with a sealing joint. The vacuum control device is provided with a suction nozzle, when the vacuum control device is connected to the vacuumizing channel, the suction nozzle is inserted and connected to the sealing joint in an airtight way; when the air pressure of the inner chamber of the box body is higher than the preset threshold, the vacuum control device can pump the air to maintain the inner chamber of box body in a vacuum state.

Owner:DONGGUAN PHEATON ELECTRONICS TECH

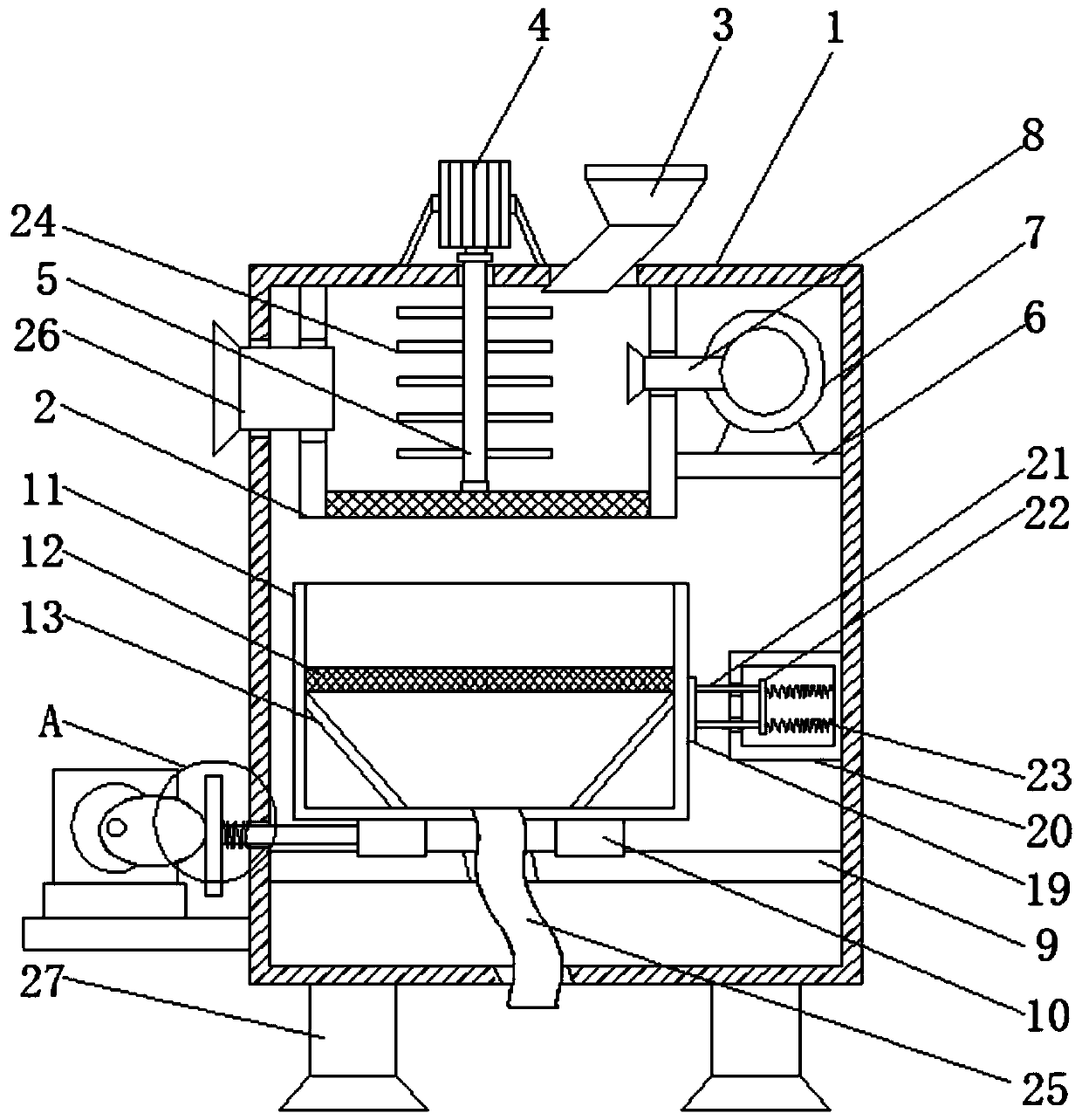

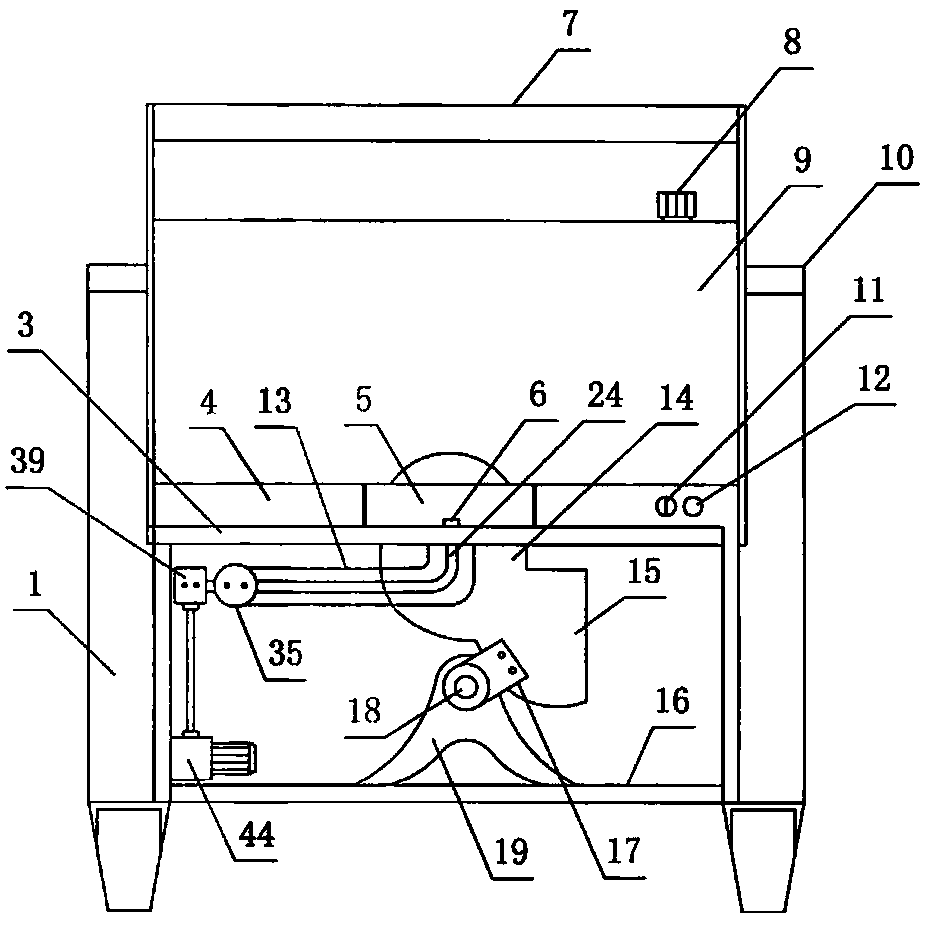

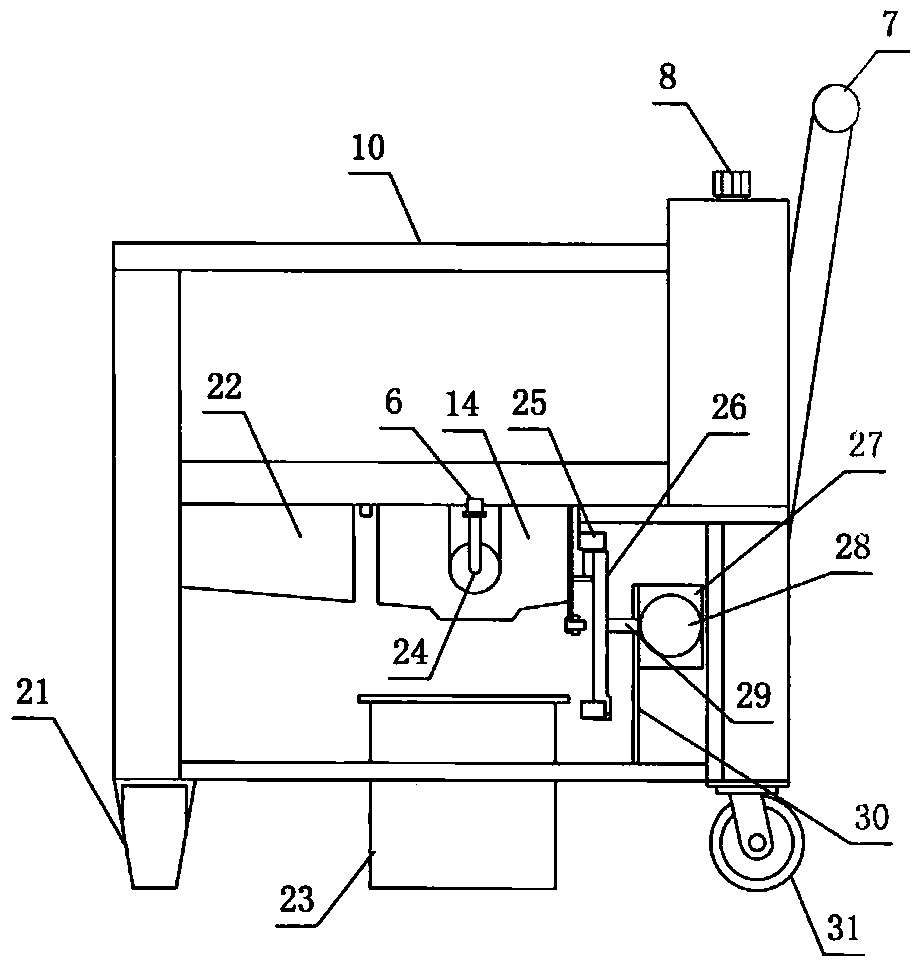

Agricultural grain screening device

InactiveCN109731783AImprove work efficiencyShorten the timeSievingGas current separationCouplingAgricultural engineering

The invention discloses an agricultural grain screening device, and relates to the technical field of rice screening. The agricultural grain screening device comprises a box body. A rectangular frameis fixedly connected to the top of the inner wall of the box body, a feeding hopper is fixedly connected to one side of the top of the box body, a first motor is fixedly connected to the top of the box body and located on one side of the feeding hopper, one end of an output shaft of the first motor is fixedly connected with a rotating shaft through a coupling, and the bottom end of the rotating shaft sequentially penetrates through the box body and the rectangular frame and extends to the interior of the rectangular frame. According to the agricultural grain screening device, stirring blades are driven to stir the rice with greater intensity to screen the rice by the rotation of the rotating shaft, the working efficiency is improved, the working time is shortened, the multi-layer screeningdevice screens the rice, the screening is more convenient, the screening time is short, the labor intensity is low, the production efficiency is improved, and processing and production costs are reduced.

Owner:肥西县堰丰农业农民专业合作社

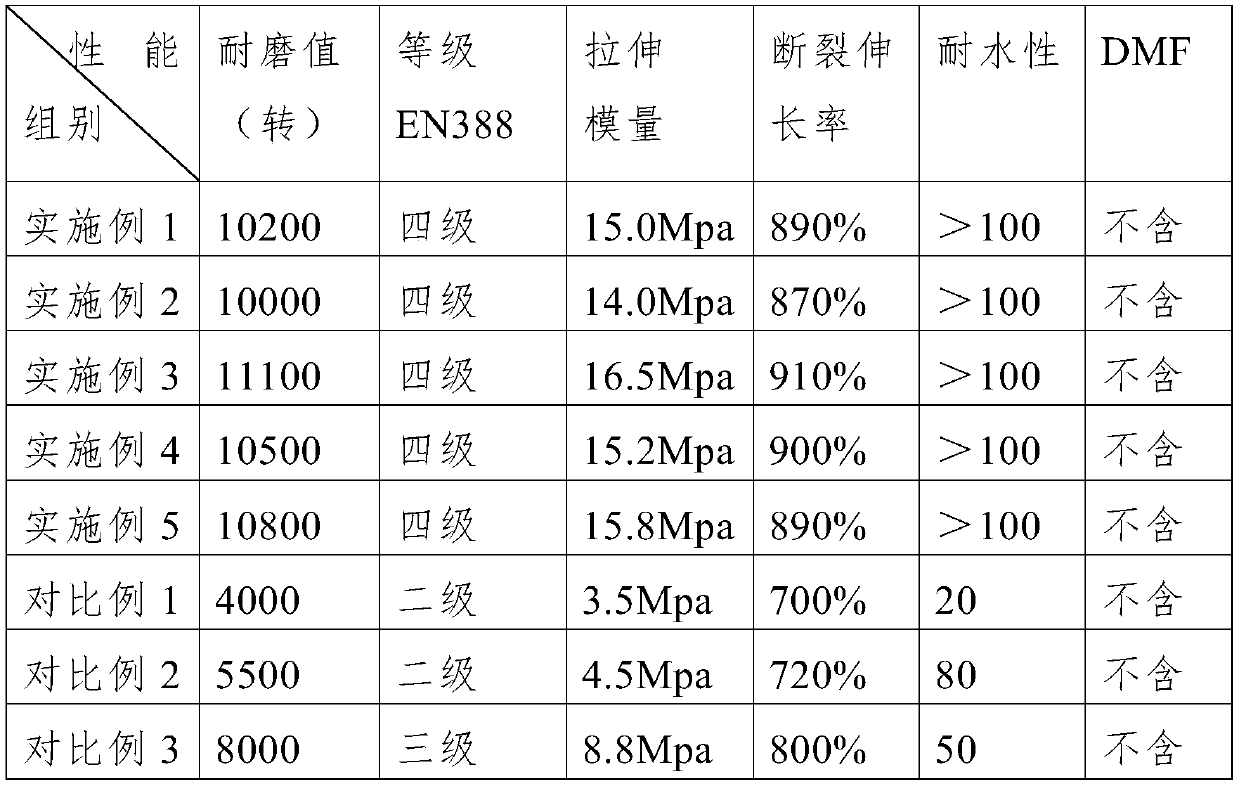

Waterborne polyurethane emulsion, preparation method and impregnated gloves

InactiveCN110452351AReduce pollutionReduce potential energyGlovesProtective garmentSolventSilicon nanoparticle

The present invention relates to a waterborne polyurethane emulsion. During preparation of the waterborne polyurethane emulsion, raw materials comprise an organosilicon polyol and modified silicon nanoparticles capable of reacting with hydrophilic groups in polyurethane molecular chains, so that the waterborne polyurethane molecular chains are introduced into reactive organosilicon and the modified silicon nanoparticles. The preparation method comprises the following steps: during preparation of a polyurethane prepolymer, taking an isocyanate and polyol as raw materials, and carrying out a reaction in the presence of a catalyst and a chain extender to obtain the polyurethane prepolymer, wherein the polyol contains at least one organosilicon polyol; and during preparation of the waterbornepolyurethane emulsion, mixing the polyurethane prepolymer with a water solution containing the modified silicon nanoparticles for emulsification to obtain the waterborne polyurethane emulsion. Compared with an existing mode of adding a filler by physical mixing to modify the waterborne polyurethane resin, the method provided by the invention has the advantages that water resistance / solvent resistance, low-temperature flexibility and wear resistance of the waterborne polyurethane resin can be improved, and retention timeliness of the excellent performance is longer.

