Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Large part" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

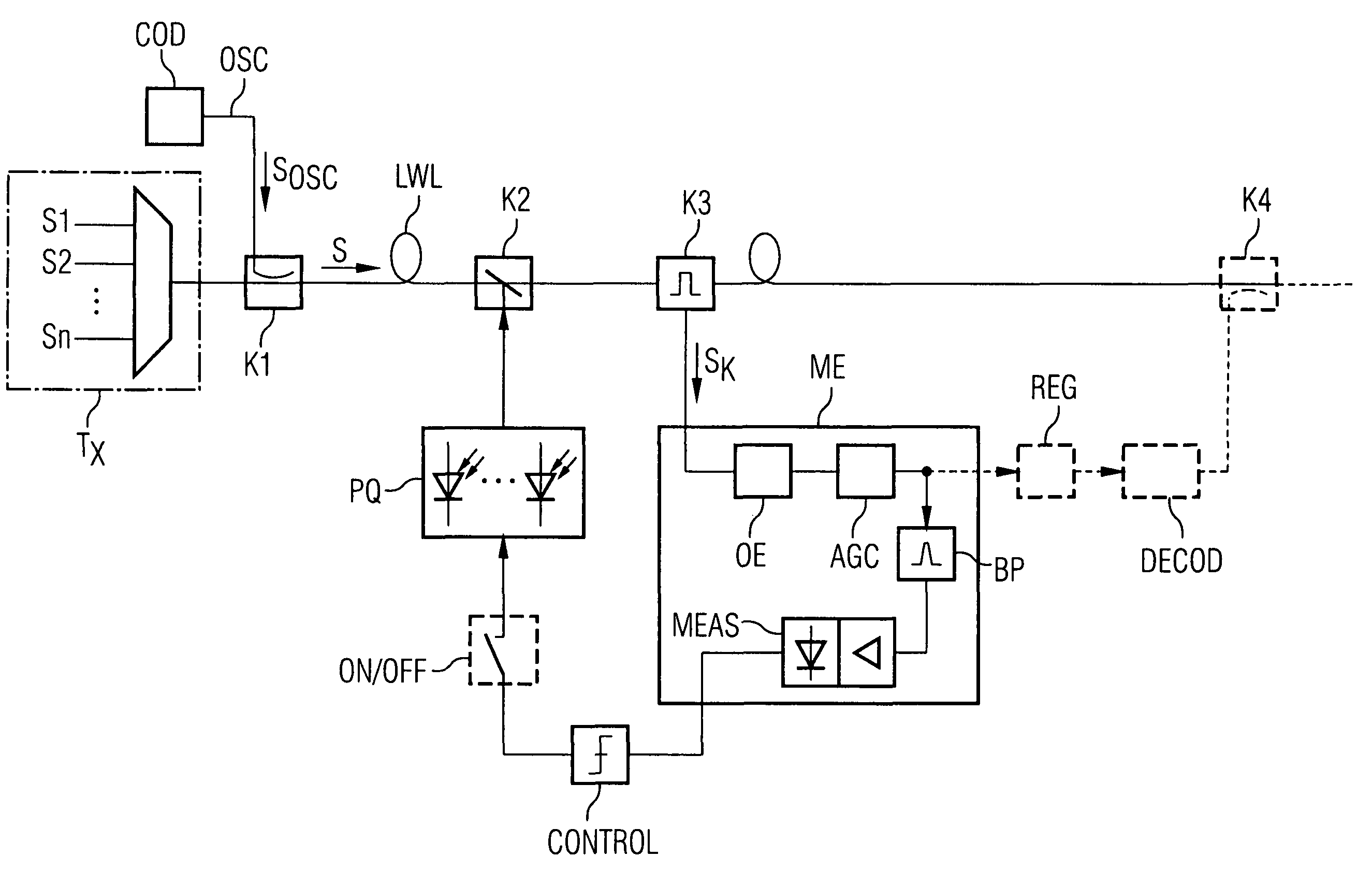

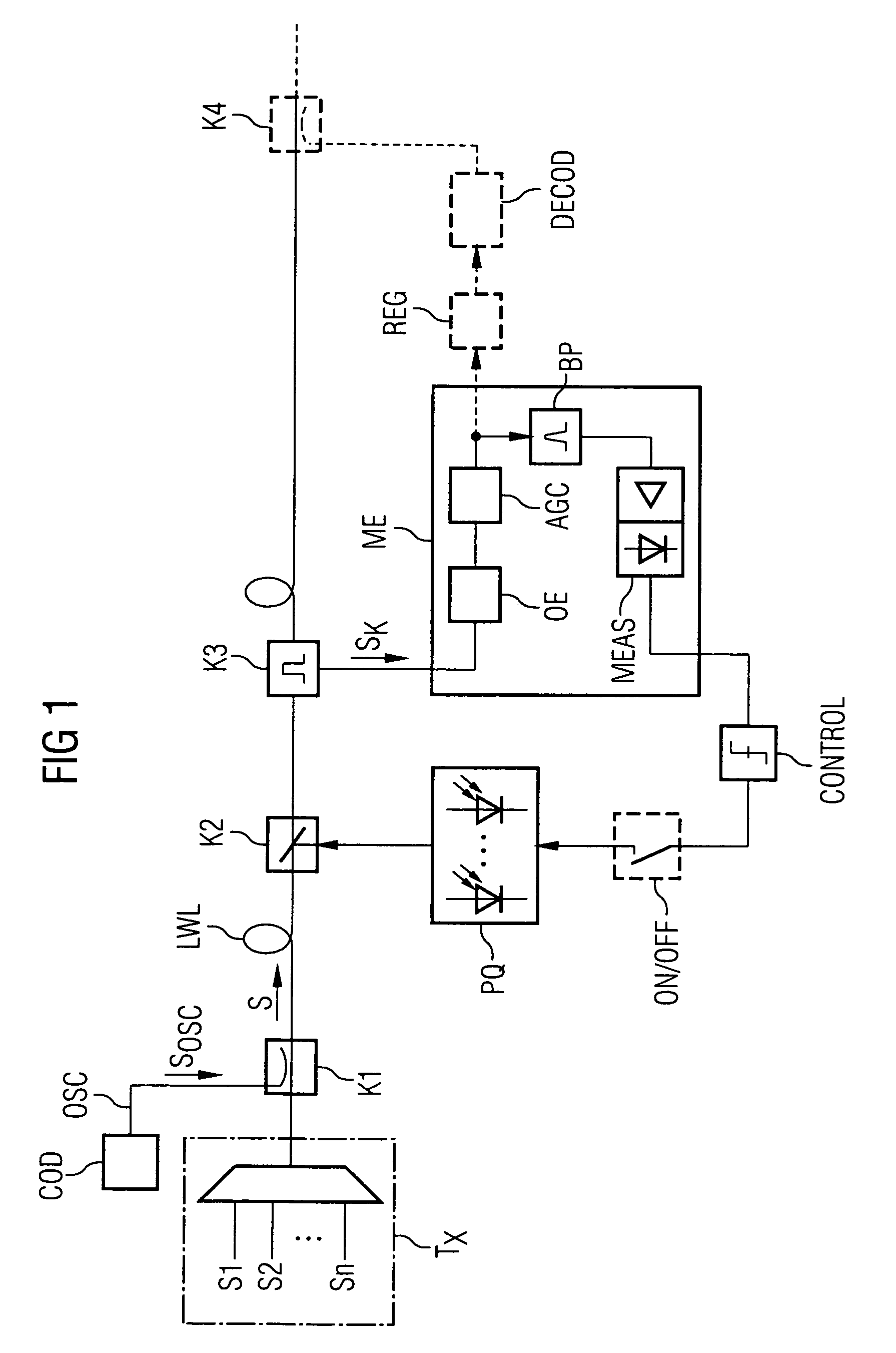

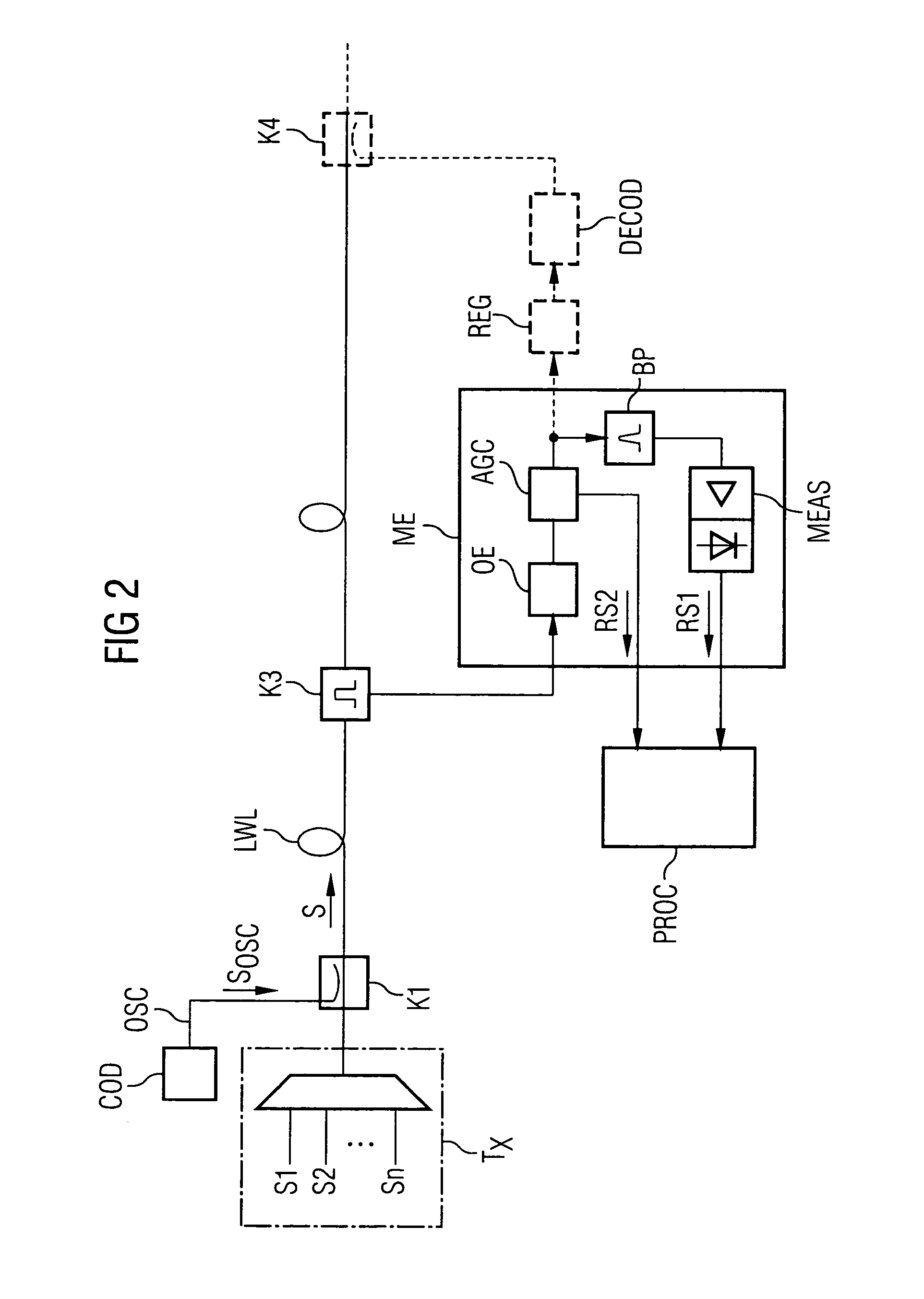

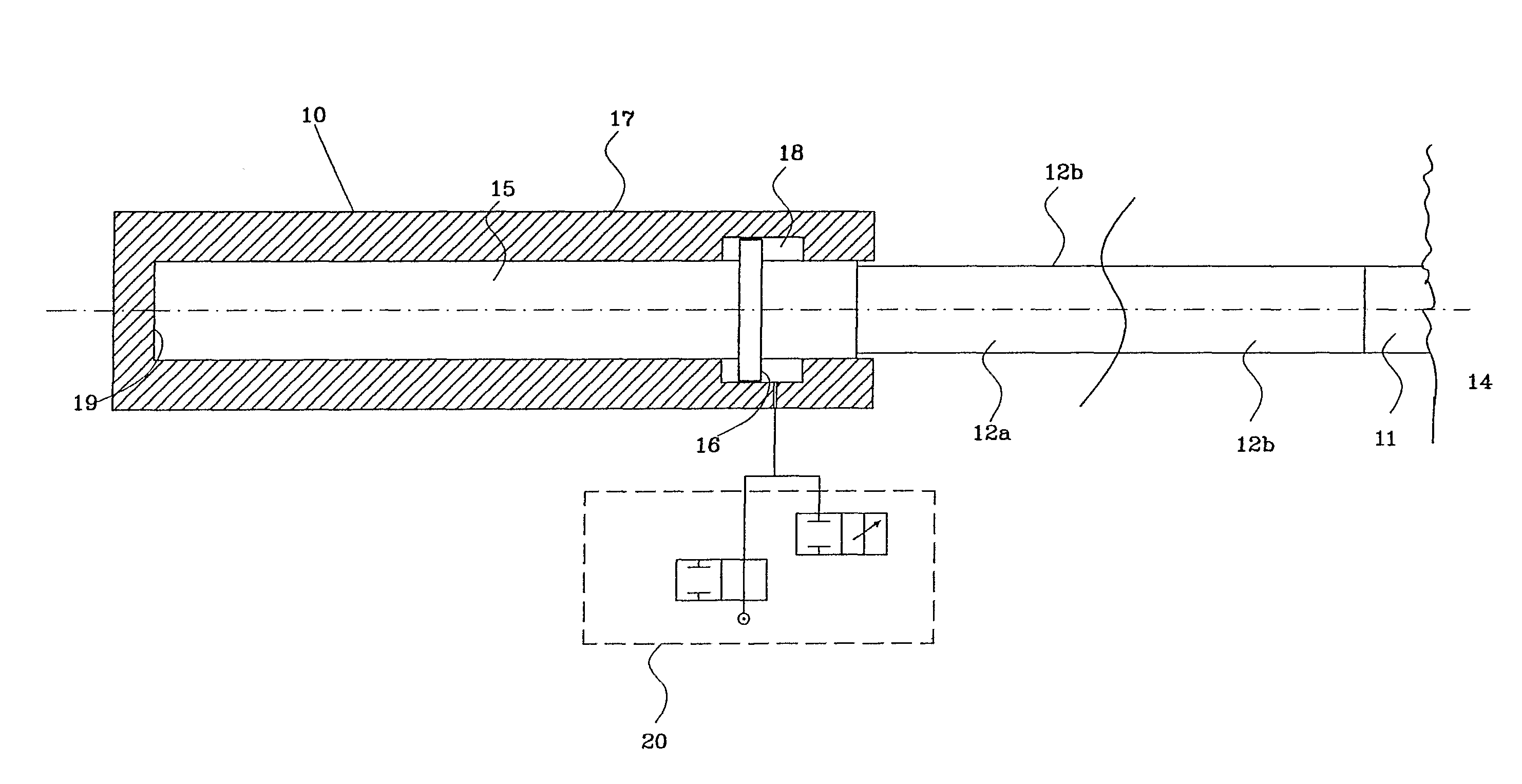

Method for detecting a check-back signal in an optical transmission system

InactiveUS7920787B2Increase productionSimple signalTransmission monitoringTransmission monitoring/testing/fault-measurement systemsUltrasound attenuationTransport system

The invention relates to a method for detecting a check-back signal in a transmission system for optical signals. According to said method, a constant proportion of the output in a defined frequency range of the check-back signal is concentrated in a narrow-band spectral range and is determined after a transmission phase by means of a narrow-band detection of the concentrated energy around the spectral range. If no signal is identified during the narrow-band detection, a line interruption is determined and no pump source is switched on for safety reasons. The narrow-band detection of the check-back signal also allows the transmission attenuation of the transmission system to be measured.

