A Hall plate installation structure based on zero-flux Hall high-current sensor

A Hall plate, high current technology, applied in the direction of voltage/current isolation, etc., can solve the problems of large magnetic flux leakage, poor operability, unstable installation, etc., and achieve the effect of small magnetic flux leakage, good economic benefits, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

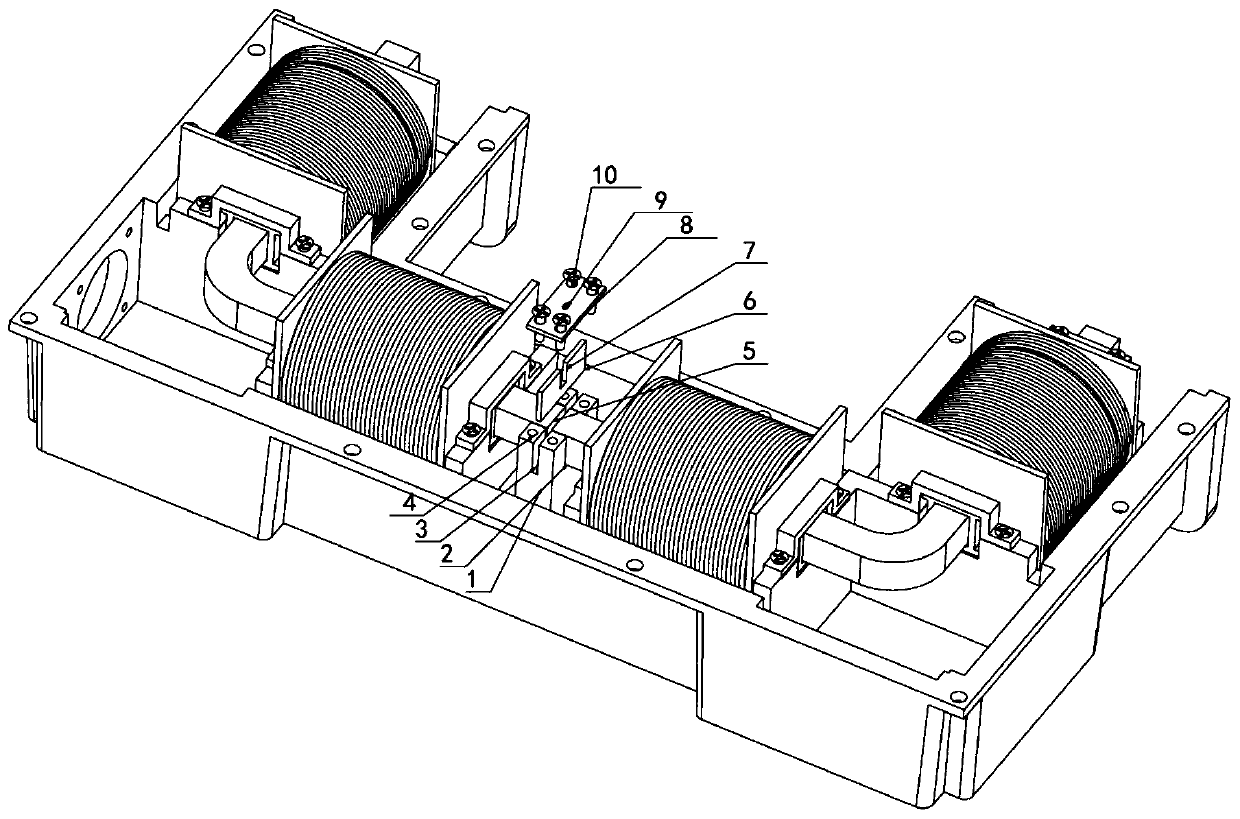

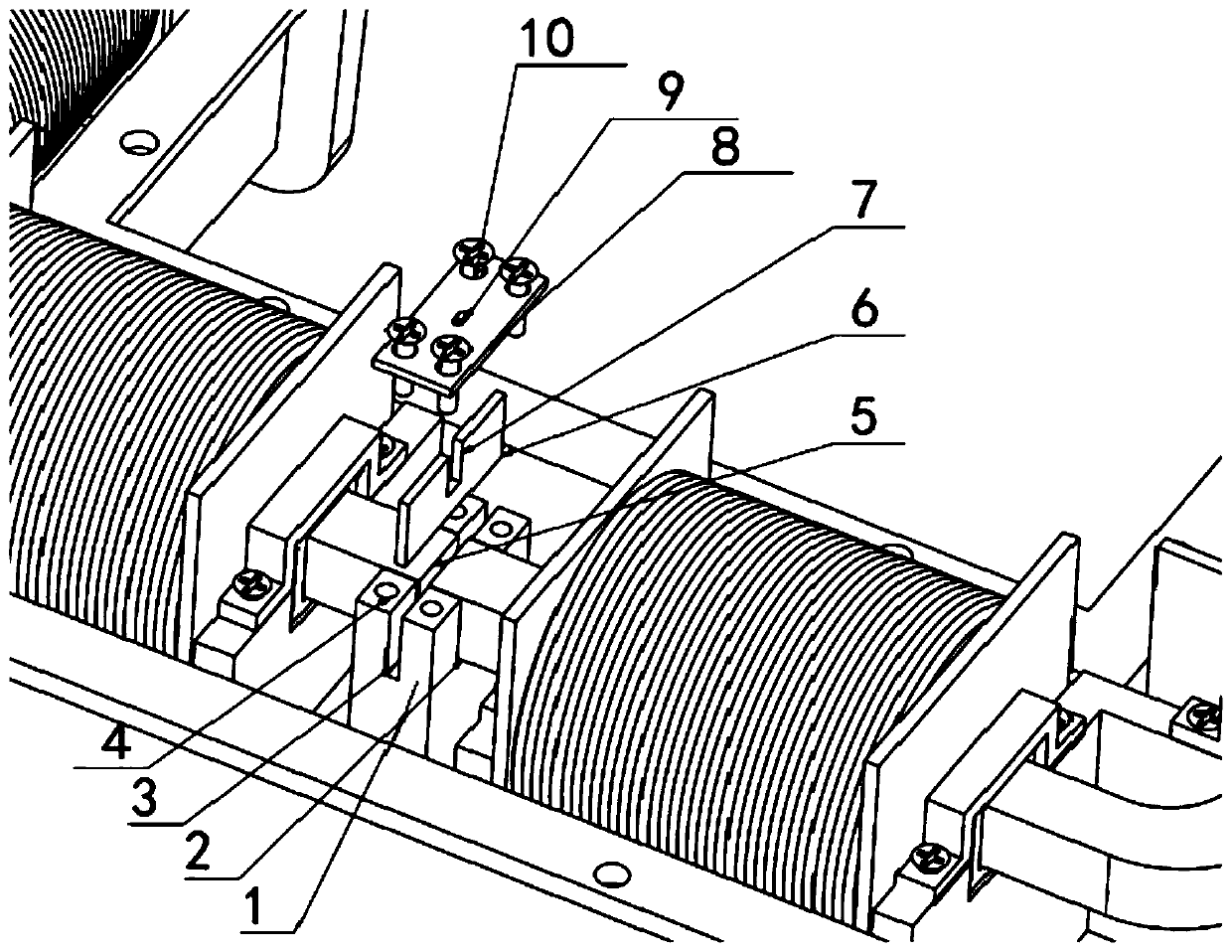

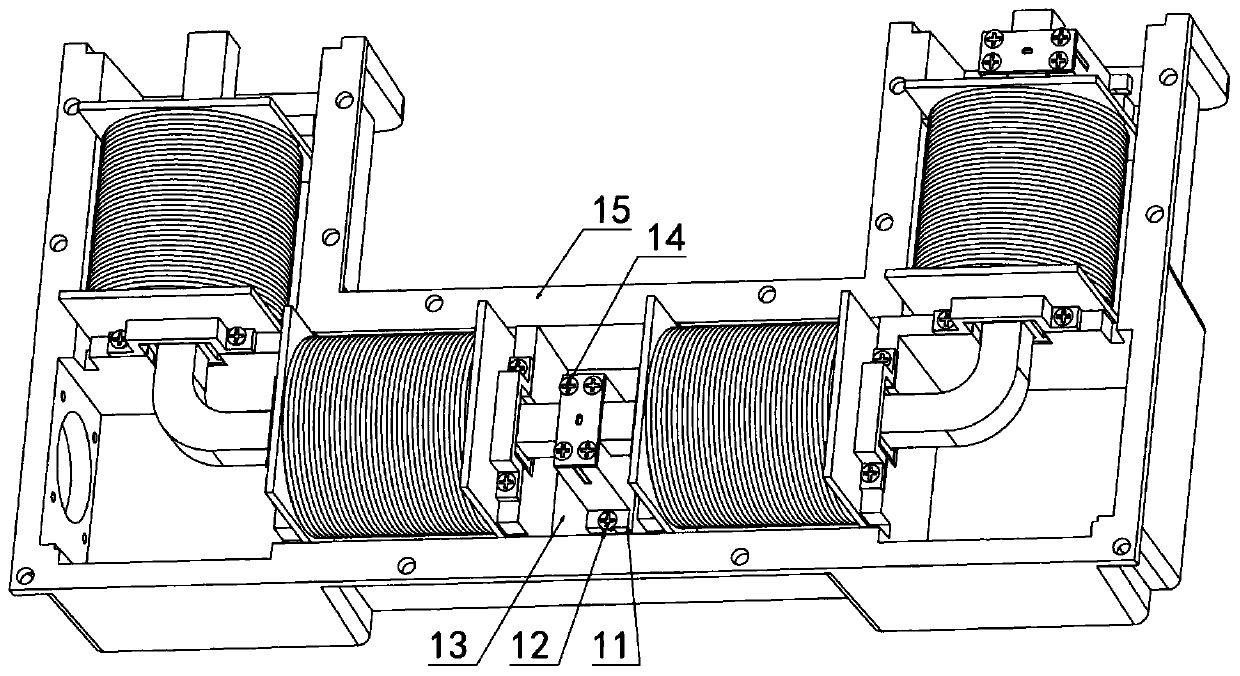

[0013] like figure 1 , 2 , 3, and 4, a Hall plate installation structure based on a zero-flux Hall high-current sensor includes an installation body 1 and accessories, and the accessories include a Hall plate fixing plate 8 and a Hall plate installation The plate 6 has a magnetic core fixing groove 2 vertically on the installation main body 1, and the width of the magnetic core fixing groove 2 is equal to the width of the magnetic core 16, and a hall plate installation plate placement groove 3 is opened on the installation main body 1 horizontally The width of the Hall plate mounting plate placement groove 3 is equal to the thickness of the Hall plate mounting plate 6, and the Hall plate mounting plate placement groove 3 and the magnetic core fixing groove 2 are intercommunicated in a cross shape, at the top of the installation body 1 A plurality of mounting taps 4 are provided, and a U-shaped groove 7 is opened transversely at the middle position of the Hall plate mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com