Owner:SHANDONG XINGYU GLOVES

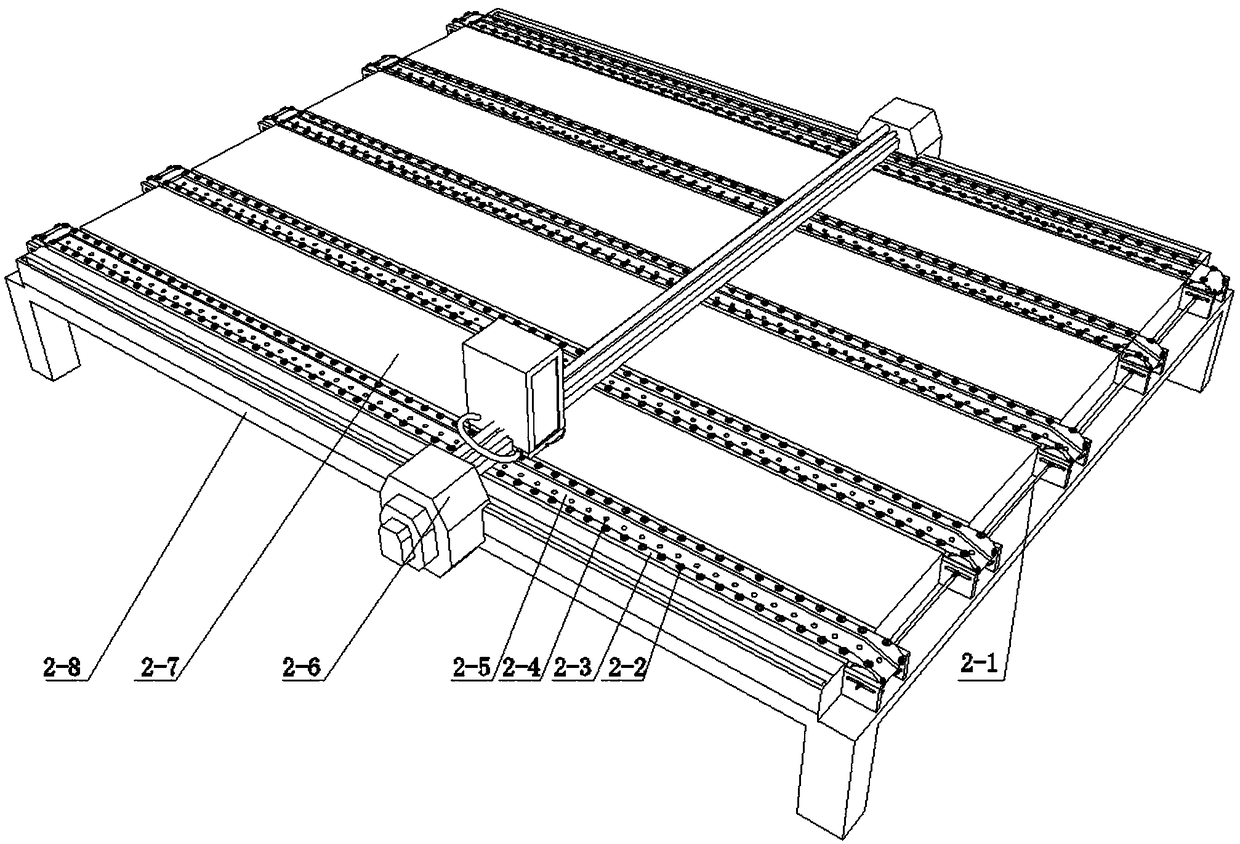

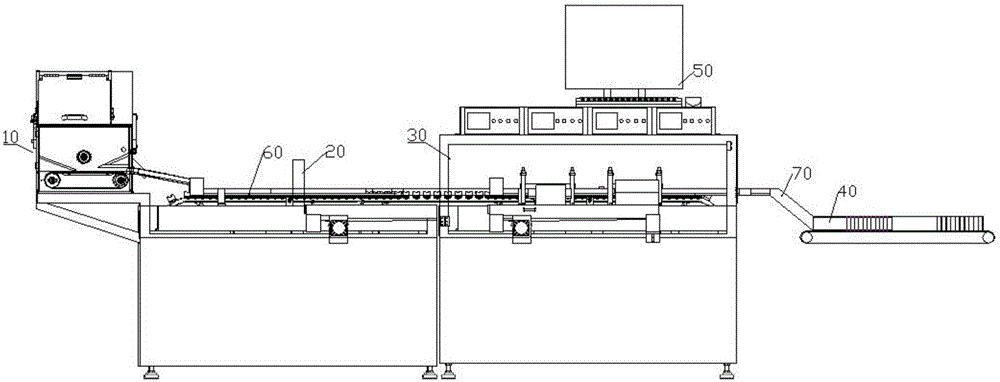

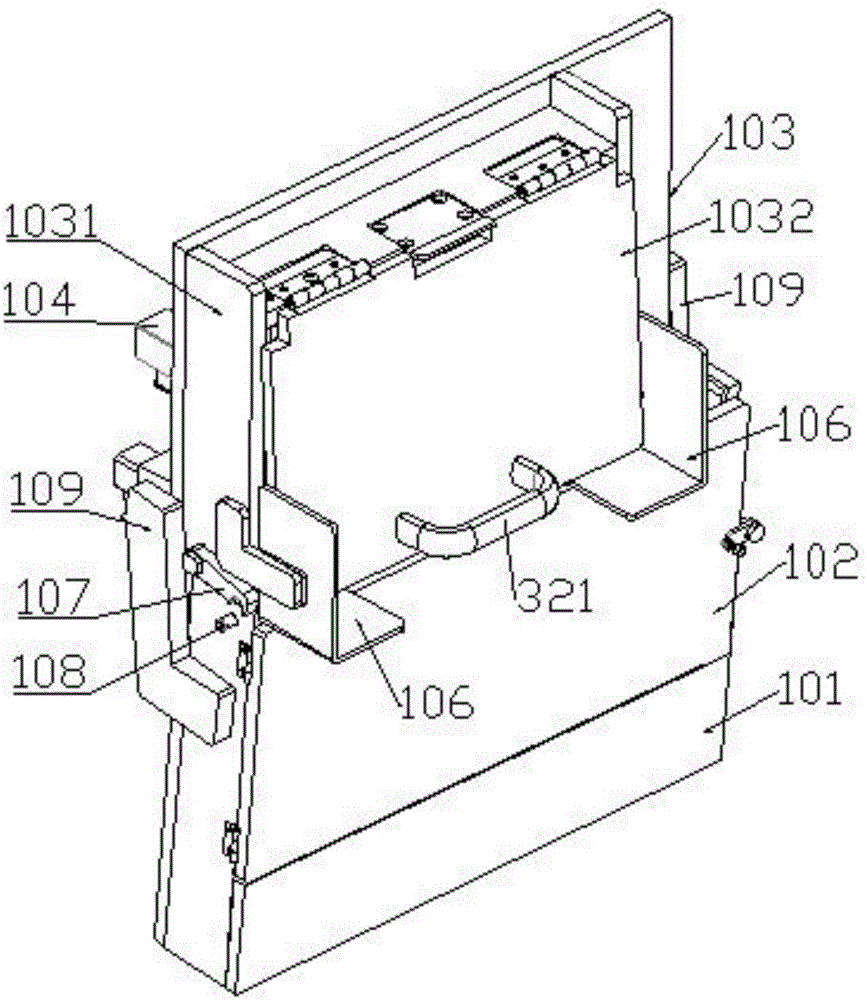

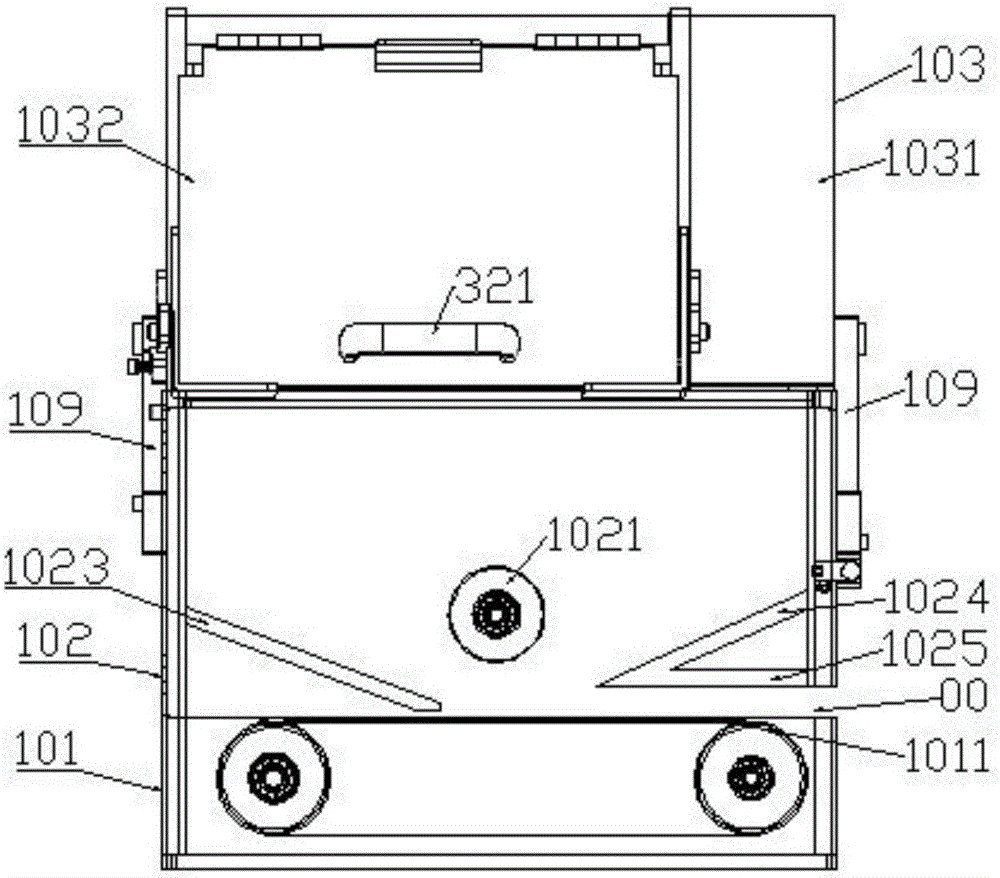

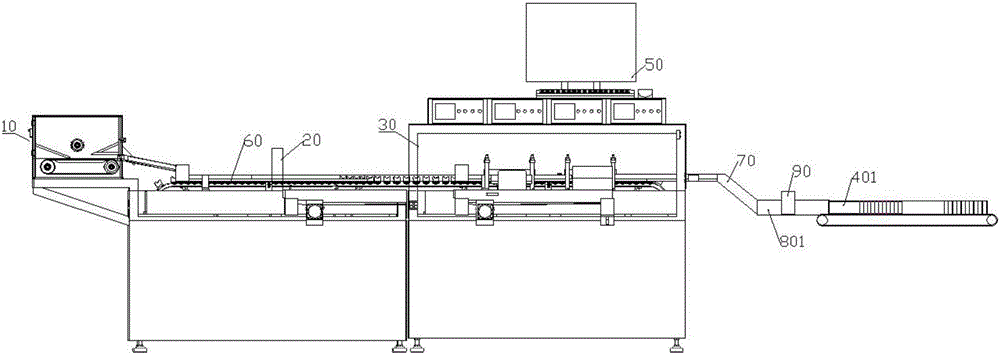

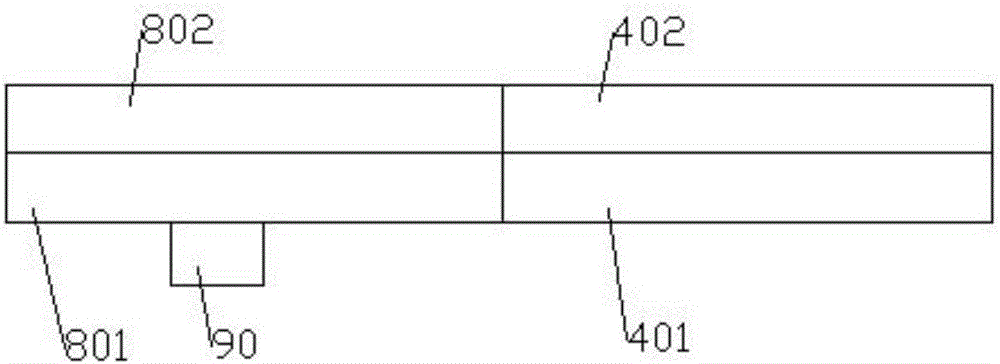

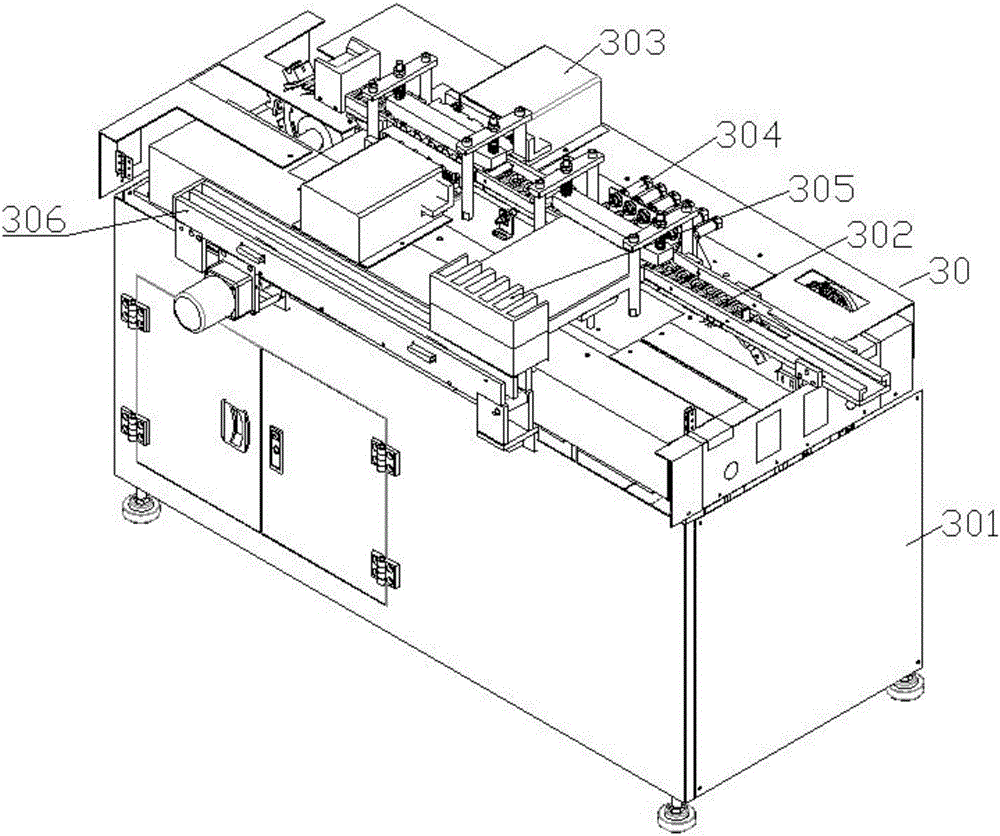

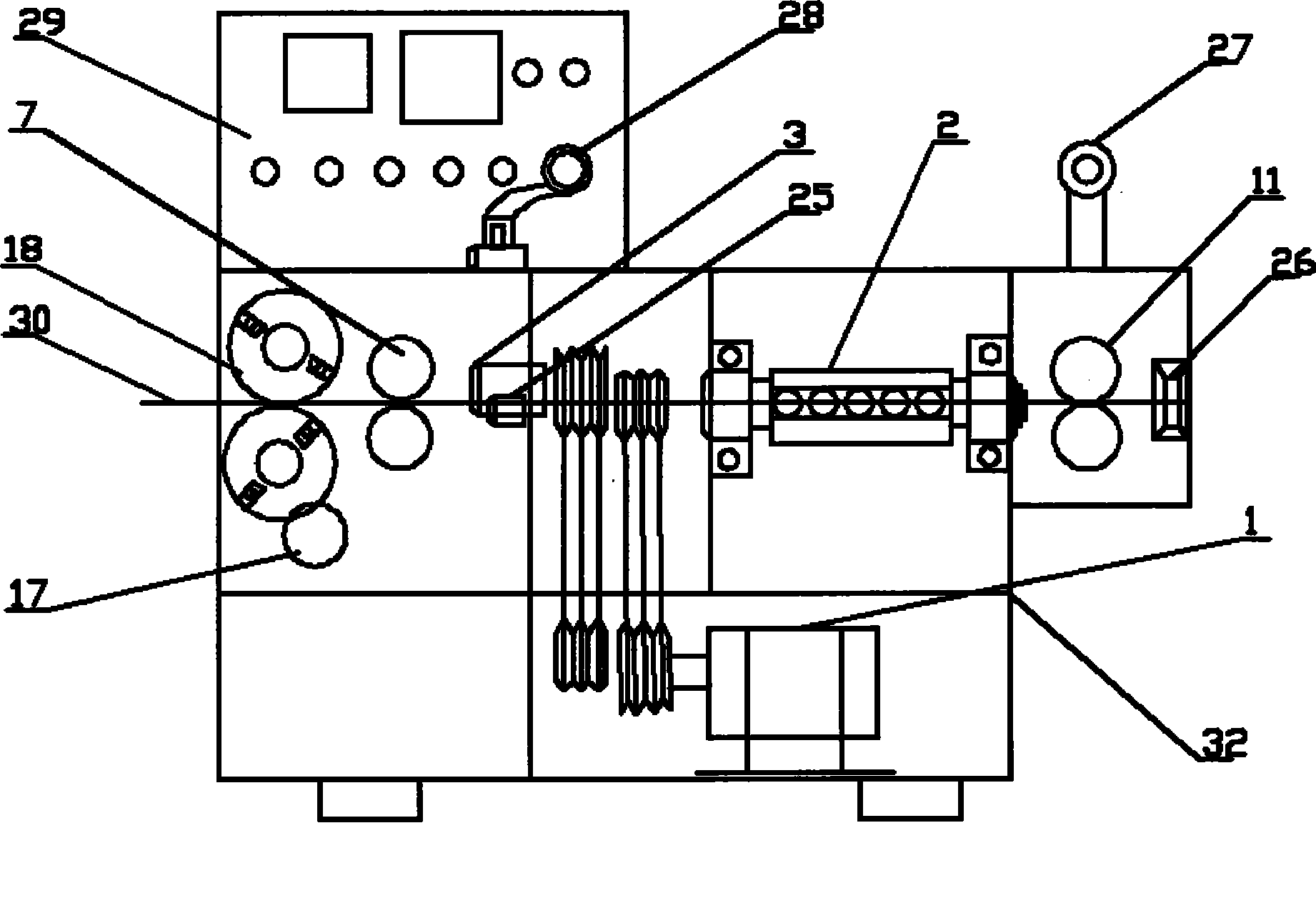

Full-automatic glass slitting and edge-grinding assembly line

PendingCN108943422ALow processing and production costsHigh degree of automationWorking accessoriesStone-like material working toolsTime efficientWater resources

The invention relates to a full-automatic glass slitting and edge-grinding assembly line. The assembly line is sequentially provided with a full-automatic glass loading machine, a full-automatic glasscutting machine, an automatic glass breaking table and a full-automatic glass edge grinding machine in the moving direction of glass. The assembly line can achieve the effects of full-automatic glassloading, feeding, cutting, breaking and edge grinding, the trouble of manual glass loading, manual cutting, manual breaking and manual edge grinding is avoided, moreover, the production environment protection efficiency of workers in each link is improved, machining of the glass is finer, the resource waste is reduced by utilizing recycling of the water resources, meanwhile, the equipment is protected, the automation degree is high, the production efficiency is high, the product percent of pass is high, the labor is saved, the time is saved, the glass slitting cost is reduced, and the safetyis high.

