Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Judge eligibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

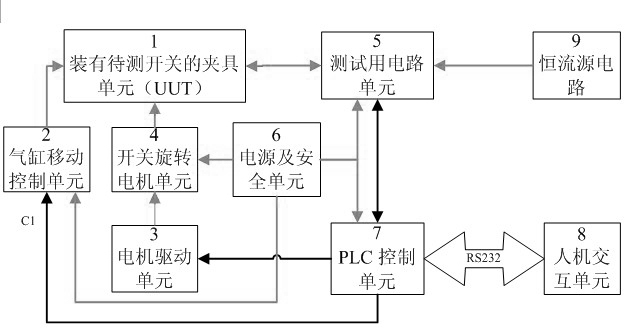

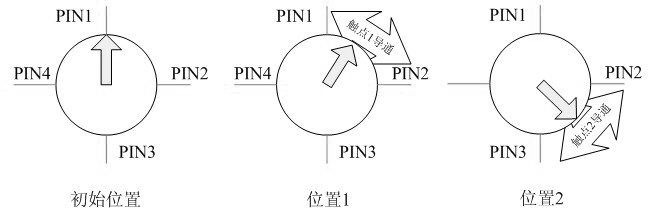

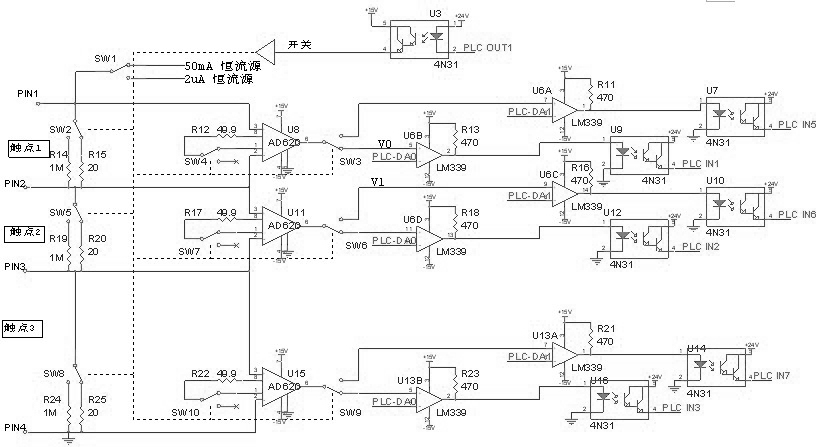

Automatic test system for performance of multi-position switch and test method for same

InactiveCN102520349ARealize detectionImprove test accuracyCircuit interrupters testingElectricityElectrical resistance and conductance

The invention discloses an automatic test system for the performance of a multi-position switch, which is characterized by comprising a switch clamp unit, a switch rotation motor unit, a test circuit unit, a PLC (programmable logic controller) unit, a power control unit and a man-machine interaction unit, wherein a test end of the test circuit unit is connected with the switch to be tested, an output end of the test circuit unit is connected with the PLC unit, and a control end of the PLC unit is connected with an input end of the test circuit unit. A test method includes: testing on-resistance and open resistance of contacts at positions by the aid of the test circuit unit; converting corresponding constant current into voltage; comparing the voltage with reference voltage provided by the PLC unit; and outputting decision outcome to the PLC unit. The test circuit unit is used for testing the on-resistance and the open resistance of each contact of the multi-position switch and converting the resistance into the voltage to be tested, so that the electrical performance of the multi-position switch is automatically tested.

Owner:苏州佳世德检测技术有限公司

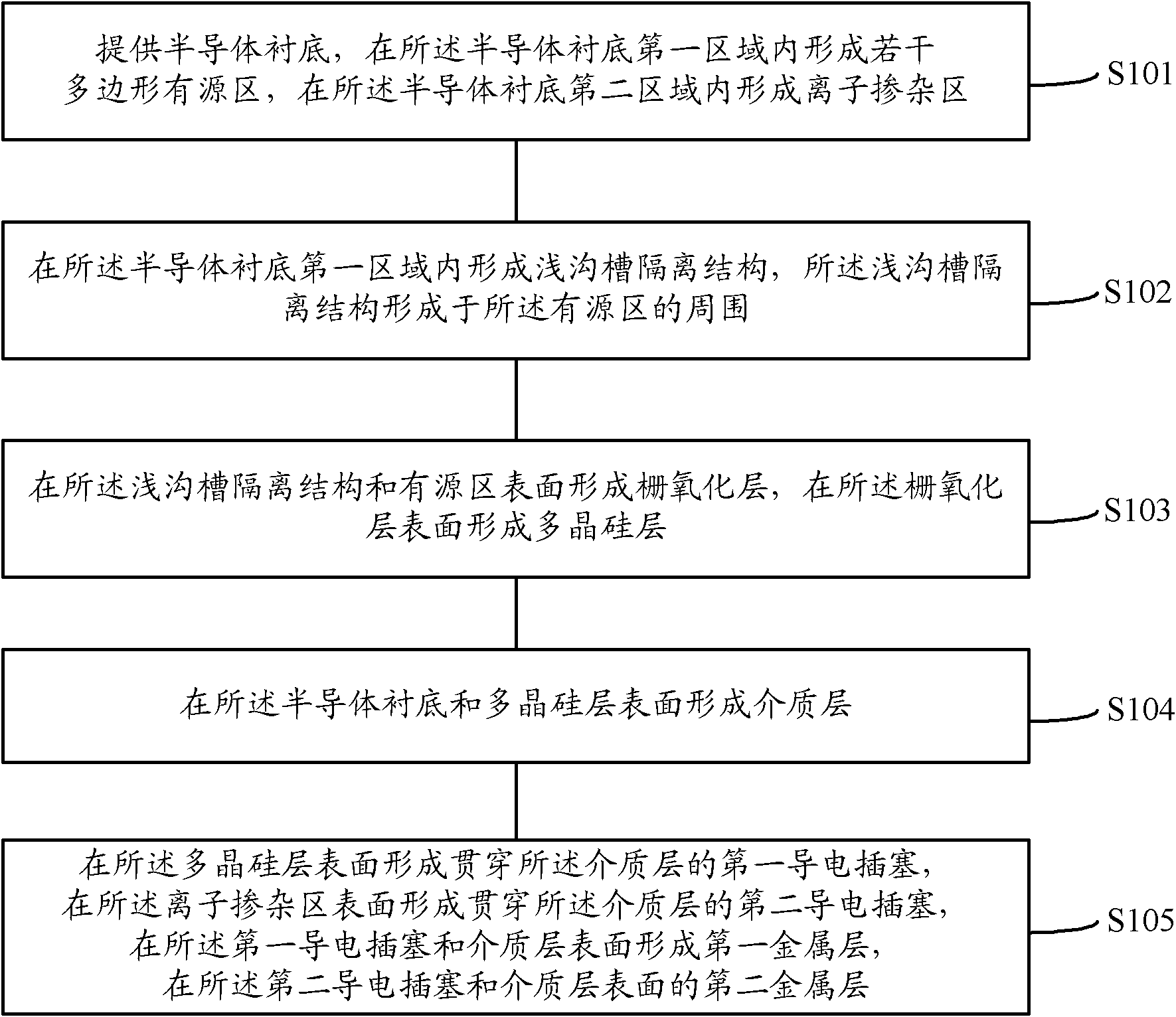

Detecting structure, forming method and detecting method

ActiveCN102931170AJudge eligibilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsIon mixingGate oxide

The invention discloses a detecting structure, a forming method and a detecting method. The detecting structure comprises a plurality of polygon active areas, a shallow channel isolation structure, an ion mixing area, a gate oxide layer, a polycrystalline silicon layer, a dielectric layer, a first conducting plug, a second conducting plug, a first metal layer and a second metal layer, wherein the polygon active areas are positioned in a first area of a semiconductor substrate; the shallow channel isolation structure is positioned in the first area of the semiconductor substrate and is formed surrounding the active areas; the ion mixing area is positioned in a second area of the semiconductor substrate; the gate oxide layer covers the active area and the shallow channel isolation structure; the polycrystalline silicon layer is positioned on the surface of the gate oxide layer; the dielectric layer covers the semiconductor substrate and the polycrystalline silicon layer; the first conducting plug is positioned on the surface of the polycrystalline silicon layer; the second conducting plug is positioned on the surface of the ion mixing layer, and the first metal layer and the second metal layer are positioned on the surface of the dielectric layer. According to the detecting structure disclosed by the invention, whether a corner of the active area of the detecting structure is damaged or not can be detected by measuring the puncture voltage of the gate oxide layer for one time, and thus whether a corner of an active area of a to-be-detected semiconductor device is damaged or not can be judged.

Owner:SEMICON MFG INT (SHANGHAI) CORP

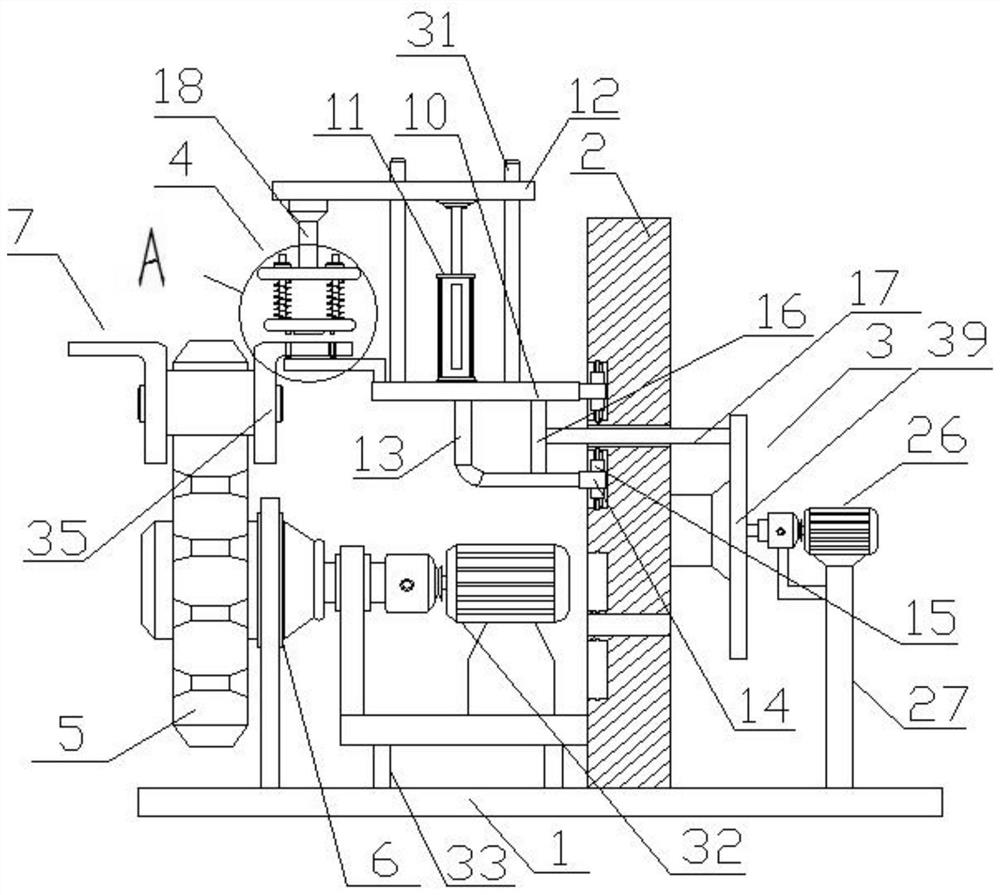

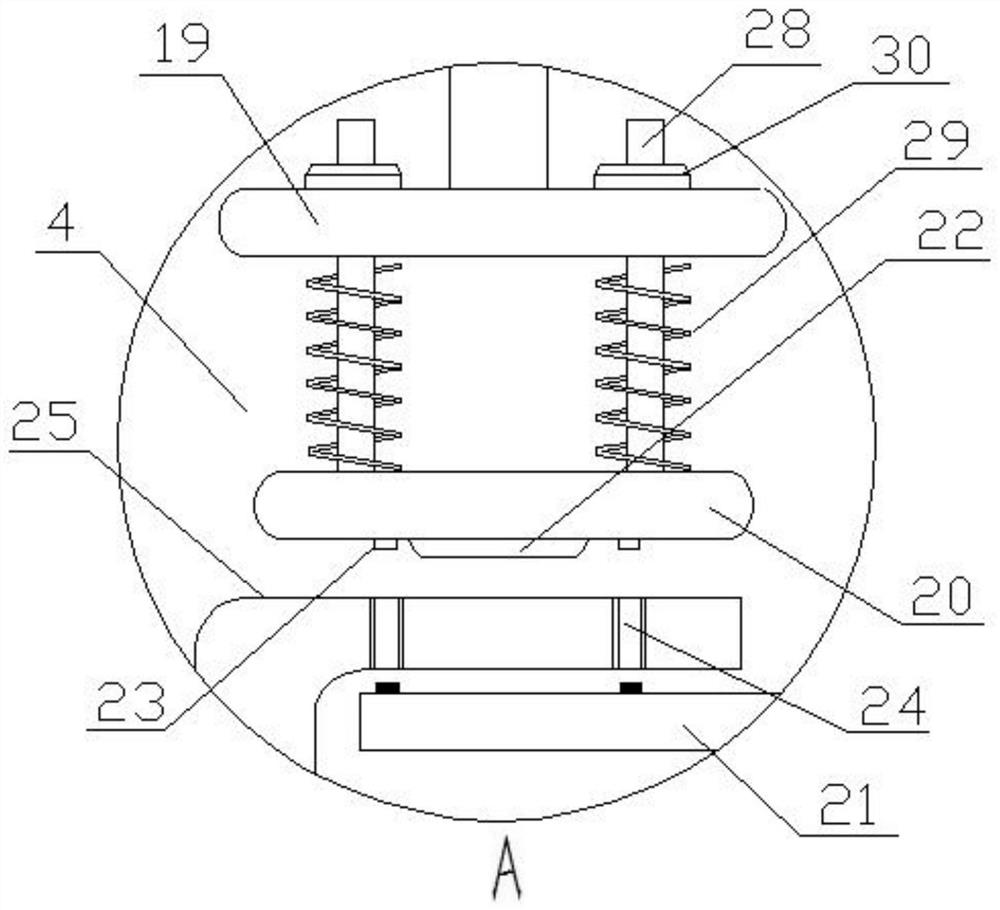

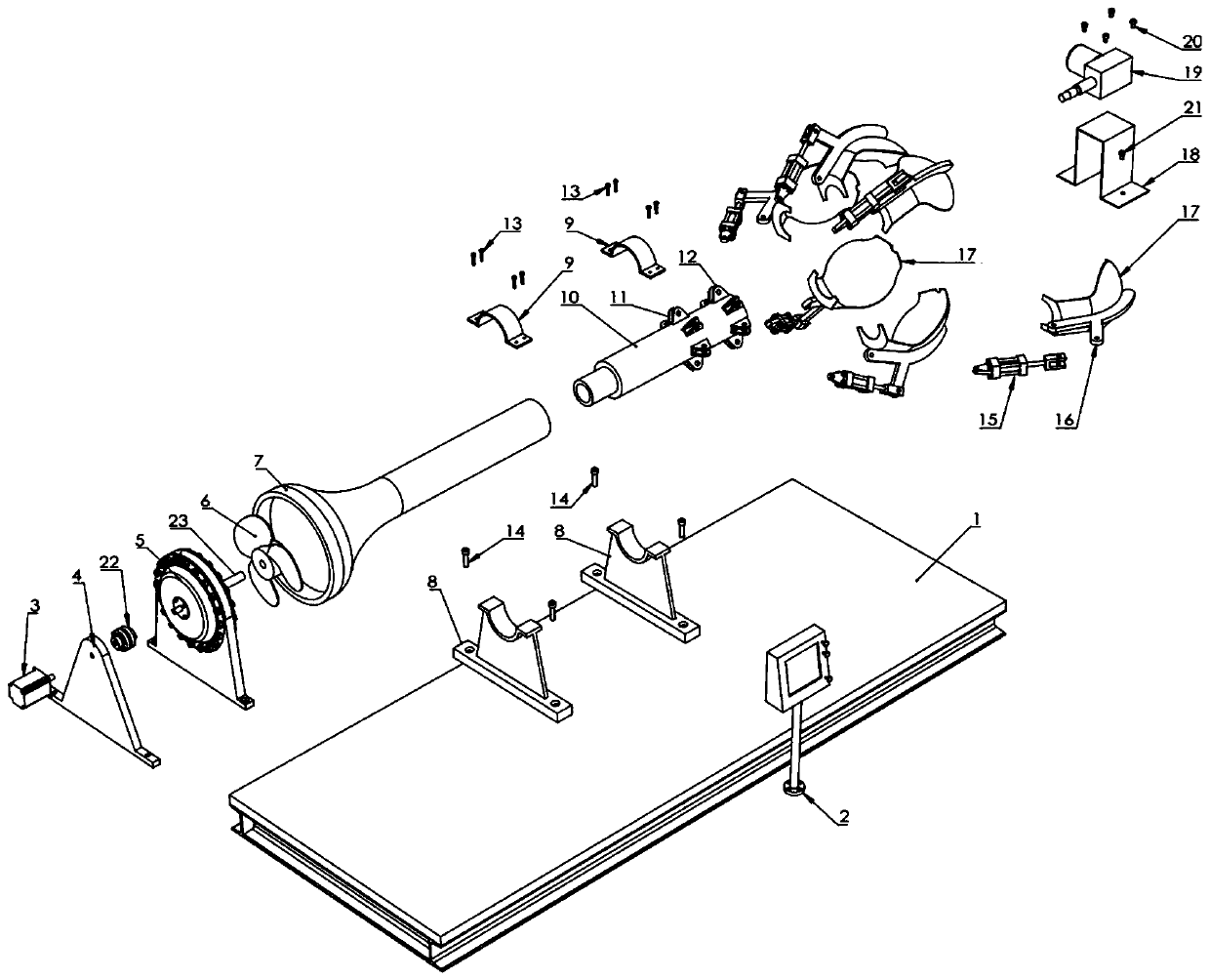

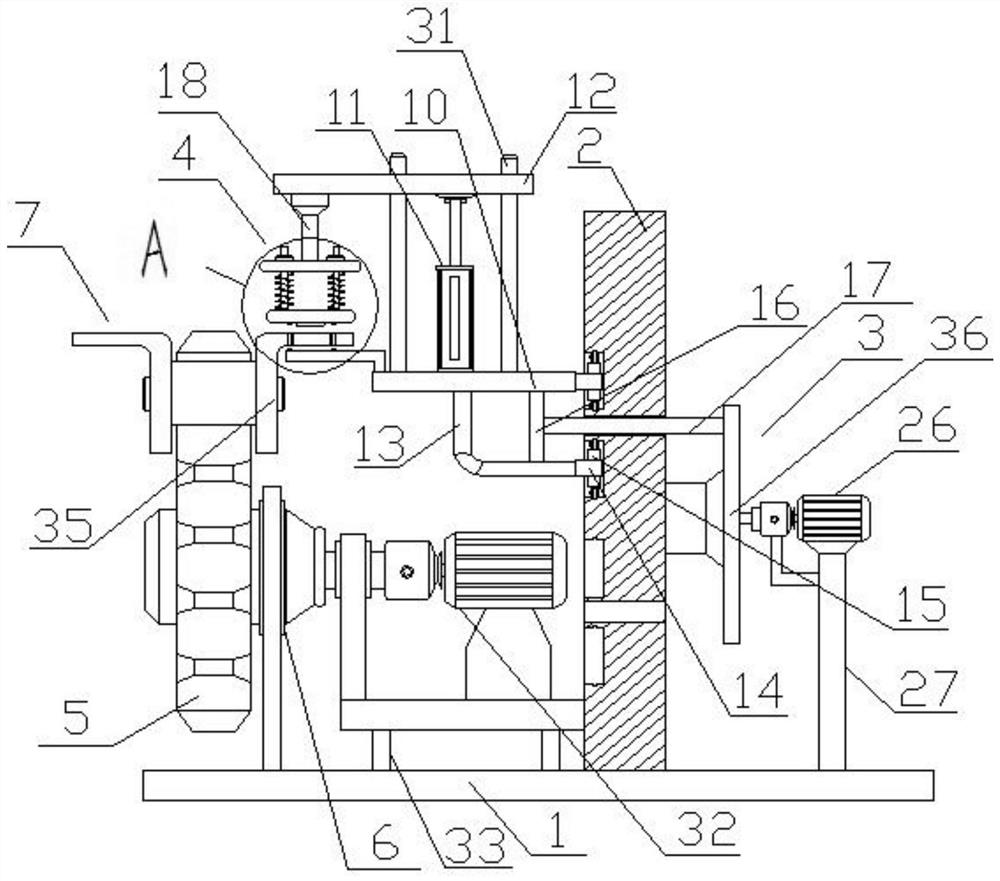

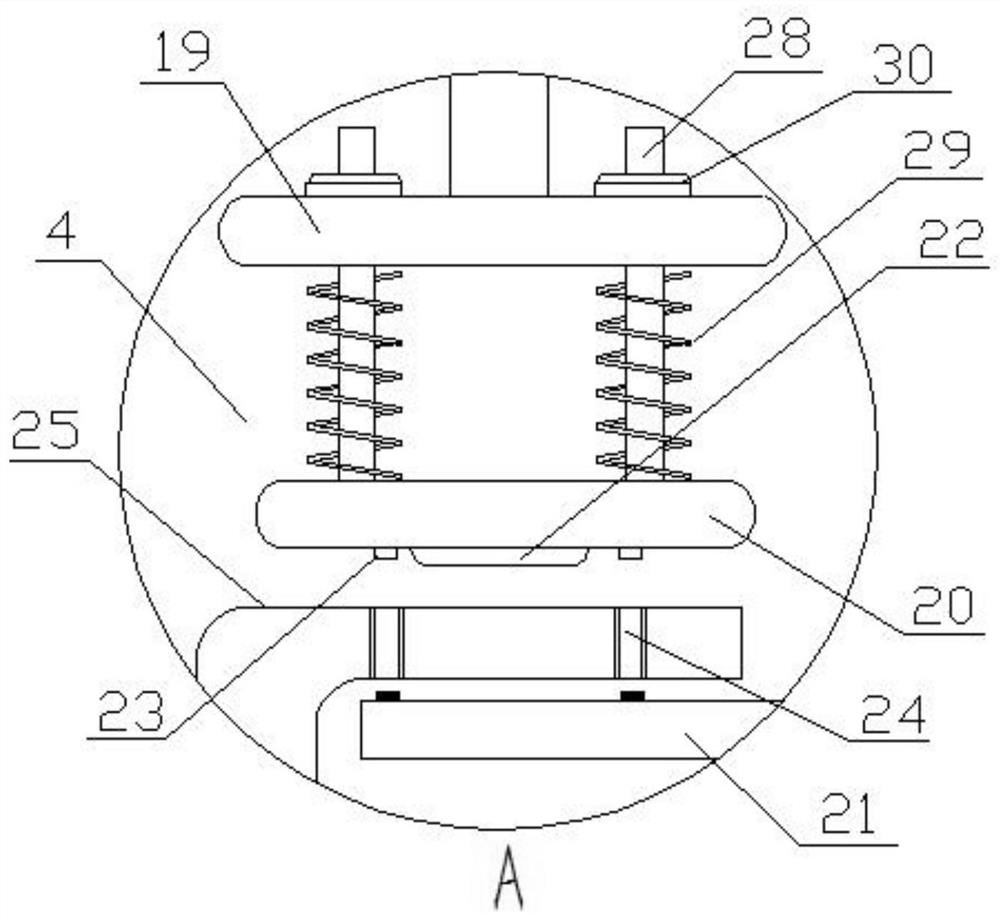

Chain detection mechanism

The invention discloses a chain detection mechanism which comprises a rack, an auxiliary plate, an eccentric transmission assembly, a lifting assembly, a detection assembly and a power assembly. The power assembly comprises a transmission assembly, two chain wheels and two chain wheel seats; the bottom of the auxiliary plate is fixed on the rack; the lifting assembly comprises a fixed plate, a hydraulic cylinder and a top plate; the eccentric transmission assembly comprises an inner fluted disc, an inner gear, a rotating base, a first gear motor, a fixing frame and a rotating shaft; the detection assembly comprises a connecting rod, an upper pressing plate, a lower pressing plate and a distance measuring plate. The mechanism is ingenious in design and convenient to operate.

