Automatic test system for performance of multi-position switch and test method for same

A switch performance and automatic detection technology, applied in the direction of circuit breaker testing, etc., can solve problems such as useless, manual or semi-manual testing status, etc., and achieve the effects of wide application range, clear qualification and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

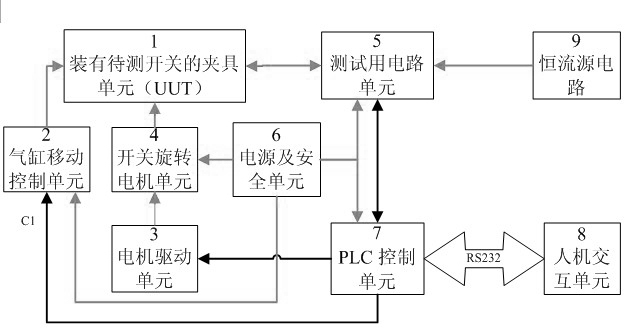

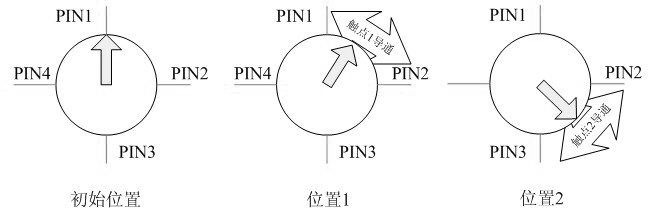

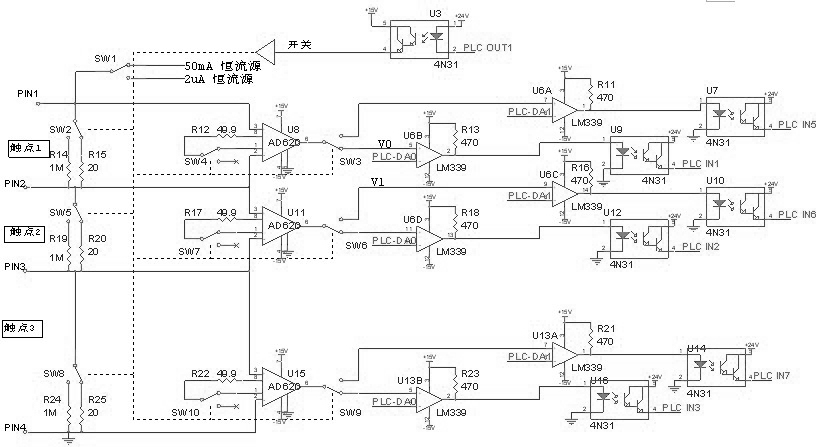

[0035] Embodiment one: see Figure 1-7 As shown, a multi-speed switch performance automatic detection system and detection method include a fixture unit equipped with a switch to be tested, a cylinder movement control unit, a switch rotation motor unit, a circuit unit for testing, a PLC control unit, a constant current source circuit, Power control unit and human-computer interaction unit:

[0036] A gas switch is provided at the gas inlet of the cylinder movement control unit, the power supply end of the gas switch is connected to the power supply control unit, and the cylinder movement control unit is mainly composed of a clamp movement cylinder, a motor movement cylinder and a needle cylinder , the output end of the clamp moving cylinder is connected with the clamp unit, its control end is connected with the PLC control unit through a solenoid valve, the output end of the motor moving cylinder is connected with the switch rotation motor unit, and its control The terminal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com