Owner:XIEON NETWORKS SARL

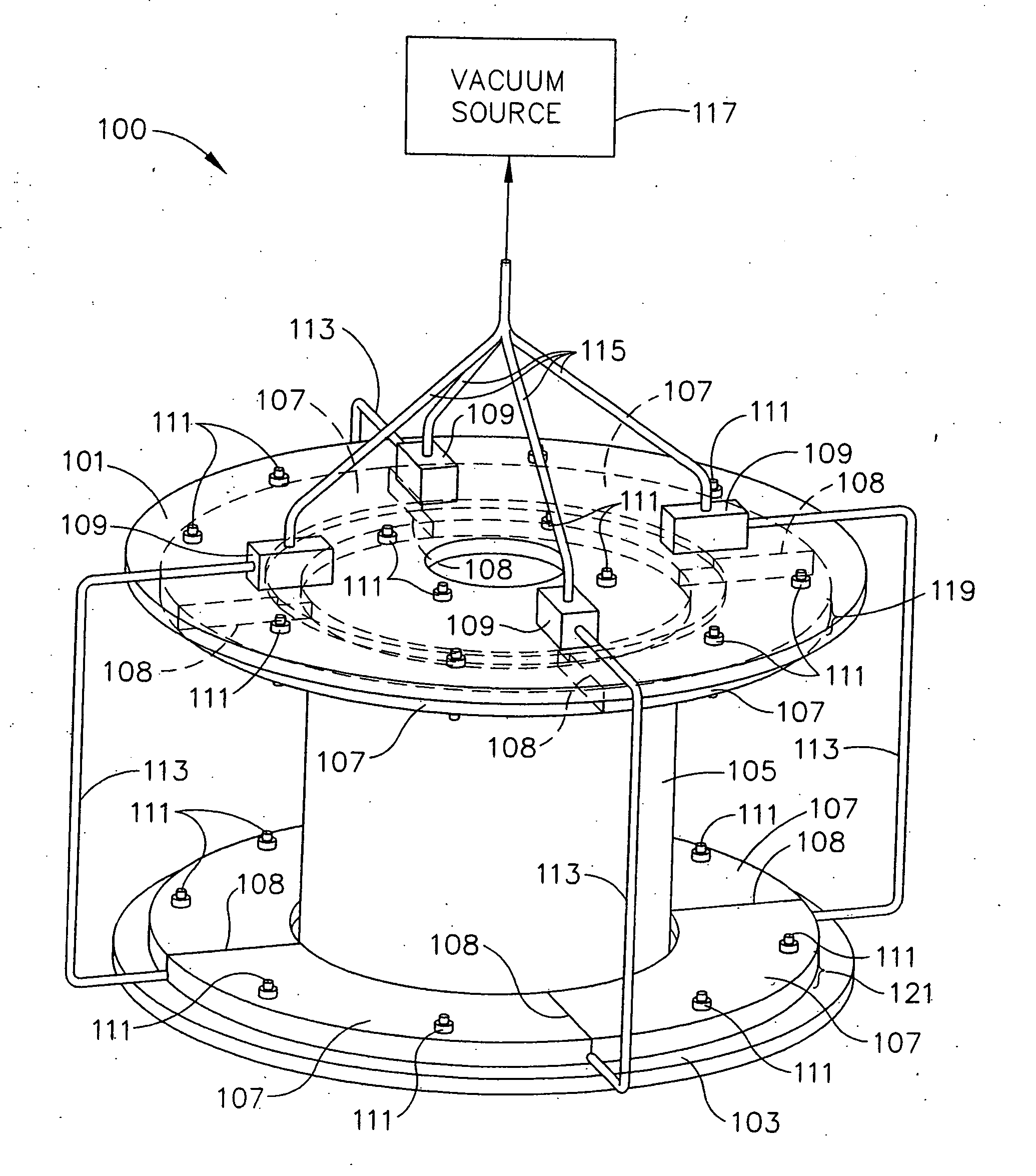

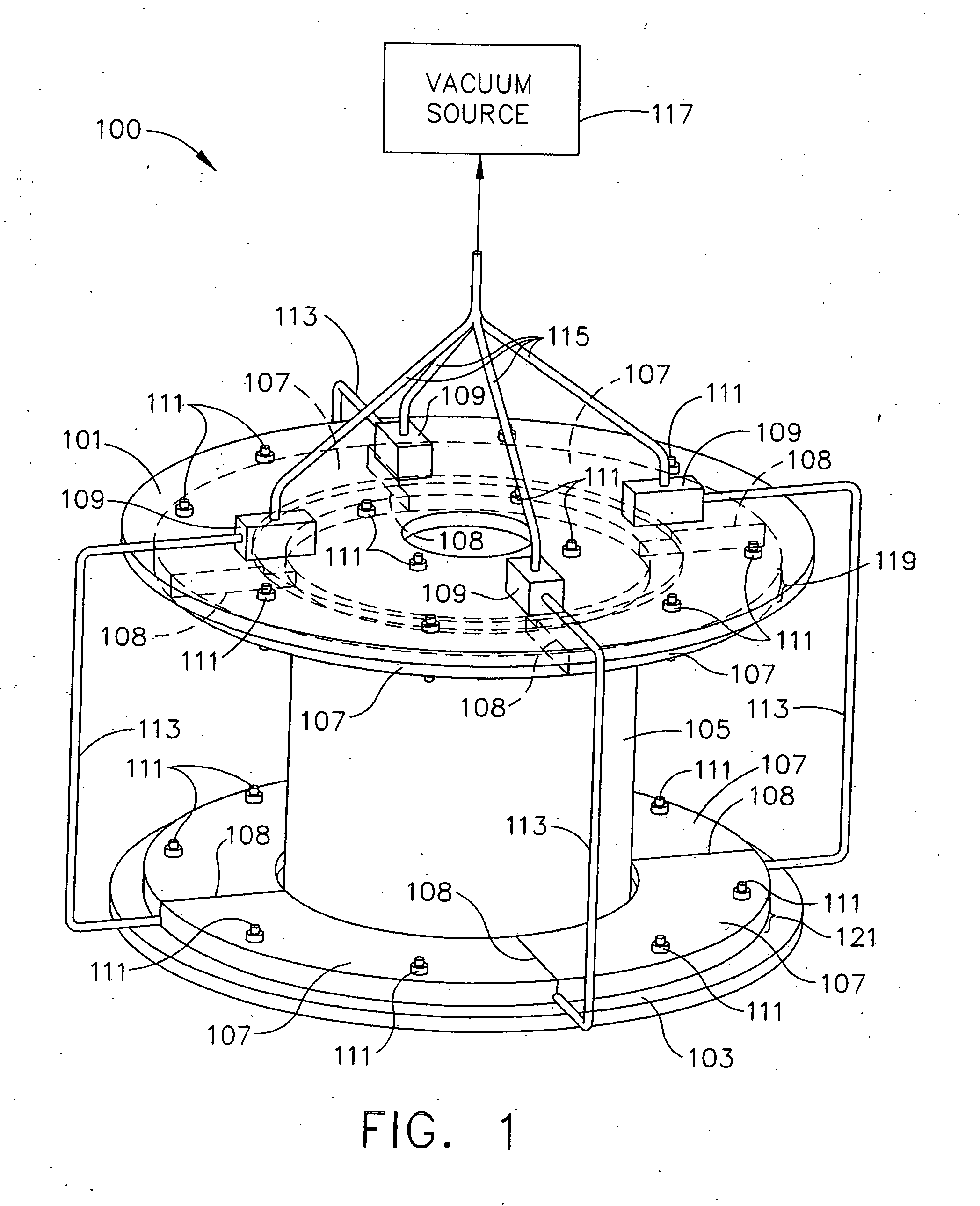

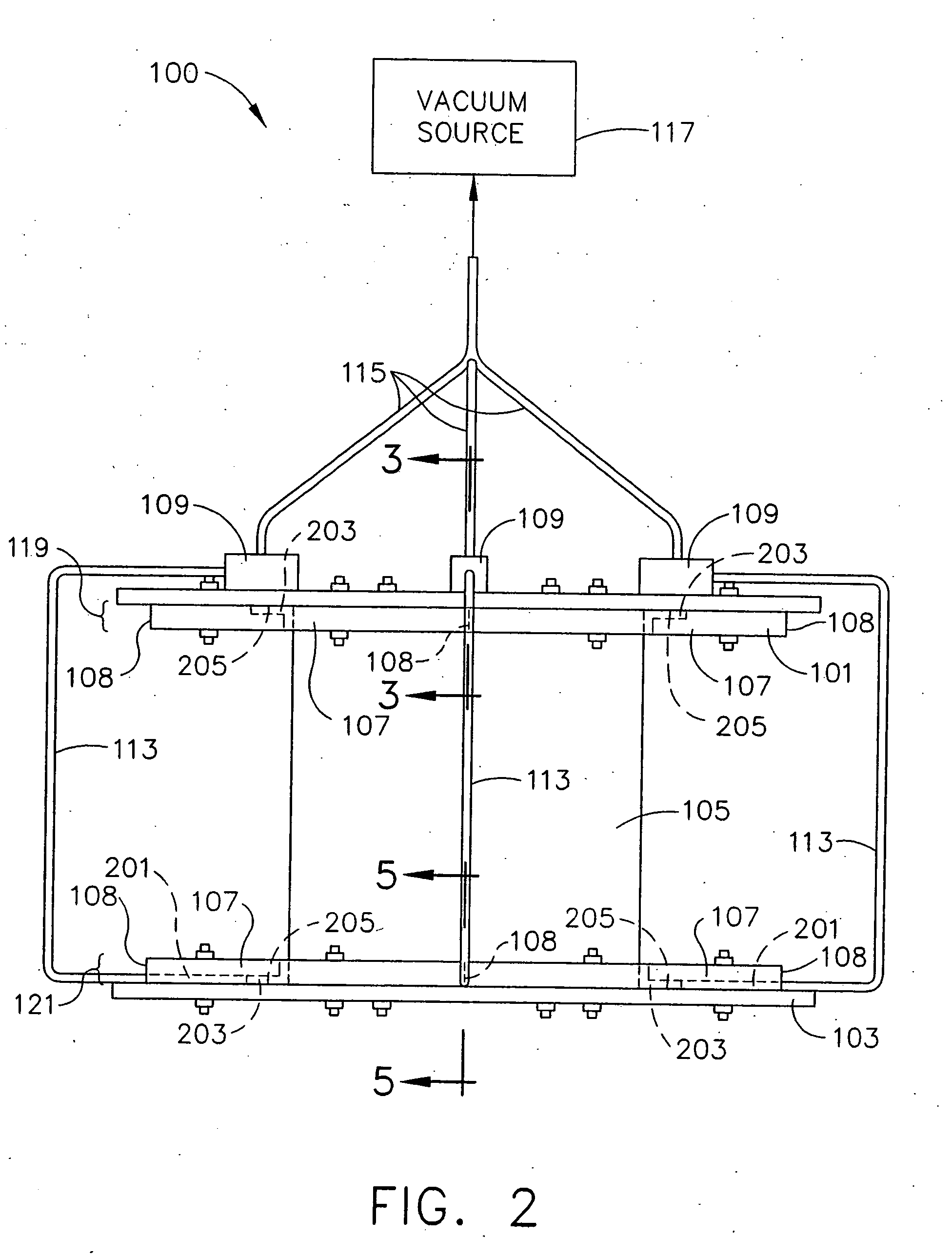

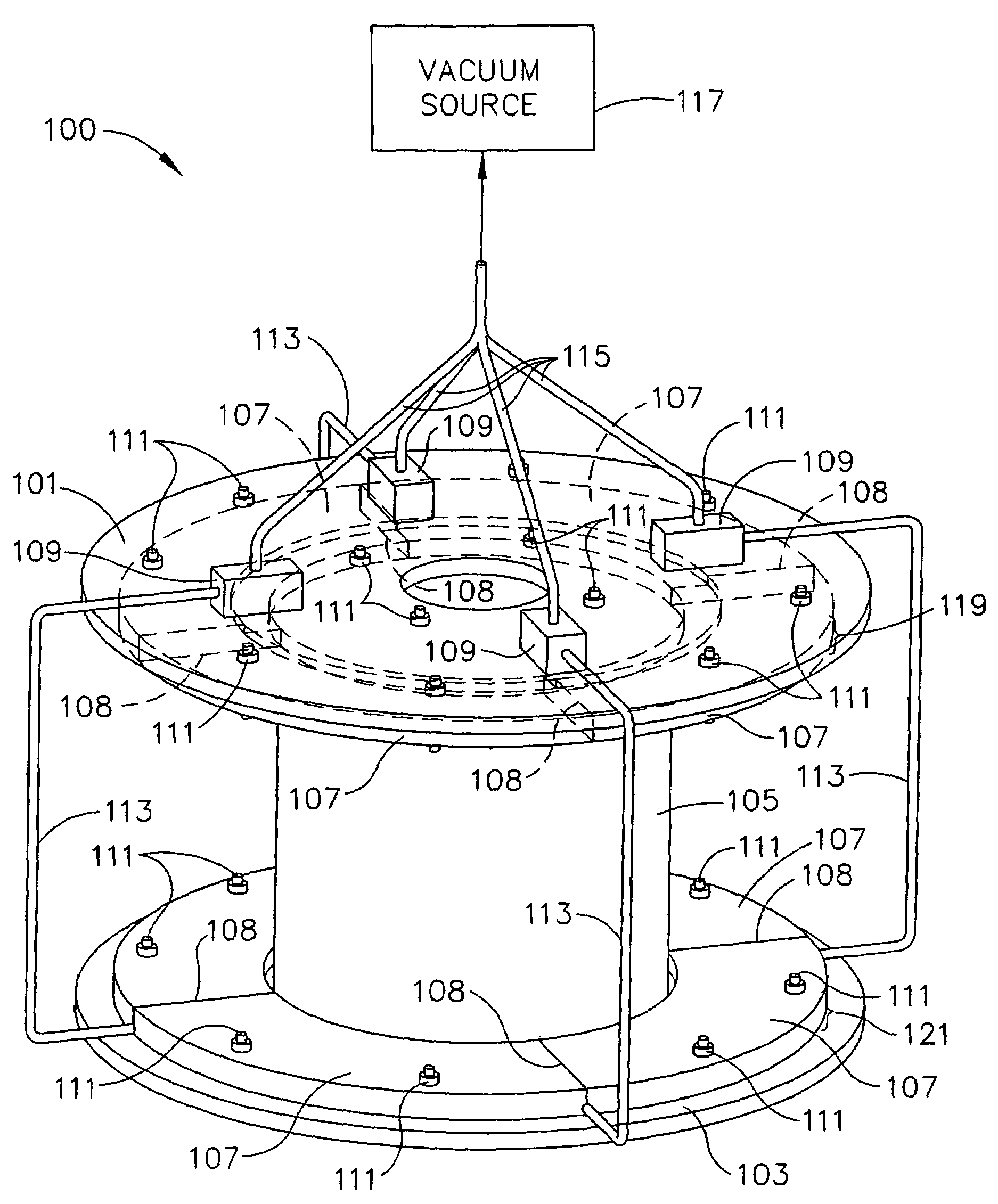

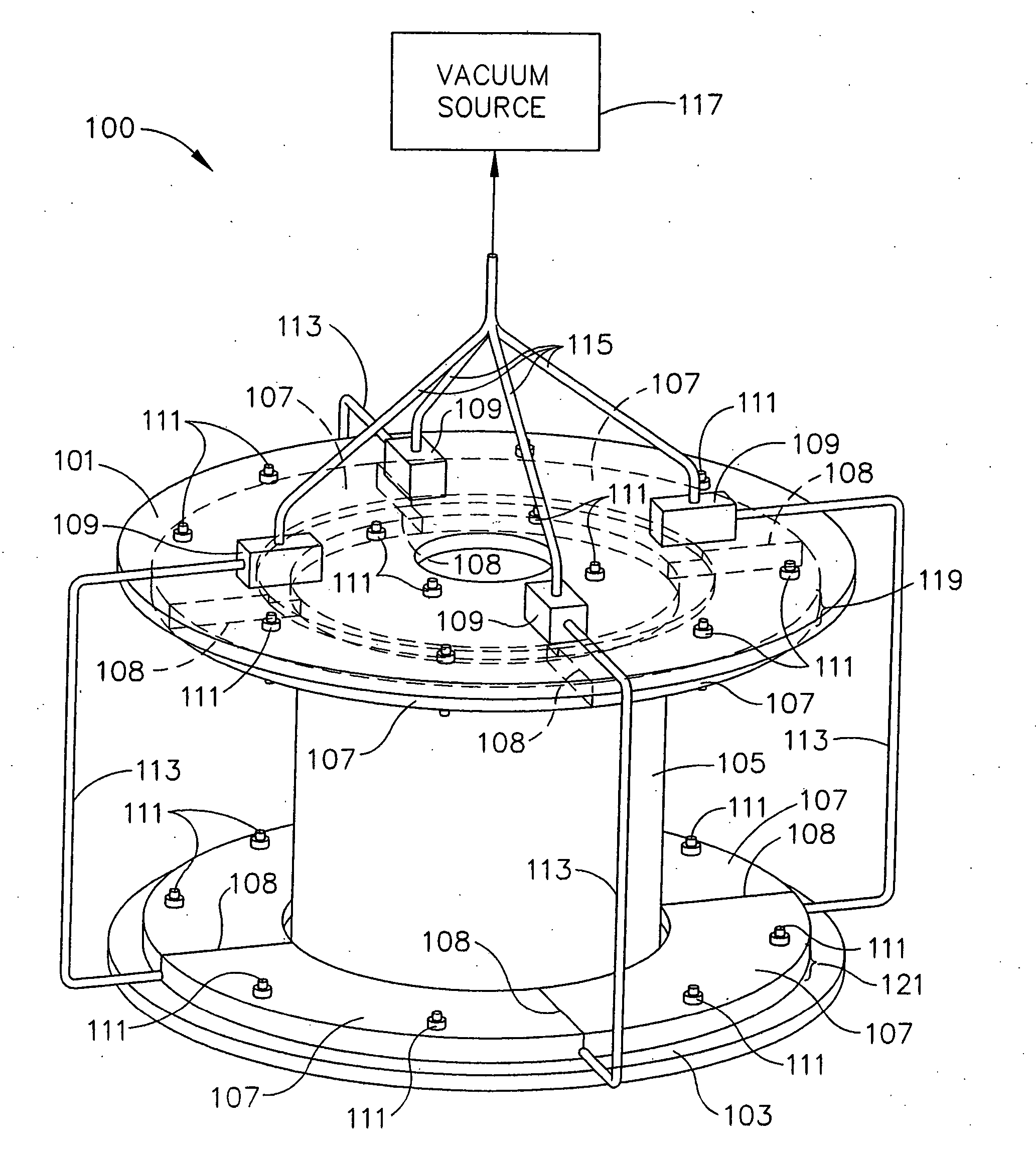

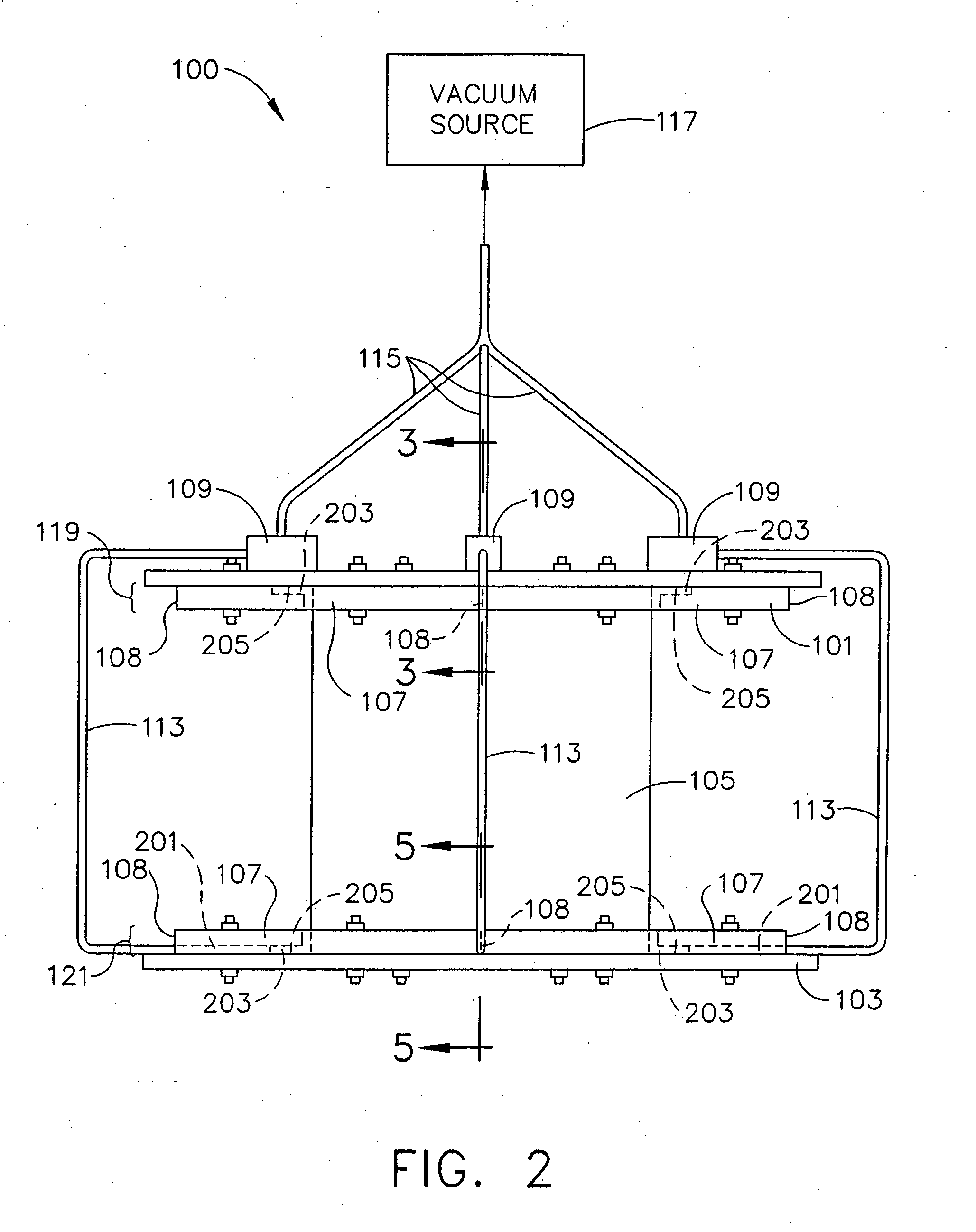

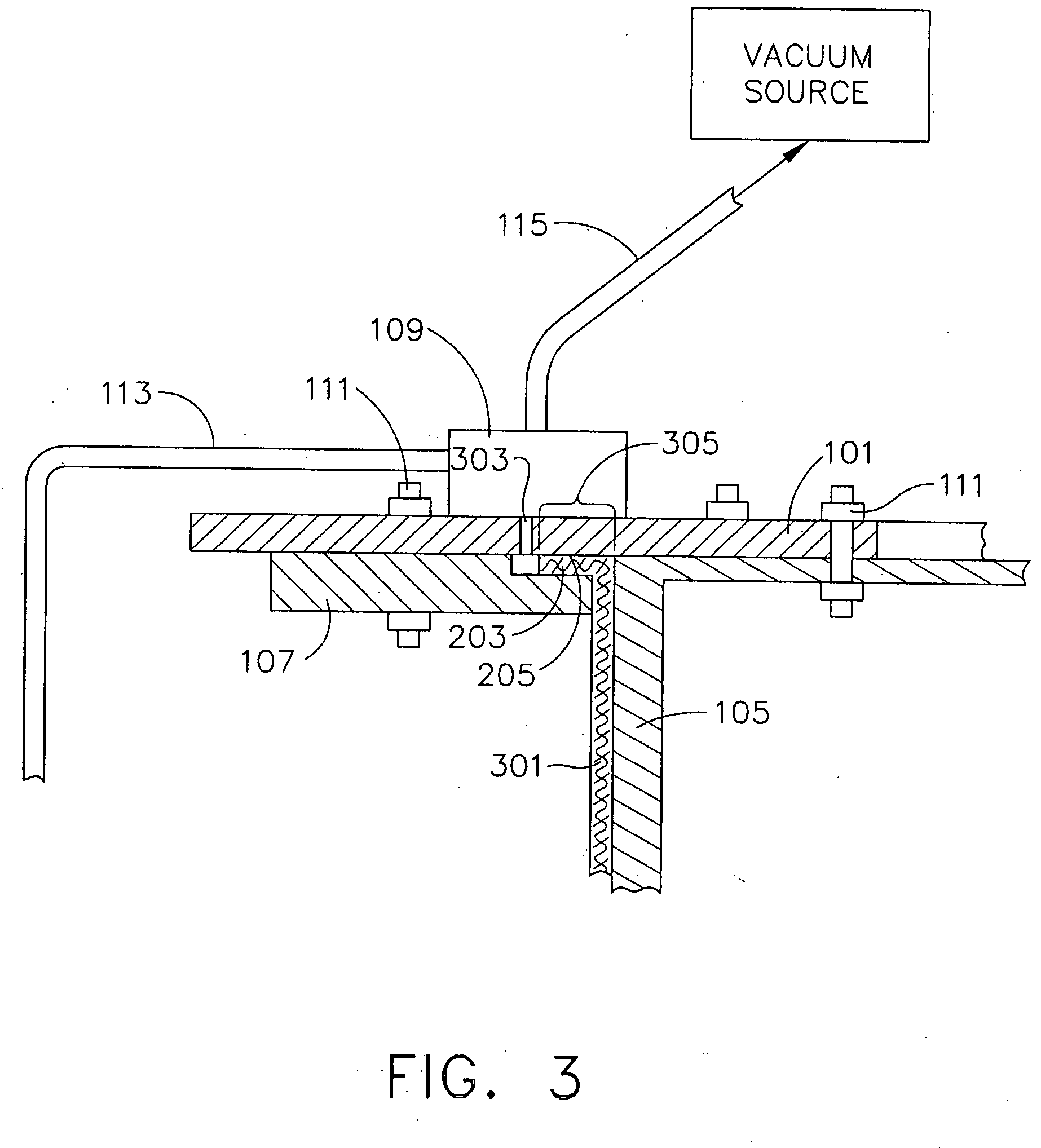

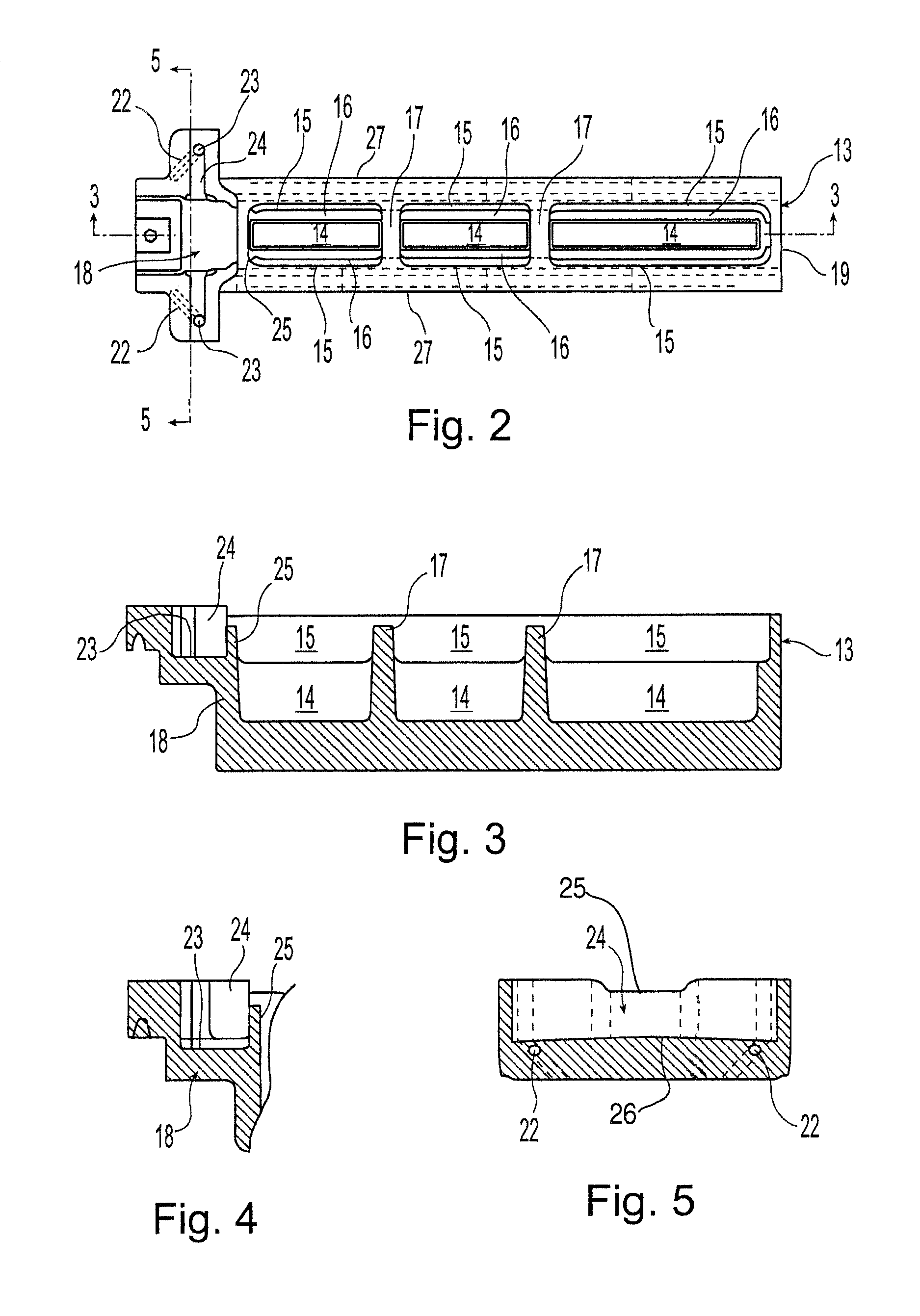

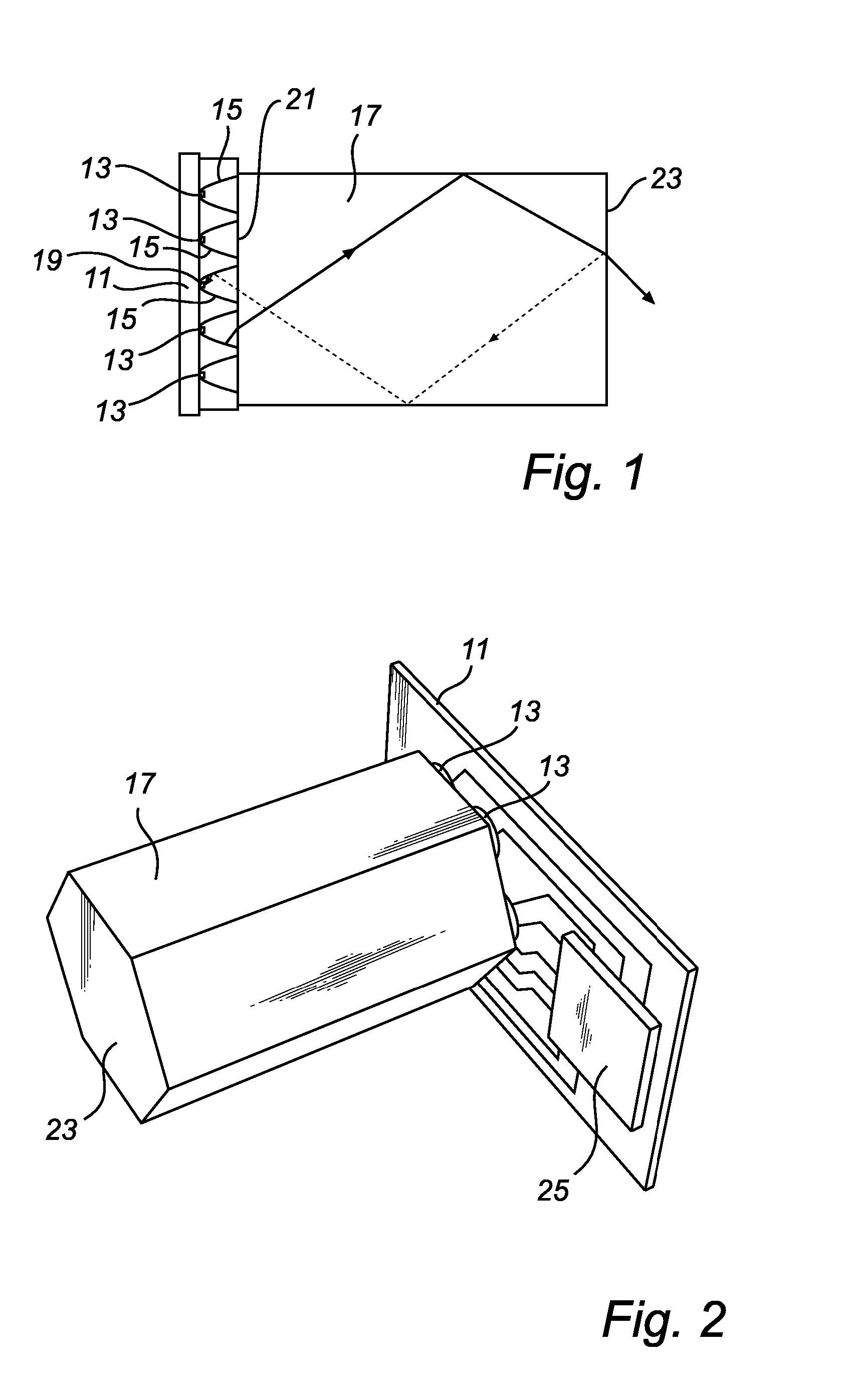

Apparatus for fabricating reinforced composite materials

A mold tool for forming a reinforced matrix composite part for a gas turbine engine, comprising a body. The body comprises a body surface capable of receiving a first portion of a composite preform. A first endplate and second endplate are attached to the body and include a substantially planar surface disposed perpendicular to the body surface. A first and second set of plates are attached to the first and second endplate adjacent to the body surface and have a geometries that includes a first and second cavity bounded by the first and second plate and first and second endplate. The first and second cavities have a volume sufficient to receive a second portion of a composite preform. The second cavity is in fluid communication with the first cavity, which is in fluid communication with a vacuum source.

