Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Long reaction cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

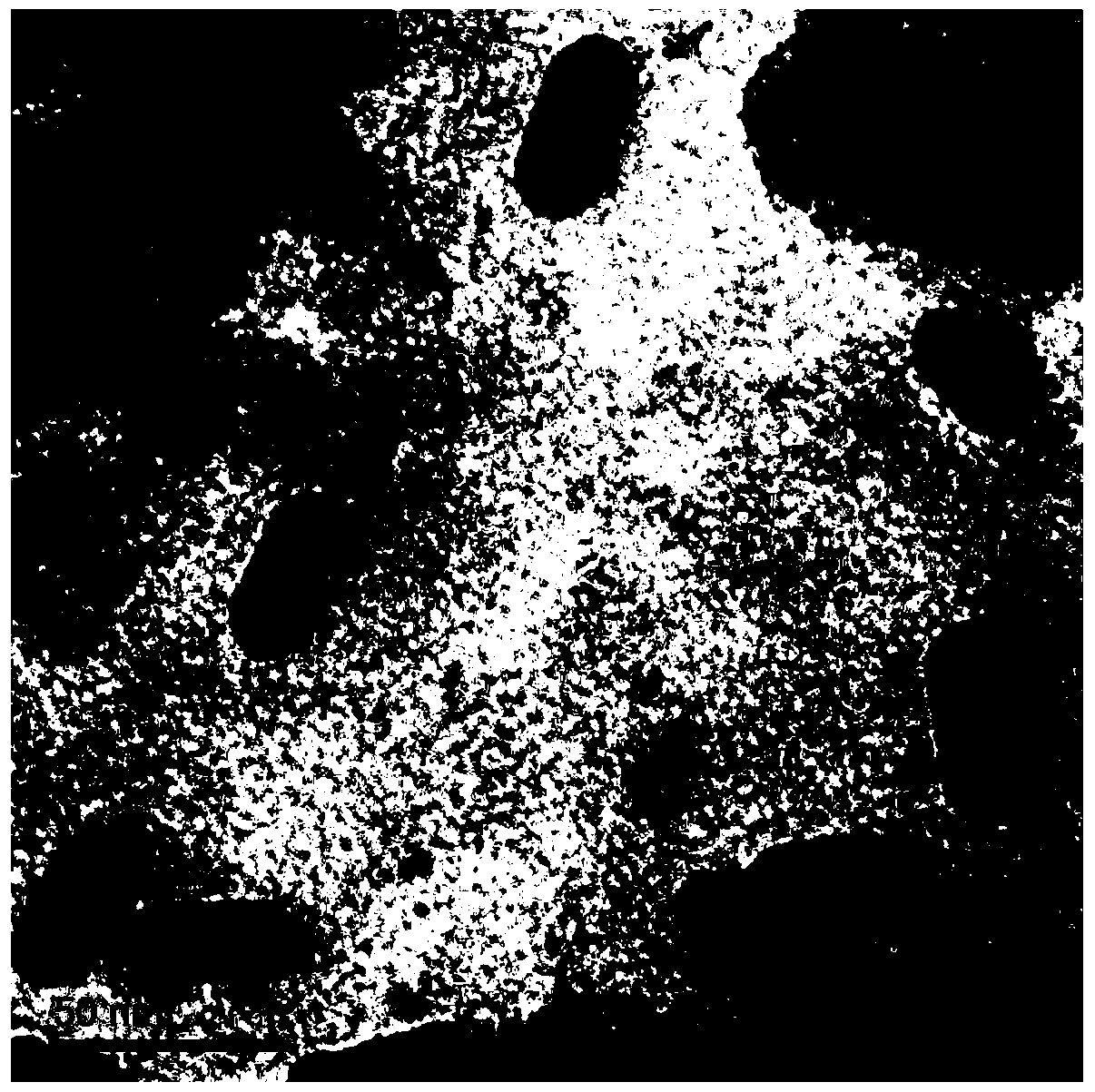

Preparation method of graphene/zinc-aluminium oxide composite material and application of composite material in super capacitor

InactiveCN103107023AReduce reunionLong reaction cycleHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneTube furnace

The invention belongs to the field of chemical and provides a preparation method of a graphene / zinc-aluminium oxide composite material and application of the composite material in a super capacitor. The preparation method comprises the steps of: dissolving a graphite oxide precursor, a zinc salt precursor and an aluminium salt precursor in an organic solvent, adding a small amount of deionized water, and ultrasonically dispersing the mixture to be uniform; transferring a mixed solution to a microwave reactor and then slowly dropwise adding an alkali source compound; and washing a product with alcohol for multiple times, then drying the product in vacuum, putting the product in a tubular furnace, introducing Ar / H2 mixed gas, and carrying out high-temperature thermal pyrolysis, thereby obtaining the finished product, namely the graphene / zinc-aluminium oxide composite material. No toxic chemical agent is used in the reduction of graphene, so that harm to human bodies and environment pollution, caused by a great quantity of harmful chemical agents such as hydrazine hydrate serving as a strong reducing agent used in a chemical reduction method, are eliminated fundamentally.

Owner:JIANGNAN UNIV

Method for preparing liquid octylated diphenylamine antioxidant

InactiveCN102320983APrevent thermal oxidation and elastic flex agingGood oil solubilityAmino preparation from aminesAmino compound preparation by condensation/addition reactionsChemical synthesisViscous liquid

The invention discloses a method for preparing a liquid octylated diphenylamine antioxidant, which belongs to the field of chemical synthesis, and particularly relates to a method for synthesizing high-content mono-octyl diphenylamine. The method comprises the following steps of: under the action of a catalyst, making diphenylamine react with diisobutylene to generate an octylated diphenylamine mixture; introducing isobutene for reacting; and distilling to obtain the liquid octylated diphenylamine antioxidant, wherein the catalyst is dehydrated active white clay. The prepared liquid octylated diphenylamine antioxidant is a light-yellow viscous liquid at normal temperature, and the moving viscosity is 50-300 mm<2> / s at the temperature 40 DEG C. The liquid octylated diphenylamine antioxidant can be effectively applied to turbines, aircrafts and various oil products and lubricating agents which are applied at high operation temperatures, and can be applied to high-polymer rubber products to prevent rubber from being thermally oxidized and aged by elastic deflection.

Owner:JIANGSU FEIYA CHEM IND

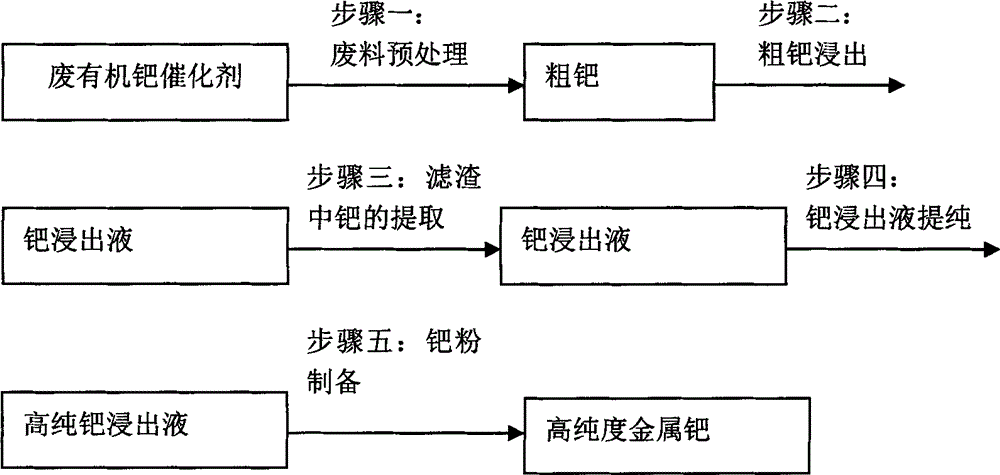

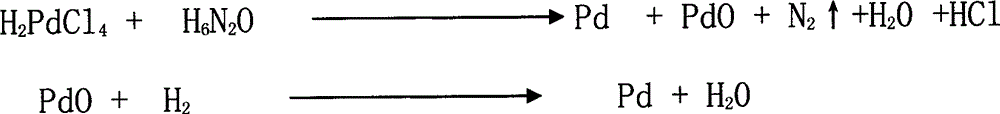

Method for recovering high-purity metal palladium from organic waste palladium contained catalyst

InactiveCN103555957AEasy to useMature post-processing technologyProcess efficiency improvementPalladiumReaction step

The invention relates to the class of chemical technologies, belongs to the field of solid waste recovery and particularly relates to a method for recovering high-purity metal palladium from an organic waste palladium contained catalyst. The method comprises the steps of waste pretreatment, leaching, extraction, purification and hydrogenation preparation, thereby finally obtaining high-purity metal palladium. The method provided by the invention is simple in reaction step, short in time and capable of saving reagents; in addition, the recovery rate of palladium is up to over 99.2%, and the purity of recovered palladium is higher than 99.98%.