Owner:绩溪山合机械有限公司

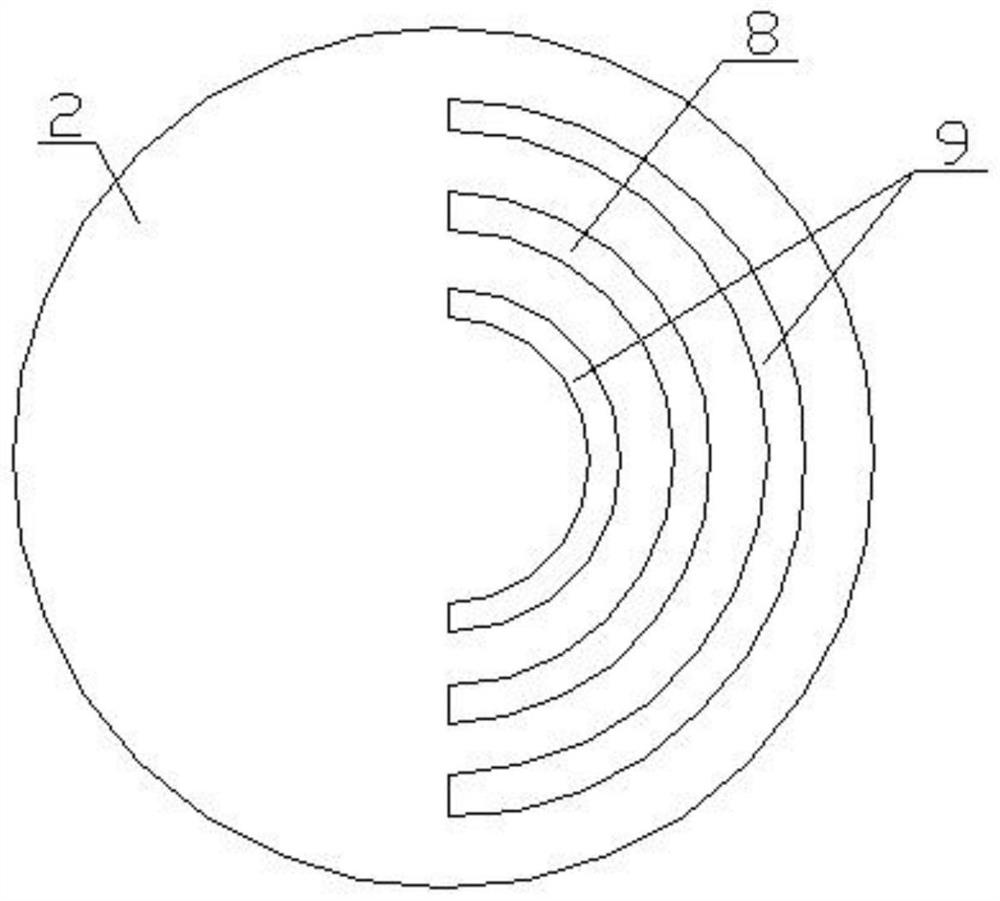

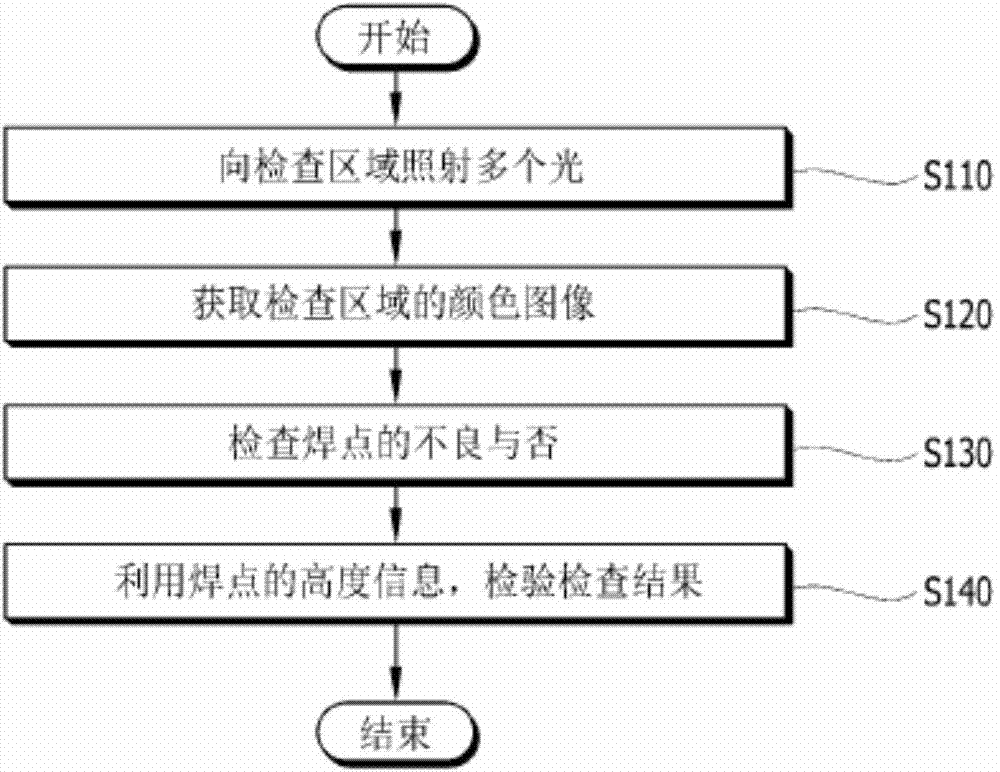

Board inspection method

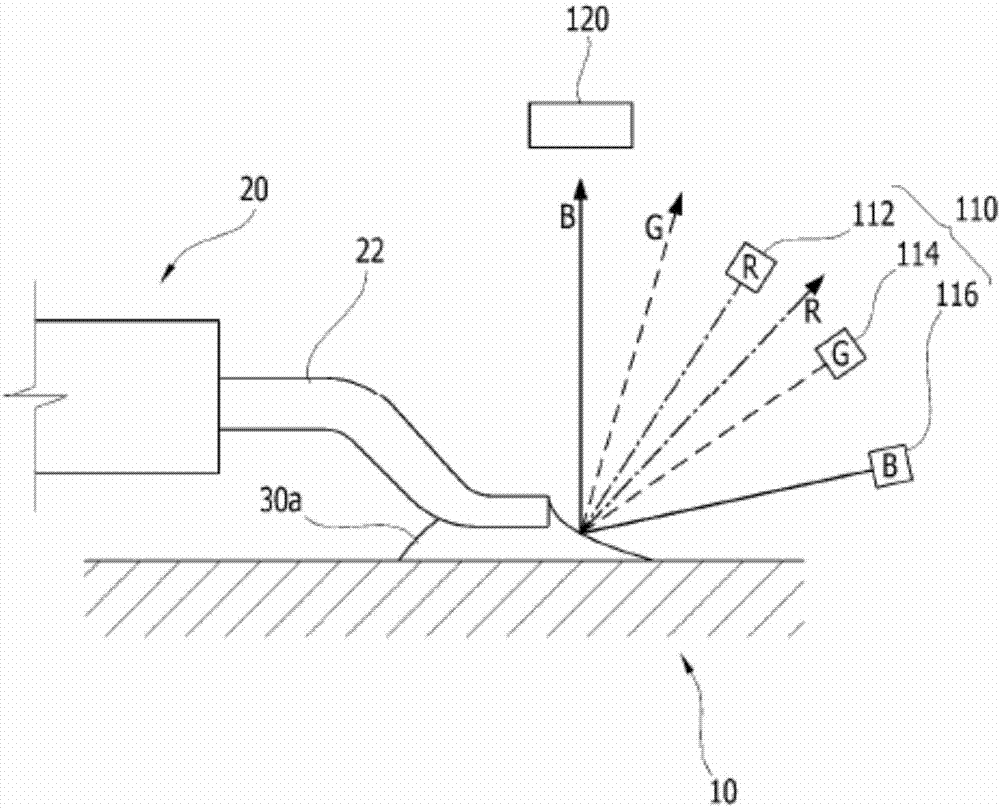

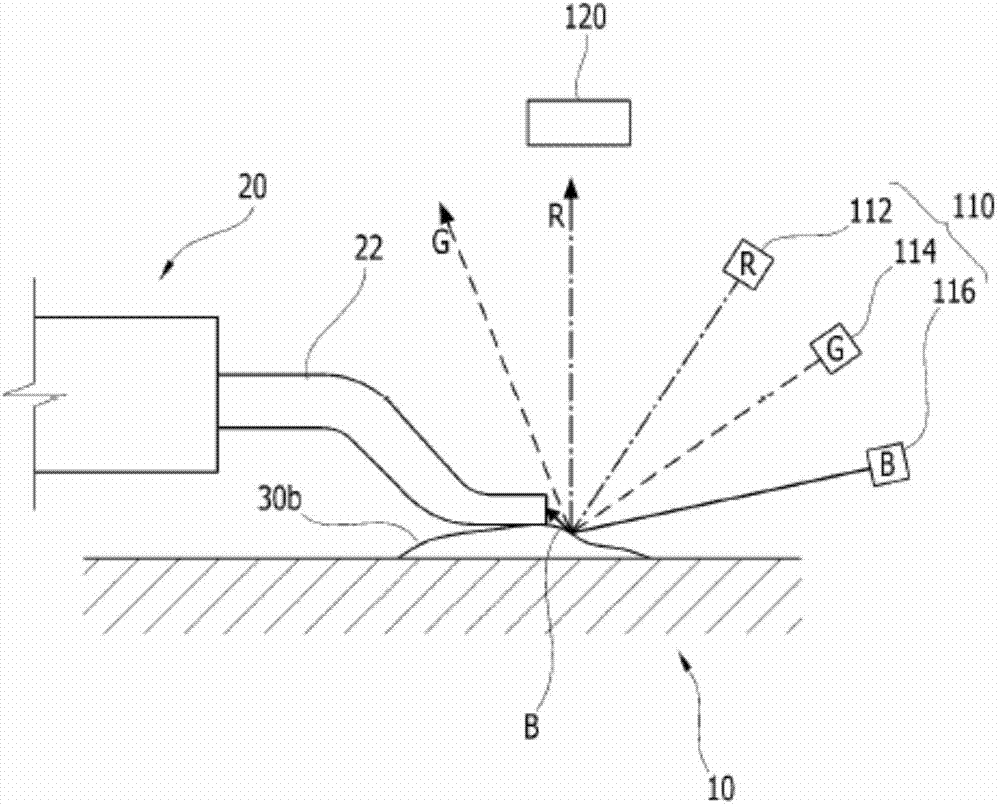

InactiveCN103808270AReduce distractionsReduce mutual interferenceMaterial analysis by optical meansUsing optical meansColor imagePhysics

The invention provides a board inspection method. In order to inspect a board, first, an inspection area including a solder joint is provided with a first light having a first color, a second light having a second color and a third light having a third color at a first inclination angle, a second inclination angle smaller than the first inclination angle and a third inclination angle smaller than the second inclination angle with respect to the board, respectively. Then, a color image of the inspection area is acquired according to the first light, the second light and the third light provided to the inspection area. Thereafter, it is inspected whether the solder joint is good or bad by using a color distribution in the color image. Then, the inspection result is verified by using pre-measured height information of the solder joint. Thus, an inspection error may be prevented.

Owner:KOHYOUNG TECH

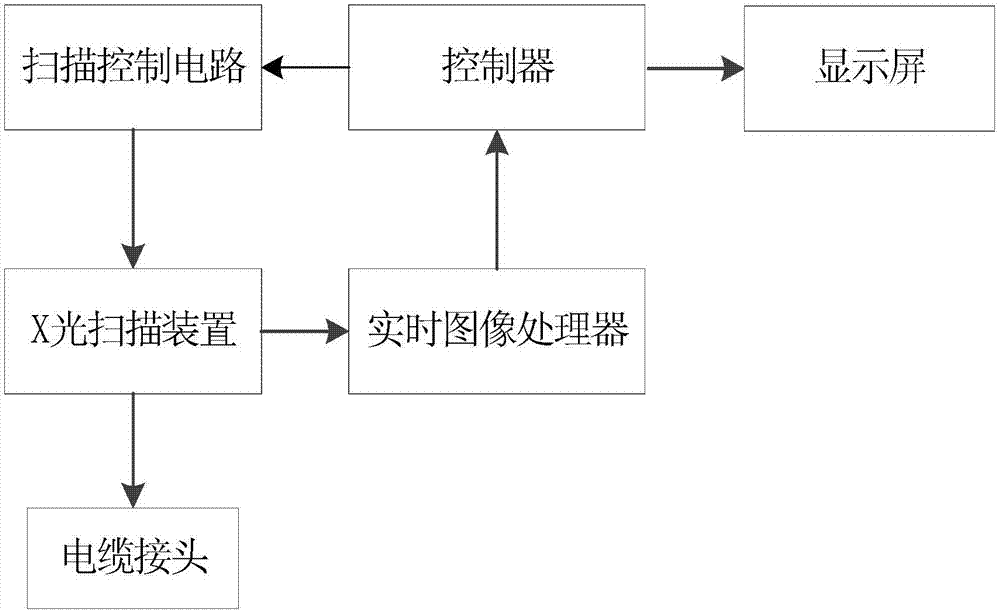

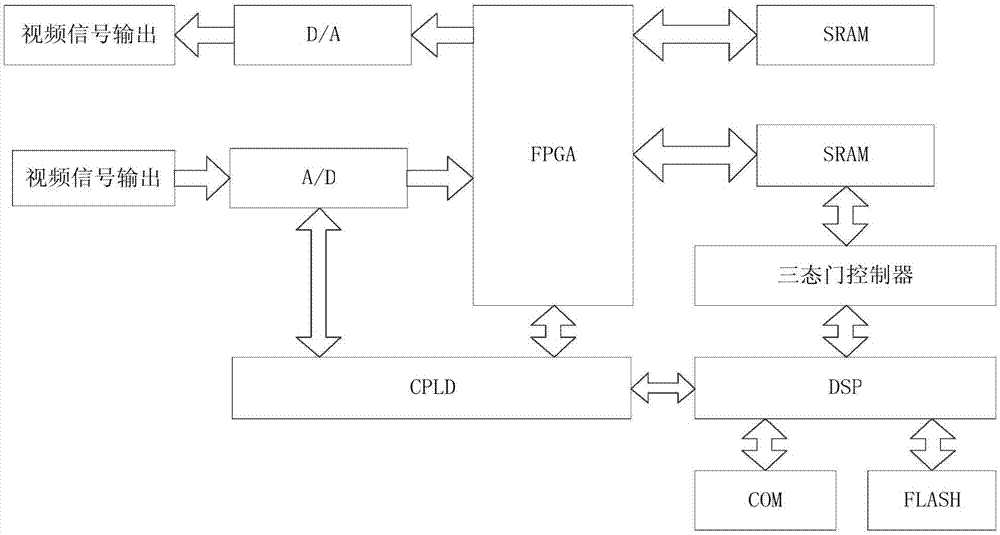

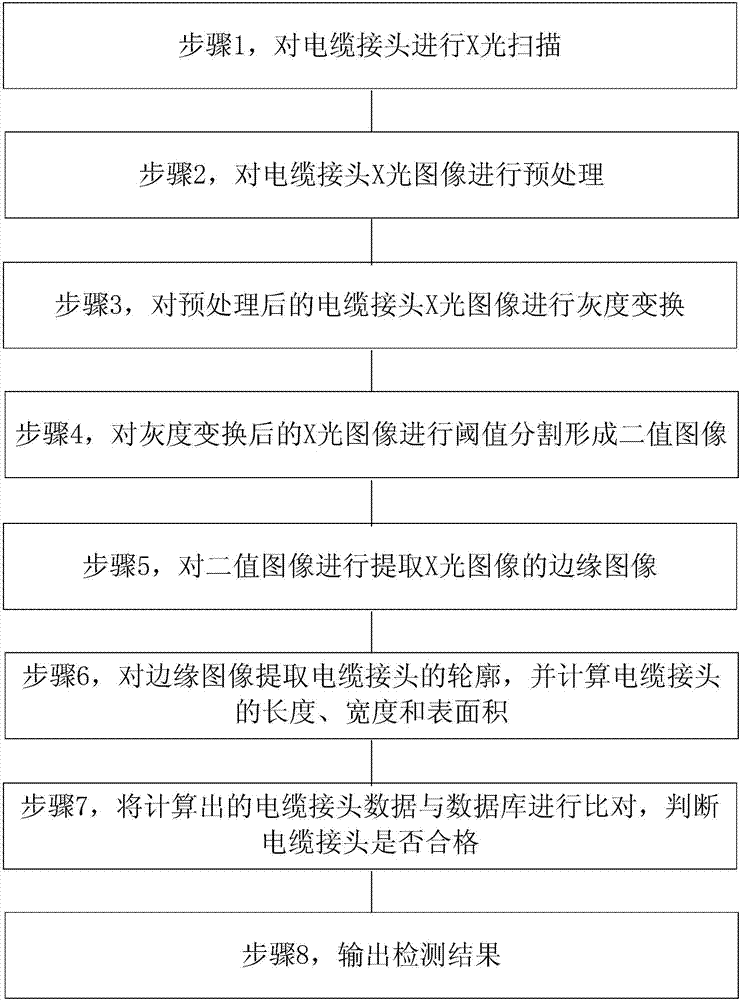

Cable joint detection device and method based on X-ray scanning

InactiveCN107957534ARealize live operationEnsure safetyFault location by conductor typesFailure rateX-ray

The invention discloses a cable joint detection device and a cable joint detection method based on X-ray scanning. The cable joint detection device comprises an X-ray scanning device, a real-time image processor, a scanning control circuit, a controller and a display screen, wherein the X-ray scanning device is used for performing X-ray scanning on a cable joint; an input end of the real-time image processor is connected with an output end of the X-ray scanning device; an output end of the real-time image processor is connected with the controller, and is used for preprocessing an X-ray imageof the cable joint and transmitting the preprocessed X-ray image of the cable joint to the controller for carrying out cable joint detection processing; an input end of the scanning control circuit isconnected with the controller, an output end thereof is connected with a control end of the X-ray scanning device, and the scanning control circuit is used for controlling the X-ray scanning device;and the display screen is connected with the controller, and is used for outputting a detection result of the cable joint. The cable joint detection device and the cable joint detection method can beused for performing effective detection on the integrity of the cable joint, and reduce the cable failure rate caused by the quality problem of the cable joint.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

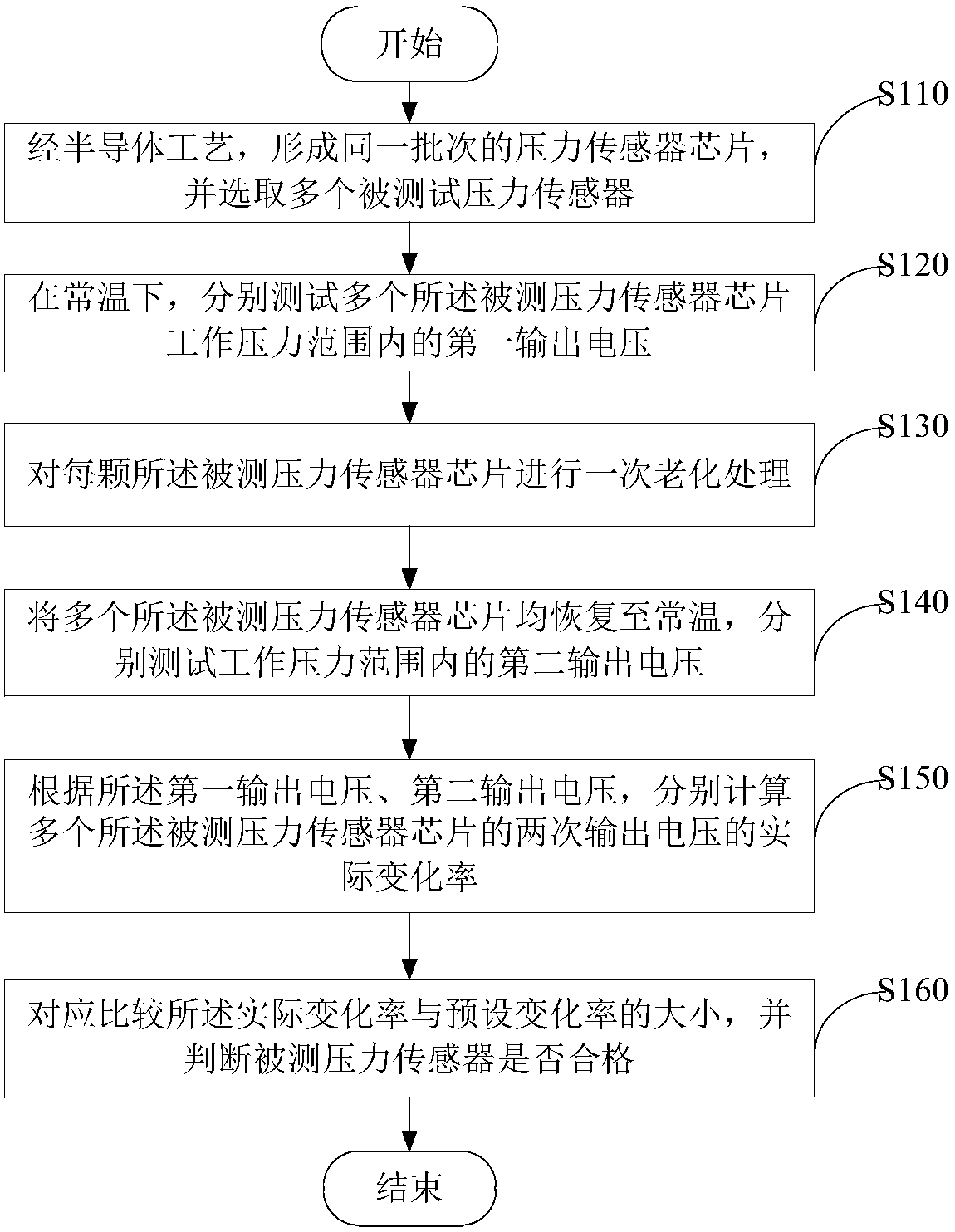

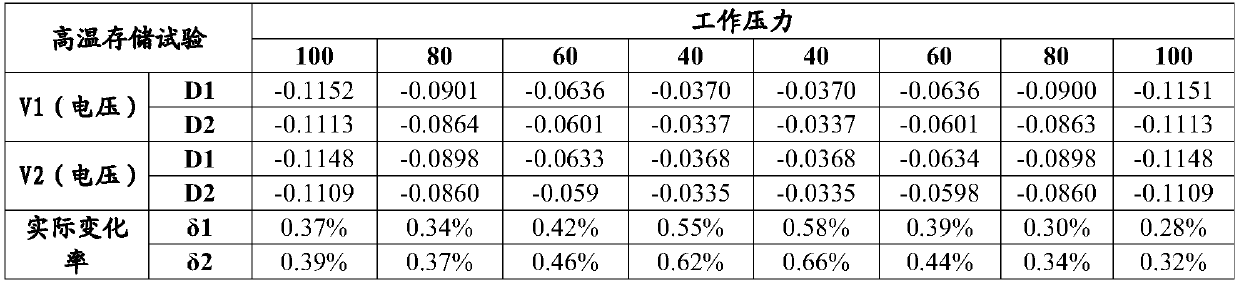

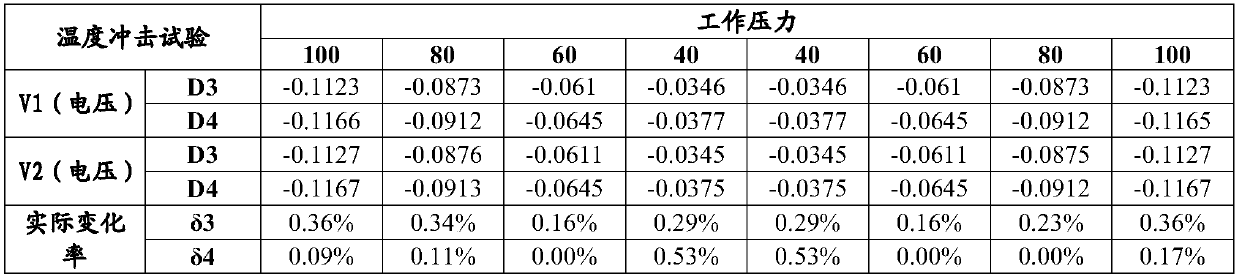

Test method of pressure sensor chip

InactiveCN107560788ATest accurateEasy to testFluid pressure measurementForce/torque/work measurement apparatus calibration/testingVoltageEngineering

The invention relates to a test method of a pressure sensor chip. The method comprises steps of under the normal temperature, testing first output voltage of multiple tested pressure sensor chips within a working pressure range; carrying out different aging processing on the tested pressure sensor chips; recovering the tested pressure sensor chips subjected to the aging processing to be in the normal temperature and testing second output voltage within the working pressure range; calculating the actual change rate of the two output voltage of the tested pressure sensor chips; and by comparingthe actual change rate and a preset change rate, precisely judging whether the tested pressure sensor chips are qualified or not. According to the invention, performance of the pressure sensor chips can be directly, rapidly and accurately tested, and the method can be used for verifying and monitoring technique reliability of the pressure sensor chips.