Owner:鹏凯(天津)玻璃有限公司

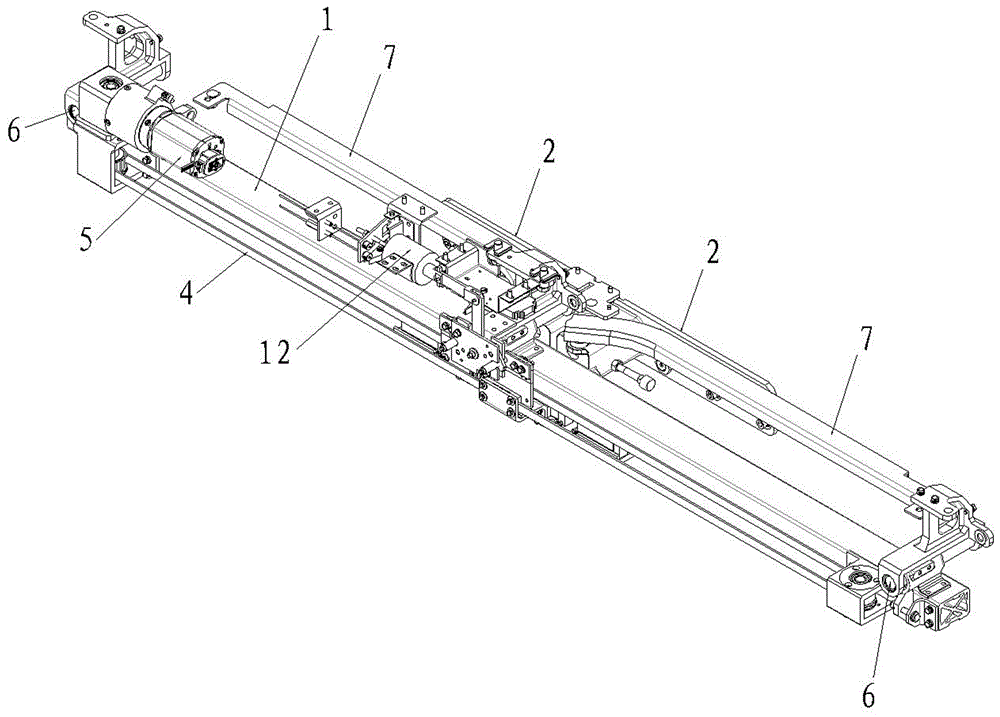

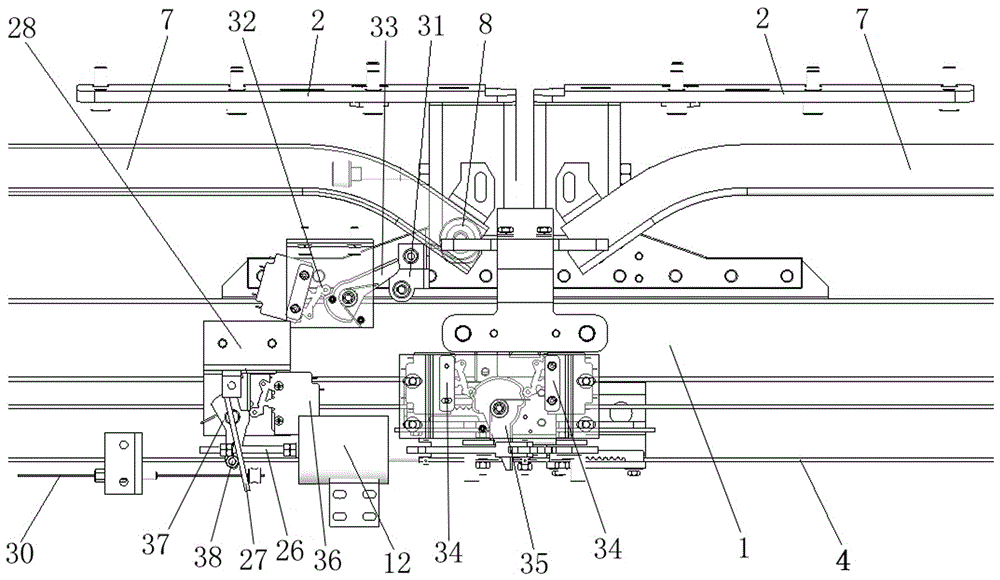

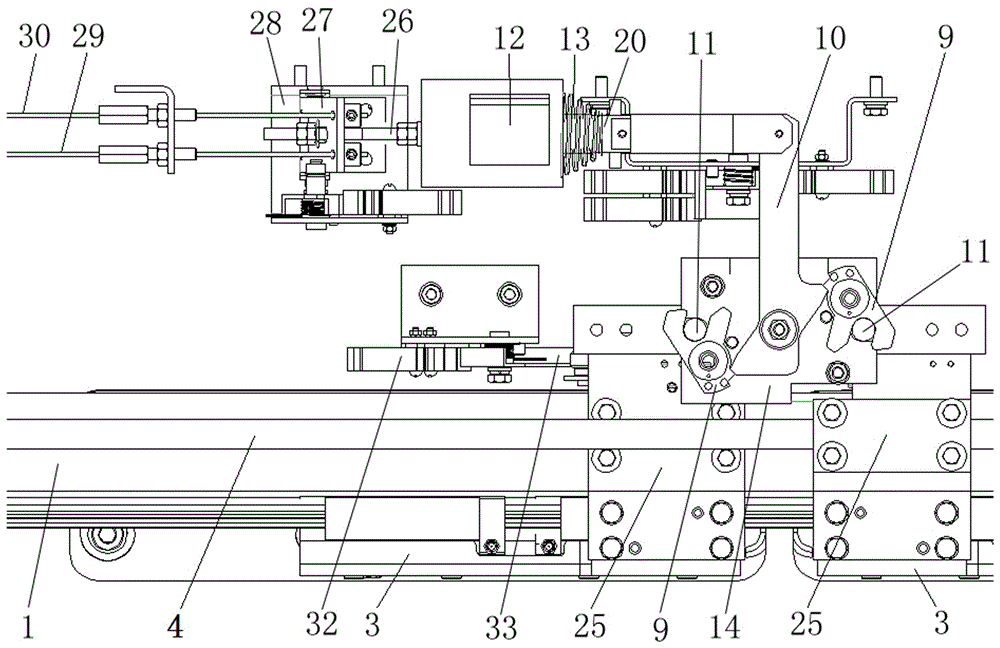

Rotary type train door locking system

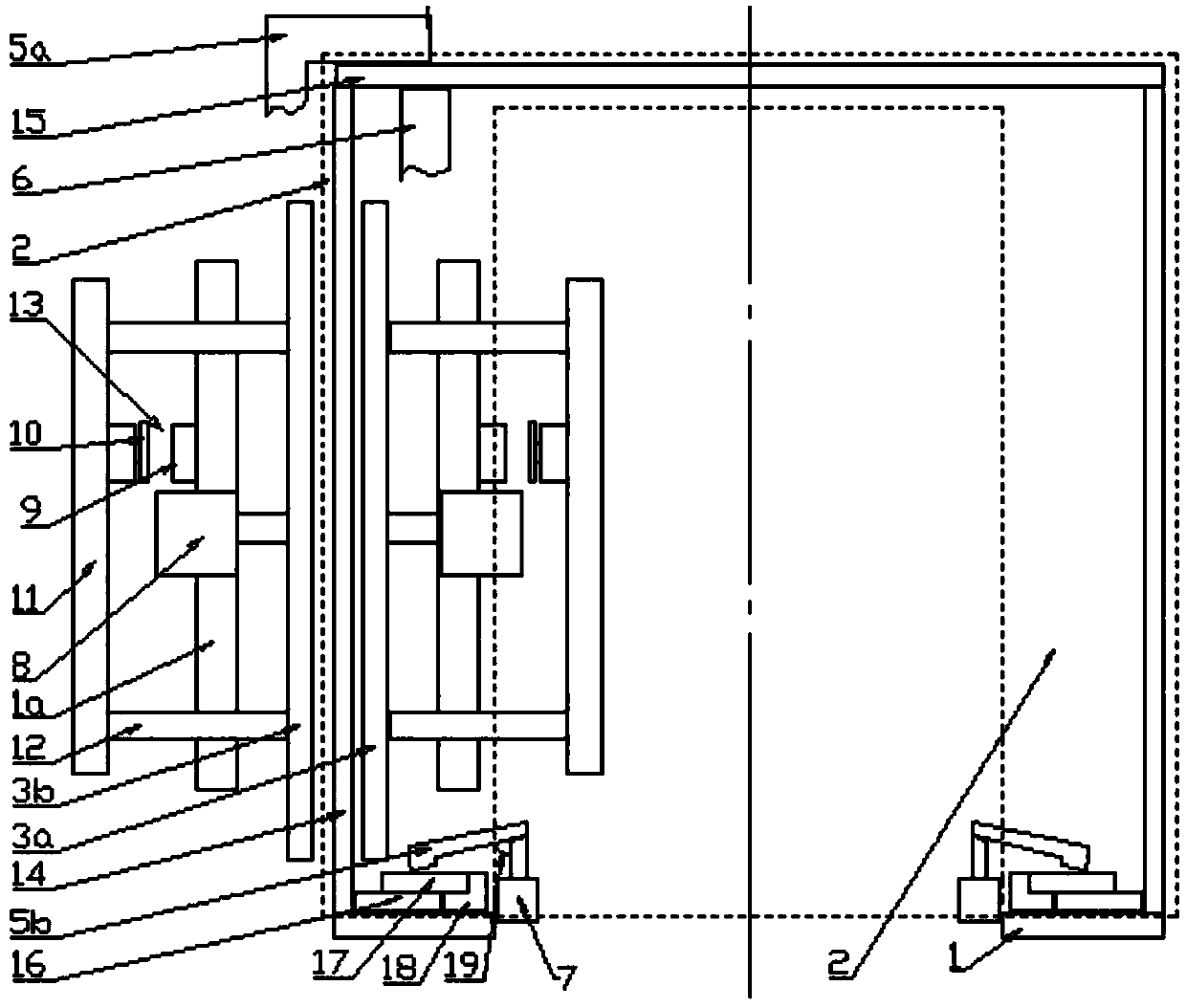

ActiveCN106401356AAchieve lockingAchieve unlockPower transmission/actuator featuresPower-operated mechanismLocking mechanismElectrical and Electronics engineering

The invention discloses a rotary type train door locking system which comprises a portal crane beam, a transverse linear guide rail assembly, two train door connecting plates, a synchronous belt transmission assembly, a longitudinal linear bearing assembly, a locking mechanism and the like. According to the rotary type train door locking system, the plugging and pulling movement of the train door on the horizontal plane can be achieved, the effect of completely locking the train door is achieved by locking the transverse movement of the train door through the locking mechanism, the locking principle is simple, and structure installation and maintenance are convenient.

Owner:FANGDA INTELLIGENT INNOVATION TECH CO LTD

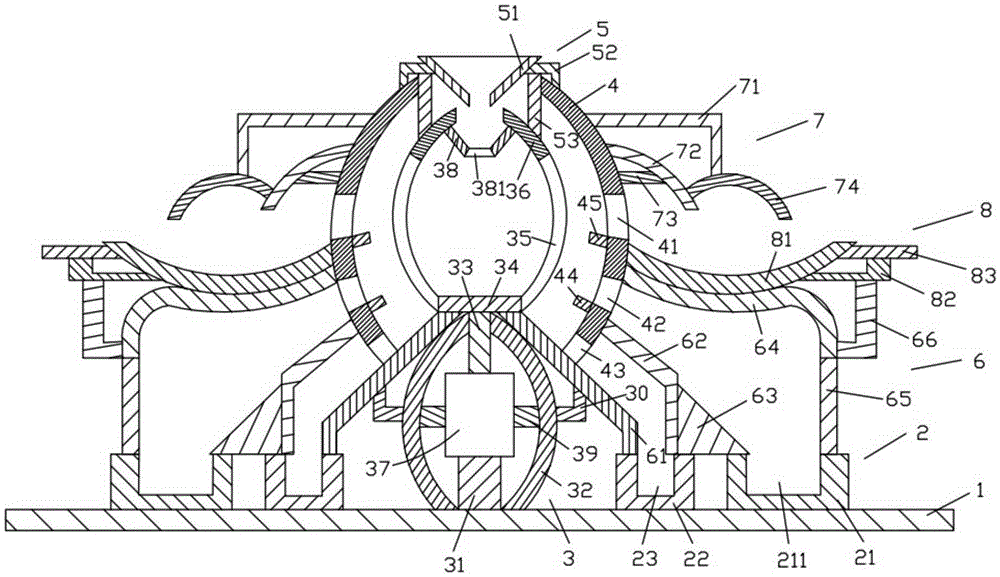

Separable type automatic vacuum pumping storage container

ActiveCN105501686AEasy to seal the connectionLow processing and production costsRemovable lids/coversPackaging under vacuum/special atmosphereVacuum pumpingEngineering

The invention discloses a separable type automatic vacuum pumping storage container. The separable type automatic vacuum pumping storage container comprises a box body and a vacuum control device, wherein a vacuum pumping passage is formed in the box body; the vacuum control device is detachably connected with the vacuum pumping passage; one end of the vacuum pumping passage is communicated with an inner cavity of the box body; a sealing joint is arranged on the other end of the vacuum pumping passage; the vacuum control device is provided with a gas pumping nozzle; the gas pumping nozzle is inserted in the sealing joint and is in air-tight connection with the sealing joint when the vacuum control device is connected with the vacuum pumping passage, and the inner cavity of the box body is enabled to keep a vacuum state by the vacuum control device by pumping gas when the air pressure of the inner cavity of the box body is greater than a preset threshold value. Compared with an existing vacuum storage box, the separable type automatic vacuum pumping storage container disclosed by the invention has the advantages that more effective vacuum pumping can be realized, and the vacuum degree in the box body can be better maintained; more convenience is realized when the separable type automatic vacuum pumping storage container is used by a user, and the requirements on vacuum pumping or vacuum releasing can be realized without too much operation.

Owner:东莞泓叶电子科技有限公司

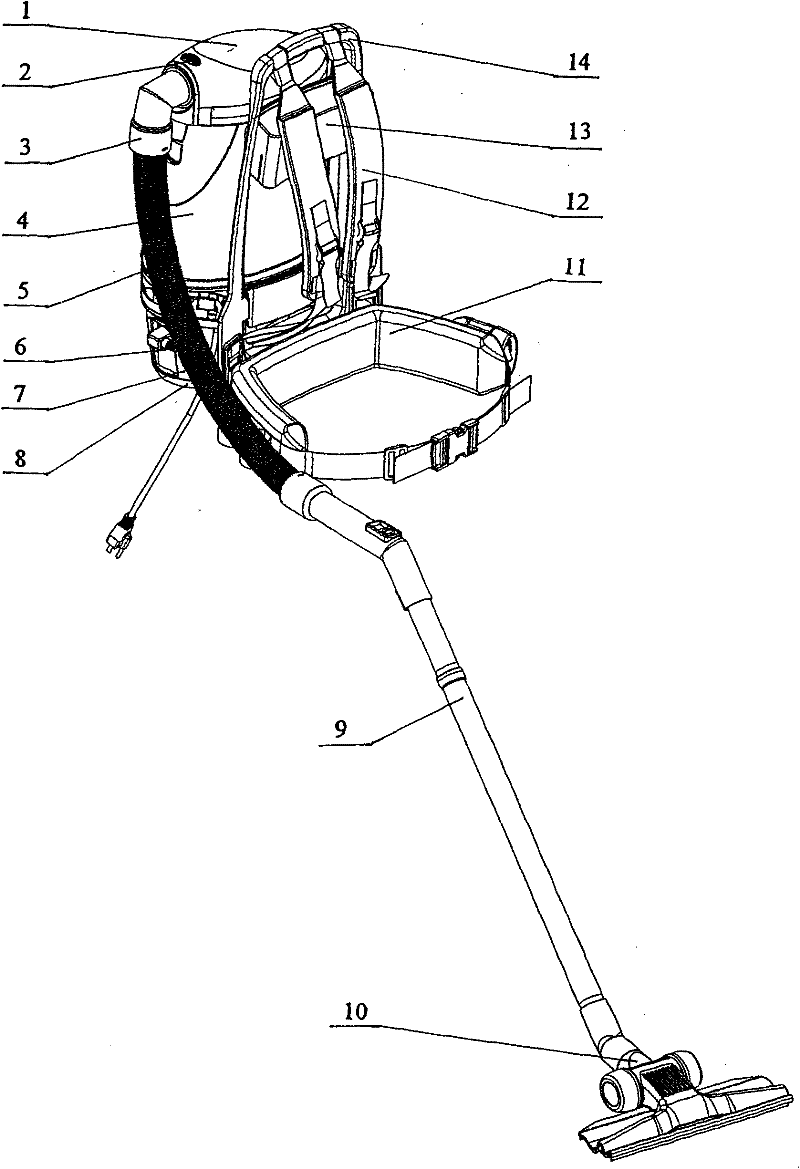

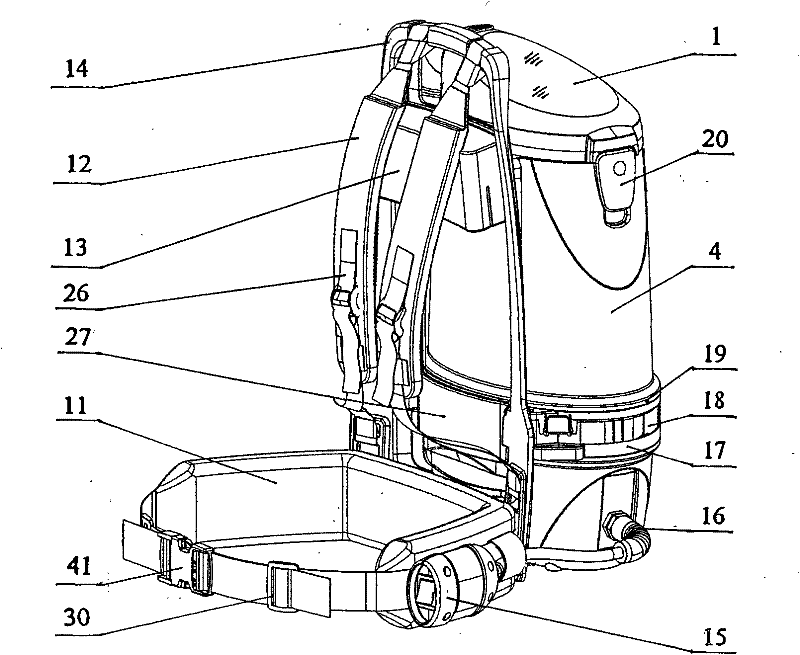

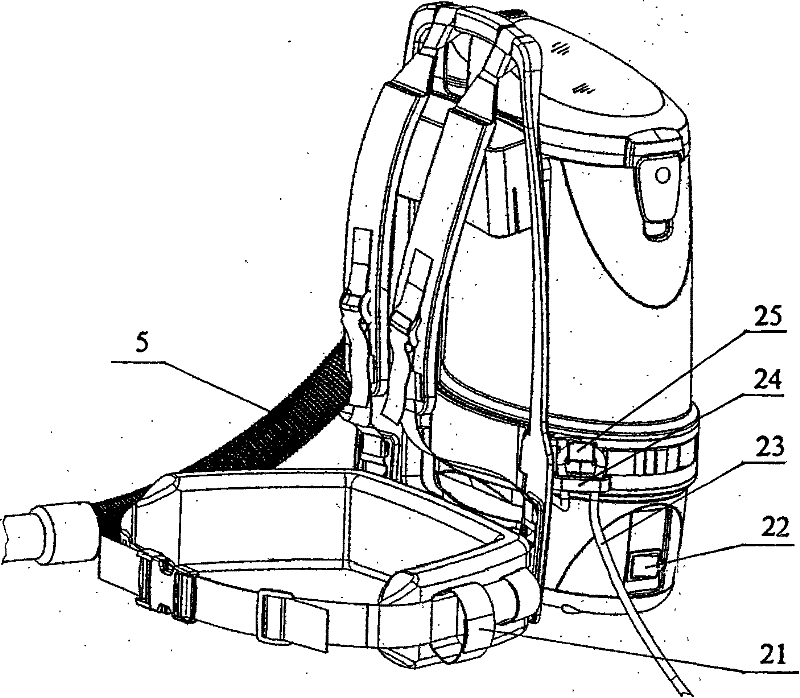

Knapsack type dust collector

InactiveCN101744565AFixed, safe and reliableCompact structureSuction filtersElectric equipment installationFilter matingEngineering