Owner:GENERAL ELECTRIC CO

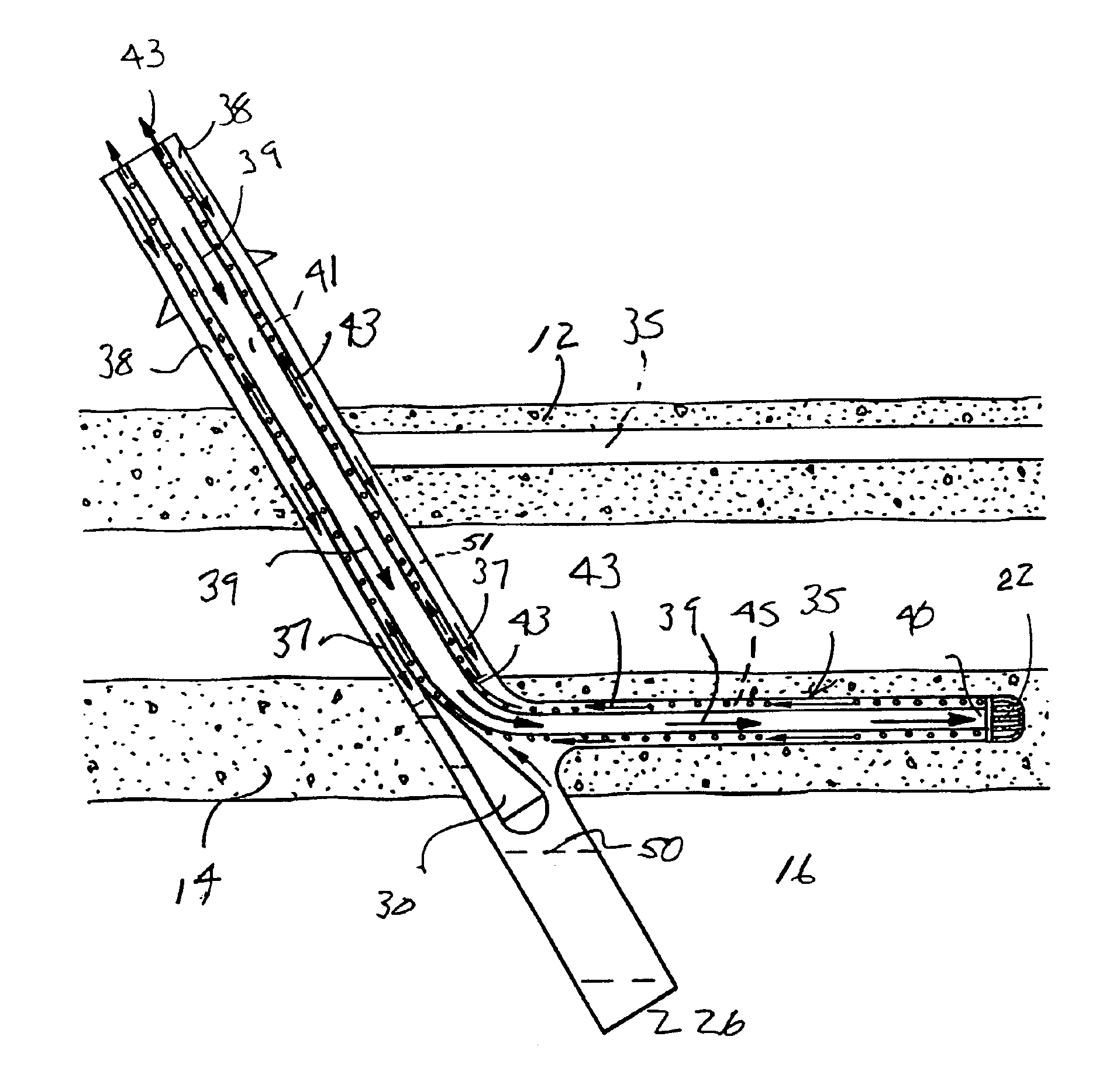

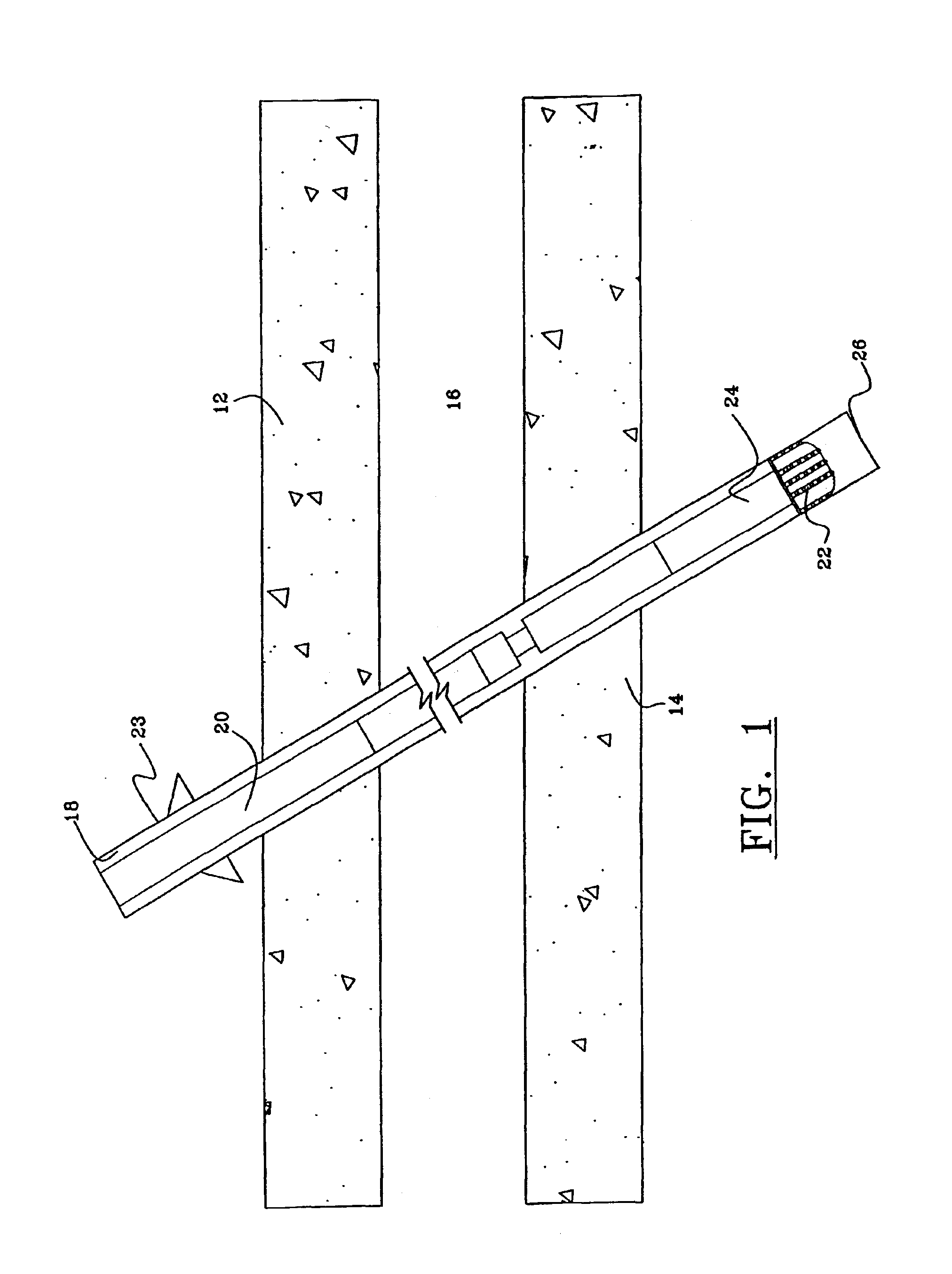

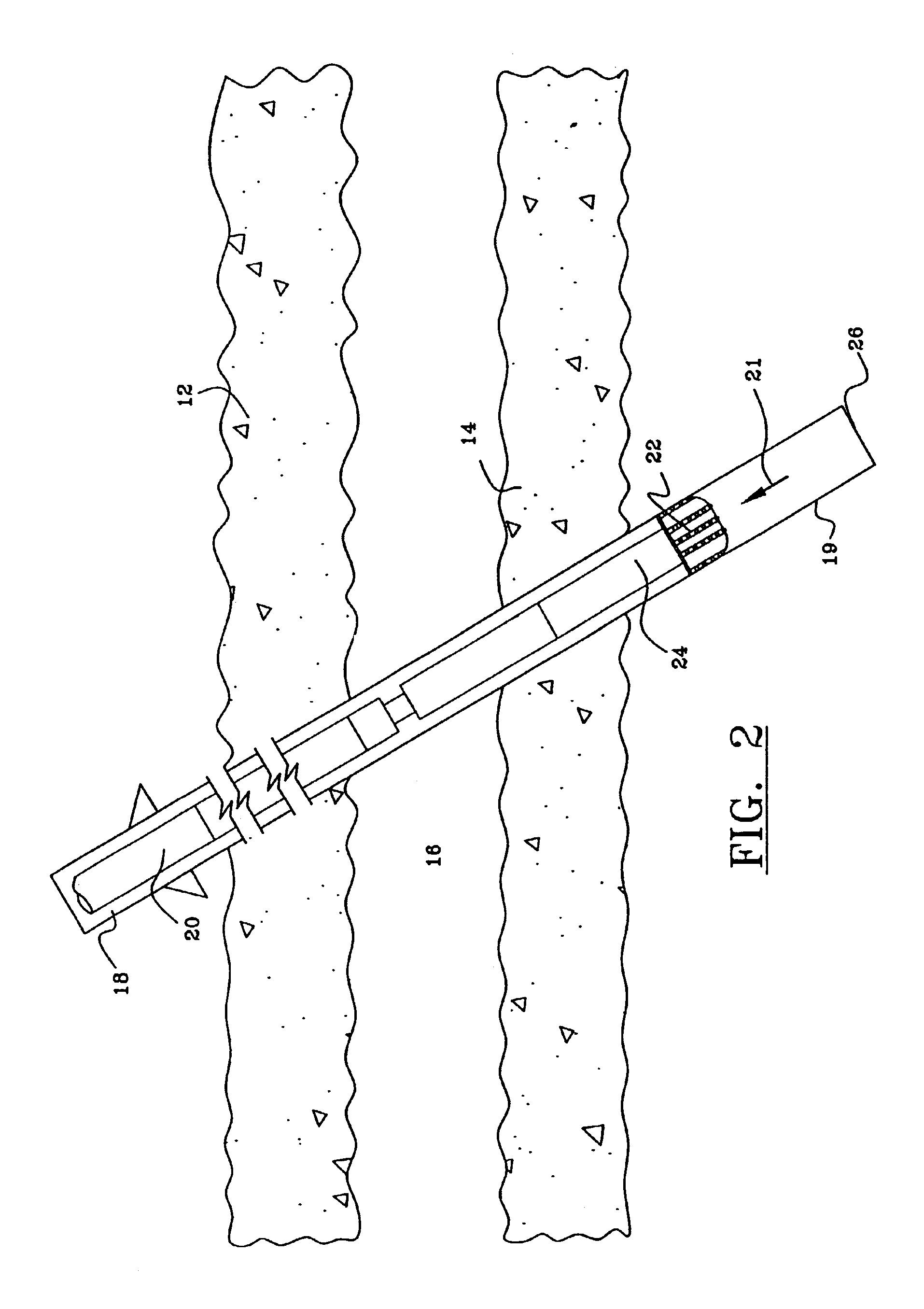

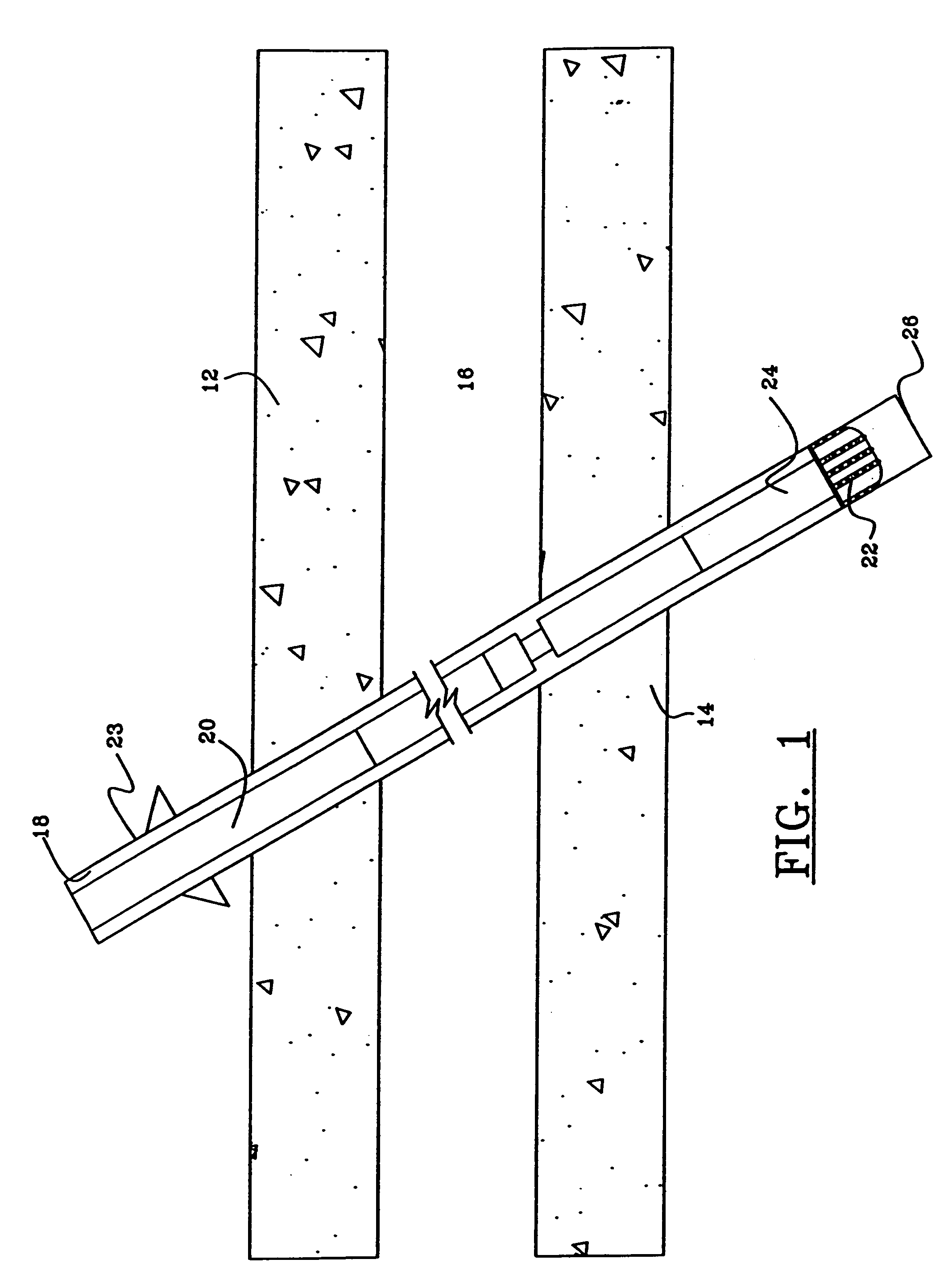

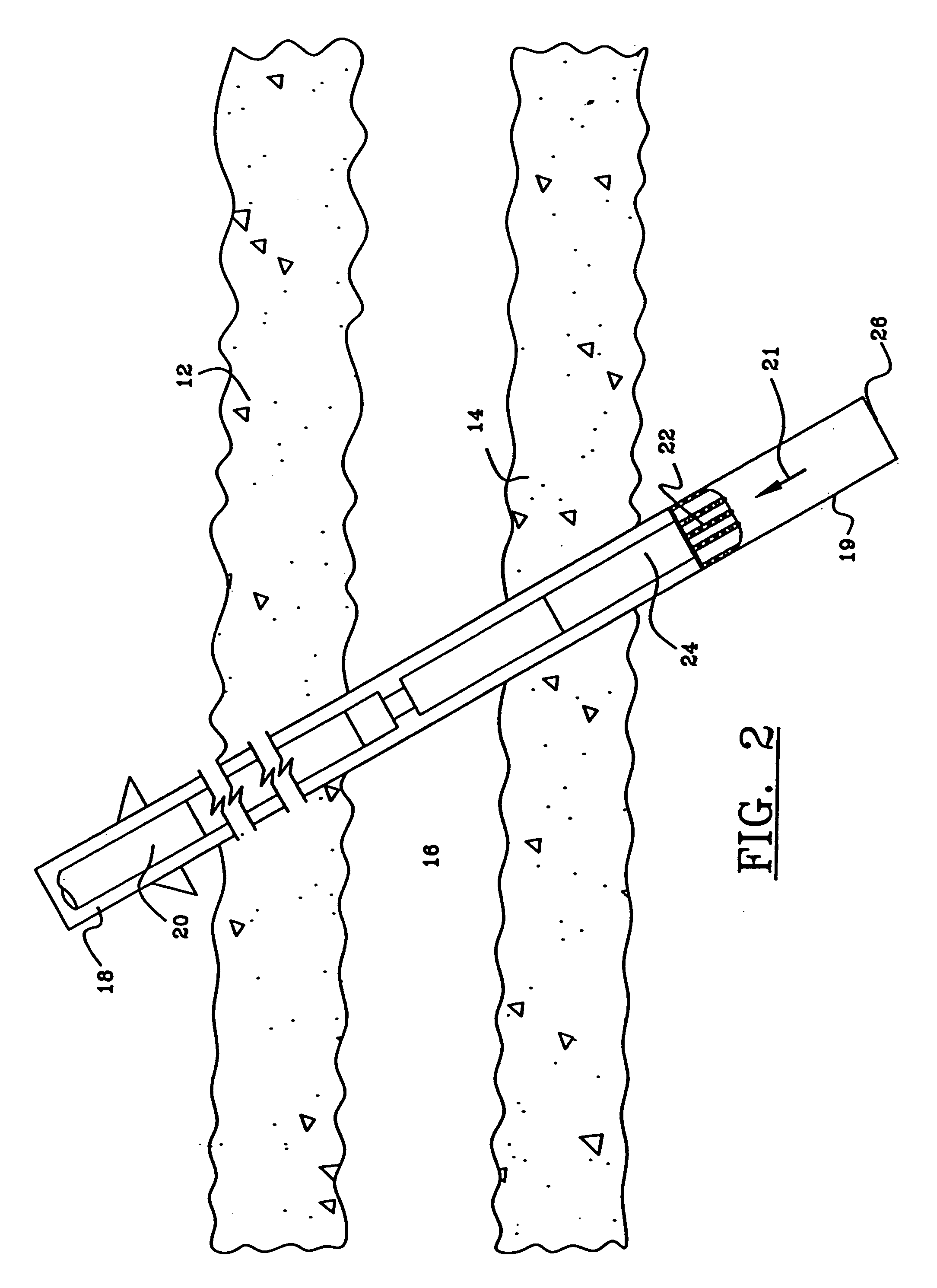

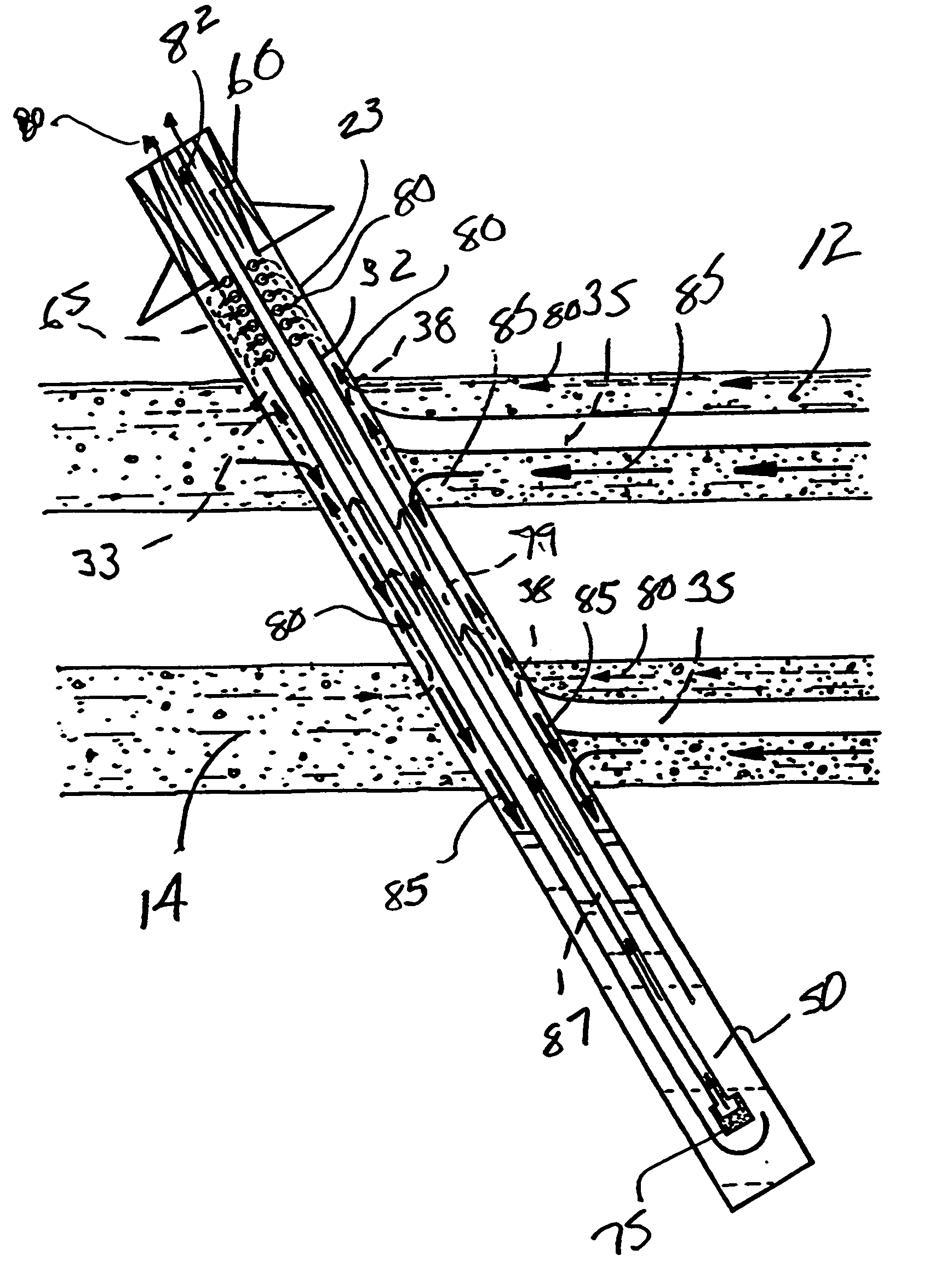

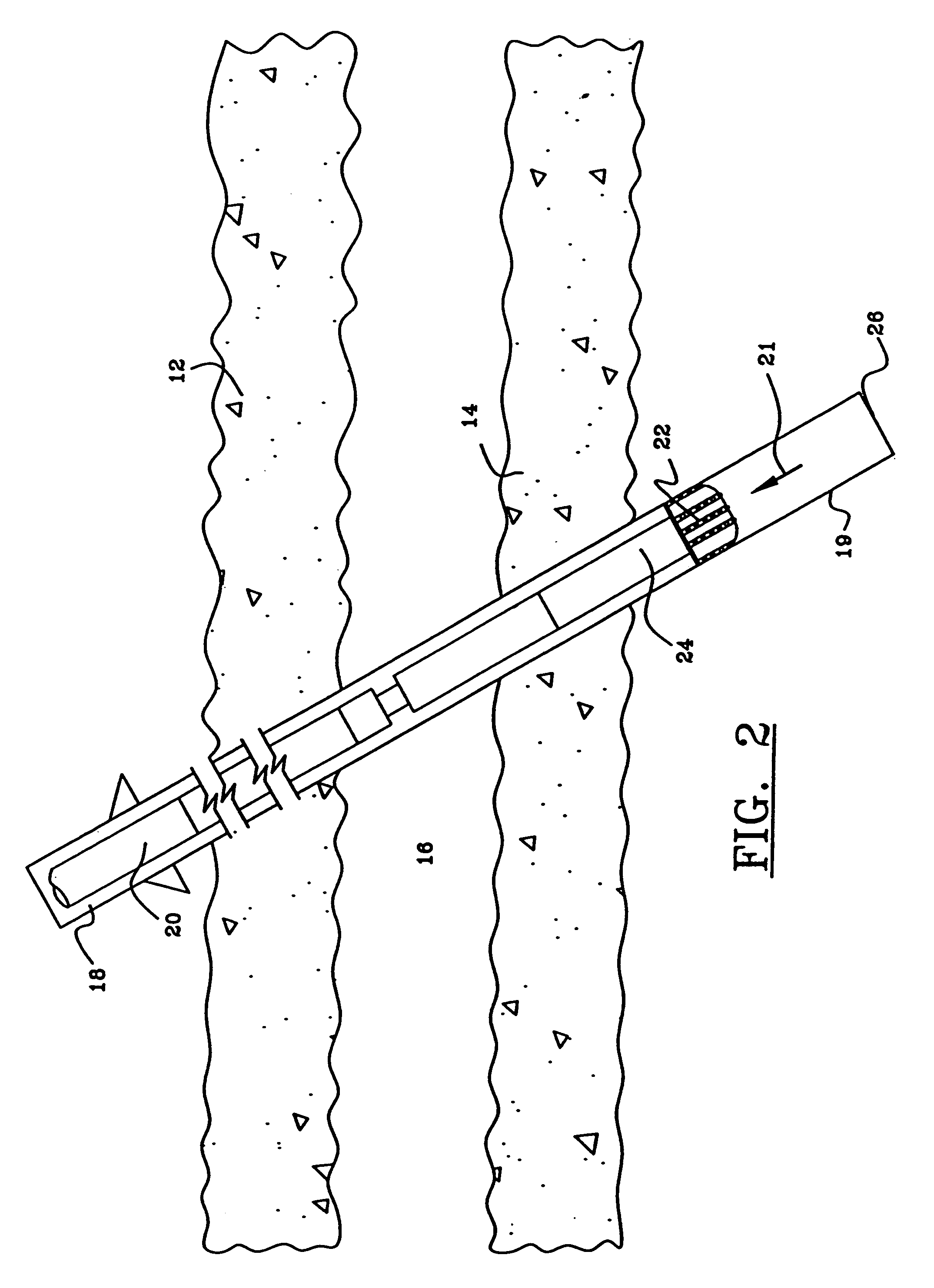

Multi seam coal bed/methane dewatering and depressurizing production system

InactiveUS6923275B2Minimal environmental impactEliminate infrastructure long-term maintenance and environmental impactFluid removalDirectional drillingWell drillingProduct gas

A process for underbalanced drilling into multiple coal and shale formations, and dewatering the drilled formations, which includes drilling a first borehole through several coal seams to a certain depth, defined as a cased borehole; lowering an upstock on the end of a carrier string to the depth of the upper coal seam; lowering a drill string in the carrier string, and angling off of the upstock, to drill a lateral or horizontal borehole within the coal seam; repeating the process for the second coal seam; setting a packer in place above the first coal seam in the annulus between the cased borehole and the carrier string; forming perforations in the wall of the carrier string below the packer; retrieving the upstock from the carrier string; lowering an electrical submersible pump to the bottom of the principal borehole, defined as a sump portion of the borehole; collecting methane gas from the two coal seams through the annulus between the second drill string and the carrier string to the surface; pumping water from the sump portion to the surface within the annulus of the second drill string, while gas within the annulus between the carrier string and the outer casing enters the plurality of perforations in the carrier string to be carried up to the surface.