Owner:ZHEJIANG METALLURGICAL RES INST

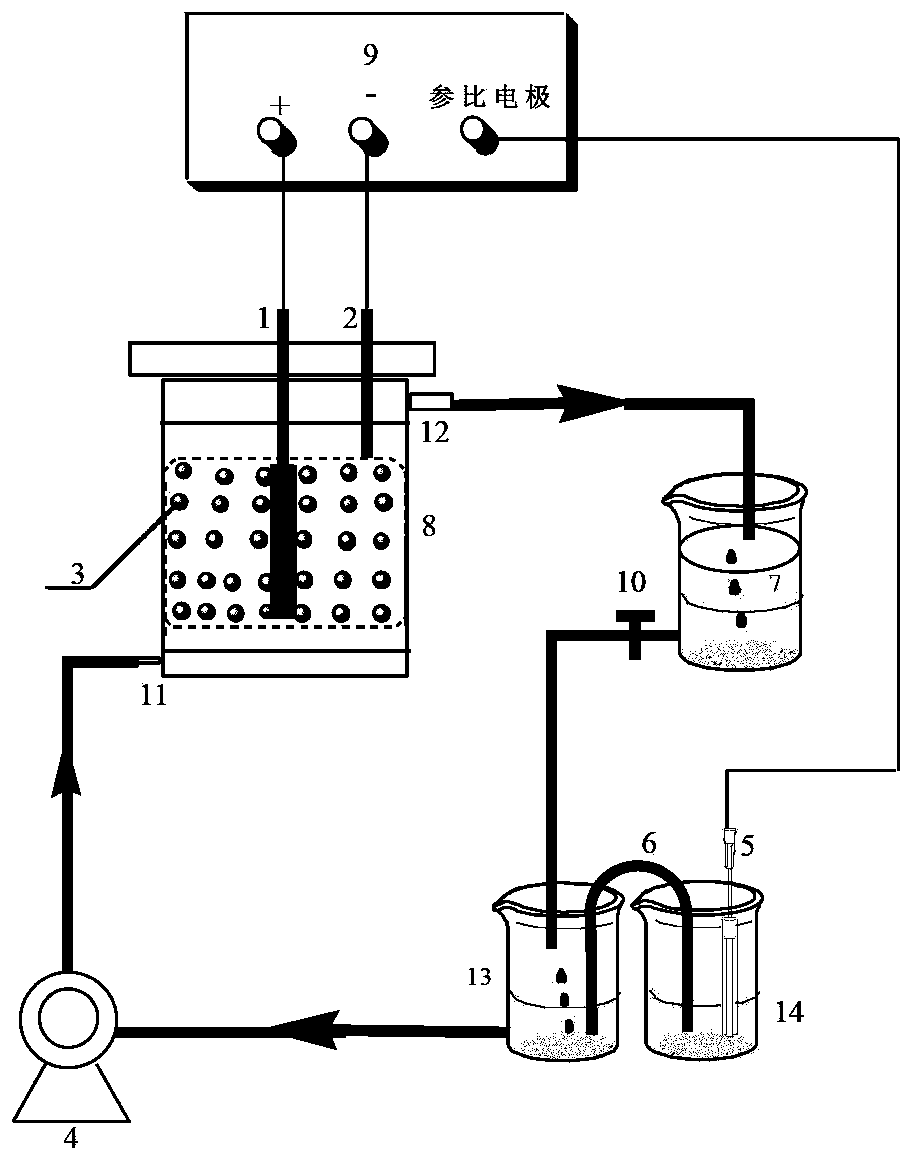

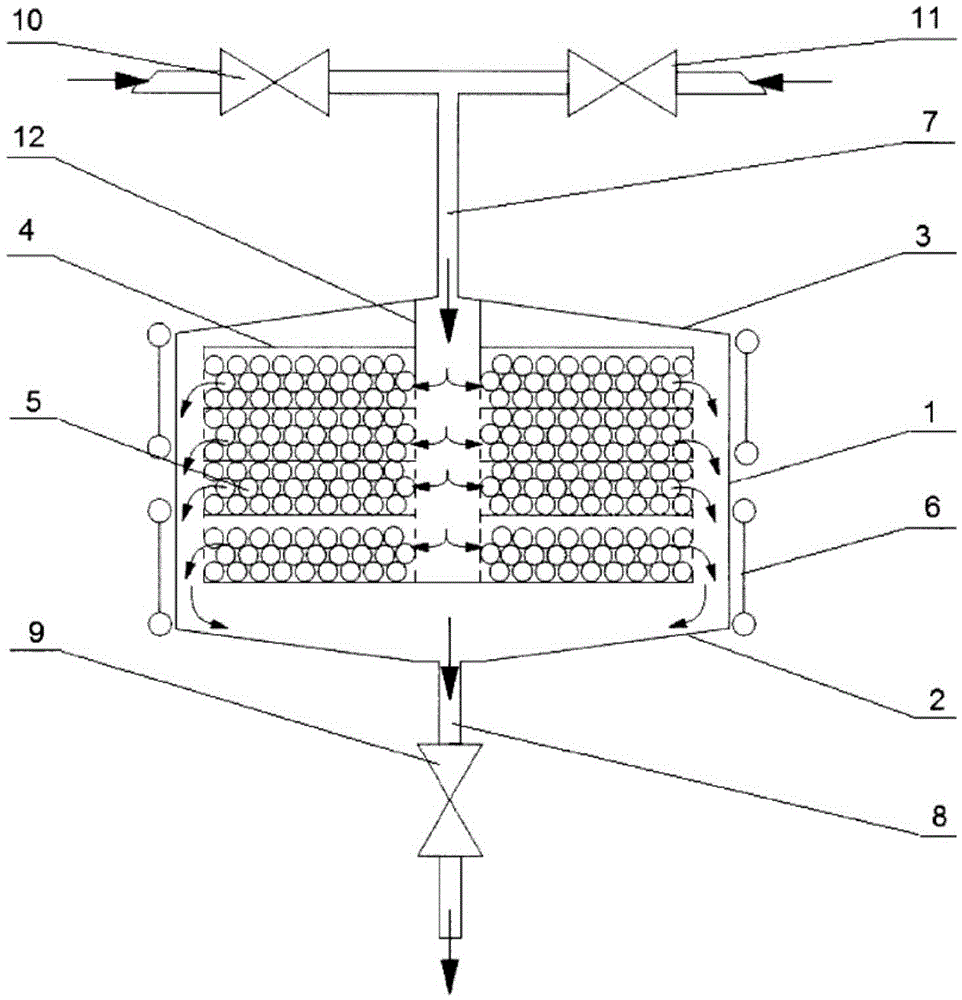

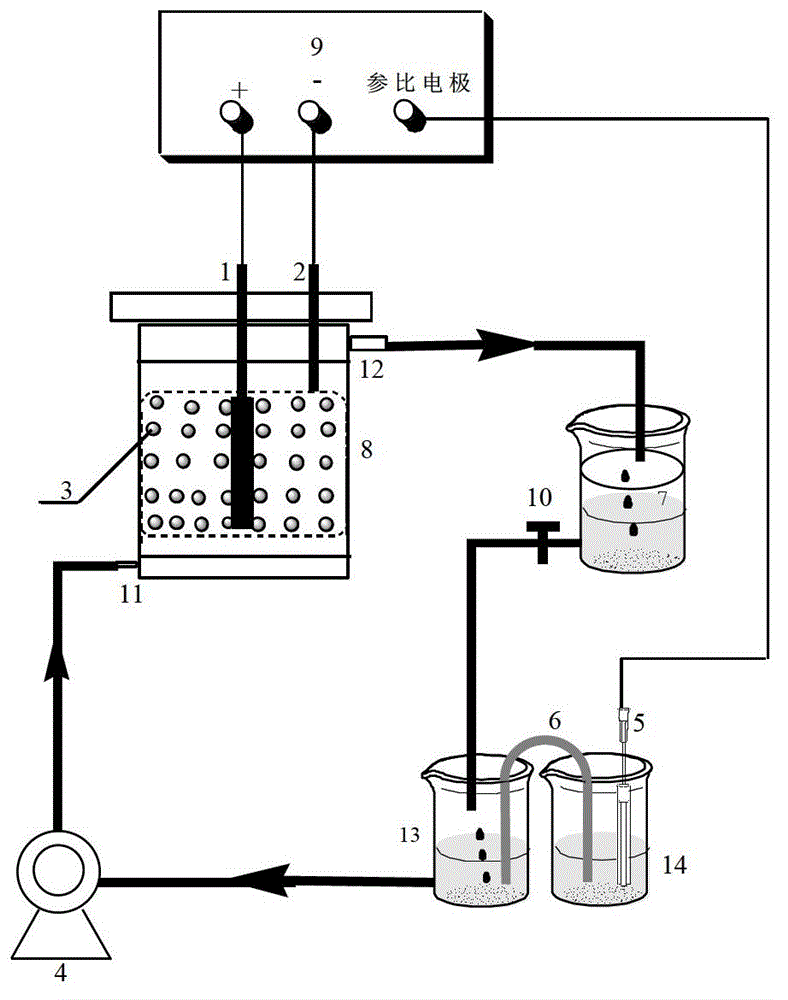

Process for preparing diisobutyl phthalate by electro-catalytic degradation of lignin in fixed bed reactor

ActiveCN103469243AMild reaction conditionsSimple technologyElectrolysis componentsOrganic chemistryAuxiliary electrodeSolvent

The invention relates to a method for preparing diisobutyl phthalate by electrochemically degrading lignin. According to the method, a three-dimensional fixed bed reactor is formed by using Ti / SnO2-Sb2O3-Fe(NO3)3 / PbO2 as a working electrode, a copper mesh electrode as an auxiliary electrode, filled nutshell activated carbon as a third electrode and a standard saturated calomel electrode as a reference electrode. Electro-catalytic degradation of the lignin is combined with an integrated process for continuous electro-catalytic degradation and solvent extraction separation, so that degraded products can be separated from a lignin alkali solution rapidly. By combining the electro-catalytic degradation of the lignin with the integrated process for continuous electro-catalytic degradation and solvent extraction separation, reaction conditions are mild; process technology is simple and can be operated easily; byproduct-lignin of a paper-making factory is used relatively well; and a fine chemical product-diisobutyl phthalate is obtained; and the method has relatively good industrial application values.

Owner:HEBEI UNIV OF TECH

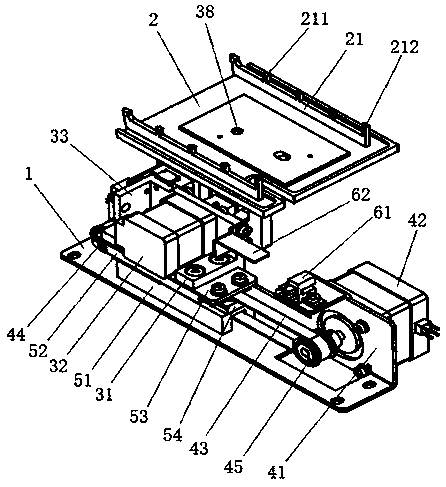

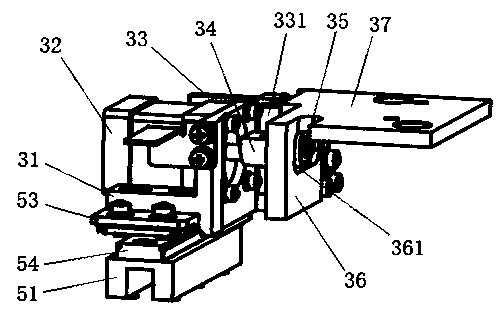

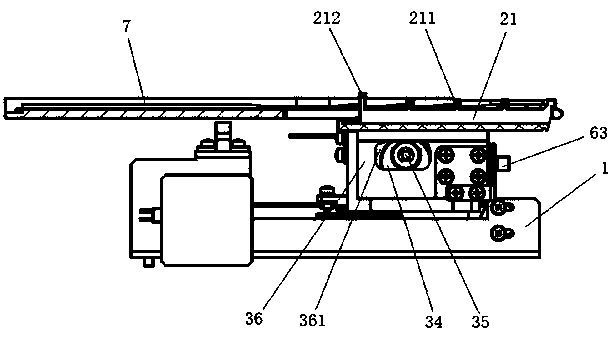

Test paper conveying device and method

ActiveCN109696555ALong reaction cycleResponse cycle increases or decreasesBiological testingPulp and paper industryTest strips

The invention discloses a test paper conveying device and method. The test paper conveying device comprises a bottom plate, a lifting driving mechanism arranged on the bottom plate and a tooth plate arranged on the lifting driving mechanism, wherein two sides of the upper end of the tooth plate are provided with racks for pushing test papers; the rack comprises multiple semi-height teeth arrangedin a spaced mode and full-height teeth arranged at the tail ends of the racks; and the bottom plate is also provided with a horizontal driving mechanism for driving the tooth plate to move horizontally. Through the matched design between the full-height teeth and the semi-height teeth of the racks, in a condition of not changing the whole structure of the device, the purpose of enabling the test speed to be increased or decreased by a test paper reaction period is realized.

Owner:DIRUI MEDICAL TECH CO LTD

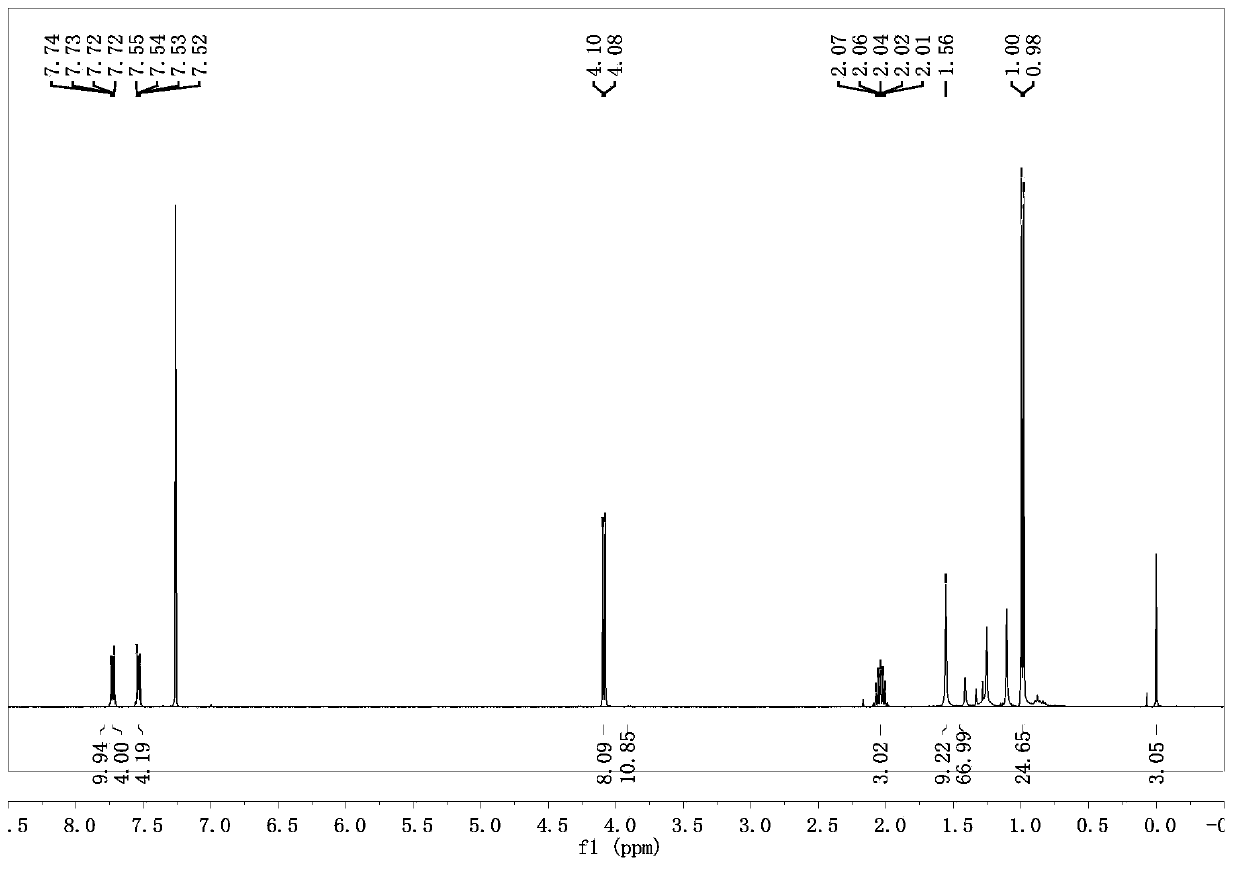

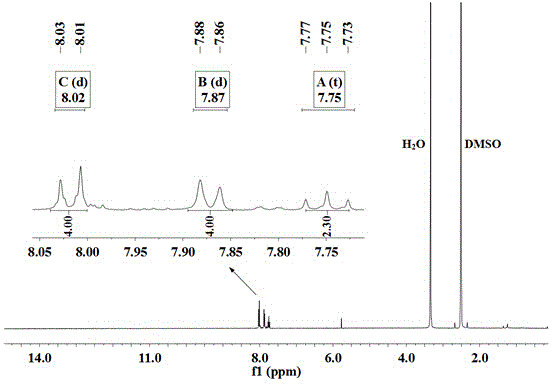

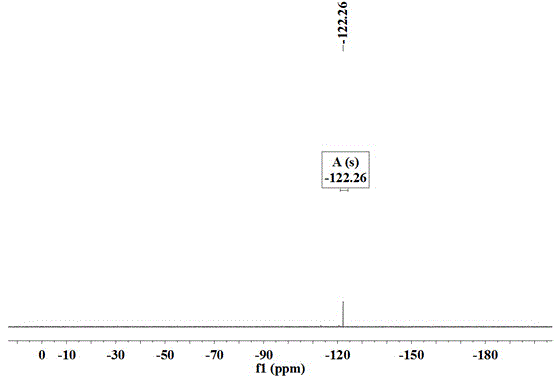

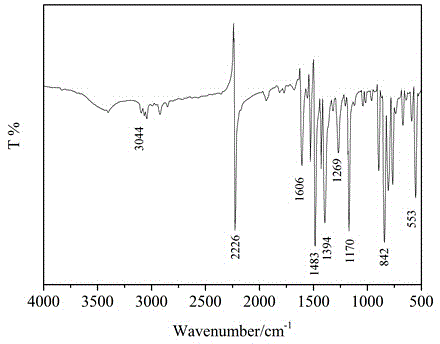

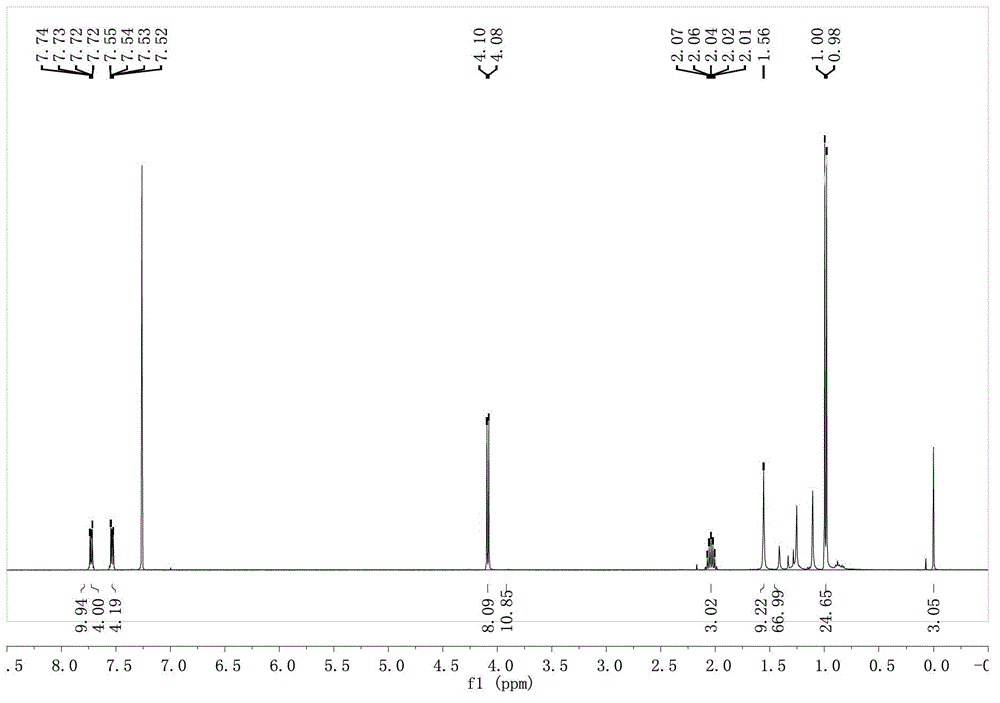

Synthetic method of mercapto functionalized polyaryl carboxylic acid compound

InactiveCN104447452AImprove protectionLong reaction cycleThiol preparationPtru catalystPalladium catalyst

The invention relates to the technical field of compound synthesis and in particular discloses a synthetic method of a mercapto functionalized polyaryl carboxylic acid compound. The synthetic method concretely comprises the following steps: in the presence of a palladium catalyst, putting aryl fluoride, aryl boric acid and alkali metal salt serving as raw materials into a mixed system of water / organic solvent, and carrying out a series of subsequent reactions including Suzuki reaction to obtain the mercapto functionalized polyaryl carboxylic acid compound. According to the synthetic method disclosed by the invention, as the Suzuki reaction is realized in the air environment firstly, the reaction condition is greatly simplified, the reaction time is shortened from 2d to 1h, and the productivity and the yield are greatly increased; in addition, by adopting the environment-friendly solvent, the environment is beneficially protected; the mercapto functionalized polyaryl carboxylic acid compound synthesized by utilizing the synthetic method can be largely applied to metal organic compounds to build a series of novel porous materials with novel structures and excellent performances.