Owner:CSMC TECH FAB2 CO LTD

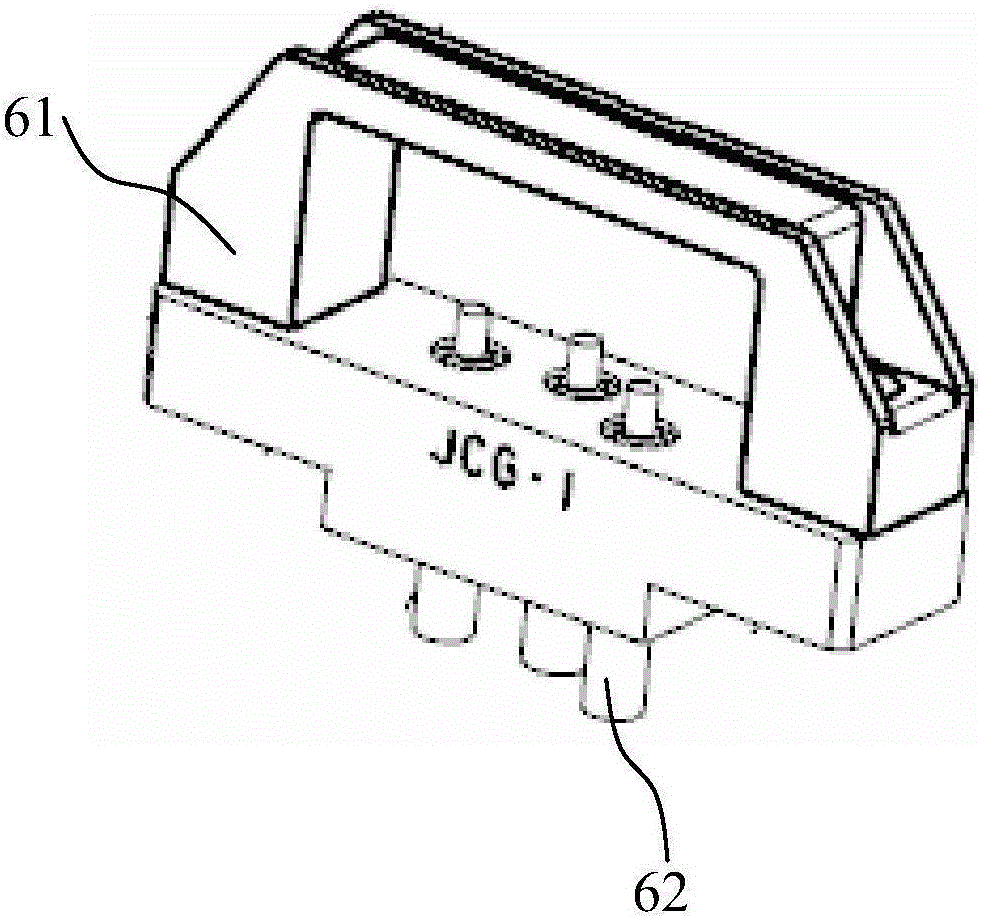

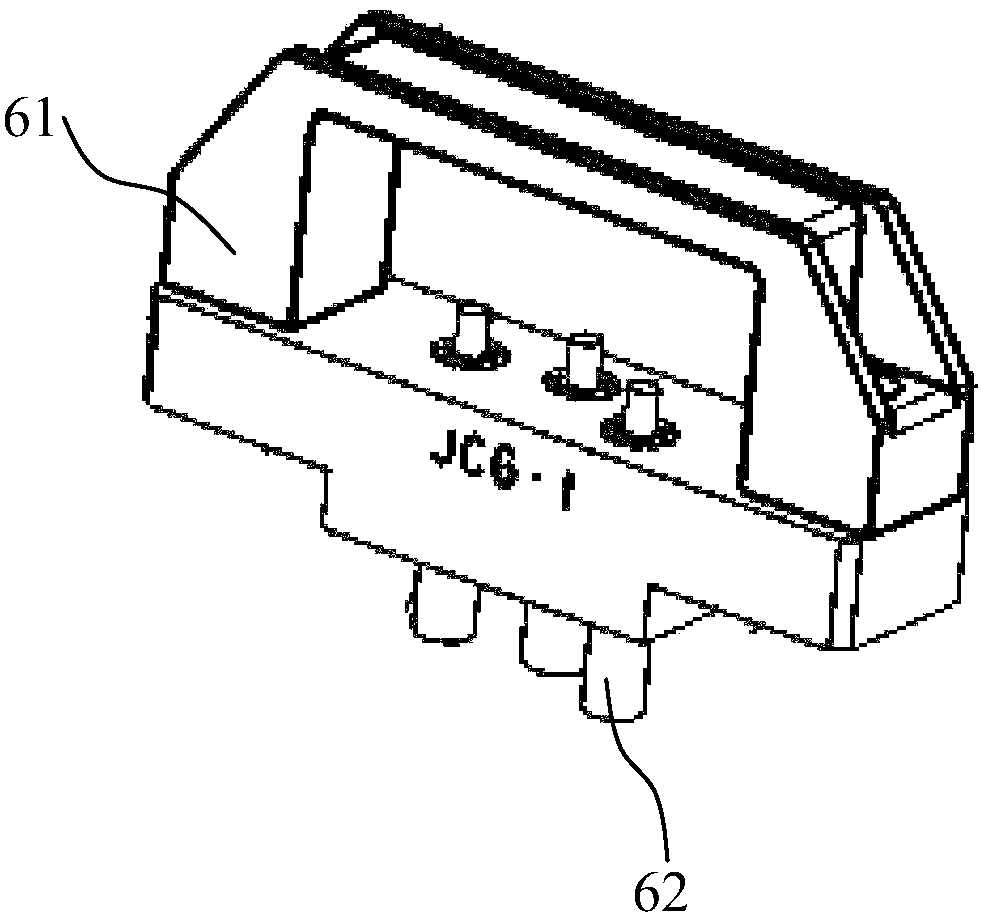

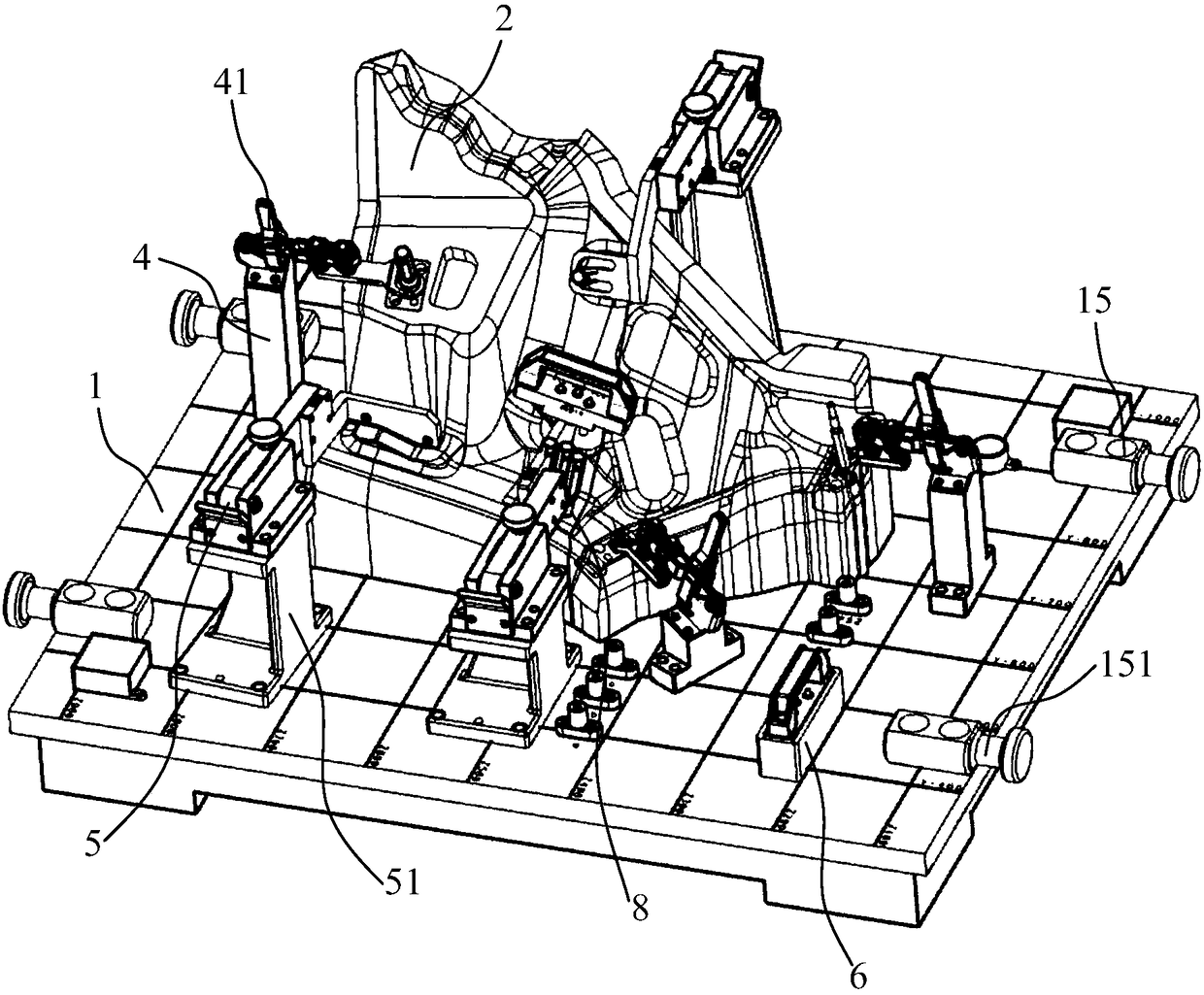

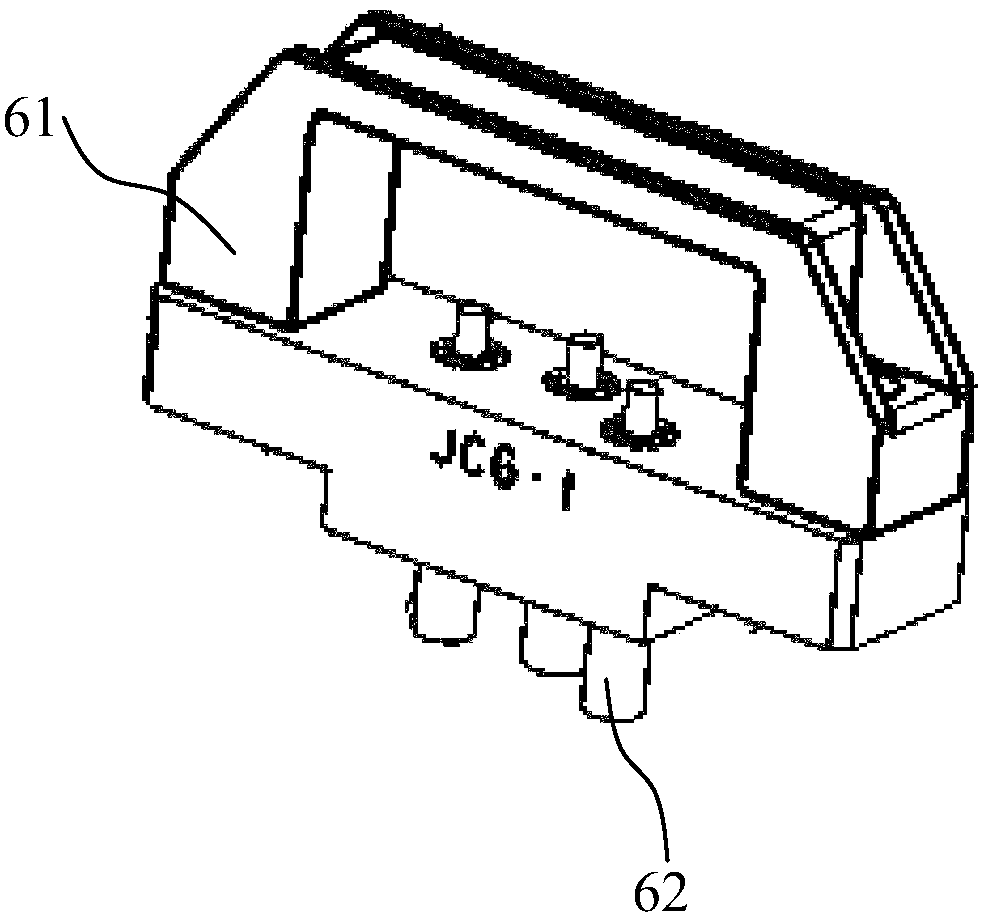

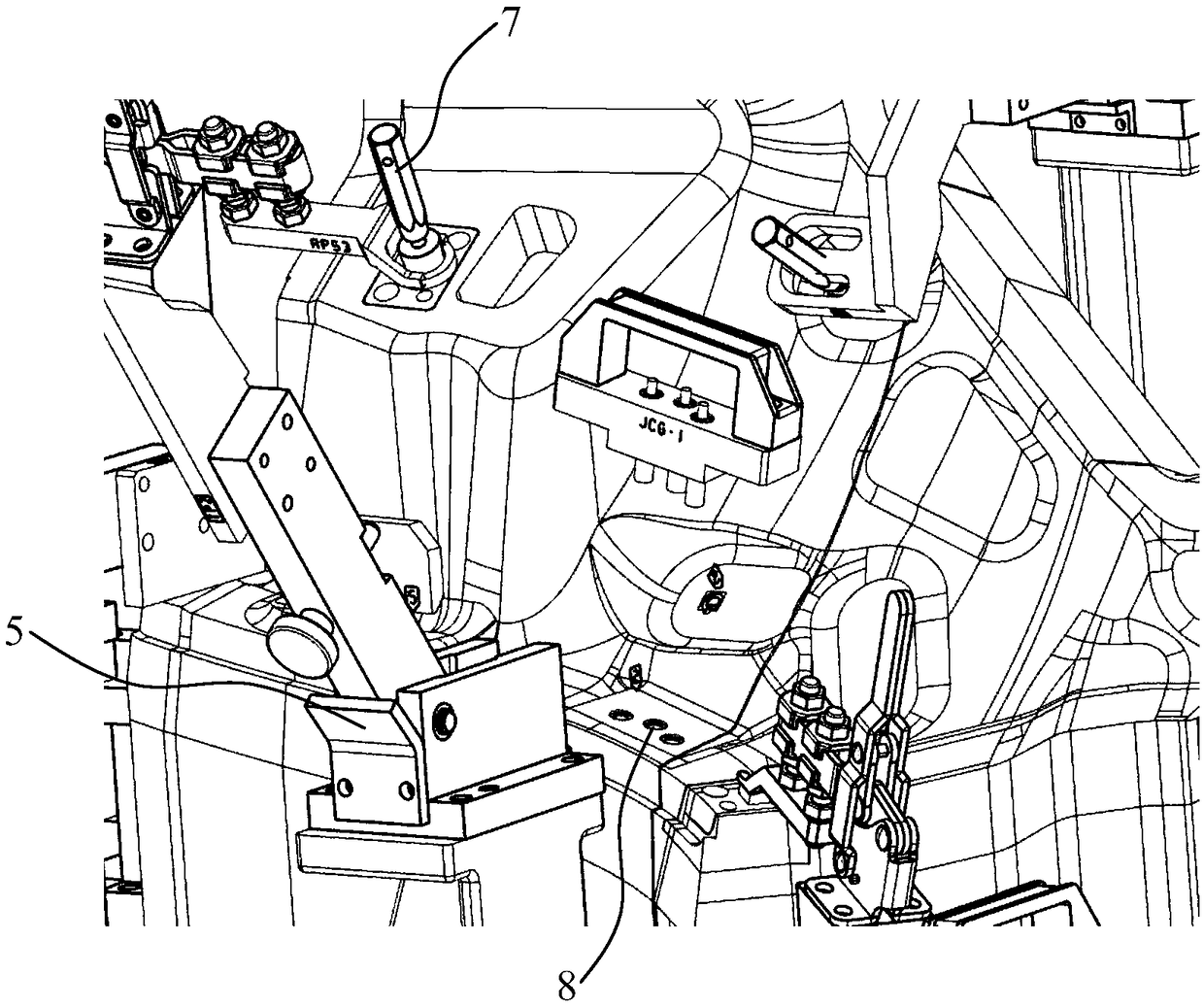

Integrated detection device used for automobile tail lamp board

ActiveCN106017248AConvenient radiusEasy to detectMechanical diameter measurementsMechanical clearance measurementsEngineeringElectrical and Electronics engineering

The invention discloses an integrated detection device used for an automobile tail lamp board. The integrated detection device comprises a coordinate base, a simulation block base used for carrying a to-be-detected part, a detection rod, a clamping mechanism, a gap detection mechanism, a through hole position detection mechanism, and a Go / No Go gauge latch. The clamping mechanism and the gap detection mechanism are disposed on the coordinate base. A clamp disposed on the upper end of the clamping mechanism is used to clamp the to-be-detected part disposed on the upper surface of the simulation block base, and the through hole position detection mechanism further comprises a handle base and at least two second latches disposed on the bottom surface of the handle base. The gap detection mechanism further comprises a base, a clamping board; a left fixing board and a right fixing board, which are parallely disposed on the upper surface of the base. The integrated detection device is advantageous in that part gaps are quickly and visually detected, and detection reliability is high, whether the parts are qualified can be determined quickly and visually, and a basis is provided for the further adjustment of the parts.