The invention discloses a knapsack type dust collector. A knapsack device is formed by fixing a waist belt and shoulder belts on a backing plate through tying belts; the backing plate is an integral formed by fastening an rabbet on the backing plate and a groove on the upper end of a large cylinder; a dust collecting device is formed by the matching of a paper filter bag and an advanced filter fixed on a motor cavity, wherein the paper filter bag is connected with an air inlet pipe and placed into a bag dust filter; and a strap joint is an integral formed by fixing a transparent cover connected with the air inlet pipe and a cover connected with a warped switch. The knapsack type dust collector has a filtering ratio up to 99.90 percent, and is particularly suitable for hospital, laboratories and other places special cleaning requirements. The invention can be conveniently put on the shoulders, is labor-saving and convenient, is more convenient for long-time operation, is particularly suitable for working in narrow spaces on planes, high-speed railway locomotives, deluxe coaches and other transportation vehicles, and reduces labor intensity. Moreover, dust can be observed directly through the transparent cover, which is convenient for real-time processing and avoids secondary pollution, and the strap joint is connected with the dust collecting pipe and a dust collecting head through a connection pipe capable of rotating omnidirectionally, thereby avoiding pipe-winding phenomenon.

Owner:上海钒钠特环保制品有限公司

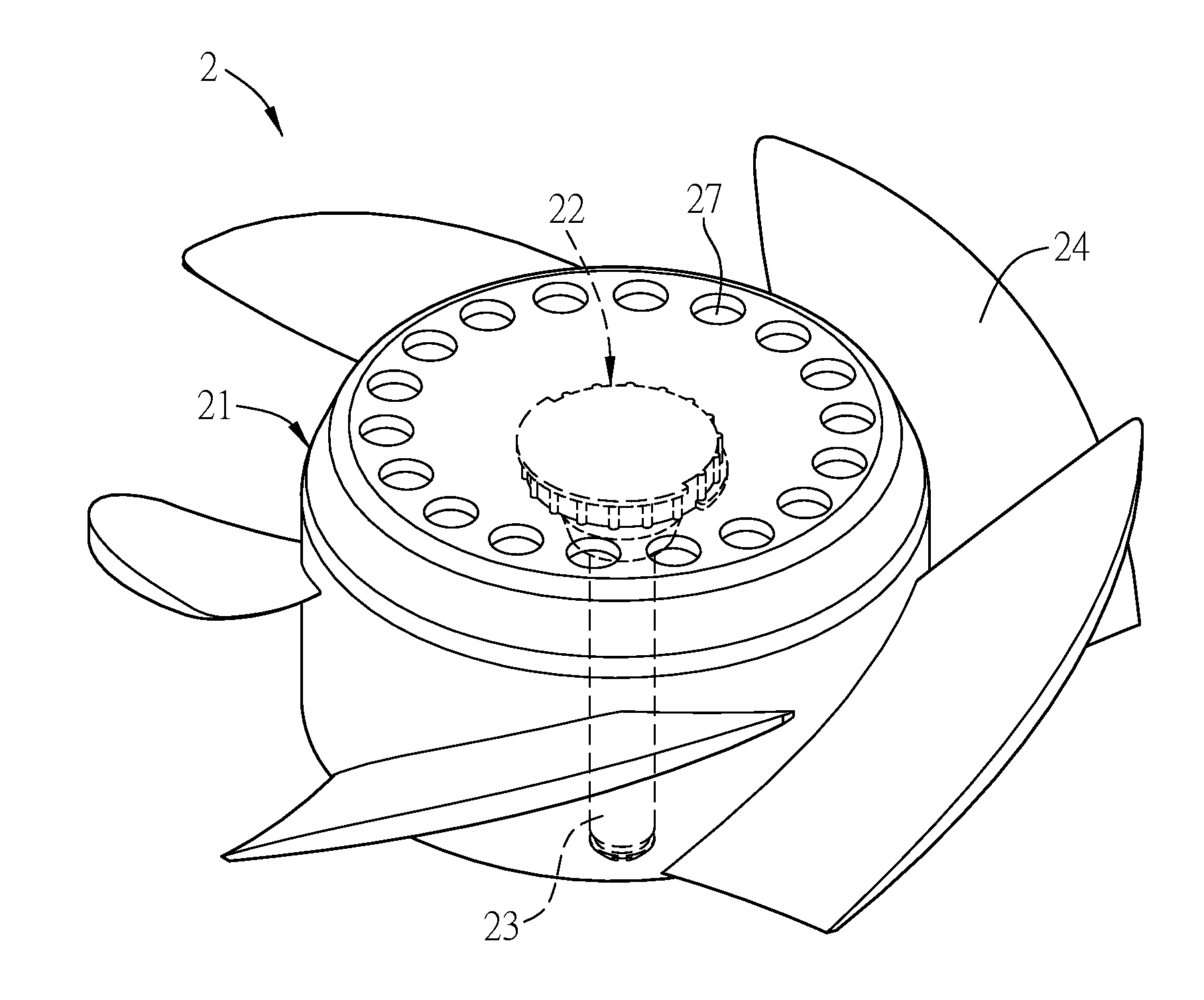

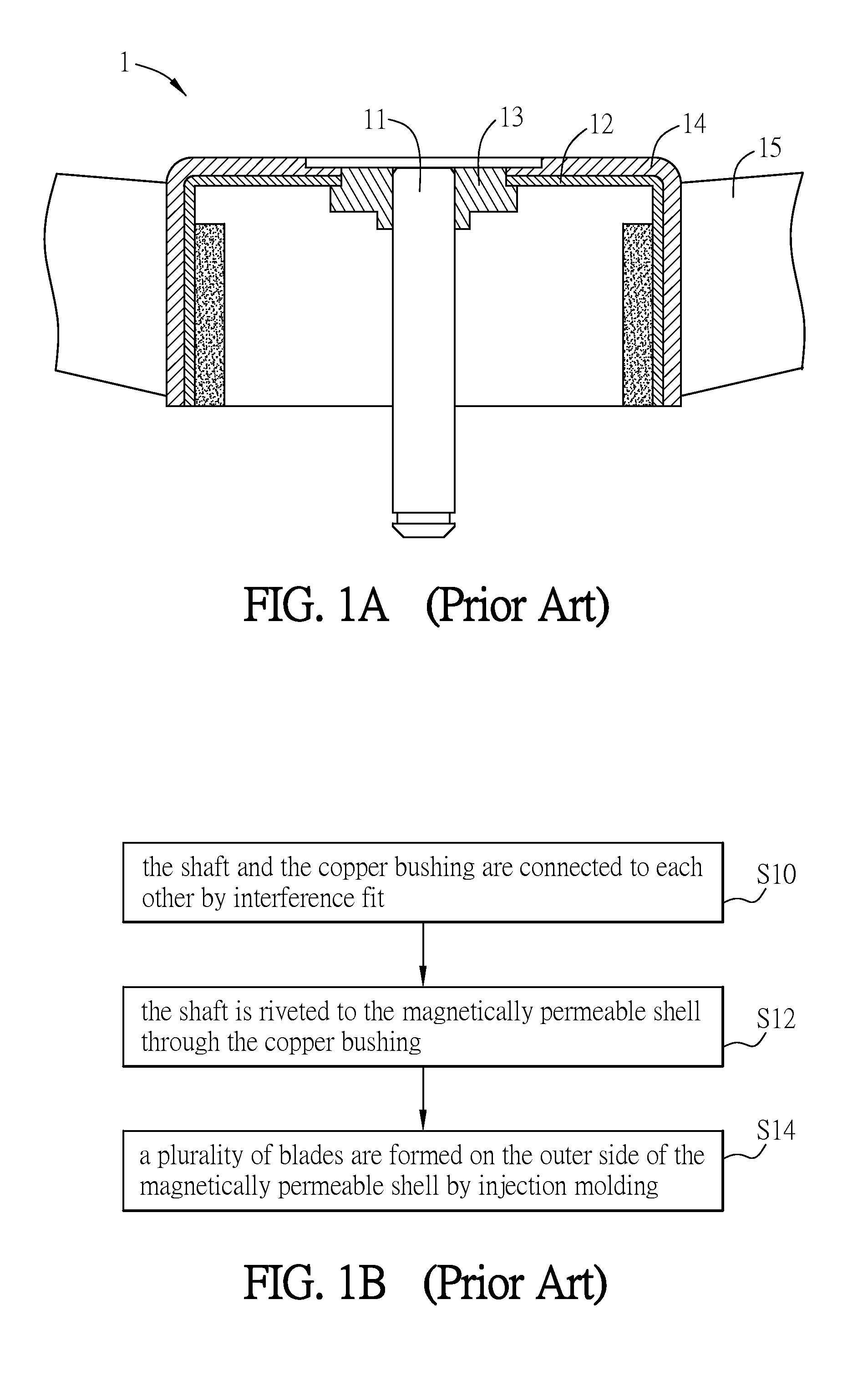

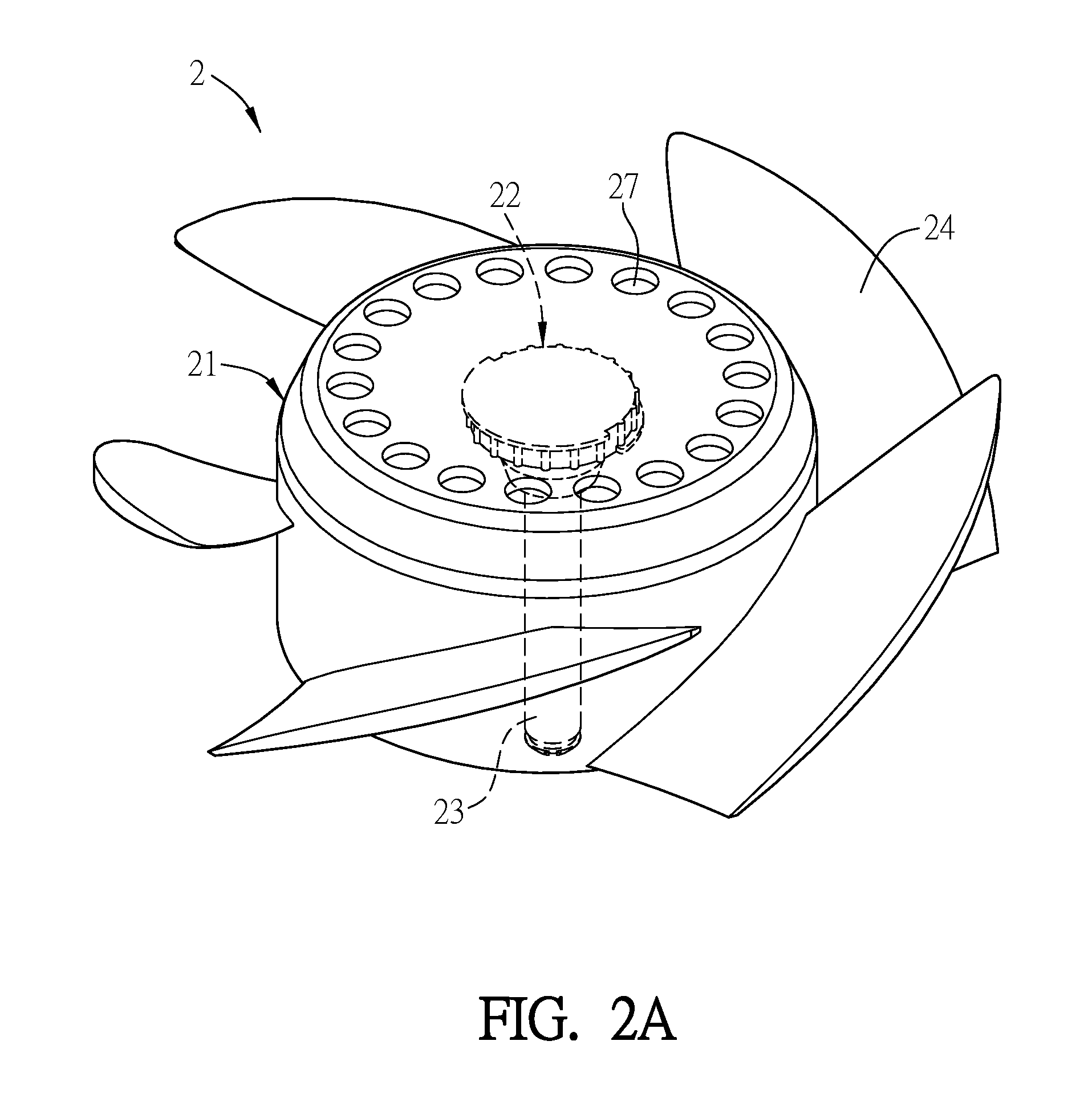

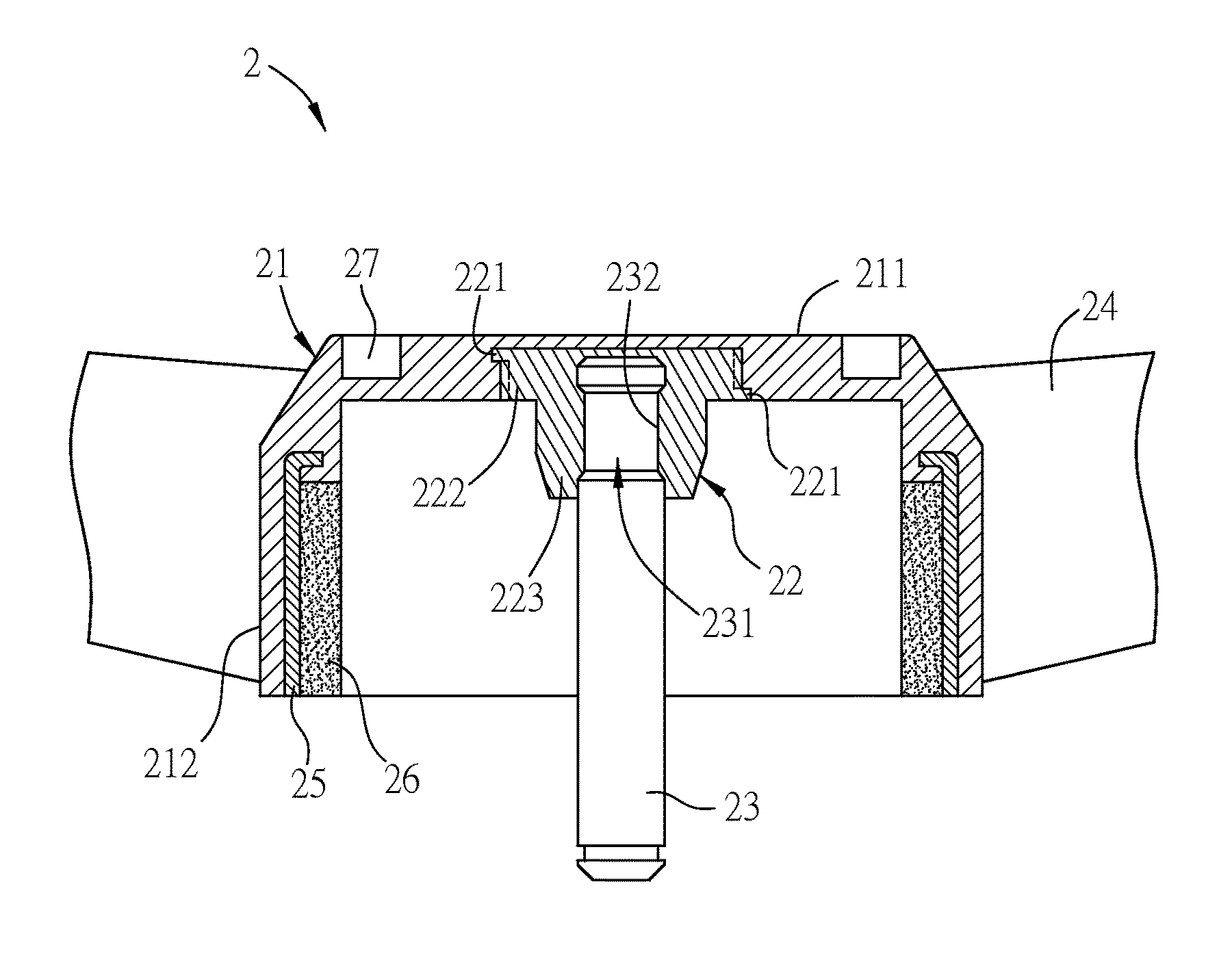

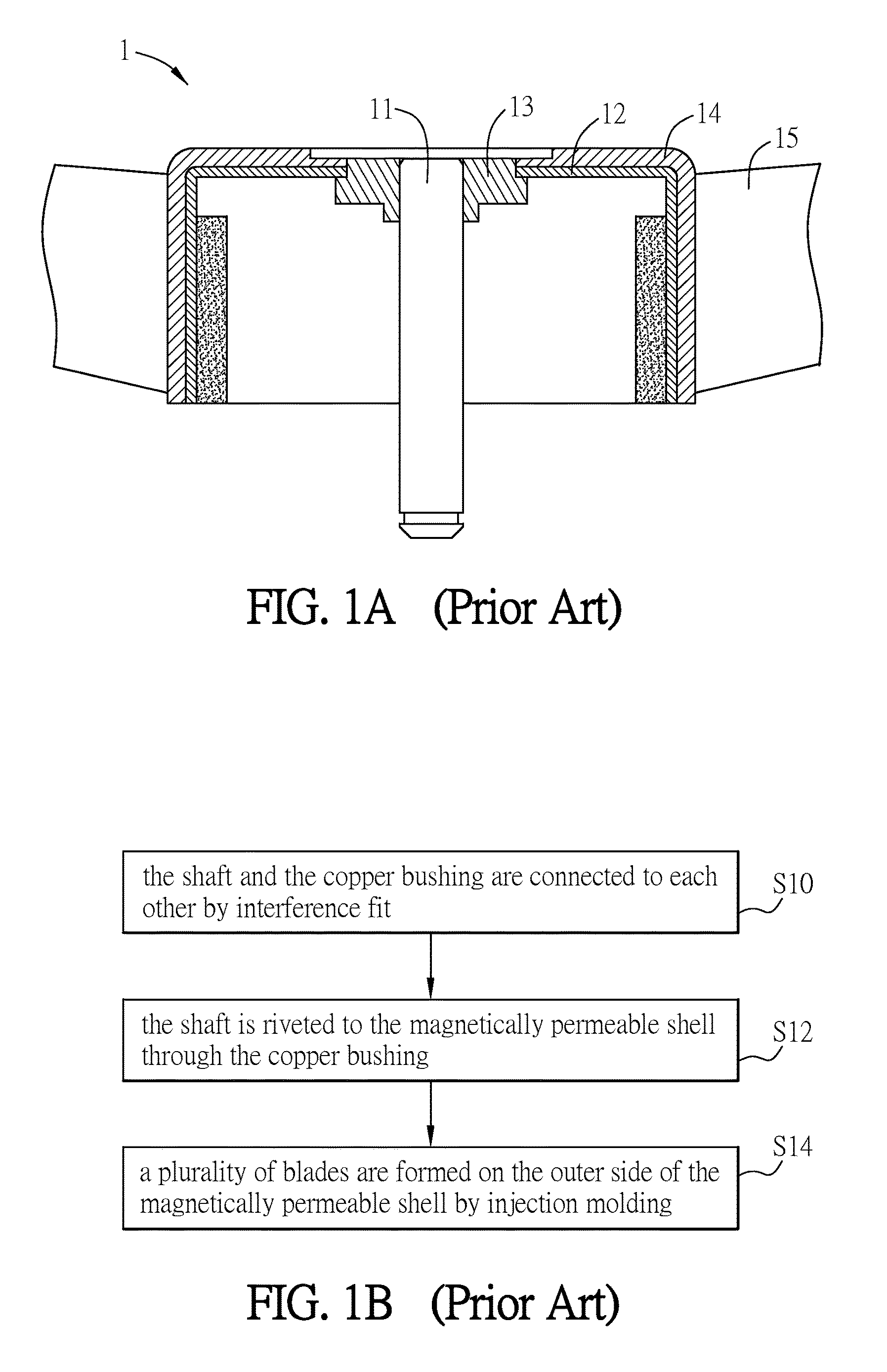

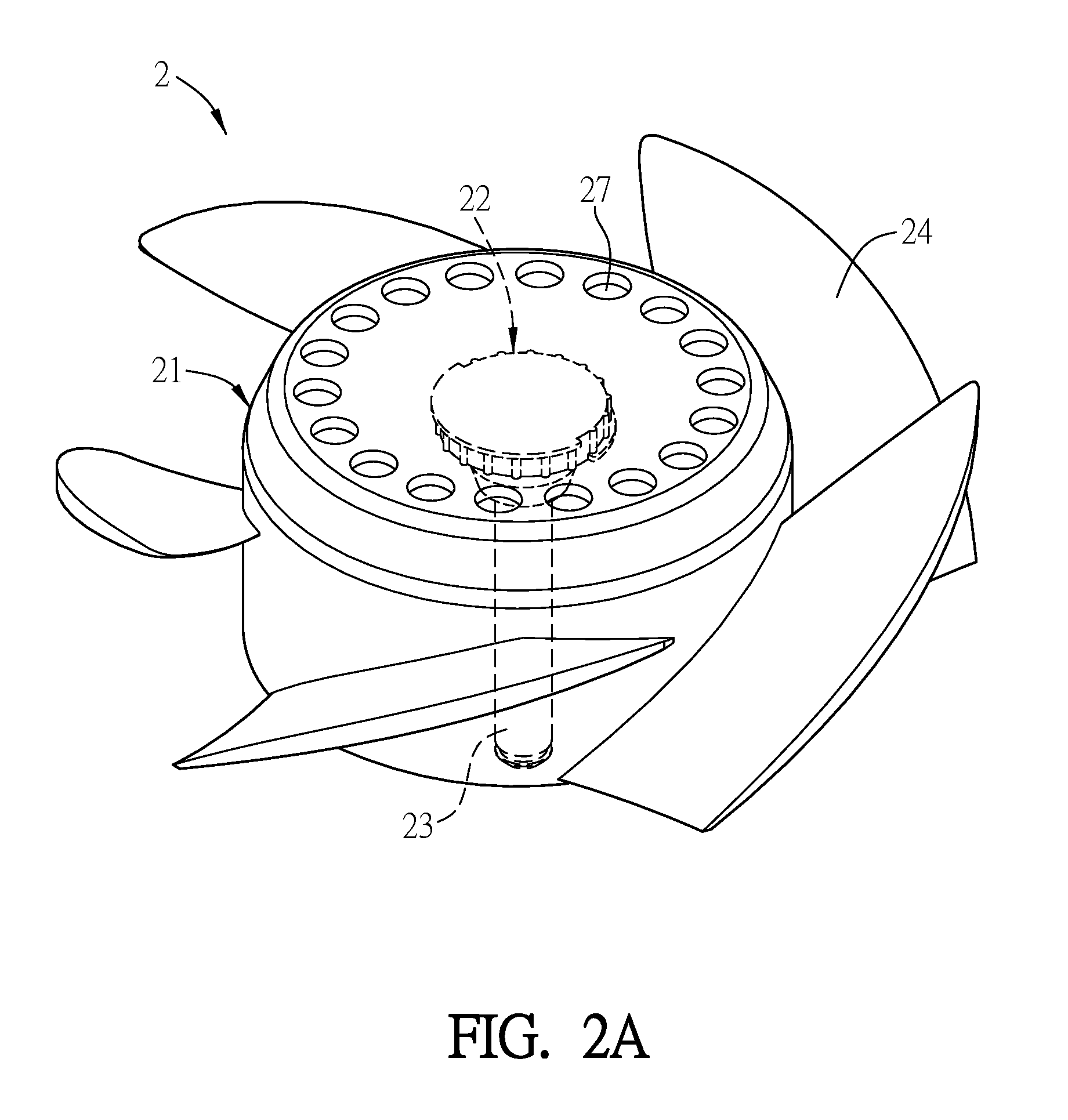

Rotor struture of fan and manufacturing method thereof

ActiveUS20150064009A1Simple processReduce processing costsPropellersPump componentsEngineeringMechanical engineering

A rotor structure of a fan includes a bushing, a hub, a shaft and a plurality of blades. The hub has a top portion and a sidewall, and the top portion of the hub covers the bushing. The hub and the bushing are made by the same material. One end of the shaft is connected to the bushing, and the shaft is disposed inside the top portion. The blades are disposed on the outer side of the sidewall of the hub. A manufacturing method of the rotor structure is also disclosed.

Owner:DELTA ELECTRONICS INC

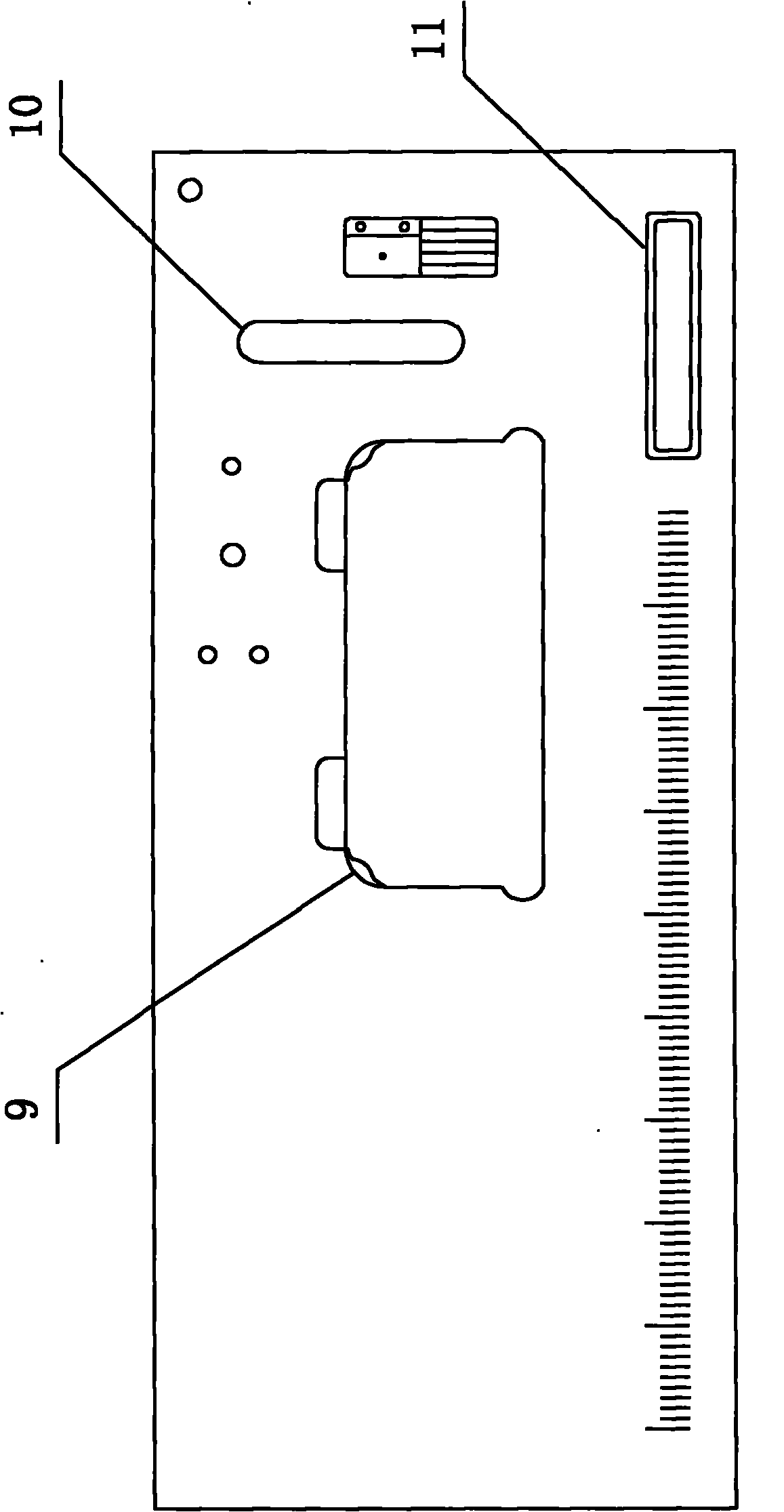

Automatic feeding, detecting and positioning system of batteries

PendingCN106694403AOvercoming the high processing and production costsLow processing and production costsElectrical testingSortingElectrical batteryElectrical and Electronics engineering