Owner:GUANGDONG UNIV OF TECH

Long-acting catalyst for electrolytic silver

InactiveCN1935365AGood air permeabilityReduce resistanceOrganic chemistryPhotography auxillary processesLong actingChemical products

The present invention relates to a long-acting electrolytic silver catalyst made up by using DC powder supply 1% pulsating component. When the chemical product formaldehyde is produced, said silver catalyst can make period be up to 120-180 days. The catalyst silver ed is low in resistance, good in air permeability and high in conversion rate.

Owner:李洪伟 +1

System for purifying a gaseous medium of hydrogen and method for the use thereof

ActiveCN105556613AImprove reliabilityImprove operational safetyNuclear energy generationCatalytic ignitersNuclear reactorHydrogen

Disclosed is a hydrogen igniter for igniting hydrogen contained in a gaseous medium, said hydrogen igniter comprising a housing with openings for the supply and discharge of a gaseous medium, and a filler in the form of bismuth oxide and / or lead oxide, disposed inside the housing. Also disclosed are a system for purifying a gaseous medium of hydrogen having such a hydrogen igniter, and a method for the repeated use of such a system. The igniter and the system can be used in a nuclear reactor facility.

Owner:JOINT CO AKME ENG

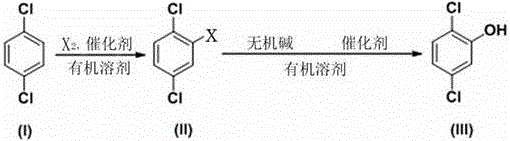

Synthesizing process of 2, 5-dichlorophenol

InactiveCN105884582AReduce the treatment amount of three wastes in the processReduce manufacturing costOrganic compound preparationHalogenated hydrocarbon preparationBromineBenzene

The invention discloses synthesizing process of 2, 5-dichlorophenol and belongs to the technical field of fine chemical industry. The synthesizing process includes halogenation and hydrolysis. The synthesizing process has the advantages that bromine or iodine which can be substituted more easily than chlorine is used, the bromine or iodine substituent group is hydrolyzed into hydroxyl after dichlorobenzene is halogenated, and halogenation depth is controlled by controlling the adding amount of the bromine or iodine so as to reduce the content of 2, 5-dichloro-1, 4-dihalogen benzene in the halogenation product; the conversion rate of 2, 5-dichloro halobenzene reaches above 92.0%, and the synthesizing process is short in synthetic route, simple, low in cost, few in produced three wastes and suitable for large-scale production.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

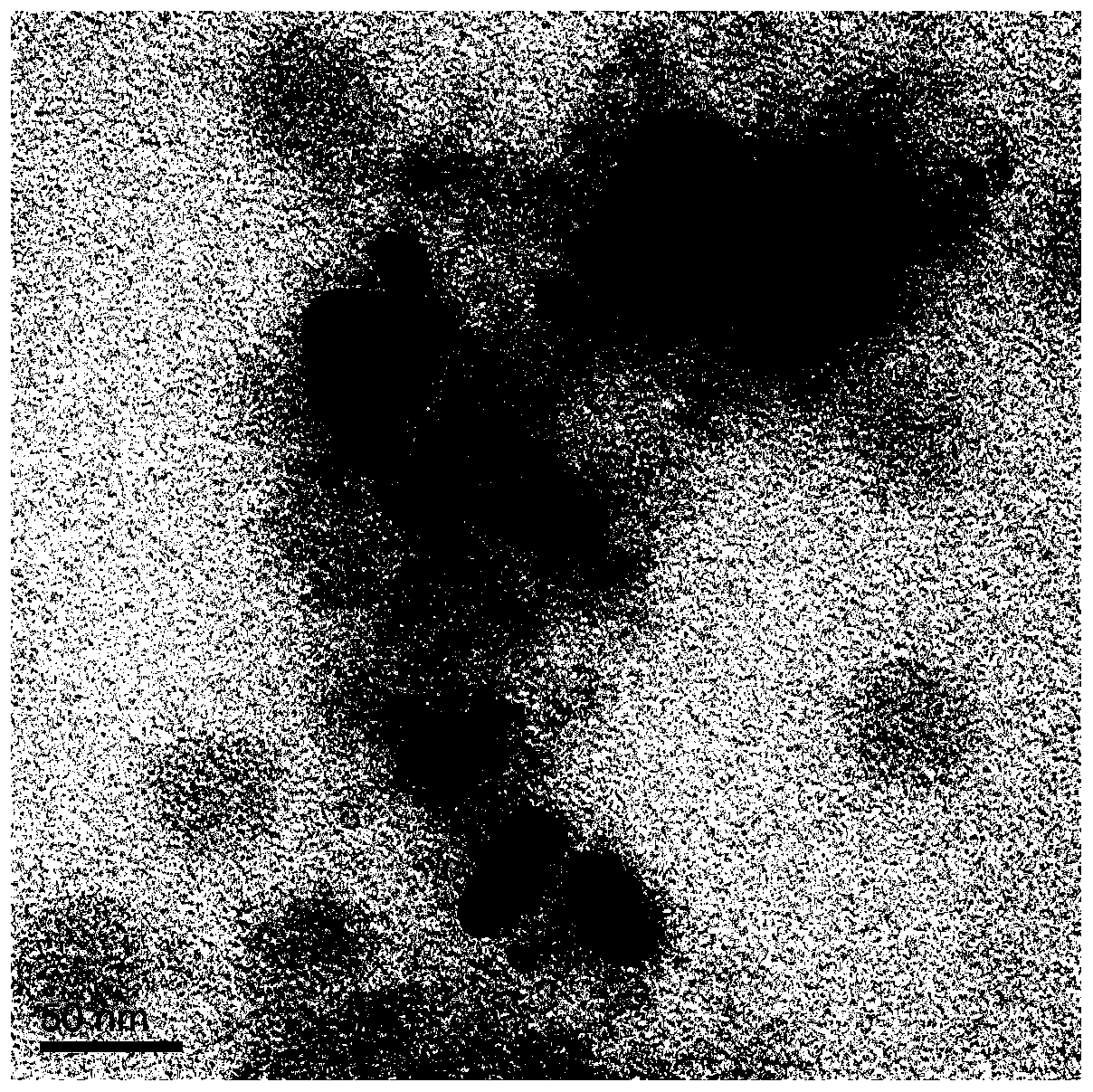

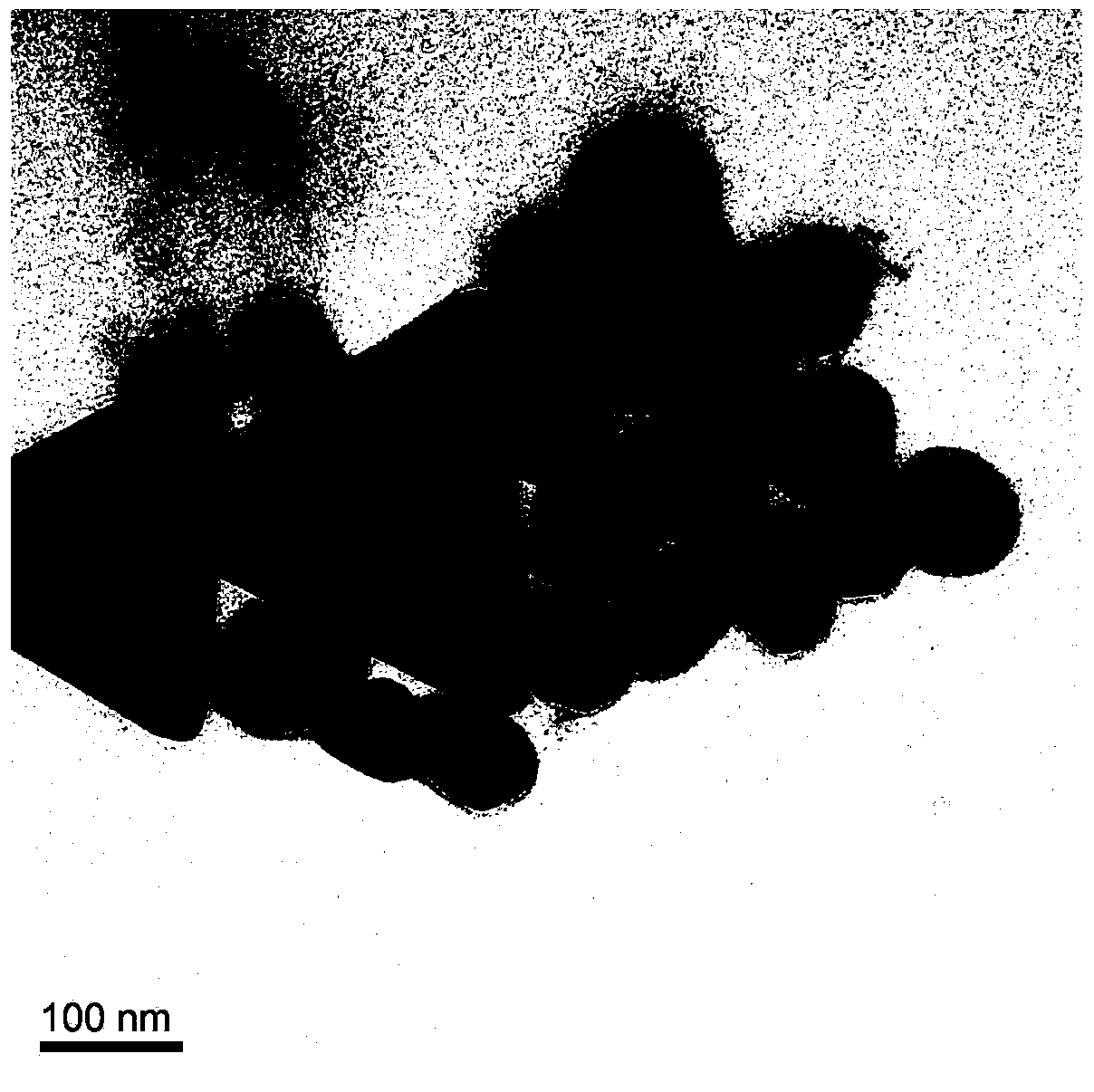

Preparation method for gold nanorods

PendingCN110842214AImprove stabilityMild reaction conditionsMaterial nanotechnologyTransportation and packagingGold nanorodNanoparticle

The invention discloses a preparation method for gold nanorods, and belongs to the field of synthetic preparation of metal nanomaterials. The method comprises the steps that an aqueous solution of a polyoxyethylene-polypropylene oxide-polyoxyethylene amphiphilic block copolymer is prepared and then pre-heated, a chloroauric acid solution with the same temperature is quickly injected, even mixing is conducted, water-bath heating is conducted, and after a reaction is completed, a mixture is naturally cooled to the room temperature. According to the preparation method, by regulating and controlling the self-assembling process of the amphiphilic block copolymer, the rodlike micelle morphology is formed and taken as a template to regulate and control growth of gold nanoparticles, and thus the gold nanorod particles are obtained. Meanwhile, under the alkaline condition, hydrophobic interaction between the amphiphilic block copolymer Pluronic and nanogold is enhanced, the Pluronic is adsorbedon the surface of the nanogold, and the gold nanorods can be stabilized in the solution for several months and do not agglomerate. The gold nanorod particles existing in the solution do not have cytotoxicity and can be used for biological substance detection and bioaffinity drug vectors.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

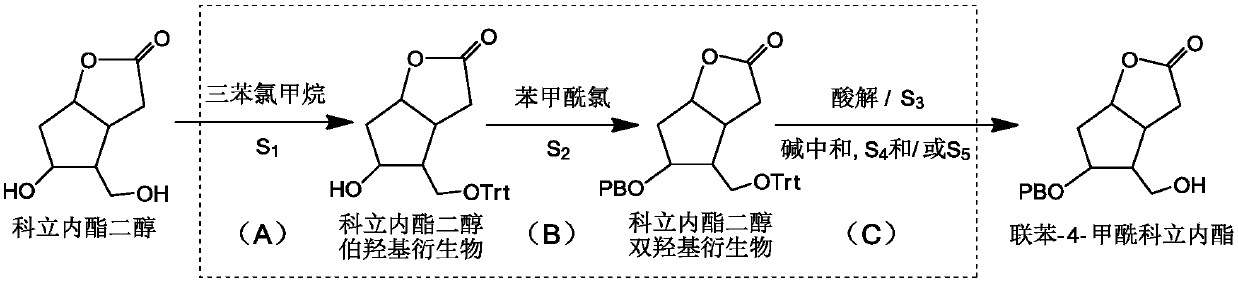

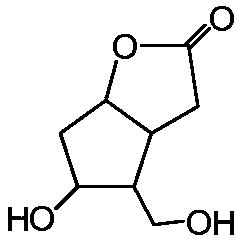

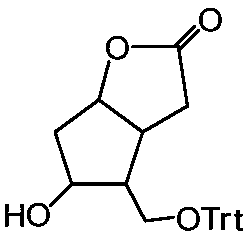

Method for preparing biphenyl-4-formyl corey lactone by using one-pot method

The invention discloses a method for preparing biphenyl-4-formyl corey lactone by using a one-pot method. The method comprises the following steps: in a same reaction container, with corey lactone glycol as a raw material, adding a solvent S1 and triphenyl chlorometha to carry out an alkylation reaction in a primary hydroxyl position so as to obtain a solvent S1 reaction system with a corey lactone glycol primary hydroxyl derivative, further adding benzoyl chloride to carry out an acylation reaction in a secondary hydroxyl position, adding a solvent S2, and performing recrystallization so as to obtain a corey lactone glycol double-hydroxyl derivative; adding a solvent S3 and an acid solution to carry out a hydrolysis reaction in a primary hydroxyl position so as to obtain a crude product of biphenyl-4-formyl corey lactone; adding a solvent S4 or / and a solvent S5, and performing recrystallization, thereby obtaining the biphenyl-4-formyl corey lactone with corresponding optical activityat one time. The method is capable of avoiding the situation that materials are repeatedly fed in different steps of tedious reactions, is sufficient in reaction, small in side reaction, high in purity, simple in aftertreatment, high in yield, simple in operation, short in time, high in efficiency, low in material quantity, low in cost and applicable to industrial production.

Owner:JINLIN MEDICAL COLLEGE

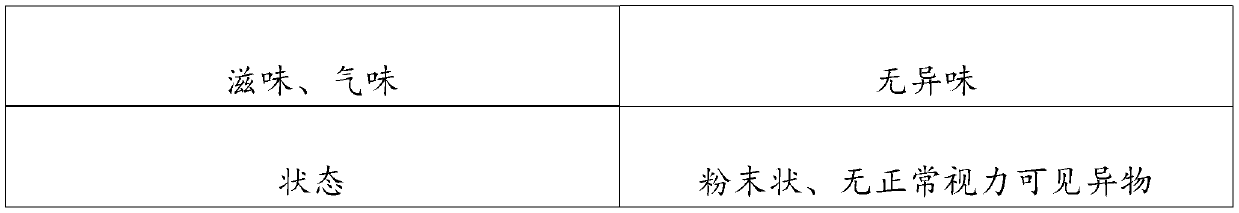

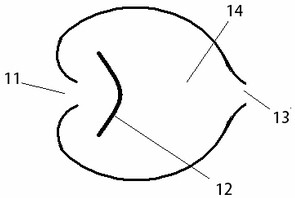

Hydrolyzed fish collagen processing process

InactiveCN109971812ASimple processing technologySimple methodConnective tissue peptidesPeptide preparation methodsSolubilityDamages tissue

The invention discloses a hydrolyzed fish collagen processing process. The process includes steps: removing fish scales and fish skin, draining after clearing, and keeping for standby application; soaking the fish scales and the fish skin in water, and performing sterilization treatment; subjecting the fish scales and the fish skin to enzymolysis, filtering, and removing filter residues to obtainenzymatic hydrolysate; feeding the enzymatic hydrolysate into a molecular weight screening system to obtain collagen solutions graded according to collagen molecular weights; concentrating the collagen solutions, drying, and treating with a magnetic rod to obtain fish collagen. The hydrolyzed fish collagen processing process has advantages that before enzymolysis, the fish scales and the fish skinare subjected to high-temperature sterilization to damage tissues in the fish scales and the fish skin, so that acid and alkali swelling treatment can be avoided, enzyme activity can be guaranteed, and enzymolysis completeness is improved; a fish collagen product is free of fishy smell, low in ash content, simple in production process, low in cost, great in taste, high in water solubility and lowin salt content.