Owner:GARDES ROBERT

Multi seam coal bed/methane dewatering and depressurizing production system

InactiveUS20050252689A1Eliminate infrastructure long-term maintenance and environmental impactLarge partFluid removalDirectional drillingUnderbalanced drillingDrill hole

A process for underbalanced drilling into multiple coal and shale formations, and dewatering the drilled formations, which includes drilling a first borehole through several coal seams to a certain depth, defined as a cased borehole; lowering an upstock on the end of a carrier string to the depth of the upper coal seam; lowering a drill string in the carrier string, and angling off of the upstock, to drill a lateral or horizontal borehole within the coal seam; repeating the process for the second coal seam; setting a packer in place above the first coal seam in the annulus between the cased borehole and the carrier string; forming perforations in the wall of the carrier string below the packer; retrieving the upstock from the carrier string; lowering an electrical submersible pump to the bottom of the principal borehole, defined as a sump portion of the borehole; collecting methane gas from the two coal seams through the annulus between the second drill string and the carrier string to the surface; pumping water from the sump portion to the surface within the annulus of the second drill string, while gas within the annulus between the carrier string and the outer casing enters the plurality of perforations in the carrier string to be carried up to the surface. Under a first option, water from the two coal seams is pumped by the ESP through perforations in the wall of the casing, to a first lower water injection zone below the coal seams. In a second option, the water can be first delivered to the surface, and then returned down the annulus between the outer casing and carrier string to be injected into a water injection zone above the coal seams. It is foreseen that multiple wells can be drilled, and when the water is returned to the surface, the water would be routed to one of the wells which would return the water to the water injection zone. The objective of underbalanced drilling of coal and shale is to have the hydrostatic pressure of the drilling process to be lower than the formation pressure, as to not invade the formation with fines that may plug the fractures or fluid that may interact with the formation causing the swelling of clay particles or phase trapping commonly referred to as formation damage.

Owner:GARDES ROBERT

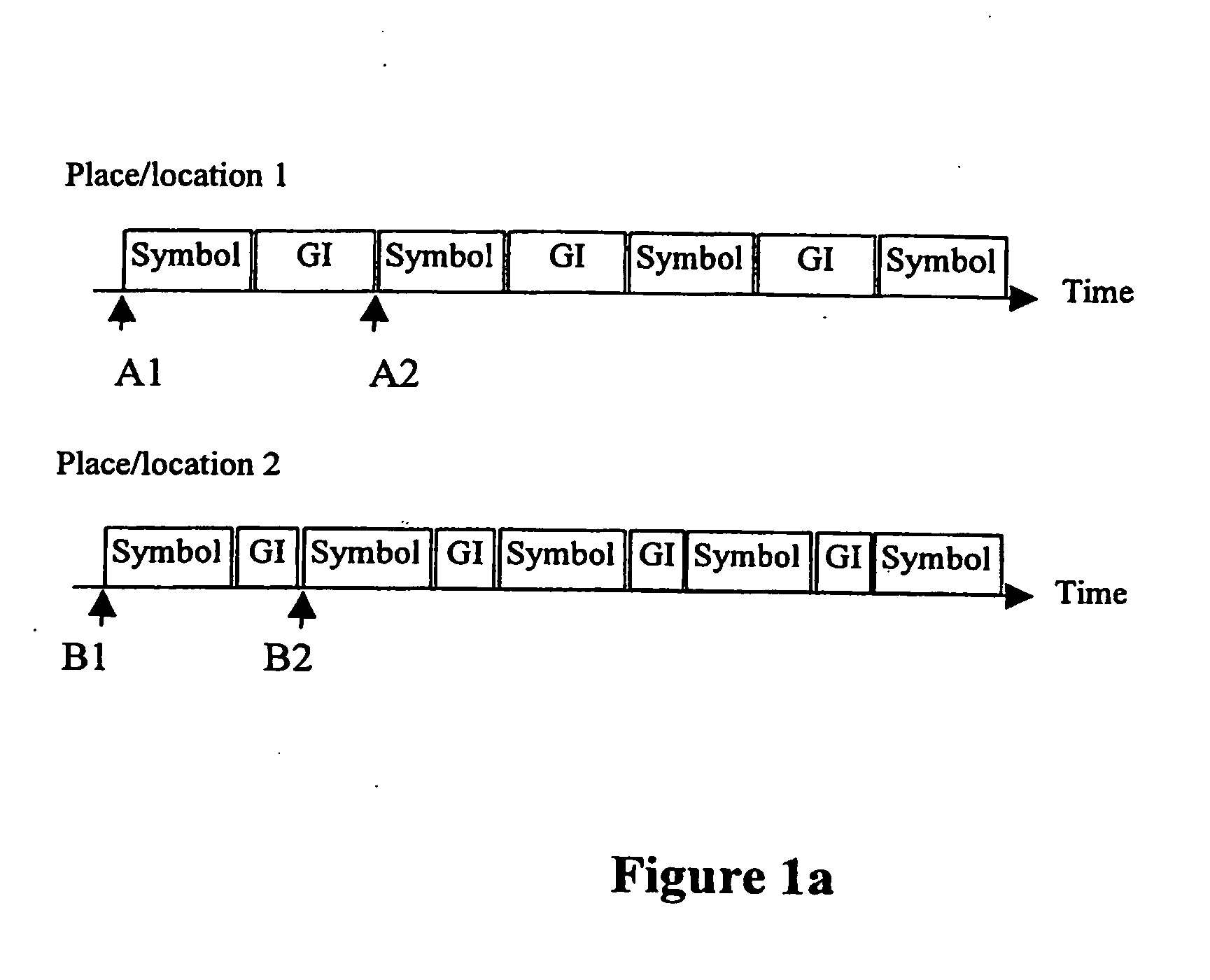

Position adjusted guard time interval for ofdm-communications system

ActiveUS20070159957A1Wasted capacityLarge partError preventionLine-faulsts/interference reductionMultiplexingCommunications system

A device and a method within a communications system where at least some part of the transmission is executed by means of radio waves, and where symbols are transmitted by means of Orthogonal Frequency Divisional Multiplexing, so called OFDM-technology, between a transmitting unit and a receiving unit, at which the symbol transmission is executed over a transmission channel in blocks of binary digits with a guard interval GI between said blocks, where transmitting unit is equipped with means to control the length of the guard interval (GI) with regard to the physical conditions for / of the transmission channel, so that the guard interval can be reduced without the disturbance susceptibility being increased, but instead increasing the capacity / throughput of the transmission channel by the time that is set free / made available being used to transmit information. One embodiment of the invention includes a guard interval adjustment unit connected to other OFDM-equipment in transmitting and / or receiving unit.

Owner:TAMIRAS PER PTE LTD LLC

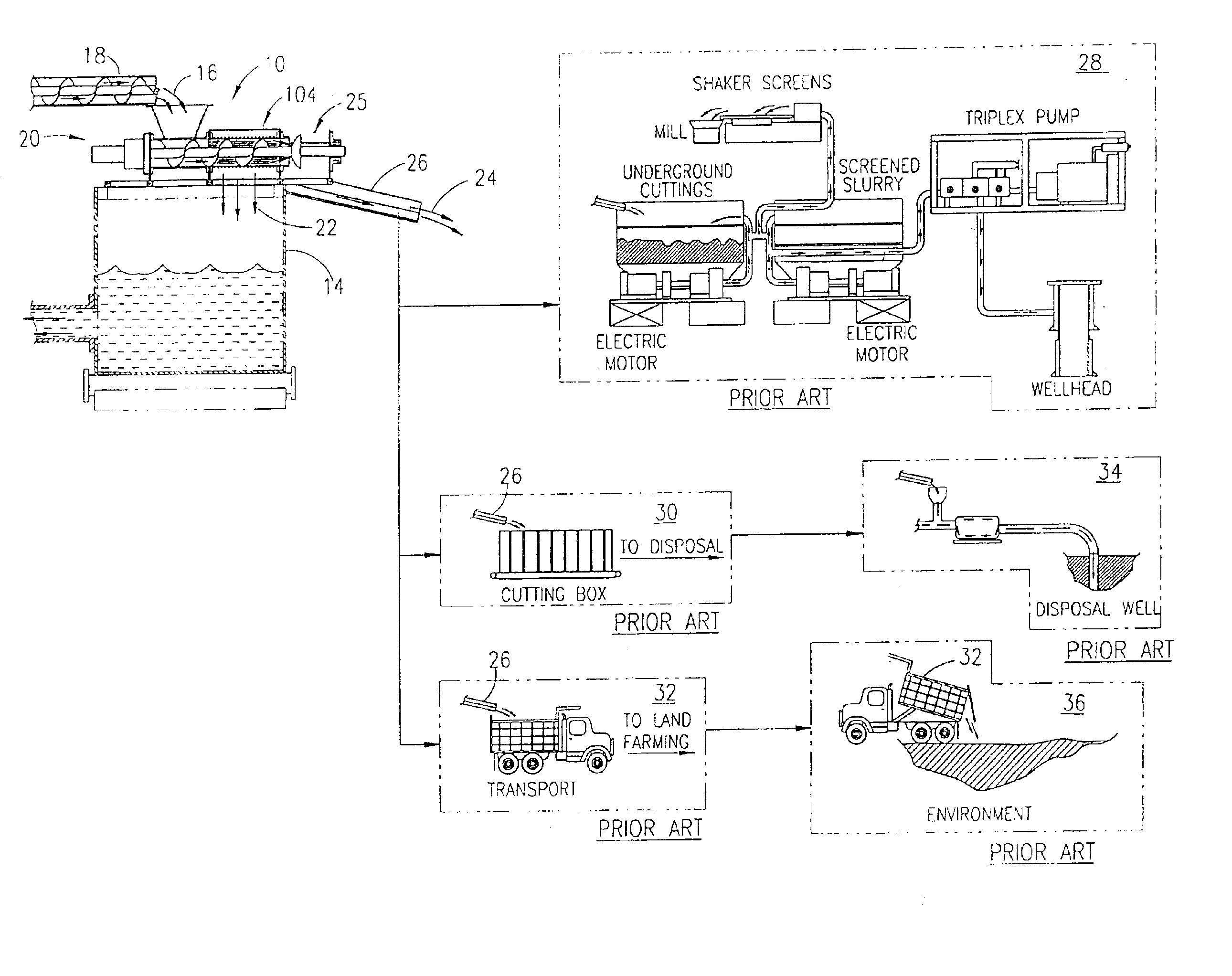

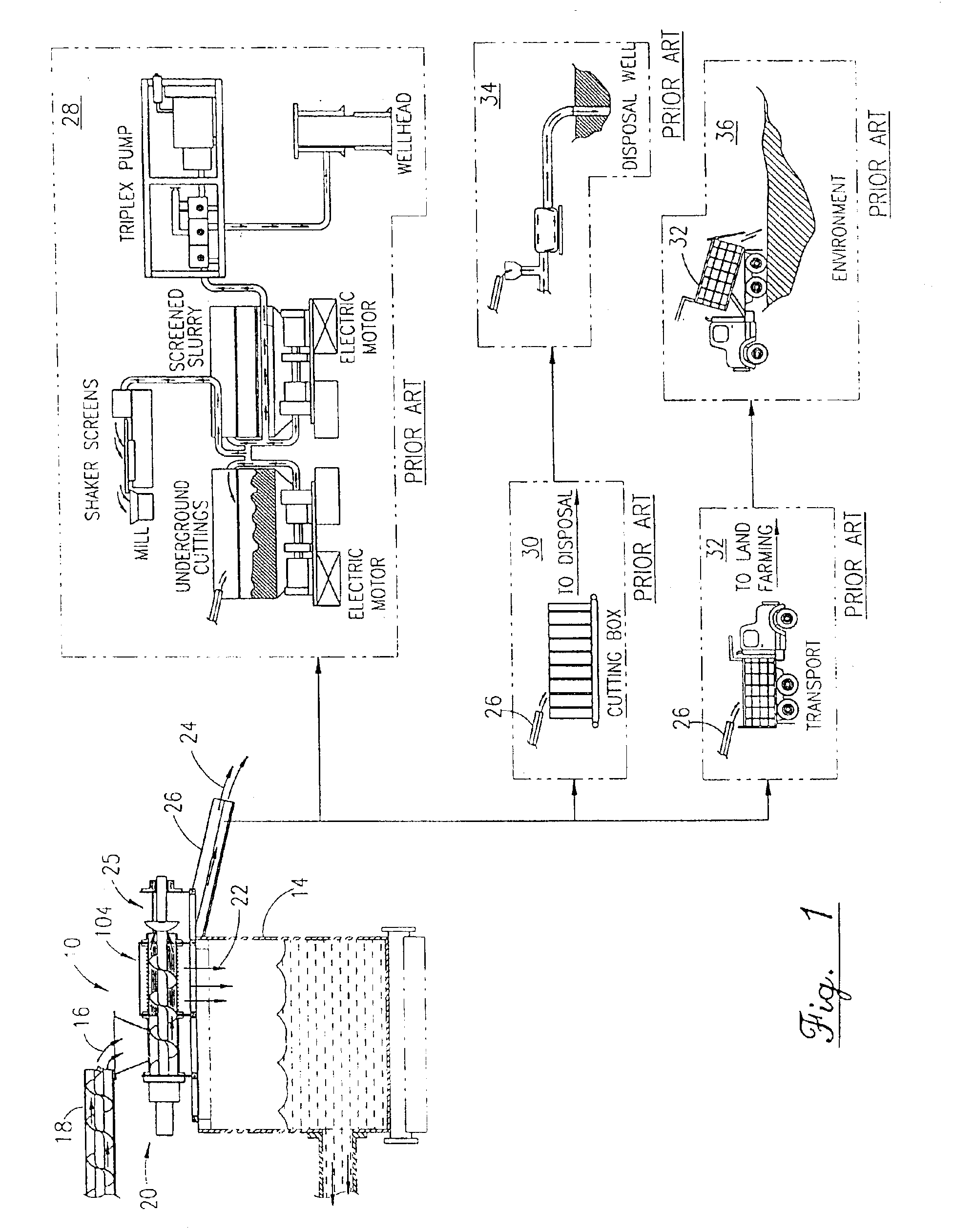

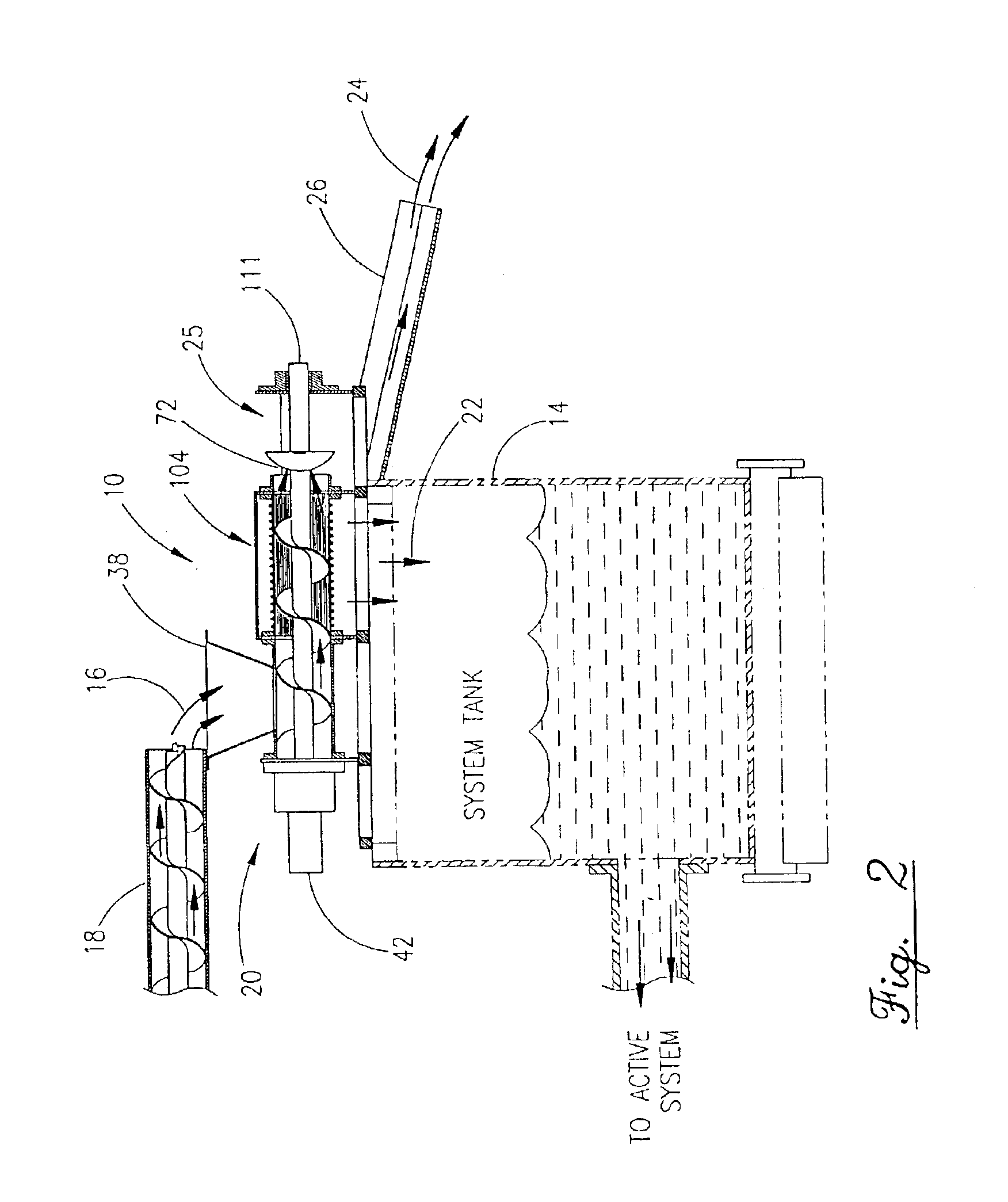

Drilling fluid recovery and cuttings processing system

InactiveUS6910411B2Reduce liquid contentDischarge volume reductionFlushingDrilling compositionProcess systemsDistillation

A drill cuttings slurry process system is disclosed for defluidizing earth drill cuttings, thereby extracting valuable drilling additives and returning them to the drilling system while producing a dense, drier material which may be discharged directly in the environment at or near the well being drilled or chemically treated for distillation and / or better dissolution into the environment, thereby reducing, cost in transportation and environmental treatment chemicals thus reducing environmental contamination. The system comprising a cuttings press having solids / fluids separation a dryer and / or a retort for flashing off any residual petroleum residue and moisture, a fines grinder and a chemical injection system. The retort including an analyzer system for weighing and determining rate of throughput and analyzing the cuttings for residual petroleum residue content prior to discharge to environment or further refinement prior to reinjection into the well or transport to environmental depository sites.