The invention discloses an automatic feeding, detecting and positioning system of batteries. A battery feeding mechanism is designed, a storage mechanism is arranged on a middle sorting box, a rotatable structure is arranged between the storage mechanism and the middle sorting box, and therefore when a battery feeding device is used, the storage mechanism is flatly put firstly, the purchased batteries in the whole box are completely buckled in the storage mechanism, a storage shell cover is closed, the storage mechanism is vertically put, and therefore it is ensured that positive electrode directions and the negative electrode directions of the batteries are consistent in the storage mechanism, and use of a mechanical arm for adjusting the directions of the positive electrodes and the negative electrodes of the batteries is avoided; in addition, an unqualified battery removing mechanism is designed and is provided with at least one air cylinder and at least one battery removing sliding groove matched with the air cylinder on the two sides of a conveying belt, and therefore use of the mechanical arm for picking out unqualified batteries is avoided, the machining and producing cost of a lithium battery module is saved, and meanwhile the machining efficiency of the lithium battery module is improved.

Owner:无锡福源自动化系统工程有限公司

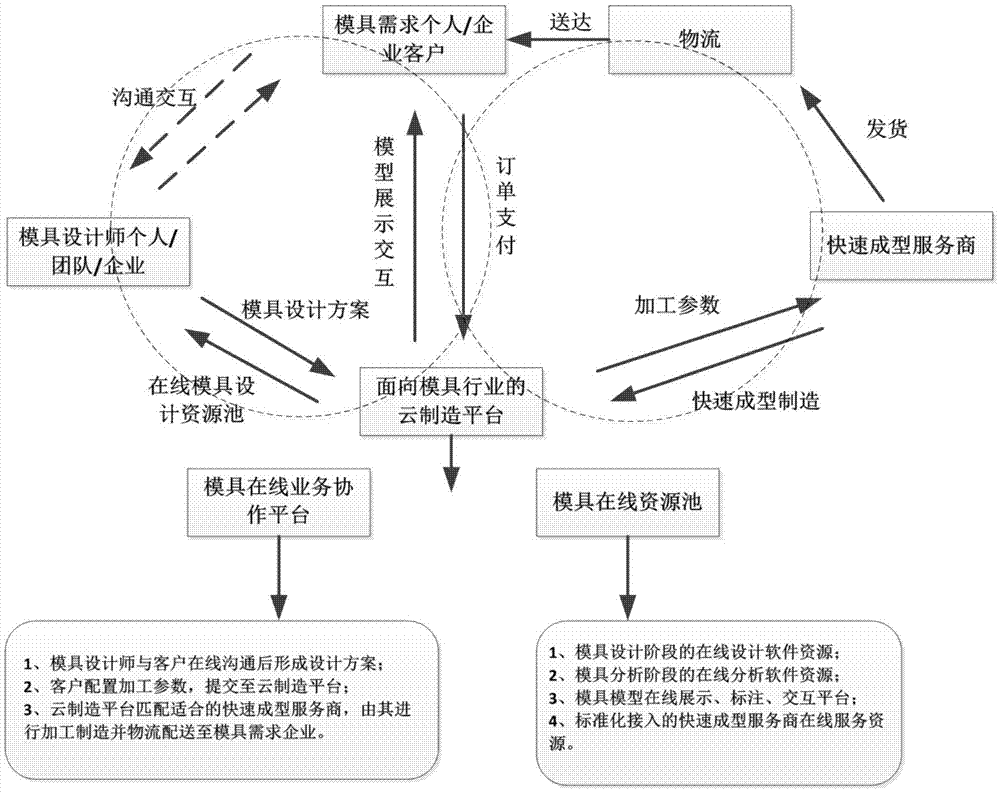

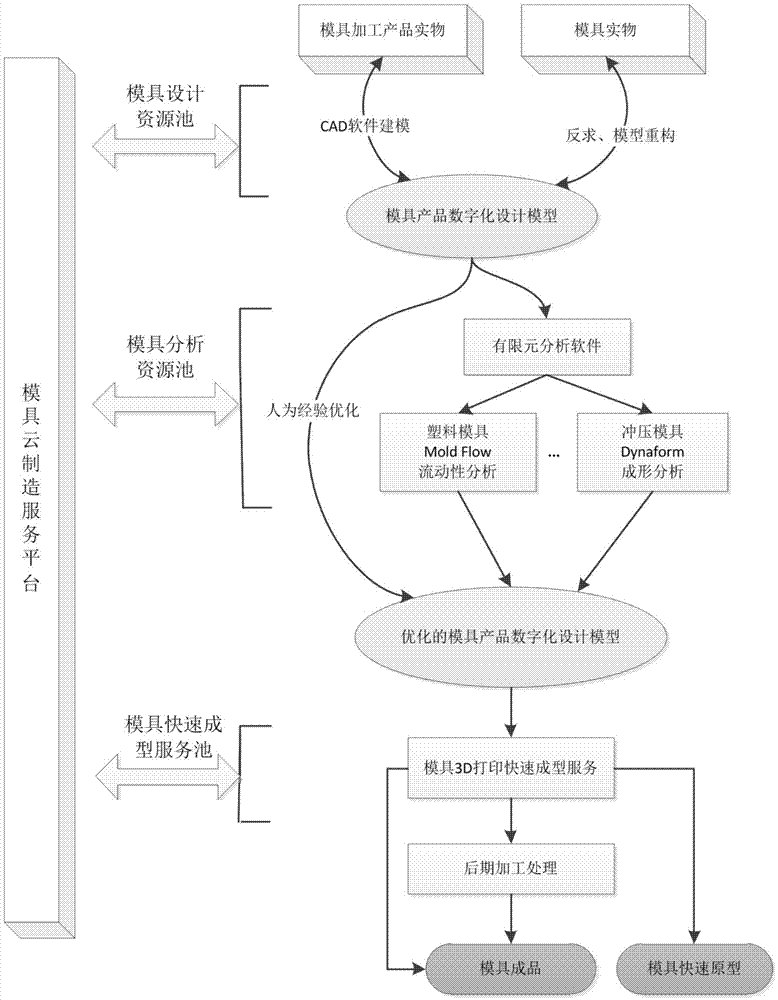

Mold rapid molding method based on cloud manufacturing

InactiveCN107016138AImprove machining accuracyImprove abilitiesGeometric CADAdditive manufacturing apparatusDesign teamInter organizational

The invention discloses a mold rapid molding method based on cloud manufacturing. Steps of the method comprises: S1, based on a mold cloud manufacturing service platform, establishing online requirement interaction of mold demand sides, mold design teams / enterprises, mold rapid molding service providers, determining a mold model design scheme corresponding to the mold demand sides; S2, based on the mold cloud manufacturing service platform, performing online design analysis on the molds of the demand sides, to obtain a model file of the mold design scheme; S3, using inter-organizational interactive iteration of a three-dimensional model to repeatedly modify and improve the model file of the mold design scheme, submitting a final version model file of the mold design scheme to the mold demand side; S4, based on the mold cloud manufacturing service platform, converting the model files in different formats, to obtain model files in a standard STL format; S5, based on communication of the mold demand sides and the mold rapid molding service providers, using the model files in a standard STL format to manufacture molds.