Owner:王明

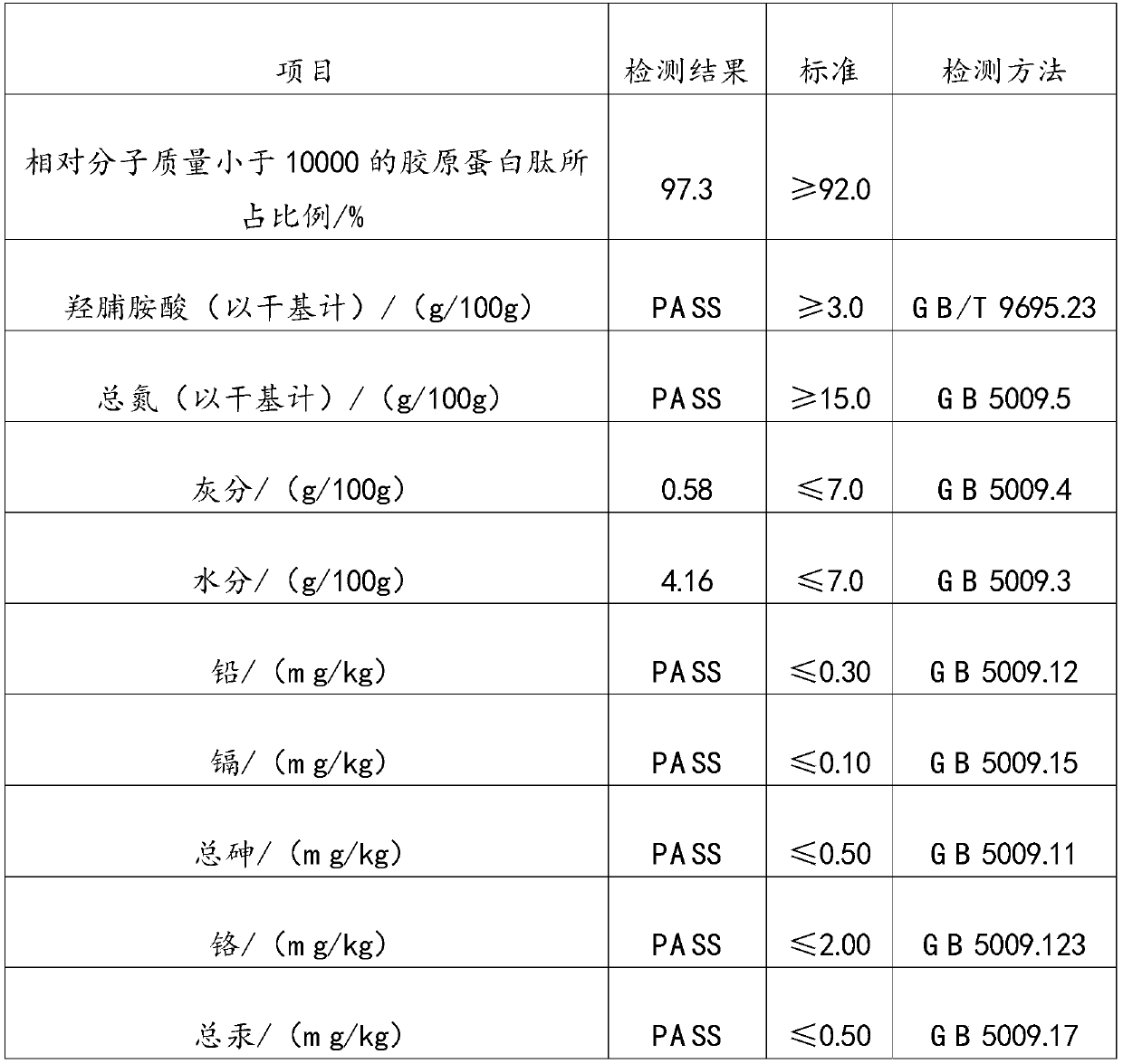

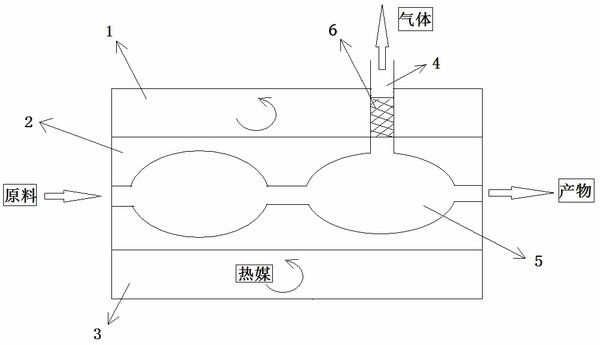

Micro-channel reactor and preparation method of high-content dichlorvos

ActiveCN111793084ATime consumingHigh energy consumptionGroup 5/15 element organic compoundsChemical industryPhosphorous acidDichlorvos

The invention discloses a micro-channel reactor. The micro-channel reactor is of a three-layer sandwich structure, wherein a flowing heating medium is arranged in the upper layer and the lower layer,and the middle layer is a reaction space of a multi-stage series heart-shaped structure; a vacuum pumping hole communicating with the middle-layer reaction space is locally reserved in the upper layer; and the hole is covered with a molecular sieve or a semipermeable membrane with a pore diameter of 0.6-0.7 nm. The micro-channel reactor is used for producing dichlorvos, the temperature of the heating medium is 40-50 DEG C, and the air pressure of the reaction space is minus 0.02 to minus 0.08 Mpa. According to the invention, when methyl chloride and water vapor volatilize, trimethyl phosphiteand trichloracetic aldehyde cannot be entrained, side reactions cannot be generated, trichloracetic aldehyde cannot form hydrate, and a reaction speed and a conversion rate are increased.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

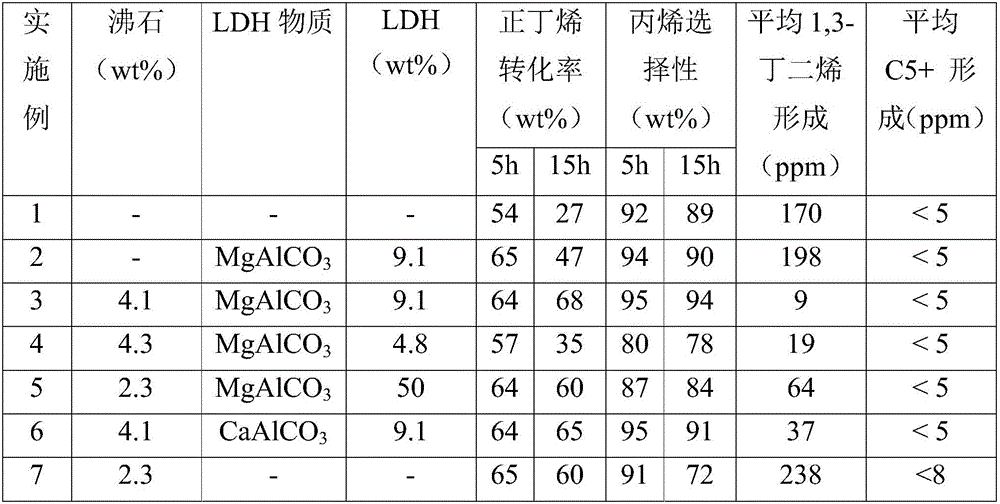

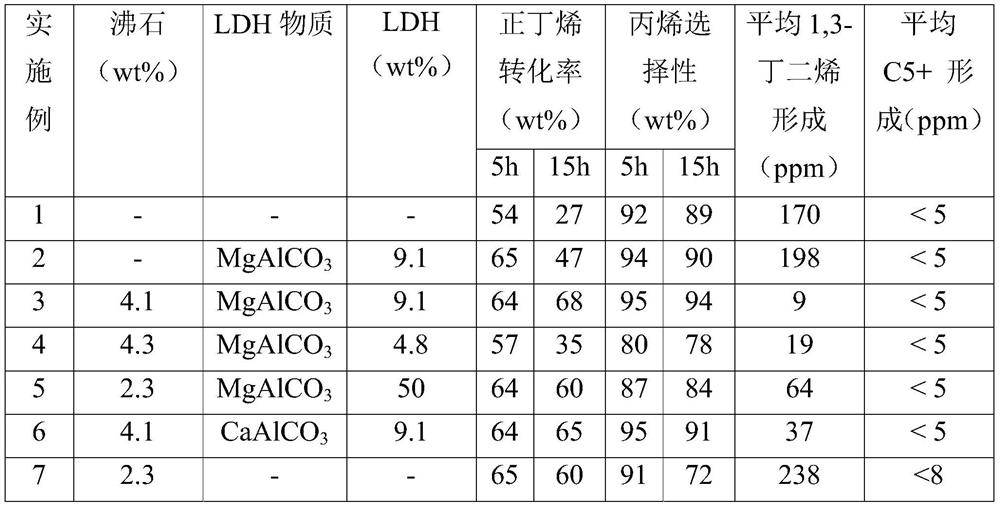

Metathesis catalyst and process for producing olefin

ActiveCN107438482AExtend your lifeHigh activityMolecular sieve catalystsMolecular sieve catalystPtru catalystEngineering

The present invention provides a catalyst comprising a transition metal, an inorganic support, a zeolite, and a layered double hydroxide. Using of the catalyst according to the present invention in an olefin production process exhibits high activity and high selectivity with decreased deactivation rate, therefore longer reaction cycle can be performed and catalyst life is prolonged.