Owner:KUNSHAN DAYA AUTO PARTS

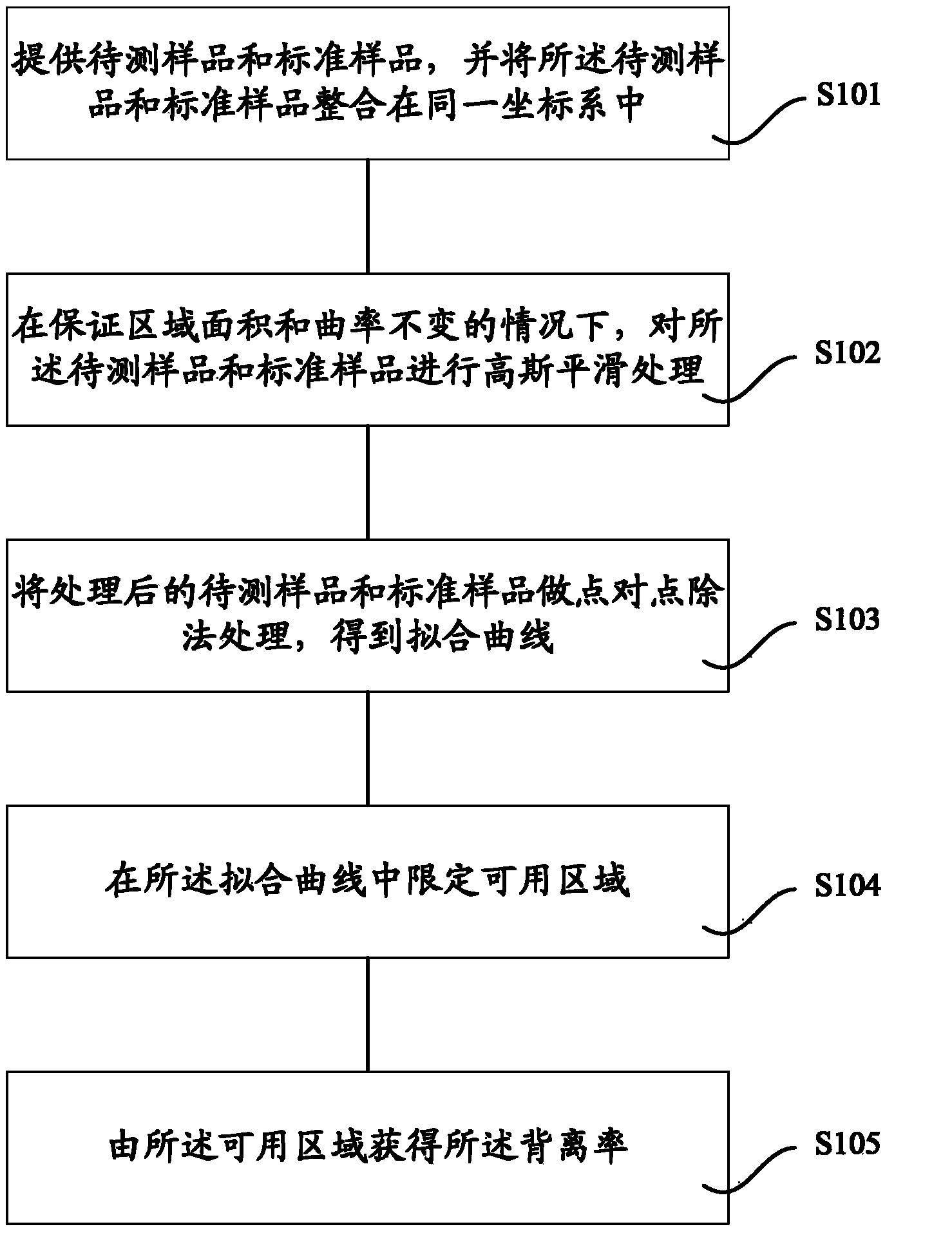

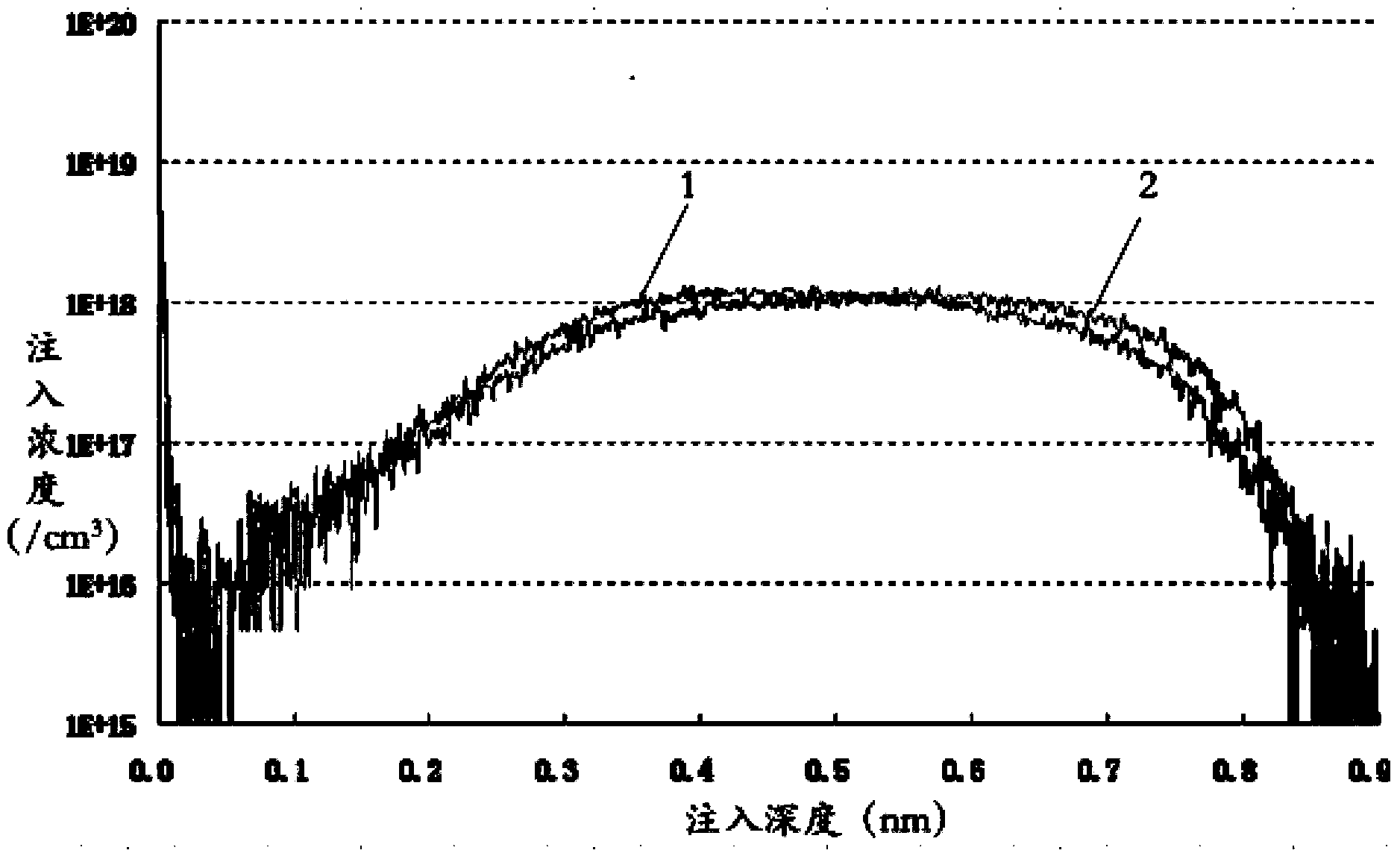

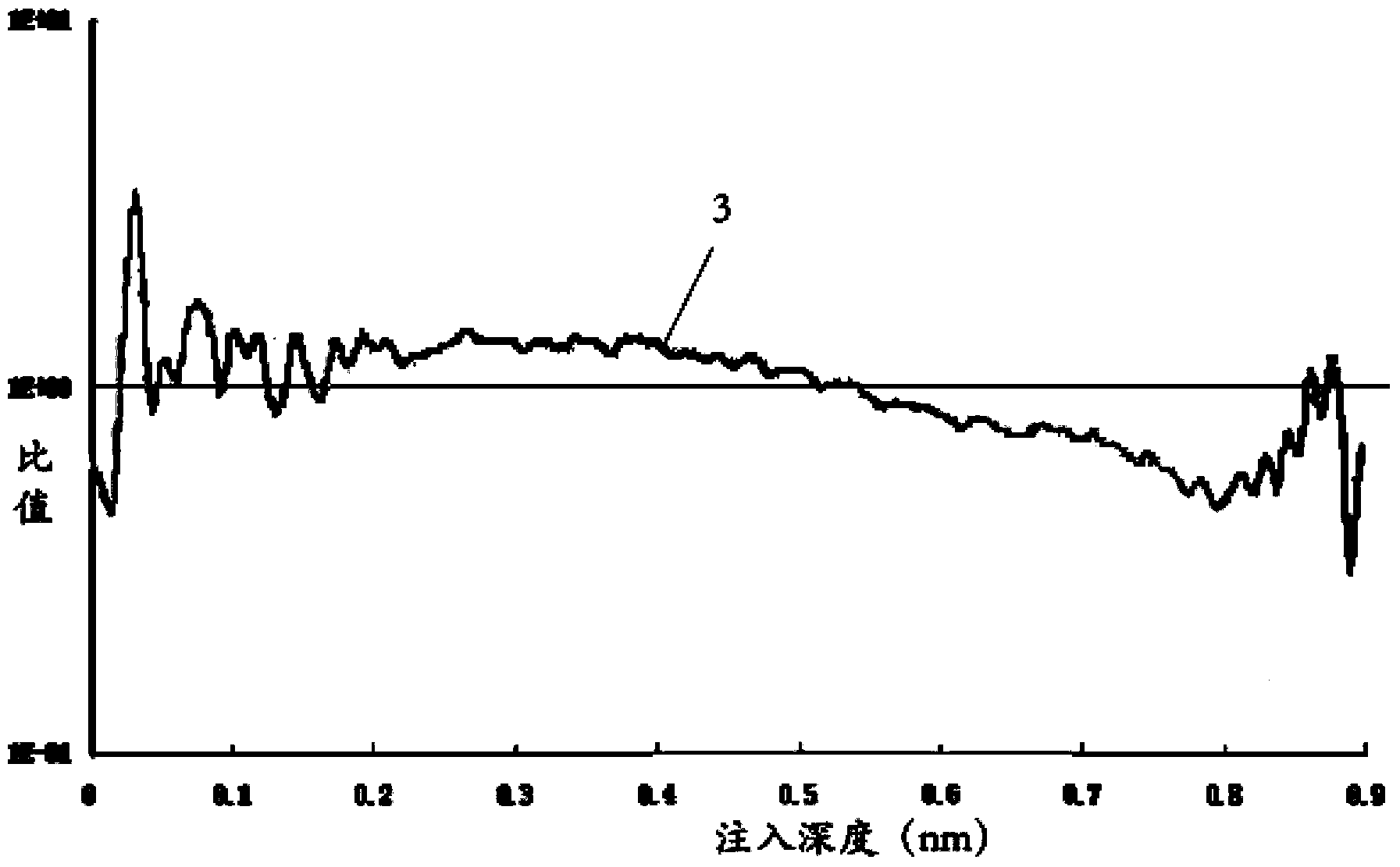

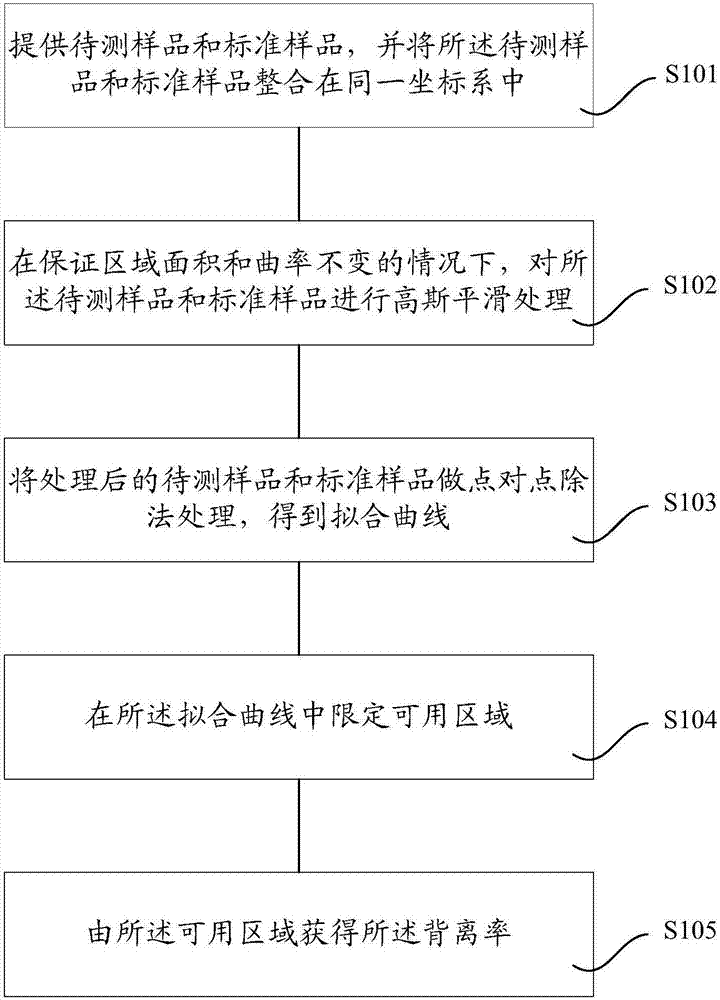

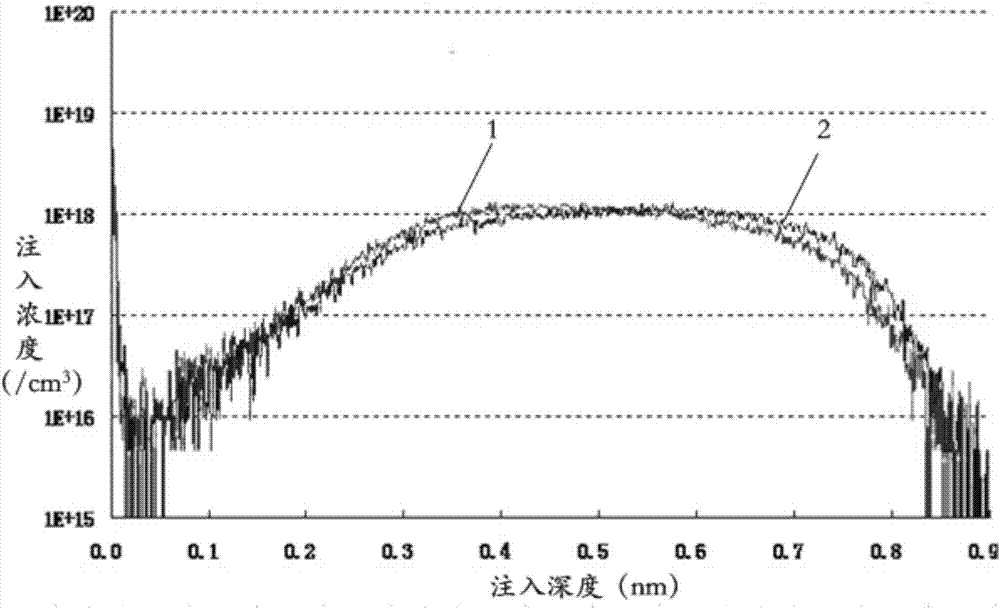

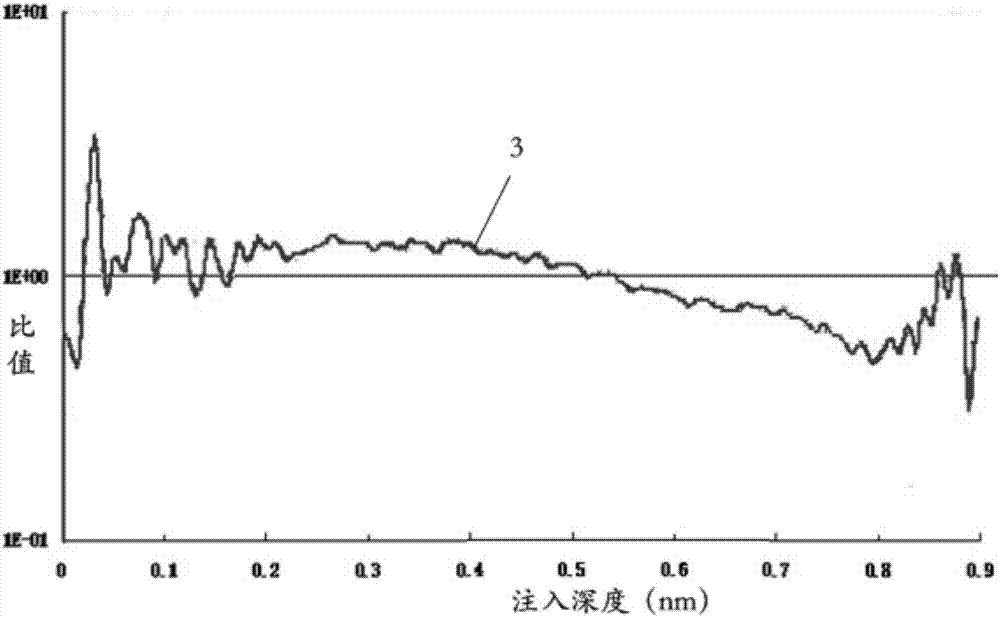

Calculation method of deviation rate and method for secondary ion mass spectrometry

ActiveCN104237279AReduce usageShorten the recovery detection timeMaterial analysis using wave/particle radiationPhysicsMass spectrum analysis

The invention discloses a calculation method of deviation rate and a method for secondary ion mass spectrometry. According to the invention, a sample to be tested and a standard sample are provided, and the sample to be tested and the standard sample are integrated in a same coordinate system; under the situation of guaranteeing regional area and curvature unchanged, the sample to be tested and the standard sample undergo Gaussian smoothing treatment; the treated sample to be tested and the treated standard sample undergo point-to-point division treatment so as to obtain a fitted curve; an available region is restricted in the fitted curve; deviation rate is obtained according to the available region; deviation rate which is proportional to ion implantation angle deviation is obtained so as to definitely judge whether equipment needs to be maintained and save time and consumable items; and early minimal abnormity of an ion implanter can be detected and improvement direction can be provided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

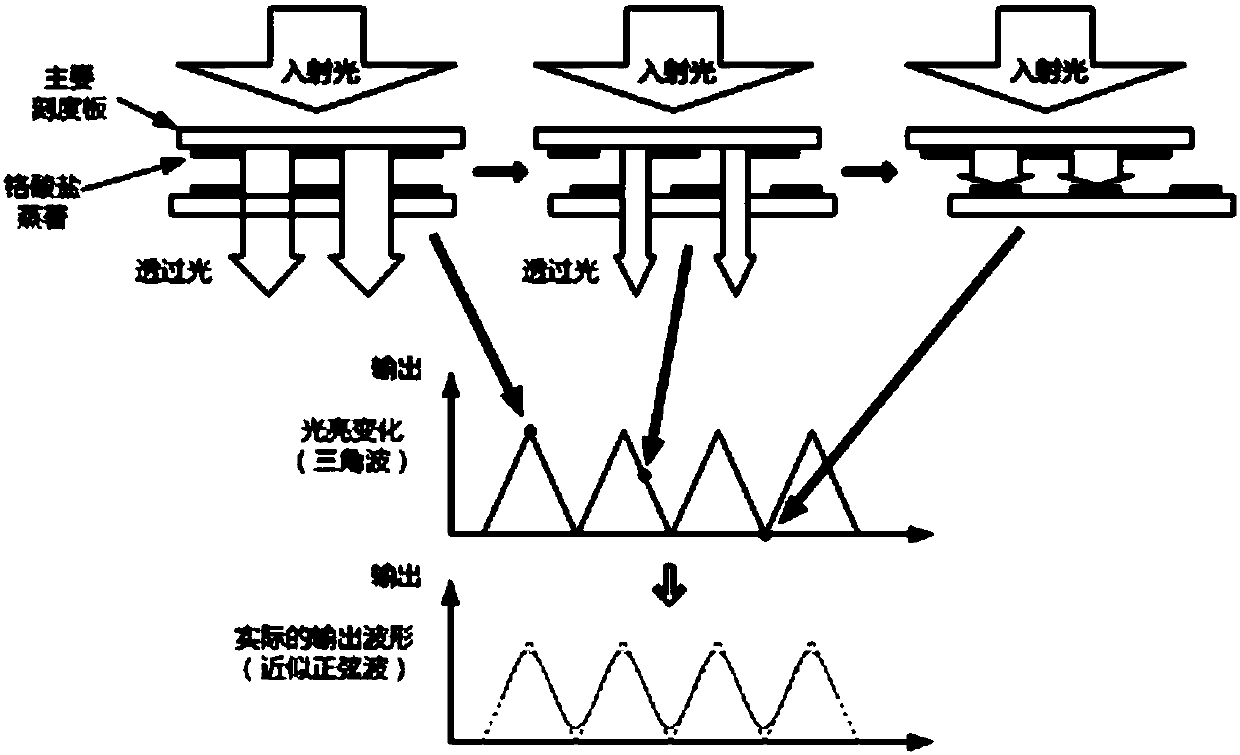

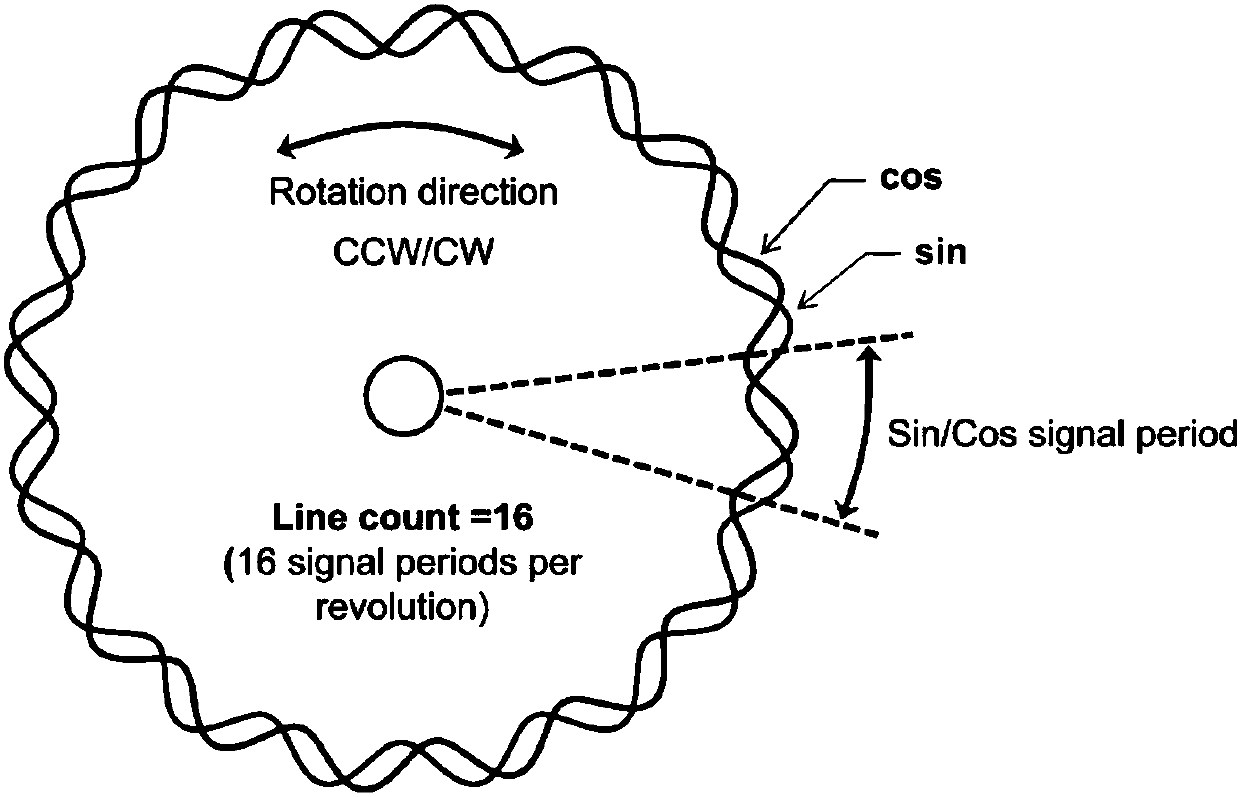

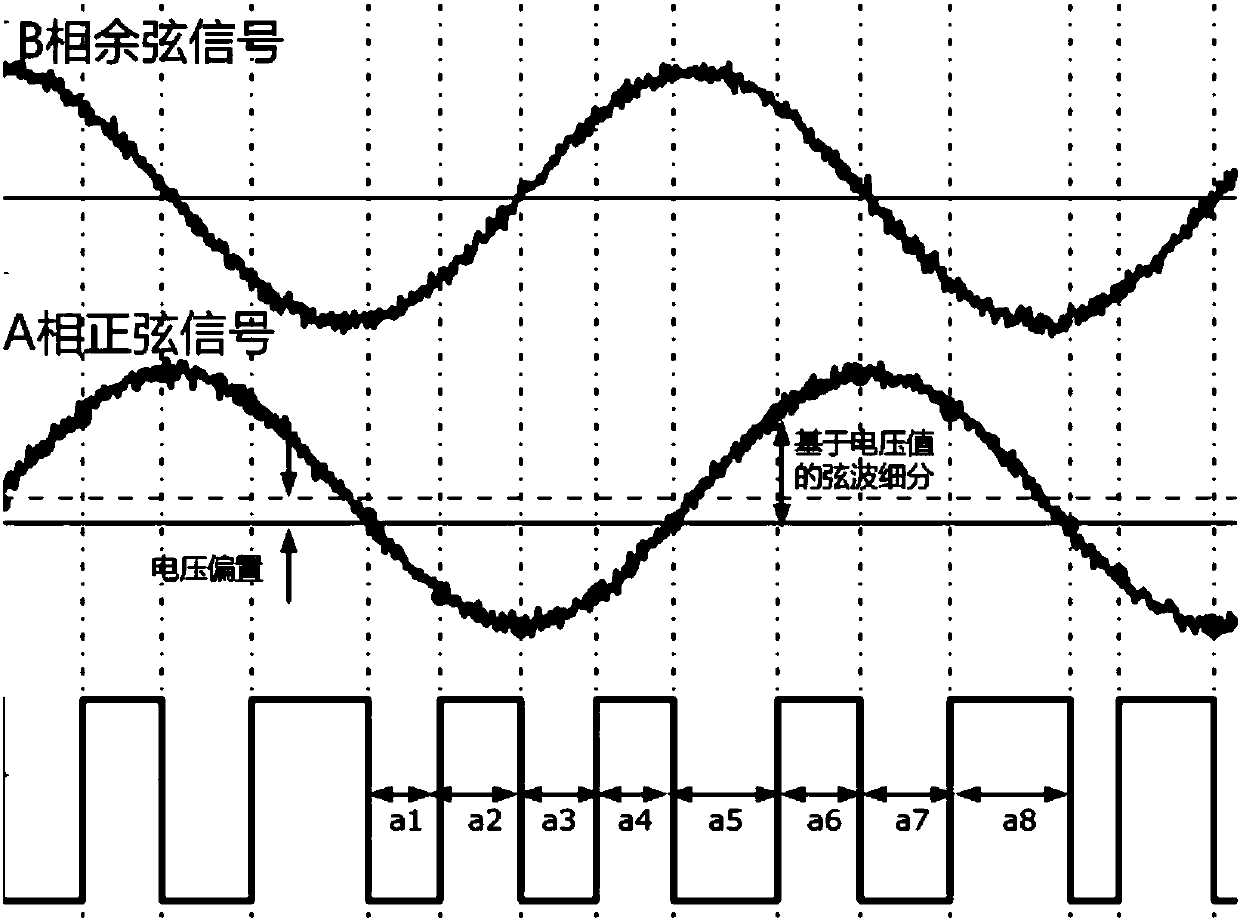

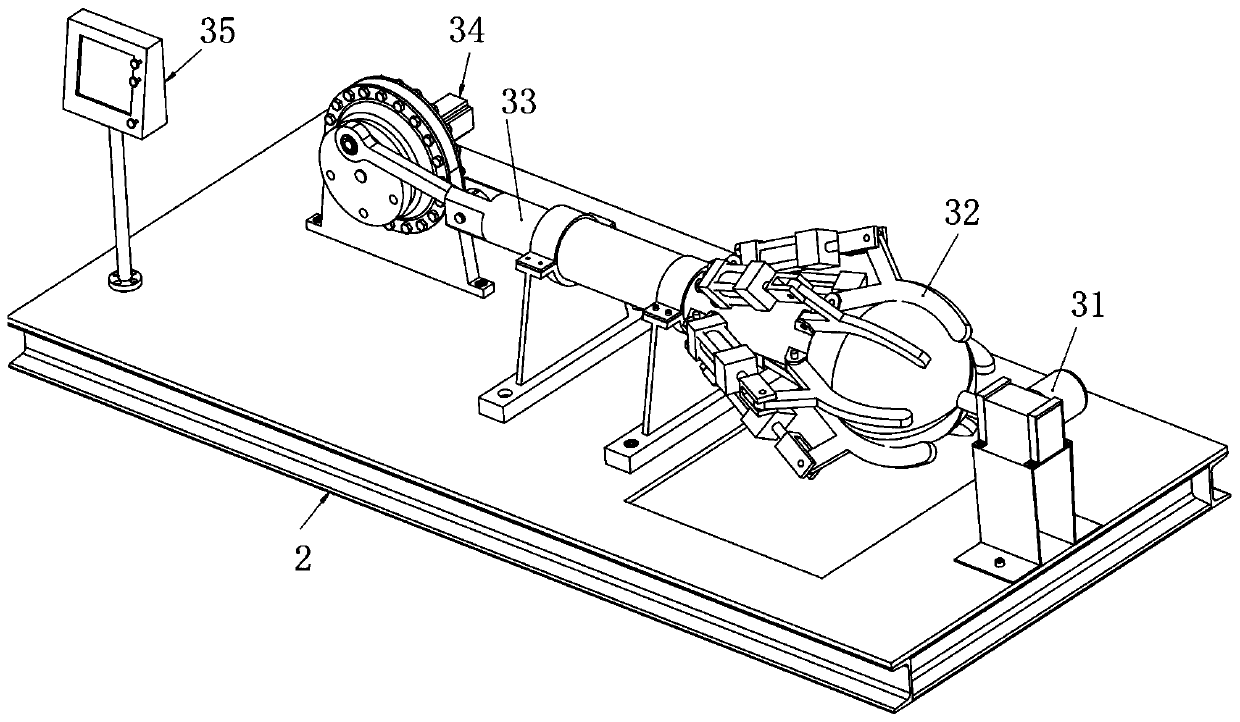

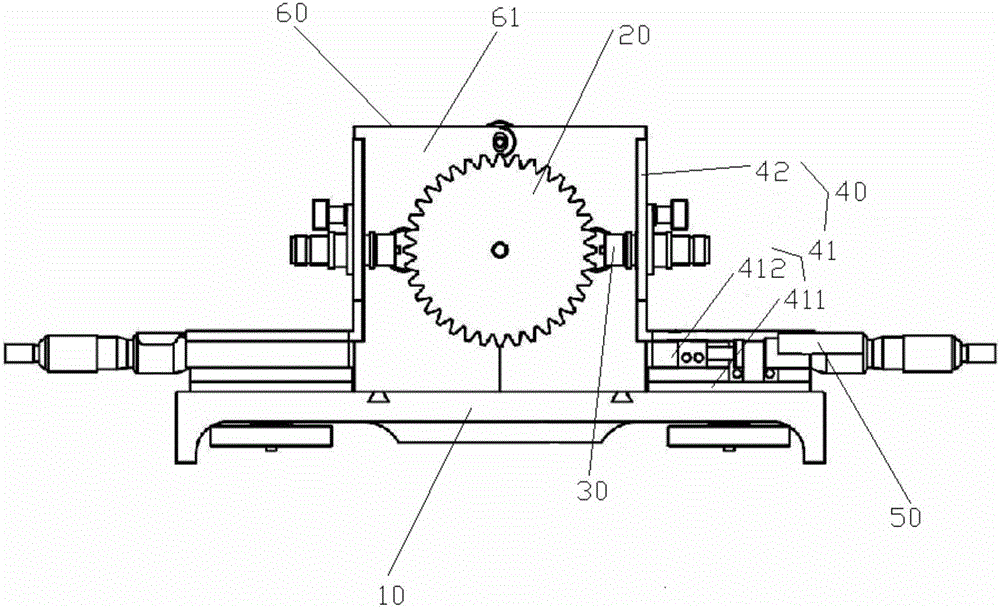

Encoder detection method

The invention discloses an encoder detection method. The encoder detection method comprises the following steps: 1, an encoder is mounted on a test bench and dragged by a motor to rotate; 2, a squarewave output by the encoder is detected through a detector; 3, a pulse interval sequence composed of all pulse intervals a1, a2,...a<n> of the square wave in one mechanical rotation cycle is calculated; and 4, all the pulse intervals a1, a2,...a<n> of the pulse interval sequence are subjected to data analysis. The pulse intervals of the output square wave are analyzed through a data analysis method, whether the encoder has defects in the manufacturing process or not is subjected to backward reasoning, and whether the encoder has problems such as bias, waveform distortion and sampling in the manufacturing process or not can be quickly and effectively detected.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