Owner:BAKER HUGHES INC

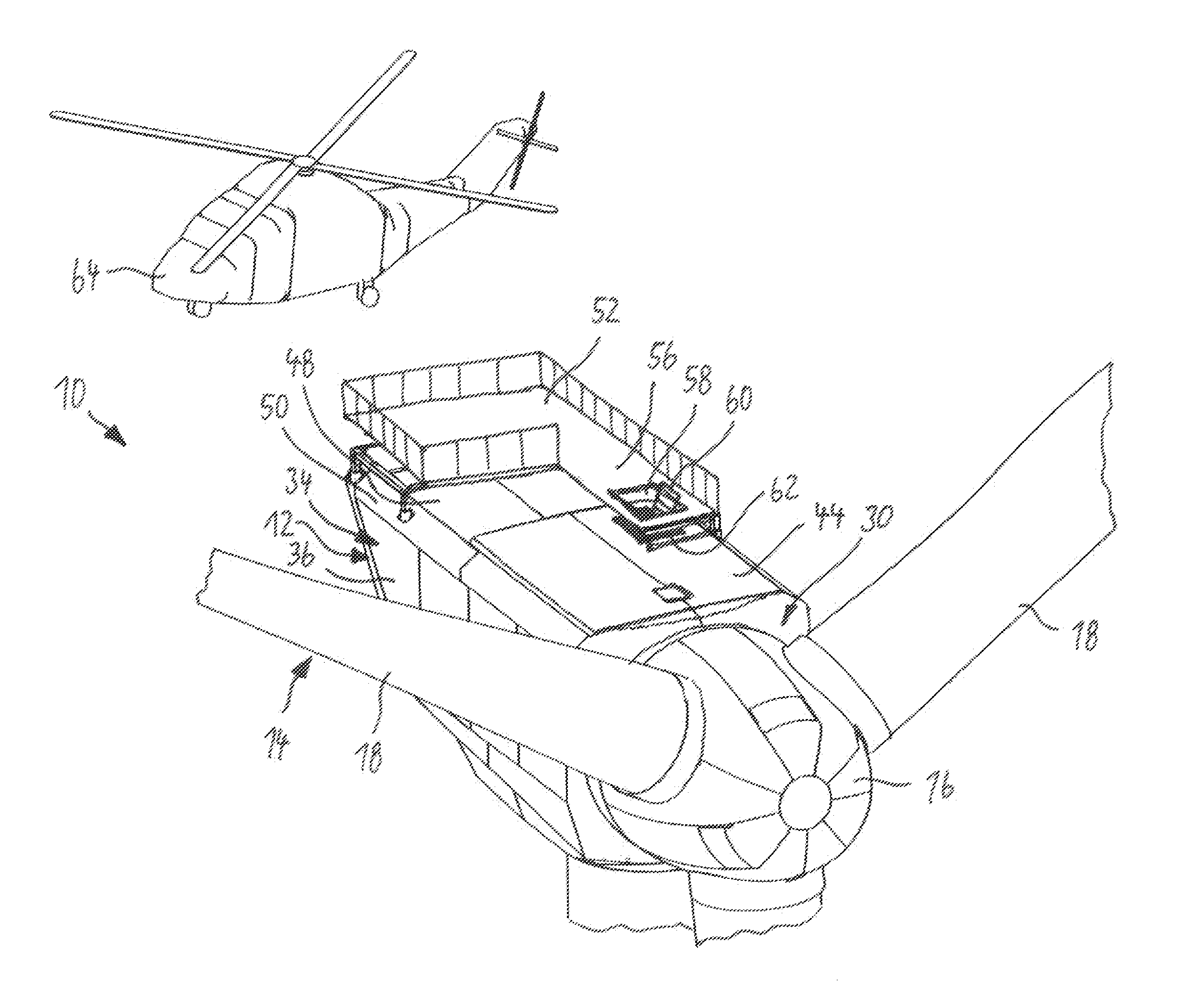

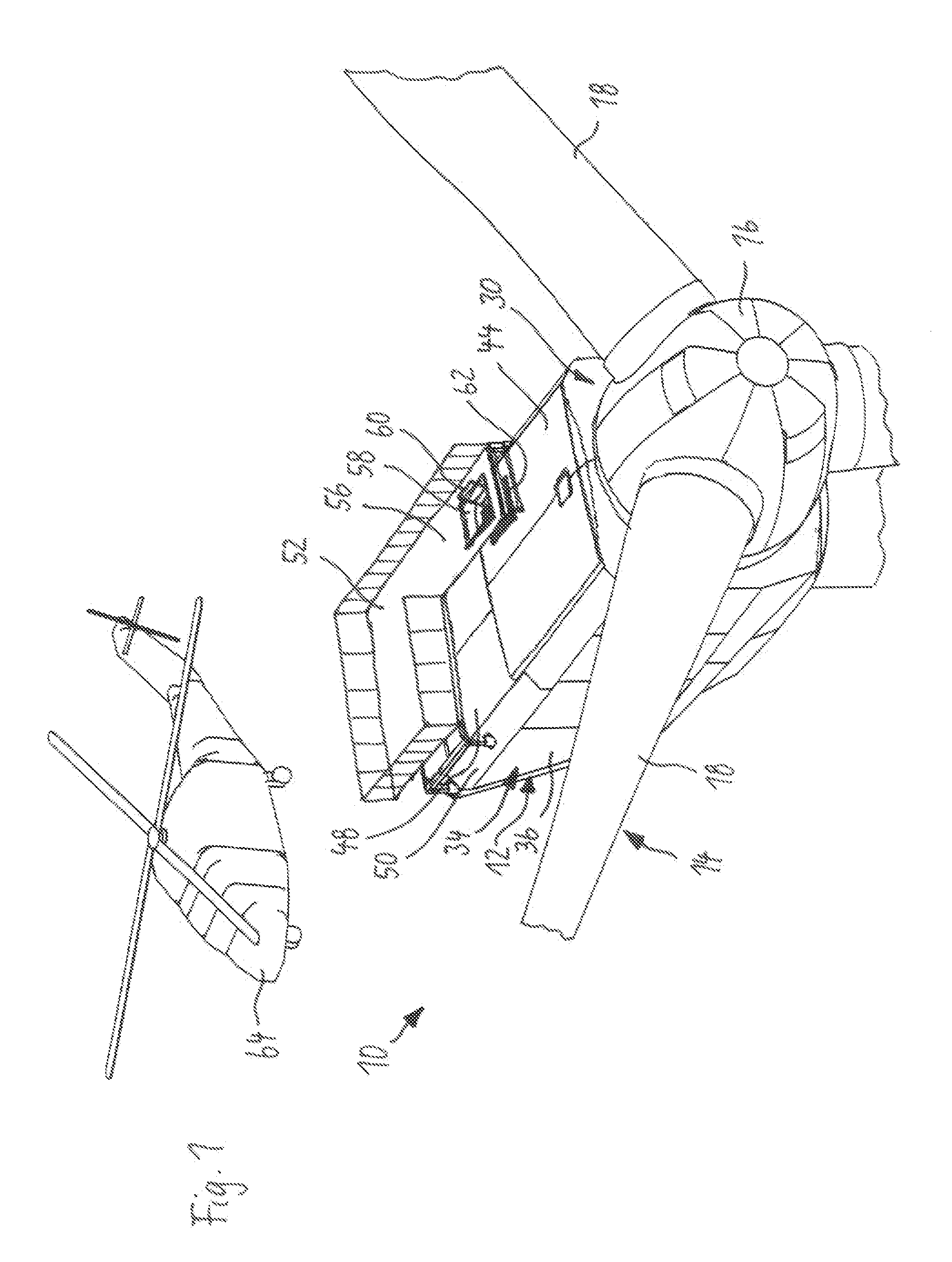

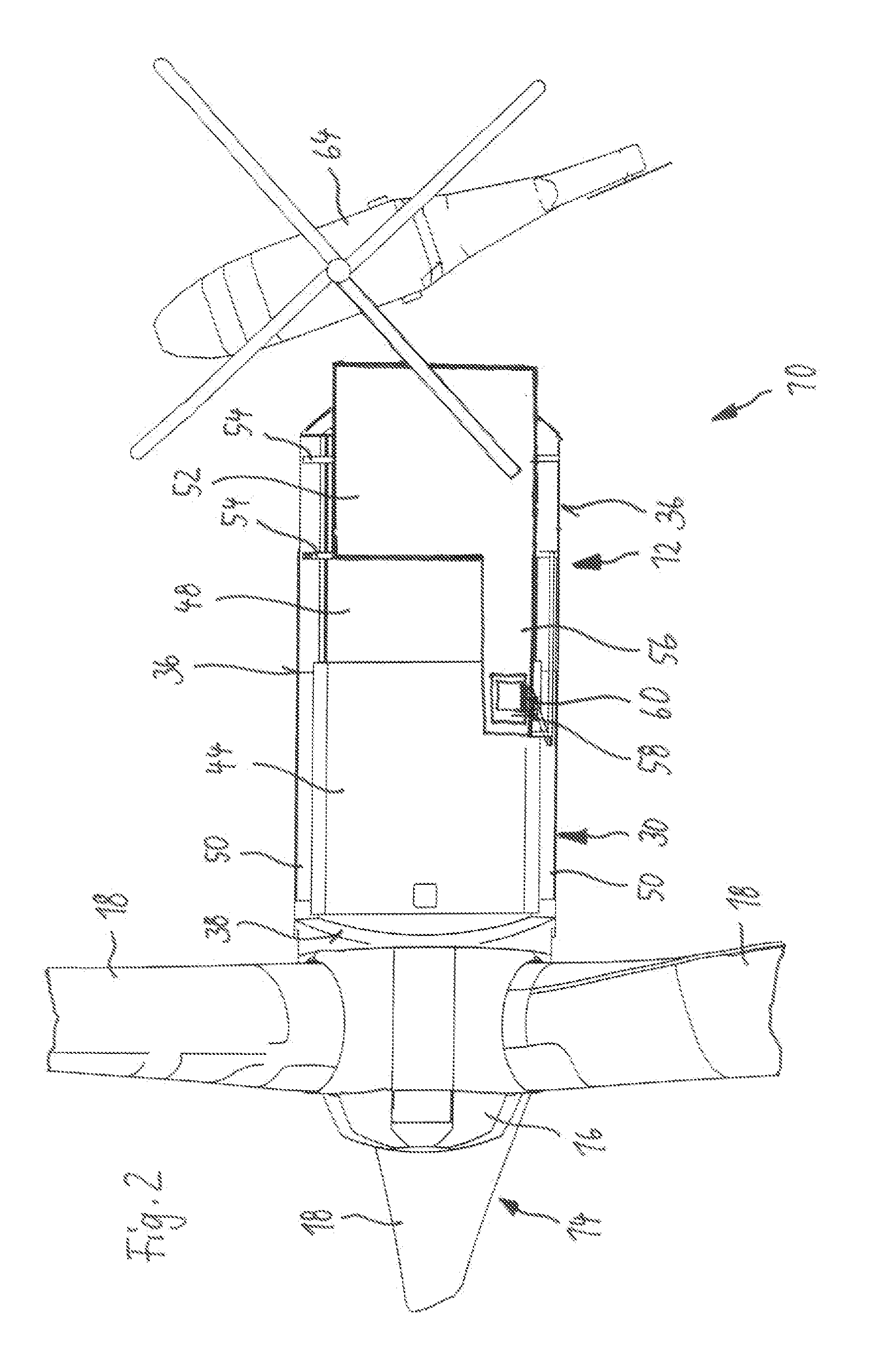

Paneling of a Nacelle of a Wind Energy Installation

ActiveUS20110097202A1Wide openLarge partEngine manufacturePump componentsNacelleAerospace engineering

A paneling (30) of a nacelle (12) of a wind energy installation (10), in which an upturned panel ceiling (40) is provided in installation position, is created with a hatch opening (46), that is provided in the panel ceiling (40). The hatch opening (46) is advantageously provided so large, that components of the entire area of a drive train (24) of the wind energy installation (10) can be removed upwards, or inserted from above into the nacelle (12) through the hatch opening (46). Furthermore, such a hatch opening (46) is choosingly closable by means of a hatch cover (44).

Owner:MULTIBRID

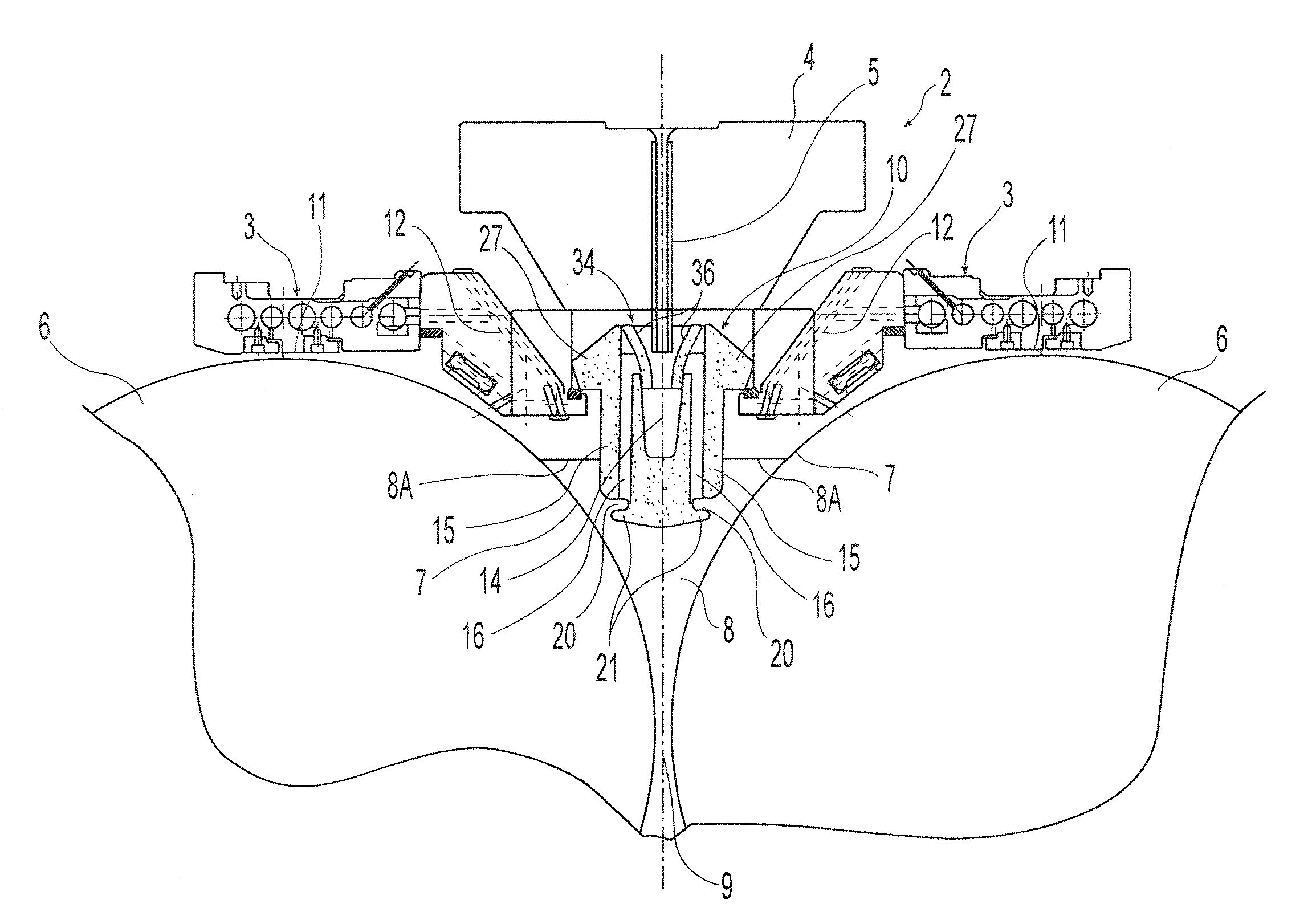

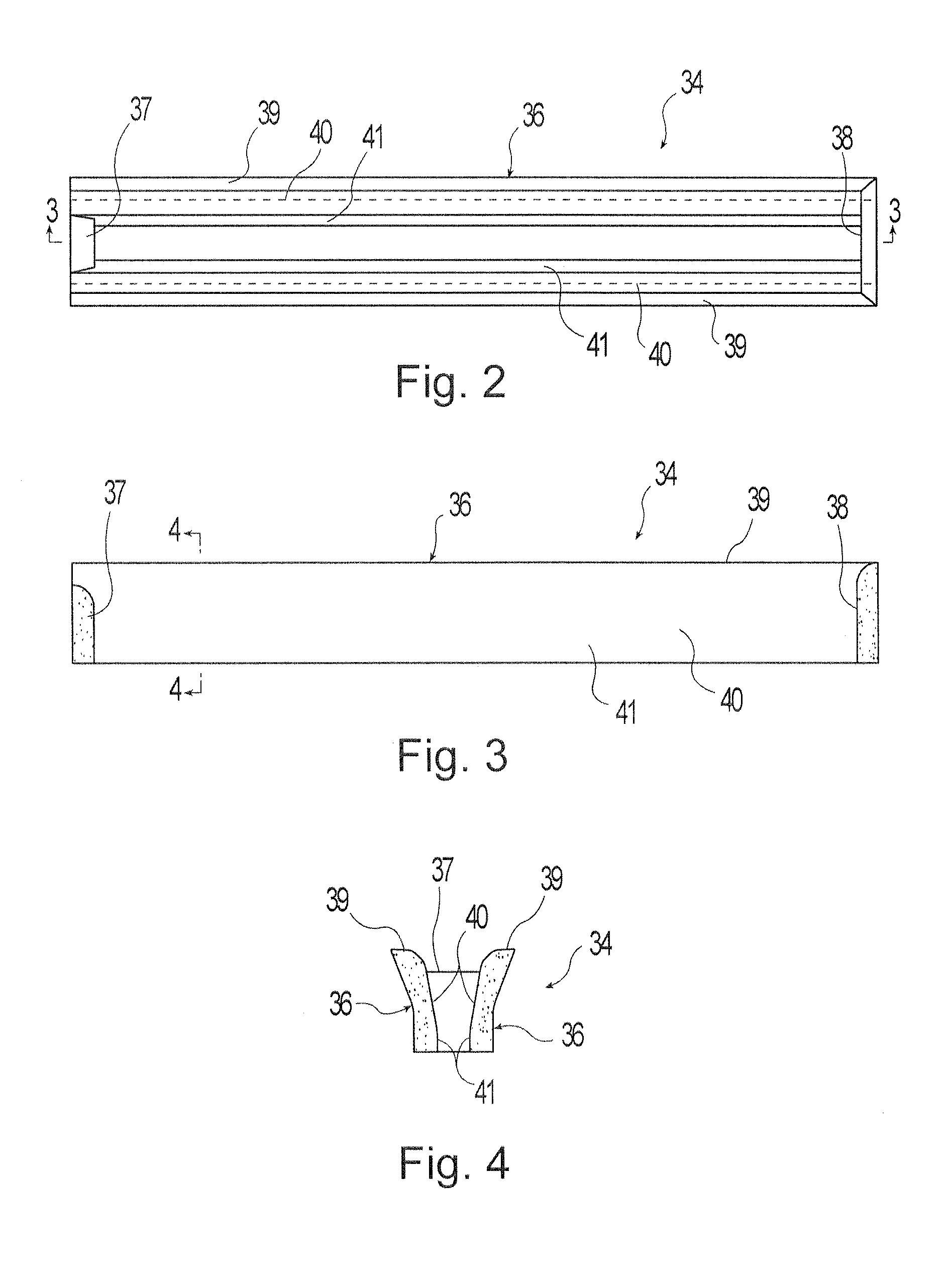

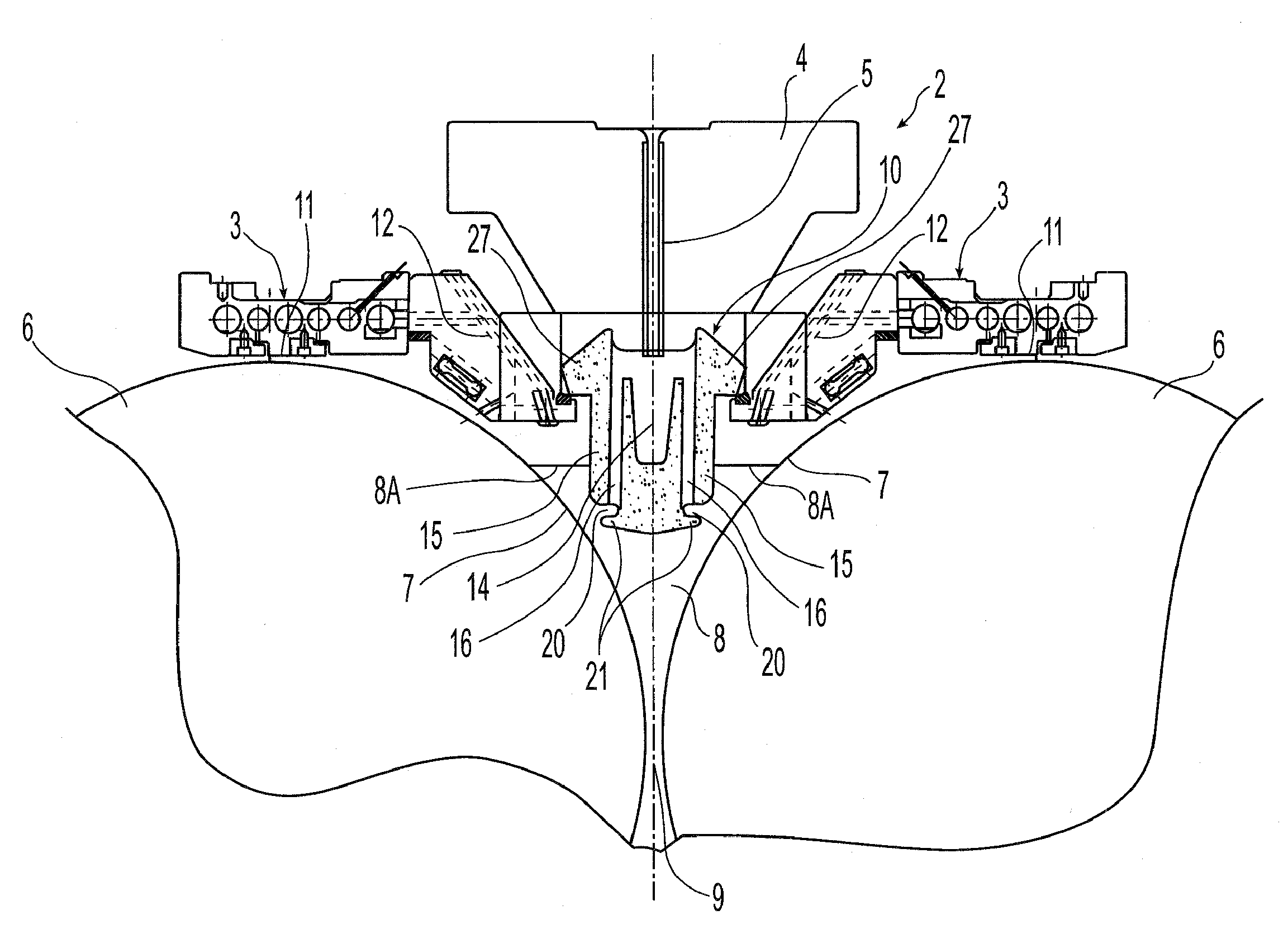

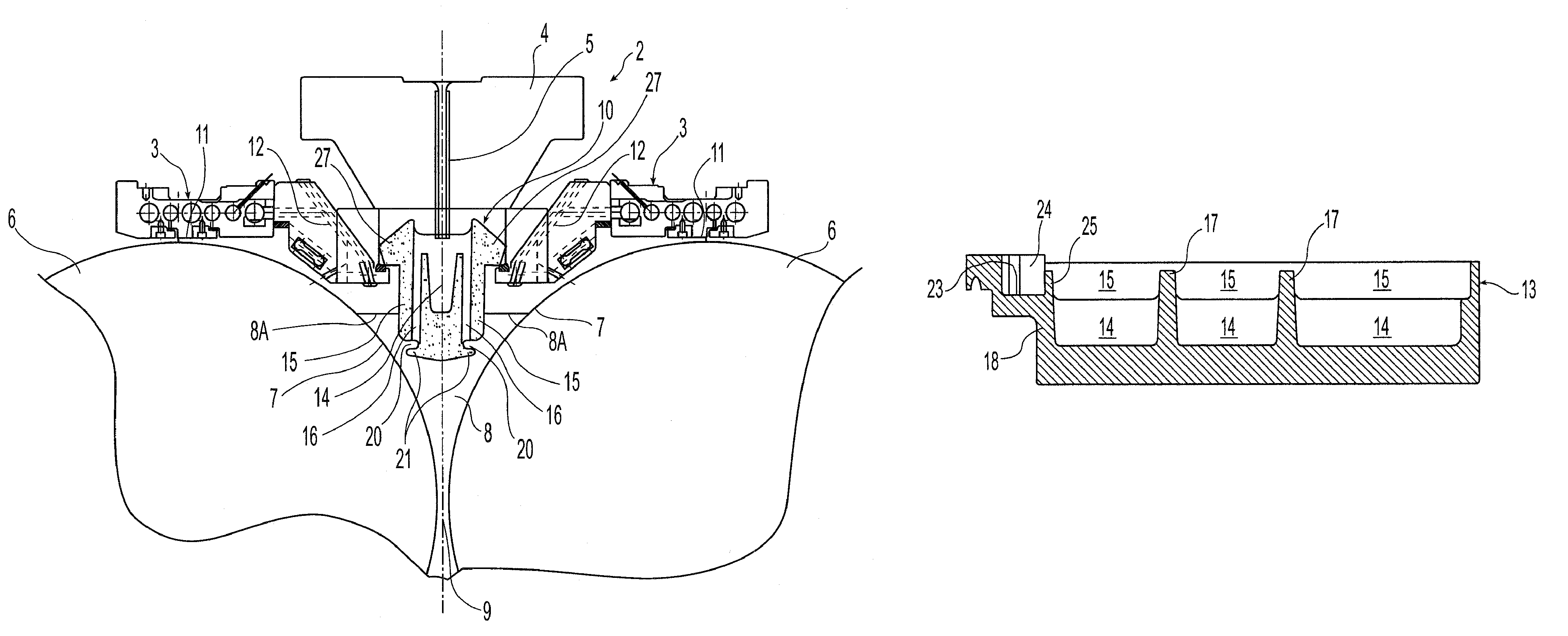

Casting delivery nozzle with insert

InactiveUS20080264599A1Easy to replaceReduces turbulence in flowMolten metal pouring equipmentsMolten metal supplying equipmentsMolten metalNozzle

A metal strip casting apparatus and a method of casting continuous metal strip includes assembling a pair of counter-rotatable casting rolls having casting surfaces positioned laterally forming a nip between for casting, and delivering molten metal through a delivery nozzle disposed above the nip capable to form a casting pool supported on the casting rolls. The delivery nozzle comprises segments each having elongate nozzle body with longitudinally extending side walls, end walls and a bottom part to form an inner trough, a nozzle insert disposed above bottom portions of the inner trough of each segment and supported relative to the nozzle body through which incoming molten metal may be delivered to the inner trough of each segment of the delivery nozzle, and the elongate nozzle body of each segment having passageways in fluid communication with the inner trough and outlet openings capable of discharging molten metal from the nozzle body outwardly into the casting pool.

Owner:NUCOR CORP

Multi seam coal bed/methane dewatering and depressurizing production system

InactiveUS7243738B2Eliminate infrastructure long-term maintenance and environmental impactLarge partFluid removalDirectional drillingUnderbalanced drillingMaterial Perforation

A process for underbalanced drilling into multiple coal and shale formations, and dewatering the drilled formations, which includes drilling a first borehole through several coal seams to a certain depth; lowering an upstock on the end of a carrier string to the depth of the upper coal seam; lowering a drill string in the carrier string, and angling off of the upstock, to drill a lateral or horizontal borehole within the coal seam; repeating the process for the second coal seam; setting a packer in place above the first coal seam in the annulus between the cased borehole and the carrier string; forming perforations in the wall of the carrier string below the packer; retrieving the upstock from the carrier string; lowering an electrical submersible pump to the bottom of the principal borehole; pumping water from the sump portion to the surface within the annulus of the second drill string.