Owner:SMH CO LTD

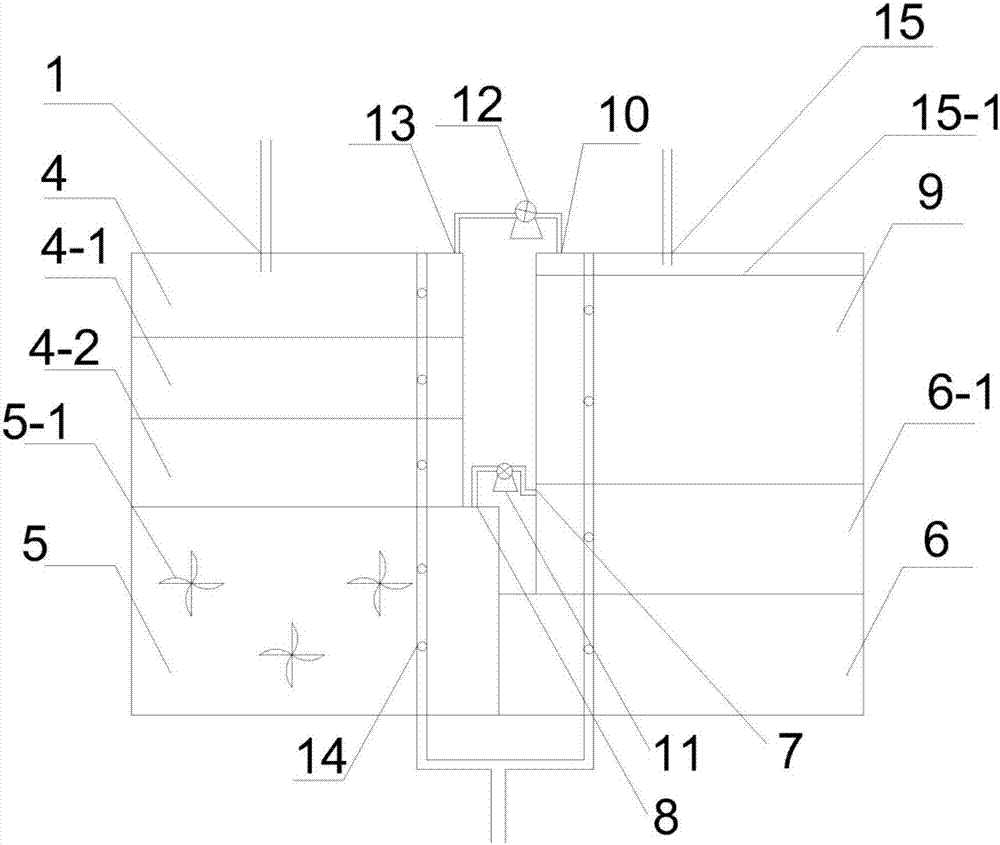

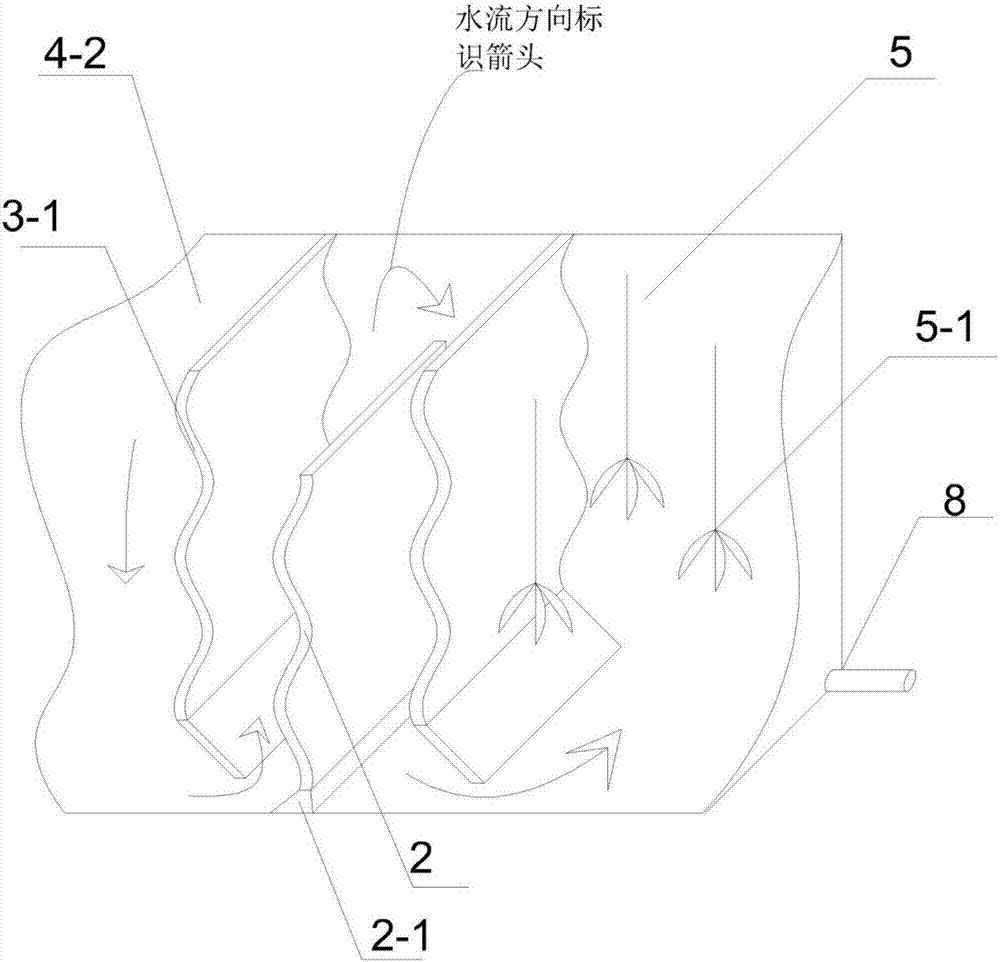

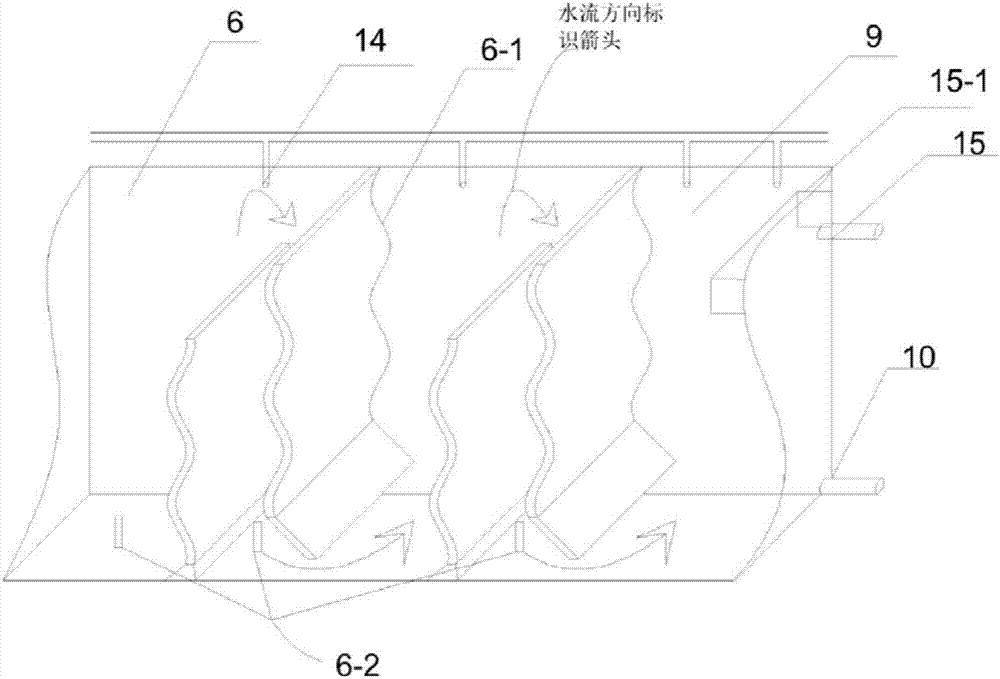

AAO process water treatment equipment

InactiveCN107176684AGood removal effectIncrease hydraulic retention timeWater/sewage treatment by irradiationWater contaminantsConstructed wetlandRural area

The invention discloses an AAO process water treatment equipment, which relates to the technical field of water treatment. It adopts the combination of A / A / 0 process and ABR baffle reactor to solve the problem of high nitrogen and phosphorus content in the sewage treatment process of artificial wetlands in rural areas. Sewage treatment is difficult, the backlog of solid suspended matter reduces the service life of constructed wetlands, and the technical problems of low effluent quality. The present invention includes anaerobic compartment A, anaerobic compartment B, anaerobic compartment C, and anoxic compartment in series. , the aerobic compartment A, the aerobic compartment B and the sedimentation chamber, the compartments are separated by a wave-shaped baffle, and the bottom of the aerobic compartment A, the aerobic compartment B and the sedimentation chamber downstream area is provided with a tree Branch-shaped porous aeration head, the tail end of the aerobic compartment B is connected to the anoxic compartment through the pipeline, and the sedimentation chamber is connected to the anaerobic compartment A through the pipeline. , phosphorus effect and volume utilization.

Owner:弘毅天承知识产权股份有限公司

A kind of preparation method of improving the free fiber silk of sodium carboxymethyl cellulose aqueous solution

Owner:CHONGQING LIHONG FINE CHEM

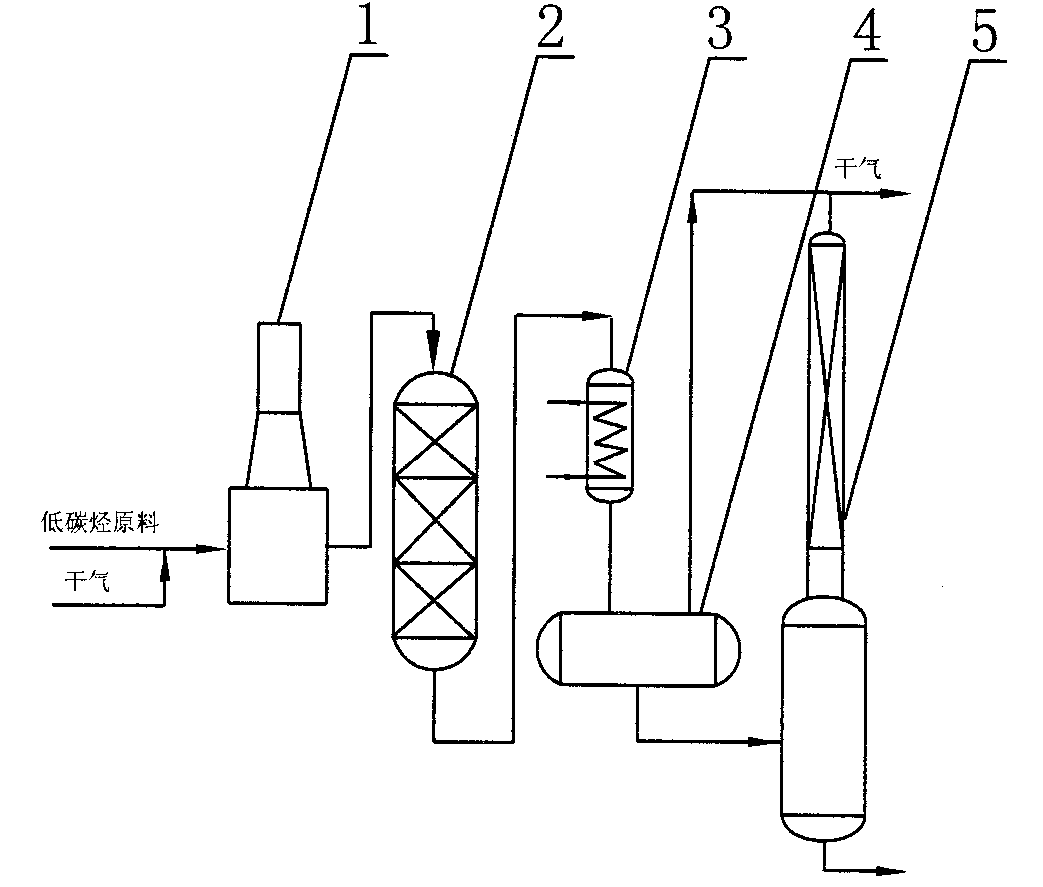

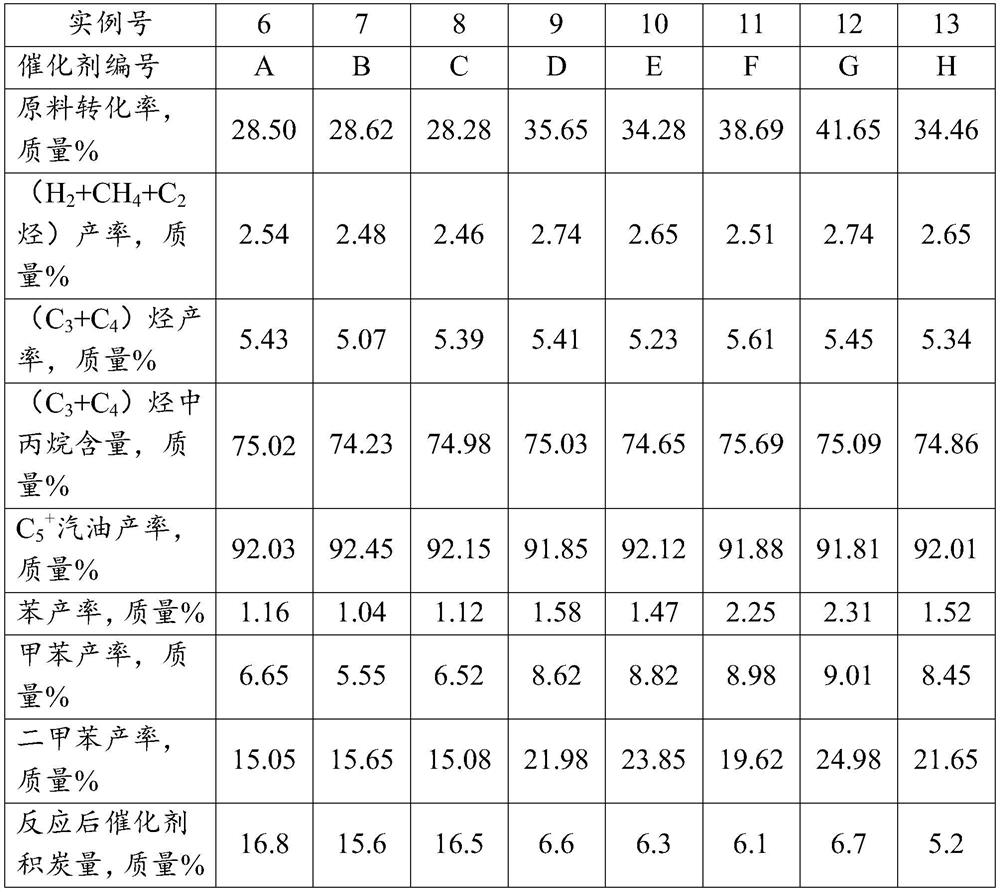

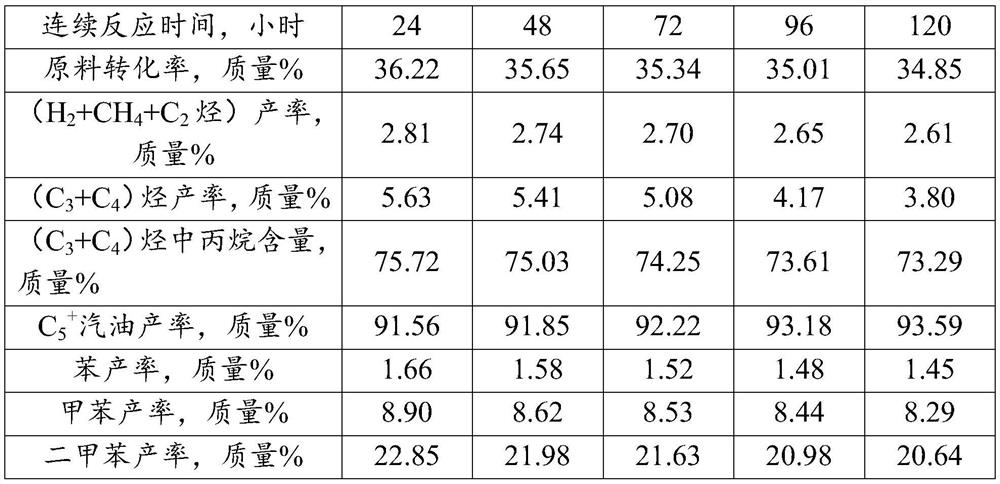

Method for improving quality and reaction period in production of gasoline by using low-carbon hydrocarbons

ActiveCN101880546BReduce the ratioRaise the ratioLiquid hydrocarbon mixtures productionAromatizationGasoline

Owner:SHANDONG DAQI PETROLEUM CHEM DESIGN

Metathesis catalysts and methods for the production of olefins

ActiveCN107438482BExtend your lifeHigh activityMolecular sieve catalystsMolecular sieve catalystPtru catalystEngineering

The present invention provides a catalyst comprising a transition metal, an inorganic support, a zeolite and a layered double hydroxide. The use of catalysts according to the invention in olefin production processes exhibits high activity and high selectivity with reduced deactivation rates, thus enabling longer reaction cycles and prolonging catalyst life.