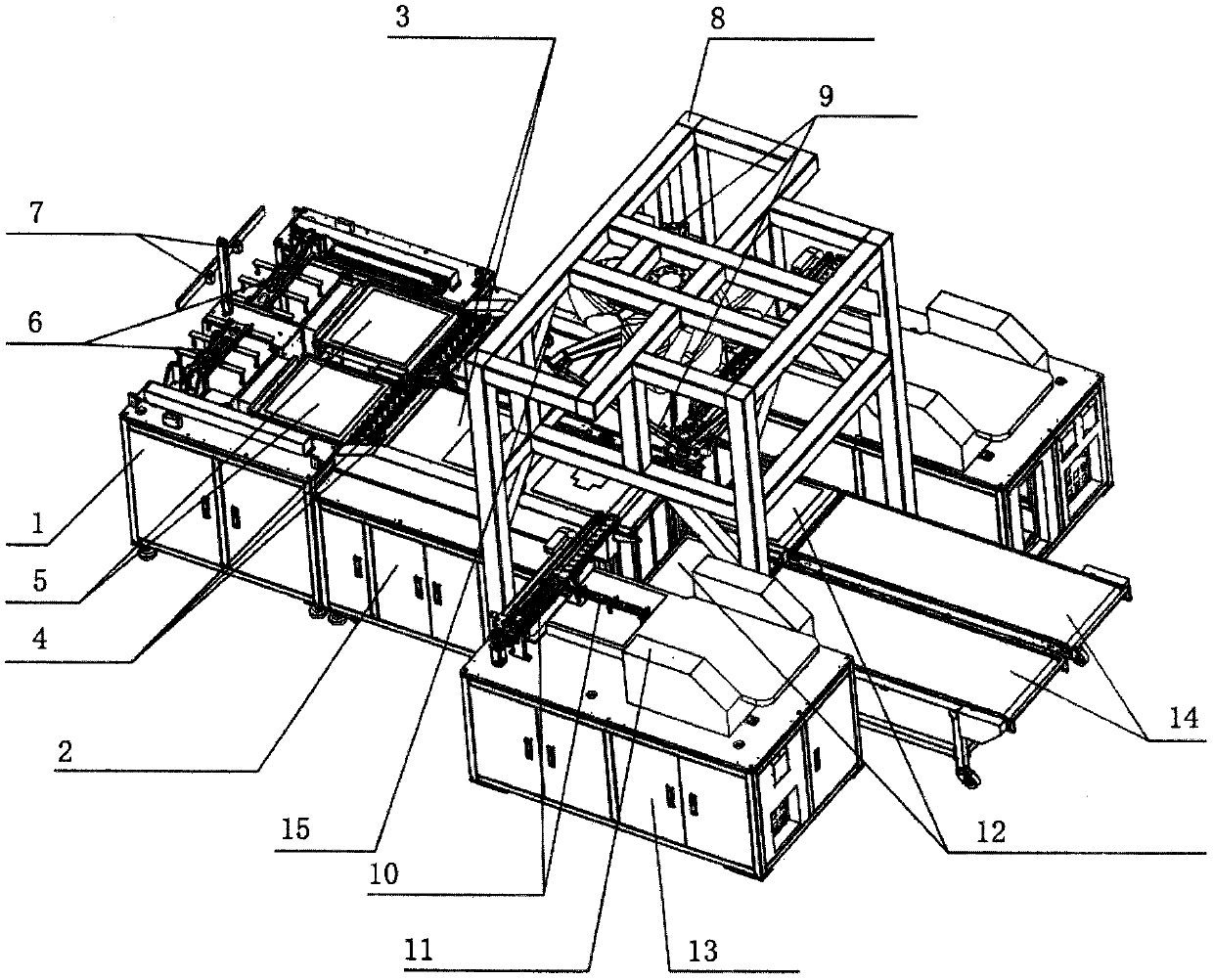

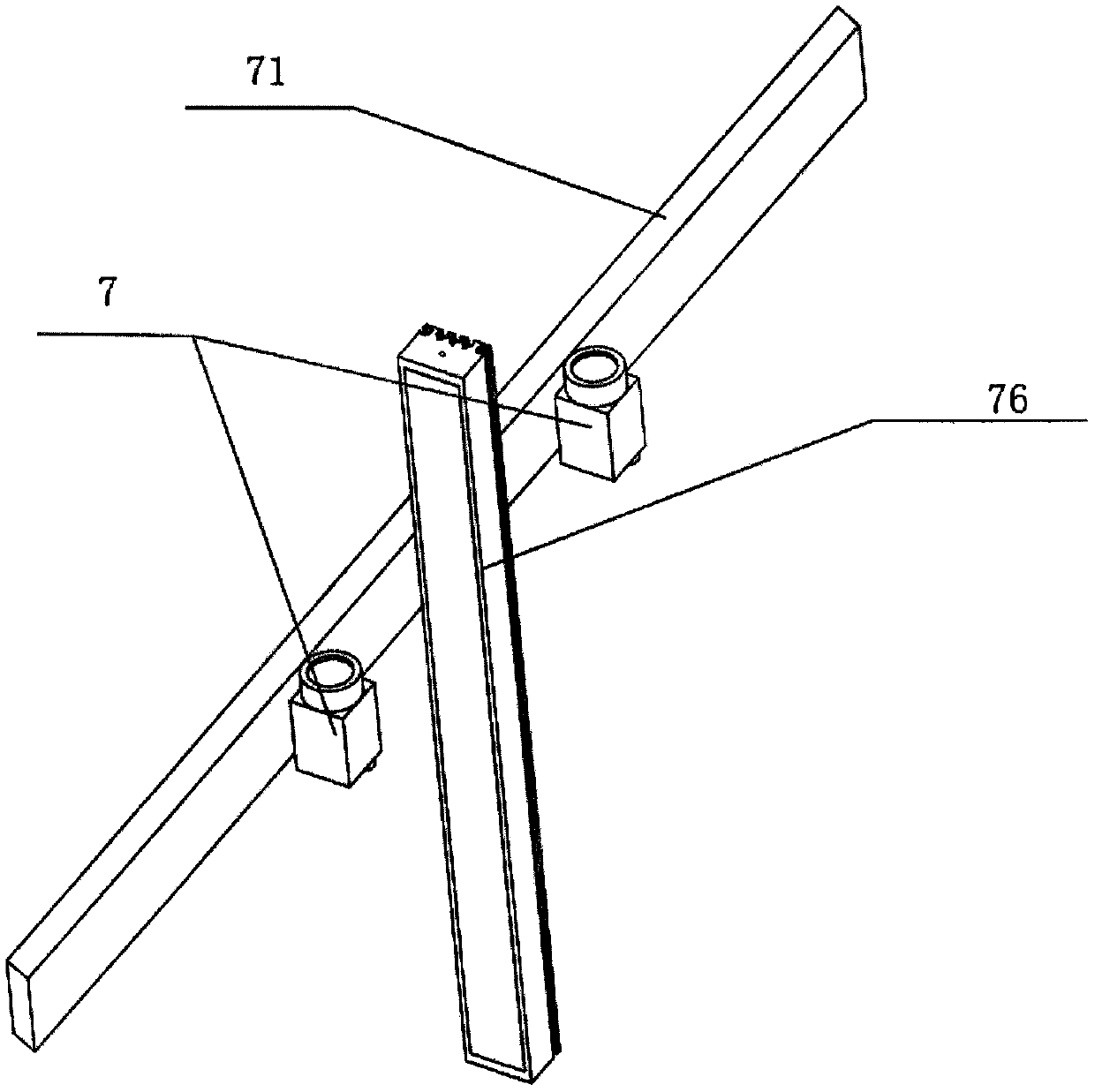

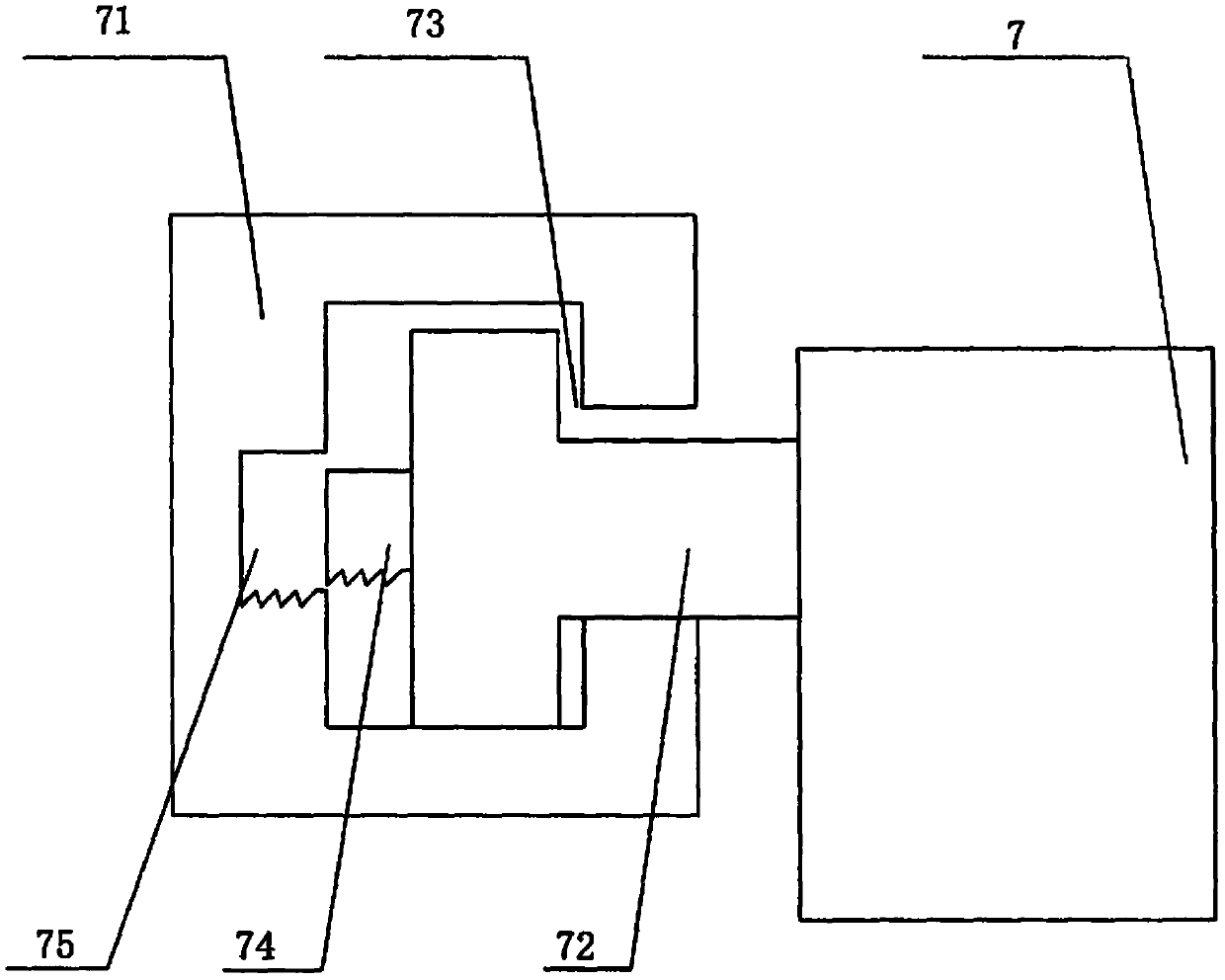

PCB laminated plate counting equipment based on a parallel robot

PendingCN109711524AEasy accessEasy to adjustCounting mechanisms/objectsSortingEngineeringMechanical engineering

The invention discloses PCB lamination counting equipment based on a parallel robot. The device comprises a first electric cabinet and a second electric cabinet, the first electric cabinet is positioned in front of the second electric cabinet; two PCB front-section conveying lines are fixedly installed between the outer surfaces of the upper ends of the two first electric cabinets. a PCB feeding mechanism is fixedly mounted on the outer surface of the front end of the PCB front-section conveying line; a first camera is arranged above the PCB feeding mechanism, a PCB rear-section conveying lineis arranged behind the PCB front-section conveying line, and an NG plate taking mechanism is fixedly installed between the PCB front-section conveying line and the PCB rear-section conveying line. Byarranging a series of structures, a user can conveniently adjust the position of the first camera in the using process of the equipment, so that the material number period of the PCB is obtained, thequalification of the PCB is judged, corresponding subsequent processing is conducted according to the qualification of the PCB, the working efficiency of the equipment is improved, and the using process is optimized.

Owner:广东若贝特设备制造有限公司

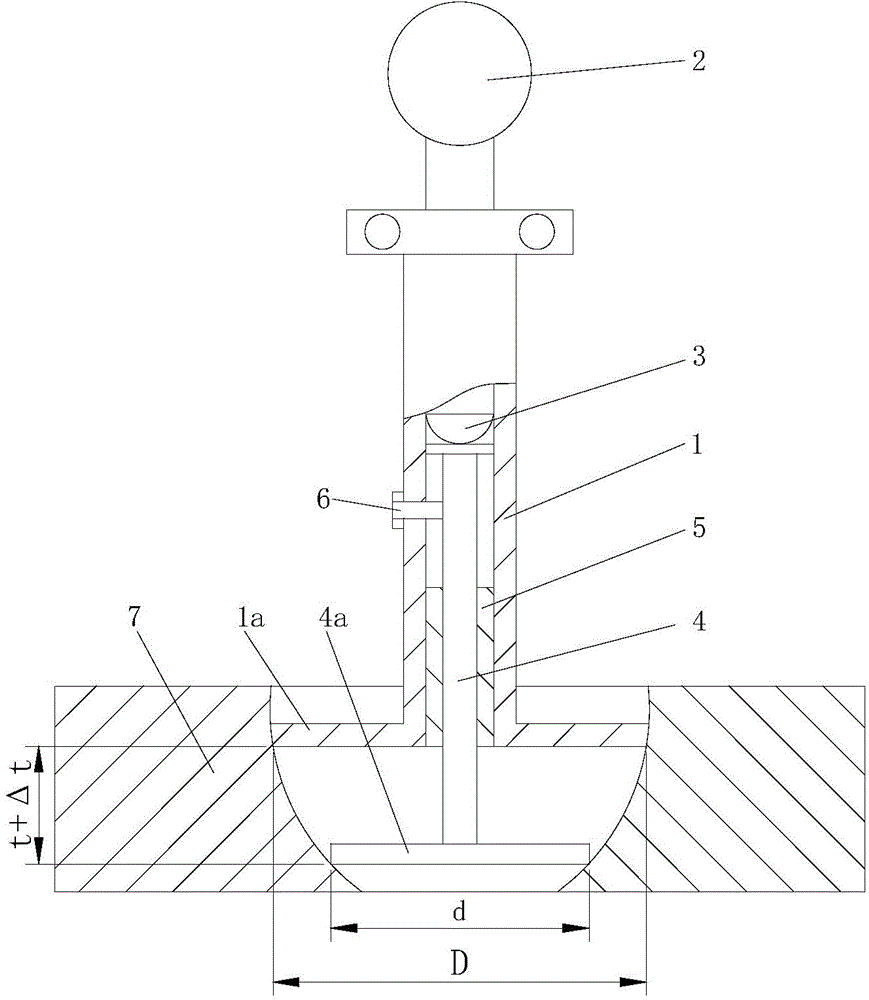

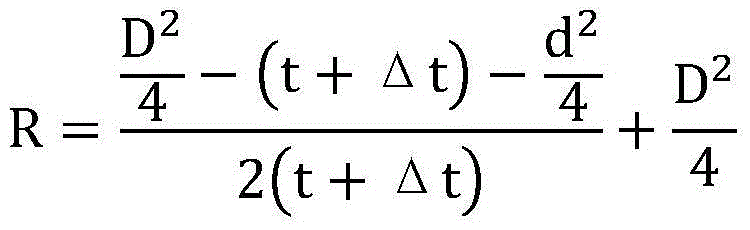

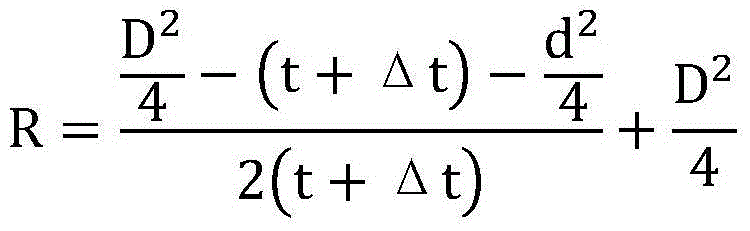

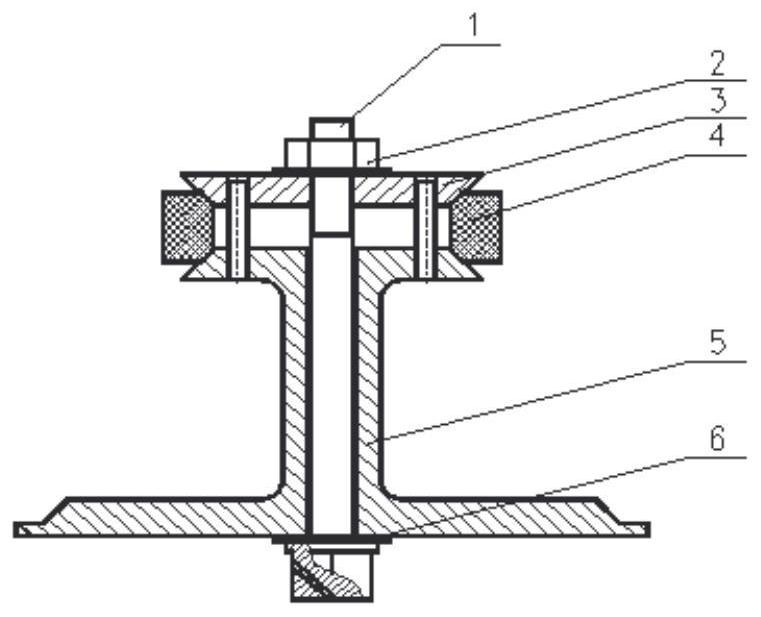

Measuring tool for spherical hole radius

InactiveCN104422369AQuick measurementJudge eligibilityMechanical diameter measurementsFlangeEngineering

The invention relates to a measuring tool for spherical hole radius. The tool comprises a measuring anvil, a dial indicator, a measuring head, and a measuring rod. The measuring anvil is provided with a hole. The hole is arranged along the axial direction of the measuring anvil. One end of the measuring anvil is connected with the dial indicator, and the other end of the measuring anvil is a flange. The flange extends to the radial direction of the measuring anvil. The measuring head of the dial indicator extends into the hole on the measuring anvil. One end of the measuring rod extends into the hole of the measuring anvil and is connected with the measuring head. The other end of the measuring rod out of the hole is provided with a radial bulge. The radius of the radial flange is smaller than the radius of the flange on the measuring anvil. The tool can rapidly measure the radius and the deviation of a sphere after a workpiece is processed, so as to determine whether the workpiece is qualified.

Owner:CHANGZHOU XILI ALLOY TOOLS

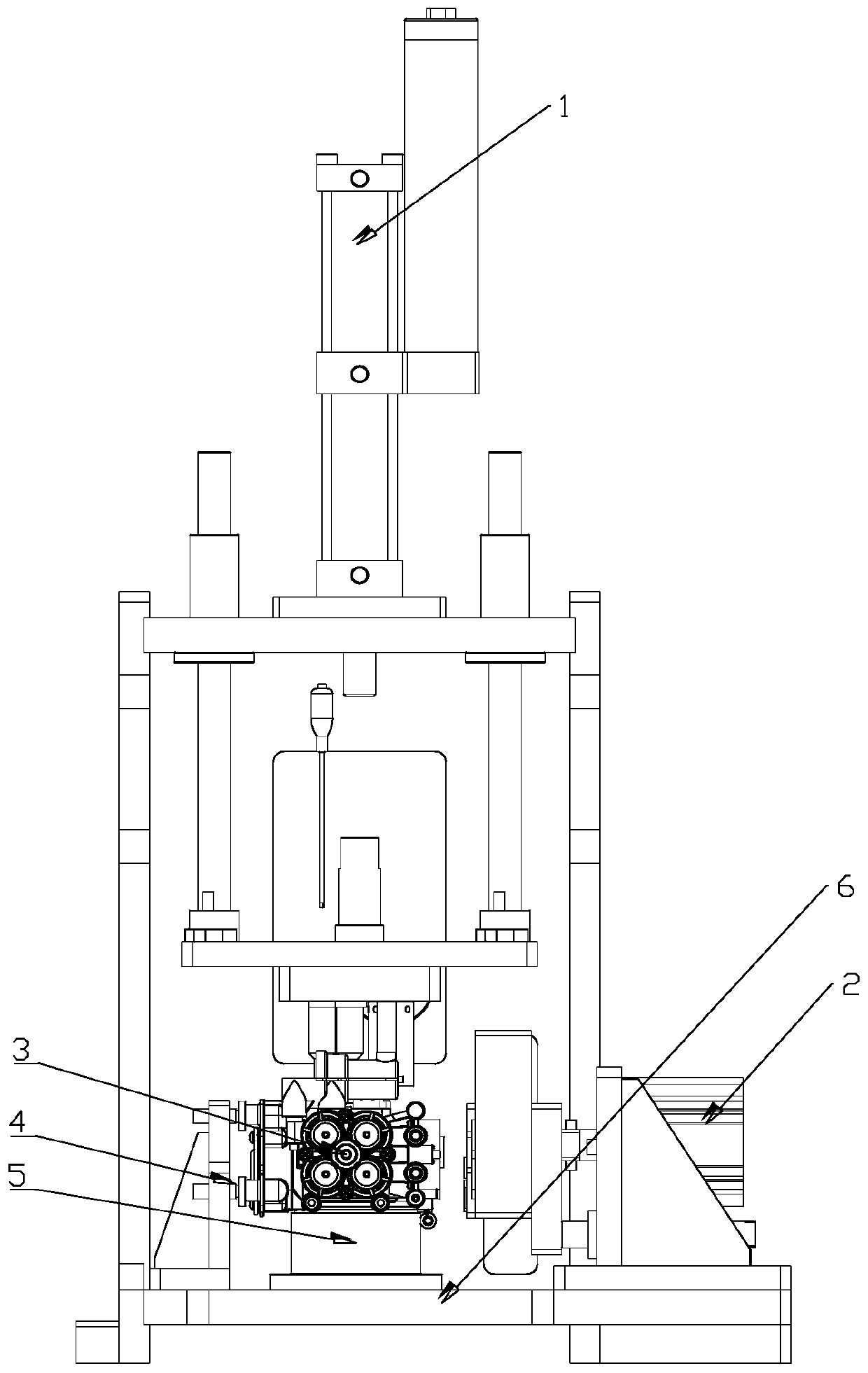

Piston type medium-frequency air pressure sensor detection device

InactiveCN111256804AJudgment stabilityJudgment reliabilityVibration measurement in fluidEngineeringGas pressure transducer

The invention discloses a piston type medium-frequency air pressure sensor detection device which comprises a base, a cylinder barrel, a cylinder, a second connecting rod and a driving mechanism. A piston is arranged in one side of the cylinder barrel; the end part of the piston can move along the front-back direction of the cylinder barrel under the action of the driving mechanism; a first hingepoint and a second hinge point are arranged outside the other side of the cylinder barrel; one end of the cylinder is hinged to the second hinge point; the second connecting rod comprises a blade connecting strut and a cylinder connecting strut; the end of the blade connecting strut is hinged to the first hinge point, the blade connecting strut is arc-shaped, arc-shaped blades are fixedly arrangedon the arc-shaped inner side of the blade connecting strut, the arc-shaped outer side of the blade connecting strut is fixedly connected with one end of the cylinder connecting strut, and the other end of the cylinder is hinged to the other end of the cylinder connecting strut. The measurement precision of the intermediate-frequency air pressure sensor can be measured and calibrated quickly and accurately, the detection of different types of medium-frequency air pressure sensors can be satisfied, and the effective measurement range of the sensor can be verified.

Owner:CHANGZHOU INST OF TECH

Blade type high-frequency air pressure sensor detection device

InactiveCN111238626AAvoid security issuesImprove handling comfortVibration measurement in fluidPhysicsEngineering

The invention discloses a blade type high-frequency air pressure sensor detection device. The device comprises a base, a guide pipe , a cylinder, a connecting rod and a gas input mechanism, one side of the guide pipe is connected with the gas input mechanism, a first hinge point and a second hinge point are arranged outside the other side of the guide pipe, one end of the cylinder is hinged to thesecond hinge point, the connecting rod comprises a blade connecting strut and a cylinder connecting strut, the end of the blade connecting supporting rod is hinged to the first hinge point, the bladeconnecting supporting rod is arc-shaped, arc-shaped blades are fixedly arranged on the arc-shaped inner side of the blade connecting supporting rod, the arc-shaped outer side of the blade connectingsupporting rod is fixedly connected with one end of the cylinder connecting supporting rod, and the other end of the cylinder is hinged to the other end of the cylinder connecting supporting rod. According to the invention, the measurement precision of the high-frequency air pressure sensor can be rapidly and accurately measured and calibrated, pressure gases with different frequencies can be generated, the detection of high-frequency air pressure sensors with different models can be satisfied, and the effective measurement range of the sensor can be verified.

Owner:CHANGZHOU INST OF TECH

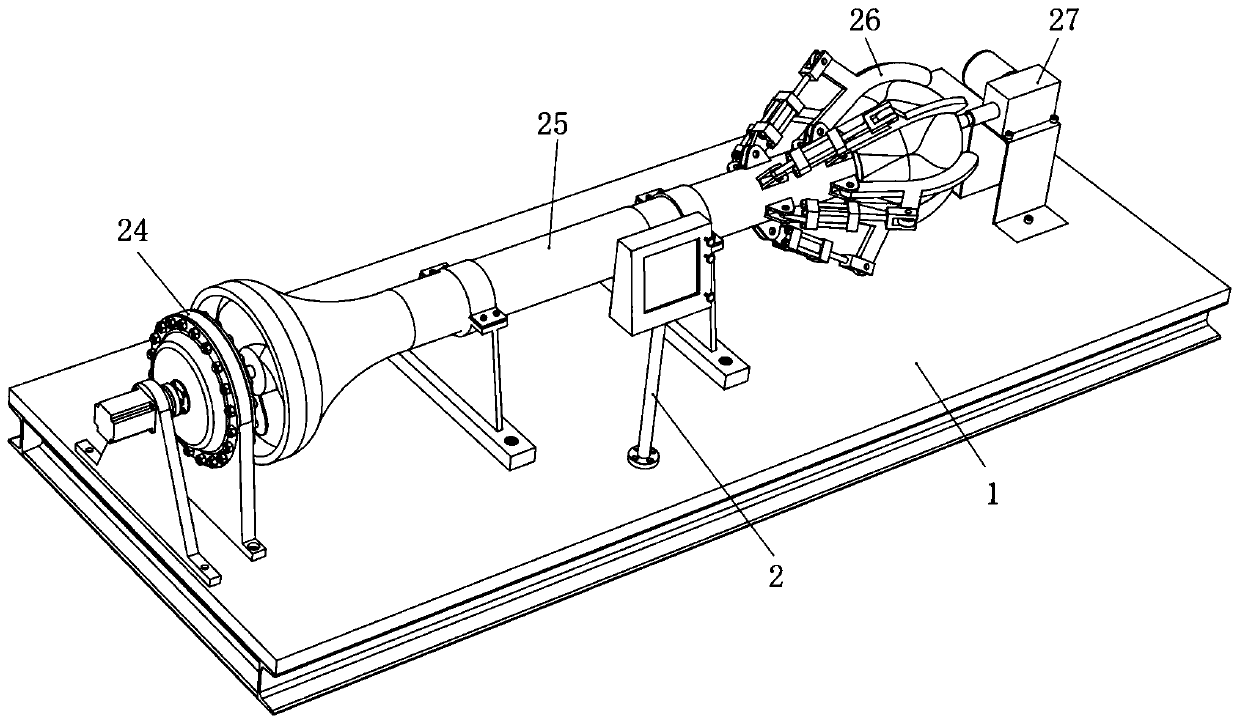

Sensor output test platform

ActiveCN105842482ADetection output performanceJudge eligibilityTesting/calibration of speed/acceleration/shock measurement devicesTest platformLow noise

Owner:CHINA AVIATION POWER MACHINE INST

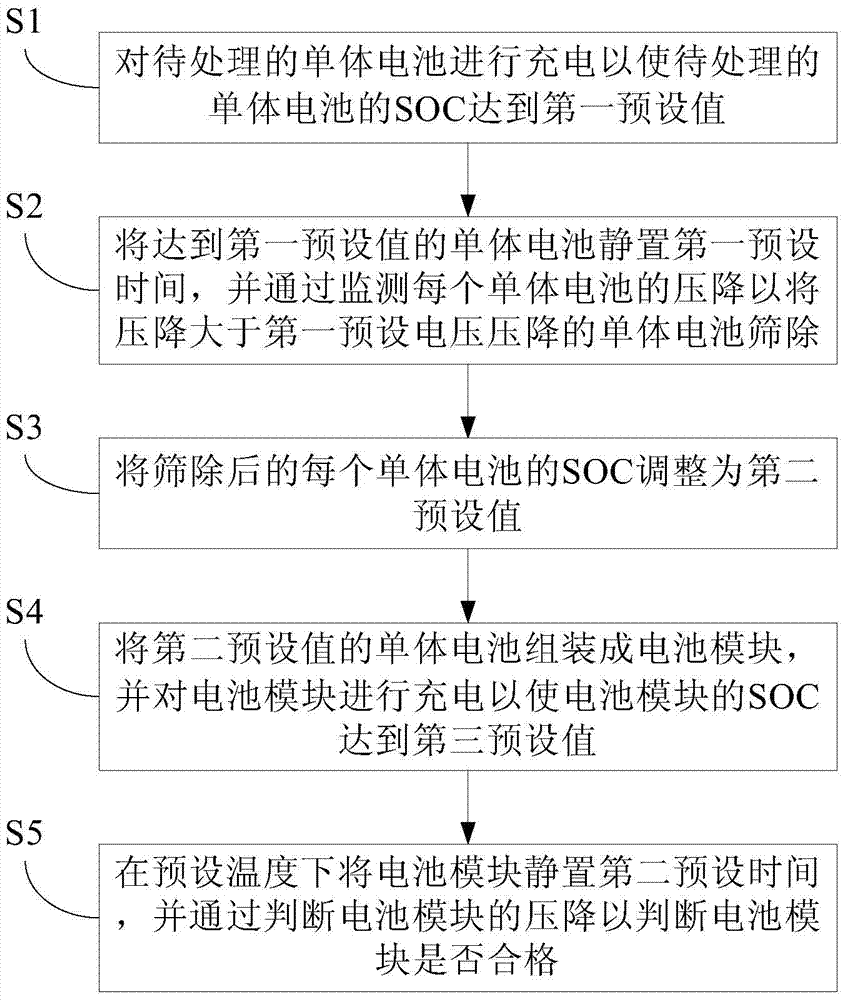

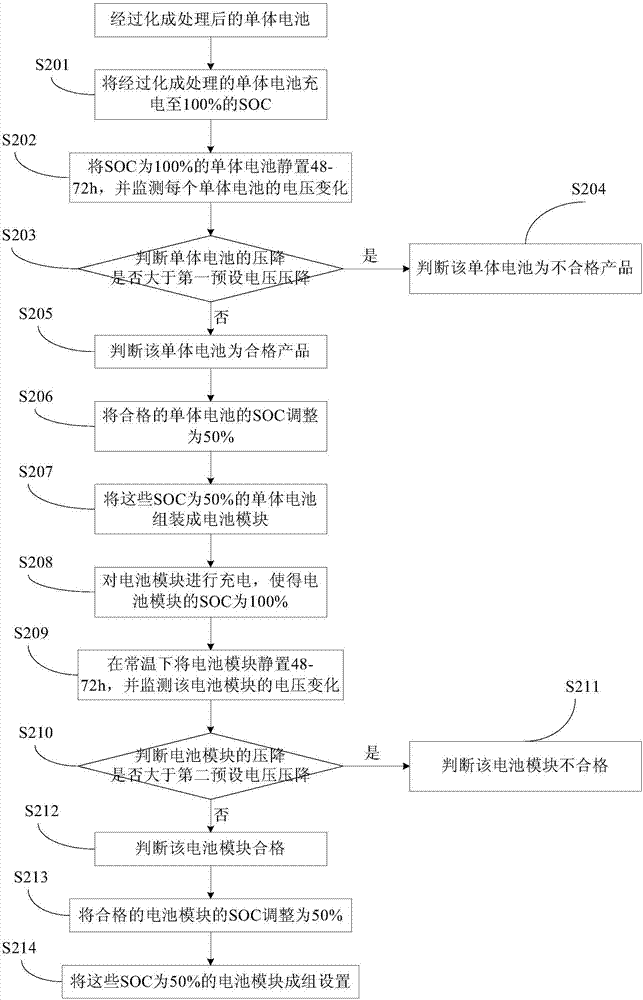

Battery pretreatment method for battery system

ActiveCN104835987BAccurate judgmentJudge eligibilitySecondary cells servicing/maintenanceComputer moduleEngineering

The invention discloses a battery pre-treatment method used for a battery system, wherein the method includes following steps: (1) charging a to-be-treated battery cell to enable the SOC of the to-be-treated battery cell to reach a first preset value; (2) allowing the to-be-treated battery cell of which the SOC reaches the first preset value to stand for a first preset time, and meanwhile monitoring voltage reduction of each battery cell to screen-out the battery cells of which the voltage reduction is higher than a first preset voltage reduction; (3) adjusting the SOC of the rest battery cells to a second preset value; (4) assembling the battery cells with the second preset value to form a battery module, and charging the battery module to enable the SOC of the battery module to reach a third preset value; and (5) at a preset temperature, allowing the battery module to stand for a second preset time and detecting the voltage reduction of the battery module to determine whether the battery module is qualified or not. The battery pre-treatment method can accurately determine whether the battery cell is internally shorted or not and can effectively avoid a problem of failure due to the internal short of the battery cell, and can reduce the period of pre-treatment of a battery.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Chip character detection and counting device

PendingCN111781211AKeep stackingRealize automated detectionMaterial analysis by optical meansEngineeringMachine

The invention aims to provide the chip character detection and counting device which is simple in structure, can save manpower, can improve the detection efficiency, can avoid the problems of missingdetection, false detection and the like, and ensures the detection quality of chip characters. The device comprises a machine table, a conveying mechanism, a CCD detection mechanism, a feeding mechanism and a discharging mechanism. The conveying mechanism is arranged below the feeding mechanism and the discharging mechanism. The detection end of the CCD detection mechanism is arranged above the conveying mechanism; the feeding mechanism and the discharging mechanism are arranged on the two sides of the CCD detection mechanism respectively. The feeding mechanism and the discharging mechanism each comprise a tray module and a lifting module. The tray module comprises a first machine frame arranged on the machine table and a plurality of first air cylinders arranged on the first machine framein a surrounding mode, the lifting module is arranged below the first machine frame, the output ends of the first air cylinders are provided with bearing protrusions, and the bearing protrusions arematched with grooves in a tray. The device is applied to the field of automatic detection.