Owner:BEIJING SIMULATION CENT

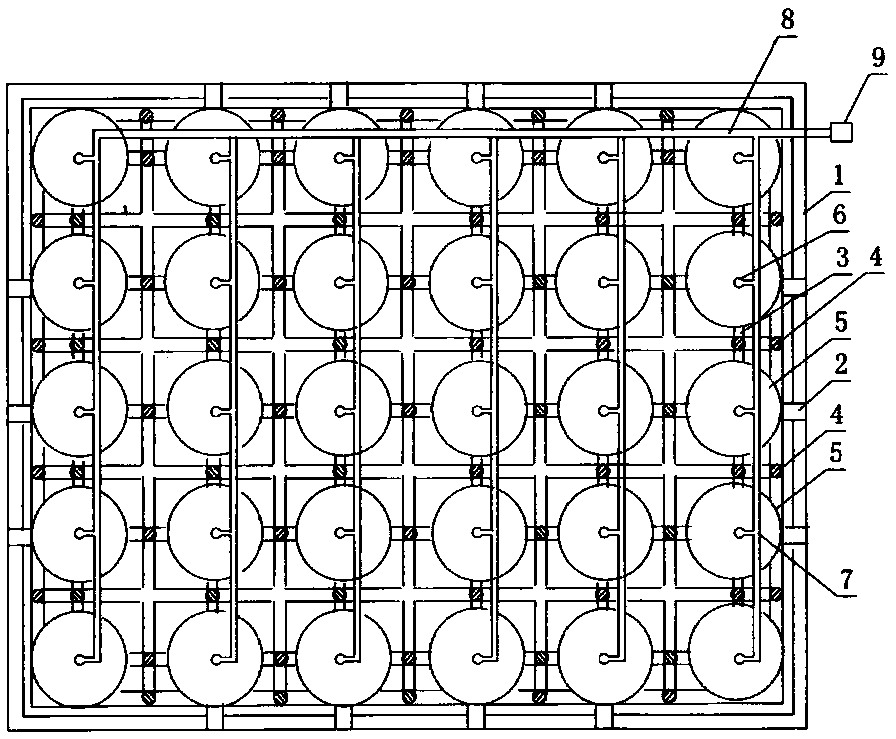

Automatic feeding, detecting and sorting system of batteries

PendingCN106697880AOmit to useOvercome the problem of high processing and production costsSortingConveyor partsProduction lineElectrical battery

The invention discloses an automatic feeding, detecting and sorting system of batteries, and belongs to the field of a battery machining production line. According to the automatic feeding, detecting and sorting system of the batteries, an unqualified battery removing mechanism is arranged behind a voltage and resistance detecting mechanism and is in the conveying direction of a conveying mechanism, and comprises at least one air cylinder arranged on one side of the conveying mechanism and at least one battery removing sliding groove which is matched with the air cylinder and formed in the other side of the conveying mechanism, and therefore use of a mechanical arm for picking out unqualified batteries is avoided, the problem that in the prior art, many mechanical arms are adopted, and the machining and producing cost of a lithium battery module is high is solved, the machining and producing cost of the lithium battery module is saved, and meanwhile the machining efficiency of the lithium battery module is improved.

Owner:无锡福源自动化系统工程有限公司

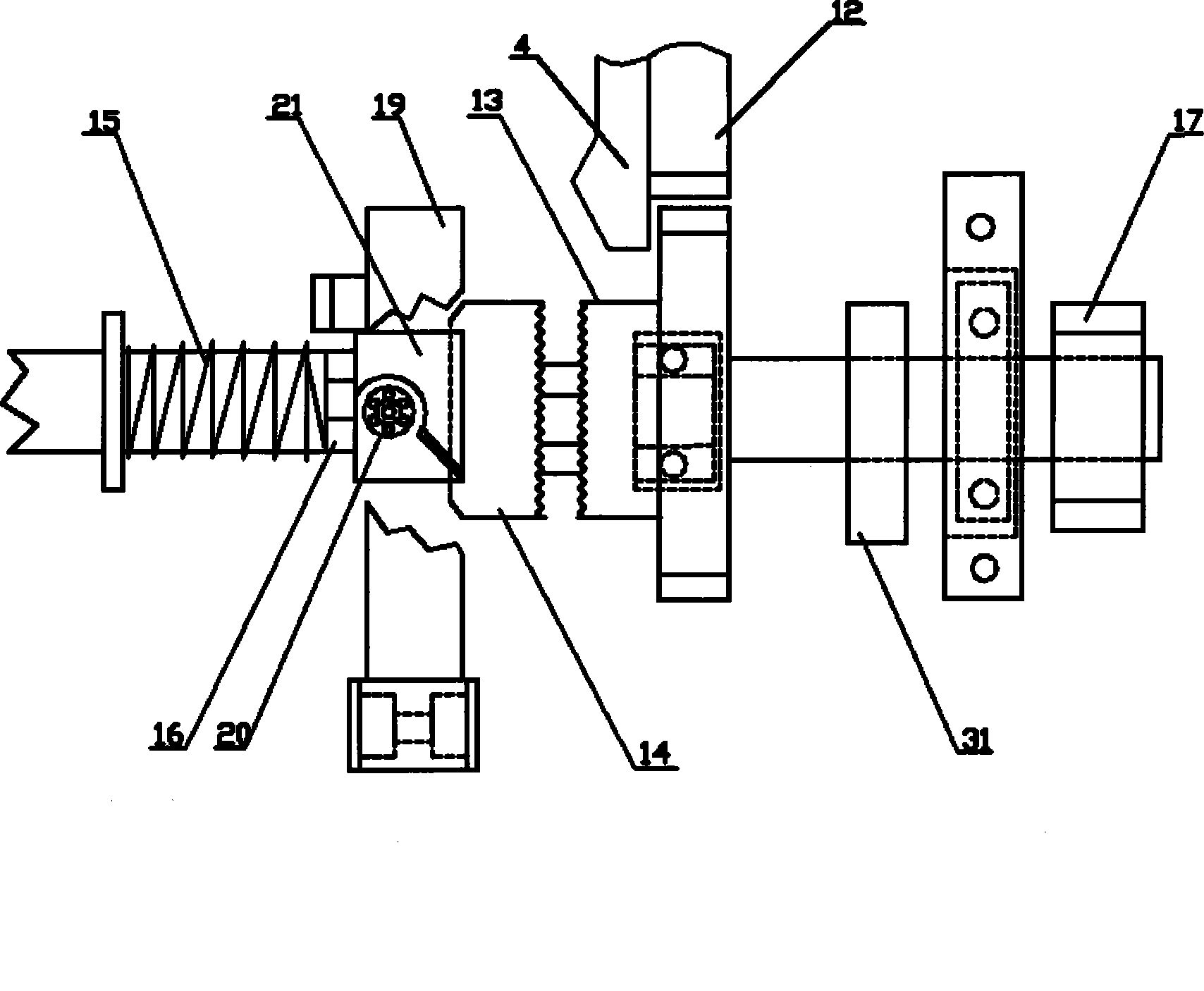

Quick energy-saving automatic aligning cutting-off device

The invention relates to a fast and energy-saving automatic straightening cutting machine, which is mainly used for the automatic straightening and fixed-length stock cutting of linear materials such as reinforcing steel bars used in the construction field, and has the main structure as follows: a straightening drum is driven by an electric motor by a belt; simultaneously, the electric motor sequentially drives an angle tooth belt pulley, a rear axle angle gear, a plate gear and a front feeding main shaft by another belt; the front feeding main shaft drives a feeding assembly and a traction assembly; and the plate gear drives a cutting assembly. The straightening cutting machine has the advantages that: the rear axle angle gear is directly decelerated to drive the plate gear on the front feeding main shaft, and the gear on the main shaft simultaneously drives the gear transmission structure along which a clutch gear, an upper compress roller and a back feeding roller rotate simultaneously, thus reducing multistage speed change of the overall unit as well as the amount of a plurality of gears and shafts; the structure is extremely simple, the machine can work only needing one 5.5kW electric motor, and about 6 kilowatt-hours of electricity are needed for straightening and cutting one ton of reinforcing steel bars, thus extremely saving the electricity and energy.

Owner:龙乐武

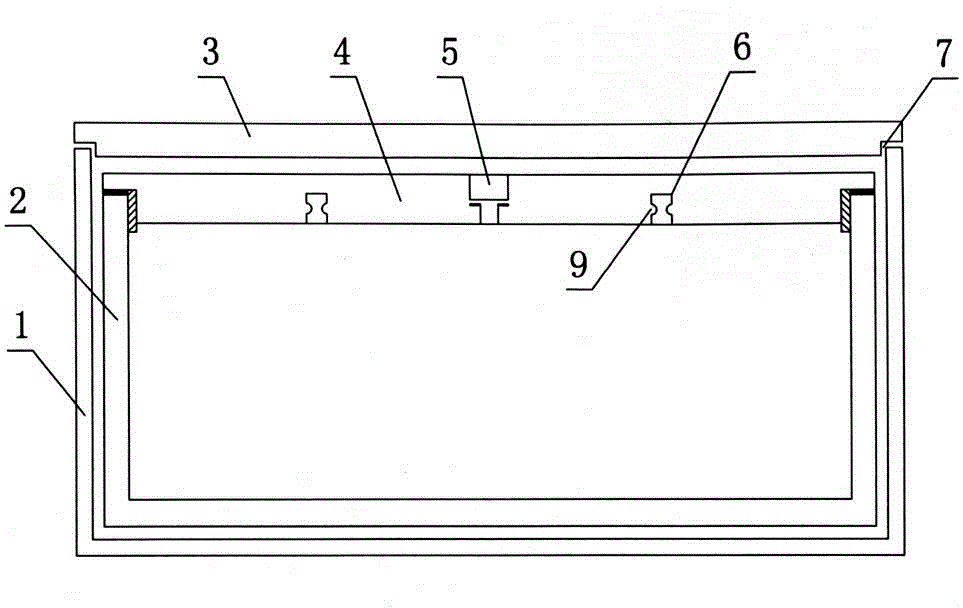

Closed double-layer vacuum cinerary casket

The invention discloses a closed double-layer vacuum cinerary casket. An outer casket cover is arranged at the upper end of an outer casket body; a lower buckle edge is arranged at the lower end of the outer casket body; the outer casket cover is buckled on the outer casket body through the lower buckle edge; an inner casket is arranged in the outer casket body; an inner casket cover is arranged at the upper end of the inner casket; a vacuum air extraction valve is arranged in the middle of the inner casket cover; an inner buckle edge is arranged on the bottom side of the inner casket cover; a fixed pin is arranged on the periphery of the inner buckle edge; locking grooves are formed in two sides of the fixed pin; a fixed lock corresponding to the fixed pin is arranged at the inner upper end of the inner casket body; a sealing ring is arranged at the joint of the inner casket body and the inner casket cover. In the assembling process, the inner casket cover is placed on the inner casket body, is pressed down and is locked with the inner casket body; air can be extracted outwards by pressing down a valve element; after the air is completely extracted, the vacuum air extraction valve is automatically closed, and the inner casket is in a vacuum state.

Owner:王俊才

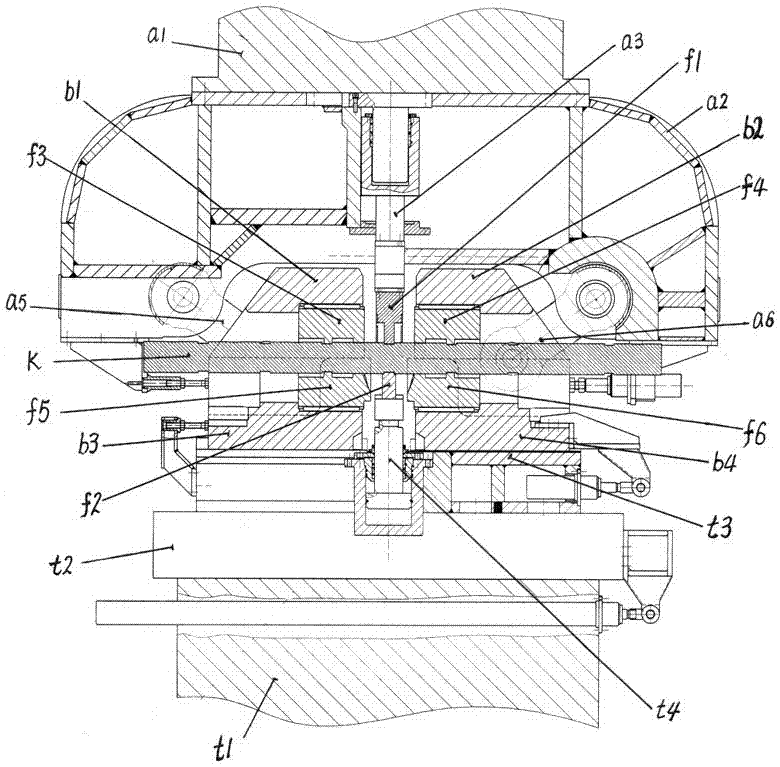

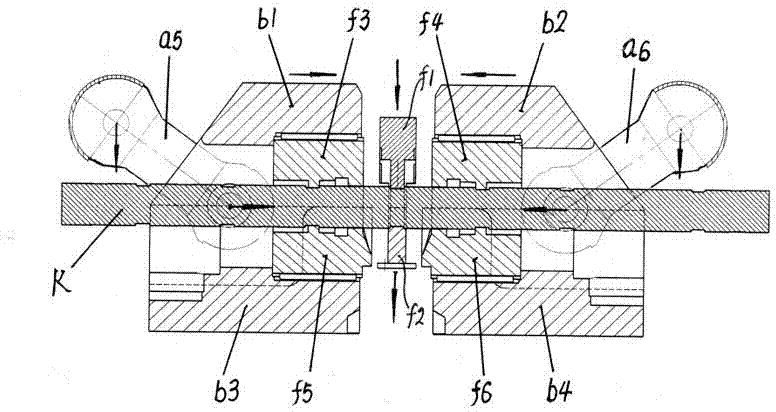

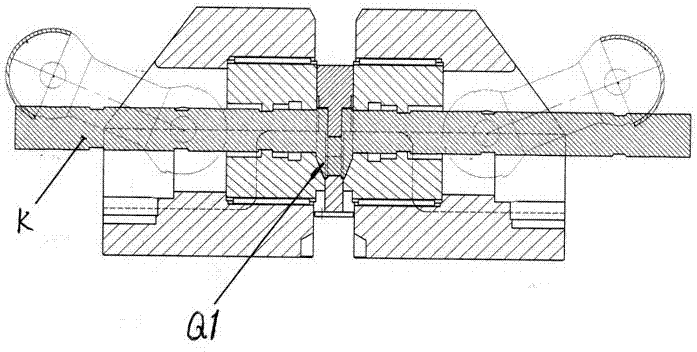

Crankshaft crank throw upsetting, forming and axial positioning combined die

ActiveCN106853503ALow cost of processing materialsReduce manufacturing costForging/hammering/pressing machinesEngine componentsCrankshaftManufacturing engineering

The invention discloses a crankshaft crank throw upsetting, forming and axial positioning combined die. Each of a right upper die (f4), a right lower die (f6), a left upper die (f3) and a left lower die (f5) installed on a right upper die base (b2), a right lower die base (b4), a left upper die base (b1) and a left lower die base (b3) consists of four die pieces superposed axially, the four die pieces of the upper die and the four die pieces of the lower die are vertically and correspondingly combined in a one-to-one mode, the die pieces can be machined by using one round plate material to form an inner cavity and then are divided into the corresponding upper and lower die pieces through linear cutting, machining is simple and convenient, and the die pieces can be mutually replaced and used. Compared with manufacturing of an integral die, the die machining material cost and the die manufacturing cost can be greatly reduced, and the shortcoming that the whole die is required to be manufactured after local parts of the integral die are damaged is overcome.