Owner:SMH CO LTD

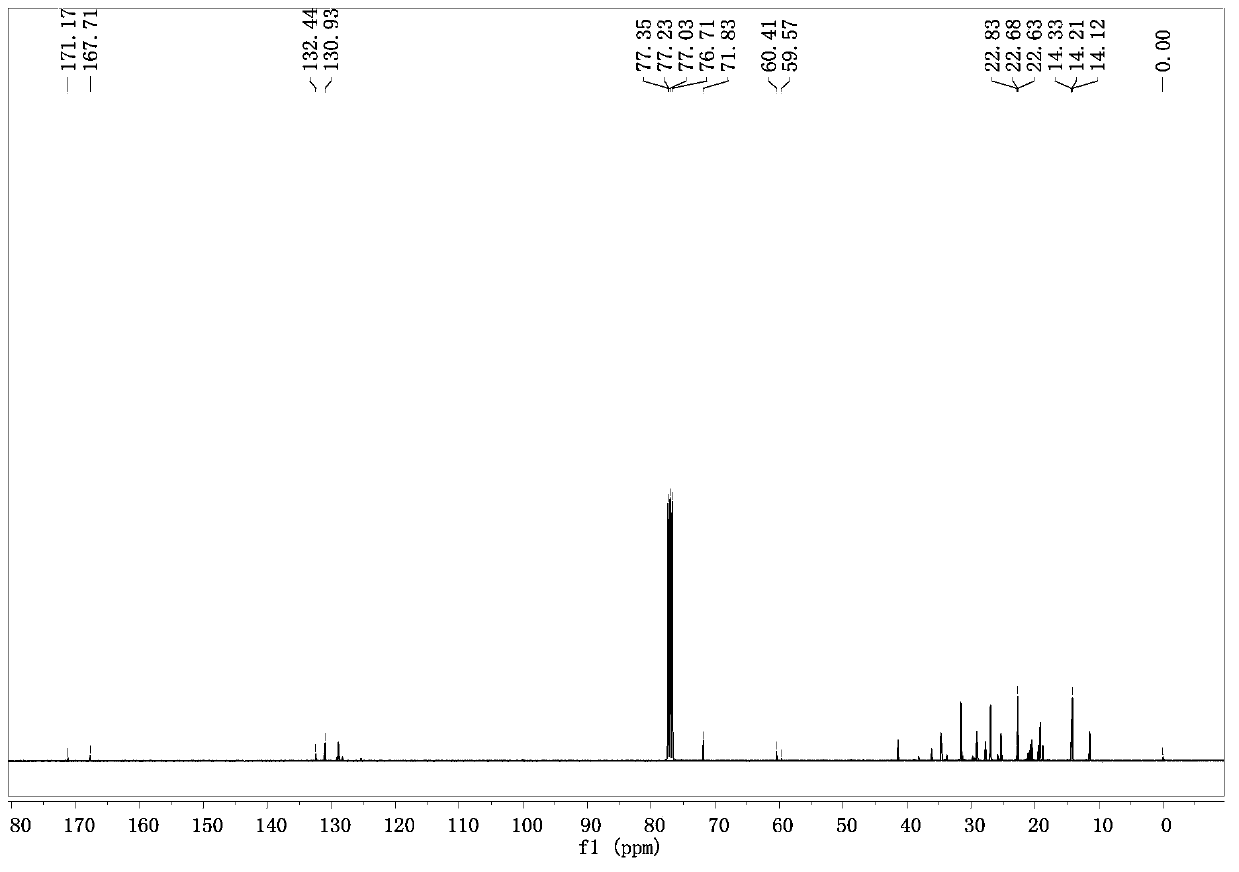

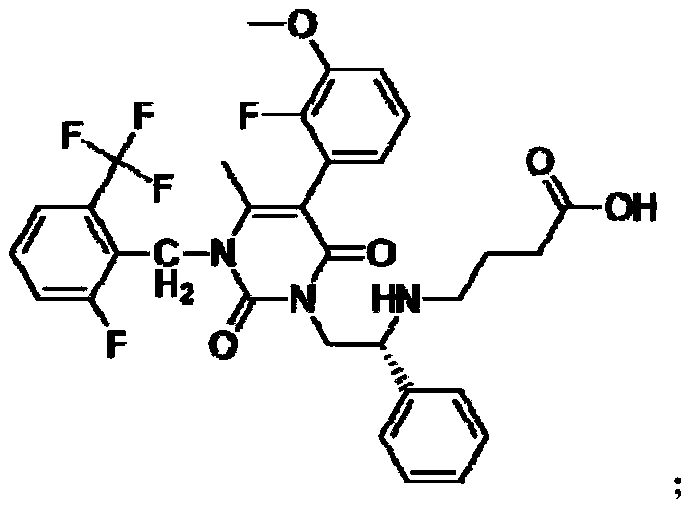

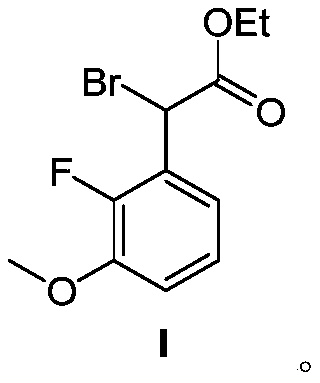

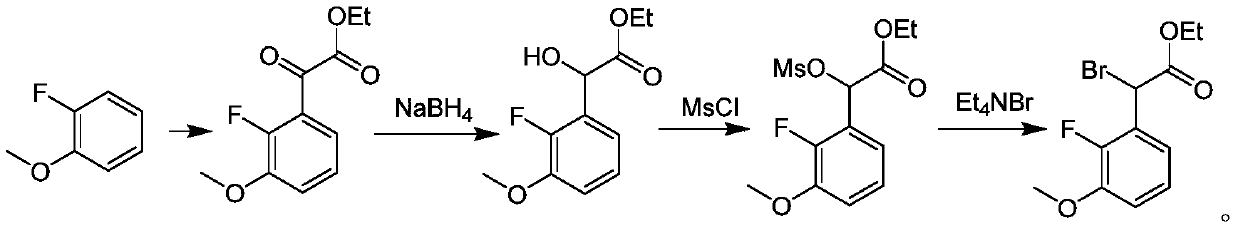

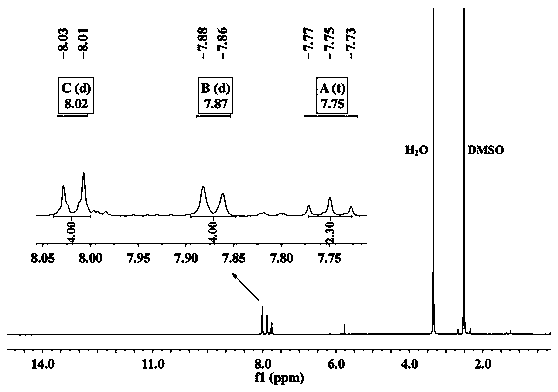

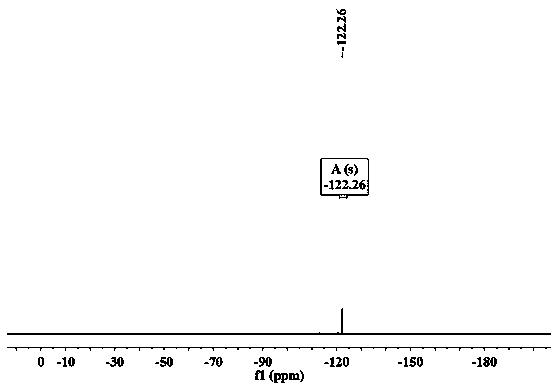

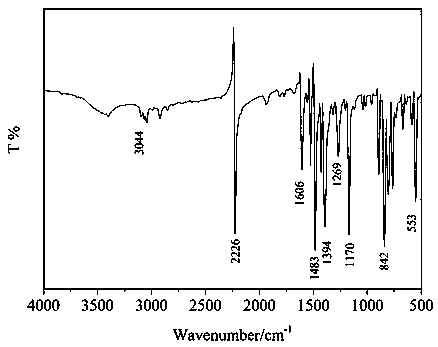

Synthesis method of 2-bromo-2-(2-fluoro-3-methoxyphenyl)ethyl acetate

InactiveCN109704961AFew reaction stepsLong reaction cycleOrganic compound preparationCarboxylic acid esters preparationAcetic acidSynthesis methods

The invention discloses a synthesis method of 2-bromo-2-(2-fluoro-3-methoxyphenyl)ethyl acetate. The synthesis route is as shown as the follows. The synthesis method comprises the following two stepsof synthesizing a compound represented by a formula I and synthesizing a compound represented by a formula VI. The target compound is prepared by adopting a two-step method according to the synthesisscheme disclosed by the invention, reaction energy consumption is low, "three wastes (waste gas, waste water and industrial residue)" are few, the preparation period is short, and impurity productioncapacity is low.

Owner:安徽华胜医药科技有限公司

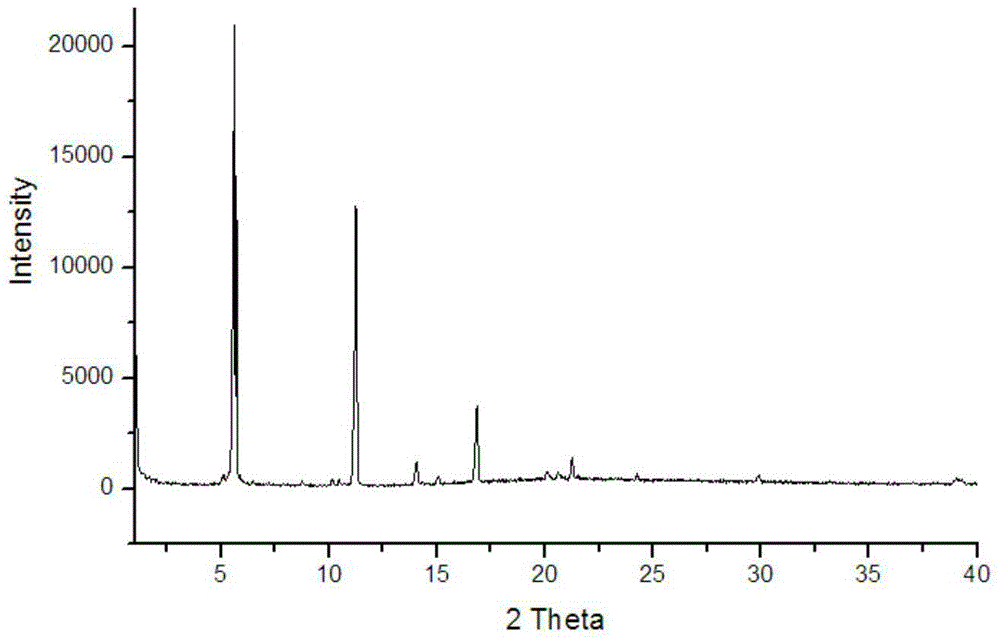

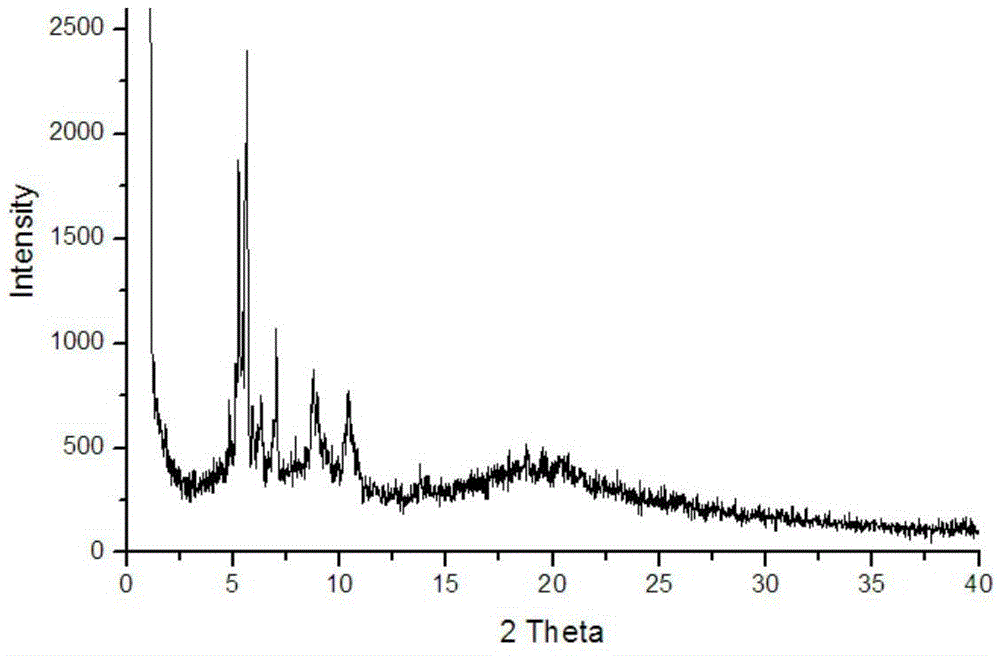

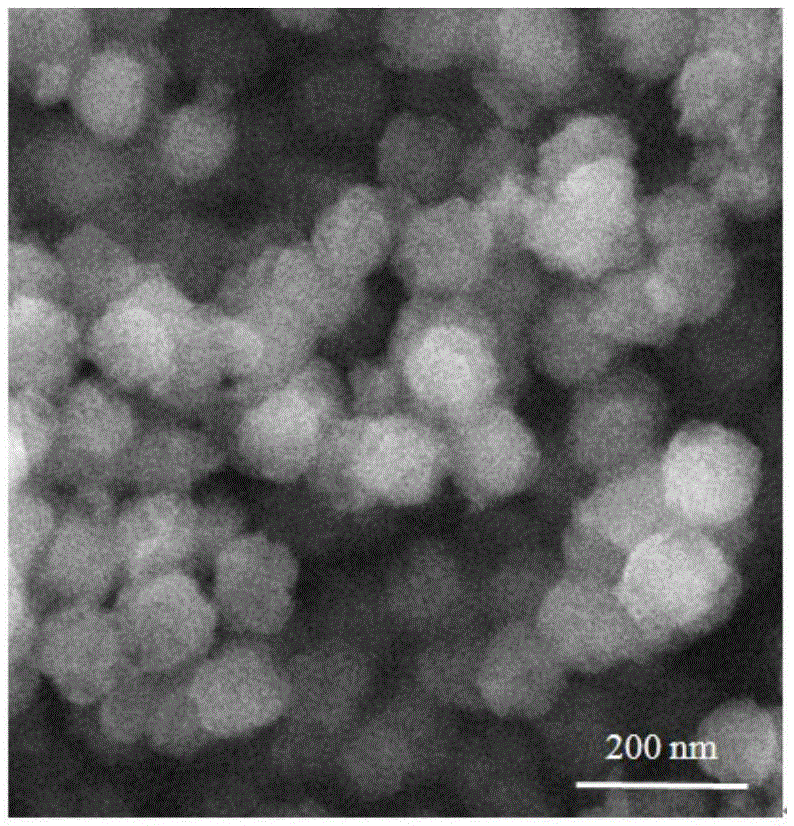

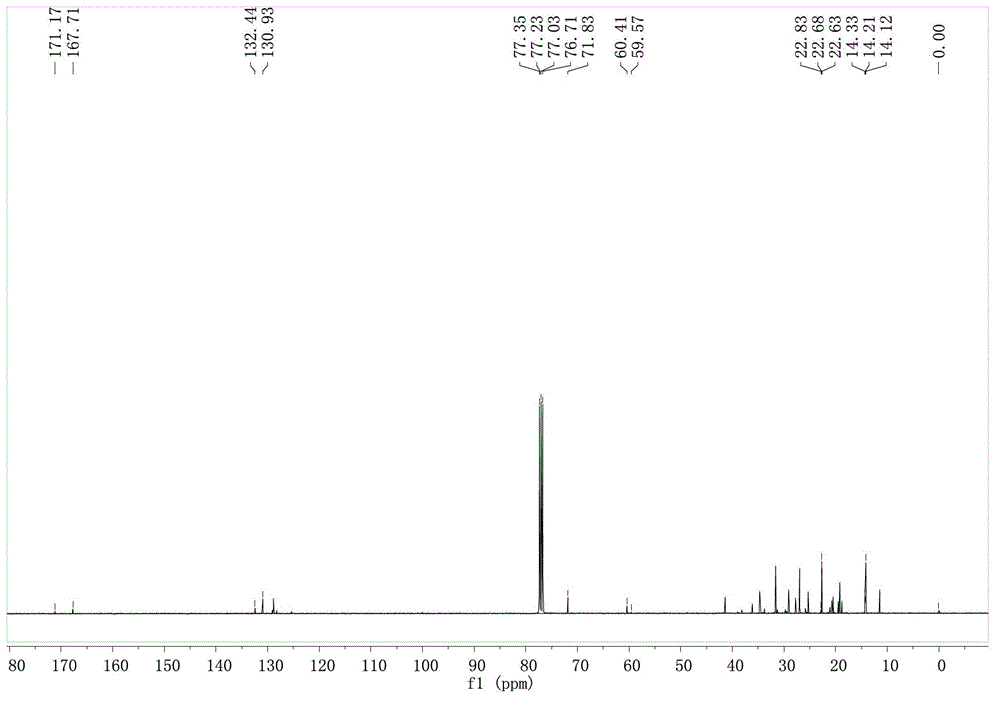

Preparation method and application of a water-stable nanocomplex

InactiveCN104774185BSimple methodReduce energy consumptionOrganic chemistryOther chemical processesN dimethylformamidePotassium hydroxide

Owner:孙欣雨

A kind of synthetic method of mercapto functionalized polyaryl carboxylic acid compound

InactiveCN104447452BImprove protectionLong reaction cycleThiol preparationPalladium catalystCarboxylic acid

The invention relates to the technical field of compound synthesis and in particular discloses a synthetic method of a mercapto functionalized polyaryl carboxylic acid compound. The synthetic method concretely comprises the following steps: in the presence of a palladium catalyst, putting aryl fluoride, aryl boric acid and alkali metal salt serving as raw materials into a mixed system of water / organic solvent, and carrying out a series of subsequent reactions including Suzuki reaction to obtain the mercapto functionalized polyaryl carboxylic acid compound. According to the synthetic method disclosed by the invention, as the Suzuki reaction is realized in the air environment firstly, the reaction condition is greatly simplified, the reaction time is shortened from 2d to 1h, and the productivity and the yield are greatly increased; in addition, by adopting the environment-friendly solvent, the environment is beneficially protected; the mercapto functionalized polyaryl carboxylic acid compound synthesized by utilizing the synthetic method can be largely applied to metal organic compounds to build a series of novel porous materials with novel structures and excellent performances.

