Full-automatic drilling machine

A drilling machine, fully automatic technology, applied in the direction of boring/drilling, drilling/drilling equipment, maintenance and safety accessories, etc., can solve the problems of increased processing costs, low work efficiency, and reduced production efficiency, and achieve Reduce processing and production costs, save processing time, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

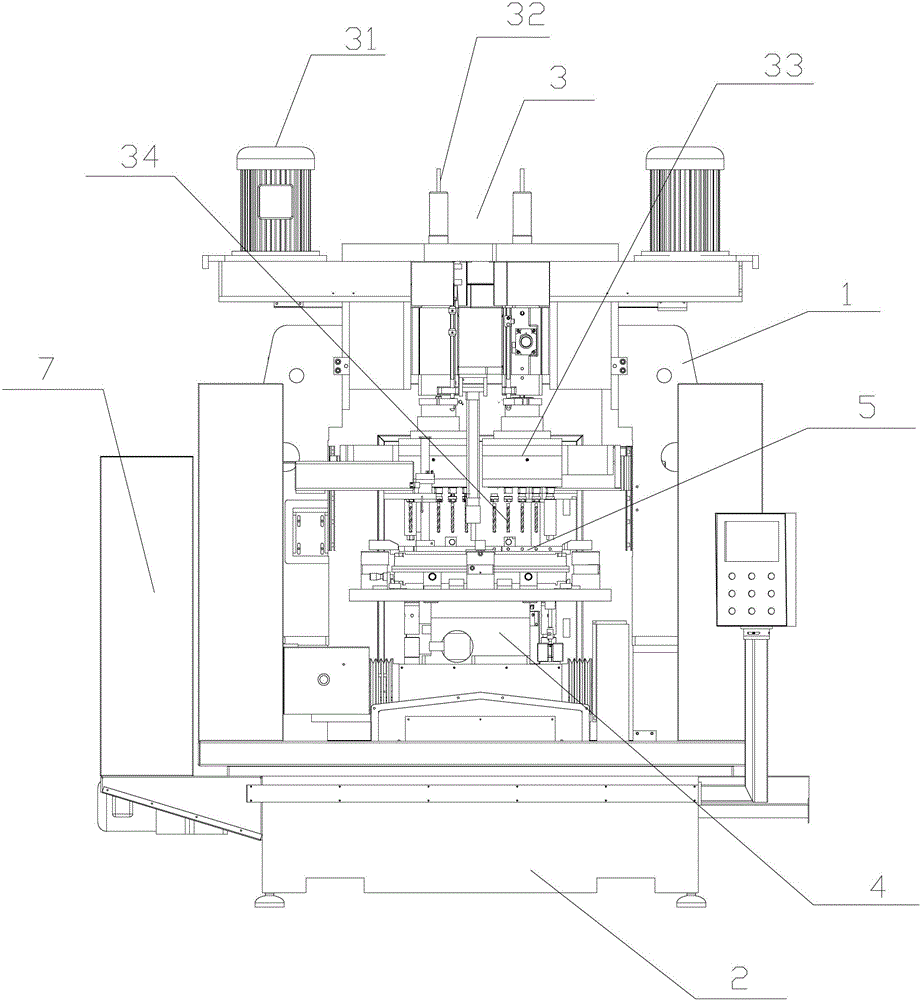

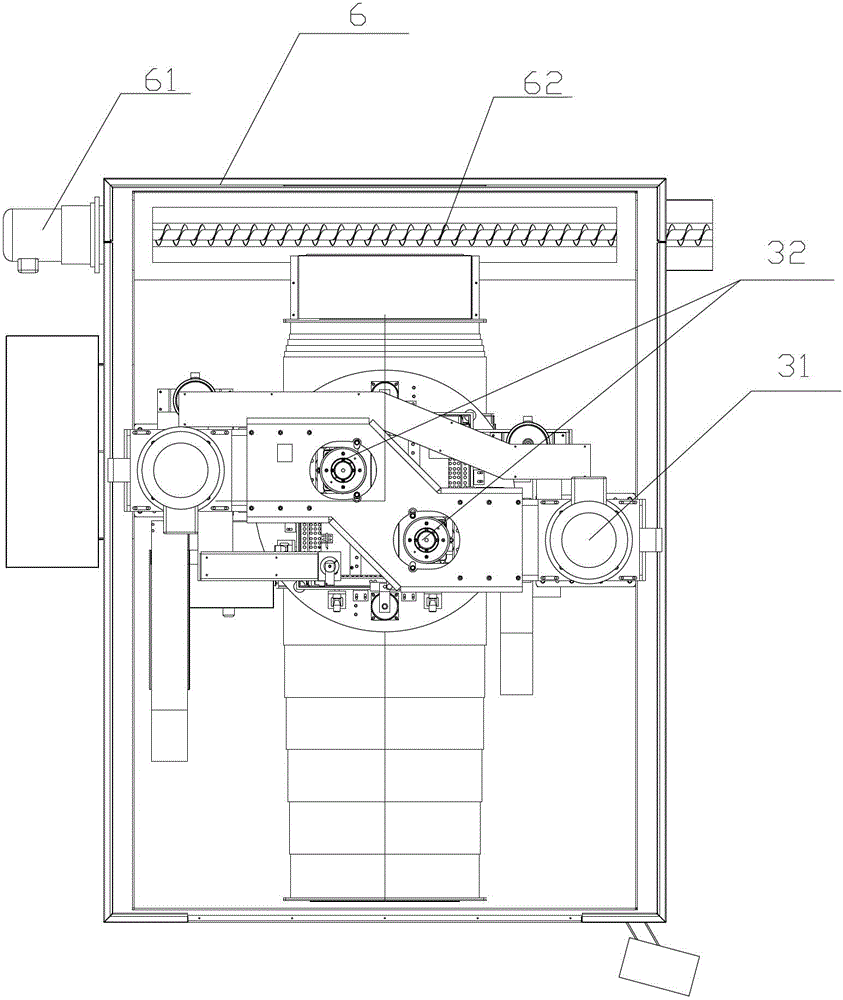

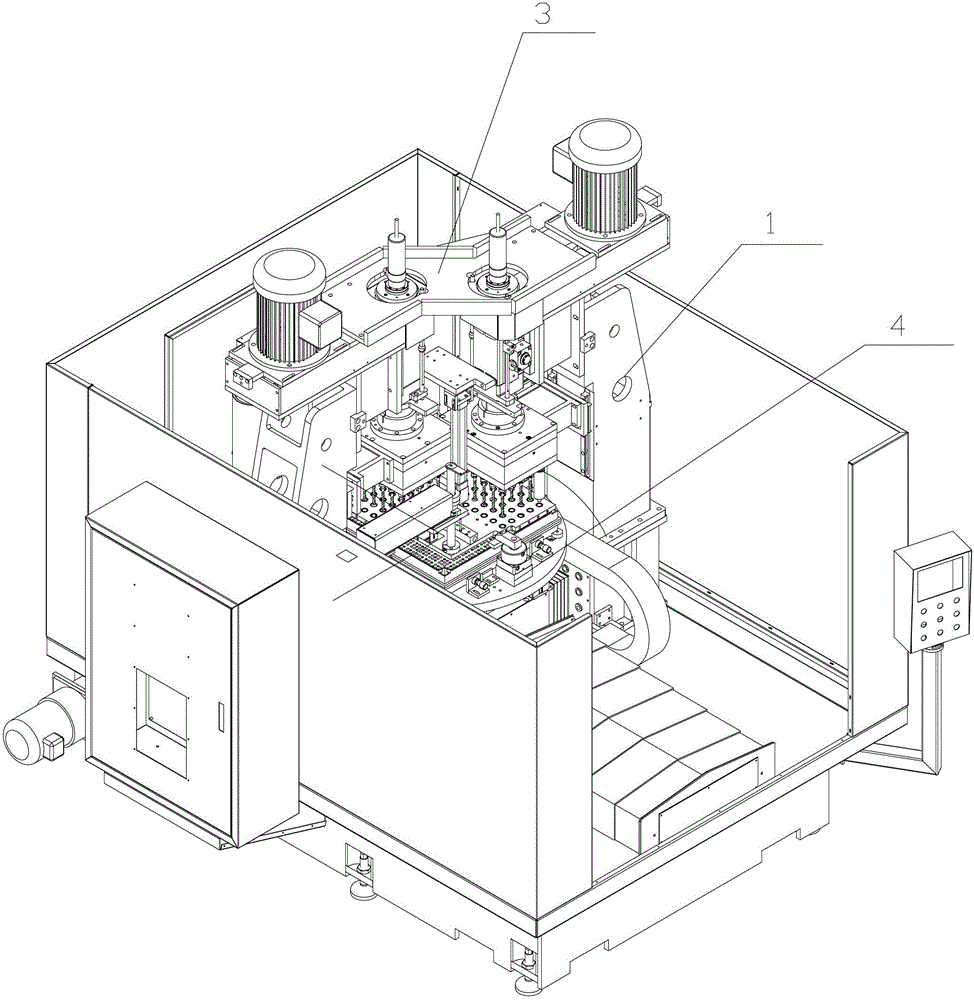

[0034] Traditional drilling machines are mostly single-hole processing, and need to be manually operated, which consumes more equipment resources and processing time, thereby reducing production efficiency, and consumes too much man-hours, increasing a large amount of processing costs, and there is a positioning accuracy of the workpiece Poor problems and deficiencies.

[0035] Aiming at the deficiencies in the prior art, the present invention proposes a fully automatic drilling machine. By setting multiple sets of drilling mechanisms, the multi-hole processing can be performed at the same time, the work efficiency can be improved, and the workpiece can be effectively positioned to avoid the occurrence of processing. Error, the purpose of improving product quality.

[0036] The technical solutions of the present invention will be clearly and completely described below through specific embodiments. Apparently, the described embodiments are only some of the embodiments of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com