Owner:GARDES ROBERT

Apparatus for fabricating reinforced composite materials

A mold tool for forming a reinforced matrix composite part for a gas turbine engine, comprising a body. The body comprises a body surface capable of receiving a first portion of a composite preform. A first endplate and second endplate are attached to the body and include a substantially planar surface disposed perpendicular to the body surface. A first and second set of plates are attached to the first and second endplate adjacent to the body surface and have a geometries that includes a first and second cavity bounded by the first and second plate and first and second endplate. The first and second cavities have a volume sufficient to receive a second portion of a composite preform. The second cavity is in fluid communication with the first cavity, which is in fluid communication with a vacuum source.

Owner:GENERAL ELECTRIC CO

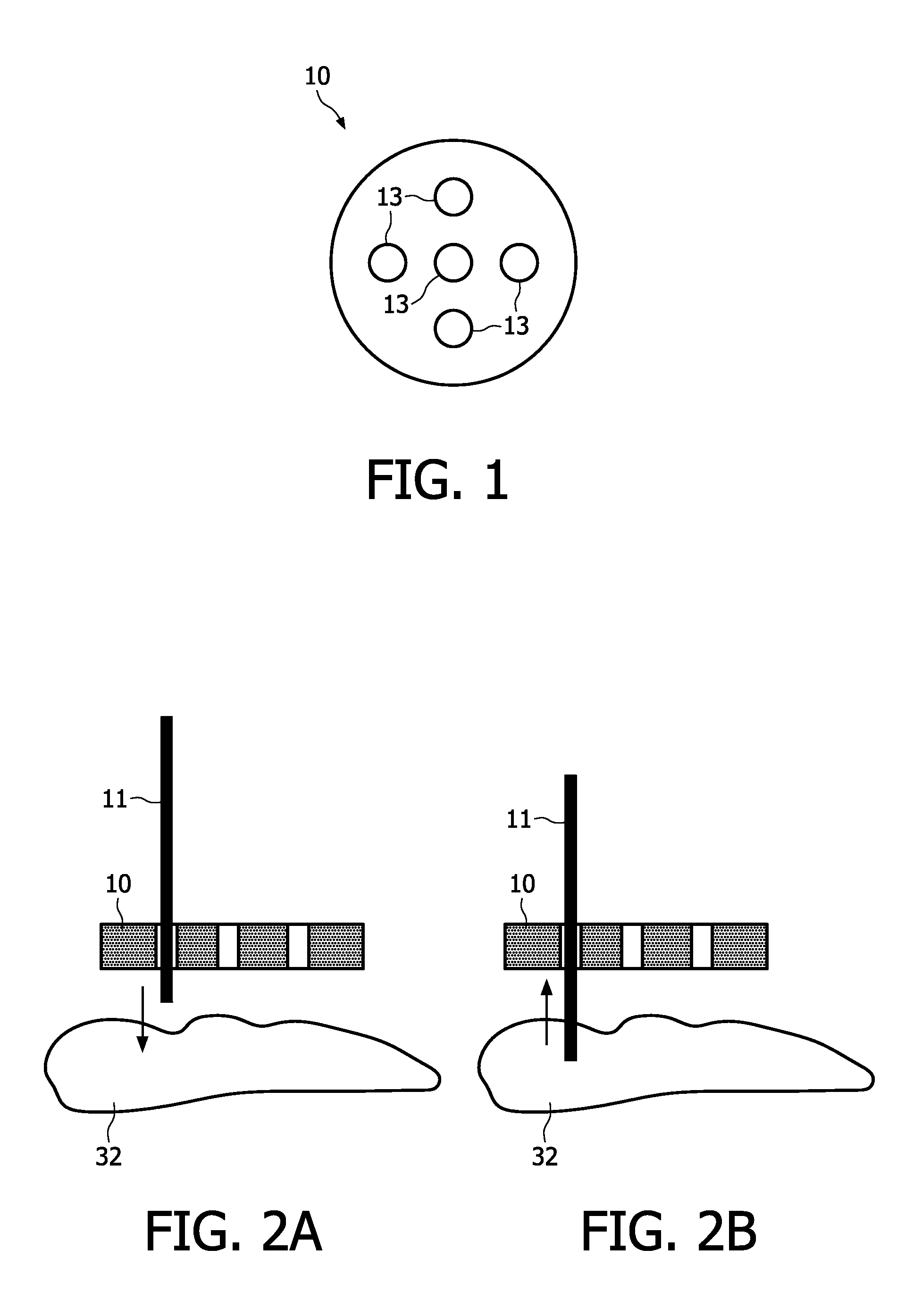

Neurosurgical guiding tool

ActiveUS20110208225A1Reduce riskLarge partHead electrodesDiagnosticsEngineeringNeurosurgical Procedure

The present invention regards a guiding tool for neurosurgery. The guiding tool comprises subunits and a holder. The subunits are arranged in the holder so that holes for guiding a probe are created in the interface between said subunits, which allows easy release of the probe. The invention further regards a system for guiding neurosurgery probes.

Owner:MEDTRONIC BAKKEN RES CENT

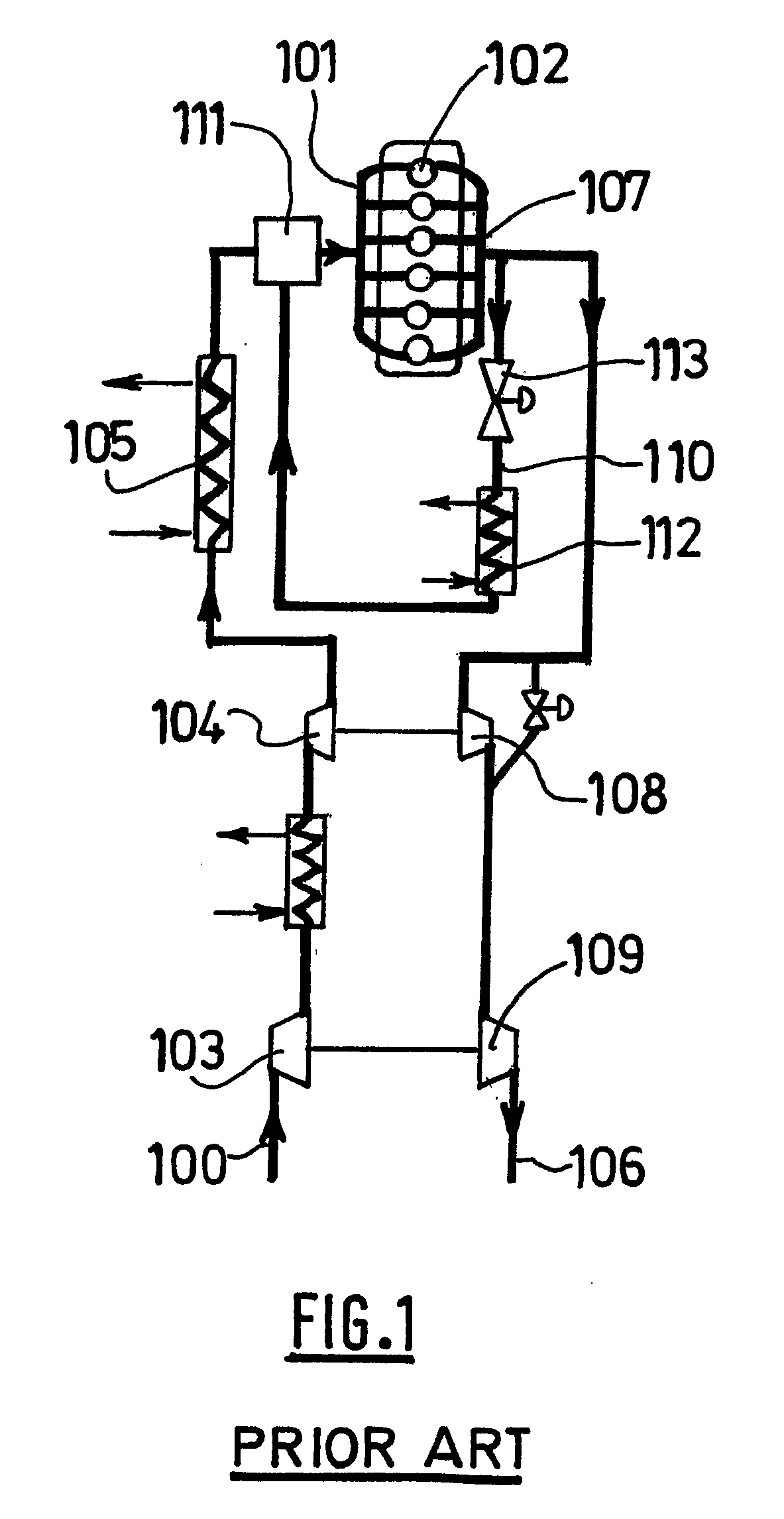

Internal combustion engine comprising an exhaust gas recirculation system

ActiveUS20100064685A1Well mixedReduce nitrogen oxide emissionsNon-fuel substance addition to fuelInternal combustion piston enginesExhaust valveExternal combustion engine

An internal combustion engine includes a plurality of cylinders, an air intake line and an exhaust line collecting exhaust gas. The engine also includes an EGR line for rerouting a part of the exhaust gas from the exhaust line towards the air intake line and at least a first turbocharger comprising a first turbine driven by the exhaust gas flowing towards the atmosphere, linked to a first compressor located on the air intake line. The engine further includes a variable geometry EGR turbine located on the EGR line, driven by the EGR gas flowing in the EGR line. Thus, thanks to the pressure reduction occurring in the turbine, the EGR gas temperature is lowered, and less cooling power from the engine cooling system is required to cool down the EGR.

Owner:VOLVO LASTVAGNAR AB

Installation structure and method for optical parts and electric parts

InactiveUS20020071642A1Large toleranceImprove accuracyPrinted circuit assemblingFinal product manufactureOptical ModuleAngular deviation

The invention relates to an installation technique for optical parts and electric parts. More particularly, it provides an installation structure and an installation method for optical modules that are applied to an optical communication field. The installation structure and the installation method can permit large tolerance of angular deviation in the provisional mounting, and can realize automatic positioning with high precision in the final mounting. The structure includes: a substrate on which a plurality of first metal pads are formed; a part to be mounted having second metal pads corresponding to the positions of the first metal pads; and solder bumps for connecting between the first and second metal pads to match the installation positions of these metal pads based on the surface tension of the solder bumps when the solder bumps are fused. In this structure, the substrate and / or the mounted part has at least two metal pads having larger areas than those of other metal pads, in the vicinity of the center of the substrate and / or the mounted part.

Owner:FUJITSU LTD

Method for fabricating reinforced composite materials

InactiveUS20060130993A1Light weightHigh strengthAdhesive processes with surface pretreatmentLaminationFiber structureMetallurgy

Owner:GENERAL ELECTRIC CO

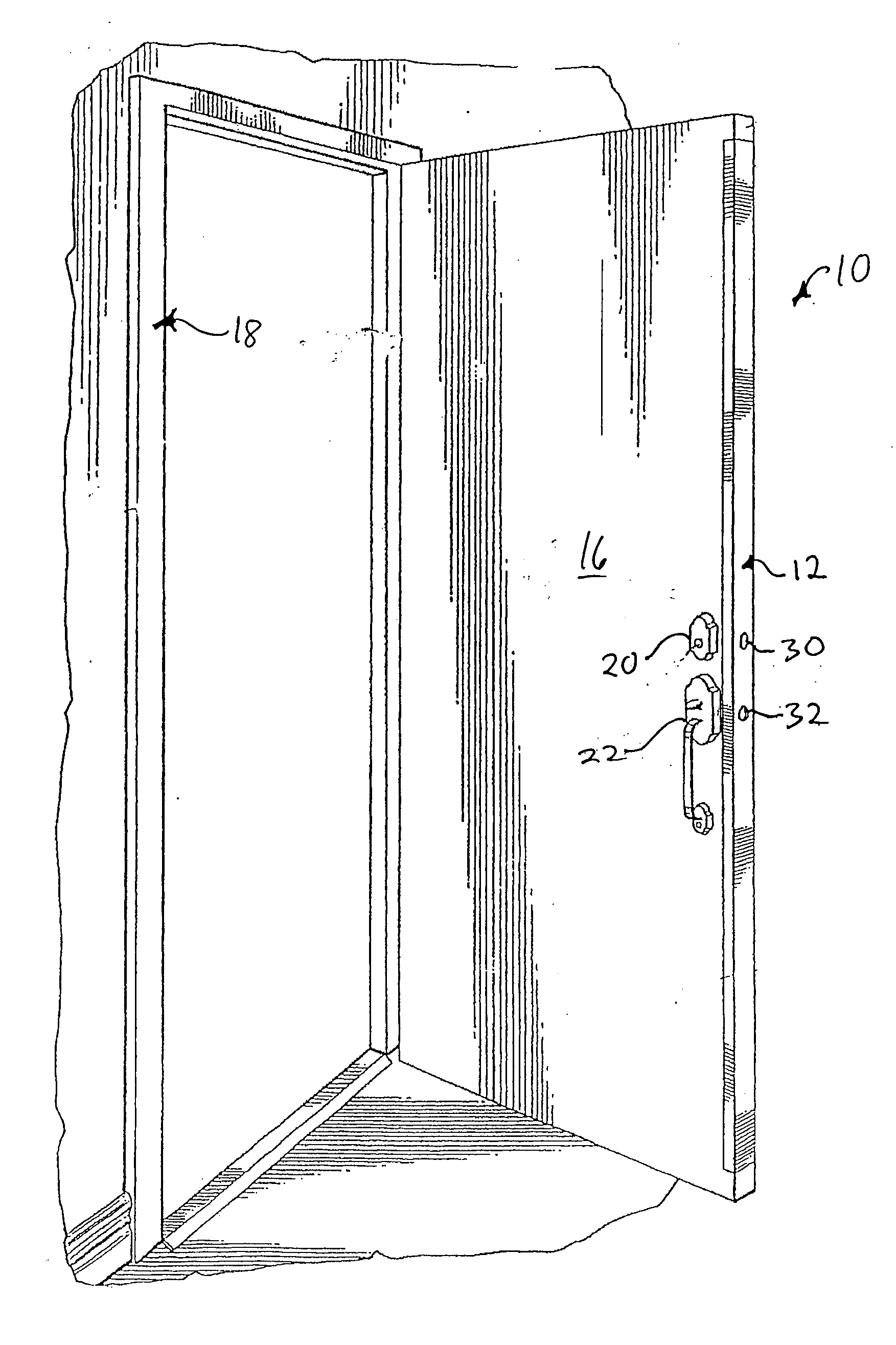

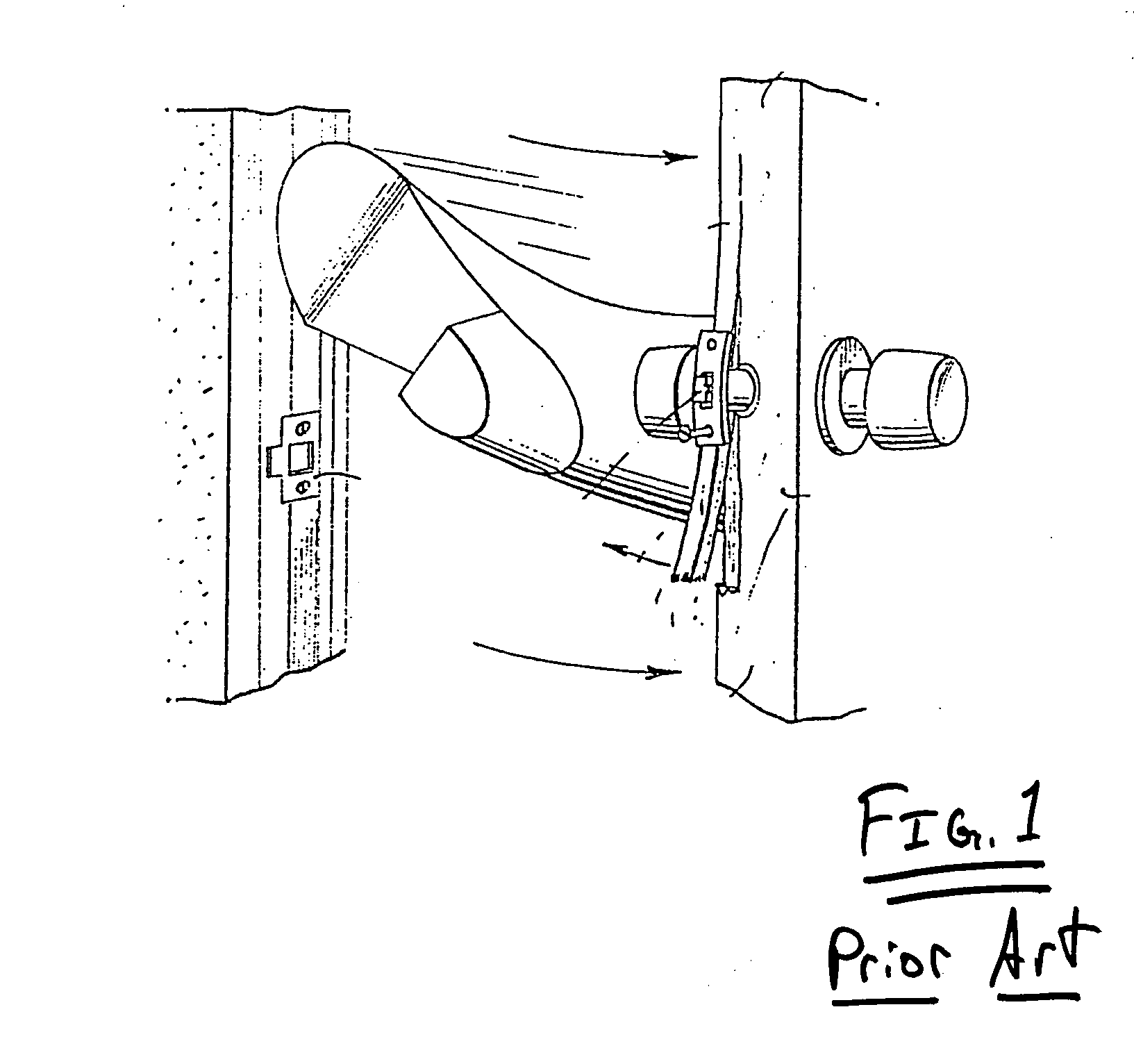

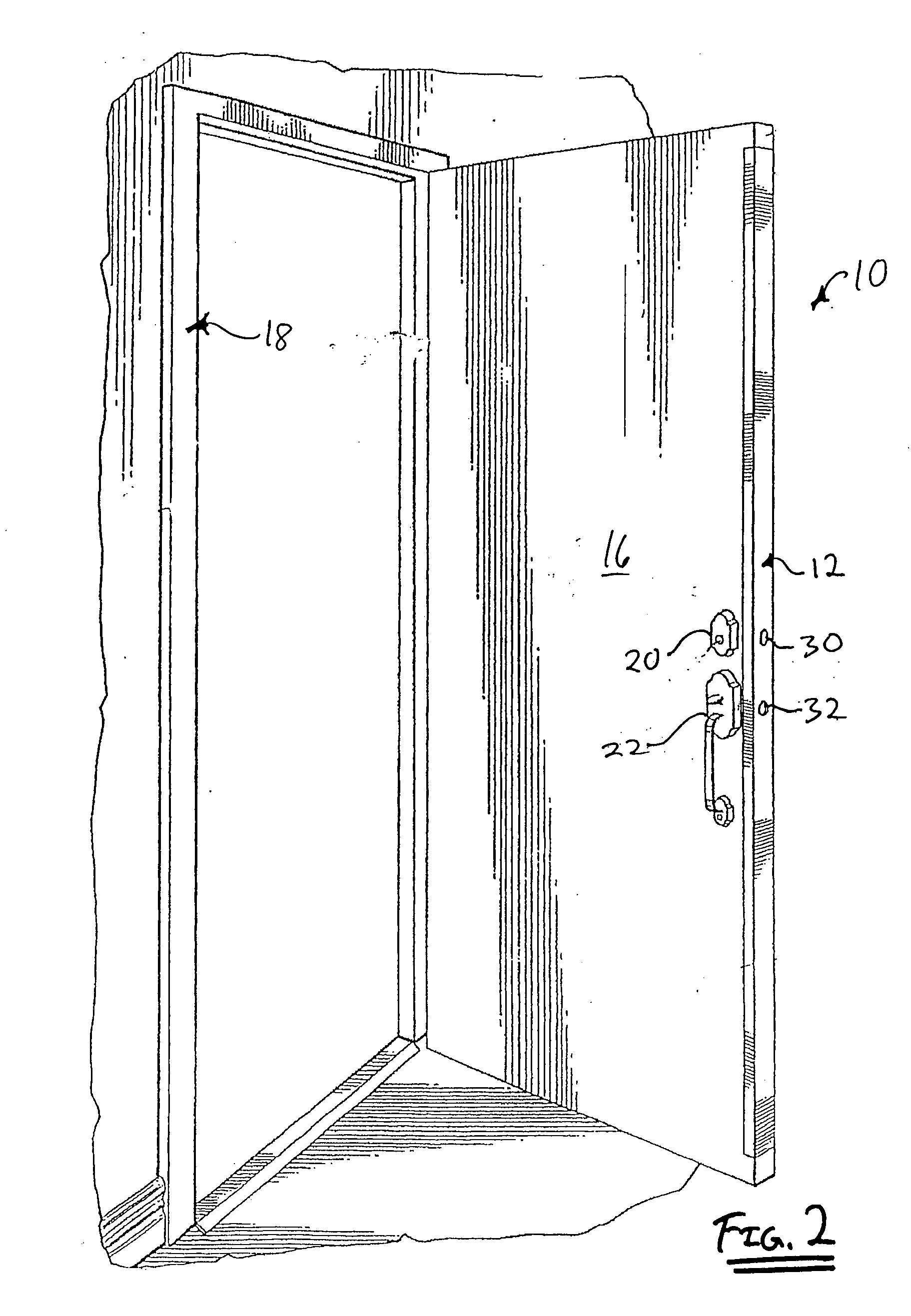

Security device for a door

ActiveUS20050011132A1Large partDistribute forceBurglary protectionWing handlesVertical edgeEngineering

A security device for a door comprises a U-shaped reinforcing plate on the vertical edge of a door on the deadbolt side of the door and an elongated frame plate. The door reinforcing plate and the frame plate are made of a hardened material such as cold rolled steel. The door reinforcing plate extends substantially the entire length of the door. A force applied to the door by a would-be intruder is transmitted from the deadbolt to the door reinforcing plate and the elongated frame plate, which then distribute the force over the vertical edge of the door and a significant part of the frame, respectively.

Owner:GRIFFIN JR JAMES PATRICK +1

Composite corner and method for making composite corner

InactiveUS20080060755A1High uniformity of compositionFew defectLaminationLamination apparatusFiberHost material

A gas turbine engine component and a method for making a composite gas turbine engine component, the method includes providing a tool having a first and second surface, the first and second surface arranged at an angle to each other. A fibrous segment is applied to the first surface. The fibrous segment has an end terminating adjacent to the angle between the first surface and the second surface. A fibrous preform is positioned on the fibrous segment and on the second surface. A matrix material is then provided on one or more of the fibrous preform or the fibrous segment. The fibrous segment and fibrous preform are heated to a temperature sufficient to allow expansion of the end of the fibrous segment. The matrix material is then cured to form a composite article having an angular portion having substantially uniform fiber distribution.