Owner:LIAONING 518 INTERNAL COMBUSTION ENGINE FITTINGS

Continuous casting forming equipment and process method for electromagnetic ejection filling core of cladding material

The invention relates to continuous casting forming equipment and a process for an electromagnetic ejection filling core of a cladding material, belonging to the field of the continuous casting processing in metal material. The equipment provided by the invention comprises upper and lower temperature control crystallizers, a temperature measuring instrument, a metal temperature control furnace of the core, an outer metal temperature control furnace, a filling core tube, an electromagnetic pump, a secondary cooling device, a limiting device, a pressure sensor and a recession device, wherein the upper and lower temperature control crystallizers and a metal liquid filling core tube of the core are arranged on the same axis along the continuous casting direction; the electromagnetic pump is installed outside the upper and lower temperature control crystallizers and assembled on the same axis with the upper and lower temperature control crystallizers; the upper end of the metal liquid filling core tube of the core is connected with a metal temperature control crucible of the core, and the lower end is inserted into outer metal liquid; the outer metal liquid and the metal liquid of the core are isolated through the metal liquid filling core tube of the core; the outer metal liquid is cooled to form an outer metal tube; the metal liquid of the core is poured into the outer metal tube through the metal liquid filing core tube of the core; and a composite blank is ejected out by exerting the pressure through the electromagnetic pump. The invention eliminates cracks and vibration marks which are easy to occur in a common continuous casting blank, can continuously cast the cladding material once, obtains a composite interface of high quality and has the advantages of low production cost and high efficiency of subsequent processing.

Owner:UNIV OF SCI & TECH BEIJING

Multifunctional nursing seat with automatic flushing pedestal pan

InactiveCN103821216AVersatileReasonable structureWater closetsFlushing devicesWater storage tankWarm water

The invention discloses a multifunctional nursing seat with an automatic flushing pedestal pan. Handrails are arranged on the left side and the right side of the seat, a push-pull handle is arranged at the rear upper end of each handrail, a water storage tank is arranged on the rear back of the seat, a rack is arranged in the middle of the seat, a cushion is arranged at the upper end of the rack, a U-shaped groove is arranged in the middle of the cushion, a stool tank is mounted on a fixing support, an anus cleaning tank is arranged on the left side of the stool tank, a urine tank, the stool tank and the anus cleaning tank are positioned at the lower end of the U-shaped groove, a stool outlet is arranged on the bottom side of the stool tank, a warm air elbow is mounted in the anus cleaning tank, a warm water connecting hose is arranged in the warm air elbow, an anus cleaning water nozzle is arranged at the upper end of the warm water connecting hose, a power source control cabinet is arranged at the rear end of the seat, a circuit board is arranged in the power source control cabinet, an electricity leakage protector is arranged on the circuit board, an externally-connected power source is connected with a power source connecting line of a plug, a motor, a warm air blower, a hot water tank and a water pump, a power source switch and a motor starting switch are arranged at the upper end of the seat, and the warm air blower is arranged on the left lower side of the seat.

Owner:陈大才

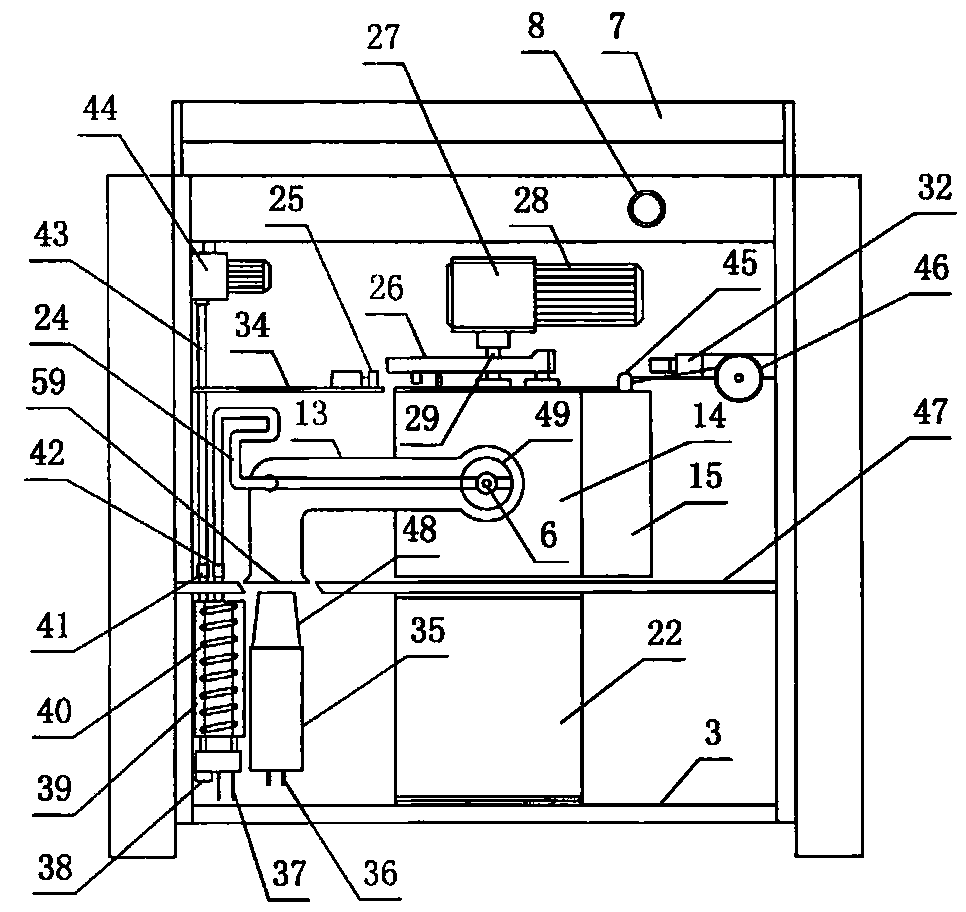

Spiral type grain conveyor

InactiveCN103508166ASimple structureReasonable designPackagingSupporting framesSpiral bladeAgricultural engineering

The invention discloses a spiral type grain conveyor. A front support and a back support are arranged on the bottom side of a machine frame, a front moving wheel is arranged at the bottom end of the front support, a back moving wheel is arranged at the bottom end of the back support, a conveying roller for conveying grain is arranged inside the machine frame, an upper bearing base and a lower bearing base are arranged at the upper end of the machine frame, a spiral shaft is arranged in the upper bearing base and the lower bearing base, a spiral blade is arranged on the spiral shaft, the upper end of the spiral shaft is provided with a belt wheel, a motor support is arranged at the upper right end of the machine frame and is provided with a motor, a main shaft of the motor is provided with a motor belt wheel, a transmission belt is arranged on the motor belt wheel and the spiral shaft belt wheel, a feed hopper is arranged at the lower end of the conveying roller, and a discharge port is formed in the upper end of the conveying roller. In the process of working, the motor belt wheel drives the spiral shaft belt wheel to drive the spiral shaft to rotate, and the grain is discharged out of the discharge port through the spiral blade.

Owner:杨可秀

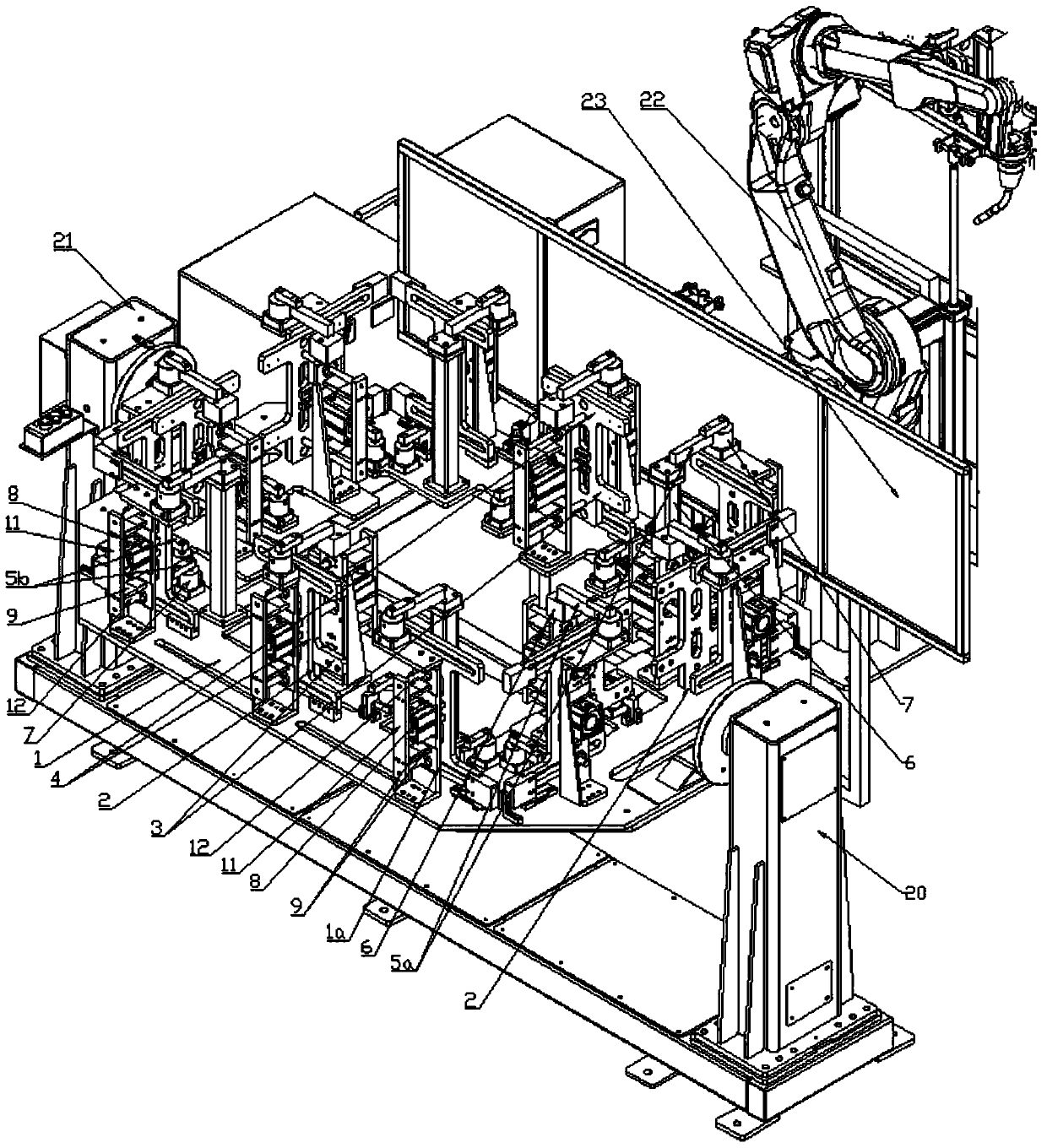

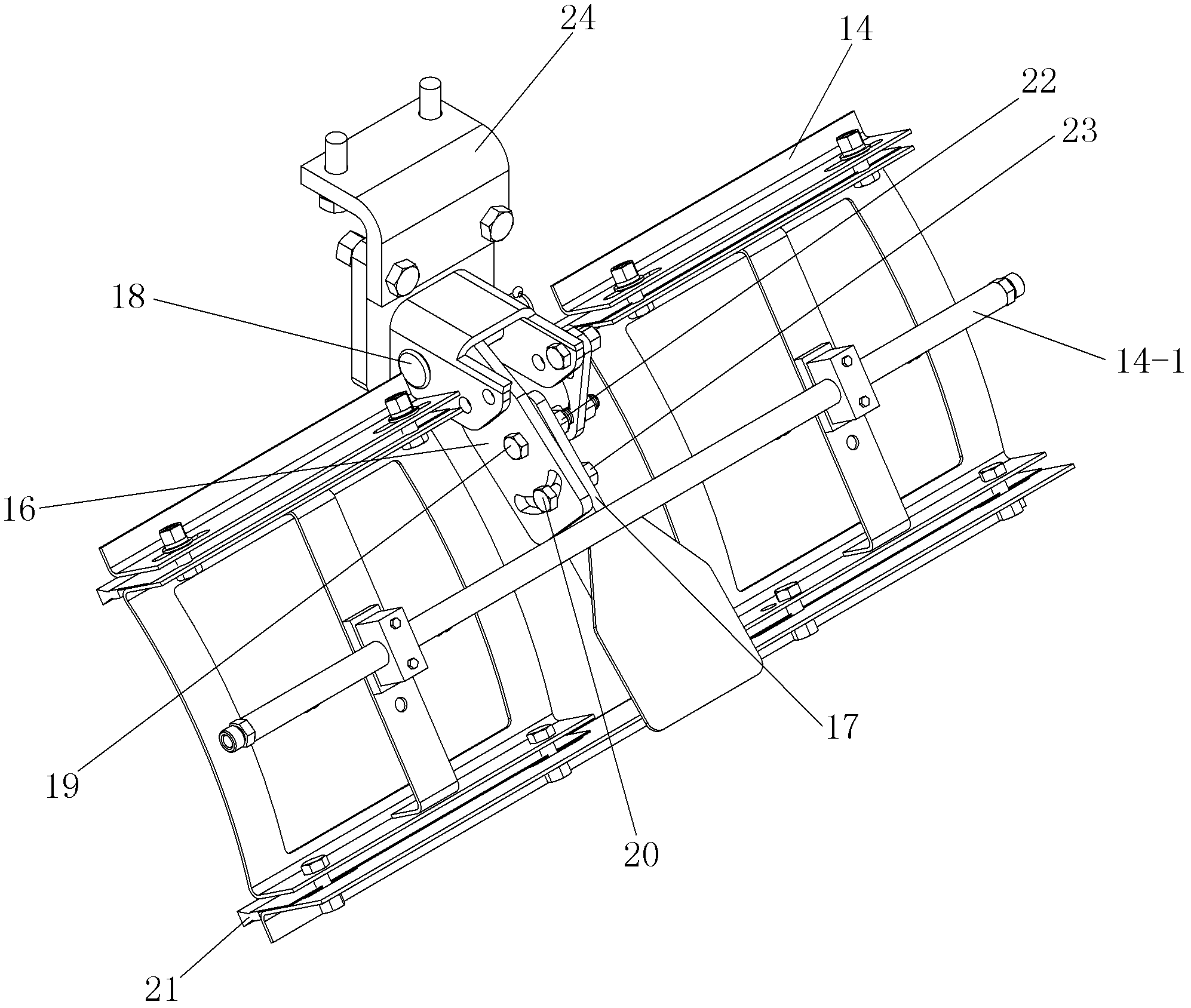

Gun cabinet frame welding robot fixture

PendingCN107775252ASimple structureThe clamping method is scientific and reasonableWelding/cutting auxillary devicesAuxillary welding devicesWorkbenchRobot

The invention discloses a gun cabinet frame welding robot fixture. The fixture comprises a workbench and a corresponding workpiece accommodating part arranged on the workbench, wherein the workpiece accommodating part comprises frame type stereoscopic accommodating channels, inner and outer shifting clamping devices corresponding to corresponding workpieces are arranged on two opposite sides of the periphery of each frame type stereoscopic accommodating channel, and flat pressing limiting devices corresponding to corresponding workpieces are also arranged on the workbench. The gun cabinet frame welding robot fixture is simple and reasonable in structure, can perform inside and outside and / or front and back welding operation, has multiple functions and is reliable in clamping, high in accuracy, simple and convenient to operate and high in working efficiency.