Owner:珠海市捷锐科技有限公司

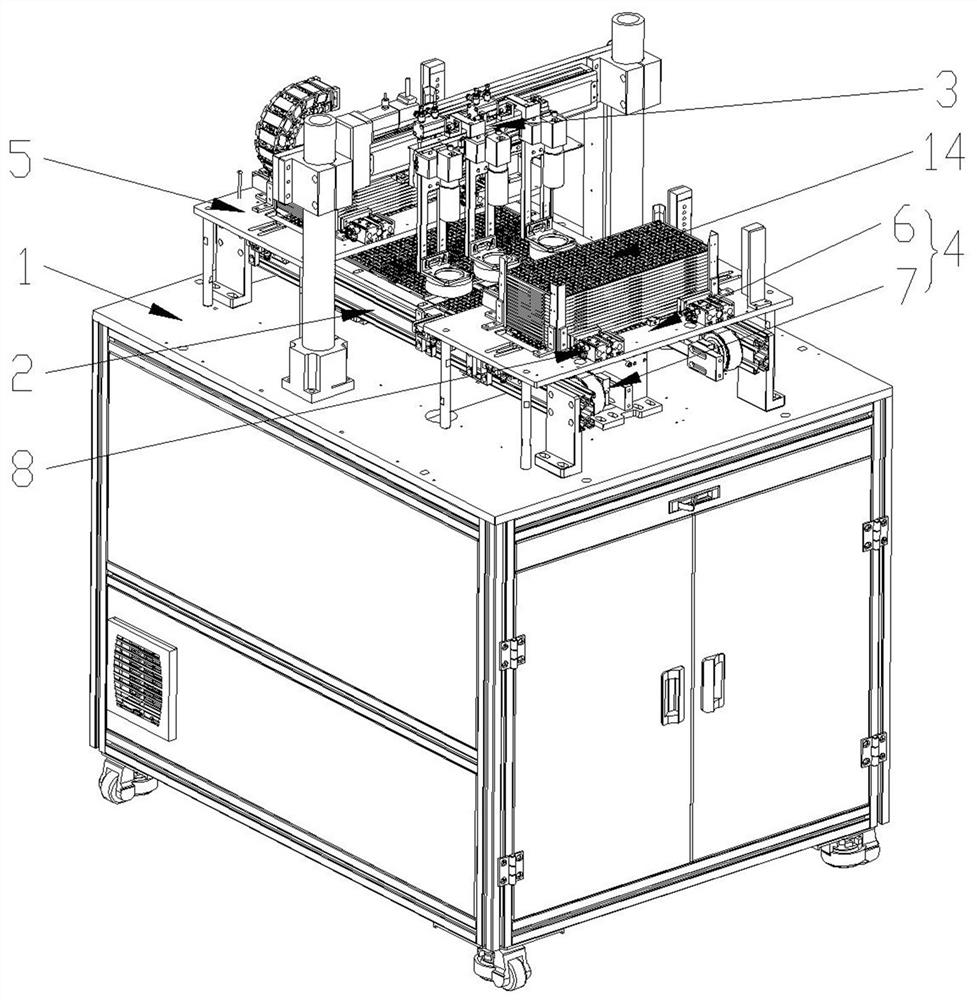

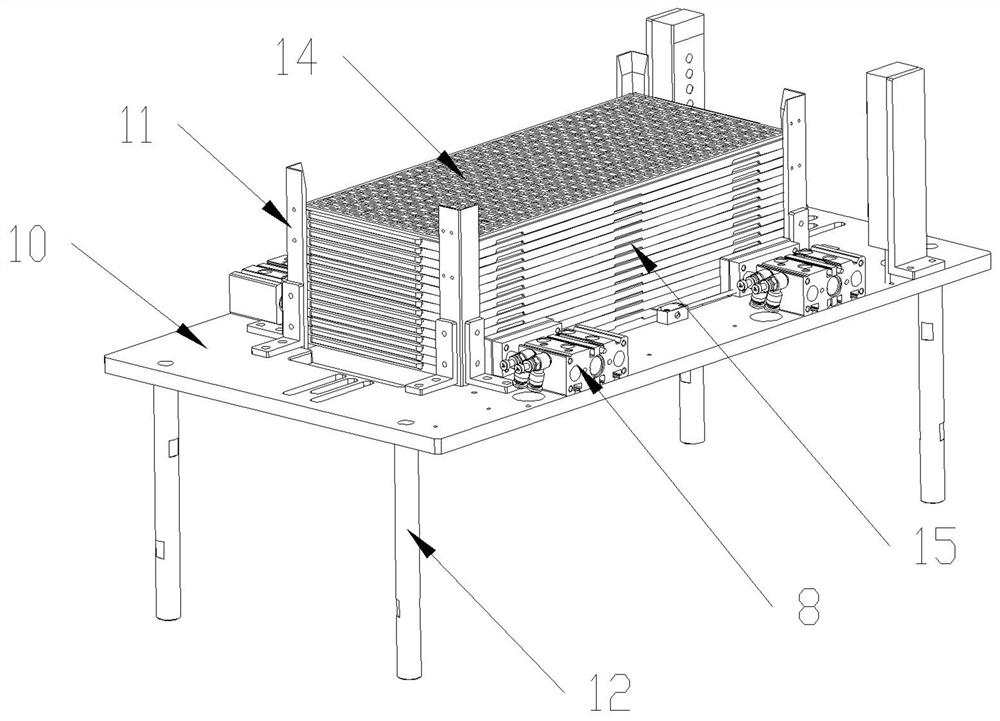

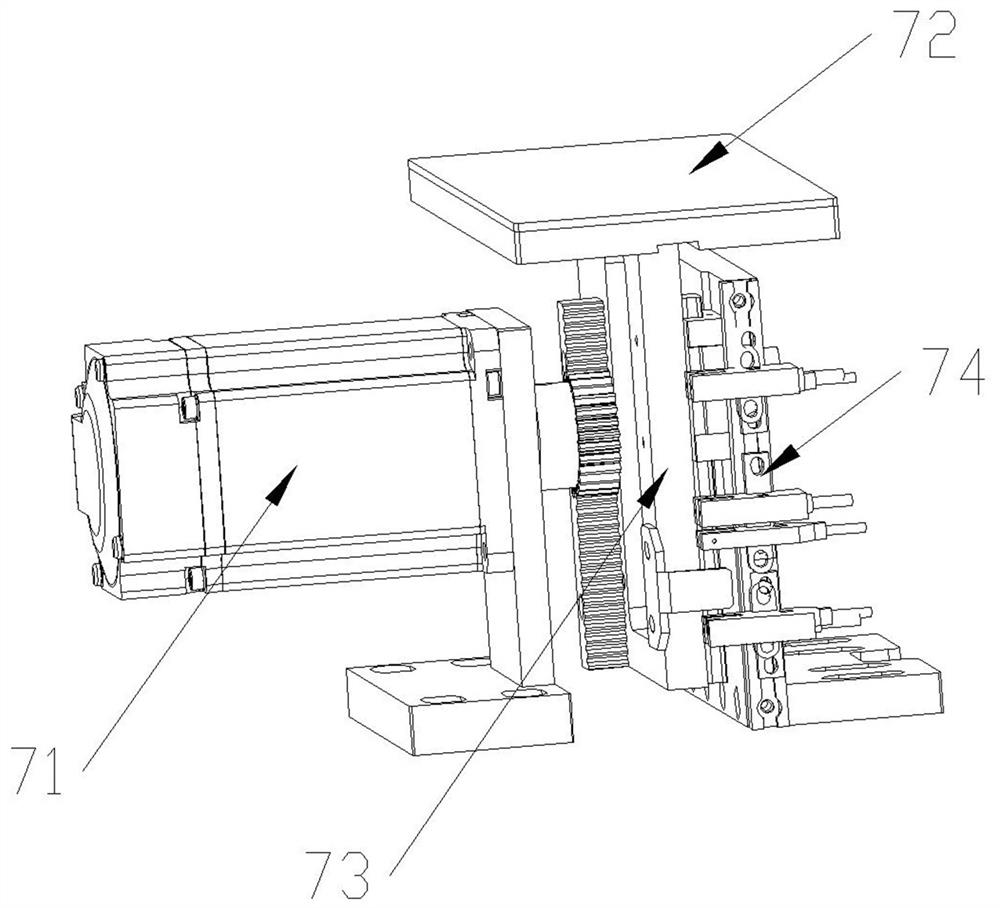

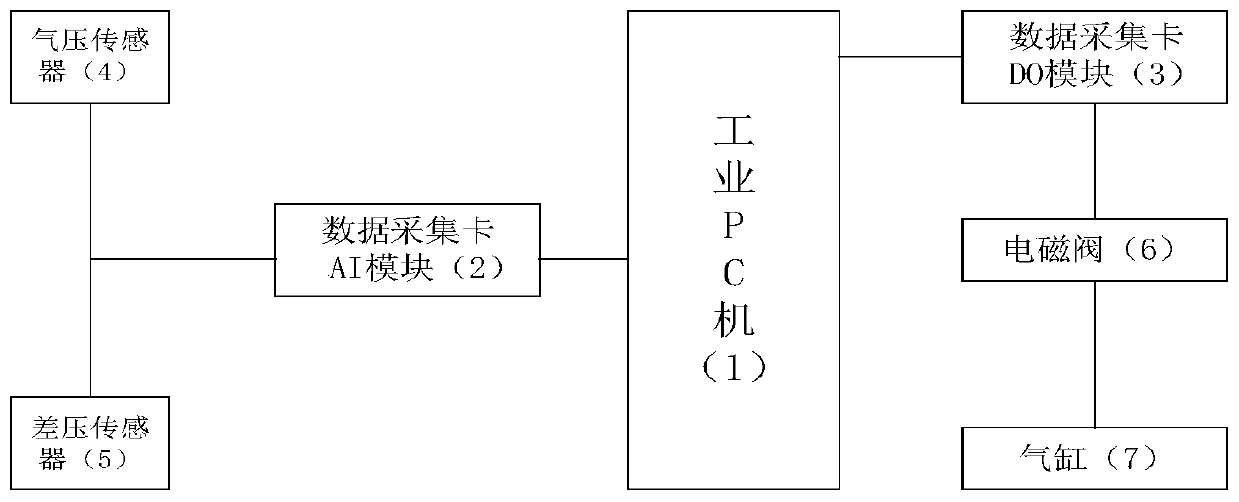

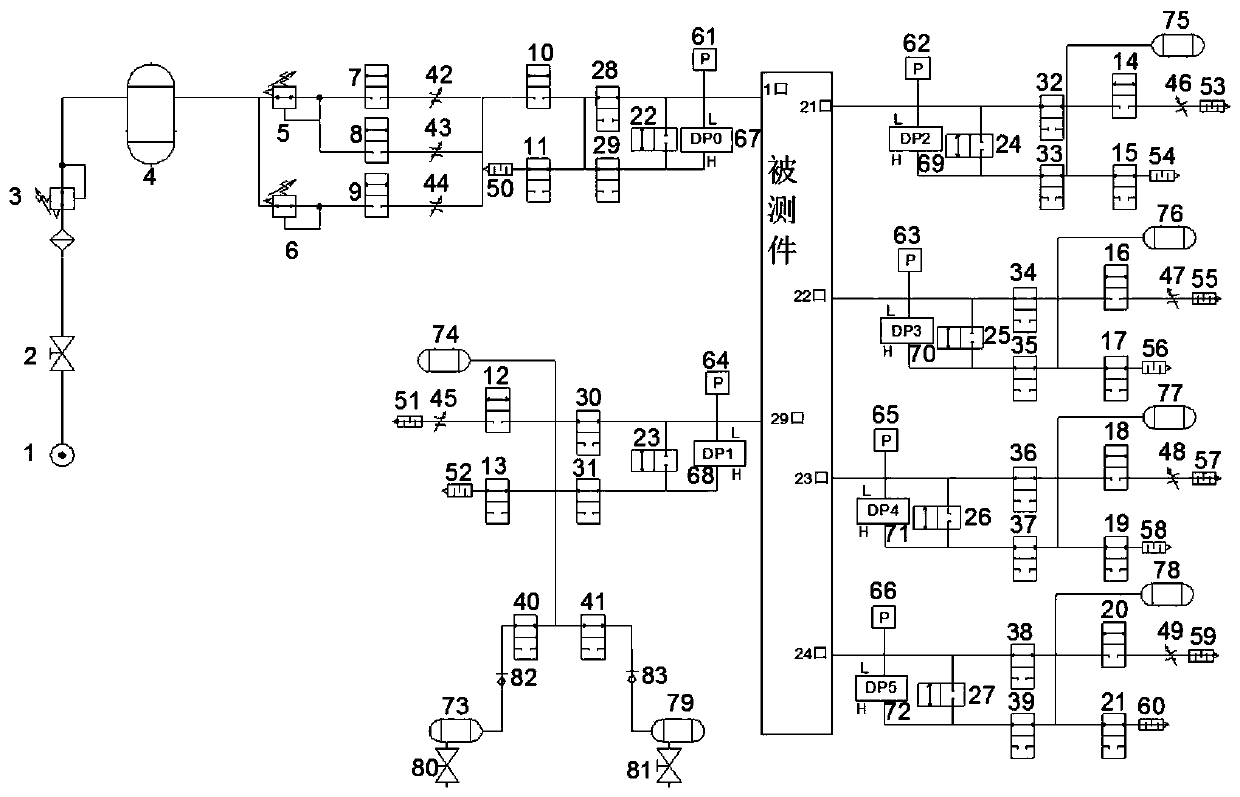

Backflow time and regeneration volume testing system and method for composite dryer

PendingCN110553805AJudge eligibilityAvoid interferenceVehicle testingMachine part testingDifferential pressureData acquisition

The invention discloses a backflow time and regeneration volume testing system for a composite dryer. The system comprises an industrial PC, a data acquisition card AI module, an air pressure sensor,a differential pressure sensor, a data acquisition card DO module, a duplex piece, an air storage tank, an electromagnetic valve, a silencer, an air cylinder and a reference cavity, wherein the industrial PC is simultaneously connected with the data acquisition card AI module and the data acquisition card DO module; the data acquisition card AI module is connected with the air pressure sensor andthe differential pressure sensor; the data acquisition card DO module is connected with the electromagnetic valve; the electromagnetic valve is connected with the air cylinder; the air pressure sensoris arranged at an air inlet and an air outlet of the composite dryer; the differential pressure sensor is arranged at the air inlet and the air outlet of the composite dryer; and the silencer is connected to the air outlet of the electromagnetic valve. The backflow time and regeneration volume testing system of the composite dryer can carry out rapid and stable testing, interference caused by human factors is avoided in the testing process, and the accuracy is greatly improved.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

Chain crater detection method

ActiveCN109883834AJudge eligibilityAvoid deformation defectsMaterial strength using tensile/compressive forcesManufacturing technologyComputer science

The invention relates to the technical field of manufacturing of protection chains, and in particular relates to a chain crater detection method comprising the steps of S1, stamping a crater of a detection object; and S2, detecting the position of the crater of the detection object, and if the position of the crater of the detection object is cracked, it indicates that the crater is detected to beunqualified. In the technical scheme, the position of the crater of the detection object is stamped, if the crater of the detection object is welded by one or more of cold solder joint and dry joint,the position of the crater is wholly cracked. Therefore, whether the crater is qualified can be easily judged. The defect that when the tensile test mode is used, the detection object needs to be prevented from being deformed under the effect of the tensile force is avoided, and the condition that the detection object flies out and causes a safety accident during a detection process is avoided.

Owner:DEQING GENERAL IND CO LTD

Layered sculpturing method

ActiveCN104827815AReduce scrap rateAvoid missing engravingDecorative surface effectsReference modelFloat Value

The invention discloses a layered sculpturing method. The layered sculpturing method comprises the following steps: S1, acquiring a sculpturing model; S2, selecting an original point, carrying out point decomposition on the surface layer of the sculpturing model, and establishing a coordinate according to the concentrated decomposed points of surface layer points; S3, establishing a reference model in a coordinate point in the step S2, wherein the reference model consists of not less than one reference point, and each concentrated decomposition point of the surface points corresponds to one reference point of the reference model; S4, generating a feeding value according to the corresponding relationship between each decomposition point and the reference point; S5, dividing the intervals of the decomposition points according to the feeding value, wherein the maximal difference of the feeding values of every two decomposition points in each interval is not greater than the preset floating value; S6, establishing a sculpturing path aiming at each interval; and S7, sculpturing a blank body according to the sculpturing path. According to the invention, the blank body is sculptured in a layered mode, and the blank body scrappage rate is reduced.

Owner:安徽华智智能卡科技有限公司

Rapid test method for the oxidation condition of copper wire in high temperature environment

InactiveCN108051372AJudge eligibilitySimple test methodColor/spectral properties measurementsTest comparisonNatural ventilation

The invention provides an electric cable raw material incoming inspection process, and specifically relates to a rapid test method for the oxidation condition of a copper wire in a high temperature environment, wherein a natural ventilation type high-temperature oven is used. The rapid test method comprises: increasing the temperature of the natural ventilation type high-temperature oven to 200+ / -2 DEGC, intercepting a copper wire with a length of not less than 5 m, placing the copper wire in the high-temperature oven, standing for 5 min, taking out the copper wire, and comparing the taken copper wire to RAL color card. According to the present invention, the rapid test method has characteristics of simple test device, short test time and simple test comparison method; and with the rapid test method, whether the copper wire is blackened, reddened, whitened and is subjected to other conditions after the copper wire passes through the continuous vulcanization pipe can be judged accordingto the oxidation condition of the copper wire after the test, and whether the copper wire is qualified can be rapidly judged by the inspection personnel.