Owner:GENERAL ELECTRIC CO

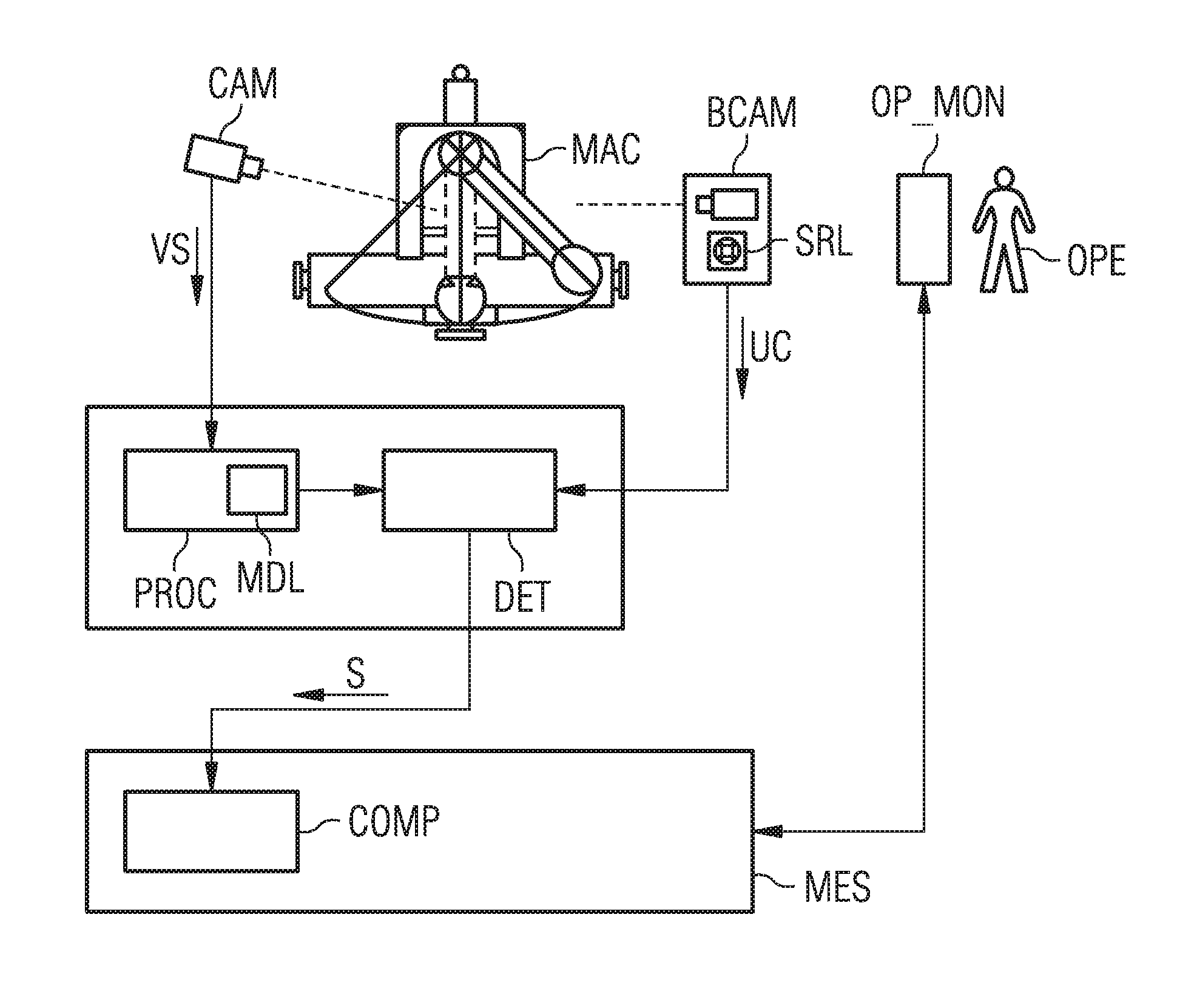

Monitoring system of a dynamical arrangement of pieces taking part in a process related to a manufacturing executing system

InactiveUS20110141266A1Large partProgramme controlColor television detailsManufacturing execution systemSpatial motion

A monitoring system of a dynamical arrangement of pieces takes part in a process related to a manufacturing executing system is presented. At least one of the pieces is spatially movable and the arrangement is free of interfacing signals for signaling a spatial position of the pieces at a control unit of the manufacturing executing system. The monitoring system contains a camera which is spatially positionable in a free selected neighborhood closed to predefined pieces and which acquires an image of a field of interest of the dynamical arrangement, a motion detection unit at an output of the camera that provides a detection of a spatial motion of one of the pieces, and an interface at the output of the camera for transmitting the acquired image to an input of a monitoring unit to extract information on a status of the arrangement which is interpretable in the control unit.

Owner:SIEMENS AG +1

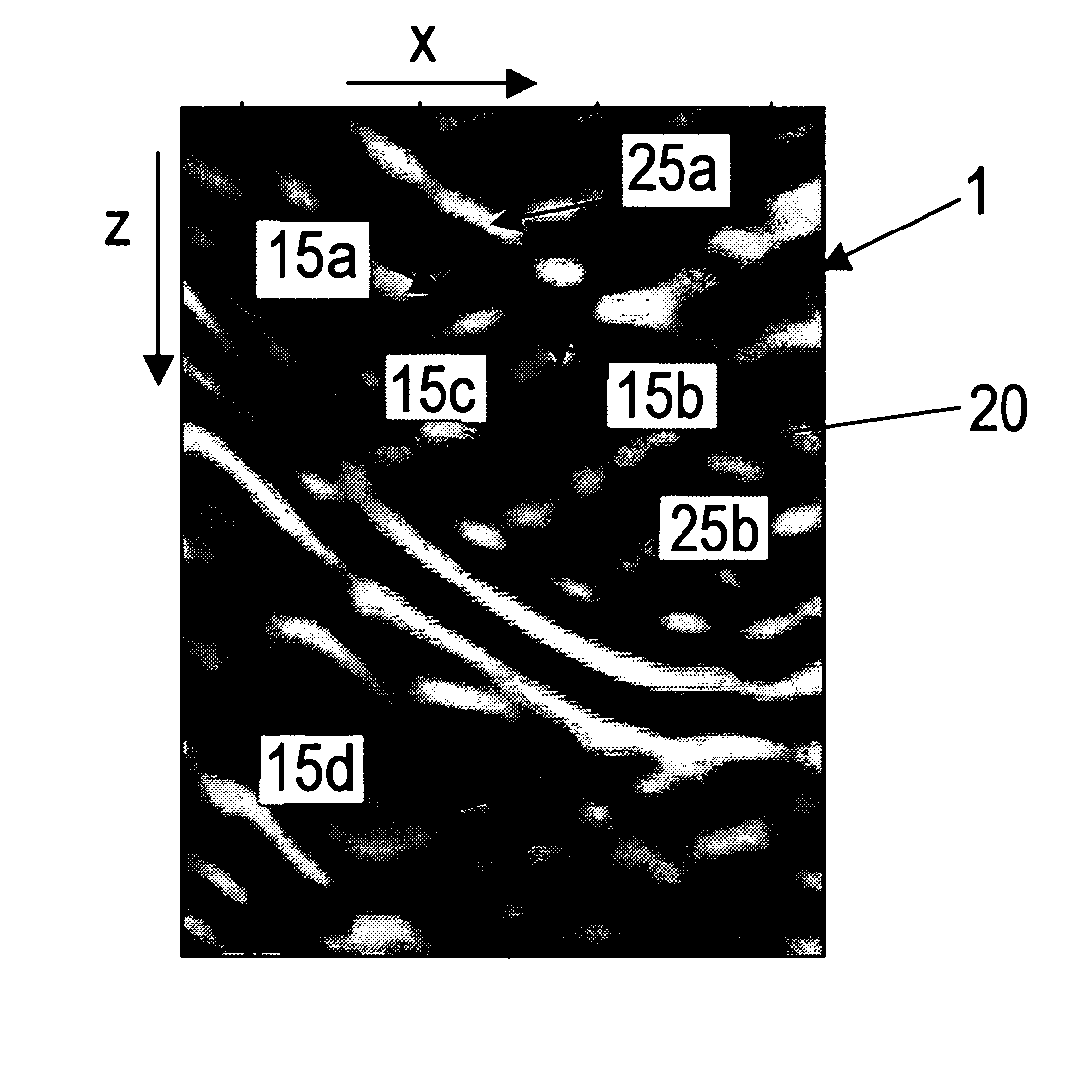

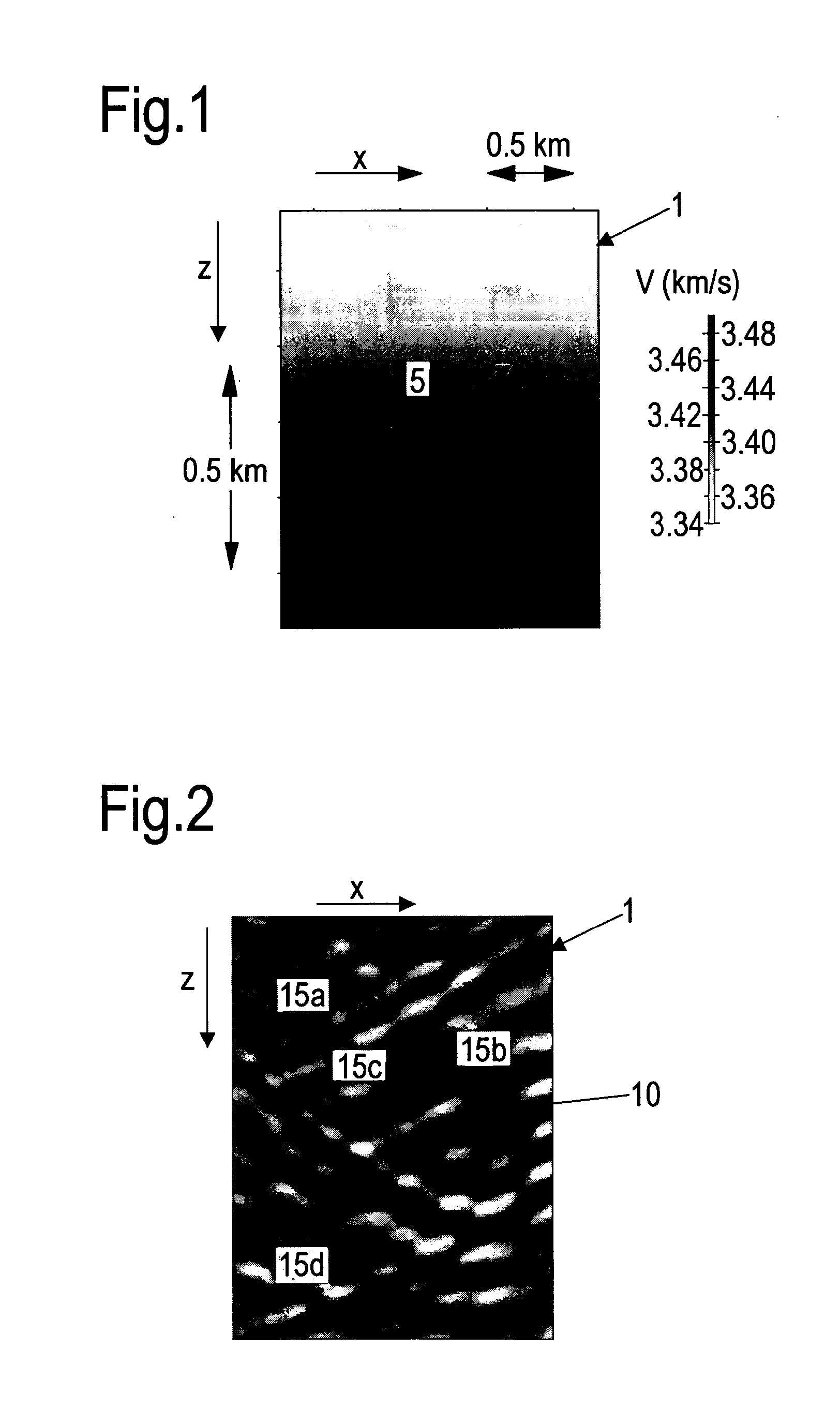

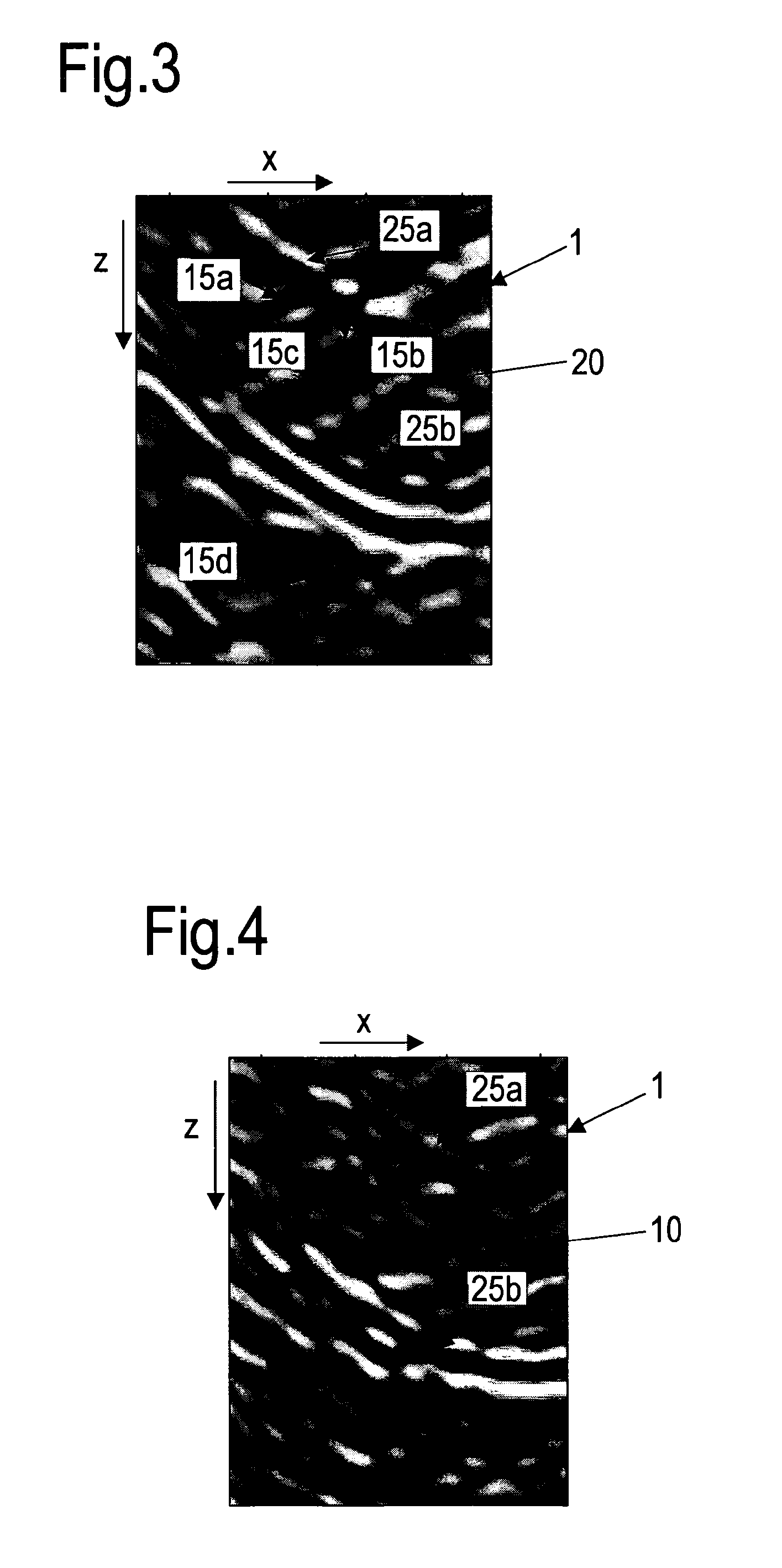

Method of processing data obtained from seismic prospecting

ActiveUS20100268471A1Reduce in quantityReduce uncertaintySeismic signal processingSeismology for water-loggingWave equationSeismic processing

Owner:SHELL USA INC

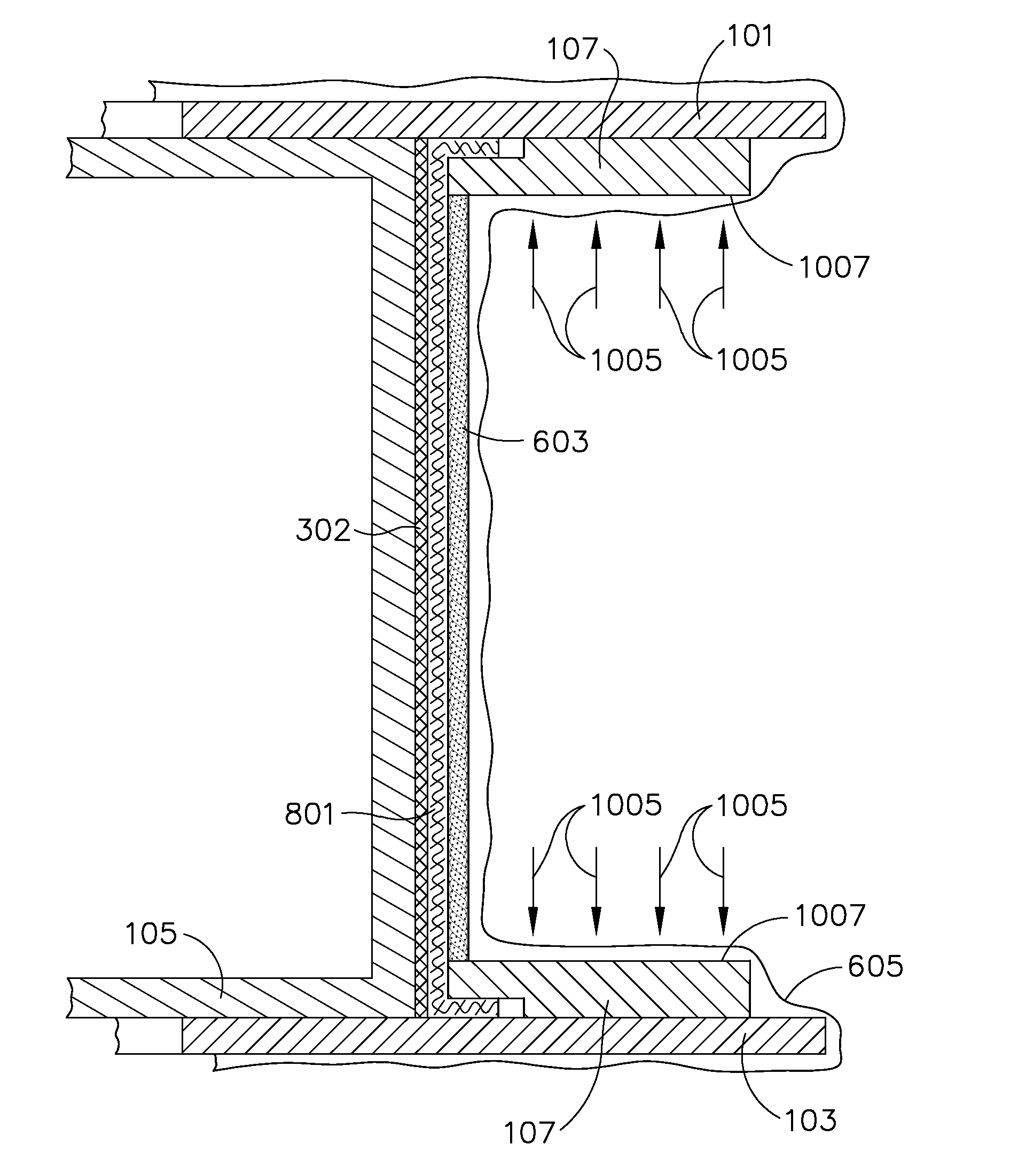

Reinforced matrix composite containment duct

ActiveUS20060134396A1Light weightHigh strengthEfficient propulsion technologiesMachines/enginesGas turbinesPre stressing

A reinforced matrix composite containment duct for gas turbine engines comprising a reinforced matrix composite containment duct having high strength integral flanges and pre-stressed reinforcing fibers, the reinforced matrix composite having uniform distribution of matrix material; and the reinforced matrix composite having less than or equal to 2.5% void space.

Owner:GENERAL ELECTRIC CO

Delivery nozzle with more uniform flow and method of continuous casting by use thereof

InactiveUS20080173424A1Reduce kinetic energyLarge partMelt-holding vesselsBlast furnace componentsEngineeringMolten metal

A method of and apparatus for casting metal strip involving assembling a pair of casting rolls laterally disposed to form a nip between them, assembling an elongated metal delivery nozzle extending along and above the nip between the casting rolls, with at least one segment having opposing side walls and end walls, an inner trough extending longitudinally within between side walls and forming passages between the side walls and the inner trough and communicating with side outlets adjacent bottom portions, introducing molten metal through the elongate metal delivery nozzle to form a casting pool of molten metal supported on the casting rolls above the nip, such that molten metal is caused to flow into the inner trough of the delivery nozzle, from the inner trough through the passages between the inner trough and sidewalls, and from the passages through the side outlets in a substantially lateral direction into the casting pool, and counter rotating the casting rolls to deliver cast strip downwardly from the nip.

Owner:NUCOR CORP

System and method for performing automated testing of a merchant message

InactiveUS20070124210A1Reduce setup timeQuick fixHand manipulated computer devicesFinanceValidation ruleComputer science

Error-testing of merchant messages to be used with point-of-sale (POS) devices is performed by an automated system that receives a formatted message to be tested from a merchant or an agent of the merchant, performs a computer-implemented evaluation of the message according to predefined message-validation rules to detect one or more errors, and notifies the merchant or the agent of evaluation results. The evaluation results include a listing of each detected error, if any.

Owner:LIBERTY PEAK VENTURES LLC

Control device

InactiveUS8051926B2Reduce pressureReduce reflectionDrill bitsReciprocating drilling machinesShock waveCounter pressure

The present invention relates to a control device for an impulse-generating device for inducing a shock wave in a tool, in which said impulse-generating device comprises an impact element for transmitting said shock wave to said tool, a counter pressure chamber acting against the impact element and a device for reducing a pressure in the counter-pressure chamber. The control device comprises control means for regulating the reduction of the pressure in said computer-pressure chamber. The invention also relates to an impulse-generating device.