Owner:GUANGDONG UNIV OF TECH

A high-efficiency and environment-friendly catalyst for regeneration of waste tire oil

ActiveCN104399512BGreat tasteLimit depositionCatalytic crackingMolecular sieve catalystsPour pointPollution

Owner:山东久硕环保科技有限公司

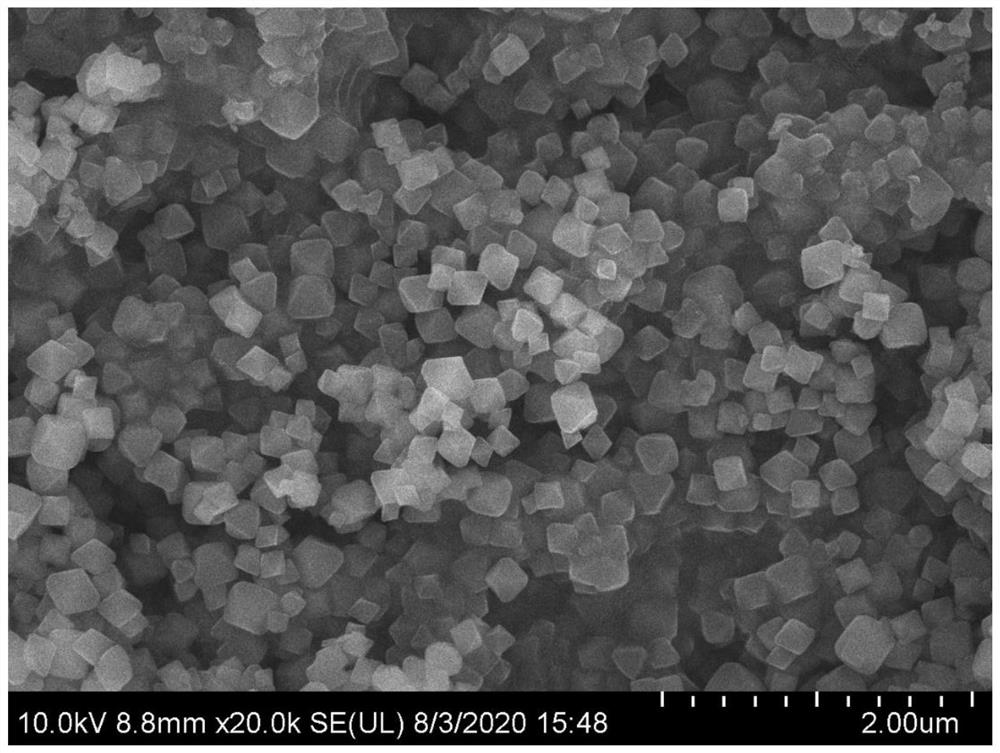

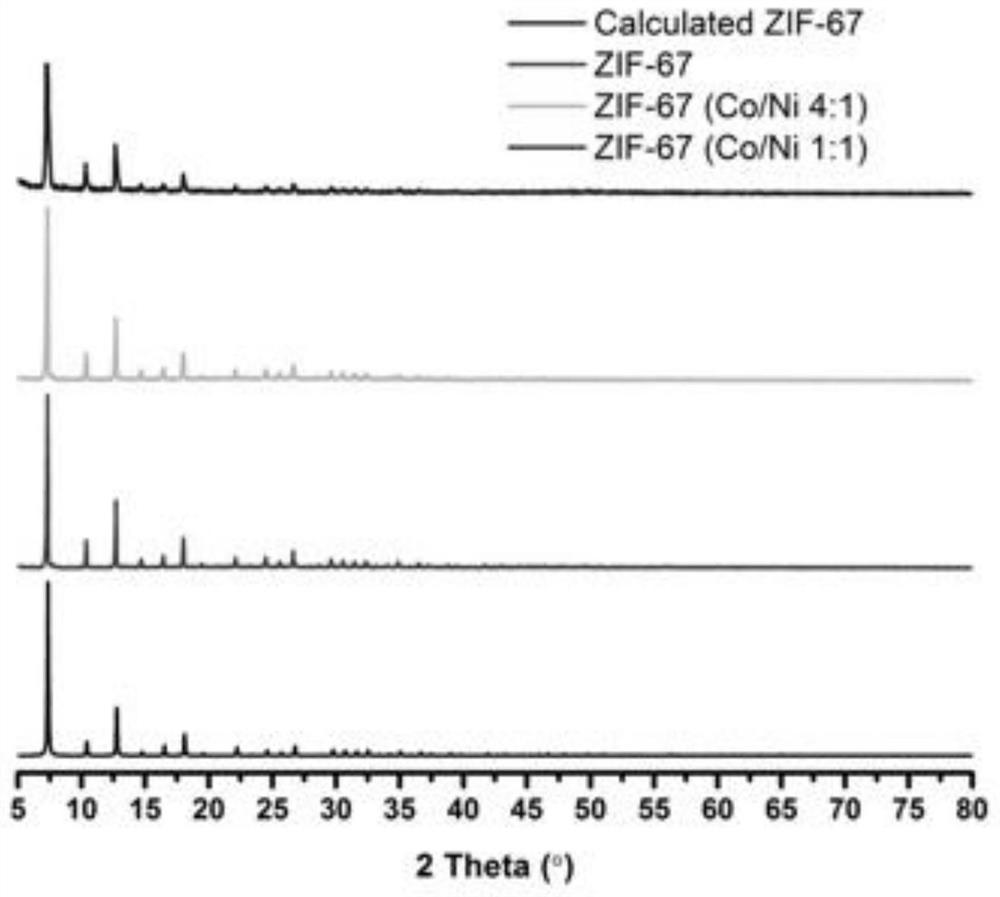

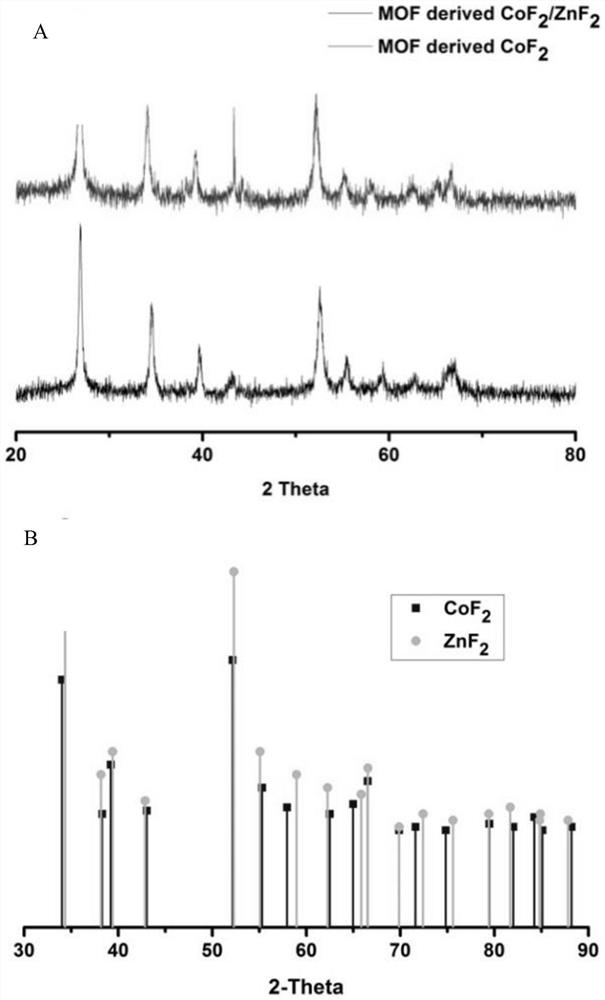

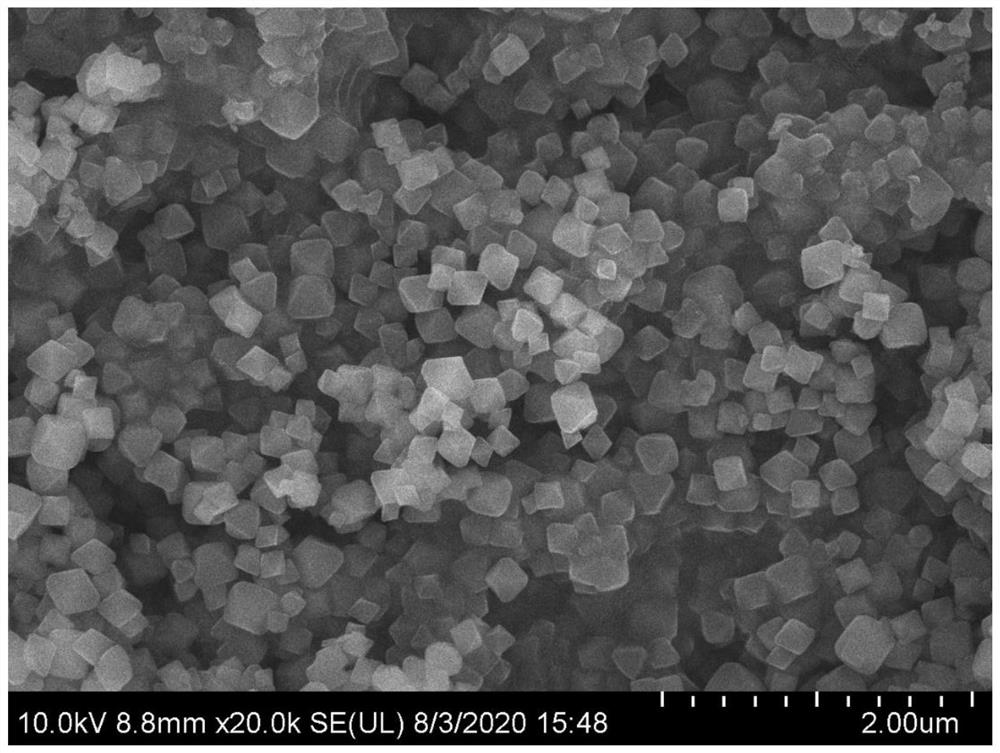

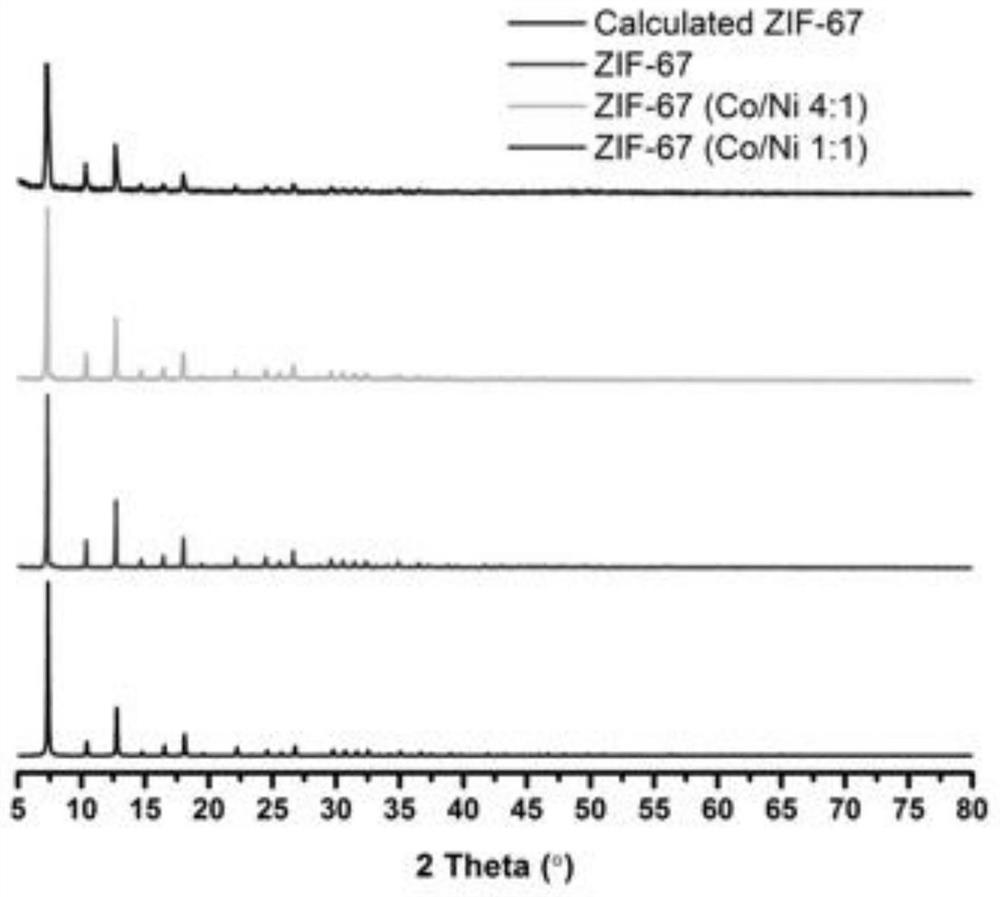

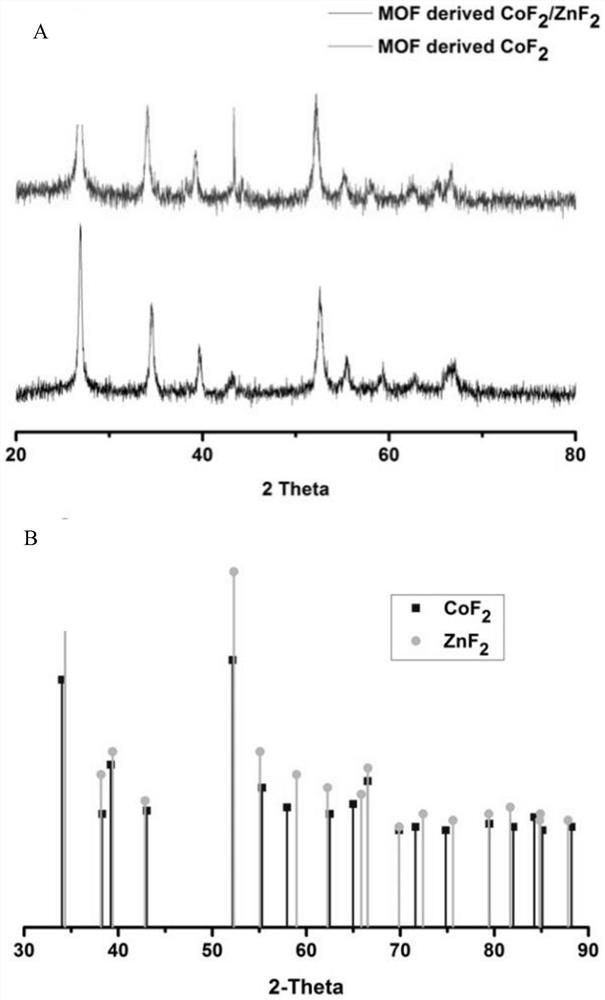

Bimetal fluoride, preparation method thereof and application of bimetal fluoride in lithium-free positive electrode