Owner:SHANGHAI QIFAN CABLE CO LTD

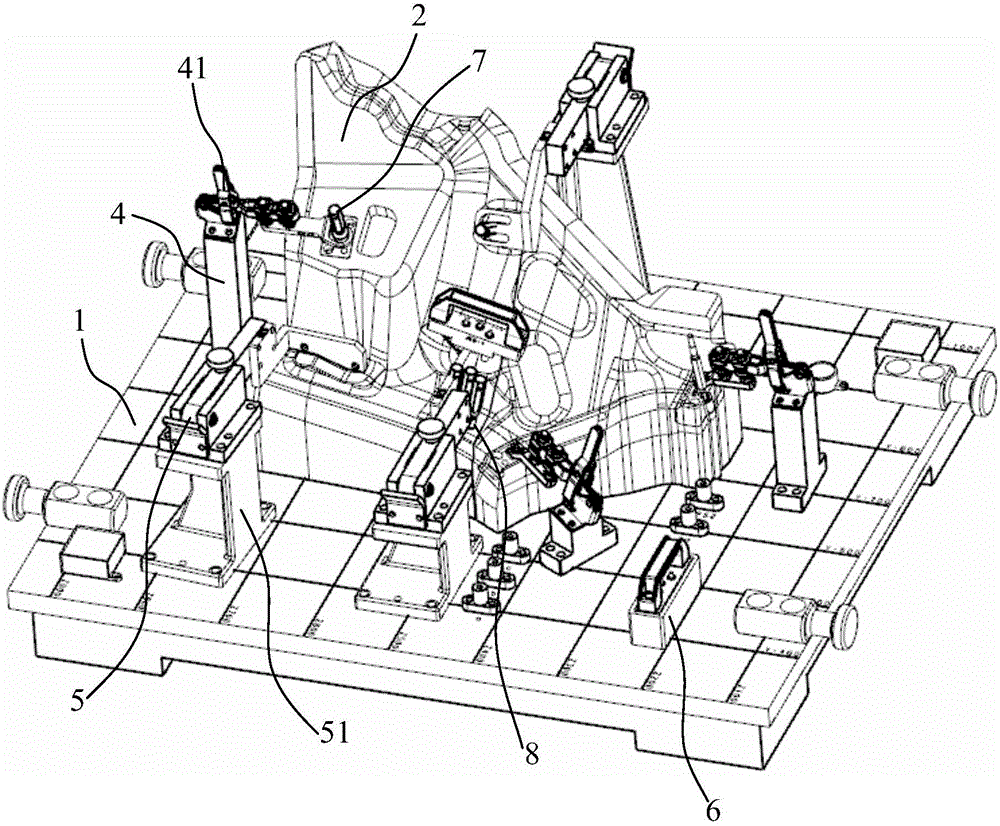

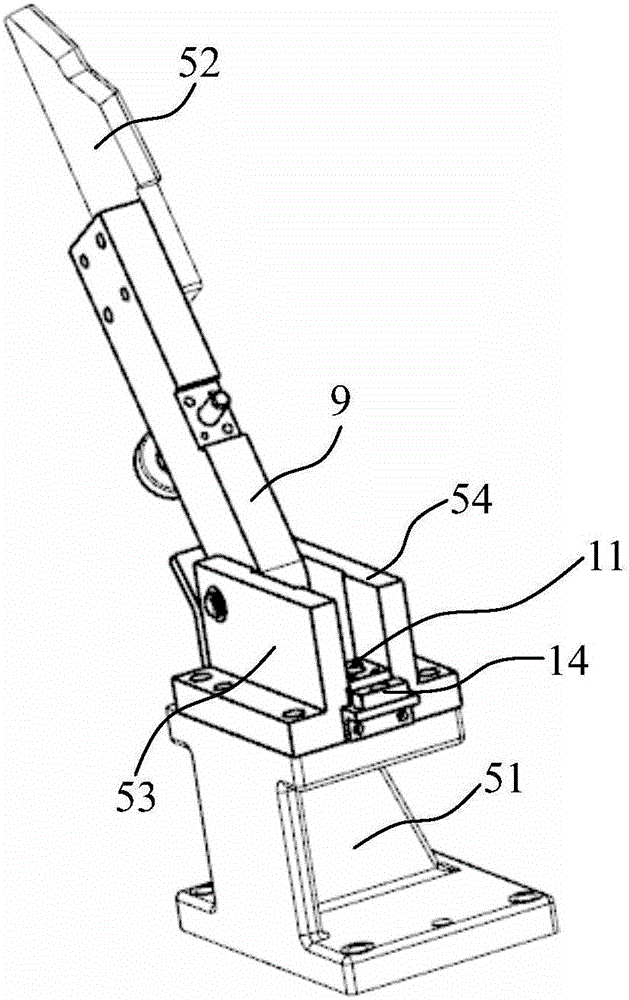

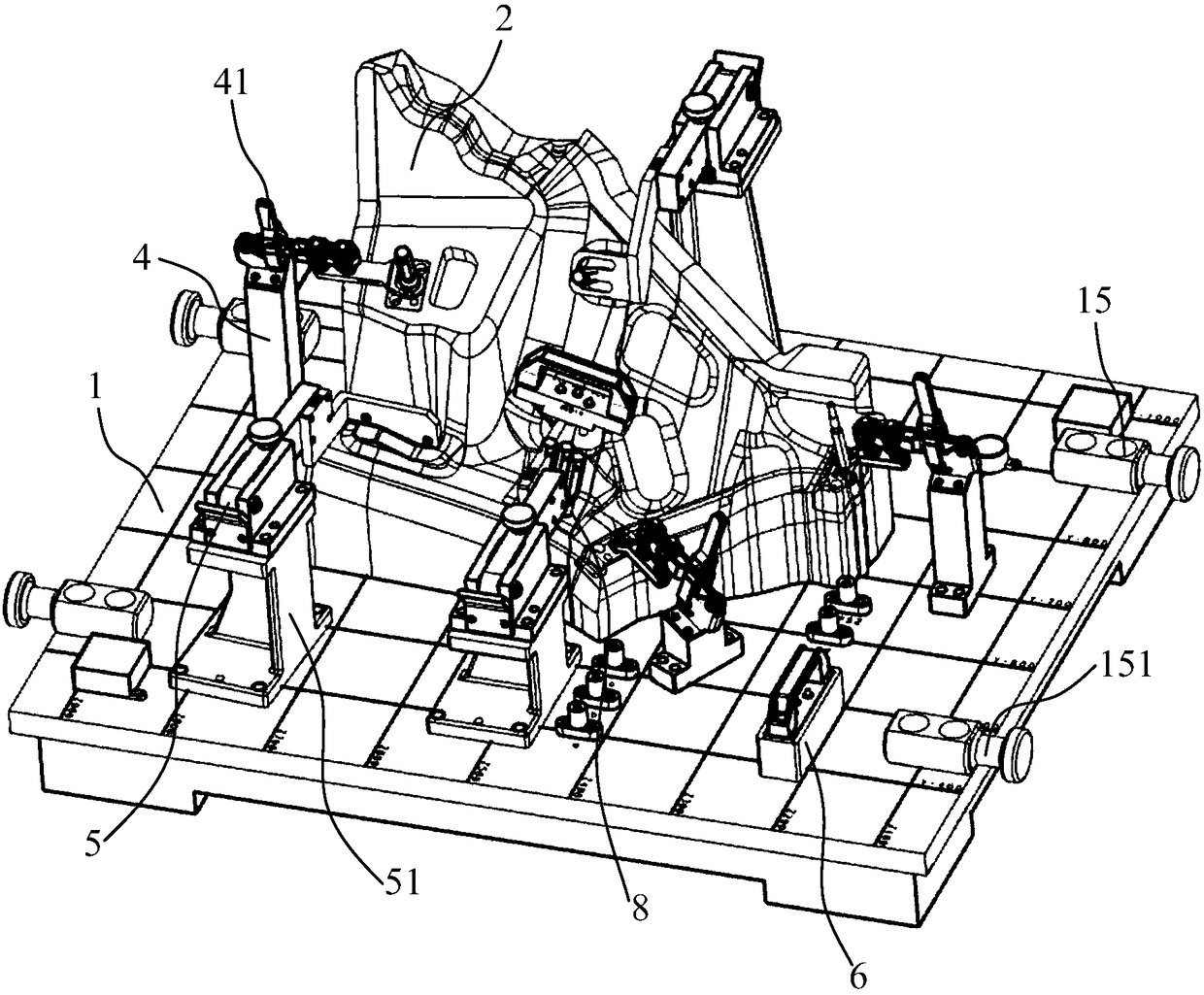

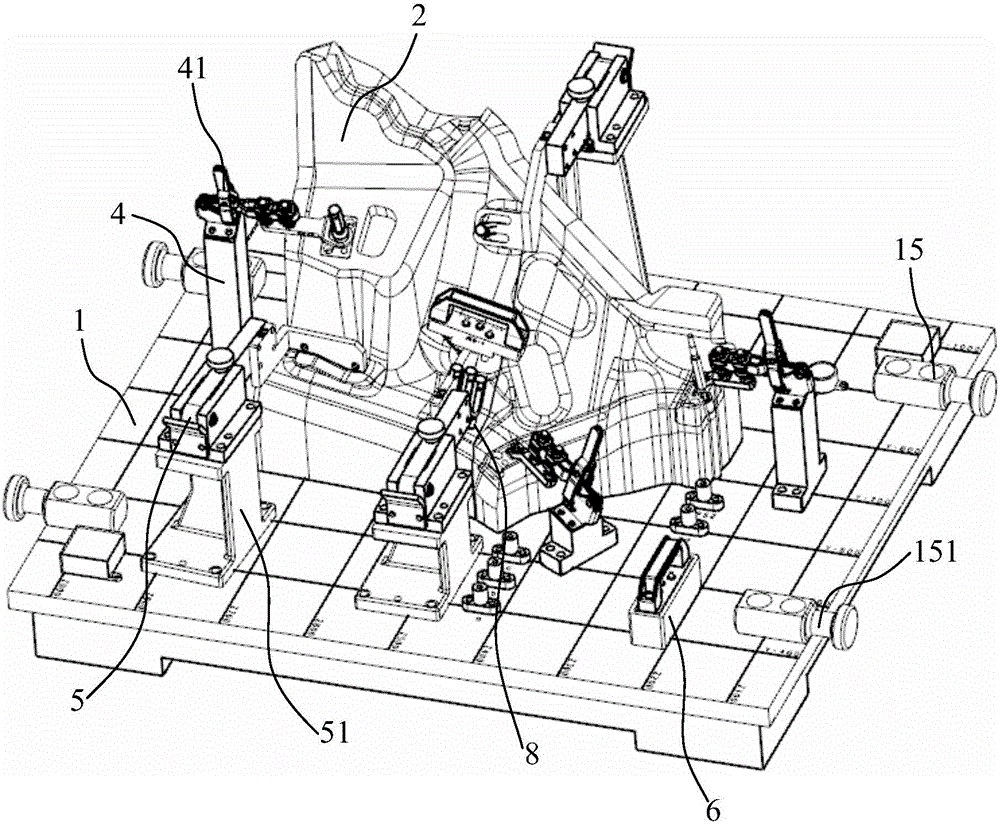

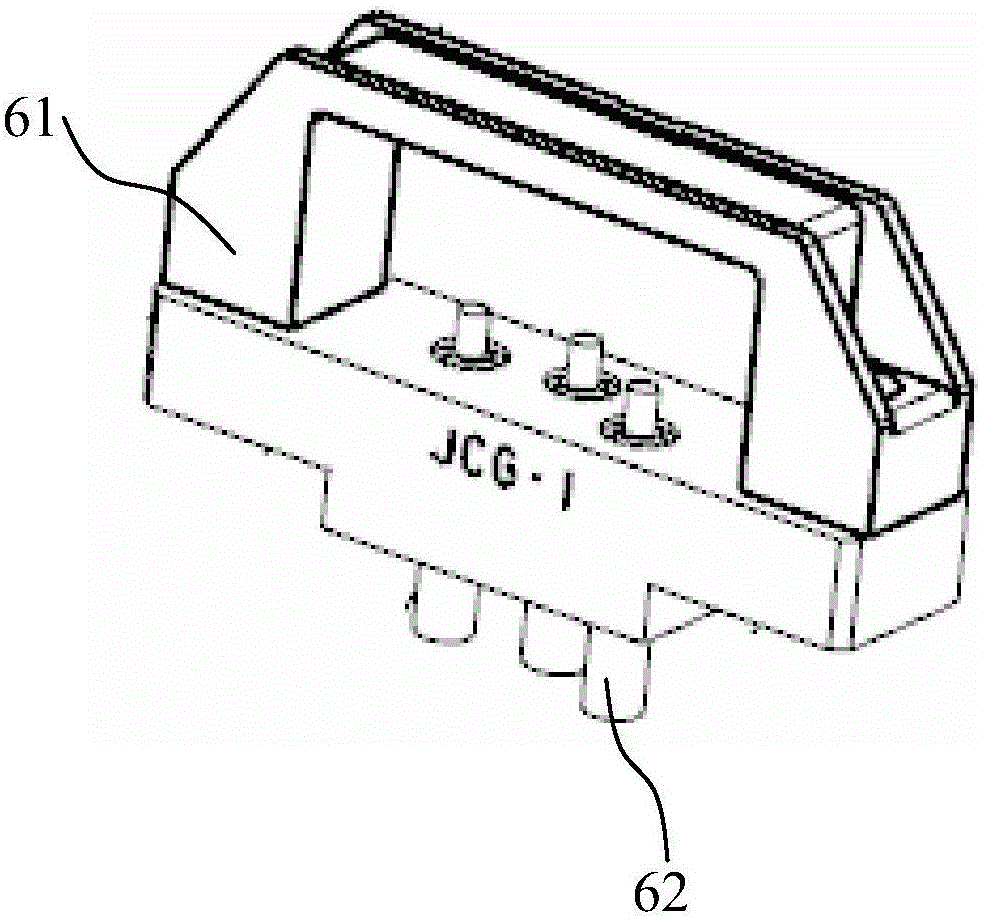

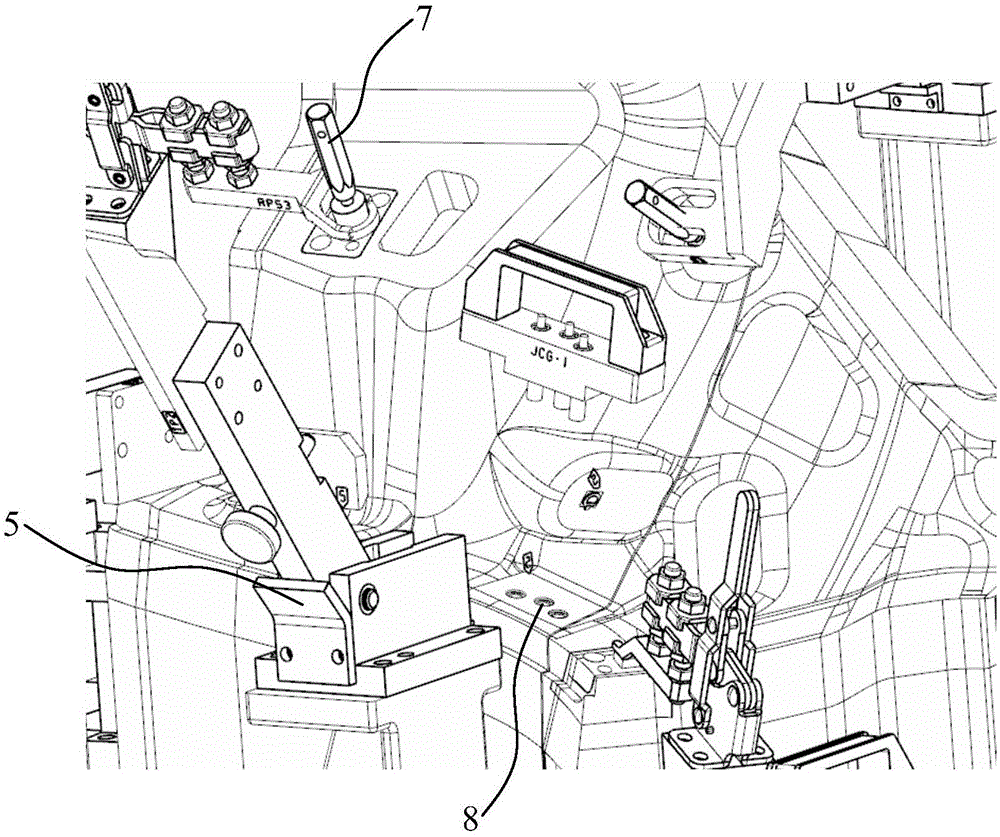

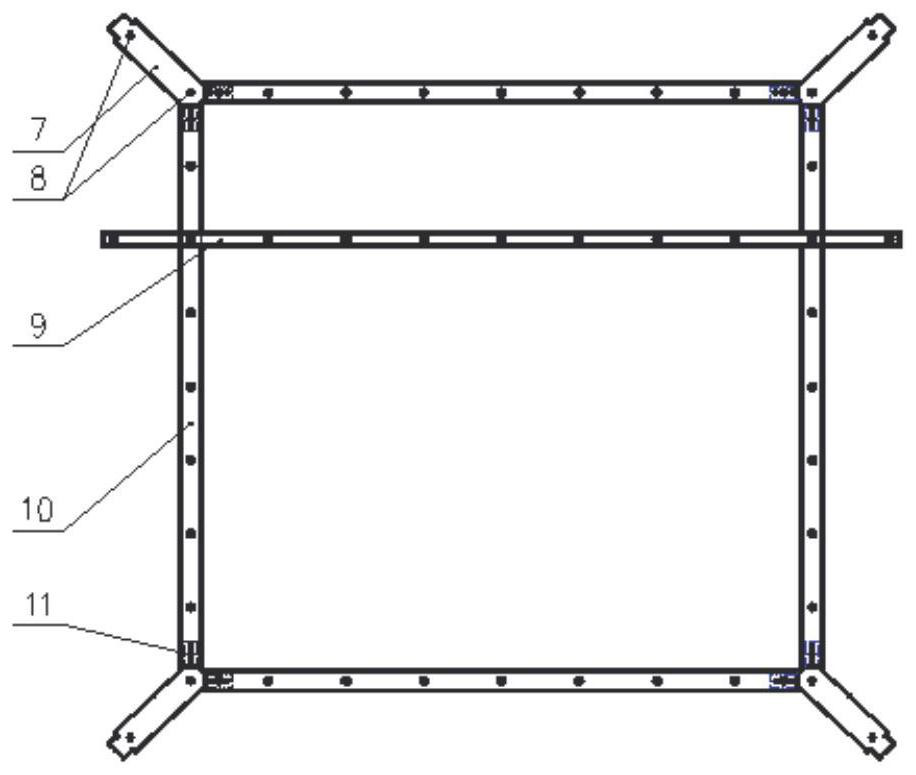

Matching accuracy tester for auto parts

ActiveCN105806176BJudge eligibilityEasy to detectMechanical diameter measurementsMechanical clearance measurementsEngineeringGap detection

The invention discloses a matching precision detector for an automobile part.A clamping mechanism and a gap detection mechanism of the matching precision detector are installed on a coordinate base, a clamp located at the upper end of the clamping mechanism is used for clamping a to-be-detected part placed on the upper surface of a simulation block base, and a first safety pin is positioned on the lower portion of a go / no go gauge safety pin.A go gauge part and a no-go gauge are sequentially arranged in the middle of the go / no go gauge safety pin from bottom to top, and the upper portion of the go / no go gauge safety pin is provided with a push rod part.The gap detection mechanism further comprises a base, a clamping plate, a left fixed plate and a right fixed plate, wherein the left fixed plate and the right fixed plate are located on the upper surface of the base and parallelly arranged.The rear end of a rotating arm is movably installed between the left fixed plate and the right fixed plate, the clamping plate is installed at the front end of the rotating arm, and four corners of the coordinate base each are provided with a hanging rod.According to the matching precision detector, part gaps can be detected quickly and visually, and the matching precision detector is high in detection reliability and detection efficiency and enables users to quickly and visually judge whether the part is qualified.

Owner:KUNSHAN DAYA AUTO PARTS

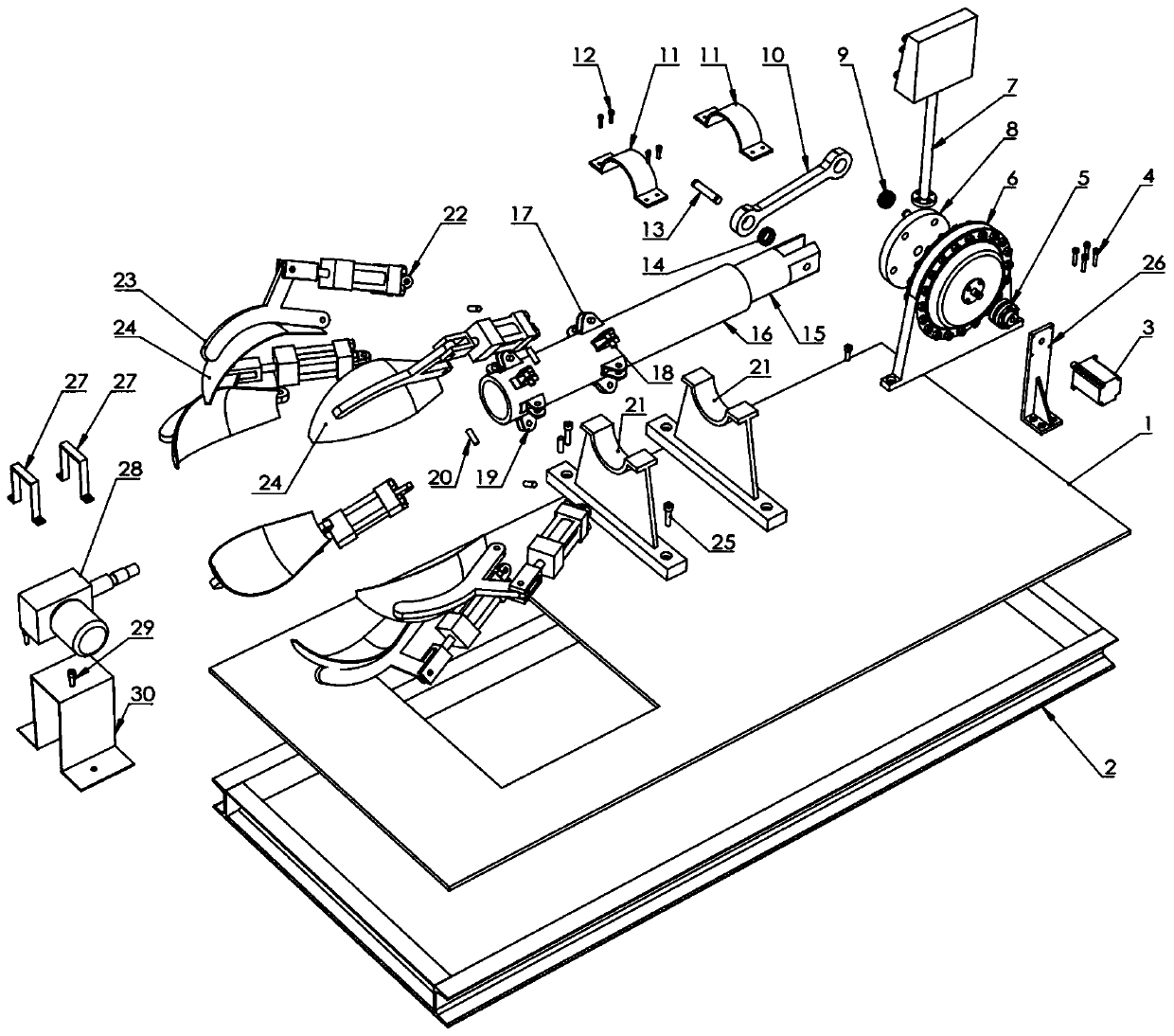

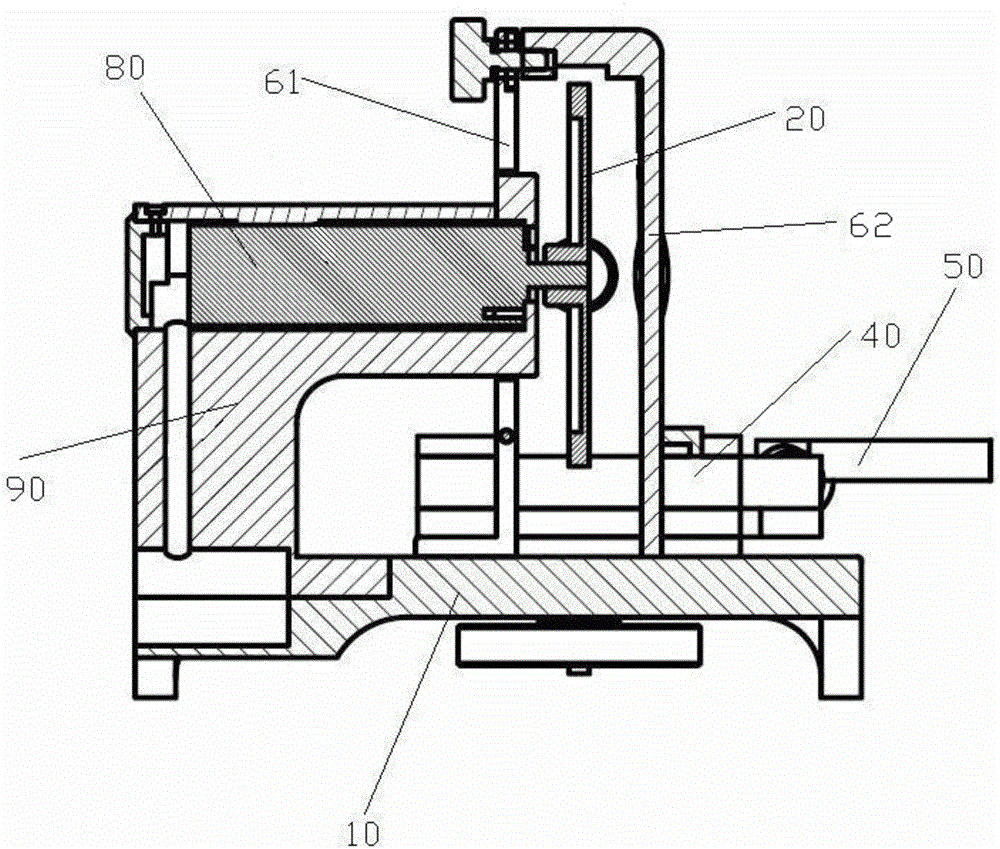

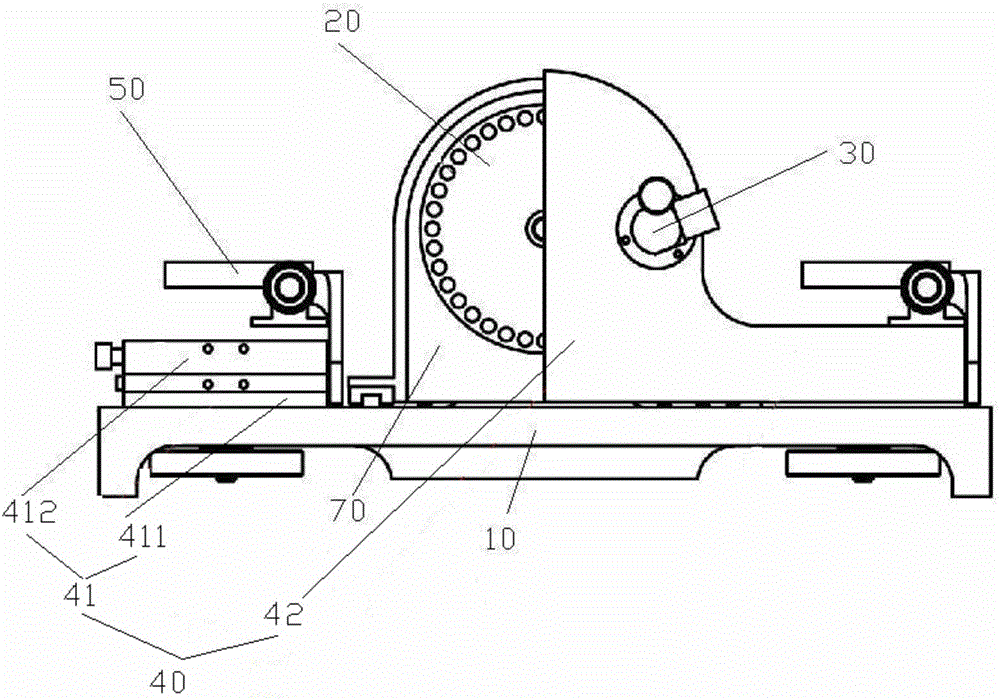

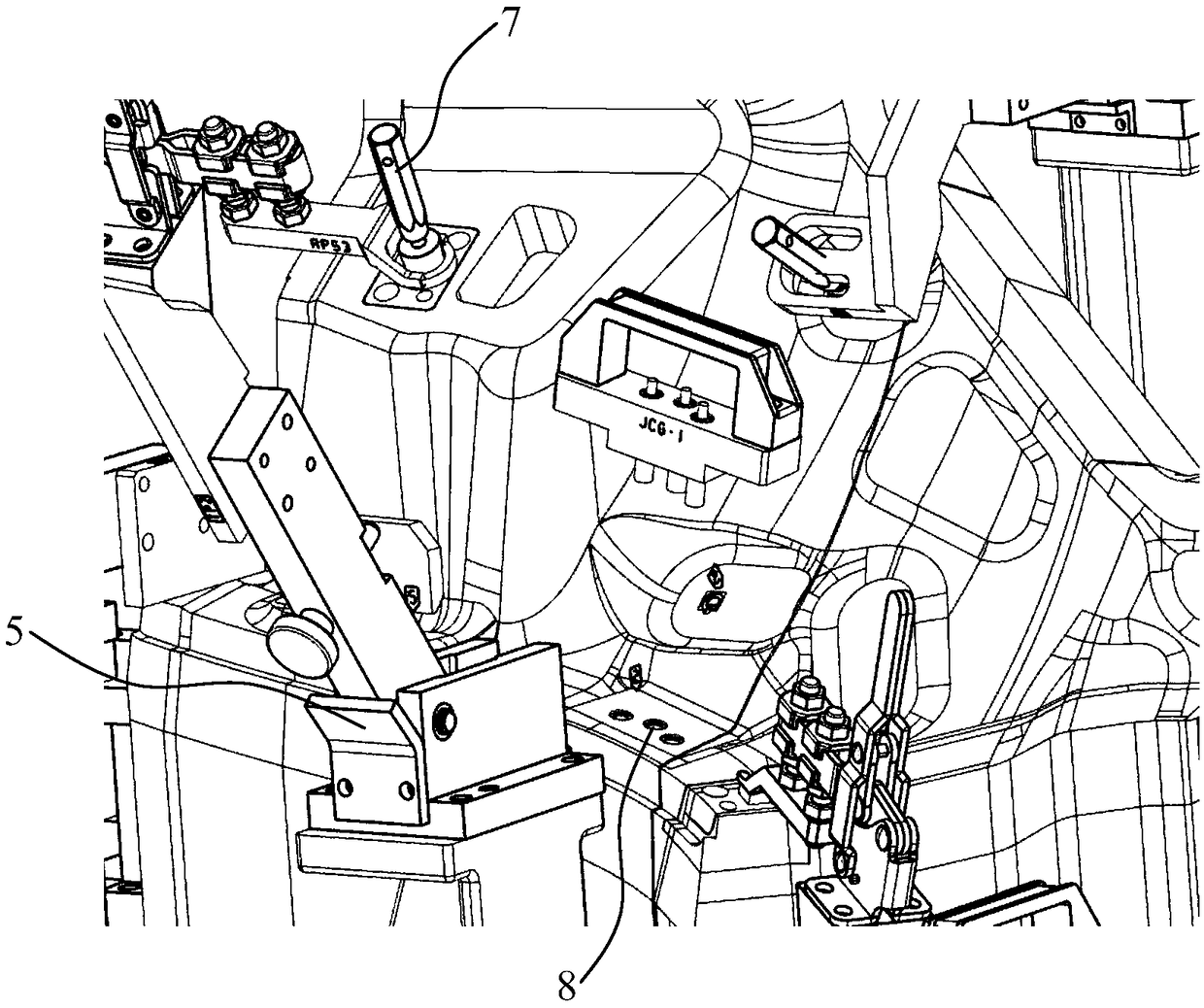

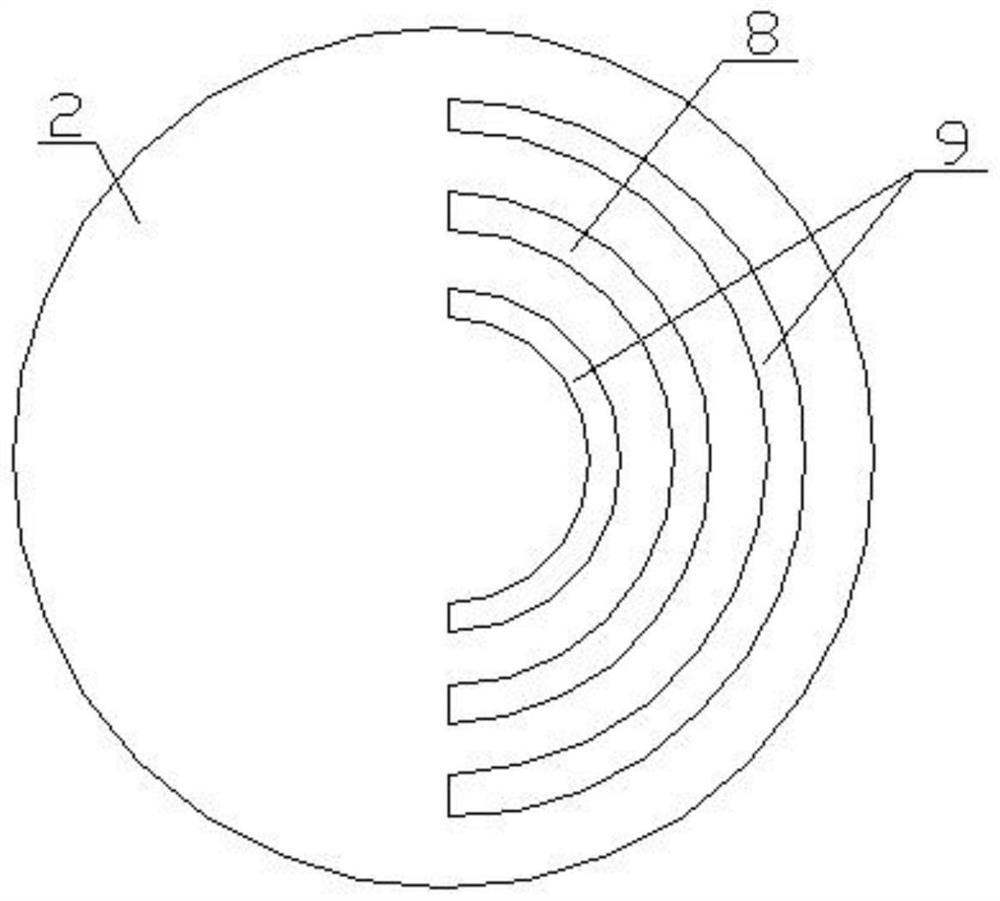

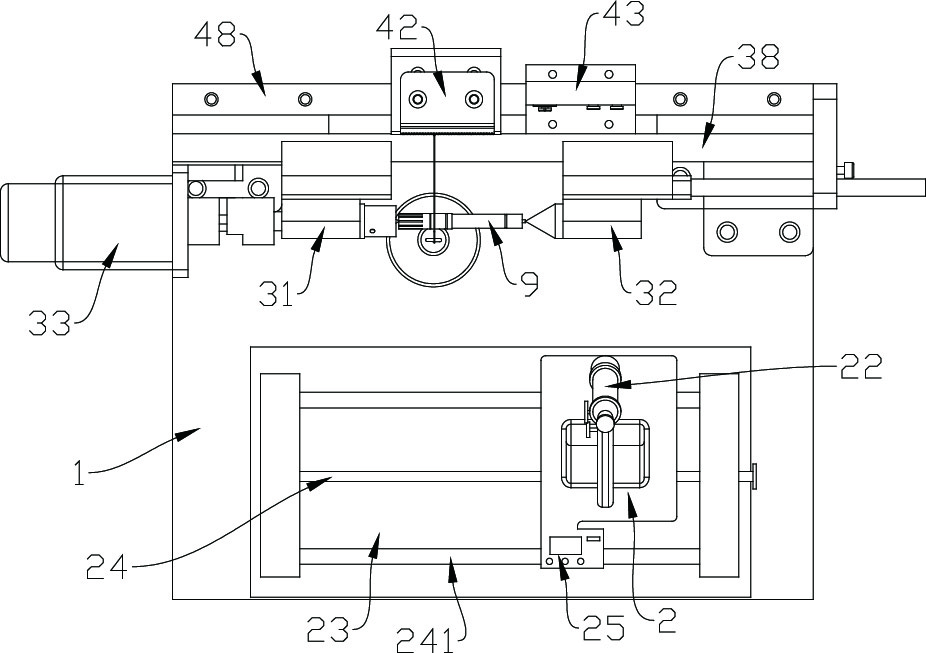

Sampling inspection device for bent plate chain

The invention discloses a sampling inspection device for a bent plate chain. The sampling inspection device comprises a rack, an auxiliary plate, an eccentric transmission assembly, a lifting assembly, a detection assembly and a power assembly, wherein the power assembly comprises a transmission assembly, two chain wheels and two chain wheel seats; the bottom of the auxiliary plate is fixed to therack; the lifting assembly comprises a fixing plate, a hydraulic cylinder and a top plate; and the detection assembly comprises a connecting rod, an upper pressing plate, a lower pressing plate and adistance measuring plate. The sampling inspection device is ingenious in design and convenient to operate.