Owner:ATLAS COPCO ROCK DRILLS

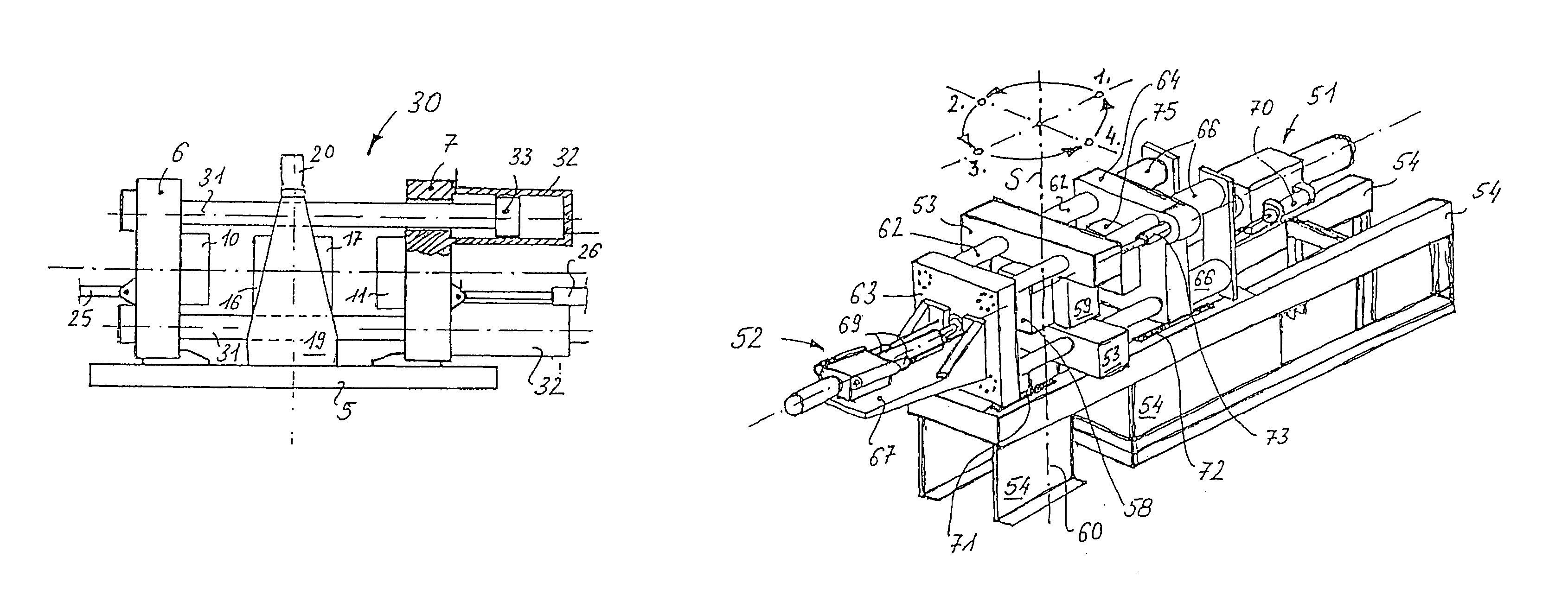

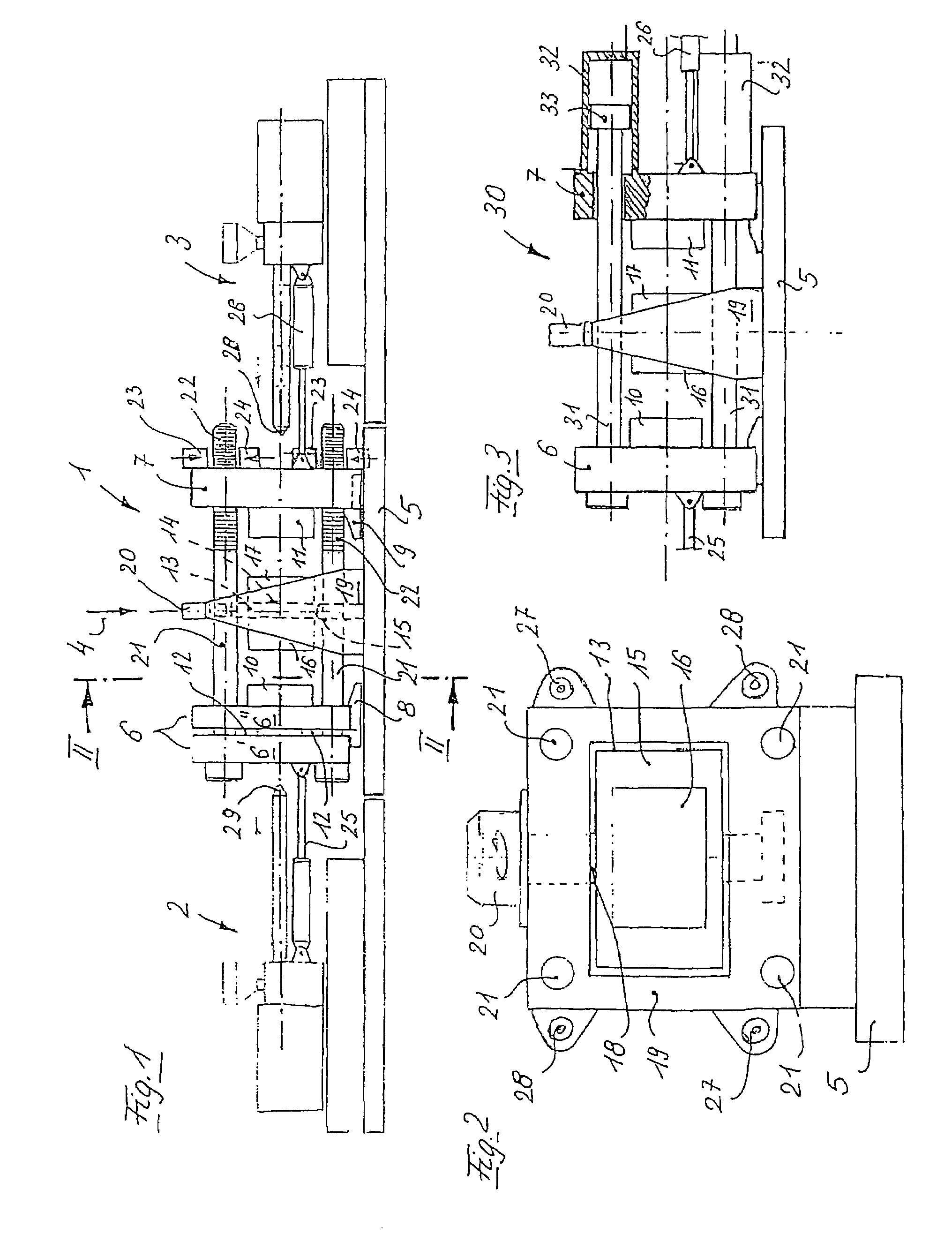

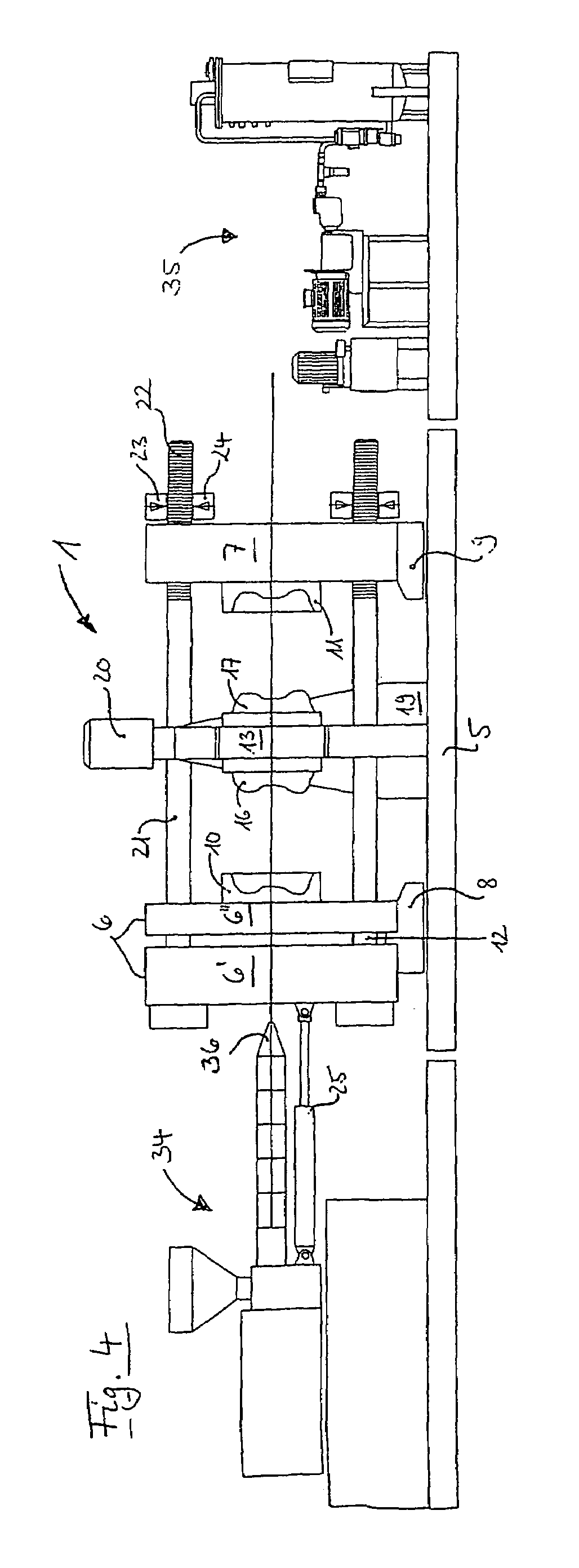

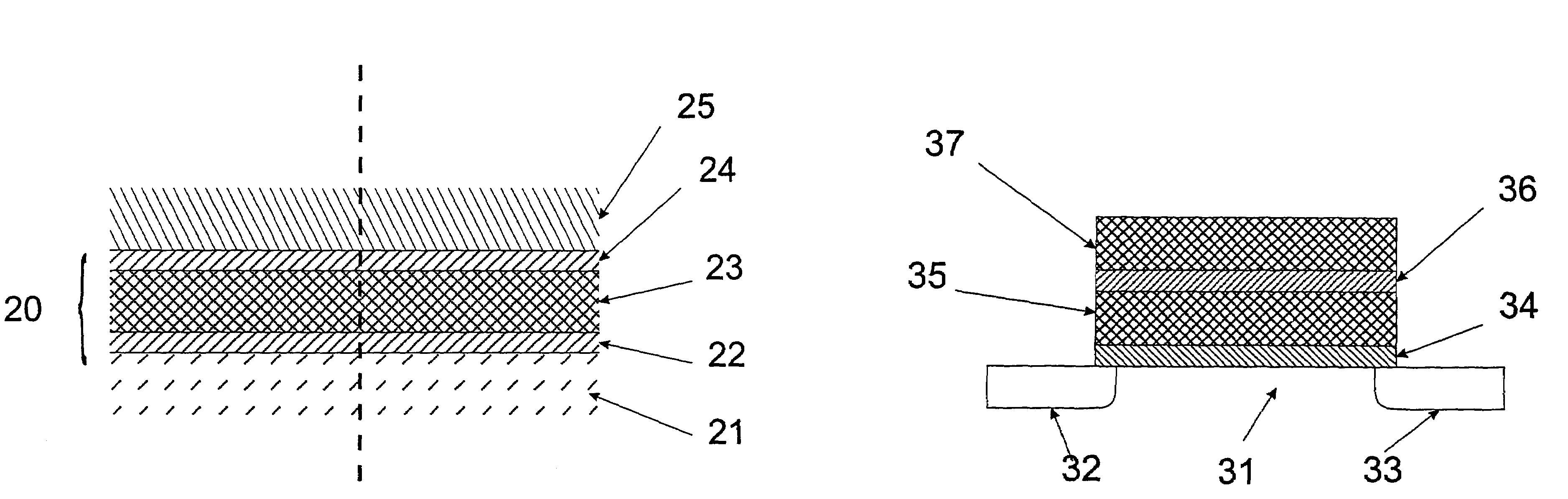

Mold closing device for an injection molding machine

InactiveUS7018189B2Improve adhesionShorten cycle timeTailstocks/centresConfectioneryBraced frameEngineering

A mold closing device of an injection molding machine for producing plastic parts made of two or more plastic components includes a central mold carrier element which is arranged between two outer mold mounting plates and has two or four opposing mold mounting areas arranged in pairs for affixing two or four mold halves and which is fitted with a turning device supported in a supporting frame. Each of the mold halves of the mold carrier element can be closed against the mold halves of the outer mold mounting plates by a drive mechanism and a mold pressure unit. The outer mold mounting plates are interconnected by columns which extend through the supporting frame for the central mold carrier element. The supporting frame is fixedly connected to the machine frame while the outer mold mounting plate is displaceably supported on the machine frame.

Owner:KRAUSS MAFFEI KUMSTSTOFFTECHNIK GMBH

Insulating barrier, NVM bandgap design

InactiveUS7026686B2Strong dependenceHigh dielectric constantTransistorNanoinformaticsDielectricCharge carrier

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Delivery nozzle with more uniform flow and method of continuous casting by use thereof

InactiveUS7926549B2Avoid surface defectsIncrease temperatureMelt-holding vesselsBlast furnace componentsEngineeringMolten metal

A method of and apparatus for casting metal strip involving assembling a pair of casting rolls laterally disposed to form a nip between them, assembling an elongated metal delivery nozzle extending along and above the nip between the casting rolls, with at least one segment having opposing side walls and end walls, an inner trough extending longitudinally within between side walls and forming passages between the side walls and the inner trough and communicating with side outlets adjacent bottom portions, introducing molten metal through the elongate metal delivery nozzle to form a casting pool of molten metal supported on the casting rolls above the nip, such that molten metal is caused to flow into the inner trough of the delivery nozzle, from the inner trough through the passages between the inner trough and sidewalls, and from the passages through the side outlets in a substantially lateral direction into the casting pool, and counter rotating the casting rolls to deliver cast strip downwardly from the nip.

Owner:NUCOR CORP

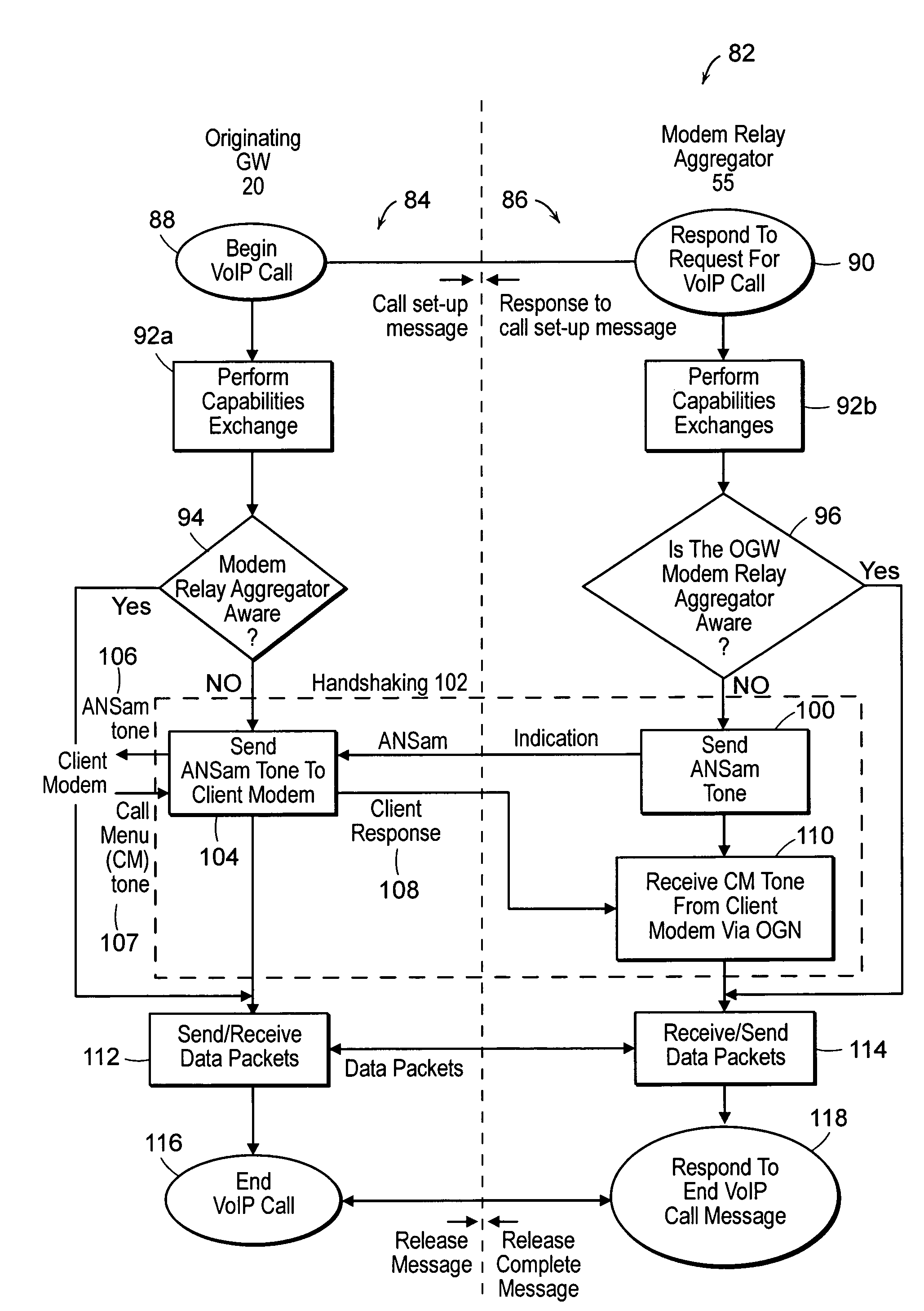

Device to terminate a modem relay channel directly to an IP network

ActiveUS7543063B1Large partSimpler terminationInterconnection arrangementsData switching by path configurationDigital signal processingModem device

A modem data aggregating gateway that supports modem relay functionality for permitting reliable switching of modem traffic between a VoIP network and a data packet switch Internet Protocol (IP) network, s.a. the Internet. The modem relay aggregator may receive modem data encapsulated as Voice over IP (VoIP) data packets in accordance with a Simple Reliable Protocol Transport (SRPT) mechanism. The packet data may be error corrected and / or decompressed before being repackaged for forwarding to the ultimate destination. In the event that the destination is itself an IP device, the modem relay aggregator may forward the packets directly over the IP network. As a result, if the destination of a modem call is an IP device (such as a Web site or other Internet-enabled device) the technique eliminates two points from a processing path in which digital signal processing (DSPs) would otherwise have to perform modem protocol processing. Otherwise, minimal modem reformatting can be performed at the aggregation point.

Owner:CISCO TECH INC

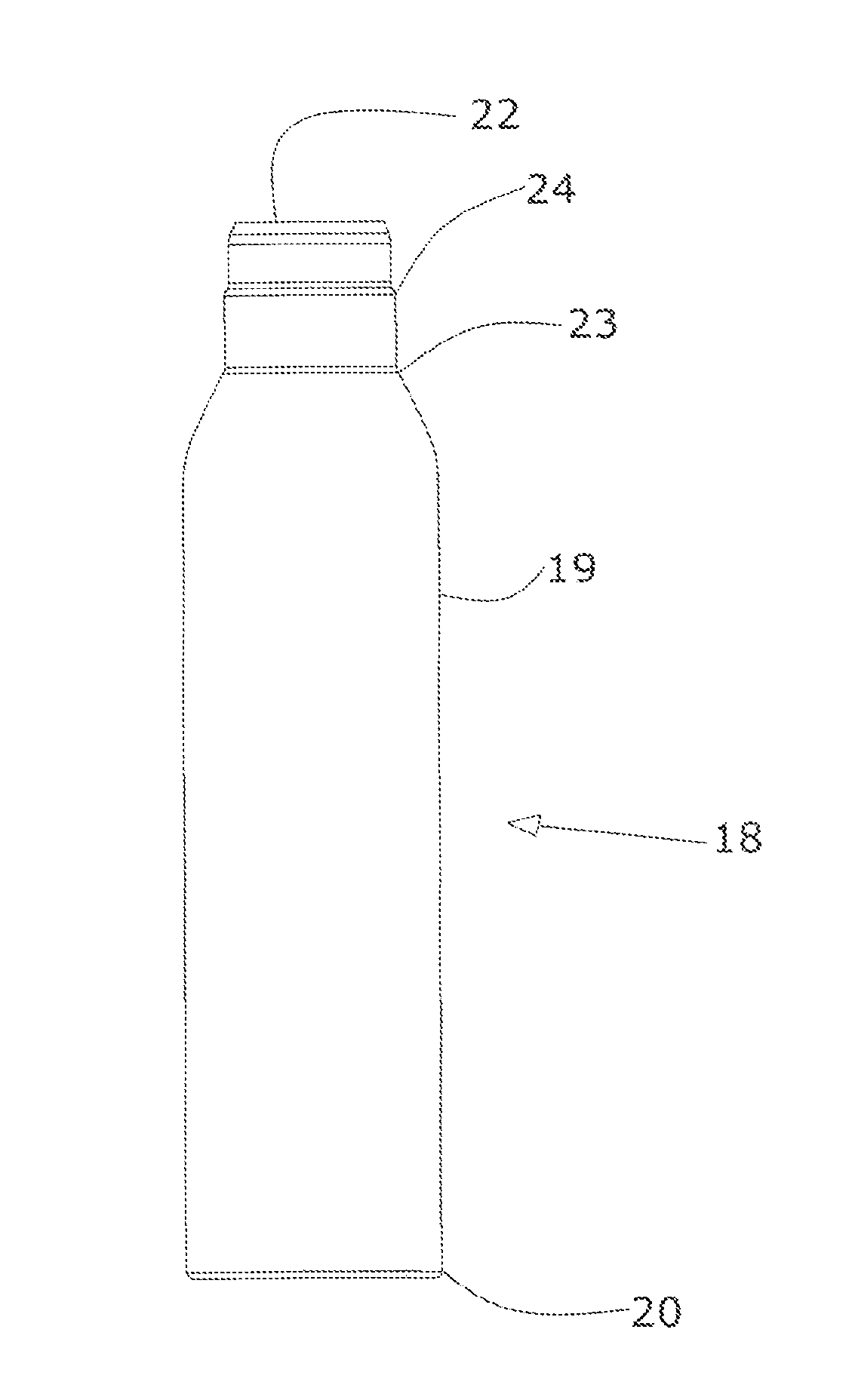

Method for blow molding metal containers

ActiveUS20150273560A1Large workIncrease the dislocation densityIncreasing energy efficiencyFurnace typesBlow moldingMetallurgy

A method is disclosed for pressure forming a metal preform including shock annealing of the preform and subsequently preheating the preform prior to pressure forming. Shock annealing may be carried out as differential shock annealing in which different regions of the preform are annealed to different degrees. Preheating may be carried out by differentially preheating, optionally shock preheating, different regions of the preform for preheating at least those regions of the preform which will be subject to elevated expansion during pressure forming. Shock annealing by induction heating can lower energy consumption, reduce processing times and allow for larger expansion of the preform.

Owner:MONTEBELLO TECH SERVICES LTD +1

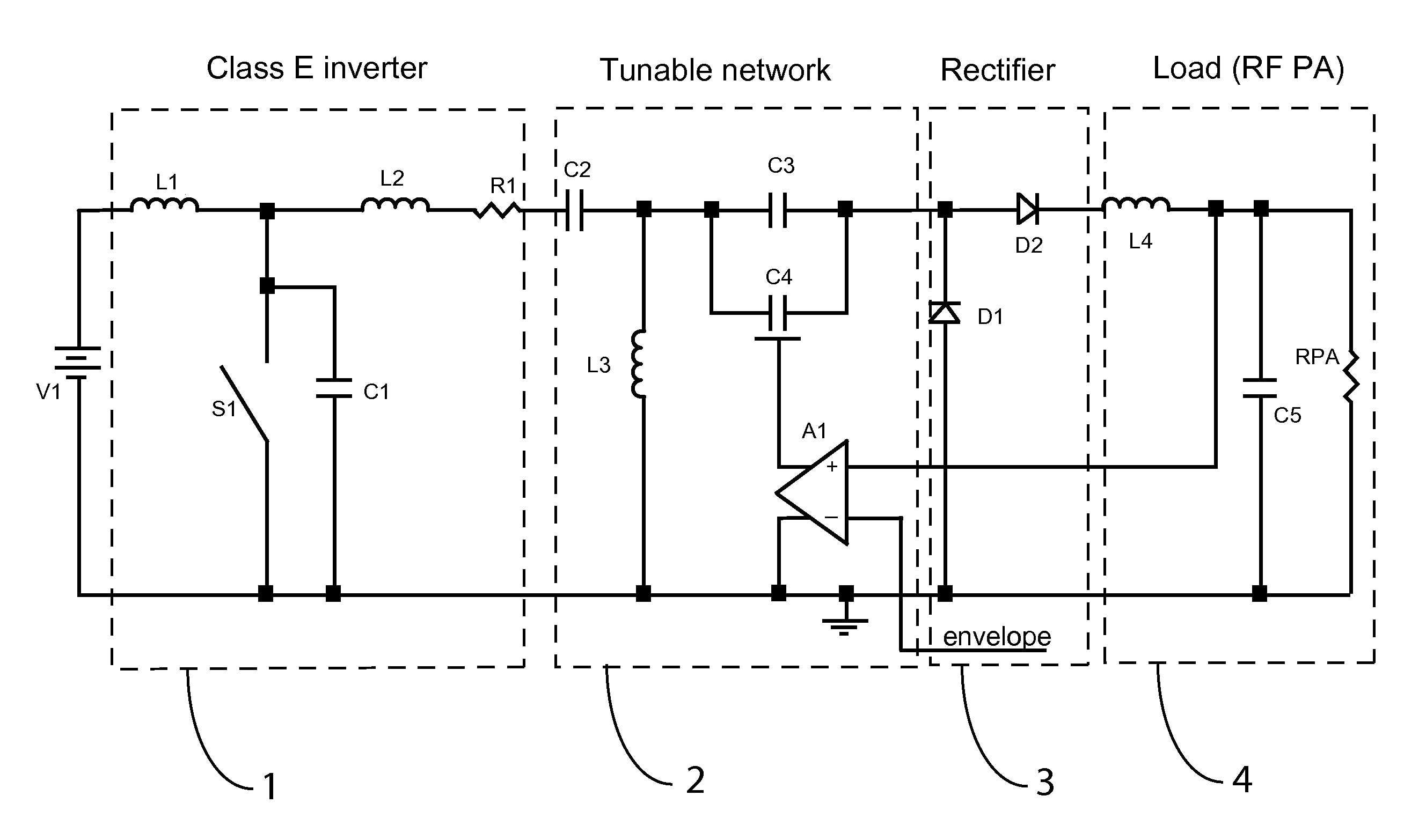

Tunable Envelope Tracking

InactiveUS20160087590A1Large partReduce switching lossesHigh frequency amplifiersPower amplifiersResonant power convertersSelf adaptive

A novel method to provide power management to a radio frequency amplifier is described. The method makes use of a DC-AC resonant switching power converter, a resonant tunable network and a rectifier to track the envelope signal of a radio amplifier system. This system provides a fast, efficient and clean supply to the radio frequency amplifier. The resonant power converter may be implemented with a class E inverter. The resonant power converter may be operated efficiently by switching at zero voltage switching or zero current switching. By operating the resonant switching power converter at the same frequency of the radio frequency amplifier, the spectrum of the power converter is immune from undesired harmonics while meeting the bandwidth requirement. By adaptively tuning the tunable resonant network, the output voltage of the rectifier is controlled to track the envelope signal.

Owner:QUALCOMM INC

Feedback controlled illumination system having an array of leds, and a detector among the leds

InactiveUS20090237003A1Drawback can be obviatedLoss minimizationPoint-like light sourceElectric circuit arrangementsLighting systemCollimator

The present invention relates to an illumination system having an array of differently coloured LEDs, a plurality of collimators, wherein each collimator holds at least one LED, a light mixing element, arranged to mix light generated by the LEDs into a mixed light that is emitted from the illumination system, and a control system for controlling the colour balance of the mixed light. The control system comprises a detector, which is placed among said collimators and encircled by a light shield. The detector detects a fraction of the mixed light that is reflected at an exit window of the mixing element. In this structure the detected light twice passes the mixing element, which provides for a proper mixing of the different colours as well as a proper homogenisation of the light.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com