ActiveCN113394394AEasy to cleanDoping ratio controllablePositive electrodesLi-accumulatorsMetal frameworkFluoride

The invention provides a bimetallic fluoride, a preparation method thereof and an application of the bimetallic fluoride in a lithium-free positive electrode. The preparation method comprises the following steps: selecting a transition metal-based organic metal framework material as a metal framework precursor, selecting common transition metal nitrate as a doping element source, and doping the transition metal-based organic metal framework material with other types of transition metal elements to obtain a multi-metal cation framework; and further carrying out fluoridation treatment on the bimetallic fluoride to prepare the bimetallic fluoride. The bimetallic fluoride has a uniform pore structure and a high ion / electron mixed conductive support structure, so that the capacity of the metal fluoride can be efficiently utilized, and the technical defects of low capacity utilization rate, large voltage lag and poor cycling stability of a traditional metal fluoride cathode in the prior art are effectively overcome.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation of diisobutyl phthalate by electrocatalytic degradation of lignin in a fixed bed reactor

ActiveCN103469243BLong reaction cycleIncreased cost of industrializationOrganic chemistryElectrolysis componentsElectrochemical degradationAuxiliary electrode

The invention is a method for electrochemically degrading lignin to prepare diisobutyl phthalate. The method uses Ti / SnO 2- Sb 2 o 3 -Fe(NO 3 ) 3 / PbO 2 As the working electrode, the copper mesh electrode is used as the auxiliary electrode, the loaded activated carbon is used as the third electrode, and the standard saturated calomel electrode is used as the reference electrode to form a three-dimensional fixed-bed reactor for electrocatalytic degradation of lignin, combined with continuous electrocatalytic degradation The integrated process of separation with solvent extraction enables the degradation products to be separated from the lignin alkali solution quickly. The present invention combines the integrated process of continuous electrocatalytic degradation and solvent extraction separation with electrocatalytic degradation of lignin, which has mild reaction conditions, simple and easy-to-operate process technology, and better development and use of lignin, a by-product of paper mills, to obtain The fine chemical product diisobutyl phthalate has good industrial application value. <pb pnum="1" / >

Owner:HEBEI UNIV OF TECH

Synthetic preparation method of wintergreen oil

ActiveCN109456184APromote decompositionConsume moreOrganic compound preparationCarboxylic acid esters preparationChemical synthesisCatalytic method

The invention relates to the field of chemical synthesis, and particularly discloses a synthetic preparation method of wintergreen oil. The synthetic preparation method comprises the following steps:(1) methanol, salicylic acid and methyl carboxylate are sequentially put into a reaction kettle according to the molar ratio of (2 to 3):1:(0.1 to 0.3); (2) a synthetic reaction is generated under theconditions of heating and pressurization, and a mixed solution A containing the wintergreen oil is obtained; and (3) the mixed solution A is distilled and separated to obtain the wintergreen oil. According to the method, the defects of a traditional concentrated sulfuric acid catalytic method are overcome, and the methyl carboxylate serves as a catalyst, so that the beneficial effects that raw materials are easy to obtain, the reaction flow is simple, the catalyst can be removed only through simple distillation, subsequent treatment is easy, and the prepared wintergreen oil is large in product purity and high in conversion rate are achieved.

Owner:江西省隆南药化有限公司

A kind of bimetallic fluoride and its preparation method and application in lithium-free positive electrode

ActiveCN113394394BEasy to cleanDoping ratio controllablePositive electrodesLi-accumulatorsMetal frameworkLow voltage

The invention provides a double metal fluoride, a preparation method thereof and an application in a lithium-free positive electrode. The preparation method is as follows: selecting a transition metal-based organic metal framework material as a metal framework precursor, selecting a commonly used transition metal nitrate as a doping element source, and doping the transition metal-based organic metal framework material with other types of transition metal elements , thus obtaining a multimetallic cation framework, and then further fluorinating it to prepare the obtained double metal fluoride. The bimetallic fluoride has a uniform pore structure and a high ion / electronic mixed conductive scaffold structure, so that the capacity of the metal fluoride can be efficiently utilized, effectively overcoming the capacity utilization of the traditional metal fluoride cathode in the prior art The technical defects of low voltage, large voltage hysteresis, and poor cycle stability.

Owner:HUAZHONG UNIV OF SCI & TECH

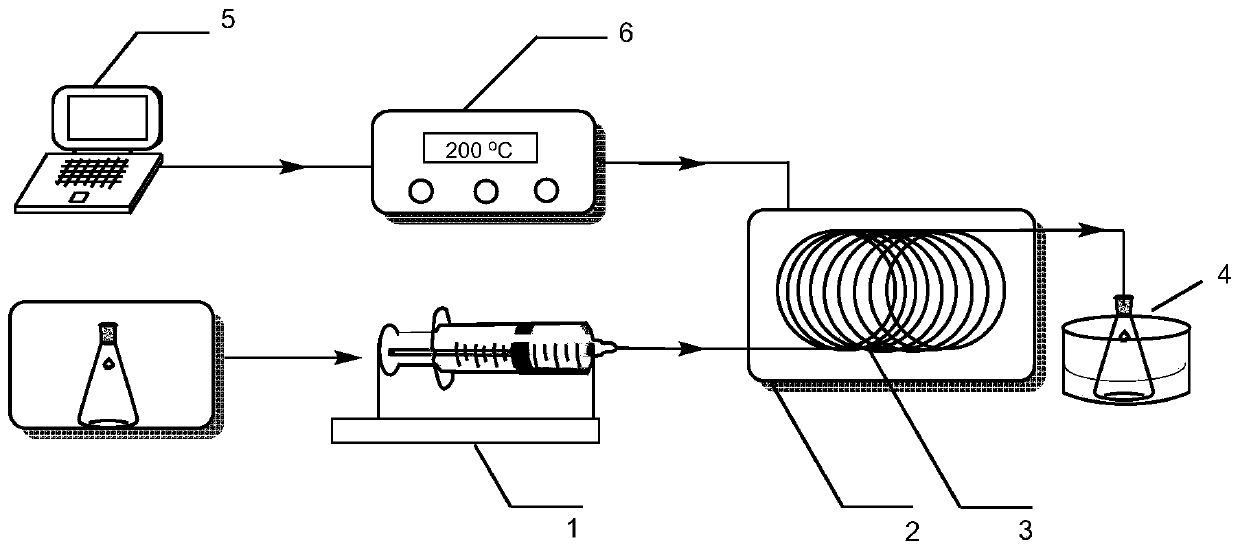

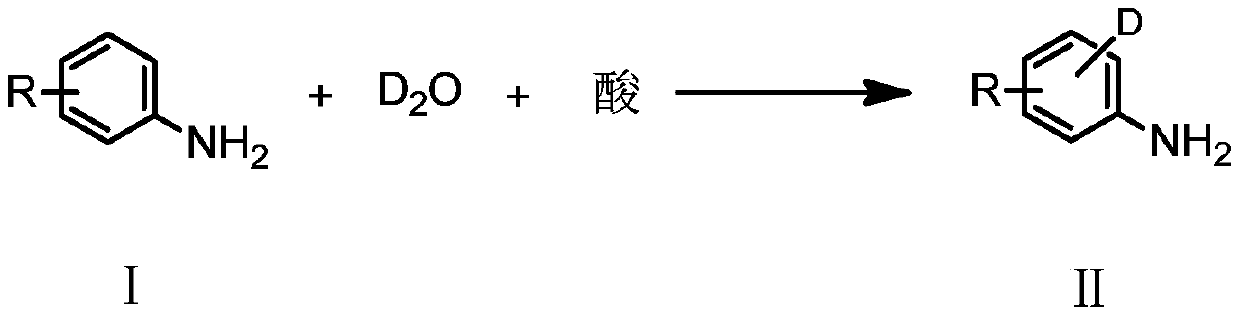

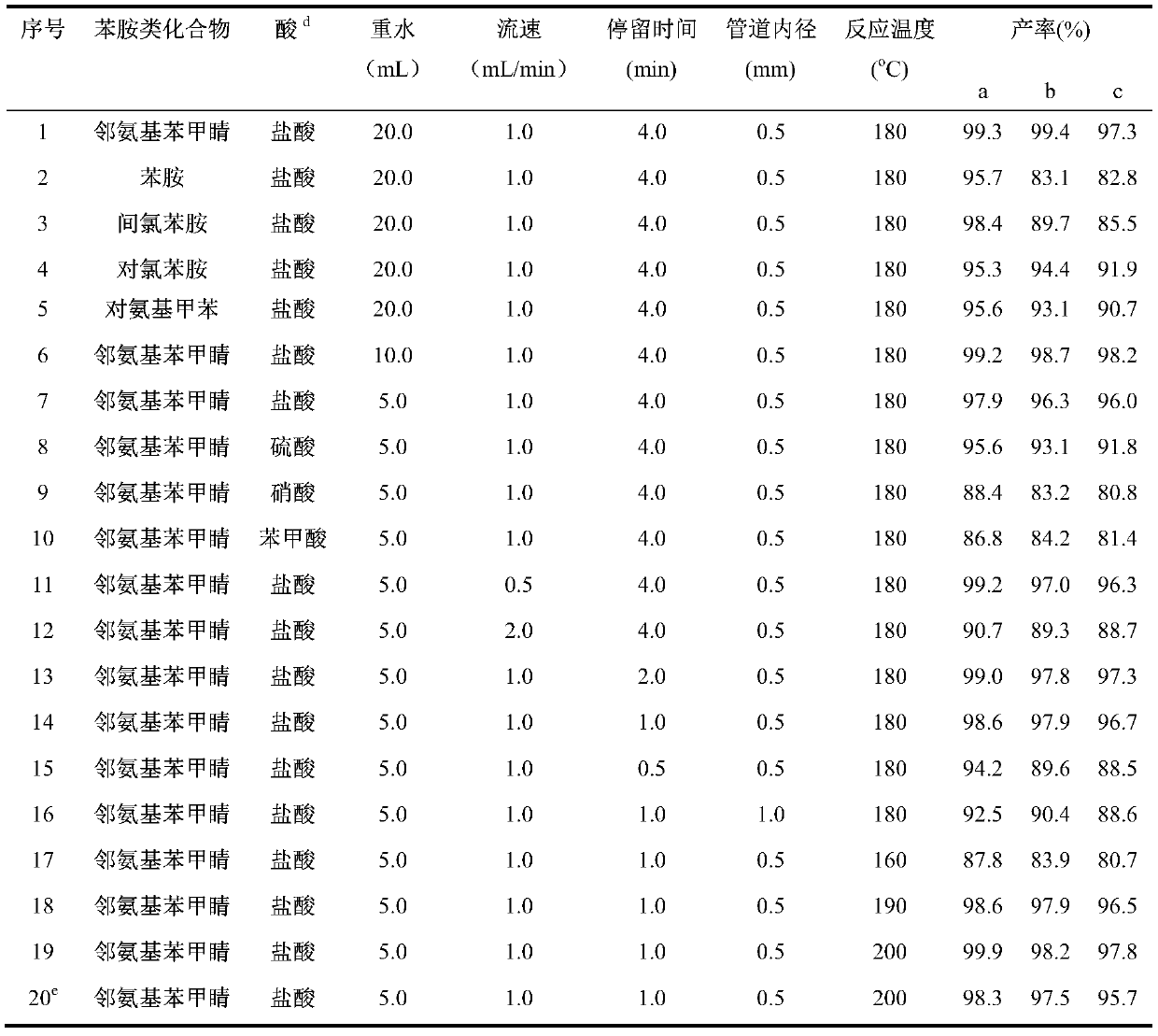

A kind of method utilizing microchannel reaction device to prepare deuterated aniline compounds

ActiveCN106892790BEffective collisionAvoid disadvantagesCarboxylic acid nitrile preparationAmino preparation from aminesUltrasound - actionDeuterated benzene

The invention discloses a method for preparing a d-phenylanine compound by using a microchannel reaction device. The method comprises the following steps: (1) mixing an aniline compound I, an acid and heavy water, implementing ultrasonic treatment evenly to obtain a mixed solution; and (2) pumping the mixed solution obtained in the step (1) into a microchannel reactor of the microchannel reaction device, reacting under the action of a microwave field or ultrasonic wave; and collecting a reaction liquid after finishing the reaction to obtain the d-phenylanine compound II. The method has the advantages of higher conversion rate, higher deuterium content, higher yield and reduction of the quantity of the heavy water used in the reaction. Therefore, the post-processing is simple, and a high-purity product is obtained.

Owner:NANJING TECH UNIV

Heavy aromatics lightening catalyst as well as preparation method and application thereof

ActiveCN112439447ALong reaction cyclePromote regenerationMolecular sieve catalystsHydrocarbonsPtru catalystAromatic hydrocarbon

The invention discloses heavy aromatics lightening catalyst. The catalyst comprises a composite carrier and VA group element oxide with the content of 0.5-10.0% by mass calculated based on the composite carrier, and the composite carrier comprises 10-45% by mass of ZSM5 zeolite, 10-45% by mass of EU1 zeolite and 10-80% by mass of aluminum oxide. The catalyst is used for the non-hydrogen lighteningreaction of C9-C12 heavy aromatics, and can obtain higher light aromatic hydrocarbon yield and byproduct propane-rich high-quality liquefied gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for accelerating sludge anaerobic digest speed rate of sewage plant

InactiveCN1228259CAnaerobic digestion improvesIncreased rate of anaerobic digestionSludge processingBiological sludge treatmentReaction temperatureEconomic benefits

The present invention discloses a method for accelerating the anaerobic digestion rate of sewage plant sludge. Aiming at the current difficulty that the anaerobic digestion cycle of sludge is relatively long, it provides a method for accelerating the anaerobic digestion rate of sewage plant sludge. The method reacts The cycle is short, the cost is low, and the gas production can be increased at the same time, which has good economic benefits. The specific steps of the method for accelerating the anaerobic digestion rate of sewage plant sludge are: sieve the remaining sludge from the sewage plant with a sieve with a mesh size of 5-50 mm to remove impurities with larger particles; Irradiate it with high-penetrating γ-rays to control the radiation dose absorbed by the sludge at 2.48-30kGy; the irradiated sludge and the inoculated sludge are inoculated at a ratio of 1-5:1. For anaerobic digestion reaction, the stirring speed is controlled at 70-120 rpm, the reaction temperature is 20-60°C, and the reaction time is 10-20 days. This technology can be used in sludge treatment systems in sewage plants.

Owner:NANJING UNIV

A kind of synthetic preparation method of wintergreen oil

ActiveCN109456184BPromote decompositionConsume moreOrganic compound preparationCarboxylic acid esters preparationChemical synthesisMethanol water

The invention relates to the field of chemical synthesis, and specifically discloses a synthetic preparation method of wintergreen oil. The method comprises the following steps: (1) according to the molar ratio of 2-3:1:0.1-0.3, methanol, salicylic acid and methyl carboxylate are sequentially put into the reactor; (2) under the condition of heating and pressurizing , a synthesis reaction occurs to obtain a mixed solution A containing wintergreen oil; (3) distilling and separating the mixed solution A to obtain wintergreen oil. This method not only overcomes the defects of the traditional concentrated sulfuric acid catalytic method, but also uses methyl carboxylate as the catalyst, which has the advantages of easy access to raw materials, simple reaction process, simple distillation to remove the catalyst, and simple follow-up treatment. The prepared wintergreen oil has beneficial effects such as high product purity and high conversion rate.

Owner:江西省隆南药化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com