Owner:安徽省绩溪县飞奔链传动有限公司

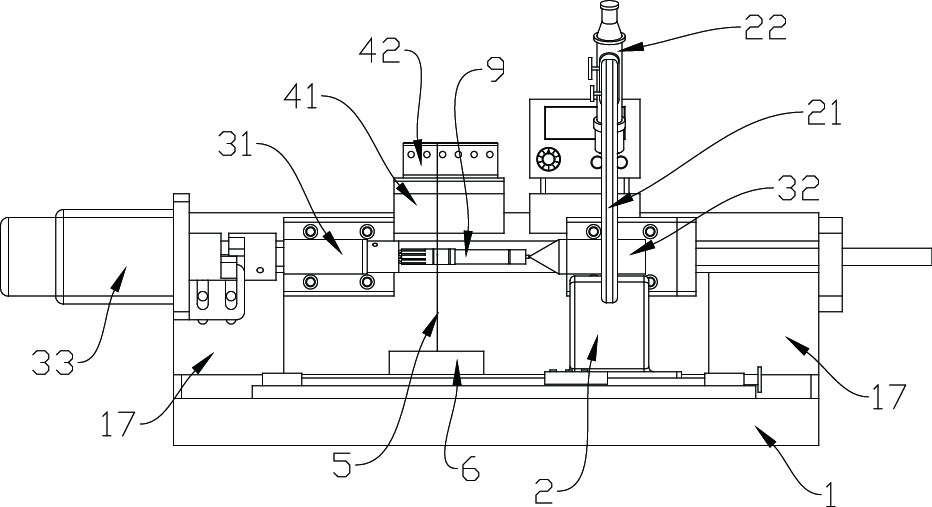

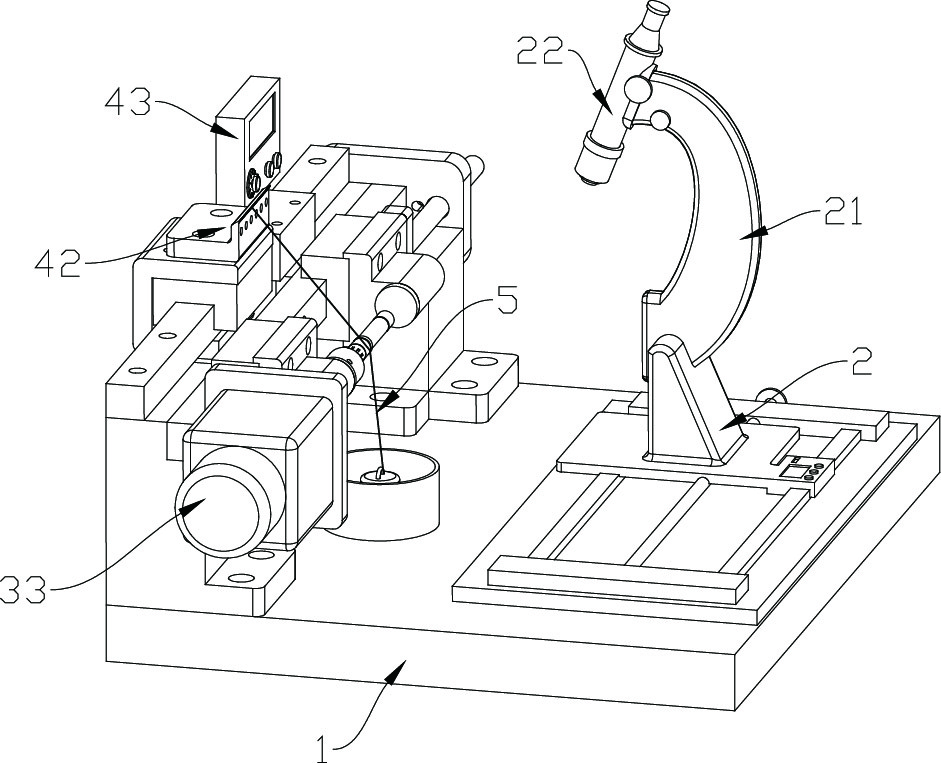

Detection method and device for representing grinding lines of columnar part

PendingCN112415023ANo damageEasy to operateMaterial analysis by optical meansUsing optical meansLap jointSmooth surface

A detection method for representing grinding lines of a columnar part comprises the steps that S10 the columnar part needing to be detected is fixed through a clamping assembly, and a nylon wire withthe smooth surface is arranged on the surface of the columnar part in a lap joint mode; S20 the upper end of the nylon wire is fixed, and the lower end of the nylon wire is connected with a weight, sothat the nylon wire is kept in a falling and tensioning state; S30 a microscope or an magnifying lens is moved, and the visual field area of the microscope or the magnifying lens is aligned with theposition of the nylon wire on the columnar part; S40 the clamping assembly drives the columnar part to rotate for a plurality of circles, then rotation is stopped, the position of the nylon wire on the columnar part in the visual field area of the microscope or the magnifying lens is observed, and the deviation between the position and the position of the nylon wire before rotation is calculated;and S50 whether the detection of the grinding lines of the columnar part is qualified or not is judging according to the deviation. The invention further relates to a detection device, the position ofthe nylon wire on the surface of the part is adopted for calibration, operation is convenient, and no damage is caused to the surface of the part.

Owner:NINGBO XIASHA GEARS

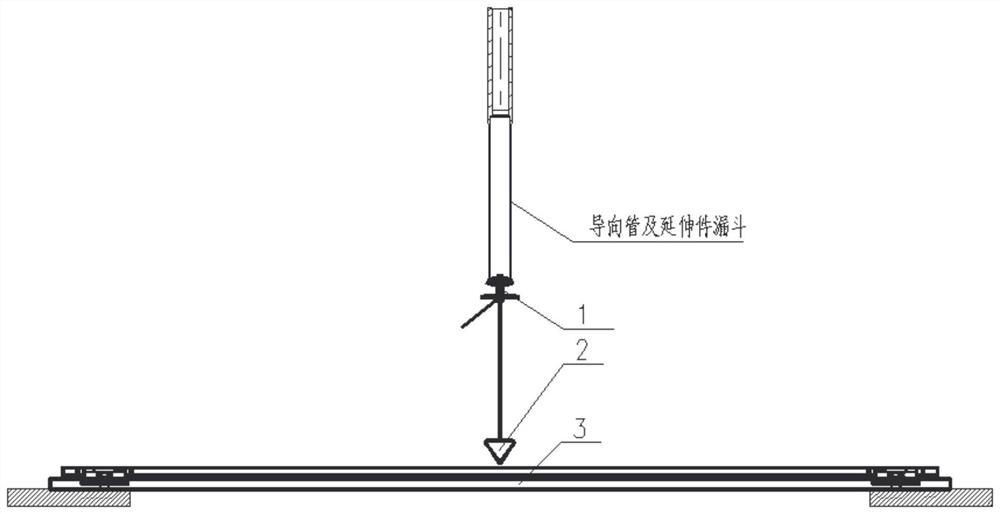

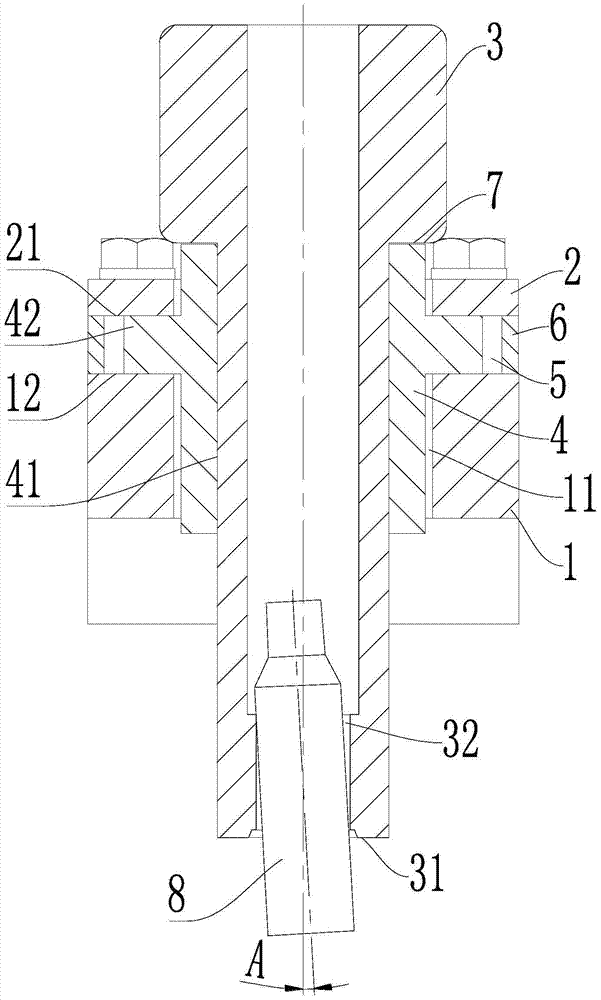

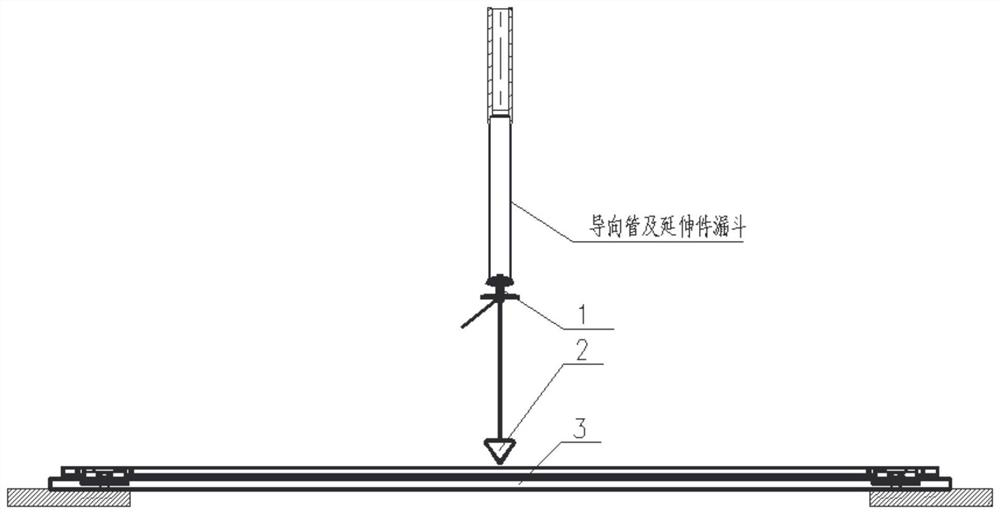

Device and method for measuring nozzle positioning

ActiveCN113267106BPositioning is intuitive and effectiveSolve the problem that it is difficult to accurately locate the center line of the nozzleMechanical measuring arrangementsStructural engineeringControl theory

The invention discloses a nozzle positioning and measuring device and method, comprising a positioning mechanism, a measuring mechanism and a wire hammer; the positioning mechanism includes an adjusting bolt, a nut, an adjusting plate, an expansion ring and a positioning seat; the top of the positioning seat is fixed with a plurality of The guide column is provided with a positioning hole on the adjustment plate, the positioning hole is matched with the guide column, and there is a certain distance between the adjustment plate and the top of the positioning seat, and an expansion ring is fixed between the adjustment plate and the positioning seat , the adjusting bolt passes through the positioning seat and the adjusting plate in turn from the bottom of the positioning seat upwards, and cooperates with a nut; the measuring mechanism includes a frame for connecting with the top head of the pressure vessel and a detection ruler fixed on the frame. The detection ruler is provided with a plurality of circular grooves, and the circular grooves are used to judge the center of the wire hammer; the wire hammer is fixed at the center of the bottom of the adjusting bolt.

Owner:SHANDONG NUCLEAR POWER EQUIP MFG

Profile detection device used for automobile parts

ActiveCN106091861AImprove detection accuracyConvenient radius detectionMechanical diameter measurementsMechanical clearance measurementsMotor vehicle partEngineering

The invention discloses a profile detection device used for automobile parts A clamping mechanism and a gap detecting mechanism are disposed on a coordinate base, and a clamp disposed on the upper end of the clamping mechanism is used for clamping a to-be-detected part disposed on an upper surface of a simulation block base. A lower part of a latch of a go / no go gauge is a first latch, and the middle part of the latch of the go / no go gauge is, from bottom to top, provided with a go gauge part and a no go gauge part sequentially, and the upper part of the go / no go gauge is a push rod part. The gap detecting mechanism further comprises a base, a clamping board; a left fixing board and a right fixing board, which are parallely disposed on the upper surface of the base; and a rotating arm, the rear end of which is disposed between the left fixing board and the right fixing board. The clamping board is disposed on the front end of the rotating arm, and four corners of the coordinate base are respectively provided with a hoisting rod. The profile detection device used for the automobile parts is advantageous in that the gaps between the parts are detected quickly and visually, and the reliability of the detection is high, the efficiency of the detection is high, and whether the parts are qualified is determined quickly and visually.

Owner:KUNSHAN DAYA AUTO PARTS

Calculation method of deviation rate and secondary ion mass spectrometry analysis method

ActiveCN104237279BReduce usageShorten the recovery detection timeMaterial analysis using wave/particle radiationTest sampleStandard samples

The invention discloses a deviation rate calculation method and a secondary ion mass spectrometry analysis method. Including providing the sample to be tested and the standard sample, and integrating the sample to be tested and the standard sample in the same coordinate system; and performing Gaussian smoothing on the sample to be tested and the standard sample while ensuring that the area and curvature of the area remain unchanged processing; the processed sample to be tested and the standard sample are subjected to a point-to-point division process to obtain a fitting curve; the available area is defined in the fitting curve; the deviation rate is obtained from the available area; the ion implantation angle is obtained The deviation is proportional to the deviation rate, so that it can be clearly judged whether the equipment needs maintenance, saving time and consumables; and it can detect the early minor abnormalities of the ion implanter and give the direction of improvement.

Owner:SEMICON MFG INT (SHANGHAI) CORP

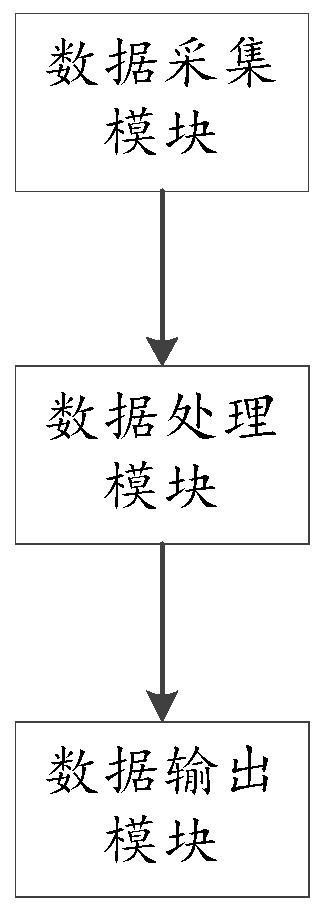

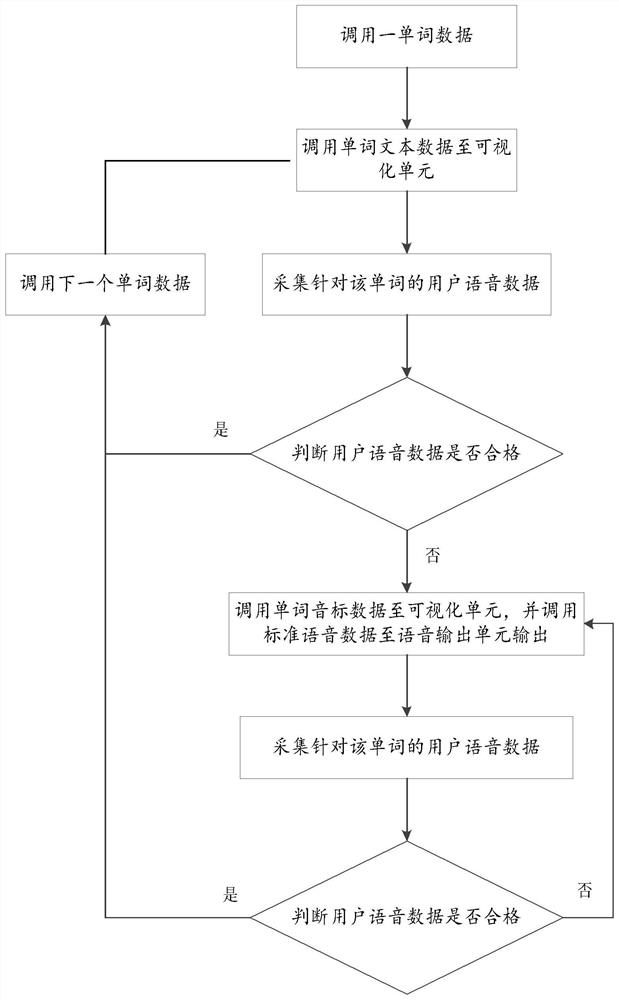

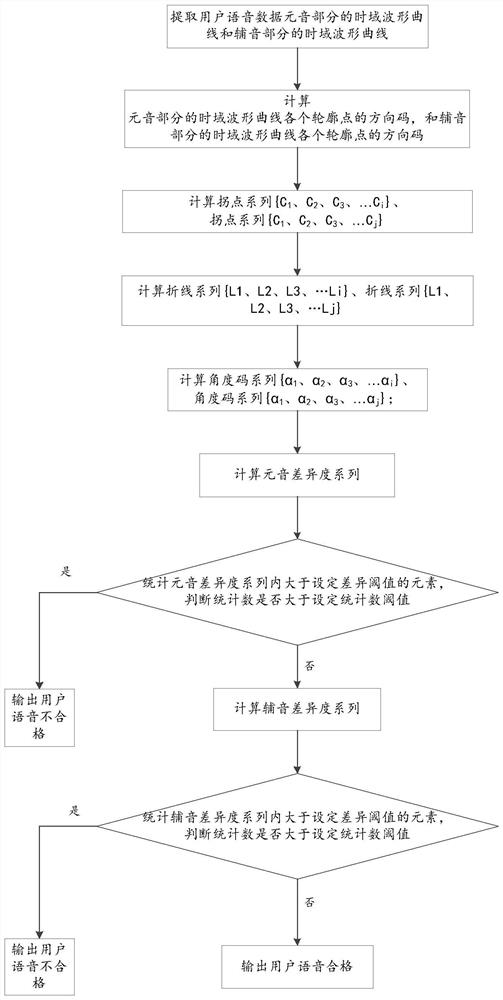

word pronunciation training system

ActiveCN110277104BUniqueness guaranteedJudge eligibilitySpeech analysisData acquisitionHuman–computer interaction

The invention discloses a word pronunciation training system, comprising a data collection module, a data processing module and a data output module; the data collection module is used to collect user voice data; the data processing module is used to judge whether the user voice data is qualified; the data output module is used to for outputting standard voice data. The invention can evaluate the user's voice, and when the user's voice is inaccurate, send out a standard voice for the user to learn.

Owner:SHANGHAI SQUIRREL CLASSROOM ARTIFICIAL INTELLIGENCE TECH CO LTD

A detection tool for output shaft of wiper connecting rod

ActiveCN105043189BImprove accuracyJudge eligibilityAngles/taper measurementsEngineeringExtreme position

The invention provides a detection tool for a wiper linkage output shaft and belongs to the technical field of vehicle part detection. The detection tool is used for detecting the eligibility of wiper linkage output shafts. The detection tool comprises a base, a sleeve, a floating block and a position-limiting part. A cover plate connected with the base is arranged above the base. A horizontal channel is formed between the base and the cover plate. The base is provided with an installation hole arranged to pass through the base. The aperture of the hole is larger than the outer diameter of the floating block and the hole is perpendicular to the upper surface of the base. The floating block is arranged in the installation hole. The floating block is provided with a peripheral flange that extends towards the channel. The flange is in sliding fit with the channel. The position-limiting part limits the sliding range of the flange. The floating block is provided with a through hole matched with the sleeve. The sleeve is provided with a detection hole configured to axially pass through the bottom surface of the sleeve. The sleeve is also provided with a position-limiting structure used for limiting the downward-sliding extreme position of the sleeve. According to the technical scheme of the invention, the detection tool can be used for comprehensively detecting the angle and the locating information of the wiper linkage output shaft. The detection accuracy is improved. Meanwhile, the quality problem and the scrapped condition of qualified products are avoided.

Owner:成都华川电装有限责任公司

Pipe orifice positioning and measuring device and method

ActiveCN113267106APositioning is intuitive and effectiveSolve the problem that it is difficult to accurately locate the center line of the nozzleMechanical measuring arrangementsEngineeringHead (vessel)

The invention discloses a pipe orifice positioning and measuring device and method. The pipe orifice positioning and measuring device comprises a positioning mechanism, a measuring mechanism and a plumb bob. The positioning mechanism comprises an adjusting bolt, a nut, an adjusting plate, an expansion ring and a positioning seat; a plurality of guide columns are fixed to the top of the positioning seat, positioning holes are formed in the adjusting plate and matched with the guide columns, a certain distance is reserved between the adjusting plate and the top of the positioning seat, an expansion ring is fixed between the adjusting plate and the positioning seat, and an adjusting bolt sequentially penetrates through the positioning seat and the adjusting plate upwards from the bottom of the positioning seat, and is matched with a nut; the measuring mechanism comprises a frame used for being connected with a top sealing head of the pressure vessel and a detection ruler fixed to the frame, and a plurality of circular grooves are formed in the detection ruler and used for judging the center of the plumb bob; the plumb bob is fixed to the center of the bottom of the adjusting bolt.

Owner:SHANDONG NUCLEAR POWER EQUIP MFG

Shape and surface inspection device for auto parts

ActiveCN106091861BJudge eligibilityEasy to detectMechanical diameter measurementsMechanical clearance measurementsMotor vehicle part

The invention discloses a profile detection device used for automobile parts A clamping mechanism and a gap detecting mechanism are disposed on a coordinate base, and a clamp disposed on the upper end of the clamping mechanism is used for clamping a to-be-detected part disposed on an upper surface of a simulation block base. A lower part of a latch of a go / no go gauge is a first latch, and the middle part of the latch of the go / no go gauge is, from bottom to top, provided with a go gauge part and a no go gauge part sequentially, and the upper part of the go / no go gauge is a push rod part. The gap detecting mechanism further comprises a base, a clamping board; a left fixing board and a right fixing board, which are parallely disposed on the upper surface of the base; and a rotating arm, the rear end of which is disposed between the left fixing board and the right fixing board. The clamping board is disposed on the front end of the rotating arm, and four corners of the coordinate base are respectively provided with a hoisting rod. The profile detection device used for the automobile parts is advantageous in that the gaps between the parts are detected quickly and visually, and the reliability of the detection is high, the efficiency of the detection is high, and whether the parts are qualified is determined quickly and visually.

Owner:KUNSHAN DAYA AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com