Owner:JIANGXI ZHUOER METAL EQUIP GROUP

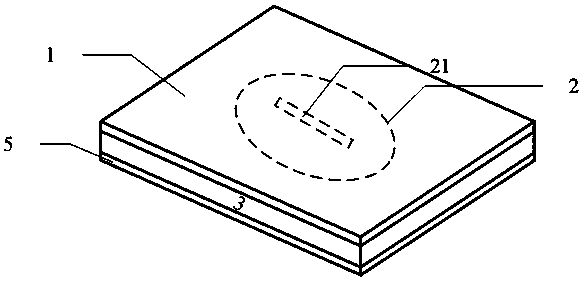

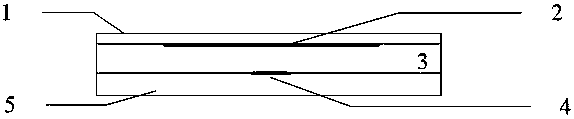

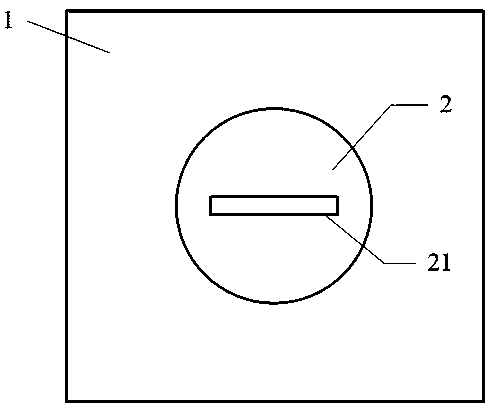

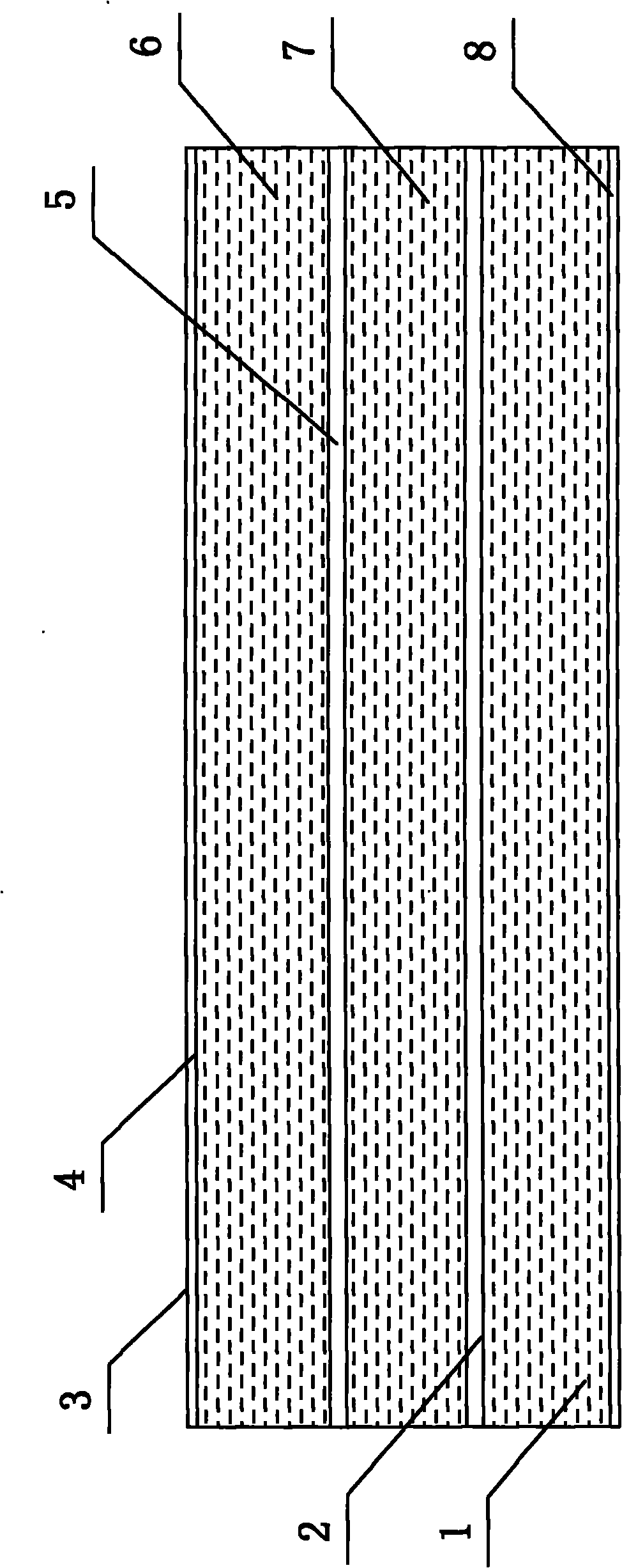

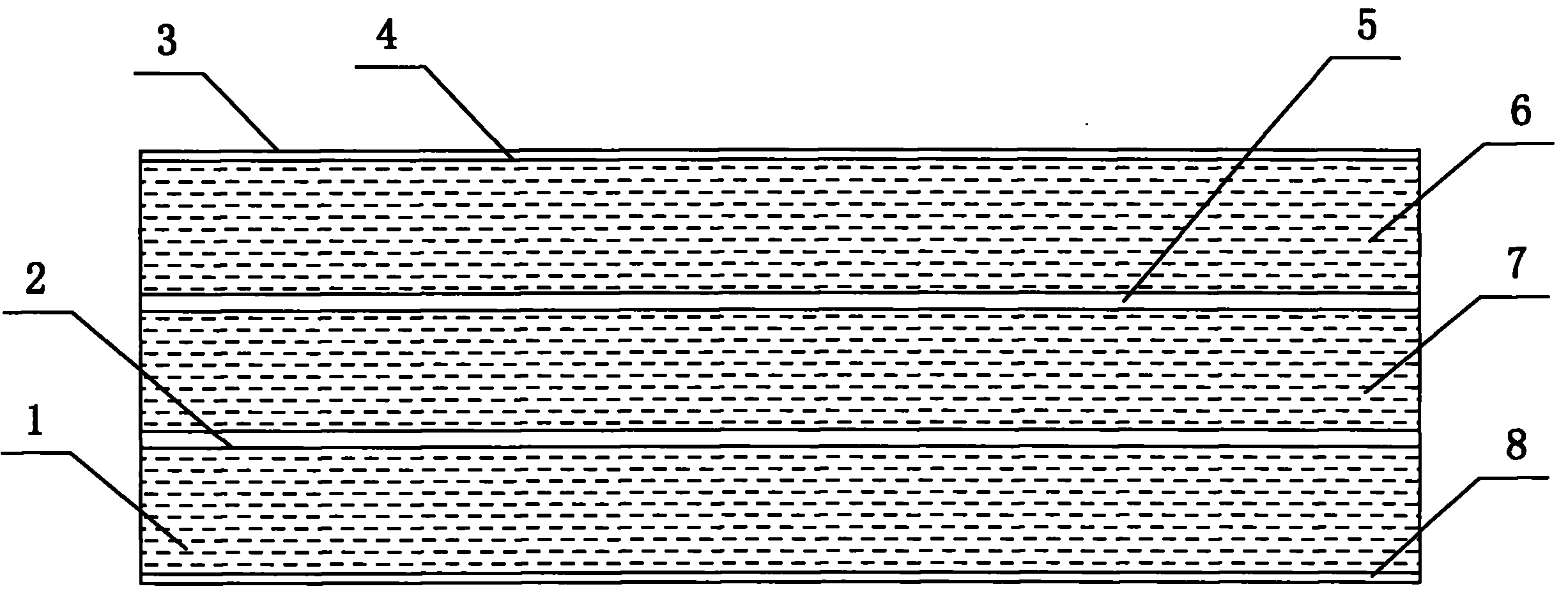

Multilayer packaging antenna

InactiveCN109149090AEasy to implementLow processing and production costsAntenna supports/mountingsRadiating elements structural formsDielectric layerMicrostrip

A multilayer packaging antenna comprises an upper dielectric layer, an upper layer metal patch, a lower dielectric constant insulating dielectric layer, a feeding microstrip, and a lower layer dielectric layer. An upper layer metal patch as a radiator is attached to the lower surface of the upper layer medium base layer, and the upper layer metal patch is provided with a groove; A low dielectric constant insulate dielectric layer is sandwiched between that upper layer dielectric layer and the lower layer dielectric layer; The upper surface of the lower layer dielectric layer is the feed structure of the antenna. The antenna can be arranged in a chip package, in particular to a frequency-adjustable packaging antenna suitable for millimeter wave communication.

Owner:陈彭

Construction waste wood formwork and industrial sewing machine table manufactured by pressing production formwork leftover material

ActiveCN101962882ASave resourcesLow processing and production costsSewing-machine elementsWood working apparatusFireproofingEngineering

The invention discloses a construction waste wood formwork and an industrial sewing machine table manufactured by pressing a production formwork leftover material, which is manufactured from edgings and edge and corner waste materials sawed from a wood formwork, waste wood pattern shell slabs and fine saw used in construction as well as rubber. The production process comprises the following steps: preparing materials, processing the raw materials, arranging the slabs in layers, carrying out cold pressing and sizing, carrying out hot pressing and strengthening, planning, setting the thickness,carrying out hot pressing and facing, sawing edges and finishing, polishing and shaving, pasting a fireproofing board by cold pressing, repairing deckle edge, sealing edge by hot melting, milling by an engraving and milling machine and the like. In the invention, waste wood formwork shells as well as edgings and edge and corner wastes sawed from the wood formwork are adopted to be processed to manufacture into the industrial sewing machine table, which not only saves limit wood resources, but also lowers the processing production cost to a large extent. Compared with the like product, the industrial sewing machine table has the advantages of good planeness, light weight, no product deformation, strong stability and long service life and the like.

Owner:MENGCHENG COUNTY HUA FEI SEWING EQUIP MFG

Packing box provided with buffer airbags

InactiveCN109132207ASimple structureIngenious designContainers to prevent mechanical damageEngineeringAirbag

The invention discloses a packing box provided with buffer airbags. Egg box ventilation holes are formed in four side surfaces of an egg box; a base is arranged at the bottom end of the egg box; a pressure-resistance longitudinal and transverse base is arranged at the upper end of the base, and is provided with multiple pressure-resistance columns; multiple airbags are arranged in frames of the pressure-resistance columns; flat intake pipes are arranged above the airbags; a flat intake main pipe is arranged at the upper end of the box body; the intake main pipe is provided with an inflation port; the inflation port is connected with an automatic inflator; and a box cover is arranged above the egg box. The packing box is simple in structure, low in production cost and excellent in use effect.

Owner:周丽莉

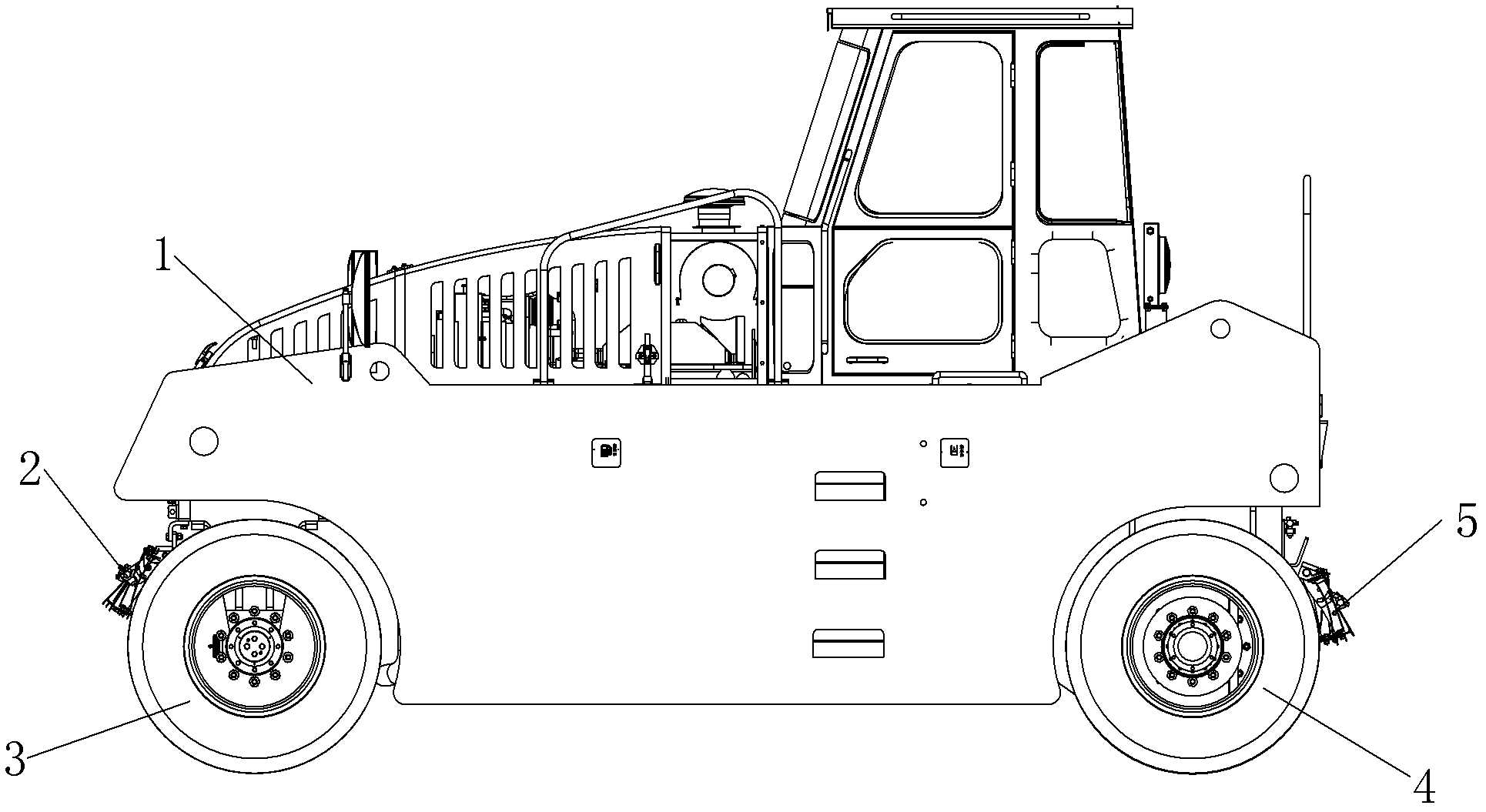

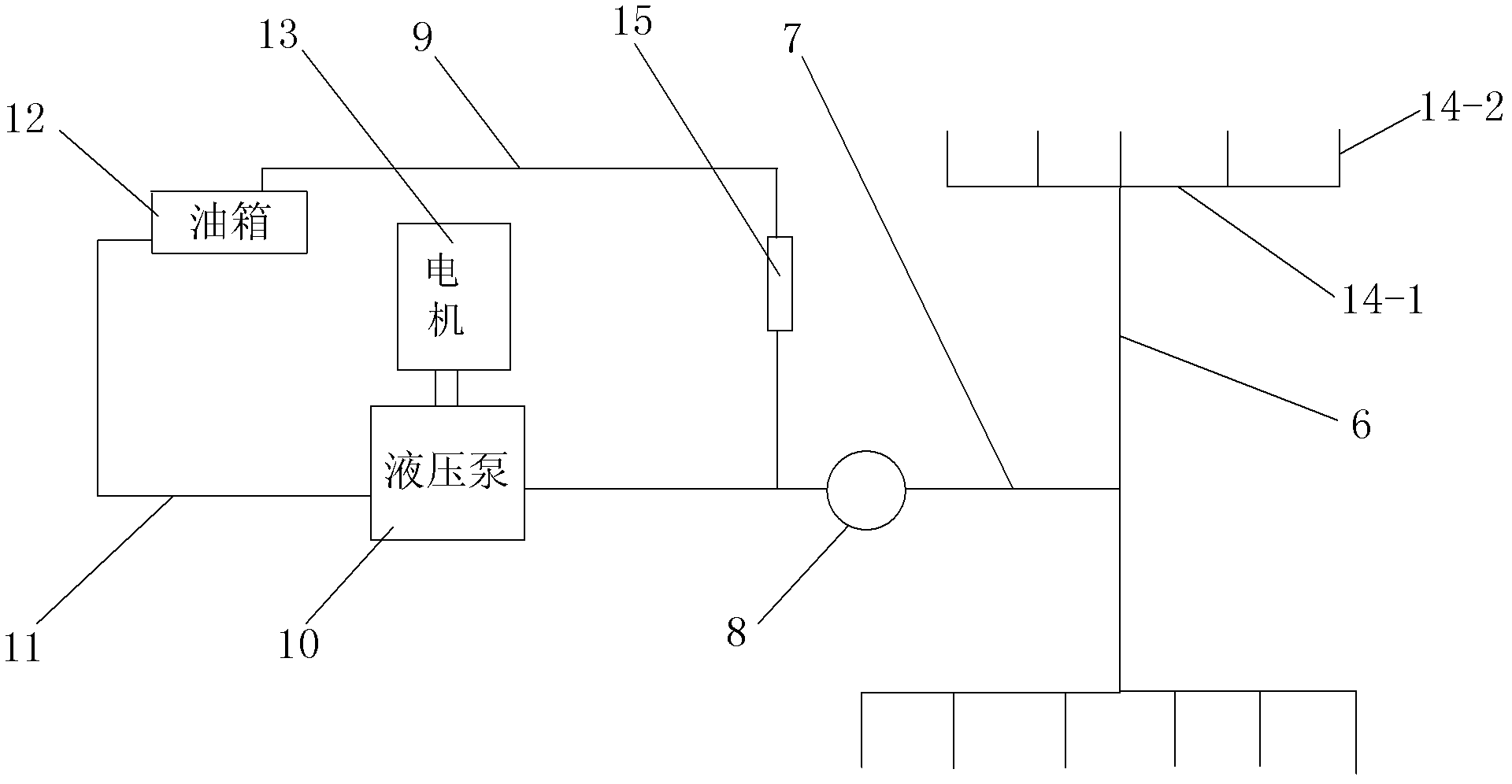

Rubber wheel road roller front wheel and back wheel oil brushing device

InactiveCN103132433ASimple structureNovel and reasonable designRoads maintainenceBristleHydraulic pump

The invention discloses a rubber wheel road roller front wheel and back wheel oil brushing device which comprises an oil tank, a hydraulic pump, a motor used for driving the hydraulic pump, a front oil brushing frame arranged above a front wheel of the road roller, and a back oil brushing frame arranged above a back wheel of the road roller. The front oil brushing frame and the back oil brushing frame both comprise oil brushing frame bodies and fixing frames used for connecting the oil brushing frame bodies on a body of the road roller. An oil pipe is arranged on each oil brushing frame. An oil spraying opening connected with each oil pipe is arranged on each oil brushing frame. The oil pipes are connected with a second pipeline through a first pipeline. The second pipeline is connected with the hydraulic pump which is connected with the oil tank through a third pipeline. Brushing bristles used for brushing oil on the road roller front wheel and the road roller back wheel are arranged on the lower portions of the oil brushing frame bodies. The rubber wheel road roller front wheel and back wheel oil brushing device is simple in structure, and convenient to use, man power is saved, working efficiency is improved, and popularization and application are convenient.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

Rotor structure of fan and manufacturing method thereof

ActiveUS9568008B2Simple manufacturing processImprove structural strengthPump componentsPump installationsEngineeringMechanical engineering

A rotor structure of a fan includes a bushing, a hub, a shaft and a plurality of blades. The hub has a top portion and a sidewall, and the top portion of the hub covers the bushing. The hub and the bushing are made by the same material. One end of the shaft is connected to the bushing, and the shaft is disposed inside the top portion. The blades are disposed on the outer side of the sidewall of the hub. A manufacturing method of the rotor structure is also disclosed.

Owner:DELTA ELECTRONICS INC

Coal mine screening device

A coal mine screening device comprises a base, a storage box device, a rotating device, a fixing frame, a feeding device, a first storage device, second storage devices and a baffle device. The storage box device comprises a first storage box and a second storage box. The rotating device comprises a first supporting column, a motor, a second supporting column, a rotary table, a first filtering net, a rotating frame, a material collecting hopper, first cross rods, third supporting columns and first supports. The fixing frame is provided with second through holes, third through holes, fourth through holes, first material collecting rings and second material collecting rings. The feeding device comprises a feeding hopper, second supports and closing rings. The first storage device comprises first storage plates, second storage plates, triangular blocks, third storage plates, fourth supporting columns and third supports. The second storage devices comprise storage frames, fourth supports and holding rods. The baffle device comprises fifth supports, first baffles, second cross rods and second baffles. The number of coal mines needing to be processed is reduced, and the work efficiency of enterprises is improved.

Owner:张萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com